USER'S MANUAL

ZERO-UP

200W/400W/800W

Programmable DC Power Supplies

Constant Voltage/Constant Current

TESTING EQUIPMENT

65SA

LISTED

USC

TUV Rheinland

geprufte

Sicherheit

..

..

DENSEI-LAMBDA

Built-in RS232 & RS485 Interface

with GPIB option.

We Nemic-Lambda Ltd., located at Karmiel Industrial Zone, Israel, declare under our sole

responsibility that the product:

Product Name: Programmable Regulated Power Supplies, ZUP Series

Models:

Conforms to the following product specifications:

Safety: EN61010-1/04.93, EN61010-1 A2/07.95

UL3111-1

Electromagnetic Emissions:

EN55011:1991 Conducted Emissions: Class B

Radiated Emissions: Class A

IEC1000-4-2:1995 4.0KV CD, 4.0KV AD

IEC1000-4-3:1995 3V/m

IEC1000-4-4:1995 1.0KV AC Power Lines

0.5KV Communication Lines

IEC1000-4-5:1995 2.0KV AC Power Lines

1.0KV AC to Ground

1.0KV Communication Lines

IEC1000-4-6:1996 3V

IEC1000-4-11:1994

IEC1000-3-2:1995 Class A

IEC1000-3-3:1995

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the

EMC directive 89/336/EEC for Electrical Equipment used in Measurement Control and Laboratory

environments, and carries the CE mark accordingly.

Our importer to the EU is Coutant Lambda Limited, located at Kingsley Avenue, Ilfracombe, Devon

EX34 8ES, UK. Further, all products covered by this declaration are manufactured by processes which

ensure continued compliance of the products with the requirements of the Low voltage and the EMC

directives.

Name of Authorized Signatory:

Signature of Authorized Signatory:

Position of Authorized Signatory:

Date:

Place where signed:

Adam Rawicz-Szczerbo

Managing Director, Coutant Lambda

Ilfracombe, UK

ZUP6-33

ZUP10-20

ZUP20-10

ZUP36-6

ZUP60-3.5

ZUP6-66

ZUP10-40

ZUP20-20

ZUP36-12

ZUP60-7

ZUP6-132

ZUP10-80

ZUP20-40

ZUP36-24

ZUP60-14

KARMIEL INDUSTRIAL ZONE, POB 500, ZC-20101, ISRAEL.

TEL: 972-4-9887491 FAX: 972-4-9887487

DECLARATION OF CONFORMITY

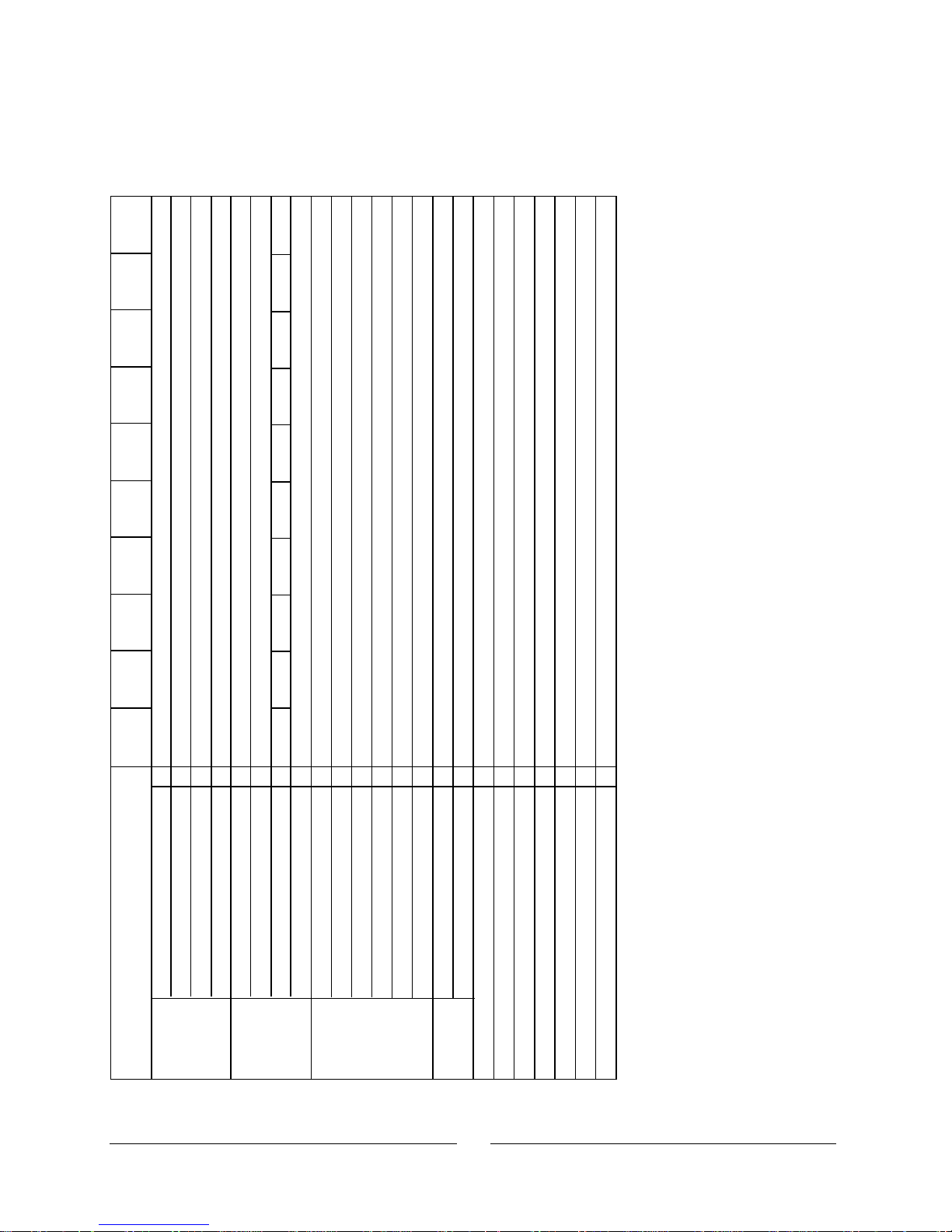

TABLE OF CONTENTS: ZUP SERIES

SAFETY INSTRUCTIONS .....................................................................

WARRANTY ..........................................................................................

CHAPTER 1. General Information

CHAPTER 2. Specifications

CHAPTER 3. Installation

......................................................

1.1 User manual content

1.2 Introduction

1.2.1 General description

1.2.2 Configurations

1.2.3 Control via the serial communication port

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.7 Cooling and mechanical construction .....................................

1.3 Accessories

1.3.1 General

1.3.2 Serial link cables

1.3.3 AC cables

1.3.4 Front panel outputs option

................................................................

2.1 200W/400W Series

800W Series...................................................................................

2.2 Supplemental characteristics .........................................................

.....................................................................

3.1 General

3.2 Initial inspection

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC source requirements

3.4 Cooling and placement

3.5 Rack mounting

3.6 Power connection

3.7 Connecting the load .......................................................................

3.7.1 Selecting wire size

3.7.2 Wire termination .....................................................................

3.7.3 Single load connection, local sense

3.7.4 Single load connection, remote sensing ................................

3.7.5 Multiple load connections, radial distribution method

3.7.6 Multiple load connections with distribution terminals .............

3.7.7 Grounding outputs

3.8 External control connector

3.8.1 General

3.8.2 Pin description .......................................................................

3.8.3 Technical description

3.8.4 Default connections................................................................

3.9 Repackaging for shipment

pg. 2

pg. 1

pg. 5

pg. 6

pg. 7

pg. 9

pg. 11

pg. 12

pg.13

pg.14

pg.15

pg.16

pg.17

pg.18

Table 4-1: Front panel controls and indicators .......................................

4.2.2 Rear panel ............................................................................

4.2.3 Rear panel connections description .....................................

4.3 Turn-on Checkout Procedure

4.3.1 General

4.3.2 Prior to operation

4.3.3 Constant Voltage check

4.3.4 Constant Current check ........................................................

4.3.5 OVP check

4.3.6 UVP check

4.3.7 Foldback check

4.3.8 Output On/Off

4.3.9 Address setting

4.3.10 Local/Remote Operation

4.4 Local Operation ...............................................................................

4.4.1 Introduction

4.4.2 Constant Voltage Operation

4.4.3 Constant Current Operation

4.4.4 Automatic Crossover ..............................................................

4.4.5 Over Voltage protection (OVP)

4.4.6 Under Voltage Protection (UVP)

4.4.7 Foldback Protection ................................................................

4.4.8 Output On/Off Control

4.4.9 Last Setting memory ...............................................................

4.4.10 Output Voltage & Current programming by external resistor

4.4.11 Output Voltage Programming by external voltage .................

4.4.12 Output Current programming by external voltage

4.4.13 Auto Parallel operation...........................................................

4.4.14 Series Operation ....................................................................

4.4.15 Output good signal.................................................................

.....................................

5.1 Introduction

5.2 Configuration

5.2.1 Address setting

5.2.2 RS232 or RS485 selection

5.2.3 Baud rate setting

5.2.4 Local/remote selection

CHAPTER 5. RS232 & RS485 remote control

.................................................

4.1 Introduction

4.2 Controls and Indicators

4.2.1 Front Panel

CHAPTER 4. Operating Instructions.

pg.23

pg.22

pg.24

pg.25

pg.26

pg.27

pg.28

pg.29

pg.30

pg.32

pg.33

pg.37

pg.38

pg.35

TABLE OF CONTENTS: ZUP SERIES

3.10 Outline drawings: ZUP 200W & 400W series.................................

3.11 Outline drawing: ZUP 800W series...............................................

3.12 Outline drawing: front panel connector option ...............................

pg.19

pg.20

pg.21

5.4.1 Introduction

5.4.2 RS485 cable

5.4.3 Linking power supplies

5.5 ZUP series command set description

5.5.1 ID control commands...............................................................

5.5.2 Initialization control

5.5.3 Output control..........................................................................

5.5.4 Status control ..........................................................................

5.5.4.1 Registers structure

5.5.4.2 Status control commands ....................................................

5.6 Communication Protocol..................................................................

5.6.1 General information

5.6.2 Accessing a ZUP unit

5.6.3 End of message

5.7.Service Request..............................................................................

..................................................................

6.1 Introduction

6.2 Units under warranty

6.3 Periodic Maintenance

6.4 Adjustment and calibration

6.5 Part replacement and repairs

6.6 Fuse ratings

.....................................................................

CHAPTER 6. Maintenance

USER’S MANUAL INDEX

pg.45

pg.42

pg.46

pg.43

pg.47

pg.49

pg.48

pg.50

5.7.1 Service Request (SRQ)

5.7.2 Service Request message

5.7.3 Service Request enable/disable commands

TABLE OF CONTENTS: ZUP SERIES

5.3 Remote programming via RS232.....................................................

5.3.1 Introduction

5.3.2 Rear panel connectors pinout

5.3.3 RS232 cable ............................................................................

5.3.4 Linking power supplies

5.4 Remote programming via RS485 .....................................................

pg.39

pg.40

pg.41

WARRANTY SERVICE

WARRANTY

DISCLAIMER

LIMITATION OF WARRANTY

TRADEMARK INFORMATION

This product must be returned to an authorized Nemic-Lambda service facility for repairs or other

warrantyservice.Forproductsreturnedto Nemic-Lambda for warranty service, the buyer shall prepay

shipping charges to Nemic-Lambda and Nemic-Lambda shall pay the shipping charges to return the

producttothebuyer.

ThisNemic-Lambda product is warranted against defects inmaterialsandworkmanshipfora period of

threeyearsfromdateofshipment .Duringthe warranty period, Nemic-Lambda will, at it’soption,either

repairorreplaceproducts whichprovetobedefective.

The information contained in this document is subject to change without notice. Nemic-Lambda shall

not be liable for errors contained in this document or for incidental or consequential damages in

connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of

Nemic-Lambda.

Thewarranty shallnotapply todefectsresulting fromimproperor inadequateusageor maintenanceby

the buyer , buyer supplied products or interfacing. The warranty shall not apply to defects resulting

from unauthorizedmodifications or from operation exceeding the environmental specifications ofthe

product.

Nemic-Lambda does not warrant the buyers circuitry or malfunctions of Nemic-Lambda products

resulting from the buyer’s circuitry. Furthermore, Nemic-Lambda does not warrant any damage

occurringasaresult ofthebuyer’s circuitryorthebuyer’s-suppliedproducts.

Noother warrantyis expressed orimplied.

Microsoft andWindows aretrademarksof MicrosoftCorporation.

1

SAFETY INSTRUCTIONS

CAUTION

INSTALLATION CATEGORY

GROUNDING

FUSES

LIVE CIRCUITS

PART SUBSTITUTIONS & MODIFICATIONS

ENVIRONMENTAL CONDITIONS

INPUT RATINGS

The following safety precaution must beobserved during allphases of operation, serviceand repair of

this equipment. Failure to comply with the safety precautions or warnings in this document violates

safetystandards ofdesign, manufactureandintended useofthis equipmentand mayimpairthe built-in

protectionswithin.

Nemic-Lambdashall notbe liableforuser’s failuretocomply withthese requirements.

The ZUP Series has been evaluated to INSTALLATION CATEGORY II. Installation Category (over

voltage category) II: local level, appliances, portable equipment etc.. With smaller transient over

voltagesthan InstallationCategory (overvoltagecategory) III.

Thisproductisa Safety Class 1 instrument. Tominimizeshock hazard, the instrumentchassismustbe

connected toan electrical ground. The instrument must be connected to the AC power supply mains

through a three conductorpower cable, with the ground wire firmly connected to an electrical ground

(safetyground)atthe poweroutlet.

For instruments designed tobe hard- wired tothe supplymains, theprotective earthterminal mustbe

connected tothe safety electrical ground before an other connection ismade. Any interruption of the

protective ground conductor, or disconnection of the protective earth terminal will cause a potential

shockhazard thatmight causepersonalinjury.

Fusemustbechangedby authorized Nemic-Lambda service personnel only.For continued protection

againstriskoffire,replaceonlywith thesame typeandrating offuse.Refertomaintenance instructions

inchapter6for fuserating.

Operating personnel must not remove the instrument cover. No internal adjustment or component

replacement is allowed by non-Nemic-Lambda qualified service personnel. Never replace

components with power cable connected. To avoid injuries, always disconnect power, discharge

circuitsand removeexternal voltagesourcesbeforetouchingcomponents.

PartsubstitutionsandmodificationsareallowedbyauthorizedNemic-Lambdaservicepersonnelonly.

Forrepairsormodifications, theinstrumentmust bereturned toaNemic-Lambda servicefacility.

TheZUP seriessafety approvalappliesto thefollowing operatingconditions:

*Indooruse * Ambient temperature:0 Cto50 C

*Maximum relativehumidity: 90%(nodew drop) * Altitude: upto3,000m

*Pollutiondegree2

OO

Do not use AC supply which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequencyrating of the ZUPSeries is; 100-240V~, 50/60Hz.For safety reasons, the

mainssupplyvoltagefluctuations shouldnotexceed+/-10% ofnominalvoltage.

2

SAFETY INSTRUCTIONS

SAFETY SYMBOLS

Instructionmanualsymbol. The instrument will be marked with thissymbolwhenitis

necessaryfor theuser torefertotheinstruction manual.

Indicates hazardous voltage.

Indicates ground terminal.

The WARNING signdenotesa hazard.An attentiontoa procedureis called.

Notfollowing procedurecorrectly couldresultin personalinjury.

AWARNINGsign shouldnotbeskippedand allindicatedconditionsmustbe

fullyunderstood andmet.

The CAUTION sign denotesahazard. An attentiontoaprocedure iscalled.

Not following procedure correctly could result in damage to the equipment.

Do not proceed beyond a CAUTION sign until all indicated conditions are

fullyunderstoodandmet.

FCCCOMPLIANCE NOTICE:

Note:Thisequipment has been tested and found to comply with the limits for a Class A digital

device,pursuant topart15ofthe FCCRules.These limitsaredesigned toprovide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment.Thisequipmentgeneratesuses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interferenceat hisown expense.

!

WARNING

CAUTION

3

OUTPUT TERMINALS COVER

After connection of the load wires (refer to par. 3-7 ), attach the plastic cover to the rear panel of the

powersupply,usingtwo selftappingscrewssuppliedwith theunit. RefertoFig. 1-1for details.

Fig.1-1:Terminals coverassembly

REAR PANEL

LOAD WIRES

PLASTIC COVER

WARNING

Hazardous voltages may exist at the output terminals of the 60V models.

Attach the terminals cover, supplied with the unit, to the chassis after

connecting the load wires as described below.

SAFETY INSTRUCTIONS

4

CHAPTER 1 GENERAL INFORMATION

1.1 USER’S MANUAL CONTENT

1.2 INTRODUCTION

1.2.1 General description

1.2.2 Configurations

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.3 Control via the serial communication port

This user’s manual contains the operating instructions, installation instructions and specifications of

the ZUP series. For information relatedto operation with GPIBcontrol, refer toNemic-Lambda GP485

user’smanual.

TheZUP seriesarewide rangeoutputswitching powersupplieswith laboratoryperformance.The ZUP

series is power factor corrected and operates from worldwide AC voltage range continuously.Output

voltageand currentarecontinuously displayedandLED indicatorsshowthe completeoperatingstatus

ofthepower supply.The front panel controlsallowtheuserto set the output parameters, theprotection

levels (over-voltage / under-voltage)and arm the foldback protection to disable the output if the unit

switchesfromConstant-voltagemodetoConstant-currentmode.

TheZUP canbe configuredintoa programmablepowersystemofup to31DC outputsusing thebuilt-in

RS232 or RS485 communication port inthe powersupply.In a GPIBsystem theGP485 controller can

controlupto31 ZUPunitsinasingle GPIBaddress.

Output connections are madeto rear panel bus-bars. Either the positive or negative terminal may be

grounded or the output may be floated. The maximum potential (including the output voltage) that

either output terminal is from ground must not exceed 60V.Local or remote sense may be used. In

remotesense, themaximum voltagedropon eachwire is0.5V.

Analog inputs are provided at the rear panel for analog voltage programming of output voltage and

current, and On/Off control. Inputs are provided for resistive programming of the output voltage and

current.

ZUP unitsof the same output voltage and current rating can be paralleled in master-slave

configuration

withautomatic currentsharingforpower-uppurposes.

Thefollowing parameterscan beprogrammedvia theserial communicationport:

1.Output voltagesetting

2.Output currentsetting

3.Output On/Off

4.Arming orrelease ofthefoldback protection

5.Over-voltage protectionsetting

6.‘Soft’ under-voltagelimit

7.Output voltagemeasurement

8.Outputcurrentmeasurement

9.Power supplystart-up mode

(lastsettingorsafe mode)

10.Over-voltageprotectionsetting read

11.Under-voltagelimitread

12.Remote/Local Control

5

1.3.1 General

1.3.4 Front Panel Outputs option

1.3.3 AC Cables

1.3.2 Serial link cables

1.3 ACCESSORIES

Accessoriesaredeliveredwith thepowersupplyorseparately uponordering.

Belowarelistedpossible accessoriesand orderingnumbers.

PARTNo. DESCRIPTION

NL100 19”rack, 3Uheight

NL101 Blankpanel for19” rack

NL102 Additionalinstruction manual

PART No. MARKET DESCRIPTION

NC301 USAand Japan 15A,125V,unshielded,2m typ.length,withIEC320connector onone

sideandNEMA-5-15Pconnector theonotherside.

NC302 Europe 10A,250V,unshielded,2mtyp. length,with IEC320connectoron one

sideandINT’L7 standardVII,dualearthingon theotherside.

NC303 General 10A,250V,unshielded,2mtyp. length,withIEC320connectoron one

sideandunterminatedstripped wiresontheotherside. Usethecable

onlywithplugapproved bythenationalsafetystandards ofthecountry

ofusage.

In cases where load connection at the front panel is required, optional Front Panel output Jacks for a

load current of 20A maximumis available. Please note thatthe power supplyheight is increased with

thisoption. Referto outlinedrawing(par.3.12)fordetails.

ORDERNo. DESCRIPTION

ZUP /L 20AFrontPanel Output Jacks

Seriallink cable,forlinkingpower suppliesbyRS485 communication isprovidedwith thepowersupply

accordingtoorder.Cabledescription: 0.5m typ. length,shielded,EIA-568A typeplugs,8contacts.

Refertopar.5.3.4,for details.

1.2.7 Cooling and mechanical construction

TheZup series is fan cooled. Uponinstallation take careto allow freeair flow into thepower supply via

the front panel and out of the power supply via the rear panel. The ZUP series is contained in a

compact, lightweight package which allows for easy installation and space saving in the application

6

V

A

W

-

mVmVmS

-

mSmSmS

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

-

%

A

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

(pk to pk 20MHz Bandwidth)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

INPUT VOLTAGE (*8)

INPUT CURRENT (*6)

INPUT CURRENT HARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUSH CURRENT (*7)

100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRAM-

MING

(*3)

DISPLAY

OVERVOLTAGE PROTECTION (*5)

HOLD UP TIME

OUTPUT PROTECTIONS

INPUT

ZUP60-

7

0 ~ 7

10

5.6 / 2.7

80 / 84

0 ~ 12

15

5.6 / 2.7

80 / 84

0 ~ 20

30

5.6 / 2.7

79 / 83

0 ~ 40

50

5.6 / 2.7

79 / 82

0 ~ 66

0.005% +2mV from no load to full load, constant input voltage

0.005% +1mV from 85-132VAC or 170-265VAC, constant load

5

50

30ppm/ C from rated voltage following 30-minute warm-up

0.01% +2mV change in output over 8-hour interval under constant line, load and ambient

temperature following 30-minute warm-up

50mS (From zero volts to full scale, resistive load, current setting at max.)

50

100

5.6 / 2.7

74 / 77

15 15 15 15 15

ZUP60-

3.5

0 ~ 3.5

5

2.9 / 1.4

75 / 79

0 ~ 6

7.5

2.9 / 1.4

76 / 80

0 ~ 10

15

2.9 / 1.4

74 / 78

0 ~ 20

25

2.9 / 1.4

73 / 77

0 ~ 33

198 396 200 400 200 400 216 432 210 420

50

3.0 / 1.5

69 / 72

15 / 30 15 / 30 15 / 30 15 / 30 15 / 30

ZUP36-

12

ZUP36-

6

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

250

0 - 7.5

1

350

0 -13

0.5

400

0 - 24

0.2

0.01% + 5mA for load voltage change equal to unit voltage rating , constant input voltage.

0.01% +2mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output voltage and output current

100ppm/ C from rated current following 30 minute warm-up

O

Better than 0.028% of rated output voltage

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

0.4% + 40mA

Better than 0.03% of rated output current

0.02% +5mA change in output over 8-hour interval under constant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V) 3.5 digits (10V) accuracy: 0.2% +/- 2 digits

3 digits accuracy: 0.5% +/- 3 digits

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63Hz

Complies with EN61000-3-2, Class A

0.99 at 100/200VAC, 100% Load

500

0 - 40

0.2

750

0 - 66

0.2

0 ~ 6

0 ~ 10

0 ~ 20

0 ~ 36

0 ~ 60

ZUP6-

33

CHAPTER 2 SPECIFICATIONS

2.1 SPECIFICATIONS: 200W/400W Series

7

O

-

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*9)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

SAFETY STANDARDS

EMC STANDARDS

APPROVALS

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL RESET BY AC INPUT RECYCLING.(OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT POWER.

* 7 FOR 200W UNITS - AT COLD START Ta = 25

O

C.

* 8 FOR CASES WHERE CONFORMANCE TO VARIOUS SAFETY SPECS, (UL, IEC ETC.) ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLATE.

* 9 WHEN MOUNTED WITH MOUNTING SCREWS.

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

ZUP60-

7

3.2 3.2 3.2 3.2 3.2

ZUP60-

3.5

2.9 2.9 2.9 2.9 2.9

ZUP36-

12

ZUP36-

6

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

0 ~ 50 C: 100% Load.

O

-20 ~ 70 CO30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude (sweep 1min) Less than 2G, X,Y, Z, 1 hour each.

70 x 124 x 350.

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

Possible, maximum 0.5V drop on each load wire

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC part 15 (class A)

Master - slave method: up to 5 units, refer to instruction manual

Up to 2 units, refer to instruction manual

More than 100MOhm at 25 C and 70% R.H.

O

EN55022-B, FCC-B, VCCI-2

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-1

Input-Chassis: 2.0kVAC 1 min. Input-Output: 3.0kVAC 1 min. Output-Chassis: 500VAC 1min.

ZUP6-

33

2.1 SPECIFICATIONS: 200W/400W Series continued

8

V

A

W

-

mVmVmS

-

mSmSmS

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

%

A

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

(pk to pk 20MHz Bandwidth)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

INPUT VOLTAGE (*7)

INPUT CURRENT (*6)

INPUT CURRENT HARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUSH CURRENT

100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRAM-

MING

(*3)

DISPLAY

OVERVOLTAGE PROTECTION (*5)

HOLD UP TIME

OUTPUT PROTECTIONS

INPUT

ZUP60-14

0 ~ 14

20

11.2 / 5.4

80 / 84

0 ~ 24

30

11.2 / 5.4

80 / 84

0 ~ 40

60

11.2 / 5.4

79 / 82

0 ~ 80

100

11.2 / 5.4

77 / 81

0 ~ 132

792 800 800 864 840

200

11.2 / 5.4

74 / 77

30

0.005% +2mV from no load to full load, constant input voltage

0.005% +1mV from 85-132VAC or 170-265VAC, constant load

5

80

30ppm/ C from rated voltage following 30-minute warm-up

O

0.01% +2mV change in output over 8-hour interval under constant line, load and ambient

temperature following 30-minute warm-up

50

ZUP36-24

ZUP20-40

ZUP10-80

ZUP6-132

250

0-7.5

1

100

8

70

5

350

0-13

0.5

90

8

60

5

400

0-24

0.2

0.07% + 10mA for load voltage change equal to unit voltage rating , constant input voltage.

0.01% +5mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output voltage and output current

100ppm/ C from rated current following 30 minute warm-up

O

0.05% +10mA change in output over 8-hour interval under constant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V) 3.5 digits (10V) accuracy: 0.2% +/- 2 digits

3.5 digits (132A), all others 3 digits accuracy: 0.5% +/- 3 digits

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63Hz

Complies with EN61000-3-2, Class A

0.99 at 100/200VAC, 100% Load

500

0-40

0.2

750

0-66

0.2

0 ~ 6

0 ~ 10

0 ~ 20

0 ~ 36 0 ~ 60

2.1 SPECIFICATIONS: 800W Series

Better than 0.028% of rated output voltage

0.4% + 40mA

Better than 0.03% of rated output current

60mS (From zero volts to full scale, resistive load, current setting at max.)

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

9

-

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*8)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

APPLICABLE SAFETY STANDARDS

APPLICABLE EMC STANDARDS

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

ZUP60-

14

5.8

ZUP36-

24

ZUP20-

40

ZUP10-

80

ZUP6-

132

0 ~ 50 C: 100% Load.

O

-20 ~ 70 CO30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude ( sweep 1min ) Less than 2G, X,Y, Z, 1hour each.

140 x 124 x 350 refer to outline drawing

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

Possible, maximum 0.5V drop on each load wire

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC part 15 (class A)

Master - slave method: up to 5 units, refer to instruction manual

Up to 2 units, refer to instruction manual

More than 100MOhm at 25 C and 70% R.H.

O

EN55022-B, FCC-B, VCCI-2

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-1

Input - Chassis: 2.0kVAC 1 min. Input - Output: 3.0kVAC 1 min. Output - Chassis: 500VAC 1 min.

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL RESET BY AC INPUT RECYCLING. (OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT POWER.

* 7 FOR CASES WHERE CONFORMANCE TO VARIOUS SAFETY SPECS, (UL, IEC ETC.) ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLATE.

*8 WHEN MOUNTED WITH MOUNTING SCREWS.

2.1 SPECIFICATIONS: 800W Series continued

10

2.2 SUPPLEMENTAL CHARACTERISTICS

The supplemental characteristics give typical but non-warranted performance characteristics. The

supplementalcharacteristics areusefulinaccessingapplications forthepowersupply.Several kinds

ofsupplemental characteristicsare listedbelow.

1.EVALUATIONDATA: Typicalperformanceofthe powersupply.

2.RELIABILITY DATA: Reliabilityperformanceofthepower supply.

3.IEC1000DATA: Performanceof thepower supplyunderIEC 1000test conditions.

4.EMIDATA: TypicalEMI (conductedand radiated)performanceof thepowersupply.

The supplemental characteristics data are held in each Nemic-Lambda sales and service facility.For

furtherdetailspleasecontact theNemic-Lambdaofficenearestyou.

11

CHAPTER 3 INSTALLATION

3.1 GENERAL

3.2 INITIAL INSPECTION

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC SOURCE REQUIREMENTS

3.4 COOLING & PLACEMENT

3.5 RACK MOUNTING

3.6 POWER CONNECTION

NOTE

CAUTION

This chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment.Connection toPC, linkingZUPunits andsetting theaddressare describedin chapter 5.

Prior to shipment this powersupply was inspected and foundfree of mechanical or electricaldefects.

Uponunpacking ofthepower supply,inspectforany damage whichmayhave occurredintransit.Keep

all packing materials until inspection has been completed.If any damage is detected,file a claim with

thecarrierimmediatelyand notifytheNemic-Lambda salesor servicefacilitynearest you.

Themechanical inspectionshouldconfirm thatthereis noexteriordamage tothepower supplysuchas

brokenknobsorconnectors andthatthefrontpanel andmeterfacearenot scratchedorcracked.

In order tobe operational the power supplymust be connected to an appropriate AC source.The line

voltagemustbewithinthe power supply specification. DO NOT apply power before reading paragraph

3.3.

The ZUP series can be operated from a nominal 100V to 240V,single phase, 47 ~ 63Hz. The input

voltage range and current required for each model is specified in chapter 2. Make sure that under

heavyload,theAC voltagesuppliedtothepower supplydoesnotfallbelow “lowlimit”specifications.

This power supply is fan cooled. Upon installation ensure sufficient space for air intake (front panel)

andexhaust(rearpanel).Thepowersupplyshouldbeusedinanarea wherethe ambient temperature

doesnotexceed+50 C

O

ZUP models can be mountedin a standard19” rack(3U height).The 200W and400W models occupy

1/6 rack length. The 800Wmodel occupies1/3 racklength. Thepower suppliesshould befixed byM4

screwsreplacing therubberfeetonthe bottomofthe powersupply.Thescrewsmust notprotrudemore

than6mmintothe powersupply.Refertothe outlinedrawinginthischapter formounting details.

Connection of this power supply to an AC power source should

be made by an electrician or other qualified personnel.

ZUP series power supplies generate a magnetic field which might affect the

operation of other instruments. If your equipment is susceptible to magnetic fields,

do not position adjacent to the ZUP.

12

This power supply is equipped with athree conductorpower cable. The third conductor is the ground

conductor.When the cable is plugged-in to anappropriate receptacle,the power supply is grounded.

Under no circumstances should this power supply be operated without an adequate ground

connection. If a two contact receptacle is encountered, it must be replaced by a three contact

receptacle, properly grounded. This operation should be done by a qualified electrician. It is

recommended to keep the AC input wires separate from the DC output and signal wires to avoid

interference.

Tomeet radiated EMIspecification, the EMI suppressor clampshould be attachedto the ACcable as

closeas possibleto theACinlet ofthe powersupply.

WARNING

WARNING

Some components inside the power supply are at AC voltage even when the

On/Off switch is in the “Off” position. To avoid the hazard of electric shock,

disconnect line cord and load and wait 2 minutes before removing cover.

Turn off the AC input power before making or changing any rear panel connection.

Make sure that all connections are securely tightened before applying power.

3.7 CONNECTING THE LOAD

3.7.1 Selecting wire size

Twofactorsmustbeconsidered inselectingwiresize.

1. Wires should be at least heavy enough to avoid overheating while carrying the power supply load

current at the rated load, or the current that would flow in the event the load wire were shorted,

whicheverisgreater.

2.Wire sizeshouldbe selected toenablevoltage dropperleadto belessthan 0.5Vattherated current.

It is recommended to minimize voltage drop on the wires to prevent excessive output power

consumptionfrom thepower supply.

Please refer to Tables 3-1 and 3-2 for maximum wire length to limit voltage drop by American and

Europeanmeasurements respectively.

Table 3-1: Maximum wire length for

0.5V drop on lead (in feet)

wire size

AWG

5A

40 20 10 4 1

63 31 15 6 1.7

100 50 25 10 3

160 80 40 16 5

253 126 63 25 8

400 200 100 40 13

640 320 160 64 21

1016 508 254 102 34

14

12

10

8

6

4

2

0

2.526

1.589

0.9994

0.6285

0.3953

0.2486

0.1564

0.0983

Maximum length in feet to limit voltage drop to 0.5V or less

10A 20A 50A 150A

Resistivity

Ohm/kft

13

13

Forcurrentnotshown intables3-1and3-2 useformula: Maximumlength=500/(current*resistivity)

Wherecurrent isexpressed inampersandresistivityin ohms/kmorohms/1000ft.

Table 3-2: Maximum wire length for 0.5V drop on lead (in meters)

cross sect.

area

(mm 2)

5A

12.2 6.1 3.0 1.2 0.4

19.6 9.8 4.9 2.0 0.7

29.5 14.7 7.4 2.9 1.0

51.3 25.6 12.8

5.1

1.7

80.6 40.3 20.2 8.1 2.7

125.8 62.9 31.4 12.6 4.2

177.0 88.5 44.2 17.7 5.9

2.5

4

6

10

16

25

35

8.21

5.09

3.39

1.95

1.24

0.795

0.565

Maximum length in meters to limit voltage drop to 0.5V or less

10A 20A 50A 150A

<

Resistivity

Ohm/km

3.7.2 Wire termination

3.7.3 Single load connection, Local Sensing

The wires should be properly terminated with terminals securely attached. DO NOT use non

terminatedwires forload connectionatthepowersupply.

Fig. 3-1 illustrates the connection of a single load to the power supply using local sensing. This

connectionismadevia the “External Control Connector” located on the rear panel of the power supply.

Localsensingissuitable forapplications where loadregulationisnotcritical.

Fig.3-1: Singleload connection,LocalSensing

14

2

- LS

- S

- V

- S

+LS

+LS

- LS

+S

On/Off

+V

- S

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

POWER

SUPPLY

+

_

RCCP

1

CAUTION

At local sensing, short between +LS or +S to -V or -S or -LS will cause damage to the

power supply. Reversing the sense wires might cause damage to the power supply

at local and remote sensing.

14

3.7.4 Single load connection, Remote Sensing

3.7.5 Multiple load connections, radial distribution method

Remote Sensing is usedin cases where, inConstant Voltagemode the loadregulation isimportant at

the load terminals. Use twisted orshielded wires tominimize noise pick-up.If shielded wiresare used,

the shield should beconnected to the groundat onepoint, eitherthe power supply chassisor the load

ground. The optimalpoint forthe shield groundshould be determinedby experimentation. AtRemote

Sensing,the maximumvoltage dropallowedat theload wiresis0.5Vperwire.

In cases of multiple loads connected to one supply, each load should be connected to the power

supply’s output terminals using separatepairs of wires. It is recommended thateach pair of wires will

be as short as possible and twisted or shielded to minimize noise pick-up and radiation. The sense

wiresshouldbe connectedtothepower supply outputterminalsorto the loadwiththe most criticalload

regulationrequirement.

Fig.3-2: RemoteSensing, singleload.

Fig.3-3: Multipleload connectionswithdistribution terminal

2

2

- LS

- LS

+ S

- V

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

+ V

- S

COM

COM

Output Good

Output Good

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI

VCCP

VCCP

RCVP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

LOAD #1

LOAD #2

LOAD #3

POWER

SUPPLY

POWER

SUPPLY

To Load Terminals

Shield

+

+

+

+

_

_

_

_

RCCP

RCCP

1

1

+S

- V

+LS

- LS

+V

- S

15

3.7.6 Multiple load connections with distribution terminals

3.7.7 Grounding outputs

3.8 EXTERNAL CONTROL CONNECTOR

3.8.1 General

Ifremotely located output distribution terminals areused, the power supplyoutput terminals shouldbe

connected to the distribution terminals by a pair of twisted or shielded wires. Each load should be

separately connected tothe remote distribution terminals. If Remote Sensing isrequired, the sensing

wiresshouldbeconnected tothedistribution terminalsor atthemostcriticalload.

Either the positive or negativeoutput terminals can be grounded. Toavoid noise problems caused by

common-mode current flowing from the load to ground, it is recommended to ground the output

terminalascloseas possibletothepowersupply output.

Always use two wires to connect the load to the power supply regardless of how the system is

grounded.

The external control connector, used for analog programming of the power supply,is located on the

rearpanelofthe unit,(Fig.4-2,item4).The pinassignmentisshownin Fig.3-5 below.

Fig.3-4:Multipleload connectionswithdistributionterminal

Fig.3-5:

ExternalControl connectorpin assignment

(ZUPrear panelview)

1

14

13

DISTRIBUTION

TERMINAL

LOAD #1

LOAD #2

LOAD #3

POWER

SUPPLY

+

+

+

_

_

_

2

+S

- V

- V

+V

+V

- S

To Dristribution Terminals

WARNING

The maximum potential (including output voltage) that either output terminal

is from ground, must not exceed the specified voltage on the front panel.

2

- LS

- S

+LS

+S

On/Off

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

RCCP

1

16

3.8.2 Pin Description

3.8.3 External Control Connector - Technical description

1. Connector type : AMP, Part No: 102617-5 14 contacts, double row.

2. Receptacle : AMP, Part No: 87631-9, Polarized, 14 contacts, double row.

3. Receptacle contacts : AMP, Part No: 87523-5 (strip form) or 87523-6 (loose piece).

4. Wires : AWG: 24 to 20.

5. Hand tool for wire connection : AMP, Part No: 90202-2.

6. Applicator for stripper/crimper machine : AMP, Part No: 466905-1

#

Name

1 RCVP

2 RCCP

3 VRFI

4 VCCP

5 VRFV

6 VCVP

7 OUTPUT

GOOD

8 P

9 ON/OFF

10 COM

11 + LS

12 + S

13 - LS

14 - S

Description

Resistive Constant Voltage programming

Resistive Constant Current programming

Reference voltage for Constant Current control. (connected to

VCCP pin except external voltage or resistive programming).

Input of the Constant Current control circuit.

Reference voltage for Constant Voltage control. (connected to

VCVP pin except external voltage or resistive programming).

Input of the Constant Voltage control circuit.

Open collector output. 0~0.8V during normal operation, open at

fault condition (OVP, FOLD and Over-Temp.).

Parallel connection pin.

On/Off control pin.

Common pin for programming, On/off control and Output Good

signal. Internally connected to - Sense.

Positive Local sensing pin.

Positive Sensing pin for remote sense operation.

Negative Local sensing pin.

Negative Sensing pin for remote sense operation.

4.4.10

4.4.10

4.4.10, 11, 12

4.4.10, 11, 12

4.4.10, 11, 12

4.4.10, 11, 12

4.4.15

4.4.13

4.4.8

4.4.10, 11, 12

4.4.8

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

Par.

Table3-3: ExternalControlconnector pindescription

CAUTION

COM pin (10) is connected internally to the - Sense potential. Connection of the COM to another

potential or other than shown in this manual may cause damage to the power supply.

17

3.9 REPACKAGING FOR SHIPMENT

Toensure safe transportation of the instrument, it is recommended to use the original package. The

original packaging material is reusable. If the original package is not available, contact the NemicLambda Sales or service facility near you for details on obtaining suitable packaging and shipping

information. Please attach a tagto the powersupply describing theproblem andspecifying the owner,

modelnumberandserial numberofthe powersupply.

3.8.4 External Control Connector -

Default configuration connections

Theexternal control connector is configured for Localsensing and no externalOn/Off control. Refer to

Fig: 3-6 below for the default configuration description. The default configuration is: Local sensing,

Rearpanel On/Offdisabled (On/Offcan becontrolledby theFrontpanel orbytheserialcommunication

port), and outputvoltage and currentare controlled bythe Front panel or by the serial communication

port. For other configurations, remove the contact that should be modified, and replace it with a new

one with a suitable connection. Replacement contacts are supplied in the packaging of the power

supply.

Fig.3-6:

ExternalControl connector- defaultconfiguration

(ZUPrear panelview)

1

14

13

2

- LS

- S

+LS

+S

On/Off

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

RCCP

18

3.10 OUTLINE DRAWINGS

ZUP200WandZUP 400WSeries

DIMENSIONS: mm

200W /400W units: 70x124x350

WEIGHT: Kg

200W units: 2.9 400W units: 3.2

20.0

20.0

13.0

13.0

59.5

30.0

21.5 19.0

External

Control

Connector

(Note3)

IEC320

AC Inlet

RS232/RS485

communication

connectors

70.0

201.5

11.0

+

+

0.5

1

_

_

+

+

0.5

0.5

_

_

350.0

+

1

_

290.0

+

1

_

+

1

_

124.0

131.0

48.0

11.0

Mounting Holes

Tap M4 x 4 marked ‘A’

(See note 1)

Notes:

1. Mounting screws must not

protrude more than 6mm

into the power supply.

2. Use M6 or 1/4” screw for

load wires connection,

enclosed in the package

at time of shipment.

3. Receptacle: AMP, 87631-9,

14 contacts, double row.

Pin: 87523-5 or 87523-6.

Rubber Bumpers

4 places marked ‘B’

(removable)

10.6

B

B

B

B

A

A

A

A

48.4

_

+

0.5

A

ALM

CC

CV

V

POWER SUPPLY

ADDR OVP/UVP

POWER

NEMIC-LAMBDA LTD.

H

19

Rubber Bumpers:

4 places marked ‘B’ (removable)

3.11 OUTLINE DRAWINGS

ZUP800W Series

DIMENSIONS:

140x124x350 mm.

WEIGHT:

5.8 kg.

20.0

22.0

22.0

30.0

46.3

47.0

External

Control

Connector

(Note3)

IEC320

AC Inlet

RS232/RS485

communication

connectors

REMOVABLE HANDLE

11.0

+

1.0

_

350.0

+

1

_

290.0

+

1

_

139.5

107.5

Mounting Holes: Tap M4 x 4 marked ‘A’

(See note 1)

Notes:

1. Mounting screws must not

protrude more than 6mm

into the power supply.

2. Use M8 or 5/16” screw for

load wires connection,

enclosed in the package

at time of shipment.

3. Receptacle: AMP, 87631-9,

14 contacts, double row.

Pin: 87523-5 or 87523-6.

140.0

+

0.5

_

+

0.5

_

124.0

+

1.0

_

99.6

201.50

+

0.5

_

59.5

10.4

B

B

B

A

A

A

A

118.90

_

+

0.5

B

18.5

POWER

20.0

+

1.0

_

131.0

20

Physical Dimensions in mm.

392.0 Max.

153.0

+

1.0

_

70.0

+

0.5

_

FrontPanelOutputJacks Option:availablefor ZUP200W, ZUP400Wand ZUP800Wseries.

ZUP200/L and ZUP400/ L

Up to 20A output current via front panel jacks.

CAUTION: ZUP800 front panel output is protected against overcurrent by 25A 125V Fast acting fuse.

For continued protection against risk of fire, replace only with same type and rating of fuse.

3.12 OUTLINE DRAWINGS

ZUP800/L

153.0

+

1.0

_

140.0

+

0.5

_

21

This chapter describes the operatingmodes, controls and indicators of the ZUPpower supply series.

Details of local operation via the front panel and various modes of operation are described in this

chapter, including remote analog control via the rear panel. For computer control via the Serial port

(RS232or RS485),refer tochapter5.

CHAPTER 4 OPERATING INSTRUCTIONS

4.1 INTRODUCTION

4.2 CONTROLS AND INDICATORS

4.2.1 Front panel

Fig.4-1: Frontpanel controlsandindicators

22

13

12

11

10

3

5

6

4

7

8

9

1

2

Table 4-1: Front panel controls and indicators

#

Control/Indicator

1 AMPS Display

2 VOLTS Display

3 CV Indicator

4 CC Indicator

4.4.2

4.4.3

4.4.5

4.4.6

5.2.1

4.4.8

4.4.9

5.2.4

4.4.7

5 ADJUST knob

(Rotary pulse generator)

6 ALM Indicator

7 OUT Pushbutton

8 REM Pushbutton

9 FOLD Pushbutton

Description

Actual output current display at normal operation. While

adjusting the output current, the set value will be shown.

The display will automatically return to show the actual

currentapprox.3secfrom completionofadjustment.

Actual output voltage display at normal operation. The

measurement circuits monitor the voltage at the sensing

points, hence at remote sensing where there is voltage

drop on the load wires, the voltage at the power supply

output terminals will be higher than the displayed value.

Attention should be taken not to exceed the output power

rating.While adjusting the outputvoltage, the setvalue will

beshown. The display will automatically returnto show the

actualvoltageapprox.3sec aftercompletionof adjustment.

CV LED indicates that the power supply is regulating it’s

outputataconstant voltage.

CC LED indicates that the power supply is regulating it’s

outputataconstant current.

The ADJUST knob functions to determine the following

outputparameters:

1.Outputvoltageadjust -asdeterminedbyV/A pushbutton

2.Outputcurrentadjust -asdeterminedbyV/A pushbutton

3.Overvoltageprotection adjust-asdeterminedby

OVP/UVPpushbutton

4.Undervoltagesoft limitadjust-asdetermined

byOVP/UVPpushbutton

5.Addressselection

ALM indicates alarm caused by activation of one of the

followingprotections:

* Over voltageprotection

* Over temperatureprotection

* Foldback protection

Mainfunction: Enableor disablethepowersupplyoutput.

Auxiliary function: Press and hold OUT pushbutton for

approx. 3sec to change function to select between safe

moderestart andautomatic restart.

Mainfunction: Selectbetween localorremoteoperation.

Auxiliary function: Press and hold REM pushbutton for

approx. 3sec to change function to select between RS232

orRS485communication.

Pressing FOLD pushbutton arms foldback protection

whichshutsdownoutput ifsupplytransitsfromCV toCC.

Par.

23

Table 4-1 contd.: Front panel controls and indicators

4.2.2 Rear Panel

#

Control/Indicator

10 AC ON/OFF

11 V/A Pushbutton

12 OVP / UVP

13 ADDR

Description

TurnsACpower Onand Off.

Selects the voltage or current adjust mode. fast or slow

adjustment speed can be selected by pressing the

pushbutton consecutively.Adjustment is made by rotating

theAdjustknob.

Makes selection between Over-voltage or Under-voltage

adjust mode. Adjustment is made by rotating the Adjust

knob.

Main function: Selects the address for remote control.The

adjustmentis madeby rotatingtheAdjustknob.

Auxiliary function: Holding ADDR pressed for approx.

3sec.changesthefunction toBaud-rateselection.

Par.

Fig.4-2: Rearpanel connections

4.4.2

4.4.5

4.4.3

4.4.6

5.2.1

5.2.3

24

4

3

2

6

1

5

4.2.3 Rear Panel Connections description

#

Connection

1 AC Inlet

2 Remote In

3 Remote Out

4 External control

5 Output Bus Bars

6 Ground thread

Description

IECtypeapplianceinlet.

EIA/TIA-568A type connector, used for connecting power

supply to RS232 or RS485 port of computer for remote

control purposes. When using several power supply units

in a power system, the first unitRemote-in is connected to

the computer and the remaining units are chained,

Remote-IntoRemote-Out.

EIA/TIA-568 type connector, used for chaining power

suppliestoforma serialcommunicationbus.

Connector containing control and signal lines for external

(remote) control of the power supply. +/- Sense, On/Off,

Output voltage and current programming by external

resistor and Output voltage and current programming by

externalvoltageandOutput Goodsignal.

Bus bars for outputconnection. Use M6 or 1/4” screws for

loadwireconnections.

M4 thread for grounding either the positive or negative

output.

Par.

4.3 TURN-ON CHECKOUT PROCEDURE

4.3.1 General

4.3.2 Prior to operation

4.3.3 Constant Voltage check

The following procedure ensures that the power supply is operational and may be used as a basic

incominginspection check.

Check that the Rear panel external control receptacle is properly inserted into the connector and the

wiresare connected as shown in Fig: 3-6. Connectthe unit to anAC source as described inparagraph

3.6.Connect aDVM totheoutput terminals.

Turn-on the power supply. Turn on the output by pressing OUT pushbutton so the OUT LED

illuminates. Momentarily press V/A pushbutton, until the V LED illuminates and the VOLTS display

showsFA_V.TheAMPS display will show the last settingof the output voltage. Rotate the Adjust knob

at the front panel and check thatthe output voltage can be varied throughoutthe entire range. Check

thatthe AMPSdisplayshows the correctoutput voltage (withinthedisplay specifications).Momentarily

press V/A pushbuttonagain, sothe A LEDilluminates andthe VOLTSdisplay shows FA_A. The AMP

display will showthe lastsetting of the outputcurrent. Rotate the Adjustknob and check thatthe AMP

displayvaries. SettheAMPdisplayto therated outputcurrent.

3.6

3.8

5.3.4

5.3.4

3.7

25

4.3.4 Constant Current check

4.3.5 OVP check

4.3.6 UVP check

4.3.7 Foldback check

4.3.8 Output On/Off

4.3.9 Address setting

4.3.10 Local/Remote operation

Turn off the power supply.Connect an electronic load with suitable voltage and current rating to the

outputterminals,asexplainedinparagraph 3.7.3. Turn-onthe power supply.Varytheload current and

check that the unit regulatesthe output voltagewhile theload current issmaller thanthe powersupply

current rating. Furtherincrease the load current andcheck that thepower supply regulates the output

current.

Adjust the output voltageto zerousing thefront panelknob. Momentarilypress OVP/UVP pushbutton

untilthe OVP LED illuminatesandtheVOLTSdisplay shows OUP.TheAMPSdisplaywill show the last

settingoftheOVPlevel. Rotate the Adjust knob to 50% of the supply’svoltagerating.Adjusttheoutput

voltagetoward it’smaximum andcheckthattheoutput voltagecannotbe increasedmorethantheOVP

setting.

Adjustthe output voltage to the rated voltageusing the front panel knob.Momentarily press OVP/UVP

pushbutton until the UVPLED illuminatesand theVOLTSdisplay shows UUP..The AMPS displaywill

show the lastsetting ofthe UVP level. Rotatethe ADJUST knobto 50%of the supply’svoltage rating.

Adjust the outputvoltage towardit’s minimum and checkthat the outputvoltage cannotbe decreased

belowthe UVPsetting.

Set the load current to50% of the supply rating. Momentarily pressFOLD pushbutton and check that

the FOLD LED illuminates. Increase the loadcurrent toward the supply current rating. Check that the

outputvoltageandcurrentfalltozerowhentheloadcurrentreachestheConstantCurrentsetting.The

FOLDLED shouldflash,theALMLEDilluminates andtheoutput isdisabled inthiscondition.

Reduce the load current setting below the power supply current rating and momentarily press OUT

pushbutton. Check that the output voltage and current recover and FOLD continuously illuminates.

Momentarilypress theFOLD pushbuttonandcheck thatFOLDLEDturnsoff.

RepeatedlypressOUTpushbutton and check that the power supplyoutputisturnedOnand Off. While

theoutput isOn,theOUTLED illuminates.While theoutputis Off,theLEDis Off.

Momentarily press ADDR pushbutton so the ADDR LED illuminates and the AMPS display shows

Addr.The VOLTSdisplay showsthe last address setting.Rotate the ADJUST knoband check thatthe

VOLTSdisplayvariesbetween 0and31.

Repeatedly press REM pushbutton and check thatREM LED turnson and off. While the powersupply

is at Remote mode, theLED is on andwhile at Localmode, theLED is off. While theLED is off,turn off

thepower supply,removetheDVMand theload wires.

26

4.4 LOCAL OPERATION

4.4.1 Introduction

4.4.2 Constant Voltage Operation

This paragraph describes the operating modes not involved inprogramming thepower supply via it’s

serialcommunication port. Operation utilizing the frontand rear panel aredescribed in this paragraph.

Forinformationregardingserial portusage,please referto chapter5.

The REM LED on thefront panel indicateswhether thepower supplyis in Localor Remotemode. The

extinguishedLEDindicates Localoperation. If the LED illuminates, the REM pushbutton (fig.4-1, item

8),shouldbepressedto changetheoperatingmodeto Local.

1.Inconstantvoltage mode,thepowersupplymaintains theoutputvoltageatthe selectedvaluewhile

theloadcurrentvaries asrequiredbytheload.

2.Whilethepower supplyisoperatingatconstant voltage,theCVLEDon thefront panelilluminates.

3. For coarse output voltage adjustment, press V/A consecutively, until the V LED illuminates, and

the VOLTS display shows FA_V. The AMPS display will show the output voltage setting value.

Rotate the ADJUST knob to set the output voltage. At this mode, approx. 6 turns are required to

adjust the entire range. Approx. 3sec after the adjustment, the display returns to show the actual

voltage and current.

3.Forcoarseoutput currentadjustment,press V/Aconsecutively,untiltheALEDilluminates, and

the VOLTS display shows FA_A. The AMPS display will show the output current setting value.

Rotate the ADJUST knob to set the output current. At this mode, approx. 6 turns are required to

adjust the entire range. Approx. 3sec after the adjustment, the display returns to show the actual

voltage and current.

4.4.3 Constant Current Operation

NOTE

NOTE

4.For fineadjustment ofoutputvoltage,pressV/A consecutivelyuntilthe VLEDilluminatesandthe

VOLTSdisplayshowsSL_V.TheAMPSdisplaywillshowtheoutput voltagesettingvalue.Rotate

theADJUST knobto settheoutput voltage.At thismodethe adjustmentresolution ismaximal.

Approx3sec. aftertheadjustment,thedisplay returnsto showtheactual voltage andcurrent.

4.For fineadjustment ofoutputcurrent, pressV/A consecutivelyuntilthe ALEDilluminatesand the

VOLTSdisplayshowsSL_A.TheAMPSdisplay willshow theoutputcurrent settingvalue. Rotate

theADJUST knobto settheoutput current.At thismodetheadjustmentresolution ismaximal.

Approx3sec. aftertheadjustment,thedisplay returnsto showtheactual voltage andcurrent.

1.In constantcurrent modethepower supplymaintains theoutputcurrentatthe selectedvalue,while

theloadvoltagevaries withtheloadrequirement.

2.While thepower supplyisoperating atconstant current,theCCLEDon thefrontpanelilluminates.

If after completing the adjustment the display shows a different value than the setting, the power

supply may be at current limit. Check the load condition and the power supply current limit setting.

The maximum and minimum setting values of the output voltage are limited by the over voltage and

under voltage protection settings. Refer to par. 4.4.5 and 4.4.6 for details.

27

4.4.4 Automatic Crossover

4.4.5 Over Voltage Protection (OVP)

If the power supply operates in Constantvoltage mode while the loadcurrent is increased to greater

thanthe current limitsetting,the power supplywillautomatically switch toConstantcurrentmode. If the

load is decreased toless thanthe currentlimit setting,the power supply willautomatically switchback

toConstantvoltagemode.

MODEL (by output voltage) 6V

7.5V

10V

13V

20V

24V

36V

40V

60V

66VMaximum OVP

1.TheOVP circuitmonitorsthevoltageat thepower supplysensingpoints thusguaranteeing the

protectionlevelatthe load.UpondetectionofOver Voltagecondition,the powersupplywillshut

down.Toresumeoperation,the powerswitchshould beturned offfor approx.30sec.Priortoturn-on,

checkcarefully thatthe sensewiresareconnectedcorrectly andsecured.

2.OVP settingvaluesarelimitedat theminimum andmaximumlevels. Atminimum level,theOVPlevel

is limited bythe OutputVoltage setting,therefore theOVP levelcannotbeadjustedbelow the

Output Voltage.Atmaximumlevel, theOVPlevelislimited tothevaluesshownin Table4-1.

Table4-1:MaximumOVPsettinglevels.

4.4.6 Under Voltage Protection (UVP)

3.Forover voltageprotectionadjustment,pressOVP/UVP consecutively,untiltheOVPLED

illuminatesandtheVOLTSdisplayshowsOUP.TheAMPSdisplay willshow theover voltage

protectionsetting value.Rotate theADJUSTknob toset theovervoltageprotectionlevel. Approx.

3secaftertheadjustment, thedisplayreturnstoshow theactualvoltageandcurrent.

4.In orderto seethevalue ofthe OVP,pressOVP/UVPpushbutton,sothattheOVP LEDilluminates.

Atthistimethe displaywillshowtheOVP setvalueforapprox.3sec.

5. The minimum over voltage level is approx. 105% of the output voltage set value. Attempting to

adjust the over voltage protection below this value will result in no response to the adjustment

attempt.

6. In case the OVP is triggered, the front panel control is disabled unitl the AC input is recycled by

turning the AC ON/OFF switch to OFF and after approx. 10 sec. to ON.

1.TheUVPpreventsadjustment oftheoutputvoltagebelow acertainlimit.Thecombination ofUVP

andOVPfunctionsallows theusertocreatea protectionwindowforsensitiveloads circuitry.

2.Forundervoltage protectionadjustment,press OVP/UVPconsecutively untiltheUVP LED

illuminatesandtheVOLTSdisplayshowsUUP.TheAMPSdisplay willshow theundervoltage

protectionsetting value.Rotate theADJUSTknob toset theundervoltageprotectionlevel.

3.Inorderto seethesetvalueof theUVP,pressOVP/UVPpushbutton,sothatthe UVPLED

illuminates.At thistime thedisplaywillshowthe UVPsetvalueforapprox. 3sec.

4.Themaximumunder voltagelevelisapprox.95% oftheoutputvoltageset value.Anattemptto

adjustthe undervoltage protectionabovethisvaluewill resultinnoresponseto theadjustment

attempt.

5.Theundervoltageprotection isasoftware protectiononly.

28

4.4.8 Output ON/OFF Control

4.4.7 Foldback Protection

The ON/OFF circuithas two controls; a front panel pushbuttonand a rearpanel connection.priority is

givento therear panelconnection.

1.Foldback protectionwill shutdownthepowersupply outputifthe loadcurrent exceedsthecurrent

limitsetting level.This protectionisuseful whenthe loadcircuitryissensitiveto overcurrent

condition.

2.ToarmtheFoldback protection,theFOLD pushbuttonshouldbepressedso theFOLD LED

illuminates.At thiscondition transitionfromConstant VoltagetoConstant Currentmodewillactivate

theFoldbackprotection.

3. Activation oftheFoldbackprotectiondisables thepower supply’soutput, turnsonthe ALM(alarm)

LEDand flashesthe FOLDLED.

4.There are2 modesof releasing anactivated Foldbackprotection.

1.Short presson FOLDpushbuttonenables theoutputandre-armsthe protectioncircuit. Iftheload

issmaller thanthecurrentlimit level,thepowersupplywillrestore normaloperation.Ifthe loadis

greaterthan thecurrentlimitlevel,theoutput willbedisabledagainand Foldbackindicatorswill

beon.

2.Long press(approx. 3sec)onFOLD pushbuttonwill disabletheFoldbackprotectioncircuit and

enabletheoutput.The powersupplywillrestoreoperation toConstantVoltageorConstant

Current mode dependingon theloadcharacteristics andpower supplysetting.

1. Rear panel ON/OFF Control

2. Front panel ON/OFF Control

Contacts 9, 10 at the rear panel External Control connector (fig. 4-2, item 4) serve as ON/OFF

terminals.Either shortcircuitor TTL‘0’ levelenablesthe powersupply outputandopen circuitorTTL‘1’

level disables the power supply’s output. An open collector transistor can be used for the ON/OFF

controlasshownin fig. 4-3, with sink current ability of morethan2.5mA.Pleasenotethatpin10 (COM)

is internally connected tothe - Sensepotential, thereforefor floating ON/OFF Controla photocoupler

shouldbeusedas showninFig.4-4.

TheFront PanelON/OFF is controlled by the OUT pushbutton. Toenabletheoutput, OUT pushbutton

should be pressed so that OUT LED illuminates. The operation of OUT pushbutton is enabled only if

therearpanelON/OFF isconfiguredto‘ON’.

Fig.4-3: ON/OFFControl, referencesto - Sense.

(ZUPrear panelview)

Fig.4-4:FloatingON/OFF Control

(ZUPrear panelview)

2 2

- LS

- LS

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

2.5mA

ON

ON

OFF

OFF

COM

COM

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI

VCCP

VCCP

RCVP

RCVP

RCCP

RCCP

1 1

Output Good

Output Good

29

1. Automatic start mode

4.4.9 Last Setting Memory

In this mode thepower supplyrestores it’slast operationsetting andsets theOUT to ‘ON’ state.Upon

start-up, the output is enabled and the power supply delivers power to the output terminals.Toselect

this mode press and hold OUT pushbutton. After approx. 3sec., the display will continuously cycle

between AS ON (auto-start on) and AS OFF (auto-start off), approx. every 3sec. Releasing the OUT

pushbutton while AS ON isdisplayed, will setthe power supplyto automaticstart mode.(holding OUT

depressed for more than 1sec. does not change the output on/off status). In cases where the Over

Voltage or Over Temperature or Foldback protection has been activated , the unit will automatically

changetosafestart modeaftertheACvoltage recycling.

The ZUP series is equipped with Last Setting Memory which stores all power supply parameters at

each ac turn-off sequence ofthe power supply.The OUT parameter storageis determined prior tothe

acturn-offtoallow twomodesof re-startofthe powersupply.

STOREDPARAMETERS

1. Output Voltage

2. Output Current

3. OVP Levels

4. UVP Levels

5. FOLD

6. Re-start mode

7. REMOTE/LOCAL

8. ADDRESS

9. Communication Standard(RS232/RS485)

10.Baud-rate

11.Servicerequestparameters

(Items8-10 arerelated tocomputercontrolled

operationand explainedin chapter5).

2. Safe start mode

4.4.10 Output Voltage & Current programming

by external resistor

In this mode,the power supplyrestores it’slast operation settingand sets theOUT to the‘OFF’ state.

Toselectthis mode, pressand hold OUT pushbutton. Afterapprox. 3sec., the displaywill continuously

cycle between AS ON (auto-start on)and AS OFF (auto-start off), approx. every 3sec. Releasing the

OUTpushbuttonwhileASOFFisdisplayedwillsetthe powersupply to safe start mode. At startup, the

outputis disabled and theoutputvoltage and current arezero.Toenabletheoutput and restore thelast

outputvoltage andcurrent values,OUTpushbutton shouldbe momentarilypressed.

1.Forresistiveprogramming, internalcurrentsources,foroutput voltageand/or output currentcontrol,

supply1mAcurrentthrough externalprogrammingresistors. Thevoltage acrosstheprogramming

resistorsisusedas aprogrammingvoltageforthe powersupply.Resistanceof0~4kohm programs

theoutputfrom0 tofullscale(fullscale is105% oftheratedvoltageor current).

Avariableresistorcan controltheoutputoverit’sentirerange, ora combinationofvariable resistor

andseries/parallel resistorscan controltheoutput overa restrictedportionof it’srange.Alternatively,

aswitchcanbe usedto selectfixedvalues ofprogramming resistancetoobtain asetofdiscrete

voltagesorcurrents.Care mustbetakentoavoid opencircuitattheprogramming resistors,asitwill

causeover-voltage atthe output.Inthiscase,no damagetothepowersupply willbecaused

however,itisrecommendedto setOVP limittoalevelwhich issafe fortheload circuitry.

2.Tomaintainthetemperature stabilityspecificationof thepowersupply,theresistors usedfor

programmingshould bestable andlownoiseresistors,with temperaturecoefficientoflessthan

25ppmandpowerrating of1/4Wormore.

3.Where externalresistor programmingisused,frontpanel control andcomputercontrol (viaserial

communication)of theoutput voltageandcurrent aredisabled.

30

4.OUTPUTVOLTAGEPROGRAMMINGBYEXTERNAL RESISTOR

Fig 4-5 shows a typical set-up for programming the output voltage. A variable programming resistor,

0~4Kohm produces aproportional output voltagefrom zero tofull scale. Inorder to setthe low limit, a

seriesresistor canbeconnected to theprogrammingresistor.For example; a1kohmseries resistorwill

set the lower limit to 25% of full scale. In order to set the upper limit, a resistor can be connected in

parallel to the programming resistor. The resultant programming resistance of the series/parallel

resistorsmustbebetween 0and4Kohm.

NOTE

Resistive programming is possible for local and remote sensing.

Fig.4-5:

Constantvoltage resistiveprogramming.

2

2

- LS

- LS

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

0~4K

programming resistor

0~4K

programming resistor

Optional

sets lower

limit

Optional

sets lower

limit

Optional

sets upper limit

Optional

sets upper limit

External control connector

(ZUP rear panel view)

External control connector

(ZUP rear panel view)

COM

COM

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI

VCCP

VCCP

RCVP

RCVP

RCCP

RCCP

1

1

5.OUTPUTCURRENT PROGRAMMINGBYEXTERNALRESISTOR

Fig 4-6 shows the set-up for constant current resistive programming. The explanation given for

constantvoltage resistiveprogramming alsoappliesfor constantcurrent.

Fig. 4-6:

Constant current resistive programming.

Output Good

Output Good

14

14

13

13

31

4.4.11 Output Voltage Programming by external voltage

4.4.12 Output Current Programming by external voltage

CAUTION

CAUTION

Fig. 4-7 shows the set-up for external voltage programming of the output voltage. A voltage source

variablefrom0 to 4V,programs the output voltage proportionally from zero tofull scale. The static load

current on the programming source is less than 2uA. The source resistance should be less than

10Kohm to avoid degradation of offset and drift specifications. When external voltage is used for

programmingthe frontpanel andthecomputer control(via theserialcommunication) aredisabled.

Note:Full scaleis 105%oftheratedoutput voltage.

Fig. 4-8 shows the set-up for external voltage programming of the output current. A voltage source

variable from 0 to 4V,programs the outputcurrent proportionally fromzero to fullscale. The staticload

current on the programming source is less than 2uA. The source resistance should be less than

10Kohmto avoiddegradation ofoffsetanddriftspecifications.

Note:Full scaleis 105%oftheratedoutput current.

The Com pin at the external control connector is connected to the -Sense potential. NEVER

connect the Com pin (pin10) to any potential, as it may damage the power supply.

Avoid connection of resistors greater than 4kohm or voltage greater than 4V for external resistor

or voltage programming, as it may cause the output voltage and current to exceed the power

supply rating. The display will NOT show the actual voltage and current when such resistor

or voltage is applied for programming.

Fig.4-7:

Outputvoltage programming

byexternal voltagesource.

(ZUPrear panelview)

Fig.4-8:

Outputcurrentprogramming

byexternalvoltagesource.

(ZUPrearpanelview)

0~4VDC

Voltage

source

0~4VDC

Voltage

source

+

+

_

_

2

2

14

14

- LS

- LS

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

External control connector

External control connector

COM

COM

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI