Nelson Installation and Maintenance Manual: GA-2490, CM-3-32 Heat Trace Circuit Management System Manuals & Guides

Page 1

Page 2

CM3-32 Installation and Operations Manual

TABLE OF CONTENTS

I. FEATURES .................................................................................................................. 3

Control & Monitoring ............................................................................................................. 3

II. INSTALLATION .......................................................................................................... 5

Location .................................................................................................................................... 5

Control Power ......................................................................................................................... 5

Ventilation ................................................................................................................................ 5

Conduit Routing ..................................................................................................................... 5

III. OPERATION .............................................................................................................. 8

Channel Select ........................................................................................................................ 8

Channel Display ...................................................................................................................... 8

Individual Channel Enable/Disable .................................................................................... 9

Trip Reset Function ............................................................................................................... 9

Alarm Indication ................................................................................................................... 10

Output Alarm Reset ............................................................................................................. 10

Alarm Log Display ................................................................................................................ 11

Advanced Operations - Maintenance Alerts ................................................................. 12

Maintenance Alert Log ........................................................................................................ 12

Maintenance Alert Status ................................................................................................... 13

IV. START-UP ............................................................................................................... 14

Turning the System On ....................................................................................................... 14

Programming System Parameters ................................................................................... 14

Temperature Units ............................................................................................................... 14

Ground Fault Delay .............................................................................................................. 15

Automatic Test Cycle .......................................................................................................... 16

Programming Individual Channels (Circuits) ............................................................... 16

Sensor Failure Mode ........................................................................................................... 17

Ground Fault Control .......................................................................................................... 18

Global Programming of Channels (Circuits) ................................................................. 19

Advanced Setup Features .................................................................................................. 20

Ambient Control ................................................................................................................... 20

Maintenance Alerts .............................................................................................................. 21

Event Log and Display Settings ....................................................................................... 21

User Login and Passwords ............................................................................................... 23

Changing User Passwords ................................................................................................ 24

Changing Modbus Slave Address (-EC Option) ........................................................... 25

V. TROUBLESHOOTING.............................................................................................. 27

System Operation ................................................................................................................ 27

Section I .................................................................................................................................. 28

Communications Alarm ...................................................................................................... 28

Section II ................................................................................................................................. 29

Temperature Alarm .............................................................................................................. 29

Section III ................................................................................................................................ 30

Load Current Alarm ............................................................................................................. 30

Section IV ............................................................................................................................... 31

Ground Fault Alarm ............................................................................................................. 31

VI. SPECIFICATIONS ................................................................................................... 32

VII. GENERAL COMMUNICATION INFORMATION (-EC OPTION) ............................. 33

VIII. COMMUNICATIONS ............................................................................................. 33

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 2 -

Page 3

CM3-32 Installation and Operations Manual

I. FEATURES

Control & Monitoring

The CM3-32 Circuit Management System is a microprocessor based control and

monitoring system utilizing standard industrial automation products specifically integrated

for use with electrical heat tracing systems. The system provides temperature and current

monitoring for each heat tracing circuit while communicating additional information to

operations personnel such as temperature alarms, sensor failures, electrical circuit faults,

and overall operational conditions.

The CM3-32 Circuit Management System is mounted in a NEMA 12, 4, or 4X free-standing

industrial enclosure. The system is available in standard configurations up to a maximum

of 32 control circuits per enclosure. The CM3-32 is configured from standard PLC

automation components interfaced with specialized current modules and power handling

devices designed for this specific application. Individual CM3-32 systems can be network

connected through the provided Modbus® RTU communications protocol.

Color Touch Screen Graphics Terminal – 5.7” Color LED analog touch pad, resolution

1024 x 1024, compact flash card memory for user application

Process Temperature Display – actual pipe/vessel temperature is displayed with alarm

indication by animation and color change

Load Current Display – actual heater load current is displayed with alarm indication by

animation and color change

Ground Fault Leakage Display – actual ground fault leakage is displayed with alarm

indication by animation and color change

Heater Status, Condition, and Alarm Displays – real time status of individual channel

control is displayed by alarm banners, animated light bars and/or animated backgrounds

Programmable Setpoint Values – direct programming of the following values is provided:

Maintain Temperature

Deadband

Hi Temperature Alarm

Lo Temperature Alarm

Hi Current Alarm

Lo Current Alarm

Ground Fault Alarms, Alarm and Trip Values

Programmable Operational Features – direct programming of the following features is

provided:

Temperature Units

Ground Fault Delay Option

Automatic Test Cycle Function and Time Intervals

Sensor Failure Mode

Ground Fault Trip Control Function

Ambient Control Function and Channel Identification

Maintenance Alert Function and Settings

System Override Option

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 3 -

Page 4

CM3-32 Installation and Operations Manual

Global Programming – allows programming of all control setpoint values from a single

input screen

Modbus® Communications – remote monitoring capabilities provided via Modbus® RTU

protocol using simple 2-wire, RS-485 hardware

Web Gate and Web Page Server (ET Suffix Only) – direct control and monitoring is

provided through Ethernet connection to the Graphics Terminal, Web Gate server with

remote terminal diagnostics from the navigator on your PC

Maintenance Alerts – trend analysis of each channel’s electrical characteristics is

provided with actual value indication and alert messaging for use by operations personnel

to focus periodic maintenance efforts more efficiently

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 4 -

Page 5

CM3-32 Installation and Operations Manual

II. INSTALLATION

Location

The CM3-32 should be located in a suitable location on a flat and level surface. The

enclosure should be bolted to the base and/or wall surface, or adequately supported by

other methods to prevent unsafe installation and/or operational conditions.

NEMA Type 12 (IP55)

Enclosures are intended for indoor use primarily to provide a degree of protection

against dust, falling dirt, and dripping non-corrosive liquids.

NEMA Type 4 (IP66)

Enclosures are intended for indoor or outdoor use primarily to provide a degree

of protection against windblown dust and rain, splashing water, and hose

directed water, undamaged by the formation of ice on the enclosure.

NEMA Type 4X (IP66)

Enclosures are intended for indoor or outdoor use primarily to provide a degree

of protection against corrosion, windblown dust and rain, splashing water, and

hose directed water, undamaged by the formation of ice on the enclosure.

The basic CM3-32 is designed for use in ordinary, non-classified locations. Protecting

electrical equipment in hazardous, classified, locations requires special considerations.

NEMA 4 and 4X Panels supplied with a P Suffix are provided with Type Z Purge equipment

to ensure safe operation within a hazardous location. The protective gas purge supply

must be clean, dry, and free of hydrocarbons or corrosive materials. All protective gas

purge supply pressures must be set correctly and all enclosure doors must be closed

securely. Purged enclosures must not be opened unless power is removed from the

equipment and the area is known to be non-hazardous.

Control Power

The CM3-32 accepts universal voltages of 100-240VAC single phase, 60/50Hz. The panel

is equipped with (2) Form C Alarm Relays that are energized during normal operation.

Should the panel lose control power or activate an alarm, the relays will de-energize

indicating an alarm condition.

Ventilation

The CM3-32 is provided with continuously operating internal circulation fans. These fans

are used for static ventilation and aid heat dissipation from the enclosure by passive

radiation and convection. The accumulation of heat in an enclosure is potentially damaging

to electrical and electronic devices. Overheating can shorten the life expectancy of costly

electrical components or lead to premature failure.

Conduit Routing

When routing conduit to the CM3-32 enclosure, clear space is provided on the top, right

side, and bottom areas. Top entry should be avoided if possible. Top entry provides a

potential moisture path to the electronics and interconnecting wiring. If top entry cannot be

avoided, do not locate conduit entries directly over any exposed electrical equipment. Drip

loops are recommended for all top and/or side entry. A drip loop is a dip or bend in the

wiring to block or shed moisture that may follow a wire to the connection point.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 5 -

Page 6

CM3-32 Installation and Operations Manual

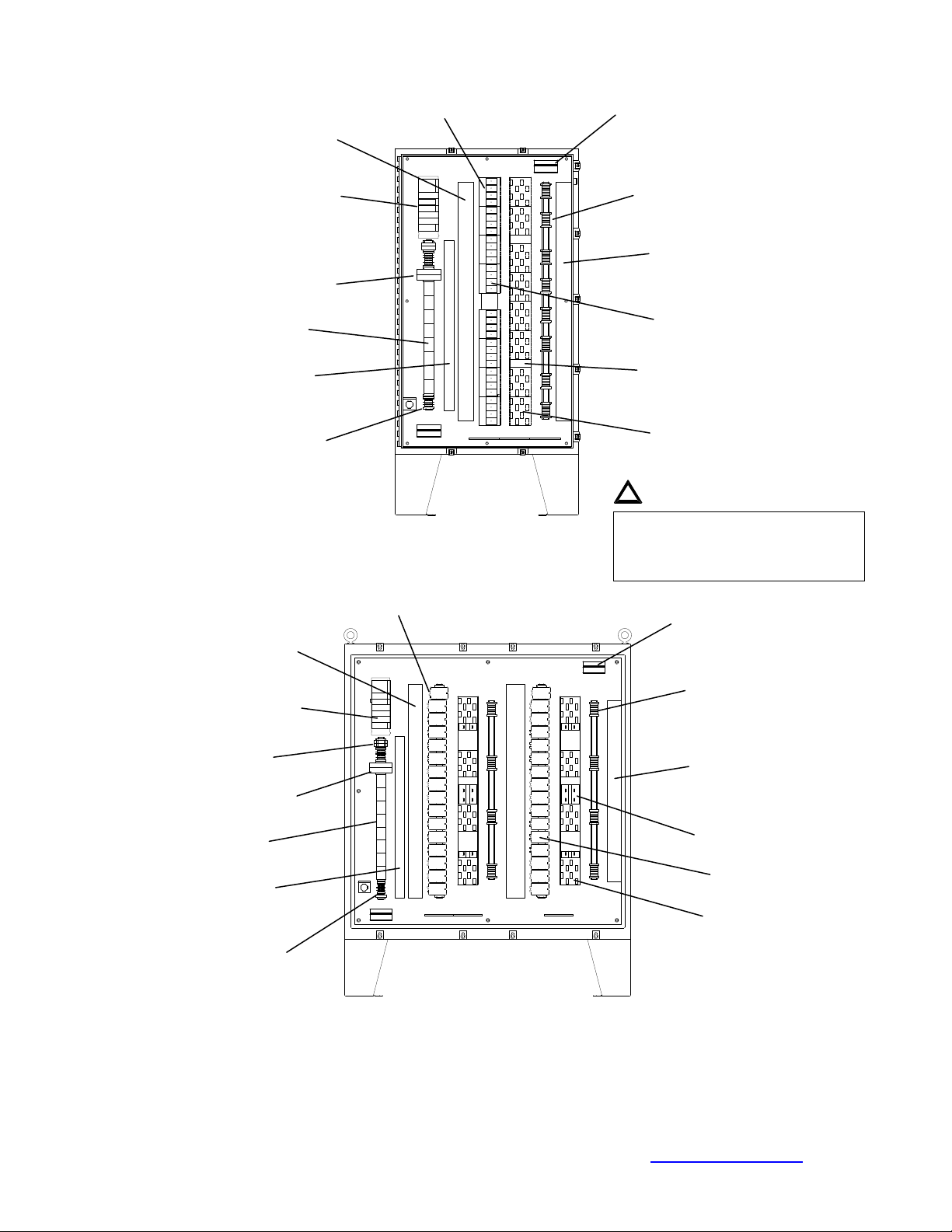

WARNING:

Modul

e Assembly

Alarm Relays

Terminal Blocks

Wire Trough

Terminal Blocks

Terminal Blocks

Trough

Module Assembly

Alarm Relays

Terminal Blocks

Wire Trough

Terminal Blocks

Contactors

Moisture intrusion can damage the

modules,

relays

or con

trol wiring.

Processor and I/O

Power Supply

RTD Input

Modules

Sensor Wire

Control Power

Line In

Processor and I/O

Power Supply

RTD Input

Modules

Sensor Wire

Trough

Control Power

Line In

Line In

Terminals

Line In

CM3-32-R2

Figure 1

CM3-32-C

Figure 2

Ventilation Fans

Line Out

Line Out

Wire Trough

Power Relays

(GC-695)

Communications

Interface Modules

CT Modules

(GC0710)

!

CM-3 electronics. Do not place

conduit entry directly over the control

Ventilation Fans

Line Out

Line Out

Wire Trough

Voltage Drivers

(GC0577X01)

CT Modules

(GC0710)

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 6 -

Page 7

CM3-32 Installation and Operations Manual

Note:

Power Supply

Processor Module

missing or faulty

Discrete I/O Module

(Alarm Relays)

Analog

I/O Module

(RTD Sensors)

Display

RUN LED (green) Processor running

ERR LED (red) Processor or system fault

I/O LED (red) I/O module fault

SER COM LED (yellow) Activity present

CARD ERR LED (red) Memory card

Display

OK LED (green)

24 V LED

(green)

Flash Memory card

RS-485 Internal

communications cable

connection

D25SUB Connector

High Density Connections

to PLC Input Modules

Refer to Assembly and Wiring

Diagrams supplied with panel for

specific connection details

Display

RUN LED (green) Normal

ERR LED (red) On=Internal fault, Flashing=Comm fault

I/O LED (red) On=External fault, Flashing=Terminal

block fault

Channel LED’s (green) On=Normal, Off=Alarm

Display

RUN LED (green) Normal

ERR LED (red) On=Internal fault, Flashing=Comm

fault

I/O LED (red) On=External fault, Flashing=Cable fault

Channel LED’s (green) On=Normal, Flashing=Sensor

failure or no sensor connected

USB cable

connection to

Graphics Display

PLC Module Details

Figure 3

RTD Interface Module

Figure 4

High density cable

connections to RTD

Interface Modules

RTD Interface Module

Part No. 2900774

Instrument Wire for Sensor

Connections (Typical)

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 7 -

Page 8

CM3-32 Installation and Operations Manual

III. OPERATION

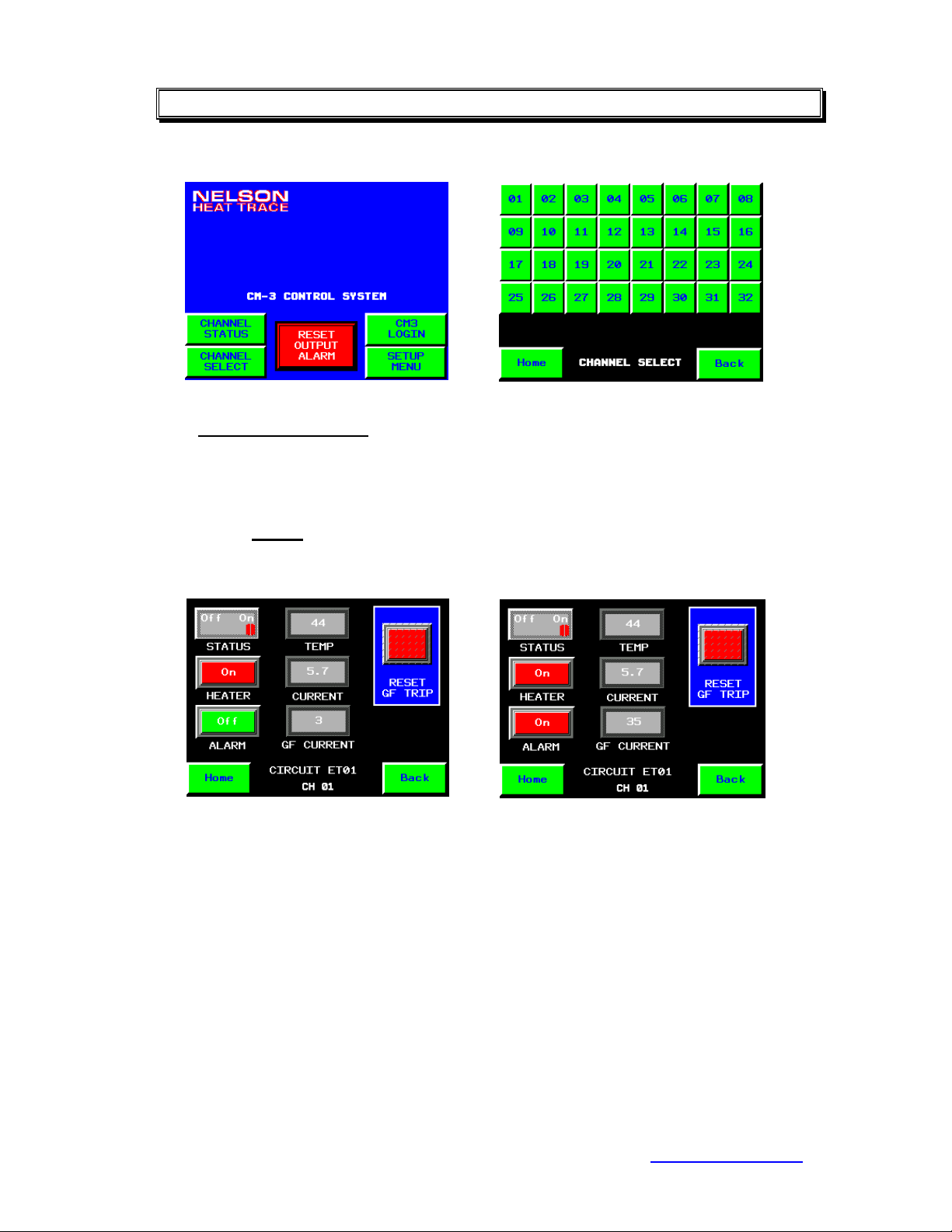

Channel Select

To view the current status of each individual control channel, press

< CHANNEL SELECT > found in the lower left corner of the Home page.

This action will access the CHANNEL SELECT page allowing the direct

selection of each individual channel. Press the channel number to access

the specific page required.

Press < Home > on any displayed page to return to the Home page screen.

Channel Display

Individual channel pages display the current status of all operational

conditions. Actual values are compared to programmed values and

indicated by color and/or animation. The actual values are only shown

when the heater is energized. These values will be shown as 0’s during any

de-energized condition.

The status of each heater output control is shown by the switch labeled

STATUS. The HEATER indication bar light will notify the operator as to

whether the heat tracing is currently Off (Green) or On (Red).

When actual conditions are within programmed parameters, the specific

value will be shown in steady-white. If the actual condition is outside of the

programmed parameters, the specific value and ALARM indication bar light

will flash slow off-and-on. If the current condition exceeds the

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 8 -

Page 9

CM3-32 Installation and Operations Manual

programmed value for Ground Fault Trip, the specific value will change to

flash fast off-and-on.

To view a different channel, press < Back > to access the Channel

Selection page.

Press < Home > on any displayed page to return to the Home page screen.

Individual Channel Enable/Disable

Press < ON > side of the STATUS switch to automatically control the

individual channel by the programmed set point temperature. Press the

< OFF > side of the STATUS switch to disable the displayed channel.

When the STATUS switch is in the < OFF > position, the channel will not be

included during the System Override function or the Auto Test-Cycle

function and all alarms will be disabled.

Press < Home > on any displayed page to return to the Home page screen.

Trip Reset Function

If the Ground Fault Trip function is programmed to be < ON >, a tripped

condition will be indicated by the flashing background around the RESET

GF TRIP button. All ground fault trip conditions must be manually reset.

This operational parameter will disable the heater output device until the

condition is corrected and the reset button is pressed. To reset the tripped

circuit, press < RESET GF TRIP >.

If the Ground Fault Trip function is programmed to < OFF >, the reset switch

will be replaced by the GROUND FAULT TRIP DISABLED indication.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 9 -

Page 10

CM3-32 Installation and Operations Manual

Safety Warning:

The system will still reflect ground fault alarm conditions, but the

heater will not be de-energized during any high ground leakage

conditions.

Press < Home > on any displayed page to return to the Home page screen.

Alarm Indication

When an alarm is triggered by the CM-3, a banner will appear at the top of

the Home page and begin scrolling each active alarm condition. This

indication gives the operator the current active alarm(s) and channel

number(s). The Alarm Banner will remain active until the alarm condition is

corrected.

Output Alarm Reset

The CM-3 is equipped with two separate alarm output relays, one is used

for Common Alarm indication and the other is specific to any Ground Fault

conditions only. To clear these alarm outputs, press < RESET OUTPUT

ALARM >. Additional alarm conditions will activate these alarm outputs

accordingly. These alarm contacts are designed to be used for external

indication of alarm status.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 10 -

Page 11

CM3-32 Installation and Operations Manual

Alarm Log Display

To view all current alarms, press < CHANNEL STATUS > in the lower left

corner of the page. This will display the Channel Summary page. Any

channels that are currently in alarm will be represented by the Alarm Banner

on the lower portion of the page and the specific channel number will be

flashing off-and-on. Acknowledge specific Channel Alarms by pressing

the appropriate channel number. Press < Alarm Log > to directly access

the stored list of alarms.

This page will show all current alarms and their status. Alarm messages

shown in Red are active, those shown in Green have returned to normal.

All alarms are stamped with the Date and Time. You can directly select a

specific alarm message by pressing the block directly to the left of the

message as shown by the black and white arrow above.

These icons move the cursor up or down one row. Cursor Up moves the

cursor up one row. Cursor Down moves the cursor down one row.

These icons scroll one page up or down. Page Up and Page Down are

useful when there are too many alarms to fit on a single page of the alarm

summary. Page Up moves the display up one page. Page Down moves

the display down one page.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 11 -

Page 12

CM3-32 Installation and Operations Manual

The Clear and Clear All icons remove all instances of an alarm from the

alarm summary. The variable remains in the alarm state, but the associated

alarm message will not appear anymore in the alarm summary display.

Return to normal alarms cannot be cleared with these operations.

The purpose of this operation is to remove an alarm message that displays

erroneously. This could be the result of equipment failure such as a faulty

sensor, or of a single alarm generating multiple alarm messages.

The Delete and Delete All icons delete alarms from the current alarm list.

Advanced Operations - Maintenance Alerts

If the Maintenance Alert function is activated during system set-up,

additional features allowing access to the Alert Log and Alert Status pages

are visible to the operator.

Maintenance Alert Log

This page will show all maintenance alerts and their status. Alert messages

shown in Red are active, those shown in Green have been reset in the Alert

Status page for each individual channel. All alerts are stamped with the

Date and Time. You can delete all alerts or individual alerts from this page.

You may scroll up/down or right/left using the displayed scroll bars.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 12 -

Page 13

CM3-32 Installation and Operations Manual

Maintenance Alert Status

To view active alert statistics, press < Alert Status > on the Channel

Display page. This page will provide the operator with the highest value

that the temperature sensor has recorded and the initial values for load

current and ground fault leakage.

If the actual value exceeds the calculated values programmed during the

set-up operations, the current actual values will be displayed on the CH

STATISTICS page and a message will be added to the Alert Log.

An individual message on the Alert Log can be acknowledged by pressing

< RESET ALERTS > on the STATISTICS page for that channel. Alert

messages shown in Red are active, those shown in Green have returned to

normal.

Once maintenance or replacement has been completed on these circuits,

press < RESET VALUES > to replace the initial values used in the

maintenance alert calculations with current actuals.

For a detailed description of the operational icons, refer to the Alarm Log

Display section.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 13 -

Page 14

CM3-32 Installation and Operations Manual

IV. START-UP

Turning the System On

Using the branch breaker providing control power to the internal power

supplies, energize the CM-3 system and allow the unit to complete its selfcheck sequence and display the Home page. On initial start-up, the unit

may require programming of the System Parameters and the Channel

Parameters for the specific application. To access the CONTROLLER

SET-UP page, press < SETUP MENU >. From this page you can access

the all application pages required to completely program the CM-3.

The SYSTEM OVERRIDE switch is also located on the CONTROLLER

SET-UP page. By selecting the < ON > position, all channels that are

currently enabled will be forced ON regardless of process conditions. For

safety reasons, this switch will not override any circuits that are tripped out

due to high ground fault conditions.

Programming System Parameters

To access the System Set-Up Parameters, press < System Setup > from

the CONTROLLER SET-UP page. Access to this page requires the PROG

user name and password.

Temperature Units

To select the CM-3 operation to either Fahrenheit or Celsius, press

< F > or < C > on the UNITS switch. This selection converts the actual

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 14 -

Page 15

CM3-32 Installation and Operations Manual

sensor readings and compares its value to the programmed setpoint values.

Programmed Setpoint Values:

Setpoint

Deadband

Hi Temp

Lo Temp

All setpoint values must be input in the correct unit selected, the CM-3

does not automatically convert values between units.

Ground Fault Delay

The CM-3 is equipped with a ground fault delay feature that will delay the

alarm and trip functions during unidentified transient conditions.

During normal operation, the CM-3 will trip (de-energize) the heat tracing

circuit immediately when a high ground fault condition is observed.

In some situations, unidentified transient conditions can lead to nuisance

tripping of heater circuits that require manual resetting to maintain plant

operations. Some examples of this might be; high dew point conditions

during shut down, high amperage circuit wiring in close proximity to heater

circuits, motors/compressors wiring in close proximity to heater circuits, high

gain antennas, etc. In those situations, the ground fault delay may be used.

By turning the GROUND FAULT DELAY switch to < ON >, a 10 second

delay is provided to allow those transient conditions to pass without causing

false alarms or tripping of the heat tracing circuits.

Safety Warning:

It is recommended that any abnormal ground fault leakage conditions

be thoroughly investigated before activating this feature.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 15 -

Page 16

CM3-32 Installation and Operations Manual

Automatic Test Cycle

The CM-3 can be programmed to perform an Auto Test-Cycle function for

periodic maintenance for seasonal heating applications. This feature will

energize all enabled channels at programmed intervals and report any

alarm conditions that may have developed during the system idle period.

To activate this feature, press the < ON > side of the AUTO-TEST CYCLE

switch. Next, select the HOUR INTERVALS to determine the length of time

between test cycles. The CM-3 can be programmed up to 720 hours (30

days) between cycles. The minimum and maximum values are displayed

with each input selection. To change the cycle time, press the display field

and enter the new value. Press < Enter > to input this value in to the

operational program.

To continue programming the CM-3, press < Back > to return to the

Controller Setup page.

Press < Home > on any displayed page to return to the Home page screen.

Programming Individual Channels (Circuits)

To program individual control channels, press < SETUP MENU > found in

the lower right corner of the Home page screen. This action will access the

CONTROLLER SET-UP page. Press < Channel Setup > to access the

CHANNEL SET-UP page allowing the direct selection of each individual

channel. Access to this page requires a MAINT user name and password.

Press the < CH > number to access the specific channel page required.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 16 -

Page 17

CM3-32 Installation and Operations Manual

Program any setpoint value by pressing the display field for the value to be

changed. A Data Entry screen will be displayed. The minimum and

maximum values are displayed with each input selection. Enter the new

value from the keyboard. Press < Enter > when finished.

Setpoint: value range = -328 to +1392

Deadband: value range = 1 to 10

Hi-Temp: value range = -328 to +1392

Lo-Temp: value range = -328 to +1392

Description: value range = 15 Characters

Sensor Failure Mode

When a shorted or open sensor is detected, you can select the heater

output to energize or de-energize under failure conditions. Press the

< ON > side of the Sensor Failure Mode switch if you want the heater to be

energized, press the < OFF > side of the switch if you want the heater to be

de-energized. When the sensor is operational, the CM-3 will return to

normal operation automatically.

Press < Page 2 > to access additional setpoint and control options.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 17 -

Page 18

CM3-32 Installation and Operations Manual

Program any setpoint value by pressing the display field for the value to be

changed. A Data Entry screen will be displayed. The minimum and

maximum values are displayed with each input selection. Enter the new

value from the keyboard. Press < Enter > when finished.

High Current: value range = 0 to 30 amps

Low Current: value range = 0 to 30 amps

GF Alarm: value range = 0 to 900 milliamps

GF Trip: value range = 0 to 900 milliamps

To enter a value less than 1, a zero must be entered before the decimal

point. Example: 0.2, 30.0, etc.

Ground Fault Control

The Ground Fault Trip feature is used in applications where, for either

process or safety reasons, the facility has elected to allow the heater to

remain energized under fault conditions. The CM-3 is programmed with all

channels defaulted with the GF Control switch in the < ON > position. The

GF Trip display field is hidden when the GF Control switch in the < OFF >

position.

The specific requirements for this operational feature can be found in

the National Electric Code, Article 427, and Equipment Protection.

Safety Warning:

By programming the GF Control switch to the < OFF > position, the specific channel will alarm

and show an indication that the ground leakage has exceeded the programmed trip value but

the heater will remain energized.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 18 -

Page 19

CM3-32 Installation and Operations Manual

Global Programming of Channels (Circuits)

To access the CONTROLLER SET-UP page, press < SETUP MENU > on

the Home page. To access the Global Program Setup Parameters, press

< Global Setup >. Access to this page requires a MAINT user name and

password.

Program any setpoint value by pressing the display field for the value to be

changed. A Data Entry screen will be displayed. The minimum and

maximum values are displayed with each input selection. Enter the new

value from the keyboard. Press < Enter > when finished.

Set point: value range = -328 to +1392

Dead band: value range = 1 to 10

Hi-Temp: value range = -328 to +1392

Lo-Temp: value range = -328 to +1392

High Current: value range = 0 to 30 amps

Low Current: value range = 0 to 30 amps

GF Alarm: value range = 0 to 500 milliamps

GF Trip: value range = 0 to 500 milliamps

To enter a value less than 1, a zero must be entered before the decimal

point. Example: 0.2

The Sensor Failure Mode and Ground Fault Trip feature cannot be

programmed globally. These features have safety related concerns and the

programming conditions should be viewed on an individual basis.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 19 -

Page 20

CM3-32 Installation and Operations Manual

When all displayed values have been programmed, enter all values by

pressing < ENTER > Values.

Press < Home > on any displayed page to return to the Home page screen.

Advanced Setup Features

To access the Controller Set-Up page, press < SETUP MENU > on the

Home page. To access the Advanced Setup features, press

< Advanced Setup >. Access to this page requires a MAINT user name

and password.

Ambient Control

The Ambient Control feature on the CM-3 allows the system to be

configured for single sensor input. To activate this feature, press the

< ON > side of the AMBIENT CONTROL switch. Next, select the number of

circuits to be connected and controlled by the single sensor input. Program

the value by pressing the display field for the value to be changed. A Data

Entry screen will be displayed. Enter the new value from the keyboard.

Press < Enter > when finished.

The CM-3 can be programmed for any number combination of process and

ambient controlled circuits. All Ambient Controlled circuits will operate

utilizing the temperature sensor connected to RTD Input #1.

In the input example shown above, Channels 1-8 will use the temperature

sensor connected to RTD Input #1 and the remaining channels will operate

from their individually connected sensors

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 20 -

Page 21

CM3-32 Installation and Operations Manual

Maintenance Alerts

The Maintenance Alerts feature on the CM-3 provides operations personnel

with an additional tool for scheduling system maintenance. Like similar

features found on process control systems, this option monitors each

heating cable and looks for trends that relate to future maintenance

requirements. This feature is designed to detect possible maintenance

situation before programmed alarm thresholds are exceeded.

When active, the CM-3 monitors the actual load current and ground fault

leakage of each individual circuit and compares them to their initial values.

If a value is outside of the programmed parameters, it records the specific

value and triggers a Maintenance Alert message for use by operational

personnel.

To activate this feature, press the < ON > side of the MAINT ALERTS

switch. Next, input the percentage of initial load current that will trigger a Lo

Current maintenance alert. Program the value by pressing the display field

for the value to be changed. A Data Entry screen will be displayed. Enter

the new value from the keyboard. Press < Enter > when finished.

Each time the heater is cycled, the current and ground fault values are

stored. The load current value is compared to the programmed percentage

value to determine if any preventive action should be taken. The ground

fault value is compared to previous readings looking for increasing levels of

leakage that may result in future safety concerns.

Event Log and Display Settings

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 21 -

Page 22

CM3-32 Installation and Operations Manual

To access the CONTROLLER SET-UP page, press < SETUP MENU > on

the Home page.

Event Log

To access the Event Log Summary, press

< Event Log >. The Event Log provides detailed system level information

regarding the operation of the graphics terminal. This can be used to

troubleshoot any problems related to normal communications with the PLC

processor.

Display Settings

To access the Display Settings features, press

< Display Settings >.

From the System page, you can modify several parameters within the

graphic display module.

Date and Time

To set the Date and Time, press the display field for the value to be

changed. A Data Entry screen will be displayed. Enter the new value from

the keyboard. Press < Enter > when finished.

Restart

You may elect to Restart the Graphics Display Unit in the event the unit

loses its connection to the PLC or an updated program has been provided in

the form of a compact flash card.

Brightness

You may elect to change the brightness and contrast on the display to better

suit the installed light conditions.

If all modified parameter on this page have been completed, you can press

< To Run Mode > and return to the operating program or press < Offline >

to access additional parameters.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 22 -

Page 23

CM3-32 Installation and Operations Manual

From the Offline page, you can modify additional parameters within the

graphic display module.

Network and Web Gate – ET Version Only

To set the Network IP Address, press the display field for the value to be

changed. A Data Entry screen will be displayed. Enter the new value from

the keyboard. Press < Enter > when finished. You may also change the

Security Settings for network access on this page.

Backlight

The Backlight settings allow the user to set the duration of time allowed

before the display activates a screen saver mode. The unit can also be set

for continuous use. This setting will reduce the operational life of the light

source.

User Login and Passwords

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 23 -

Page 24

CM3-32 Installation and Operations Manual

To enter the user name and password, access the User Login screen by

pressing < CM3 LOGIN > in the lower right hand corner of the screen. The

Login page allows the user to enter a user name and password allowing

access the desired programming pages. The MAINT user name and

password allows the operator to access all Channel and Global

programming pages. The PROG user name and password allows the

operator to access all system programming pages.

Input the User Name and Password by pressing the appropriate display

field. A Data Entry screen will be displayed. Enter the new value from the

keyboard. Press < Enter > when finished.

Once both the User Name and Password have been input, you must press

the < Lock > icon to complete the login process. A successful login will

show the input name in the Current User field. Press < Home > icon to

return to the Home page screen.

The CM-3 will automatically return to a secure condition after 15 minutes of

inactivity. To logout immediately, press < LOGOUT > on the Home page

screen.

Changing User Passwords

The default passwords in the CM3 may be changed when the login process

has been completed by the PROG level user. The < CHANGE

PASSWORD > icon will become visible on the HOME page.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 24 -

Page 25

CM3-32 Installation and Operations Manual

To change a password, first select the appropriate Group. SecurityGroup01

= MAINT level access and SecurityGroup02 = PROG level access. Insert

the new password by pressing the appropriate display field. A Data Entry

screen will be displayed. Enter the new password from the keyboard and

press < Enter > when finished.

Once the new Password has been entered and confirmed, press the

< Exchange > icon to complete the process. Press the < Exit > icon to

return to the previous programming page.

Changing Modbus Slave Address (-EC Option)

The Modbus Slave Address in the CM3 may be changed when the login

process has been completed by the PROG level user. The < MODBUS

ADDRESS > icon will become visible on the HOME page.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 25 -

Page 26

CM3-32 Installation and Operations Manual

Input the new Modbus slave address by pressing the appropriate display

field. A Data Entry screen will be displayed. Enter the new value from the

keyboard. Press < Enter > when finished.

When a new value is entered, the status indication bar light will change to

Red.

When all displayed value has been programmed, enter the new address by

pressing the < ENTER > button. If the address change is successful, the

status indication bar light will turn to Green to indicate the new address is

now active in the control system.

Press < Home > on any displayed page to return to the Home page screen.

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 26 -

Page 27

CM3-32 Installation and Operations Manual

V. TROUBLESHOOTING

System Operation

S

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 27 -

Page 28

CM3-32 Installation and Operations Manual

Section I

Communications Alarm

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 28 -

Page 29

CM3-32 Installation and Operations Manual

Section II

Temperature Alarm

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 29 -

Page 30

CM3-32 Installation and Operations Manual

Section III

Load Current Alarm

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 30 -

Page 31

CM3-32 Installation and Operations Manual

Section IV

Ground Fault Alarm

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 31 -

Page 32

CM3-32 Installation and Operations Manual

VI. SPECIFICATIONS

Supply Voltage (1-Phase)

Power Input

R2 Version

R2 Version (CWP)

C Version

C Version (CWP)

Operating Environment

Operational (Standard)

Operational (with Cold Weather

Package)

Storage

Relative Humidity

Sensor Input

Temperature Range

Accuracy

Power Handling

R2 Version

C Version

Load Current Range

Accuracy

Ground Fault Leakage Range

Accuracy

Display

Operator Interface

Programming Options

Auto-Test Cycle Frequency

Sensor Failure Output

Control Mode

Channel Enable/Disable

Hi Temp Alarm

Lo Temp Alarm

Hi Current Alarm

Lo Current Alarm

Ground Fault Alarm

Ground Fault Trip Level

Ground Fault Trip Enable/Disable

Sensor Failure Alarm

Alarm Output Type

Alarm Output

Communications (-EC Option)

Communications Options

Universal Input, 85 to 264VAC, 50-60Hz

220 Watts Nominal

645 Watts Nominal

290 Watts Nominal

855 Watts Nominal

-15 to +40ºC

-40 to +40ºC

-40 to +85ºC

0-95% Non-condensing

RTD, 100, Platinum, 3-Wire

-328 to +1392ºF (-200 to +756ºC)

1% of Range

100 to 277VAC, Relays

100 to 600VAC, Contactors

0.1 to 24.0 Amps

±10%

1-900 milliamps

±10%

Color LED, CFL 75,000 h

Analog Touch Pad, Resolution 1,024 x 1,024

Individual Channel, Global

1 to 720 Hours

On/Off, Selectable per Channel

On/Off with Adjustable Deadband

Yes, Selectable per Channel

Adjustable over Temperature Range

Adjustable over Temperature Range

Adjustable, 0.0 to 30.0A

Adjustable, 0.0 to 30.0A

Adjustable, 0 to 500mA

Adjustable, 0 to 500mA

Yes, Selectable per Channel

Yes, Open and Shorted

Common and Separate Ground Fault

Form C, 7.0A @ 120/240VAC

Modbus® RTU, Slave Mode Only, Non-Isolated

RS-485, 2-Wire Operation

Consult Factory

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 32 -

Page 33

CM3-32 Installation and Operations Manual

VII. GENERAL COMMUNICATION INFORMATION (-EC OPTION)

Serial Port:

Baud Rate:

Data Bits:

Stop Bits:

Parity:

Device Address:

Select the serial port that corresponds to your RS-485 Adapter.

USB to Serial adapters may be used for devices without serial connections.

9600

8

1

Even

User Defined

VIII. COMMUNICATIONS

The Nelson Heat Trace CM332-EC supports a subset of the Modbus® RTU protocol format that provides

monitoring, programming, and control functions using Read (3) and Write (6) register commands. The

actual address for each register is a combination of 3 elements; Data Type, Specific Address and the

Channel Number. Example: The Actual Temperature for Channel 12 would be located at address

%MW1712.

DATA TYPE, %M = Discrete Variable, %MW = Integer Variables

VARIABLE NAME MODBUS ADDRESS DESCRIPTION / VALUE RANGE

Alarm WORD %MW 1 XX

,0 Enable Channel

,1 Common Alarm

,2 Not Used

,3 Sensor Failure Alarm

,4 High Temperature Alarm

,5 Low Temperature Alarm

,6 High Current Alarm

,7 Low Current Alarm

,8 Ground Fault Alarm

,9 Ground Fault Trip

,10 Not Used

,11 Not Used

,12 Not Used

,13 Statistics Enable

,14 Low Amperage Alert

,15 High Ground Fault Current Alert

Alarm Acknowledge %M 1 XX = momentary ON to reset

Ambient Control OFF %M 4 = momentary ON to reset

Ambient Control ON %M 5 = 0 if OFF, = 1 if ON

Ambient Controlled Circuit Count %MW 1 0 to 32 ( = number of circuits)

Amperage Percent Value %MW 2 0 to 100 ( = percent)

Auto Test Active %M 6 = 0 if OFF, = 1 if ON

Auto Test Cycle OFF 7 = momentary ON to reset

Auto Test Cycle ON %M 8 = 0 if disabled, = 1 if enabled

Auto Test Frequency in Hours %MW 3 1 to 720 ( = x if set to x Hours)

SPECIFIC ADDRESS

CHANNEL NUMBER, XX = 01 thru 32

WORD to BIT, if applicable

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 33 -

Page 34

CM3-32 Installation and Operations Manual

VARIABLE NAME MODBUS ADDRESS DESCRIPTION / VALUE RANGE

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error CT Module

Communications Error Interface

Communications Error Interface

Ground Fault Alarm Setpoint

Ground Fault Current (Actual) %MW 5 XX

Ground Fault Trip Control OFF %M 10 XX

Ground Fault Trip Control ON %M 9 = momentary ON to reset

Ground Fault Trip Reset %M 11 XX = momentary ON to reset

Ground Fault Trip Setpoint

High Current Alarm Setpoint

High Ground Fault Level Alert %M 14 XX = 0 if OFF, = 1 if ON

High Ground Fault Level

High Temperature Alarm %M 16 XX = 0 if OFF, = 1 if ON

High Temperature Alarm Setpoint

Initial Ground Fault Current

Low Amperage Level Alert %M 17 XX = 0 if OFF, = 1 if ON

Low Current Alarm Setpoint

Low Temperature Alarm %M 19 XX = 0 if OFF, = 1 if ON

Common Alarm %M 3 XX = 0 if disabled, = 1 if enabled

GF1

GF2

GF3

GF4

GF5

GF6

GF7

GF8

Module RI1

Module RI2

Deadband

Disable Channel %M 4 XX = momentary ON to reset

Enable Channel

Exposure Temperature %MW 3 XX

Force Channel %M 6 XX = 0 if disabled, = 1 if enabled

Ground Fault Alarm

Ground Fault Delay %M 21

Ground Fault Trip %M 8 XX = 0 if OFF, = 1 if ON

Heater ON %M 12 XX = 0 if OFF, = 1 if ON

High Current Alarm

Initial Amperage

Low Amperage Level

Low Current Alarm

%M 11 = 0 if disabled, = 1 if enabled

%M 12 = 0 if disabled, = 1 if enabled

%M 13 = 0 if disabled, = 1 if enabled

%M 14 = 0 if disabled, = 1 if enabled

%M 16 = 0 if disabled, = 1 if enabled

%M 17 = 0 if disabled, = 1 if enabled

%M 18 = 0 if disabled, = 1 if enabled

%M 19 = 0 if disabled, = 1 if enabled

%M 10 = 0 if disabled, = 1 if enabled

%M 15 = 0 if disabled, = 1 if enabled

%MW 2 XX

%M 5 XX

%M 7 XX

%MW 4 XX

%MW 6 XX

%M 13 XX

%MW 7 XX

%MW 8 XX

%MW 9 XX

%MW 10 XX 1 to 500 ( = x if set to x/10 Amps)

%MW 11 XX

%MW 12 XX

%M 18 XX

%MW 13 XX

10 to 100 ( = x if set to x/10 Degrees)

For 2 degree, actual value = 20

= 0 if disabled, = 1 if enabled

( = x if reading x/10 Degrees)

For 125 degrees, actual value = 1250

= 0 if OFF, = 1 if ON

1 to 900 ( = x if set to x mA)

For 30mA, actual value = 30

( = x if reading x/10 mA)

For 10mA, actual value = 100

= 0 if OFF, = 1 if ON

= 0 if enabled, = 1 if disabled

1 to 900 ( = x if set to x mA)

For 50mA, actual value = 50

= 0 if OFF, = 1 if ON

1 to 500 ( = x if set to x/10 Amps)

For 30.0 amps, actual value = 300

1 to 900 ( = x if set to x mA)

For 30mA, actual value = 30

-3280 to 13820 ( = x if set to x/10 Degrees)

For 125 degrees, actual value = 1250

For 2.5 amps, actual value = 25

1 to 900 ( = x if set to x mA)

For 30mA, actual value = 30

1 to 500 ( = x if set to x/10 Amps)

For 2.5 amps, actual value = 25

= 0 if OFF, = 1 if ON

1 to 500 ( = x if set to x/10 Amps)

For 2.5 amps, actual value = 250

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 34 -

Page 35

CM3-32 Installation and Operations Manual

VARIABLE NAME MODBUS ADDRESS DESCRIPTION / VALUE RANGE

Low Temperature Alarm Setpoint

Load Current (Actual) %MW 15 XX

Override OFF

Override ON %M 24 = 0 if OFF, = 1 if ON

Reset Channel Alerts

Reset Initial Values %M 23 XX = momentary ON to reset

Reset Output Alarm Relays

Sensor Failure Mode OFF %M 25 XX = momentary ON to reset

Sensor Failure Mode ON

Sensor Failure Alarm %M 20 XX = 0 if OFF, = 1 if ON

Setpoint

Statistics Disable %M 27 = momentary ON to reset

Statistics Enable %M 28 = 0 if OFF, = 1 if ON

System Alarm WORD %MW 10

System Information WORD %MW 11

Temperature (Actual) %MW 17 XX

Units Celsius OFF

Units Celsius ON %M 30 = 0 if OFF, = 1 if ON

%MW 14 XX

%M 23

%M 21 XX

%M 25

%M 24 XX

%MW 16 XX

,0 Auto Test Active

,1 Not Used

,2 Communications Error CT Module GF1

,3 Communications Error CT Module GF2

,4 Communications Error CT Module GF3

,5 Communications Error CT Module GF4

,6 Communications Error CT Module GF5

,7

,8 Communications Error CT Module GF7

,9

,10 Not Used

,11 Communications Error Interface Module RI1

,12 Communications Error Interface Module RI2

,13 Not Used

,14 Override All ON

,15 Not Used

,0 Activate 16 Channels

,1 Activate 24 Channels

,2 Activate 32 Channels

,3 Not Used

,4 Ambient Control Enabled

,5 Auto Test Enabled

,6 Ground Fault Delay Enabled

,7 Statistics Enabled

,8 Units Enabled for Celsius

,9 Not Used

,10 Override All ON

,11 Not Used

,12 Not Used

,13 Not Used

,14 Not Used

,15 Not Used

%M 29

-3280 to 13820 ( = x if set to x/10 Degrees)

-3280 to 13820 ( = x if set to x/10 Degrees)

For 34 degrees, actual value = 340

( = x if reading x/100 Amps)

For 2.5 amps, actual value = 250

= momentary ON to reset

= momentary ON to reset

= momentary ON to reset

= 0 if OFF, = 1 if ON

For 40 degrees, actual value = 400

Communications Error CT Module GF6

Communications Error CT Module GF8

( = x if reading x/10 Degrees)

For 125 degrees, actual value = 1250

= momentary ON to reset

PO Box 726 Tulsa, OK 74101 918-627-5530 Fax 918-641-7336 www.nelsonheaters.com

©2010 Nelson Heat Tracing Systems GA-2490 Rev. 3

August 2012

- 35 -

Loading...

Loading...