Needle Cooler NC-1 User Manual

NC-1

NEEDLE

A M

C I

C

~'>-----

-<fT'i

E

Co~pressed

~

a1r

supply

0

R

I

E

s

f---

--1,.------,lf---

Pr-f

I U inlet

Model9003

Manual Drain

Filter

(

,...._

Model9027

011

Removal

Filter

(not Included)

COOLER

-.1

N

To

~er

I

c

0

0

L

E

R

INSTRUCTIONS

Mini Cooler System

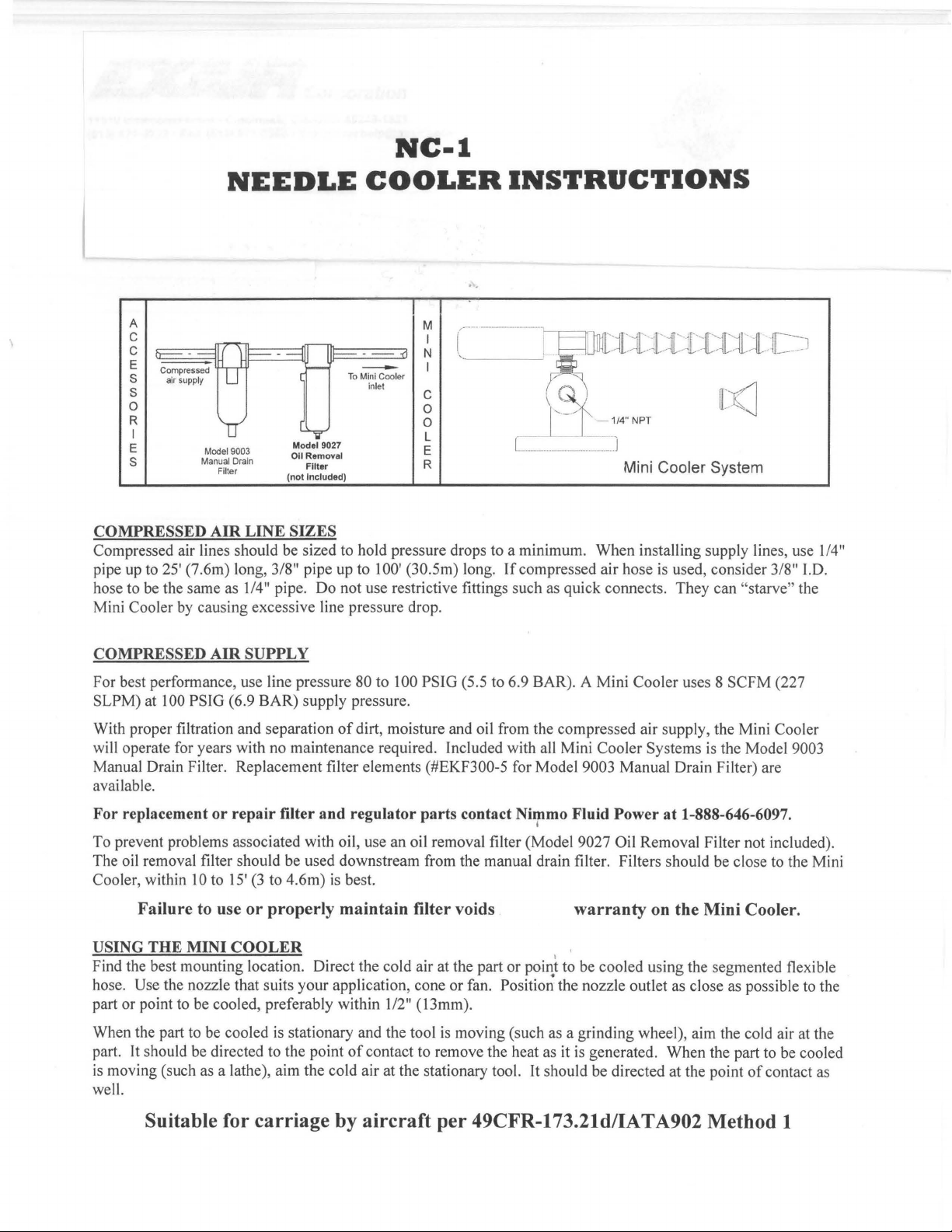

COMPRESSED AIR LINE SIZES

Compressed air lines should be sized to hold pressure drops to a minimum. When installing supply lines, use 1/4"

pipe

up

hose to

to 25' (7.6m) long, 3/8" pipe up to 1 00' (30.5m) long.

be

the same as 1/4" pipe. Do not use restrictive fittings such as quick connects. They can "starve " the

If

compressed air hose

is

used, consider 3/8" I. D.

Mini Cooler by causing excessive line pressure drop.

COMPRESSED

AIR

SUPPLY

For best performance, use line pressure 80 to 100 PSIG (5.5 to 6.9 BAR). A Mini Cooler uses 8 SCFM (227

SLPM) at 100 PSIG (6.9 BAR) supply pressure.

With proper filtration and separation

will operate for years with no maintenance required. Included with all Mini Cooler Systems

of

dirt, moisture and oil from the compressed air supply, the Mini Cooler

is

the Model 9003

Manual Drain Filter. Replacement filter elements (#EKF300-5 for Model 9003 Manual Drain Filter) are

available.

For replacement or repair filter and regulator parts contact Nimmo Fluid Power at 1-888-646-6097.

I

To prevent problems associated with oil, use an oil removal filter (Model 9027 Oil Removal Filter not included).

The oil removal filter should be used downstream from the manual drain filter. Filters should be close to the Mini

Cooler, within

Failure to use or properly maintain filter voids

USING THE MINI COOLER

Find the best mounting location. Direct the cold air at the part or point to be cooled using the segmented flexible

hose. Use the nozzle that suits your application, cone or fan.

10

to 15'

(3

to 4.6m)

is

best.

Positio;

warranty on the Mini Cooler.

I

the nozzle outlet as close as possible to the

part or point to be cooled, preferably within 1/2" (13mm).

When the part to be cooled

part. It should be directed to the point

is

moving (such as a lathe), aim the cold air at the stationary tool.

is

stationary and the tool

of

contact to remove the heat as it is generated. When the part to

is

moving (such as a grinding wheel), aim the cold air at the

be

It

should be directed at the point

of

contact as

cooled

well.

Suitable for carriage by aircraft per 49CFR-173.21d/IATA902 Method 1

CONTROLLING THE

The Mini cooler gives instant cold air when compressed air

of

cold air can be reduced by regulating the compressed air supply with the pressure regulator. Lower pressures

give less cold flow and reduce compressed air consumption.

COLD

AIR

is

supplied to

it.

If

less cold air

is

needed, the volume

TROUBLESHOOTING &

If

the Mini Cooler Does Not Perform Properly, check the four common problems listed below:

1.

Inlet Pressure - Low inlet pressure supply will cause poor performance. Measure the pressure at the

compressed air inlet

can cause excessive pressure drops and deteriorate performance.

2.

Inlet Temperature - A Mini Cooler provides a temperature drop from supply air temperature. In some cases,

the supply air is warmer than ambient air due to compressed air lines running across ceilings, near furnaces,

direct sun, etc. In this case, the cold air may be warmer than anticipated and adequate refrigeration may not

be available for the application.

3.

Back

Pressure-

Use only the flexible segmented hose included with the Mini Cooler.

Cold

4. No

internal freezing. This can reduce or even stop cold air flow. Drain the filter often, or crack open for a small

continuous air bleed.

(a) Blow air (use an air gun) into the cold end fitting with the Mini Cooler off.

(b) Turn the Mini Cooler

(c) Put a dryer on the compressed air supply.

The Mini Cooler has no moving parts. Maintenance

However,

1.

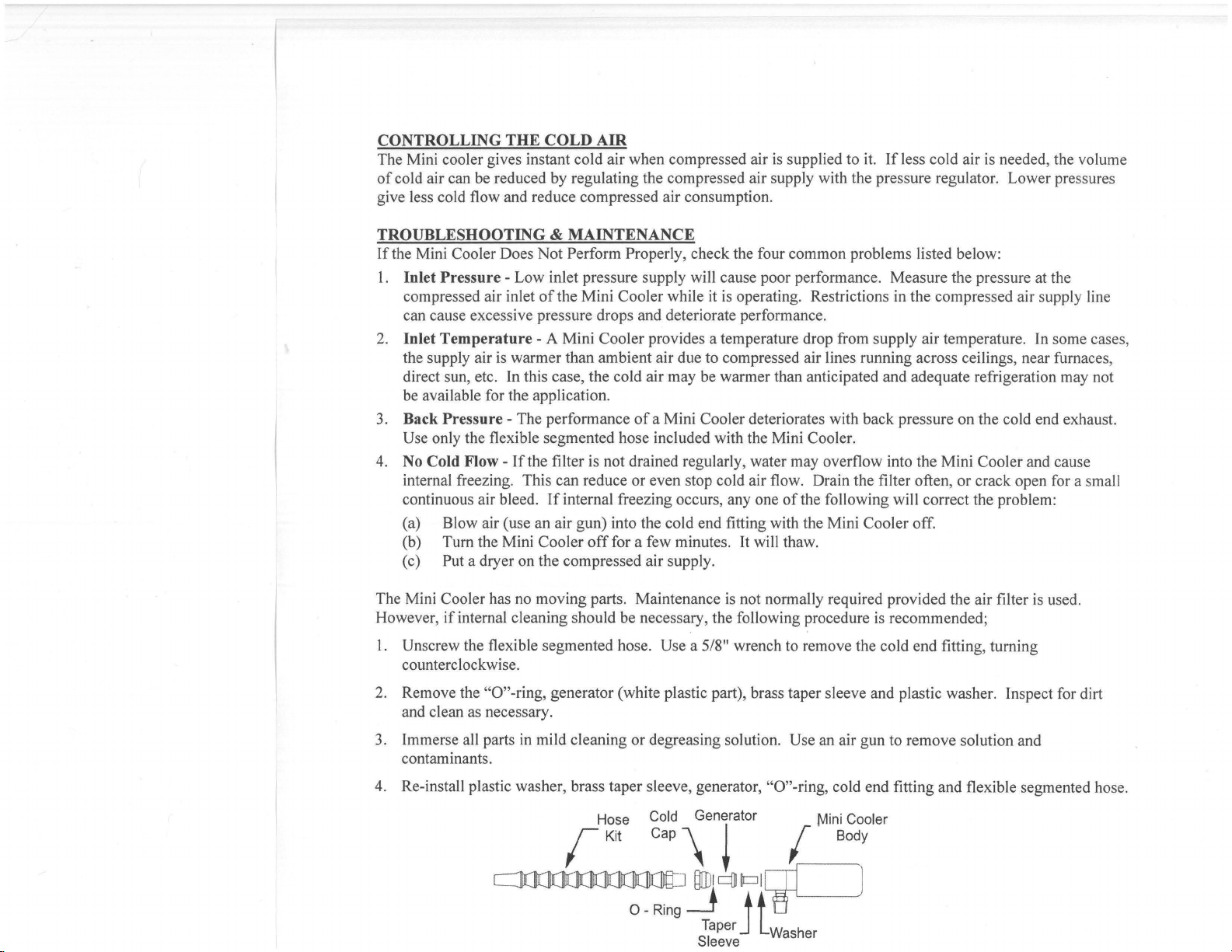

Unscrew the flexible segmented hose. Use a 5/8" wrench to remove the cold end fitting, turning

counterclockwise.

Flow-

if

internal cleaning should be necessary, the following procedure

The performance

If

MAINTENANCE

of

the Mini Cooler while it is operating. Restrictions in the compressed air supply line

of

a Mini Cooler deteriorates with back pressure on the cold end exhaust.

the filter is not drained regularly, water may overflow into the Mini Cooler and cause

If

internal freezing occurs, any one

off

for a few minutes. It will thaw.

is

of

the following will correct the problem:

not normally required provided the air filter

is

recommended;

is

used.

2.

Remove the

and clean as necessary.

3. Immerse all parts in mild cleaning or degreasing solution. Use an air gun to remove solution and

contaminants .

4. Re-install plastic washer, brass taper sleeve, generator, "0"-ring, cold end fitting and flexible segmented hose.

"0"-ring,

generator (white plastic part), brass taper sleeve and plastic washer. Inspect for dirt

C ]C))JOJOCJOJ

Hose

r

Kit

Cold

Cap

\

CID

0-Ring_:]

Generator

~

§ID

1 q 1o1

Jt

Taper

Sleeve

[_

nJI

~

Washer

Mini

Cooler

Body

Loading...

Loading...