Page 1

Operating the

Capacitor Discharge

NCD+ 3200 Stud Welding Unit

Operations Manual

(729-110-037)

For Software Version 1.06 and later

These instructions are for experienced

the principles of operation and safe practices for arc welding equipment, we urge you to

read AWS SP -“Safe Practices” available from the American Welding Society. Do not

permit untrained persons to install, operate or maintain this equipment. Do

not

attempt to install or operate this equipment until you have read and fully

understand

contact your supplier for further information. Be sure to read the Safety section before

utilizing this equipment.

these

instructions.

operators.

If you do not fully understand these instructions,

.

If you are not fully familiar with

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 2

NCD+ 3200 Limited Warranty

MODEL NO.

SERIAL NO.

SHIPPING DATE

VOLTAGE

REQUIRED

NELSON’S only warranty is that goods being sold will be free from defects in workmanship and

material. This warranty is expressly in lieu of other warranties, expressed or implied and

whether statutory or otherwise, including any implied warranty of merchantability or fitness for a

particular purpose.

NELSON’S liability for breach of warranty shall arise only upon return of the defective goods at

Buyer’s expense after notice to NELSON of the claimed breach, and shall be limited to

furnishing a like quantity of such goods free from such defects or, at NELSON’S option, to

refunding the purchase price (less reasonable depreciation based on actual use); provided,

however, that NELSON will not accept receipt of equipment returned unless buyer has

previously afforded NELSON’S personnel a reasonable opportunity to inspect and repair said

equipment at buyer’s facility or such other location as is mutually agreeable. Notice to NELSON

must be given within 30 days of such defect or failure and within one year or 500,000

welds from the date the equipment was delivered, whichever comes first. No compensation or

reimbursement for transportation costs of any kind will be allowed.

Please note that this warranty does not extend beyond the original registered purchaser,

and does not warrant equipment that has been modified by any party other than NELSON, or

equipment that has been improperly installed, improperly operated, or misused based upon

industry standards, or equipment which has not had reasonable and necessary maintenance, or

equipment which has been used for operation outside of specifications for the equipment.

NELSON shall never be liable for consequential damages.

NELSON reserves the right to make engineering and/or part changes, at any time without

notice, as a result of our commitment to continuous improvement.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 3

WARNING

The following Safety section is

for your protection. It

summarizes precautionary

information from the references

listed in the Additional Safety Information section. Before performing

any installation or operating procedures, be sure to read and follow the

safety precautions listed below as well as all other manuals, material

safety data sheets, labels, etc. Failure to observe these precautions can

result in injury or death.

ELECTRICAL SHOCK

Contact with live electrical parts and ground can cause

severe injury or death. DO NOT use welding current in

damp areas, if movement is confined, or if there is

danger of falling. Faulty or improperly electrified

equipment can cause injury or death. Therefore:

1. Always have qualified personnel perform the installation, troubleshooting,

and maintenance work unless you are qualified to perform such work.

2. Install equipment in accordance with the U.S. National Electrical Code, all

local codes and the manufacturer’s recommendations.

3. Be sure the power source frame (chassis) is connected to the ground

system of the input power.

4. Connect the work piece to a good electrical ground.

5. Connect the work cable to the work piece. A poor or missing connection

can expose you or others to a fatal shock.

6. Use well-maintained equipment. Replace worn or damaged cables.

7. Keep everything dry, including clothing, work area, cables, torch/electrode

holder and power source.

8. Make sure that all parts of your body are insulated from work and from the

ground.

9. Do not stand directly on metal or the earth while working in tight quarters or

a damp area; stand on dry boards or an insulating platform and wear

rubber soled shoes.

10. Put on dry, hole-free gloves before turning on the power.

11. Refer to ANSI/ASC Standard Z49.1 for specific grounding

recommendations. Do not mistake the work lead for a ground cable.

12. Before performing any work inside a power source, disconnect the power

source from the incoming electrical power using the disconnect switch at

the fuse box before working on the equipment.

PROTECT YOURSELF AND OTHERS

Some welding, cutting, and gouging processes are

noisy and require ear protection. The arc, like the

sun, emits ultraviolet (UV) rays and other radiation

which can harm the skin and eyes. Hot metal can

cause burns. Training in the proper use of the

processes and equipment is essential to prevent

accidents. Therefore:

1. Always wear safety glasses with side shields in any work area, even if

welding helmets, face shields and goggles are also required.

2. Use a face shield fitted with filter shade #3 per ANSI Z87.1. Cover

sparks and rays of the arc when operating or observing operations.

Warn bystanders not to watch the arc and not to expose themselves

to the rays of the electric-arc or hot metal.

3. Wear flameproof gauntlet type gloves, heavy long-sleeve shirt,

cuffless trousers, high topped shoes, and a welding helmet or cap for

hair protection, to protect against arc rays and hot sparks or hot metal.

A flameproof apron may also be desirable as protection against

radiated heat and sparks.

4. Hot sparks or metal can lodge in rolled up sleeves, trousers cuffs or

pockets. Sleeves and collars should be kept buttoned and open

pockets eliminated from the front of clothing.

5. Protect other personnel from arc rays and hot sparks with suitable

nonflammable partitions or curtains.

6. Use goggles over safety glasses when chipping slag or grinding.

Chipped slag may be hot and can fly far. Bystanders should also wear

goggles over safety glasses.

ELECTRICAL AND MAGNETIC FIELDS

Electric and magnetic fields may be dangerous. Electric

current flowing through any conductor causes localized

Electric and Magnetic Fields (EMF). Welding and cutting

current creates EMF around welding cables and welding

machines. Therefore:

1. Operators having pacemakers should consult their physician before

welding. EMF may interfere with some pacemakers.

2. Exposure to EMF may have other health effects which are unknown.

3. Operators should use the following procedures to minimize exposure to

EMF:

4. Route the electrode and work cables together. Secure them with tape when

possible.

5. Never coil the torch or work cable around your body.

6. Do not place your body between the torch and work cables. Route cables

on the same side of your body.

7. Connect the work cable to the work piece as close as possible to the area

being welded.

8. Keep welding power source and cables as far away from your body as

possible.

FIRES AND EXPLOSIONS

Heat from flames and arcs can start fires. Hot

slag or sparks can also cause fires and

explosions. Therefore:

Remove all combustible materials well away from the work area or

cover the materials with a protective nonflammable covering.

Combustible materials include wood, cloth, sawdust, liquid and gas

fuels, solvents, paints and coatings, paper, etc.

Hot sparks or hot metal can fall through cracks or crevices in floors

or wall openings and cause a hidden smoldering fire or fires on the

floor below. Make certain that such openings are protected from hot

sparks and metal.

Do not weld, cut, or perform other hot work until the work piece has

been completely cleaned so that there are no substances on the

work piece which might produce flammable or toxic vapors. Do not

do hot work on closed containers. They may explode.

Have appropriate fire extinguishing equipment handy for instant

use, such as a garden hose, water pail, sand bucket or portable fire

extinguisher. Be sure you are trained for proper use.

Do not use equipment beyond its ratings. For example, overloaded

welding cable can overheat and create a fire hazard.

After completing operations, inspect the work area to make certain

there are no hot sparks or hot metal which could cause a later fire.

Use fire watchers when necessary.

For additional information, refer to NFPA Standard 51B, “Fire

Prevention in Use of Cutting and Welding Processes,” available

from the National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269

MOVING PARTS CAN CAUSE INJURY

Electric fan can start at any time without warning and

cause severe injury, therefore:

1. Always disconnect electrical power prior to service to prevent the fan from

starting unexpectedly.

2. Keep all doors, panels, covers, and guards closed and securely in place.

3. Have only qualified people remove guards or covers for maintenance and

troubleshooting as necessary.

4. Keep hands, hair, loose clothing, and tools away from moving parts.

5. Reinstall panels or guards and close doors when servicing is finished and

before reenergizing welder.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 4

FUMES AND GASES

Fumes and gases can cause discomfort or harm,

particularly in confined spaces. Do not breathe fumes

and gases. Shielding gases can cause asphyxiation.

Therefore:

1. Always provide adequate ventilation in the work area by natural or

mechanical means. Do not weld, cut, or gouge on materials such as

galvanized steel, stainless steel, copper, zinc, lead, beryllium, or

cadmium unless positive mechanical ventilation is provided. Do not

breathe fumes from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc

rays can react with chlorinated hydrocarbon vapors to form phosgene, a

highly toxic gas, and other irritant gasses.

3. If you develop momentary eye, nose, or throat irritation while operating,

this is an indication that ventilation is not adequate. Stop work and take

necessary steps to improve ventilation in the work areas. Do not continue

to operate if physical discomfort persists.

4. Refer to ANSI/ASC Standard Z49.1 (see listing on next page) for specific

ventilation recommendations.

EYE PROTECTION

Flying metal can injure eyes. Welding, chipping, wire

brushing and grinding can cause sparks and flying

metal. As welds cool, they can throw off slag.

Therefore:

1. Wear approved safety glasses with side shields even under your

welding helmet.

2. Warn others nearby about flying metal hazard.

HEARING PROTECTION

Prolonged Noise from Capacitor Discharge welding

applications can damage hearing if levels exceed

limits specified by OSHA. Therefore:

1. Use Approved ear plugs or ear muffs if noise level is high.

2. Warn others nearby about noise hazard.

3. For additional information, refer to OSHA Safety Standards 3074.

CYLINDER HANDLING

Cylinders, if mishandled, can rupture and violently

release gas. Sudden rupture of cylinder, valve, or

relief device can injure or kill. Therefore:

1. Use the proper gas for the process and use the proper pressure reducing

regulator designed to operate from the compressed gas cylinder. Do not

use adaptors. Maintain hoses and fittings in good condition.

2. Always secure cylinders in an upright position by chain or strap to

suitable hand trucks, undercarriages, benches, walls, post, or racks.

Never secure cylinders to work tables or fixtures where they may become

part of an electrical circuit.

3. When not in use, keep cylinder valves closed. Have valve protection cap

in place if regulator is not connected. Secure and move cylinders by

using suitable hand trucks. Avoid rough handling of cylinders.

4. Locate cylinders away from heat, sparks, and flames. Never strike an arc

on a cylinder.

5. For additional information, refer to CGA Standard P-1, “Precautions for

Safe Handling of Compressed Gases in Cylinders”, which is available

from Compressed Gas Association, 1235 Jefferson Davis Highway,

Arlington, VA 22202.

ADDITIONAL SAFETY INFORMATION

For more information on safe practices for electric

arc welding, refer to the following publications.

1. ANSI/ASC Z49.1 Safety in Welding and Cutting

2. AWS C5.1 Recommended Practices for Plasma Arc Welding

3. AWS C5.6 Recommended Practices for Gas Metal Arc Welding

4. AWS SP Safe Practices (Reprint) Welding Handbook

5. ANSI/AWS F4.1 Recommended Safe Practices for Welding and Cutting

of Containers That Have Held

Hazardous Substances.

EQUIPMENT MAINTENANCE

Faulty or improperly maintained equipment can cause

injury or death. Therefore:

1. Always have qualified personnel perform the installation, troubleshooting,

and maintenance work. Do not perform any electrical work unless you are

qualified to perform such work.

2. Before performing any maintenance work inside a power source,

disconnect the power source from the incoming electrical power.

3. Maintain cables, grounding wire, connections, power cord, and power

supply in safe working order. Do not operate any equipment in faulty

condition.

4. Do not abuse any equipment or accessories. Keep equipment away from:

heat sources such as furnaces, wet conditions such as water puddles

and inclement weather oil or grease corrosive atmospheres.

5. Keep all safety devices and cabinet covers in position and in good repair.

6. Use equipment only for its intended purpose. Do not modify it in any

manner.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 5

CONTENTS

1 Connection and Installation ............................................................................................. 6

1.1 Installation Precautions ................................................................................................. 6

1.2 Connection ................................................................................................................... 7

1.2.1 Input Connection ............................................................................................... 8

1.2.2 Connection of Gun Welding Cable .................................................................... 9

1.2.3 Connection of Gun Control Cable ...................................................................... 9

1.2.4 Dual Connection of Workpiece Ground Cable ..................................................10

1.2.5 Connection of the Workpiece ...........................................................................10

1.3 Specifications .............................................................................................................. 11

1.3.1 Mechanical Drawing .........................................................................................12

2 Control and Display Elements ........................................................................................13

2.1 Front Panel Controls and Displays Weld Parameter ................................................... 13

2.1.1 Voltage Display Modes .....................................................................................14

2.2 Stud Expert ................................................................................................................. 15

2.3 Process Monitor (PM) ................................................................................................. 16

2.3.1 Teaching Welds ...............................................................................................17

2.3.2 Setting Tolerances ...........................................................................................18

2.3.3 Operating Process Monitor ...............................................................................19

3 Normal Operation .............................................................................................................20

3.1 Powering Up ............................................................................................................... 20

3.2 Welding Operations .................................................................................................... 20

3.3 Error Codes ................................................................................................................ 21

3.4 Weld Quality Visual Inspection .................................................................................... 22

4 Welding Parameters.........................................................................................................23

4.1 Contact Gun................................................................................................................ 23

4.2 Auto-Gap Gun ............................................................................................................. 23

4.3 Weld Setting Recommendations ................................................................................. 24

5 NCD+ 3200 Parts List & Exploded View .........................................................................25

6 Wiring Diagrams for NCD+ ..............................................................................................29

6.1 Standard System ........................................................................................................ 29

6.2 Autofeed System ........................................................................................................ 30

7 Nelson NCD+ Welding Modes .........................................................................................31

7.1 Contact Mode Capacitor Discharge Welding ............................................................... 31

7.2 Auto-Gap Mode Capacitor Discharge Welding ............................................................ 31

8 Contact Information .........................................................................................................32

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 6

NCD+ 3200 Manual | Connection and Installation

SAFETY SYMBOLS

ATTENTION!

BE ALERT!

WELDING CAN BE

HARMFUL TO YOURSELF

AND OTHERS.

Used to call attention to

immediate hazards which, if not

avoided, will result in immediate,

serious personal injury or loss of

life.

Used to call attention to potential

hazards which could result in

personal injury or loss of life.

Used to call attention to hazards

which could result in minor

personal injury.

1 Connection and Installation

1.1 Installation Precautions

Attention must be paid to the fact that the welding unit is installed on a horizontal, vibration-free and

non-slip surface. The load-carrying capacity of the floor space should be at least double the weight of

the unit. When working in high-lying locations, such as bridges, ladders or platforms, the NCD+ must be

secured against the risk of falling.

The NCD+ must be adequately protected against the intrusion of liquids. It may not be installed on

liquid- bearing pipelines.

In order to guarantee unimpeded temperature exchange with the environment, a minimum clearance of

39.4 inch (1 m) to existing heat sources must be observed.

Attention must be paid to the fact that the ventilation slits on the unit casing are kept free.

NCD+ models may be exhibit permanent failure or abnormal operation when

used in the vicinity of high frequency interference. TIG processes and similar

high frequency processes tend to interfere with and damage NCD+ circuit

boards, particularly when sharing the same work piece. For more information

please consult your local Nelson service support.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 7

NCD+ 3200 Manual | Connection and Installation

1 Gun Welding Cable Connection (-) x1

3 Workpiece Ground Cable Dual Connection (+) x3

2 Gun Control Cable Connection x2

4 Input Power Cable Connection

4

3

Figure 1.1 NCD+ Connection

2

1

1.2 Connection

With the exception of the input power cable, all of the connections are located on the front plate

of the NCD+.

Prior to any connection work, the NCD+ welding unit must be switched

off. The input power switch must be in the >>0<< position.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 8

NCD+ 3200 Manual | Connection and Installation

1.2.1 Input Connection

The NCD+ unit can only be operated with 110-120 VAC 50/60 Hz input power (Item 4 of Figure 1.1,

Page 7). See the rating plate on the back panel of the unit.

The input power must be wired with the earth ground connection. It is not

acceptable to use an isolation plug to isolate the earth ground connection. It

could result in unsafe conditions.

Fusing with slow response characteristics.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 9

NCD+ 3200 Manual | Connection and Installation

Figure 1.2 Gun Welding Cable Socket

Figure 1.3 Gun Control Cable Socket

1.2.2 Connection of Gun Welding Cable

The Gun Welding Cable connects to the NCD+ via the Gun Welding Cable socket (Item 1 of Figure

1.1, Page 7). It must be noted that the procedural safe operation of the system can only be guaranteed

when either a Nelson Contact or a Nelson Auto Lift gun is connected.

Gun Welding Cable Connection (X1)

Align the locking pin of the welding cable plug to the locking groove of the welding

cable socket. Turn to the welding cable plug 1/3 of a turn to the right clockwise to

secure the connection.

Connect Gun Welding Cable to X1 for straight polarity and to X3 for reverse polarity.

1.2.3 Connection of Gun Control Cable

The Gun Control Cable socket (Item 2 of Figure 1.1, Page 7) permits the connection of the control

cable to the NCD+ unit. The signals to control the gun are transmitted via the control cable.

The control cable socket of the unit has a 12-pin design.

Gun Control Cable Connection (X2)

Pin 1: LED Green

Pin 2: LED Red

Pin 3: Trigger

Pin 4: Trigger

Pin 5: Gun Coil

Pin 6: Gun Coil

Pin 7: Weld (+)

Pin 8: Weld (-)

Pin 9: Spark Shield

The connection must be secured by aligning the index of the control cable plug with the index of the

control cable socket. Once the indices are aligned, turn the collar ring to the right until it’s tight. Now,

the connection is secure.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 10

NCD+ 3200 Manual | Connection and Installation

Figure 1.4 Workpiece Ground Cable

1.2.4 Dual Connection of Workpiece Ground Cable

The welding current return takes place via the Workpiece Ground Cable, which must

be connected as follows to one of the Workpiece Ground Cable sockets (Item 3 of

Figure 1.1, Page 7) on the front panel of the NCD+.

Workpiece Ground Cable Dual Connection (X3)

Connect the Workpiece Ground Cable plug into one of the proper NCD+ sockets.

Turn the Workpiece Ground Cable plug 1/3 to the right clockwise to secure the

connection.

Place the 2 ground clamps on the opposite ends of the weld area to minimize arc blow.

Prior to any connection task, the NCD+ welding unit must be switched off and

the input power switch must be in the >>0<< position.

1.2.5 Connection of the Workpiece

When connecting the workpiece ground terminals, attention must be paid to the following:

The workpiece ground terminals must be connected directly to the workpiece or to the workpiece fixture

(welding bench, welding grid). Steel constructions, tracks, pipelines, etc. may not be used as current

conductors, unless they themselves are the workpieces to be welded. The welding current circuit may

not be earth grounded. The exception is the workpiece itself or the workpiece fixture are earth

grounded compulsorily (pipelines, shipbuilding, etc.). Place the workpiece ground terminals, if possible,

at the same distance from the point of welding when two ground clamps are used.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 11

1.3 Specifications

NCD+ 3200™ CD WELDING UNIT

MIN.

MAX.

Input Voltage (V) / Current (A)

120/20

Input Line Frequency (Hz)

60

Capacitor Voltage (VDC) (Continuously Adjustable)

70

200

Stored Energy (Ws)

3750

Capacitance (mF) (High/Low Switchable)

81

189

Weight

64 lbs (30 kg)

Weld Rate

(studs/min)

Low Capacitance, 120V

20

High Capacitance, 180V

8

Maximum Stud Thread

Diameter

Steel/Stainless (TFTC/S)

3/8″ Flanged

Aluminum (TFTA)

5/16″ Flanged

Dimensions (Length x Width x Height)

20″ x 13.25″ x 8.5″

(508 mm x 336.5 mm x 216 mm)

Power Cord

9 ft (2.75 m)

Idle Power (W)

80 or less

Operating Temperature (°C)

-20 to +40

Storage Temperature (°C)

-40 to +60

Gun Connector

12-Pin Binder

Weld Connector

Dinse

Dual Ground

Yes

Compatible Guns

NCD+ Contact, NCD+ Auto-Gap

Process Monitor

Yes – Optional

Contact Safety Check

Yes

Chuck Saver

Yes

Stud Expert

Yes

Display

Graphic Color Display

NCD+ 3200 Manual | Connection and Installation

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 12

NCD+ 3200 Manual | Connection and Installation

Figure 1.5 Front & Side Views of NCD+ 3200 with Dimensions

1.3.1 Mechanical Drawing

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 13

NCD+ 3200 Manual | Control and Display Elements

1

Circuit Breaker

Primary circuit breaker to protect the welding transformer from overloads (resettable).

2

On/Off Power

Switch

The main switch controls the input power to the machine. Upon powering up, the internal

control software performs a series of diagnostic tests to ensure correct connection and

safe operation of the power source.

3

Function Mode

Press the knob to alternate between modes.

4

Adjustment of

Voltage

and Other

Parameters

Enables voltage selection. The voltage is increased turning the knob in the clockwise

direction (or decreased by turning it in the counterclockwise direction). The power supply

will take a moment to achieve and display the new voltage setting.

Note: Small changes make it easier to reach a new voltage level.

5

Voltage Display

LCD display of voltage setting

6

Weld Tool Icon

The graphical display of gun function and welding process.

7

Capacitance

Selector Switch

This switch enables toggling between high and low capacitance. When set to low

capacitance, three out of seven capacitors are utilized. The low setting is typically used

for studs less than 3/8" diameter.

When set to high capacitance, all seven capacitors are utilized. This setting is typically

used for 3/8" studs.

Figure 2.1 Front Panel Controls

2 Control and Display Elements

2.1 Front Panel Controls and Displays Weld Parameter

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 14

NCD+ 3200 Manual | Control and Display Elements

RED when charging is in progress. GREEN when actual voltage matches with setpoint.

Voltage

Setpoint

Cap Charge Status

Ready

(GREEN)

Charging

(WHITE)

Not Ready

(RED)

Discharging

(WHITE)

Workpiece

Icon indicates

contact with

workpiece

when green

Indicates actual voltage

to which capacitors have

been charged

Trigger Icon indicates trigger

contact when green

Error Display

(If error is present)

Bar graph of Actual Cap

Voltage

Figure 2.2 Voltage Display (Enlarged View of Items 5 & 6 of Figure 2.1)

2.1.1 Voltage Display Modes

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 15

NCD+ 3200 Manual | Control and Display Elements

Figure 2.3 Stud Expert

3

2

1

Resulting Cap Voltage

Exit the Screen

2.2 Stud Expert

NOTE: Once the unit is powered up, press the knob once to enter the Process Monitor screen.

NOTE: To access the Setup screen, return to the Voltage Selection screen (the home screen).

From the Voltage Selection screen, press and hold the knob for 5 seconds to enter the Setup

screen. To exit Setup at anytime and return to the Voltage Selection screen, press and hold the

knob again for 5 seconds.

The Stud Expert mode allows the user to choose welding parameters based on the desired stud size,

stud material and welding process. The resulting cap voltage is set once the stud is selected.

One parameter (stud size, stud material, welding process) can be selected, or all 3, depending on what

are the job requirements.

Turn the knob to scroll through the choices. Once the desired choice is highlighted, push the knob to

select and confirm the choice. The

1. Select the desired stud size (1/4in (M6)) as shown in Item 1

of Figure 2.3.

2. Choose from available studs materials, such as Carbon

Steel, as seen in Item 2.

3. Choose your desired welding mode; view the resulting cap

voltage; or exit the screen as exemplified in Item 3.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 16

NCD+ 3200 Manual | Control and Display Elements

Figure 2.4 Process Monitor

1 2 3

4

2.3 Process Monitor (PM)

NOTE: Once the unit is powered up, press the knob once to enter the Process Monitor screen.

The Process Monitor uses a series of “teaching welds" as a target to check each production weld and

to determine if the characteristics of a production weld fall within the natural scatter of teaching welds

(“pass”).

1. Select Teach as shown in Item 1 of Figure 2.4.

2. Before entering Teach mode, the target must be cleared.

Select Yes (Item 2) to confirm that you want to clear any

existing target before proceeding.

3. Turn the dial to desired selection and click.

4. Perform welds (ex. 8-10). PM in progress with 5 welds

recorded.

5. Click Done (Item 3) once finished.

6. Verify results with Pass/Fail Production view (Item 4).

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 17

NCD+ 3200 Manual | Control and Display Elements

PM Waveform View

Tracks Welding Data

Here, no target has

been taught. To enter

teaching mode, turn

dial to Teach and

click. Perform welds to

teach; click Exit to

leave the Teach Mode

(Item 3). This will

configure a target.

Blue

Current

Yellow

Voltage

Green

Overlap

Figure 2.5 PM Waveform View

1

2

3

2.3.1 Teaching Welds

NOTE: Once the unit is powered up, press the knob once to enter the Process Monitor screen.

NOTE: If you are unable to find the Process Monitor screen, make sure that WAVESCNENBL=ON

in the Setup screen. To enter the Setup screen, return to the Voltage Selection screen (the home

screen) and press and hold the knob for 5 seconds. Then, follow the diagram to enter the WAVE

SCN ENBL screen and to turn the mode ON.

1. To access PM Waveform view, enter Setup mode.

2. Select WAVE SCN ENBL (Item 1 of Figure 2.5) and select ON

to enable (Item 2).

3. Scroll the knob until the green arrow points to Teach.

4. Press the knob once to reach the Clear Target? dialog.

Scroll to select Yes to clear the target.

5. The Teaching (0) at the bottom will appear signifying that there

have been no teaching welds made so far. Produce as good of a

weld as you can. After welding, make sure that the scope chart

updates and says Teaching (1). (See diagram for the

interpretation of the PM Waveform View).

NOTE: THE CHART LEGEND: The horizontal axis is displayed in

milliseconds, the left vertical is displayed in arc voltage

(volts) sensed at the gun and the right vertical is displayed

in kiloamps.

6. Repeat good welds as necessary (30 welds are recommended

as a minimum for teaching welds to be statistically significant).

7. Scroll the green arrow over to select Done.

8. Select Exit.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 18

NCD+ 3200 Manual | Control and Display Elements

1. From the Voltage Selection screen, press and hold knob for 5 seconds to enter Setup screen.

2. Scroll down to highlight MAIN TOL MULT (Figure 2.7). Press the knob once to select the mode.

MAIN TOL MULT is the multiplier (1x, 2x, 3x…) for Teach

mode which automatically selects individual tolerances.

Factory default is 3x. The tolerance of each parameter can

be individually adjusted.

Higher values allow more room for leniency; whereas lower

values tighten the process.

Must retrain unit after adjusting MAIN TOL MULT. Adjusting

individual tolerances does not require retraining.

Represents Actual Deviation from Target

Parameter results less than Main Tolerance

Mult, or MAIN TOL MULT, are ‘good’

For example:

Main Tolerance = 3x

ArcT is less than 3 = Good

AvgI is greater than 3 = Bad

Scroll down for more parameters.

Figure 2.6 Weld Results Screen

1

2

Figure 2.7 MAIN TOL MULT Screen

2.3 Teaching Welds (Cont’d)

Scroll knob to go to the Weld Results screen which should read NO TARGET (Item 1 of Figure 2.6) as

the last weld wasn’t monitored. The subsequent welds will be monitored by the new target, and the first

line should indicate pass or fail (Item 2).

NOTE: There are 2 places to monitor the results for

teaching: the Process Monitor screen (where the

green bar = good results and the red bar = bad

results) and the Weld Details screen. Each line

represents a calculated parameter being monitored.

The number in the square brackets indicates the deviation

from the mean as a multiplier of the standard deviation.

The green line means the deviation falls within the

tolerance set for that parameter, and the red means it fell

outside.

2.3.2 Setting Tolerances

NOTE: Once the unit is powered up, press the knob once to enter the Process Monitor screen.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 19

NCD+ 3200 Manual | Control and Display Elements

Adjust or disable individual parameters (ArcT, ENERGY, TIP,

etc) to override tolerances automatically set by teaching and

MAIN TOL MULT (Figure 2.8).

Scroll down through the Setup screen for more individual

tolerances.

Figure 2.8 IPLUNGE TOL Screen

2.3.3 Operating Process Monitor

NOTE: Once the unit is powered up, press the knob once to enter the Process Monitor screen.

To setup the tolerances effectively, destructive testing is needed to separate the good from the bad

welds.

To test the Process Monitor (PM):

First, perform several normal welds which should pass. If they fail, go to the Weld Details screen and

check which parameter(s) have failed (they will appear in red) and go to the Setup screen to open up

the tolerance or disable the parameter for checking. One of the conditions below should fail the PM:

1. Stud welded out of perpendicular position to the workpiece.

2. Damaged timing tip on stud.

3. Workpiece contamination.

4. Poor quality weld ground connections.

The unit can be configured to lock the user out if there is a failure. Go to Setup screen and turn on

STOP ON BAD WLD.

After a suspect weld is detected, a popup screen will display FAILED WELD. Click on knob to

acknowledge message before proceeding with another weld.

There is also a resettable good weld counter and a bad weld count within the Setup screen.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 20

NCD+ 3200 Manual | Normal Operation

3 Normal Operation

NOTE: Refer to Figure 2.1 (Page 13) for item references throughout the following instructions.

3.1 Powering Up

Before power up, ensure that all cables are properly connected. Press the On/Off Power switch (Item

2) to the right of the knob to start the unit.

Wait for a few seconds while the power supply initiates and completes both a self test and self

diagnostics test (Note: Self tests occur between every weld.). Once the tests have completed, the

power supply will charge the unit to the voltage setpoint (adjust voltage if necessary). When fully

charged, the Cap Charge Status icon (Figure 2.2, Page 14) will become a green checkmark to show

that the unit is fully charged and ready to weld.

3.2 Welding Operations

1. Set the welding voltage. Wait until the Voltage Display screen (Item 5) lights up green.

2. Rotate the knob (Item 3) to the desired level of voltage.

3. Set the spring pressure.

4. Adjust foot/leg assembly to set the plunge.

5. Load the stud into the chuck. Press the stud against the workpiece (Ensure that the stud is

perpendicular to the workpiece). The Workpiece icon will light up green.

6. Pull the trigger to weld the stud. The Trigger icon will turn green when the trigger switch is depressed

(Figure 2.2, Page 14).

Note: If the stud does not make contact with the workpiece, it will not weld.

7. Remove the chuck from the welded stud.

8. The unit automatically recharges - wait for the Cap Charge Status icon (Figure 2.2, Page 14) to turn

green again before proceeding with the next weld. The unit will not recharge even if the trigger is pulled

again before the chuck is removed from the welded stud known as the Chuck Saver™.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 21

NCD+ 3200 Manual | Normal Operation

Error

Number

Malfunction

Solution

E01

Abnormal presence of

voltage on studs when

there should be no voltage.

Stop using the Power Source until issue is resolved.

Measure weld terminals voltage (VDC) to confirm.

If ≥ 30VDC, check SCR Gate Leads and replace SCR.

If < 30VDC, replace Control board and Power board.

E02

Capacitors won’t charge

(after 3 seconds, capacitors

still less than 20V)

Replace power board. If the problem is not solved, replace SCR. If

neither resolves the issue, replace the wiring harness.

E03

Capacitors are unable to

discharge – either because

the SCR did not fire or

because the weld circuit

was broken.

1. Check weld circuit continuity.

2. Check SCR.

3. Replace Control Board.

4. Replace Power Board.

TEMP

X°

If Thermal Sensor trips…

At 45°C or higher ambient

temperature

Let it cool down and reset it to 35°C.

At 45°C or lower ambient

temperature

Replace control board.

TEMP

SW

Trip with thermal switch

mounted on heat-sink

Let it cool down. Check for loose cable connections.

3.3 Error Codes

Only qualified personnel should perform maintenance. Some functional errors are highlighted by

appearance of an error code with the display EXX.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 22

NCD+ 3200 Manual | Normal Operation

Issue: Too cold

Weld Flash: Not Visible

Weld: Very weak, Will break

Adjustments: Increase voltage,

reduce spring pressure, or

increase capacitance

Issue: Acceptable Weld

Weld Flash: Normal, No

significant weld splatter

Weld: Good, strong

Adjustments: None required

Issue: Too Hot

Weld Flash: Excessive flash

and weld splatter

Weld: Weak, May break

Adjustments: Reduce voltage,

increase spring pressure, or

reduce capacitance

3.4 Weld Quality Visual Inspection

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 23

NCD+ 3200 Manual | Welding Parameters

Stud Size

Material

Plunge Depth

Pressure

Capacitance

NCD+™ 3200

Voltage

in

mm

lbs N %

#6 (M3)

Carbon Steel

0.12

3

12

53

100

Low

80

Stainless Steel

0.12

3

12

53

100

Low

70

#8 (M4)

Carbon Steel

0.12

3 6 27 0 Low

80

Stainless Steel

0.12

3

11

49

100

Low

80

#10 (M5)

Carbon Steel

0.12

3 9 40

50

Low

90

Stainless Steel

0.12

3 7 31

25

Low

80

1/4" (M6)

[6.4 mm]

Carbon Steel

0.12

3

10

45

75

Low

120

Stainless Steel

0.12

3 7 31

25

Low

115

5/16" (M8)

[7.9 mm]

Carbon Steel

0.12

3 9 40

50

Low

180

Stainless Steel

0.12

3

10

45

75

Low

180

3/8"

[9.5 mm]

Carbon Steel

0.12

3

10

45

25

High

180

Stainless Steel

0.12

3

10

45

25

High

180

Stud Size

Material

Plunge Depth

Pressure

Capacitance

NCD+™ 3200

Voltage

in

Mm

lbs N %

#6 (M3)

Carbon Steel

0.12

3 7 31

20

Low

80

Stainless Steel

0.12

3 9 40

50

Low

80

Aluminum

0.14

3.5

6

27 0 Low

-

#8 (M4)

Carbon Steel

0.12

3 6 27 0 Low

90

Stainless Steel

0.12

3 9 40

50

Low

90

Aluminum

0.14

3.5

9

40

50

Low

95

#10 (M5)

Carbon Steel

0.12

3 6 27 0 Low

95

Stainless Steel

0.12

3 6 27 0 Low

90

Aluminum

0.14

3.5

9

40

50

Low

110

1/4" (M6)

[6.4 mm]

Carbon Steel

0.12

3 6 27 0 Low

155

Stainless Steel

0.12

3 6 27 0 Low

145

Aluminum

0.12

3 7 31

20

Low

130

5/16" (M8)

[7.9 mm]

Carbon Steel

0.08

2 6 27 0 Low

200

Stainless Steel

0.08

2 9 40

50

Low

200

4 Welding Parameters

4.1 Contact Gun

4.2 Auto-Gap Gun

NOTE: Set plunge (or stick out) to 2 mm. The Pressure is best measured by pressing the spark

shield squarely against a scale when the timing tip of the stud is flush with the end the spark

shield in the welding position.

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 24

NCD+ 3200 Manual | Welding Parameters

Weld Setting Change

Effect on Welds

Capacitance Increase

Hotter

Voltage Increase

Hotter

Spring Pressure Increase

Colder

Contact Mode-Plunge Increase

Colder

Gap Mode-Gap Increase

Colder

Stud Tip Length Increase

Hotter

4.3 Weld Setting Recommendations

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 25

NCD+ 3200 Manual | NCD+ 3200 Parts List & Exploded View

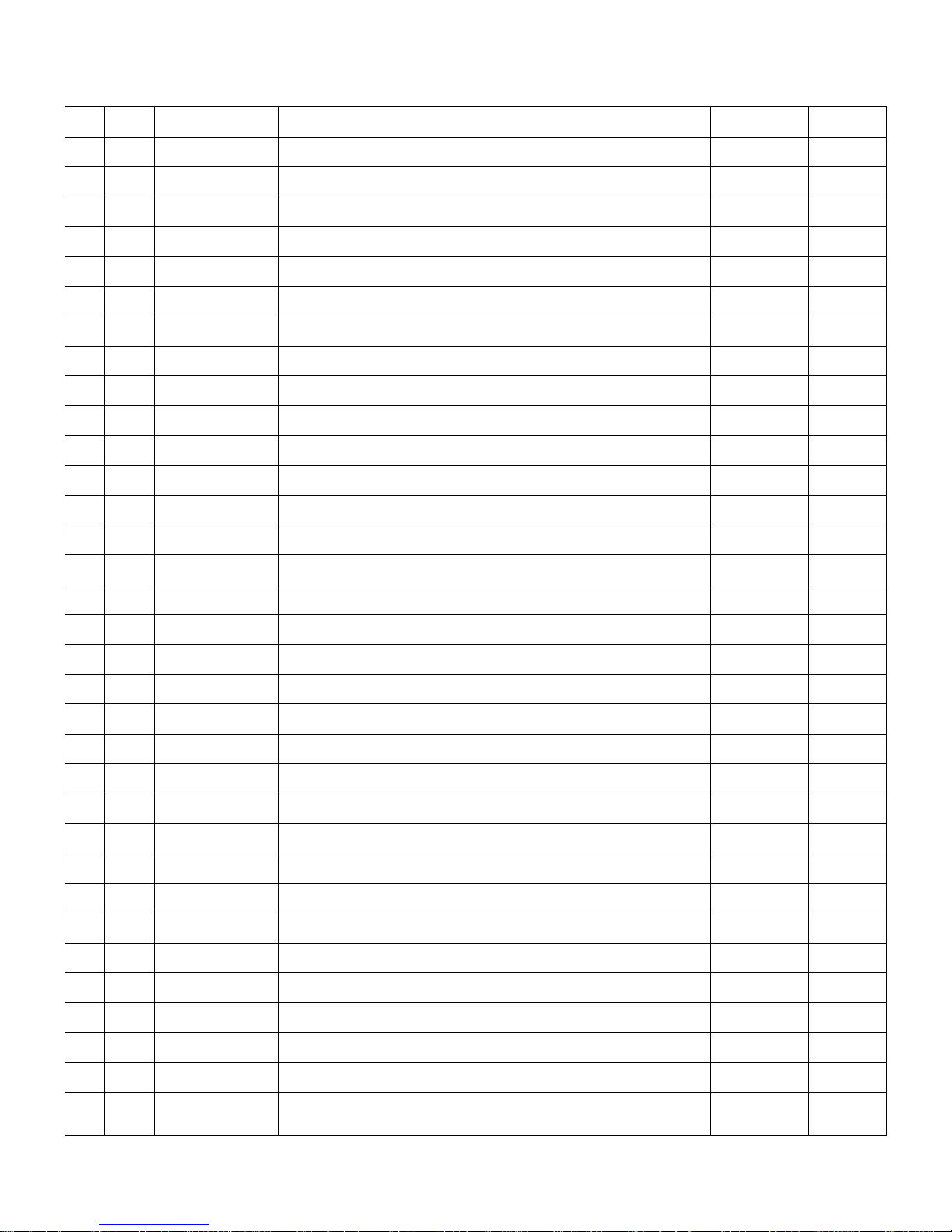

#

QTY

PART NO.

DESCRIPTION

TORQUE

*SPARE

1 1 750-614-220

Chassis, NCD+ 3200

2 2

729-114-102

Pull Handle

3 3

85-10-02

Power Connector, Dinse

50 in/lbs

4 1

723-247-111

Gun Connector, Process Monitor with EMI/Ferrite, Harness

1 5 1

709-274-010

Input Switch

6 1

701-182-001

Bridge 1 7 1

723-247-103

AC Power Cord Assembly

1 8 1

717-999-020

Adjustment Knob

9 1

701-183-000

Main SCR

30 ft/lbs

1

10 1 701-184-000

Diode

30 ft/lbs

1

11 1 709-276-001

20A Breaker

12 1 709-276-000

High/Low Decal

13 1 724-576-003

NCD+ 3200 Front Decal

14 1 750-614-022

Control CPU PCB

1

15 4 524-005-325

Screw, M4 x 8, SHCS, SS

10 in/lbs

16 5 524-005-303

Lockwasher, M4, SS

17 3 524-005-153

Nut, Nylok, M4

10 in/lbs

18 5 524-005-120

Washer, Flat, M4, SS

19 8 524-005-315

Screw, Flg, M5 x 10, HHCS, Blk. Phos.

30 in/lbs

20 1 750-614-227

NCD+ 3200 Neg. D Busbar

1

21 1 750-614-230

NCD+ 3200 Capacitor Insulator

22 1 750-614-223

NCD+ 3200 Pos. B Busbar

1

23 1 750-614-224

NCD+ 3200 Pos. A Busbar

1

24 1 750-614-228

NCD+ 3200 Dinse Link Bar

25 1 750-614-222

NCD+ 3200 Neg. B Busbar

1

26 1 750-614-225

NCD+ 3200 Neg. A Busbar

1

27 3 750-614-231

NCD+ 3200 Capacitor Clamp Bushing

28 3 750-614-232

NCD+ 3200 Capacitor Clamp Spacer

29 1 750-614-226

NCD+ 3200 Neg. C Busbar

30 2 705-610-002

Shunt

31 1 750-614-221

NCD+ 3200 Cover

5 NCD+ 3200 Parts List & Exploded View

*SPARE PARTS ARE INDICATED BY QUANTITIES IN SPARE COLUMN IN TABLE

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 26

NCD+ 3200 Manual | NCD+ 3200 Parts List & Exploded View

32 5 524-005-339

Nut, Hex, M6, SS

20 in/lbs

33

10

524-005-273

Nut, KEPS, M6, SS

20 in/lbs

34 1 524-005-279

Screw, M4 x 16, PHMS, SS

10 in/lbs

35 1 750-614-229

NCD+ 3200 Shunt Connector

36

16

524-005-311

Washer, Belleville, M6, SS

14

37

33

524-001-309

Washer, Flat, 1/4″, SS

14

38 1 717-999-013

Fan

39 1 714-033-000

Grommet

40 3 524-005-270

Screw, M4 x 60 PHMS, SS

20 in/lbs

41 4 524-005-272

Nut, KEPS, M3, SS

10 in/lbs

42 1 723-247-108

Transformer Assembly

43 2 724-462-010

Nelson Logo Decal

44 3 524-005-337

All Thread, M6 x 160

45 2 524-005-293

Screw, M6 x 30, HHCS, SS

80 in/lbs

46

0.4″

103-479-000

Thermal Tape

47 1 750-614-060

NCD+ Power Board Assembly

1

48

17

524-005-326

Screw, M6 x 14, HHCS, SS

40 in/lbs

14

49 1 724-576-017

NCD+ 3200 Rating Decal

50 1 724-485-010

Electrical Ground Label

51 1 524-005-289

Nut, M8 SS

52 1 87-05-19

Unplug Before Service Label

53 1 724-569-000

Warning Label

54 1 724-576-015

Made In USA Label

55 4 524-005-329

Screw, M8 x 12 PHMS, SS

40 in/lbs

56 5 524-005-288

Lock Washer, M8, SS

57 7 702-119-000

Capacitor, 27mf

2

58 5 524-005-287

Washer, M8 Flat, SS

60 in/lbs

59 4 524-005-271

Screw, M3 x 12 PHMS, SS

10 in/lbs

60 1 87-09-35

Cardiac Pacemaker Label

61 6 724-485-015

Small High Voltage Label

62 2 524-005-302

Washer, M3 Flat, SS

63 1 524-005-354

Screw, M8 X 16 HHCS, SS

NS 1 723-247-101

Power Board to Control Board Harness

NS 1 723-247-102

Power Board to Shunt, XFMR,

Discharge Resistor & Cap Switch Harness

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 27

NCD+ 3200 Manual | NCD+ 3200 Parts List & Exploded View

NS 1 723-247-104

Power Board to Caps, Fan & Bridge Harness

NS 1 723-247-105

(-) DC Bridge to (-) Cap Buss Harness

NS 1 723-247-107

Voltage Sense Resistor Harness

NS 1 723-247-012

Power Switch to Circuit Breaker Wire

NS 1 723-247-206

Voltage Selection Jumper Plug

NS 1 560-300-015

NCD+ 3200 Inner Carton

NS 1 750-614-249

NCD+ 3200 Harness Kit

NS 1 750-614-248

NCD+ 3200 Sheetmetal Kit

NS 1 750-614-247

NCD+ 3200 Assembly Kit

NS 1 560-200-005

NCD+ 3200 Foam Inserts

NS 1 560-300-014

NCD+ 3200 Shipping Carton

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 28

NCD+ 3200 Manual | NCD+ 3200 Parts List & Exploded View

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 29

NCD+ 3200 Manual | Wiring Diagrams for NCD+

6 Wiring Diagrams for NCD+

6.1 Standard System

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 30

6.2 Autofeed System

NCD+ 3200 Manual | Wiring Diagrams for NCD+

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 31

NCD+ 3200 Manual | Nelson NCD+ Welding Modes

7 Nelson NCD+ Welding Modes

There are 2 modes of the CD welding process offered with the NCD+ line of equipment: Contact and AutoGap. Each method has its own uses and set-up requirements. The method you select will be determined by

the metals to be joined, the esthetics strength and fixturing. Nelson Stud Welding will assist you in determining

which method best suits your needs.

7.1 Contact Mode Capacitor Discharge Welding

7.2 Auto-Gap Mode Capacitor Discharge Welding

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Page 32

NCD+ 3200 Manual | Contact Information

North America Sales Offices and Warehouses

*Chicago

18601 Graphic Court

Tinley Park, IL 60477

708.430.3770

Phone: 800.635.9353

Fax: 708.430.3975

*Philadelphia

260 Boot Road

Downingtown, PA 19335

Phone: 610.873.0012

800.635.9353

Fax: 610.873.2550

**Elyria

7900 West Ridge Road

P.O. Box 4019

Elyria, OH 44036-2019

Phone: 440.329.0400

Fax: 440.329.0521

*Westlake

835 Sharon Drive

Westlake, OH 44145

Phone: 440.250.9242

*Dallas

2211 Century Center Blvd.

Suite 105

Irving, TX 75062

Phone: 972.721.9055

800.635.9353

Fax: 972.438.7883

*San Francisco

23765 Foley Street

Hayward, CA 94545

510.293.0660

Phone: 800.635.9353

Fax: 510.293.0677

*Toronto

6199A Danville Rd.

Mississauga, Ontario

Canada L5T 2H7

Phone: 905.795.8277

800.635.9353

905.795.8275

*Los Angeles

20621B East Valley

Blvd. Walnut, CA

91789-2731

Phone: 909.468.2105

800.635.9353

Fax: 909.468.2112

Subsidiaries

International

England

Nelson U.K. Ltd.

47-49 Edison Rd.

Rabans Lane Ind’l Estate

Aylesbury HP19 8TE, UK

Phone: 44.1296.433500

Fax: 44.1296.487930

Middle East & Asia/Pacific

7900 West Ridge Rd.

P.O. Box 4019

Elyria, OH 44036-2019 USA

Phone: 440.329.0400

Fax: 440.329.0597

World Wide Web: NelsonStudWelding.com

E-mail: Nelson.Sales@NelsonStud.com

France

Nelson Frances S.A.S.

Z. 1 du Chemin Vert

8 rue de l’Angoumois F-95100 Argenteuil,

France

Phone: 33.1.3411.9400

Fax: 33.1.3411.2033

Central & South America

P.O. Box 3990

Seminole, FL 33775 USA

Phone: 727.596.9600

Fax: 727.593.3494

Germany

Nelson Germany

Mailing Address

Postfach 40-20

58272 Gevelsberg

Germany

Shipping Address

Flurstrasse 7-19

58285 Gevelsberg

Germany

Phone: 49.2332.661.0

Fax: 49.2332.661.165

For Distributors in

specific areas call:

440.329.0400

General Offices

7900 West Ridge Rd. P.O. Box 4019

Elyria, OH 44036-2019 USA

Phone: 440.329.0400

Fax: 440.329.0597

World Wide Web: NelsonStudWelding.com

E-mail: Nelson.Sales@NelsonStud.com

Italy

Nelson Italy

Via Miraflores, 20

Nichelino, (TO) I-10042

Italy

Phone:39.011.6059238

Fax: 39.011.6059230

8 Contact Information

Part No. 729-110-037 Rev. 1.31 | May 2016 © 2014 Nelson Stud Welding, Inc. All Rights Reserved.

Loading...

Loading...