Page 1

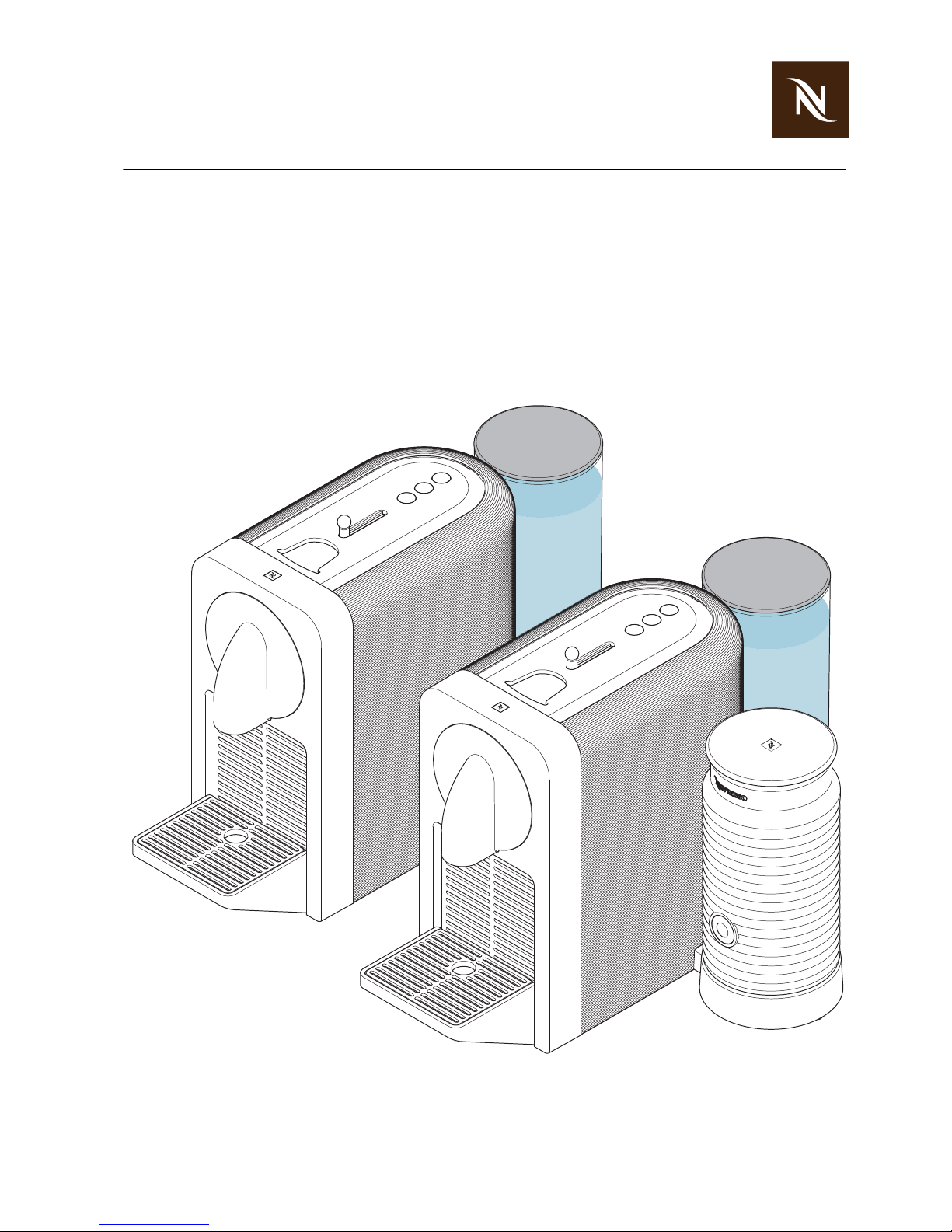

SERVICE MANUAL

COFFEE MACHINES

PRODIGIO C70 / D70

PRODIGIO&MILK C75 / D75

Version 1.0 en, 12.02.2016

Page 2

Prodigio service manual Version 1.0 en

2

CONTENTS

1 General safety notes .........................................................................................6

2 Main components...............................................................................................7

2.1 Overview - Prodigio&milk coffee machine.......................................................... 7

2.1.1 Overview - milk frother (Aero 3)................................................................8

2.2 Interior view of coffee machine .......................................................................... 9

2.3 Interior view of swivel arm................................................................................ 10

2.4 Fluid system..................................................................................................... 11

3 Technical data...................................................................................................12

3.1 Rating plates.................................................................................................... 12

3.1.1 Example of brand specific rating plate.................................................. ..12

3.1.2 Examples of country specific rating plates..............................................12

3.1.3 Rating plate details (example) ................................................................13

3.2 Technical specifications.................................................................................... 14

3.2.1 Coffee machines.....................................................................................14

3.2.2 Milk frother (Prodigio&milk)...................................... ... ... .... ... ... ... ............16

3.2.3 Dimensions, weight and size ..................................................................17

4 Operation............................................................................................................18

4.1 General information..................... ... .......................................... .... ... ... ... ... .... ... . 18

4.2 Status indications............................................................................................. 18

4.2.1 Status indication of coffee machine ........................................................18

4.2.2 Status indication of milk frother...............................................................19

4.3 Machine modes........................... ... .... ... ... ... .... ... ... .......................................... . 20

4.3.1 Machine modes of coffee machine .........................................................20

4.3.2 Machine modes of milk frother................................................................22

4.4 Nespresso App (application software) ........................ .... ... .............................. 22

4.4.1 Prerequisites...........................................................................................22

4.4.2 Pairing smartphone or tablet with coffee machine..................................23

4.4.3 Nespresso App - coffee machine setup..................................................26

4.4.4 Nespresso App - machine page overview ..............................................27

4.4.5 Nespresso App - coffee brewing management.......................................27

4.4.6 Nespresso App - machine management.................................................28

4.4.7 Nespresso App - capsule stock management ........................................29

4.4.8 Nespresso App - water management .....................................................30

4.4.9 Nespresso App - troubleshooting tips.....................................................30

4.5 Empty water system....................... .... ... ... .......................................... ... ... .... ... . 31

5 Maintenance......................................................................................................32

5.1 Descaling ....................... ... .... ... .......................................... .............................. 32

5.1.1 Descaling procedure................................................ ... ... .........................32

5.2 Cleaning procedure for coffee machine ........................................................... 34

5.3 Cleaning procedure for milk frother.......................................... .... ... ... ... ... .... ... . 35

6 Troubleshooting ...............................................................................................36

6.1 Check list for coffee machine................................................ ... .... ... ... ... ... .... ... . 36

Page 3

Version 1.0 en Prodigio service manual

3

6.2 Check list for milk frother ................................................................................. 38

6.3 Machine error code table...................... .... ... ... ... ... .... ... .................................... 39

7Repairs................................................................................................................ 40

7.1 Safety instructions ........................................................................................... 40

7.2 Repair and mounting tips................................................................................. 40

7.3 Tools and accessories ..................................................................................... 41

7.4 General disassembly ......................................... ... .......................................... . 42

7.4.1 Prepare coffee machine for disassembly................................................42

7.4.2 Remove outlet cover............................................................................... 43

7.4.3 Remove front cover ................................................................................44

7.4.4 Remove cover ........................................................................................ 45

7.4.5 Remove blind..........................................................................................47

7.4.6 Remove drop stop .................................................................................. 48

7.4.7 Remove MMI board and light guides...................................................... 49

7.4.8 Remove lever and light barrier ...............................................................50

7.4.9 Remove print cover ................................................................................ 51

7.4.10Remove pivot bottom, water tank connector and power cable...............52

7.4.11Remove pivot bottom, water tank connector, power cable and

Otter connector (Prodigio&milk).............................................................. 54

7.4.12Remove electronic module (main PCB).................................................. 59

7.4.13Remove main board and flowmeter........................................................ 60

7.4.14Remove high pressure tube ...................................................................62

7.4.15Remove pump ........................................................................................63

7.4.16Remove brewing unit..............................................................................64

7.4.17Disassemble brewing unit drive..............................................................67

7.4.18Remove thermoblock from capsule cage ...............................................69

7.5 Wiring diagrams - Prodigio coffee machine................. .................................... 70

7.5.1 Wiring diagram 220 V - 240 V IEC .................... ... ... .... ... ... ... .... ... ... ... ... .. 70

7.5.2 Wiring diagram 120 V UL (USA / Canada)........................................ ... .. 71

7.5.3 Wiring diagram 127 V IEC (Brazil)..... ... ... ... .... ........................................ 72

7.5.4 Wiring diagram 127 V IEC (Mexico) ..................................... .... ... ... ... ... .. 73

7.5.5 Wiring diagram 110 V IEC (Taiwan)........................................................74

7.5.6 Wiring diagram 100 V IEC (Japan)......................................................... 75

7.6 Wiring diagrams - Prodigio&milk coffee machine ........................................... . 76

7.6.1 Wiring diagram 220 V - 240 V IEC .................... ... ... .... ... ... ... .... ... ... ... ... .. 76

7.6.2 Wiring diagram 120 V UL (USA / Canada)........................................ ... .. 77

7.6.3 Wiring diagram 127 V IEC (Brazil)..... ... ... ... .... ........................................ 78

7.6.4 Wiring diagram 127 V IEC (Mexico) ..................................... .... ... ... ... ... .. 79

7.6.5 Wiring diagram 110 V IEC (Taiwan)........................................................80

8 Function tests...................................................................................................81

8.1 Safety instructions ........................................................................................... 81

8.2 Required equipment ........................................................................................ 81

8.2.1 Overview.................................................................................................81

8.3 Measure coffee temperature . .......................................... ... .............................. 82

8.4 Tightness and leakage checks........................................................................ 83

8.4.1 Preparations ...........................................................................................83

8.4.2 Test run................................................................................................... 84

8.5 Milk frother tests (Prodigio&milk)..................................................................... 85

Page 4

Prodigio service manual Version 1.0 en

4

8.5.1 Measure hot milk temperature................. ... ... ... .... ... ... ... .... ... ... ...............85

8.5.2 Measure milk froth ratio ..........................................................................85

8.6 Protective earth (PE) continuity test................................................................. 86

8.6.1 What is the protective earth continuity test about? .................................86

8.6.2 General...................................................................................................86

8.6.3 Test sequence.........................................................................................87

8.6.4 What to do if the protective earth continuity test fails..............................88

8.7 Protective insulation test .......... ... ... .... ... ... ... .... ......................................... .... ... . 89

8.7.1 What is the protective insulation test about? ..........................................89

8.7.2 General...................................................................................................89

8.7.3 Test sequence.........................................................................................90

8.7.4 What to do if the insulation test fails .............................. .... .....................92

9 Explosion drawings and parts lists.............................................................93

9.1 Explosion drawings C70.................................................. ... ... ... ........................ 93

9.2 Explosion drawings D70.................................................. ... ... ... ........................ 96

9.3 Explosion drawings C75.................................................. ... ... ... ........................ 99

9.4 Explosion drawings D75................................................................................. 102

9.5 Spare parts list................................................................................................ 105

10 Glossary of abbreviations...........................................................................109

11 Notes .................................................................................................................110

Page 5

Version 1.0 en Prodigio service manual

5

PREFACE

The purpose of this service manual is to provide the service personnel with all necessary

information with regards to correct handling, maintenance and repair of the Prodigio

coffee machines.

This manual should be used by the technicians as a valuable aid to guarantee the

permanent readiness for use of the machines. In order to t ake full advantage of all the

functions, it is absolutely necessary to follow the instructions in this manual.

Only use original spare parts from your official supplier for maintenance and repair work.

Spare parts lists and exploded drawings are subject to change. To obtain the last

version, please contact your official spare parts supplier.

Visit the Nespresso technical website periodically to check for upgr ades, technical modifications, counter measures etc. for these coffee machines:

https://business.nespresso.com

CONTENT UPDATES

Version 0.1

• First draft version of service manual for proofreading, in English only.

Version 0.2

• Updated service manual version for translation, in English only.

• Nespresso App description added.

Version 1.0

• First released service manual version.

Please keep this

manual together with

the corresponding service

documentation. This way

you are assured to have

the necessary information.

Access is restricted

and can be obtained

by asking your Nespresso

technical contact person.

Page 6

Prodigio service manual Version 1.0 en

6

GENERAL SAFETY NOTES

1 GENERAL SAFETY NOTES

The repair of these machines can only be performed by Nespresso approved af ter-sales

centers and technicians, using suitable tools and original spare parts and taking into

account the national safety regulations.

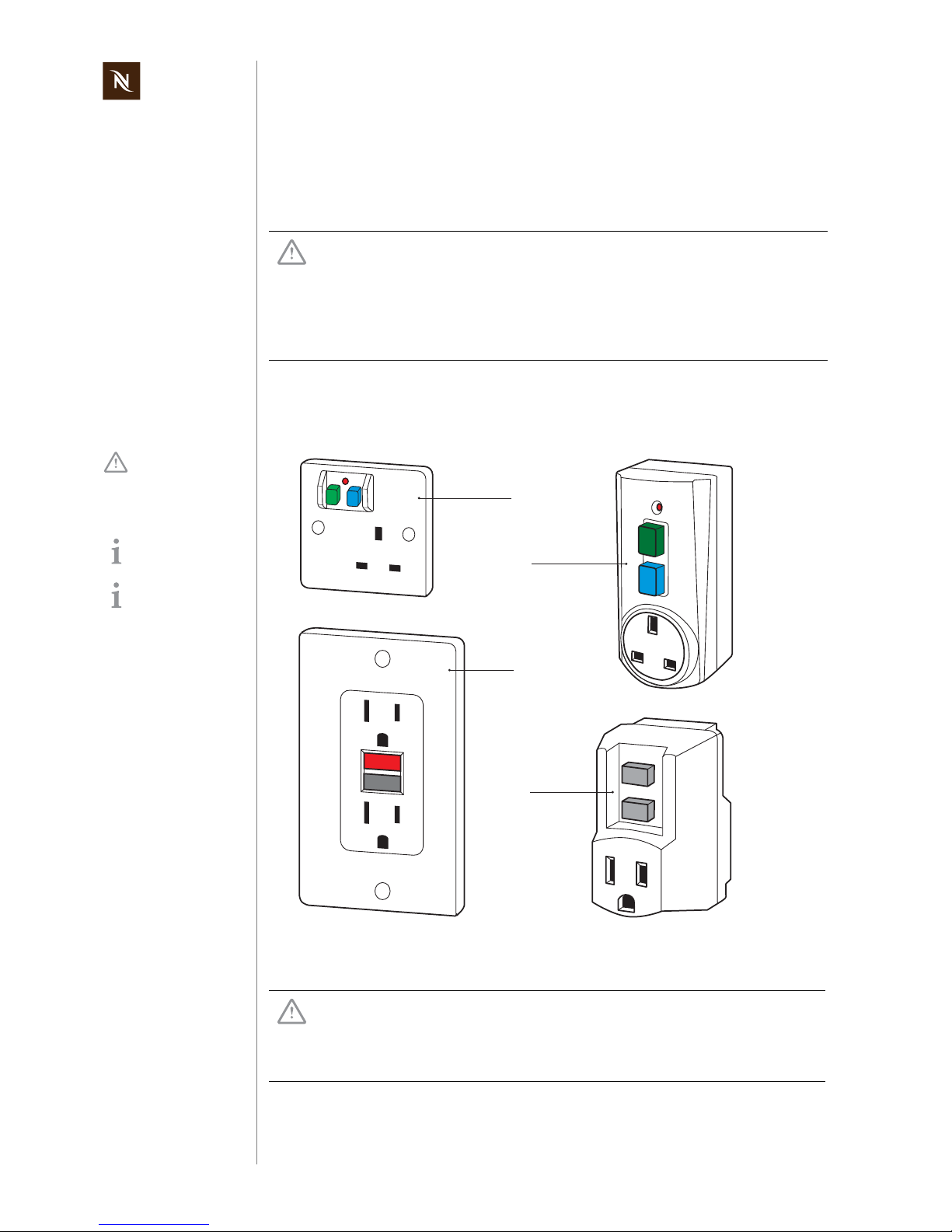

As an additional safety measure, the use of a residual current device (RCD), also called

a ground fault circuit interrupter (GFCI), in the repair centre is highly recommended.

Risk of fatal electrical shock and fire!

Mains voltage inside the coffee machine.

• Unplug appliance before cleaning.

• Never clean wet or immerse plug, cord or appliance in any fluid.

• Disconnect the mains plug before disassembly - the appliance must

be free of voltage.

This device does

not protect against

electrical shock due to

contact with both circuit

conductors.

Example illustrations

of typical devices.

Use a GFCI with a trip

level of 4 - 6 mA (USA)

resp. a RCD with a trip level

of 15 - 30 mA (Europe).

A trip level above 30 mA

provides only very limited

protection against harm

from an electric shock.

1) RCD protected socket-outlet

2) Plug-in RCD unit

3) GFCI socket

4) Plug-in GFCI

Danger of burns!

Hot parts and water under pressure inside the coffee machine

(particularly in the thermoblock).

• Let coffee machine cool down before cleaning or disassembly.

1

2

RESET

TEST

RESET

TEST

3

4

Page 7

Version 1.0 en Prodigio service manual

7

MAIN COMPONENTS

2 MAIN COMPONENTS

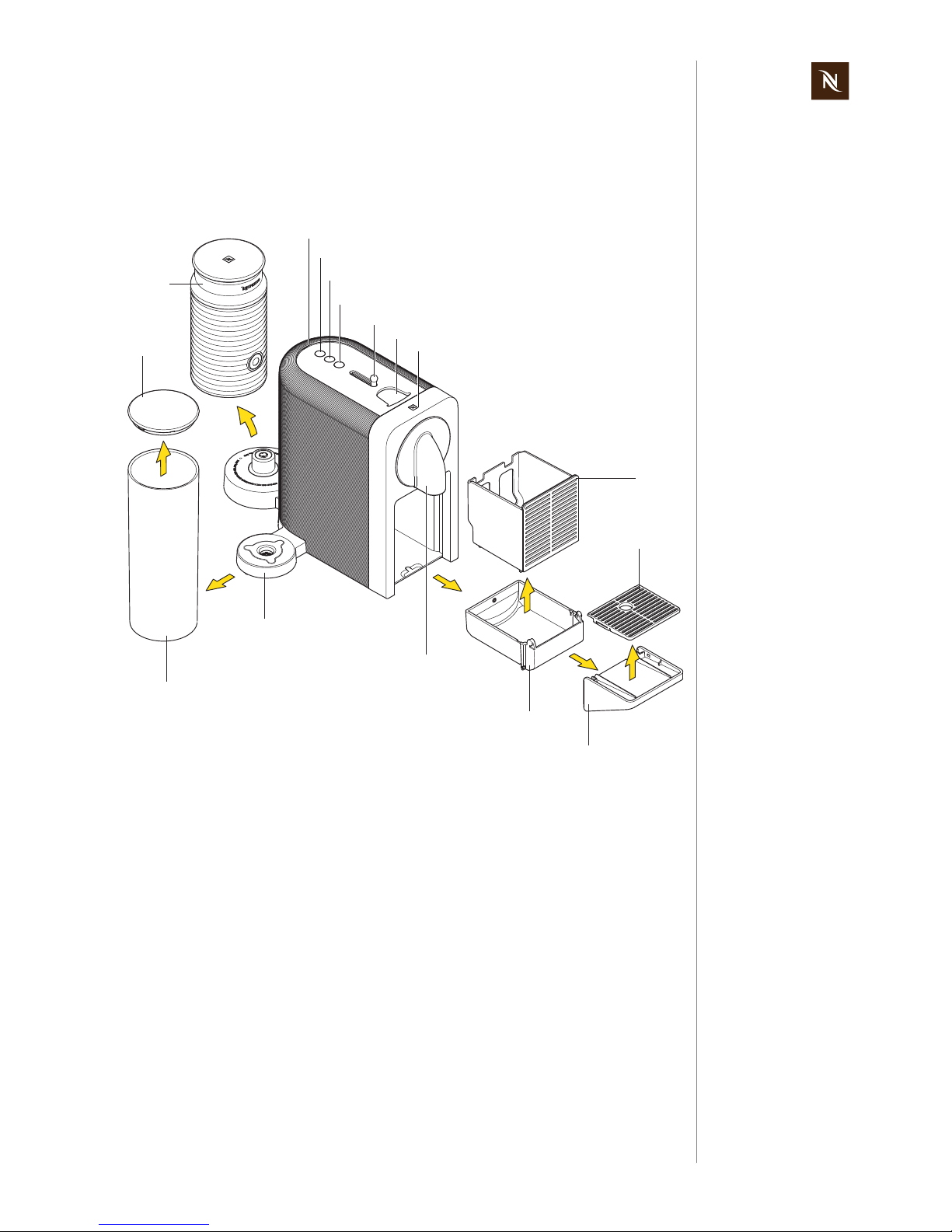

2.1 Overview - Prodigio&milk coffee machine

The coffee buttons (2, 3, 4) and the Nespresso logo (7) are backlighted in white.

The swivel arm version (13) of the Prodigio can be rotated by 180 degrees, while the

version of the Prodigio&milk can be rotated by 90 degrees only.

A magnet fixing holds the water tank (14) on the swivel arm (13) securely.

The maintenance unit consists of the parts 8 - 11. A position switch monitors the used

capsule container (8) and drip tray (11) in the coffee machine.

A light barrier detects a jammed used capsule or a full resp. missing cap sule cont ainer (8).

1) Maintenance light, orange

2) Lungo coffee button, 110 ml / 3.7 oz

3) Espresso coffee button, 40 ml / 1.35 oz

4) Ristretto coffee button, 25 ml / 0.84 oz

5) Slider for capsule insertion cover

6) Capsule insertion slot

7) Nespresso logo, backlighted

8) Used capsule container

9) Drip grid

10) Removable cup support

11) Drip tray

12) Coffee outlet

13) Swivel arm for water tank and milk

frother (only for Prodigio&milk)

14) Water tank

15) Water tank lid

16) Milk frother

2

3

4

5

8

9

16

10

11

6

12

14

13

15

1

7

Page 8

Prodigio service manual Version 1.0 en

8

MAIN COMPONENTS

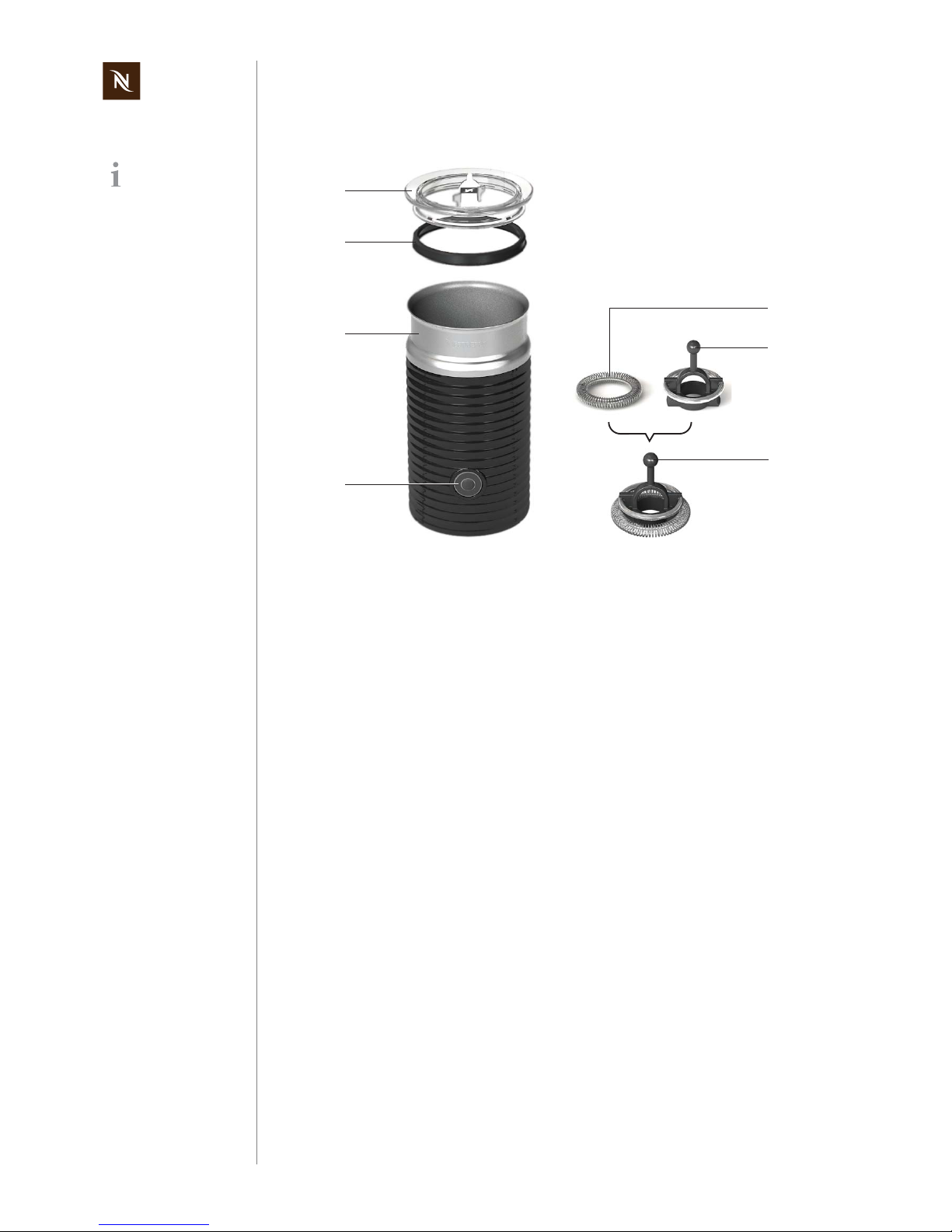

2.1.1 Overview - milk frother (Aero 3)

The lid (1) has a holding fixture for the frothing spring (5).

The inside of the jug (3)

- has level marks for hot milk and milk foam preparation,

- is surface-coated for easy cleaning.

The milk frother is

part of the coffee

machine Prodigio&milk.

1) Lid

2) Seal

3) Jug

4) Start/stop button

5) Frothing spring (for milk froth only)

6) Mixer for hot milk

7) Spring whisk for milk foam

1

2

3

4

5

6

7

Page 9

Version 1.0 en Prodigio service manual

9

MAIN COMPONENTS

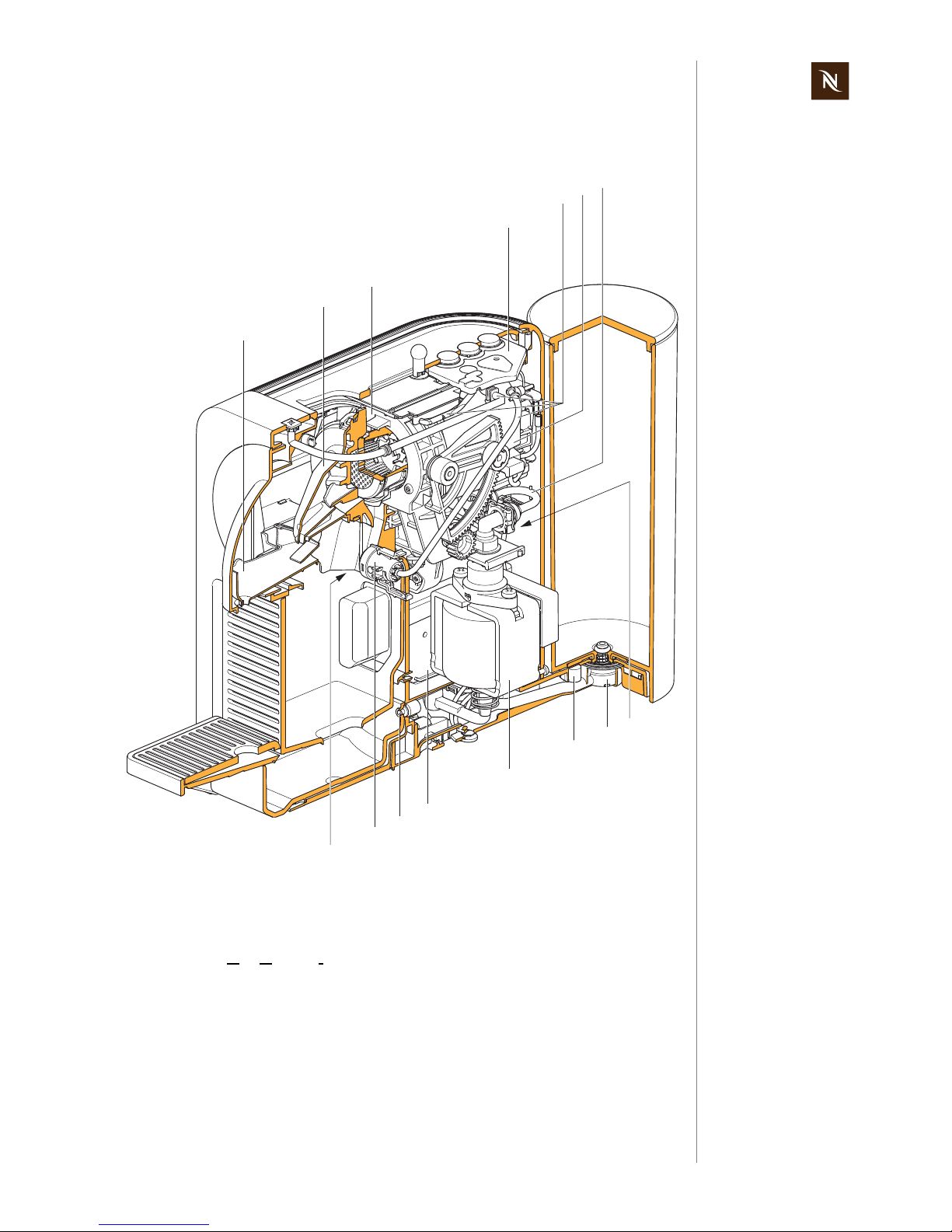

2.2 Interior view of coffee machine

1) Drop stop

2) Steam cover

3) Brewing unit

4) MMI board (M

en Machine Interface)

with reinforced silicone keypad

5) Light guides

6) Thermoblock

7) High pressure connector

8) Motor

9) Water tank connector

10) Magnet fixing for water tank

(3 permanent magnets)

11) Pump

12) Electronic module with flowmeter

13) Magnet fixing for drip tray

14) Light barrier

15) Position switch for used capsule container

11

4

15

13

10

9

12

1

2

3

14

5

6

7

8

Page 10

Prodigio service manual Version 1.0 en

10

MAIN COMPONENTS

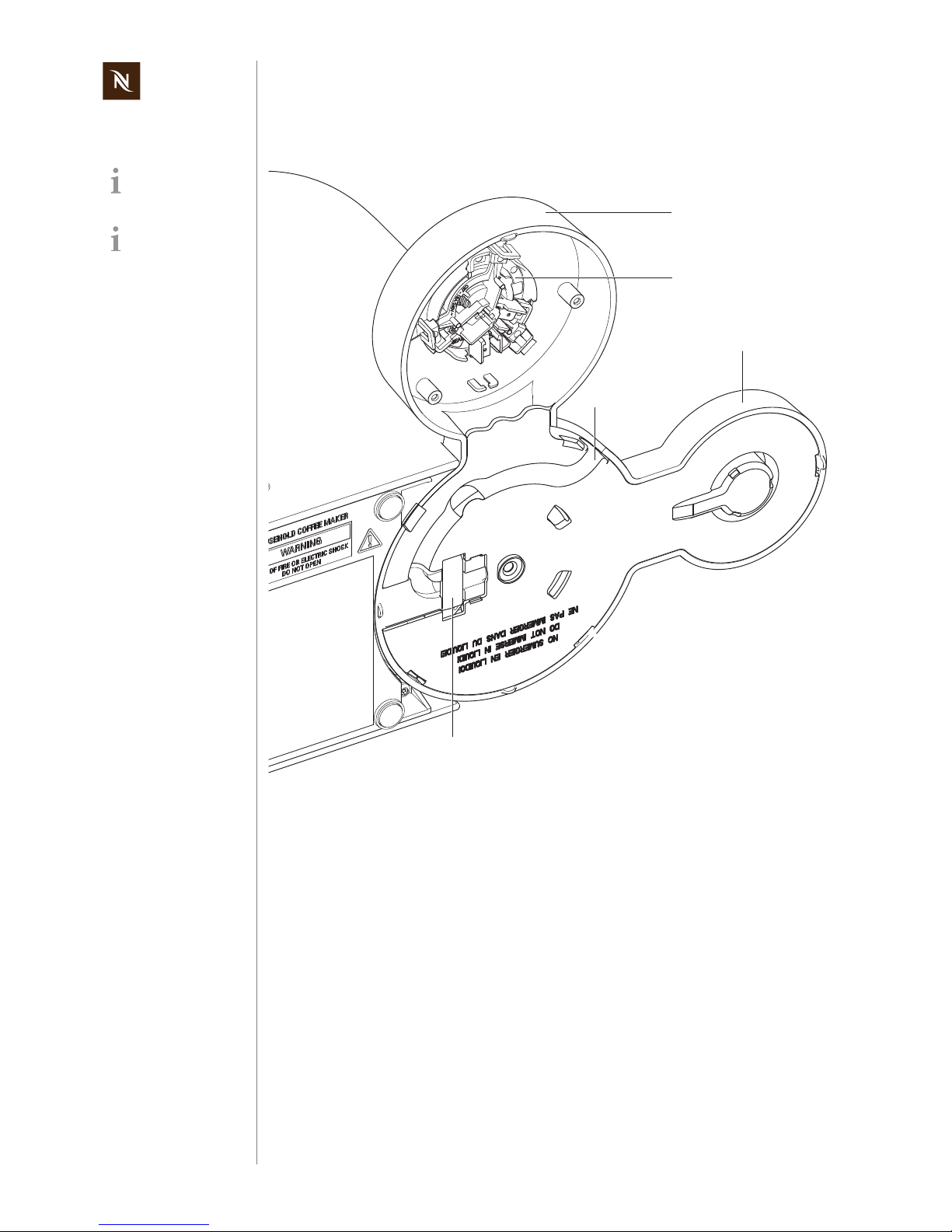

2.3 Interior view of swivel arm

Swivel arm of

Prodigio&milk - view

from below.

Beside the special

swivel arm, the two

coffee machine types have

the same internal design.

1) Support for milk frother

2) Otter connector for milk frother

3) Support for water tank

4) Cable duct for power cord

5) Cable strain relief

2

5

1

3

4

Page 11

Version 1.0 en Prodigio service manual

11

MAIN COMPONENTS

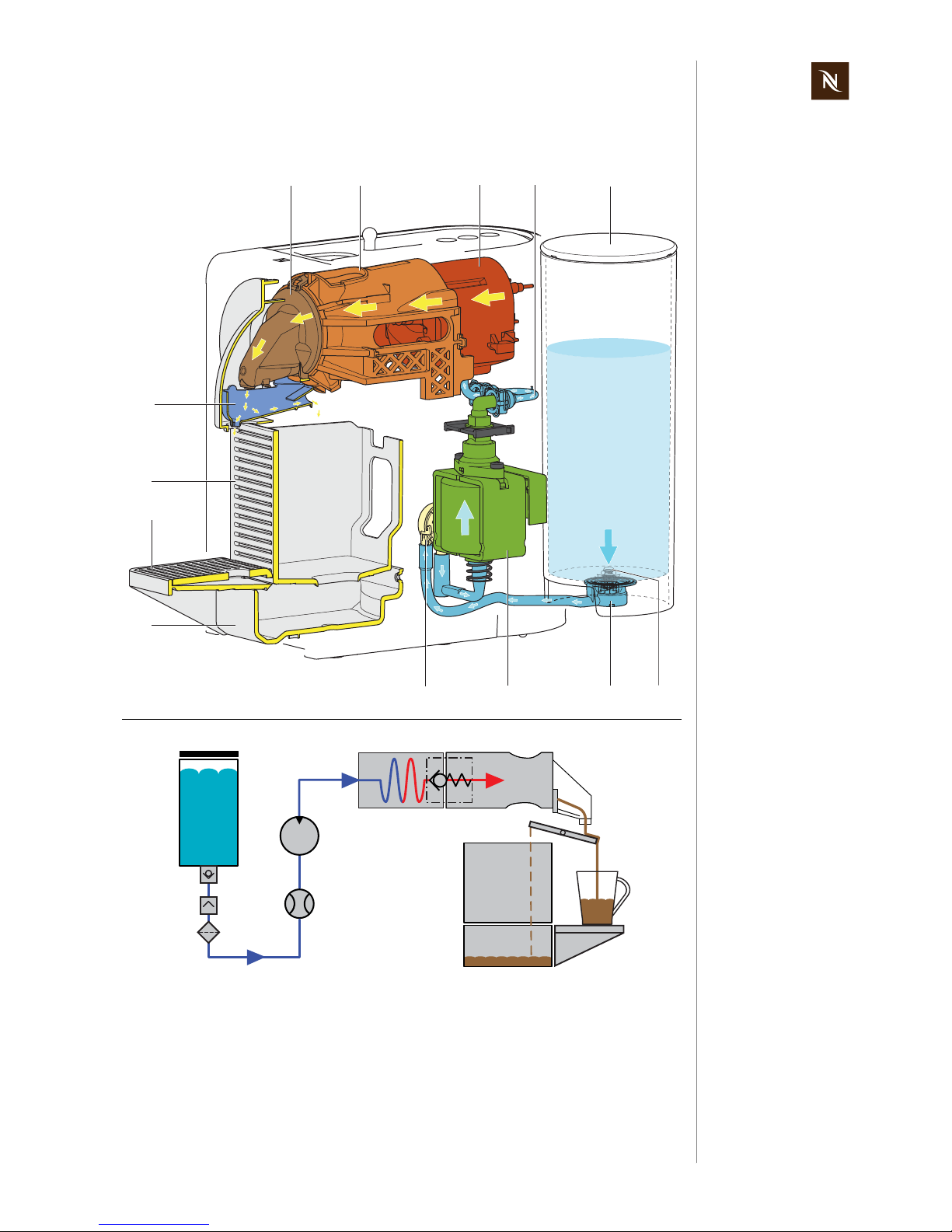

2.4 Fluid system

1) Coffee outlet

2) Brewing unit

3) Thermoblock

4) High pressure connector

5) Water tank

6) Water tank valve

7) Water tank connector with filter

8) Pump

9) Flowmeter

10) Drip tray

11) Cup support

12) Used capsule container

13) Drop stop

13

8

5

3

21

12

10

11

4

7

9

6

BU

TB

WT

FM

6

8

9

3

1

12

10

11

4

25

7

13

Page 12

Prodigio service manual Version 1.0 en

12

TECHNICAL DATA

3 TECHNICAL DATA

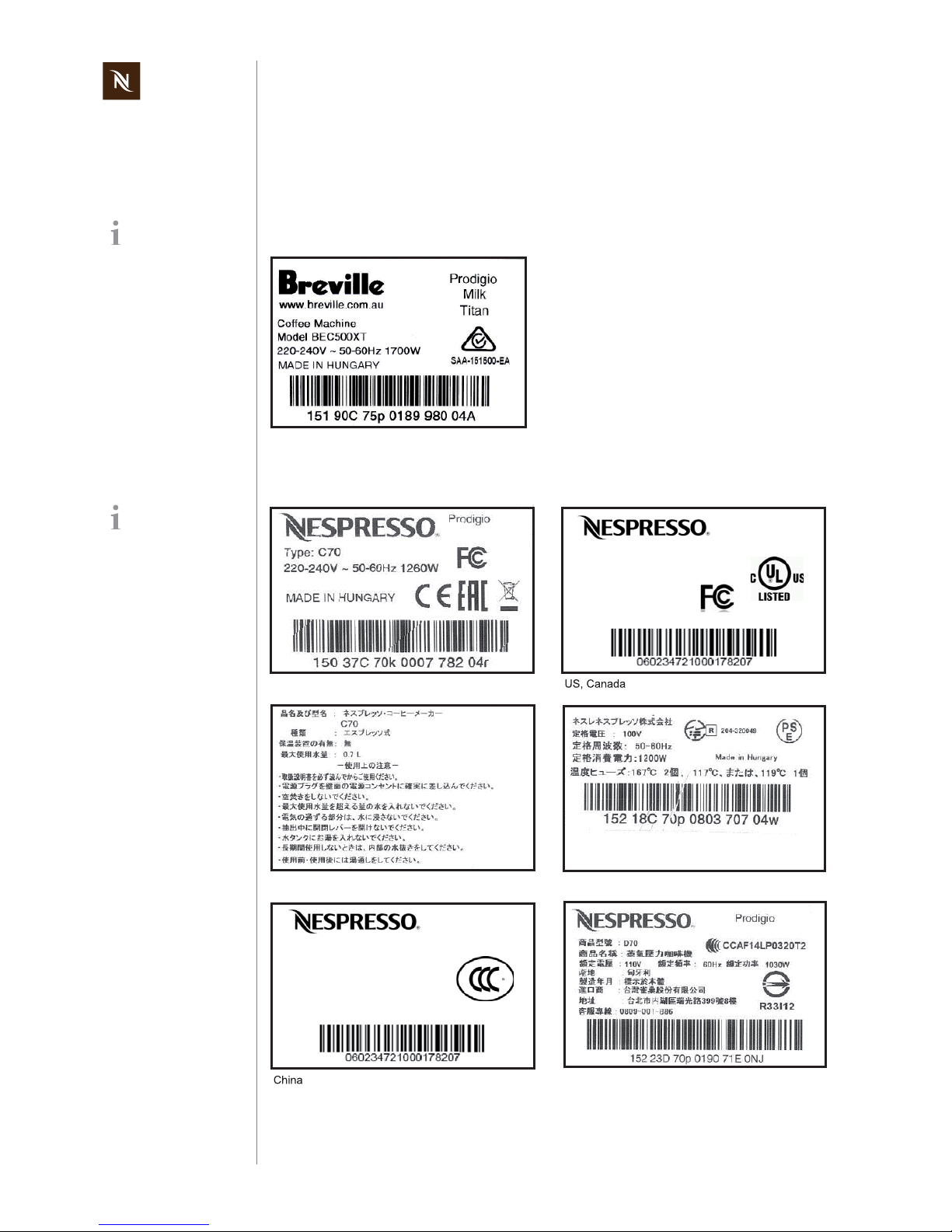

3.1 Rating plates

3.1.1 Example of brand specific rating plate

3.1.2 Examples of country specific rating plates

The rating plate can

be found at the bottom of the coffee machine.

A

ustralia

This overview shows

examples for various

countries and is subject to

alterations.

Prodigio

Type: D70

HOUSEHOLD COFFEE MAKER

MACHINE A CAFÉ POUR LA MAISON

120 V~ 60 Hz 1160 W

MADE IN HUNGARY

FABRIQUÉ EN HONGRIE

4SM3

ṏရྡ⛠䠖ၲᮘ

ᆺྕ䠖C70

桅ᐃ䓝⌳ཬ桅ᐃ根⋡䠖220 V~ 50 Hz

桅ᐃ弻ධຌ⋡䠖1150 W

ไ㐀ၟ䠖Flextronics International Kft.

୰ᅜ༊௦⌮ၟ䠖ி㞛ᕡዉ᪁ὴ⣴ၲ᭷㝈බྖ

MADE IN HUNGARY ∳ไ㐀

Prodigio

Europe

Japan (two-piece rating plate)

Japan

Taiwan

Page 13

Version 1.0 en Prodigio service manual

13

TECHNICAL DATA

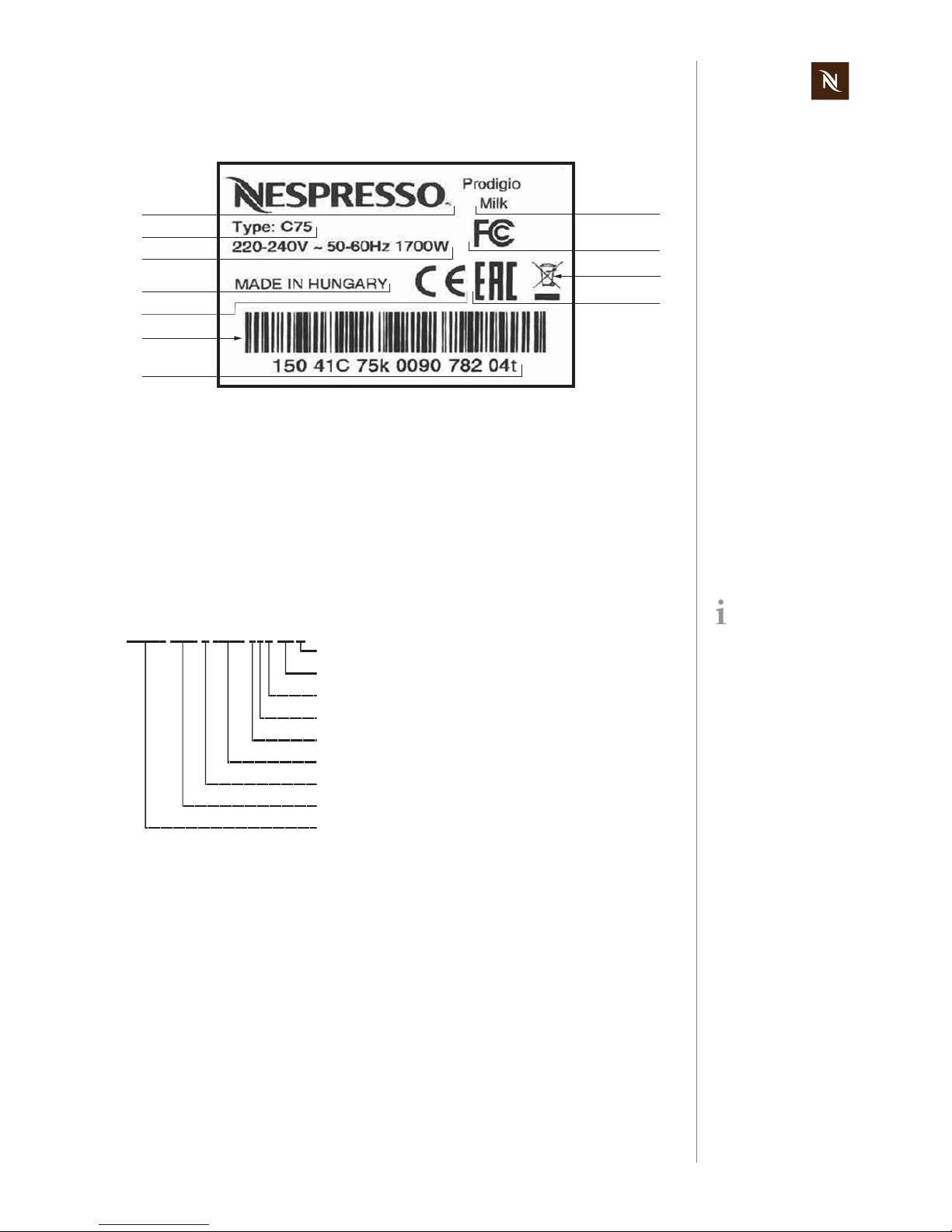

3.1.3 Rating plate details (example)

Decoding the alphanumeric serial number

Example:

1) Brand name

2) Machine type

3) Voltage and power rating

4) Place of manufacture

5) Sign of conformity (CE)

6) Bar code

7) Serial number

8) Machine name

9) FCC approval

10) Special disposal icon

(do not dispose with ordinary waste)

1 1) Eurasian conformity mark

1

2

3

7

8

10

9

4

5

11

6

By decoding the date

of production and

machine type, the coffee

machine can be identified

exactly.

Checksum

Color version

Type of mains plug

Mains voltage

Distributing partner

Incremental number per production day

Manufacturing plant

Manufacturer designation of the machine type (C75)

15041 ... Date of production

(15 = year 2015, 041 = forty-first day of the year)

15041 C75 k 0090 782 04 t

Page 14

Prodigio service manual Version 1.0 en

14

TECHNICAL DATA

3.2 Technical specifications

3.2.1 Coffee machines

Mains voltage ranges

Prodigio coffee machine

Europe, RU, AU, CN, KR, SG, HK, ME, ZA, IL, BR, AR................ 220-240 V, 50/60 Hz

USA, Canada ........................................................................................120 V, 50/60 Hz

BR, MX..................................................................................................127 V, 50/60 Hz

Japan.................................................................................................... 100 V, 50/60 Hz

Taiwan....................................................................................................... 110 V, 60 Hz

Prodigio&milk coffee machine

Europe, RU, AU, CN, KR, SG, HK, ME, ZA, IL, BR, AR................ 220-240 V, 50/60 Hz

USA, Canada ........................................................................................120 V, 50/60 Hz

BR, MX.......................................................................................................127 V, 60 Hz

BR, KR .......................................................................................................220 V, 60 Hz

CN.................. .... ... ... .......................................... ... .....................................220 V, 50 Hz

Power consumption

Prodigio coffee machine

220-240 V mains voltage......................................................................approx. 1’260 W

100/110/120/127 V mains voltage.........................................................1’160 - 1’370 W

Prodigio&milk coffee machine

220-240 V mains voltage......................................................................approx. 1’700 W

100/110/120/127 V mains voltage........................................................approx. 1’900 W

Power consumption of coffee machine main components

(for all voltages and frequencies)

Thermoblock...................................................................................................... 1’200 W

Pump......................................................................................................................60 W

Milk frother (Prodigio&milk).........................................................................410 - 490 W

Energy consumption (CECED / FEA 2009 method)

Prodigio coffee machine

Energy efficiency class level ..............................................................................A - 40%

Daily energy consumption....................................................................................76 Wh

Annual energy consumption...............................................................................28 kWh

EuP ... Energy using

Products

See commission regulation

no. 1275/2008 of the European Union.

Approvals UL and FCC for USA and Canada, CE, PSE, EAC, Ctick,

CCC, KTL, SPRING, SASO, SABS, ISI, IRAM, NOM

EuP standard The coffee machine is EuP 2013 compliant

Page 15

Version 1.0 en Prodigio service manual

15

TECHNICAL DATA

Prodigio&milk coffee machine

Energy efficiency class level..............................................................................A - 40%

Daily energy consumption....................................................................................89 Wh

Annual energy consumption .............................................................................. 33 kWh

Pump

Pump pressure

- Max. permissible.................................................................................... 20 bar ± 3 bar

- During coffee preparation (depending on the type of coffee)........................ 9 - 16 bar

Capacities

Water tank...................................................................................................approx. 0.8 l

Drip tray water capacity................................................................................min. 100 ml

Capsule container.......................................................................... approx. 10 capsules

Volume of prepared coffee

- factory settings

Small cup "Ristretto" ................................................................................... 25 ml (±7%)

Small cup "Espresso".................................................................................. 40 ml (±7%)

Large cup "Lungo"..................................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... . 110 ml (±7%)

- customer settings

Programmable setting range.........................................................................20 - 200 ml

Environmental conditions

Operating temperature.............. ... ... ... .... ..+ 5 °C up to + 45 °C (+ 41 °F up to + 113 °F)

Storage temperature.................................. - 25 °C up to + 65 °C (- 13 °F up to 149 °F)

Altitude............................................................................up to 2’500 m above sea level

Humidity................................................................................................... no restrictions

Various data

Preheating time....................................................................................... approx. 25 sec

Automatic shut off time.................................................................after 9 min of non-use

Safety temperature (electronically controlled)........................................120 °C (248 °F)

Safety temperature (thermal cut-off)......................................................167 °C (333 °F)

Coffee temperature at outlet ...........................................86 °C ± 3 °C (187 °F ± 5,4 °F)

Descaling temperature.................................................................setting 70 °C (158 °F)

Advised water tank

capacity to avoid

spilling.

Page 16

Prodigio service manual Version 1.0 en

16

TECHNICAL DATA

3.2.2 Milk frother (Prodigio&milk)

Mains voltage

EU ............................................................................................... 220-240 V / 50-60 Hz

US/CA ..........................................................................................120-127 V / 50-60 Hz

AU ..................................................................................................... 240-260 V / 50 Hz

The milk frother

- is available in 3 different models, depending on above mains voltage ranges,

- has to match the mains voltage range of the associated coffee machine.

Capacity

Hot milk ...................................................................................................... max. 240 ml

Hot/cold milk for milk froth...........................................................................max. 130 ml

Performance data

Preparation times

(with full, semi-skimmed or skimmed milk at 8 °-10 °C fridge temperature)

Hot milk froth (120 ml)..... ... ... ... ... .... ... ... ........................................................50 - 80 sec

Cold milk froth (120 ml) .................................................................................60 - 80 sec

Hot milk (240 ml) .......................................................................................120 - 180 sec

Temperature

Hot milk .............................................................................................+ 60 °C to + 70 °C

Foam milk..........................................................................................+ 60 °C to + 70 °C

If replacing a defect

milk frother, check

mains voltage range.

Page 17

Version 1.0 en Prodigio service manual

17

TECHNICAL DATA

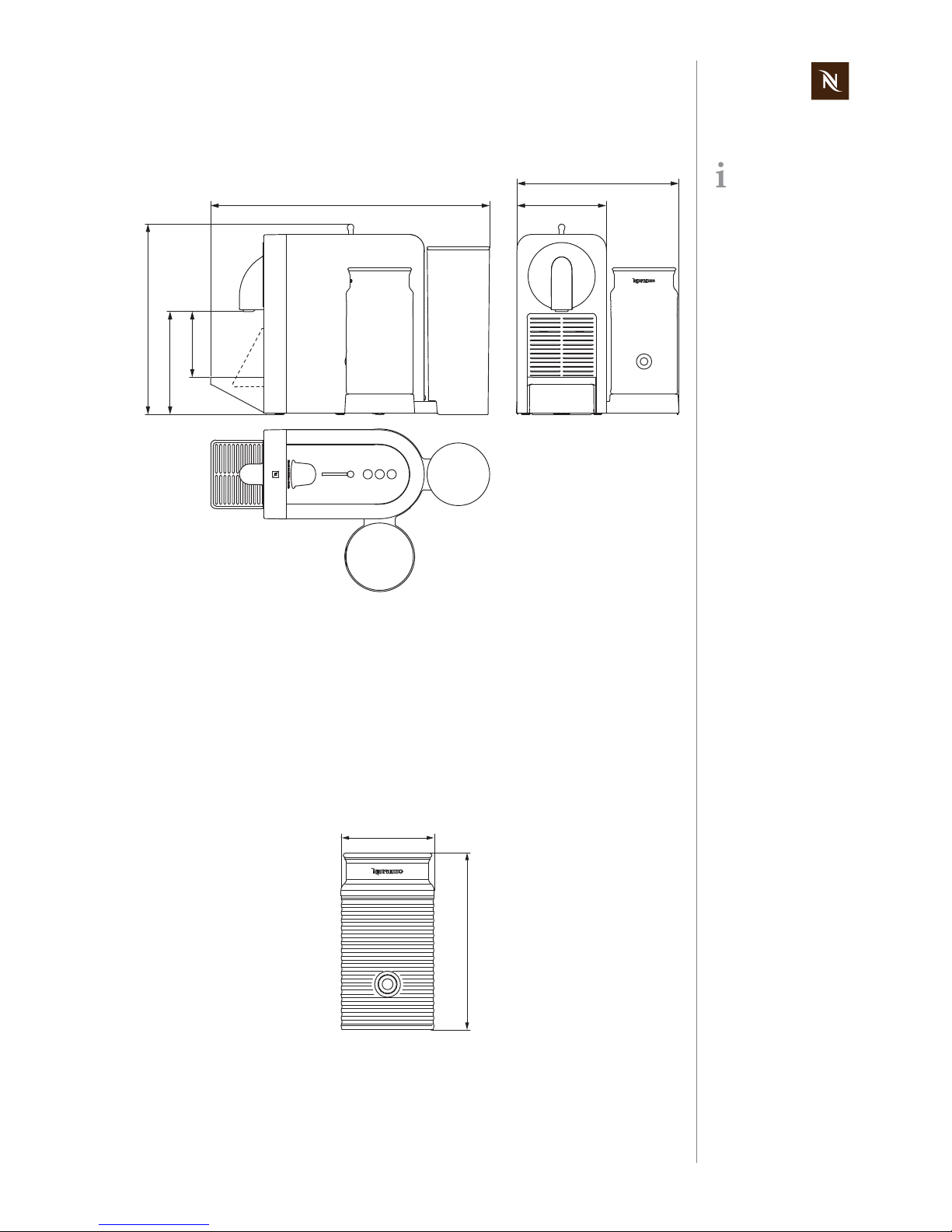

3.2.3 Dimensions, weight and size

Prodigio dimensions (length x width x height)......................... 374 x 119.5 x 255.3 mm

Prodigio&milk dimensions (length x width x height)................ 374 x 218.4 x 255.3 mm

Distance drip grid - coffee outlet: .............................................88 mm (Espresso mode)

Distance bottom - coffee outlet: .......................................... 138 mm (Macchiato mode)

Power cable length ...................... ... ... .. min. 0.8 m (depending on national regulations)

Prodigio weight (without water).............................................. ... ... .... ...........approx. 3 kg

Prodigio&milk weight (without water).................................................. ... .....approx. 4 kg

Milk frother

Dimensions of jug cpl. (diameter x height)................................................ 91 x 170 mm

Whisk for foam (diameter x height).............................................................. 33 x 32 mm

Weight (with whisk)............................................................................................... 0.7 kg

Dimensions in [mm].

119.5374

88

138

255.3

218.4

Ø

91

170

Page 18

Prodigio service manual Version 1.0 en

18

OPERATION

4 OPERATION

4.1 General information

For an overview of operational controls see “Main components” on page 7.

For basic operation of the machine such as preparing a coffee and other related infor-

mation, refer to the user manual.

4.2 Status indications

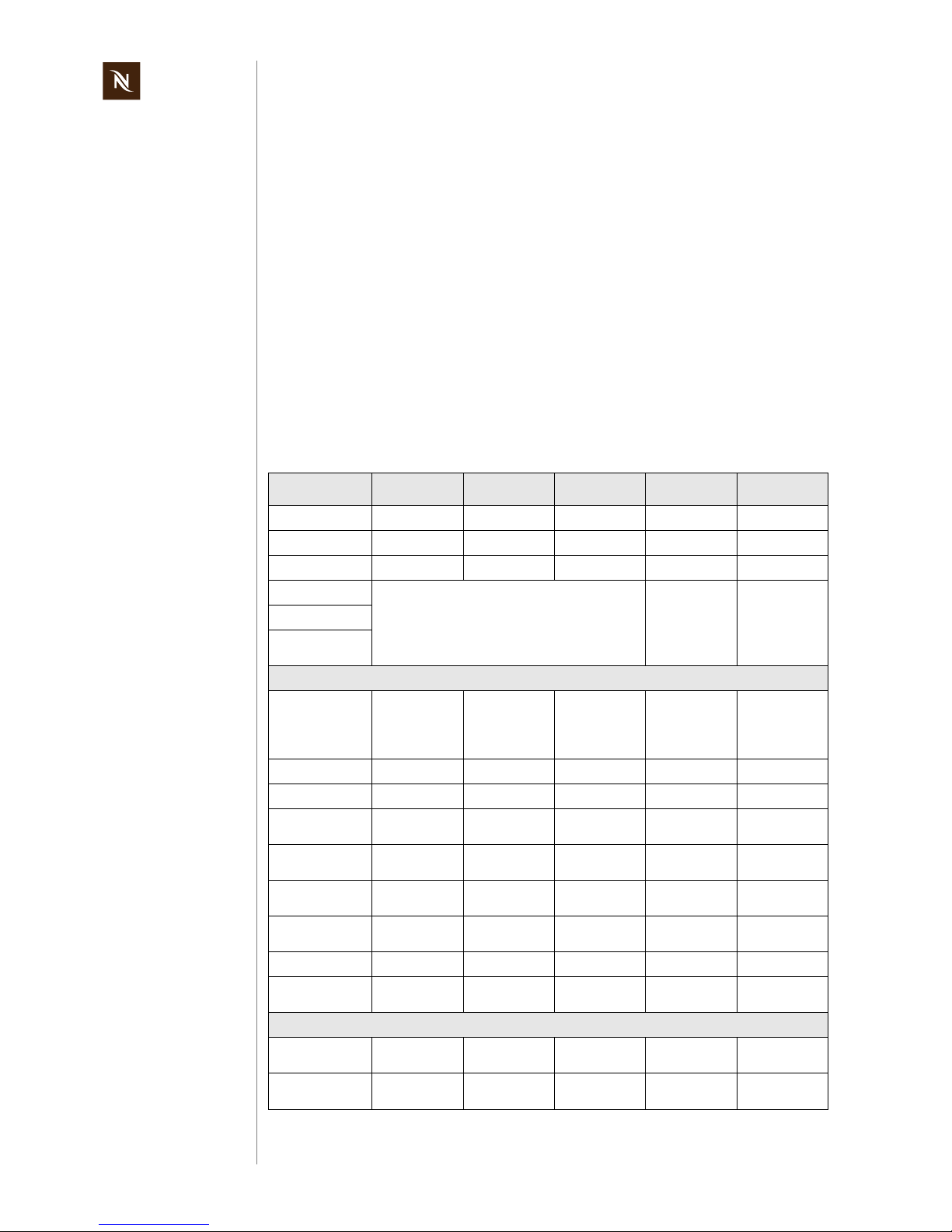

4.2.1 Status indication of coffee machine

According to the following table the status of the coffee machine is shown by

- light signals of the 3 coffee buttons Lungo, Espresso and Ristretto (white LEDs)

- maintenance light (M-light, orange LED)

- Nespresso logo backlight (N-light, white LED)

Machine status Lungo Espresso Ristretto M-light N-light

Off or standby

Off Off Off Off Off

Heating up

Blinking, 1 Hz Blinking, 1 Hz Blinking, 1 Hz — —

Ready

On On On — —

Brewing coffee

One coffee button is blinking, 1 Hz — —

Pre-order active

Programming

coffee cup size

Special functions

Programming

cup size confirmation for

-Lungo

Off On, 0.5 sec On, 0.5 sec — —

- Espresso

On, 0.5 sec Off On, 0.5 sec — —

- Ristretto

On, 0.5 sec On, 0.5 sec Off — —

Descaling ready,

pump on/off

Blinking, 2 Hz Blinking, 2 Hz Blinking, 2 Hz On —

Emptying

confirmation

Off On, 0.5 sec Off On —

Emptying

running

Off Off Off On —

Switch standby

time to 30 min

Off On, 3 x 0.5 sec Off Off —

- to 9 min

Off On, 0.5 sec Off Off —

Reset to factory

settings

On, 2 sec On, 2 sec On, 2 sec On, 2 sec On, 2 sec

Nespresso App. related

First pairing

Off Off Off Off Blinking,

3 x 0.5 sec

Low capsule

stock

————On

Page 19

Version 1.0 en Prodigio service manual

19

OPERATION

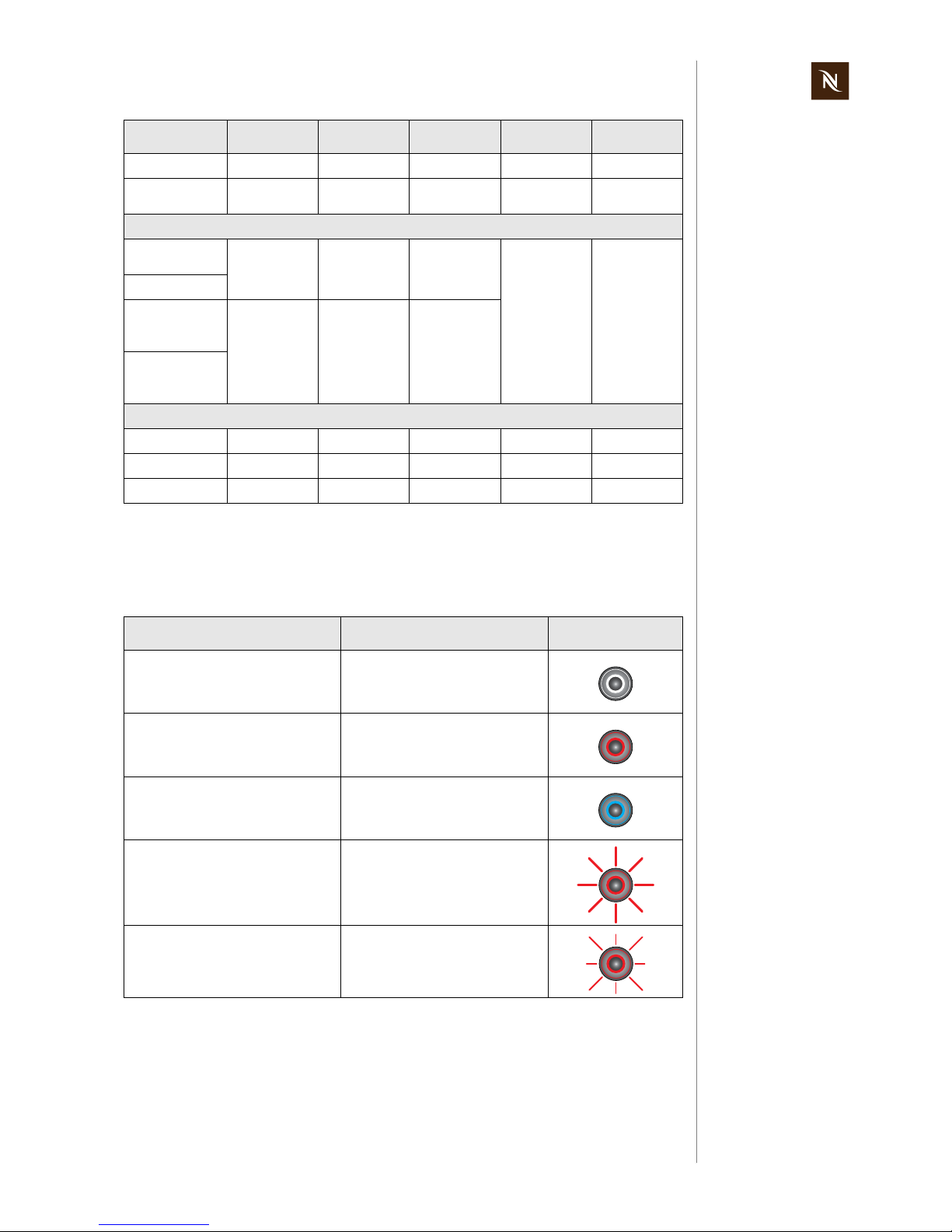

4.2.2 Status indication of milk frother

The operating button with its red/blue backlight shows the status of the milk frother

according to the following table:

Software update

Off Off Off Off Blinking, 2 Hz

Device identification

————Blinking,

5 x 0.5 sec

User intervention required

Notification descaling needed

———On—

Out of water

Capsule con-

tainer full or

removed

Off Off Off

Obstacle detection (capsule

ejection)

Errors

Invalid user input

— — — Blinking , 3 x —

Overheating

Blinking, 1 Hz Blinking, 1 Hz Blinking, 1 Hz On —

Device error

— — — Blinking, 2 Hz —

Machine status State events Operating button

Off Backlight off

On - hot milk preparation Red backlight on

On - cold milk froth preparation Blue backlight on

Failure/malfunction

(e.g. overheating because of bu r nt

milk, too less or no milk)

Blinking red backlight

(1 Hz, 0.5 sec on, 0.5 sec off)

Failure: milk frother has wrong

mains voltage range

Fast blinking red backlight

(2 Hz, 0.25 sec on, 0.25 sec off

Machine status Lungo Espresso Ristretto M-light N-light

Page 20

Prodigio service manual Version 1.0 en

20

OPERATION

4.3 Machine modes

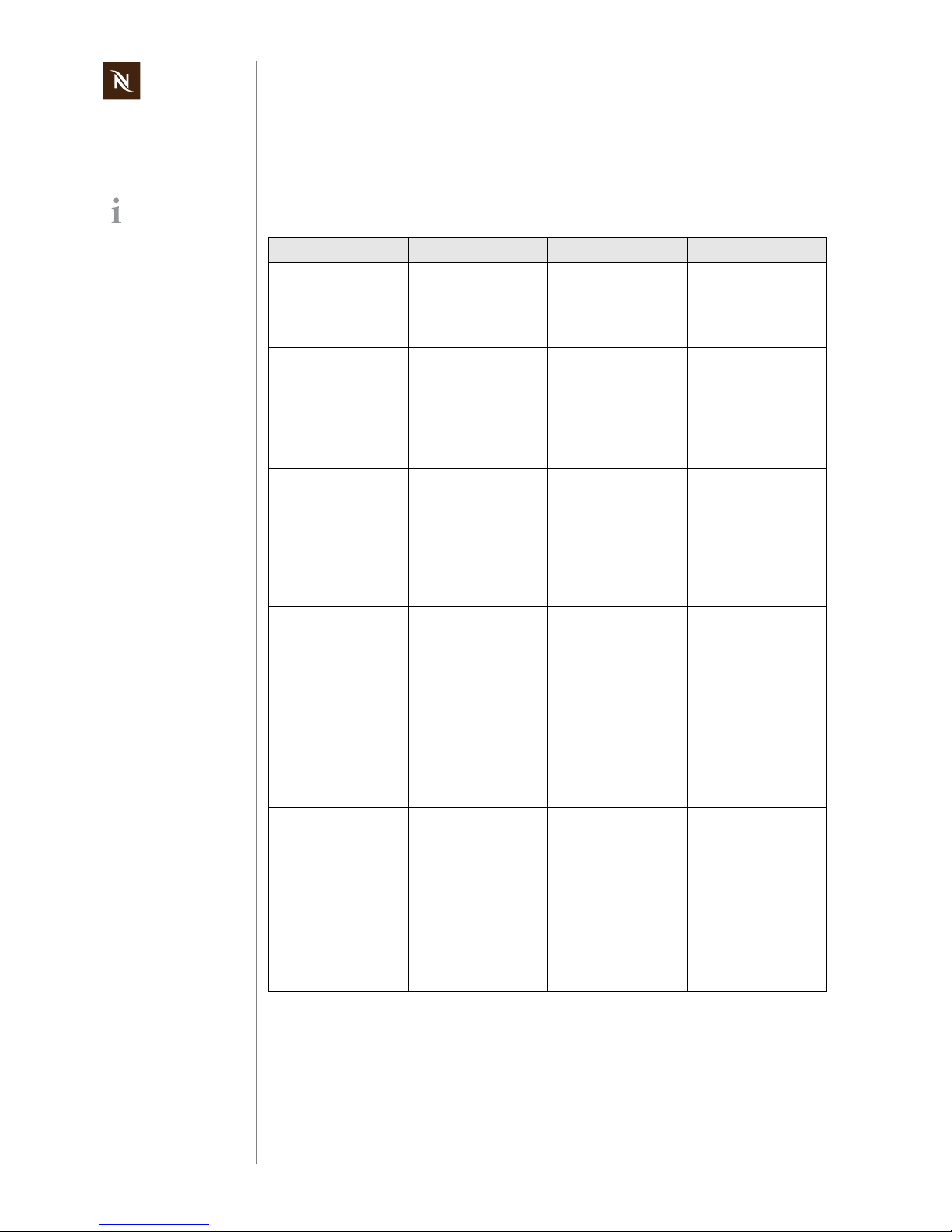

4.3.1 Machine modes of coffee machine

This table helps to understan d the operating modes of the Prodigio coffee machine:

This table also contains the keying

sequences for

- volume programming

- descaling

- water system emptying

- resetting

- changing the automatic

switch off time.

Machine mode Enter mode Actions Exit mode

1 Heat up mode

Every time after switching on machine

Heat up thermoblock to

ready temperature 90

°C within 30 sec without overshooting target

temperature

e.g. switching off

machine

2 Self test mode

Every time after switching on machine

Tests:

• NTC short circuit

• NTC connected

• Checks if thermoblock reaches ready

temperature within

2 min after switch on

e.g. switching off

machine

3 Ready mode

• After heat up and self

test mode was ok

• After brewing or

volume brewing

coffee

• After reset mode

• After leaving

descaling mode

Keep thermoblock

temperature at 90 °C

e.g. switching off

machine

4a Brewing mode

4b Volume brewing

mode (programming cup size)

Brewing mode:

• Press and release

any coffee button

Programming mode:

• Open and close the

slider

• Press and hold any

coffee button for

more than 3 sec

• Press and release

any coffee button

when machine is in

brewing mode or

automatic exit given

by the flowmeter

• Release corresponding coffee

button when

machine is in

programming mode

• Switch off machine

5 Descaling mode

• Switch on the

machine and wait

until ready

• Press and hold all

three coffee buttons

for at least 6 sec until

confirmation with a

beep.

• Regulate temperature to 70 °C (after

pump was started)

• Stop and start pump

with any coffee

button, no volume

brewing in descaling

mode

• Press and hold all

three coffee buttons

for at least 6 sec until

confirmation with a

beep.

Note: When machine is

switched off during any

descaling mode, then it

goes to descaling

mode ready state after

next switch on.

Page 21

Version 1.0 en Prodigio service manual

21

OPERATION

6 Emptying mode

(evaporing)

• When slider is open

press and hold the

Ristretto and Lungo

coffee buttons

together for at least

6 sec. The other

coffee button flashes

for confirmation.

• Close the slider to

start the procedure.

1) Start pump

2) Heat up thermoblock to 105 °C

(100% power)

3) Stop pump wh e n

thermoblock temperature of 105 °C

is reached

4) Switch off thermoblock

5) Switch off machine

6) Block machine for

10 min

Switch off machine

7 Resetting mode

• Swi tch off machine.

• Press and hold the

Espresso and Lungo

coffee buttons

together for at least

4sec.

• Reset programmed

volumes to factory

settings (Ristretto

25ml, Espresso

40ml, Lungo 110ml)

• Reset automatic off

mode to 9 min.

• Reset water hard-

ness to "hard".

• Reset capsule

counter and

descaling counter

• Cancel pairing with

Nespresso App.

device

• Activate Bluetooth

®

Proceeds with self test

mode automatically

8 Auto switch off mode

(factory setting of 9 min

can be changed to

30 min)

• Automatica lly after a

certain period of nonuse.

• Manually at any time

by pressing Lungo

and Espresso coffee

buttons together for

more

than 3 sec

.

• Change automatic

OFF mode between

9 and 30 minutes:

Ensure machine is

turned off.

Press and hold Lungo

and Ristretto coffee

buttons together for

at least 3 sec.

• Switch off machine

after 9 min resp.

30 min if no coffee is

brewed or 9 min

resp. 30 min after

last brewed coffee

9 Failure mode

Automatically by following failures:

a) NTC short circuit

b) NTC not connected

c) Heat up too slow

d) Motor short circuit

e) Motor not connected

Machine indicates failure with blinking maintenance light as long as

the failure is present

When failure is fixed

Machine mode Enter mode Actions Exit mode

Page 22

Prodigio service manual Version 1.0 en

22

OPERATION

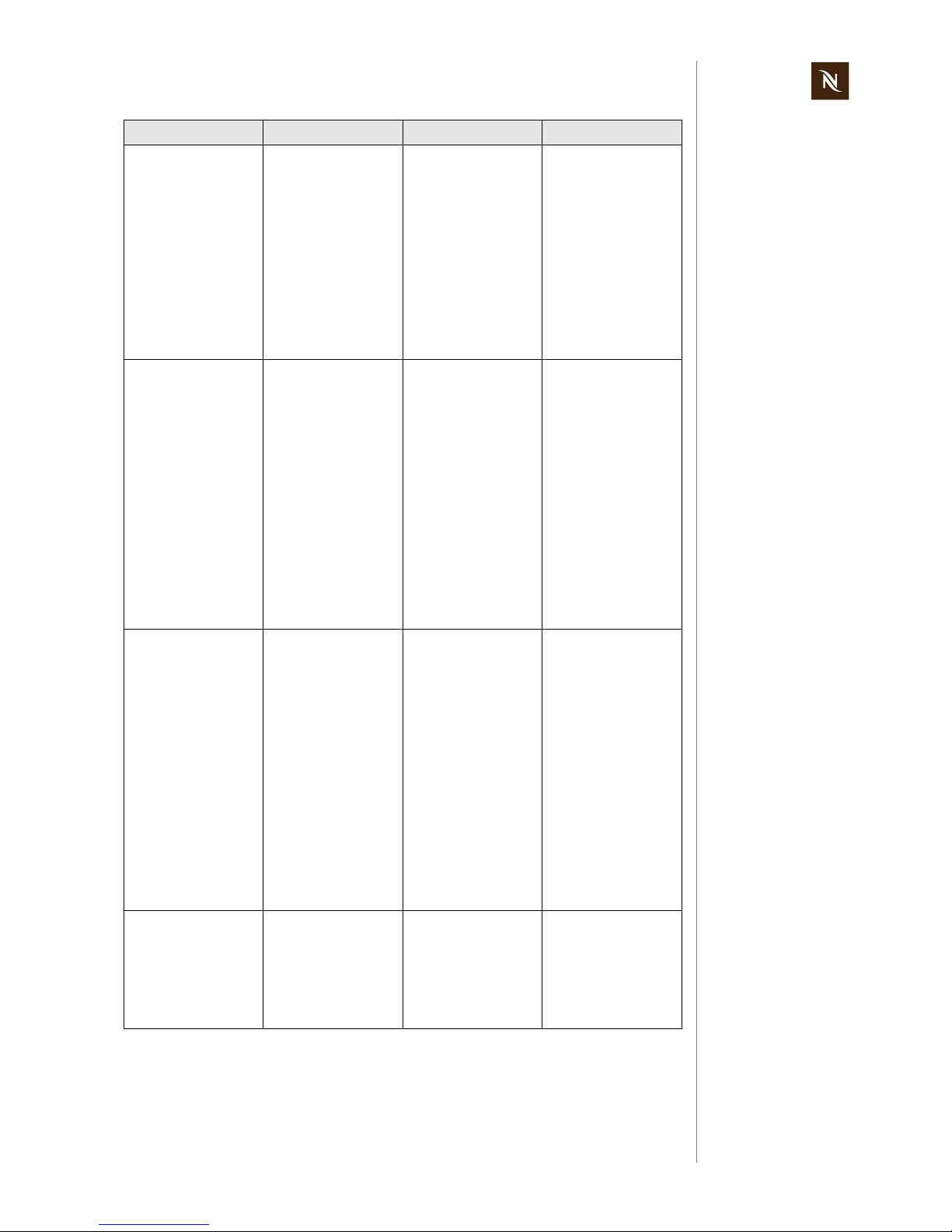

4.3.2 Machine modes of milk frother

The following table helps to understand the operating modes of the milk frother:

4.4 Nespresso App (application software)

The MMI PCB of the coffee machine is equipped with a Bluetooth® LE (low energy)

module that can establish a wireless connection to a smartphone or tablet.

A special application software (app) is necessary to enable the dat a exchange between

the devices.

The new, of ficial Nespresso App extends the functionality of the Prodigio coffee machine

with:

• Capsule stock management

- Out-of-stock notification

- Automatic counter update after capsule purchase

• Remote and programmed brewing

• Alerts notifications

- Capsule container full

- Capsule blocked

- Water tank empty

• Maintenance notifications

- Descaling

- Machine Errors

• Tutorials

4.4.1 Prerequisites

Smartphone / tablet

Compatible smartphones or tablets with Apple iOS 8.1 or newer:

- iPhone 4S and newer

- iPad 3rd Generation and newer

- iPad mini

- iPod touch 5th Generation and newer

Compatible smartphones or tab lets with Android op erating system version 5.0 or ne wer

and Bluetooth

®

Smart functionality:

- Galaxy S3 / S4 / S4 mini/ S5

- Nexus 5 / 6

Machine mode Enter mode Actions Exit mode

1 Hot milk / milk

froth preparation

Press start button briefly

Start button lights up red.

Milk is heated and mixed.

Automatic switch-off

after preparation

2 Cold milk froth

preparation

Keep start button pressed

for approx. 2 sec

Start button lights up blue.

Milk is mixed only.

Automatic switch-off

after preparation

Check compatibility

of other smartphones

or tablets on this website:

www.nespresso.com/prodigio

Page 23

Version 1.0 en Prodigio service manual

23

OPERATION

Nespresso App

Download the official Nespresso App version free of charge on your smartphone or

tablet depending on the operating system:

Check Bluetooth® function

• Check that Bluetooth® is enabled on the smartphone or tablet. Look for the Bluetooth

®

symbol on top of the screen or check settings.

• Make sure that the coffee machine is switched on a nd in re ady mode. Th en sear ch

for a Bluetooth

®

device with a compatible smartphone or tablet and ch eck if the

Prodigio coffee machine appears on the Bluetooth

®

devices screen.

If the coffee machine cannot be detected as a Bluetooth

®

device

- the Bluetooth

®

function is deactivated

- or the machine is already paired with a device (fixed CMID).

In both cases a reset of the coffee machine is necessary:

• Switch off machine.

• Press and hold the Espresso and Lungo buttons together for at least 4 sec.

• All the buttons will turn on for 2 sec. as a confirmation.

4.4.2 Pairing smartphone or tablet with coffee machine

Pairing is necessary to link the coffee machine to the smartphone or ta blet resp. the

Nespresso App.

The CMID (client machine identification) of the smar tp h one or tablet and th e ser ia l

number of the coffee machine are used for identification.

Operating system Store

Apple iOS

Android

Bluetooth® symbol:

It is possible to deactivate the Bluetooth

®

function of the coffee

machine with the following

procedure:

Press simultaneously Ristretto and Espresso buttons and remove the plug

from the mains.

A reset of the coffee

machine enables the Bluetooth

®

function again.

Beside the pairing of

2 Bluetooth

®

devices,

multiple pairing is also possible:

• Pair 1 coffee machine

with several Bluetooth

®

devices (same NNSA

account).

• Pair 2 coffee machines

with the same Bluetooth

®

device.

Page 24

Prodigio service manual Version 1.0 en

24

OPERATION

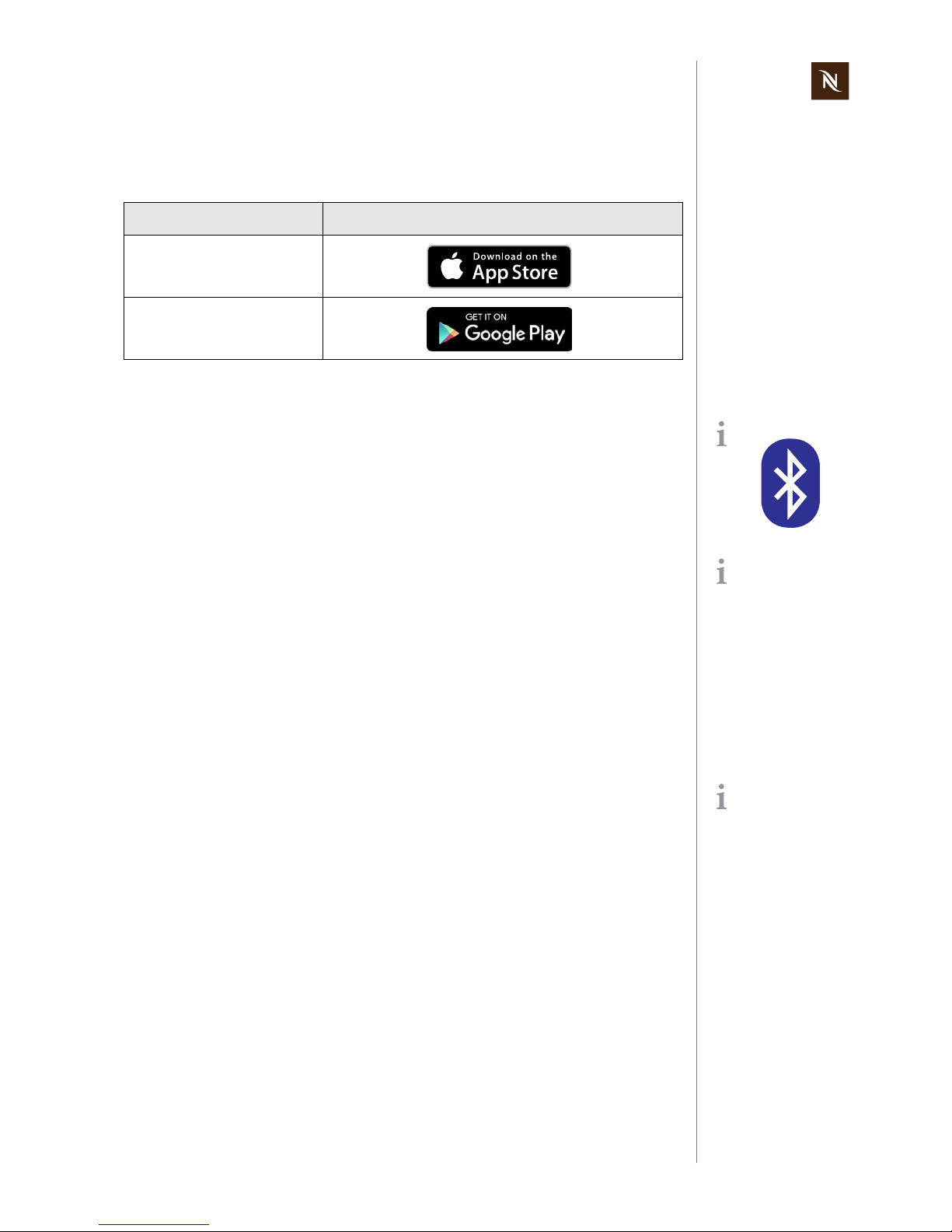

Pairing procedure

Nespresso App illus-

trations are either

symbolic or subject to

change depending on the

app version.

Even better, touch

coffee machine with

smartphone or tablet.

Pairing is not possible if the

distance between the two

devices is too big!

1) Switch on coffee machine by pressing

any coffee button.

2) Wait until lights stop blinking and

machine is in ready mode.

3) Hold a compatible smartphone or tablet in close proximity to the coffee

machine.

4) Launch Nespresso App on smartphone or tablet.

5) Touch machine icon.

6) Start search for coffee machine by

touching the Bluetooth

®

symbol.

7) Wait until coffee machine is detected.

Page 25

Version 1.0 en Prodigio service manual

25

OPERATION

If pairing has failed

• Make sure the smartphone or tablet is in close enough proximity to the coffee

machine.

• Charge up the smartphone or tablet before pairing. Its smart power management

may turn off Bluetooth

®

if the battery level is too low.

• Make sure not to turn on any microwave close to the machine during pairing.

• Maintain a sufficient distance to devices that can interfere with the pairing process

such as a Wi-Fi/WLAN router.

Special advice for service technician

If a customer’s coffee machine was paired in the re pair center (e .g. for troubleshootin g):

• Reset settings after pairing.

• Reset settings of Nespresso App after use and before sending back the machine to

the customer. Otherwise it is not possible for the customer to pair the coffee

machine.

• Advice customer to pair the coffee machine agai n at home and to check and ad just

the settings.

Multiple devices can

be connected to the

Prodigio coffee machine

only if using a unique

Nespresso club members

number (NNSA account).

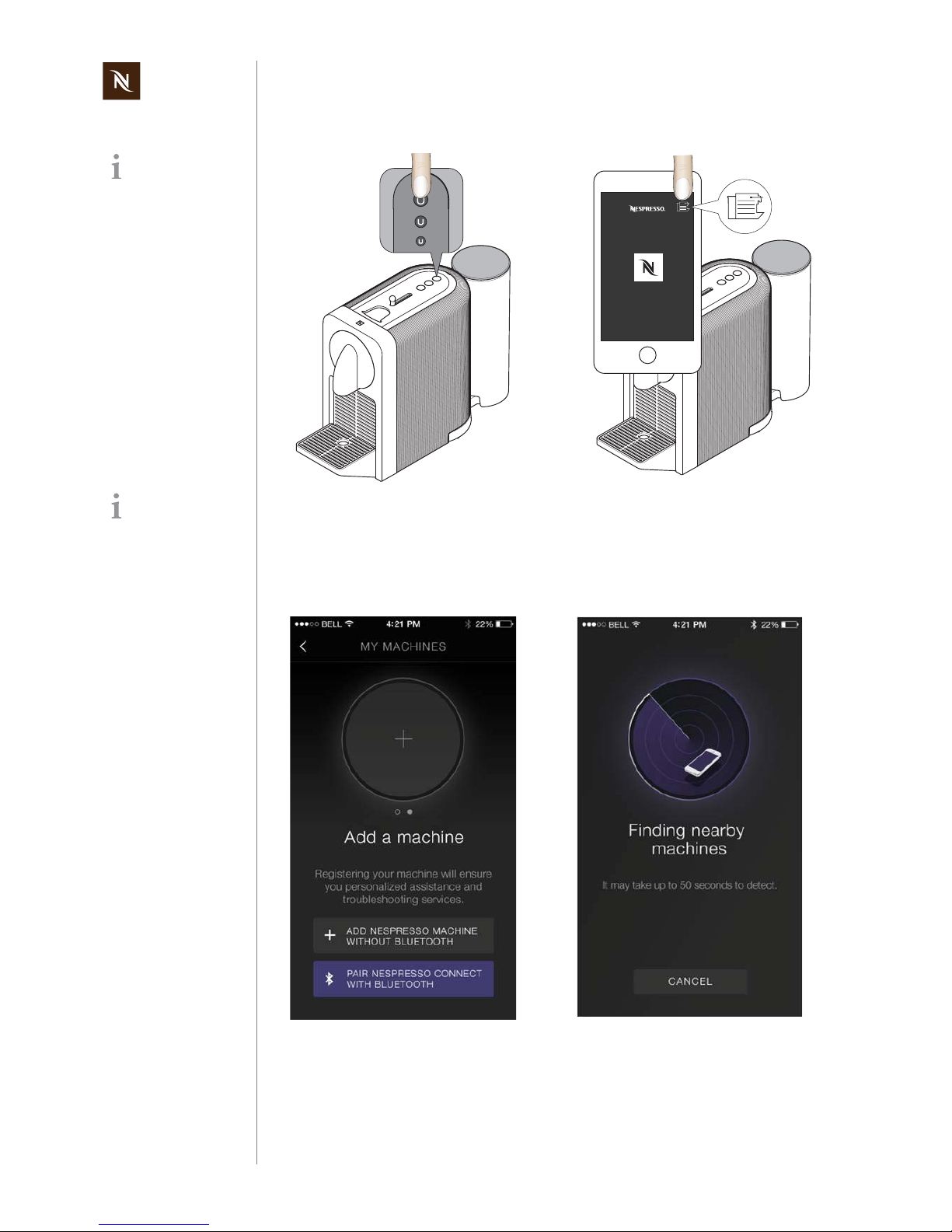

8) Ensure the smartphone or tablet is

placed next to the coffee machine during pairing.

9) Pairing takes place automatically.

10) When the pairing is completed, the

Nespresso logo on the front of the coffee machine will blink 3 times.

The Bluetooth® mod-

ule of the coffee

machine is situated at the

top, beside the coffee buttons.

Page 26

Prodigio service manual Version 1.0 en

26

OPERATION

4.4.3 Nespresso App - coffee machine setup

If the water hardness

test is omitted, level 5

(very hard water) is used as

default setting.

1) Enter name for coffee machine. 2) Use a test strip to determine the local

water hardness.

3) Select appropriate level. 4) Set the capsule counter.

Page 27

Version 1.0 en Prodigio service manual

27

OPERATION

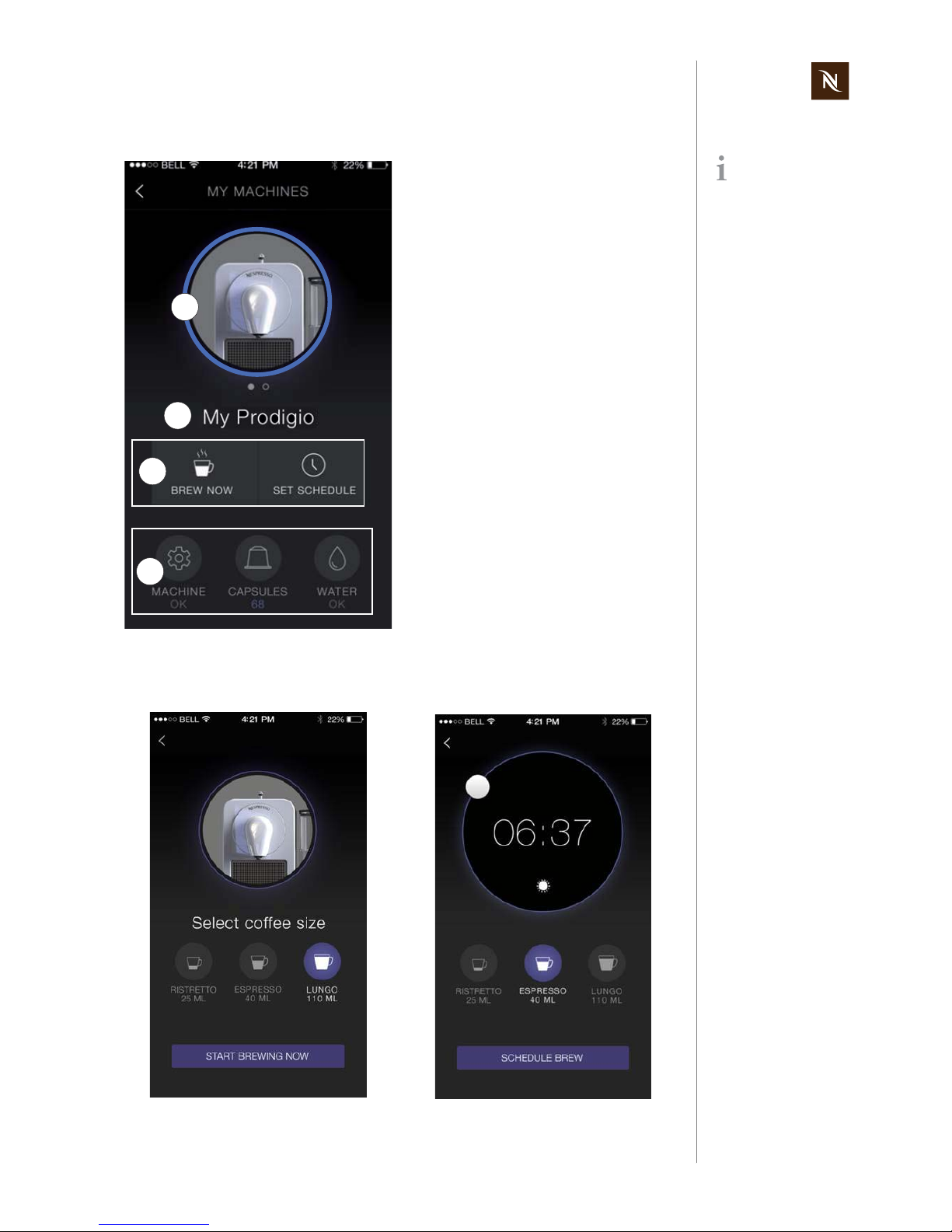

4.4.4 Nespresso App - machine page overview

4.4.5 Nespresso App - coffee brewing management

Touch the desired brewing menu icon on the machine page: Brew now / Set schedule

After multiple pairing,

different machine pictures can appear in the

machine menu.

1) Machine menu with

- corresponding machine picture

- ring showing overall machine status

(blue ... ok, orange ... problem,

error)

2) Individual machine name

3) Brewing menu

•Brew now

• Set schedule for coffee preparation

4) Status menu

• Machine

• Capsules

•Water

2

3

4

1

Page 28

Prodigio service manual Version 1.0 en

28

OPERATION

4.4.6 Nespresso App - machine management

Touch machine icon at the bottom of the machine page to display this submenu:

Touch desired submenu on machine management page for more information:

Example if machine status is ok (blue ring

around machine picture).

Example if machine status is not ok

(orange ring around machine picture).

Use the error code for

troubleshooting. Refer

to error code table on page

39.

Example of an error message.

Page 29

Version 1.0 en Prodigio service manual

29

OPERATION

Unpairing submenu

4.4.7 Nespresso App - capsule stock management

Touch capsule icon at the bottom of the machine page to display this submenu:

Caution!

In case of an unpairing, all setup s and specifications will be lost and the

coffee machine will be reset to factory settings.

1) Capsule stock management with

- stock status

- automatic adjustment

- manual adjustment

2) Change settings

3) Ordering portal

• Order history

• New order

2

3

1

Page 30

Prodigio service manual Version 1.0 en

30

OPERATION

4.4.8 Nespresso App - water management

Touch water drop icon at the bottom of the machine page to display this submenu:

4.4.9 Nespresso App - troubleshooting tips

1) Water tank management with

- message if customer needs to refill

the water tank

- no water alert

2) Descaling submenu with

- warning message before threshold

for descaling is reached

- link to descaling tutorial

3) Water hardness submenu

• Adjustment of water hardness level

Problem Remedy

The Nespresso App does not start.

Check internet connection of smartphone or tablet.

No orders or customer information about

capsule consumption are communicated to

Nespresso by the app.

Machine icon is missing on start screen of the

Nespresso App.

A flag icon appears instead of the machine

icon.

The services of the Nespresso App are not available in the current country.

Touch flag icon and select another country.

A programmed coffee preparation was not

executed

The command was not sent to the coffee

machine.

Touching the arrow in the top left corner of the

screen does not program the machine.

Press "Back to My Machine" and retry.

Someone has interacted with the coffee machine

manually or reprogrammed the machine with the

Nespresso app.

2

3

1

Page 31

Version 1.0 en Prodigio service manual

31

OPERATION

4.5 Empty water system

After every operation, some water (max. 25 ml / 0.85 oz) remains in the coffee machine.

Therefore the water system must be emptied

- if the coffee machine will not be used for a long time

- as an antifreeze measure

- for repairs and shipment.

After this procedure,

the coffee machine

will not be ready for approx.

10 min (until the thermoblock cools down to

below 100 °C).

Danger of scalding!

Very hot steam and water drops spray out of the coffee outlet.

• Do not reach under coffee outlet.

• Maintain a safe distance to the coffee outlet.

1) Remove the water tank.

2) Place a container under the coffee

outlet.

3) Close an open slider.

4) Press and hold the Ristretto and

Lungo coffee buttons together for at

least 6 sec.

The Espresso coffee button flashes

for confirmation.

5) Emptying process starts. Machine

turns to Off mode automatically when

empty.

6) Remove and empty the container.

Page 32

Prodigio service manual Version 1.0 en

32

MAINTENANCE

5 MAINTENANCE

5.1 Descaling

Descaling frequency based on water hardness:

5.1.1 Descaling procedure

Only use Nespresso descaler (5034) or Nespresso descaling kit

(3035/CBU-2)

– never use vinegar!

Descaler can damage casing and surfac e s.

Immediately clean drops of descaling solution.

The water hardness

can be adjusted any

time with the Nespresso

App.

Estimated cup capac-

ity: 40 ml / 1.35 oz

fH: French water hardness

dH: German water hardness

CaCO3 (Calcium Carbonate) in mg/l: American

water hardness

Water hardness

Test strip Level °fH °dH CaCO

3

Descaling after

0 < 5 < 3 < 50mg/l 4’000 cups

1 > 7 > 4 > 70 mg/l 3’000 cups

2 > 13 > 7 > 130 mg/l 2’000 cups

3 > 25 > 14 > 250 mg/l 1’500 cups

4 > 38 > 21 > 380 mg/l 1’000 cups

Observe the safety

instructions on the

descaler package.

Duration of descaling

procedure: approxi-

mately 15 minutes

1) Empty the drip tray and the used

capsule container.

2) Fill the water tank with 1 unit of

Nespresso descaling liquid and add

0.5 l /17 oz of water.

0.5 l

Use a container with a

capacity of min. 0.6 l /

20 oz.

3) Re-insert water tank and place a container under the coffee outlet.

4) To enter the descaling mode, press

and hold the 3 coffee buttons for at

least 6 sec.

A short beep sounds for confirmation

and the coffee buttons start blinking.

Page 33

Version 1.0 en Prodigio service manual

33

MAINTENANCE

The brewing unit stays

closed until the end of

the descaling mode.

5) Close an open slider.

6) Press any coffee button to start descaling.

Machine stops when water tank is

empty.

7) Refill the water tank with the used descaling solution collected in the container.

8) When ready, press any coffee button

to repeat the procedure. Machine

stops when water tank is empty.

9) Empty and rinse water tank, capsule

container and drip tray thoroughly.

10) Fill water tank with potable water.

11) Re-insert water tank.

12) Press any coffee button to rinse the

machine. Machine stops when water

tank is empty.

13) To exit the descaling mode, press and

hold the 3 coffee buttons for at least

6sec.

A short beep sounds for confirmation.

Page 34

Prodigio service manual Version 1.0 en

34

MAINTENANCE

5.2 Cleaning procedure for coffee machine

Risk of fatal electrical shock and fire!

Never clean wet or immerse plug, cord or appliance in any fluid.

Unplug appliance and let it cool down to avoid burns.

Risk of damage!

The lenses of the light barrier and the water tank can be scratched.

The surfaces of coffee machine and accessories are not abrasion-proof.

Do not use any strong or abrasive cleaning agent or solvent cleaner.

Do not use a brush to clean the water tank.

Do not put any part in a dishwasher.

Only use a damp cloth or sponge and a mild cleaning agent if necessary.

1) Empty maintenance unit (capsule

container and drip tray) daily.

2) Rinse and clean parts thoroughly if

dirty and wipe them dry with a soft

cloth.

3) Clean both lenses of the light barrier

inside the capsule ejection chute with

a clean, soft, slightly damp cloth.

4) Then clean area of maintenance unit.

Page 35

Version 1.0 en Prodigio service manual

35

MAINTENANCE

5.3 Cleaning procedure for milk frother

5) Rinse water tank and wipe dry with a

soft cloth.

6) Clean the coffee outlet regularl y with a

damp cloth.

Risk of damage!

The inside of the jug is coated for easy cleaning.

Never use brushes and/or cleaning agents that contain abrasive or

aggressive, chemical components resp. solvents.

Do not put any part in a dishwasher.

Use only a damp cloth and a mild cleaning agent if necessary.

Keep Otter connec-

tors dry (on swivel

arm and at underside of

milk frother).

The milk frother is

water-proof.

1) Remove milk frother from swivel arm.

2) Remove lid and whisk.

3) Remove seal from lid.

4) Rinse and clean milk frother together

with whisk, lid and seal.

5) Clean outside of milk frother with a

damp cloth if necessary.

Page 36

Prodigio service manual Version 1.0 en

36

TROUBLESHOOTING

6 TROUBLESHOOTING

6.1 Check list for coffee machine

After an initial inspec -

tion in accordance

with this check list, errors

are quickly found and corrected with the appropriate

measure.

Therefore, adhere to the

sequence of the check list.

Repair every occurring error

and work the check list

through until it is completed.

Check Error symptoms

Measure /

repair work

Further measures /

repair work

1 Check the coffee

machine for visible damage

1.1 Housing parts broken or damaged

YES - replace housing parts if

necessary

NO - continue

1.2 Power cord damaged

YES - replace power cord

NO - connect power cord of

machine to the mains and continue

2 Check mechani-

cal components

2.1 Cup support with

capsule container

and drip tray does

not remain in fitting

position

YES - check if drip tray has its

metallic plate for magnetic

mounting

NO - continue

NO - replace drip tray

2.2 Slider malfunction

YES - slider does not close or

open properly

NO - continue

YES - empty the capsule container

YES - check that no capsule is

blocked inside the machine

NO - replace slider unit

2.3 Capsule is not

ejected correctly

YES - replace brewing unit

NO - continue

3 Fill water tank 3.1 Water tank leaks

YES - replace water tank

NO - continue

4 Plug in machine to

perform automatic self test

4.1 Coffee machine is

not working

(does not function)

a) YES - power cord is okay

(loose connection)

YES - continue

NO - replace power cord

b) YES - pump works (press a

coffee button)

YES - continue with point d)

NO - continue with point c)

c) YES - all three coffee buttons are working

YES - replace pump

NO - replace electronic device

(main PCB) and/or touch pad

PCB (MMI PCB).

d) YES - fine wire fuses or triac

on thermoblock defective

YES - replace thermoblock

NO - continue

e) YES - wiring is okay

NO - continue with point 4.2

YES - replace main PCB (see

page 59)

NO - replace defective cables

4.2 Maintenance light

(orange) is blinking

with 2 Hz

YES - thermoblock is hot

NO - self test ok - continue with

point 4.3

YES - check / replace MMI

PCB (see page 49) and main

PCB (see page 59)

NO - replace thermoblock,

check / replace MMI PCB and

main PCB

4.3 Maintenance light

(orange) permanently lit

YES - capsule container full or

capsule ejection chute blocked

NO - continue

YES - empty capsule container

or remove obstacle

NO - clean lenses of light barrier (see page 34)

Page 37

Version 1.0 en Prodigio service manual

37

TROUBLESHOOTING

5 Test Bluetooth®

function

5.1 Pairing the

machine with a

compatible device

and Nespresso

App. does not work

a) YES - compatible device

with Nespresso App. has Bluetooth

®

mode activated and is

placed within a distance of

10 cm / 4 inch to the coffee

machine.

YES - continue

NO - try again and place compatible device with Nespresso

App. next to coffee machine

b) YES - Bluetooth

®

mode of

coffee machine switched off

YES - Reset coffee machine

(see page 21)

NO - Replace MMI board (see

page 49)

c) YES - pairing not possible

after replacement of MMI PCB

and main PCB

YES - retrieve machine serial

number from an original PCB of

the coffee machine.

5.2 Retrieve error code

with Nespresso

App

YES - check error code table

and begin with repair

NO - continue

(see page 39)

6 Rinse coffee

machine

6.1 No water at coffee

outlet

YES - a) water system is empty

YES - fill the water system

NO - continue

YES - b) coffee machine is calcified

NO - continue

YES - descale coffee machine

(see page 32)

YES - c) pyramide plate

blocked

YES - replace brewing unit

NO - continue

YES - d) flowmeter blocked YES - clean or replace flowme-

ter

NO - continue

YES - e) pump cannot produce

sufficient water pressure

YES - replace pump

NO - continue

7 Measure coffee

temperature during coffee preparation (see page

82)

7.1 Temperature is too

low (below 83°C)

YES - descale coffee machine

(see page 32)

NO - continue

7.2 Temperature too

high (over 89 °C)

YES - replace thermoblock

NO - continue with point 8

8 Check for leakage

and sufficient flow

rate

8.1 Hose connections

leak

YES - replace high pressure

connector

NO - continue

8.2 Brewing unit leaks

YES - replace brewing unit

NO - continue

8.3 Rate of flow not

within standard

range (60-120ml in

30 sec)

YES - coffee machine is calcified

NO - continue with point 9

YES - descale coffee machine

(see page 32)

NO - replace pump

9

Descale coffee

machine

(if necessary)

9.1 Coffee machine is

calcified

YES - descale coffee machine

(see page 32)

NO - continue with point 10

10 Check water tank

contents after descaling and rinsing

10.1 Particles of calcium and rust visible in water

YES - descale and rinse coffee

machine again to clean water

circuit

(see page 32)

NO - continue

YES - inform customer to descale coffee machine periodically and to use the specified

descaling product only.

10 Final cleaning

(see page 34)

No errors found according to

check list?

YES - for more information

please contact Nespresso

Service Division

End of check list

Check Error symptoms

Measure /

repair work

Further measures /

repair work

Page 38

Prodigio service manual Version 1.0 en

38

TROUBLESHOOTING

6.2 Check list for milk frother

The milk frother is part

of the Prodigio&milk

coffee machine.

Check Error symptoms

Measure /

repair work

Further measures /

repair work

1 Check milk frother

and accessory for

visible damage

1.1 Lid/seal broken or

damaged

YES - replace lid/seal

NO - continue

1.3 Whisk broken or

damaged

YES - replace whisk or spring

NO - continue

4 Place milk frother

on swivel arm

connector.

Attach whisk.

Plug in coffee

machine.

Press start button

briefly (hot milk

preparation).

4.1 Milk frother is not

working (does not

function)

YES - a) coffee machine is

heating up

YES - continue

NO - continue with check list for

coffee machine

YES - b) connector on swivel

arm is ok (test it with another

milk frother)

YES - replace milk frother

NO - replace connector on

swivel arm (see page 54)

4.2 Abnormal noise

during preparation

YES - replace milk frother

NO - continue

4.3 Milk frother does

not switch off automatically

YES - replace milk frother

NO - continue

4.4 Inside of jug stays

cold

YES - replace milk frother

NO - continue

5 Press start button

for at least 2 sec

(cold milk preparation)

5.1 Start button is not

backlighted in blue

YES - replace milk frother

6 Final cleaning

(see page 35)

No errors found according to

check list?

YES - for more information

please contact Nespresso

Service Division

End of check list

Page 39

Version 1.0 en Prodigio service manual

39

TROUBLESHOOTING

6.3 Machine error code table

Use the Nespresso

App to get an error

code for troubleshooting

(see page 28).

This error code table

is for machine errors

only. See Nespresso technical website for a complete table.

Error code Machine error / error level Description

1001

Electronic malfunction / serious error

SPI communication error during firmware update or

serious electronic component failure

Upp voltage observation:

input short to ground or to V

DD

Upp voltage observation error

1002

General malfunction / serious error RESET state timeout

1003

Heating-up not complete / serious error Thermoblock timeout during heatup

1004

Heating-up not working / serious error No reaction from thermoblock

1005

Motor malfunction / serious error

Motor BU current input short to V

DD

Motor BU current input error

Motor moving BU timeout after direction has been

reversed

Motor moving BU timeout while moving to end posi-

tion the first time

Current measurement error

Voltage measurement error

1006

Pump overheat / safety timeout The pump may overheat when brewing too many

coffees in a row. This error is due to an overheat

prevention mechanism. Wait a few minutes before

brewing the next coffee.

1007

Inappropriate temperature detected /

serious error

The thermoblock temperature is too high. Wait a few

minutes before brewing the next coffee. Repair if

error continues.

1008

Temperature sensor malfunction / serious error

NTC1200 short to ground

NTC1200 short to V

DD

NTC measurement error

1009

Capsules container full or not present /

harmless error.

Brewing while capsules container is full or not

present. The machines’ capsule container is not well

placed in the machine or the capsules container

capacity is exceeded. The same detector is used to

handle both cases.

End of machine error code table

Page 40

Prodigio service manual Version 1.0 en

40

REPAIRS

7 REPAIRS

These repair instructions

- are based on exploded drawings with position numbers combined with repair and

mounting tips,

- presuppose basic knowledge in repairing Nespresso coffee machines.

7.1 Safety instructions

7.2 Repair and mounting tips

These general advices are completed with specific repair tips in this chapter.

Additional information

The Prodigio coffee machine is shown for general repair procedures while the

Prodigio&milk coffee machine is shown solely for the repair resp. replacement of the

swivel arm with the Otter connector.

For components not mentioned in this repair chapter, refer to the chapter "Explosion

drawings and parts lists" on page 93.

Snap connections

Parts of the case and component s of the cof f ee machine a re connected scre wless with

latches.

When loosening these latches, proceed with care and patience to avoid

causing any damage.

Designation of spare parts

The components in the following illustrations are indexed with position numbers.

See separate spare parts list for corresponding spare part numbers.

Electrostatic discharge (ESD) protection

The service technician must observe basic ESD protection measures when installing a

new MMI board or electronic module.

Risk of fatal electrical shock!

Mains voltage inside the coffee machine.

Disconnect the mains plug before disassembly - the coffee machine

must be free of voltage.

Danger of burns!

Hot parts and water under pressure inside the coffee machine

(thermoblock in particular).

Let coffee machine cool down before disassembly.

Only use original spare p arts from your official su pplier for maintenance

and repair work.

Position numbers are

subject to change

without notice.

Page 41

Version 1.0 en Prodigio service manual

41

REPAIRS

Wiring arrangement

Random changes in the wiring arrangement of the wired model version during a repair

can cause

- electromagnetic interferences,

- squeezed wires,

- insulation defects due to contact with hot parts,

- insulation problems if low and high voltage wires are not separated,

- interference with and damage to electronics.

Protective measures:

• Refer to wiring diagram when reconnecting cables and wires.

Residual water

• If it is necessary to pull off hoses, hold ready a small receptacle and a towel to collect

and wipe away leaking water.

• A special procedure is necessary to empty the fluid system of the coffee machine for

repair or shipment (refer to "Empty water system" on page 31).

7.3 Tools and accessories

With the following assortment of tools, all repairs described can be made:

A bit holder with

appropriate bits can

also be used.

1) Torx screwdriver TX10 with safety pin

2) Torx screwdriver TX20

3) Flat blade screwdriver e.g. no. 01

(3.5 mm blade width)

4) Pointed pliers

5) Side cutting pliers

6) Receptacle and towel to catch and

wipe away leaking water

1

TX 10

3.5 mm

4

5

3

TX 20

2

Page 42

Prodigio service manual Version 1.0 en

42

REPAIRS

7.4 General disassembly

This subchapter shows all necessary disassembly steps to gain access to the main

assembly (slider unit, brewing unit, thermoblock, pump and electronic device).

7.4.1 Prepare coffee machine for disassembly

1. Check and remove any capsule from the brewing unit. Close the slider.

2. Empty the water system if hoses have to be detached for repair (see “Empty water

system” on page 31).

3. Disconnect power plug and let coffee machine cool down.

4. Remove all detachable parts from coffee machine:

Drip tray with cup support and drip grid, used capsule cont ainer , water t ank with lid

and milk frother (Prodigio&milk only).

1

3

4

Close brewing unit if

drop stop (7) has to

be removed (see page 47).

Page 43

Version 1.0 en Prodigio service manual

43

REPAIRS

7.4.2 Remove outlet cover

• Press up outlet cover (8) and pull it out from front cover (64).

64

8

Page 44

Prodigio service manual Version 1.0 en

44

REPAIRS

7.4.3 Remove front cover

• Reach into circular opening and release 2 latches of front cover (encircled).

• Swing out front cover (64) at the bottom until it touches the drop stop (7).

• Press up drop stop and continue swivelling the front cover (6 4) until the 2 hinges on

its top are released.

Assembly hint

• Insert both hinges on top of front cover (64) into counterparts on blind (2) first.

• Then swivel front cover downwards over drop stop (7) and snap it into place.

2

64

7

Take care not to

scratch the surface

and keep the front cover at

a safe place.

Page 45

Version 1.0 en Prodigio service manual

45

REPAIRS

7.4.4 Remove cover

• Loosen 1 screw (40, Torx screw TX10 with safety pin) at the rear side of the cover

(1) - see detail.

• Loosen 2 screws (15, Torx screws TX10 with safety pin) on underside of chassis (6).

15

6

40

1

Page 46

Prodigio service manual Version 1.0 en

46

REPAIRS

• At the bottom of the cover (1): Push both sides away from chassis (6).

• Then push cover to the rear and upwards.

6

1

If the cover (1) is only

pushed backwards, 2

of its ribs (encircled) will

break.

Page 47

Version 1.0 en Prodigio service manual

47

REPAIRS

7.4.5 Remove blind

1. Release 4 latches (2 on each side) with screwdriver and remove blind (2) from print

cover (5).

Assembly checkpoint

• Check functionality of slider (73) if print cover (5) was removed subsequently.

5

2

73

57

Take care no to damage the light guide

(57).

Page 48

Prodigio service manual Version 1.0 en

48

REPAIRS

7.4.6 Remove drop stop

• Press drop stop (7) together by hand to release pivots.

• Push drop stop underneath steam cover (34).

T o dismantle the drop

stop, the brewing unit

must be closed.

Use a a cordless drill

driver connected to

the motor to close the unit

or, before dismantling the

machine, start a coffee

without a capsule and

remove the power plug during extraction.

7

34

Page 49

Version 1.0 en Prodigio service manual

49

REPAIRS

7.4.7 Remove MMI board and light guides

1. Remove light guide (60) from MMI board (3) and light guide rack (63).

2. Remove second light guide (60) on other side of machine (not shown).

3. Unplug flat cable from electronic module (81).

4. Remove MMI board (3) together with silicon keypad (54).

.A replacement PCB (MMI PCB or main PCB) has no stored machine serial number

but will retrieve it from the other original PCB after switching on the coffee machine.

Assembly checkpoints

• Use ESD protection measures when installing a new MMI board (3).

• Check that flat cable is inserted in slot on print cover (5) - see red circle.

• In case MMI PCB and main PCB have to be replaced together:

• Replace first PCB only.

• Plug in and switch on coffee machine. Wait for a sho rt time.

• Then switch off and unplug coffee machine.

• Continue with repair and replace second PCB.

• Check if pairing is still possible after repair.

81

54 + 3

60

60

60

5

63

Handle with care!

Light guide connectors on MMI board and

chassis are fragile.

Caution - Nespresso App can be locked!

Do not replace MMI PCB together with main PCB at once. Otherwise the

machine serial number, stored on the original PCBs, will be lost and

pairing resp. using the Nespresso App is not possible anymore.

Page 50

Prodigio service manual Version 1.0 en

50

REPAIRS

7.4.8 Remove lever and light barrier

• Remove spring (68).

• Remove lever (67) - see upper detail:

• Press latch (circled in red) against lever and turn lever clockwise.

• Pull out lever.

• Remove light guide rack (63) together with lens (62) - see lower detail:

• Release 2 latches of light guide rack.

• Insert a finger in capsule ejection chute and press it against the lens to push out

the light guide rack.

• Lever lens (62) out of light guide rack (63) with a small screwdr iver.

• Remove second light guide rack (63) and lens (62) on opposite side of coffee

machine the same way.

68

63

62

67

63

62

Handle with care!

Do not scratch new

lenses.

Page 51

Version 1.0 en Prodigio service manual

51

REPAIRS

7.4.9 Remove print cover

1. Check position of ratchets (4) for reassembly.

2. Release 4 latches (2 on each side) with screwdrive r an d re m ov e pr int cove r (5)

from chassis (6).

3. Remove light guides (56, 57, 58) from print cover if necessary.

Assembly checkpoint

• Align ratchets (4) on print cover (5) before assembly.

4

5

6

57

56 58

Handle with care!

Ratchets (4) can drop

from the print cover and get

lost.

Incorrect positioned

ratchets (4) will block

the slider in the blind (2).

Page 52

Prodigio service manual Version 1.0 en

52

REPAIRS

7.4.10 Remove pivot bottom, water tank connector and

power cable

• Release 5 clips on pivot bottom (19) with a screwdriver.

• Remove pivot bottom from pivot top (17).

• Remove water tank connector (20) from pivot bottom and pull off it s hose from flow-

meter (22) in electronic module.

20

19

17

22

Page 53

Version 1.0 en Prodigio service manual

53

REPAIRS

• If necessary turn pivot top (17) to gain access to the cable bracket (18).

• Remove the cable bracket (18) with a screwdriver.

• To remove the connection cable (48):

• Unplug both insulated angled Faston receptacles with the help of a screwdriver

or pointed pliers from electronic module (see lower detail).

• Unplug Faston receptacle of protective earth cable from thermoblock (35) - see

upper detail.

Assembly checkpoint

• Never re-use a damaged connection cable (48).

Do not try to remove

the cable bracket (18)

from the underside of the

coffee machine. The cable

bracket will then probably

be destroyed.

The cable bracket is

hooked at one side.

Place screwdriver like

shown in detail.

18

17

The cable bracket

(18) is under tension.

Therefore, fix the cable

bracket with your finger

when unlatching it.

48

35

Caution - fragile

insulation on Faston receptacles.

Handle with care if connection cable (48) is to be

re-used.

Page 54

Prodigio service manual Version 1.0 en

54

REPAIRS

7.4.1 1 Remove pivot bottom, water tank connector , power

cable and Otter connector (Prodigio&milk)

• Loosen 3 screws (TX10 torx screws) from pivot bottom milk (19).

• Release 5 clips on pivot bottom milk (19) with a screwdriver.

19

19

Page 55

Version 1.0 en Prodigio service manual

55

REPAIRS

• Remove pivot bottom milk (19) from pivot top milk (17).

• Remove water tank connector (20) from pivot bottom milk and pull off its hose from

flowmeter (22) in electronic module.

• Remove cable bracket (18) - see procedure on page 53.

20