Page 1

INSTALLATION

NEP-ZL129306

OPERATION &

MAINTENANCE

NEPTUNE

Series 7000

Non-Controlled

Mechanical

“dia-PUMP”

Models

MP7100, MP7120,

MP7130, MP7150,

MP7180

03.2018_REV 1

Page 2

1

WARNING

SAFETY INSTRUCTIONS:

ZL129306

LOCKOUTS ARE REQUIRED BEFORE

SERVICING THIS EQUIPMENT.

Shut off/Lockout Pump Power before Servicing.

Be certain pump isolation valves are

03.2018_REV 2

Closed and chemical is shut off.

Bleed pressure before servicing.

Page 3

2

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction and result in serious injury.

This equipment is for professional use only.

Do not allow pump to run dry for a long periods of time.

PRESSURIZED EQUIPMENT HAZARD

Spray from leaks, ruptured components can splash fluid in the eyes or on the skin and cause serious injury.

Shut off the pump and depressurize before performing any maintenance.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and result in

fire or explosion and serious injury.

Please read thoroughly before installation, operation or maintenance of any Neptune pump

•

• Read all instruction manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended use.

• Do not alter or modify this equipment.

• Be certain all operators of this equipment have been trained for safe working practices,

understand its limitations, and wear safety goggles and/or equipment when required.

• Do not exceed the maximum working pressure of the system as mentioned on the pump tag.

• Do not use the pump head or the suction or discharge piping to pull the equipment.

• Do not move pressurized pump.

• Use fluids or cleaning agents for cleaning that are compatible with the pump parts. Read the

fluid and cleaning agent manufactures warnings and also refer to the material compatibility

chart

• Comply with all applicable local, state and national safety regulation.

•

•

• Do not tamper with or perform unspecified alteration of this device .

• Use only pipe, hose, and hose fittings rated for maximum rated pressure of the pump or the

pressure at which the pressure relief valve is set at.

• Always wear protective clothing, face shield, safety glasses and gloves when working on or

near your metering pump.

• Additional precautions should be taken depending on the solution being pumped. Refer to

MSDS precautions from your solution supplier.

• Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Tighten all fluid connections before operating the equipment.

• Replace worn, damaged, or loose parts immediately.

• Before performing any maintenance requiring pump head and or valve (wetted parts)

disassembly, be sure to relieve pressure from the piping system and where hazardous process

chemicals are present.

• Make the pump safe to handle for the personal and the environment by cleaning and

chemically neutralizing the pump as appropriate.

• Wear protective clothing and use proper tools as appropriate to avoid any injury.

• If the diaphragm has failed, process chemical may have contaminated the pump oil. Handle

with appropriate care and personnel equipment. Clean the pump and replace oil as necessary.

Discard the contaminated oil as per the local code.

Page 4

3

•

Ground the equipment. See motor installation instruction for grounding procedure.

correct the problem before starting up the pump.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in eyes or on the skin,

Know the specific hazards of the fluid you are using. Read the fluid manufactures warnings.

installed on the gear box.

SOUND HAZARD

The sound pressure level of the pump may exceed 80dBA in some pumps.

Observe all safety precautions when operating the pump within close proximity for extended

tinnitus, tiredness, stress, and other effects such as loss of balance and awareness.

MECHANICAL HAZARD

The pump may shake or vibrate during operation.

Vibration could occur due to loose mechanical component and foundation bolts, causing

• Do not pump non recommended flammable or explosive fluids.

• Static electricity may generate by fluid moving through pipes and hoses. A static spark could

be produced by high fluid flow rate. Earthling of the pump is a must.

• Provide fresh air ventilation to avoid the possible buildup of flammable fumes from the

process chemicals.

• Keep the pump area free of debris, including cleaning agent, rags, and any flammable material.

• Follow the cleaning agent and other cleaning recommendations as mentioned in the operation

and instruction manuals.

• Use cleaning agent with the highest possible flash point to clean the pump parts if needed.

• If there is any static sparking while using the equipment, stop operation at once. Identify and

swallowed, or inhaled.

•

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all

local, state and national guidelines.

• Wear the appropriate protective clothing, gloves, eyewear and respirator.

• Pipe and dispose of the exhaust air safely. If diaphragm fails, the fluid may be exhausted along

with the air in mechanical diaphragm pump. Also oil vapor may flow through the air breather

•

periods by wearing hearing protectors.

• Extended exposure to elevated sound levels will result in permanent loss of hearing acuteness,

•

piping rupture and leakage of chemical to cause bodily injury. The pump should be bolted

down to the base during operation.

• Spills or drips of oil may occur during maintenance of pump, causing the operator to slip or

fall. Clean and neutralize the area as soon as possible with an appropriate cleaning agent.

Always wear protective clothing and gears.

• Pump may overturn when being transported if the motor is too heavy. Secure the pump on its

base before transportation.

Page 5

4

I

COMMON PARTS LIST

17

GEAR BOX PARTS LIST PER MODEL

17

V

MECHANICALLY ACTUATED PUMP

SECTION PARAGRAPH TABLE OF CONTENTS PAGE

GENERAL DESCRIPTION 5

LIMITED WARRANTY 6

PARTS ORDERING INSTRUCTIONS 7

II

1

2

3

4

5

III

6

IV 7 MOTOR OPERATING CONDITIONS 20

INSTALLATION INSTRUCTIONS

GENERAL

SUCTION PIPING

DISCHARGE PIPING

INSTALLATION OUTDOORS

STARTUP PROCEDURE

NORMAL MAINTENANCE

MAINTENANCE

PARTS LIST 17

LIQUID HEAD PARTS LIST PER MODEL 18,19

TROUBLE SHOOTING CHART 20

8

9

10

10

10

11

DRAWINGS

MODEL MP7120-3N5

CROSS SECTION (HEAD AREA) MP7120-2N5,-2N8

SPARE PARTS KITS 21

MSDS for Hypoid Gear Oil SAE 80W-90 22

PUMP DATA / MAINTENANCE LOG

13-16

18

35

Page 6

5

SECTION I

GENERAL DESCRIPTION

The Neptune MP7000 Mechanical Diaphragm metering pump is a reliable metering pump of the low-pressure diaphragm

type. Under constant conditions of temperature, pressure, and capacity setting, a +/- 2% metered discharge volume is

maintained. Rugged contoured composite diaphragm designed for high metering accuracy.

A reciprocating rod set at a fixed stroke length and rate actuates a flexible, chemically inert, Teflon faced diaphragm

creating the pumping action.

Precision-engineered liquid ends meters mild solutions, aggressive chemicals, high viscosity polymers (up to 2500cP) and

slurries (hydrated lime slurries up to 4 lb/gallon of water, activated carbon slurries up to 1 lb/gallon of water). If metering of

liquids with higher viscosity is required please contact factory.

Metering accuracy is maintained by the ball check valves in the suction and discharge pump heads. Screw-in cartridge

ball check valves eases maintenance.

Temperature limitations on the plastic heads are: 36 – 125°F (2 - 52°C) for PVC; 36 - 200°F (2-93°C) for PVDF.

PLEASE READ INSTRUCTION MANUAL COMPLETELY BEFORE INSTALLING PUMP.

Page 7

6

SECTION I

IMPORTANT NOTICE

NEPTUNE CHEMICAL PUMP COMPANY

LIMITED WARRANTY

All Neptune Pumps are tested at the factory prior to shipment. Each part used in their construction has been carefully

checked for workmanship.

If the pump is installed properly, Neptune Chemical Pump Company warrants to the purchaser of this product for a period

of twelve months from the date of first use or eighteen months from shipment, whichever occurs first, this product shall be

free of defects in material and/or workmanship, as follows:

1 Neptune Chemical Pump Company will replace, at no charge, any part that fails due to a defect in material and/or

workmanship during the warranty period, FOB our factory, North Wales, Pennsylvania. To obtain warranty service,

you must forward the defective parts to the factory for examination, freight pre-paid.

2 This warranty period does not cover any product or product part, which has been subject to accident, misuse, abuse

or negligence. Neptune Chemical Pump Company shall only be liable under this warranty if the product is used in

the manner intended by the manufacturer as specified in the written instructions furnished with this product.

Any express warranty not provided in this warranty document, and any remedy for breach of contract that, but for this

provision, might arise by implication or operation of law, is hereby excluded and disclaimed. Under no circumstances shall

Neptune Chemical Pump Company be liable to purchaser or any other person for any charge for labor, repairs, or parts,

performed or furnished by others, nor for any incidental consequential damages, whether arising out of breach of warranty,

express or implied, a breach of contract or otherwise. Except to the extent prohibited by applicable law, any implied warranty

of merchantability and fitness for a particular purpose are expressly limited in duration to the duration of this limited warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long

any implied warranty lasts, so the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may have other rights, which may vary from state to state.

1

IMPORTANT

SHOULD IT BE NECESSARY TO SEND THE PUMP TO THE FACTORY FOR REPAIR OR MAINTENANCE REBUILDING;

DRAIN ALL OIL AND CHEMICAL FROM PUMP BEFORE SHIPPING. FAILURE TO DO SO CAN CAUSE EXTENSIVE

DAMAGE TO THE MOTOR.

SEE IMPORTANT NOTICE – RETURN GOODS AUTHORIZATION

1

RETURN GOODS AUTHORIZATION

(1) All equipment returned to Neptune Chemical Pump Company requires proper Returned

Goods Authorization Number (RGA) and tags.

(2) All equipment returned to the factory for repair or service must first be thoroughly flushed and have

all chemical contact areas neutralized.

(3) All equipment which has been in contact with chemicals must be accompanied by a copy of the

Chemical Product Material Safety Data Sheet (MSDS).

(4) Failure to comply with the above instructions will result in equipment being returned to sender, freight

collect, without service.

Page 8

7

A C OM PA NY

www.neptune1.com

DOVER

CHEMICAL PUMP CO.

North Wales PA 19454

TEL: 215-699-8700

SECTION I

PARTS ORDERING INSTRUCTIONS

The complete model number and serial number of the pump must be furnished to insure

prompt and accurate parts service. These numbers are found on the name plate (sample

below) located on the back cover of the pump.

Please refer to page number (17), (18), (19) for parts list. Ballooned drawing of the pumps

can be found on pages (13), (14), (15), (16) and (18).

Spare Parts Kits are found on page 21.

Send all orders or inquiries for parts to:

Parts Department

Neptune Chemical Pump Company, Inc.

295 DeKalb Pike

North Wales, PA 19454

Tel.: 215-699-8700

1 -888-3NEPTUNE (888-363-7886)

FAX: 215-699-0370

Web: www.neptune1.com

Email: pump@neptune1.com

NOTE: PLEASE SUPPLY BOTH MODEL AND SERIAL NUMBERS.

Page 9

8

1.0 GENERAL

1.0.1 UNPACKING & INSPECTION

When unpacking a pump or chemical feed system, be certain that no parts are thrown away. Examine the

equipment for possible damage. If damage has occurred, file claim with the common carrier within 24

hours. Neptune will assist in estimating the repair costs.

1.0.2 The Mechanically Actuated Diaphragm metering pumps should be located on a level surface. Four

mounting holes are provided to anchor the pump base securely to the mounting surface. All piping to the

pump should be supported to prevent stress on the pump inlet and discharge fittings.

1.0.3 Before connecting the pump make sure that all fittings are completely clean by flushing thoroughly.

Foreign matter with sharp edges entering the pump can damage the diaphragm and severely limit the life

of the pump.

1.0.4 A “Y” STRAINER (AT LEAST ONE PIPE SIZE LARGER THAN SUCTION PORT SIZE OF THE PUMP)

MUST BE INSTALLED IN THE SUCTION LINE OF THE PUMP TO INSURE AGAINST FOREIGN

MATTER ENTERING THE PUMP

1.0.5 It is recommended that isolation valves and unions be placed in the suction and discharge lines if

possible. Such an arrangement will facilitate servicing the pump.

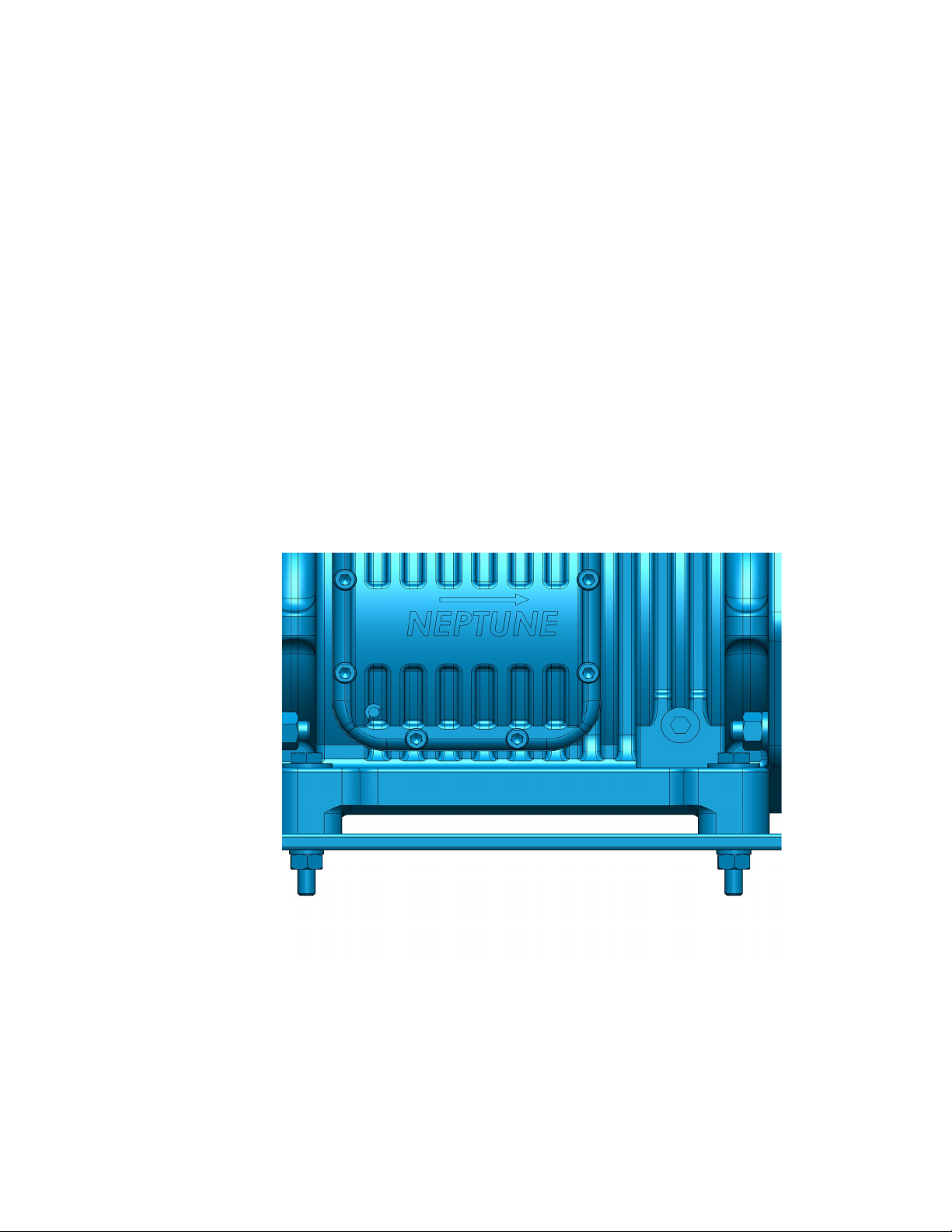

1.0.6 The electrical supply to the pump must match the motor nameplate characteristics. The motor rotation is

counterclockwise when viewed from the top of the motor or looking down on the pump. An arrow mark on

the side cover of the gearbox is indicating the correct rotation (Figure 1).

SECTION II

INSTALLATION INSTRUCTIONS

FIGURE 1

Operation with the incorrect rotation will damage the pump and motor.

IMPORTANT: On single-phase units, the rotation is set at the factory and must not be changed

1.0.7 Fill gearbox and pump by removing the breather and pouring the specified gear oil (drive lubricant) or oil

provided with pump through the Breather port. Pour oil in slowly until it covers the worm gear.

1.0.8 For dry pump (pump shipped from factory without oil) the oil volume is 27ozs (800cc) to fill the pump.

Page 10

9

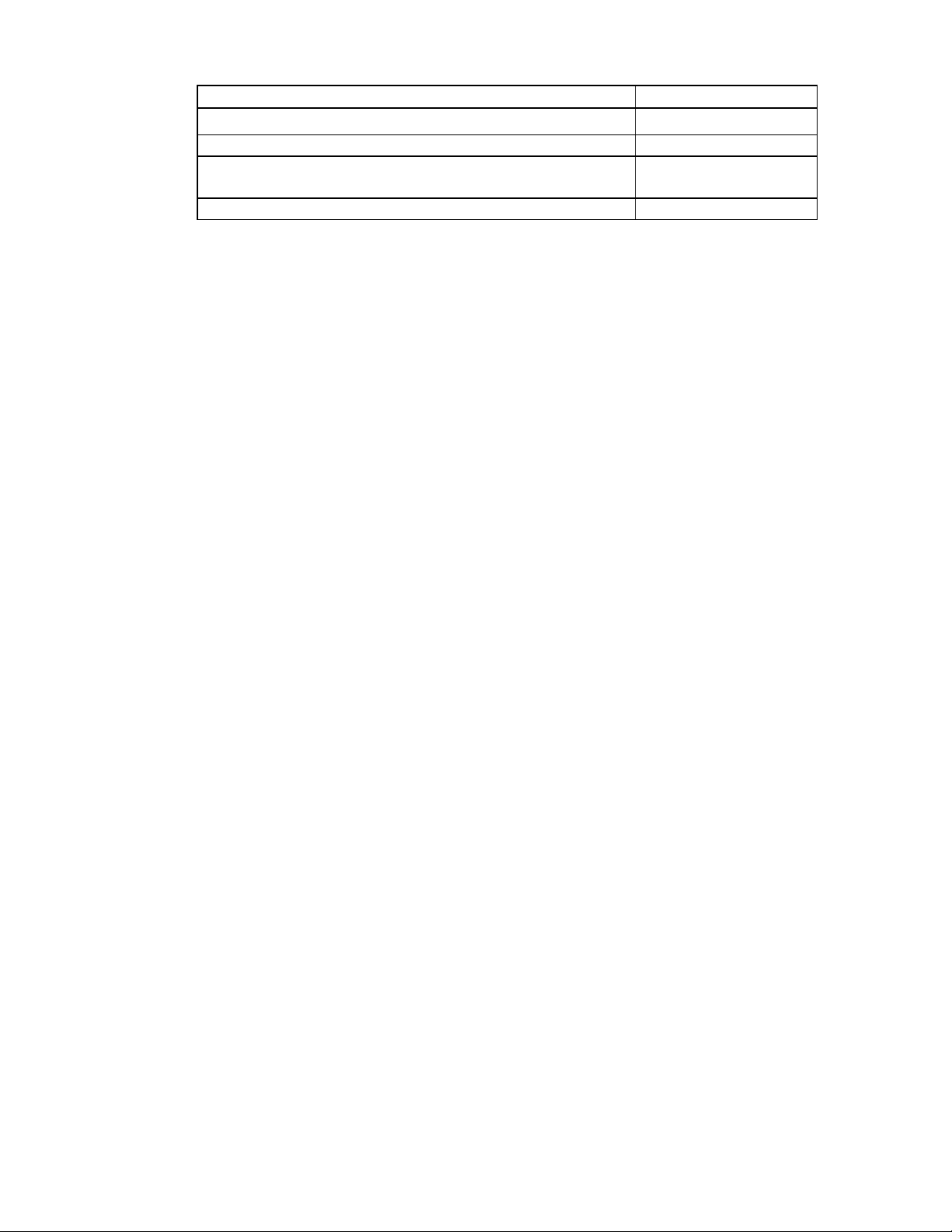

Alternate Oils

Manufacturer

Mobil Delvac Gear Oil 80W-90

Mobil Oil

Pennzoil® Gearplus®SAE 80W- 90 GL-5 Gear Oil

Pennzoil

The oil supplied by Neptune is:

PREMIUM PERFORMANCE HYPOID GEAR OIL SAE 80W-90,

Common sources for Gear Oil are:

Spirax S3 80W-90 Advance transmission Hypoid Gear Oil Shell Oil

NOTE: THE FACTORY SUPPLIED CHECK VALVES ARE FITTED WITH VITON O-RINGS. CHECK CHEMICAL

COMPATIBILITY, IF NOT COMPATIBLE REPLACE WITH SUPPLIED TEFLON O-RINGS.

All piping systems should include:

1.1.1 A separate system relief valve to protect piping and process equipment, including the pump, from excess

process pressures.

MULTIGEAR 80W-90

Geartex EP-A 85W-90

Texaco

*An external relief valve is required to safeguard pump and the piping system.

1.1.2 Isolation valves and unions (or flanges) on suction and discharge piping. This permits check valve

inspection without draining long runs of piping. Isolation valves should be of the same size as

connecting pipe. Full flow ball valves are preferred since they offer minimum flow restriction.

1.1.3 An inlet strainer, if the product is not slurry. Pump check valves are susceptible to dirt and other solid

contaminants unless designed for that service, and any accumulation can cause malfunction. The strainer

should be located between the suction isolation valve and the pump suction check valve. It must be sized

to accommodate the flow rate and the anticipated level of contamination. A 100-mesh screen size is

recommended.

1.1.4 Check valve housings or other portions of the liquid head must not support piping weight, as the resulting

stresses can cause leaks. In piping assembly, use a sealing compound chemically compatible with the

process material.

SUCTION PRESSURE REQUIREMENTS

Although Mechanical Diaphragm metering pumps have suction lift capability, a flooded suction is

preferable whenever possible. The pump should be located as close as possible to the suction side

reservoir or other source keeping suction piping as short as possible.

The pump will self-prime with 10 ft. (3 meters) of water suction lift (wetted valves, zero back pressure, full

stroke and speed, water like solutions). A foot valve is required to maintain prime. Once primed, the

pump is capable of up to 20 feet (6 meters) of water suction lift.

Neptune Mechanically Actuated Diaphragm metering pumps are designed for continuous service at the

rated discharge pressure. The discharge pressure must exceed suction pressure by at least 25 psiA (or

1.75 Bar). This can be achieved where necessary by the installation of a backpressure valve in the

discharge line.

2.0 SUCTION PIPING

2.0.1 The suction piping to the pump must be absolutely airtight for optimum operation any leakage in the

suction line will reduce or even eliminate pumping capacity. Suction pipe should be at least one size

larger than suction port size of the pump’s Liquid Head. It is suggested that the suction piping be tested

with low air pressure and a soap solution to assure that no leaks exist. Limit the total length of the suction

line to 5-8 feet for suction lift or 8-10 feet for flooded suction. Minimize bends, elbows, or other restrictions

for better pumping efficiency.

2.0.2 NEPTUNE RECOMMENDS THAT THE MECHANICALLY ACTUATED DIAPHRAGM METERING

Page 11

10

PUMPS BE OPERATED WITH A FLOODED SUCTION, AS THIS WILL FACILITATE START-UP AND

INCREASE THE SERVICE LIFE OF THE PUMP.

2.0.3 It is recommended that all solution tanks be furnished with a low level cut off switch or low-level alarm

and cut off switch to prevent the pump from running dry. Although the pump can run dry for a few

minutes, OPERATION AGAINST A DRY SYSTEM UNDER THE PRESSURE FOR A PROLONGED

PERIOD MAY CAUSE DAMAGE TO THE PUMP DIAPHRAGM AND REDUCE THE OPERATING LIFE

OF THE PUMP.

3.0 DISCHARGE PIPING

3.0.1 It is recommended that the Mechanically Actuated Diaphragm metering pump operate against a suitable

back pressure to facilitate better operation of the check valves.

3.0.3 To protect the pump, it is recommended that an external relief valve as manufactured by Neptune Chemical

Pump Company, or equal, be placed in the discharge line of the pump to avoid over pressure.

3.0.4 Discharge piping should at least equal to discharge port size of the pump’s Liquid Head.

NOTE: All pipes and valves must have a working pressure at least twice the system maximum pressure.

CAUTION : Do not attempt to run the pump in excess of its nameplate rating.

4.0 INSTALLATION OUTDOORS

The Mechanically Actuated Diaphragm metering pump is a totally enclosed pump, which can be used outdoors or

indoors. When installed outdoors, make sure that the pump is protected against extremes of nature as follows:

4.0.1 Running of the pump when exposed to tropical sunshine with ambient temperature above 100°F (37.8°C)

would cause excessive oil and motor temperatures. The pump should be shaded and located in such a

way as to permit an ample degree of air circulation.

Under cold conditions, the pump should be insulated and a heat tracing should be supplied in order to

4.0.2

maintain the hydraulic fluid at an ambient temperature above 36°F (2°C.)

5.0 START UP PROCEDURE

The following start up procedure is complete and does repeat instructions on filling the gearbox and pump.

5.0.1 Open suction and discharge valves. (See recommendation 1.0.5)

5.0.2 Adjust backpressure close to zero.

5.0.3 Start pump.

5.0.4 On initial start-ups: Check for proper motor rotation (Refer to Paragraph 1.0.6). Listen for any abnormal

motor or crank noises, and if present, refer to trouble shooting chart (page 20)

5.0.5 Adjust system pressure to requirement.

SECTION III

NORMAL MAINTENANCE

6.0 MAINTENANCE

Under normal conditions, the Mechanically Actuated Diaphragm metering pumps should not require any

Page 12

11

significant amount of maintenance. It is advised that periodic visual observations be made of the oil level to make

sure that it is over the worm gear. The liquid end of the pump should also be inspected for leakage and check the

liquid head bolt torque. These observations should be made regularly.

The gear oil should be drained and replaced at least every 6 months. Oil changes are usually scheduled with the

normal factory maintenance at seasonal periods. The recommended oil change intervals are dependent upon the

operating environment and hours of pump usage.

6.1.0 OIL CHANGE

6.1.1 Disconnect the power source to the drive motor

6.1.2 Relieve all pressure from the piping system.

6.1.3 Drain the oil by removing the drain plug (item#71) at the lower side of the gearbox.

(Same side where the side cover is located)

6.1.4 Replace the drain plug (item#71)

6.1. 5 Remove breather from the gearbox.

6.1.6 Fill gear box with oil as recommended in 1.0.7

6.1.7 Replace breather.

6.2.0 CHECK VALVE REMOVAL CLEANING AND REPLACEMENT.

Should the valves need cleaning, remove as follows:

6.2.1 Disconnect the power source to the drive motor.

6.2.2 Relieve all pressure from the piping system.

6.2.3 Close the isolation valves on suction and discharge piping.

6.2.4 Loosen and remove the suction and discharge check valves gradually to drain any trapped liquid.

6.2.5 Clean valves with suitable solvent. Both valves are complete and integral units and should not be

disassembled for cleaning. If the valves are found to be worn and in need of replacement, an

entire valve in either suction or discharge should be ordered.

6.2.6 To replace, reverse above procedures. Make sure that the port orientation is correct.

6.2.7 For valves with O-rings make sure that the O-rings are in good condition. Install new O-rings if

necessary.

Page 13

12

6.3.0 LIQUID HEAD REMOVAL, INSPECTION, AND REINSTALLATION

CAUTION: If the diaphragm failed, process fluid will pass through the bleed hole located behind the diaphragm. Handle any liquid with appropriate care.

(Refer to liquid manufacturer’s MSDS)

Mechanical diaphragms should operate for approximately 2000+ hours under normal operating

conditions; however, the accumulation of foreign material or debris and abnormal operating condition

or simply age can cause failure. Failure can also occur as a result of hot pumping fluid or system over

pressure. Periodic diaphragm inspection and replacement are recommended.

6.3.1 Disconnect the power source to the drive motor.

6.3.2 Relieve all system pressure from the piping system.

6.3.3 Take all precautions described under “Caution” to prevent environmental and personnel

exposure to hazardous materials.

6.3.4 Disconnect piping to the Liquid Head and drain any process liquid.

6.3.5 Drain gear box oil.

6.3.6 Place a pan underneath the pump head adaptor to catch any liquid leakage.

6.3.7 Remove all but two top Liquid Head bolt. Process fluid or Oil or both will leak out between the

pump head adaptor and Liquid Head as the bolts are loosened.

6.3.8 Tilt the head and pour out any liquids retained by the check valves into a suitable container,

continue to follow safety precautions as appropriate.

6.3.9 Remove the final bolt and rinse or clean the Liquid Head with an appropriate material.

6.3.10 Inspect the diaphragm. The diaphragm must be replaced if it is cracked, separated, or

obviously damaged. Remove the diaphragm if necessary, by turning counter-clockwise.

6.3.11 If diaphragm cannot be unscrewed from push rod, remove 1/8 NPT dry seal plug (item #69)

from the interim chamber.

6.3.12 Use a 1/8” diameter steel implement, insert it through the hole for the dry seal plug and into

the cross hole in the push rod. Start to turn diaphragm to feel the steel implement engage the

hole in push rod. This will lock the push rod from turning with diaphragm allowing diaphragm

removal.

6.3.13 To install a diaphragm, first ensure that the critical sealing areas of: diaphragm, Liquid Head,

and pump head adapter are clean and free of debris. Assemble the diaphragm with backup

plate (item #28). For MP71XX-3N3, 5, 8 and MP71XX-4N3, 5, 8 install spacer nut (item #30)

onto the diaphragm threads.

6.3.14 Thread the diaphragm (clockwise) completely on the push rod. Use step 6.3.11 to hold push

rod in place when turning the diaphragm. Put back dry seal plug in interim chamber, and add

oil as specified in 6.1.0.

6.3.15 Install the liquid head, faceplate (for plastic heads), and bolts. Tighten bolts in an alternating

crossing pattern to ensure an even pressure on all bolts. Recommended torque is 12-13 ft-lb

for pump MP 71XX-2N3, 5, 8 and 18-19 ft-lb for pump MP71XX-3N3, 5, 8, MP71XX-4N3, 5, 8

Page 14

13

MODEL MP7120-3N5

MECHANICALLY ACTUATED PUMP

(SHOWN WITH PVC #3 LIQUID HEAD)

HORIZONTAL CROSS SECTION

Page 15

14

VERTICAL CROSS SECTION

Page 16

15

PUMP SIDE VIEW (LEFT SIDE)

Page 17

16

PUMP SIDE VIEW (TOP VIEW)

Page 18

17

PARTS LIST

ITEM

NO. DESCRIPTION

QTY.

PART

NO.

1

Gear Box

1

004760

2

GEARS Worm Gear 37 SPM*

004778

Worm Gear 72 SPM*

004779

Worm Gear 58 SPM*

004780

Worm Gear 117 SPM*

004781

Worm Gear 176 SPM*

004782

3

SIDE COVER

1

005124

4

O-RING, VITON

1

104756

6

SLEEVE BUSHING FOR ALUM

GEAR BOX

2

104673

7

GEAR SHAFT

1

104677

8

TRUST COLLAR

1

004785

9

PUSH ROD

1

004786

10

BUSHING

1

104674

11

O-RING, VITON

2

104757

12

INTERMEDIATE CHAMBER

1

004849

17

BLANK COVER INTERMEDIATE

CHAMBER

1

005191

20

O-RING, NITRILE

1

107580

24

RETAINING RING EXTERNAL

2

106593

31

RETAINING RING INTERNAL

2

106592

32

OIL SEAL

2

106586

33

O-RING, NITRILE

1

107600

34

BUSHING

1

104675

35

SPRING

1

108023

38

BACK COVER MECH DIAPH PUMP

1

004793

ITEM

NO.

DESCRIPTION

QTY.

PART

NO.

40

WORM 1 WORM 37 SPM

000170

WORM 72 SPM

000172

WORM 58 SPM

004710

WORM 117 SPM

000169

WORM 176 SPM

000171

41

BEARING WAVE SPRING

1

107599

42

BALL BEARING

1

106180

43

MOTOR FLANGE ADAPTER, 56C & IEC 71

1

004812

44

MOTOR WORM SHAFT

1

004156

45

BREATHER

1

000191

48

BOLT 2 100267

49

BEARING CUP

1

100179

50

BEARING CONE

1

100180

51

SPRING PIN

1

100181

52

SCREW

4

105108

58

LOCK WASHER

20

100170

59

NUT

16

108175

60

BOLT 4 100648

61

WASHER

4

108426

62

LOCK WASHER

4

100169

63

NUT

4

100448

64

WASHER

4

100069

65

BOLT

4

100109

66

SCREW

8

100358

67

SCREW

4

100216

68

SCREW

4

128032

69

PIPE PLUG

1

100196

70

MOTOR 1

71

PIPE PLUG

1

100332

73

BREATHER VENT

1

104447

ITEM

NO. DESCRIPTION

QTY.

PART

NO.

5

UNIVERSAL CAM

1

005029

23

STROKE ADJUSTER DISK

1

001133

36

BALL BEARING

1

100359

39

PUMP MOUNTING BRACKET

1

001415

ITEM

NO.

DESCRIPTION

QTY.

PART

NO.

5

UNIVERSAL CAM

1

004784

23

STROKE ADJUSTER DISK

1

004857

36

BALL BEARING

1

004683

37

BEARING, SLEEVE

1

104735

39

PUMP MOUNTING BRACKET

1

004852

COMMON PARTS LIST

GEAR BOX PARTS LIST PER MODEL

PUMPS MP7100, 120, 130, 150, 180-2NX PUMPS MP120, 130, 150, 180-2NX

Page 19

18

CROSS SECTION (HEAD AREA) MP7120-2N5,-2N8

FOR PUMPS: MP7100, 120, 130, 150, 180

-2N3

-2N5

-2N8

ITEM NO

DESCRIPTION

QTY.

PART NO.

PART NO.

PART NO.

25

PLATE, HEAD, #2

1

N/A

004858

004858

26

LIQUID HEAD #2 316SS

1

0047959

N/A

N/A

26

LIQUID HEAD, #2, PVC

1

N/A

004950

N/A

26

LIQUID HEAD, #2, PVDF

1

N/A

N/A

004951

27

DIAPHRAGM , #2 ASSEMBLY

1

104743

104743

104743

28

BACK-UP PLATE #2

1

004774

004774

004774

29

PUMP HEAD ADAPTER, #2

1

004797

004797

004797

46, 47

CHECK VALVE ASSEMBLY, 1/2” NPT, 316SS

2

005011

N/A

N/A

46, 47

CHECK VALVE ASSEMBLY, 1/2” NPT, PVC

2

N/A

003279

N/A

46, 47

CHECK VALVE ASSEMBLY, 1/2” NPT, PVDF

2

N/A

N/A

003332

74

HEX HEAD BOLT

8

N/A

128033

128033

74

SOCKET HEAD CAP SREW

8

100207

N/A

N/A

64

FLAT WASHER

8

N/A

100069

100069

LIQUID HEAD PARTS LIST PER MODEL

Page 20

19

LIQUID HEAD PARTS LIST PER MODEL

FOR PUMPS: MP7100, 120, 130, 150, 180

-3N3

-3N5

-3N8

ITEM NO

DESCRIPTION

QTY.

PART NO.

PART NO.

PART NO.

25

PLATE, HEAD, #3

1

N/A

004859

004859

26

LIQUID HEAD #3 316SS

1

004799

N/A

N/A

26

LIQUID HEAD, #3, PVC

1

N/A

004877

N/A

26

LIQUID HEAD, #3, PVDF

1

N/A

N/A

004809

27

DIAPHRAGM , #3 ASSEMBLY

1

127160

127160

127160

28

BACK-UP PLATE #3

1

004794

004794

004794

29

PUMP HEAD ADAPTER, #3

1

004808

004808

004808

30

SPACER NUT

1

005070

005070

005070

46, 47

CHECK VALVE ASSEMBLY, 1” NPT, 316SS

2

005032

N/A

N/A

46

CHECK VALVE ASSEMBLY, 1” NPS PVC, DISCHARGE

1

N/A

005106

N/A

47

CHECK VALVE ASSEMBLY, 1” NPS PVC, SUCTION

1

N/A

005108

N/A

46

CHECK VALVE ASSEMBLY, 1” NPS, PVDF, DISCHARGE

1

N/A

N/A

005110

47

CHECK VALVE ASSEMBLY, 1” NPS, PVDF, SUCTION

1

N/A

N/A

005112

53

SOCKET HEAD CAP SCREW

12

120831

120831

120831

54

HEX NUT

8

100642

100642

100642

55

LOCK WASHER

12

100217

100217

100217

56

FLAT WASHER

4

106087

106087

106087

57

HEX HEAD BOLT

8

104678

104678

104678

75

O-RING KIT (USED WITH PVC & PVDF CHECK VALVES)

1

N/A

129300

129300

FOR PUMPS: MP7100, 120, 130, 150, 180

-4N3

-4N5

-4N8

ITEM NO

DESCRIPTION

QTY.

PART NO.

PART NO.

PART NO.

25

PLATE, HEAD, #4

1

N/A

004862

004862

26

LIQUID HEAD #4 316SS

1

4810

N/A

N/A

26

LIQUID HEAD, #4, PVC

1

N/A

004878

N/A

26

LIQUID HEAD, #4, PVDF

1

N/A

N/A

004811

27

DIAPHRAGM , #4 ASSEMBLY

1

128035

128035

128035

28

BACK-UP PLATE #4

1

005093

005093

005093

29

PUMP HEAD ADAPTER, #4

1

005091

005091

005091

30

SPACER NUT

1

005070

005070

005070

46, 47

CHECK VALVE ASSEMBLY, 1 1/2” NPT, 316SS

2

005096

N/A

N/A

46

CHECK VALVE ASSEMBLY, 1 1/2” NPS, PVC, DISCHARGE

1

N/A

005098

N/A

47

CHECK VALVE ASSEMBLY, 1 1/2” NPS, PVC, SUCTION

1

N/A

005100

N/A

46

CHECK VALVE ASSEMBLY, 1 1/2” NPS, PVDF, DISCHARGE

1

N/A

N/A

005102

47

CHECK VALVE ASSEMBLY, 1 1/2” NPS, PVDF, SUCTION

1

N/A

N/A

005104

53

SOCKET HEAD CAP SCREW

12

120831

120831

120831

54

HEX NUT

8

100642

100642

100642

55

LOCK WASHER

12

100217

100217

100217

56

FLAT WASHER

4

106087

106087

106087

57

HEX HEAD BOLT

8

104678

104678

104678

75

O-RING KIT (USED WITH PVC & PVDF CHECK VALVES)

1

N/A

129301

129301

Page 21

20

SECTION IV

SYMPTOMS

CAUSES

REMEDIES

1. Pump Motor Will Not

Operate.

A. Blown Fuse.

Check for short circuit or overload

B. Open thermal overload device in

starter.

Reset.

C. Low liquid level in tank (where low

level cut-off is used).

Fill tank.

D. Broken wire.

Locate and repair.

E. Low voltage.

Check for too light wiring.

F. Oil “frozen” in pump.

Thaw out.

2. Pump Does Not Deliver

Rated Capacity

A. Starved suction.

Look for blockage in suction line.

B. Leaky suction piping.

Replace suction piping with larger size.

Pressure test, repair or replace defective piping.

C. Excessive suction lift.

Rearrange equipment location to reduce suction lift.

D. Liquid too close to boiling point.

Lower temperature or increase suction pressure slightly.

E. Worn or dirty valves or seats, or

both

Clean or replace valve assembly.

F. Viscosity of liquid too high

1. Reduce viscosity by heating or other means

2. Increase size of suction piping

3. Increase suction pressure slightly

G. Low discharge pressure

A minimum discharge pressure of 25 psi is required to

insure proper capacity control

Repair or replace piping.

3. Pump delivers

erratically.

A. Leaky suction line.

Clean or replace valve assembly.

B. Worn or dirty valves or seats, or

both.

Increase backpressure.

C. Excessive excursion of ball valves

from seats (indicated by ball chatter).

Increase suction pressure.

D. Insufficient suction pressure

Raise tank level.

E. Liquid too close to boiling point,

Reduce temperature or raise suction pressure.

F Leaky system relief valve.

Repair or replace relief valve

4. Motor overheats thermal

overload activates,

A. Power supply does not match motor.

Check power supply against motor nameplate data.

B. Overload caused by operating pump

beyond rated capacity

Check operating pressure against pump manufacturer

data plate maximum rating

5. Noisy Operation

5.1. In Pump

A. Pump Valves.

Valves must move to open and close, and they will make

functioning.

5.2. In Gear Reducer

A. Pounding noise at high discharge

pressure

Fluid compressibility causes reversal of load on gears at

end of pressure stroke, Not considered detrimental.

6. Oil level Low

A. Flexible diaphragm punctured

Replace diaphragm

MOTOR OPERATING CONDITIONS

7.0 The normal temperature rise for standard motors is 40°C above ambient temperature and, thus, it might appear

that the motor is operating at a higher than normal temperature. This situation is normal.

As a precaution against motor overheating, it is recommended that the pump be located where adequate

ventilation is available, It is also recommended that a MOTOR STARTER WITH THE PROPER OVERLOAD

PROTECTION BE SUPPLIED AS AN ADDITIONAL SAFETY DEVICE.

SECTION V

TROUBLESHOOTING CHART

a clicking noise as they operate. These noises are

sometimes amplified by natural resonances in piping

system. They are usually indications of normal valve

Page 22

21

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #2 ASSEMBLY

1

104743

KIT NUMBER 005178

46, 47

CHECK VALVE ASSEMBLY 1/2” NPT

2

005011

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #2 ASSEMBLY

1

104743

KIT NUMBER 005179

46, 47

CHECK VALVE ASSEMBLY 1/2” NPT

2

003279

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #2 ASSEMBLY

1

104743

KIT NUMBER 005180

46, 47

CHECK VALVE ASSEMBLY 1/2” NPT

2

00003332

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #3 ASSEMBLY

1

127160

KIT NUMBER 005181

46, 47

CHECK VALVE ASSEMBLY 1” NPT

2

005032

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #3 ASSEMBLY

1

127160

KIT NUMBER 005182

46

CHECK VALVE ASSEMBLY 1” NPS DISCHARGE

1

005106

47

75

CHECK VALVE ASSEMBLY 1” NPS SUCTION

O-RING KIT

1 1 005108

129300

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #3 ASSEMBLY

1

127160

KIT NUMBER 005183

46

CHECK VALVE ASSEMBLY 1” NPS DISCHARGE

1

005110

47

75

CHECK VALVE ASSEMBLY 1” NPS SUCTION

O-RING KIT

1 1 005112

129300

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #4 ASSEMBLY

1

128035

KIT NUMBER 005184

46, 47

CHECK VALVE ASSEMBLY 1 1/2” NPT

1

005096

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #4 ASSEMBLY

1

128035

KIT NUMBER 005185

46

CHECK VALVE ASSEMBLY 1 1/2” NPS DISCHARGE

1

005098

47

75

CHECK VALVE ASSEMBLY 1 1/2” NPS SUCTION

O-RING KIT

1 1 005100

129301

ITEM

NO. DESCRIPTION

QTY.

PART

NUMBER

27

DIAPHRAGM #4 ASSEMBLY

1

128035

KIT NUMBER 005186

46

CHECK VALVE ASSEMBLY 1 1/2” NPS DISCHARGE

1

005102

47

75

CHECK VALVE ASSEMBLY 1 1/2” NPS SUCTION

O-RING KIT

1 1 005104

129301

SPARE PARTS KITS

MP71XX-2N3

MP71XX-2N5

MP71XX-2N8

MP71XX-3N3

MP71XX-3N5

MP71XX-3N8

MP71XX-4N3

MP71XX-4N5

MP71XX-4N8

Page 23

22

MSDS FOR GEAR OIL SAE 80W-90

Page 24

23

Page 25

24

Page 26

25

Page 27

26

Page 28

27

Page 29

28

Page 30

29

Page 31

30

Page 32

31

Page 33

32

Page 34

33

Page 35

34

Page 36

35

Pump Model___________________________

Serial #_______________________________

PUMP DATA / MAINTENANCE LOG

Strokes per Minute______________________

Diaphragm diameter ____________________

Spare Parts Kit #____________________________________________________________

Maximum Flow________________________

Maximum Pressure_____________________

NEPTUNE CHEMICAL PUMP CO. Tel.: 215-699-8700 • FAX: 215-699-0370

DATE SERVICED BY MAINTENANCE PERFORMED

Loading...

Loading...