DATA SHEET

MOS INTEGRATED CIRCUIT

PD16676

µµµµ

1/16, 1/32 DUTY LCD CONTROLLER/DRIVER

DESCRIPTION

µPD16676 is a controller/driver containing RAMs capable of full-dot LCD displays. One of these IC chips can drive

the full-dot LCD up to 61-by-16 dots.

These ICs are the most suitable for Kanji character or Chinese character pagers, as well as graphic pagers,

displaying 16-by-16 dots per character.

FEATURES

LCD driver with built-in display RAM

•

Dot display RAM: 2560 bits

•

Output: 61 segments & 16 commons

•

8-bit parallel interface

•

Oscillation circuit incorporated

•

•

ORDERING INFORMATION

Part Number Package

PD16676P Chips

µ

PD16676W Wafer

µ

PD16676GF-3BA 100-PIN PLASTIC QFP (14 x 20 mm)

µ

Remark

Purchasing the above products in terms of chips per wafer requires an exchange of other documents as

well, including a memorandum of the product quality. Therefore, those who are interested in this regard

are advised to contact an NEC salesperson for further details.

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. S10561EJ5V0DS00 (5th edition)

Date Published June 1999 NS CP(K)

Printed in Japan

The mark

••••

shows major revised points.

©

1996

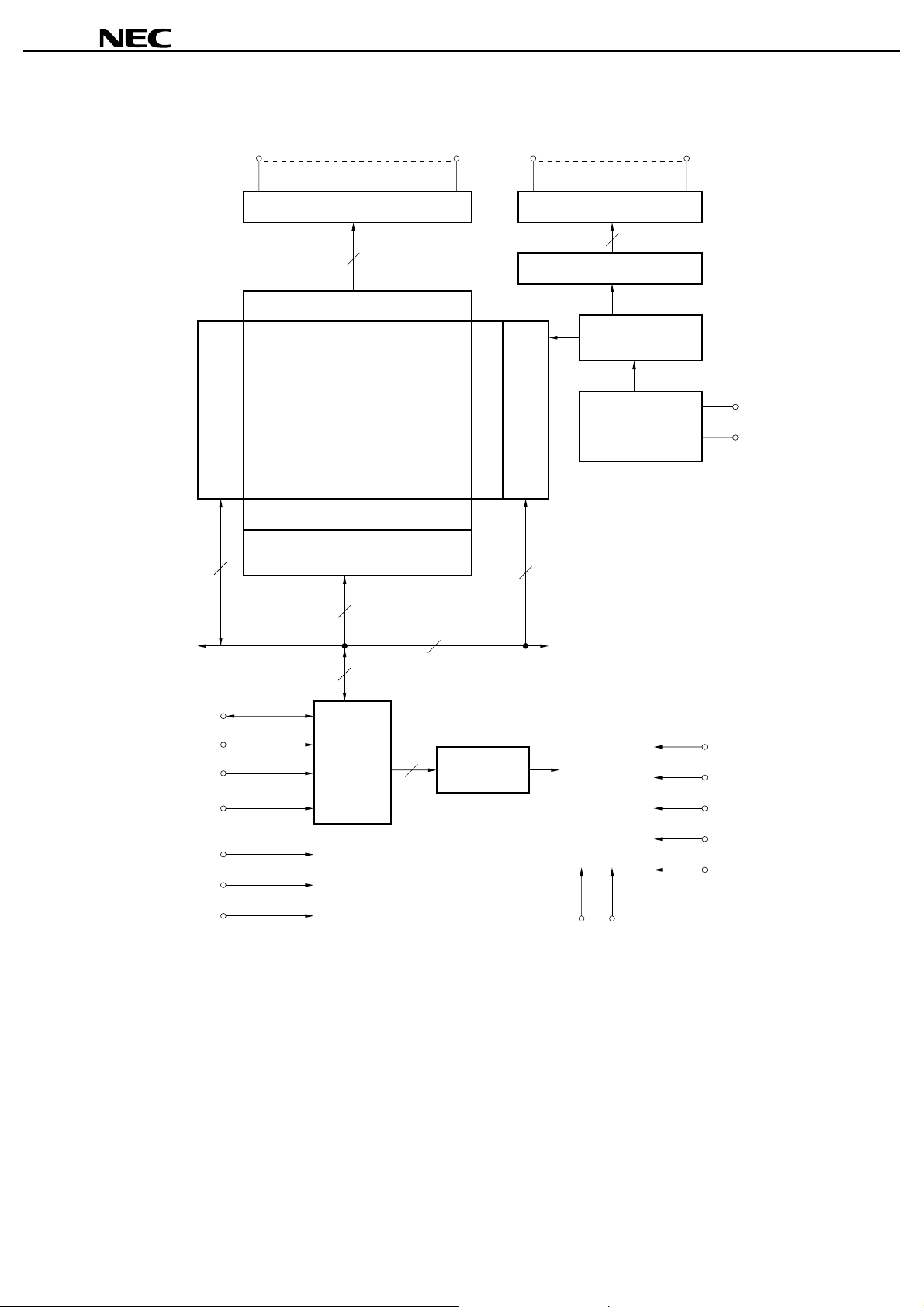

1. BLOCK DIAGRAM

SEG

µµµµ

PD16676

0

SEG

60

COM

0

COM

15

RAM Read/Write

Controller

Column Address Decoder

8

Segment Driver

61

61-bit Latch

Display Data RAM

(2560 bits)

Column Address

Counter & Register

8

Line Preset

Line Address Decoder

8

Common Driver

16

Common Counter

Timing

Generator

Internal

Oscillator

Register & Counter

8

OSC

OSC

1

2

Remark

DB0-DB

7

A0

E(/RD)

R,/W(/WR)

/RESET

M,/S

FR

/xxx indicates active low signals.

8

Parallel

Interface

8

Command

Decoder

VDDV

V

LC1

V

LC2

V

LC3

V

LC4

V

LC5

SS

2

Data Sheet S10561EJ5V0DS00

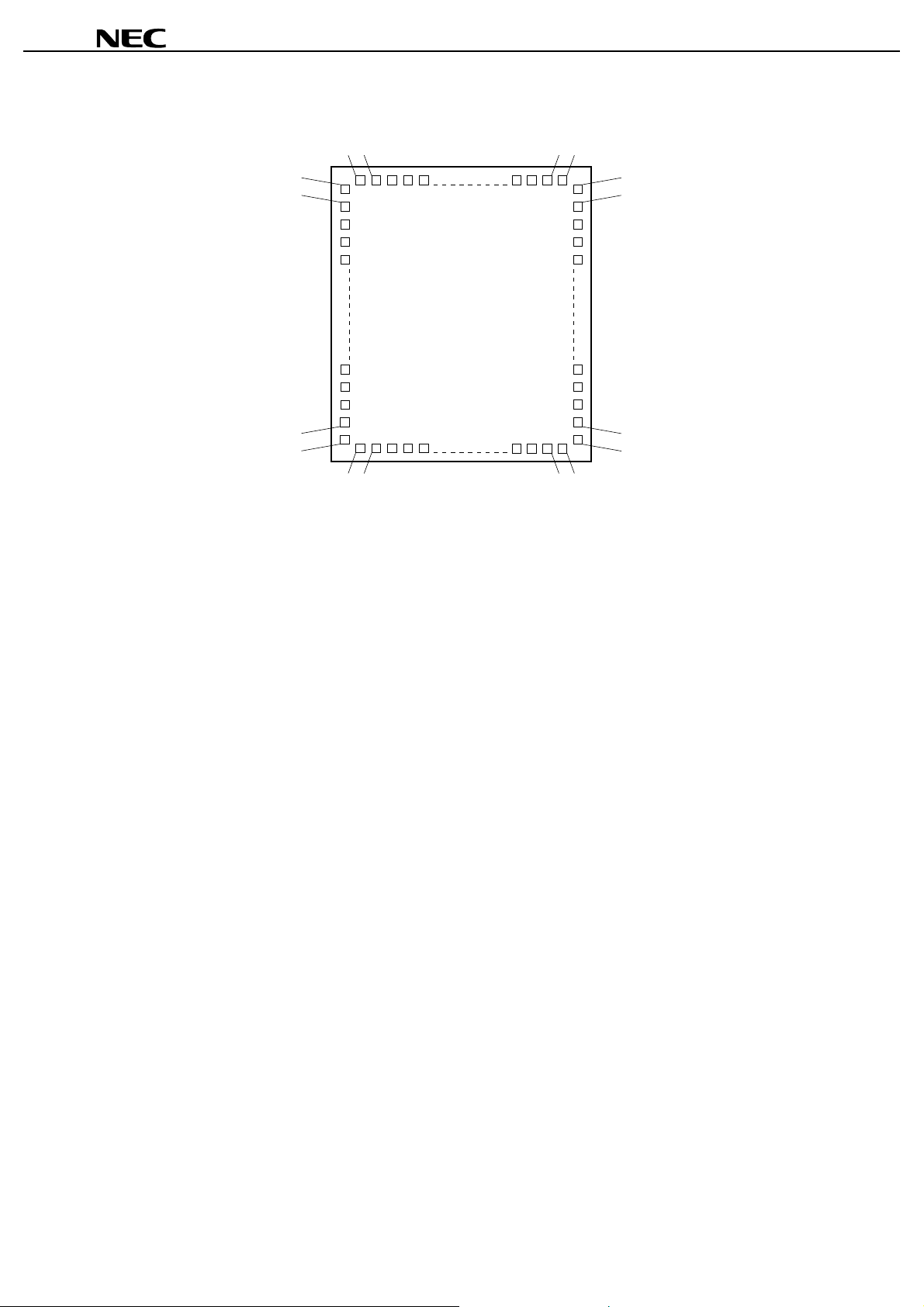

2. PIN CONFIGURATION (Pad Layout)

5049 3231

µµµµ

PD16676

51

52

79

80

30

29

2

1

9981 82

100

Data Sheet S10561EJ5V0DS00

3

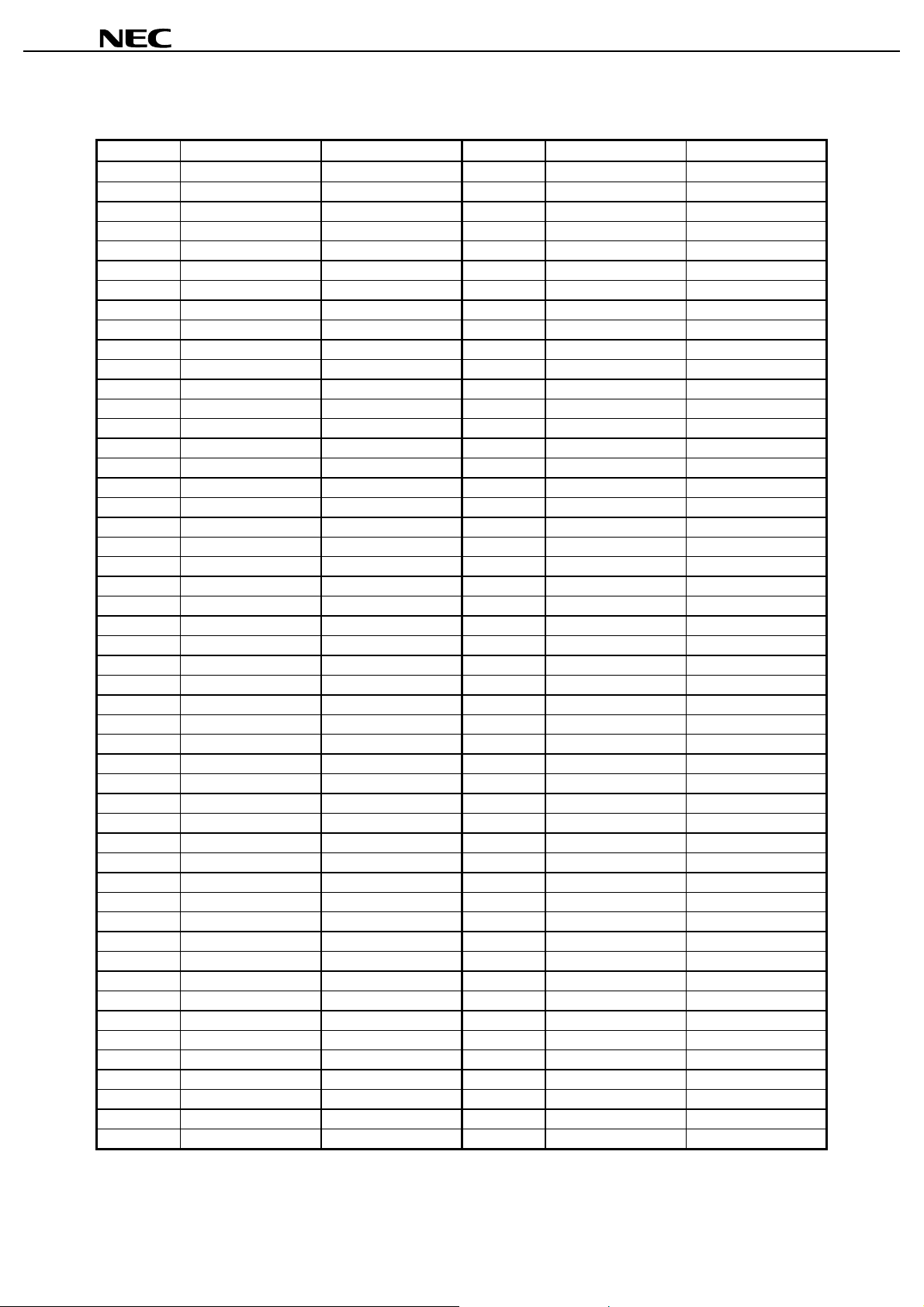

3. PIN CONNECTION

Pin No. Pin Symbol I/O Pin No. Pin Symbol I/O

1COM5Output 51 SEG

2COM6Output 52 SEG

3COM7Output 53 SEG

4COM8Output 54 SEG

5COM9Output 55 SEG

6COM10Output 56 SEG

7COM11Output 57 SEG

8COM12Output 58 SEG

9COM13Output 59 SEG

10 COM

11 COM

12 SEG

13 SEG

14 SEG

15 SEG

16 SEG

17 SEG

18 SEG

19 SEG

20 SEG

21 SEG

22 SEG

23 SEG

24 SEG

25 SEG

26 SEG

27 SEG

28 SEG

29 SEG

30 SEG

31 SEG

32 SEG

33 SEG

34 SEG

35 SEG

36 SEG

37 SEG

38 SEG

39 SEG

40 SEG

41 SEG

42 SEG

43 SEG

44 SEG

45 SEG

46 SEG

47 SEG

48 SEG

49 SEG

50 SEG

14

15

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

Output 60 SEG

Output 61 SEG

Output 62 SEG

Output 63 SEG

Output 64 SEG

Output 65 SEG

Output 66 SEG

Output 67 SEG

Output 68 SEG

Output 69 SEG

Output 70 SEG

Output 71 SEG

Output 72 SEG

Output 73 A0 Input

Output 74 OSC

Output 75 OSC

Output 76 E(/RD) Input

Output 77 R,/W(/WR) Input

Output 78 V

Output 79 DB

Output 80 DB

Output 81 DB

Output 82 DB

Output 83 DB

Output 84 DB

Output 85 DB

Output 86 DB

Output 87 V

Output 88 /RESET Input

Output 89 FR Input/Output

Output 90 V

Output 91 V

Output 92 V

Output 93 M,/S Input

Output 94 V

Output 95 V

Output 96 COM

Output 97 COM

Output 98 COM

Output 99 COM

Output 100 COM

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1

2

SS

0

1

2

3

4

5

6

7

DD

LC5

LC3

LC2

LC4

LC1

0

1

2

3

4

µµµµ

PD16676

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Input

Output

—

Input/Output

Input/Output

Input/Output

Input/Output

Input/Output

Input/Output

Input/Output

Input/Output

—

—

—

—

—

—

Output

Output

Output

Output

Output

4

Data Sheet S10561EJ5V0DS00

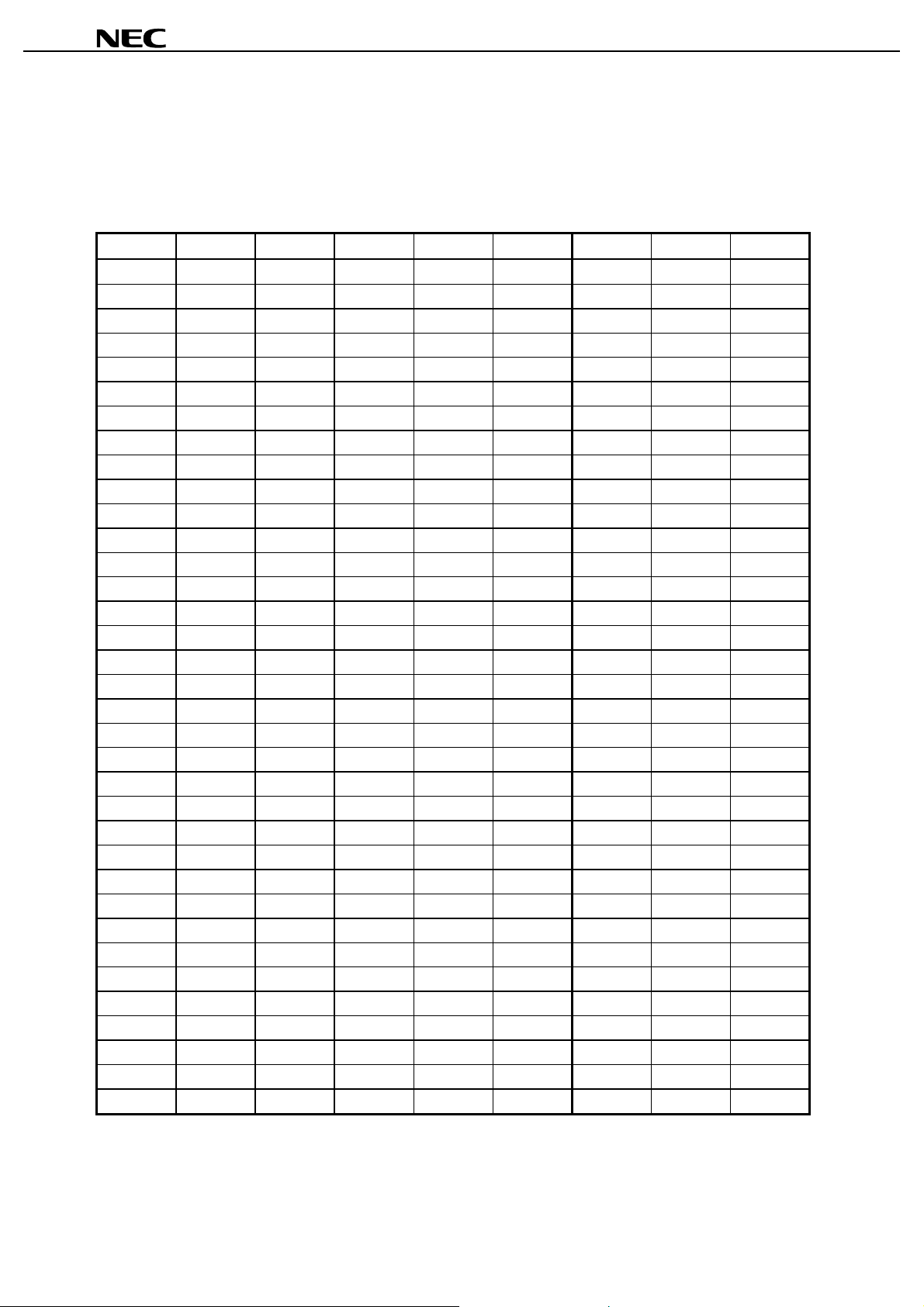

4. PIN COORDINATES

µµµµ

PD16676

Chip Size : 4.04 x 5.53 mm

Pad Size Al Area : 120 x 120 µm

Pad Size Open Area : 108 x 108 µm

Pin No. X (µm) Y (µm) Pin No. X (µm) Y (µm) Pin No. X (µm) Y (µm)

1 1771

2 1771

3 1771

4 1771

5 1771

6 1771

7 1771

8 1771

9 1771

10 1771

11 1771

12 1771

13 1771

14 1771

15 1771

16 1771 80 51

17 1771 234 52

18 1771 388 53

19 1771 542 54

20 1771 696 55

21 1771 850 56

22 1771 1004 57

23 1771 1158 58

24 1771 1312 59

25 1771 1466 60

26 1771 1620 61

27 1771 1774 62

28 1771 1928 63

29 1771 2082 64

30 1771 2236 65

31 1418.8 2517.2 66

32 1268.8 2517.2 67

33 1118.8 2517.2 68

34 968.8 2517.2 69

35 818.8 2517.2 70

2230 36 668.8 2517.2 71

−

2076 37 518.8 2517.2 72

−

1922 38 368.8 2517.2 73

−

1768 39 218.8 2517.2 74

−

1614 40 68.8 2517.2 75

−

1460 41

−

1306 42

−

1152 43

−

998 44

−

844 45

−

690 46

−

536 47

−

382 48

−

228 49

−

74 50

−

2

2

2

1771

−

1771

−

1767.8

−

1767.8

−

1767.8

−

81.2 2517.2 76

−

231.2 2517.2 77

−

381.2 2517.2 78

−

531.2 2517.2 79

−

681.2 2517.2 80

−

831.2 2517.2 81

−

981.2 2517.2 82

−

1131.2 2517.2 83

−

1281.2 2517.2 84

−

1431.2 2517.2 85

−

1771 2242.8 86

−

1771 2092.8 87

−

1771 1942.8 88

−

1771 1792.8 89

−

1771 1642.8 90

−

1771 1492.8 91 69.8

−

1771 1342.8 92 219.8

−

1771 1192.8 93 369.8

−

1771 1042.8 94 569.8

−

1771 892.8 95 719.8

−

1771 742.8 96 952.4

−

1771 592.8 97 1102.4

−

1771 442.8 98 1252.4

−

1771 292.8 99 1402.4

−

1771 142.8 100 1552.4

−

1771

−

1771

−

1771

−

1771

−

1771

−

−

157.2

−

307.2

−

457.2

−

607.2

−

7.2

1767.8

−

1767.8

−

1767.8

−

1767.8

−

1767.8

−

1745

−

1595

−

1395

−

1245

−

1045

−

895

−

682.6

−

532.2

−

382.2

−

106.6

−

757.2

−

907.2

−

1149.4

−

1299.4

−

1489.4

−

1639.4

−

1839.4

−

1989.4

−

2139.4

−

2289.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

2513.4

−

Data Sheet S10561EJ5V0DS00

5

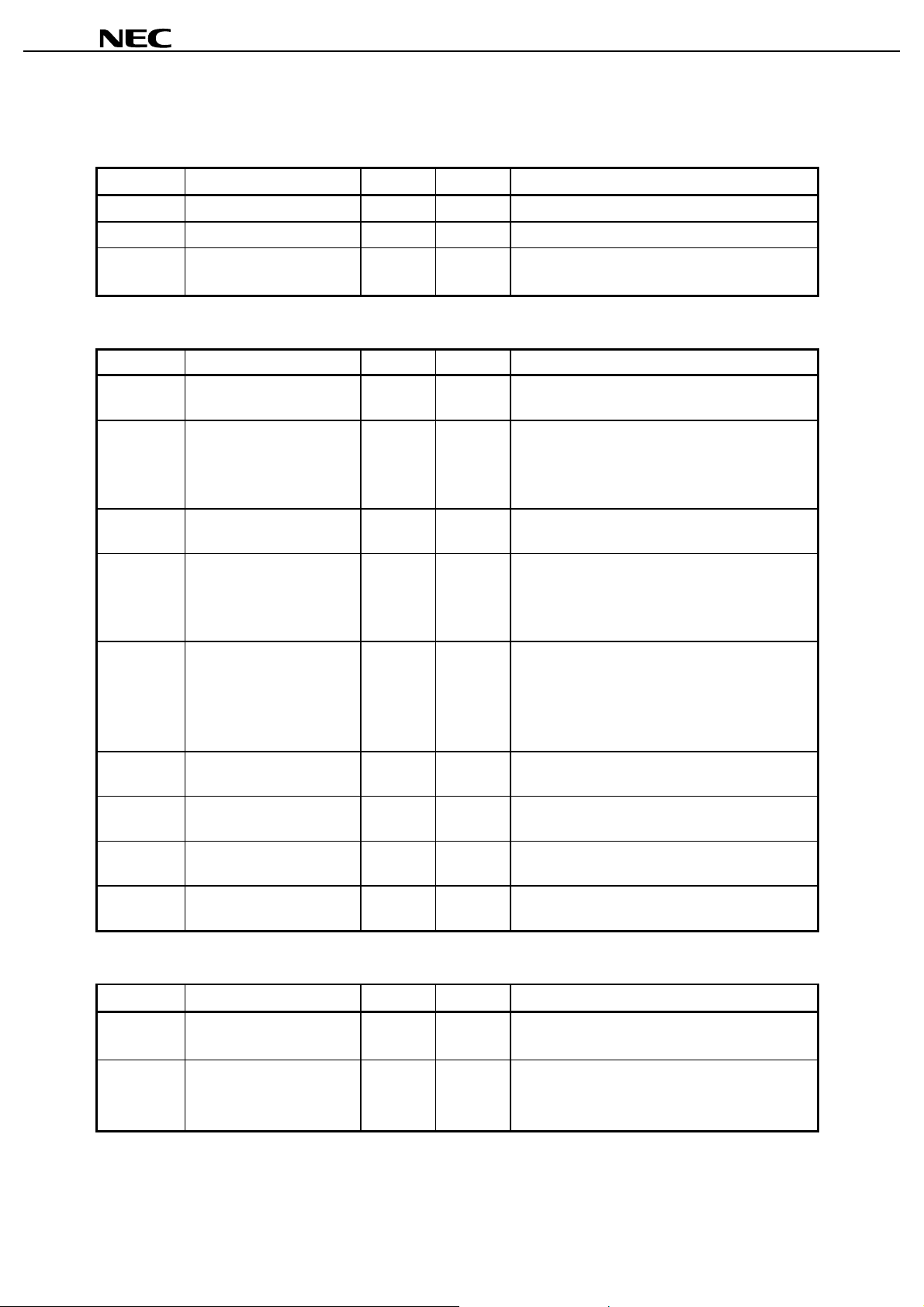

5. PIN DESCRIPTIONS

5.1 Power System

Pin Symbol Pin Name Pin No. I/O Function Description

µµµµ

PD16676

DD

V

SS

V

LC1

V

to V

Power supply pin

Ground 78

LC5

Reference power supply for

drivers

87 —

90,91,92,

94,95

5.2 Logic system

Pin Symbol Pin Name Pin No. I/O

M,/S Master/Slave selection 93

FR LCD to AC signal 89

DB0 to DB7Data Bus 79 to 86

A0 Data/Instruction Switching 73

/RESET Reset and 68/80-series

switching

E(/RD) Enable and read enabl e 76

R,/W(/WR) Read/Write and Write

enable

1

OSC

OSC

2

Oscillation pin 74

Oscillation pin 75

88

77

—

—

Input

Input/

Output

Input/

Output

Input

Input

Input

Input

Input

Output

Power supply

Ground

Reference power supply for LCD driving

Function Description

Switches between the master c hi p and the slave

chip.

Exchanges synchronizing signals (LCD-to-AC

signals) in connecting c ascades.

This pin is for output if the chip is the master, and for

input if the chip is t he slave.

Data inputs/outputs

This pin is used for switchi ng between the display

data and the instruction.

High level : Display data

Low level : Instruction

This pin performs reset at the edge of the low-level

pulse. At that level, i t performs switching 68/80

series modes.

High level : 68 series MPU int erface

Low level : 80 series MPU interfac e

68 series mode : Enable s i gnal

80 series mode : Read enable si gnal

68 series mode : Read/Write signal

80 series mode : Write enable signal

Oscillation (connected with a register bet ween

2

)

OSC

Oscillation (connected with a register bet ween

1

)

OSC

5.3 Driver System

Pin Symbol Pin Name Pin No. I/O Description

SEG0 to

SEG

COM0 to

COM

6

Segment 72 to 12

60

Common 96 to 100,

15

1 to 11

Data Sheet S10561EJ5V0DS00

Output

Output

Segment output pins

Common output pins

If the chip is a slave, these pins correspond to

16

to COM31.

COM

6. COMMANDS

µµµµ

PD16676

(0 to 3)

0

performed independent of the

display RAM’s data or internal

state.

1: ON, 0: OFF (Power save at

static drive ON)

Determines the RAM lin e

displayed on the uppermost li ne

(COM

Sets display RAM pages i n the

page address register.

Sets display RAM’s column

address in the column addres s

register.

BUSY

1: During internal operation

0: READY status

ADC

1: Clockwise output(Normal

rotation)

0: Counterclockwise output

(Reverse)

ON/OFF

1: Display OFF, 0: Display ON

RESET

1: Being reset, 0: Norm al

data bus data

and writes it

onto the

display RAM.

in the display

RAM onto the

data bus.

reverse the correspondence

relationship between display

RAM’s column addresses and

segment driver outputs.

0: Clockwise output (Normal

rotation)

1: Counterclockwise output

(Reverse)

display operation and the stati c

all-lamp-driven display.

1: Static drive (Power save)

0: Normal display operati on

liquid-crystal cel l dri vi ng duties.

1: 1/32 duty

0: 1/16 duty

counter only when writing the

display data; but not when

reading it.

register to the first l i ne.

Sets the column address

counter and the page address

register to 0.

Function

Note

0

) of the display.

Accesses the

display RAM of

a pre-specified

address. After

access, the

column

address is

incremented.

Note

Command /RD /WR A0 DB7DB6DB5DB4DB3DB2DB1DB

1Display ON/OFF 10010101110/1ON/OFF of the whole display is

2Display start line 100110 Display start address

3 Page address set 100101110 Pages

4 Column(s egment)

address set

5 Status read 0 1 0 B

6 Display dat a write 1 0 1 Write Data Displays the

7 Display data read 0 1 1 Read data Reads the data

8ADC select 10010100000/1This command is used to

9 Static drive

ON/OFF

10Duty select 10010101000/1Selects between two different

11 Read modify write 10011100000Increments the column address

12END 10011101110Cancels read modify write mode

13Reset 10011100010Sets the display start line

Note

If the static drive is turned ON in the display OFF state, the machine is placed in the power save state.

1000 Column addresses

A

O

U

D

S

C

Y

10010100100/1Selects between the normal

R

N

E

/

S

O

E

F

T

F

(0 to 31)

(0 to 79)

0000Reads status

Data Sheet S10561EJ5V0DS00

7

7. DISPLAY RAM MAP

DB

0

DB

7

µµµµ

PD16676

Column Address

079

0

Page 0

(640 bits)

7

8

Page 1

(640 bits)

15

16

23

24

31

Line Address

Page 2

(640 bits)

Page 3

(640 bits)

8

Data Sheet S10561EJ5V0DS00

•

8. Line Address Circuit

As is shown in Figure 8-1, the line address circuit specifies the line address that corresponds to a COM output for

displaying the contents of display data RAM. The display start line address set command specifies line address of to

0

the COM

output.

The screen can be scrolled by dynamically changing the line address via the display start line address set

command.

Figure 8-1. Specification of Display Start Line Address in Display Data RAM

µµµµ

PD16676

Page

Address

DB

DB1

0

0

1

1

3BH

14H

3CH

13H

60

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

0

0

DB

0

ADC

1

LCD

DB

Out

Column

Address

Data

0

DB0

DB1

DB2

DB3

0

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

1

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

0

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

1

DB4

DB5

DB6

DB7

00H

01H

02H

03H

04H

05H

4FH

4EH

4DH

4CH

4BH

4AH

SEG0SEG1SEG2SEG3SEG4SEG5SEG6SEG

06H

49H

07H

48H

7

Page0

Page1

Page2

Page3

35H

36H

37H

38H

39H

3AH

1AH

19H

18H

17H

16H

15H

SEG53SEG54SEG55SEG56SEG57SEG58SEG59SEG

COM

Output

COM

COM1

COM2

COM3

COM4

COM5

COM6

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

COM16

COM17

COM18

COM19

COM20

COM21

COM22

COM23

COM24

COM25

COM26

COM27

COM28

COM29

COM30

COM31

0

Remark

16

COM

to COM31 are valid in only 1/32 duty.

Data Sheet S10561EJ5V0DS00

9

•

9. ELECTRICAL SPECIFICATIONS

µµµµ

PD16676

Absolute Maximum Ratings (TA = 25

C, VSS = 0 V)

°°°°

Parameter Symbol Rating Unit

Supply voltage V

Driver reference supply input volt age V

Driver reference supply input volt age V

Logic system input vol t age V

Logic system output vol tage V

Logic system input / output voltage V

Driver system output voltage V

Operating ambient tem perature T

Storage temperature T

DD

LC1

LC5

IN1

OUT1

I/O1

OUT2

A

stg

to V

LC4

–0.3 to +6.5 V

VDD–13 to VDD+0.3 V

VDD–13 to +0.3 V

DD

0.3 to V

−

0.3 to V

−

0.3 to V

−

LC5

V

–0.3 to VDD + 0.3 V

−

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

40 to +85

−

65 to +150

Cautions 1. If the absolute maximum rating of even one of the above parameters is exceeded even

momentarily, the quality of the product may be degraded. Absolute maximum ratings, therefore,

specify the values exceeding which the product may be physically damaged. Be sure to use the

product within the range of the absolute maximum ratings.

DD

LC1

LC2

LC3

LC4

2. Ensure that the phase relationship is V

Recommended Operating Range (V

Parameter Symbol MIN. TYP. MAX. Unit

SS

= 0 V)

V

V

V

≥≥≥≥

≥≥≥≥

≥≥≥≥

V

≥≥≥≥

LC5

V

.

≥≥≥≥

C

°

C

°

Supply voltage V

Reference supply voltage V

Reference supply voltage V

Logic system input vol t age V

DD

LC1

LC5

IN1

to V

LC4

2.7 5.5 V

VDD–12 V

DD

V

VDD–12 0 V

0V

DD

V

10

Data Sheet S10561EJ5V0DS00

µµµµ

PD16676

Electrical Characteristics (Unless otherwise specified, T

Parameter Symbol Condition MIN.

High-level input voltage V

High-level input voltage V

Low-level input voltage V

Low-level input voltage V

High-level input current I

Low-level input current I

High-level output voltage V

High-level output voltage V

High-level output voltage V

Low-level output voltage V

Low-level output voltage V

Low-level output voltage V

High-level output voltage V

High-level output voltage V

High-level output voltage V

Low-level output voltage V

Low-level output voltage V

Low-level output voltage V

High-level leak current I

Low-level leak current I

Driver output ON resistor R

Driver output ON resistor R

Static current consumption I

Dynamic current consumption I

Dynamic current consumption I

Input capacitance C

Oscillator frequency f

Oscillator frequency f

Reset time t

IH1

IH2

IL1

IL2

IH

IL

OH1

OH2

OH3

OL1

OL2

OL3

OH1

OH2

OH3

OL1

OL2

OL3

LOH

LOL

ON

ON

DD0

DD1

DD3

IN

OSC

OSC

R

A0, DB0 to DB7, E, R,/W 0.8 V

FR, M,/S, /RESET 0.8 V

A0, DB0 to DB7, E, R,/W 0.2 V

FR, M,/S, /RESET 0.2 V

A0, E, R,/W, /RESET

A0, E, R,/W, /RESET –1

OUT

I

= –3 mA, DB0 to DB7,

DD

= 4.5 to 5.5 V

V

OUT

I

= –2 mA, FR, VDD = 4.5 to 5.5 V 0.8 V

OUT

I

= –120 µA, OSC2,

DD

= 4.5 to 5.5 V

V

OUT

I

= 3 mA, DB0 to DB7,

DD

= 4.5 to 5.5 V

V

OUT

I

= 2 mA, FR, VDD = 4.5 to 5.5 V 0.2 V

OUT

I

= 120 µA, OSC2,

DD

= 4.5 to 5.5 V

V

OUT

I

= –1.5 mA, DB0 to DB7,

DD

= 2.7 to 4.5 V

V

OUT

I

= –1 mA, FR, VDD = 2.7 to 4.5 V 0.8 V

OUT

I

= –80 µA, OSC2,

DD

= 2.7 to 4.5 V

V

OUT

I

= 1.5 mA, DB0 to DB7,

DD

= 2.7 to 4.5 V

V

OUT

I

= 1 mA, FR, VDD = 2.7 to 4.5 V 0.2 V

OUT

I

= 80 µA, OSC2,

DD

= 2.7 to 4.5 V

V

DB0 to DB7, V

DB0 to DB7, V

TA = 25 °C, VDD = 5 V, V

TA = 25 °C, VDD = 3.5 V, V

External clock: 18 kHz 15.0

Self-oscillation: R = 1.3 M

During access: t

TA = 25 °C, f = 1 MHz 8.0 pF

In self-oscillation, VDD = 5.0 V,

R = 1.3 M

Ω ±

In self-oscillation, VDD = 3.0 V,

R = 1.3 M

Ω ±

/RESET↓→Internal reset release 1.0 1000

A =

0 to +85

−4

−4

−4−4

C, V

°°°°

DD

= 2.7 to 5.5 V)

TYP.

DD

DD

DD

0.8 V

DD

DD

0.8 V

DD

0.8 V

DD

DD

0.8 V

IN/OUT

IN/OUT

= V

= V

DD

SS

LC5

SS

= V

LC5

SS

= V

Ω

CYC

= 200 kHz 500

15 18 21 kHz

2%

11 16 21 kHz

2%

Note

MAX. Unit

DD

DD

1

DD

0.2 V

DD

DD

0.2 V

DD

0.2 V

DD

DD

0.2 V

3

–3

7.5 k

50 k

1.0

30.0

V

V

V

V

A

µ

A

µ

V

V

V

V

V

V

V

V

V

V

V

V

A

µ

A

µ

Ω

Ω

A

µ

A

µ

A

µ

A

µ

s

µ

Remark

The TYP. value is a reference value when T

Data Sheet S10561EJ5V0DS00

A

= 25 °C.

11

AC Characteristics 1 (Unless otherwise specified, TA =

80 Series MPU Read/Write Timing

Parameter Symbol Condition MIN. TYP. M AX. Unit

4

0 to +85

−−−−

C, V

°°°°

DD

= 4.5 to 5.5 V)

µµµµ

PD16676

Address hold time t

Address setup time t

System cycle time t

Control pulse width t

Data setup time t

Data hold time t

/RD access time t

Output disable time t

68 Series MPU Read/Write Timing

Parameter Symbol Condition MIN. TYP. MAX. Unit

System cycle time t

Address setup time t

Address hold time t

Data setup time t

Data hold time t

Output disable time t

Access time t

Enable pulse width READ t

WRITE 80 ns

AH8

AW8

CYC8

CC

DS8

DH8

ACC8

OH8

CYC6

AW6

AH6

DS6

DH6

OH6

ACC6

EW

A0 10 ns

20 ns

/WR, /RD 1000 ns

200 ns

DB0 to DB

7

80 ns

10 ns

DB0 to DB7 , CL = 100 pF 90 ns

10 60 ns

A0, R,/W 1000 ns

20 ns

10 ns

DB0 to DB

7

80 ns

10 ns

DB0 to DB7, CL = 100 pF 10 60 ns

90 ns

E 100 ns

12

Data Sheet S10561EJ5V0DS00

AC Characteristics 2 (Unless otherwise specified, TA =

80 Series MPU Read/Write Timing

Parameter Symbol Condition MIN. TYP. M AX. Unit

4

0 to +85

−−−−

C, V

°°°°

DD

= 2.7 to 4.5 V)

µµµµ

PD16676

Address hold time t

Address setup time t

System cycle time t

Control pulse width t

Data setup time t

Data hold time t

/RD access time t

Output disable time t

68 Series MPU Read/Write Timing

Parameter Symbol Condition MIN. TYP. MAX. Unit

System cycle time t

Address setup time t

Address hold time t

Data setup time t

Data hold time t

Output disable time t

Access time t

Enable pulse width READ t

WRITE 160 ns

AH8

AW8

CYC8

CC

DS8

DH8

ACC8

OH8

CYC6

AW6

AH6

DS6

DH6

OH6

ACC6

EW

A0 20 ns

40 ns

/WR, /RD 2000 ns

400 ns

DB0 to DB

7

160 ns

20 ns

DB0 to DB7 , CL = 100 pF 180 ns

20 120 ns

A0, R,/W 2000 ns

40 ns

20 ns

DB0 to DB

7

160 ns

20 ns

DB0 to DB7, CL = 100 pF 20 120 ns

180 ns

E 200 ns

Data Sheet S10561EJ5V0DS00

13

Test Point of Switching Characteristics

V

IH

Input

V

IL

V

OH

Output

V

OL

Waveforms of Switching Characteristics

80 Series MPU Read/Write Timing

A0

µµµµ

PD16676

V

IH

V

IL

V

OH

V

OL

t

AH8

t

AW8

/WR,/RD

DB0 - DB

(WRITE)

DB

0

- DB

(READ)

7

7

68 Series MPU Read/Write Timing

E

R,/W

t

ACC8

t

AW6

t

t

CYC8

CC

t

DS8

t

CYC6

t

DH8

t

OH8

t

EW

t

AH6

A0

DB0 - DB

(READ)

DB0 - DB

(READ)

14

t

t

DS6

7

t

ACC6

7

Data Sheet S10561EJ5V0DS00

DH6

t

OH6

Reset

/RESET

µµµµ

PD16676

t

R

Internal Status

OSC

OSC

1/f

OSC

Reset status

Data Sheet S10561EJ5V0DS00

15

•

10. Application Circuit Example

16 COM

V

DD

M,/S

µ

PD16676

Master Chip

61 SEG

FR

LCD

OSC

OSC

µµµµ

PD16676

1

2

A0,

/RESET,

E,/RD,

R,/W, /WR

DB

0

- DB

61 SEG

16 COM

4

7

8

M,/S

GND

PD16676

µ

Slave Chip

FR

OSC

1

16

Data Sheet S10561EJ5V0DS00

•

11. PACKAGE DRAWING

100 PIN PLASTIC QFP (14x20)

µµµµ

PD16676

A

B

80

81

100

1

F

G

H

M

I

P

S

N

NOTE

Each lead centerline is located within 0.15 mm of

its true position (T.P.) at maximum material condition.

51

50

detail of lead end

S

CD

31

Q

30

R

J

K

M

L

S

ITEM MILLIMETERS

A 23.2±0.2

B 20.0±0.2

C 14.0±0.2

D

17.2±0.2

F

0.8

G

0.6

H 0.32±0.08

I

0.15

J

0.65 (T.P.)

K 1.6±0.2

L 0.8±0.2

M 0.17

N 0.10

P 2.7

Q

R5°±5°

S 2.825±0.175

+0.08

−0.07

0.125±0.075

S100GF-65-3BA-4

Data Sheet S10561EJ5V0DS00

17

•

12. RECOMMENDED SOLDERING CONDITIONS

Please consult with our sales offices for soldering conditions of the µPD16676.

Type of Surface Mount Device

µPD16676GF-3BA : 100-PIN PLASTIC QFP (14 x 20 mm)

µµµµ

PD16676

18

Data Sheet S10561EJ5V0DS00

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

DD

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

or GND with a resistor, if it is considered to have a possibility of

µµµµ

PD16676

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet S10561EJ5V0DS00

19

µµµµ

PD16676

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...