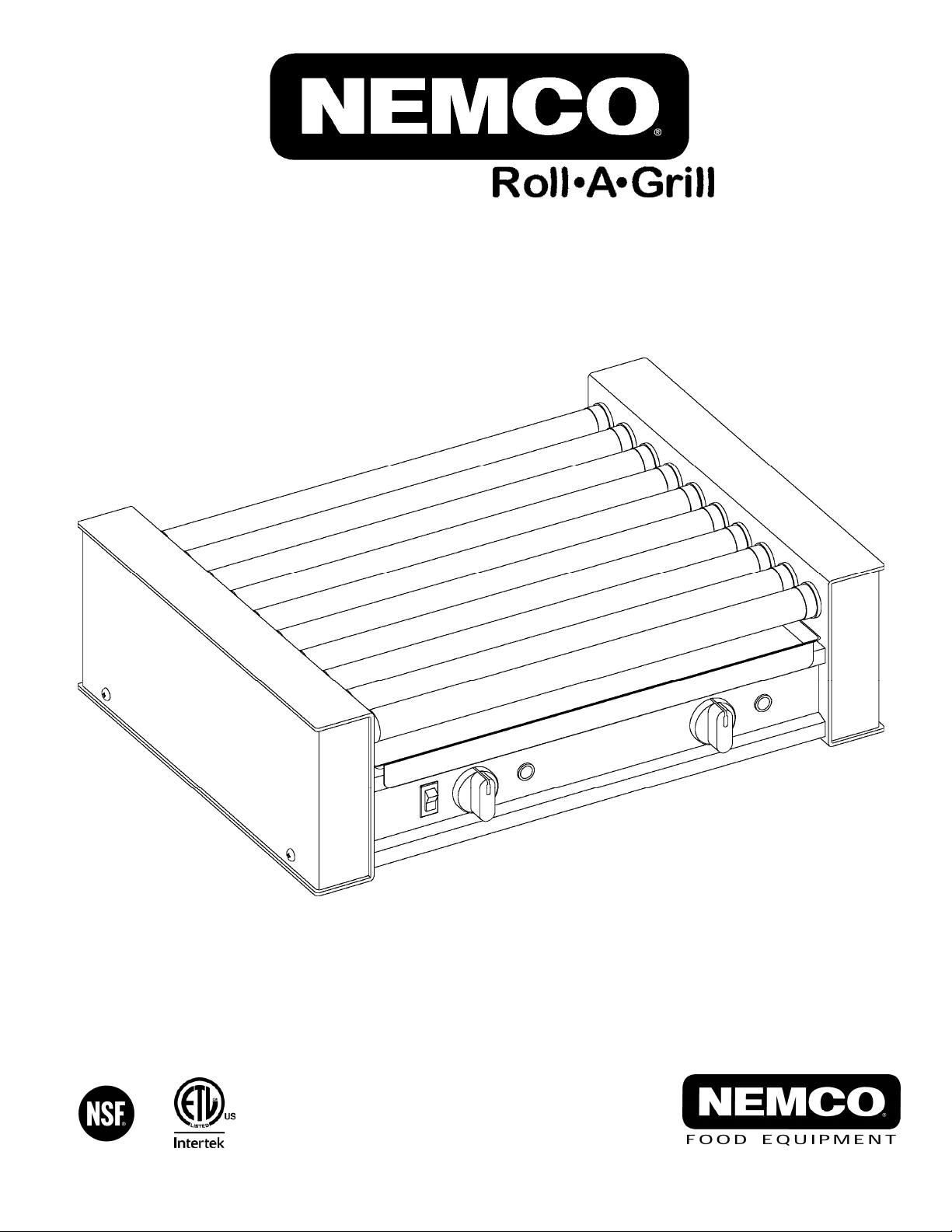

Nemco Food Equipment Hot Dog Roller Grills Operations Manual

Model Series: 8010(V), 8018, 8027, 8036, 8045W, 8045N, & 8075

Includes Chrome, or GripsIt, Flat or Slant, and 120 Volt or 220 Volt Units

OPERATING AND MAINTENANCE INSTRUCTIONS

AND SERVICE PARTS LIST

INTRODUCTION

1. Please read instructions before using

2. Clean machine thoroughly before and after all uses using cleaning instructions below

3. This machine will be HOT during use and for a short time after it is turned off – BE CAREFUL

SAFETY INSTRUCTIONS

1. Plug electrical cord into a certified electrical outlet with a corresponding voltage rating as listed on the

machine model labels. Units with two cords must be plugged into outlets on individual branch circuits.

2. There is one motor in the units that have one on/off switch.

3. There are two motors in units that have two on/off switches. The left switch controls the rotation of the

front set of rollers and the right switch controls the rotation of the rear set of rollers.

4. On units with two temperature controls, the left dial controls the front half of the rollers which are

denoted by black bearings. The right dial controls the rear rollers which have white bearings.

5. Units with four temperature controls operate from left to right across front panel.

♦ Switch #1 controls the heat in the front four rollers 1-4 which are designated by black bearings.

♦ Switch #2 controls the heat in the next four rollers 5-8 which are designated by white bearings.

♦ Switch #3 controls the heat in the next four rollers 9-12 which are designated by white bearings.

♦ Switch #4 controls the heat in the next four rollers 13-16 which are designated by black bearings.

PREPARATION

1. Set unit on a flat surface

2. Position unit near the power outlet. Avoid the use of extension cords.

3. Clean unit thoroughly before use.

4. If unit fails to operate properly when first installed call NEMCO customer service at 1-800-782-6761.

STARTUP

1. Turn on/off switches to the on position and make sure rollers are turning.

2. Turn temperature controls to desired temperature

♦ Knob setting #2: temperature is at 150º ; HOLD

♦ Knob setting #4: temperature is at 180º ; HOLD

♦ Knob setting #8: temperature is at 220º ; COOK

♦ Knob setting #10: temperature is at 300º ; PREHEAT

3. Allow rollers to heat for 5 to 10 minutes before placing product on rollers.

4. Plastic tongs are included with units with Silverstone or GripsIt rollers. Use plastic to prevent serious

damage to these rollers. Never use metal utensils or tools on the Silverstone or GripsIt rollers.

ELECTRICAL REQUIREMENTS

Refer to the product tag (serial plate) on the back of the unit for voltage and wattage requirements. Be sure to

plug unit into outlet with sufficient power.

2

OPERATION

1. During slow sales periods, turn rear rollers on low heat and fill rollers with product. Keep front rollers on

medium and serve product from there. Shift product from the rear to the front and reload.

2. During busy periods, set rear control to medium and front control to high. Serve from the front rollers

first.

3. During very busy periods, set all thermostats on high. Fill all of the rollers with product. At this

temperature, product should be sold within 15 minutes.

IMPORTANT: Never serve product from low heat if not approved by the health department.

NEVER CHANGE PRODUCT FROM HIGH TO LOW HEAT AS THIS CHANGE IN TEMPERATURE CAUSES

THE PRODUCT TO SHRIVEL.

CLEANING

NOTE: Proper maintenance plays an important part in the life span and functioning of the unit

1. Turn temperature controls on high and turn rollers on before cleaning.

2. ALWAYS START AT THE END OF THE ROLLERS AND WIPE TOWARD THE CENTER. This prevents

extra grease from entering the sides of the unit and into the bearings.

♦ Silverstone rollers: Use a scratch proof sponge made for non-stick coated products or a soft cloth to

wipe the rollers clean. If the build up on the rollers cannot be removed by just wiping with a wet

sponge, wrap some ice cubes inside a soft towel and rub over the rollers. NOTE: never use any metal

object on the Silverstone rollers at any time. Metal will cause serious damage to the rollers.

♦ GripsIt rollers: Use a soft cloth to wipe the rollers clean. If the build up on the rollers cannot be

removed by just wiping with a wet cloth, wrap some ice cubes inside a soft towel and rub over the

rollers. NOTE: Never use any metal objects on the GripsIt rollers at any time. Metal will cause serious

damage to the rollers.

♦ Chrome rollers: Each unit comes with a two sided sponge. Use the rough side of the sponge to remove

all residue from the rollers. If build up of residue cannot be removed from the rollers by wiping with a

course sponge you may use any type of kitchen abrasive to clean the rollers.

3. After cleaning the rollers, remove the drip pan and clean with mild soap and water.

SERVICE INSTRUCTIONS

IF ROLLERS WON’T TURN

1. Check power source to be sure machine is plugged into the proper voltage outlet and that the outlet is in

proper working order

2. IMPORTANT: Disconnect the unit from the power source before disassembly.

3. Remove the end covers

4. If the drive chain is off the idler sprocket, reinstall it.

5. Remove the drive chain from the sprocket on the motor shaft and if the rollers turn easily, then replace

the motor.

6. Remove the chain guard and inspect the sprockets on the end of each roller. If they are loose, worn, or

out of alignment, then replace the roller.

7. If the rollers are hard to turn by hand (without the chain attached) remove and clean out any

accumulated foreign matter in the bearings and on the rollers.

8. Before reconnecting the chain to the motor, pull the chain by hand. The chain should pull the rollers

easily and freely and should not ride up on the sprockets of the rollers and jam against the top of the

chain guard. If the chain pulls freely, the motor can be reconnected. Do not reconnect if there is any

difficulty with the chain turning since undue strain on the motor will shorten its life.

9. IMPORTANT: Reassemble the machine completely before reconnecting to the power source.

IF MACHINE BLOWS A FUSE OR CIRCUIT BREAKER

1. Check capacity of the circuit being used to be sure it isn’t overloaded

2. Unplug the unit and check it’s wiring for short circuits.

3

Loading...

Loading...