Page 1

™

NELSON

HEAT TRACE CONTROLLER

Installation and Operating Instructions

CM-2201

Page 2

Contents CM-2201

1.0 Introduction 4

1.1 Getting Started

2.0 General Application Information 5

3.0 Installation 6

3.1 Selecting Installation Location

3.2 Mounting

3.3 Wiring

4.0 Initial Set-up

4.1 Display Modes

4.2 Password Protection

4.3 Security Levels

5.0 General Operation 7

5.1 Display

5.2 Keypad

5.3 LED Functions

5.4 Monitoring

5.5 Alarm Management

5.6 Soft-Start Feature

5.7 Current-Limiting Feature

5.8 Ground Faults

6.0 Control Modes 8

6.1 On-Off Control

6.2 Proportional Control

6.3 Forced Control Feature

7.0 Programming 9

7.1 Setpoints

7.2 Heater Setup

7.3 System Setup

8.0 Communications 15

9.0 Troubleshooting 16

10.0 Maintenance 20

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

2

Page 3

CM-2201 Contents

Appendix A – Specifications 21

Appendix B – Wiring Diagrams 22

Appendix C – Typical Installation Diagram 23

Appendix D – Modbus Parameters 24

Appendix E – RTD Tables 29

Appendix F – Warranty 38

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

3

Page 4

Introduction CM-2201

1.0 Introduction

The Nelson Heat Trace CM-2201 is designed to monitor and

control one heating circuit in ordinary and Class I, Division

2, Class I, Zone 2, and Zone 2 hazardous locations. This

manual provides information pertaining to the installation,

operation, testing, communications and maintenance of

this device. See Appendix A for additional details.

1.1 Getting Started

The CM-2201 should be connected to external RTDs; power

and communication based on Appendix B and C. If any

problems occur, call Nelson technical support or follow the

Troubleshooting section.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

4

Page 5

CM-2201 Application Information

2.0 General Application Information

The CM-2201 is designed to operate on input voltages

between 100 and 277 Vac and 50/60 Hz. Load switching is

handled by a 2-Pole solid-state relay and can control resistive loads of 30A continuous @ 40°C ambient.

The CM-2201 is designed to control one heating circuit by

monitoring one or two temperature inputs via industry

standard 3-wire, 100Ω, Platinum RTDs. Two separate RTDs

may be utilized to customize the temperature control inputs.

Several different modes are user selectable as well as the

sensor failure operational mode.

The CM-2201 assembly is rated UL Type 4X (IP66) and can

be operated in temperatures of -40°F to +104°F (-40°C to

+40°C).

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

5

Page 6

Installation and Initial Set up CM-2201

3.0 Installation

The CM-2201 must be installed only in areas for which it

has been approved and in accordance with all applicable

electrical codes and ordinances. All conduit entry holes

must be appropriately installed and sealed to maintain

ingress protection rating.

Do not install this unit prior to functional testing if shipping

container or internal packaging shows signs of damage.

Notify the appropriate individuals immediately if damage is

suspected.

3.1 Selecting Installation Location

The CM-2201 should be installed in an area protected

from the elements as much as possible. It is possible to

install the unit in unprotected areas, but such often limits

maintenance/access. Further, installation in unprotected

areas must be carefully considered to ensure it is always

in operating conditions consistent with specifications. See

Appendix A for additional details.

3.2 Mounting

The CM-2201 should be mounted at a convenient height to

suit operator interaction. Conduit entries should be made

in the bottom of the enclosure to prevent damage to the

internal electronics from moisture intrusion. Conduit

entries should be drilled, and the use of suitable bushings

is required to maintain the environmental ratings.

3.3 Wiring

Electrical wiring diagrams and schematics are provided in

Appendix B and C of this manual. Ensure that all wiring and

connections are in accordance with applicable wiring codes.

Enclosure grounding must be in accordance with applicable

wiring codes for non-metallic devices.

4.0 Initial Set-Up

Upon initial power-up, the CM-2201 display will run selfcheck, display the software version, then the main program

will start.

4.1 Display Modes

This feature determines what messages and functions are

displayed during normal operations. If set to “normal user,”

only basic information is displayed. If set to “advanced

user,” all controller information is displayed. Each

parameter shown in this manual will list the Display

Mode required to view information and access each function

during programming.

4.2 Password Protection

The CM-2201 can have password protection enabled to

ensure that sensitive operating parameters are not

inadvertently adjusted. If password protection is enabled,

the user will be prompted to enter a valid value to access

any protected features. The user may also replace the default password value (1,2,3,4) with their own unique value

for greater protection of operational parameters. The password can be disabled indefinitely if no protection is desired.

4.3 Security Levels

CM-2201 has two levels of security; the high level (Advanced Display) uses password protection. Disabling the

password from the Password Enable / Disable menu will

keep the password disabled indefinitely – any parameter

can be changed without the use of a password. At this level,

all the functions and monitoring parameters are open. The

low level (Normal Display) does not give access to parameter settings, but is open for monitoring a few parameters,

such as temperature, current, GFI, etc.

If the password is “Enabled”, by going to the parameter to

be changed, after the ‘up’ or ‘down’ arrow is pressed, the

controller will ask to type the password, and after that, the

parameter can be changed and saved. The

password will stay disabled for 15 min, then be automatically re-enabled. During the 15 min period when the

password is disabled, other parameters can be changed

and saved.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

6

Page 7

CM-2201 General Operation

5.1 Display

The CM-2201 utilizes a 2 line x 16 character

alphanumeric display, viewable from the front keypad. The

top line is reserved for the function or operation and the

bottom line displays the value range.

5.2 Keypad

The keypad is touch sensitive. The operator must touch the

area on the main label and the controller will respond.

5.3 LED Functions

LED indicators will show the status of the respective

functions. The power LED will be illuminated when the

controller is connected to a source voltage. The heater LED

will be illuminated when voltage is applied to the heater.

The system LED will illuminate if there is an internal

hardware issue with the controller. The comm LED will

illuminate when the controller is sending data through

external communication. The alarm LED will flash when

there is a current active alarm condition; the alarm LED

will illuminate solid when an alarm was present, but is not

currently active.

5.4 Monitoring

By touching the “Actual” button, followed by an arrow, the

controller will display all the active parameters, one at a time.

5.5 Alarm Management

All the alarm(s) will be saved in the alarm log. If the alarm

is not active (alarm LED solid red), the Alarm LED can be

turned off by touching “Reset”, one alarm at a time. If the

alarm is active (alarm LED flashing red), the user cannot

reset the alarm.

5.6 Soft-Start Feature

The Soft-Start feature enables self-regulating cables to be

energized at low temperatures without causing excessive

load on the electrical system, and extends cable life by

reducing cable internal heating due to inrush currents. The

resistance of self-regulating cables decreases as these

cables get colder, which results in higher current draw.

5.6 Soft-Start Feature Continued

This can result in breaker trips if temperatures are very cold

and the installed length of cable is high. The Soft-Start

feature operates by initially only energizing the cable for a

very short period of time – while the current draw may be

high during this period, the period is usually short enough

to reduce average load on the electrical system. This short

energization period is repeated and eventually increased;

after a few minutes, the cable is usually warm enough such

that the resistance has increased and the current decreased

to the point where it can be continuously energized.

5.7 Current-Limiting Feature

The Current-Limiting feature operates similarly to the

Soft-Start in that it restricts the amount of time the cable

is energized during any given period, thereby reducing the

average current draw of the cable during that period. For

example, if a cable normally draws 8 Amps, but current

limit is set to 6 Amps, then the cable would be energized

only 75% of the time.

5.8 Ground Faults

Ground faults typically are the result of damaged or

improperly installed cables which allow current-carrying

conductors/surfaces/parts to be in contact with grounded

objects. For example, if a heating cable has been secured

to a pipe with a clamp, and if the clamp has been

overtightened, then the ground braid and/or the pipe may

come in contact with current carrying parts within the

cable. This would result in current leakage to ground

through the ground braid of the cable and/or the pipe itself.

This type of fault can eventually become serious, resulting

in overheating/fire/shock hazards. Current leakage to

ground can be monitored by electronic circuitry, and the SPC

can be programmed to either alarm or trip when leakage

current exceeds the specified maximum allowable amount.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

7

Page 8

Control Modes CM-2201

6.0 Control Modes

The CM-2201 allows the user to select different control

modes based on their individual process control

parameters.

6.1 On-Off Control

This control method simply energizes the cable until the

actual monitored temperature rises to the setpoint value

plus half the deadband value (upper limit). The cable is

then de-energized until the actual monitored temperature

drops to the setpoint value minus half the deadband value.

Note that this type of control can result in some temperature

“overshoot”; this is because the cable is de-energized

when the monitored temperature reaches the upper limit.

However, the residual heat in the cable continues to transfer

to the pipe, and this will cause the pipe temperature to

increase slightly above the upper limit. Similarly, there can

be some temperature “undershoot”.

6.2 Proportional Control

This control method uses the typical proportional control

algorithm, wherein the cable is cycled on and off at a rate

proportional to the difference between the setpoint value

and the actual monitored temperature. As the difference

between the setpoint value and the actual monitored

temperature increases, the amount of time the cable is

energized increases proportionately. This helps reduce the

“overshoot” and “undershoot” commonly associated with

On/Off control.

6.3 Forced Control Feature

This control method simply allows the user to force the

cable on or off as desired.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

8

Page 9

CM-2201 Programming

7.0 Programming

7.1 Program - Setpoints

7.1.1 Setpoint Value

This message displays the name of the sub-menu when

entered.

1. Display Mode: All

2. Range: N/A

3. Default: N/A

7.1.2 Maintain Temp

This value sets the control setpoint temperature for

all operating modes. For On-Off control, the circuit is

energized if the control temperature is less than the

maintain temperature minus the deadband. The circuit is

de-energized if the control temperature is greater than the

maintain temperature plus the deadband. If maintain temp

is set to None then the heater circuit will have temperature

monitoring with no control temperature. If the maintain

temp is set to Off then the heater circuit will have no

temperature monitoring or control.

1. Display Mode: All

2. Range: -50°C to 500°C, none or -58°F to +932°F,

none, Off

3. Default: 10°F or 50°F

7.1.3 Low Temp Alarm

This value sets the Low Temperature Alarm setpoint. It

must be less than the maintain temperature minus the

Deadband. To disable this alarm set the value to “Off’.

When the measured temperature of either RTD A or RTD

B (if activated) is less than or equal to this setpoint, the

Low Temperature Alarm is activated and a “LOW TEMP

ALARM” message is added to the alarm stack. This alarm

deactivates when the temperature rises above the alarm

setpoint value.

1. Display Mode: All

2. Range: -50C to Maintain Temperature, Off, -58°F to

Maintain Temperature, Off

3. Default: 5°C or 41°F

4. Restrictions: Message does not exist if Maintain

Temperature is set to Off.

7.1.4 High Temp Alarm

This value sets the High Temperature Alarm setpoint.

It must be greater than the maintain temperature plus

deadband. To disable this alarm set the value to “Off”.

When the measured temperature of either RTD A or RTD B

(if activated) is greater than or equal to this setpoint, the

High Temperature Alarm is activated and a “HIGH TEMP

ALARM” message is added to the alarm stack. The alarm

deactivates when the temperature falls below this alarm

setpoint.

1. Display Mode: All

2. Range: Maintain Temperature to +500°C, Off,

Maintain Temperature to +932°F, Off

3. Default: Off

4. Restrictions: Message does not exist if Maintain

Temperature is set to Off.

7.1.5 Low Current Alarm

This value sets the Low Current Alarm setpoint. It must be

less than the high current alarm setpoint. To disable this

alarm set the value to “Off’. When the heater current is

less than or equal to this setpoint, the Low Current Alarm

is activated and a “LOW CURRENT ALARM” message is

added to the alarm stack. The alarm deactivates when

the Heater Current rises above this alarm setpoint. Note:

This setpoint is based on the heater at 100% power. If

Proportional Control or Current Limiting is enabled, all

current measurements will be scaled to 100% power, based

on a constant resistive load, before being compared to the

alarm setpoint.

1. Display Mode: All

2. Range: 0.1A to High Current Alarm, Off

3. Default: Off

7.1.6 High Current Alarm

This value sets the High Current Alarm setpoint. It must

be greater than the low current alarm setpoint. To disable

this alarm set the value to “Off’. When the heater current

is greater than or equal to this setpoint, the High Current

Alarm is activated and a “HIGH CURRENT ALARM” message

is added to the alarm stack. The alarm deactivates when

the heater current falls below this alarm setpoint. This

setpoint is based on the heater at 100% power.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

9

Page 10

Programming CM-2201

7.1.6 High Current Alarm Continued

If Proportional Control or Current Limiting is enabled, all

current measurements will be scaled to 100% power, based

on a constant resistive load, before being compared to the

alarm setpoint.

1. Display Mode: All

2. Range: Low Current Alarm to 30.0A, Off

3. Default: Off

7.1.7 Ground Fault Alarm

This value sets the Ground Fault Alarm setpoint. It must

be less than the ground fault trip setpoint. To disable this

alarm set the value to "Off'. When the Ground Fault Current

is greater than or equal to this setpoint, the Ground Fault

Alarm is activated and a "GROUND FAULT ALARM" message

is added to the alarm stack. The alarm deactivates when

the Ground Fault Current falls below this alarm setpoint.

1. Display Mode: All

2. Range: 10 to Ground Fault Trip, Off

3. Default: 30mA

7.1.9 Low Voltage Alarm Continued

1. Display Mode: All

2. Range: 85VAC to High Voltage Alarm, Off

3. Default: Off

7.1.10 High Voltage Alarm

This value sets the High Voltage Alarm setpoint. It must

be greater than the Low Voltage Alarm setpoint. To

disable this alarm set the value to “Off’. When the Heater

Voltage is greater than or equal to this setpoint, the High

Voltage Alarm is activated and a “HIGH VOLTAGE ALARM”

message is added to the alarm stack messages. The alarm

deactivates when the Heater Voltage drops below this alarm

setpoint.

1. Display Mode: All

2. Range: Low Voltage Alarm to 280VAC, Off

3. Default: Off

7.2 Program - Heater Setup

7.1.8 Ground Fault Trip

This value sets the Ground Fault Trip setpoint. It must be

greater than the ground fault alarm setpoint. To disable

this trip alarm set the value to “Off’. When the Ground

Fault Current is greater than or equal to this setpoint, the

heater circuit is de-energized, the Ground Fault Trip Alarm

is activated and a “GROUND FAULT TRIP” message is added

to the alarm stack. This is a latching alarm and trip. When

the cause of the alarm has been corrected, the circuit may

be energized by the manual reset function.

1. Display Mode: All

2. Range: Ground Fault Alarm to 500mA, Off

3. Default: 50mA

7.1.9 Low Voltage Alarm

This value sets the Low Voltage Alarm setpoint. It must be

less than the high voltage alarm setpoint. To disable this

alarm set the value to “Off’. When the Line Voltage is less

than or equal to this setpoint, the Low Voltage Alarm is

activated and a “LOW VOLTAGE ALARM” message is added

to the alarm stack. The alarm deactivates when the Line

Voltage rises above this alarm setpoint.

7.2.1 Heater Setup

This message displays the name of the sub-menu when

entered.

1. Display Mode: Advanced

2. Range: N/A

3. Default: N/A

7.2.2 Enable Heater

This selection enables control and monitoring of the heater

circuit. Setpoints and measured value messages cannot be

accessed unless the heater is enabled. Select “No” if the

circuit is not used.

1. Display Mode: All

2. Range: yes, no

3. Default: yes

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

10

Page 11

CM-2201 Programming

7.2.3 Heater ID

This selection allows for user defined Heater Identification.

It provides a unique, identifiable tag or label for each heater

circuit. The Heater Name allows up to 20 alphanumeric

characters which are entered one at a time from left

to right. The cursor indicates which character is being

selected. Press the [SELECT UP/DOWN] arrow keys to change

the character. Move to the next character by pressing [NEXT]

arrow. Press [ENTER] in the last character position to save

the Heater ID.

1. Display Mode: Advanced

2. Range: 20 Characters

3. Default: Blank

7.2.4 Manual Override

This selection sets the response of the heater circuit to the

Override inputs. The Override inputs respond to contact

closure. If the Override is set to “Off”, the override inputs

are ignored and control of the heater circuit operates

normally based on the measured temperature and maintain

temperature setpoint. If the Override is set to “On”, an open

contact on the override inputs forces the heater Off.

When the contact on the override input is closed, the heater

control resumes in normal manner.

1. Display Mode: Advanced

2. Range: On, Off

3. Default: Off

7.2.5 Deadband

The Deadband is defined as the difference between the

setpoint temperature and the actual maximum temperature

that is ideally allowed in excess of the setpoint temperature.

Decreasing the deadband increases the temperature control

accuracy but also increases the heater switching frequency.

1. Display Mode: Advanced

2. Range: 1 °C to 5 °C, 1 °F to 10 °F

3. Default: 2 °C or 5 °F

4. Note: Deadband is disabled for Proportional Control

mode.

7.2.6 Control Type

This selection determines the type of control method used

by the controller: either On-Off (Deadband), or Proportional

Control. The On-Off control mode is available for all heating

devices. Proportional Control mode is only available for

series type heating devices.

Warning: Proportional Control should never be selected

for use with self-regulating heating cable types due to

the constantly changing characteristics of self-regulating

cables – this will cause the control to be unstable. Further,

the continual cycling associated with Proportional Control

can result in internal heating of the cable and lead to

reduced life expectancy.

1. Display Mode: Advanced

2. Range: On-Off, Proportional

3. Default: On-Off

4. Selection does not exist if Maintain Temperature is

set to Off.

7.2.7 Current Limiting

This selection sets the maximum average current limit

allowed for the heater circuit. It is useful for reducing the

power output of constant wattage heaters. The load will be

turned on for a period of time, then turned off for a period of

time to maintain the average current draw to the value set.

1. Display Mode: Advanced

2. Range: 0.5 to 30.0 A, Off

3. Default: Off

4. Note: The value range is in 0.5A increments.

7.2.8 Soft Start Mode

This function ramps the heater output from Off to nominal

current of the heater over the set softstart cycle time. It

is useful for reducing inrush currents of self-regulating

heaters. At the end of the soft start cycle time, the load will

no longer be controlled by the soft start function.

1. Display: Advanced

2. Range: 10 to 999 seconds, Off

3. Default: Off

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

11

Page 12

Programming CM-2201

7.2.9 Auto Test Cycle

This value sets the frequency at which the Auto Test Cycle is

activated. Auto Test is a feature that exercises the system

by automatically applying power to the heater at specified

time intervals. If an alarm condition is detected during this

period, the Auto Test Alarm is activated and an “ALARM

DURING AUTO TEST” message is added to the System Status

messages. This is a latching alarm. To clear the alarm,

locate the alarm message in the Alarm Menu and press

[ENTER]. To disable this feature, set the value to “Off”. The

Auto Test Cycle does not operate if heater is forced off for

any reason, including ground fault trip. Auto Test decreases

maintenance by providing an early warning of problems that

would otherwise go undetected until the heater was needed.

1. Display Mode: Advanced

2. Range: 1 to 720 hours, Off

3. Default: 24 hours

7.2.10 RTD Operation

This selection determines how the control temperature is

utilized by the RTD inputs.

In One RTD Mode, the temperature is based on the

measured temperature from RTD-A.

In Backup Mode, control temperature is based on RTD-A. If

for any reason RTD-A fails, then RTD-B takes over.

7.2.10 RTD Operation Continued

Functions requiring two RTDs to operate, such as Average,

Lowest, Highest and High Temperature Cutoff, will operate

in One RTD mode if one of the two RTDs fail.

1. Display Mode: Advanced

2. Range: One RTD, Backup, Average, Lowest, Highest,

High Temperature Cutoff

3. Default: One RTD

4. Restrictions: Message does not exist if Maintain

Temperature is set to Off.

7.2.11 RTD Failure Mode

This selection sets the controller’s fail-safe mode. The

controller detects if RTD-A has failed and will use RTD-B if

available. If RTD-B is not installed or has also failed, the

heater will be set to its fail-safe state as selected in this

mode. For freeze protection where there is no hazard from

overheating, you may select “On” to operate the heater

continuously and prevent freeze up.

For processes where there is a potential hazard from

overheating, you may select “Off”, to de-energize the circuit

until one of the RTDs becomes available.

1. Display Mode: Advanced

2. Range: On, Off

3. Default: Off

4. Restrictions: Message does not exist if Maintain

Temperature is set to Off.

In Average Mode, the control temperature is based on the

average of RTD-A and RTD-B measured temperatures.

In Lowest Mode, control temperature is based on the lowest

of the two temperature measurements.

In Highest Mode, control temperature is based on the

highest of the two temperature measurements.

In High Temperature Cutoff Mode, control temperature is

based on RTD-A, but if the temperature from RTD-B exceeds

the high temperature alarm, the heater is turned Off and a

high temperature alarm is activated. The High Temperature

cutoff mode will operate in One RTD mode if the high

temperature alarm is turned Off.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

7.3 Program – System Setup

7.3.1 System Setup

This message displays the name of the sub-menu when

entered.

1. Display Mode: Advanced

2. Range: N/A

3. Default: N/A

7.3.2 Password

This selection determines if password protection is required

for programming changes. The display will show “Disabled”

if program access is currently enabled, and show “Enabled”

if program access is currently disabled.

1. Display Mode: All

2. Range: Enabled or Disabled

3. Default: Enabled

12

Page 13

CM-2201 Programming

7.3.3 Change Password

This selection allows the user to change the default password. The user is prompted to enter the old password, press

[ENTER]. If verified, the user is then able to enter the new

password, press [ENTER]. The user is prompted to re-enter

the new password. By not entering a password and pressing

[ENTER], the controller assumes no password.

1. Display Mode: Advanced

2. Range: Any combination of 2 to 16 characters 0 – 9,

A – Z.

3. Default: 1234

7.3.4 Units

This selection determines the unit of measure for

temperature values. All temperatures are displayed in the

selected units of either Celsius degrees (°C) or Fahrenheit

degrees (°F).

1. Display Mode: Advanced

2. Range: Celsius, Fahrenheit

3. Default: Celsius

7.3.5 Operational Costs

This value sets the cost per kWh of electrical power. This

is used to calculate energy costs for operating this control

circuit.

1. Display Mode: Advanced

2. Range: $0.01 to 1.00

3. Default: $0.05

7.3.6 Display Mode

This selection determines what messages are displayed by

the controller for operations personnel. If set to “advanced

user”, all messages are displayed. If set to “normal user,”

only the basic messages are displayed. Each message listed

throughout this manual shows the Display Mode required

to see the message. “Advanced only” indicates that the

display mode must be set to “advanced user” to view the

message.

1. Display Mode: All

2. Range: Normal, Advanced

3. Default: Advanced

7.3.7 Default Display

This function specifies the information that will be

displayed when no key has been pressed for the Display

Timeout interval as described below.

VALUE INFORMATION

DISPLAYED

System status Alarm status of all the

heaters

Heater status Alarm status of the

heater

Heater temp Temperature of the

heater

1. Display Mode: Advanced

2. Range: System Status, Heater Status, Heater Temp

3. Default: system status

4. Restrictions: Temperature messages are not

displayed if Maintain Temperature is set to Off.

7.3.8 Display Timeout

This function sets the length of time from the last key press

to automatically return to the Default Display information.

Selecting “Off’ disables this function.

1. Display Mode: Advanced

2. Range: 5 to 600 seconds, Off

3. Default: 120 seconds

7.3.9 Modbus Address

This selection sets a unique address to ensure only one

CM-2201 attempts communications with the master unit

at any time. See Section 8.0 for complete information on

Modbus communications.

1. Display Mode: Advanced

2. Range: 1 to 255 to accommodate multiple devices on

same network.

3. Default: 1

7.3.10 Baud Rate

Sets the communication baud rate for the RS485 serial port.

All controllers connected to the same data highway must

operate on the same baud rate.

1. Display Mode: Advanced

2. Range: 1200, 2400, 4800, 9600, 19200

3. Default: 9600

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

13

Page 14

Programming CM-2201

7.3.11 Reset Module

This selection resets controller memory parameters to

factory default values. If the controllers memory becomes

corrupt, resetting the module will force the controller to

overwrite each register and may correct any problems that

exist.

1. Display Mode: Advanced

2. Range: yes, no

3. Default: no

7.4 Program - System Test

7.4.1 System Test

This message displays the name of the sub-menu when

entered.

1. Display Mode: Advanced

2. Range: N/A

3. Default: N/A

7.4.4 Ground Fault Test

This function will test the ground fault trip function of the

controller to ensure proper operation. When selected, the

controller will generate an artificial ground fault current; if

the ground fault current is sensed as being greater than 30

mA, the test passes. The GF test function will verify actual

ground fault current and heater trip. Status of the test will

be displayed as pass or fail. If this test has been invoked

by the “Now” option and it passes, the user is prompted to

reset the ground fault trip, at which time the load is capable of being re-energized as required. If this test has been

invoked by the “Autotest” option, and it passes, the load is

allowed to be reenergized as required. If this test has been

invoked by the Autotest cycle, and it fails, an Autotest alarm

is generated, but the load is allowed to be reenergized as

required.

1. Display Mode: Advanced

2. Range: Autotest cycle, Now, Disabled

3. Default: Disabled

7.4.2 Alarm Output Test

This function is used for testing and commissioning

purposes allowing the alarm output to be forced On, either

for a short period of time, or continuously. At the end of the

specified time duration, the testing option is automatically

disabled. The alarm test function will not operate if the

alarm configuration is set to “Disabled”; the message

“ALARM DISABLED” will appear.

1. Display Mode: Advanced

2. Range: 1-24 hours, Disabled, Continuously

3. Default: Disabled

7.4.3 Heater Test

This function overrides heater control for maintenance

purposes. For normal operation, set to “Disabled”. If a

period of time is selected, the heater is forced On or Off for

the selected interval. If “continuous” is selected, the heater

is forced On or Off until “Disabled” is selected.

1. Display Mode: Advanced

2. Range: 1-24 hours, Disabled, On Continuously

3. Default: Disabled

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

14

Page 15

CM-2201 Communications

8.0 Communications

The Nelson Heat Trace CM-2201 supports a subset of the

®

Modbus

programming, and control functions using Read (03) and

Write (05-06) register commands.

8.1 General Information

Serial Port: Select the serial port that

Baud Rate: User Defined at 1200, 2400,

Data Bits: 8

Stop Bits: 1

Parity: None

Device Address: User Defined between 1 and 255

RTU protocol format that provides monitoring,

corresponds to your RS-485

adapter. USB to Serial adapter

may be used for devices without

serial connections.

4800, 9600 or 19200

8.2 Modbus Registers

For all Modbus registers, see Appendix D.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

15

Page 16

Troubleshooting CM-2201

9.0 Troubleshooting

9.1 Operator Checks

Upon receipt of the controller, or to check the controller for

an indication of normal operation, follow the operational

procedures shown below. These procedures are designed to

familiarize the operator with the controller and to provide an

understanding of its operation.

In order to determine if a fault is associated with the

heat tracing, wiring, or the controller, it will be necessary

to troubleshoot the wiring and tracer circuit. If the

fault remains, remove power from the controller and

exchange it with another controller. This may require some

reprogramming of the new CM2201. Refer to the following

sections for the appropriate topic.

9.1.1 RTDs

RTD failures after installation can generally be attributed

to incorrect wiring or improper installation of the sensor.

Troubleshooting of these failures is a very simple procedure

if the proper steps are undertaken in the correct order.

Some specific RTD problems and the correct methods for

troubleshooting are outlined as follows.

1. RTD Failure Alarm(s)

If the CM2201 controller indicates a failure of an RTD:

a) Ensure that the RTD is a 3-wire 100Ω (Platinum Type).

TURN THE POWER TO THE CONTROLLER OFF BEFORE

PROCEEDING!

b) Disconnect the RTD wiring from the input terminals.

c) Measure the RTD’s resistance between the source (RED)

and sense (RED) leads at the controller (it should not

exceed 40 Ω). Excessive lead resistance will cause an

RTD FAILURE ALARM, and must be corrected. Look for

loose terminals, excessive lead length, or insufficient

wire gauge, and correct as necessary.

d) Measure the RTD’s resistance between the source (RED)

or sense (RED) lead and the common (WHT) lead of the

RTD at the controller (should be between 60 and 330 Ω

depending on the temperature and the lead resistance.

Verify that the RTD is wired correctly—the heat tracing

controllers will always be terminated in the order: source

(RED), common (WHT), sense (RED). When wiring to the

CM2201, the terminals are marked as follows:

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

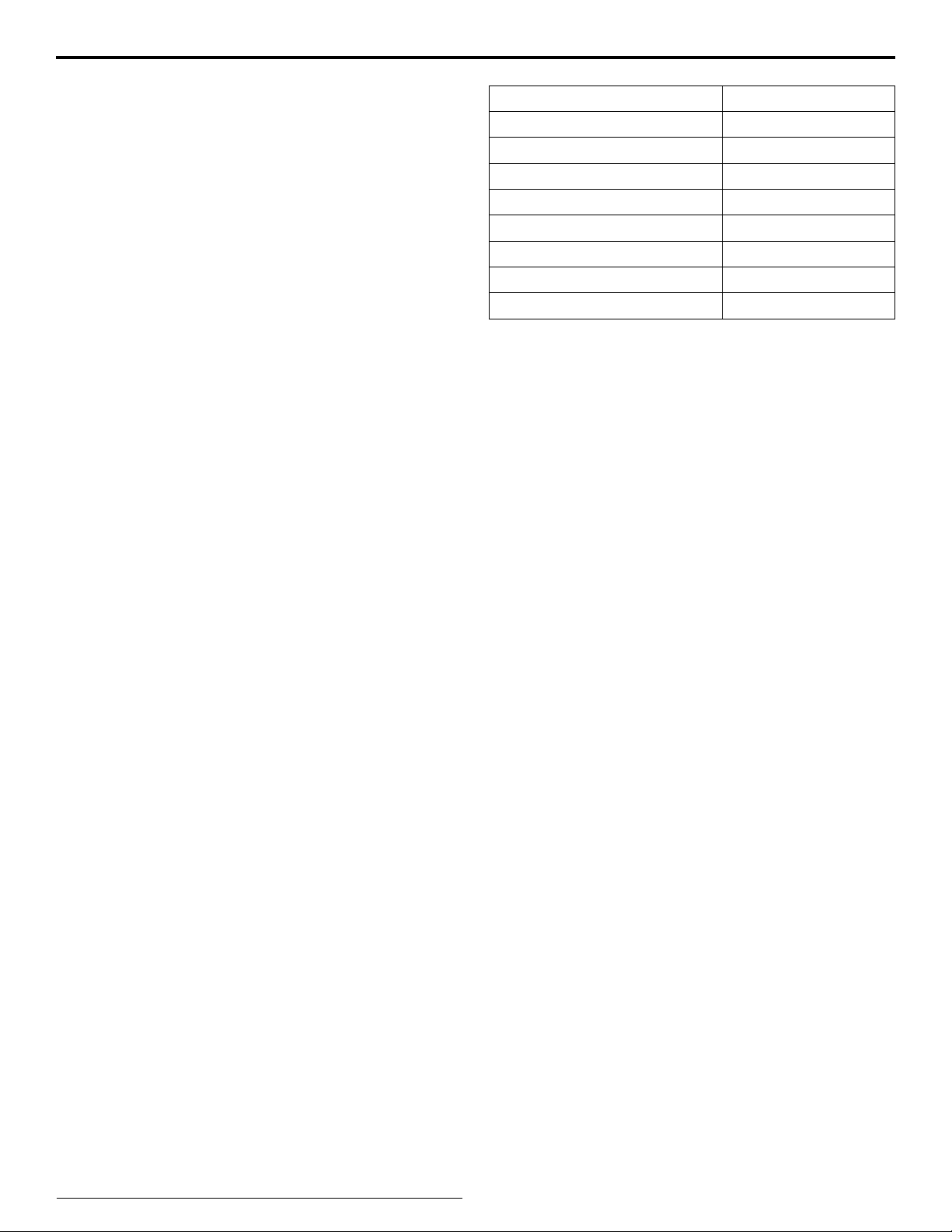

Terminal No. Description

GND Bus Shield

R1 RTD 1 Source (RED)

W1 RTD 1 Common (WHT)

R1 RTD 1 Sense (RED)

GND Bus Shield

R2 RTD 2 Source (RED)

W2 RTD 2 Common (WHT)

R2 RTD 2 Sense (RED)

The RTD manufacturer will typically color code the leads

with the source and sense being the same color, and the

common a different color. Ensure that the RTD extension

wire shield is terminated at one end only, normally using the

terminal block provided at the terminal board.

Note: Some manufacturers use the common Black-WhiteRed triad color code for the RTD connections. Usually,

the RED lead is the common connection (same as the

White-White-Red color scheme) and the White and Black

connections may be used interchangeably.

2. Temperature Verification

If you feel that the indicated or displayed temperature is not

correct, the controller and the RTD can be quickly checked

for correct operation. To verify the RTD:

TURN THE POWER TO THE CONTROLLER OFF BEFORE

PROCEEDING!

a) Disconnect the RTD wiring from the input terminals.

b) To calculate the temperature indicated by the RTD,

measure the resistance from source (red wire) or sense

(red wire) to common (white wire) and subtract the

resistance measured between source and sense. This will

give a compensated resistance value that can be crossreferenced to one of the RTD tables found in Appendix

E or Appendix F. Compare the measured resistance and

cross-referenced temperature value obtained from the

RTD table to the indicated or displayed value. These

should agree to within the accuracy standards of the

CM2201 and the RTD.

Note: Ensure you refer to the correct RTD table for the type

of RTD you are using.

16

Page 17

CM-2201 Troubleshooting

2. Temperature Verification Continued

To verify the Controller:

TURN THE POWER TO THE CONTROLLER OFF BEFORE

PROCEEDING!

a) Disconnect the RTD wiring from the input terminals.

b) Connect a 100 Ω resistor across the source or sense

terminal and common. Insert a jumper between the

source and sense terminals.

c) Apply power to the controller. The indicated or displayed

temperature should be about 32°F (0°C), depending on

the actual resistance of the test resistor if RTD TYPE is

set to 100Ω Platinum. Any resistor may have a +/- 10%

tolerance.

3. Unstable Temperature

An erratic indication of temperature can be caused by

several factors external to the controller. The controller’s

accuracy and resolution will result in an indicated

temperature change of a couple of degrees if the measured

resistance temperature falls between two discrete values

(this is sometimes referred to as quantization error).

If the instability is excessive, check:

3. Unstable Temperature Continued

d) Check, one by one, if the all RTD leads are connected to

the connector.

e) Lastly, it is possible for the RTD itself to fail on an

intermittent basis but this failure mode should be

considered unusual. This kind of failure is probably the

most difficult to find, but fortunately, it is also the least

likely as a failure mechanism.

9.2 Ground Fault

Ground fault warning/alarms can be due to incorrect

installation as well as leakage resulting from wet system

components or faulted cables.

The CM2201 Controller detects ground faults by summing

the outgoing and return trace currents through an internal

current transformer. Under normal operating conditions (no

ground fault condition), this current will be zero. When there

is a flow of current from one of the trace supply wires to

ground, a ground fault condition occurs.

If a ground fault alarm is present on start-up of a new

installation, it is likely due to a wiring error or damaged

cable. To verify this condition:

a) Wire used for extension of the RTD should be three-wire,

twisted and shielded with the shield grounded at the

controller only. Each of the three lead wires must be of

the same gauge.

b) The ideal installation has a separate conduit for the

RTD leads (if they have been extended).It is not usually

a problem to run low signal levels in the same conduit

as the power leads even in high power applications, as

long as the RTD wire is a twisted, shielded type with an

insulation rating equal to or greater than the highest

voltage in the conduit. Follow the proper Electrical Code

requirements for your particular installation.

c) Check the specifications for the particular cable

being used to ensure that it does not have excessive

capacitance when used in long lengths. This can cause a

temperature offset between what the controller reads and

what the RTD actually measures. This again is normally

not a problem since the controller compensates for all

but the worst cases of this.

a) Check that the heating circuit neutrals return to

the controller and are not connected directly to the

distribution panel. This can be a common problem if the

installation is a retrofit situation.

b) On paralleled circuits, be certain that ALL neutrals

return. The late addition of a circuit may not be obvious

Note: The controller monitors the integrity of the ground

fault (GF) detection. If a fault is detected, the controller will

generate a GFI warning/alarm, depending on the settings.

9.3 Common Warnings/Alarms - What to Look for

The CM-2201 has a wide range of warning and alarming

features that may be selectively enabled or disabled to

allow the monitoring and indication of trouble conditions.

Described below are the different warning and alarm

conditions available on the CM2201, their meanings, and

possible causes. The warning settings must be below alarm

settings. If an alarm is activated, the two low power SSRs

will be activated.

.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

17

Page 18

Troubleshooting CM-2201

9.3.1 High RTD 1/ RTD 2 Temperature Reading

This warning/alarm appears when the temperature exceeds

the HIGH RTD WARNING/ALARM temperature setting.

Cause of Warning/Alarm:

• Warning/Alarm temperature setting too close to maintain

temperature

• Flow of hot product

• Steaming out lines

• Incorrect tracer wiring

9.3.2 Low RTD 1/ RTD 2 Temperature Reading

This warning/alarm appears when the temperature

decreases below the LOW RTD WARNING/ALARM temperature

setting.

Cause of Warning/Alarm:

• Warning/Alarm temperature setting too close to maintain

temperature

• Flow of cold product

• Empty pipe

• Damaged, wet, or missing insulation

• Heating cable not sized properly for the application

9.3.3 RTD 1/ RTD 2 Failure

This alarm indicates a sensor is not operating properly. The

temperature sensor may fail due to an “open” or “shorted”

condition.

Cause of Alarm:

• Incorrect or damaged eld wiring - open leads or excess

resistance (either intermittent or continuous) may be due

to broken or damaged wires or loose terminals.

• Damaged or inoperative temperature sensors

9.3.4 High Current Warning/Alarm

This warning/alarm activates when current levels are

greater than the HIGH CURRENT WARNING/ALARM setting

for the application.

9.3.4 High Current Warning/Alarm Continued

Cause of Warning/Alarm:

• Warning/Alarm setting too close to normal operating

current

• High in-rush current from “cold start” of self regulating

cable

• Damaged or partially shorted heating cable

• “As built” cable length is greater than design value

9.3.5 Low Current Warning/Alarm

This alarms current levels which are less than the LOW

CURRENT WARNING/ALARM setting.

Cause of Warnings/Alarm:

• Warning/Alarm setting too close to normal operating

current

• Low source voltage

• Damaged or inoperative heating cable

• Open connection—wiring problem

• SSR or contactor failed open

9.3.6 High GFI Warning

This warns that ground fault current levels are greater than

the HIGH GFI WARNING setting.

Cause of Warning:

• Warning setting too close to normal leakage current

• Damaged cable insulation and/or moisture present

• Moisture in junction box

• Poor splice or termination

• Moisture provides conductive ground path, which allows

ground fault current

9.3.7 GFI Alarm

This value sets the upper limit of allowable ground fault

leakage. Exceeding this limit will result in the output switch

being latched off, and the alarm activated to indicate a

ground fault condition.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

18

Page 19

CM-2201 Troubleshooting

9.3.7 GFI Alarm Continued

Cause of Alarm:

• Trip setting too close to normal leakage current

• Damaged cable insulation and/or moisture present

• Moisture in junction box

• Poor splice or termination

• Moisture provides conductive ground path, which allows

ground fault current

9.3.8 High Voltage Warning/Alarm

This warning/alarms voltage levels that are greater than the

HIGH VOLTAGE WARNING/ALARM setting.

Cause of Warning/Alarm:

Warning/Alarm setting too close to normal operating voltage

•

• Incorrect wiring

• Power surge

9.3.9 Low Voltage Warning/Alarm

This warns/alarms of voltage levels that are less than the

LOW VOLTAGE WARNING/ALARM setting.

Cause of Warning/Alarm:

• Warning/Alarm setting too close to normal operating

voltage

• Damaged power cable

• Incorrect VOLTAGE TURNS RATIO

• “Brown-out” conditions

• Loss of power to the circuit

9.3.11 Switch Failure

This alarm indicates that the controller senses current flow

when the output switch should be off.

Cause of Alarm

• Some other device energized heat trace

• Output switch has failed “closed”

9.3.12 Power Limiting (Current Limiting)

This alarm indicates that the solid state relay is limiting the

average amount of power that is applied to the trace circuit

as defined by the MAXIMUM POWER setting.

Cause of Alarm:

• Power applied to trace circuit is being limited to the

MAXIMUM POWER setting

9.3.13 EEPROM Data Failure

This alarm indicates that the controller has detected a

failure in its non-volatile memory (this is where all of the

controller’s configuration and calibration settings are

stored). This indicates an internal problem, and the CM2201

should be replaced and returned to the factory for repair.

Cause of Alarm:

• The CM-2201 cannot bypass the failed area of its memory

and has loaded factory defaults into this failed area.

9.3.10 Overcurrent Trip

If the controller is unable to start the cable due to high

current, or after attempting to soft-start it, the controller

will trip its output switch off.

Cause of Alarm:

• Excessive in-rush current

• Incorrect CM-2201 settings

• Incorrect wiring

• Damaged cable

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

19

Page 20

Maintenance CM-2201

10.0 Maintenance

The CM-2201 should be regularly maintained as follows:

a) Check fit of door gasket and adjust as required. Clean

door gasket.

b) Verify that moisture is not entering enclosure; repair as

required.

c) Check terminals to ensure connections are secure.

d) Check wiring for any signs of overheating.

e) Clean front panel with mild soap on damp cloth.

Do not use any cloth from synthetic material or similar.

During the cleaning process, the front label may charge

electrostatically, and touching the front panel may generate

sparks.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

20

Page 21

CM-2201 Appendices

Appendix A – Specifications

Model: CM-2201

Rating: 110 – 277 Vac, 30 Amps (Solid

State Relays)

Maximum Current: 30 Amps

Frequency: 50 or 60 Hz

Switching: Solid State Relay (STDP)

Normally Open (NO)

Enclosure: NEMA 4X

Alarm Outputs: 1. 24VAC to 277VAC @ Max. 0.5

Amps

2. 30VDC @ Max. 0.1 Amps

Agency Approval for

Hazardous Locations:

Temperature Code: T4 (135 °C)

cCSAus

Class1, DIV.2, Groups A, B, C, D

Class 1, Zone 2: IIC

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

21

Page 22

Appendices CM-2201

Appendix B - Wiring Diagram

Notes:

1. Solid State Contact

2. Install Jumper at JP1 (120 OHM Resistor) on both terminals if CM-2201 is last device on network. Else install jumper on one terminal only of JP1.

3. If “Force “ feature is activated by external “dry contact”, use “+5V” and “IN” terminals; Ground connection is not required. If activated by external voltage signal, use

“IN” and “G” (Ground) terminals as noted.

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

22

Page 23

CM-2201 Appendices

Appendix C - Typical Installation Diagram

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

23

Page 24

Appendices CM-2201

Appendix D

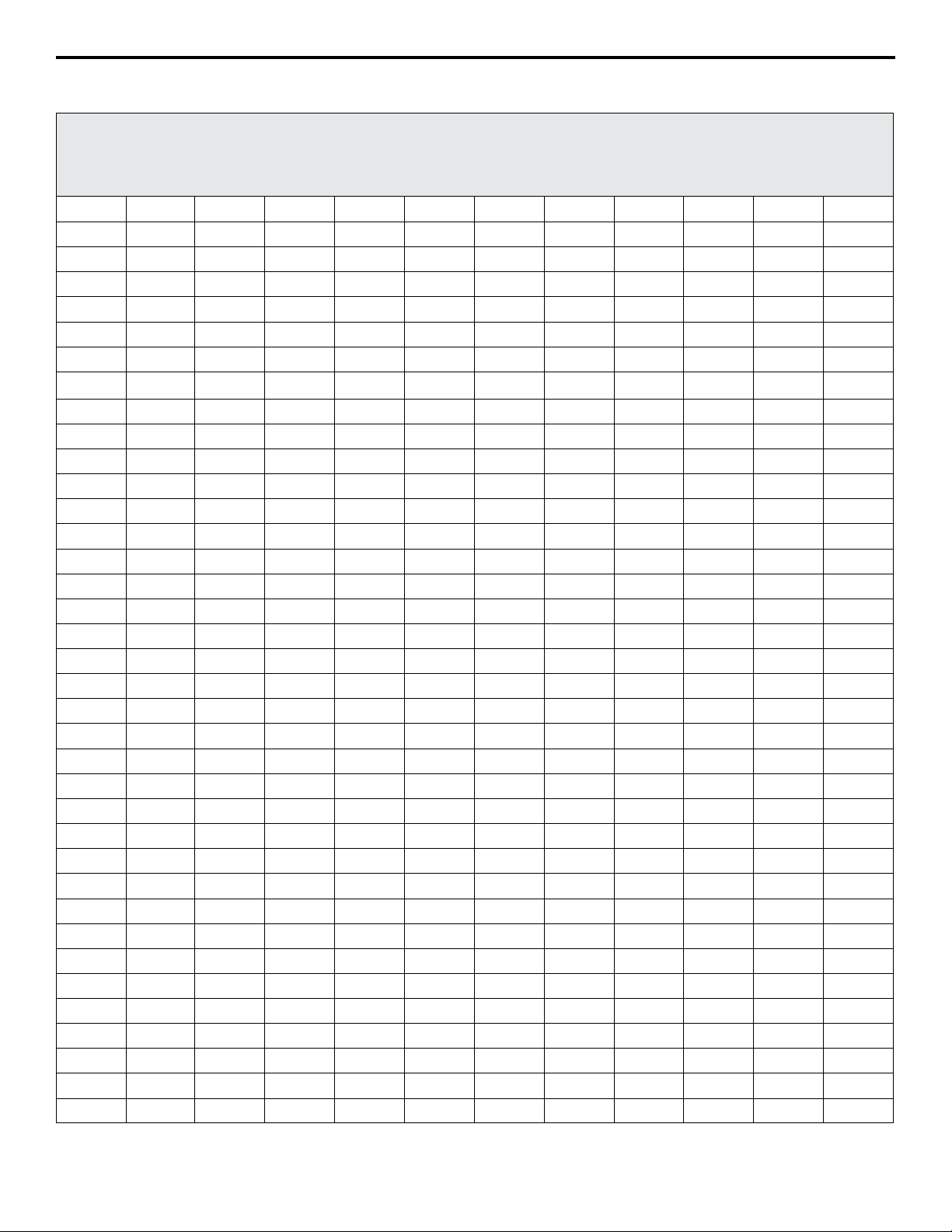

D.1 Module Setup Group (Read/Write)

Modbus

Register

40001 0 2 Maintain Temp in °F

40002 1 2 Maintain Temp in °C

40003 2 2 Low Temp Alarm in °F

40004 3 2 Low Temp Alarm in °C

40005 4 2 High Temp Alarm in °F

40006 5 2 High Temp Alarm in °C

40007 6 2 Deadband in °F = x per 1°F (1 to 10)

40008 7 2 Deadband in °C = x per 1°C (1 to 5)

40009 8 2 Low Current Alarm

40010 9 2 High Current Alarm

40011 10 2 Ground Fault Alarm

40012 11 2 Ground Fault Trip

40013 12 2 Low Voltage Alarm

40014 13 2 High Voltage Alarm

40015 14 2 Power Control

40016 15 2 SoftStart

40017 16 2 Auto Test Time

40018 17 2 Display Time

40019 18 2 Cost per kwh = x per $0.01 (1 to 100)

40020 19 2 Reserved

40021 20 2 Reserved

40022 21 2 Reserved

40023 22 2 Alarm Test

Index

Value

Length

Bytes

Variable Name Description/Value Range

= x per 1°F (-58 to +932)

= 32766 if Set to None

= 32767 if Set to Off

= x per 1°C (-50 to +500)

= 32766 if Set to None

= 32767 if Set to Off

= x per 1°F (-58 to +932)

= 32767 if Set to Off

= x per 1°C (-50 to +500)

= 32767 if Set to Off

= x per 1°F (-58 to +932)

= 32767 if Set to Off

= x per 1°C (-50 to +500)

= 32767 if Set to Off

= x per 0.1A (1 to 300)

= 32767 if Set to Off

= x per 0.1A (1 to 300)

= 32767 if Set to Off

= x per 1mA (10 to 500)

= 32767 if Set to Off

= x per 1mA (10 to 500)

= 32767 if Set to Off

= x per 1V (85 to 280)

= 32767 if Set to Off

= x per 1V (85 to 280)

= 32767 if Set to Off

= x per 10% (1 to 10)

= 32767 if Set to Off

= x per 1 Second (10 to 999)

= 32767 if Set to Off

= x per 1 Hour (1 to 720)

= 32767 if Set to Off

= x per 1 Second (5 to 600)

= 32767 if Set to Off

= x per 1 Hour (1 to 24)

= 32764 if Set to Disable

=32765 if Set to Continuously

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

24

Page 25

CM-2201 Appendices

D.1 Module Setup Group (Read/Write) Continued

Modbus

Register

40024 23 2 Heater Test

40025 24 2 Reserved

40026 25 16 Heater Name

40043 42 4 Heater Settings

Index

Value

Length

Bytes

Variable Name Description/Value Range

= x per 1 Hour (1 to 24)

= 32764 if Set to Disable

=32765 if Set to Continuously

b0:Units

0 = Fahrenheit

1 = Celsius

b1:Enable Heater

0 = No

1 = Yes

b2:Manual Override

0 = Off

1 = On

b3:Control Type

0 = On/Off

1 = Proportional

b4-b6:RTD Operation

000 = Single RTD Mode

001 = Backup

010 = Average

011 = Lowest

100 = Highest

101 = High Temp Cutout

b7:RTD Failure Mode

0 = Off

1 = On

b8:Enable Password

0 = Disable

1 = Enable

b9:Display Mode

0 = Normal

1 = Advanced

b10-b11:Default Display

00 = System Status

01 = Heater Status

10 = Heater Temp

b12-b14:Baud Rate

000 = 1200 bps

001 = 2400 bps

010 = 4800 bps

011 = 9600 bps

100 = 19200 bps

b15-b16:GF Test

00 = Auto Test Cycle

01 = Now

10 = Disable

b17:Heater Type

0 = Fixed Resistance

1 = Self-Regulating

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

25

Page 26

Appendices CM-2201

D.2 Module Monitoring Group (Read Only)

Modbus

Register

40045 44 2 System Temp in °F

40046 45 2 System Temp in °C

40047 46 2 Low Temp Alarm in °F

40048 47 2 Low Temp Alarm in °C

40049 48 2 High Temp Alarm in °F

40050 49 2 High Temp Alarm in °C

40051 50 2 Heater Power = x per 10%

40052 51 2 Reserved

40053 52 2 Current

40054 53 2 GF Current

40055 54 2 Voltage

40056 55 2 Reserved

40057 56 2 Max Temp in °F

40058 57 2 Max Temp in °C

40059 58 2 Min Temp in °F

40060 59 2 Min Temp in °C

40061 60 2 Max Current

40062 61 2 Max GF Current

40063 62 2 Max Volt

Index

Value

Length

Bytes

Variable Name Description/Value Range

= x per °F

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °C

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °F

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °C

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °F

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °C

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per 0.1A

= 32766 as Out of Range

= x per 1V

= 32766 as Out of Range

= x per °F

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °C

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °F

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per °C

= 32765 if RTD Open

= 32767 if RTD Shorted

= x per 0.1A

= 32766 as Out of Range

= x per 1mA

= 32766 as Out of Range

= x per 1V

= 32766 as Out of Range

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

26

Page 27

CM-2201 Appendices

D.2 Module Monitoring Group (Read Only) Continued

Modbus

Register

40064 63 2 Min Volt

Index

Value

Length

Bytes

Variable Name Description/Value Range

= x per 1V

= 32766 as Out of Range

40065 64 2 Energy

40066 65 2 Cost

40067 66 2 Reserved

40068 67 2 Heater On Time

40069 68 2 Reserved

40070 69 2 Heater on % = x per 1%

40071 70 2 Alarm Stack 01

40072 71 2 Alarm Stack 02

40073 72 2 Alarm Stack 03

40074 73 2 Alarm Stack 04

40075 74 2 Alarm Stack 05

40076 75 2 Alarm Stack 06

40077 76 2 Alarm Stack 07

40078 77 2 Alarm Stack 08

40079 78 2 Alarm Stack 09

40080 79 2 Alarm Stack 10

40081 80 2 Alarm Stack 11

40082 81 2 Alarm Stack 12

40083 82 2 Alarm Stack 13

40084 83 2 Alarm Stack 14

40085 84 2 Alarm Stack 15

40086 85 2 Alarm Stack 16

40087 86 2 Alarm Stack 17

40088 87 2 Alarm Stack 18

40089 88 2 Alarm Stack 19

40090 89 2 Alarm Stack 20

= x per 1MWh

= 32766 as Out of Range

= x per $0.01

= 0x7FFFFFFF as Out of Range

= x per 1 Hour

= 1500000 as Out of Range

0 = No Alarm

1 = Low Temp Alarm

2 = High Temp Alarm

4 = Low Current Alarm

8 = High Current Alarm

16 = GF Alarm

32 = GF Trip

64 = Low Voltage Alarm

128 = High Voltage Alarm

256 = Auto Test Alarm

512 = Continuity Failure Alarm

1024 = SSR Failed Shorted Alarm

2048 = RTD-A Open Alarm

4096 = RTD-A Shorted Alarm

8192 = RTD-B Open Alarm

16384 = RTD-B Shorted Alarm

32768 = Self Check Failure

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

27

Page 28

Appendices CM-2201

D.3 Module Reset Group (Write Only)

Modbus

Register

00092 91 2 Acknowledge All = Set to 1 to Reset

00093 92 2 Reset Max Temp = Set to 1 to Reset

00094 93 2 Reset Min Temp = Set to 1 to Reset

00095 94 2 Reset Max Current = Set to 1 to Reset

00096 95 2 Reset Max GF = Set to 1 to Reset

00097 96 2 Reset Max Voltage = Set to 1 to Reset

00098 97 2 Reset Min Voltage = Set to 1 to Reset

00099 98 2 Reset Energy = Set to 1 to Reset

00100 99 2 Reset Cost = Set to 1 to Reset

00101 100 2 Reset Heater On Time (Hours) = Set to 1 to Reset

00102 101 2 Reset Heater On Percentage = Set to 1 to Reset

00103 102 2 Reset Statistics = Set to 1 to Reset

00104 103 2 Reset Low Temp = Set to 1 to Reset

00105 104 2 Reset High Temp = Set to 1 to Reset

00106 105 2 Reset Low Current = Set to 1 to Reset

00107 106 2 Reset High Current = Set to 1 to Reset

00108 107 2 Reset GF = Set to 1 to Reset

00109 108 2 Reset GF Trip = Set to 1 to Reset

00110 109 2 Reset Low Voltage = Set to 1 to Reset

00111 110 2 Reset High Voltage = Set to 1 to Reset

00112 111 2 Reset Auto Test = Set to 1 to Reset

00113 112 2 Reset Continuity Failure = Set to 1 to Reset

00114 113 2 Reset SSR Shorted = Set to 1 to Reset

00115 114 2 Reset RTD-A Open = Set to 1 to Reset

00116 115 2 Reset RTD-A Shorted = Set to 1 to Reset

00117 116 2 Reset RTD-B Open = Set to 1 to Reset

00118 117 2 Reset RTD-B Open = Set to 1 to Reset

00119 118 2 Reset Self-Check Failure = Set to 1 to Reset

Index

Value

Length

Bytes

Variable Name Description/Value Range

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

28

Page 29

CM-2201 Appendices

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (-200°C to 239°C)

Temperature Coefficient - 0.00385 Ohms/Ohm/°C

°C Ohms °C Ohms °C Ohms °C Ohms °C Ohms °C Ohms

-200 18.49 -160 35.53 -120 52.11 -80 68.33 -40 84.27 0 100.00

-199 18.93 -159 35.95 -119 52.52 -79 68.73 -39 84.67 1 100.39

-198 19.36 -158 36.37 -118 52.92 -78 69.13 -38 85.06 2 100.78

-197 19.79 -157 36.79 -117 53.33 -77 69.53 -37 85.46 3 101.17

-196 20.22 -156 37.21 -116 53.74 -76 69.93 -36 85.85 4 101.56

-195 20.65 -155 37.63 -115 54.15 -75 70.33 -35 86.25 5 101.95

-194 21.08 -154 38.04 -114 54.56 -74 70.73 -34 86.64 6 102.34

-193 21.51 -153 38.46 -113 54.97 -73 71.13 -33 87.04 7 102.73

-192 21.94 -152 38.88 -112 55.38 -72 71.53 -32 87.43 8 103.12

-191 22.37 -151 39.30 -111 55.78 -71 71.93 -31 87.83 9 103.51

-190 22.80 -150 39.71 -110 56.19 -70 72.33 -30 88.22 10 103.90

-189 23.23 -149 40.13 -109 56.60 -69 72.73 -29 88.62 11 104.29

-188 23.66 -148 40.55 -108 57.00 -68 73.13 -28 89.01 12 104.68

-187 24.09 -147 40.96 -107 57.41 -67 73.53 -27 89.40 13 105.07

-186 24.52 -146 41.38 -106 57.82 -66 73.93 -26 89.80 14 105.46

-185 24.94 -145 41.79 -105 58.22 -65 74.33 -25 90.19 15 105.85

-184 25.37 -144 42.21 -104 58.63 -64 74.73 -24 90.59 16 106.24

-183 25.80 -143 42.63 -103 59.04 -63 75.13 -23 90.98 17 106.63

-182 26.23 -142 43.04 -102 59.44 -62 75.53 -22 91.37 18 107.02

-181 26.65 -141 43.45 -101 59.85 -61 75.93 -21 91.77 19 107.40

-180 27.08 -140 43.87 -100 60.25 -60 76.33 -20 92.16 20 107.79

-179 27.50 -139 44.28 -99 60.66 -59 76.73 -19 92.55 21 108.18

-178 27.93 -138 44.70 -98 61.06 -58 77.13 -18 92.95 22 108.57

-177 28.35 -137 45.11 -97 61.47 -57 77.52 -17 93.34 23 108.96

-176 28.78 -136 45.52 -96 61.87 -56 77.92 -16 93.73 24 109.35

-175 29.20 -135 45.94 -95 62.28 -55 78.32 -15 94.12 25 109.73

-174 29.63 -134 46.35 -94 62.68 -54 78.72 -14 94.52 26 110.12

-173 30.05 -133 46.76 -93 63.09 -53 79.11 -13 94.91 27 110.51

-172 30.47 -132 47.18 -92 63.49 -52 79.51 -12 95.30 28 110.90

-171 30.90 -131 47.59 -91 63.90 -51 79.91 -11 95.69 29 111.28

-170 31.32 -130 48.00 -90 64.30 -50 80.31 -10 96.09 25 109.73

-169 31.74 -129 48.41 -89 64.70 -49

-168 32.16 -128 48.82 -88 65.11 -48 81.10 -8 96.87 27 110.51

-167 32.59 -127 49.23 -87 65.51 -47 81.50 -7 97.26 28 110.90

-166 33.01 -126 49.64 -86 65.91 -46 81.89 -6 97.65 29 111.28

-165 33.43 -125 50.06 -85 66.31 -45 82.29 -5 98.04 30 111.67

-164 33.85 -124 50.47 -84 66.72 -44 82.69 -4 98.44 31 112.06

-163 34.27 -123 50.88 -83 67.12 -43 83.08 -3 98.83 32 112.45

-162 34.69 -122 51.29 -82 67.52 -42 83.48 -2 99.22 33 112.83

-161 35.11 -121 51.70 -81 67.92 -41 83.88 -1 99.61 34 113.22

80.70 -9 96.48 26 110.12

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

29

Page 30

Appendices CM-2201

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (-200°C to 239°C)

Temperature Coefficient - 0.00385 Ohms/Ohm/°C

°C Ohms °C Ohms °C Ohms °C Ohms °C Ohms °C Ohms

35 113.61 76 129.37 117 144.93 158 160.30 198 175.10 239 190.09

36 113.99 77 129.75 118 145.31 159 160.67 199 175.47

37 114.38 78 130.13 119 145.68 160 161.04 200 175.84

38 114.77 79 130.51 120 146.06 160 161.04 201 176.21

39 115.15 80 130.89 121 146.44 161 161.42 202 176.57

40 115.54 81 131.27 122 146.81 162 161.79 203 176.94

41 115.93 82 131.66 123 147.19 163 162.16 204 177.31

42 116.31 83 132.04 124 147.57 164 162.53 205 178.04

43 116.70 84 132.42 125 147.94 165 162.90 206 178.41

44 117.08 85 132.80 126 148.32 166 163.27 207 178.78

45 117.47 86 133.18 127 148.70 167 163.65 208 179.14

46 117.85 87 133.56 128 149.07 168 164.02 209 179.51

47 118.24 88 133.94 129 149.45 169 164.39 210 179.88

48 118.62 89 134.32 130 149.82 170 164.76 211 180.24

49 119.01 90 134.70 131 150.20 171 165.13 212 180.97

50 119.40 91 135.08 132 150.57 172 165.50 213 181.34

51 119.78 92 135.46 133 150.95 173 165.87 214 181.71

52 120.16 93 135.84 134 151.33 174 166.24 215 182.07

53 120.55 94 136.22 135 151.70 175 166.61 216 182.44

54 120.93 95 136.60 136 152.08 176 166.98 217 182.80

55 121.32 96 136.98 137 152.45 177 167.35 218 183.17

56 121.70 97 137.36 138 152.83 178 167.72 219 183.53

57 122.09 98 137.74 139 153.20 179 168.09 220 183.17

58 122.47 99 138.12 140 153.58 180 168.46 221 183.53

59 122.86 100 138.50 141 153.95 181 168.83 222 183.90

60 123.24 101 138.88 142 154.32 182 169.20 223 184.26

61 123.62 102 139.26 143 154.70 183 169.57 224 184.63

62 124.01 103 139.64 144 155.07 184 169.94 225 184.99

63 124.39 104 140.02 145 155.45 185 170.31 226 185.36

64 124.77 105 140.39 146 155.82 186 170.68 227 185.72

65 125.16 106 140.77 147 156.19 187 171.05 228 186.09

66 125.54 107 141.15 148 156.57 188 171.42 229 186.45

67 125.92 108 141.53 149 156.94 189 171.79 230 186.82

68 126.31 109 141.91 150 157.31 190 172.16 231 187.18

69 126.69 110 142.29 151 157.69 191 172.53 232 187.54

70 127.07 111 142.66 152 158.06 192 172.90 233 187.91

71 127.45 112 143.04 153 158.43 193 173.26 234 188.27

72 127.84 113 143.42 154 158.81 194

73 128.22 114 143.80 155 159.18 195 174.00 236 189.00

74 128.60 115 144.17 156 159.55 196 174.37 237 189.36

75 128.98 116 144.55 157 159.93 197 174.74 238 189.72

173.63 235 188.63

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

30

Page 31

CM-2201 Appendices

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (240°C to 629°C)

Temperature Coefficient - 0.00385 Ohms/Ohm/°C

°C Ohms °C Ohms °C Ohms °C Ohms °C Ohms °C Ohms

240 190.45 278 204.16 316 217.70 354 231.07 392 244.28 430 257.32

241 190.81 279 204.52 317 218.05 355 231.42 393 244.62 431 257.66

242 191.18 280 204.88 318 218.41 356 231.77 394 244.97 432 258.00

243 191.54 281 205.23 319 218.76 357 232.12 395 245.31 433 258.34

244 191.90 282 205.59 320 219.12 358 232.47 396 245.66 434 258.68

245 192.26 283 205.95 321 219.47 359 232.82 397 246.00 435 259.02

246 192.63 284 206.31 322 219.82 360 233.17 398 246.35 436 259.36

247 192.99 285 206.67 323 220.18 361 233.52 399 246.69 437 259.70

248 193.35 286 207.02 324 220.53 362 233.87 400 247.04 438 260.04

249 193.71 287 207.38 325 220.88 363 234.22 401 247.38 439 260.38

250 194.07 288 207.74 326 221.24 364 234.56 402 247.72 440 260.72

251 194.44 289 208.10 327 221.59 365 234.91 403 248.07 441 261.06

252 194.80 290 208.45 328 221.94 366 235.26 404 248.41 442 261.40

253 195.16 291 208.81 329 222.29 367 235.61 405 248.76 443 261.74

254 195.52 292 209.17 330 222.65 368 235.96 406 249.10 444 262.08

255 195.88 293 209.52 331 223.00 369 236.31 407 249.45 445 262.42

256 196.24 294 209.88 332 223.35 370 236.65 408 249.79 446 262.76

257 196.60 295 210.24 333 223.70 371 237.00 409 250.13 447 263.10

258 196.96 296 210.59 334 224.06 372 237.35 410 250.48 448 263.43

259 197.33 297 210.95 335 224.41 373 237.70 411 250.82 449 236.77

260 197.69 298 211.31 336 224.76 374 238.04 412 251.16 450 264.11

261 198.05 299 211.66 337 225.11 375 238.39 413 251.50 451 264.45

262 198.41 300 212.02 338 225.46 376 238.74 414 251.85 452 264.79

263 198.77 301 212.37 339 225.81 377 239.09 415 252.19 453 265.13

264 199.13 302 212.73 340 226.17 378 239.43 416 252.53 454 265.46

265 199.49 303 213.09 341 226.52 379 239.78 417 252.87 455 265.80

266 199.85 304 213.44 342 226.87 380 240.13 418 253.22 456 266.14

267 200.21 305 213.80 343 227.22 381 240.47 419 253.56 457 266.48

268 200.57 306 214.15 344 227.57 382 240.82 420 253.90 458 266.82

269 200.93 307 214.51 345 227.92 383 241.17 421 254.24 459 267.15

270 201.29 308 214.86 346 228.27 384 241.51 422 254.59 460 267.49

271 201.65 309 215.22 347 228.62 385

272 202.01 310 215.57 348 228.97 386 242.20 424 255.27 462 268.17

273 202.36 311 215.93 349 229.32 387 242.55 425 255.61 463 268.50

274 202.72 312 216.28 350 229.67 388 242.90 426 255.95 464 268.84

275 203.08 313 216.64 351 230.02 389 243.24 427 256.29 465 269.18

276 203.44 314 216.99 352 230.37 390 243.59 428 256.63 466 269.51

277 203.80 315 217.35 353 230.72 391 243.93 429 258.98 467 269.85

241.86 423 254.93 461 267.83

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

31

Page 32

Appendices CM-2201

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (240°C to 629°C)

Temperature Coefficient - 0.00385 Ohms/Ohm/°C

°C Ohms °C Ohms °C Ohms °C Ohms °C Ohms °C Ohms

468 270.19 499 280.56 530 290.83 561 300.98 592 311.02 623 320.95

469 270.52 500 280.90 531 291.16 562 301.31 593 311.34 624 321.27

470 270.86 501 281.23 532 291.49 563 301.63 594 311.66 625 321.59

471 271.20 502 281.56 533 291.81 564 301.96 595 311.99 626 321.91

472 271.53 503 281.89 534 292.14 565 302.28 596 312.31 627 322.22

473 271.87 504 282.23 535 292.47 566 302.61 597 312.63 628 322.54

474 272.20 505 282.56 536 292.80 567 302.93 598 312.95 629 322.86

475 272.54 506 282.89 537 293.13 568 303.26 599 313.27

476 272.88 507 283.22 538 293.46 569 303.58 600 313.59

477 273.21 508 283.55 539 293.79 570 303.91 601 313.91

478 273.55 509 283.89 540 294.11 571 304.23 602 314.24

479 273.88 510 284.22 541 294.44 572 304.56 603 314.56

480 274.22 511 284.55 542 294.77 573 304.88 604 314.88

481 274.55 512 284.88 543 295.10 574 305.20 605 315.20

482 274.89 513 285.21 544 295.43 575 305.53 606 315.52

483 275.22 514 285.54 545 295.75 576 305.85 607 316.16

484 275.56 515 285.87 546 296.08 577 306.18 608 316.48

485 275.89 516 286.21 547 296.41 578 306.50 609 316.48

486 276.23 517 286.54 548 296.74 579 306.82 610 316.80

487 276.56 518 286.87 549 297.06 580 307.15 611 317.12

488 276.89 519 287.20 550 297.39 581 307.47 612 317.44

489 277.23 520 287.53 551 297.72 582 307.79 613 317.76

490 277.56 521 287.86 552 298.04 583 308.12 614 318.08

491 277.90 522 288.19 553 298.37 584 308.44 615 318.40

492 278.23 523 288.52 554 298.70 585 308.76 616 318.72

493 278.56 524 288.85 555 299.02 586 309.09 617 319.04

494 278.90 525 289.18 556 299.35 587 309.41 618 319.36

495 279.23 526 289.51 557 299.68 588 309.73 619 319.68

496 279.56 527 289.84 558 300.00 589 310.05 620 319.99

497 279.90 528 290.17 559 300.33 590 310.38 621 320.31

498 280.23 529 290.50 560 300.65 591 310.70 622 320.63

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

32

Page 33

CM-2201 Appendices

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (-328°F to 1220°F)

Temperature Coefficient - 0.00385 Ohms/Ohm/°F

°F Ohms °F Ohms °F Ohms °F Ohms °F Ohms °F Ohms

-328 18.52 -292 27.10 -256 35.54 -220 41.80 -184 52.11 -148 60.26

-327 18.76 -291 27.33 -255 35.78 -219 44.11 -183 52.34 -147 60.48

-326 19.00 -290 27.57 -254 36.01 -218 44.34 -182 52.56 -146 60.71

-325 19.24 -289 27.81 -253 36.24 -217 44.57 -181 52.79 -145 60.93

-324 19.48 -288 28.04 -252 36.47 -216 44.80 -180 53.02 -144 61.16

-323 19.72 -287 28.28 -251 36.71 -215 45.03 -179 53.25 -143 61.38

-322 19.96 -286 28.51 -250 36.94 -214 45.26 -178 53.47 -142 61.61

-321 20.20 -285 28.75 -249 37.17 -213 45.48 -177 53.7 -141 61.83

-320 20.44 -284 28.98 -248 37.40 -212 45.71 -176 53.93 -140 62.06

-319 20.68 -283 29.22 -247 37.64 -211 45.94 -175 54.15 -139 62.28

-318 20.92 -282 29.46 -246 37.87 -210 46.17 -174 54.38 -138 62.5

-317 21.16 -281 29.69 -245 38.10 -209 46.40 -173 54.61 -137 62.73

-316 21.39 -280 29.93 -244 38.33 -208 46.63 -172 54.83 -136 62.95

-315 21.63 -279 30.16 -243 38.56 -207 46.86 -171 55.06 -135 63.18

-314 21.87 -278 30.40 -242 38.8 -206 47.09 -170 55.29 -134 63.4

-313 22.11 -277 30.63 -241 39.03 -205 47.32 -169 55.51 -133 63.63

-312 22.35 -276 30.87 -240 39.26 -204 47.55 -168 55.74 -132 63.85

-311 22.59 -275 31.10 -239 39.49 -203 47.78 -167 55.97 -131 64.08

-310 22.83 -274 31.34 -238 39.72 -202 48.00 -166 56.19 -130 64.30

-309 23.06 -273 31.57 -237 39.95 -201 48.23 -165 56.42 -129 64.52

-308 23.3 -272 31.80 -236 40.19 -200 48.46 -164 56.65 -128 64.75

-307 23.54 -271 32.04 -235 40.42 -199 48.69 -163 56.87 -127 64.97

-306 23.78 -270 32.27 -234 40.65 -198 48.92 -162 57.1 -126 65.2

-305 24.02 -269 32.51 -233 40.88 -197 49.15 -161 57.32 -125 65.42

-304 24.25 -268 32.74 -232 41.11 -196 49.38 -160 57.55 -124 65.64

-303 24.49 -267 32.98 -231 41.34 -195 49.6 -159 57.78 -123 65.87

-302 24.73 -266 33.21 -230 41.57 -194 49.83 -158 58.00 -122 66.09

-301 24.97 -265 33.44 -229 43.88 -193 50.06 -157 58.23 -121 66.31

-300 25.20 -264 33.68 -228 43.65 -192 50.29 -156 58.45 -120 66.54

-299 25.44 -263 33.91 -227 43.42 -191 50.52 -155 58.68 -119 66.76

-298 25.68 -262 34.14 -226 43.19 -190 50.74 -154 58.9 -118 66.99

-297 25.91 -261 34.38

-296 26.15 -260 34.61 -224 42.73 -188 51.2 -152 59.35 -116 67.43

-295 26.39 -259 34.84 -223 42.49 -187 51.43 -151 59.58 -115 67.66

-294 26.62 -258 35.08 -222 42.26 -186 51.65 -150 59.81 -114 67.88

-293 26.86 -257 35.31 -221 42.03 -185 51.88 -149 60.03 -113 68.10

-225 42.96 -189 50.97 -153 59.13 -117 67.21

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

33

Page 34

Appendices CM-2201

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (-328°F to 1220°F)

Temperature Coefficient - 0.00385 Ohms/Ohm/°F

°F Ohms °F Ohms °F Ohms °F Ohms °F Ohms °F Ohms

-112 68.33 -76 76.33 -40 84.27 -4 92.16 32 100.00 68 107.79

-111 68.55 -75 76.55 -39 84.49 -3 92.38 33 100.22 69 108.01

-110 68.77 -74 76.77 -38 84.71 -2 92.60 34 100.43 70 108.23

-109 71.00 -73 76.99 -37 84.93 -1 92.82 35 100.65 71 108.44

-108 70.78 -72 77.21 -36 85.15 0 93.03 36 100.87 72 108.66

-107 70.55 -71 77.43 -35 85.37 1 93.25 37 101.09 73 108.87

-106 70.33 -70 77.66 -34 85.59 2 93.47 38 101.30 74 109.09

-105 70.11 -69 77.88 -33 85.81 3 93.69 39 101.52 75 109.3

-104 69.89 -68 78.1 -32 86.03 4 93.91 40 101.74 76 109.52

-103 69.66 -67 78.32 -31 86.25 5 94.12 41 101.95 77 109.73

-102 69.44 -66 78.54 -30 86.47 6 94.34 42 102.17 78 109.95

-101 69.22 -65 78.76 -29 86.69 7 94.56 43 102.39 79 110.17

-100 68.99 -64 78.98 -28 86.91 8 94.78 44 102.60 80 110.38

-99 71.22 -63 79.2 -27 87.13 9 95.00 45 102.82 81 110.6

-98 71.45 -62 79.42 -26 87.34 10 95.21 46 103.04 82 110.81

-97 71.67 -61 79.64 -25 87.56 11 95.43 47 103.25 83 111.03

-96 71.89 -60 79.86 -24 87.78 12 95.65 48 103.47 84 111.24

-95 72.11 -59 80.09 -23 88.00 13 95.87 49 103.69 85 111.46

-94 72.33 -58 80.31 -22 88.22 14 96.09 50 103.90 86 111.67

-93 72.56 -57 80.53 -21 88.44 15 96.3 51 104.12 87 111.89

-92 72.78 -56 80.75 -20 88.66 16 96.52 52 104.34 88 112.10

-91 73.00 -55 80.97 -19 88.88 17 96.74 53 104.55 89 112.32

-90 73.22 -54 81.19 -18 89.10 18 96.96 54 104.77 90 112.53

-89 73.45 -53 81.41 -17 89.32 19 97.17 55 104.98 91 112.75

-88 73.67 -52 81.63 -16 89.54 20 97.39 56 105.20 92 112.96

-87 73.89 -51 81.85 -15 89.75 21 97.61 57 105.42 93 113.18

-86 74.11 -50 82.07 -14 89.97 22 97.83 58 105.63 94 113.39

-85 74.33 -49 82.29 -13 90.19 23 98.04 59 105.85 95 113.61

-84 74.55 -48 82.51 -12 90.41 24 98.26 60 106.07 96 113.82

-83 74.78 -47 82.73 -11 90.63 25 98.48 61 106.28 97 114.04

-82 75.00 -46 82.95 -10 90.85 26 98.7 62 106.50 98 114.25

-81 75.22 -45 83.17 -9

-80 75.44 -44 83.39 -8 91.29 28 99.13 64 106.93 100 114.68

-79 75.66 -43 83.61 -7 91.50 29 99.35 65 107.15 101 114.90

-78 75.88 -42 83.83 -6 91.72 30 99.57 66 107.36 102 115.11

-77 76.11 -41 84.05 -5 91.94 31 99.78 67 107.58 103 115.33

91.07 27 98.91 63 106.71 99 114.47

©2015 Nelson Heat Tracing Systems www.nelsonheaters.com GA2497 Rev. 3

34

Page 35

CM-2201 Appendices

Appendix E - RTD Tables

Temperature Conversion

Platinum Resistance (-328°F to 1220°F)

Temperature Coefficient - 0.00385 Ohms/Ohm/°F

°F Ohms °F Ohms °F Ohms °F Ohms °F Ohms °F Ohms

104 115.54 140 123.24 176 130.90 212 138.51 248 146.07 284 153.58

105 115.76 141 123.46 177 131.11 213 138.72 249 146.28 285 153.79

106 115.97 142 123.67 178 131.32 214 138.93 250 146.49 286 154.00

107 116.18 143 123.88 179 131.53 215 139.14 251 146.70 287 154.21

108 116.40 144 124.09 180 131.74 216 139.35 252 146.91 288 154.42

109 116.61 145 124.31 181 131.96 217 139.56 253 147.11 289 154.62

110 116.83 146 124.52 182 132.17 218 139.77 254 147.32 290 154.83

111 117.04 147 124.73 183 132.38 219 139.98 255 147.53 291 155.04

112 117.26 148 124.95 184 132.59 220 140.19 256 147.74 292 155.25

113 117.47 149 125.16 185 132.8 221 140.4 257 147.95 293 155.46

114 117.68 150 125.37 186 133.01 222 140.61 258 148.16 294 155.66

115 117.90 151 125.59 187 133.23 223 140.82 259 148.37 295 155.87

116 118.11 152 125.80 188 133.44 224 141.03 260 148.58 296 156.08

117 118.33 153 126.01 189 133.65 225 141.24 261 148.79 297 156.29

118 118.54 154 126.22 190 133.86 226 141.45 262 149.00 298 156.49

119 118.76 155 126.44 191 134.07 227 141.66 263 149.21 299 156.7

120 118.97 156 126.65 192 134.28 228 141.87 264 149.41 300 156.91

121 119.18 157 126.86 193 134.5 229 142.08 265 149.62 301 157.12

122 119.4 158 127.08 194 134.71 230 142.29 266 149.83 302 157.33

123 119.61 159 127.29 195 134.92 231 142.5 267 150.04 303 157.53

124 119.82 160 127.50 196 135.13 232 142.71 268 150.25 304 157.74