INSTRUCTION MANUAL

ENGLISH

0

1

CAPTURE AT SOURCE

F

No. 148546 / 03

2006-10-01

List of contents

CE, Declaration of conformity

page

3

Installation

Operating

Starting

Settings

Service

Repair

Delivery check

IMPORTANT! Safety imformation

Pre-installation

Technical data

Dimensions

Mounting instructions

Mounting the filter cartridges

Compressed air connection

Electrical installation

Accessories, electrical installation

Earth control measuring

Applications

Wiring diagram

Connection of several FilterMax to one system

Connection of 2 or 3 pilot boxes

Fans

Duct dimensioning / System installation

Operating description

Starting the system

Monitoring system, settings

Monitoring system, general descriptions

Monitoring system, fault indications

Service instructions

Trouble-shooting schedule

Spare parts

3

4

4

4

5

6

7

8

9

9 - 11

12

12

13

14

15

15

16

17

18

18 - 19

20

21 - 22

23 - 25

26 - 28

29

Accessories

Protocols

Accessories

Installation protocol

Service protocol

Service notes

0

1

30

31 - 32

33 - 36

37

0

0

1

1

FilterMax F 30

FilterMax F 60 FilterMax F 90

2

This product is designed to meet the

requirements of the relevant EC directives.

To maintain this status all installation, repair

and maintenance work must be carried out by qualified

personnel using only original spare parts. Contact your

nearest authorised dealer or AB Ph. Nederman & Co. for

advice on technical service or if you require spare parts.

AB Ph. Nederman & Co.

Sydhamnsgatan 2

S-252 28 Helsingborg

Sweden

2006-10-01

Lennart Andersson, Product Manager

DELIVERY CHECK

The following modules should be mounted

together to assemble the complete FilterMax F.

When delivered A - C are already assembled

(units shipped by sea may contain more

components).

A. Filter unit (1, 2 or 3 pcs.)

B. Stand

C. Control box

D. Collector (2 x 40 litres or 2 x 100 litres

with stand extentions)

E. Inlet

F. Outlet

G. Filter cartridges

(6 pcs./filter unit)

A

E

Declaration of conformity

We, AB Ph. Nederman & Co., declare under our sole

responsibility that the Nederman product: FilterMax F

serial 667 with accessories, to which this declaration

relates, are in conformity with the following directives,

underlying standards or other normative documents:

Directive: 98/37/EC - Safety of machinery

Applied standards EN 292 Part 1,2, EN ISO 4871

Directive: 89/336/EEC - Electromagnetic compatibility.

Applied standards EN 50082-1, EN 61000, EN 55011

and EN 55022

Directive: 73/23/EEC - Low voltage equipment.

Applied standards EN 60204-1,EN 60947-1

Directive: 87/404/EEC - Simple pressure vessels

Applied standards EN 286-1 part 1

F

G

The units should be checked for any

damage that may have occured during

transport. If there is damage or parts

missing, the carrier and your local

Nederman representative should be

notified immediately.

FilterMax F can be supplemented by

a number of accessories (see page 30).

B

D

C

0

1

D

3

IMPORTANT! SAFETY INFORMATION

Nederman FilterMax F is designed for collecting and

filtering fume and non-explosive dry dust.

To guarantee the correct function and a minimal service

FilterMax F must only be used for these purposes and

according to the instructions in this manual. The manual

contains important warning directions which have to be

read and followed.

Any functional disorders, especially those affecting the

safety of the machine, should be rectified immediately.

For safe and reliable results assembling

work, electrical installation, use, service

and trouble-shooting should be performed

by qualified personnel. Special training may

also be necessary.

Please contact your nearest authorised

dealer or AB Ph. Nederman & Co. for

technical advice.

PRE-INSTALLATION

FilterMax FI is for indoor installation.

FilterMax FO is for outdoor installation.

FilterMax F should be located with consideration for easy

handling of the collected dust and for convenience of

service and maintenance.

FilterMax F is usually installed on a reinforced concrete

foundation. However, installation on another structure is

also possible. When calculating for foundation or supporting

structure the following factors should be taken into consideration (see technical data):

• Total weight of FilterMax F

• Max. weight of collected contamination

• Possible wind load

• Possible snow load

IMPORTANT! Location must be clear of all obstructions

such as utility lines etc. Pay particular attention to the

anchor bolt location. Anchor bolts (M16) must extend at

least 60 mm above foundation. If you intend to secure the

unit by using expansion bolts or equivalent fittings, the

concrete floor must be prepared accordingly.

max. 155°

1200

min. 100

min. 5001000

50

20

FILTERMAX

1320

967

TECHNICAL DATA

Filtration

Operating airflow

Filterarea / filter cartridge

Filter material

Operating temperature

Process air (dry) temperature

Material description

Environment classes *

Compressed air requirements

Compressed air consumption

Compressed air connection

Voltage supply

Protection class

Relay voltage, accessory

Working pressure

Pulse noise

Weight

Basic PW filter: 99% at 0,3 µm (after some time in operation), BIA class C

PTFE filter: 99,9% at 0,3 µm (after some time in operation), BIA class C

1 module: 2400 - 3600 m3/h (depending on load and application)

2 modules: 4800 - 7200 m3/h (depending on load and application)

3 modules: 7200 - 10800 m3/h (depending on load and application)

1 module: 60 m2, 2 modules: 120 m2, 3 modules: 180 m

2 layer polyester / polypropylene

-20°C to +60 °C

0 °C to +60 °C, not condensing

3 mm painted steel (FilterMax FI, FO), epoxy based zinc primer and top coat (FO only))

C2 = low corrosion risk, indoors, unheated air varying temperature (FilterMax FI)

C4 = high corrosion risk, outdoors polluted urban areas and coastal areas (FilterMax FO)

0,6 MPa (6 bar, 87 psi), water and oil free

32 N-litres / cleaning pulse at 0,6 MPa (6 bar, 87 psi)

1/2" R 15, max. 0,6 MPa (6 bar, 87 psi)

100 V, 120 V, 230 V, 50/60 Hz

IP 54

24 V AC, max. 60 VA

0 to -5 kPa, not overpressure

Lp Aeq, 30 s, 50 dB

1 module: 615 kg, 2 modules: 890 kg, 3 modules: 1150 kg

2

*according to EN ISO 12944

4

G

DIMENSIONS

3 MODULES

2 MODULES

OUTLET

1 MODULE

ABC

FE

135

INLET

D

H

2270 3190 4120

115

1180

open angle 155

°

50

20

1515

1690

1320

970

1030

1160

2 x 40 litres

containers

NB!

The height dimensions for the

filter are only valid when using

the 40 litres containers.

In/Outlet inner diameters (mm)

500

-

400

2440

3365

4290

3540

4470

1445

395

-

2565

3490

4415

-

4600

1465

445

A

B

C

D

E

F

G

H

250

2450

3370

275

-

-

-

-

-

315

2375

3300

2560

3480

4410

1430

325

130

5

MOUNTING INSTRUCTION

WARNING!

Risk of personal injuries

and/or product damages!

Use approved lifting equipment for

unloading, assembly and installation

of the units.

0

1

Use schackles,

not hooks on the

lifting sling.

x 3

Connect the lifting sling

to 4 cabinet lifting lugs.

Distribute loads equally.

NB! Maximum 2 units should be

lifted at the same time.

IMPORTANT!

Ensure that the inlet, outlet and

all filter units always are mounted

together with bolts in all intended

holes. Always use toothed washers

to ensure electric connection.

1. Mount the dust containers. If dust containers

2 x 100 litre should be mounted the stand extensions

also must be mounted.

2. FilterMax is usually anchored to a concrete foun-

dation with expansion bolts or similar. Fit the fixing bolts

and use adjusting pieces, if necessary, to get the filter

unit in level. Check with a spirit level.

For more stabilty, the filter unit can be braced

against the wall.

3. For FilterMax F 60 and F 90 two and three

filter units are used respectively. Mount the units

together to build the complete filter unit.

6

NB! The inlet and outlet are reversable

and concequently they can be positioned

for duct connection on the

right or left side of

the filter.

4. Fit the inlet and outlet.

(NB! The inlet is equipped with

an inspection cover on top.)

MOUNTING THE FILTER CARTRIDGES

1. Unscrew the two fixing screws on the

access door. Use the enclosed T-key or a 10 mm

standard hexagon key. Open the door.

2. Loosen the nuts

on the filter holders

but don’t screw them

off completely.

Remove the filter

holders.

3. Handle the filter cartridges carefully to

avoid mechanical damage to the filter surface.

4. Insert the filter

cartridges. NB! The

mark on the back end

cap should be put on

the angled sheet-metal

plate just inside the

filter hole.

WARNING!

Risk of personal injury!

For FilterMax F equipped with 2 or 3 modules

(12 or 18 filter cartridges), an approved lifting

platform (see figure) has to be used when

mounting or replacing the filter cartridges.

5. Hang the filter holders on the screws

and fasten the nuts.

6. Shut the access door and

fasten the two fixing screws.

7

COMPRESSED AIR CONNECTION

Connect the compressed air supply line

to the compressed air connection of

the filter. Use pipe sealant on all

compressed air connections.

Compressed air components

(accessories, see page. 30)

A shut off valve for service work and a

filter regulator should be installed in the

compressed air pipe line (Note the flow

direction during the installation).

Important! the filter regulator

must be positioned in a frost free

environment.

Recommended connection size:

minimum 1/2".

Compressed air tank, module no. 3

Water drain valve

Compressed air tank, module no. 2

Water drain valve

FilterMax F

Control box

Pressure switch

(accessory)

Service valve with

integrated drain valve

(accessory)

Filter regulator,

recommended pressure

0,5 MPa (5 bar / 73 psi)

(accessory)

Compressed

air connection

Compressed air tank, module no. 1

Water drain valve

IMPORTANT!

• The compressed air supply pressure has

to be = 0,4 - 0,6 MPa (4 - 6 bar / 58 - 87 psi).

• The compressed air shall have a dew point

below the minimum temperature at which the

system is ment to be used.

• The compressed air supply must be both oil

and water free.

• Improper air pressure or contamination in

the compressed air can result in cleaning

valve failure, poor cleaning and filter

performance.

• Purge compressed air lines to remove debris

before connecting to the compressed air

manifold.

• Do not use thread-sealing tape after the

filter regulator.

• Quick couplings throttle the air too much

and are not recommended.

• Turn off and bleed off compressed air supply

before doing any service work.

• Do not pressurise the system if the air tem perature is below the minimum operating

temperature, that is -20 °C. At lower air tem perature the process could be started and be

in operation for a while (approx. 15 min.) after

which the system can be pressurised.

8

ELECTRICAL INSTALLATION

IMPORTANT!

All electrical work must be done by a qualified

WARNING!

Risk of personal injury!

Disconnect the electrical power

before servicing any electrical component.

All exposed conductive parts of the electrical

equipment and the machine shall be connected

to the protective earthing (see wiring diagram).

electrician according to local regulations.

Connect FilterMax F to the mains and connect fan and

other components and accessories according to the

following wiring diagrams.

A lockable safety switch should be fitted on the

mains connection cable.

Electrical connection together with Nederman Fan Starter

or Fan Inverter is described on wiring diagrams supplied

with these products.

ACCESSORIES, ELECTRICAL CONNECTION

Connecting fan and other accessories to the FilterMax F

as well as connecting the FilterMax F to the mains must

be done by a qualified electrician.

Connection block JP 1: Digital inputs

External START/STOP

Pressure switch, compressed air

High dust level

Pressure switch, high dP /

low airflow / simple dP control

Spare, not used

Fan motor protector

Fire alarm

14 109876532

97 98

Dielectric detector PNP

132

> P

JP1

The accessories must be equipped with

a potential free contact

Connection block JP 6: Outputs

Max. 2 A

Fan starter (24 V AC)

Down time damper (24 V AC)

Dust feeder (24 V AC)

Automatic depressurising of

compressed air tanks at fire

Alarm signal (A or S), 24 V AC

A-Alarm, potential free

contact, 24 V AC

Fan starter

potential free

contact, 24 V AC

14 10119876532

Alarm device

Start contactor

Damper motor

JP6

Compressed

air tank on

FilterMax F

P > 3 bar

Fan start equipment

Pressure switch

Automatic depressuring of compressed air tanks at fire

Frost free

Normally closed

valve with big bore.

Normally

opened valve.

Compressed

air connection.

Filter

regulator

Both valves shall be connected to

JP6:4, 10/11, so they will be activated (drawn) at normal operation.

At a possible fire alarm (or a power

failure) the valves are switching and

the compressed air tanks will be

depressurised.

9

ACTIVATING THE MENU

0

1

1

0

P

Push the P-button and the 0/1-button more than 4 seconds.

ACTIVATING INPUTS AND OUTPUTS

The inputs or outputs should be activated when accessories

have been connected. Push the P-button to activate actual

input/output. The LED’s indicate, where appropriate, with

red blinking lights.

The inputs are activated in the following order:

Selecting OFF, nC or nO

Push the 0/1-button and OFF, nC or nO comes up on the display.

OFF The selected input is not activated.

nC Normally closed: The selected input is activated.

nO Normally opened: The selected input is activated.

Select NC or NO depending on type of contact on the connected

accessory. Make a note of the setting which has been selected.

or nC or nO

P

A

OFF

Red blinking

B

OFF

Red blinking

C

OFF

or nC or nO

or nC or nO

0

1

0

1

Motor protector, fan

Push the P-button.

Activated input: JP1: 6

Set OFF, nC or nO with the 0/1-button.

OFF nC nO

P

0

1

0

1

High dust level indicator

Push the P-button.

Activated input: JP1: 3

Set OFF, nC or nO with the 0/1-button.

OFF nC nO

P

0

1

0

1

Pressure switch, compressed air

Push the P-button.

Activated input: JP1: 2

Set OFF, nC or nO with the 0/1-button.

OFF nC nO

D

OFF

Red blinking

or nC or nO

Red blinking

P

0

1

0

1

P

Pressure switch

high dP / low airflow

Push the P-button.

Activated input: JP1: 4

Set OFF, nC or nO with the 0/1-button.

OFF nC nO

10

E

EA OFF

or nC or nO

0

1

0

1

Fire alarm

Push the P-button.

Activated input: JP1: 7

Set OFF, nC or nO with the 0/1-button

OFF nC nO

P

F

G

H

or OFF or Int

dF On

00 - 60 s

dA 00

or OFF

LO ON

Dust feeder

Push the P-button.

0

1

0

1

P

0

1

0

1

P

0

1

0

1

P

Activated output: JP6: 3

Direct controlled by contactor or other 24 V relay.

On: The dust feeder is in operation

OFF: The dust feeder is not in operation

Int: Intermittent operation of the dust feeder

Set On, OFF or Int with the 0/1-button.

On OFF Int

Down time damper delay

Push the P-button.

Activated output: JP6: 2

24 V AC supply for opening a damper motor with

spring return or magnetic valve for compressed air.

Is used to reduce the starting current at fan start.

Delay time for opening the down time damper:

10 - 60 s after fan start. Set the required delay time

with the 0/1-button.

Local START/STOP

Push the P-button.

Activated input: JP1: 1

Inactivates the start/stop button on the control box.

Only remote start is possible in OFF-position.

Set On or OFF with the 0/1-button.

On OFF

or FAN

J

PULSE

Red fixed light

In the Fan start mode

Start signal Stop signal

In the Pre-coate mode

ST PA IN PA IN PA

Start signal

0

Stop signal

0

1

1

P

Pre-Coate Control

In some applications with FilterMax it is necessary to inject

dust. The purpose can be to reduce the fire risk or improve

cleaning of the filter cartridges. The input JP6:1 can be

used in 2 ways. When the function of the motor protection

has been chosen, the fan LED will show fixed red light.

Then you are able to choose the use of JP6:1 PULSE or

FAN with the 0/1-button. PULSE is the pre-coate mode.

PULSE FAN

If PULSE is set there will be a choise of parameters to set:

ST - Start. The initial injection time: 0, 1, 2, 3, 4, 5, 7, 10,

15, 20, 30, 40, 60 or 90 s.

IN - Injection. The injection time: 0, 1, 2, 3, 4, 5, 7, 10, 15,

20, 30, 40 or 60 s.

PA - Pause. The pause time between the injections: 0 or

20 s. 1, 2, 5, 10, 20 or 60 min.

If FAN is set JP6:1 will run in parallel with JP6:8,9 serving

as a 24 V fan start signal.

11

EARTH CONTROL MEASUREMENT

Earth control measuring must only be done by a

person with necessary knowledge.

IMPORTANT!

All metal parts of the filter unit must be earthed

reciprocally and connected to earth. To secure

this, the following procedure must be followed.

6

When the FilterMax F has been installed and during maintenance

work the earthing shall be measured. The measuring is done

between GND1 (in the Control Box, see picture below) and the

following components on FilterMax F. Disconnect protection earth

from GND1 before measuring.

1. Inlet

2. Cleaning access point (on the inlet)

3. Dust container

4. Adapter for dust container

5. Filter cartridge

6. Filter module

7. Door

Reconnect protection earth to GND1.

Circuit card

FilterMax F

Control Box

JP3

230

120

100

0

1

2

7

0

1

4

3

GND1

0

24

APPLICATIONS

Nederman FilterMax F separates for instance welding

fume, metal oxides, talcum, lime stone, dust

and grinding dust.

FilterMax F must not be used for separating

explosive contaminations.

Explosive dusts are dry organic dusts and some metallic

dusts. The metallic dusts are, for example, aluminium,

magnesium, titanium, chromium and fine virgin dusts of

other metals. Welding fumes from these metals are not

explosive, but grinding dust is a problem. Please contact

your Nederman representative in case of doubts.

Various combinations of semi combustible fumes/dusts

(oil, grease) and sparks can cause fires when grinding or

welding. The most important action is to prevent sparks

from entering the extraction devices. Secondly it is very

important to perform regular cleaning of the extraction

arms/devices and the duct system.

FilterMax F does not separate gases.

Disconnect at earth

control measuring

WARNING!

Risk of personal injury!

• In some countries the purified air must not be

recycled in the workshop if FilterMax F is used

to separate welding fume or some contaminations

that may be a health hazard.

• Use a safety filter if the air is recycled in the

workshop.

Risk of fire or explosion!

• Do not use FilterMax F to separate explosive

fume or dust.

• Connect a fire alarm to the filter controling

processor, which means the filter will stop at

a possible fire.

• Care should be taken when working with

painted or oiled material. Consult your Nederman

representative for advice.

• FilterMax F must not be exposed for burning/

glowing material.

12

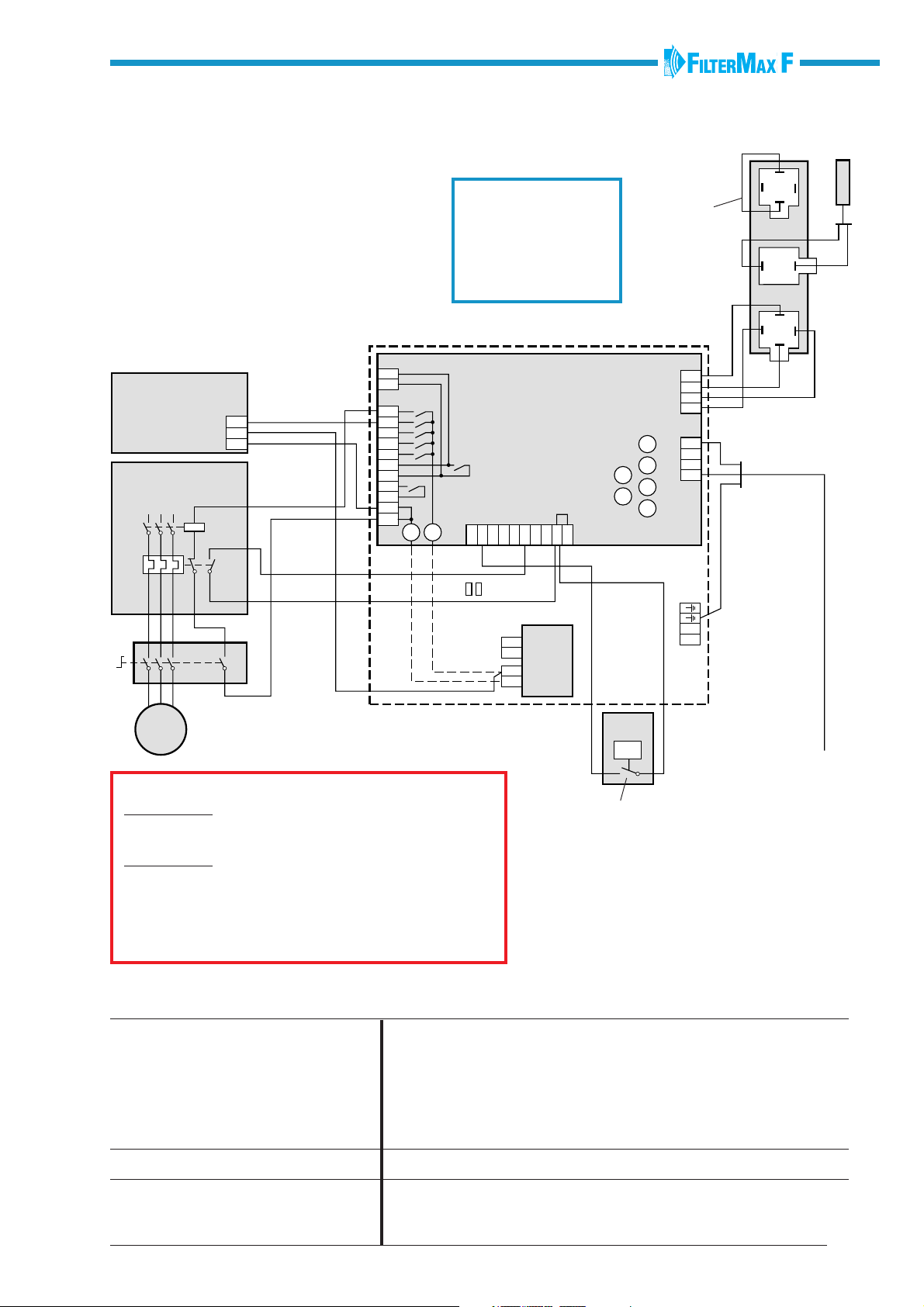

CONNECTION TO THE MAINS

WIRING DIAGRAM

Pilot box

CONNECTION OF:

• FAN STARTER

• SAFETY SWITCH (Nederman accessory)

• AFTER CLEANING DAMPER

• PRESSURE SWITCH (Nederman accessory)

• PILOT BOX (included in the delivery)

• FAN (Nederman accessory)

NB! After cleaning damper with spring

return should be connected only to JP6

no. 2 and no.10 or 11.

Motor

After cleaning

damper

1

Fan contactor

Control voltage 24 V

2 A max

135

246

135

246

135

246

Open

Supply

Com

95 97

96 98

13

14

JP5

JP6

1

2

1

2

3

4

5

6

7

8

9

10

11

F8 F7

Designations, Circuit card

FilterMax F control box:

JP1: Inputs

JP3: Power supply

JP4: Pilot box

JP5: A-alarm off

JP6: Outputs

Circuit card

FilterMax F

Control box

123456789

0

24

0

24

JP1

10

2

1

2

34

NB! connection

between 3 and 4

JP4

4

Door

{

3

Pilot

-

2

control

+

1

Brown

JP3

230

F1

120

100

F2

F6

F3

F5

F4

GND1

0

24

0

Output

Input

1

34

Black

Black

Blue

Connection of

2 or 3 pilot boxes,

see page 15

2

Door switch

M

For fan start, two alternatives are possible.

Alternative 1:

Connection to block JP6: 1 (24 V AC), for direct control

by contactor or other 24 V relay.

Alternative 2:

Connection to block JP6: 8 - 9, potential free relay

output, is used when the start equipment has its own

24 V control voltage, for example Nederman Fan Starter

(which is recommended). The complete connection is

described in the Fan Starter Instruction Manual.

BASIC FUNCTIONS

1. Down time damper

Alt. 1. Electric motor open and close

Alt. 2. Electric motor open, Spring return

Alt. 3. Magnetic valve for compressed air

operated damper with spring return.

2. Transformer

FilterMax F

Wire to JP6 : 2 and 10 or 11(common) and the lower

24 V AC output from the transformer (2).

Wire to JP6 : 2 and 10 or 11(common).

3

> P

Pressure switch

Fuses

F1: T 1 A, 230 Vac power supply

F2: T 1,6 A, 120 Vac power supply

F3: T 2 A, 100 Vac power supply

F4: T 2 A, 100, 120, 230 Vac power supply

F5: 2 A, Basic card, inputs, dP card and

operator terminal power supply

F6: 2 A, Basic card, inputs, dP card and

operator terminal power supply

F7: 2 A, Outputs power supply

F8: 2 A, Outputs power supply

Mains-connection

100/120/230 V,

PE, 50/60 Hz

3. Pressure switch, compressed air

FilterMax F - Wire to JP1 : 2 and 9 or 10(common).

Select nO in the software setting if an OPEN contact indicates OK.

Select nC in the software setting if a CLOSED contact indicates OK.

13

CONNECTION OF TWO FILTERMAX TO ONE SYSTEM

LINE 1

0

1

LINE 2

LINE 1 LINE 2

1

2

34

1

2

1

1

34

2

34

2

34

0

1

NB! connection between

3 and 4 on the last pilot box.

1

1

1

1

2

34

2

34

2

34

2

34

NB! Remove the connection

between 3 and 4 on the output

contact before the cable from the

pilot box above is connected.

JP5

1

2

JP6

1

2

3

4

5

6

7

8

9

10

11

Circuit card

FilterMax F

Control Box

123456789

JP1

10

Door

Pilot

control

GND1

1

2

34

JP4

4

{

3

2

-

1

+

JP3

230

120

100

0

IN OUT

4

3

2

0

24

1

1

4321

2

34

4

3

2

1

IN OUT

4

3

2

1

GND to

filter house

1

2

34

1

2

34

4321

4

3

2

1

GND to

filter house

NB! connection between 3 and 4

14

CONNECTION OF 2 OR 3 PILOT BOXES

1

JP4

2

34

1

2

34

4

3

2

1

NB! Remove the connection between 3 and 4 on the output

contact before the cable from the pilot box above is connected.

1

1

2

34

2

34

1

1

2

34

2

34

NB!

connection

between 3 and

4 on the last

pilot box.

Total pressure

Pa

4000

3000

2000

NCF 40/25

NCF 30/25

NCF 30/15

FANS

NCF 160/25

NCF 120/25

NCF 50/25

NCF 80/25

NCF 80/15

NCF 120/15

1000

0

0

Each FilterMax F can be connected to an

existing central fan or to a fan dimensioned

specially for the system.

An adequate fan can be selected from the

Nederman NCF-range. Please contact your

2000 4000 6000 8000 10000 12000 14000 m /h

3

Air flow

Nederman representative for

dimensioning the right fan capacity.

Calculated air pressure drop over

the filter is approximately 1200 Pa.

15

STARTING THE SYSTEM

1. Turn on the compressed air supply to the cartridge filter.

Adjust to 0,4 - 0,6 MPa (4 - 6 bar, 58 - 87 psi) of pressure.

Pressure of 0,5 MPa is the most typical setting for

satisfactory cleaning performance.

2. Close the regulating damper halfway, see figure,

page 16. (As an alternative the airflow can be controlled

by a Nederman FanInverter).

3. Start the fan and check fan impeller rotation. Refer to

the rotation sticker on the fan motor. Proper fan impeller

rotation is extremely important. Contact a qualified

electrician if the impeller rotation must be reversed.

WARNING!

Risk of personal injury!

Stand clear of blower fan exhaust area as

debris can be exhausted and cause injury.

4. IMPORTANT! It is necessary to adjust the airflow

to the dimensioned value using the regulating damper

(or Nederman FanInverter). The air flow can be measured

with a fixed airflow meter (or a pitot tube) and a micromanometer.

IMPORTANT! Too much airflow can dramatically

reduce the life of the filter element.

Impeller rotation

direction

5. All the solenoid valves should open and close

continuously with a set interval time between each

cleaning pulse (factory set of 30 seconds).

Check operation of the solenoid valves in the following

way: Set the pause time on tst (see below). NB! This

is only a control setting and should not be used for normal operation. Start the system and count the number

of air pulses. It should be 6 pulses per module.

NB! Return the pause time to the original value

after checking.

MONITORING SYSTEM, SETTINGS

CLEANING DURING OPERATION

FilterMax F is in its standard design equipped with a fully

automatic compressed air cleaning of the filter cartridges.

A piping system directs, by a system of solenoid valves,

air pulses of 100 ms into the filter cartridges. The pause

time between the air pulses is factory set at 30 s, but can

be set between 5 s and 90 s. Shorter pause time can be

used if more than 1 module is used or if FilterMax F is

used for heavy load.

RECOMMENDATIONS FOR

PAUSE TIME SETTINGS

The pause time setting depends on the size of the filter

(i.e. the number of cartridges) and the load at which the

filter is working.

• Light load - A dust that is easy to clean off the filter

cartridges, such as dry stone dust or grinding dust.

• Normal load - Applications such as welding fume or

light dusts in heavy concentrations.

• Heavy load - Typically metal cutting with laser or

plasma and heavy welding.

With light load the cleaning pressure could be reduced

to 0.4 MPa (4 bar). Check that the filter pressure drop

does not rise too quick. If so, the pause time could be

reduced with one step and the cleaning pressure could

be increased, but maximum to 0.6 MPa (6 bar).

Model / Dust load

FilterMax F 30

FilterMax F 60

FilterMax F 90

The factory setting is 30 s for all FilterMax F.

* or no on line cleaning

pt 30

Setting the pause time

Push the P-button until pt is shown in the display.

Set one of the following values for pause times with

the 0/1-button. tst = test position, all valves will be

opened 1 time with 1 s interval.

tst

10 s

15 s

20 s

30 s

45 s

Light

90 s *

60 s

30 s

Normal

60 s

30 s

15 s

60 s

90 s

No cleaning

during operation

Heavy

30 s

15 s

10 s

1

0

0

1

P

18

CLEANING AFTER OPERATION

It is possible to choose cleaning after operation, that

is when the fan has stopped. This is more efficient

than cleaning during operation and is therefore

recommended. The pause time at cleaning after

operation is always 15 s.

If cleaning after operation has been chosen, one

has to set the desired number of cleaning cycles,

where one cycle means the cleaning of all filter

cartridges, that is 6, 12 or 18 cartridges, depending

on the number of modules in operation. 2 - 3 cycles

are recommended depending on the dust load

(light - normal) When cleaning after operation it is

recommended to use an after cleaning damper

(see accessories page 30).

0

1

dt 3

0

1

P

A-ALARM FUNCTION

The alarm-function is always ON when the system

operates, which means if there are negative

or Go

0

1

dL StP

0

1

P

Setting the cleaning cycles

Push the P-button until dt is shown in the

display. Set the desired number of cleaning

cycles with the 0/1-button.

0

1 cycle

2 cycles

influences on the function during operation, the alarm

will release, that is LED no. 7 will show a red fixed light.

3 cycles

4 cycles

5 cycles

Setting the alarm-function

Push the P-button until dL is shown in the display. Choose

any of the functions Go or StP with the 0/1-button. For fume/

dust generating processes that can’t be stopped immediately

when a fault accurs it is recommended to set Go and that a

clearly visible alarm device is installed.

Go: The system does not stop when the A-alarm is

activated, with exception for explosion/fire-alarm, motor

protection and with the access door open. The system

always stops for these functions.

StP: The system stops automatically when the alarm is

activated.

REMOTE START

It is possible to choose the functions Aut or OFF

with the 0/1-button. For most filters that are remotly

started from a machine or a process eg. it is

convenient to choose Aut.

or OFF

0

1

rE Aut

0

1

P

The remote start control should be connected to JP 1 and

9 or 10 (see page 9). If remote start is used, the system

can not be stopped with the 0/1-button. The text rE is

shown in the display for a short time.

Remote start, setting

Push the P-button until rE is shown in the display.

Choose Aut or OFF with the 0/1-button.

OFF: When using remote start there is no automatic

restart when a fault has been rectified. The remote started

mashine must be stopped and the FilterMax F must be

reset by one push on the start button before a new remote

start can be done.

Aut: When using remote start there is automatic restart

when a fault has been rectified or after a power failure.

19

MONITORING SYSTEM, GENERAL DESCRIPTIONS

The LED:s can indicate the following:

0

1

0

1 2 3 4 5 6 7

The display on the control box gives information

about the number of operating hours, cleaning

process, alarm functions and possible faults.

Blinks when the cleaning

function operates.

1

0

1

1, 2, 3, 4, 5 green fixed light: All functions normal

and correct

1

1, 2, 3, 4, 5 green fixed light alternating with blinking red:

The system operates. Incorrect function

has been rectified (alarm memory)

1, 2, 3, 4, 5 red fixed light: Incorrect function which

P

requires investigations.

6 yellow fixed light: Incorrect function which

requires attention.

7 red blinking light: Incorrect function which

requires immediate investigations.

1, 3, 4, 5 is only active after the inputs for the

accessories has been activated

(see page 10).

0

1

Fixed red light when

the system operates.

P

0

1

1 2 4

r E

Both "point" and 11 blinks when cleaning after operation is in progress.

0

1

The total number of operating

P

hours are displayed.

0

1

0

1

r E is displayed when trying to stop

the system from the control box when

P

the system is remote started.

0

1

0

1

1

The system has stopped and the cleaning

after operation is active. If the 0/1 button is

pressed once more the cleaning after ope-

P

ration is stopped immediately.

20

MONITORING SYSTEM, FAULT INDICATIONS

0

1

0

1

The fan motor overload protector is released.

Check the cause. Rectify the fault and reset

P

Red blinkingRed fixed

light

the motor protector. FilterMax F always stops

when the motor protector is released.

Red

fixed light

Red fixed light

Yellow

fixed light

Red blinkingRed fixed light

0

1

0

1

P

0

1

0

1

P

0

1

0

1

P

Possible faults (depending on how the input

has been used):

1. The pressure drop over the filter is high.

2. The air flow in the system is too low.

• Check if the filter cartridges are saturated,

change if necessary.

• Check if any damper is not open enough.

• Check the inlet for dirt. Clean if necessary.

Low pressure in the compressed air supply.

FilterMax F will not start.

FilterMax F has stopped due to low compressed

air pressure (less than 0,4 MPa (4 bar)).

FilterMax F will not start until correct pressure

is resumed.

EA

1

0

Red blinking

1

0

Red blinking

0

1

P

0

1

P

A-alarm! Means acute problems which could disturb

the function of the system. Action should be taken as

soon as possible. Call for a service technician.

Example:

• More than 1 valve is defective or does not work.

It is displayed which valves that are defective (Err +

1, 2, 3, ........ 18) are displayed, alternating with the

number of operating hours).

• Electronic faults on the circuit card.

Fire alarm. Call for service technician. Check

the reason and do not start the system until

the fault has been rectified.

21

Red fixed light

0

Yellow fixed light

0

Red blinkingRed fixed light

0

0

1

1

Service requirements! Should be rectified

as soon as possible.

1

Example:

• One valve is defective or does not work. It is

displayed what valve that is defect (Err + the

defective valve no. (1 - 18) is displayed, alternating

P

with the number of operating hours.

0

1

The door has been opened during

P

system operation. Shut the door.

0

1

1

The door is open and FilterMax F

P

will not start.

Red fixed light Yellow fixed light

r E A

light

p F a i l

Red blinkingRed fixed

Yellow fixed light

0

1

0

1

The dust container is full.

P

Empty the container.

0

1

0

1

r E A is diplayed (alternating with the

number of operating hours) in combination

with a motor error and a desplayed

P

A-alarm at remote controlling.

0

1

0

1

There has been a power failure.

Reset by pressing the 0/1-button. If

the filter is remotely started it will start

P

directly when the 0/1-button is pressed.

22

or another digit

0

1

Err 0

0

1

See B, Trouble-shooting Schedule,

P

page 26

SERVICE INSTRUCTIONS

In order to ensure that the system continues to operate correctly,

the following should be checked at periodic intervals depending

on what kind of contaminations that are separated and the

amount of use. Defective and worn parts should be replaced

immediately.

EMPTYING THE DUST CONTAINER

IMPORTANT!

Empty the dust containers when they are approximately

70 % full. Do not let them overfill. It can cause poor filter

performance and cause an extensive clean up work due to

overflow of dust when removing the containers.

Normal working light is required for emtying the containers.

Inspect how much the containers have been filled in the

beginning of the filtering process, to make it possible to

estimate a normal emptying interval.

1. Switch off the FilterMax F.

2. Put a pallet, which can be operated by a lift truck, under

the dust containers.

3. Loosen the dust containers by realising the excentric

locks. Let the containers down to the pallet.

4. Empty the dust containers. Disposal of dust should be

in accordance with local regulations.

5. Check that the gasket between the filter and dust

container not is damaged.

6. Put the dust containers back under the filter and fit

them with the excentric locks, Check that the gasket

between the filter and container is correctly fitted and

seals after locking.

WARNING!

Risk of personal injury!

Use protective goggles, breathing

mask and gloves when doing servicing and repairing work inside the

system, specially when replacing

the filter cartridges and emptying

the dust containers.

Avoid contact or exposure to dust as

much as possible during servicing or

maintenance.

Shut-off and bleed compressed air

supply before opening the inspection

door and servicing any compressed

air components.

Disconnect electrical power before

servicing.

CHECK WHEN EMPTYING THE DUST CONTAINER

Check if there is water (or oil) in the filter regulator. In that

case, the compressed air is not dry enough and there is a risk

of damage to the filter cartridges. Check that the pressure is

set to 0.4 - 0.6 MPa (4 - 6 bar, 58 - 87 psi). If there is water in

the filter regulator container, check that there is no water in

the pressure tank (tanks), by opening the drain nipple on the

right bottom side of the tank.

Filter regulator

container

23

SERVICE AFTER 1000 OPERATION HOURS,

BUT AT LEAST ONCE EVERY 6TH MONTH

• Check that all valves in the cleaning system operate properly. Count the

number of air pulses, 6 per module, that is 6, 12 or 18 per cycle.

• Remove dust collections from the lower part of the clean air room.

SERVICE AFTER 2000 OPERATION HOURS, BUT AT LEAST

ONCE A YEAR OR WHEN REPLACING FILTER CARTRIDGES

• Unscrew the inspection cover on top of the inlet.

Check the seals. Clean when necessary.

• Check that there is no water in the pressure tank

(tanks), by opening the drain nipple on the right bottom

side of the tank.

• Check the filter cartridges. They should be replaced if

the outer surfaces are damaged or if the air flow through

FilterMax is insufficient due to saturation of the filter

cartridges despite repeated cleaning.

• Take measures against possible corrosion by

grinding, primer and touch up paint.

• Earth control measurement (see page 12)

GND1 - Inlet

GND1 - Inlet cleaning access cover

GND1 - Dust container

GND1 - Dust container adapter

GND1 - Filter cartridges

GND1 - Filter units

GND1 - Doors

REPLACING THE FILTER CARTRIDGES AT

DAMAGE OR INSUFFICIENT FILTER FUNCTION,

BUT AT LEAST AFTER 6000 OPERATION HOURS

Inspection cover

WARNING!

Risk of personal injury!

For FilterMax F equipped with 2 or 3 modules

(12 or 18 filter cartridges), an approved lifting

work platform (see figure) has to be used

when exchanging the filter cartridges.

Instructions for replacing the filter cartridges,

see next page.

After 6000 operating hours, also check

that the cables not are damaged or

connected incorrectly.

24

REPLACING THE FILTER CARTRIDGES

1. Switch off the FilterMax F.

2. Shut off and bleed the compressed air.

3. Unscrew the two fixing screws on the

access door. Use the enclosed T-key or a 10 mm

standard hexagon key. Open the door.

4. Loosen the nuts

on the filter holders

but don’t screw them

off completely.

8. Remove the mounting frame

and fold the plastic bag in a way

5. Remove the

filter holders.

that the filter cartridge will be

completely enclosed and sealed.

9. Proceed in the same way with the

remaining filter cartridges.

7. Hang the mounting frame

with the plastic bag over the

end of the filter cartridge. Draw

the whole cartridge in to the

plastic bag.

10. Inspect the filter housing and look for damage,

dust layers etc. Clean inside the filter housing.

A vacuum cleaner is recommended.

11. Handle the new filter cartridges carefully

to avoid damage.

12. Insert the new filter cartridges. NB! The mark on the

back end of the filter cartridge should be put on the angled

sheet-metal plate just inside the filter housing.

13. Hang the filter holders on the screws and

fasten the nuts.

14. Check the access door seal. Shut the door and

fasten the two fixing screws.

15. Turn on the compressed air supply.

6. Draw a plastic bag

through the opening in

the enclosed mounting

frame, as the picture

shows.

25

TROUBLE-SHOOTING SCHEDULE

FilterMax F will not start.

Are there any LED’s on the

controlbox panel that are on.

NO

YES

A

Is the A-alarm LED no. 7, on?

Possible faults

Control questions

Actions

IMPORTANT!

• Turn off the compressed air

supply with the service valve

before doing any work on the

cleaning system.

• Do not pressurise the system

if the air temperature is below

the minimum operating temperature (= -20 °C). At lower air

temperatures the process can

be started and operated for a

while (approx. 15 min.) whereafter the system can be

pressurised.

Check the fuses on the card and

the power supply to the card. If

the power supply and the fuses

are fully functional, contact your

nearest Nederman representative

for more assistence.

FilterMax F starts, but stops after

a while and the display shows

Err + a digit.

Is the display showing Err 0 ?

YES

The cable connecting the controller

to the first pilot box is not properly

connected.

NO

NO

Are you trying to remote start

the filter?

NO

Contact your nearest Nederman

representative for advice.

YES

YES

B

Is the display showing Err +

another digit than 0 ?

NO

Contact your nearest Nederman

representative for advice.

YES

Correct the error indicated by the

function LED’s, see page 21 - 22.

Check that the wiring is correct.

Closing 1 + 9 or 10 shall start

the filter.

There is an electrical fault in one

or more of the pilot valves. The

number/s shown after Err are the

number of the faulty valve/s.

Depressurise the system. Check

that the leads to the valve coil are

properly connected. Remove the

leads and measure the resistance

of the coil, it shall be approximately 26 Ω . If the resistance is

more than 29 Ω or less than 23 Ω

or if the coil circuit is cut, replace

the pilot valve.

FilterMax F starts, but the fan will

not start.

C

Check that the electrical wiring

for the fan start is done correctly

between 1 and output common

(10 or 11) on the outputs (block

JP6). See wiring diagram, page 13.

26

The FilterMax F pressure

resistance is high.

Is the cleaning system fully

functioning?

NO

YES

D

Check the pressure of the compressed air. It should be 0,4 - 0,6

MPa (4 - 6 bar, 58 - 87 psi).

Are there some valves that are

functioning?

NO

Go to B

The airflow is insufficient.

Is the pressure resistance high

( >1000-1500 Pa)?

YES

Go to F

If the ∆ P Control is installed go

to the ∆ P Control manual section

regarding the adjustment of

cleaning the system.

Otherwise, check the pause time

set on the timer (see page 18).

The default value is 30 s. A heavy

application or a 2 - 3 module unit

(12 - 18 filter cartridges) will require

shorter times. A very light application can use longer times.

If the cleaning has been adjusted

previously you may have to replace

the filter cartridges.

E

YES

Go to D

Contact your nearest Nederman

representative for advice.

NO

Has the airflow been satisfactory?

NO

Is the fan operating correctly?

Does the impeller rotate in the

right direction?

YES

Check the rotating direction of

the fan impeller. Compare with

the arrow on the label on the fan

motor. It is very important that

the rotation direction is right.

If the impeller rotates in the wrong

direction, the fan gives only 40 %

of its possible air volume. Contact

a qualified electrician if the impeller rotation must be reversed.

YES

NO

Check if the system contains any

dampers and the position of these.

Open dampers to adjust the flow,

but don’t exceed the dimensioned

airflow for the filter unit.

Check that the filter unit’s inspection

panels are closed.

Check the fan for blocked outlet or

other damage.

Open the filter unit’s inlet inspection

door on the top of the inlet and

check for blockage, clean if

necessary.

If the inlet is blocked/partly blocked

by sticky dust/particles open the

inspection panel on the top off the

unit and clean the preseparator.

27

H

H

G

G

A valve is not operating correctly

(but there are functioning valves).

F

Does the display on the control

box show Err + a digit?

YES

Go to B

NO

G

Leaking compressed air system

(notified by sound)

Are the external connections

leaking?

Is the air temperature below 0 °C ?

NO

Check which valve is malfunctioning by listening. The valve

sequence is 4, 5, 6, 1, 2, 3 (where

1 is to the left when the door has

been opened).

Dismantle the valve housing and

check that the little air hole in the

diaphragm not is blocked.

Change defective valves (spare

part) or repair them with a repair

set (spare part). Mounting/repairing

instructions comes with the spare

parts.

YES

IMPORTANT!

Turn off the compressed air

supply with the service valve

(accessory) before doing any

work on the cleaning system.

If you have compressed air with a

dew point close to or higher then

the air temperature, the pilot valve

may freeze. An indication is that the

valve starts operating again when

the temperature increases.

IMPORTANT!

Do not pressurise the system

if the temperature is below the

minimum operating temperature

(= -20 °C). At lower air temperatures the process can be started

and operated for a while (approx.

15 min.) whereafter the system

can be pressurised.

YES

Repair the external connections.

NO

H

High emission. Abnormal emission

levels in the exhaust air.

Stop the system! Shut off the

compressed air and drain the tank.

Are all cartridges properly installed?

NO

Install them properly.

YES

Stop the system. Decrease the

system pressure to < 1 bar. Open

the access door and find the leak.

Shut off the pressure and drain the

tank.

Is a pulse-jet valve leaking ?

YES

Dismantle the valve and check for

contamination or damaged parts.

Clean and/or replace damaged

parts.

Look into the cartridges and check

if there are any traces of dust. Dust

on the clean side indicates a leak.

Replace damaged cartridges.

NO

Replace other damaged parts.

28

SPARE PARTS

Ordering Instructions

When ordering spare parts always

indicate the following.

A. Part No. and Control No.

(see FilterMax identification plate)

B. The spare part’s name and number

(see Spare Parts List)

C. Quantity of parts required.

5

Spare Parts List

Name

1 Filter cartridges (6-pack)

2 Circuit card (monitoring system)

3 Control box, complete

incl. electric components

4 Cover with display

5 Pulse valve

8

2

0

1

6 Pilot box, complete

7 Cleaning pipe (x 6)

8 Door gasket

9 Transformer

10 Pilot valve

10

6

0

1

4

7

REPLACEMENT CARTRIDGES (6-pack)

Basic PW

Dual layer polyester /

polypropylen.

Suitable for fumes

and fine particles.

Efficiency:

99 % at 0,5 µm

Filter area: 10 m

BIA class C

Part no. 12372055

2

Poly Web

Spun bound polyester.

Suitable for medium to

coarse particles.

Efficiency:

99 % at 0,5 µm

Filter area: 10 m

Washable

BIA class C

Part no. 12373279

2

Poly Web PTFE

PTFE membrane,

laminated to spun

bound polyester.

Suitable for fine to

medium particles.

Efficiency:

99,9 % at 0,5 µm

Filter area: 10 m

Washable

BIA class C

Part no. 12372060

2

3

9

1

29

ACCESSORIES

INLET

With cleaning access

panel on the top

Connection

diameter

Ø 250 mm

Ø 315 mm

Ø 400 mm

Ø 500 mm

for FilterMax FI

Part no.

12372070

12372071

12372072

12372073

for FilterMax FO

Part no.

12373561

12373562

12373563

12373564

OUTLET

Connection

diameter

Ø 315 mm

Ø 400 mm

Ø 500 mm

for FilterMax FI

Part no.

12372057

12372058

12372059

for FilterMax FO

Part no.

12373565

12373566

12373567

DUST HANDLING SYSTEM

All container kits contains adapter and

suitable extension legs if required.

FilterMax FI

Part no.

Container kit

2 x 40 l

Container kit

2 x 100 l, on wheels

Container, 40 l

Container, 100 l

incl. lid

∆

P-CONTROL KIT

Is used for controlling the cleaning more efficiently and

with better supervision. Saves pressured air in some

applications with intermittent load. Equipped with alarm

functions for high fall of pressure for filter.

Part no. 12373603

12372140

12372067

12372228

12372655

FilterMax FO

Part no.

12373881

12373897

12373898

12373899

FILTER REGULATOR

Is used for setting the correct air pressure.

Separates dust in the pressured air why

it also protects the valves. Should be

installed in the compressed air pipe line.

Must be positioned in a frost free

environment

Part no. 12372064

SHUT OFF VALVE FOR

COMPRESSED AIR

An air venting type. Should be installed in

the compressed air pipe line. Is used to turn

off the compressed air supply before

any service on the system is done.

Part no. 12372083

PRESSURE GAUGE KIT

Measures the pressure drop over the

filter cartridges. Is mounted on the

FilterMax’ stand.

Part no. 12372079

1500

500 1500

0

2000

PRESSURE SWITCH FOR

COMPRESSED AIR

Protects the filter from damage during use

without compressed air. Must not be

placed in explosion risk areas.

Part no. 12372142

PRESSURE SWITCH

(Not a Nederman product). Is used to indicate

low airflow or high fall of pressure over the filter.

AFTER CLEANING DAMPER

(Not a Nederman product) The damper closes

the duct when FilterMax F is shut off, which will

prevent dust from being transported back into the

workshop by the air pulses from the down time

cleaning. The damper should be mounted close

to the FilterMax F inlet.

SAFETY FILTER

Is recommended if the filtered air is recirculated

into the facility. Please contact your Nederman

dealer for more information.

30

INSTALLATION PROTOCOL, PAGE 1

If controls give results (for example measured values) which

differ much from earlier results, this must be understood as a

warning signal and lead to more careful investigations.

FilterMax F No.

Performed by

Control points

1. Delivery control (page 3)

A. Missing components

B. Transport damage

2. Installation control (page 4, 6 - 7)

A. Safe mounting / foundation

B. Fixing bolts / Traction forces

C. Wind / Snow load

D. Weight FilterMax F / collected dust

E. Conductible screw fittings

F. Inlet and Outlet

G. Dust container or Dust feeder

H. (2 or 3 filter units)

J. Filter cartridges

Date

Result Result Result Note

3. Compressed air connection (page 8)

A. Service valve

B. Filter regulator

C. Pressure switch

D. Pressure 0,4 - 0,6 MPa

E. Dew point

F. Oil / Moisture

G. Cleaning compressed air connections

4. Duct dimensioning (page 16)

A. Duct diameters

B. Inlet duct, length/inclination

C. Cleaning access covers

D. Fire damper

E. After cleaning damper

F. Flow meter

G. NCF fan

H. Extraction arms

31

INSTALLATION PROTOCOL, PAGE 2

FilterMax F No.

Performed by

Control points

5. Electrical installation (page 9-15)

A. Overload protector

B. Safety switch

C. After cleaning damper

D. Pilot box (1, 2 or 3)

E. Fan

F. Fan Starter

G. Extern START/STOP

H. Pressure switch, compressed air

J. Pressure switch, high dP/low airflow

K. Fire alarm

L. Dust feeder

M. Sum alarm, alarm signal devices

N. A-alarm

O. Activating, in/outputs

Date

Result Result Result Note

6. Earth control measurement (page 12)

A. GND1 - Inlet

B. GND1 - Inlet cleaning access cover

C. GND1 - Dust container

D. GND1 - Dust container adapter

E. GND1 - Filter cartridges

F. GND1 - Filter units

G. GND1 - Doors

7. Monitoring system, settings

(page 18-19)

A. Cleaning during operation

B. Pause time setting

C. Cleaning after operation

D. A-alarm function

E. Remote control

8. System start

A. Dimensioned airflow

B. Actual airflow

C. Filter ∆ P

32

SERVICE PROTOCOL (page 12, 23 - 25)

FilterMax F No.

Operating hours

Performed by

Control points

1. Dust container / Filter regulator

A. Empty the dust container (when 70 % full)

B. Water check filter regulator

C. Water check pressure tank

2. Magnetic valves,

function check

3. Remove dust,

clean air room

every 2000 h *

every 1000 h *

4. Cleaning access covers, cleaning

A. Check pre-separator inlet

5. Water check pressure tank

6. Checking the filter cartridges

Date

Result Result Result Result Result

every 6000 h *

A. Check cartridges for damage.

B. Measure cartridge ∆ P. If higher that

1500 Pa replace the cartridges.

7. Remove corrosion by grinding,

primer and touch up paint

8. Earth control measurement (page 12)

A. GND1 - Inlet

B. GND1 - Inlet cleaning access cover

C. GND1 - Dust container

D. GND1 - Dust container adapter

E. GND1 - Filter cartridges

F. GND1 - Filter units

G. GND1 - Doors

9. Replacing the filter cartridges

(page 25)

10. Check that the cables not are

damaged or connected incorrectly

11. Airflow (adjust if neccesary)

A. Dimensioned airflow

B. Actual airflow

*

Every 1000 hours or at least once every 6th month.

Every 2000 hours or at least once a year or when replacing filter cartridges.

Every 6000 hours or at damage or insufficient filter function.

33

SERVICE PROTOCOL (page 12, 23 - 25)

FilterMax F No.

Operating hours

Performed by

Control points

1. Dust container / Filter regulator

A. Empty the dust container (when 70 % full)

B. Water check filter regulator

C. Water check pressure tank

2. Magnetic valves,

function check

3. Remove dust,

clean air room

every 2000 h *

every 1000 h *

4. Cleaning access covers, cleaning

A. Check pre-separator inlet

5. Water check pressure tank

6. Checking the filter cartridges

Date

Result Result Result Result Result

every 6000 h *

A. Check cartridges for damage.

B. Measure cartridge ∆ P. If higher that

1500 Pa replace the cartridges.

7. Remove corrosion by grinding,

primer and touch up paint

8. Earth control measurement (page 12)

A. GND1 - Inlet

B. GND1 - Inlet cleaning access cover

C. GND1 - Dust container

D. GND1 - Dust container adapter

E. GND1 - Filter cartridges

F. GND1 - Filter units

G. GND1 - Doors

9. Replacing the filter cartridges

(page 25)

10. Check that the cables not are

damaged or connected incorrectly

11. Airflow (adjust if neccesary)

A. Dimensioned airflow

B. Actual airflow

*

Every 1000 hours or at least once every 6th month.

Every 2000 hours or at least once a year or when replacing filter cartridges.

Every 6000 hours or at damage or insufficient filter function.

34

SERVICE PROTOCOL (page 12, 23 - 25)

FilterMax F No.

Operating hours

Performed by

Control points

1. Dust container / Filter regulator

A. Empty the dust container (when 70 % full)

B. Water check filter regulator

C. Water check pressure tank

2. Magnetic valves,

function check

3. Remove dust,

clean air room

every 2000 h *

every 1000 h *

4. Cleaning access covers, cleaning

A. Check pre-separator inlet

5. Water check pressure tank

6. Checking the filter cartridges

Date

Result Result Result Result Result

every 6000 h *

A. Check cartridges for damage.

B. Measure cartridge ∆ P. If higher that

1500 Pa replace the cartridges.

7. Remove corrosion by grinding,

primer and touch up paint

8. Earth control measurement (page 12)

A. GND1 - Inlet

B. GND1 - Inlet cleaning access cover

C. GND1 - Dust container

D. GND1 - Dust container adapter

E. GND1 - Filter cartridges

F. GND1 - Filter units

G. GND1 - Doors

9. Replacing the filter cartridges

(page 25)

10. Check that the cables not are

damaged or connected incorrectly

11. Airflow (adjust if neccesary)

A. Dimensioned airflow

B. Actual airflow

*

Every 1000 hours or at least once every 6th month.

Every 2000 hours or at least once a year or when replacing filter cartridges.

Every 6000 hours or at damage or insufficient filter function.

35

SERVICE PROTOCOL (page 12, 23 - 25)

FilterMax F No.

Operating hours

Performed by

Control points

1. Dust container / Filter regulator

A. Empty the dust container (when 70 % full)

B. Water check filter regulator

C. Water check pressure tank

2. Magnetic valves,

function check

3. Remove dust,

clean air room

every 2000 h *

every 1000 h *

4. Cleaning access covers, cleaning

A. Check pre-separator inlet

5. Water check pressure tank

6. Checking the filter cartridges

Date

Result Result Result Result Result

every 6000 h *

A. Check cartridges for damage.

B. Measure cartridge ∆ P. If higher that

1500 Pa replace the cartridges.

7. Remove corrosion by grinding,

primer and touch up paint

8. Earth control measurement (page 12)

A. GND1 - Inlet

B. GND1 - Inlet cleaning access cover

C. GND1 - Dust container

D. GND1 - Dust container adapter

E. GND1 - Filter cartridges

F. GND1 - Filter units

G. GND1 - Doors

9. Replacing the filter cartridges

(page 25)

10. Check that the cables not are

damaged or connected incorrectly

11. Airflow (adjust if neccesary)

A. Dimensioned airflow

B. Actual airflow

*

Every 1000 hours or at least once every 6th month.

Every 2000 hours or at least once a year or when replacing filter cartridges.

Every 6000 hours or at damage or insufficient filter function.

36

SERVICE NOTES

Point no. Date Note

FilterMax F No.

37

www.nederman.com

Nederman is represented in:

Australia, Austria, Bahrain, Belgium, Brazil, Bulgaria, Canada, China, the Czech Republic, Cyprus, Denmark, Egypt, Estonia, Finland, France,

Germany, Greece, Hong Kong, Hungary, Iceland, India, Iran, Ireland, Italy, Japan, Korea, Latvia, Lithuania, Malaysia, the Netherlands, Norway,

Philippines, Poland, Portugal, Romania, Russia, Saudi Arabia, Serbia & Montenegro, Singapore, Slovenia, South Africa, Spain, Sweden,

Switzerland, Taiwan R.O.C., Thailand, Turkey, United Arab Emirates, United Kingdom, USA.

Loading...

Loading...