CM2001

HEA T TRACING CONTROL

OPERA TOR’S MANUAL

CM2001 Contents

1 Product Overview......................................................................................................... 1.1

Introduction ..............................................................................................................................................1.1

Specifications...........................................................................................................................................1.2

Summary of Features ..............................................................................................................................1.3

Use of this Manual ...................................................................................................................................1.3

Conventions .............................................................................................................................................1.3

Shipping Content......................................................................................................................................1.3

Theory of Operation ................................................................................................................................. 1.4

2 Installation .................................................................................................................... 2.1

Unpacking the Controller..........................................................................................................................2.1

Control Module.........................................................................................................................................2.1

Mounting the Controller ............................................................................................................................ 2.3

Wire Sizing...............................................................................................................................................2.3

Conduit and Cabling.................................................................................................................................2.3

Power Wiring ...........................................................................................................................................2.3

Heater Wiring...........................................................................................................................................2.3

Ground Connection .................................................................................................................................. 2.3

RTD Sensor Wiring.................................................................................................................................. 2.3

Communication Wiring.............................................................................................................................2.4

Alarm Wiring ............................................................................................................................................ 2.4

3 Getting Started.............................................................................................................. 3.1

Introduction .............................................................................................................................................. 3.1

Enabling the Heater .................................................................................................................................3.1

Entering Setpoints....................................................................................................................................3.1

Testing Heater & Alarms...........................................................................................................................3.3

Monitoring System Status.........................................................................................................................3.4

4 Front Panel Operation.................................................................................................. 4.1

Overview ..................................................................................................................................................4.1

Operating the Keypad ..............................................................................................................................4.1

St atus Lights.............................................................................................................................................4.1

Alphanumeric Display .............................................................................................................................. 4.1

Keypad.....................................................................................................................................................4.1

Display Contrast.......................................................................................................................................4.1

Heater Numbering....................................................................................................................................4.1

St artup Messages .................................................................................................................................... 4.3

St atus Messages...................................................................................................................................... 4.3

Flash Messsages .....................................................................................................................................4.4

5 Measured Values .......................................................................................................... 5.1

Overview ....................................................................................................................... ........................... 5.1

Operating ................................................................................................................................................. 5.2

Statistics...................................................................................................................................................5.3

6 Setpoint Values............................................................................................................. 6.1

Overview ..................................................................................................................................................6.1

Setpoints Entering....................................................................................................................................6.2

Setpoint Access Security .......................................................................................................................... 6.2

Operating ................................................................................................................................................. 6.2

Heater Setup............................................................................................................................................6.5

System Setup...........................................................................................................................................6.8

Setpoint Tests......................................................................................................................................... 6.11

ContentsCM2001

7 Alarms ........................................................................................................................... 7.1

Overview ..................................................................................................................................................7.1

Trip or Failure Alarms ............................................................................................................................... 7.1

Process Alarms ........................................................................................................................................ 7.2

Warning Alarms........................................................................................................................................7.3

Reset Alarms............................................................................................................................................7.3

8 Communications .......................................................................................................... 8.1

Overview ..................................................................................................................................................8.1

Physical Layer..........................................................................................................................................8.1

Modbus Protocol ......................................................................................................................................8.2

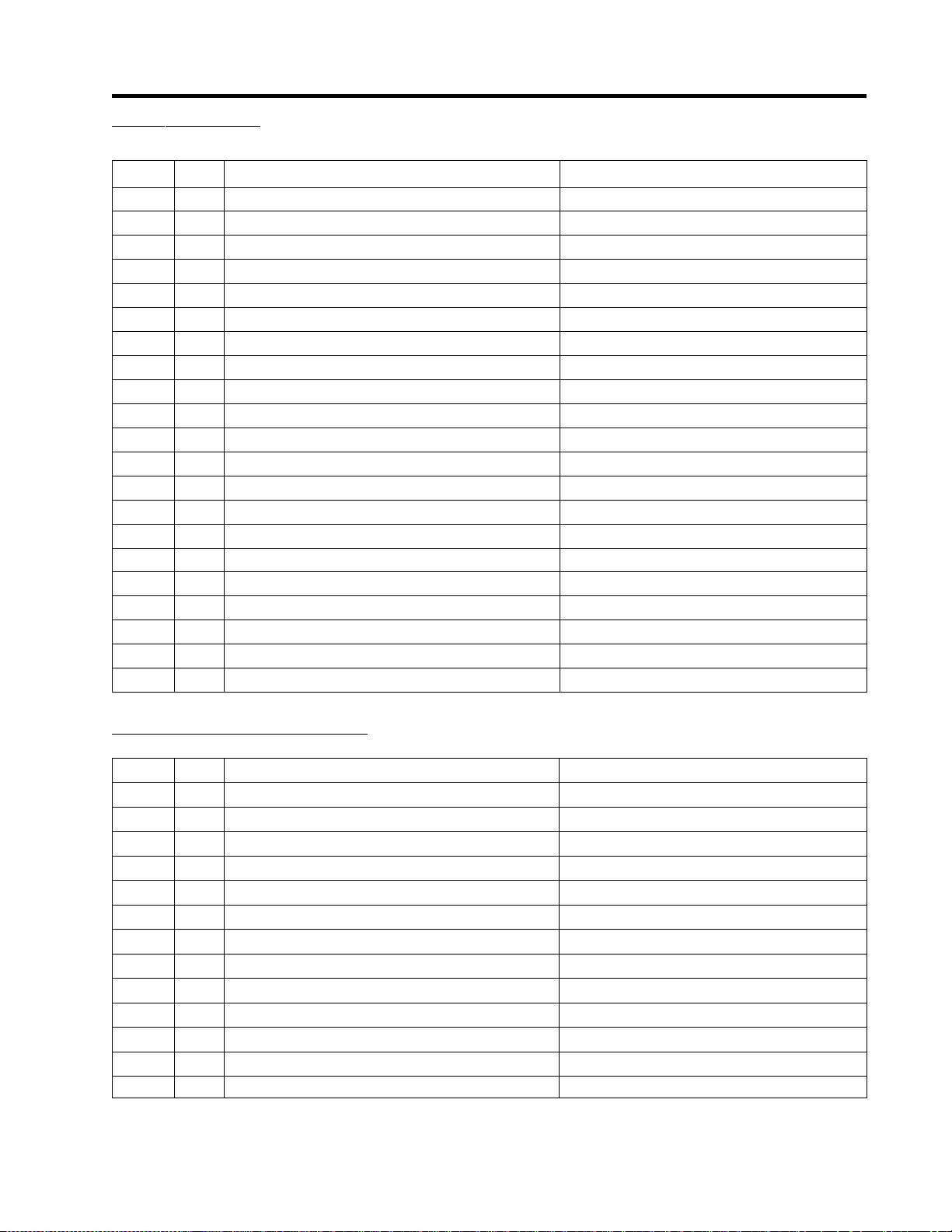

Modbus Memory Map ..............................................................................................................................8.4

Modbus Map Data Format .......................................................................................................................8.6

9 Commissioning ............................................................................................................ 9.1

Overview ..................................................................................................................................................9.1

Requirements........................................................................................................................................... 9.1

RTD Input Test .........................................................................................................................................9.1

Heater Volt age and Current Test ..............................................................................................................9.2

Ground Fault Current Test........................................................................................................................9.3

Alarm Output Test ....................................................................................................................................9.3

Override Input Test...................................................................................................................................9.4

Placing the Controller in Service ..............................................................................................................9.4

Completing the Installation ....................................................................................................................... 9.6

Warranty

The manufacturer warrants each control that it manufactures to be free from

defective material or workmanship for a period of 12 months from date of

purchase.

Under this warranty , the obligation of the manufacturer is limited to repairing

or replacing the defective control at its option, when returned to the manufacturer’s factory with shipping charges prepaid.

If failure has been caused by misuse, incorrect application or alteration of the

control, this warranty will be void.

UNLESS SPECIFICALLY PROVIDED FOR IN WRITING IN THIS WARRANTY, EACH CONTROL IS PROVIDED WITHOUT ANY WARRANTY OF

ANY KIND EITHER EXPRESSED OR IMPLIED. IN PARTICULAR, WITHOUT LIMITING THE GENERALITY OF THE FOREGOING, THE FOLLOWING IMPLIED WARRANTIES AND CONDITIONS ARE EXPRESSLY DISCLAIMED:

a). ANY IMPLIED WARRANTY OR CONDITION THA T THE CON-

TROL WILL MEET YOUR REQUIREMENTS.

b). ANY IMPLIED WARRANTY OR CONDITION THA T THE OP-

ERA TION OF THE CONTROL WILL BE UNINTERRUPTED OR

ERROR FREE; AND

c). ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANT ABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

The user shall be made aware that if the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may

be impaired.

CM2001

Introduction

The CM2001 single-point heat tracing controller uses a

microprocessor and is intended for stand-alone heat trace

applications. It can be for use with mineral-insulated, selfregulating or constant-wattage cable for freeze protection,

process control and instrument tracing. The CM2001 is

intended for indoor or outdoor installations in ordinary or

hazardous locations.

CM2001 offers many advantages over other heat tracing

control schemes, which generally use some combination

of mechanical thermostats, custom-built panels or programmable controls to provide control, monitoring and

alarm functions. Budgetary constraints usually limit the

degree of system fault monitoring to less than optimal

levels. This results in periodic costly process shutdowns

due to process or hardware malfunctions. Equipment

reliability concerns often force plant procedures to

include annual thermostat performance checks to ensure

that the device is still operating as intended. This can be

a tedious, labour intensive job.

Chapter 1

A controller is mounted near the pipe being traced to

monitor the heater point. This controller can communicate with a single master unit to give complete system

monitoring and control from a convenient location. Up to

32 controllers can be monitored on a RS485 data highway

to a centrally located master. By connecting controls to a

data highway , the CM2001 can immediately flag alarms

caused by heat tracing malfunctions, altered setpoints and

monitor actual values from a central location. Each local

control is completely independent and will continue to

function if the master fails or if the communication link

fails. This ensures maximum reliability and minimizes

vulnerability in the event of a hardware failure. Additional points can easily be added at any time as easily as a

mechanical thermostat can be installed. Unlike control

schemes using programmable controllers, no software

development is required. The complete system is operational as soon as it is installed.

Product Overview

Figure 1.1 Typical CM2001 Installation

1.1

CM2001

Chapter 1

Product Overview

Specifications

Temperature Input

Range: -50 to +500°C (-58 to 932°F)

Accuracy: ±2°C

Repeatability: ±1°C

RTD: Two, 100 ohm platinum, 3-wire RTD

20 ohms maximum lead resistance

Heater Switching

Configuration: -S1 single pole or -S2 two pole

dual SCR per phase

800 amp 1 cycle inrush

Ratings: 85-280Vac, 30A continuous

Line Frequency: 50 or 60Hz

Current Measurement: 0.1 to 30A 3%±0.2A

GF Measurement: 10 to 1000mA 5%±2mA

Voltage Measurement: 0 to 300Vac 3%±2V

Control Power

Power Requirement: Control power from heater voltage

85-280VAC, 10VA max

Protection: Control power from heater voltage

protected by 2A fuse

MOV transient protection

Communications

Port: (1) Serial network connection

Type: RS485

Protocol: Modbus® RTU.

Transmission Rate: 600,1200, 2400, 4800, 9600 baud.

Interconnect: 2-wire, shielded, twisted pair.

Highway Distance: 4,000 feet without repeater.

Modules per Highway: 32 Control Modules.

Measured Values

Temperature: -50 to 500°C (-58 to 932°F)

Minimum Temperature: -50 to 500°C (-58 to 932°F)

Maximum Temperature: -50 to 500°C (-58 to 932°F)

Heater Current: 0.1 to 60A

Ground Fault Current: 10 to 1000mA

Min. Heater Voltage: 85 to 300Vac

Max. Heater Voltage: 85 to 300Vac

Power Consumption: 0 to 1,000 MWh

Operating Cost: 0 to $1,000,000.00

User Interface

Display: 16-character x 2-line LCD Alpha-

numeric display

Keypad: 9 tactile keys, polyester faceplate

- Setpoint, actual, status

- Message Up, Message Down

- Value Up, Value Down

- Reset

- Enter

Contrast: Adjustable by potentiometer

Panel Indicators: Power on

Heater on

Serial communication active

System fail

Process alarm

Security: Controller parameters password protected

Environment

Approvals: CSA NRTL/C and FM

Class I, Div. 2, Groups A,B,C,D

Class I, Zone 2, Groups IIC

Class II, Div. 1, Groups E,F and G

Class III

Operating Temperature: -40°C to +50°C

Conformal Coating: Boards conformal coated for hostile

environments

Enclosure

Type: Nema-4X

Material: -N4XS stainless steel painted black

-N4X steel painted black

Size: 10”Hx8”Wx6”D

Features: Quick release latches to open door

Flat aluminum plate to act as heatsink

and mounting flange for mounting on

Uni-Strut.

One 3/4” conduit knockout for power

and three 1/2” conduit knockouts for RTD

and signal wiring.

Alarm Output

Alarm: Programmable for NO or NC contacts

One DC opto-isolated contact

One AC triac contact

Alarm Rating: DC contact: 30Vdc/0.1A, 500mW max

AC contact: 12-240Vac@0.5A max

Alarm Output: LED Indicator: 5Vdc/50mA

Alarm Function

Temperature: High Temperature Alarm

Low Temperature Alarm

Current: Low Current Alarm

High Current Alarm

Ground Fault Current: Ground Fault Current Alarm

Ground Fault Current Trip

Voltage: High Voltage Alarm

Low Voltage Alarm

Hardware: Self-Check Failure

Switch Shorted

RTD Open

RTD Shorted

Continuity

User-Definable Options

Heater Status: Enable or Disable

Heater Name or Tag: 16 Character Alphanumeric

Temperature Units: °C or °F

Proportional Control: on or off

Deadband: 1 to 50C° (1 to 100F°)

PowerLimit: 0.1 to 30A, off

SoftStart: 10 to 999s, off

TraceCheck: 1 to 24hrs, off

Temperature Setpoint: -50 to 500°C (-58 to 932°F), off, none

High Temp Alarm: -50 to 500°C (-58 to 932°F), off

Low Temp Alarm: -50 to 500°C (-58 to 932°F), off

High Current Alarm: 0.1 to 30A, off

Low Current Alarm: 0.1 to 30A, off

Ground Fault Alarm: 10 to 1000mA, off

Ground Fault Trip: 10 to 1000mA

High Voltage Alarm: 85V to 300V, off

Low Voltage Alarm: 85V to 300V, off

RTD Definition: Single, Backup, Highest, Lowest,

Average or High Temperature Cutout

RTD Fail-safe: Heater On or Heater Off

Heat Trace Curve: disable, user, LT3, 5, 8, 10

HLT3, 5, 8, 10, 12, 15, 18, 20

Override: On or Off

Alarm Contacts: NO or NC for each contact

Alarm Light: Alarm on, Alarm off, Flash during alarm

then on, Flash during alarm then off

Ground Fault Trip

Maximum Trip Time: 3.7 seconds

1.2

CM2001

Summary of Features

Chapter 1

Product Overview

Inputs

2-RTD Sensors

1-Override

Monitoring

RTD Temperatures

Heater Current

Heater Voltage

GF Current

Alarms

Low and High Current

(Compensated by heat trace curve for

Self-regulating cable)

Low and High T emperatures

Continuity

GF Alarm

GF Trip

Switch Failure

Sensor Failure

Self-Test Failure

Outputs

1-AC Triac Contact

1-DC Opto-Isolated Contact

1-LED Alarm Indicator

Statistics

Minimum and Maximum T emperatures

Maximum Current

Maximum Ground Fault

Minimum and Maximum Voltage

Energy (MWh)

Energy Cost

Control

Temperature (On/Of f- Deadband)

Temperature -Proportional

PowerLimiting

Softstart

Early Warning (TraceCheck)

Low and High Current

Continuity

GF Alarm

GF Trip

Communications

1-RS485

Modbus Protocol

Environment

CSA Certified and FM Approved for Hazardous

Locations

W eatherproof, NEMA-4X Enclosure

-40°C to +50°C Operating Temperature Range

User Interface

32 Character LCD Display

LED Indicators on Faceplate

Clear, English Language Messages

Intuitive Message Structure

Tactile Keys

Access Security

Using This Manual

Detailed information relating to switch and output ratings,

accuracy and so forth are detailed in Chapter 1 Specifica-

tions. Chapter 2 Installation discusses important mounting and wiring issues for reliable operation. Chapter 3

Getting Started provides a step-by-step tutorial for a heat

trace application. The remainder of this manual should be

read and kept for reference to provide the maximum

benefit of the CM2001.

Conventions

The following conventions are used in this manual.

? User Changeable Values

& Retrieved Data

[ ] Key Press

Shipping Content

CM2001 Heat Trace Controller

CM2001 Instruction Manual with Warranty Card

1.3

CM2001

Theory of Operation

Controller functions are controlled by a Intel 80C32 8-bit

microprocessor that measures all analog signals and logic

inputs, control heater output and alarm contacts, and

reads all user input including communications and outputs

to the faceplate display and LEDs. Consult the hardware

block diagram in figure 1.8 for details. The remainder of

this chapter describes the algorithms and operation of

some of the controller functions.

RTD Sensing

Chapter 1

linearization algorithm.

Current, Ground Fault and Voltage Sensing

Current transformers and high impedance voltage dividers

are used to scale-down the incoming heater current,

ground fault current and voltage. All three signals are then

passed through a full wave rectifier and filter to obtain a

DC signal. The DC signals are then converted to digital

values by a 10 bit A/D converter before finally being

passed on to the CPU for analysis.

Product Overview

An RTD changes its resistance in a precision relationship

to temperature. This resistance is sensed by passing a

constant current through the RTD and measuring the

resulting voltage across the RTD (resistance = voltage/

current). The voltage appearing across RTD1 terminals

6&8 and RTD2 terminals 10&12 also includes the

resistance of the inter-connecting wiring to the R TD,

which varies with wire length, size and ambient temperature. By using a three-wire sensing scheme and a lead

resistance compensation circuit, the lead resistance is

cancelled out to give a voltage proportional to the true

R TD sensor temperature.

R TDs respond in a known but non-linear fashion to

temperature, which if uncorrected could lead to significant errors over the temperature range of the controller.

Consequently , some means is needed to convert the input

voltage to a linear and useful range. The CPU applies

gain, offset and non-linearity corrections through a

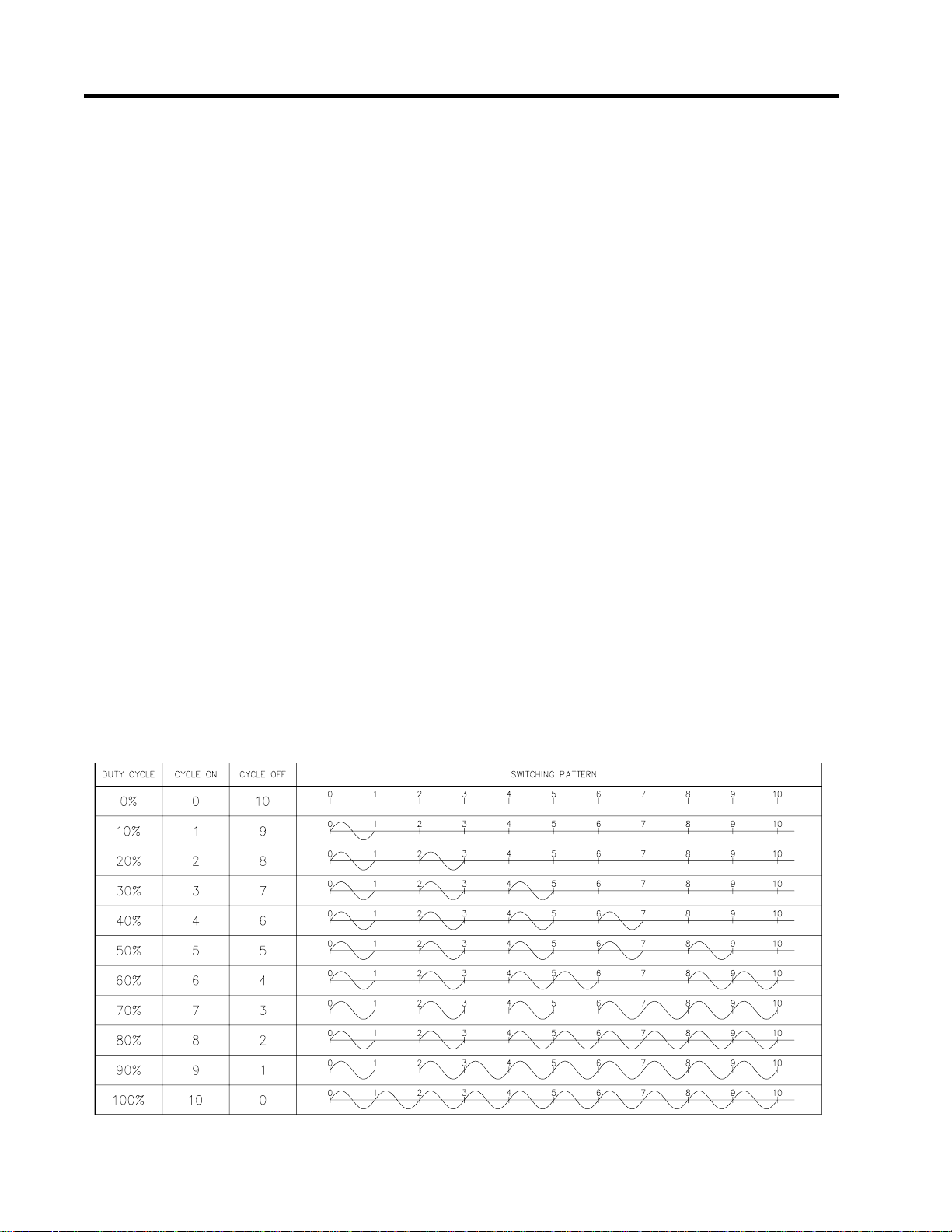

Figure 1.2 Cycle Modulation - 10 Cycle Frame

Each of the three DC signals are sampled 300 times with

zero cross synchronization so that the sampling covers an

exact span of ten power cycles. This is to ensure that

heater current values are consistently measured when the

heater output cycle is modulated by the powerlimit,

softstart or proportional control functions.

Powerlimit

The powerlimit function allows the heater to operate

below its rated power by cycle modulation. Cycle

modulation is accomplished by controlling the integral

number power cycles into the heater over a periodic time

frame. The CM2001 uses a ten cycle time frame. The

integral number of power cycles per time frame is called a

duty cycle. With a ten cycle time frame, there are ten duty

cycles possible. For each duty cycle, there is a fixed

pattern that defines the number of power cycles in which

the heater is on and off. This is shown in figure 1.2:

1.4

CM2001

Chapter 1

Product Overview

Cycle modulating the current through the heater has the

effect of turning the heater on and off rapidly and

therefore, power output is reduced in the long run. Since

the switching is zero-cross controlled, the controller

knows exactly when power cycles start and finish. Zerocross switching also helps reduce power harmonics that

generate unnecessary interference.

The heater current (average current) measured by the

controller while cycle modulation is in effect may be

approximated as follows:

Heater Current at 100% x Duty Cycle = Average Current

When powerlimit is enabled, a powerlimit current is set

by the user. This is essentially the desired average current.

The powerlimit control algorithm ensures that the actual

current will not exceed the powerlimit setting while

optimizing the maximum duty cycle possible. When the

average current exceeds the powerlimit setting, the duty

cycle is reduce by 10%. When the average current is

below the powerlimit setting, the duty cycle is increased

by 10%. Before the algorithm increases or decreases the

duty cycle, the controller waits until the heater current has

reached steady-state at the current duty cycle setting. If

the heater is initially off and the controller calls for heat,

the duty cycle starts at zero and increases by 10%

increments until it reaches a steady-state value. This

ramping up effect provides a current-driven softstart

whenever the controller calls for heat unlike the softstart

function, which is time driven.

Softstart

During cold temperature startups with self-regulating heat

trace cables, the current driven softstart built into the

powerlimit function may not be long enough to overcome

the inrush current. The softstart function is separate from

powerlimit and is time driven where for when you set the

softstart period. Having the two separate functions is

desirable when powerlimit may not be required by the

application but softstart is essential to avoid nuisance

breaker trips during cold startups. The controller applies

the softstart function initial startup when the controller is

powered up.

During controller power-up and assuming the controller is

calling for heat, the duty cycle starts at 10% and increments by 10% until full power is reached. Since there are

ten duty cycle increments, the time that the controller

maintains each duty cycle setting is the softstart setting

(softstart period) divided by 10. The softstart operation

powerlimit and proportional control off is shown by the

curve in figure 1.3.

Figure 1.3 Softstart Curve with Powerlimit and

Proportional Control Disabled

With powerlimit enabled, the only dif ference is that

instead of the duty cycle ramping to 100%, it stops at the

value determined by the powerlimit function such that the

average current does not exceed the powerlimit current

set by the user. The maximum duty cycle setting is

approximated by the controller initially so that the time

period for each duty cycle increment can be determined.

The softstart operation with powerlimit enable is shown

by the curve in figure 1.4.

Figure 1.4 Softstart Curve with Powerlimit Enabled

Operation of the softstart function varies depending on

whether or not powerlimit and/or proportional control are

enabled. When powerlimit and proportional control are

off, operation is simplified. The softstart function uses

cycle modulation to gradually increase power output over

the softstart period. Since most circuit breakers are the

thermal type, the cycle modulated output appears as a

reduced load to the circuit breaker.

When proportional control is turned on, the maximum

duty cycle available to the controller is constrained by the

powerlimit current if enabled and softstart.

1.5

CM2001

Proportional Control

Chapter 1

Product Overview

Unlike on/off control where the heater is fully on or off,

proportional control can partially turn on the heater. The

heater output is proportional to the difference between

actual temperature and heater setpoint. The relationship is

expressed as follows:

(actual temperature – heater setpoint) x k = heater output

where k is the proportional gain

T o partially turn on the heater, the proportional control

function uses cycle modulation in the powerlimit function.

By incorporating cycle modulation into the proportional

control equation, the algorithm is expressed using the

following equations:

0)(0)(

≤=

teiftd

)(

te

)(

td

DB(t)

<<=

≥=

=

td

cycleduty)(Where

tDB

Ts

T(t)

ÿTTs-T(t)e(t)

t

The deadband factor DB(t) is a time constant that

determines the slope of change of the proposed heater on

duty cycle with the temperature difference. It is adjusted

between 1 to 10 each hour to minimize the difference

between the measured temperature and the temperature

setpoint. Every hour after power up, the controller

calculates the absolute values of the temperature

differences e(t) and sums them during the hour. Then the

total absolute temperature difference is divided by the

number of temperature readings taken during the hour.

The result is called the Average Absolute Temperature

Difference (AATD) for the hour. If current AA TD is

smaller than the AATD in the previous hour , the deadband

factor will be increased or decreased in the same

direction. If current AATD is larger than the AA TD in the

previous hour, the deadband factor will be increased or

decreased in the reversed direction. At steady state, the

deadband factor used will fluctuate around a optimum

value.

=

secondsintime

)()(0

tDBteif

)()(1)(

tDBteiftd

°=

C)(peratureheater tem

°=

C)(

°==

cycle)C/duty(infactordeadband)(

C)(emperaturesetpoint theater

°=

Figure 1.5 shows the relationship between the proposed

heater on duty cycle and the temperature difference for

different deadband factors used.

Figure 1.5 Proportional Control

Duty Cycle vs. Temperature Difference

On/Off Control with Deadband

The default control mode of the controller is deadband

control or simply on/off control with the proportional

control setting turned off. On/off control without

deadband (that is deadband set to 0 C° or 0 F°; note that

these units denote the temperature differential with “°”

placed to the right of the unit) means that the heater turns

on when actual temperature is below setpoint and turns

off when above setpoint. However, this causes oscillations

when the actual temperature is very close to setpoint. To

eliminate oscillations, hysterisis is applied to the on/off

control by a deadband value. The on/off control with

deadband operation is described by the hysterisis curve in

figure 1.6. Assume that actual temperature is well below

(setpoint - deadband setting), the controller calls for heat.

As the actual temperature rises, the controller continues to

call for heat until the actual temperature has reached

(setpoint + deadband setting). The controller no longer

calls for heat and the heater is off. As the actual

temperature cools, the controller does not call for heat

until the actual temperature reaches (setpoint – deadband

setting). The hysterisis effect is controlled by the

momentum of the actual temperature rather than the

temperature value itself.

1.6

CM2001

Chapter 1

Product Overview

Figure 1.6 On/Off Control with Deadband

Heat Trace Curve

Monitoring low and high current alarms on self-regulating

heat tracing cable is difficult. Choosing a high current

alarm setting based on cable characteristics near the

heater setpoint temperature will produce nuisance alarms

during startup. Choosing a low current alarm setting other

than below the current draw of the cable at heater setpoint

temperature produces nuisance alarms. The heat trace

curve function allows you to program the cable characteristics so that the controller can offset the current alarm

settings.

Figure 1.7 Heat Trace Curve

The heat trace curve is described by the following linear

equation:

W = aT + b

where, W is the Watt/ft at temperature T (in degree F), a

and b are the slope and offset of the linear curve.

If the Watt per foot value of the heat trace is Ws at

setpoint temperature Ts, and the Watt per foot value of the

heat trace is W at temperature T, the offset ratio to be

applied to the high/low current alarm level is Ws/W.

That is, if the high/low current alarm level is set to Is, the

current draw of the cable at setpoint temperature of Ts,

then the high/low current alarm level at operating temperature T should be corrected to (Ws/W)*Is to compensate the effect of operating temperature on the allowed

maximum/minimum heater current. The heat trace curve

is shown in figure 1.7.

If no heat trace curve is used, the offset ratio is set to 1

and no correction to the high/low current alarm level is

done.

1.7

CM2001

Figure 1.8 Hardware Block Diagram

Chapter 1

Product Overview

1.8

CM2001

Unpacking the Controller

Chapter 2

Installation

Check the shipping cartons for damage, or other signs of

rough handling or abuse. If damaged, notify the shipping

carrier at once.

Carefully remove the CM2001 from the shipping box.

Save the packing materials in case the unit needs to be

transported at a later date.

Inspect face plate for damage and check electronics for

loose wiring or damage. Report any damage to the carrier

at once.

Control Module

See Figure 3.1 Main Board Layout and Figure 3.2 Power

Board Layout to locate the following:

•S1 Address Enable: When the switch is set to DIS, the

Module Number cannot be changed from a master on

the data highway. When set to EN, the Module Number

can be changed for the next two minutes from a master

on the data highway. During this time the ADDRESS

ENABLE light is on.

•S2 Program Enable: When the switch is set to DIS,

programming is disabled; setpoints and configuration

cannot be changed. When set to EN, programming is

allowed.

•S3 RS485-120: When the jumper is set to IN, the

RS-485 line is terminated by a 120 ohm resistor. Only

the last Control Module on the data highway should be

set to IN.

Terminals: Refer to Figure 3.1 Typical Wiring Diagram,

for power, heater and RTD field connections.

•T1 Alarm Contacts: The opto-isolated dc output is

rated 30 Vdc @ 0.1 A (terminals 22 and 23) and the

triac ac output is rated 240Vac@0.5A (terminals 20

and 21). Contacts are configurable for normally open

or closed.

•T2 Alarm Light Output: The output is configurable for

normally open, closed or flash. Output is rated 5 Vdc

@ 50 mA for an LED type lamp (terminals 18+ and

19-).

• T3 Override Input: W ith the Override function

(SETPOINTS\HEATER SETUP\OVERRIDE) set to

on, the heater output is affected by the override input.

When the terminals are open, the heater is forced off.

When the terminals are closed, the heater is controlled

by the RTDs unless the heater setpoint is set to of f. In

this case, the heater is solely controlled by the override

input. The logic of this input allows either ambient

temperature override or load shedding on multiple

controllers (terminals 24+ and 25-).

•T4 RTD1A and RTD1B Inputs: 3 wire RTD input.

Ground terminal connects to shield or case. Lead

resistance compensated. (terminals 6-13).

•T5 Earth Ground: (terminal 1).

•T6 Heater Power Input: 85-280Vac/30A max

continuous ( terminals 2 and 3).

•T7 Heater Power Output: 85-280Vac/30A max

continuous ( terminals 4 and 5).

•T8 Safety Ground: Terminate to ground stud. Termina-

tion of safety ground is required for transient protection circuit on RTD inputs and RS485 serial port to

operate properly (terminal 14).

Status Lights:

•L1 Power: Light is on when control power is present.

•L2 Address Enable: Light is on when controller is in

Address Enable mode. Light must be on to allow the

Module Number to be changed from a master on the

data highway.

•L3 Transmit: Flashes when data is being transmitted

from the serial port to the data highway.

•L4 Receive: Flashes when data is being received at the

serial port from the data highway .

•L5 Override: Light is on when the Override Input terminals are shorted.

Communication Ports:

•C1 Interface to Main/Power Board: Connector to

interconnect power and main board via ribbon cable.

•C2 Serial Port 1: Connection to an RS-485

data highway via a 2-conductor, shielded, twisted pair

cable. Maximum Cable length with 32 devices without

repeater is 4,000 feet. ( terminals 15+, 16-,17 SHD).

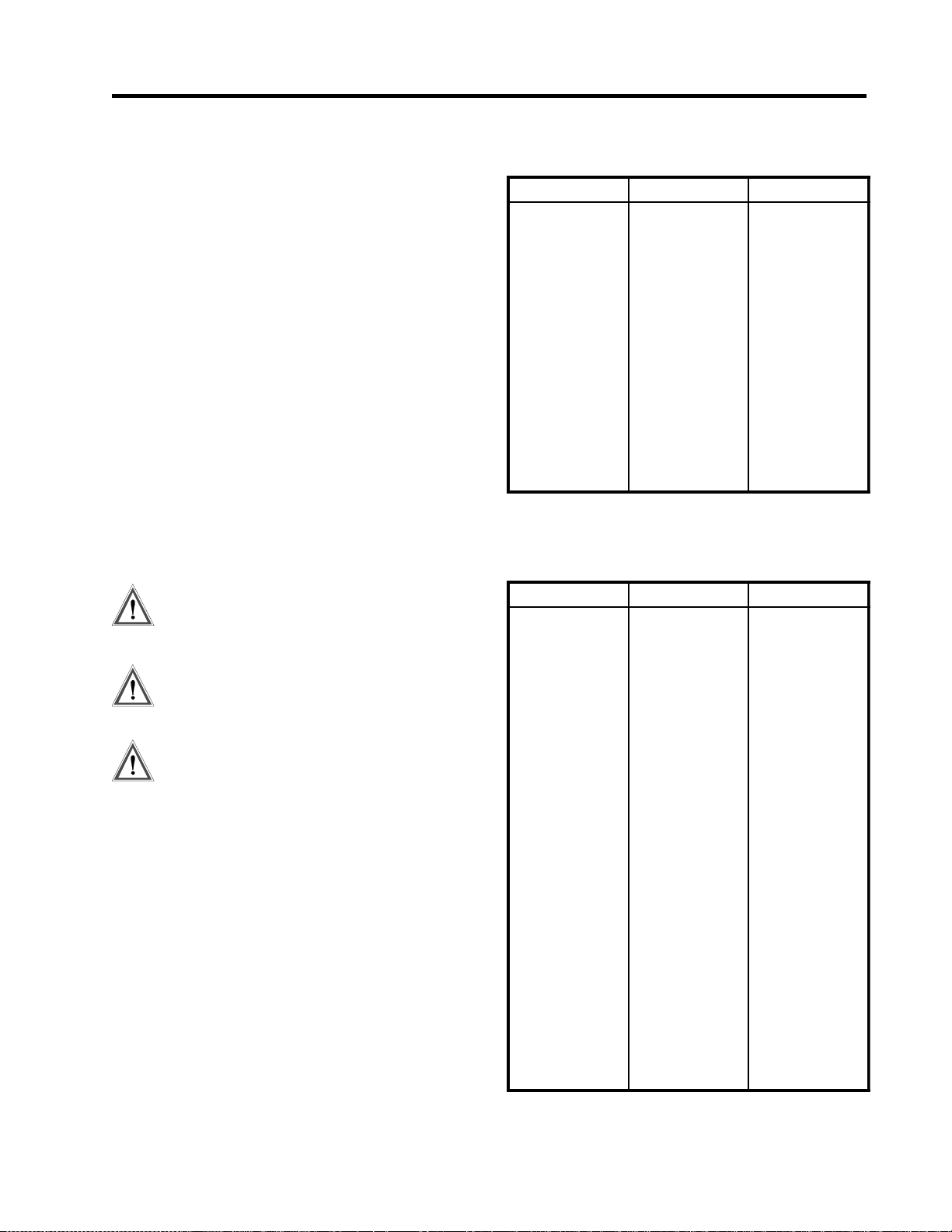

Warning - The ground fault trip function is

intended for equipment protection only and

should not be used in place of ground fault

protection for personnel protection where

this is required.

2.1

CM2001

Figure 3.1 Main Board Layout

Chapter 2

Installation

Figure 3.2 Power Board Layout

2.2

CM2001

Chapter 2

Installation

Mounting the Controller

Mount the control panel with Unistrut brackets using 1/2”

bolts. The Unistrut (or equivalent) mounting allows air

circulation to cool the heat-sink. This is important to

ensure proper operation of the CM2001. For optimum

readability, mount with the display at eye level and not

in direct sunlight. Mounting dimensions are shown in

Figure 3.6.

Wire Sizing

Wiring methods should comply with Canadian

Electrical or National Electrical Code and

local codes. Power and signal wires should not

be run in the same conduit system. Wiring

should be rated at least 90 °C.

)GWA(eziSeriW)A(daoLtnerruC

60305

80304

014205

216105

tneibmA.xaM

suitable for #10 stud.

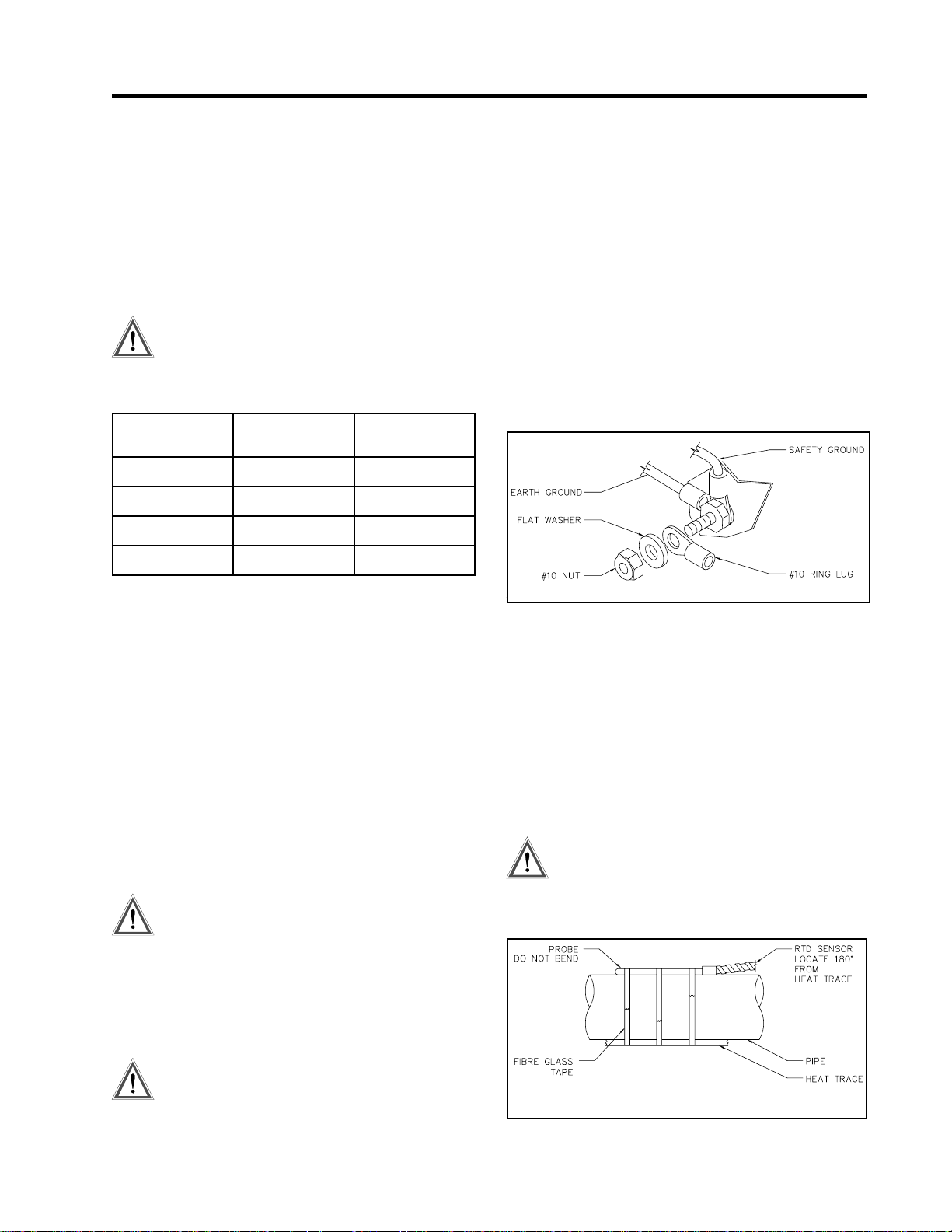

Ground Connection

Connect the controller grounding stud directly to a ground

bus using the shortest, practical path. Use a tinned copper,

braided bonding cable such as Belden 8660. As a guideline, the ground cables should be minimum 96 strands,

number 34 AWG each.

The grounding is not only a safety requirement but is

necessary for the input transient protectors or the RTD

and communication inputs to work properly. The transient

protection network is grounded through terminal 14,

safety ground, which is bonded to the chassis ground stud.

T o install the ground connection, remove the outside nut,

washer and #10 ring lug provided on the ground stud.

Crimp the ground cable onto the ring lug and re-assemble

Figure 3.3 Ground Connection

onto the ground stud using the washer and nut.

)C°(erutarepmeT

Conduit and Cabling

The CM2001 comes with one 3/4” and two 1/2” conduit

knockouts located on the bottom of the enclosure.

Conduit hubs should be NEMA-4X rated, such as T&B

H050-0.5 and H075-0.75 or Myers equivalent, to maintain a watertight seal. Unused knockouts should be sealed

using NEMA-4X rated seals.

Power Wiring

The power input terminals supply power to both the heat

trace and controller. Size power input wires appropriately

to the breaker size and maximum ambient operating

temperatures. Maximum breaker size is 30A. Connect

power wires to input terminals 2 and 3. See Figure 3.7.

The supply voltage must be within the power

supply range of 85-280Vac and rated voltage

range of the heat trace cable.

Heater Wiring

Connect heating cable wiring to terminals 4 and 5. See

Figure 3.7. If the heating cable has a braid, it should be

terminated to the ground stud using a ring terminal

RTD Sensor Wiring

R TD sensors should be 3-wire, 100 ohm, platinum to DIN

standard 43760. Mount the RTD element on the pipe,

away from the heat trace and 30° to 45° from the bottom

of the pipe. The total circuit resistance per conductor

from the RTD to the control panel must be less than 10

ohm. Exceeding this resistance will result in a non-linear

temperature measurement. Beldon cable 8770 or equivalent allows RTDs to be placed up to 1,000 feet from the

control panel. Complete all RTD wiring according to

Figure 3.6 Typical Wiring Diagram.

The RTD probe is delicate and should not

be bent or used as a tool to puncture

insulation.

Figure 3.4 RTD Mounting

Wiring methods must conform to Class I,

Division 2 or Class I, Zone 2 requirements.

2.3

CM2001

Chapter 2

Installation

You must install the RTD sensor on the pipe surface or

thermal well before the pipe insulation to ensure proper

thermal contact. The RTD position should be 180° from

the electric heat trace cable which is the coldest spot of

the pipe. The R TD sensor may be secured to the pipe by

fiber-glass tape. If additional wiring is required for the

R TD, shielded 3-lead wire sized 18 or 20AWG must be

used for the RTD sensor to minimize the effects of noise

pickup. A typical RTD installation is shown in Figur e 3.4.

Communication Wiring

The CM2001 is equipped with a communication port that

provides continuous monitoring and control from a

remote computer, SCADA system or PLC. Communications protocol is Modicon Modbus as discussed in the

communications chapter.

Communication is RS-485 mode where data transmission

and reception are done over a single twisted pair with

transmit and receive data alternating over the same pair of

wires.

Shielded twisted pair such as Beldon cable 9841 or

equivalent is recommended to minimize error from noise.

You must observe polarity. For each CM2001 controller,

you must connect A+ terminals together and B- terminals

together. The shield terminal (labelled SHD) connect to

shield wire of the cable.

T o avoid loop currents, the shield should be grounded at

one point only. Connect between controllers in daisychain fashion. The total length of this daisy-chain should

not exceed 4,000 feet. The maximum number of devices

connected is 32 to avoid exceeding driver capability. Y ou

can use commercially available repeaters to increase the

number of devices over 32. Avoid star or stub

connections.

T erminate the first and last device in the daisy-chain loop.

Each controller is equipped with a termination jumper as

shown in Figure 3.2.

The controller comes unterminated from the factory

(JP401 and JP402 in OUT position). If the controller is

the first or last device, it can be terminated by moving the

two jumpers (JP401 and JP402) to the IN position.

The communication port is powered by an isolated power

supply with opto-coupled data interface to eliminate noise

coupling. In addition, surge protection devices are

employed at the front end of the port to protect against

lightening strikes and ground surge currents. These may

cause large, momentary voltage differences between

devices on the data highway .

Alarm Wiring

The CM2001 has two passive alarm contacts and one

active alarm output for driving an LED alarm indicator.

Both the alarm contacts are software configurable for

normally open or closed. The alarm LED output is

software configurable for alarm on, alarm off or flash

during alarm. Refer to Figure 3.7 for alarm output

terminals.

The AC triac alarm output is rated 12-240Vac, 0.5A. The

DC alarm output is an opto-isolated transition output

rated 30Vdc/100mA, 500mW max.

The alarm LED output is rated 5Vdc, 50mA. It can drive

a 6Vdc LED indicator. Alarm outputs are designed for

interface to annunciator, panels, PLC or DCS.

Figure 3.5 Communication Wiring

2.4

DC ALM

Rev. 1

May, 2005

CM2001

Introduction

The CM2001 has many features that provide trouble-free

operation of heat tracing installations.

An example is presented to illustrate CM2001 setup and

operation on a specific installation. CM2001 is easy to

program and setting up a unit to your specific requirements should be straight forward.

In this example, a CM2001 will control a heavy feed line.

Chapter 3

Install and commission the control in the following order:

STEP 1: Enabling the heater

STEP 2: Entering setpoints

STEP 3: Testing heater and alarms

STEP 4: Monitoring system status

Enabling the Heater

Getting Started

Example: Heater will be programmed as:

Configuration:

1) 2 RTDs for temperature sensing

2) Mineral insulated (MI) cable is used for the heater.

3) Normally open alarm contact to remote programmable

control

4) Northern climate installation outdoors.

Operating temperatures: -40° to +40 °C

NEMA-4X weatherproof enclosure.

tniopteSderiuqeRegnaR

niatniamdiulF

erutarepmet

erutarepmetwoL

mrala

erutarepmethgiH

mrala

retaehlanimoN

tnerruc

retaehlanimoN

egatlov

pirttluafdnuorG

tnerruc

mralatluafdnuorG

tnerruc

esicrexemetsyS

lavretniemit

ttawoliKreptsoC

ruoh

emanretaeHLIOYVAEH

F°221ffo/F°239ot85-

enon/

F°59ffo/F°239ot85-

mralaonffo/C°003ot05-

spma5A0.001ot0.0

ffo/

CAV511caV006ot001

Am03Am0001ot01

Am02Am0001ot01

ffo/

sruoh8ffo/42-1

60.0$05.0$-10.0$

sretcarahc61

ENIL

T o enable the heater circuit,

1. Press [SETPOINTS] once to access the Setpoints

Operating Values group of messages.

2. Press [MESSAGE ò] until the following message

appears:

HEATER ENABLED?

NO?

3. Press [VALUE ñ ] or [VALUE ò] keys to toggle

Heater Enabled between YES and NO.

4. When YES is displayed, press [STORE].

Now that the heater circuit is enabled, we can program

setpoints for each control.

Entering Setpoints

Accessing the Program: Since the heater control display

and keypad are normally accessible to passers-by who

may wish to read measured values, a program disable

feature is used to prevent accidental changes to the

setpoints. So before any setpoints can be entered, the

PROGRAM ENABLE dip switch (located on the bottom

of the board behind the enclosure door) or PROGRAM

ACCESS function (SETPOINT\SYSTEM

SETUP\PROGRAM ACCESS) must be set in the ENABLE position.

When programming is complete, set the PROGRAM

ENABLE dip switch and PROGRAM ACCESS function

to DISABLE to prevent accidental changes to the

setpoint.

If you try to store a setpoint without the dip switch or

PROGRAM ACCESS function in the ENABLE setting,

the setpoint will not be saved and this message will flash

on the screen:

NOT STORED

PROG DISABLED

Now that the CM2001 control is ready for programming, l

enter the setpoints for this example. For further information about the organization of all the messages or for

details on the range and application of each message see

3.1

CM2001

Chapter 3

Getting Started

Chapter 6 Setpoint Values. It is not necessary to enter

setpoints in any particular order and any setpoint can be

changed later.

Entering Temperature Units °C/°F: Temperature values

can be displayed in degrees Celsius or Fahrenheit. To

enter values in preferred units, enter this selection first.

T o enter temperature units,

1. Press [SETPOINTS] 3 times for System Setup mode

and [MESSAGE ò] 5 times until the following

message is displayed:

TEMPERATURE

UNITS: Celsius

2. Press [VALUE ñ] or [VALUE ò] to toggle selection

between Celsius and Fahrenheit.

3. When Fahrenheit is displayed press [STORE]. A brief

message appears:

SETPOINT

STORED

Then the message reverts back to the previously

entered value for verification. If instead you get the

message:

NOT STORED -

PROG DISABLED

the PROGRAM ENABLE dip switch or PROGRAM

ACCESS function has not been set to the ENABLE

setting. This must be done to proceed with setpoint

programming.

Assuming the setpoint was stored, all values will be

displayed in °F . Temperature values can automatically be

converted to °C at any time by selecting Celsius using this

message.

TEMPERATURE

UNITS: Celsius

T o assign a heater name,

1.Press [SETPOINTS] twice to enter the Heater Setup

group of setpoints.

2. Press the [MESSAGE ò] key until the heater name

message appears:

HTR NAME:

NONAME ?

Note: The heater default name when CM2001 is

shipped from the factory is “NONAME”.

You can program each letter separately with upper and

lower case characters, numbers, space or the special

symbols !@#$%^&*()?.,”’:;}]{[. Uppercase characters are generally more legible. For this example the

name has arbitrarily been chosen as:

HEAVY OIL LINE

(The cursor appears under the first letter N in

“NONAME”).

3. Press and hold down [VALUE ñ] or [VALUE ò] until

the desired letter you want appears above the cursor,

then press [STORE].

4. Press [STORE] to save the current letter displayed and

advance the cursor to the next letter.

For Example:

H: Press [VALUE ñ] or [VALUE ò] until Happears.

Press [STORE]. The letter H now appears in the first

character position and the cursor is under the second

character.

E: Press [VALUE ò] until E appears. Press the [STORE].

The first 2 letters are now HE and the cursor is under

character position 3.

HTR NAME:

HENAME?

5. Continue entering each letter this way until the complete new name is displayed.

6. W ith the cursor under the last character position at the

right edge of the message screen (blank character),

press [STORE] until the cursor is at the end of the line.

A brief message will flash:

ASSIGNING HEATER NAME: T o assist operators in

troubleshooting, you can program each CM2001 control

with a heater name. You can assign up to 16 characters to

the name of the heater.

NAME

STORED

3.2

CM2001

Chapter 3

Getting Started

followed by the new name that has been stored:

HTR NAME:

HEAVY OIL LINE

The new heater name is now saved in non-volatile

memory and will remain until you change it.

If a character is accidentally entered incorrectly ,

1. Either press [RESET] to start over,

or

go to the end of the line to save the displayed message

with the error.

2. Press [MESSAGE ñ] or [MESSAGE ò] to exit and

return to the 1st character position.

3. Press [STORE] until the cursor is under the incorrect

character. Proceed as before until new letters are

entered.

4. Press [STORE] to skip over the correct letters until on

the last character position.

5. Press [STORE] to save the corrected message.

You can now enter setpoint information for the system

configuration and data for the heater. Turn to Chapter 6

Setpoint Values. Read the first few pages to see how the

messages are organized and get a summary of all

setpoints. Skip the latter part of this chapter which gives

a detailed description of each message.

ENTERING SETPOINT TEMPERATURE:

Set the desired maintained temperature for the fluid in the

pipe being traced by this heater temperature setpoint.

In this example, the temperature at which the control

will turn on and supply full system voltage to the heater

is now set to 112 °F.

4. Press [MESSAGE ò] after each setpoint to access the

next setpoint.

5. Hold [VALUE ñ] down until the word OFF appears to

defeat any setpoint not required. For example, if a

high current alarm is not required, set the value to off.

A detailed description of each message is found in

Chapter 6 Setpoint Values.

T esting Heater & Alarms

You can force heater and alarm outputs on using the test

mode. Like setpoints, this mode requires that the PROGRAM ENABLE dip switch or PROGRAM ACCESS

function be set to ENABLE or when you try to store a test

value a message will flash:

Testing a Heater:

T o test operation of a heater, it can temporarily be forced

on.

1. Press [SETPOINT] 4 times.

2. Press [MESSAGE ò] until the message appears:

SETPOINT

STORED

NOT STORED -

PROG DISABLED

To enter the heater setpoint,

1. Press SETPOINT] once to display this message::

HEATER SETPOINT

68 °F?

2. Press and hold [VALUE ñ] until 122°F is displayed.

Notice that if you press [VALUE ñ] once, the displayed temperature increments by 1. Holding [VALUE

ñ] causes the diplayed value to increment rapidly after

a short delay. [VALUE ò] works the same way. If you

pass the required value, use [VALUE ò] to decrease

the number displayed.

3. Press [STORE] to save the new value. When a new

value is successfully stored a brief acknowledgement

message will flash on the screen:

HEATER TEST

DISABLED?

3. Press and hold [VALUE ñ] or [VALUE ò] to set the

ON time in hours. The range is DISABLED/1-24

hours/ON-CONTINUOUSLY. For example, to turn

on the heater for one hour, press [VALUE ñ] to

display ‘1 hour’ then press [STORE]. The heater will

be energized no matter what the heater temperature

setpoint is unless there is a ground fault trip. After the

selected time period the heater will automatically go

off.

While the heater is on, the front panel HEA TER ON

indicator will be illuminated. To override the test

mode, press [VALUE ò] until DISABLE appears and

then store this value. Holding the [VALUE ñ] key

until the word ON CONTINUOUSL Y appears leaves

3.3

CM2001

Chapter 3

Getting Started

the heater always energized until the CM2001 controller

is manually powered off or until this setpoint is set to

DISABLE. Consequently, selecting a value of ON

CONTINUOUSLY should be used with caution since

it overrides normal control operation and could lead to

excessive heating or waste power if accidentally left

on. A warning message appears in the status mode

(press status key to enter status mode) whenever a

heater or alarm is forced on.

4. Press [STORE] to save the value.

5. W ith the heater forced on, verify that the expected

current is flowing using the actual current message,

located in ACTUAL\OPERATING VALUES\HEATER

CURRENT . You can use a clamp-on ammeter attached

to one of the heater wires to compare readings. W ith

proportional control selected, the readings may differ

due to harmonics in the current waveform. As a

safeguard, the heater will automatically timeout after

the selected time and go back to automatic operation.

Testing Alarms: The manual alarm setpoint works exactly

like the manual heaters setpoint except that it energizes

the output alarm and indicator. This setpoint is useful for

commissioning a new system or checking alarm circuits.

Normally this setpoint will be DISABLED.

Monitoring System Status

Now that the CM2001controller has been programmed

for a specific application, you can check system status. If

no keys are pressed for the time specified in DISPLAY

TIMEOUT message located in SETPOINT\SYSTEM

SETUP\DISPLAY TIMEOUT, the display will automatically go into the default message mode. System Status

mode is recommended; that is, the display will automatically display all alarms. If desired, you can change this to

a specific message later by reprogramming the default

message.

Access actual values by pressing [ACTUAL]. These are

divided into 2 groups. Pressing [ACTUAL] once accesses the group of messages that show current values of

temperature, current, etc. Pressing [ACTUAL] twice

displays the statistics data such as minimum/maximum

temperature, power consumption, running hours etc.

Unlike setpoints, you cannot change actual values using

[VALUE ñ] , [VALUE ò] or [STORE].

There is a summary of all Actual Values messages at the

beginning of Chapter 5 Actual Values.

T o view the actual values,

1. Press [ACTUAL].

2. Press [MESSAGE ò] to view each actual value.

3. Continue examining each value of interest by pressing

the [MESSAGE ò] key and referring to Chapter 5

Actual Values.

Monitoring Heater Temperature

T o monitor the heater temperature,

1. Press [ACTUAL] once to display:

CONTROL TEMP:

125 °F

This is the temperature value that the controller will use

with the heater setpoint to determine the heater output.

The CM2001 calculates the control temperature from the

actual temperature of RTD1A and RTD1B (if used) based

on the RTD DEFINITION setting (SETPOINT\HEATER

SETUP\RTD DEFINITION). Using only one RTD, you

must place the RTD probe at a location that best represents the average pipe temperature. However, fluid

temperature will vary somewhat along the pipe. Using

two RTDs and RTD DEFINITION set to TWO RTDs

AVERAGED eliminates this problem. If no RTD sensor

is connected or a lead is broken the value OPEN RTD

appears. This is an alarm condition.

When the temperature falls below the heater setpoint, 122

°F in our example, CM2001 switches on to supply power

to the heater. It stays on until the temperature rises above

the heater setpoint (122 °F). Once the system has been

running for a few hours, the heater temperature should be

at or above this setpoint value.

If hot fluid is being pumped through the pipe, the measured temperature may be much higher than the setpoint

temperature. But in this case, no power should be supplied to the heater and the HEA TER ON indicator will

be off.

If the heater temperature is less than the minimum display

value (-50 °C/-58 °F), the word RTD FAIL appears. If

the temperature is over the maximum value (+ 500 °C /

932 °F), the maximum value ( i.e. 500 °C ) will be shown.

If an abnormal value appears, particularly on a new

installation, check that the correct RTD sensor type has

been installed (100 OHM platinum DIN 43760) and that

the three RTD wires are wired to the correct terminals.

Monitoring Actual Current:

T o monitor the actual current,

3.4

CM2001

Chapter 3

Getting Started

1. Press [ACTUAL].

2. Press [MESSAGE ò] 5 times to display:

HEATER CURRENT

5.5 A

This value is the actual measured current of the heater.

Resolution is to 0.1 amp over a range of 0.0 to 60.0 amps.

Above 60.0 amps the value displayed reads O.L (Overload).

With MI (Mineral Insulated) cable used in this example, it

will either be 0.0 if the heater is not energized or a fairly

constant current such as 5.0 amps.

Monitoring Ground Fault Current: Some stray current

always flows to ground due to capacitance effects and

leakage.

T o monitor ground fault current,

1. Press the [MESSAGE ò] key from the heater voltage

message

or

Press [ACTUAL] then [MESSAGE ò] 6 times to

display:

GROUND F AULT

CURRENT: 15 mA

In this example, any value above 20 mA would cause an

alarm and if a ground fault current above 30 mA were

detected, CM2001 would remove power to the heater. If

the heater is off, the value displayed would be 0. For

values over 15 mA, check the system for insulation

leakage problems.

You have now checked all actual values.

Press [ACTUAL] twice to display the first message in

this group. Either way displays a brief message to

indicate the start of the statistics page followed by the

first value message:

ACTUAL:

ST ATISTICS

Since this is a new installation any random data should

be cleared.

2. Press [MESSAGE ò] in this group until the message

appears:

RESET STATISTICS:

yes?

3. Reset statistics for a new measurement interval. The

CM2001 keeps track of when the measurement interval

started. See Chapter 5 Actual Values for a complete

description of how data is gathered and application

ideas.

This completes setpoint programming and system testing.

Set the PROGRAM ENABLE dip switch and PROGRAM ACCESS function to DISABLE to prevent

accidental setpoint changes or tampering. By following

this procedure, it should be fairly easy to install a similar

control application. More details about each message is

provided in Chapter 5 and Chapter 6.

As you use the system, some setpoints may need adjusting. For example, frequent low temperature alarms might

indicate that the setpoint value was set too close to normal

heater temperature swings and needs to be lowered. Once

the system has been operating normally for a while an

alarm will indicate a change that needs investigation.

Viewing S tatistical Data: In addition to actual values that

are present, such as current and temperature, the CM2001

continuously gathers and computes historic information

about the heat tracing system to determine cost of operation, utilization, trends etc. This can be quite useful in

spotting potential problems or in designing similar

systems for other applications. Data is saved indefinitely

but you can be clear it anytime.

T o view statistical data,

1. Press [MESSAGE ò] from the actual value messages

just displayed to take you to the statistics values group

or

The flexibility and many features of the CM2001 system

significantly reduces problems caused by heat tracing

malfunctions.

3.5

CM2001

Overview

The front panel provides the local operator with LCD

alphanumeric display and keypad. The display and status

indicators update alarm and status information automatically. The keypad is used to select the appropriate

message for entering setpoints or displaying actual values.

The 32 character, backlit, LCD display provides English

messages that are visible under various lighting conditions. When the display and keypad are not being used,

the screen displays system information, which is definable

through three user selected default messages. These

default messages only appear after a user defined period

of inactivity. Press either [SETPOINT], [ACTUAL] or

[STATUS] to override the default messages.

Operating the Keypad

The CM2001 display messages are organized into pages

under headings Setpoints and Actual values.

[SETPOINT]: Provides entry to the Setpoint Menu

which allows you to navigate through

user settable parameters. See Chapter 6

Setpoint Values for detailed messages.

[ACTUAL]: Provides entry to the Actual Values

Menu which you to navigate through

measured parameters.

[STATUS]: Provides immediate access to the

System Status Menu which displays the

alarm status for the Controller and

allows access to individual alarm

details.

[MESSAGE ñ]: Allows you to move up through the

selected menu.

[MESSAGE ò ]: Allows you to move down through the

selected menu.

[VALUE ñ]: Allows you to increase the value of the

displayed selected item.

[VALUE ò ]: Allows you to decrease the value of the

displayed selected item.

[STORE]: Allows you to save the changed value

of the selected item.

[RESET]: Allows you to clear alarms that are no

Chapter 4

Status Light s

Refer to Figure 4.1 Display, Front View.

• L10 Power: The green Power light should be on at all

times indicating that control power is applied to the

Module. If the light is off, either there is no control

power or the display has a malfunction and requires

servicing.

•L11Heater: The green Heater light is on if the heater

is energized.

• L12 Communicate: Random flashing of the green

Communicate light indicates that serial

communications are active on the controller..

• L13 System Fail: The red System Fail light should be

off, indicating that the system check was successful.

• L14 Alarm: The red Alarm light is off when there are

no alarms. The light flashes if any alarm conditions are

present. Press [ST ATUS] to view alarms.

Alphanumeric Display

Refer to Figure 4.1 Display, Front View.

• D10 Display: Two lines with 16 alphanumeric characters per line. It is backlit for viewing in low-light

conditions.

Keypad

Refer to Figure 4.1 Display, Front View.

• K10 Display Keypad: Consists of nine keys which,

when used in connection with the Alphanumeric

Display , allow complete control of programming and

monitoring of the Control Module.

Display Contrast

Refer to Figure 4.2 Contrast Control

• P2 LCD display: After the CM-2001 is field mounted,

it may be necessary to adjust the display contrast to

compensate for the viewing angle. To adjust the

contrast, open the enclosure door and locate the

potentiometer (labelled DISPLA Y CONTRAST pot)

on the board attached to the enclosure door. Turn the

set-screw clockwise or counter-clockwise until the

display is readable.

Front Panel Operation

longer active.

Heater Numbering

Each heater is identified by a number of the form “M-1”,

where “M” is the Module Number. Each Controller on

the same data highway must have a unique Module

Number.

4.1

CM2001

Figure 4.1 Display, Front View

Chapter 4

Front Panel Operation

Figure 4.2 Contrast Control

4.2

CM2001

Startup Messages

Startup messages are displayed when power is applied to

the controller.

Chapter 4

Front Panel Operation

SELF CHECKING...

CM2001 HEAT

TRACING CONTROL

NELSON HEAT

TRACING SYSTEMS

FIRMWARE VERSION

D2-02-00

SELF CHECK P ASSED

SELF CHECK F AILED

This message appears when the controller is powered-up and executing selfdiagnostic functions.

This message displays the controller model.

This message displays company name of the supplier.

This messages displays the firmware version number.

This message appears when the controller has successfully completed execution of

self-diagnostic functions.

This message appears when the controller has detected faults during self-diagnostic function execution or normal operation. This may be as result of memory or

CPU failure. The controller requires servicing.

Status Messages

Status messages are automatically displayed for any

active conditions in the controller such as trips and

alarms. These messages provide an indication of the

SYSTEM OK

NO ALARMS

**2 ALARMS**

PRESS MESSAGE DOWN

PRESS MESSAGE DOWN

FOR NEXT ALARM

This message indicates there are no alarms present.

This message indicates the number of alarms on the controller. Press

[MESSAGE ò ] to locate the problem and the cause.

This message marks the end of details to an alarm. Pressing [MESSAGE ò ] to

scroll through details of the next alarm.

current state of the controller.

Some messages prompt you to press [MESSAGE ò ] to

scroll through messages to provide additional details of

the controller status.

4.3

CM2001

Chapter 4

Front Panel Operation

NO MORE ALARMS

Flash Messages

Flash messages are warnings, errors or general information displayed in response to a key press. The duration of

SETPOINT STORED

PRESET DISABLED

ALARM ACTIVE

NAME STORED

This message appears when the user has scrolled through all alarms.

This message appears when a setpoint has been stored.

This message indicates that the alarm cannot be reset because the alarm condition

is still present.

This message appears when the heater name has been stored.

the message can be configured in SETPOINTS\SYSTEM

SETUP\SCAN TIME. The factory default is three

seconds.

NOT STORED

PROG DISABLED

This message indicates that the program enable dip switch or program access

function is set to disable and programming is not allowed. Refer to Chapter 6,

Section 6.3, for details on Setpoint Access Security.

4.4

CM2001

Overview

Chapter 5

Actual Values

Access values and statistics in the actual values mode.

The messages are organized into groups for easy reference as shown below. Throughout this chapter each group

is detailed by section.

[ACTUAL] provides access to the Actual Values Menu

which allows the user to display the actual values of the

control modules.

The Actual Values Menu is arranged in two groups.

[ACTUAL]

1

ACTUAL

OPERA TING V ALUES

[MESSAGEô ]

CONTROL TEMP

6°C

[MESSAGEô ]

HEATER IS on

& no ALARMS

[MESSAGEô ]

RTD-A ACTUAL

TEMP: 6°C

[MESSAGEô ]

RTD-B ACTUAL

TEMP: 6°C

[MESSAGEô ]

HEA TER AT 100%

POWER

[MESSAGEô ]

HEA TER CURRENT :

4.6A

[MESSAGEô ]

GROUND FAULT

CURRENT: 5mA

[MESSAGEô ]

ð

2

&

&

&

&

&

&

&

[ACTUAL]

ò

ACTUAL

ST ATISTICS

[MESSAGEô ]

MAX TEMPERA TURE:

25°C

&

[MESSAGEô ]

MIN TEMPERA TURE:

3°C

&

[MESSAGEô ]

MAX HEA TER

CURRENT: 4.7A

[MESSAGEô ]

MAX GROUND F AUL T

CURRENT: 15mA

[MESSAGEô ]

MAX VOL TAGE

130V

[MESSAGEô]

MIN VOLT AGE

110V

[MESSAGEô]

go to 3

&

&

&

&

Pressing [ACTUAL] twice quickly access the top of the

second group. [MESSAGE ñ] allows you to move up

through the selected menu. [MESSAGE ò] allows you to

move down through the selected menu.

3

TIME SINCE RESET

& 17% OF THE TIME

RESET ST ATISTICS?

FIRMW ARE VERSION

òò

TOT AL ENERGY

USED: 42.2 kWh &

[MESSAGEô ]

TOT AL ENERGY

COST: $33.92 &

[MESSAGEô ]

HEA TER ON TIME:

2.0 hrs &

[MESSAGEô]

48 hrs &

[MESSAGEô]

HEA TER IS ON

[MESSAGEô]

no ?

[MESSAGEô]

D2-02-00

[MESSAGEô]

go to 1

HEA TER VOL T AGE:

120V

&

[MESSAGEô ]

go to 2

Restrictions

Advanced User Mode

5.1

CM2001

Operating

ACTUAL:

OPERATING VALUES

CONTROL TEMP:

6°C &

HEATER IS on &

& no ALARMS

Chapter 5

MESSAGE NO: M1-01 APPLIES TO: Control Module

DEF AULT VALUE: N/A V ALUE RANGE: N/A

DISPLA Y MODE: All RESTRICTIONS: None

This message displays the name of the sub-menu when entered.

MESSAGE NO: M1-02 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: -50 to 500 °C, RTD Open

DISPLAY MODE: All RESTRICTIONS: Heater Setpoint must not be

CM2001 calculates the displayed value the actual measured temperatures of both

R TD sensors based on the RTD DEFINITION function. CM2001 controls the

heater circuit by comparing the Heater Control Temperature to the Heater Setpoint.

If the temperature is outside the value range, then RTD OPEN or R TD FAUL T is

displayed.

MESSAGE NO: M1-03 APPLIES TO: Selected Heater

DEF AULT VALUE:N/A VALUE RANGE: on, off, man on,

DISPLA Y MODE: All RESTRICTIONS: None

The displayed value is the status of the heater. It indicates whether the heater

circuit is on or off and the number of alarm messages associated with the circuit.

The heater is forced on by HEATER TEST function if man on is displayed. See

HEATER TEST function.

Actual Values

-58 to 932 °F, RTD Fault

off or none.

no: 1 to 9 alarms

RTD-A ACTUAL

TEMP: 6°C &

RTD-B ACTUAL

TEMP: 6°C &

MESSAGE NO: M1-04 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: -50 to 500 °C, RTD Open

-58 to 932 °F, RTD Fault

DISPLAY MODE: All RESTRICTIONS: Heater Setpoint must not be

off .

The displayed value is the actual measured temperature of RTD-A sensor . It

calculates the Heater Control Temperature based on the RTD DEFINITION

function. If the temperature is outside the value range, then “RTD OPEN” or RTD

FAULT is displayed.

MESSAGE NO: M1-05 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: -50 to 500 °C, RTD Open

-58 to 932 °F, RTD Fault

DISPLAY MODE: All RESTRICTIONS: Heater Setpoint must not be

off . R TD Definition must

not be 1 RTD.

The displayed value is the actual measured temperature of RTD-B sensor. It

calculates the Heater Control Temperature based on the RTD DEFINITION

function. If the temperature is outside the value range then, RTD OPEN or RTD

FAULT is displayed.

5.2

CM2001

HEA TER AT 100% &

POWER

HEATER CURRENT

4.6A &

GROUND F AULT

CURRENT: 15mA &

Chapter 5

MESSAGE NO: M1-06 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: 0 to 100%

DISPLA Y MODE: Advanced RESTRICTIONS: None

The displayed value is the percentage duty cycle of the heater circuit. For example,

with PROPORTIONAL CONTROL and/or POWERLIMIT on, a percentage duty

cycle of 30% means that the circuit is energized for 3 out of 10 power cycles. For

on/off switching, heater on is 100% and off is 0%.

MESSAGE NO: M1-07 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: 0 to 60.0 A, O.L.

DISPLA Y MODE: All RESTRICTIONS: None

The displayed value is the actual current of the heater circuit. If the heater is off,

this value is zero. If the current exceeds the value range, then O.L. is displayed.

The use of PROPORTIONAL CONTROL, SOFTSTART or POWERLIMIT

functions can reduce the current from its nominal rating. Although the controller

has a 30A rating, the extended measurement range allows you to see the inrush

current.

MESSAGE NO: M1-08 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: 0, 10 to 1000 mA,O.L.

DISPLA Y MODE: All RESTRICTIONS: None

The displayed value is the ground leakage or ground fault current. If the current

exceeds the value range, then O.L. is displayed.

Actual Values

HEATER VOLTAGE

120V &

Statistics

ACTUAL:

STATISTICS &

MAX TEMPERATURE:

25°C &

MESSAGE NO: M1-09 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: 85 to 300 V, O.L.

DISPLA Y MODE: All RESTRICTIONS: None

The displayed value is the measured supply voltage. If the voltage exceeds the

value range, then O.L. is displayed.

MESSAGE NO: M2-01 APPLIES TO: Interface Module

DEF AULT VALUE: N/A V ALUE RANGE: N/A

DISPLA Y MODE: Advanced RESTRICTIONS: None

This message displays the name of the sub-menu when entered.

MESSAGE NO: M2-02 APPLIES TO: Selected Heater

DEFAULT VALUE: N/A VALUE RANGE: -50 to 500 °C

-58 to 932 °F, RTD Open

DISPLAY MODE: Advanced RESTRICTIONS: Heater Setpoint must not be

off.

The displayed value is the highest Measured Temperature since the last reset. If the

displayed value is RTD OPEN, a value greater than the maximum range was