Neptune MAH5500B, MAH55FL Technical Information

Neptune Front Load Washer

⎯⎯

⎯Technical Information

⎯⎯

MAH5500B*, MAH55FL*

• Due to possibility of personal injury or property damage, always contact an authorized technician

for servicing or repair of this unit.

• Refer to Service Manual 16010061 for detailed installation, operating, testing, troubleshooting, and

disassembly instructions.

CAUTION

!

All safety information must be followed as provided in Service Manual 16010061.

.

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless

testing requires power.

Leaking

• Make sure supply hose connections are not

leaking. Check for rubber gasket damage due to

overtightening.

• Make sure end of drain hose is correctly inserted

and secured to drain facility.

• Avoid overloading which can push the door

partially open.

• Check internal hose connections

• Check tub cover. Remove, reposition and reinstall

the tub cover seal. Seal seam must be at the

top of the tub cover.

Display Lights Up When Door Opened

• This is normal behavior.

No Tumble

• Washer does not tumble for the first 30 seconds

after the door has been opened for safety purposes.

• Fabric cycles such as DELICATES and HAND

WASH only tumble for a few seconds every 30

seconds.

• Check for loose connections at machine control

board, motor control board and motor.

• Perform Motor and Motor Control Test.

• Washer does not tumble during some drains and

rinse fills.

!

WARNING

Noisy

• Clothes washer should be leveled properly as

outlined in installation instructions.

• Weak floors can cause vibration and walking.

• Check for loose lower front bracket

• Be sure rubber feet are installed on leveling legs.

• Check that the leveling leg lock nuts are

tightened.

• If complaint is a high-pitched noise during fill then

disconnect supply hoses and clean screens.

• Check for proper spring placement of outer tub

support springs.

• Check strut operation.

Tub is completely full of suds

• Run the clothes washer through another complete

cycle using cold water and no more detergent.

• Reduce detergent amount for that specific load size

and soil level. Towel loads have a minimal amount

of soil present and typically create more suds.

• Use high efficiency or low sudsing detergent

specially formulated for front load washers.

• Check for restricted drain system.

• Check for loose wire connections at control board

and pump.

• Check to see if belt fell off motor and pulley.

• Perform Motor and Motor Control Test.

No Water Fill

• Check to make sure water supply turned on fully.

• Normal water level is only 2.5 to 5 inches inside

the spinner.

• Check for kinks in inlet hoses.

• Check for clogged inlet screens.

• Visually check hot and cold separately at

dispenser for proper flows.

• Go to No Fill Test page 6.

16025861 1 December 2004

©2004 Maytag Services

Wet Clothes

• Very small clothes loads can cause unbalances

add additional towels.

• Excessive suds may have been present. Check

for diagnostic code 16.

• Check unbalance harness connections at all

switches and at Control Board.

Troubleshooting

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

• Check for restricted drain system.

• Perform Motor and Motor Control Test.

Will Not Lock

• Door not all the way closed.

• Check electrical connections at lock assembly and

machine control board. Go to Door Lock Test.

Will Not Unlock

• Unplug and reconnect the power cord and wait 2

minutes to see if machine unlocks.

• Check for door locked switch circuit to be closed

at machine control. (See board input/output chart)

• Check to make sure belt has not fallen off.

• Check for loose electrical connections at door lock

and at machine control board.

• Perform Motor and Motor Control Test.

Will Not Start

• Plug cord into live electrical outlet.

• Check fuse or reset circuit breaker.

• Push the START/PAUSE button to start the clothes

washer.

• Close door and push the START/PAUSE button to

start the clothes washer. START/PAUSE LED

should change from flashing to on continuously.

• Check to see if the washer is in a pause or soak

period in the cycle. Wait briefly and it may start.

• Check for restricted drain system.

Will Not Drain

• Check for restricted drain system.

• Check low and high water levels. Go to No Fill test

• Check for 120 VAC at the pump when a spin cycle

is selected.

Wrong Water Temperature

• Too Hot/Too Cold; since this product uses a low

amount of water, the board regulates the incoming flow to temper the actual temperature of the

water in the tub. This may appear to be

significantly warmer/cooler than expected.

WARNING

• Are both faucets on fully?

• Make sure temperature selection is correct.

• Make sure hoses are connected to correct

faucets and inlet connections. Flush water line

before filling washer.

• Check the water heater. It should be set to

deliver a minimum 120°F (49°C) hot water at the

tap. Also check water heater capacity and

recovery rate.

• If the water heater is located a long distance from

washer, water line may need to be purged prior to

starting wash cycle.

• Disconnect inlet hoses and clean screens.

• This washer can sense if the fill hoses have been

reversed between hot and cold. If the fill hoses on

the washer were previously installed incorrectly

and then corrected, the washer will need to be

run through a Hot / Cold cycle. If not resolved,

check for proper resistance on the water valve

thermistor. (See board input/output chart)

Codes Displayed On Console

If owner observes codes on display, see table

below.

Sd = Suds: Machine has detected high level of

suds. The machine will alter its cycle for

this situation. Use an HE detergent or cut

down on the amount of detergent slightly.

This can be more likely on towel loads,

consider HE detergent especially for these

loads.

do = Door is Open: The door of the machine is

open. Please make sure door is fully closed

before starting cycle.

December 2004 2 16025861

©2004 Maytag Services

Continued on next page..........

Troubleshooting

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

CONSUMER CODES: Cont'd

od = Open the Door: The door has not been

opened since the end of the last cycle. As a

safety check the door must be opened at the

completion of every cycle.

nF = No fill: the machine has tried to fill but cannot.

See No Water Fill.

PF = Power failure: power to the machine has been

lost during the last cycle. This may occur on

start up of a new machine due to factory

testing.

LO = Locked: Door is locked (failed to unlock) - the

machine has repeatedly tried to unlock but

cannot. Push door closed to make sure

nothing from the inside is pressing against

the door which make keep it from unlocking.

FL = Failed to lock: the machine has repeatedly

tried to lock the door but cannot. Make sure

the door is shut completely

nd = No drain - the machine has tried to drain but

retnEoT

syeKsserP

lamroN

eerFelknirW

kciuQ

nipStseTnipSkciuQesuaP/tratS

lioSthgiL

setacileD

esniR

kaoserP

Membrane Pad Check Test

While in service mode, pressing the wrinkle free

key will start a membrane pad switch check.

laicepS

noitcnuF/tseT

rotoMswohS

euqroT

bmeM

kcehC

tseT

yalpsiD

rebmuN

elcyC

tseT

sedoC

daPenar

nwoDemiTtsaF

s

erawtfoS

noisiveR

ecivreSkciuQ

tuptuOdraoB

citsongaiD

cannot.

Lr = Locked Rotor: the machine has repeatedly

tried to turn the motor but cannot.

The membrane check involves turning all the embedded LED lights on the membrane pad except

for the wrinkle free key. All the LEDs can be

System Diagnostics

SERVICE MODE

The service mode provides service personnel the

ability to verify the operation of the washing machine.

toggled by pressing the key associated with the

LED. At any point, if there are 10 minutes of inactivity, then this test will exit. Press the off key twice

within 30 seconds to cancel test.

The service mode can be entered in the middle of

any wash cycle. While in the service mode, the

servicer can start a variety of special service tests.

Fast Time Down Test

While in service mode, pressing the quick key

will advance the program to the next wash cycle.

Accessing Service Mode:

Pressing down the delicates and heavy soil keys for

3 seconds places the machine in the service mode.

Motor speed will be displayed when started. To exit

Service Mode, press delicates and heavy soil keys

for 3 seconds again. The following table lists the

various tests available while in the Service Mode,

which can be accessed by pressing the following

keys:

tixEoT

noitcnuF

esuaP/tratS

ro.ces5tiaW

eciwtffOsserp

esuaP/tratS

esuaP/tratS

esuaP/tratS

esua

P/tratS

esuaP/tratS

16025861 3 December 2004

©2004 Maytag Services

Troubleshooting

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

WARNING

Quick Service Cycle

foegatS

elcyChsaW

kaoserPkaoserPfodnE

hsaW

niarD/nipSehTfopetSyrevE

nipS

esniResniRfodnE

Quick Spin Test

While in service mode, the pressing of spin key shall

start the washer in the quick spin mode.

The following Quick Spin test steps are as follows:

1) Lock the door.

2) Spin to 350 rpm and hold for 6 seconds.

3) Spin to 550 rpm and hold for 6 seconds.

4) Spin to 600 rpm and hold for 6 seconds.

5) Spin to 650 rpm and hold for 6 seconds.

6) Spin to 800 rpm and hold for 6 seconds.

If the Spin key is pressed again during the Quick Spin

test, the current speed will be held indefinitely. Pressing the Spin key again will allow the quick test to

proceed as listed above.

When the washer is in the Service Mode, the speed

will be displayed as a two digit number or a letter/

number.

oTsecnavdA

fosetuniM5yrevE

emiThsaW

eliforP

While in service mode, pressing the delicates key

will start a quick service cycle. This will be a quick

check of all systems.

The following steps will be followed.

1. Energize the cold and bleach water valves. Fill to

Low level, then turn bleach and cold off.

2. Energize the hot and fabric softener water valves. Fill

to high level, then turn all valves off.

3. Lock the door.

4. Tumble using 7/3 tumble pattern for 12 sec.

5. Turn the drain on.

6. Spin to 800 RPM using default rates.

7. End spin and coast down.

8. Unlock the door when the RPM is zero.

9. Display a ‘PA’ (Passed) on continuously for 10 seconds if no diagnostic codes were logged during this

test.

The up arrow if pressed will advance to the next step.

The right most dot will be turned on as an indication

of failure and stay on until quick service cycle test

has reached the end. Any diagnostic code logged

during this test will result in failure of the test, but will

not necessarily stop the test. While in quick service

cycle, the pressing of the hand wash will suspend

the machine at this step for 30 minutes until the

Hand Wash key is pressed again. All LED’s will

flash on and off while the cycle is suspended, or on

hold.

Motor Drive System

To check the system, check the board for proper

output to the motor control. Performing a board

output test does this. Then perform the Motor

Control Board Output Test.

egnaRdeepSdeyalpsiD

mpr99-0)a

mpr999-001)b

December 2004 4 16025861

©2004 Maytag Services

01/deepS

Motor Control Board Output Test

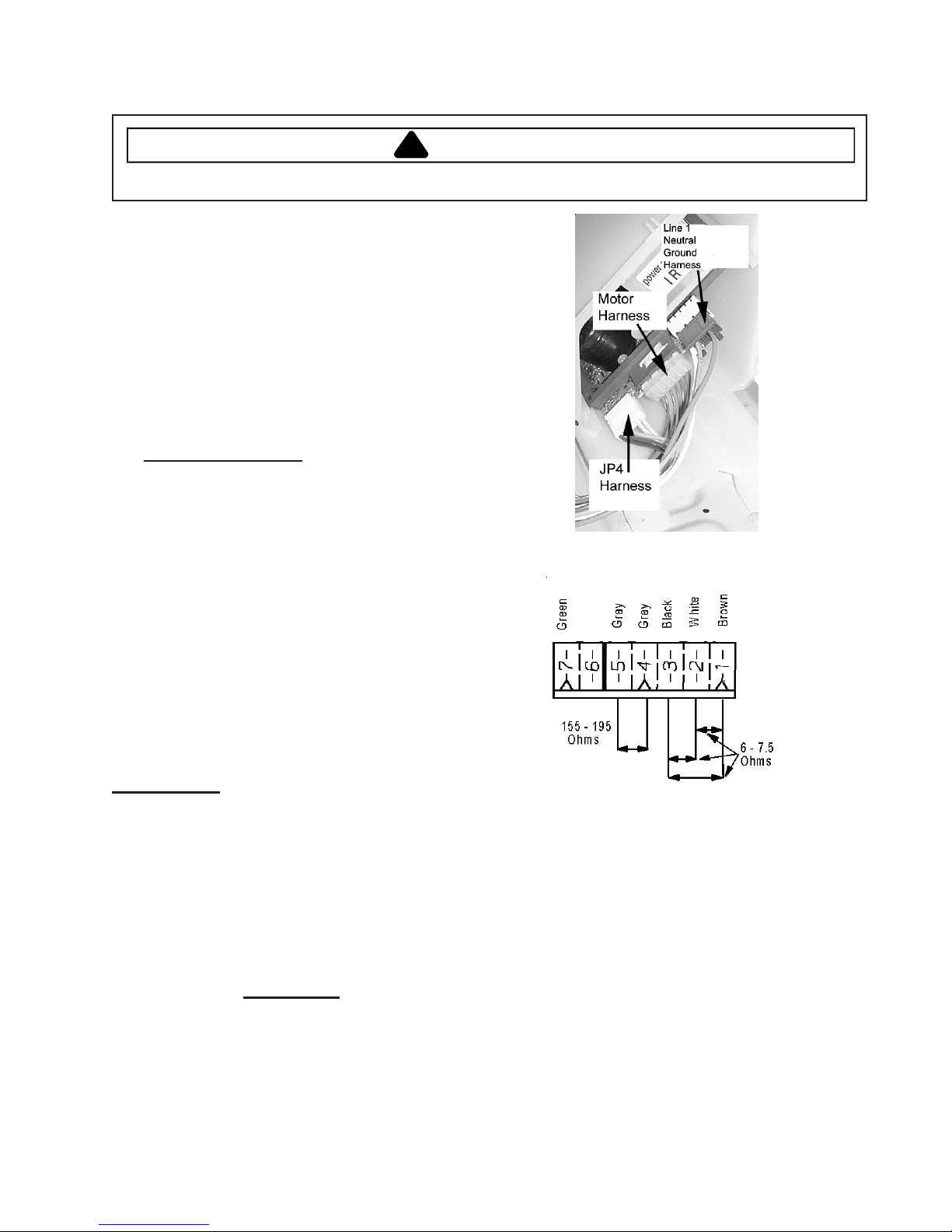

1. Disconnect power to the washer.

)lautca(99-0

2. Remove the front panel and pull the JP4 Connector

from the motor control board.

3. Reconnect the washer power cord to supply

voltage. Make sure the door is closed.

4. Press delicates and heavy soil keys for 3 sec-

onds to activate Service Mode.

Troubleshooting

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

5. Access Board Output Test by touching the rinse

key to activate.

6. The door must be locked to access Motor Con-

trol Board Output Test. To lock the door press

max extract. Press max extract again stop the

door lock output test once the door is locked.

7. Press stain cycle to start the motor control

output test. This will send 120VAC to the motor

control board. The motor control will immediately

execute a test routine and the motor should run,

rotating the spinner at 50 rpm.

8. If motor does not run;

• Check for 120 VAC at the motor control board harness. See Figure 1.

If voltage is present, then problem lies with the

motor and motor control system.

• Check for loose electrical connections at mo-

tor and motor control board.

• Check phase windings of the motor. See Fig-

ure 2. If motor windings are good, replace the

motor control board.

WARNING

Figure 1

Motor Control Board/JP4 Connector

If voltage is not present;

• Check loose electrical connections at machine

control board or broken wires in harness.

• Check door actuator switch and related wiring.

Door Lock Test

Placing the washer into the Service Mode and

manually locking and unlocking the

door mechanism through the control panel can

verify the door lock. Note: The relay on the control

board for the door unlock mechanism is disabled if

the motor control board indicates the spinner speed

is > 7 RPM.

1. Place the washer into Service Mode. (See

Service Mode)

2. Advance to the Board Output Test and press

max extract to lock the door. A lock signal

will be sent to the solenoid every second for 10

seconds. If the door does not lock; use a

voltmeter, look for 120VAC, 60 millisecond

pulse to the locking solenoid.

Figure 2– Schematic – Motor Harness

3. If signal is present, then the door lock sole-

noid is bad and the door lock mechanism must

be replaced. (Assuming the door was fully

closed.) To stop the signal, press max extract

again.

4. If signal is not present, check electrical

connections at switch or at control board.

Check for proper outputs from the control board

at Conn P1(1) and Neutral leg of power cord. If

voltage is present, fix electrical connections or

change wire harness. If no voltage is found, go

to P8(4) and Neutral on power cord to verify

120VAC coming into the board. If voltage is not

present check the door actuator switch. (make

sure door is closed.) If voltage is present,

change machine control board.

16025861 5 December 2004

©2004 Maytag Services

Loading...

Loading...