Page 1

P

.O. Box 247 • Lansdale, PA 19446-0247

Tel: 215-699-8700 • Fax: 215-699-0370

Toll-Free Tel: 1-888-3NEPTUNE (1-888-363-7886)

T

oll-Free Fax: 1-800-255-4017

W

eb Site: http:// www.neptune1.com

E-mail: pump@neptune1.com

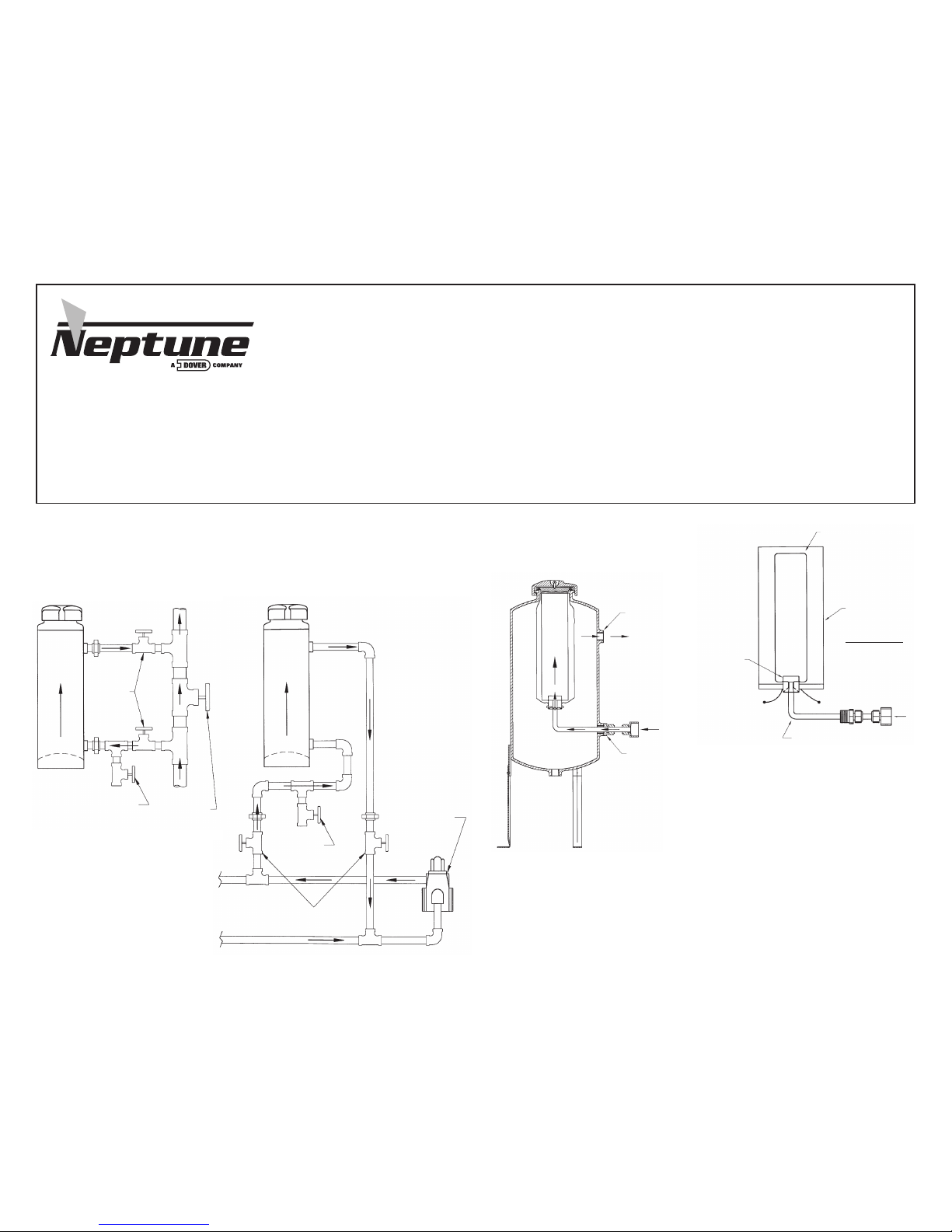

INSTALLATION & OPERATION INSTRUCTIONS – ALL MODELS

1. Pipe feeder to cause pressure drop across inlet and outlet resulting in flow through feeder.

2. Provide isolation and drain valves for servicing and draining.

3. Use with hot or cold water only. DO NOT USE FOR STEAM (300 psi @ 200°F max.).

4. Be certain gasket is positioned in groove under cap before replacing cap. (Replace gasket if cap does

not seal by hand pressure.) Cap should seal with hand tightening pressure only. Do not strike cap with

any tool to seal or unseal.

5. Open valves slowly when returning service.

6. CAUTION! DO NOT OPEN UNDER PRESSURE – close isolation valves and bleed off pressure

before opening.

7. CAUTION! CONTENTS MAY BE HOT.

8. CONSULT YOUR CHEMICAL SUPPLIER FOR THE PROPER USE OF THIS TANK WITH THE CHEMICAL.

9. DO NOT COMBINE CHEMICALS IN THIS DISPENSING DEVICE – without specific instructions from your

chemical supplier. READ AND FOLLOW LABEL DIRECTIONS FOR THE CHEMICAL IN USE.

See instructions for

optional filter bag kit

at right.

INSTALLATION INSTRUCTIONS

FOR FILTER BAG KITS

1. Loosen fitting 1 until the tubing turns in the fitting.

2. Install fitting 1 into the lower side connection of the tank with

the end of the tube pointing upward.

3. Retighten fitting 1 to the tubing. Tube should point straight up.

The ferrule on the tubing is preset for the tank diameter.

4. Place bag over the hanger wire. Pull the drawstring closed and tie tightly so the bag gathers

around the hanger base with the opening of the hanger base protruding from the bag.

5. Insert the bag and hanger base into the tank with the opening of the hanger base pointing

downward. The hanger base should engage the tube which is pointing upward and the

tubing should fit into the hanger base until the tubing rests against the edges of the wire

which protrude into the center of the hanger base.

6. The cap will keep downward force on the wire, keeping the assembly in place.

Important Note:

These instructions describe Neptune Models VTF and DBF By-Pass Feeders with

or without a filter bag plus Model DBFC By-Pass Feeders with Cartridge Filter and

Models FTF and FTF-DB Filter Feeders which use a bag inside the basket filter.

Note carefully the flow arrow shown for each type of feeder. The flow in the

standard by-pass feeder must be “upward” if a filter bag kit is to be used. The flow

on the by-pass feeder with a cartridge filter is “downward.” The filter feeder with

bag and basket filter requires “downward” flow.

Standard By-Pass Feeder

MODELS VTF & DBF

Refer to installation and operation instructions above.

Filter Bag Kit Option

(FOR MODELS VTF & DBF ONLY)

GATE

VALVE

OR

ORIFICE

SHUT

OFF

VALVES

DRAIN

VALVE

DRAIN

VALVE

OUTLET

INLET

90° ELBOW

HANGER BASE

FILTER BAG

FITG1 FITG2

FILTER BAG KITS

INCLUDES:

BAG, BAG FRAME,

TUBING AND

CONNECTORS.

HANGER

SHUT OFF

VALVES

BOILER

FEED

PUMP

Page 2

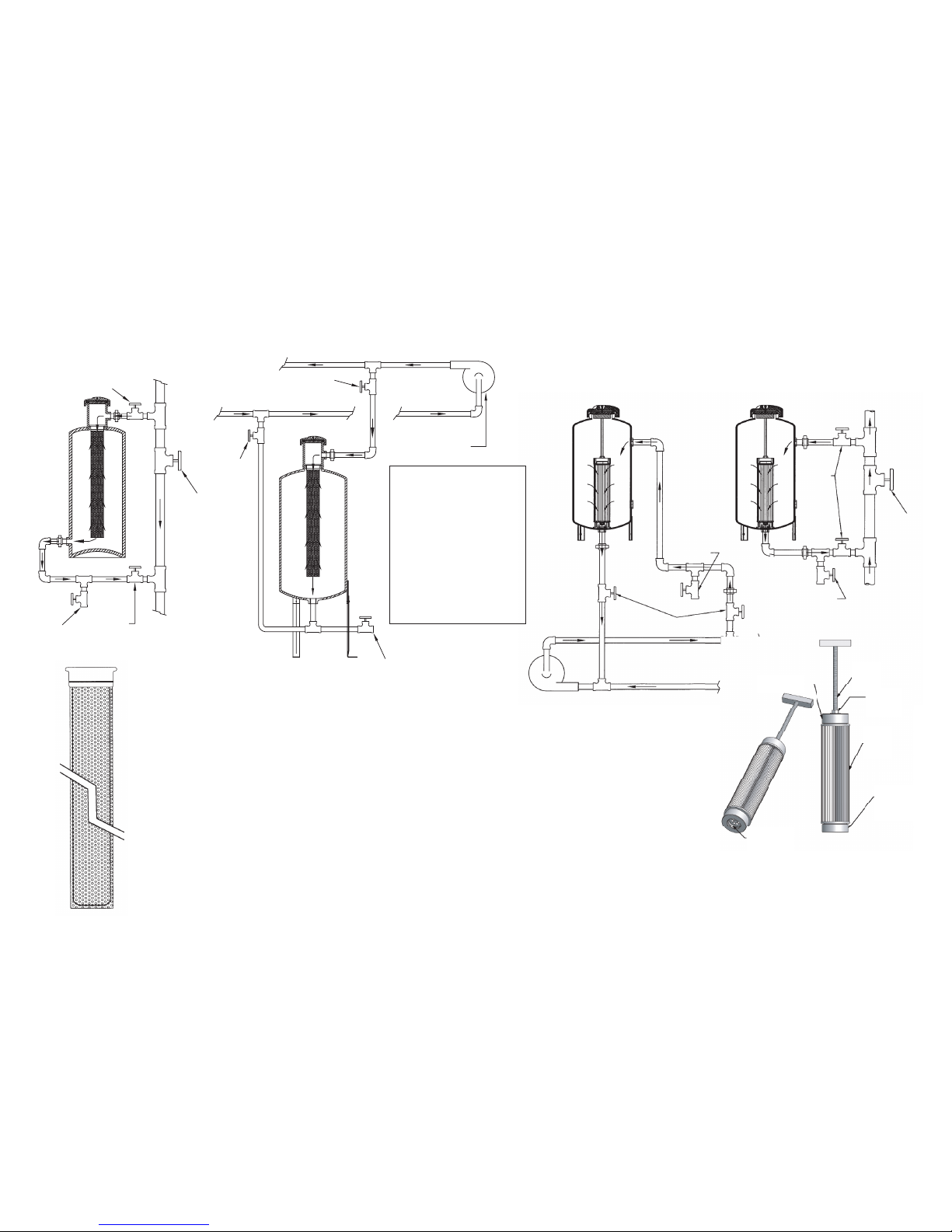

FILTER FEEDER

ASSEMBLY INSTRUCTIONS

Neptune Filter Feeders may be used as a By-Pass Feeder with

or without the basket. The basket may be used for handling

granular chemical products. A filter bag may be placed in the

basket allowing the feeder to also be used as a filter.

The filter bag is placed inside the basket. Bags are available in

1, 5, 20 and 50 micron ratings. The bag slides into the basket

and the ring rests on the top rim of the basket.

The basket is then placed into the feeder and will hang from

the support lip.

Reverse the procedure and insert a clean bag as needed.

CARTRIDGE REMOVAL/REPLACEMENT

INSTRUCTIONS

The cartridge filter assembly consists of two parts:

1. Handle Assembly 2. Filter Cartridge

Remove the cartridge filter assembly from the

vessel by holding the handle (1) and pulling

out straight. Loosen the jam nut just enough

so that the threaded rod can be turned. (This will

ensure the correct length of the handle-cartridge

assembly to fit inside the vessel.) Unscrew threaded

rod to separate bottom cap. Remove old cartridge (2) and discard. Slide a new cartridge (2)

onto the top cap. Slide in the bottom cap. Screw in the threaded rod into the bottom cap until

jam nut touches the top cap. Make sure that the ridge on the face of top and bottom caps line

up with the grooves on the ends of the filter cartridge. Snug the jam nut to secure cartridge.

Check the sealing ring inside the end of the bottom cap and replace if necessary. Slide the

cartridge filter assembly back into the vessel, taking care that the bottom cap is piloted onto

the stub in the bottom of the tank. Make certain assembly is fully seated. Replace the cap.

© 2008 Neptune Chemical Pump Company All Rights Reserved P/N ZL105669 Printed in U.S.A.

Filter Feeder

MODELS FTF & FTF-DB

Refer to installation and operation instructions on other side.

By-Pass Feeder

with Cartridge Filter

MODEL DBFC

Refer to installation and operation instructions

on other side. Maximum flow 6 GPM.

SHUT OFF VALVE

DRAIN VALVE

DRAIN VALVE

GATE VALVE

OR

ORIFICE

SHUT OFF VALVE

BOILER FEED PUMP

SHUT OFF VALVE

SHUT OFF

VALVE

CAUTION!

DO NOT OPEN

UNDER PRESSURE

– close isolation

valves and bleed

off pressure before

opening.

CONTENTS MAY

BE HOT.

JAM NUT

TOP CAP

BOTTOM

CAP

SEALING

RING

DRAIN

VALVE

DRAIN

VALVE

SHUT OFF

VALVES

S

HUT

O

FF

V

ALVES

GATE

VALVE

OR

ORIFICE

CARTRIDGE FILTER

ASSEMBLY

Loading...

Loading...