Neotecha Manuals: SAPRO® Sampling Valve SV for sampling with piston syringes, Neotecha-EN Manuals & Guides

NEOTECHA SAPRO® SAMPLING VALVE SV FOR SAMPLING WITH PISTON SYRINGES

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

1 GENERAL INFORMATION

These installation and maintenance

instructions contain the information necessary

for safe and correct installation and operation

of the valve in the prescribed manner. If any

difficulties are encountered during installation

or operation which cannot be solved with

the aid of the installation and maintenance

instructions, please contact the supplier/

manufacturer for more information.

These installation and maintenance

instructions comply with the relevant applicable

EN safety standards.

When installing the valve, the operator

or the person responsible for the design

oftheinstallation must ensure that applicable

national regulations are complied with.

The manufacturer reserves all rights to make

technical changes and improvements at

anytime.

The use of these installation and maintenance

instructions assumes that the user is qualified

to 'Qualified Personnel' level.

Operating staff must be given appropriate

training in the operating and maintenance

instructions.

1.1 Validity of the installation and

maintenance instructions

These installation and maintenance

instructions are valid for all SAPRO

sampling valves for sampling into piston

syringes, whichhave been manufactured

since 28November 2001 by the Neotecha

AGcompany. The validity is only guaranteed

until the next revision change!

2 SAFETY

Please read these notes carefully.

2.1 General potential danger due to:

a. failure to observe the instructions

b. improper use

c. insufficiently qualified personnel

2.2 Correct use

2.2.1 Area of application

SAPRO sampling valves are valves which

allow a precisely measured sample of

highly corrosive, hot liquids and gases

tobe taken. Aspecial feature of the SV

isthe interchangeable soft seal, which can

be supplied in TFM or Perfluorelastomer,

depending on the medium used, together

with the different body, adaptor and operating

element variants.

The SV is suitable for vertical mountingand

also, subject to certain restrictions,

forhorizontal mounting. When the valve

is installed horizontally, it must always be

ensured that the pipe is filled with sufficient

medium, so that a representative sample can

be taken.

All product-wetted components are

manufactured in PFA/PTFE/TFM materials or in

stainless high-grade steel.

The materials used for components under

pressure are Mat. Nos. 1.4581, 1.0425,

1.4435, 1.4541. Depending on the medium,

other materials, various types of Hastelloy,

forexample, can also be used.

2.2.2 Method of operation

The valve spindle seals against the sampling

adaptor in the soft seat. Before and during

thespindle is lifted it must be ensured that

themedia pressure and temperature are in

themaximum allowable specification according

to the pressure and temperature diagram.

When the spindle is lifted by the plunger of

thepiston syringe, the spindle opens the

outlet and the medium flows into the cylinder

of the piston syringe. The air in the syringe

is compressed, but this does not present

aproblem, as the volume of air concerned

isnot very large.

When the valve spindle is closed, the

SAPRO sampling valve behaves almost

like a continuous section of pipe, because

of thespecially adapted shape of the body.

Verylow friction losses and turbulence

duetothe valve spindle are to be expected.

Emerson.com/FinalControl

© 2017 Emerson. All Rights Reserved.

VCIOM-01978-EN 17/12

NEOTECHA SAPRO® SAMPLING VALVE SV FOR SAMPLING WITH PISTON SYRINGES

InstallatIon and MaIntenance InstructIons

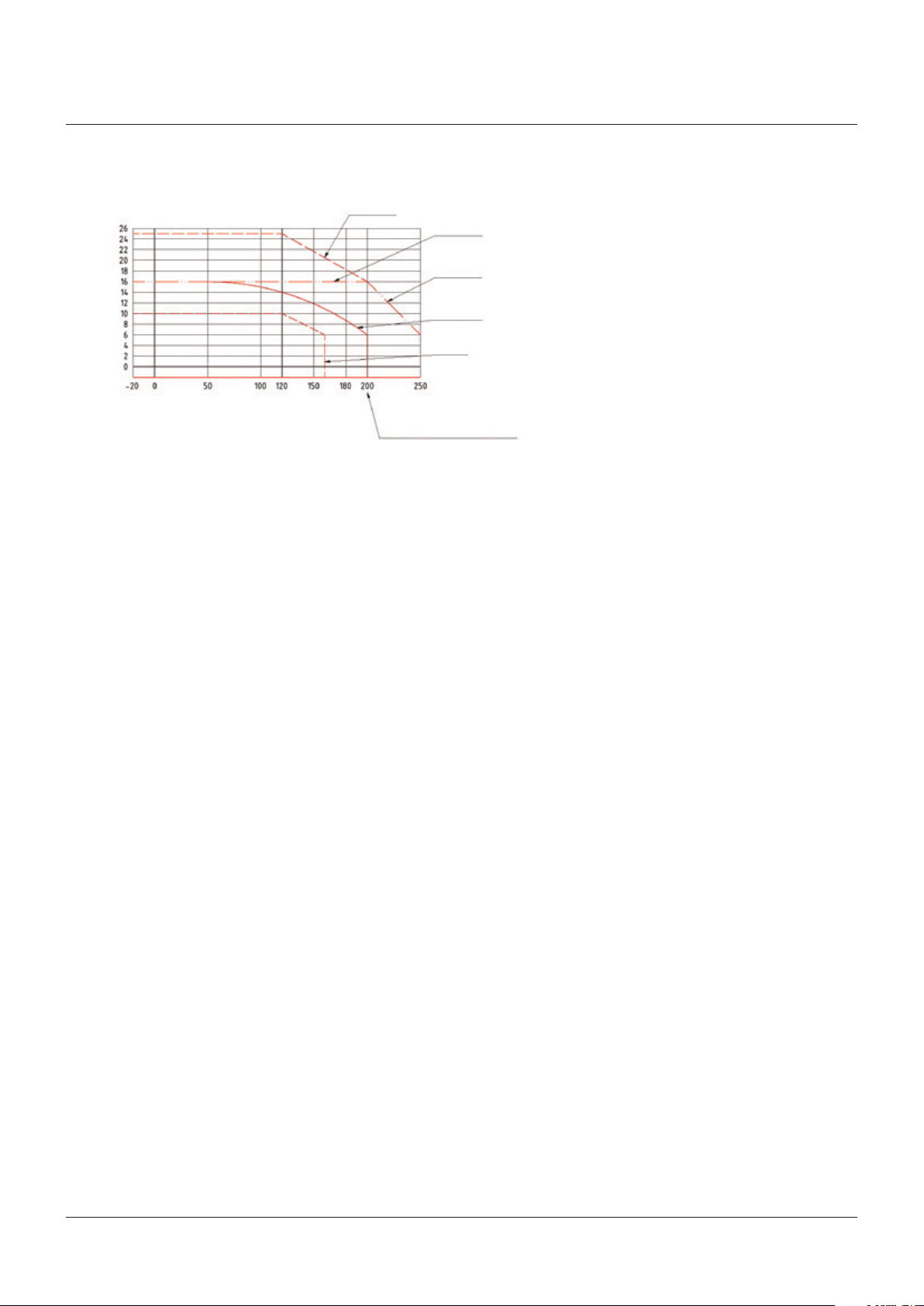

PRESSURE - TEMPERATURE DIAGRAM (VALVE)

2.2.3 Performance data

Pressure range:

20Pa vacuum to 16 bar, the syringe can onlybe

pressurized up to 10bar, because of the glass

cylinder!

Temperature range: See diagram

Nominal diameters: DIN PN 16

DN 15 - 100

Nominal diameters: ANSI Class 150

NPS ½ - 4

Test pressure - body: 1.5 x PN = 24 bar

Test pressure - syringe: 1.5 x PN = 15 bar

20Pa

Vacuum

Pressure

(bar)

Sapro with bellows

PN25

From 200°C only with bellows

and seat sealing TFM/Pertemp!

Sapro with bellows

PN16

Sapro with bellows

PN16/PN25

Sapro with sleeve

PN16

Syringe

PN10

Temperature

(°C)

2.2.4 Usage restrictions

The product-wetted components must be

classified as resistant to the product to be

conveyed. Refer to appropriate literature or

consult the manufacturer or distributor for advice.

2.2.5 Modification prohibition

Mechanical modifications to the valves or the

use of other manufacturers’ parts for repair

purposes are not permissible. Safety is not

guaranteed ifthis requirement is disregarded.

Repair work must only be carried out by the

manufacturer’s trained personnel.

2.2.6 Warning about foreseeable misuse

Valves and their accessories must not be

misused as climbing aids.

2.2.7 Duty to comply with the instructions

foroperation, maintenance and servicing

These operating instructions are part of

thedelivery package and must be kept clean

andmade accessible to the user.

2.3 Sources of danger

2.3.1 Chemical external

The steel/PFA bodies of the DN 65 - 100

valves are made from mechanically processed

steel coated with a 2-part polyester paint.

Thecoating can be attacked externally by

strong solvents, leading to corrosion of

the body. Ifdamage of this nature occurs,

the effects on the environment should be

investigated and thedamage to the coating

made good.

2.3.2 Electrical

If static charges can lead to explosions,

thevalve must be earthed by means of the

earthing accessory.

Alternative: use valves with electrically

conductive linings. Please contact your

supplier!

2.3.3 Thermal

Due to the range of operating temperatures

between -20°C and +200°C, surface

temperatures from -20°C to over +200°C

can be present on thevalve body. Suitable

precautions should be taken at the installation

stage to protect against burns due to high or

freezing temperatures. Insulated gloves should

be worn when using thevalve.

In case of fire, the mechanical strength of the

PFA coatings is no longer guaranteed above

250°C.

2.3.4 Protection against inadvertent opening of the

sampling valve

The SAPRO sampling valve for sampling with

thepiston syringe can only be opened by

the attached piston syringe; under normal

circumstances, it is impossible for the valve to

remain open when the syringe is detached.

2.4 Qualified personnel

This means people who are familiar with

theerection, installation, commissioning,

operation and maintenance of the product and

have appropriate qualifications relating to their

activities and functions, such as, for example:

- Instruction in and duty to comply with all

installation-related, regional and internal

works regulations and requirements.

- Training or instruction in accordance with

theSafety Standards for personal care

and use of appropriate safety equipment

and protective workgear, like, for example,

personal protection equipment (insulated

gloves or similar), suitable for the operating

conditions.

Furthermore, these people must have read and

understood these instructions.

2

NEOTECHA SAPRO® SAMPLING VALVE SV FOR SAMPLING WITH PISTON SYRINGES

InstallatIon and MaIntenance InstructIons

3 TRANSPORT/STORAGE

3.2 Storage

- Storage temperature -20°C to +65°C, dry and

The valve is supplied with protective covers.

Do not remove the protective covers until

immediately prior to installation. They protect

the PFA surfaces from dust and mechanical

dust-free.

- A drying agent or heating is required

indamp storage areas to protect against

condensation.

influences.

3.3 Handling prior to installation

3.1 Transport

- Transport temperature -20°C to +65°C.

- Protect against external force (impact, shock,

vibration).

- Do not damage the coating.

- Do not remove the protective caps until

immediately prior to installation.

- Protect against the effects of weather,

suchas dampness, (or else use a drying

agent).

- Proper treatment prevents damage.

4 FEATURES

4.1 General features

Flange drillings DIN 2501-1 PN16

ANSI B16.5 Class 150

Other drillings (PN25/40,ANSI Class 300) are available on request

Body variants Wafer type

Flanged to DIN standard

Flanged to ANSI standard

Bolted joint A2 bolt quality for all bolts subjected to pressure

Adaptor variants Bayonet adaptor forsampling with piston syringes

Operating element variants Piston syringe (the spindle is lifted by the plunger ofthe piston

syringe)

Weights The values given in thefollowing table are only approximate, as the weight

can vary additionally, because of the different adaptor and operating element

variants.

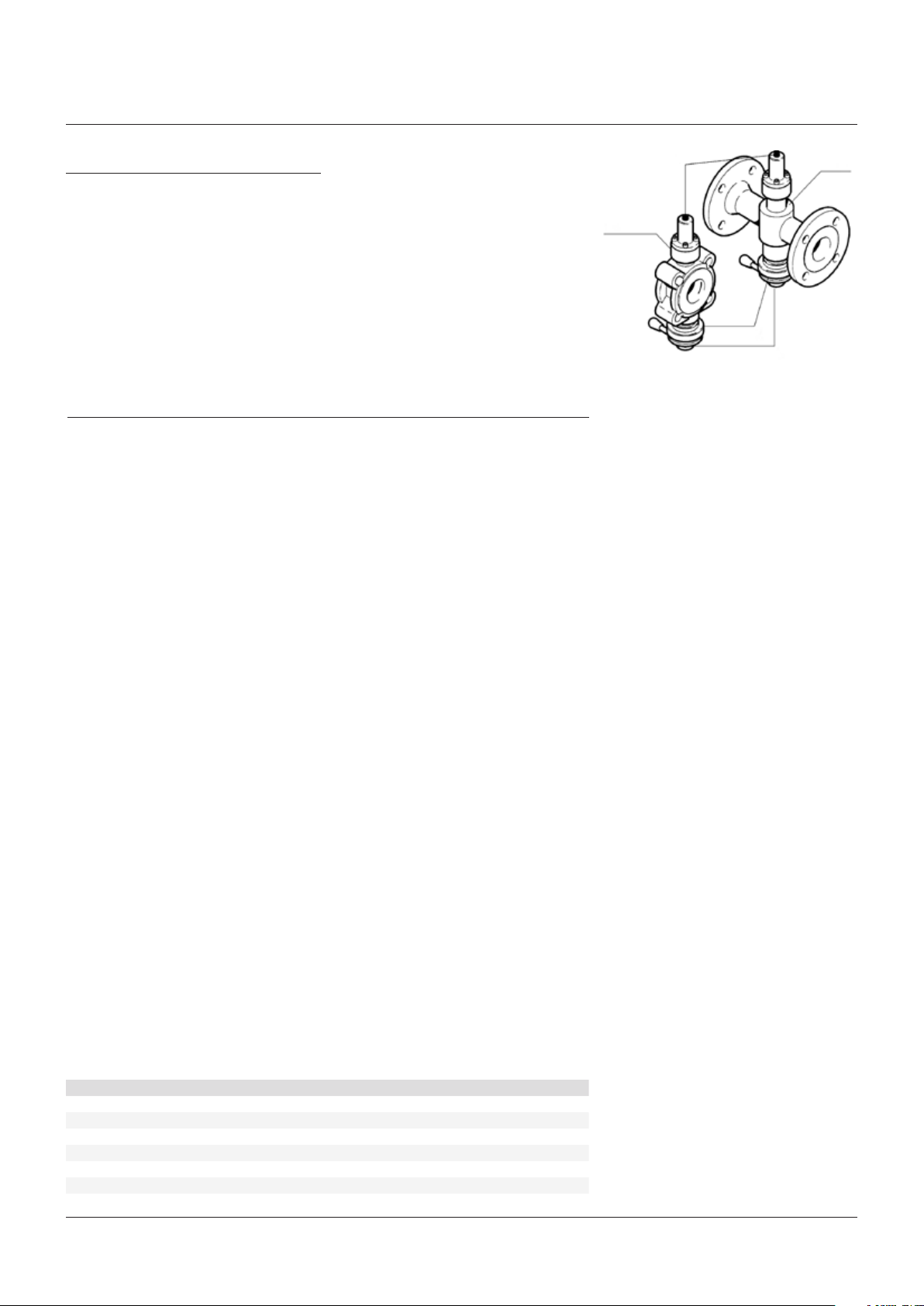

4

1a

2

3

1b

Figure 1

4.1.1 Sampling valve for sampling with piston

syringes (Figure 1)

1a. SAPRO sampling valve wafer type

face-to-face dimension (DIN/ANSI).

1b. SAPRO sampling valve flanged face-to-face

dimension (DIN or ANSI).

2. Bayonet coupling.

3. Blanking plug.

4. Lift indicator.

WEIGHTS

DN NPS Weight compact design Weight flanged face to face

25 1 4.0 6.5

40 1½ 5.1 8.7

50 2 6.1 10.6

65 2½ 8.7 16.0

80 3 10.0 18.0

100 4 13.7 20.0

3

Loading...

Loading...