DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD17P236

4-BIT SINGLE-CHIP MICROCONTROLLER

FOR SMALL GENERAL-PURPOSE INFRARED

REMOTE CONTROLLER

The µPD17P236 is a model of the µPD17236 with a one-time PROM instead of an internal mask ROM.

Since the user can write programs to the µPD17P236, it is ideal for experimental production or small-scale

µ

production of the

When reading this document, also read the documents related to the µPD17230, 17231, 17232, 17233, 17234,

17235, and 17236.

Detailed functions are described in the following user's manual. Read this manual when designing your system.

PD17230, 17231, 17232, 17233, 17234, 17235, or 17236 systems.

µ

PD172×× Series User's Manual: U12795E

FEATURES

• Pin compatible with µPD17230, 17231, 17232, 17233, 17234, 17235, and 17236 (except PROM programming

function)

• Carrier generator circuit for infrared remote controller (REM output)

• 17K architecture: General-purpose register method

• Program memory (one-time PROM): 32 Kbytes (16,384 × 16)

• Data memory (RAM): 223 × 4 bits

• Low-voltage detection circuit

• Input/output of P1A

Input/output of P1A0 pin Output Input Output Input

Clock (RfX) selection for carrier generation RfX = fX/2 RfX = fX

• Supply voltage: VDD = 2.2 to 3.6 V (fX = 4 MHz: high-speed mode, 4 µs)

APPLICATIONS

Preset remote controllers, toys, and portable systems

0 pin, clock selection for carrier generation

µ

PD17P236M1µPD17P236M2µPD17P236M3µPD17P236M4

VDD = 3.0 to 3.6 V (fX = 8 MHz: high-speed mode, 2 µs)

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. U14776EJ1V0DS00 (1st edition)

Date Published June 2000 J CP(K)

Printed in Japan

©

2000

ORDERING INFORMATION

Part Number Package

µ

PD17P236M1GT 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M1MC-5A4 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M2GT 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M2MC-5A4 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M3GT 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M3MC-5A4 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M4GT 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M4MC-5A4 30-pin plastic SSOP (7.62 mm (300))

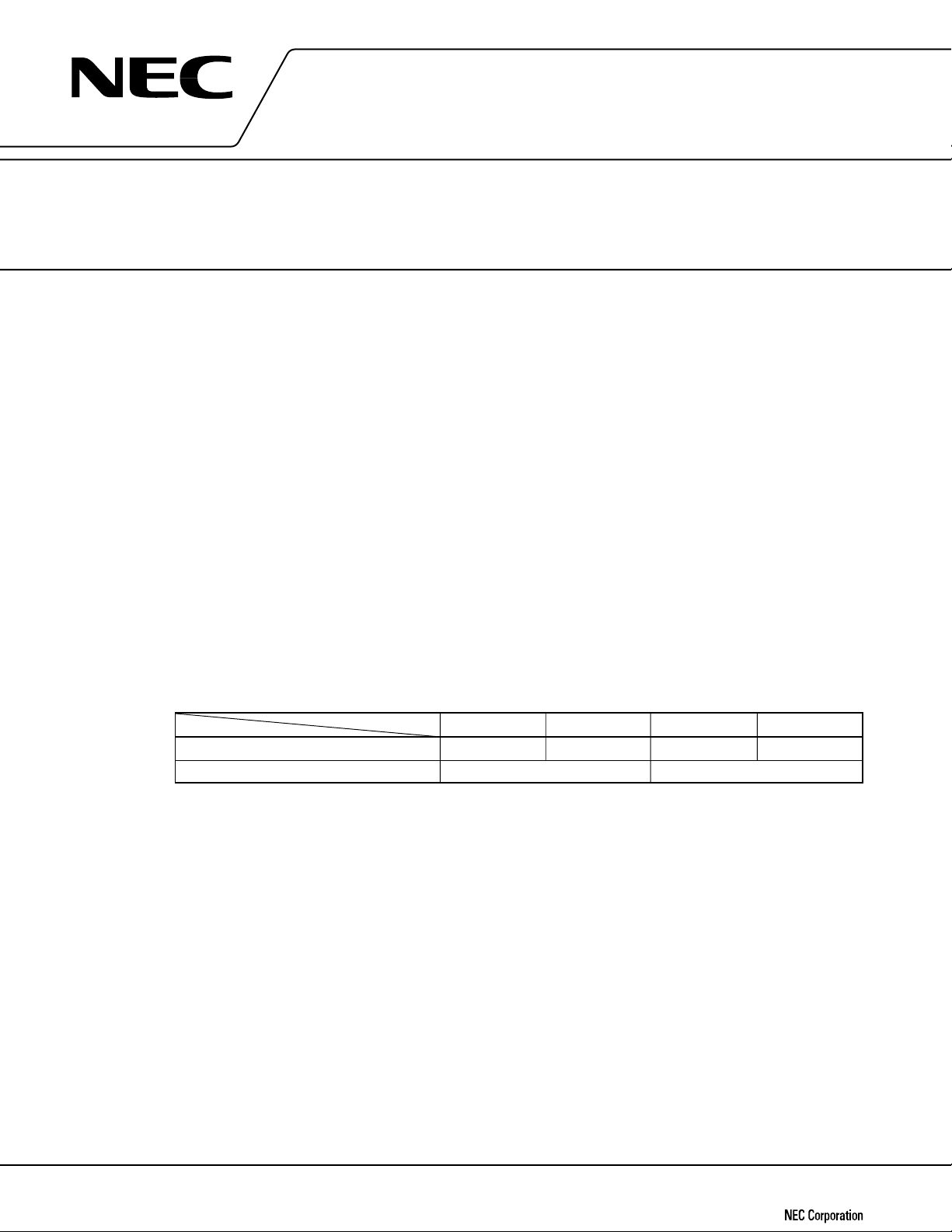

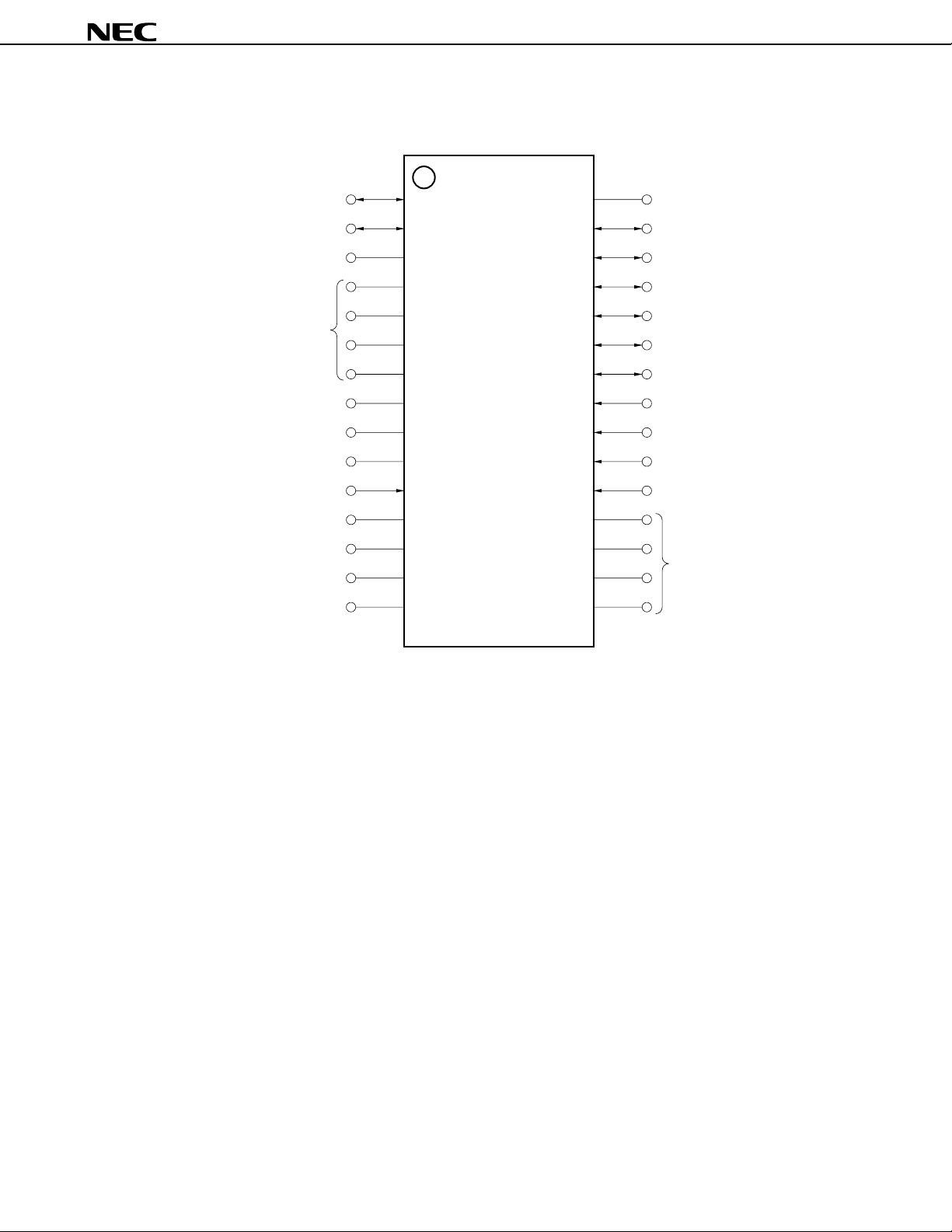

PIN CONFIGURATION (TOP VIEW)

(1) Normal operation mode

• 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M1GT, 17P236M2GT, 17P236M3GT, 17P236M4GT

µ

PD17P236

P0D

P0D

INT

P0E

P0E

P0E

P0E

REM

V

X

OUT

X

GND

RESET

P1A

2

3

1

2

3

0

1

2

3

4

5

6

7

8

DD

9

10

IN

11

12

13

0

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

P0D

P0D

P0C

P0C

P0C

P0C

P0B

P0B

P0B

P0B

P0A

P0A

P0A

P0A

1

0

3

2

1

0

3

2

1

0

3

2

1

0

2

Data Sheet U14776EJ1V0DS00

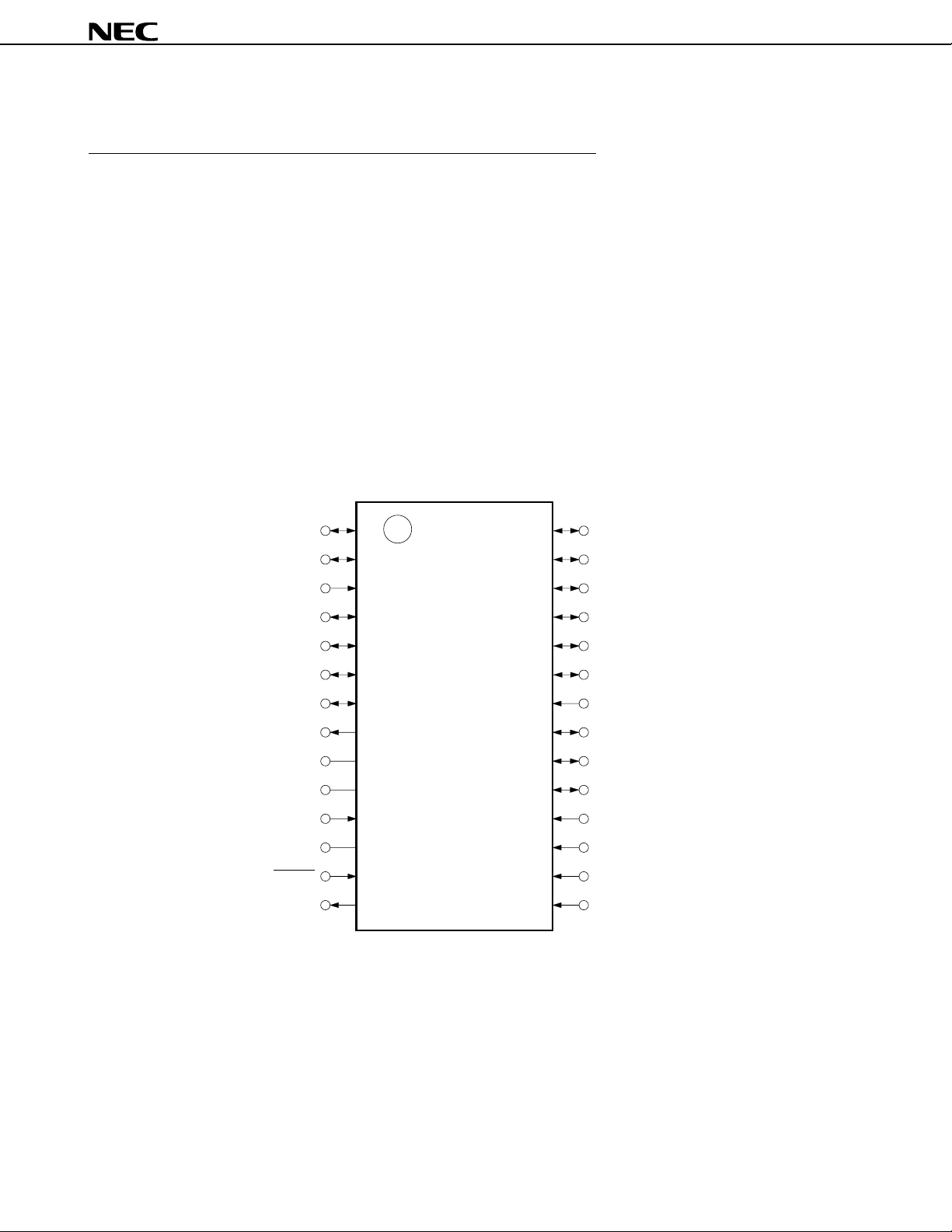

• 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M1MC-5A4, 17P236M2MC-5A4, 17P236M3MC-5A4, 17P236M4MC-5A4

µ

PD17P236

P0D

P0D

INT

P0E

P0E

P0E

P0E

REM

V

X

OUT

X

GND

RESET

P1A

IC1

2

3

1

2

3

0

1

2

3

4

5

6

7

8

DD

9

10

IN

11

12

13

0

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

IC2

P0D

P0D

P0C

P0C

P0C

P0C

P0B

P0B

P0B

P0B

P0A

P0A

P0A

P0A

1

0

3

2

1

0

3

2

1

0

3

2

1

0

GND : Ground

IC1, IC2 : Internally connected

Note 1

INT : External interrupt request signal input

P0A0-P0A3 : Input port (CMOS input)

0-P0B3 : Input/output port (CMOS input/N-ch open-drain output)

P0B

P0C0-P0C3 : Input/output port (CMOS input/N-ch open-drain output)

P0D0-P0D3 : Input/output port (CMOS input/N-ch open-drain output)

0-P0E3 : Input/output port (CMOS push-pull output)

P0E

P1A0 : Input port (CMOS input) or output port (N-ch open-drain output)

REM : Remote controller output (CMOS push-pull output)

RESET : Reset input

DD : Power supply

V

XIN, XOUT : Resonator connection

Notes 1. This pin cannot be used. Leave open.

2. Input port or output port is selected depending on the product (see 2. PIN

FUNCTIONS).

Note 2

Data Sheet U14776EJ1V0DS00

3

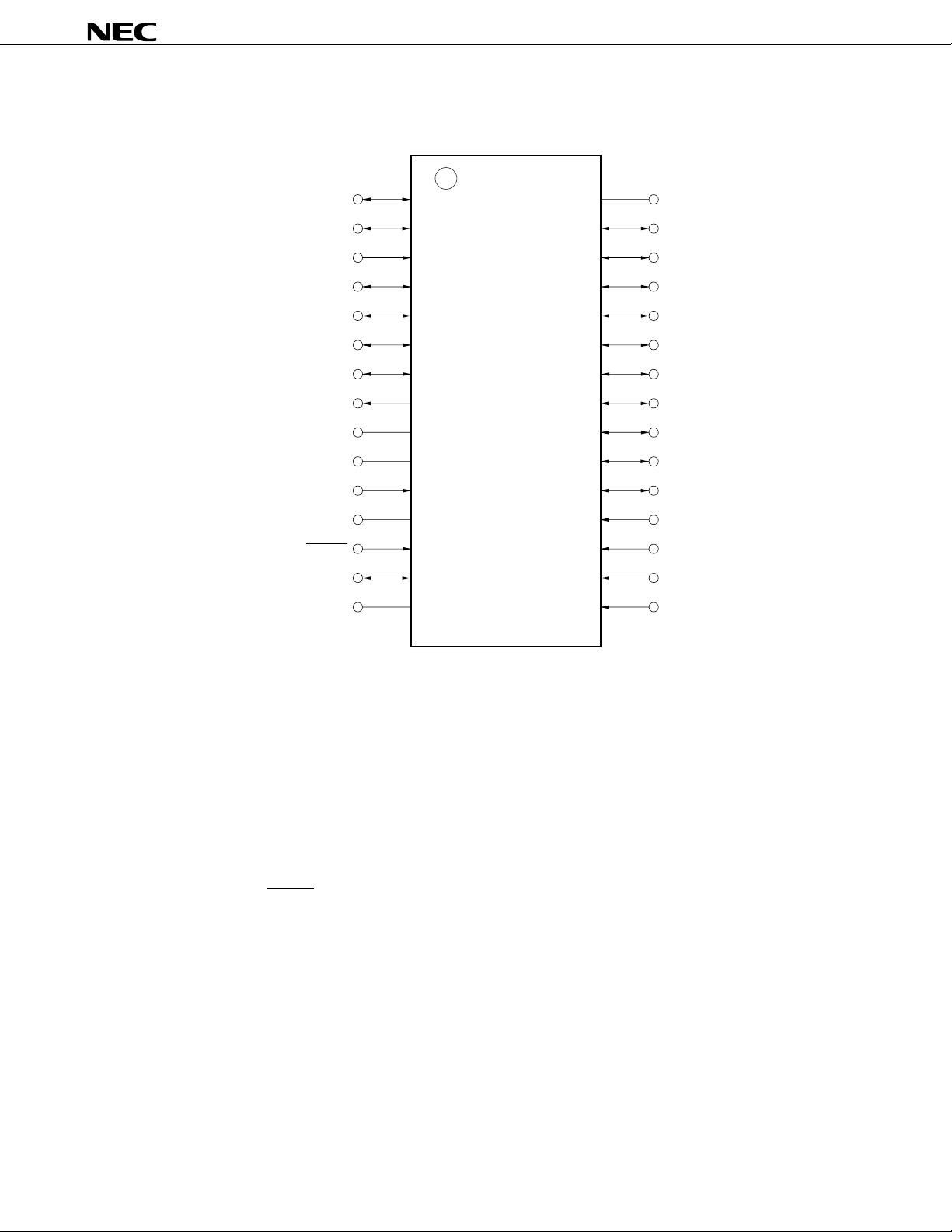

(2) PROM programming mode

• 28-pin plastic SOP (9.53 mm (375))

µ

PD17P236M1GT, 17P236M2GT, 17P236M3GT, 17P236M4GT

D

2

D

3

V

PP

(L)

µ

PD17P236

D

D

D

D

D

D

MD

1

0

7

6

5

4

3

1

2

3

4

5

6

7

28

27

26

25

24

23

22

(Open)

V

(Open)

CLK

GND

(L)

(Open)

MD

MD

MD

2

1

0

8

DD

9

10

11

12

21

20

19

18

17

(L)

13

14

16

15

4

Data Sheet U14776EJ1V0DS00

• 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M1MC-5A4, 17P236M2MC-5A4, 17P236M3MC-5A4, 17P236M4MC-5A4

µ

PD17P236

D

D3

VPP

(L)

(Open)

V

(Open)

CLK

GND

(L)

(Open)

(Open)

2

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

(Open)

D

1

D0

D7

D6

D5

D4

MD3

MD2

MD1

MD0

(L)

Caution Contents in parentheses indicate how to handle unused pins in PROM programming mode.

L : Connect to GND via a resistor (470

Ω) separately.

Open : Leave unconnected.

CLK : Clock input for PROM

0-D7 : Data input/output for PROM

D

GND : Ground

0-MD3 : Mode select input for PROM

MD

VDD : Power supply

VPP : Power supply for PROM writing

Data Sheet U14776EJ1V0DS00

5

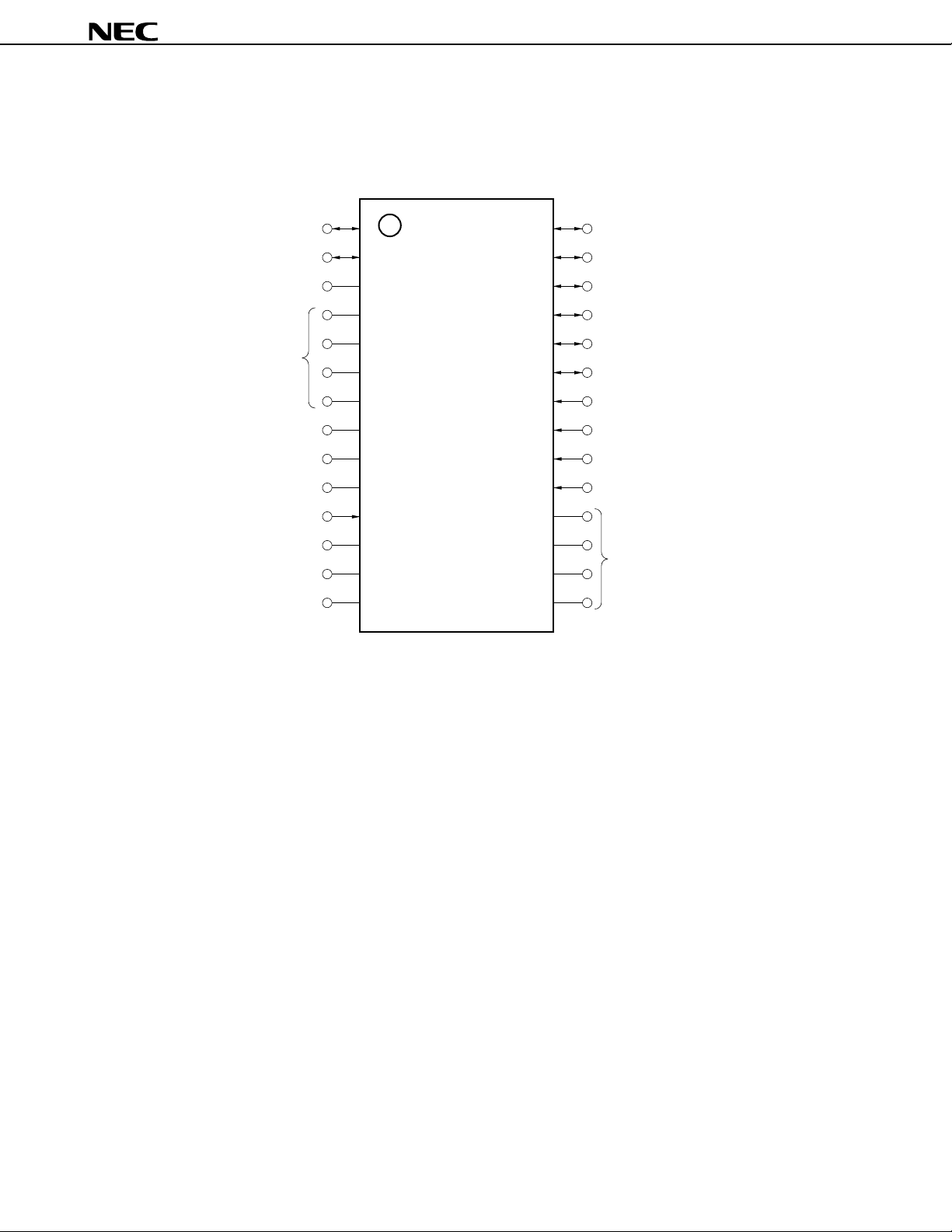

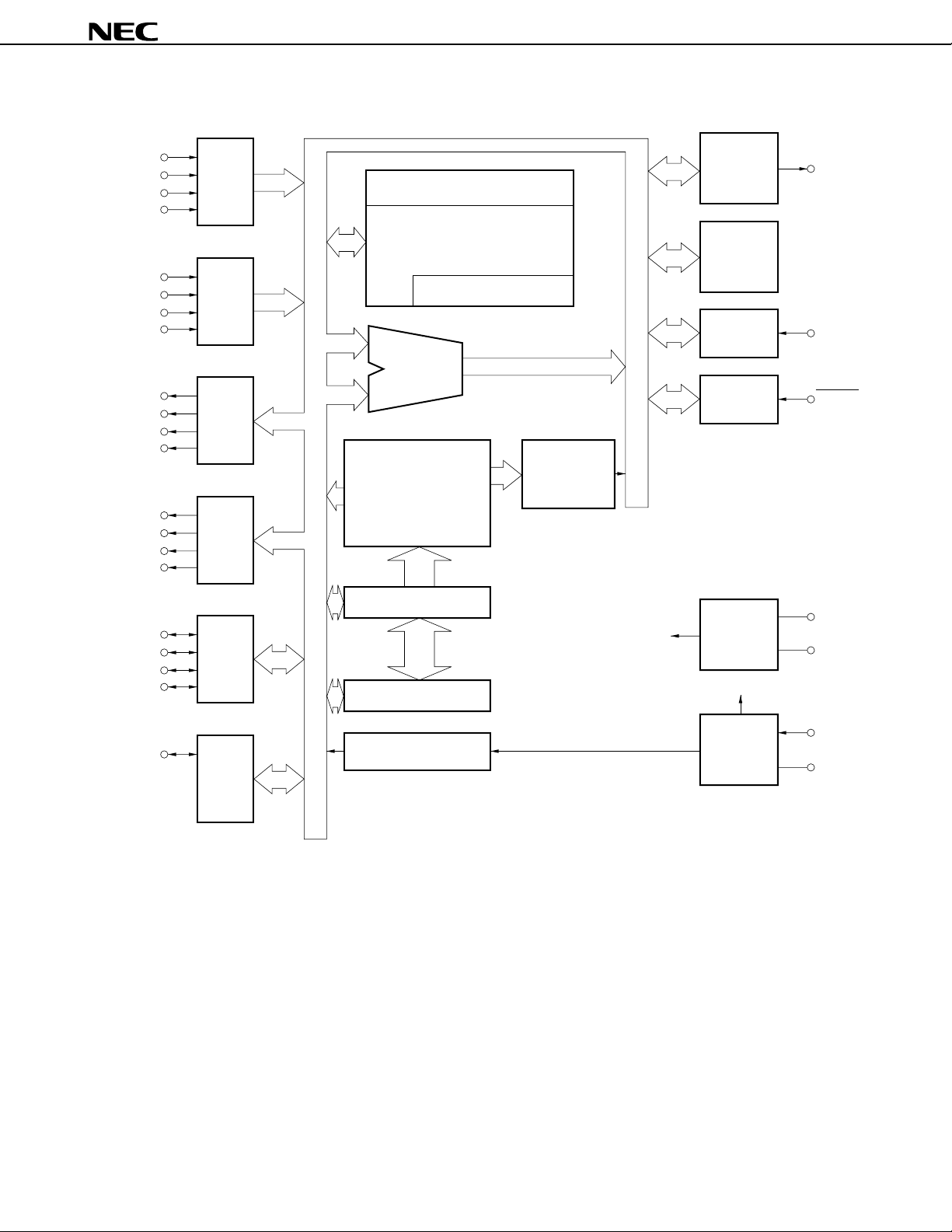

BLOCK DIAGRAM

µ

PD17P236

P0A

P0A

P0A

P0A

P0B0 (MD0)

1

(MD1)

P0B

2

(MD2)

P0B

3

(MD3)

P0B

P0C0 (D4)

1

(D5)

P0C

2

(D6)

P0C

3

(D7)

P0C

P0D0 (D0)

1

(D1)

P0D

2

(D2)

P0D

3

(D3)

P0D

0

1

2

3

P0A

RF

Remote

Control

Divider

REM

RAM

223 × 4 bits

8-bit

timer

P0B

SYSTEM REG.

Interrupt

Controller

INT (V

PP

)

ALU

Reset

Controller

RESET

P0C

Instruction

One Time PROM

Decoder

16,384 × 16 bits

P0D

Program Counter

Power

P0E

P1A

P0E

P0E

P0E

Note

0

0

1

2

3

P0E

Stack (5 levels)

Basic Interval/

Watchdog Timer

Supply

Circuit

CPU Clock

P1A

Note Input port or output port is selected depending on the product (see 2. PIN FUNCTIONS).

Remark ( ): During PROM programming mode

OSC

DD

V

GND

IN

X

OUT

X

(CLK)

6

Data Sheet U14776EJ1V0DS00

µ

PD17P236

CONTENTS

1. DIFFERENCES BETWEEN µPD17236 AND µPD17P236 ........................................................... 8

2. PIN FUNCTIONS ........................................................................................................................... 9

2.1 Normal Operation Mode .................................................................................................................... 9

2.2 PROM Programming Mode ............................................................................................................... 10

2.3 Input/Output Circuits ......................................................................................................................... 11

2.4 Processing of Unused Pins .............................................................................................................. 12

2.5 Notes on Using the RESET and INT Pins ........................................................................................12

3. WRITING AND VERIFYING ONE-TIME PROM (PROGRAM MEMORY) .................................... 13

3.1 Operating Mode When Writing/Verifying Program Memory .......................................................... 13

3.2 Program Memory Writing Procedure ............................................................................................... 14

3.3 Program Memory Reading Procedure .............................................................................................15

4. ELECTRICAL SPECIFICATIONS ................................................................................................. 16

5. PACKAGE DRAWING .................................................................................................................. 23

6. RECOMMENDED SOLDERING CONDITIONS ............................................................................ 25

APPENDIX. DEVELOPMENT TOOLS................................................................................................ 27

Data Sheet U14776EJ1V0DS00

7

µ

PD17P236

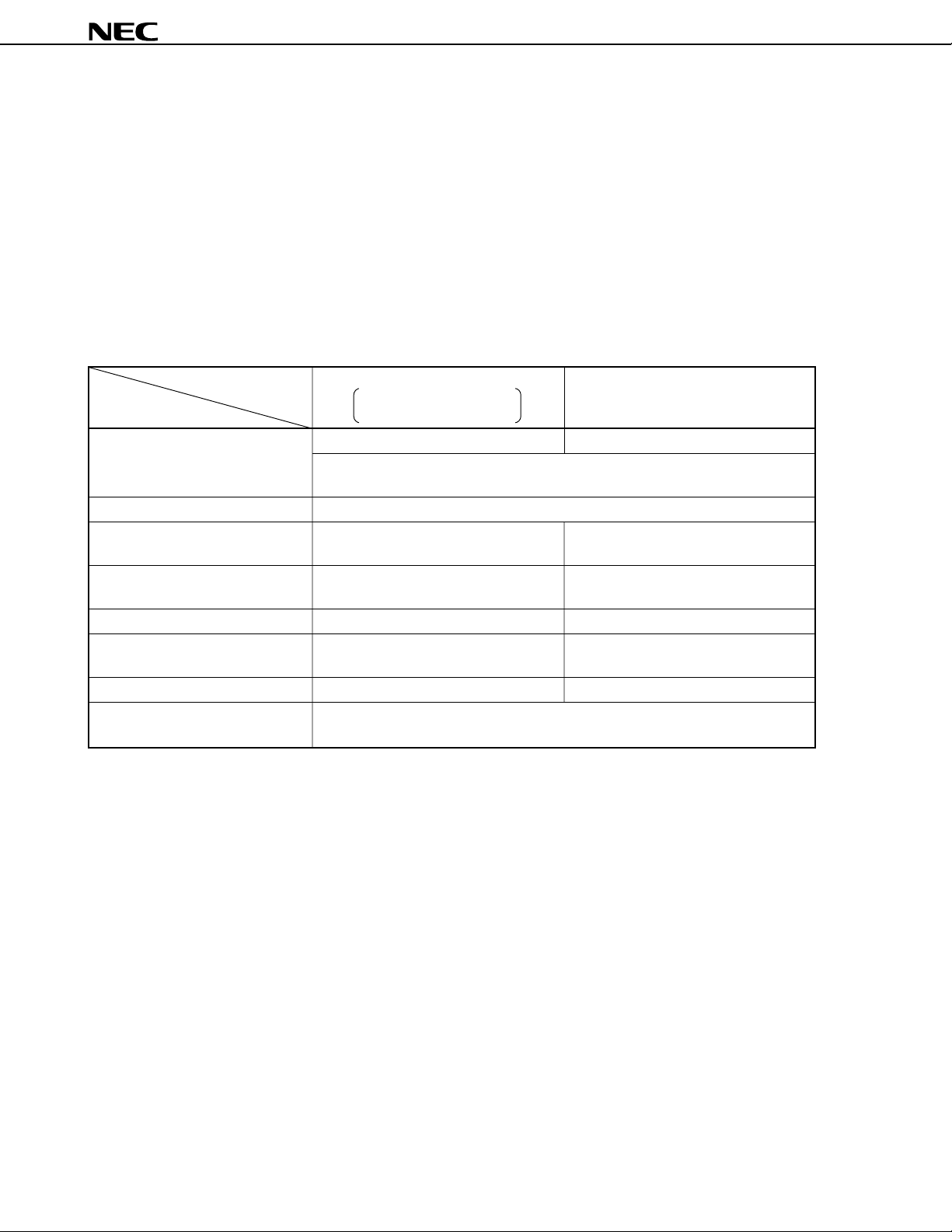

1. DIFFERENCES BETWEEN µPD17236 AND µPD17P236

µ

PD17P236 is equipped with PROM to which data can be written by the user instead of the internal mask ROM

(program memory) of the µPD17236.

µ

Table 1-1 shows the differences between the

The CPU functions and internal hardware of the µPD17P236, 17230, 17231, 17232, 17233, 17234, 17235, and

17236 are identical. Therefore, the µPD17P236 can be used to evaluate the program developed for the µPD17230,

17231, 17232, 17233, 17234, 17235, and 17236 system. Note, however, that some of the electrical specifications

such as supply current and low-voltage detection voltage of the

µ

PD17230, 17231, 17232, 17233, 17234, 17235, and 17236.

Table 1-1. Differences among

PD17236 and µPD17P236.

µ

PD17P236 are different from those of the

µ

PD17236 and µPD17P236

Product Name

Item 17P236M3, 17P236M4

Program memory One-time PROM Mask ROM

32 Kbytes (16,384 × 16)

(0000H-3FFFH)

Data memory 223 × 4 bits

Input/output of P1A0 pin • Input (µPD17P236M2, 17P236M4) Any (mask option)

• Output (µPD17P236M1, 17P236M3)

Clock (RfX) selection for carrier • RfX = fX/2 (µPD17P236M1, 17P236M2) Any (mask option)

generation • RfX = fX (µPD17P236M3, 17P236M4)

Low-voltage detection circuit

Instruction execution time • 2 µs (VDD = 3.0 to 3.6 V) • 2 µs (VDD = 2.2 to 3.6 V)

Supply voltage VDD = 2.2 to 3.6 V VDD = 2.0 to 3.6 V

Package • 28-pin plastic SOP (9.53 mm (375))

Note

Provided Any (mask option)

• 4 µs (VDD = 2.2 to 3.6 V) • 4 µs (VDD = 2.0 to 3.6 V)

• 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236

µ

PD17P236M1, 17P236M2,

µ

PD17236

Note Although the circuit configuration is identical, its electrical characteristics differ depending on the product.

8

Data Sheet U14776EJ1V0DS00

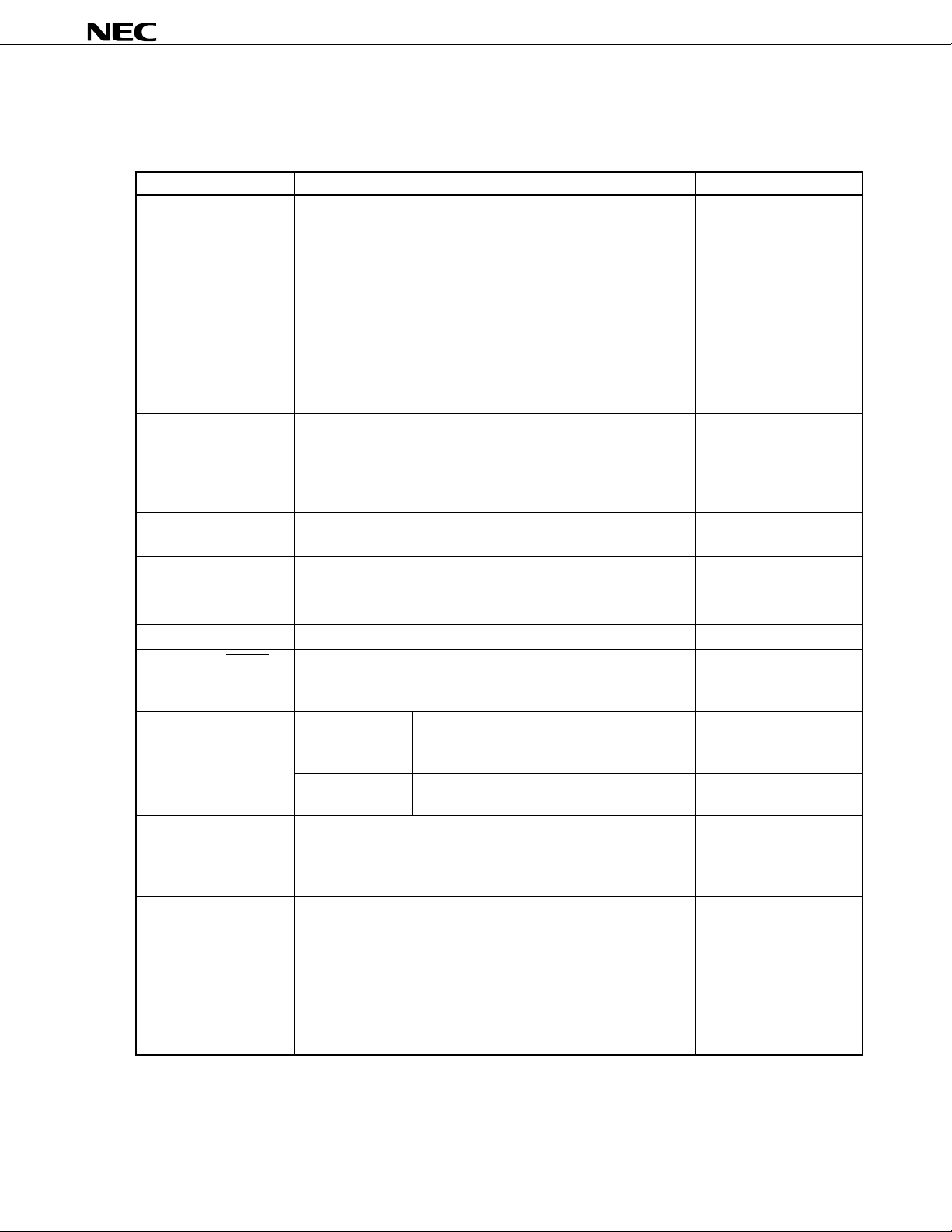

2. PIN FUNCTIONS

2.1 Normal Operation Mode (1/2)

µ

PD17P236

Pin No. Symbol Function

27 (28) P0D0 These pins constitute a 4-bit I/O port which can be set in the input N-ch Low-level

28 (29) P0D1 or output mode in 4-bit units (group I/O). open-drain output

1 (1) P0D2 In the input mode, these pins serve as CMOS input pins with a

2 (2) P0D3 pull-up resistor, and can be used as key return input lines of a key

matrix. The standby status must be released when at least one of

the input lines goes low. In the output mode, these pins are used

as N-ch open-drain output pins and can be used as the output

lines of a key matrix.

3 (3) INT External interrupt request signal. This signal releases the standby – Input

status if an external interrupt request signal is input to it when the

INT pin interrupt enable flag (IP) is set.

4 (4) P0E0 These pins constitute a 4-bit I/O port that can be set in the input or CMOS Input

5 (5) P0E1 output mode in 1-bit units. push-pull

6 (6) P0E2 In the output mode, this port functions as a high current CMOS

7 (7) P0E3 output port. In the input mode, function as CMOS input and can be

specified to connect pull-up resistor by program.

8 (8) REM Outputs transfer signal for infrared remote controller. CMOS Low-level

Active-high output. push-pull output

9 (9) VDD Power supply – –

10 (10) XOUT Connects ceramic resonator for system clock oscillation – (Oscillation

11 (11) XIN stops)

12 (12) GND Ground – –

13 (13) RESET Turns ON pull down resistor if POC or watchdog timer overflows – Input

and if the stack pointer overflows or underflows, and resets the

system. Usually, the pull-down resistor is ON.

14 (14) P1A0

15 (16) P0A0 These pins are CMOS input pins with a 4-bit pull-up resistor. – Input

16 (17) P0A1 They can be used as the key return input lines of a key matrix.

17 (18) P0A2 If any one of these pins goes low, the standby status is released.

18 (19) P0A3

19 (20) P0B0 These pins constitute a 4-bit I/O port that can be set in the input or N-ch Input

20 (21) P0B1 output mode in 1-bit units. open-drain

21 (22) P0B2 In the input mode, these pins are CMOS input pins with a pull-up

22 (23) P0B3 resistor, and can be used as the key return input lines of a key

µ

PD17P136M1, This pin is 1-bit output port (N-ch open-drain N-ch High-

µ

PD17P136M3 output) and can be used as the output lines of open-drain impedance

a key matrix. output

µ

PD17P136M2, This pin is 1-bit input port (CMOS input). – Input

µ

PD17P136M4 However, it cannot release the STOP mode.

matrix. The standby status is released when at least one of these

pins goes low.

In the output mode, they serve as N-ch open-drain output pins and

can be used as the output lines of a key matrix.

Output Format

At Reset

Remark The number in parenthesis in the Pin No. column indicates the pin numbers of the 30-pin plastic SSOP.

Data Sheet U14776EJ1V0DS00

9

2.1 Normal Operation Mode (2/2)

µ

PD17P236

Pin No. Symbol Function

23 (24) P0C0 These pins constitute a 4-bit I/O port that can be set in the input or N-ch Low-level

24 (25) P0C1 output mode in 4-bit units (group I/O). open-drain output

25 (26) P0C2 In the input mode, these pins are CMOS input pins with a pull-up

26 (27) P0C3 resistor, and can be used as the key return input lines of a key

matrix. The standby status is released when at least one of these

pins goes low.

In the output mode, they serve as N-ch open-drain output pins and

can be used as the output lines of a key matrix.

(15) IC1 These pins cannot be used. – –

(30) IC2 Leave open.

Output Format

At Reset

Remark The number in parenthesis in the Pin No. column indicates the pin numbers of the 30-pin plastic SSOP.

2.2 PROM Programming Mode

Pin No. Symbol Function

3VPP Power supply for PROM programming. – –

Apply +12.5 V to this pin as the program voltage when writing/

verifying program memory.

9VDD Power supply. Apply +6 V to this pin when writing/verifying – –

program memory.

11 CLK Inputs clock for PROM programming. – –

12 GND Ground. – –

19 (20) MD0 Input pins used to select operation mode when PROM is – Input

programmed.

22 (23) MD3

23 (24) D4 Input/output 8-bit data for PROM programming CMOS Input

push-pull

26 (27) D7

27 (28) D0

28 (29) D1

1D2

2D3

Output Format

At Reset

Remarks 1. The other pins are not used in the PROM programming mode. How to handle the other opins are

described in PIN CONFIGURATION (2) PROM programming mode.

2. The number in parenthesis in the Pin No. column indicates the pin numbers of the 30-pin plastic

SSOP.

10

Data Sheet U14776EJ1V0DS00

2.3 Input/Output Circuits

The equivalent input/output circuit for each µPD17P236 pin is shown below.

µ

PD17P236

(1) P0A

Input buffer

(2) P0B, P0C, P0D

Data

Output

disable

Output

latch

Selector

VDD

N-ch

(4) P1A

• Input mode (

µ

PD17P236M2, 17P236M4)

Input buffer

• Output mode (µPD17P236M1, 17P236M3)

V

DD

data N-ch

P-ch

Output

latch

(5) RESET

V

DD

P-chReset input

(3) P0E

Data

Data

Output

disable

Pull-up

register

Output

latch

Selector

Input buffer

Input buffer

V

DD

P-ch

N-ch

Input buffer

Schmitt trigger input with

hysteresis characteristics

V

DD

N-ch

(6) INT

P-ch

Input buffer

Schmitt trigger input with hysteresis

characteristics

(7) REM

V

DD

Data

P-ch

Output

disable

Data Sheet U14776EJ1V0DS00

N-ch

11

2.4 Processing of Unused Pins

Process the unused pins as follows:

Table 2-1. Processing of Unused Pins

Pin Recommended Connection

P0A0-P0A3 Leave open.

P0B0-P0B3

P0C0-P0C3

P0D0-P0D3

P0E0-P0E3 Input : Individually connect to VDD or GND via resistor.

P1A0 Connect to GND.

REM Leave open.

INT Connect to GND.

IC1, IC2 These pins cannot be used.

Output : Leave open.

Leave open.

µ

PD17P236

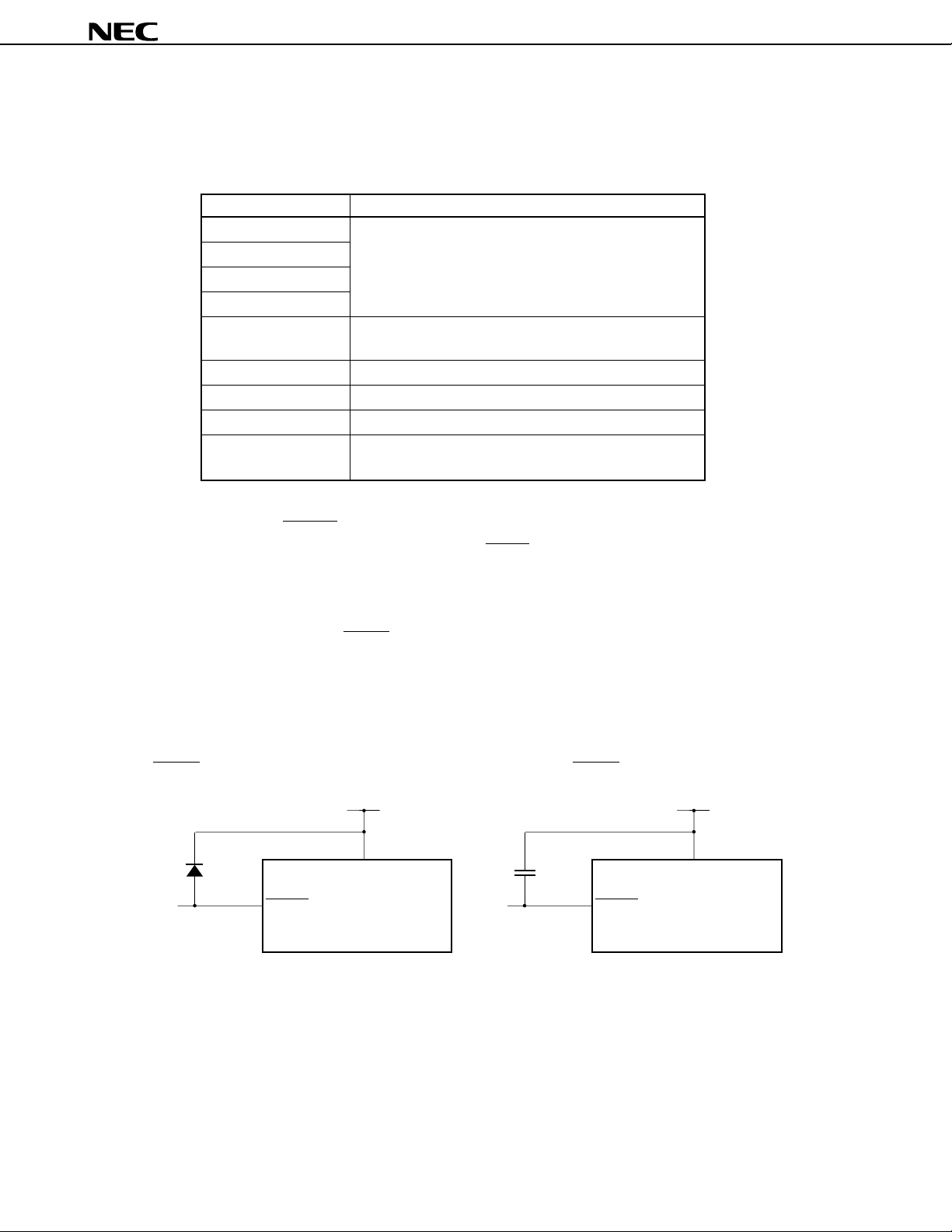

2.5 Notes on Using the RESET and INT Pins

In addition to the functions shown in 2. PIN FUNCTIONS, the RESET pin also has the function of setting a test mode

µ

(for IC testing) in which the internal operations of the

When a voltage higher than VDD is applied to either of these pins, the test mode is set. This means that, even during

µ

normal operation, the

PD17P236 may be set in the test mode if noise exceeding VDD is applied.

For example, if the wiring length of the RESET or INT pin is too long, noise superimposed on the wiring line of the pin

may cause the above problem.

Therefore, keep the wiring length of these pins as short as possible to suppress the noise; otherwise, take noise

preventive measures as shown below by using external components.

• Connect diode with low V

F between VDD • Connect capacitor between VDD

and RESET/INT pin and RESET/INT pin

Diode with

low V

F

RESET, INT

V

DD

PD17P236 are tested.

V

DD

RESET, INT

V

DD

V

DD

12

Data Sheet U14776EJ1V0DS00

µ

PD17P236

3. WRITING AND VERIFYING ONE-TIME PROM (PROGRAM MEMORY)

The program memory of the µPD17P236 is a one-time PROM of 16,384 × 16 bits.

To write or verify this one-time PROM, the pins shown in Table 3-1 are used. Note that no address input pin

is used. Instead, the address is updated by using the clock input from the CLK pin.

Table 3-1. Pins Used to Write/Verify Program Memory

Pin Name Function

VPP Supplies voltage when writing/verifying program memory.

Apply +12.5 V to this pin.

VDD Power supply.

Supply +6 V to this pin when writing/verifying program memory.

CLK Inputs clock to update address when writing/verifying program memory.

By inputting pulse four times to CLK pin, address of program memory is updated.

MD0-MD3 Input to select operation mode when writing/verifying program memory.

D0-D7 Inputs/outputs 8-bit data when writing/verifying program memory.

3.1 Operating Mode When Writing/Verifying Program Memory

The µPD17P236 is set in the program memory write/verify mode when +6 V is applied to the VDD pin and +12.5

V is applied to the VPP pin after the µPD17P236 has been in the reset status (VDD = 5 V, RESET = 0 V) for a specific

time. In this mode, the operating modes shown in Table 3-2 can be set by setting the MD0 through MD3 pins. Leave

all the pins other than those shown in Table 3-1 unconnected or connect them to GND via pull-down resistor

(470 Ω). (See PIN CONFIGURATION (2) PROM programming mode.)

Table 3-2. Setting Operation Mode

Setting of Operating Mode Operating Mode

VPP VDD MD0 MD1 MD2 MD3

+12.5 V +6 V H L H L Program memory address 0 clear mode

L H H H Write mode

L L H H Verify mode

H × H H Program inhibit mode

×: don’t care (L or H)

Data Sheet U14776EJ1V0DS00

13

µ

PD17P236

3.2 Program Memory Writing Procedure

The program memory is written at high speed in the following procedure.

(1) Pull down the pins not used to GND via resistor. Keep the CLK pin low.

(2) Supply 5 V to the V

(3) Supply 5 V to the V

(4) Set the program memory address 0 clear mode by using the mode setting pins.

(5) Supply +6 V to VDD and +12.5 V to VPP.

(6) Set the program inhibit mode.

(7) Write data to the program memory in the 1-ms write mode.

(8) Set the program inhibit mode.

(9) Set the verify mode. If the data have been written to the program memory, proceed to (10). If not, repeat

steps (7) through (9).

(10) Additional writing of (number of times of writing in (7) through (9): X) × 1 ms.

(11) Set the program inhibit mode.

(12) Input a pulse to the CLK pin four times to update the program memory address (+1).

(13) Repeat steps (7) through (12) up to the last address.

(14) Set the 0 clear mode of the program memory address.

(15) Change the voltages on the V

(16) Turn off power.

DD pin. Keep the VPP pin low.

PP pin after waiting for 10

DD and VPP pins to 5 V.

µ

s.

The following figure illustrates steps (2) through (12) above.

Repeated X time

Reset

V

PP

DD

V

V

PP

GND

VDD+1

V

V

DD

DD

GND

CLK

D0-D

MD

MD

7

0

1

Hi-Z Hi-Z Hi-Z Hi-Z

Write

Data input

Verify

Data output

Additional write

Data input

Address

increment

14

MD

MD

2

3

Data Sheet U14776EJ1V0DS00

µ

PD17P236

3.3 Program Memory Reading Procedure

(1) Pull down the pins not used to GND via resistor. Keep the CLK pin low.

(2) Supply 5 V to the VDD pin. Keep the VPP pin low.

(3) Supply 5 V to the VPP pin after waiting for 10 µs.

(4) Set the program memory address 0 clear mode by using the mode setting pins.

(5) Supply +6 V to V

(6) Set the program inhibit mode.

(7) Set the verify mode. Data of each address is output sequentially each time the clock pulse is input to

the CLK pin four times.

(8) Set the program inhibit mode.

(9) Set the program memory address 0 clear mode.

(10) Change the voltage on the V

(11) Turn off power.

The following figure illustrates steps (2) through (9) above.

Reset

VPP

DD and +12.5 V to VPP.

DD and VPP pins to 5 V.

VPP

V

VDD

GND

DD+1

V

VDD

DD

GND

CLK

D0-D7

MD0

MD1

MD2

Hi-Z Hi-Z

"L"

One cycle

Data output Data output

MD3

Data Sheet U14776EJ1V0DS00

15

µ

PD17P236

4. ELECTRICAL SPECIFICATIONS

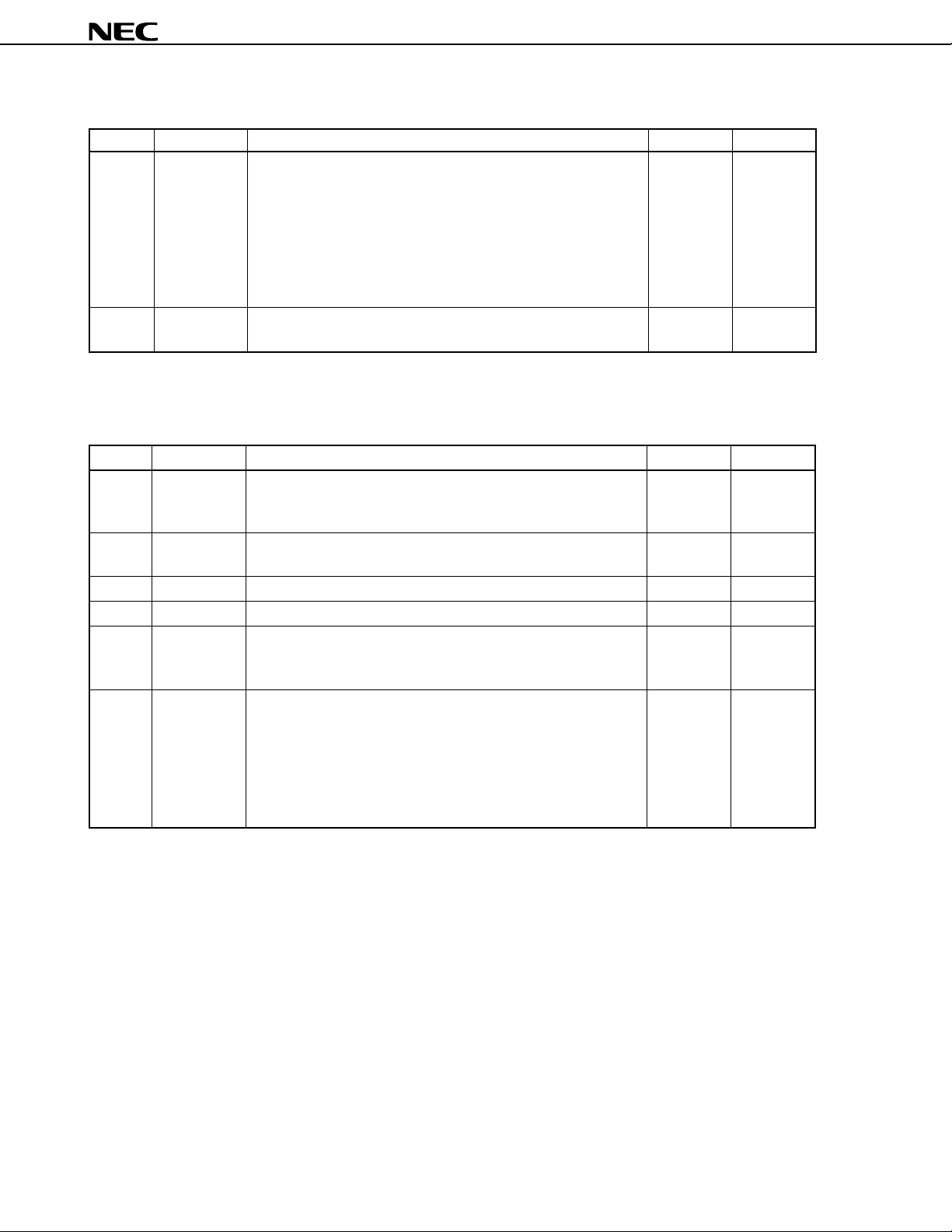

Absolute Maximum Ratings (TA = 25°C)

Item Symbol Conditions Ratings Unit

Supply voltage VDD –0.3 to +7.0 V

PROM power supply VPP –0.3 to +13.5 V

Input voltage VI –0.3 to VDD + 0.3 V

Output voltage VO –0.3 to VDD + 0.3 V

High-level output current

Low-level output current

Operating temperature TA –40 to +85 °C

Storage temperature Tstg –65 to +150 °C

Power dissipation Pd TA = 85°C 180 mW

Note

Note

IOH REM pin Peak value –36.0 mA

rms value –24.0 mA

1 pin (P0E pin) Peak value –7.5 mA

rms value –5.0 mA

Total of P0E pins Peak value –22.5 mA

rms value –15.0 mA

IOL 1 pin (P0B, P0C, P0D, Peak value 7.5 mA

P0E, P1A0, or REM pin)

Total of P0B, P0C, P0D, Peak value 22.5 mA

P1A0, REM pins

Total of P0E pins Peak value 30.0 mA

rms value 5.0 mA

rms value 15.0 mA

rms value 20.0 mA

Note The rms value should be calculated as follows: [rms value] = [Peak value] × √ Duty

Caution Product quality may suffer if the absolute maximum rating is exceeded even momentarily for any

parameter. That is, the absolute maximum ratings are rated values at which the product is on

the verge of suffering physical damage, and therefore the product must be used under conditions

that ensure that the absolute maximum ratings are not exceeded.

16

Data Sheet U14776EJ1V0DS00

µ

PD17P236

Recommended Operating Ranges (TA = –40 to +85 °C, VDD = 2.2 to 3.6 V)

Item Symbol Conditions MIN. TYP. MAX. Unit

Supply voltage VDD1 fX = 1 MHz High-speed mode 2.2 3.6 V

(Instruction execution time: 16 µs)

VDD2 fX = 4 MHz High-speed mode

(Instruction execution time: 4 µs)

VDD3 fX = 8 MHz Ordinary mode

(Instruction execution time: 4 µs)

VDD4 High-speed mode 3.0 3.6 V

(Instruction execution time: 2 µs)

Oscillation frequency fX 1.0 4.0 8.0 MHz

Operating temperature TA –40 +25 +85 °C

Low-voltage detector circuit

Note

tCY 432

Note Reset if the status of VDD = 2.05 V (TYP.) lasts for 1 ms or longer. Program hang-up does not occur even

if the voltage drops, until the reset function is effected. Some oscillators stop oscillating before the reset

function is effected.

µ

s

(MHZ)

10

9

8

7

6

5

)

Z

4

(MH

X

3

(Normal mode)

2

System clock: f

1

fX vs VDD

Operation

guaranteed area

0.4

20 2.2 3 3.6 4

Supply voltage: V

DD

(V)

Remark The region indicated by the broken line in the above figure is the guaranteed operating range in the high-

speed mode.

Data Sheet U14776EJ1V0DS00

17

µ

PD17P236

System Clock Oscillator Characteristics (TA = –40 to +85 °C, VDD = 2.2 to 3.6 V)

Resonator Recommended Item Conditions MIN. TYP. MAX. Unit

Constants

Ceramic Oscillation frequency 1.0 4.0 8.0 MHz

resonator (fX)

X

IN

X

OUT

Note 1

Oscillation After VDD reached MIN. 4 ms

stabilization time

Note 2

in oscillation voltage

range

Notes 1. The oscillation frequency only indicates the oscillator characteristics.

2. The oscillation stabilization time is necessary for oscillation to be stabilized, after VDD application or

STOP mode release.

Caution To use a system clock oscillator circuit, perform the wiring in the area enclosed by the dotted

line in the above figure as follows, to avoid adverse wiring capacitance influences:

• Keep wiring length as short as possible.

• Do not cross a signal line with some other signal lines. Do not route the wiring in the vicinity

of lines through which a large current flows.

• Always keep the oscillator capacitor ground at the same potential as GND. Do not ground the

capacitor to a ground pattern, through which a large current flows.

• Do not extract signals from the oscillator.

External circuit example

X

IN

X

OUT

R1

C2C1

Remark For the resonator selection and oscillator constant, customers are requested to either evaluate the

oscillation themselves or apply to the resonator manufacturer for evaluation.

18

Data Sheet U14776EJ1V0DS00

µ

PD17P236

DC Characteristics (TA = –40 to +85 °C, VDD = 2.2 to 3.6 V)

Item Symbol Conditions MIN. TYP. MAX. Unit

High-level input voltage VIHI1 P1A0 (input), RESET, INT 0.8VDD VDD V

VIH2 P0A, P0B, P0C, P0D 0.7VDD VDD V

VIH3 P0E 0.8VDD VDD V

Low-level input voltage VIL1 P1A0 (input), RESET, INT 0 0.2VDD V

VIL2 P0A, P0B, P0C, P0D 0 0.3VDD V

VIL3 P0E 0 0.35VDD V

High-level input leakage ILIH P0A, P0B, P0C, P0D, P0E, VIH = VDD 3

current P1A0, RESET, INT

Low-level input leakage ILIL1 INT, P1A0 VIL = 0 V –3

current

Internal pull-up resistor R1 P0E, RESET (pulled up) 25 50 100 kΩ

Internal pull-down resistor R3 RESET (pulled down) 2.5 5 10 kΩ

High-level output current IOH1 REM VOH = 1.0 V, –6 –13 –24 mA

High-level output voltage VOH P0E, REM IOH = –0.5 mA VDD–0.3 VDD V

Low-level output voltage VOL1

Low-voltage detection VDT RESET pin pulled down, VDT = VDD 2.05 2.2 V

voltage

Data retention voltage VDDDR RESET = low level or STOP mode 1.3 3.6 V

Supply current IDD1 Operating mode VDD = 3 V ±10% fX = 1 MHz 0.55 1.1 mA

ILIL2 P0E VIL = 0 V –3

w/o pull-up resistor

R2 P0A, P0B, P0C, P0D 100 200 400 kΩ

VDD = 3 V

P0B, P0C, P0D, P1A0 (output), REM

VOL2 P0E IOL = 1.5 mA 0 0.3 V

(high-speed)

IDD2 Operating mode VDD = 3 V ±10% fX = 1 MHz 0.5 1.0 mA

(low-speed)

IDD3 HALT mode VDD = 3 V ±10% fX = 1 MHz 0.4 0.8 mA

IDD4 STOP mode VDD = 3 V ±10% 2.0 20.0

built-in POC

IOL = 0.5 mA 0 0.3 V

fX = 4 MHz 1.0 2.0 mA

fX = 8 MHz 1.3 2.6 mA

fX = 4 MHz 0.75 1.5 mA

fX = 8 MHz 0.9 1.8 mA

fX = 4 MHz 0.5 1.0 mA

fX = 8 MHz 0.6 1.2 mA

TA = 25°C 2.0 5.0

µ

A

µ

A

µ

A

µ

A

µ

A

Data Sheet U14776EJ1V0DS00

19

AC Characteristics (TA = –40 to +85 °C, VDD = 2.2 to 3.6 V)

Item Symbol Conditions MIN. TYP. MAX. Unit

CPU clock cycle time

(instruction execution time)

INT high/low level width tINTH, tINTL 20

RESET low level lwidth tRSL 10

Note

tCY1 3.8 33

tCY2 VDD = 3.0 to 3.6 V 1.9 33

µ

PD17P236

µ

s

µ

s

µ

s

µ

s

Note The CPU clock cycle time (instruction execution time)

is determined by the oscillation frequency of the resonator

connected and SYSCK (RF: address 02H) of the register

file.

The figure on the right shows the CPU clock cycle time

CY vs. supply voltage VDD characteristics.

t

tCY vs V

40

33

10

9

8

7

6

µ

( s)

5

CY

4

3.8

3

2

1.9

CPU clock cycle time t

1

Supply voltage VDD (V)

DD

Operation

guaranteed

area

2.2 3.6

201 34

20

Data Sheet U14776EJ1V0DS00

µ

PD17P236

DC Programming Characteristics (TA = 25°C, VDD = 6.0 ±0.25 V, VPP = 12.5 ±0.3 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

High-level input voltage VIH1 Other than CLK 0.7VDD VDD V

VIH2 CLK VDD – 0.5 VDD V

Low-level input voltage VIL1 Other than CLK 0 0.3VDD V

VIL2 CLK 0 0.4 V

Input leakage current ILI VIN = VIL or VIH 10

High-level output voltage VOH IOH = –1 mA VDD – 1.0 V

Low-level output voltage VOL IOL = 1.6 mA 0.4 V

VDD supply current IDD 30 mA

VPP supply current IPP MD0 = V IL, MD1 = VIH 30 mA

Cautions 1. Keep VPP to within +13.5 V including overshoot.

2. Apply V

DD before VPP and turns it off after VPP.

AC Programming Characteristics (TA = 25°C, VDD = 6.0 ±0.25 V, VPP = 12.5 ±0.3 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Address setup time

MD1 setup time (vs. MD0↓)tM1S 2

Data setup time (vs. MD0↓)tDS 2

Address hold time

Data hold time (vs. MD0↑)tDH 2

MD0↑→ data output float delay time tDF 0 130 ns

VPP setup time (vs. MD3↑)tVPS 2

VDD setup time (vs. MD3↑)tVDS 2

Initial program pulse width tPW 0.95 1.0 1.05 ms

Additional program pulse width tOPW 0.95 21.0 ms

MD0 setup time (vs. MD1↑)tMOS 2

MD0↓→ data output delay time tDV MD0 = MD1 = VIL 1

MD1 hold time (vs. MD0↑)tM1H tM1H+tM1R ≥ 50 µs2

MD1 recovery time (vs. MD0↓)tM1R 2

Program counter reset time tPCR 10

CLK input high-, low-level width tXH, tXL 0.125

CLK input frequency fX 4.19 MHz

Initial mode set time tI 2

MD3 setup time (vs. MD1↑)tM3S 2

MD3 hold time (vs. MD1↓)tM3H 2

MD3 setup time (vs. MD0↓)tM3SR When program memory is read 2

Note

Address

Address

MD3 hold time (vs. MD0↑)tM3HR When program memory is read 2

MD3↓→ data output float delay time tDFR When program memory is read 2

Reset setup time tRES 10

→ data output delay time

Note

Note

(vs. MD0↓)tAS 2

µ

µ

µ

Note

(vs. MD0↑)tAH 2

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

tDAD When program memory is read 2

→ data output hold time tHAD When program memory is read 0 130 ns

µ

µ

µ

µ

µ

A

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

Note The internal address increment (+1) is performed on the fall of the 3rd clock, where 4 clocks compreise one

cycle. The internal clock is not connected to a pin.

Data Sheet U14776EJ1V0DS00

21

Program Memory Write Timing

t

RES

V

PP

V

V

DD

PP

GND

V

DD

+1

DD

V

V

DD

GND

CLK

0-D7

Hi-Z

t

I

0

1

2

3

D

MD

MD

MD

MD

t

VPS

t

VDS

Data input

t

DS

t

t

PCR

t

M1S

t

M3S

PW

t

t

M1H

µ

PD17P236

t

XH

t

Data output

t

DF

t

t

M1R

DV

t

MOS

DH

Data input Data input

t

DS

t

OPW

XL

t

DH

t

AH

t

AS

t

M3H

Program Memory Read Timing

t

RES

V

PP

V

V

V

DD

PP

GND

DD

+1

V

V

DD

DD

GND

CLK

D

0-D7

t

I

MD

0

MD

1

"L"

t

PCR

t

VPS

t

VDS

t

XH

t

XL

t

HAD

t

DAD

Data output Data output

t

DV

t

M3HR

t

DFR

22

MD

MD

2

t

M3SR

3

Data Sheet U14776EJ1V0DS00

5. PACKAGE DRAWING

28-PIN PLASTIC SOP (9.53 mm (375))

28 15

114

A

detail of lead end

P

µ

PD17P236

F

G

H

I

J

S

C

D

M

M

B

L

S

N

K

E

NOTE

Each lead centerline is located within 0.12 mm of

its true position (T.P.) at maximum material condition.

ITEM

MILLIMETERS

A

B

C

D

E

F

G

H

I

J

K

L

N

P

P28GM-50-375B-5

17.9±0.17

0.78 MAX.

1.27 (T.P.)

+0.08

0.42

−0.07

0.1±0.1

2.6±0.2

2.50

10.3±0.3

7.2±0.2

1.6±0.2

+0.08

0.17

−0.07

0.8±0.2

0.12M

0.15

+7°

3°

−3°

Data Sheet U14776EJ1V0DS00

23

30-PIN PLASTIC SSOP (7.62 mm (300))

30 16

µ

PD17P236

detail of lead end

F

G

T

P

115

A

E

S

C

D

M

M

N

S

NOTE

Each lead centerline is located within 0.13 mm of

its true position (T.P.) at maximum material condition.

B

K

L

U

H

I

ITEM

MILLIMETERS

A

9.85±0.15

0.45 MAX.

B

0.65 (T.P.)

C

D

0.24

E

0.1±0.05

F

1.3±0.1

1.2

G

8.1±0.2

H

6.1±0.2

I

1.0±0.2

J

K

0.17±0.03

0.5

L

0.13

M

0.10

N

3°

P

T

0.25

0.6±0.15U

S30MC-65-5A4-2

J

+0.08

−0.07

+5°

−3°

24

Data Sheet U14776EJ1V0DS00

µ

PD17P236

6. RECOMMENDED SOLDERING CONDITIONS

For the µPD17P236 soldering must be performed under the following conditions.

For details of recommended conditions for surface mounting, refer to information document "Semiconductor

Device Mounting Technology Manual" (C10535E).

For other soldering methods, please consult with NEC personnel.

Table 6-1. Soldering Conditions of Surface Mount Type

µ

PD17P236M1GT: 28-pin plastic SOP (9.35 mm (375))

(1)

µ

PD17P236M2GT: 28-pin plastic SOP (9.35 mm (375))

µ

PD17P236M3GT: 28-pin plastic SOP (9.35 mm (375))

µ

PD17P236M4GT: 28-pin plastic SOP (9.35 mm (375))

Soldering Method Soldering Conditions Symbol

Infrared reflow Package peak temperature: 235°C, Time: 30 seconds max. (210°C min.), IR35-107-2

Number of times: 2 max. Number of days: 7

necessary at 125°C for 10 hours)

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked

before unpacking.

VPS Package peak temperature: 215°C, Time: 40 seconds max. (200°C min.), VP15-107-2

Number of days: 7

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked

before unpacking.

Wave soldering Solder bath temperature: 260°C max, Time: 10 seconds max., Number of times: WS60-107-1

once, preheating temperature: 120°C max. (package surface temperature)

Number of days: 7

Partial heating Pin temperature: 300°C max., Time: 3 seconds max. (per side of device) —

Note

(after that, prebaking is necessary at 125°C for 10 hours)

Note

(after that, prebaking is necessary at 125°C for 10 hours)

Note

(after that, prebaking is

Note After opening the dry pack, store it at 25 °C or less and 6.5 % RH or less for the allowable storage period.

Caution Do not use different soldering methods together (except for partial heating).

Data Sheet U14776EJ1V0DS00

25

µ

PD17P236

(2)µPD17P236M1MC-5A4: 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M2MC-5A4: 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M3MC-5A4: 30-pin plastic SSOP (7.62 mm (300))

µ

PD17P236M4MC-5A4: 30-pin plastic SSOP (7.62 mm (300))

Soldering Method Soldering Conditions Symbol

Intrared reflow Package peak temperature: 235°C, Time: 30 seconds max. (210°C min.), IR35-103-2

Number of times: 2 max. Number of days: 3

necessary at 125°C for 10 hours)

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked

before unpacking.

VPS Package peak temperature: 215°C, Time: 40 seconds max. (200°C min.), VP15-103-2

Number of times: 2 max. Number of days: 3

necessary at 125°C for 10 hours)

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked

before unpacking.

Wave soldering Solder bath temperature: 260°C max, Time: 10 seconds max., Number of times: WS60-103-1

once, preheating temperature: 120°C max. (package surface temperature)

Number of days: 3

Partial heating Pin temperature: 300°C max., Time: 3 seconds max. (per side of device) —

Note

(after that, prebaking is necessary at 125°C for 10 hours)

Note

(after that, prebaking is

Note

(after that, prebaking is

Note After opening the dry pack, store it at 25 °C or less and 6.5 % RH or less for the allowable storage period.

Caution Do not use different soldering methods together (except for partial heating).

26

Data Sheet U14776EJ1V0DS00

µ

PD17P236

APPENDIX. DEVELOPMENT TOOLS

To develop the programs for the µPD17P236 subseries, the following development tools are available:

Hardware

Name Remarks

In-circuit emulator

IE-17K,

IE-17K-ET

Note 1

SE board This is an SE board for µPD17236 subseries. It can be used alone to evaluate a system

(SE-17235) or in combination with an in-circuit emulator for debugging.

Emulation probe EP-17K28GT is an emulation probe for 17K series 28-pin SOP (GM-375B). When used with

(EP-17K28GT) EV9500GT-28

Emulation probe EP-17K30GS is an emulation probe for 17K series 30-pin SSOP (MC-5A4). When used

(EP-17K30GS) with EV-9500GT-30

Conversion adapter The EV-9500GT-28 is a conversion adapter for the 28-pin SOP (GM-375B). It is used to connect

(EV-9500GT-28

Conversion adapter The EV-9500GT-30 is a conversion adapter for the 30-pin SSOP (MC-5A4). It is used to

(EV-9500GT-30

PROM programmer AF-9706, AF-9708, and AF-9709 are PROM programmers corresponding to µPD17P236.

(AF-9706

AF-9709

Note 2

) the EP-17K28GT and target system.

Note 3

) connect the EP-17K30GS and target system.

Note 4

, AF-9708

Note 4

) programmed.

Note 4

Program adapter PA-17P236 are adapters that is used to program µPD17P236, and is used in combination

(PA-17P236) with AF-9706, AF-9708, or AF-9709.

IE-17K and IE-17K-ET are the in-circuit emulators used in common with the 17K series

microcontroller.

IE-17K and IE-17K-ET are connected to a PC-9800 series or IBM PC/ATTM compatible machines

as the host machine with RS-232C.

By using these in-circuit emulators with a system evaluation board corresponding to the

microcomputer, the emulators can emulate the microcomputer. A higher level debugging

environment can be provided by using man-machine interface

Note 2

, it connects an SE board to the target system.

Note 3

, it connects an SE board to the target system.

SIMPLEHOST

TM

.

, By connecting program adapter PA-17P236 to this PROM programmer, µPD17P236 can be

Notes 1. Low-cost model: External power supply type

2. Two EV-9500GT-28 are supplied with the EP-17K28GT. Five EV-9500GT-28 are optionally available

as a set.

3. Two EV-9500GT-30 are supplied with the EP-17K30GS. Five EV-9500GT-30 are optionally available

as a set.

4. These are products from Ando Electric Co., Ltd. For details, consult Ando Electric Co., Ltd. (Tel: 033733-1166).

Data Sheet U14776EJ1V0DS00

27

µ

PD17P236

Software

Name Outline Host Machine OS Supply Order Code

17K assembler PC-9800 Japanese WindowsTM3.5" 2HDµSAA13RA17K

(RA17K) series

The RA17K is an assembler common

to the 17K series products. When

developing the program of devices,

RA17K is used in combination with

a device file (AS17235).

IBM PC/AT Japanese Windows 3.5" 2HCµSAB13RA17K

compatible

machine

English Windows

µ

SBB13RA17K

Device file PC-9800 Japanese Windows 3.5" 2HDµSAA13AS17235

(AS17235) series

Support PC-9800 Japanese Windows 3.5" 2HDµSAA13ID17K

software series

(

SIMPLEHOST

The AS17235 is a device file for

µ

PD17230, 17231, 17232, 17233,

17234, 17235, and 17236 and is

used in combination with an

assembler for the 17K series

(RA17K).

SIMPLEHOST

that enables man-machine interface

)

on the Windows when a program is

developed by using an in-circuit

emulator and a personal computer.

is a software package

IBM PC/AT Japanese Windows 3.5" 2HCµSAB13AS17235

compatible

machine

IBM PC/AT Japanese Windows 3.5" 2HCµSAB13ID17K

compatible

machine

English Windows

English Windows

µ

SBB13AS17235

µ

SBB13ID17K

28

Data Sheet U14776EJ1V0DS00

µ

PD17P236

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

DD or GND with a resistor, if it is considered to have a possibility of

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet U14776EJ1V0DS00

29

µ

PD17P236

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, please contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

• Device availability

• Ordering information

• Product release schedule

• Availability of related technical literature

• Development environment specifications (for example, specifications for third-party tools and

components, host computers, power plugs, AC supply voltages, and so forth)

• Network requirements

In addition, trademarks, registered trademarks, export restrictions, and other legal issues may also vary

from country to country.

NEC Electronics Inc. (U.S.)

Santa Clara, California

Tel: 408-588-6000

800-366-9782

Fax: 408-588-6130

800-729-9288

NEC Electronics (Germany) GmbH

Duesseldorf, Germany

Tel: 0211-65 03 02

Fax: 0211-65 03 490

NEC Electronics (UK) Ltd.

Milton Keynes, UK

Tel: 01908-691-133

Fax: 01908-670-290

NEC Electronics (Germany) GmbH

Benelux Office

Eindhoven, The Netherlands

Tel:040-2445845

Fax: 040-2444580

NEC Electronics (France) S.A.

Velizy-Villacoublay, France

Tel:01-30-67 58 00

Fax: 01-30-67 58 99

NEC Electronics (France) S.A.

Spain Office

Madrid, Spain

Tel: 91-504-2787

Fax: 91-504-2860

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel:2886-9318

Fax: 2886-9022/9044

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-528-0303

Fax: 02-528-4411

NEC Electronics Singapore Pte. Ltd.

United Square, Singapore 1130

Tel:65-253-8311

Fax: 65-250-3583

NEC Electronics Taiwan Ltd.

NEC Electronics Italiana s.r.l.

Milano, Italy

Tel: 02-66 75 41

Fax: 02-66 75 42 99

NEC Electronics (Germany) GmbH

Scandinavia Office

Taeby, Sweden

Tel: 08-63 80 820

Fax: 08-63 80 388

Taipei, Taiwan

Tel: 02-2719-2377

Fax: 02-2719-5951

NEC do Brasil S.A.

Electron Devices Division

Rodovia Presidente Dutra, Km 214

07210-902-Guarulhos-SP Brasil

Tel: 55-11-6465-6810

Fax: 55-11-6465-6829

30

J99.1

Data Sheet U14776EJ1V0DS00

µ

PD17P236

SIMPLEHOST

Windows is either a registered trademark or a trademark of Microsoft Corporation in the United States

and/or other countries.

PC/AT is a trademark of IBM Corporation.

The export of this product from Japan is regulated by the Japanese government. To export this product may be prohibited

without governmental license, the need for which must be judged by the customer. The export or re-export of this product

from a country other than Japan may also be prohibited without a license from that country. Please call an NEC sales

representative.

is a trademark of NEC Corporation.

Data Sheet U14776EJ1V0DS00

31

µ

PD17P236

•

The information in this document is current as of June, 2000. The information is subject to change

without notice. For actual design-in, refer to the latest publications of NEC's data sheets or data

books, etc., for the most up-to-date specifications of NEC semiconductor products. Not all products

and/or types are available in every country. Please check with an NEC sales representative for

availability and additional information.

•

No part of this document may be copied or reproduced in any form or by any means without prior

written consent of NEC. NEC assumes no responsibility for any errors that may appear in this document.

•

NEC does not assume any liability for infringement of patents, copyrights or other intellectual property rights of

third parties by or arising from the use of NEC semiconductor products listed in this document or any other

liability arising from the use of such products. No license, express, implied or otherwise, is granted under any

patents, copyrights or other intellectual property rights of NEC or others.

•

Descriptions of circuits, software and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these

circuits, software and information in the design of customer's equipment shall be done under the full

responsibility of customer. NEC assumes no responsibility for any losses incurred by customers or third

parties arising from the use of these circuits, software and information.

•

While NEC endeavours to enhance the quality, reliability and safety of NEC semiconductor products, customers

agree and acknowledge that the possibility of defects thereof cannot be eliminated entirely. To minimize

risks of damage to property or injury (including death) to persons arising from defects in NEC

semiconductor products, customers must incorporate sufficient safety measures in their design, such as

redundancy, fire-containment, and anti-failure features.

•

NEC semiconductor products are classified into the following three quality grades:

"Standard", "Special" and "Specific". The "Specific" quality grade applies only to semiconductor products

developed based on a customer-designated "quality assurance program" for a specific application. The

recommended applications of a semiconductor product depend on its quality grade, as indicated below.

Customers must check the quality grade of each semiconductor product before using it in a particular

application.

"Standard": Computers, office equipment, communications equipment, test and measurement equipment, audio

and visual equipment, home electronic appliances, machine tools, personal electronic equipment

and industrial robots

"Special": Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

"Specific": Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems and medical equipment for life support, etc.

The quality grade of NEC semiconductor products is "Standard" unless otherwise expressly specified in NEC's

data sheets or data books, etc. If customers wish to use NEC semiconductor products in applications not

intended by NEC, they must contact an NEC sales representative in advance to determine NEC's willingness

to support a given application.

(Note)

(1) "NEC" as used in this statement means NEC Corporation and also includes its majority-owned subsidiaries.

(2) "NEC semiconductor products" means any semiconductor product developed or manufactured by or for

NEC (as defined above).

M8E 00. 4

Loading...

Loading...