Page 1

MACH 10®Ultrasonic Meter

Installation and Maintenance Guide

Page 2

Page 3

MACH 10®Ultrasonic Meter

Installation and Maintenance Guide

Page 4

Copyright

This manual is an unpublished work and contains the trade secrets and

confidential information of NeptuneTechnologyGroupInc., which are not to be

divulged to third parties and may not be reproduced or transmitted in whole or

part, in any form or by any means, electronic or mechanical for any purpose,

without the express written permission of NeptuneTechnologyGroupInc. All

rights to design or inventions disclosed herein, including the right to

manufacture, are reserved to NeptuneTechnologyGroupInc.

Neptune engages in ongoing research and development to improve and

enhance its products. Therefore, Neptune reserves the right to change product

or system specifications without notice.

Trademarks Used in this Manual

MACH 10®and E-CODER®are registered trademarks of Neptune Technology

Group Inc. MACH 10®)R900i™, and ProRead™ are trademarks of Neptune

Technology Group Inc. Other brands or product names are the trademarks or

registered trademarks of their respective holders.

FCCNotice

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

l This device may not cause harmful interference.

l This device must accept any interference received, including interference that

may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCCRules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of

the following measures.

l Reorient or relocate the receiving antenna.

l Increase the separation between the equipment and receiver.

l Connect the equipment to an outlet on a circuit different from that to which

the receiver is connected.

l Consult the dealer or an experienced radio / TV technician for help.

Page 5

Changes or modifications not expressly approved by the party responsible for

compliance could void the users' authority to operate the equipment.

Professional Installation

In accordance with section 15.203 of the FCCrules and regulations, the MIU

must be professionally installed by trained meter installers. Changes or

modifications not expressly approved by the party responsible for compliance

void the user's authority to operate the equipment.

Industry Canada

This Class B digital apparatus meets all requirements of theCanadian

Interference Causing Equipment Regulations. Operation is subject to the

following two conditions.

l This device may not cause harmful interference.

l This device must accept any interference received, including interference that

may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de

l'interférence canadienne causant des règlements d'équipement. L'opération est

sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l'interférence nocive, et (2) ce dispositif doit accepter n'importe quelle

interférence reçue, y compris l'interférence qui peut causer l'opération peu

désirée.

Page 6

MACH 10®Ultrasonic Meter

Installation and Maintenance Guide

Literature No. IMMACH 10 12.18

Part No. 13505-051

Copyright © 2003 - 2018

NeptuneTechnologyGroupInc.

All Rights Reserved.

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

Tel: (800) 633-8754

Fax: (334) 283-7293

Page 7

Contents

Chapter 1: Product Description 1

Introduction 1

Understanding Ultrasonic Technology 2

Transit-Time Technology

Summary

Chapter 2: MACH 10

Chapter 3: General Installation Guidelines 11

®

Specifications

Environmental and Performance Specifications 5

Weight and Dimension Specifications 6

Additional Specifications 8

Fluid Compatibility 8

Maincase 8

Transducers 8

Battery Requirement 9

Tools and Materials 11

Safety and Preliminary Checks 12

Installation and Application Considerations 12

2

3

5

Water Temperature 12

Meter Installation 12

Water Flow 12

Meter Sizing and Selection 12

Chapter 4: Installing MACH 10® Ultrasonic Meters

Installation Instructions for MACH 10® Meters

New Meter Installation

Wiring the MACH 10®

Completing the Wiring

13

13

13

14

16

MACH 10®Installation and Maintenance Guide v

Page 8

Contents

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

Activating the LCD Meter Display 19

Timeout Period 19

Meter Display 19

LCD Panel 20

How to Read the Meter 20

Alarms 20

LCD Icons 21

Consumption and Unit of Measure 22

Rate of Flow 22

Flow Direction 22

AMR / AMI Output 23

Endpoint Reading Resolution 23

Bench Testing the Meter 23

19

Chapter 6: Maintenance and Troubleshooting 25

Maintenance 25

Replacement Parts 25

Troubleshooting 25

Checklist 25

Contact Information 26

By Phone 26

By Fax 26

By Email 26

Appendix A: MACH 10®)R900i™

Product Description

MACH 10®)R900i™ Programming

RF Protocol Error Detection

MACH 10®)R900i™ Specifications

27

27

27

27

28

Electrical Specification 28

Transmitter Specifications 28

vi MACH 10®Installation and Maintenance Guide

Page 9

Contents

Environmental Conditions 28

Functional Specifications 28

Dimensions 29

Appendix B: MACH 10®)R900i™ Flags

Glossary 33

Index 37

31

MACH 10®Installation and Maintenance Guide vii

Page 10

Contents

This page intentionally left blank.

viii MACH 10®Installation and Maintenance Guide

Page 11

Figures

Figure 1 – MACH 10® Residential Ultrasonic Meter

Figure 2 – MACH 10® Intermediate Ultrasonic Meter

Figure 3 – Transducers

Figure 4 – Transducer - Calculated Velocity

Figure 5 – Scotchlok™ Connector

Figure 6 – Seat the Connector Wires

Figure 7 – URCrimping Tool

Figure 8 – Improper Connections

Figure 9 – Three Colored Wires Connected

Figure 10 – Splice Tube

Figure 11 – Gray Wires in Slot

Figure 12 – Cover in Place

Figure 13 – MACH 10® Faceplate

1

2

2

3

14

14

15

15

16

16

17

17

19

Figure 14 – MACH 10® LCD Panel

Figure 15 – MACH 10®)R900i™ Top View

Figure 16 – MACH 10®)R900i™ Side View

20

29

29

MACH 10®Installation and Maintenance Guide ix

Page 12

Figures

This page intentionally left blank.

x MACH 10®Installation and Maintenance Guide

Page 13

Tables

Table 1 – Environmental Specifications

Table 2 – Performance Specifications

Table 3 – MACH 10® Meter Weight Specifications

Table 4 – Residential MACH 10® Dimensions

Table 5 – Intermediate MACH 10® Dimensions

Table 6 – Additional Specifications

Table 7 – Recommended Tools

Table 8 – Recommended Materials

Table 9 – Color Codes for Wires

Table 10 – MACH 10® Icons and Displays

Table 11 – Consumption and Units of Measure

Table 12 – Transmitter Specifications

Table 13 – Environmental Conditions

5

5

6

7

7

8

11

11

16

21

22

28

28

Table 14 – Functional Specifications

Table 15 – MACH 10®)R900i ™ Dimensions

Table 16 – Eighth Digit Resolution by Meter Size

Table 17 – MACH 10®)R900i™ Flags (digits)

Table 18 – MACH 10®)R900i™ Flags (minutes)

28

30

31

31

32

MACH 10®Installation and Maintenance Guide xi

Page 14

Tables

This page intentionally left blank.

xii MACH 10®Installation and Maintenance Guide

Page 15

Introduction

Chapter 1: Product Description

This chapter provides a general description of the Neptune®MACH 10®Ultrasonic Meter

(MACH 10).

The MACH 10 solid state meter uses ultrasonic transit-time technology and solid state

electronics. The meter is contained in a compact, totally encapsulated, weatherproof, and

ultraviolet (UV) resistant housing for residential and light commercial applications. Ultrasonic

technology features the following:

l Contains no moving parts

l Provides long-term accuracy

l Reduces measurement errors due to sand, suspended particles, and pressure fluctuations

The MACH 10 provides a Neptune E-CoderPLUS output signal to Neptune R900®and other

Automatic Meter Reading (AMR) / Advanced Metering Infrastructure (AMI)endpoints. The

MACH 10®)R900i™ contains a MACH 10 meter and an integrated R900 radio for

transmitting meter reading data. Consumption reflected is up to nine digits.

The meter electronics and battery are fully potted to eliminate the intrusion of moisture, dirt,

or other contaminants. It is suitable for installation in all environments including meter pits

subject to continuous flooding.

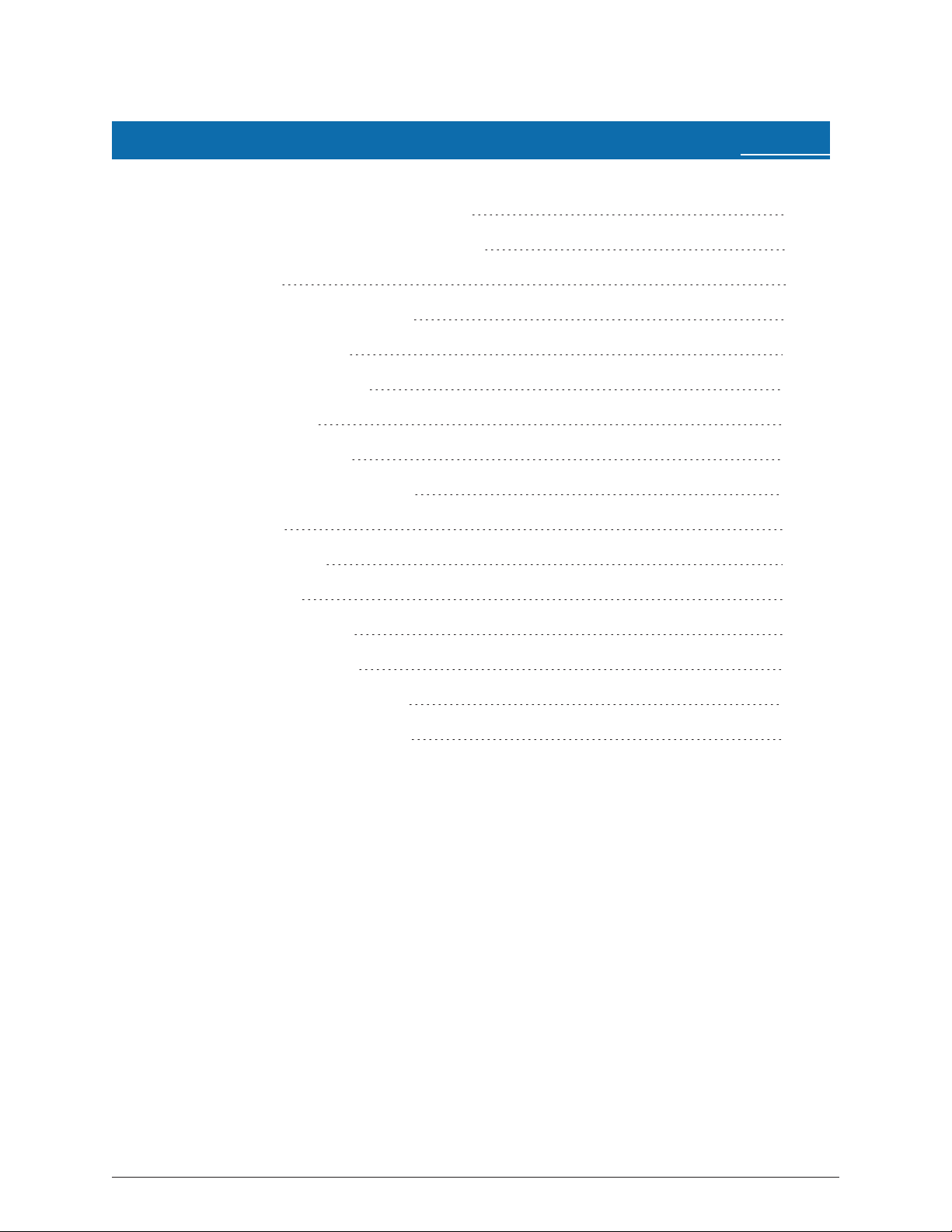

Figure 1 – MACH 10®Residential Ultrasonic Meter

MACH 10®Installation and Maintenance Guide 1

Page 16

Chapter 1: Product Description

Figure 2 – MACH 10®Intermediate Ultrasonic Meter

Understanding Ultrasonic Technology

An ultrasonic water meter uses high-frequency sound waves to measure the velocity of an

acoustically-conductive fluid moving through it. The velocity of the fluid is then converted to

volume throughput using sophisticated algorithms and electronics.

Transit-Time Technology

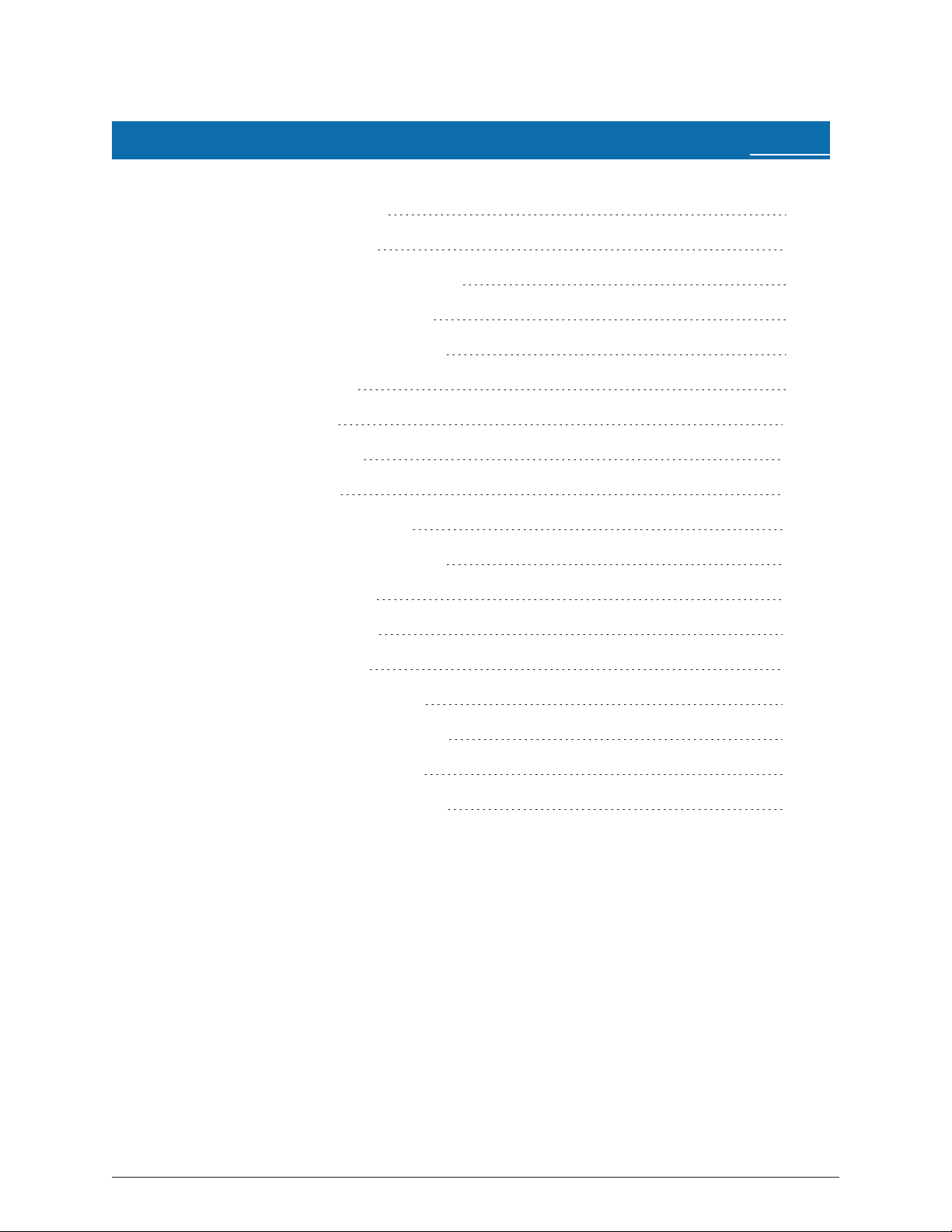

The MACH 10 utilizes transit-time ultrasonic technology. This technology takes advantage of

the principle that an acoustic signal travels faster with the flow than against the flow of the

fluid. These meters have a pair of transducers that are essentially transceivers, sending and

receiving the acoustic signals.

Figure 3 – Transducers

2 MACH 10®Installation and Maintenance Guide

Page 17

Chapter 1: Product Description

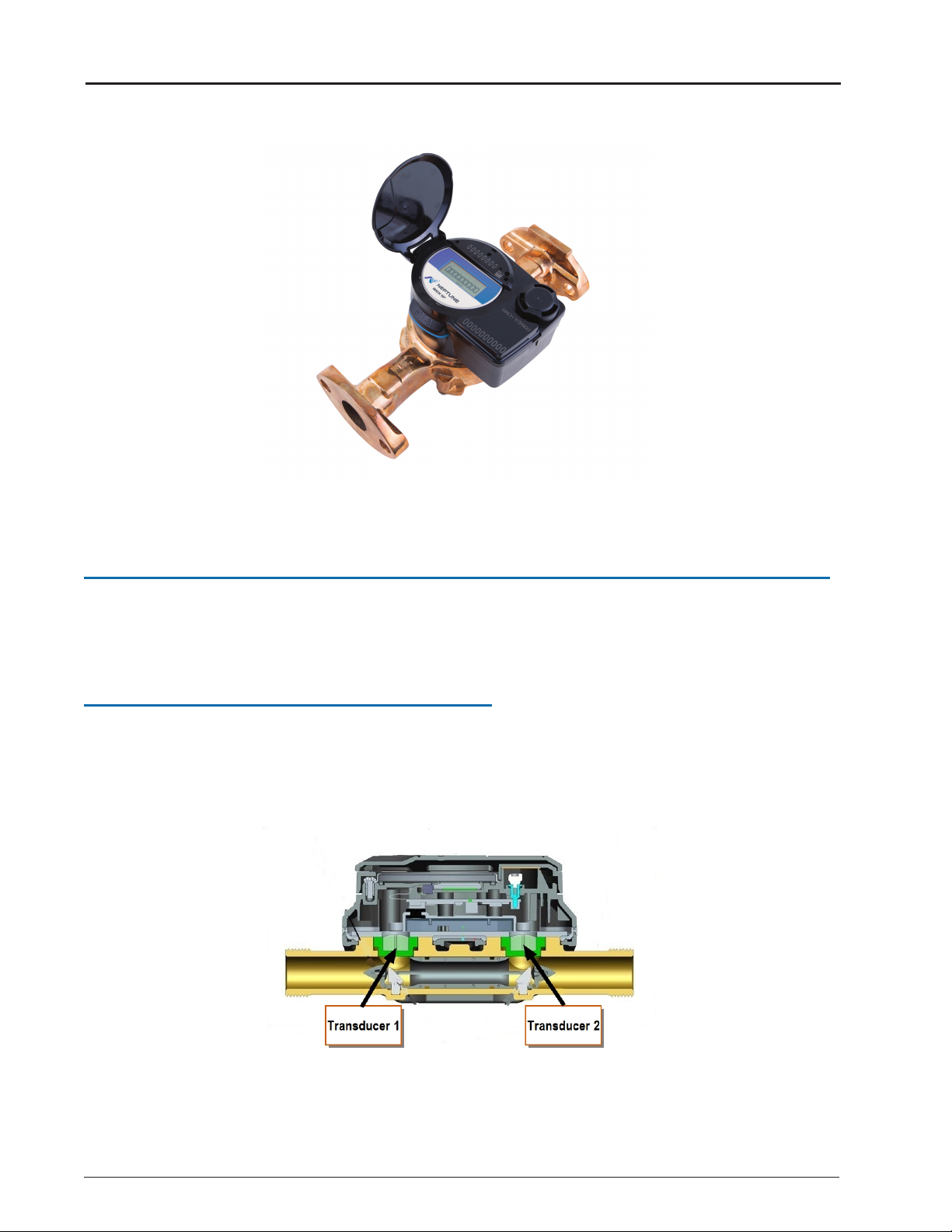

The difference between the downstream and upstream transit time—the time it takes for the

signal to travel from one transducer to the other—is proportional to the flow rate.

The calculated velocity of the water is then converted to volume based on the area of the

measurement section and by the algorithms and electronics in the register.

Figure 4 – Transducer - Calculated Velocity

Summary

The MACH 10 meter is a transit-time ultrasonic flow meter with wetted transducers. Designed

as an alternative for mechanical meters, the MACH 10 meter utilizes traditional utility pipe

connectors and lay lengths. It is totally self-contained. The battery, processor circuit, and

electronic display are fully potted and permanently sealed as an integral unit. The MACH 10

meter provides an E-CoderPLUS output signal to Neptune R900 and other AMR / AMI

endpoints. The MACH 10)R900i contains a MACH 10 meter and an integrated R900 radio for

transmitting meter reading data. See "MACH 10®)R900i™" on page27.

MACH 10®Installation and Maintenance Guide 3

Page 18

Chapter 1: Product Description

This page intentionally left blank.

4 MACH 10®Installation and Maintenance Guide

Page 19

Chapter 2: MACH 10®Specifications

Specification Description

Operating temperature 14° to 149° F (-10° to 65° C)

Storage temperature –40° to 158° F (–40° to 70° C)

Water temperature 33° to 122° F (0.5° to 50° C)

Operating humidity 0 to 100% condensing

Table 1 – Environmental Specifications

Meter Size

Normal Operating

Range @ 100%

Accuracy (± 1.5%)

AWWA C715

Standard Type 1

Extended Low Flow @

100% Accuracy (± 3%)

Residential

5/8" 0.10 to 25 U.S. gpm 0.2 to 20 U.S. gpm 0.05 U.S. gpm

3/4" 0.10 to 35 U.S. gpm 0.5 to 30 U.S. gpm 0.05 U.S. gpm

1" 0.40 to 55 U.S. gpm 0.75 to 50 U.S. gpm 0.25 U.S. gpm

Intermediate

1-1/2" 0.80 to 125 U.S. gpm

2.0 to 100 U.S gpm

0.30 U.S. gpm

2" 1.50 to 160 U.S. gpm 2.5 to 160 U.S. gpm 0.50 U.S. gpm

Table 2 – Performance Specifications

This chapter provides the specifications for the MACH 10®Ultrasonic Meter.

Environmental and Performance Specifications

This table defines environmental specifications that apply to both the Residential and

Intermediate MACH 10 meters.

This table defines performance specifications that apply to both the Residential and

Intermediate MACH 10 meters.

MACH 10®Installation and Maintenance Guide 5

Page 20

Meter Size Weight

Residential

5/8" 2.8 lbs

3/4" 2.9 lbs

1" 3.6 lbs

Intermediate

2" x 17" 15.6 lbs

1 1/2" x 13" 13.9 lbs

Chapter 2: MACH 10® Specifications

Weight and Dimension Specifications

The following tables define the weight and dimension specifications for the Residential and

Intermediate MACH 10 meters.

Table 3 – MACH 10

®

Meter Weight Specifications

The following tables define the meter dimensions as shown in the previous illustrations .

6 MACH 10®Installation and Maintenance Guide

Page 21

Meter Size A B C D NPSM

5/8" 7-1/2" 4-7/8" 2-1/2" 3/4" – 14

5/8" x 3/4" 7-1/2" 4-7/8" 2-1/2" 1" – 11-1/2

3/4" 9" 4-7/8" 2-9/16" 1" – 11-1/2

3/4" SL 7-1/2" 4-7/8" 2-9/16" 1" – 11-1/2

3/4" x 1" 9" 4-7/8" 2-9/16" 1-1/4" – 11-1/2

1" 10-3/4" 4-7/8" 2-11/16" 1-1/4" – 11-1/2

1" x 1-1/4" 10-3/4" 4-7/8" 2-11/16" 1-1/2" – 11-1/2

Meter Size Length Height Flanges

1-1/2" 10" 6-1/4" Oval

13" 6-1/4" Oval

12-5/8" 6-1/4" Internal thread

12-5/8" 6-1/4" External thread

2" 10" 6-1/2" Oval

15-1/4" 6-1/2" Oval

17" 6-1/2" Oval

15-1/4" 6-1/2" Internal thread

15-1/4" 6-1/2" External thread

Chapter 2: MACH 10

Table 4 – Residential MACH 10® Dimensions

Table 5 – Intermediate MACH 10® Dimensions

®

Specifications

MACH 10®Installation and Maintenance Guide 7

Page 22

Specification Description

Maximum operating pressure of

meter housing

175 psi (12 bar)

Register type Straight reading, permanently sealed electronic Liquid

Crystal Display (LCD); digits are 0.28" (7 mm) high

Register display l Consumption (up to nine digits)

l Rate of flow

l Alarms

l Unit of measure factory programmed for gallons, cubic

feet, or cubic meters

Battery 3.6 volt lithium thionyl-chloride; battery is fully encapsulated

within the register housing and is not replaceable

Table 6 – Additional Specifications

Chapter 2: MACH 10

®

Specifications

Additional Specifications

The following specifications are for the 5/8-inch through 2-inch Residential and Intermediate

meters.

Fluid Compatibility

The MACH 10 meter is designed and calibrated for potable, combination potable and fire

service, and reclaimed water across the defined temperature and velocity range.

Maincase

The meter maincase is manufactured using lead free bronze, and contains the wetted

elements of the meter: two transducers, pressed in reflections, and the flow conditioner.

Transducers

The piezoelectric transducer is the heart of the system. Although these transducers are very

small, they have very high measurement dynamics.

The signal path of the transducer utilizes two stainless steel reflectors. The transducers are

permanently installed and the path length and angles are fixed. Each meter is uniquely

calibrated at the factory and the calibration data is permanently stored in the meter.

8 MACH 10®Installation and Maintenance Guide

Page 23

Battery Requirement

Solid state metering technologies require a battery to power the transducers and electronics,

just like a radio Meter Interface Unit (MIU) requires a battery to perform its functions. With the

continued improvements made in battery technology, electronic metering utilizing internal

batteries is practical today. The MACH 10 uses lithium thionyl-chloride battery technology.

Chapter 2: MACH 10® Specifications

MACH 10®Installation and Maintenance Guide 9

Page 24

Chapter 2: MACH 10® Specifications

This page intentionally left blank.

10 MACH 10®Installation and Maintenance Guide

Page 25

This chapter describes tools, materials, and general installation information for the

Item Description / Recommendation Use

Tool Kit Contains standard tools including:

l Screwdrivers

l Pliers

Performing various installation

procedures

Flashlight N/A Activating the LCD

Magnet l 6 lb force

l Part No: 12287-0001

Activating the MIU

Table 7 – Recommended Tools

Item Description / Recommendation Use

Moisture Protection

Compound

Novaguard®sealant

Part No: 96018-072

Connecting the pit antenna to the

MIU

Site Work Order Documentation provided by your

utility

Receiving and recording

information about the work site

Table 8 – Recommended Materials

MACH 10®.

Tools and Materials

Table 7 and Table 8 show the recommended tools and materials you need to successfully

install the MACH 10.

Table 7 and Table 8 are not complete lists of tools and materials.

Chapter 3: General Installation Guidelines

MACH 10®Installation and Maintenance Guide 11

Page 26

Chapter 3: General Installation Guidelines

Safety and Preliminary Checks

Observe the following safety and preliminary checks before and during each installation.

l Verify that you are at the location specified on the site work order.

l Verify that the site is safe for you and your equipment.

l Notify the customer of your presence, and tell the customer that you need access to the

water meter.

l Write the ID numbers of the MACH 10 meters you are about to install on the site work

order. If the site work order already has a MACH 10 IDnumber, verify that it matches the ID

numbers on the MACH 10 you are about to install.

Installation and Application Considerations

This section provides information to consider before installing the MACH 10.

Water Temperature

The temperature range of the water is a factor in the selection of an ultrasonic meter, since

the meter is calibrated to operate within a specified range. The MACH 10 meter is calibrated

for water temperature (between 33° F and 122° F or 0.5° C and 50° C) measuring

applications.

Meter Installation

The MACH 10 meter can be installed using horizontal or vertical piping applications. The

meter features standard laying lengths for ease of retrofit of mechanical meters. A flow

direction arrow is visible on the top of the meter to aid in installation in the proper direction.

Water Flow

The MACH 10 meter is unable to measure flow when an empty pipe condition is detected. An

empty pipe is defined as a condition when the ultrasonic sensors are not fully wetted. In this

situation, the meter displays an alarm and no measurement occurs.

Meter Sizing and Selection

Traditional meter sizing methods apply to both electronic meters and mechanical meters.

That is, the maximum flow and maximum continuous flow rate requirements should be

considered when selecting a meter. Mechanical meters allow a temporary flow at a rate

higher than the maximum continuous flow. However, since electronic meters have no

moving parts, these two specifications are identical;the maximum flow rate is also the

maximum continuous flow rate.

12 MACH 10®Installation and Maintenance Guide

Page 27

Chapter 4: Installing MACH 10®Ultrasonic Meters

All MACH 10®ultrasonic meters are delivered activated and ready to be installed. When the

meter lid is opened, the meter shows the empty pipe icon and the latest volume on the LCD.

The empty pipe icon clears immediately after the condition is corrected and the pipe is full.

Installation Instructions for MACH 10®Meters

This section defines the step-by step instructions for installing the MACH 10 meter.

In outdoor settings, the meter and service line should be located deep enough in the

ground to prevent freezing.

New Meter Installation

The following are steps for installation of the MACH 10 meter.

1. Flush the service line prior to meter installation in order to remove debris in the line.

2. Place an electrical grounding strap on the service line, connecting the inlet and outlet

service lines on either side of the meter setting.

Install suitable inlet and outlet meter valves and couplings / setters if they are not already

present. Allow appropriate space in the line for the meter laying length and two coupling

gaskets. Align the pipe ends sufficiently so that the coupling and meter threads can engage

without binding or cross-threading.

3. Remove the thread protectors (if installed) before installing the meter.

Use caution; the meter threads are sharp.

4. Be sure that no debris enters the meter during installation.

5. Place the coupling gaskets, and set the meter in the line.

6. Start turning the coupling or flange nuts by hand, then using a wrench tighten sufficiently

to prevent leakage.

Be careful not to cross-thread the connections.

7. Open the upstream inlet valve.

MACH 10®Installation and Maintenance Guide 13

Page 28

Chapter 4: Installing MACH 10

8. Open the meter outlet valve slowly.

9. Open a downstream faucet, and run enough water to dissipate entrained air and flush

the line.

The Intermediate MACH 10 may take longer to completely remove air from the meter,

particularly when flow rates are less than 25% of the maximum flow rate of the meter.

10. Check to see if the meter is operating correctly, while the faucet is open.

11. Turn OFF the faucet, and check the meter installation for leaks.

®

Ultrasonic Meters

Wiring the MACH 10

The following table defines the steps to wire the MACH 10 meter while you are in the field.

If the meter is not a MACH 10 prewired and potted to an MIU, complete the following steps

to wire the MACH 10.

1. Hold the Scotchlok™ between the index finger and thumb with the red cap facing down.

2. Take one non-stripped black wire from the pigtail and one from the receptacle / MIU.

3. Insert the wires into the Scotchlok connector.

4. Insert the insulated color wires directly into the Scotchlok connector until fully seated.

®

Figure 5 – Scotchlok™ Connector

Figure 6 – Seat the Connector Wires

14 MACH 10®Installation and Maintenance Guide

Page 29

MIU Wire Color / MACH 10 Wire Color MIUType

Black/B Green/G Red/R

R900

Black/G Green/R Red/B Sensus

Black/B White/G Red/R Itron

Table 9 – Color Codes for Wires

Chapter 4: Installing MACH 10® Ultrasonic Meters

Do not strip the colored insulation from the wires, or strip and twist the bare wires before

inserting them into the connector. Insert the insulated colored wires directly into the

Scotchlok connector.

5. Place the connector red cap side down between the jaws of the UR crimping tool.

Figure 7 – URCrimping Tool

6. Check to ensure the wires are still fully seated in the connector before crimping the

connector.

7. Squeeze the connector firmly with the proper crimping tool until you hear a pop and the

gel leaks out the end of the connector.

8. Repeat steps 1 through 5 for each color wire.

Figure 8 – Improper Connections

MACH 10®Installation and Maintenance Guide 15

Page 30

MIU Wire Color / MACH 10 Wire Color MIUType

Black/G White/RRed/B Aclara

Black/G Green/B Red/R Elster

Black/G Green/R Red/B Badger

Table 9 – Color Codes for Wires (continued)

Chapter 4: Installing MACH 10® Ultrasonic Meters

Completing the Wiring

The following table outlines the steps to wire the MACH 10.

1. After you connect all three color wires, read the encoder register to ensure proper

connections and the receptacle / MIU is functioning properly.

Figure 9 – Three Colored Wires Connected

2. Take all three connected Scotchloks and push them into the splice tube until fully

enclosed by the silicone grease.

Figure 10 – Splice Tube

16 MACH 10®Installation and Maintenance Guide

Page 31

Chapter 4: Installing MACH 10® Ultrasonic Meters

3. Separate each gray wire and place them into the slots on each side.

Figure 11 – Gray Wires in Slot

4. Snap the cover closed to finish the installation.

Figure 12 – Cover in Place

MACH 10®Installation and Maintenance Guide 17

Page 32

Chapter 4: Installing MACH 10® Ultrasonic Meters

This page intentionally left blank.

18 MACH 10®Installation and Maintenance Guide

Page 33

Chapter 5: Activating and Reading MACH 10®Ultrasonic Meters

This chapter explains the operations of the MACH 10®ultrasonic meter.

Activating the LCD Meter Display

The light sensor is located in the center of the faceplate of the MACH 10, and it supplies the

power for the Liquid Crystal Display (LCD) panel.

Timeout Period

Typically, the display is OFF. The meter includes a light sensor used to activate the LCD when

you open the meter. A timed out LCD can not be reactivated just by shining a light on the light

sensor. In order to reset the meter, close and re-open the lid.

Meter Display

The Neptune MACH 10 ultrasonic meters use a nine-digit LCD to show consumption, flow

rate, and alarm information.

Figure 13 – MACH 10®Faceplate

MACH 10®Installation and Maintenance Guide 19

Page 34

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

LCD Panel

Following is an example of the MACH 10 LCD panel. The table on the following page

provides a description of each icon.

The LCD can display commas or decimals, depending on the configuration of each register,

to show digits in the tens position, ones position, tenths position, and so forth. For

example, some registers display 1,234,567.89. Others display 123,456.789, 12,345,678.9,

or 1,234,567,89 depending on the need of the meter/register combination.

How to Read the Meter

It is important to become familiar with the information available from the meter. The icons

and displays provide helpful information.

Alarms

Indicators and alarms appear in the displays as symbols that illuminate when the condition is

active, and disappear when the alarm condition is eliminated.

Figure 14 – MACH 10®LCD Panel

20 MACH 10®Installation and Maintenance Guide

Page 35

Icon Description Status Explanation

Leak Icon used to indicate a leak. Leak

status is determined by keeping

track of the number of 15minute intervals where the

volume consumption exceeds

Vmin in the previous 24-hour

period. Vmin is factory

programmed depending on

meter size. It is defined as a

change of the ninth digit on the

LCD.

OFF Number of 15-minute intervals < 50.

Flashing 50 ≤ Number of 15-minute intervals < 95.

Continuous

ON

Number of 15-minute intervals ≥ 95.

Forward and

reverse flow

Icons used to indicate the

forward and reverse direction of

flow.

OFF No flow is detected.

Continuous

ON

The meter has detected flow.

High flow

warning

Icon used to indicate excessive

flow which can be a burst pipe.

OFF Rate of flow < Maximum defined by normal

flow range specifications.

ON Rate of flow exceeds normal operating flow

limits.

Empty pipe Icon used to indicate if the pipe

is empty or there is excessive

air in the line. If this occurs,

there is no receive signal in the

expected time window.

OFF Typically OFF. Meter is operating normally.

ON Turned ON if no receive signal is seen for

1 minute.

Battery status Icon used to indicate time and

voltage of remaining battery life.

OFF > One year of battery life remaining.

Time since first power ON < 19 years.

Continuous

ON

< One year of battery life remaining or time

since first power ON> 19.5 years.

Continuous

FLASHING

Low battery or time since first power ON >

20 years.

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

LCD Icons

The following table defines the MACH 10 LCD icons and the status they indicate.

Table 10 – MACH 10® Icons and Displays

MACH 10®Installation and Maintenance Guide 21

Page 36

Capacity Display Resolution

Size Gallons Cubic Feet Cubic Meter Gallons Cubic Feet Cubic Meter

Residential

5/8" 10,000,000 1,000,000 100,000 0.01 0.001 0.0001

3/4" 10,000,000 1,000,000 100,000 0.01 0.001 0.0001

1" 10,000,000 1,000,000 100,000 0.01 0.001 0.0001

Intermediate

1" 100,000,000 10,000,000 1,000,000 0.1 0.01 0.001

2" 100,000,000 10,000,000 1,000,000 0.1 0.01 0.001

Table 11 – Consumption and Units of Measure

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

Consumption and Unit of Measure

The consumption display contains all nine digits, including leading zeros and a decimal point.

The value displayed is the sum of the forward flow minus the reverse flow.

The unit of measure and resolution are factory programmed and options include gallons,

cubic feet, and cubic meters.

Rate of Flow

The rate of flow is factory programmed for either gallons per minute or liters per minute. The

LCD displays both the unit of measure and rate of flow. The rate of flow display also serves as

the flow finder indicator. The rate of flow display is shown without leading zeros. When rate

of flow is displayed, it is updated every two seconds.

Flow Direction

An arrow on the electronic register housing shows the direction of flow. Current flow

direction can be viewed on the LCD panel.

The direction of flow arrows on the LCD are activated when the meter detects any amount of

flow. If the volume of the flow is below a predetermined measurement threshold in a given

time period, the meter does not accumulate flow.

22 MACH 10®Installation and Maintenance Guide

Page 37

AMR / AMI Output

The Neptune MACH 10 ultrasonic meter is a compact design where the electronic register is

fully potted and permanently sealed to the meter maincase. The meter provides

high resolution E-CoderPLUS protocol. It communicates status indicators to Neptune R900

RF endpoints as part of the extended encoder / meter reading message. The meter also

provides ProRead™ protocol for third-party endpoints that are not capable of reading

E-CODER®eight digit or E-CoderPLUS protocol.

Endpoint Reading Resolution

The reading resolution sent to the reading software is dependent on the endpoint to which

the encoder is connected. Readings reported from the endpoints are the

left-most significant digits for the encoding reading.

Refer to "Wiring the MACH 10®" on page14 for wiring considerations.

Bench Testing the Meter

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

Unlike other solid state meters introduced to the market, the Neptune MACH 10 ultrasonic

meter is designed to be bench tested as a traditional mechanical meter.

MACH 10®Installation and Maintenance Guide 23

Page 38

Chapter 5: Activating and Reading MACH 10® Ultrasonic Meters

This page intentionally left blank.

24 MACH 10®Installation and Maintenance Guide

Page 39

Chapter 6: Maintenance and Troubleshooting

This chapter provides information for maintaining and troubleshooting the MACH 10

meter.

Maintenance

Mechanical meters are subject to wear and are often rebuilt to extend their life. On the other

hand, the electronic MACH 10 meter does not have moving parts and requires no

maintenance. The meter enclosure, which contains electronics, transducers, battery, and

display is completely potted eliminating any maintenance. At the end of the meter's life, the

meter is simply replaced.

Replacement Parts

There are no replacement parts for the MACH 10 ultrasonic meter. If the plastic meter lid

becomes damaged or broken, it can be replaced.

Troubleshooting

Some conditions such as the following can occur.

l Battery is at low power.

l Meter starts sending colons.

l Communication stops.

®

Checklist

Before leaving the installation site, be sure to do the following.

Record the MIUID for each register.

Verify that you have followed all requirements of this Installation and Maintenance

Guide.

Verify that you have recorded all required information.

Clean up any installation debris.

Verify that the requirements of the Site Work Order have been completed.

Inform the customer that you have completed your work. If you were unable to finish,

inform the customer when you are returning to complete the project.

MACH 10®Installation and Maintenance Guide 25

Page 40

Chapter 6: Maintenance and Troubleshooting

Contact Information

Within North America, Neptune Customer Support is available Monday through Friday, 7:00

A.M. to 5:00 P.M.Central Standard Time, by telephone, email, or fax.

By Phone

To contact Neptune Customer Support by phone, complete the following steps.

1. Call (800) 647-4832.

2. Select one of the following options:

l 1 if you have a Technical Support Personal Identification Number (PIN)

l 2 if you do not have a Technical Support PIN

3. Enter the six-digit PIN and press #.

4. Select one of the following options.

l 2 for Technical Support

l 3 for maintenance contracts or renewals

l 4 for Return Material Authorization (RMA) for Canadian Accounts

By Fax

By Email

You are directed to the appropriate team of Customer Support Specialists. The specialists are

dedicated to you until the issue is resolved to your satisfaction. When you call, be prepared to

give the following information:

l Your name and utility or company name

l A description of what occurred and what you were doing at the time

l A description of any actions taken to correct the issue

To contact Neptune Customer Support by fax, send a description of your problem to (334)

283-7497. Please include on the fax cover sheet the best time of day for a customer support

specialist to contact you.

To contact Neptune Support by email send your message to support@neptunetg.com.

26 MACH 10®Installation and Maintenance Guide

Page 41

This appendix provides a general description of the MACH 10®)R900i™.

Product Description

The MACH 10®)R900i™ is manufactured by Neptune and is an integrated register that

contains both the MACH 10 meter and the R900®technologies in one register that collects

reading data. It then transmits the data for collection by the meter reader. A Neptune walk-by,

mobile, or R900®Gateway fixed network data collection system receives the data and stores

it to be downloaded into the utility billing system for processing.

The MACH 10 is easily installed and operates within a Radio Frequency (RF) band, which

does not require an operating license. The MACH 10®)R900i™ meets FCC regulations part

15.247 allowing higher output power and greater range. The MACH 10 uses frequency-

hopping spread spectrum (FHSS) technology to avoid RF interference and enhance security.

The transmitted data is updated at 15-minute intervals. It transmits a mobile message that

includes the meter reading data and the unique 10-digit MACH 10 ID every 14 to 20 seconds.

This allows the meter to be read by a hand held unit (HHU) or mobile data collection unit.

The MACH 10 also transmits a high power fixed network message every seven and one-half

minutes on an interleaved basis to an R900 Gateway.

Appendix A: MACH 10®)R900i™

The MACH 10 is designed to offer advantages to utility organizations of all sizes.

l Increases meter reading accuracy

l Eliminates hard-to-read meters

l Protects utility liability by increasing meter reader safety

l Requires no external wiring or programming

l Provides enhanced eight-digit AMRmeter reading

l Provides proactive customer service benefits (leak, tamper, and backflow detection)

MACH 10®)R900i™ Programming

The MACH 10 is not field-programmable. Each MIU is given a unique 10-digit serial number /

identification number.

RF Protocol Error Detection

The RF protocol is comprised of a header, data packet, and an error detection mechanism

that reduces the erroneous data.

MACH 10®Installation and Maintenance Guide 27

Page 42

Specification Description

Transmit Period l Every 14 to 20 seconds – standard mobile message

l Every 7-1/2 minutes – standards, high power, fixed network message

Transmitter Channels 50

Channel Frequency 910 to 920 MHz

Output Power Meeting FCC Part 15.247

FCC Verification Part 15.247

Table 12 – Transmitter Specifications

Condition Description

Operating temperature 14° to 149°F (–10° to +65°C)

Storage temperature –40° to 158°F (–40° to 70°C)

Operating humidity 0 to 100% condensing

Table 13 – Environmental Conditions

Specification Description

Register Reading l Eight digits (AMR)

l Nine digits (Visual)

MIUID 10 digits

Table 14 – Functional Specifications

Appendix A: MACH 10®)R900i™

MACH 10®)R900i™ Specifications

This section provides you with the specifications for the MACH 10®)R900i™.

Electrical Specification

Power is provided by a lithium thionyl-chloride battery.

Transmitter Specifications

The following table defines the specifications for the MACH 10 transmitter.

Environmental Conditions

The following table defines the optimal environmental conditions for the MACH 10.

Functional Specifications

The following table defines the functional specifications for the MACH 10.

28 MACH 10®Installation and Maintenance Guide

Page 43

Dimensions

Appendix A: MACH 10®)R900i™

The dimensions of the MACH 10 are shown in the following images and on page 30.

Figure 15 – MACH 10®)R900i™ Top View

Figure 16 – MACH 10®)R900i™ Side View

MACH 10®Installation and Maintenance Guide 29

Page 44

Meter A B C D NSPM

E

(external

antenna)

5/8" 7-1/2" 6-3/4" 2-1/2" 3/4" - 14 5-7/8"

5/8" x 3/4" 7-1/2" 6-3/4" 2-1/2" 1" - 11-1/2 5-7/8"

3/4" 9" 6-3/4" 2-9/16" 1" - 11-1/2 5-7/8"

3/4" SL 7-1/2" 6-3/4" 2-9/16" 1" - 11-1/2 5-7/8"

3/4" x 1" 9" 6-3/4" 2-9/16" 1-1/4" - 11-1/2 5-7/8"

1" 10-3/4" 6-3/4" 2-11/16" 1-1/4" - 11-1/2 5-7/8"

1" x 1-1/4" 10-3/4" 6-3/4" 2-11/16" 1-1/2" - 11-1/2 5-7/8"

Appendix A: MACH 10®)R900i™

The following tables define the dimensions of the Residential MACH 10 meters.

Table 15 – MACH 10®)R900i ™ Dimensions

30 MACH 10®Installation and Maintenance Guide

Page 45

Appendix B: MACH 10®)R900i™ Flags

Register Size

Eighth Digit Resolution -

Least Significant Digit

Residential

(5/8" - 1")

1/10 U.S Gallons or 1/100 Cubic feet

Intermediate (Light Commercial and Industrial)

(1-1/2" and 2"; 1-1/2" - 4" HPT)

1 U.S. Gallon or 1/10 Cubic feet

Table 16 – Eighth Digit Resolution by Meter Size

Backflow Flag (Resets After 35 Days)

Based on reverse movement of the eighth digit; eighth digit is variable

based on the meter size.

No backflow event Eighth digit reversed less than one digit

Minor backflow Eighth digit reversed more than one digit up to 100 times the eighth digit

Major backflow event Eighth digit reversed greater than 100 times the eighth digit

The three tables in this appendix describe the volume represented by the eighth digit by

meter size (Residential and Intermediate), and the flags used by the MACH 10®)R900i (digits)

and MACH 10®)R900i (minutes).

Table 17 – MACH 10®)R900i™ Flags (digits)

MACH 10®Installation and Maintenance Guide 31

Page 46

Leak Status Flag (Resets After 35 Days)

Based on total amount of 15-minute periods recorded in the previous 24-hour period.

Leak icon off Eighth digit incremented less than 50 of the 96 15-minute intervals

Flashing leak icon Eighth digit incremented in 50-95 of the 96 15-minute intervals

Solid leak icon Eighth digit incremented in all of the 96 15-minute intervals

Consecutive Days with Zero Consumption Flag (Resets After 35 Days)

Number of days the leak status was at a minimum value

Appendix B: MACH 10®)R900i™ Flags

Table 18 – MACH 10®)R900i™ Flags (minutes)

32 MACH 10®Installation and Maintenance Guide

Page 47

A

AMI

Advanced Metering Infrastructure. A system that captures, stores, and provides to the utility at

frequent intervals detailed consumption and other information, such as, usage, leak, and flow

status, to support advanced applications.

AMR

Automated or Automatic Meter Reading.

E

empty pipe

Condition whenever the measurement section of the meter is not completely filled with water.

Glossary

L

LCD

Liquid Crystal Display.

light sensor

Component located under the recess that is used to activate the Liquid Crystal Display (LCD).

M

MIU

Meter Interface Unit.

MACH 10®Installation and Maintenance Guide 33

Page 48

Glossary

S

serial number

Unique identification number given to each meter at the factory. The default value is the last

programmed plus one. Custom serial numbers are not available.

T

transceiver

Device that transmits and receives communications, in particular a combined radio transmitter

and receiver.

transducer

Device that converts one form of energy to another form of energy.

transit-time

Technology that takes advantage of the principle that an acoustic signal travels faster with the

flow than against the flow.

U

ultrasonic flow

Use of ultransonic technology to measure the velocity of an acoustically conductive liquid or gas

moving through it. The velocity of the water is then converted to volume throughput using

sophisticated algorithms and electronics.

ultrasonic meter

Electronic meter using ultrasonic technology and solid state electronics contained in a compact,

totally encapsulated, weatherproof, and ultraviolet (UV) resistant housing for residential and

light commercial applications.

34 MACH 10®Installation and Maintenance Guide

Page 49

V

Vmin

Change the ninth digit of the LCD. This is factory programmed depending on meter size.

Glossary

MACH 10®Installation and Maintenance Guide 35

Page 50

Glossary

This page intentionally left blank.

36 MACH 10®Installation and Maintenance Guide

Page 51

contaminants 1

Index

A

acoustic signal 2

acoustically 2

activating 19

LCD 11

alarm 12, 20

algorithms 2

AMI 1, 3

AMR 1

B

backflow 31

battery 1, 25

coupling gasket 13

crimping tool 15

cross-thread 13

customer support 26

D

debris 13

E

E-CoderPLUS 1

F

faucet 14

fire service 8

requirements 9

bench testing 23

C

calculated velocity 3

calibrated 12

checks

preliminary 12

safety 12

conductive 2

connections 16

consumption 19, 22

fixed network 27

flags 31

flashlight 11

flow

direction 22

rate 12

G

grounding strap 13

H

hopping, frequency 27

MACH 10®Installation and Maintenance Guide

37

Page 52

Index

I

icon

battery status 21

empty pipe 21

forward and reverse flow 21

high flow warning 21

leak 21

installation

guidelines 11

meter 12-13

installing 13

integrated 3

L

transmitter 28

maincase 8

maintenance 25

meter

bench testing 23

display 19

sizing 12

threads 13

N

Novaguard sealant 11

O

operating license 27

Other Term

LCD 19

panel 20

leakage 13

light sensor 19

M

MACH 10® 1

R900i 27

flags 31

programming 27

specifications 28

dimensions 29

electrical 28

functional 28

Subterm 8, 21, 28

output 23

P

piezoelectric 8

piping 12

potted 3, 23

product description 1

R

rate of flow 22

reading resolution 23

recommended

materials 11

38 MACH 10®Installation and Maintenance Guide

Page 53

Index

tools 11

reflectors 8

register

display 5

type 5

resolution 22

retrofit 12

RF

band 27

protocol error 27

S

sealed 3

service line 13

velocity range 8

W

water flow 12

wetted 8

wrench 13

T

temperature

water 12

Term SeeOther Term, Subterm

toolkit 11

transceivers 2

transducers 2, 8

transit-time 2

troubleshooting 25

V

valve 13

inlet 13

outlet 14

MACH 10®Installation and Maintenance Guide 39

Page 54

Page 55

IM MACH 10®12.18 Part No. 13682-001© Copyright 2003-2018,

Neptune Technology GroupInc. Neptune is a registered trademark of

Neptune Technology GroupInc.

Loading...

Loading...