Installation instructions and

how to use and look after your

built-in cooker hoods

NEFF (UK) Ltd

Abb. 1

ELECTRO

Fig. 1

GAZ

2

3

Table of contents

General Information ............................................................................................ 4

Information on protection of the environment ............................................................................... 4

Before using the appliance for the rst time ...................................................................................... 4

Safety Instructions ............................................................................................... 5

Intended use .......................................................................................................................................................... 5

Technical safety .................................................................................................................................................... 5

Special information for gas cookers ........................................................................................................ 6

Proper use ................................................................................................................................................................ 7

Correct installation ............................................................................................................................................. 7

Operating modes ................................................................................................. 8

Exhaust-air mode ................................................................................................................................................ 8

Circulating-air mode .......................................................................................................................................... 8

Operation ............................................................................................................... 9

Cleaning and Care ................................................................................................ 10

Removing and installing the grease lters ...................................................... 11

Removing and installing the metal-mesh grease lters ............................................................. 11

Installing and removing the activated carbon lters .................................................................... 11

Changing the bulbs ............................................................................................. 12

Installation instructions ...................................................................................... 13

Connecting Pipes ................................................................................................................................................ 13

Electrical Connections ...................................................................................................................................... 14

Installation ............................................................................................................. 15

Installation preparations ................................................................................................................................. 15

Attachment ............................................................................................................................................................. 16

Installing the ue ducts ................................................................................................................................... 17

4

E-no. FD

B

EFORE USING THE APPLIANCE FOR THE FIRST

TIME

NOTE: These operating instructions apply to

several appliance models It is possible that

individual features are described which do not

apply to your appliance.

Before switching on your new appliance, please read the operating instructions carefully.

They contain important information on safety

and how to use and look after the appliance.

Keep the operating and instructions in a safe

place and pass them on to any subsequent

owner of the appliance.

INFORMATION ON PROTECTION OF THE

ENVIRONMENT

Disposal of transport packaging

Your new appliance was sent to you in

protective packaging. All utilised materials are

environmentally safe and recyclable. Please

help us by disposing of the packaging in an

environmentally friendly manner.

Packaging parts can be hazardous for children.

Therefore keep them outside the reach of

children.

Disposal of the old appliance

Old appliances are not worthless rubbish.

Valuable raw materials can be reclaimed by

recycling old appliances.

This appliance is identied

according to the European

Directive 2002/96/EC on waste

electrical and electronic

equipment – WEEE). The

directive species the

framework for an EU-wide valid

return and re-use of old appliances.

Before disposing of your old appliance, render

it unusable.

Never treat your old appliance as nonrecyclable waste!

Please ask your dealer or inquire at your local

authority about current means of disposal.

Ensure that the old appliance is kept

childproof until it is disposed of.

Faults

Please contact customer service regarding any

queries or faults.

(See list of customer service centres).

When calling, please quote:

The numbers can be found on the rating plate,

after removal of the grease lter, inside the

extractor hood.

Enter the numbered in the above elds.

General information

)

5

Intended use

This extractor hood complies with the

stipulated safety regulations. Improper use

may result in injury or damage.

The extractor hood may be used in the

household only. The manufacturer is not liable

for damage which is caused by improper use or

incorrect operation.

The manufacturer cannot be made

responsible for damage which can be attributed

to non-observance of the safety instructions.

RISK OF INJURY

Do not allow children to play with the

extractor hood! Adults and children must

never operate the appliance unsupervised

– if they are not physically or mentally

capable of doing so,

– or if they do not have the knowledge and

experience to operate the appliance

correctly and safely.

Technical safety

The extractor hood left the factory in perfect

condition. Nevertheless check the appliance for

visible damage before installation. If it is

damaged, do not switch it on!

If the power cord of the extractor hood is

damaged, it must be replaced by the

manufacturer, his customer service or a

similarly qualied person to prevent hazardous

situations.

Only a qualied technician may install

(including electrical connection), service or

repair the extractor hood. Always isolate the

extractor hood by pulling out the mains plug

or switching o the fuse!

Safety instructions

If the appliance is improperly installed,

serviced or repaired, the user may be placed in

considerable danger for which the

manufacturer is not liable.

Changes to the electrical or mechanical

installation are dangerous and must not be

undertaken! They may also cause the extractor

hood to malfunction.

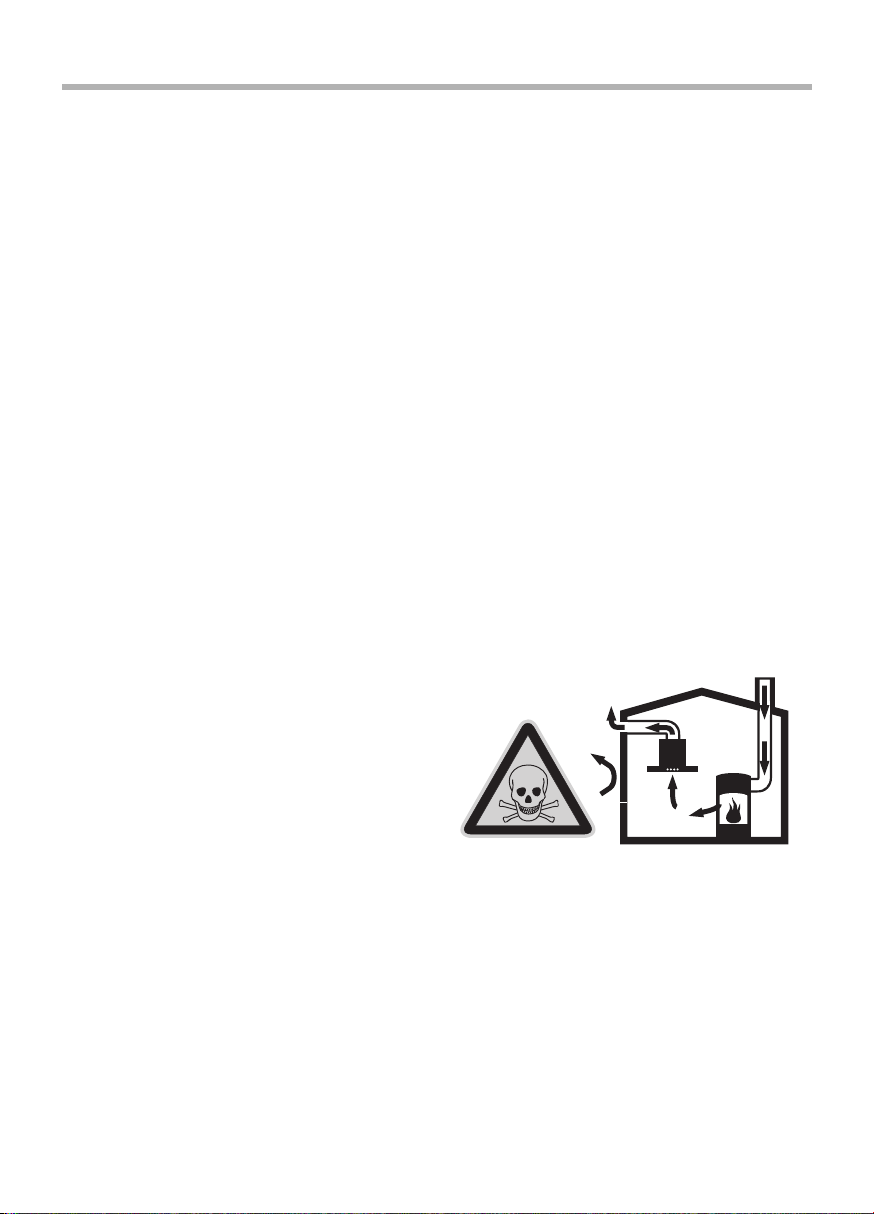

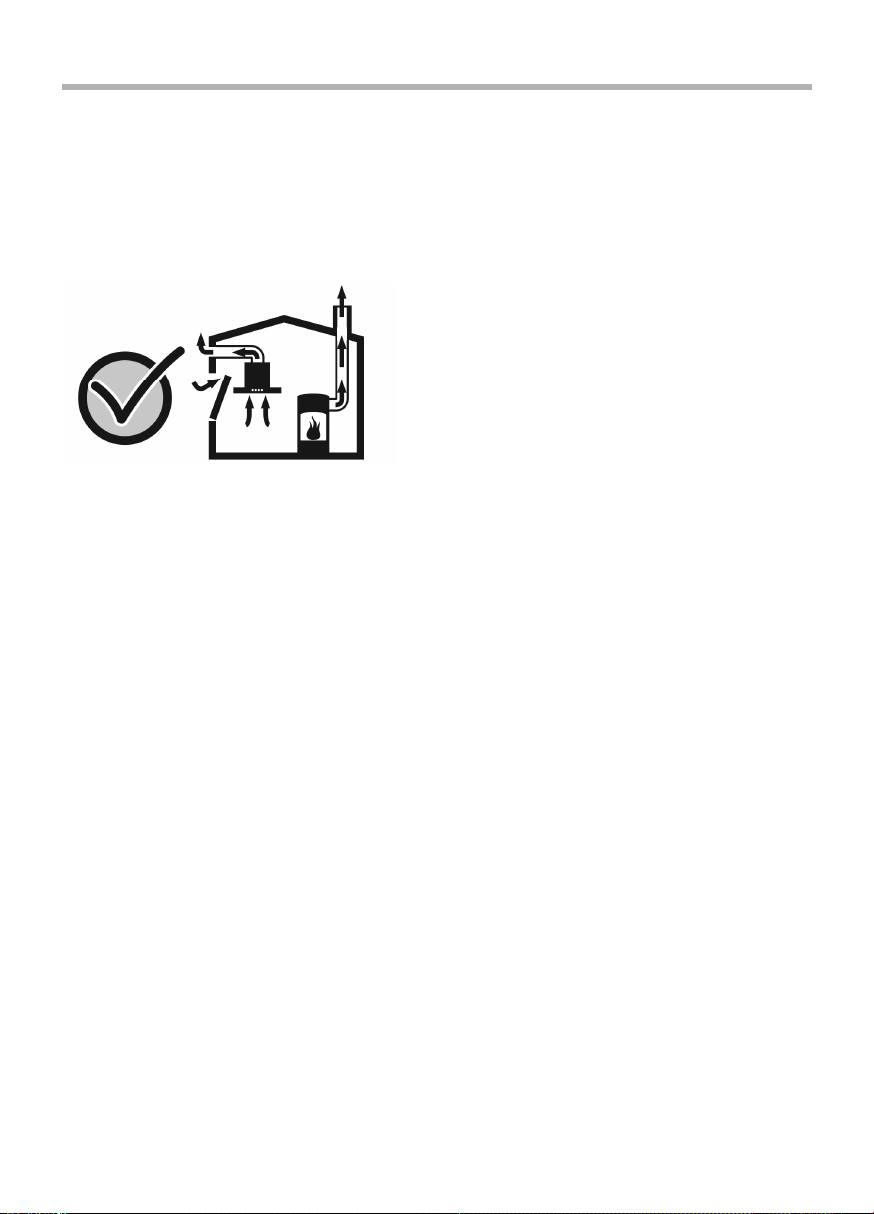

Simultaneous operation of the extractor

hood with a heating appliance which is

dependent on ambient air

Heating appliances which are dependent

on ambient air, e.g. gas, oil, wood, or solid-fuel

heaters, instantaneous water heaters, hot

water boilers, hobs or ovens, and which draw

combustion air out of the installation room

and whose exhaust gases are conveyed to the

exterior by a ue.

RISK OF POISONING

If the extractor hood is operated at the same

time as a heating appliance which is

dependent on ambient air, there is a risk of

poisoning due to combustion gases being

drawn back in.

6

Safe operation is possible provided the low

pressure in the installation room of the heating

appliance does not exceed 4Pa (0.04mbar).

This can be achieved if the combustion air can

ow through non-closable openings, e.g. in

doors, windows, in conjunction with air

intake/exhaust air wall boxes or by other

technical measures.

Adequate intake air must therefore always

be provided.

An intake/exhaust air wall box alone does not

ensure compliance with the limit value.

NOTE: When making your evaluation, always

consider the entire ventilation system in the

home. Include the advice of a competent

heating engineer when making your

evaluation.

If the extractor hood is used in circulating

air mode only, it can be operated without any

restrictions.

Special information for gas cookers

When installing the extractor hood above

gas hobs, observe the appropriate national

statutory regulations (e.g. in Germany:

Technische Regeln Gasinstallation TRGI).

Observe the currently valid installation

regulations and instructions of the gas

appliance manufacturer.

During installation, ensure that only one side

of the extractor hood is situated directly next to

a high-sided unit or a wall. Otherwise, there is a

risk of heat build-up. The gap between the

extractor hood and the wall or high-sided unit

must be at least 50 mm.

RISK OF BURNS

Do not operate more than 2 gas cooking areas

simultaneously over a period of max.

15 minutes at maximum thermal load. Due to

the eect of the heat there is a risk of burns if

the surfaces of the housing are touched!

Note that one large burner of more than

5 kW (Wok) is equivalent to the power of 2 gas

burners.

The extractor hood may be damaged by

the intense heat.

Never operate a gas cooking area without a

cooking utensil on it. Regulate the ame in

such a way that it does not project over the

cooking utensil.

Safety instructions

7

Proper use

Clean the extractor hood thoroughly before

using for the rst time.

Before cleaning and servicing the extractor

hood, isolate it from the power supply by

pulling out the mains plug or switching o the

fuse.

Bulbs (especially halogen bulbs) become

very hot during operation. Even some time

after the appliance has been switched o,

there is still a risk of burns!

Before changing bulbs, isolate the extractor

hood from the power supply and leave the

bulbs to cool down!

Do not operate the extractor hood without

bulbs inserted.

Always switch on the extractor hood if a

hotplate is being used. If the extractor hood is

not switched on, condensation may form. As a

result, the appliance may corrode.

Do not place any

objects on the

extractor hood.

RISK OF FIRE

Do not ambé under the extractor hood or

work with a naked ame. When switched on,

the extractor hood draws ames into the lter.

There is a risk of re due to deposits on the

grease lter!

Do not leave pans, frying pans or deep-fat

fryers unattended if you are cooking food with

oils or fats, e.g. chips. Overheated oils or fats

can easily ignite!

A risk of re can be prevented by cleaning

the grease lters regularly and changing the

activated-carbon lter in good time.

Never operate the extractor hood without

grease lters.

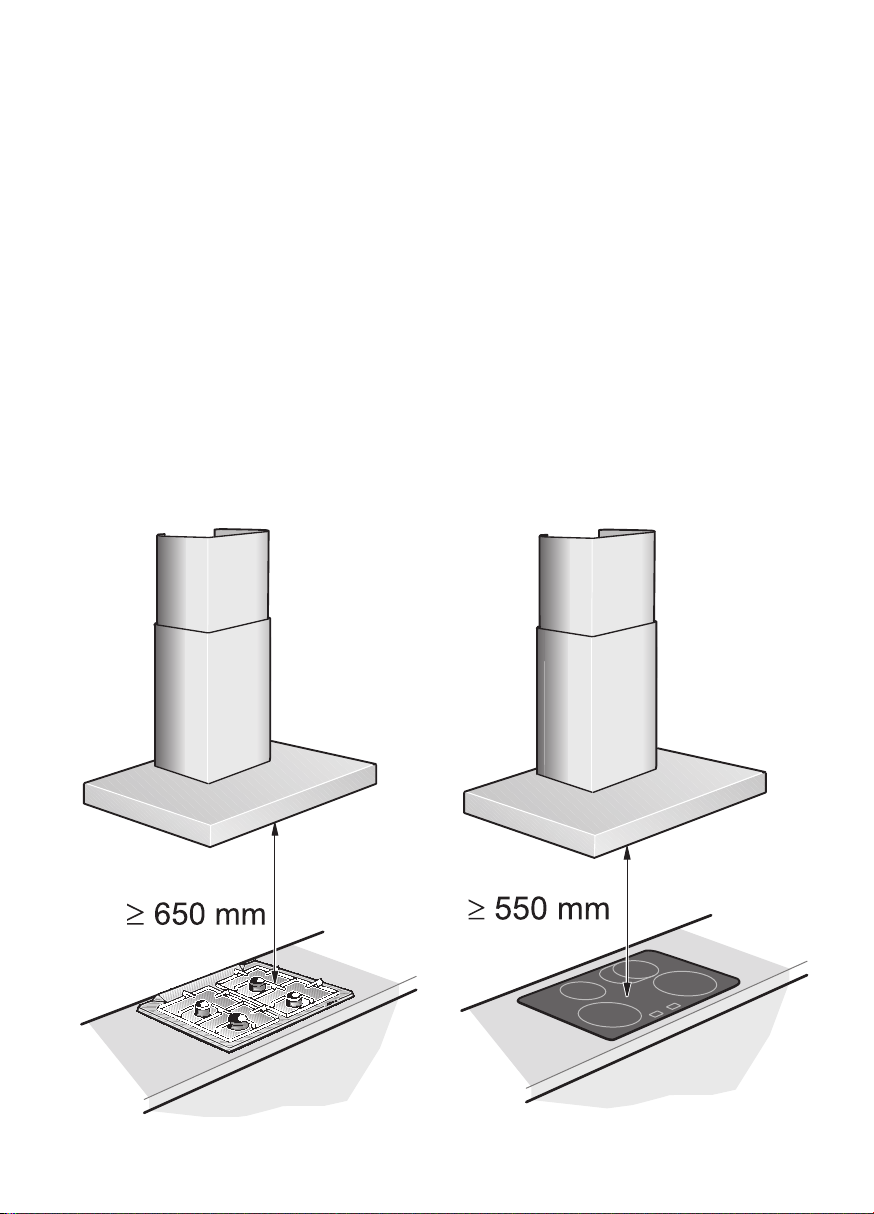

Correct installation

Check the manufacturer’s specications for

the cooker to determine whether an extractor

hood can be operated over it.

If the manufacturer of the cooker has not

specied any signicant safety distances, the

following minimum distances apply

– 550 mm between electric hob and the

lower edge of the extractor hood

– 650 mm between gas hob (upper edge of

pan support) and the lower edge of the

extractor hood,

(see g. 1, page 2).

If various cookers are used, the greatest

indicated distance applies.

The width of the extractor hood must

correspond to the width of the cooking area.

The extractor hood must not be installed

over a solid fuel heating appliance which may

be a re risk (e.g. ying sparks) unless the

heating appliance has a closed, nondetachable cover and the country-specic

regulations are observed. This restriction does

not apply to gas cookers and gas hobs.

To avoid damaging the hob, cover it when

installing the extractor hood.

Safety instructions

8

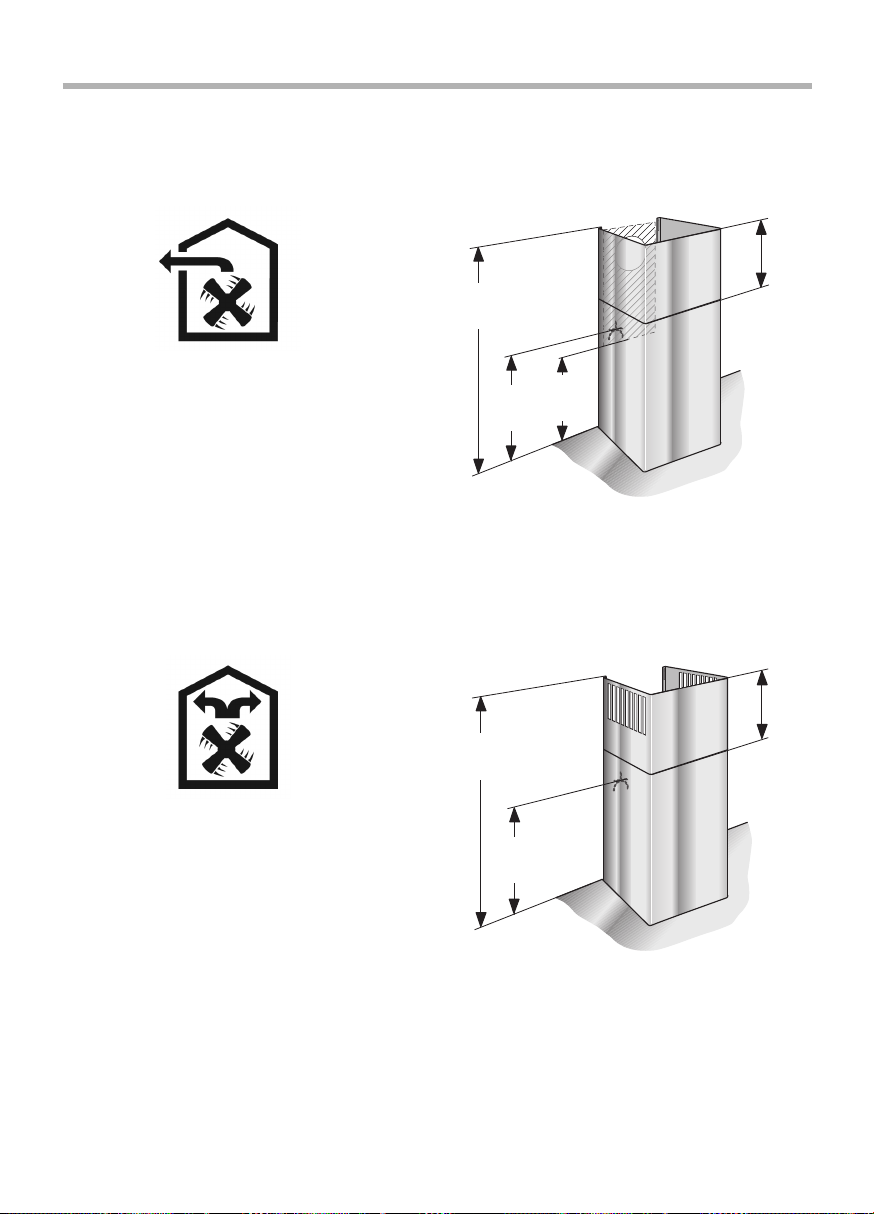

Operating modes

Appliance dimensions Exhaust air

Appliance dimensions Circulating air

min.

126

min.

450

min.

400

min. 580

max 1.030

min.

126

min.

450

min. 580

max 1.030

The extractor hood can be used in exhaust

air and circulating air mode.

Exhaust-air mode

The air which is drawn in is cleaned by the

grease lters and conveyed to the exterior by a

pipe system.

Circulating-air mode

The air which is drawn in is cleaned by the

grease lters and an activated carbon lter and

conveyed back into the kitchen.

An activated carbon lter must be installed to

bind odours in circulating-air mode (see

”Removing and installing the grease lters”).

The complete installation set as well as the

replacement lters are available from specialist

outlets, customer service or the Online Shop.

The accessory number can be found at the

end of the operating instructions.

9

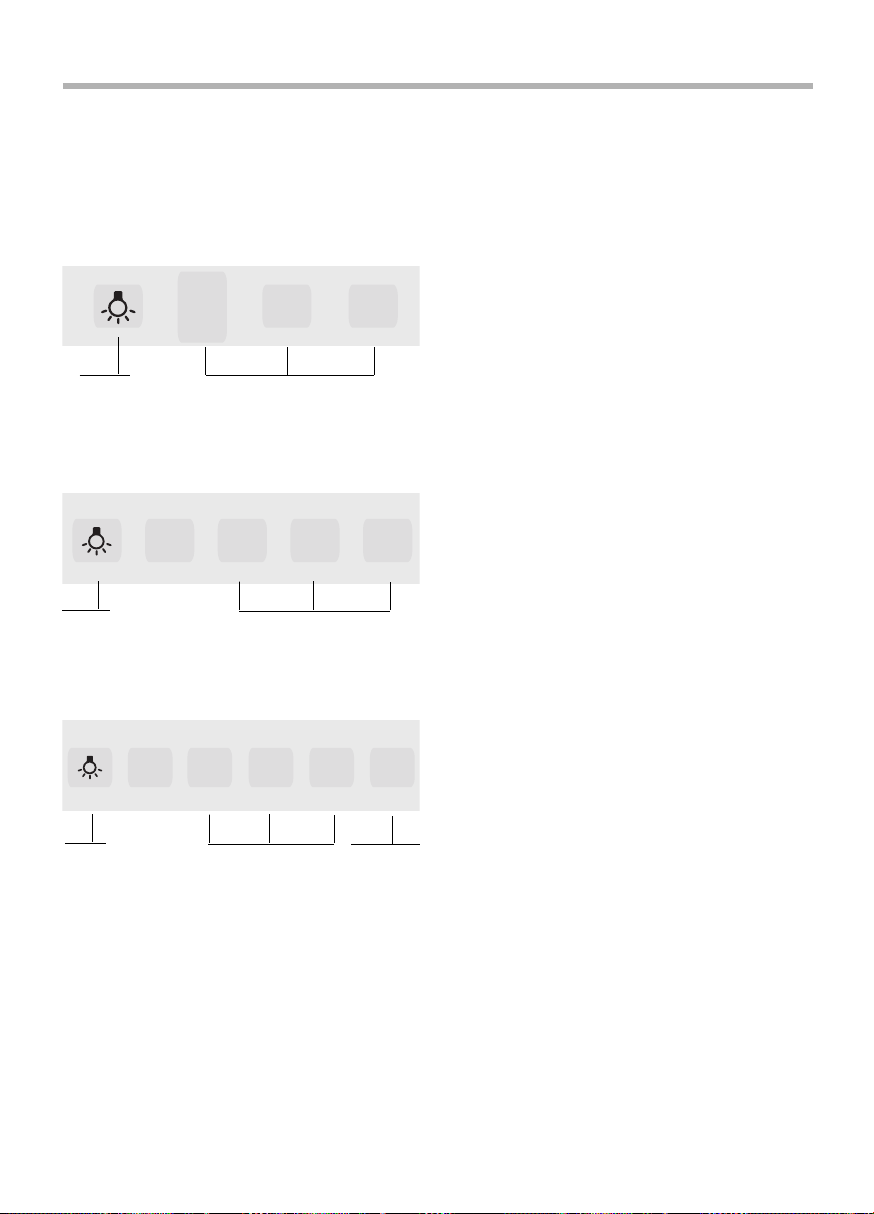

Operation

NOTE: It is recommended to switch on the

blower when you start cooking and not to

switch it o again until several minutes after

you have nished cooking. In this way the

kitchen fumes are removed most eectively.

Switching on the fan and selecting the

fan settings

Press button 1. If kitchen fumes are thicker

switch to setting 2 or 3.

Switching o the fan

Press button 0.

Light

The light can be switched on and o

independently of the fan.

For appliances with Intensive setting

The Intensive setting P generates maximum

performance. It can be used if thick fumes or

strong odours occur temporarily.

0

1

23

The description of the operation applies to

several appliance models. It is possible that

individual features are described which do not

apply to your appliance.

1230

1230P

Light Fan settings

Light

Fan settings

Light

Fan settings

Intensive

setting

10

Cleaning and care

LOOKING AFTER THE APPLIANCE

Suitable cleaning agents and care products

for your appliance can be purchased via the

Hotline or from the Online Shop (see cover

page).

Appliance surfaces

NOTE: Observe the warranty regulations in the

enclosed service booklet.

The appliance surfaces and controls are

scratch-sensitive. Therefore observe the

following cleaning instructions:

– Avoid cleaning the extractor hood with dry

cloths, abrasive sponges, scouring agents,

cleaning agents containing sand, soda, acid,

chlorine or any other aggressive substances.

– Clean the appliance surfaces and controls

with a soft, damp cloth, washing-up liquid

or a mild window cleaner only.

– Do not scrape o dried dirt, but moisten with

a damp cloth.

– Clean carefully in the area of the controls to

avoid liquid from getting into the

electronics.

NOTE: Clean the stainless steel surfaces in the

direction of the ground surface only!

Do not use stainless steel cleaner for the

control buttons!

Metal-mesh grease lters

The metal-mesh grease lters absorb the

grease particles from the kitchen fumes.

The lter mats consist of re-proof metal.

RISK OF FIRE

As the lters become more saturated with

greasy residue, the ammability increases. The

function of the extractor hood may also be

impaired.

The risk of re is prevented by cleaning the

metal-mesh grease lters in good time.

When cleaning the grease lters, also

remove grease deposits from the accessible

parts of the housing with a damp cloth.

Cleaning the metal-mesh grease lters ...

Under normal operation (daily 1 to 2 hours),

the metal-mesh grease lters must be cleaned

1x month.

... in the dishwasher

The metal-mesh grease lters can be

cleaned in the dishwasher. Slight

discolouration may occur but this will not

aect the function of the grease lters.

The lters must be placed loosely in the

dishwasher. They must not be wedged in.

NOTE: Do not clean heavily saturated metalmesh grease lters together with utensils.

... by hand

When cleaning by hand, soak the grease

lters in a hot detergent solution, brush o the

dirt, rinse thoroughly and leave to dry.

Do not use any aggressive, acidic or alkaline

cleaning agents.

If dirt is particularly stubborn, we

recommend using a special grease solvent

spray. This can be ordered via the Online Shop.

11

Removing and installing the grease filters

Activated carbon lters bind the odours in

circulating-air mode.

Installing and removing the activated

carbon lters

1. Remove the grease lters (see Removing

and installing the metal-mesh grease lters).

2. Insert the activated carbon lter.

3. Lock the catch.

4. Reinsert the grease lters (see Removing

and installing the metal-mesh grease lters).

Changing the activated carbon lter

Under normal operation (daily 1 to 2 hours)

the activated carbon lters must be replaced

approximately 2x year.

The activated carbon lter is available from

specialist outlets, customer service or the

Online Shop (see Optional accessories). Use

original lters only.

Activated carbon lters do not contain any

pollutants. They can be disposed of in the

household refuse.

Before removing and installing the grease

lters, always follow the instructions and

warnings in the chapter entitled ”Safety

instructions”!

Removing and installing the metal-mesh

grease lters

1. Open the lock and fold down the grease

lters. In doing so, hold the underside of the

grease lters with your other hand.

(for appliances with edge extraction)

2. Clean the grease lters.

3. Reinsert the cleaned grease lters.

12

Changing the bulbs

Changing the lament bulbs

1. Lift the bulb cover slightly.

2. Push the bulb cover towards the middle of

the appliance.

3. Replace the defective bulb with a new one

of the same type and equivalent power (see

rating plate).

4. Reinsert the bulb cover.

5. Restore the power supply by inserting the

mains plug or switching on the fuse.

NOTE: If the light does not function, check

whether the bulbs have been inserted

correctly.

Defective bulbs should be replaced

immediately to avoid overloading the

remaining bulbs.

Before changing the bulbs, always follow

the instructions and warnings in the chapter

entitled ”Safety instructions”!

The description of changing the bulbs

applies to several appliance models.

NOTE: Observe the warranty regulations in the

enclosed service booklet.

Changing the halogen bulbs

Halogen bulbs become very hot during

operation. Even some time after the appliance

has been switched o, there is still a risk of

burns!

Before changing the halogen bulbs, ensure

that they have cooled down fully.

1. Carefully remove the bulb ring with a

suitable tool.

2. Replace the defective bulb with a new one

of the same type and equivalent power (see

rating plate).

NOTE: When inserting halogen bulbs, do not

touch the glass tube. Therefore use a clean

cloth when inserting the bulb.

3. Reinsert the bulb cover.

4. Restore the power supply by inserting the

mains plug or switching on the fuse.

1

2

13

Prior to installation, always follow the

instructions and warnings in the chapter

entitled ”Safety instructions”!

Exhaust-air mode

The exhaust air is conveyed upwards via a

ventilation shaft or directly through the outer

wall to the exterior.

NOTE: The exhaust air must not be conveyed

into a functioning smoke or exhaust gas ue or

into a shaft which is used to ventilate

installation rooms which contain heating

appliances.

Before conveying the exhaust air into a

non-functioning smoke or exhaust gas ue,

obtain the consent of the appropriate heating

engineer.

Discharge exhaust air in accordance with

the ocial and statutory regulations (e.g.

regional building laws).

If the exhaust air is conveyed through the

outer wall, a telescopic wall box should be

used.

To ensure optimum performance, the

extractor hood requires:

– a short, straight exhaust air pipe and

– the largest possible pipe diameter.

If pipe bends cannot be avoided, ensure

the largest possible radii.

NOTE: If long, rough exhaust air pipes, a lot of

pipe bends or pipe diameters less than

150 mm are used, the air capacity will be less

than optimum and there will be an increase in

noise.

Use only pipes or hoses made of non-

combustible material for installation of the

exhaust air duct.

The manufacturer of the extractor hoods is

not responsible for complaints which can be

attributed to planning and design of the

pipework.

Connecting pipes

The diameter of the exhaust air pipes

should not be less than 150 mm.

Round pipes:

We recommend an inner diameter of

150 mm, however at least 120 mm.

Flat ducts must have the same inner cross-

section as round pipes.

There should be no sharp bends.

Ø 150 mm approx. 177 cm

2

Ø 120 mm approx. 113 cm

2

If pipe diameters differ:

Use sealing strips.

Connection of 150 mm ø exhaust air pipe

(recommended size)

Attach exhaust air pipe

directly to the air-pipe

connector and seal

appropriately. If using an

aluminium pipe, smooth the

connection area beforehand.

Connection of 120 mm ø exhaust air pipe

Attach reducing

connector directly to the airpipe connector.

Attach exhaust air pipe to

the reducing connector.

Seal both joints

appropriately.

Installation instructions

14

If a permanent connection is required

A disconnector must be provided on the

installation side. Switches with a contact

opening of more than 3 mm and all-pole

disconnection are regarded as disconnectors.

This includes LS switches, fuses and contactors.

Electrical specications

WARNING: THIS APPLIANCE MUST BE

EARTHED

IMPORTANT: Fitting a Different Plug:

The wires in the mains lead are coloured in

accordance with the following code:

Green and Yellow – Earth

Blue – Neutral

Brown – Live

If you fit your own plug, the colours of these

wires may not correspond with the identifying

marks on the plug terminals.

This is what you have to do:

1. Connect the green and yellow (Earth) wire

to the terminal in the plug marked ‘E’ or

with the symbol <, or coloured green or

green and yellow.

2. Connect the blue (Neutral) wire to the

terminal in the plug marked ‘N’ or

coloured black.

3. Connect the brown (Live) wire to the

terminal marked ‘L’, or coloured red.

The required connection data can be found on

the rating plate inside the appliance when the

grease lters have been removed.

Length of the power cord: approx. 1.30 m.

This extractor hood complies with the EC

interference suppression regulations.

ELECTRICAL CONNECTION

Before connecting the appliance to the

power supply, always follow the instructions

and warnings in the chapter entitled ”Safety

instructions”!

The extractor hood may only be connected

by a qualied electrician who is familiar with

the regulations of the relevant electricity

supply company.

RISK OF INJURY

If the power cord of the extractor hood is

damaged, it must be replaced by the

manufacturer, his customer service or a

similarly qualied person to prevent hazardous

situations.

The extractor hood may be connected to a

correctly installed earthed socket only.

Attach the earthed socket as directly as

possible behind the ue duct.

– The earthed socket should be connected via

its own circuit.

– If the earthed socket is no longer accessible

following installation of the extractor hood,

a disconnector must be tted as for a

permanent connection.

Installation instructions

15

Installation

The extractor hood is designed to be

mounted on the wall.

During installation, optional accessories may

also require fitting.

Observe the minimum distance between

hob and extractor hood (see ”Safety

instructions”)!

Avoid damaging the sensitive surfaces!

Preparing the wall

RISK OF INJURY,

DAMAGE TO PROPERTY

Before drilling the holes for the designated

installation location, check for concealed

electrical cables and other lines.

The wall must be level and vertical.

The enclosed screws and wall plugs are

suitable for solid brickwork. Use the

appropriate fixing materials for other wall

structures (e.g. plaster board, porous concrete,

poroton bricks).

Ensure that the wall has adequate load

bearing capacity.

Ensure that the depth of the drilled holes

corresponds with the length of the screws.

Ensure that the wall plugs are secure.

Max. weight in kg: 40

Design subject to modication in line with

technical development.

Installation preparations

1. Mark a centre line on the wall from the

ceiling to the lower edge of the extractor

hood.

2. Using the enclosed template, mark

positions for the screws and, to facilitate

attachment, the contour of the attachment

area. The lower edge of the template

corresponds to the lower edge of the

extractor hood.

3. Drill 2x 8 mm holes for attachment of the

extractor hood and 2x 8 mm holes for the

xing bracket for the ue duct and press in

wall plugs ush with the wall.

4. Screw on the xing bracket for the ue

duct.

5. Screw on the brackets for the extractor

hood: hand tight, max. 3 Nm.

Ensure that the washers and brackets are

positioned correctly!

0

16

Installation

Attachment and alignment

1. Initially remove the protective foil from the

back of the extractor hood and, following

installation, remove foil completely.

2.

Mount the extractor hood, ensuring that the

back is attached firmly to the brackets

Ⓐ.

3. Align the extractor hood horizontally by

turning the brackets..

If required, the extractor hood can be

moved to the right or left

Ⓑ.

Locking screws and locking caps

1. Mark the holes for the safety screws. Detach

the extractor hood, drill holes for the safety

screws and press in wall plugs ush with

the wall.

2. Attach the extractor hood and screw in the

safety screws tightly.

3. Press the safety caps with the arrow upwards

onto the brackets until they click into

position

Ⓒ.

RISK OF INJURY

Check that all locking screws and locking caps

have been attached securely!

4. Connect the pipes (see ”Connecting pipes”).

5. Connect to the power supply (see ”Electrical

connection”).

Removing the safety caps

Remove the locking caps from the brackets

using a suitable tool, e.g. a at-blade

screwdriver.

A

B

C

17

4. Place ue ducts on the extractor hood, push

the inner ue duct upwards and attach the

left and right sides to the xing bracket.

5. Screw the inner ue duct with 2 screws to

the sides of the xing bracket.

Installing the ue ducts

RISK OF INJURY

The insides of the ue ducts may have sharp

edges. We recommend wearing protective

gloves during installation.

1. Separate the ue ducts. To do this, remove

the adhesive tape.

2. Remove the protective lm from both ue

ducts.

3. Insert one ue duct into the other.

NOTE: Avoid scratching the ue ducts when

inserting them, e.g. by placing the installation

template as protection over the edge of the outer

ue duct.

Note the position of the slots in the ue

duct!

– Exhaust-air mode: Slots of the inner ue

duct downwards.

– Circulating-air mode: Slots of the inner ue

duct upwards.

Installation

18

Notes

19

Notes

20

Notes

21

Notes

22

Notes

23

Accessories

Z5131X5

Z5132X5

Z5133X5

669419

236

669659

321

669648

281

9000 347 544

Printed in Germany 0109 Es.

NEFF (UK) Ltd.

Grand Union House,

Old Wolverton Road,

Old Wolverton

Milton Keynes, MK12 5PT

Tel: 01908 328300

Fax: 01908 328399

Loading...

Loading...