DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD75P048

4-BIT SINGLE-CHIP MICROCOMPUTER

DESCRIPTION

The µPD75P048 is a One-Time PROM version of the µPD75048. The µPD75P048 is suitable for small-scale

production or experimental production in system development.

Detailed functions are described in the following user’s manual. Read this manual when designing your

system.

µ

PD75048 User’s Manual: IEU-1278

FEATURES

• The

• 8064 × 8 bits of one-time programmable ROM

• 512 × 4 bits of RAM

• 1024 × 4 bits of EEPROM (Data memory area)

• Ports 0 to 3 and 6 to 8 with software-selectable pull-up resistors

• Port 9 with software-selectable pull-down resistors

• 12 N-channel open drain input/output ports (ports 4, 5, and 10)

• Low-voltage operation possible (VDD = 2.7 to 6.0 V)

µ

PD75048 compatible

• The µPD75P048 for evaluation/pre-production, while the µPD75048 for mass-production

ORDERING INFORMATION

Part number Package Quality grade

µ

PD75P048CW 64-pin plastic shrink DIP (750 mil) Standard

µ

PD75P048GC-AB8 64-pin plastic QFP ( 14 mm) Standard

Caution Pull-up/pull-down resistor mask options are not available.

Please refer to "Quality grade on NEC Semiconductor Devices" (Document number IEI-1209) published by

NEC Corporation to know the specification of quality grade on the devices and its recommended applications.

Document No. IC-3239

(O.D. No. IC-8720)

Date Published August 1994 P

Printed in Japan

The information in this document is subject to change without notice.

The mark ★ shows major revised points.

©

1994

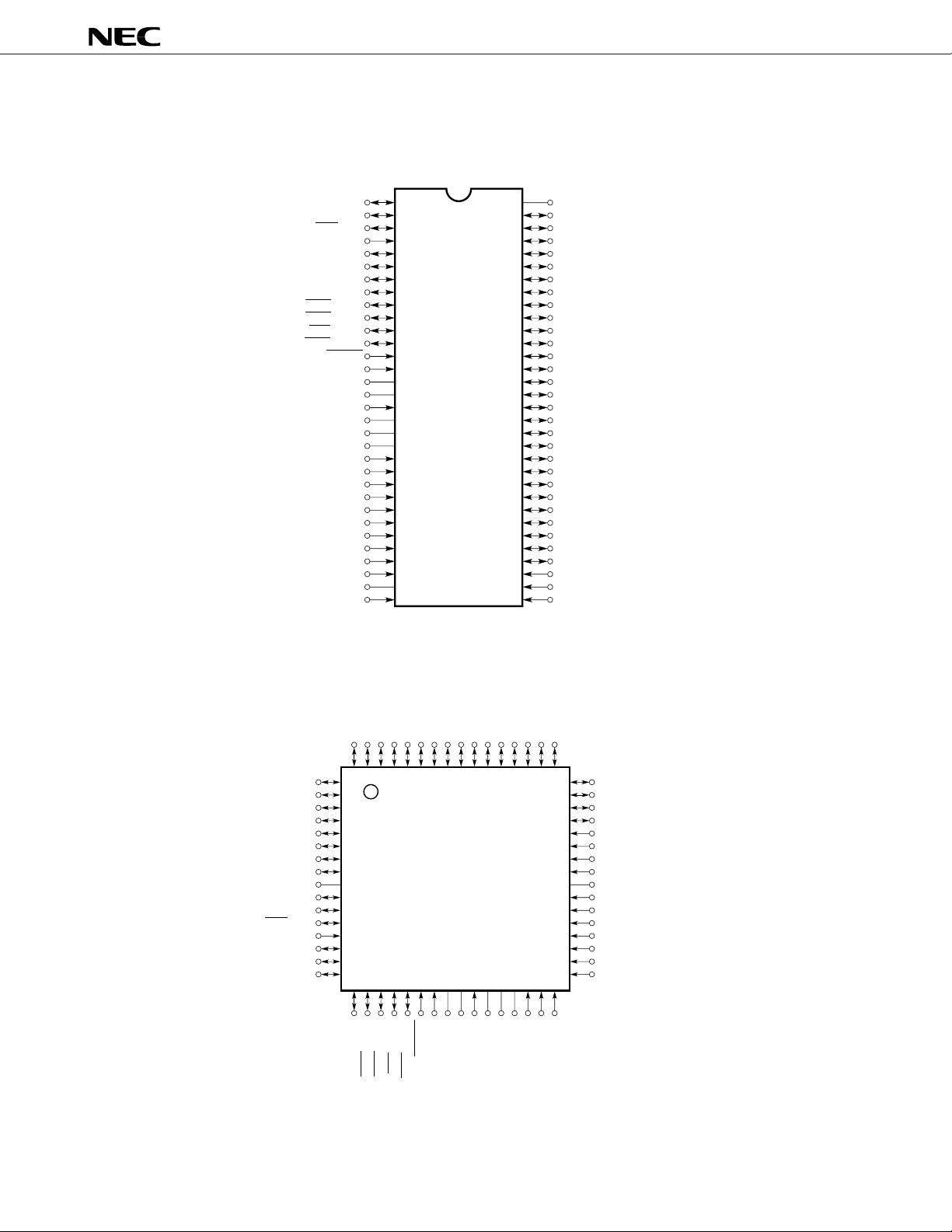

PIN CONFIGURATION (Top View)

• 64-pin plastic shrink DIP

µ

PD75P048

• 64-pin plastic QFP

SB1/SI/P03

SB0/SO/P02

SCK/P01

INT4/P00

BUZ/P23

PCL/P22

PPO/P21

PTO0/P20

MAT/P103

MAZ/P102

MAI/P101

MAR/P100

RESET

X1

X2

V

XT1

XT2

V

AVDD

AVREF+

AVREF–

AN7

AN6

AN5

AN4

AN3/P113

AN2/P112

AN1/P111

AN0/P110

AV

TI0/P13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

µ

PD75P048CW

15

16

PP

17

18

19

DD

20

21

22

23

24

25

26

27

28

29

30

31

SS

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

V

SS

P30/MD0

P31/MD1

P32/MD2

P33/MD3

P40

P41

P42

P43

P50

P51

P52

P53

P60/KR0

P61/KR1

P62/KR2

P63/KR3

P70/KR4

P71/KR5

P72/KR6

P73/KR7

P80

P81

P82

P83

P90

P91

P92

P93

P10/INT0

P11/INT1

P12/INT2

P43

P42

P41

P40

MD3/P33

MD2/P32

MD1/P31

MD0/P30

V

SB1/SI/P03

SB0/SO/P02

SCK/P01

INT4/P00

BUZ/P23

PCL/P22

PPO/P21

P50

P51

P52

P53

P60/KR0

P61/KR1

P62/KR2

P63/KR3

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

SS

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

µ

PD75P048GC-AB8

X1

X2

RESET

MAI/P101

PTO0/P20

MAT/P103

MAZ/P102

MAR/P100

P70/KR4

P71/KR5

P72/KR6

VPP

XT1

XT2

P73/KR7

P80

P81

VDD

AVDD

AVREF+

P82

AVREF–

P83

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

AN7

P90

P91

P92

P93

P10/INT0

P11/INT1

P12/INT2

TI0/P13

AV

SS

AN0/P110

AN1/P111

AN2/P112

AN3/P113

AN4

AN5

AN6

2

µ

PD75P048

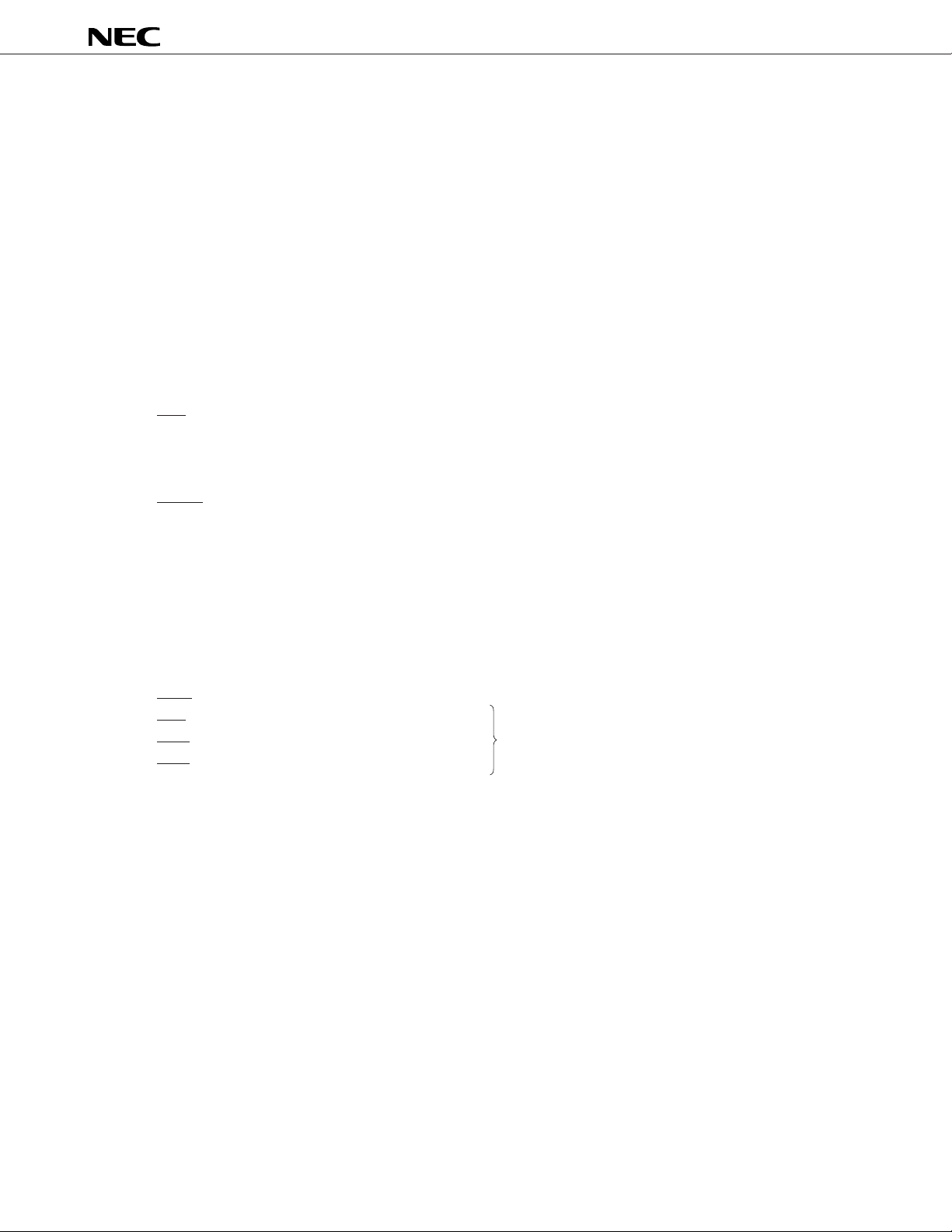

PIN IDENTIFICATION

P00-03 : Port0

P10-13 : Port1

P20-23 : Port2

P30-33 : Port3

P40-43 : Port4

P50-53 : Port5

P60-63 : Port6

P70-73 : Port7

P80-83 : Port8

P90-93 : Port9

P100-103 : Port10

P110-113 : Port11

KR0-7 : Key Return

SCK : Serial Clock

SI : Serial Input

SO : Serial Output

SB0, 1 : Serial Bus 0, 1

RESET : Reset Input

TI0 : Timer Input 0

PTO0 : Programmable Timer Output 0

BUZ : Buzzer Clock

PCL : Programmable Clock

INT0,1,4 : External Vectored Interrupt 0, 1, 4

INT2 : External Test Input 2

X1, 2 : Main System Clock Oscillation 1, 2

XT1, 2 : Subsystem Clock Oscillation 1, 2

MAR : Reference Integration Control

MAI : Integration Control

MAZ : Autozero Control

MAT : External Comparate Timing Input

PPO : Programmable Pulse Output ... MFT timer mode

AN0-7 : Analog Input 0-7

AVREF+ : Analog Reference (+)

REF- : Analog Reference (-)

AV

AVDD : Analog VDD

AVSS : Analog VSS

VDD : Positive Power Supply

VSS : Ground

VPP : Programming Power Supply

MD0-MD3 : Mode Selection

MFT

A/D

mode

★

Remarks MFT: Multi-function timer

3

4

TI0/P13

PTO0/P20

BASIC

INTERVAL

TIMER

INTBT

TIMER/

COUNTER

#0

INTT0

PROGRAM

COUNTER

SP

CY

ALU

BIT SEQ.

BUFFER

PORT 0

PORT 1 P10 - P13

P00 - P03

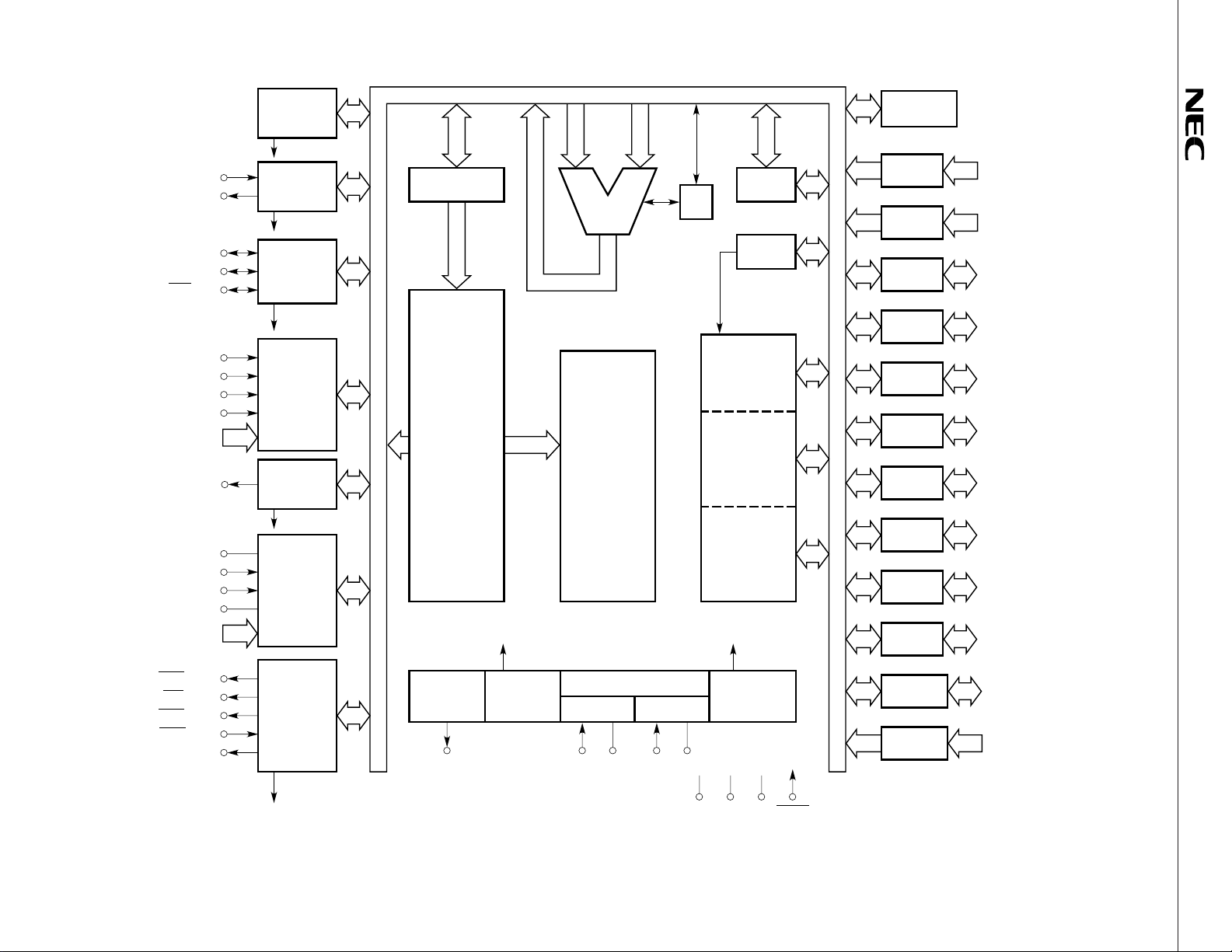

BLOCK DIAGRAM

SI/SB1/P03

SO/SB0/P02

SCK/P01

INT0/P10

INT1/P11

INT2/P12

INT4/P00

KR0 - KR3/P60 - P63

KR4 - KR7/P70 - P73

BUZ/P23

AVDD

AVREF+

AVREF–

AVSS

AN0 - AN3/P110 - P113

AN4 - AN7

MAR/P100

MAI/P101

MAZ/P102

MAT/P103

PPO/P21

SERIAL

INTERFACE

INTCSI

INTERRUPT

CONTROL

WATCH

TIMER

INTW

A/D

CONVERTER

MULTIFUNCTION

TIMER

PROM

PROGRAM

MEMORY

8064 × 8 BITS

CLOCK

OUTPUT

CONTROL

PCL/P22

N

fx/2

CLOCK

DIVIDER

DECODE

AND

CONTROL

CLOCK GENERATOR

SUB

XT1 XT2

MAIN

X1 X2

BANK

DATA

MEMORY

GENERAL REG.

RAM

512 × 4 BITS

EEPROM

1024 × 4 BITS

CPU CLOCK

Φ

STAND BY

CONTROL

PORT 2 P20 - P23

PORT 3 P30/MD0 - P33/MD3

PORT 4 P40 - P43

PORT 5 P50 - P53

PORT 6 P60 - P63

PORT 7 P70 - P73

PORT 8 P80 - P83

PORT 9 P90 - P93

PORT 10 P100 - P103

PORT 11 P110 - P113

µ

PD75P048

INTMFT

VSSVDDVPP

RESET

µ

PD75P048

CONTENTS

1. PIN FUNCTIONS ························································································································· 6

1.1 PORT PINS ·········································································································································· 6

1.2 NON-PORT PINS ································································································································· 8

1.3 PIN INPUT/OUTPUT CIRCUITS ········································································································ 10

2. DIFFERENCES BETWEEN THE µPD75P048 AND THE µPD75048 ······································· 13

3. PROM (PROGRAM MEMORY) WRITE AND VERIFY····························································· 14

3.1 PROM WRITE AND VERIFY OPERATION MODE ·········································································· 14

3.2 PROM WRITE PROCEDURE ·············································································································· 15

3.3 PROM READ PROCEDURE ················································································································ 16

4. SCREENING OF ONE-TIME PROM MODEL··········································································· 17

5. ELECTRICAL SPECIFICATIONS ·································································································· 18

6. PERFORMANCE CURVE (REFERENCE VALUE) ····································································· 32

7. PACKAGE DRAWINGS··············································································································· 34

8. RECOMMENDED SOLDERING CONDITIONS ········································································· 36

APPENDIX A. DEVELOPMENT TOOLS ·························································································· 37

APPENDIX B. RELATED DOCUMENTS ·························································································· 38

★

★

★

★

★

★

5

1. PIN FUNCTIONS

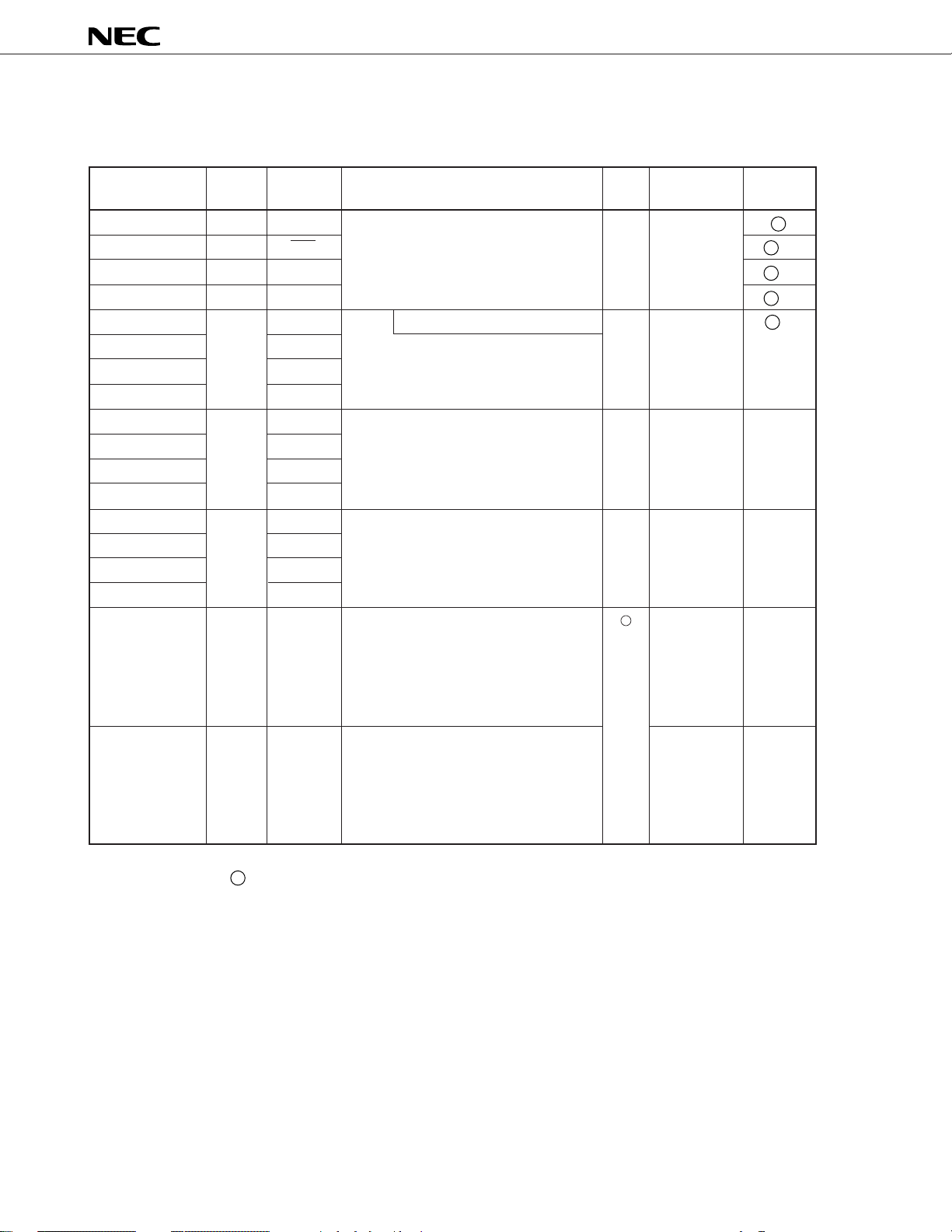

1.1 PORT PINS (1/2)

µ

PD75P048

Pin Name

P00

P01

P02

P03

P10

P11

P12

P13

P20

P21

P22

P23

Note 2

P30

Note 2

P31

Note 2

P32

Note 2

P33

P40 - P43

Note 2

Input/

Output

Input

I/O

I/O

I/O

Input

I/O

I/O

I/O

Shared

Pin

INT4

SCK

SO/SB0

SI/SB1

INT0

INT1

INT2

TI0

PTO0

PPO

PCL

BUZ

MD0

MD1

MD2

MD3

–

Function

4-bit input port (PORT0).

For P01 to P03, pull-up resistors can be

provided by software in units of 3 bits.

With noise elimination function

4-bit input port (PORT1).

Pull-up resistors can be provided by

software in units of 4 bits.

4-bit I/O port (PORT2).

Pull-up resistors can be provided by

software in units of 4 bits.

Programmable 4-bit I/O port (PORT3).

I/O can be specified bit by bit.

Pull-up resistors can be provided by

software in units of 4 bits.

N-ch open-drain 4-bit I/O port (PORT4).

Can withstand 10 V.

Data input/output pins for the PROM

write and verity (Four low-order bits).

8-Bit

I/O

×

×

×

×

When Reset

Input

Input

Input

Input

High

impedance

I/O Circuit

Note 1

Type

B

-A

F

-B

F

-C

M

-C

B

E-B

E-B

M-A

P50 - P53

Note 2

I/O

–

N-ch open-drain 4-bit I/O port (PORT5).

Can withstand 10 V.

Data input/output pins for the PROM

write and verify (Four high-order bits).

Note 1. The circle ( ) indicates the Schmitt trigger input.

2. Can directly drive LEDs.

High

impedance

M-A

6

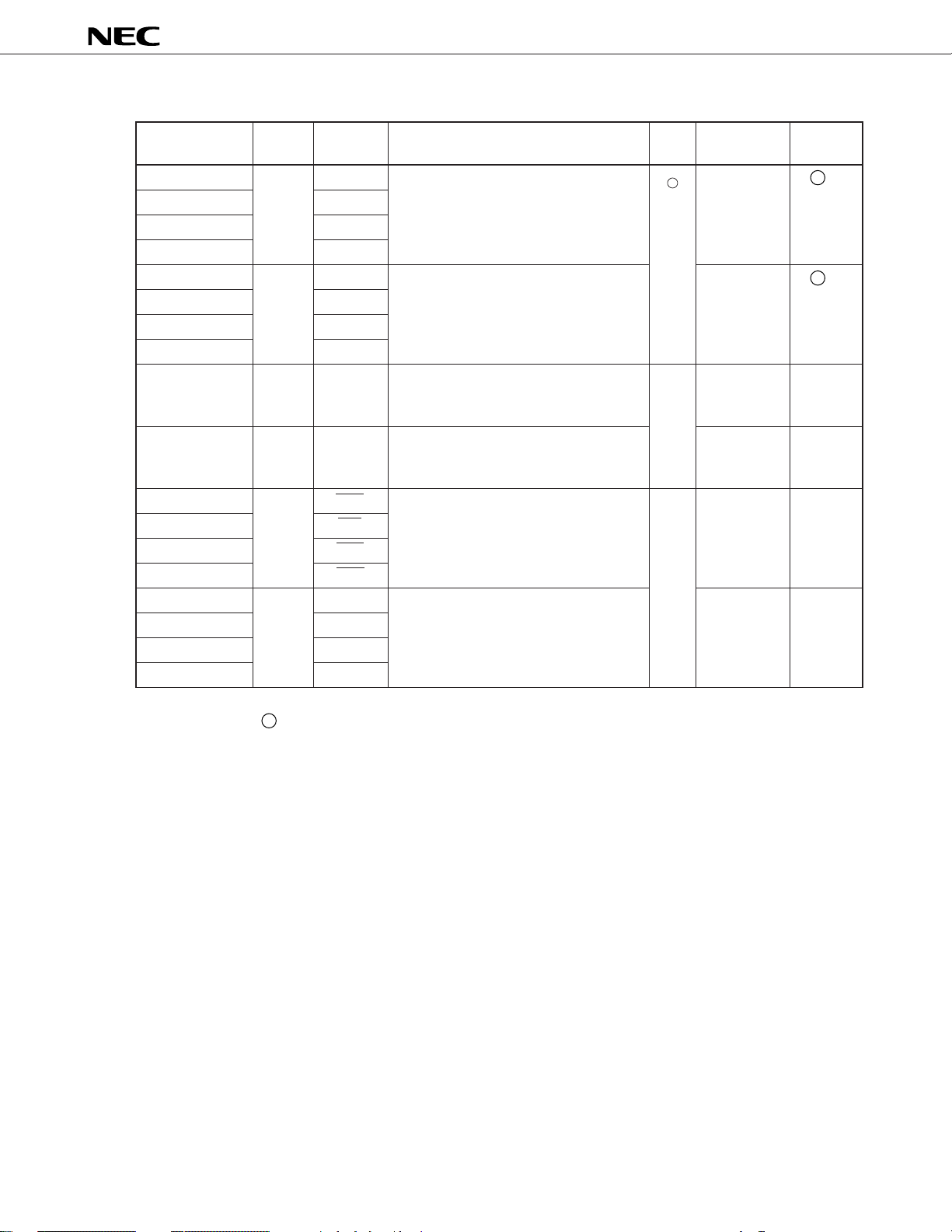

1.1 PORT PINS (2/2)

µ

PD75P048

Pin Name

P60

P61

P62

P63

P70

P71

P72

P73

P80 - P83

P90 - P93

P100

P101

P102

P103

P110

P111

P112

P113

Input/

Output

I/O

I/O

I/O

I/O

I/O

Input

Shared

Pin

KR0

KR1

KR2

KR3

KR4

KR5

KR6

KR7

–

–

MAR

MAI

MAZ

MAT

AN0

AN1

AN2

AN3

Function

Programmable 4-bit I/O port (PORT 6).

Pull-up resistors can be provided by

software in units of 4 bits.

4-bit I/O port (PORT 7).

A pull-up resistor can be provided by

software in units of 4 bits

4-bit I/O port (PORT 8).

A pull-up resistor can be provided by

software in units of 4 bits.

4-bit I/O port (PORT 9).

A pull-up resistor can be provided by

software in units of 4 bits.

N-ch open drain 4-bit I/O port (PORT 10).

Can withstand 10 V in open-drain

mode.

4-bit input port (PORT 11).

8-Bit

I/O

×

×

When Reset

Input

Input

Input

Input

High

impedance

Input

I/O Circuit

Note

Type

-A

F

-A

F

E-B

E-D

M-A

Y

★

Note The circle ( ) indicates the Schmitt trigger input.

7

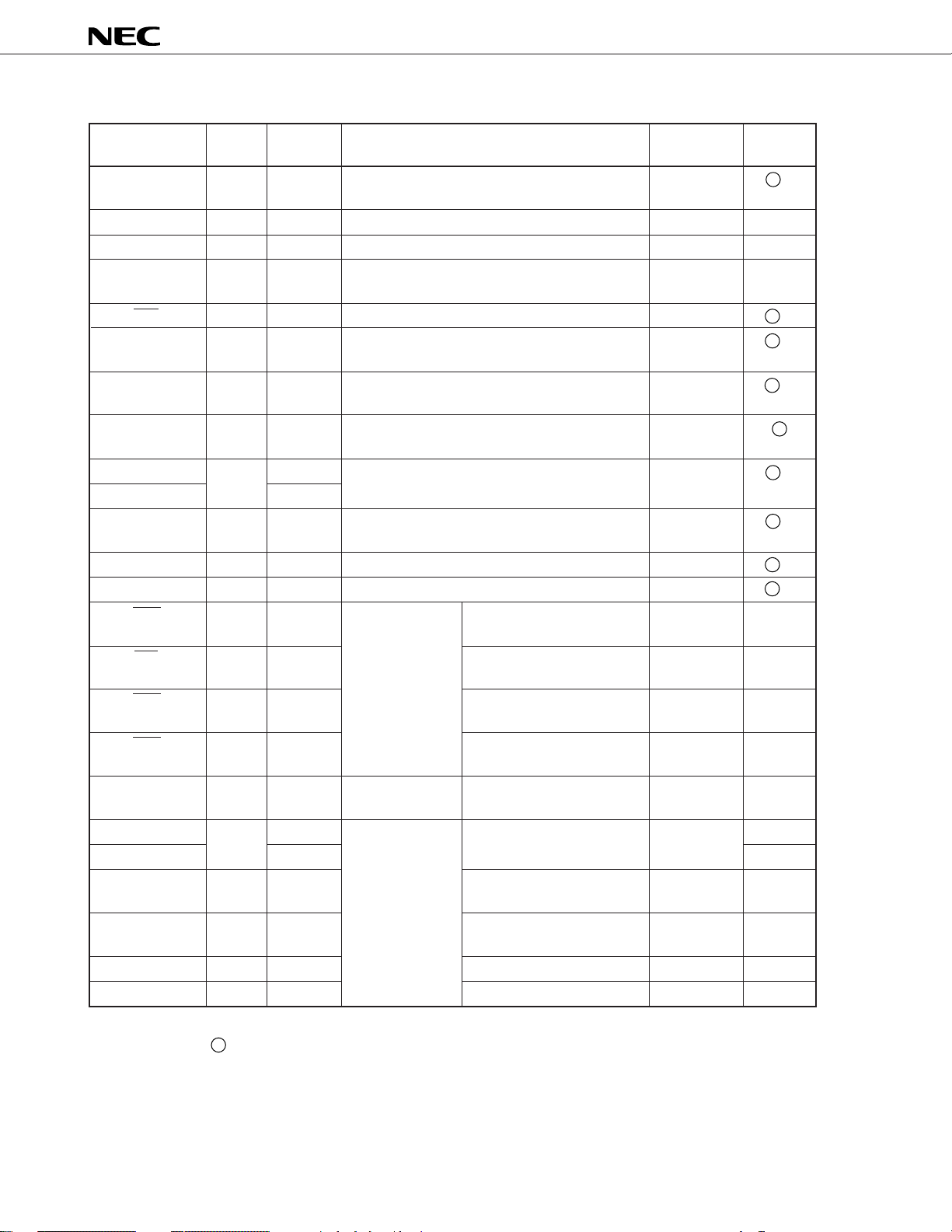

1.2 NON-PORT PINS (1/2)

µ

PD75P048

Pin Name

TI0

PTO0

PCL

BUZ

SCK

SO/SB0

SI/SB1

INT4

INT0

INT1

INT2

KR0 - KR3

KR4 - KR7

MAR

MAI

MAZ

MAT

PPO

AN0 - AN3

AN4 - AN7

AVREF+

AVREF–

AVDD

AVSS

Input/

Output

Input

I/O

I/O

I/O

I/O

I/O

I/O

Input

Input

Input

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Input

Input

Input

–

–

Shared

Pin

P13

P20

P22

P23

P01

P02

P03

P00

P10

P11

P12

P60 - P63

P70 - P73

P100

P101

P102

P103

P21

P110 - P113

–

–

–

–

–

Function

Input for receiving external event pulse signal

for timer/event counter

Timer/event counter output

Clock output

Output for arbitrary frequency output (for

buzzer output or system clock trimming)

Serial clock I/O

Serial data output

Serial bus I/O

Serial data input

Serial bus I/O

Edge detection vectored interrupt input (either

rising edge or falling edge detection)

Edge detection vectored interrupt input

(detection edge selectable)

Edge detection testable input (rising edge

detection)

Parallel falling edge detection testable input

Parallel falling edge detection testable input

In MFT integrating A/D

converter mode

In MFT timer

mode

For A/D

converter only

Reverse integration signal

output

Integration signal output

Auto-zero signal output

Comparator input

Timer pulse output

8-bit analog input

Reference voltage input

(AVDD side)

Reference voltage input

(AVSS side)

Positive power supply

GND potential

When Reset

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

High

impedance

High

impedance

High

impedance

High

impedance

Input

–

–

–

–

–

I/O Circuit

Note

Type

-C

B

E-B

E-B

E-B

-A

F

-B

F

-C

M

B

-C

B

-C

B

-A

F

F

-A

M-A

M-A

M-A

M-A

E-B

Y-A

Y-A

Z-A

Z-A

–

–

Note The circle ( ) indicates the Schmitt trigger input.

Remark MFT: Multi-Function Timer

8

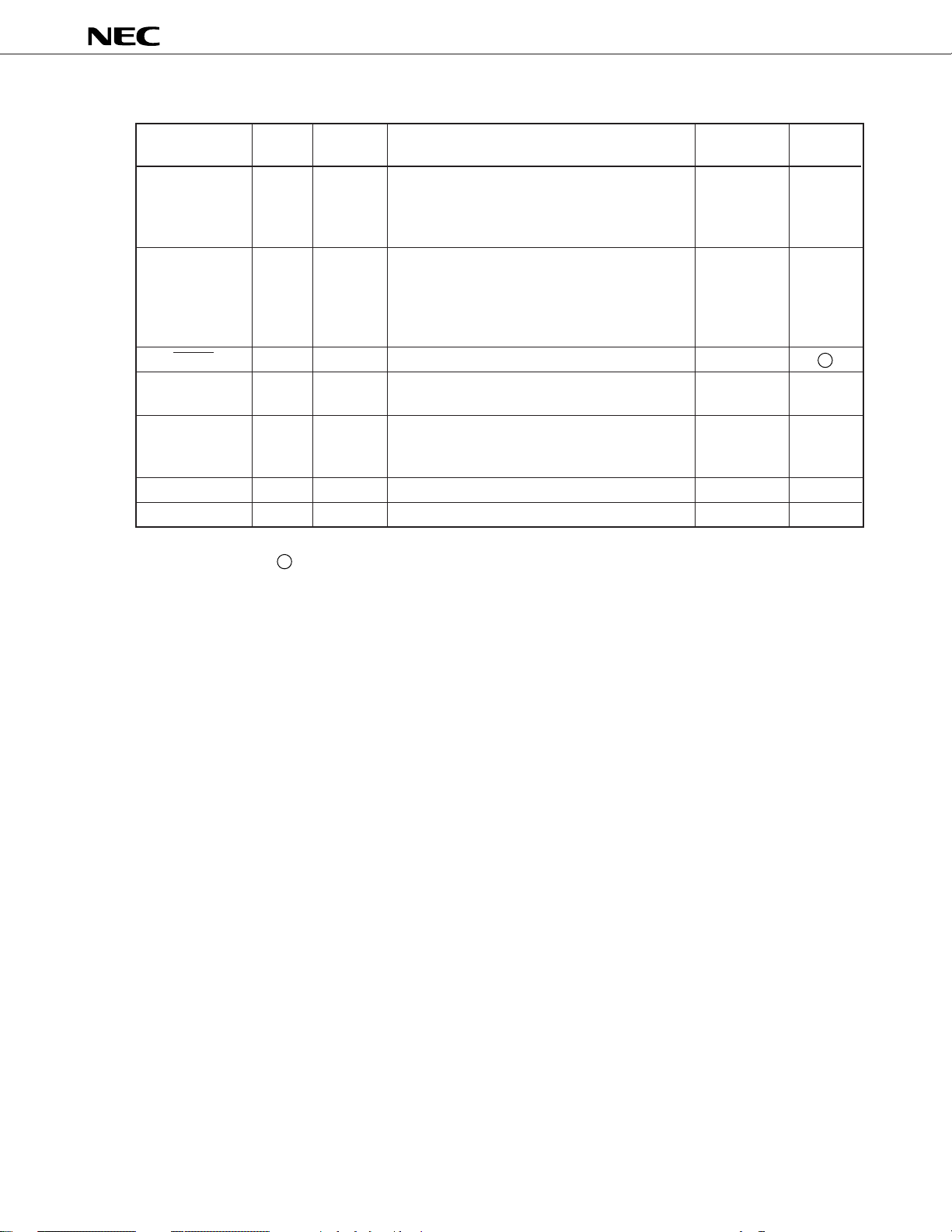

1.2 NON-PORT PINS (2/2)

µ

PD75P048

Pin Name

X1, X2

XT1, XT2

RESET

MD0 - MD3

Note 2

VPP

VDD

VSS

Input/

Output

Input

Input

Input

I/O

–

–

–

Shared

Pin

–

–

–

P30 - P33

–

–

–

Function

Crystal/ceramic resonator connection for main

system clock generation. When external clock

signal is used, it is applied to X1, and its

reverse phase signal is applied to X2.

Crystal connection for subsystem clock

generation. When external clock signal is

used, it is applied to XT1, and its reverse

phase signal is applied to XT2. XT1 can be

used as a 1-bit input (test).

System reset input

Operation mode selection pins during the

PROM write/verify cycles.

Normally connected to VDD directly; +12.5 V is

applied as the programming voltage during the

PROM write/verify cycles.

Positive power supply

GND potential

When Reset

–

–

–

Input

–

–

–

Note 1. The circle ( ) indicates the Schmitt trigger input.

2. The VPP should be connected to VDD directly in normal operation mode. If VPP and VDD pins are not

µ

connected, the

PD75P048 does not operate correctly.

I/O Circuit

Note 1

Type

–

–

B

E-B

–

–

–

9

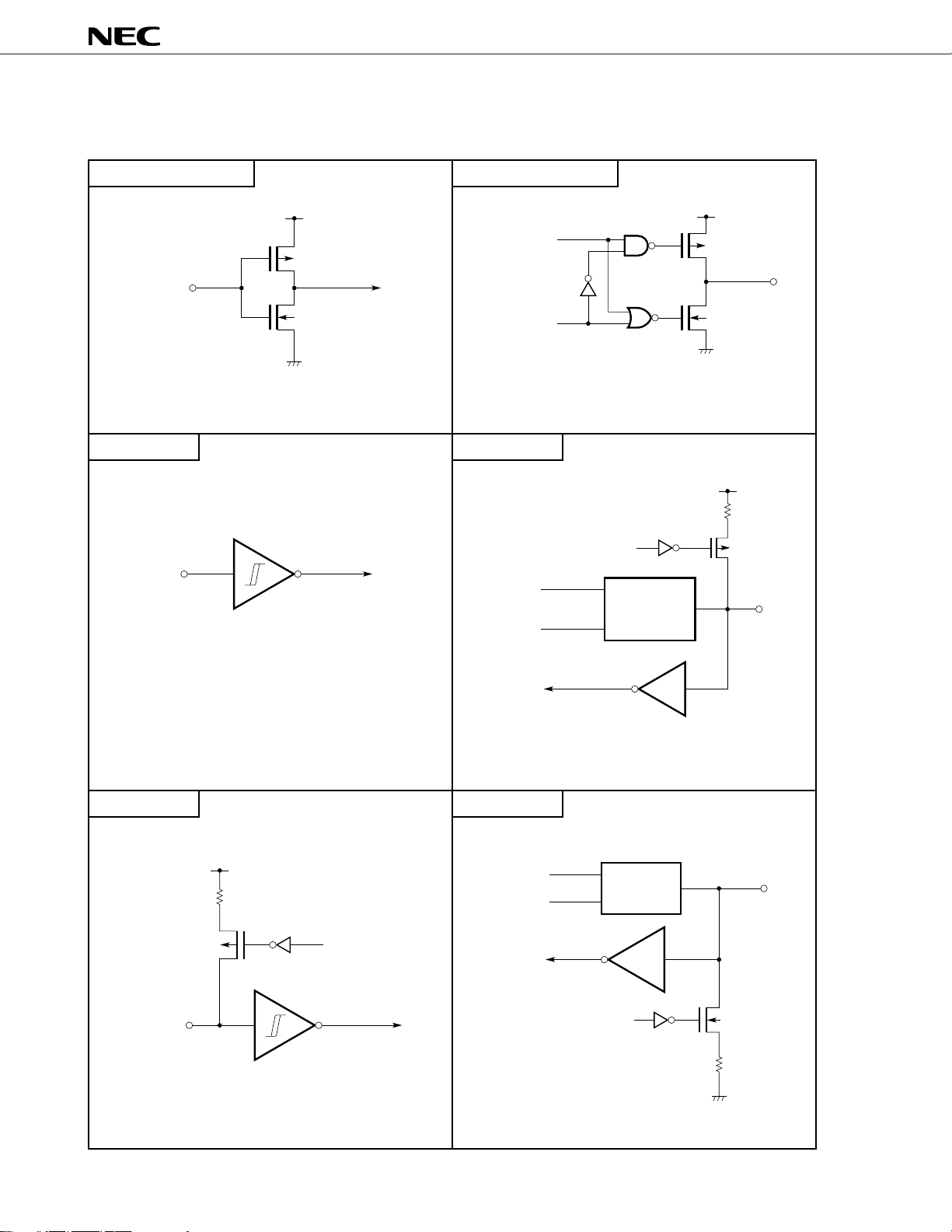

1.3 PIN INPUT/OUTPUT CIRCUITS

The input/output circuit of each µPD75P048 pin is shown below in a simplified manner.

Type A (For Type E-B)

Type D (For Type E-B, F-A)

µ

PD75P048

(1/3)

Type B

VDD

Data

P-ch

IN

N-ch

CMOS input buffer

Type E-B

IN

Output

disable

Push-pull output which can be set to high-impedance output

(off for both P-ch and N-ch)

P.U.R.

enable

Data

Output

disable

Type D

VDD

P-ch

OUT

N-ch

VDD

P.U.R.

P-ch

IN/OUT

Schmitt trigger input with hysteresis

Type B-C Type E-D

VDD

P.U.R.

P-ch

IN

P.U.R.: Pull-Up Resistor P.D.R.: Pull-Down Resistor

P.U.R.

enable

Data

Output

disable

Type A

P.U.R.: Pull-Up Resistor

Type D

Type A

P.D.R.

enable

IN/OUT

N-ch

P.D.R.

10

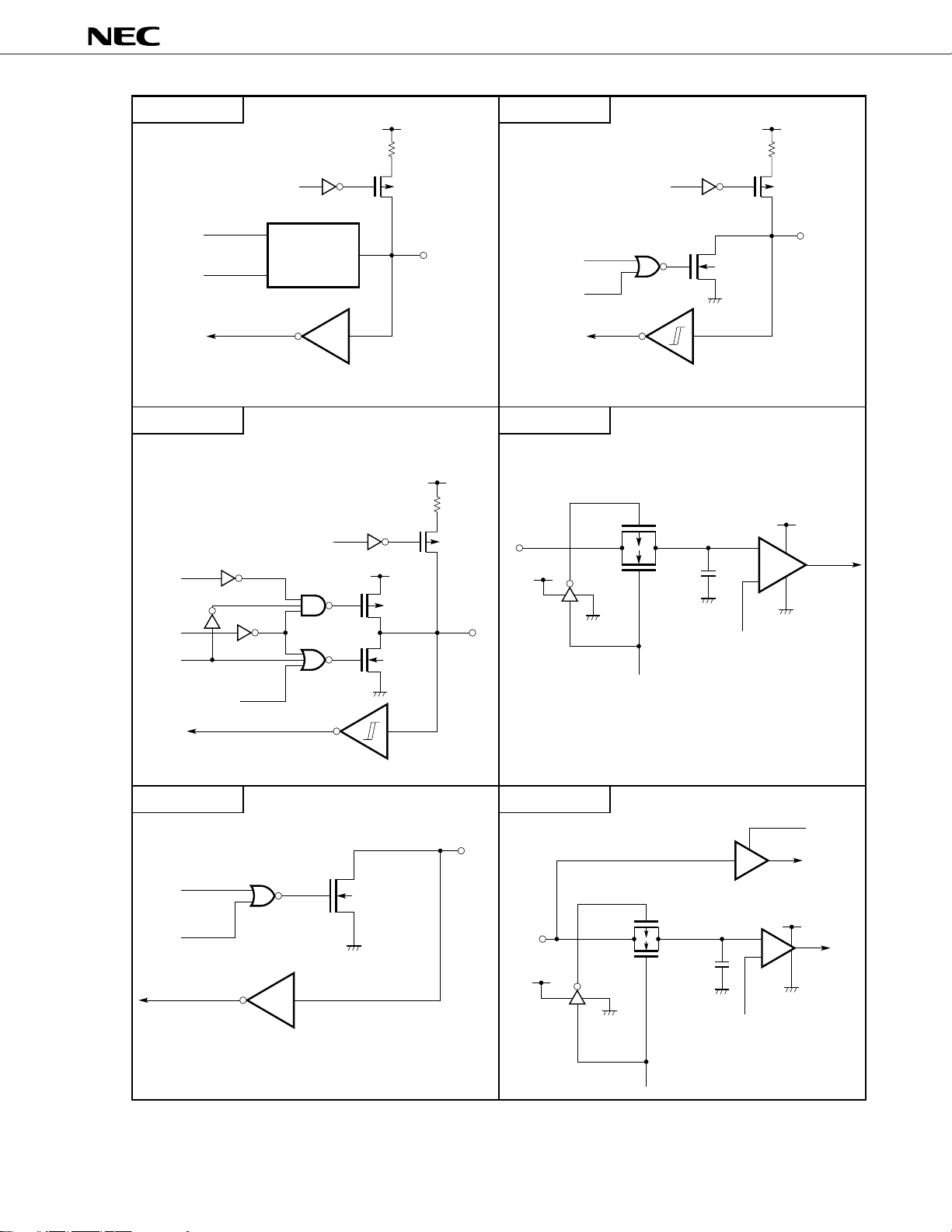

Type F-A Type M-C

VDD

µ

PD75P048

VDD

(2/3)

Output

disable

Type F-B

Output

disable

(P)

Data

Output

disable

Data

Output

disable

(N)

P.U.R.

enable

Type D

Type B

P.U.R.: Pull-Up Resistor

P.U.R.

enable

VDD

P-ch

N-ch

P.U.R.

P-ch

IN/OUT

VDD

P.U.R.

P-ch

IN/OUT

Output

disable

Type Y

IN

AVDD

Data

P.U.R.

enable

P.U.R.: Pull-Up Resistor

P-ch

N-ch

AVSS

Sampling C

Input

enable

P.U.R.

P-ch

IN/OUT

N-ch

AVDD

+

–

AVSS

Reference voltage

(from voltage tap of

series resistor string)

P.U.R.: Pull-Up Resistor

Type M-A Type Y-A

IN/OUT

Data

Output

disable

Middle-voltage input buffer

(Can withstand + 10 V)

P.U.R.: Pull-Up Resistor

N-ch

(Can with stand + 10 V)

AVDD

IN

P-ch

N-ch

AVSS

Input buffer

+

Sampling C

Reference voltage

(from voltage tap of

series resistor string)

–

IN instruction

AVDD

AVSS

11

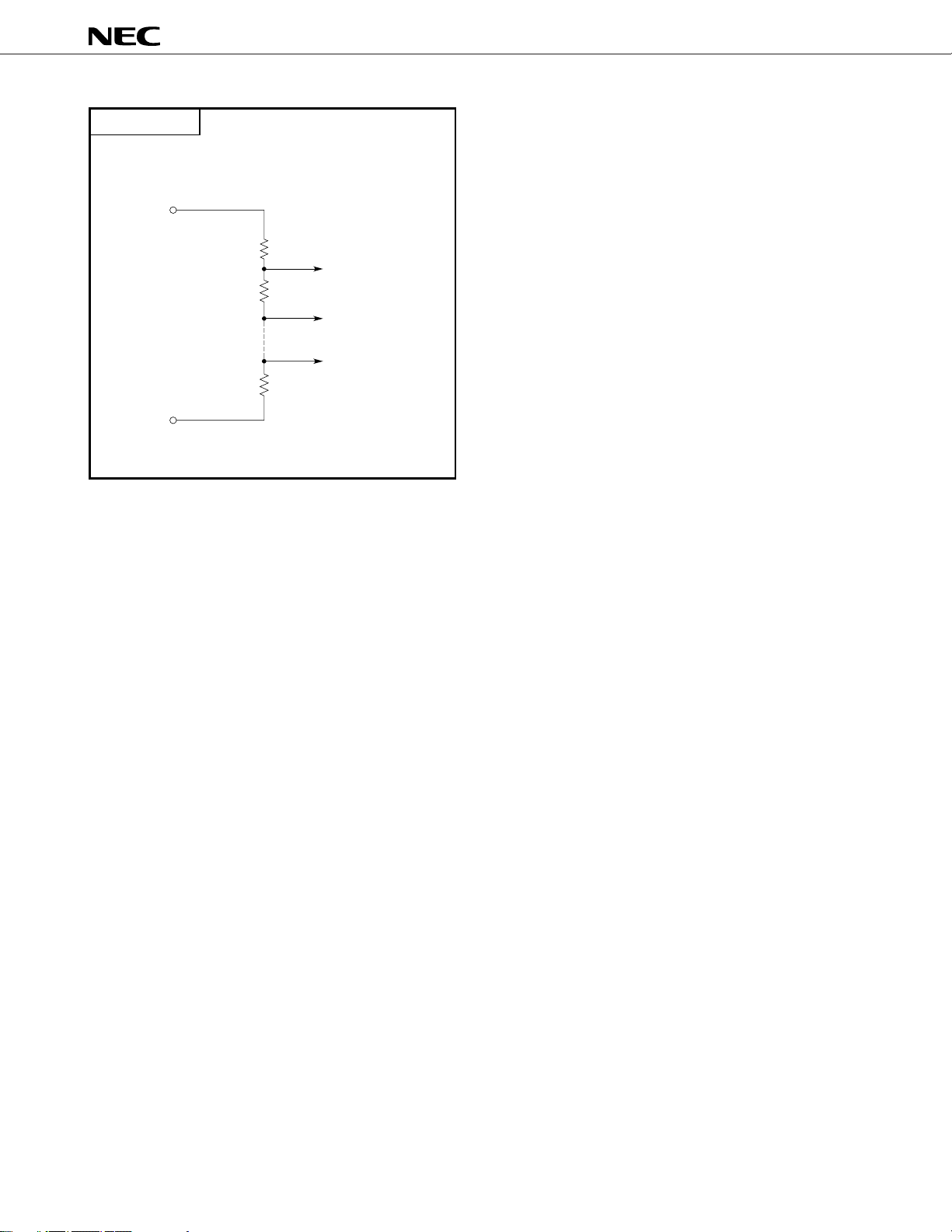

Type Z-A

AVREF+

AVREF–

Reference voltage

(3/3)

µ

PD75P048

12

µ

PD75P048

2. DIFFERENCES BETWEEN THE µPD75P048 AND THE µPD75048

The µPD75P048 is a One-Time PROM version of the µPD75048. The µPD75P048 has the same CPU and

internal hardwares. Table 2-1 shows the differences between the µPD75P048 and the µPD75048. Bear in mind

the differences between these two products when debugging or developing on an experimental basis your

application system by using the one-time PROM model, and then mass-producing the application system by

using the mask ROM model.

µ

Details for the CPU functions and internal hardwares are available in

µ

Table 2-1 Differences between the

Program Memory

Pull-up Resistors

Pull-Down Resistors

XT1 Feedback Resistor

Pin Connection

Electrical Specification

Other

Items

Ports 0 to 3 and 6 to 8

Ports 4, 5 and 10

Port 9

60 - 63 (SDIP)

5 - 8 (QFP)

16 (SDIP)

25 (QFP)

PD75P048 and the µPD75048

µ

PD75P048

One-time PROM Mask ROM

N/A Mask-option

On-chip Mask-option

P33/MD3 - P30/MD0 P33 - P30

VPP IC

Current dissipation differs. For details,

refer to Data Sheet of each model.

Circuit scale and mask layout differ.

Consequently, noise immunity and noise

radiation differ.

PD75048 User’s Manual (IEU-1278).

µ

PD75048

• 0000H to 1F7FH

• 8064 × 8 bits

Software-selectable

Software-selectable

★

★

★

Note The noise immunity and noise radiation of the PROM and mask ROM models differ. To replace the PROM

mode, which has been used for experimental production of your application system with the mask ROM

model for mass production of the application system, be sure to perform thorough evaluation by using

the CS model (not ES model) of the mask ROM model.

13

★

µ

PD75P048

3. PROM (PROGRAM MEMORY) WRITE AND VERIFY

The µPD75P048 contains 8064 bytes of PROM. The following table shows the pin functions during the write

and verify cycles. Note that it is not necessary to enter an address, because the address is updated by pulsing

the X1 clock pins.

Pin Name

VPP

X1, X2

MD0 - MD3 (P30 - P33)

P40 - P43 (lower 4 bits)

P50 - P53 (higher 4 bits)

VDD

Normally 2.7 to 6 V; 12.5 V is applied during write/verify

After a write/verify write, the X1 and X2 clock pins are

pulsed. The inverted signal of the X1 should be input to the

X2.

Note that these pins are also pulsed during a read.

Operation mode selection pins.

8-bit data input/output pins for write and verify

Supply voltage.

Normally 2.7 to 6 V; 6 V is applied during write/verify

Function

Caution The µPD75P048CW/GC do not have a UV erase window, thus the PROM contents cannot be erased

with ultra-violet ray.

3.1 PROM WRITE AND VERIFY OPERATION MODE

When 6 V and 12.5 V are applied to the V

DD and VPP pins, respectively, the PROM is placed in the write/verify

mode. The operation is selected by the MD0 to MD3 pins, as shown in the table.

The other pins should be returned to VSS potential via pull-down resistors.

VPP

+12.5 V

Operation Mode Specification

VDD

+6 V

MD0

H

L

L

H

MD1

L

H

L

×

MD2

H

H

H

H

MD3

L

H

H

H

Clear program memory address to 0

Write mode

Verify mode

Program inhibit

Operation Mode

14

×: Don’t care.

µ

PD75P048

3.2 PROM WRITE PROCEDURE

PROMs can be written at high speed using the following procedure: (see the following figure)

(1) Pull unused pins to V

SS through resistors. Set the X1 pin low.

(2) Supply 5 volts to the VDD and VPP pins.

(3) Wait for 10 µs.

(4) Select the zero clear program memory address mode.

(5) Supply 6 volts to the V

DD and 12.5 volts to the VPP pins.

(6) Select the program inhibit mode.

(7) Write data in the 1 ms write mode.

(8) Select the program inhibit mode.

(9) Select the verify mode. If the data is correct, proceed to step (10). If not, repeat steps (7), (8) and (9).

(10) Perform one additional write (duration of 1 ms × number of writes at (7) to (9)).

(11) Select the program inhibit mode.

(12) Apply four pulses to the X1 pin to increment the program memory address by one.

(13) Repeat steps (7) to (12) until the end address is reached.

(14) Select the zero clear program memory address mode.

(15) Return the V

DD and VPP pins back to + 5 volts.

(16) Turn off the power.

The following figure shows steps (2) to (12).

X repetition

Write Verify Additional write

VPP

VPP

VDD

VDD+1

VDD

VDD

X1

P40-P43

P50-P53

MD0

(P30)

Input data

Output

data

Address

increment

Input data

MD1

(P31)

MD2

(P32)

MD3

(P33)

15

µ

PD75P048

3.3 PROM READ PROCEDURE

The PROM contents can be read in the verify mode by using the following procedure: (see the following

figure)

(1) Pull unused pins to V

SS through resistors. Set the X1 pin low.

(2) Supply 5 volts to the VDD and VPP pins.

µ

(3) Wait for 10

s.

(4) Select the clear program memory address mode.

(5) Supply 6 volts to the VDD and 12.5 volts to the VPP pins.

(6) Select the program inhibit mode.

(7) Select the verify mode. Apply four pulses to the X1 pin. Every four clock pulses will output the data stored

in one address.

(8) Select the program inhibit mode.

(9) Select the clear program memory address mode.

(10) Return the V

DD and VPP pins back to + 5 volts.

(11) Turn off the power.

The following figure shows steps (2) to (9).

VPP

VPP

VDD

VDD+1

VDD

VDD

X1

P40-P43

P50-P53

MD0

(P30)

MD1

(P31)

MD2

(P32)

“L”

Output data

Output data

16

MD3

(P33)

µ

PD75P048

4. SCREENING OF ONE-TIME PROM MODEL

Because of their structure, the one-time PROM models (µPD75P48CW and µPD75P48GC-AB8) cannot be

fully tested by NEC before shipment. It is therefore recommended that you implement screening to verify

the PROM after necessary data have been written to it, and after the PROM has been stored at high temperature

under the following conditions:

Storage Temperature Storage Time

125 ˚C 24 hours

★

17

5. ELECTRICAL SPECIFICATIONS

★

ABSOLUTE MAXIMUM RATINGS (Ta = 25°C)

Parameter Symbol Conditions Ratings Unit

Supply Voltage VDD -0.3 to +7.0 V

Input Voltage VI1 Other than ports 4, 5, 10 -0.3 to VDD+0.3 V

VI2 Ports 4, 5, 10 w/pull-up -0.3 to VDD+0.3

Output Voltage VO -0.3 to VDD+0.3 V

High-Level Output IOH 1 pin -10 mA

Current

Low-Level Output IOL

Current

Operating Temperature Topt -10 to +70 °C

Storage Temperature Tstg -65 to +150 °C

Note

µ

PD75P048

resistor

Open drain -0.3 to +11 V

All pins -30 mA

Ports 0, 3, 4, 5 Peak 30 mA

1 pin

Other than ports 0, 3, 4, 5 Peak 20 mA

1 pin

Total of ports 0, 3 - 9, 11 Peak 170 mA

Total of ports 0, 2, 10 Peak 30 mA

rms 15 mA

rms 5 mA

rms 120 mA

rms 20 mA

V

Note rms = Peak value x √Duty

Caution Even if one of the parameters exceeds its absolute maximum rating even momentarily, the quality

of the product may be degraded. The absolute maximum rating therefore specifies the upper or

lower limit of the value at which the product can be used without physical damages. Be sure not

to exceed or fall below this value when using the product.

EEPROM RATINGS (T

Parameter Symbol Conditions Ratings Unit

Write Times — 100,000 times

Data Retention Time — 10 years

a = -10 to +70°C, VDD = 2.7 to 6.0 V)

CAPACITANCE (Ta = 25°C, VDD = 0 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input Capacitance CI f = 1 MHz 15 pF

Output Capacitance CO Pins other than those measured are at 0 V 15 pF

Input/Output CIO

15 pF

18

MAIN SYSTEM CLOCK OSCILLATOR CIRCUIT CHARACTERISTICS

(Ta = -10 to +70°C, VDD = 2.7 to 6.0 V)

µ

PD75P048

Oscillator

Ceramic Oscillation VDD = oscillation

Crystal Oscillation

External Clock X1 input frequency

Recommended

Constants

X1 X2

C1 C2

VDD

X1 X2

C1 C2

VDD

X1 X2

µ

PD74HCU04

Item Conditions MIN. TYP. MAX. Unit

Note 2

Note 2

Note 1

Note 1

voltage range

MIN. value of

oscillation voltage

range

2.0 5.0

2.0 4.19 5.0

2.0 5.0

Note 3

MHz

4ms

Note 3

MHz

10 ms

30 ms

Note 3

MHz

frequency(fX)

Oscillation stabiliza- After VDD come to

tion time

frequency (fX)

Oscillation stabiliza- VDD = 4.5 to 6.0 V

tion time

Note 1

(fX)

X1 input high-,

low-level widths 100 250 ns

(tXH, tXL)

Note 1. Only to express the characteristics of the oscillator circuit. For instruction execution time, refer to

AC Characteristics.

2. Time required for oscillation to stabilize after VDD has reached the minimum volue of the oscillation

voltage range or the STOP mode has been released.

3. When the oscillation frequency is 4.19 MHz < fx ≤ 5.0 MHz, do not select PCC = 0011 as the instruction

µ

execution time: otherwise, one machine cycle is set to less than 0.95

µ

minimum value of 0.95

s.

s, falling short of the rated

Caution When using the oscillation circuit of the main system clock, wire the portion enclosed in dotted

line in the figures as follows to avoid adverse influences on the wiring capacity:

• Keep the wiring length as short as possible.

• Do not cross the wiring over the other signal lines.

• Do not route the wiring in the vicinity of lines through which a high alternating current flows.

• Always keep the ground point of the capacitor of the oscillator circuit at the same potential as

DD. Do not connect the ground pattern through which a high curent flows.

V

• Do not extract signals from the oscillation circuit.

19

SUBSYSTEM CLOCK OSCILLATOR CIRCUIT CHARACTERISTICS

(Ta = -10 to +70°C, VDD = 2.7 to 6.0 V)

µ

PD75P048

Oscillator

Crystal Oscillation

External Clock XT1 input frequency

Recommended

Constants

XT1 XT2

C3 C4

V

DD

XT1 XT2

Item Conditions MIN. TYP. MAX. Unit

frequency (fXT)

R

Oscillation stabiliza- VDD = 4.5 to 6.0 V

tion time

Note 1

(fXT)

XT1 input high-,

low-level widths

(tXTH, tXTL)

Note 1

Note 2

32 32.768 35 kHz

1.0 2 s

10 s

32 100 kHz

515

µ

s

Note 1. Indicates only the characteristics of the oscillator circuit. For instruction execution time, refer to AC

Characteristics.

2. Time required for oscillation to stabilize after V

DD has reached the minimum value of the oscillation

voltage range.

Caution When using the oscillation circuit of the subsystem clock, wire the portion enclosed in dotted line

in the figures as follows to avoid adverse influences on the wiring capacity:

• Keep the wiring length as short as possible.

• Do not cross the wiring over the other signal lines.

• Do not route the wiring in the vicinity of lines through which a high alternating current flows.

• Always keep the ground point of the capacitor of the oscillator circuit at the same potential as

DD. Do not connect the ground pattern through which a high current flows.

V

• Do not extract signals from the oscillation circuit.

The amplification factor of the subsystem clock oscillation circuit is designed to be low to reduce

the current dissipation and therefore, the subsystem clock oscillation circuit is influenced by noise

more easily than the main system clock oscillation circuit. When using the subsystem clock,

therefore, exercise utmost care in wiring the circuit.

20

µ

PD75P048

DC CHARACTERISTICS (Ta = -10 to +70°C, VDD = 2.7 to 6.0 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

High-Level Input VIH1 Ports 2,3,8,9,11 0.7VDD VDD V

Voltage

Low-level Input VIL1 Ports 2-5, 8-11 0 0.3VDD V

Voltage

High-Level Output VOH VDD = 4.5 to 6.0V, IOH = -1 mA VDD-1.0 V

Voltage

Low-Level Output VOL Ports 3,4,5 VDD = 4.5 to 6.0V,

Voltage IOL = 15mA

High-Level Input ILIH1 VI = VDD Other than below 3

Leakage Current

Low-Level Input ILIL1 VI = 0V Other than below -3

Leakage Current

High-Level Output ILOH1 VO = VDD Other than below 3

Leakage Current

Low-Level Output ILOL VO = 0V

Leakage Current

Internal Pull-Up Resistor RU1 Ports 0,1,2,3,6,7,8 VDD = 5.0V±10% 15 40 80 kΩ

Internal Pull-Down RD Port 9 VIN = VDD VDD = 5.0V±10% 15 40 70 kΩ

Resistor

VIH2 Ports 0,1,6,7, RESET 0.8VDD VDD V

VIH3 Ports 4,5,10 w/pull-up resistor 0.7VDD VDD V

Open-drain 0.7VDD 10 V

VIH4 X1, X2, XT1, XT2 VDD-0.5 VDD V

VIL2 Ports 0, 1, 6, 7, RESET 0 0.2VDD V

VIL3 X1, X2, XT1, XT2 0 0.4 V

IOH = -100 µA VDD-0.5 V

0.4 2.0 V

VDD = 4.5 to 6.0V, IOL = 1.6 mA 0.4 V

IOL = 400 µA 0.5 V

SB0, 1 Open-drain pull-up

ILIH2 X1,X2,XT1 20

ILIH3 VI = 9V Ports 4,5,10

ILIL2 X1,X2,XT1 -20

ILOH2 VO = 9V Ports 4,5,10

(except P00) VI = 0V

RU2 Ports 4,5,10 VDD = 5.0V±10% 15 40 70 kΩ

VO = VDD-2.0 V

resistor ≥ 1 kΩ

(open-drain)

(open-drain)

VDD = 3.0V±10% 30 300 kΩ

VDD = 3.0V±10% 10 60 kΩ

VDD = 3.0V±10% 10 60 kΩ

0.2VDD V

20

20

-3

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

21

µ

PD75P048

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Supply IDD1 4.19MHz crystal VDD = 5V±10%

Note 1

Current

IDD2

IDD3 32.768kHz

IDD4 HALT mode VDD = 3V±10% 35 110

IDD5 XT1 = 0V VDD = 5V±10% 0.5 20

IDD6 32.768kHz oscillator VDD = 3V±10%

oscillator

C1 = C2 = 22pF

Note 4

crystal oscillator mode

STOP mode VDD = 3V±10% 0.3 10

STOP mode

VDD = 3V±10%

HALT mode VDD = 5V±10% 900 2700

Operation VDD = 3V±10%

Note 2

Note 3

VDD = 3V±10% 450 1400

Ta = 25°C 5

Note 5

5.5 17 mA

1.7 5.1 mA

100 300

620

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

Note 1. Current flowing through internal pull-up resistor. Current flowing when EEPROM is accessed is not

included.

2. When µPD75048 operates in high-speed mode with processor clock control register (PCC) set to 0011.

µ

3. When

PD75048 operates in low-speed mode with PCC set to 0000.

4. When the system clock control register (SCC) is set to 1001, the oscillation of the main system clock

is stopped, and the subsystem clock is used.

5. When STOP instruction is executed with SCC set to 0000.

Note Supply current when EEPROM is accessed is shown in EEPROM Characteristics.

22

µ

PD75P048

AC CHARACTERISTICS (Ta = -10 to +70°C, VDD = 2.7 to 6.0 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

CPU Clock Cycle Time tCY w/main system clock VDD = 4.5 to 6.0V 0.95 32

(Minimum Instruction

Execution Time

= 1 Machine Cycle)

TI0 Input Frequency fTI VDD = 4.5 to 6.0 V 0 1 MHz

TI0 Input High-, Low- tTIH, VDD = 4.5 to 6.0 V 0.48

Level Widths t

Interrupt Input High-, tINTH, INT0

Low-Level Widths t

RESET Low-Level Width tRSL 10

Note 1

TIL

INTL

w/subsystem clock

INT1, 2, 4 10

KR0-7 10

3.8 32

114 122 125

0 275 kHz

1.8

Note 2

Note 1. The CPU clock (Φ) cycle time is de-

termined by the oscillation frequency

of the connected oscillator, system

clock control register (SCC), and

processor clock control register (PCC).

The figure on the right is cycle time t

vs. supply voltage VDD characteristics

at the main system clock.

tCY or 128/fX depending on the set-

2. 2

ting of the interrupt mode register

(IM0).

CY

32

6

5

4

3

µ

tCY vs VDD

(with main system clock)

Operation

quaranteed

range

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

2

Cycle time tCY [ s]

1

0.5

0123 4 56

Supply voltage V

DD [V]

23

µ

SERIAL TRANSFER OPERATION

Two-Line and Three-Line Serial I/O Modes (SCK: internal clock output)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

SCK Cycle Time tKCY1 VDD = 4.5 to 6.0 V 1600 ns

3800 ns

SCK High-, Low-Level tKL1 VDD = 4.5 to 6.0 V tKCY1/2-50 ns

Widths

SI Set-Up Time (vs. SCK ↑) tSIK1 150 ns

SI Hold Time (vs. SCK ↑ ) tKSI1 400 ns

SCK ↓→ SO Output tKSO1 RL = 1kΩ,

Delay Time CL = 100pF

TWO-LINE AND THREE-LINE SERIAL I/O MODES (SCK: external clock input)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

SCK Cycle Time tKCY2 VDD = 4.5 to 6.0V 800 ns

SCK High-, Low-Level tKL2 VDD = 4.5 to 6.0V 400 ns

Widths

SI Set-Up Time (vs. SCK ↑) tSIK2 100 ns

SI Hold Time (vs. SCK ↑) tKSI2 400 ns

SCK ↓→ SO Output tKSO2 RL = 1kΩ, CL = 100 pF

Delay Time

Note RL and CL are load resistance and load capacitance of the SO output line.

tKH1 tKCY1/2-150 ns

Note

VDD = 4.5 to 6.0V 250 ns

1000 ns

3200 ns

tKH2 1600 ns

Note

VDD = 4.5 to 6.0V 300 ns

1000 ns

PD75P048

24

µ

PD75P048

SBI MODE (SCK: internal clock output (master))

Parameter Symbol Conditions MIN. TYP. MAX. Unit

SCK Cycle Time tKCY3 VDD = 4.5 to 6.0 V 1600 ns

3800 ns

SCK High-, Low-Level tKL3 VDD = 4.5 to 6.0 V tKCY3/2-50 ns

Widths t

SB0, 1 Set-Up Time tSIK3

(vs. SCK ↑ )

SB0, 1 Hold Time tKSI3

(vs. SCK ↑ )

SCK ↓→ SB0, 1 Output tKSO3 RL = 1kΩ,

Delay Time

SCK ↑→ SB0, 1 ↓ tKSB tKCY3 ns

SB0,1 ↓→ SCK tSBK tKCY3 ns

SB0, 1 Low-Level Width tSBL tKCY3 ns

SB0, 1 High-Level Width tSBH tKCY3 ns

KH3

CL = 100pF

tKCY3/2-150 ns

150 ns

tKCY3/2 ns

Note

VDD = 4.5 to 6.0V 0 250 ns

0 1000 ns

SBI MODE (SCK: external clock input (slave))

Parameter Symbol Conditions MIN. TYP. MAX. Unit

SCK Cycle Time tKCY4 VDD = 4.5 to 6.0 V 800 ns

3200 ns

SCK Ligh-, Low-Level tKL4 VDD = 4.5 to 6.0 V 400 ns

Widths tKH4

SB0, 1 Set-Up Time tSIK4

(vs. SCK ↑ )

SB0, 1 Hold Time tKSI4

(vs. SCK ↑ )

SCK ↓→ SB0, 1 Output tKSO4 RL = 1kΩ,

Delay Time

SCK ↑→ SB0, 1 ↓ tKSB tKCY4 ns

SB0,1 ↓→ SCK ↓ tSBK tKCY4 ns

SB0, 1 Low-Level Width tSBL tKCY4 ns

SB0, 1 High-Level Width tSBH tKCY4 ns

CL = 100pF

Note

VDD = 4.5 to 6.0V 0 300 ns

1600 ns

100 ns

tKCY4/2 ns

0 1000 ns

Note RL and CL are load resistance and load capacitance of the SB0 and SB1 output lines.

25

µ

A/D CONVERTER (Ta = -10 to +70°C, VDD = 2.7 to 6.0V, AVSS = VSS = 0V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Resolution 8 8 8 bit

Note 2

Note 3

Note 1

2.5V ≤ AVREF ≤ VDD ±1.5 LSB

tCONV 168/fX

tSAMP 44/fX

µ

s: fX = 4.19 MHz)

Absolute Accuracy

Conversion Time

Sampling Time

Analog Input Voltage VIAN AVREF- AVREF+ V

Analog Supply Voltage AVDD 2.5 VDD V

Reference Input Voltage AVREF+ 2.5V ≤ (AVref+) – (AVref-) 2.5 AVDD V

Reference Input Voltage AVREF- 2.5V ≤ (AVref+) – (AVref-) 0 1.0 V

Analog Input Impedance RAN 1000 MΩ

AVREF Current AIREF 0.25 2.0 mA

Note 1. Absolute accuracy excluding quantization error (±1–2LSB)

2. Time since execution of conversion start instruction until end of conversion (EOC = 1) (40.1 µs: fX = 4.19

MHz)

3. Time since execution of conversion start instruction until end of sampling (10.5

PD75P048

µ

s

µ

s

26

AC TIMING TEST POINT (excluding X1 and XT1 inputs)

0.8 V

DD

Test points

0.2 VDD

CLOCK TIMING

t

XL

1/f

µ

PD75P048

0.8 VDD

0.2 VDD

X

t

XH

TI0 TIMING

X1 input

XT1 input

1/f

XT

t

XTL

t

1/fTI

tTIL tTIH

XTH

V

DD

0.4 V

V

DD

0.4 V

–0.5V

–0.5V

TI0

27

SERIAL TRANSFER TIMING

THREE-LINE SERIAL I/O MODE:

SCK

µ

PD75P048

t

KCY1

t

KL1

t

SIK1

t

KH1

t

KSI1

SI

SO

TWO-LINE SERIAL I/O MODE:

SCK

t

KS01

Input data

tKCY2

tKL2

tSIK2 tKSI2

Output data

tKH2

28

SB0,1

tKSO2

SERIAL TRANSFER TIMING

BUS RELEASE SIGNAL TRANSFER:

SCK

t

KSB

SB0,1

COMMAND SIGNAL TRANSFER:

µ

PD75P048

t

KCY3,4

t

KL3,4

t

t

t

SBL

SBH

SBK

t

KH3,4

t

KS03,4

t

SIK3,4

t

KSI3,4

SCK

SB0,1

INTERRUPT INPUT TIMING

INT0, 1, 2, 4

KR0-7

RESET INPUT TIMING

tKCY3,4

tKL3,4

tKH3,4

tSBKtKSB

tINTL tINTH

tKS03,4

tSIK3,4

tKSI3,4

RESET

tRSL

29

µ

PD75P048

EEPROM CHARACTERISTICS

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Supply current for IDD7 4.19MHz crystal oscillator VDD = 5V+10%

EEPROM access

Note 1

C1 = C = 22pF

VDD = 3V+10%

Note 2

Note 3

6.5 20 mA

26mA

Note 1. Current flowing through the internal pull-up resistor is not included.

2. When the processor clock control register (PCC) is set to 0011 and the high-speed mode is used.

3. When PCC is set to 0000 and the low-speed mode is used.

EEPROM WRITE TIME

Select the write time of the EEPROM in accordance with the oscillation frequency of the main system clock

as follows:

Oscillation Frequency of Main Setting of EEPROM Control Register

System Clock (fX)

fX = 2.0 to 5.0 MHz 0 0 212 x 18/fX (17.6 ms)

fX = 2.0 to 4.2 MHz 0 1 211 x 18/fX (8.8 ms)

fX = 2.0 MHz 1 0 210 x 18/fX

EWTC1 EWTC0

Write time

Remarks ( ): fX = 4.19 MHz

LOW-VOLTAGE DATA RETENTION CHARACTERISTICS OF DATA MEMORY IN STOP MODE

(Ta = –10 to +70°C)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Data Retention Supply VDDDR

Voltage

Data Retention Supply

Note 1

Current

Release Signal Set Time tSREL 0

Oscillation Stabilization

Wait Time

Note 2

IDDDR VDDDR = 2.0 V

tWAIT Released by RESET 217/fX ms

Released by interrupt request ms

2.0 6.0 V

0.1 10

Note 3

Note 1. Does not include current flowing through internal pull-up resistor

2. The oscillation stabilization wait time is the time during which the CPU is stopped to prevent unstable

operation when oscillation is started.

3. Depends on the setting of the basic interval timer mode register (BTM) as follows:

µ

A

µ

s

BTM3 BTM2 BTM1 BTM0 WAIT time ( ): fX = 4.19 MHz

– 0 0 0 220/fX (approx. 250 ms)

– 0 1 1 217/fX (approx. 31.3 ms)

– 1 0 1 215/fX (approx. 7.82 ms)

–1112

13

/fX (approx. 1.95 ms)

30

DATA RETENTION TIMING (releasing STOP mode by RESET)

Internal reset operation

HALT mode

STOP mode

Data retention mode

DD

V

STOP instruction

execution

RESET

VDDDR

tSREL

DATA RETENTION TIMING (standby release signal: releasing STOP mode by interrupt)

µ

PD75P048

tWAIT

Operation

mode

DD

V

STOP instruction execution

Standby release signal

(interrupt request)

STOP mode

Data retention mode

VDDDR

HALT mode

Operation

mode

tSREL

tWAIT

31

★

6. PERFORMANCE CURVE (REFERENCE VALUE)

10

DD vs VDD (Crystal oscillation)

I

µ

PD75P048

(T = 25 °C)

a

5.0

1.0

0.5

0.1

High-speed mode PCC = 0011

Medium-speed mode

Low-speed mode PCC = 0000

Main system clock

HALT mode

Subsystem clock operation mode

Main system lock stopped

Main system clock stopped

Subsystem clock HALT mode

PCC = 0010

+

+

Supply current IDD [mA]

0.05

Main system clock STOP mode

Subsystem clock oscillation

0.01

X1 X2 XT1 XT2

0.005

0.001

01234567

Crystal

oscillator

4.19 MHz

22 pF 22 pF 22 pF22 pF

V

DD VDD

Crystal

oscillator

32.768 kHz

Supply voltage VDD [V]

+

330 k

Ω

Note Does not include current flowing through EEPROM.

32

10

5.0

I

DD

vs VDD (Crystal oscillation)

µ

PD75P048

(T = 25 °C)

a

High-speed mode PCC = 0011

1.0

0.5

[mA]

DD

0.1

Supply current I

0.05

Medium-speed mode

Low-speed mode PCC = 0000

Main system clock

HALT mode

Subsystem clock operation mode

Main system clock stopped

Subsystem clock HALT mode

Main system clock stopped

Main system clock STOP mode

Subsystem clock oscillation

PCC = 0010

+

+

+

0.01

X1 X2 XT1 XT2

0.005

0.001

01234567

Crystal

oscillator

2.0 MHz

22 pF 22 pF 22 pF22 pF

V

DD

Crystal

oscillator

32.768 kHz

V

DD

Supply voltage VDD [V]

Note Does not include current flowing through EEPROM.

330 k

Ω

33

7. PACKAGE DRAWINGS

64 PIN PLASTIC SHRINK DIP (750 mil)

64 33

A

µ

PD75P048

321

K

I

J

H

G

NOTE

Each lead centerline is located within 0.17 mm (0.007 inch) of

1)

its true position (T.P.) at maximum material condition.

Item "K" to center of leads when formed parallel.2)

F

M

D

N

L

B

C

ITEM MILLIMETERS INCHES

A

B

C

D

F

G

H

I

J

K

L

M

N

R

M

58.68 MAX.

1.78 MAX.

1.778 (T.P.)

0.50±0.10

0.9 MIN.

3.2±0.3

0.51 MIN.

4.31 MAX.

5.08 MAX.

19.05 (T.P.)

17.0

+0.10

0.25

–0.05

0.17

0~15°

2.311 MAX.

0.070 MAX.

0.070 (T.P.)

0.020

0.035 MIN.

0.126±0.012

0.020 MIN.

0.170 MAX.

0.200 MAX.

0.750 (T.P.)

0.669

0.010

0.007

0~15°

P64C-70-750A,C-1

+0.004

–0.005

+0.004

–0.003

R

34

64 PIN PLASTIC QFP ( 14)

µ

PD75P048

A

B

48

49

64

F

1

G

H

M

I

P

N

NOTE

Each lead centerline is located within 0.15

mm (0.006 inch) of its true position (T.P.) at

maximum material condition.

33

32

detail of lead end

C

D

S

Q

17

16

J

K

M

L

ITEM MILLIMETERS INCHES

A

B

C

D

F

G

H

I

J

K

L

M

N

17.6±0.4

14.0±0.2

14.0±0.2

17.6±0.4

1.0

1.0

0.35±0.10

0.15

0.8 (T.P.)

1.8±0.2

0.8±0.2

+0.10

0.15

–0.05

0.15

P 2.55 0.100

Q

0.1±0.1

S 2.85 MAX. 0.112 MAX.

5°±5°

P64GC-80-AB8-2

0.693±0.016

+0.009

0.551

–0.008

+0.009

0.551

–0.008

0.693±0.016

0.039

0.039

+0.004

0.014

–0.005

0.006

0.031 (T.P.)

0.071±0.008

+0.009

0.031

–0.008

+0.004

0.006

–0.003

0.006

0.004±0.004

35

★

8. RECOMMENDED SOLDERING CONDITIONS

It is recommended that µPD75P048 be soldered under the following conditions. For details on the recommended

soldering conditions, refer to Information Document "Semiconductor Devices Mounting Manual" (IEI-1207). For

other soldering methods and conditions, consult NEC.

Table 8-1 Soldering Conditions of Surface-Mount Type

µ

PD75P048GC-AB8: 64-pin plastic QFP ( 14 mm)

µ

PD75P048

Soldering Method Soldering Conditions

Infrared Reflow Package peak temperature: 235°C, IR35-00-2

time: 30 seconds max. (210°C min.),

number of times: 2 max.

<Caution>

(1) Start second reflow after device temperature

(which has risen because of first reflow) has returned to

room temperature.

(2) Do not clean flux with water after first reflow.

VPS Package peak temperature: 215°C, VP15-00-2

time: 40 seconds max. (200°C min.),

number of times: 1 max.

<Caution>

(1) Start second reflow after device temperature

(which has risen because of first reflow) has returned to

room temperature.

(2) Do not clean flux with water after first reflow.

Pin Partial Heating Pin temperature: 300°C max., —

time: 3 seconds max. (per side)

Symbol for Recommended

Condition

Caution Do not use two or more soldering methods in combination (except the pin partial heating method).

Table 8-2 Soldering Conditions of Through-Hole Type

µ

PD75P048CW: 64-pin plastic shrink DIP (750 mil)

Soldering Method Soldering Conditions

Wave soldering Soldering bath temperature: 260°C max.,

(lead parts only) time: 10 seconds max.,

Pin Partial Heating Pin temperature: 260oC max.,

time: 10 seconds max.

Caution The wave soldering must be performed at the lead part only. Note that the soldering must not be

directly contacted to the board.

36

µ

PD75P048

APPENDIX A. DEVELOPMENT TOOLS

The following development tools are readily available to support development of systems using µPD75P048:

Hardware IE-75000-R

IE-75001-R

IE-75000-R-EM

EP-75028CW-R Common emulation probe commonly used with µPD75028CW

EP-75028GC-R Emulation probe commonly used with µPD75028GC, provided with

PG-1500 PROM programmer

PA-75P036CW PROM programmer adapter commonly used with µPD75P036. It is connected

PA-75P036GC PROM programmer adapter commonly used with µPD75P036GC. It is connected

Software IE Control Program Host machine

PG-1500 Controller PC-9800 series (MS-DOSTM Ver. 3.30 to Ver. 5.00A

RA75X Relocatable IBM PC/ATTM (Refer to OS for IBM PC.)

Assembler

Note 1. Maintenance product

2. Not provided with IE-75001-R.

3. Ver. 5.00/5.00A has a task swap function, but this function cannot be used with this software.

Note 1

Note 2

EV-9200GC-64

In-circuit emulator for 75X series

Emulation board for IE-75000-R and IE-75001-R

EV-9200GC-64, 64-pin conversion socket

to PG-1500.

to PG-1500.

Note 3

)

★

Remarks For development tools from other companies, refer to 75X Series Selection Guide (IF-1027).

OS for IBM PC

As OS for IBM PC, the followings are supported.

OS Version

PC DOS

MS-DOS Ver. 3.30 to Ver. 5.00A

IBM DOS

TM

TM

Ver. 5.02 to Ver. 6.1

Note 2

5.0/V

J5.02/V

Note 2

Note 1

Note 1. Version later than 5.0 have a task swap function, but this function cannot be used with this software.

2. This supports English mode only.

37

APPENDIX B. RELATED DOCUMENTS

★

Documents related to device

Document Document No.

User’s manual IEU-1278

Instruction list —

75X series selection guide IF-1027

Documents related to development tools

Hardware IE-75000-R/IE-75001-R user’s manual EEU-1416

IE-75000-R-EM user’s manual EEU-1294

EP-750028CW-R user’s manual EEU-1314

EP-75028GC-R user’s manual EEU-1306

PG-1500 user’s manual EEU-1335

Software RA75X assembler package user’s manual Operation EEU-1346

PG-1500 controller user’s manual EEU1291

µ

PD75P048

Doument Document No.

Language EEU-1343

Other related documents

Document Document No.

Package manual IEI-1213

Semiconductor device - mounting maual IEI-1207

NEC semiconductor device quality grade IEI-1209

NEC semiconductor device reliabiliy quality control —

Static electricity discharge (ESD) test —

Semiconductor device quality guarantee guide MEI-1202

Product guide related to microcomputer - other manufacturers —

Note The documents listed above are subject to change without notice. Be sure to use the latest document

for designing.

38

µ

PD75P048

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction of

the gate oxide and ultimately degrade the device operation. Steps must be

taken to stop generation of static electricity as much as possible, and quickly

dissipate it once, when it has occurred. Environmental control must be

adequate. When it is dry, humidifier should be used. It is recommended to

avoid using insulators that easily build static electricity. Semiconductor

devices must be stored and transported in an anti-static container, static

shielding bag or conductive material. All test and measurement tools including

work bench and floor should be grounded. The operator should be grounded

using wrist strap. Semiconductor devices must not be touched with bare

hands. Similar precautions need to be taken for PW boards with semiconductor

devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input

level may be generated due to noise, etc., hence causing malfunction. CMOS

devices behave differently than Bipolar or NMOS devices. Input levels of CMOS

devices must be fixed high or low by using a pull-up or pull-down circuitry. Each

unused pin should be connected to VDD or GND with a resistor, if it is considered

to have a possibility of being an output pin. All handling related to the unused

pins must be judged device by device and related specifications governing the

devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Production

process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset

function have not yet been initialized. Hence, power-on does not guarantee

out-pin levels, I/O settings or contents of registers. Device is not initialized

until the reset signal is received. Reset operation must be executed immedi-

ately after power-on for devices having reset function.

39

[MEMO]

µ

PD75P048

NEC is manufacturing and selling the products under microcomputer (with

on-chip EEPROM) patent license with the BULL CP8.

This product should not be used for IC cards (SMART CARD).

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

The devices listed in this document are not suitable for use in aerospace equipment, submarine cables, nuclear

reactor control systems and life support systems. If customers intend to use NEC devices for above applications

or they intend to use "Standard" quality grade NEC devices for applications not intended by NEC, please contact

our sales people in advance.

Application examples recommended by NEC Corporation

Standard: Computer, Office equipment, Communication equipment, Test and Measurement equipment,

Machine tools, Industrial robots, Audio and Visual equipment, Other consumer products, etc.

Special: Automotive and Transportation equipment, Traffic control systems, Antidisaster systems, Anticrime

systems, etc.

M4 92.6

MS-DOS is a trademark of Microsoft Corporation.

IBM DOS, PC/AT and PC DOS are trademarks of IBM Corporation.

Loading...

Loading...