Page 1

E-CODER® Quick Install Guide

QUICK INSTALL GUIDE

®

E-CODER

Page 2

Page 3

1 General Instructions

Solar panel

Nine-digit

meter reading

LCD

display

The E-CODER® is an electronic absolute encoder register

designed for use with Neptune’s Automatic Reading and Billing

®

(ARB

) System. This register operates with Neptune’s R900

and R450™ MIUs, providing advanced features such as leak,

backflow, and tamper detection.

With the E-CODER register, both the homeowner and the utility

can use the following features.

• Nine-digit display for visual reading

• Eight digits for billing

• Water flow indicators

• Intermittent leak detection icon on LCD panel

• Continuous leak detection icon on LCD panel

This guide can help you identify and read information displayed

on the E-CODER register. It can also help you recognize the

common causes of leaks and what to do if a leak is found. After

the leak is repaired, this guide also contains steps to determine

that the leak is no longer evident.

®

2 Product Description

The face of the E-CODER allows you to read various types of

information available. The face of the E-CODER is shown in

Figure 1.

Figure 1 E-CODER Coder Face

1

Page 4

3 Wiring Inside Set Version

Run a three-conductor cable from the E-CODER register to the

MIU. Refer to the following steps.

1 Connect the three-conductor wire to the encoder register’s

terminals as described in the manufacturer’s instructions,

using the color code in Table 1.

Table 1 Encoder Wiring

Register Wire Color / Encoder Terminal

Neptune E-CODER Black/B Green/G Red/R

2 Remove the terminal cover with a flat-head screw driver as

shown in Figure 2.

Figure 2 Removing the Terminal Cover

3 Wire the encoder register

with the proper colors. See

Figure 3.

4 Test the wiring to verify the

read.

Figure 3 Wiring with Proper Color Wire

2

Page 5

5 Route the wire as shown in

Figure 4.

Figure 5 Applying Compound

Figure 4 Routing the Wire

6 Apply Novagard G661 or

Dow Corning

®

Compound

#4 to the terminal screws

and exposed bare wires.

See Figure 5.

Neptune recommends Novaguard G661 or Dow

Corning Compound #4.

Novagard may cause irritation to eyes and skin.

If swallowed, do not induce vomiting; dilute

with one to two glasses of water or milk and

seek medical attention. Please refer to:

• MSDS Novagard Silicone Compounds &

Grease Inc. 5109 Hamilton Ave. Cleveland,

OH 44114, 216-881-3890.

• For copies of MSDS sheets, please

call Neptune’s Customer Support

at (800) 647-4832.

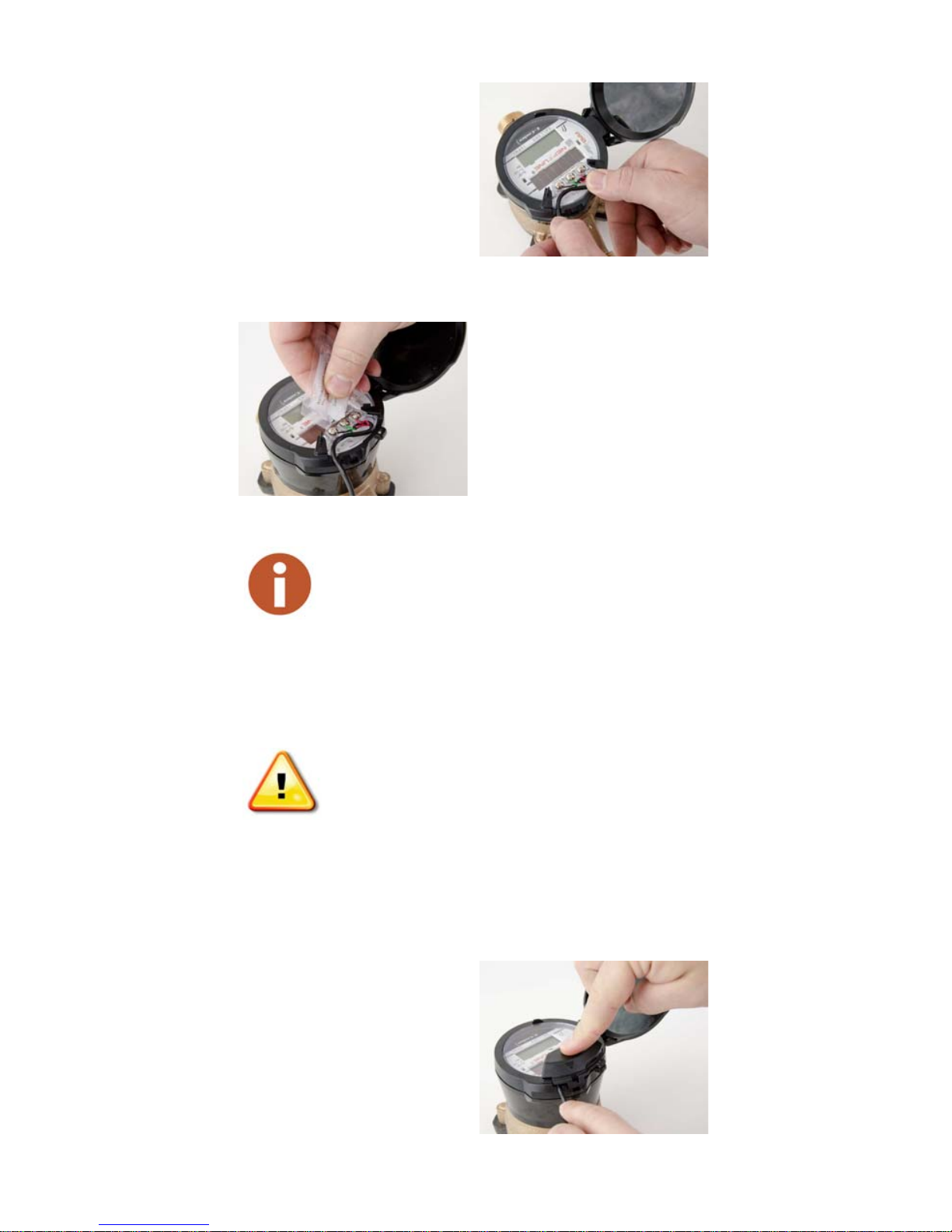

7 Place terminal cover on the

register, ensuring wire is

routed through strain relief.

See Figure 6.

Figure 6 Placing Cover on Register

3

Page 6

8 Snap the terminal cover in

place by pressing on the

molded arrow as shown in

Figure 7.

Figure 7 Snapping Cover in Place

9 Proceed to “How to Activate” on page 10.

4 Wiring the Pit Set Version

Complete the steps to wire the pit set version.

Figure 8 shows the components required for

installation.

Figure 9 Scotchlok Connector

Figure 8 Installation Components

1 Hold the Scotchlok

between the index finger

and thumb with the red cap

facing down. See Figure 9.

4

Page 7

2 Take one non-stripped black

Red and green wires not fully seated

wire from the pigtail and one

from the receptacle/MIU by

inserting the wires into the

Scotchlok connector until

fully seated. See Figure 10.

Figure 10 Seating Connector Wires

Do not strip the colored insulation from the

wires or strip and twist the bare wires prior to

inserting in the connector. Insert the insulated

colored wires directly into the Scotchlok

connector.

3 Place the connector red

cap side down between the

jaws of the UR crimping

tool as shown in Figure 11.

Refer to Table 3 on

page 10 for part numbers.

Figure 11 UR Crimping Tool

4 Check to ensure that the

wires are still fully seated

in the connector before

crimping the connector.

Figure 12 illustrates

improper connections

due to wires not being

fully seated.

Figure 12 Improper Connections

5 Squeeze the connector firmly with the proper crimping tool

until you hear a pop and gel oozes out the end of the

connector.

5

Page 8

6 Repeat steps one through five for each color wire. See

Table 2 for the wiring configuration to connect Neptune MIUs

or competitive MIUs to the E-CODER.

Table 2 Color Codes for Wires

MIU Wire Color / Encoder Terminal MIU Type

Black/B Green/G Red/R R900

Black/B Green/G Red/R R450

Black/G Green/R Red/B Sensus

Black/B White/G Red/R Itron

Black/G White/R Red/B Aclara

Black/G Green/B Red/R Elster

Black/G Green/R Red/B Badger

7 After all three color wires

have been connected, read

the encoder register to

ensure proper connections,

and the receptacle/MIU is

functioning properly. See

Figure 13.

Figure 13 Three Color Wires Connected

Figure 14 Splice Tube

8 Take all three connected

Scotchloks and push into

the splice tube until fully

covered by the silicone

grease. See Figure 14.

6

Page 9

9 Separate the gray wires,

and place in the slots on

each side of the splice tube

as shown in Figure 15.

Figure 16 Cover in Place

Figure 15 Gray Wires in Slot

10 Snap the cover closed to

finish the installation as

shown in Figure 16.

11 Proceed to “How to Activate” on page 10.

5 Installation Instructions for Networked

Receptacle/Dual Port MIUs

Enhanced R900 v4 MIUs are not Dual Port

capable. These instructions only apply to v3

MIUs.

The Dual Port R900 and R450 MIUs work only with Neptune

ProRead™ or E-CODER registers. Each register must be

programmed in “RF Network” mode prior to installation.

• E-CODER registers cannot be programmed

while connected together in a network. Each

register must be programmed separately

prior to making the network connection.

• The designations HI and LO are

Neptune's designations for the high (HI) flow

or turbine side of the compound, and the low

(LO) flow or disc side of the compound.

• The settings can also be used to designate

the primary (HI) and secondary (LO) meters

in a dual set application

7

Page 10

Programming the HI Register

To complete the following steps, use the Neptune field

programmer to select the ProRead Program tab for

programming.

1 Select RF Compound HI

format.

2 Match the Connectivity

2W.

3 Match the Dial Code 65.

4 Type the appropriate

register ID.

5 Program the register.

6 Read or query the register to

confirm correct

programming. See

Figure 17.

Figure 17 HI Register

Programming the LO Register

To complete the following steps, use the Neptune field

programmer to select the ProRead Program tab for

programming.

1 Select RF Compound LO

format.

2 Match the Connectivity 2W.

3 Match the Dial Code 65.

4 Type the appropriate register

ID.

5 Program the register.

6 Read or query the register to

confirm correct

programming. See

Figure 18.

Figure 18 LO Register

8

Page 11

6 Wiring Networked Registers

Complete the steps to wire networked registers.

1 Connect each color wire with the appropriate color wire from

the pigtail and both registers, until all three colors have been

successfully connected. See Figure 19.

Figure 19 Interconnection of Like Terminals

• Remove any bare or non-insulated wire. Make

sure that you only insert insulated wire into the

splice connector.

• Observe proper polarity when wiring the

registers, so that all terminals are

interconnected with wires of the same color:

red, black, or green. Refer to Figure 19.

2 Proceed to “How to Activate” on page 10.

7 Crimping Tool Manufacturers

To apply the Scotchlok connectors, Neptune requires the use of

a proper crimping tool. Table3 on page10 shows a list of various

manufacturers and model numbers.

9

Page 12

Table 3 Proper Crimping Tools

Manufacturer Manufacturer’s Model Number

E-9R (10:1)*

E-9BM (10:1)

3M

Eclipse Tools 100-008

* To reduce fatigue, use a tool within each splicing group with the highest

mechanical advantage indicated within the parentheses ().

E-9C/CW (7:1)

E-9E (4:1)

E-9Y (3:1)

Use of normal pliers or channel locks is highly

discouraged because they do not apply even

pressure and can result in an improper connection.

8 How to Activate

To read the E-CODER you must first activate it.

Complete the following steps to activate the E-CODER.

1 Expose the E-CODER to sunlight or activate with a flashlight

for five seconds.

If the LCD is able to power on, but there is

insufficient light to read the ASIC, the LCD displays

LO LIGHT. See Figure 20.

Figure 20 LCD Displaying LO Light

2 Verify that the following LCD displays appear.

• The All-Segment test appears for two seconds.

• The version number appears for two seconds.

• The event index value appears for 20 seconds.

• The flow rate appears for four seconds.

• The display alternates between the reading and the flow

rate every 12 seconds.

10

Page 13

9 How to Read

It is important to become familiar with the information available

from the meter. Figure21 lists various icons and displays along

with a description of each.

Figure 21 Icons and Displays

11

Page 14

10 Common Causes of Leaks

If the leak indicator is Flashing or Continuously ON, the

E-CODER is indicating that a possible leak may exist. Leaks can

result from various circumstances. To better help you identify a

possible leak, the following table contains some common causes

of leak problems that can occur.

Ta ble 4 Possible Leaks

Possible Cause of Leak

Outside faucet, garden or

sprinkler system leaking

Toilet valve not sealed

properly

Toilet running

Faucet in kitchen or

bathrooms leaking

Ice maker leaking

Soaker hose in use

Leak between the water

meter and the house

Intermittent

Leak

Continuous

Leak

Washing machine leaking

Dishwasher leaking

Hot water heater leaking

Watering yard for more than

eight hours

Continuous pet feeder

12

Page 15

Ta ble 4 Possible Leaks

Possible Cause of Leak

Water-cooled air conditioner

or heat pump

Filling a swimming pool

Any continuous use of water

for 24 hours

Intermittent

Leak

Continuous

Leak

11 How to Tell if Water is in Use

To determine if water is in use, complete the following steps.

1 Check the flow indicator by watching for two

minutes.

2 Determine which of the following conditions exists.

• If the arrow is Flashing, then water is running very

slowly.

• If the arrow is Continuously ON, water is running.

• If the arrow is not Flashing, water is not running.

12 What to Do if There is a Leak

The following checklist can be helpful if the E-CODER leak

indicator shows a possible leak.

Table 5 Checklist for Leaks

Check all faucets for possible leaks.

Check all toilets and toilet valves.

Check the ice maker and water dispenser.

Check the yard and surrounding grounds for a wet

spot or indication of a pipe leaking.

13

Page 16

13 If Continuous Leak is Repaired

If a continuous leak is found and repaired, complete the following

steps.

1 Use no water for at least 15 minutes.

2 Check the leak icon.

If the leak indicator changes from Continuously ON to

Flashing, then a continuous leak is no longer indicated.

14 If Intermittent Leak is Repaired

If an intermittent leak is found and repaired, complete the

following steps.

1 Check the leak icon after at least 24 hours.

If the leak has been correctly repaired, the leak icon

changes from Flashing to OFF.

2 Refer to the following tables which describe the standard

functions of the E-CODER flags.

Ta ble 6 E-CODER Flags

Backflow Flag (Resets After 35 Days)

Based on reverse movement of the eighth digit, the eighth

digit is variable based on the meter size.

No backflow event Eighth digit reversed less than one digit

Minor backflow

event

Major backflow

event

Leak Status Flag (Resets After 35 Days)

Based on total amount of 15-minute periods recorded in the

previous 24-hour period.

Eighth digit reversed more than one

digit up to 100 times the eighth digit

Eighth digit reversed greater than 100

times the eighth digit

Leak icon off Eighth digit incremented less than 50 of

the 96 15-minute intervals

14

Page 17

Backflow Flag (Resets After 35 Days)

Flashing leak icon Eighth digit incremented in 50 of the 96

15-minute intervals

Solid leak icon Eighth digit incremented in all of the 96

15-minute intervals

Consecutive Days with Zero Consumption Flag (Resets

After 35 Days)

Number of days the “leak status” was at a minimum value

15 Contact Information

Within the United States, Neptune Customer Support is available

Monday through Friday, 7:00 AM to 5:00 PM Central Standard

Time, by telephone, email, or fax.

By Phone

To contact Neptune Customer Support by phone, complete the

following steps.

1Call (800) 647-4832.

2 Select one of the following options.

• Press 1 if you have a Technical Support Personal

Identification Number (PIN).

• Press 2 if you do not have a Technical Support PIN number.

3 Enter the six-digit PIN number and press #.

4 Select one of the following options.

•Press 2 for Technical Support.

• Press 3 for maintenance contracts or renewals.

• Press 4 for Return Material Authorization (RMA) for

Canadian Accounts.

You are directed to the appropriate team of Customer

Support Specialists. The specialists are dedicated to you

until the issue is resolved to your satisfaction. When you

call, be prepared to give the following information.

• Your name and utility or company name.

• A description of what occurred and what you were doing at

the time.

• A description of any actions taken to correct the issue.

15

Page 18

By Fax

To contact Neptune Customer Support by fax, send a description

of your problem to (334) 283-7497. Please include on the fax

cover sheet the best time of day for a customer support specialist

to contact you.

By Email

To contact Neptune Customer Support by email, send your

message to hhsupp@neptunetg.com.

Notes

16

Page 19

Page 20

neptunetg.com

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

USA

Tel: (800) 645-1892

Fax: (334)283-7293

Neptune Technology Group (Canada) Ltd.

7275 West Credit Avenue

Mississauga, Ontario

L5N 5M9

Canada

Tel: (905) 858-4211

Fax: (905) 858-0428

Neptune Technology Group Inc.

Avenida Ejército Nacional No. 418

Piso 12, Desp. 1203

Colonia Polanco V Sección

Delegación Miguel Hidalgo

11560 México, Distrito Federal

Tel: (525) 55203 5294 / (525) 55203 4032

Fax: (525) 55203 6503

QI E-CODER 02.17 Part No. 12563-001

© Copyright 2003- 2017, Neptune Technology Group Inc.

Neptune is a registered trademark of Neptune Technology Group Inc.

Take Control

Loading...

Loading...