Page 1

TFT COLOR LCD MODULE

NL8060BC31-28D

31cm (12.1 Type)

SVGA

LVDS interface (1port)

DATA SHEET

DOD-PD-0071 (6th edition)

This DATA SHEET is updated document from

DOD-PD-0823 (5).

All information is subject to change without notice.

Please confirm the sales representative before

starting to design your system.

Document Number: DOD-MD-0071 (6th edition)

Published date: May 2006 CP(N)

1

© NEC LCD Technologies, Ltd.

2003-2006 All rights reserved.

Page 2

NL8060BC31-28D

INTRODUCTION

The Copyright to this document belongs to NEC LCD Technologies, Ltd. (hereinafter called "NEC").

No part of this document will be used, reproduced or copied without prior written consent of NEC.

NEC does and will not assume any liability for infringement of patents, copyrights or other intellectual

property rights of any third party arising out of or in connection with application of the products

described herein except for that directly attributable to mechanisms and workmanship thereof. No license,

express or implied, is granted under any patent, copyright or other intellectual property right of NEC.

Some electronic parts/components would fail or malfunction at a certain rate. In spite of every effort to

enhance reliability of products by NEC, the possibility of failures and malfunction might not be avoided

entirely. To prevent the risks of damage to death, human bodily injury or other property arising out

thereof or in connection therewith, each customer is required to take sufficient measures in its safety

designs and plans including, but not limited to, redundant system, fire-containment and anti-failure.

The products are classified into three quality grades: "Standard", "Special", and "Specific" of the

highest grade of a quality assurance program at the choice of a customer. Each quality grade is designed

for applications described below. Any customer who intends to use a product for application other than

that of Standard quality grade is required to contact an NEC sales representative in advance.

The Standard quality grade applies to the products developed, designed and manufactured in

accordance with the NEC standard quality assurance program, which are designed for such application as

any failure or malfunction of the products (sets) or parts/components incorporated therein a customer uses

are, directly or indirectly, free of any damage to death, human bodily injury or other property, like general

electronic devices.

Examples: Computers, office automation equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools, personal

electronic equipment, industrial robots, etc.

The Special quality grade applies to the products developed, designed and manufactured in accordance

with an NEC quality assurance program stricter than the standard one, which are designed for such

application as any failure or malfunction of the products (sets) or parts/components incorporated therein a

customer uses might directly cause any damage to death, human bodily injury or other property, or such

application under more severe condition than that defined in the Standard quality grade without such

direct damage.

Examples: Control systems for transportation equipment (automobiles, trains, ships, etc.), traffic control

systems, anti-disaster systems, anti-crime systems, medical equipment not specifically

designed for life support, safety equipment, etc.

The Specific quality grade applies to the products developed, designed and manufactured in accordance

with the standards or quality assurance program designated by a customer who requires an extremely

higher level of reliability and quality for such products.

Examples: Military systems, aircraft control equipment, aerospace equipment, nuclear reactor control

systems, medical equipment/devices/systems for life support, etc.

The quality grade of this product is the "Standard" unless otherwise specified in this document.

DATA SHEET DOD-MD-0071 (6th edition)

2

Page 3

NL8060BC31-28D

CONTENTS

INTRODUCTION ................................................................................................................................................... 2

1. OUTLINE............................................................................................................................................................. 4

1.1 STRUCTURE AND PRINCIPLE.................................................................................................................... 4

1.2 APPLICA TION................................................................................................................................................ 4

1.3 FEATURES...................................................................................................................................................... 4

2. GENERAL SPECIFICATIONS ......................................................................................................................... 5

3. BLOCK DIAGRAM............................................................................................................................................ 6

4. DETAILED SPECIFICATIONS........................................................................................................................ 7

4.1 MECHANICAL SPECIFICATIONS............................................................................................................... 7

4.2 ABSOLUTE MAXIMUM RATINGS............................................................................................................. 7

4.3 ELECTRICAL CHARACTERISTICS............................................................................................................ 8

4.3.1 LCD panel signal processing board.......................................................................................................... 8

4.3.2 Backlight lamp.......................................................................................................................................... 9

4.3.3 Power supply voltage ripple.................................................................................................................... 10

4.3.4 Fuse......................................................................................................................................................... 10

4.4 POWER SUPPLY VOLTAGE SEQUENCE..................................................................................................11

4.4.1 LCD panel signal processing board.........................................................................................................11

4.4.2 Inverter.....................................................................................................................................................11

4.5 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS.................................................................. 12

4.5.1 LCD panel signal processing board........................................................................................................ 12

4.5.2 Backlight lamp........................................................................................................................................ 13

4.5.3 Positions of plug and socket ................................................................................................................... 13

4.5.4 Connection between receiver and transmitter for LVDS..................................................................... ... 14

4.6 DISPLAY COLORS AND INPUT DATA SIGNALS ................................................................................... 15

4.7 DISPLAY POSITIONS.................................................................................................................................. 16

4.8 SCANNING DIRECTIONS........................................................................................................ .................. 16

4.9 INPUT SIGNAL TIMINGS........................................................................................................................... 17

4.9.1 Outline of input signal timings ............................................................................................................... 17

4.9.2 Timing characteristics...................................................................................................

4.9.3 Input signal timing chart......................................................................................................................... 19

4.10 OPTICS........................................................................................................................................................ 20

4.10.1 Optical characteristics........................................................................................................................... 20

4.10.2 Definition of contrast ratio.................................................................................................................... 21

4.10.3 Definition of luminance uniformity...................................................................................................... 21

4.10.4 Definition of response times................................................................................................................. 21

4.10.5 Definition of viewing angles................................................................................................................. 21

5. RELIABILITY TESTS...................................................................................................................................... 22

6. PRECAUTIONS ................................................................................................................................................ 23

6.1 MEANING OF CAUTION SIGNS............................................................................................................... 23

6.2 CAUTIONS................................................................................................................................................... 23

6.3 A TTE NTIONS............................................................................................................................................... 23

6.3.1 Handling of the product.......................................................................................................................... 23

6.3.2 Environment ........................................................................................................................................... 24

6.3.3 Characteristics......................................................................................................................................... 24

6.3.4 Other....................................................................................................................................................... 24

7. OUTLINE DRAWINGS.................................................................................................................................... 25

7.1 FRONT VIEW............................................................................................................................................... 25

7.2 REAR VIEW ................................................................................................................................................. 26

.......................... 18

DATA SHEET DOD-MD-0071 (6th edition)

3

Page 4

1. OUTLINE

1.1 STRUCTURE AND PRINCIPLE

Color LCD module NL8060BC31-28D is composed of the amorphous silicon thin film transistor

liquid crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film

Transistor) array and a backlight.

The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the

TFT array glass substrate and a color-filter glass substrate.

Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated

into best form for active matrix system by a signal processing circuit, and sent to the driver LSIs which

drive the individual TFT arrays.

The TFT array as an electro-optical switch regulates the amount of transmitted light from the

backlight assembly, when it is controlled by data signals. Color images are created by regulating the

amount of transmitted light through the TFT array of red, green and blue dots.

1.2 APPLICA TION

• For industrial use

1.3 FEATURES

• High luminance

• High contrast

• Wide viewing angle

• Wide temperature range

• LVDS interface

• Reversible-scan direction

• Edge light type (without inverter)

• Replaceable lamp for backlight

• Acquisition product for UL60950-1/CSA C22.2 No.60950-1-03 (File number: E170632)

NL8060BC31-28D

DATA SHEET DOD-MD-0071 (6th edition)

4

Page 5

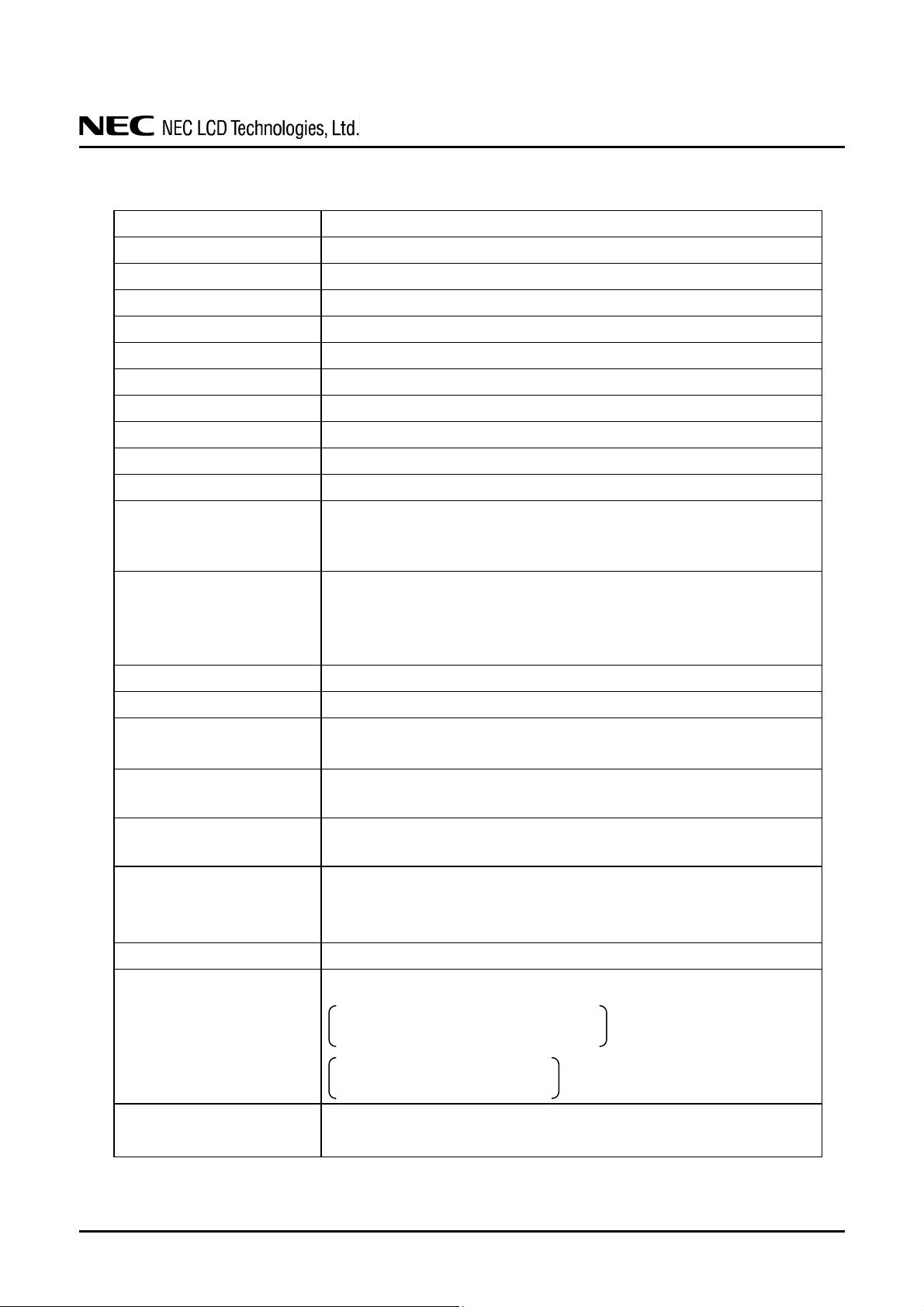

2. GENERAL SPECIFICATIONS

Display area

Diagonal size of display

Drive system

Display color

Pixel

Pixel arrangement

Dot pitch

Pixel pitch

Module size

Weight

Contrast ratio

Viewing angle

Designed viewing direction

Polarizer surface

Polarizer pencil-hardness

NL8060BC31-28D

246.0 (H) × 184.5 (V) mm

31 cm (12.1 inches)

a-Si TFT active matrix

262,144 colors

800 (H) × 600 (V) pixels

RGB (Red dot, Green dot, Blue dot) vertical stripe

0.1025 (H) × 0.3075 (V) mm

0.3075 (H) × 0.3075 (V) mm

280.0 (W) × 210.0 (H) × 13.0 (D) mm (typ.)

730 g (typ.)

600:1 (typ.)

≥

At the contrast ratio

• Horizontal: Right side 70° (typ.), Left side 70° (typ.)

• Vertical: Up side 45° (typ.), Down side 55° (typ.)

At DPS= Low or open: normal scan

• Viewing direction without image reversal: up side (12 o'clock)

• Viewing direction with contrast peak: down side (6 o'clock)

• Viewing angle with optimum grayscale (γ=2.2): normal axis

Antiglare

3H (min.) [by JIS K5400]

10:1

(perpendicular)

Color gamut

Response time

Luminance

Signal system

Power supply voltage

Backlight

Power consumption

At LCD panel center

40 % (typ.) [against NTSC color space]

←→

Ton+Toff (10%

33 ms (typ.)

At IBL= 5.0mArms / lamp

350 cd/m

LVDS 1port (Receiver: THC63LVDF84B, THine Electronics Inc. or

equivalent)

6bit digital signals for data of RGB colors, Dot clock (CLK),

Data enable (DE)

LCD panel signal processing board: 3.3V

Edge light type: 2 cold cathode fluorescent lamps

Replaceable part

Recommended inverter (Option)

At IBL=5.0mArms / lamp, Checkered flag pattern

6.4 W (typ., Power dissipation of the inverter is not included.)

2

(typ.)

• Lamp holder set: Type No. 121LHS18

• Inverter: Type No. 121PW181

90%)

DATA SHEET DOD-MD-0071 (6th edition)

5

Page 6

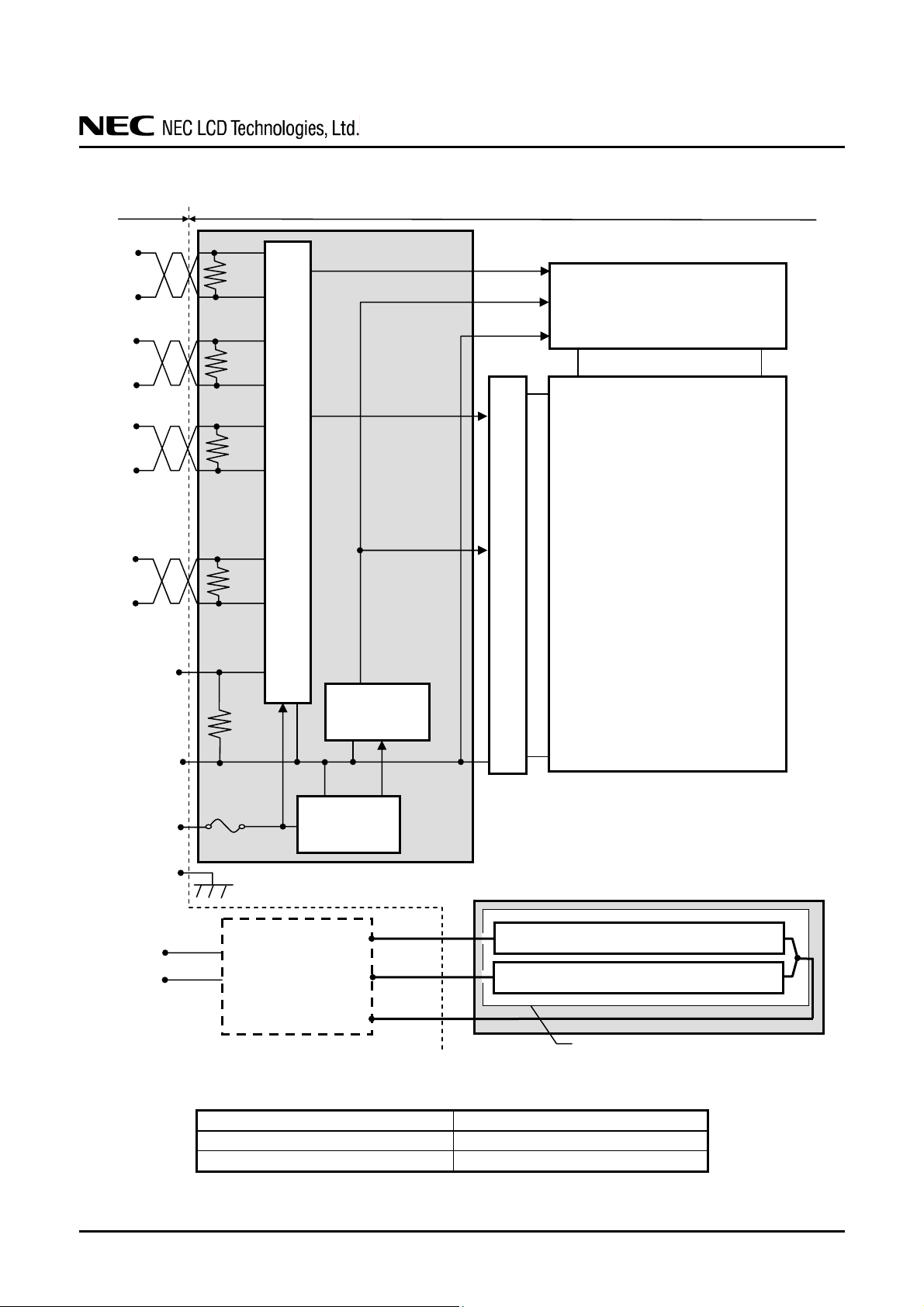

NL8060BC31-28D

3. BLOCK DIAGRAM

Host

LCD module (Product)

D0+

100Ω

H-driver

D0D1+

100Ω

D1D2+

100Ω

2,400 lines

D2-

LCD panel

CLK+

100Ω

Controller with receiver for LVDS

H: 800 × 3 (R, G, B)

V: 600

600 lines

V-driver

CLK-

DPS

Power supply

for gradation

47kΩ

GND

Note1

Note2

VCC

FG

Note1

Fuse

LCD panel signal processing board

DC/DC

converter

Backlight (Edge light type)

Note2

VBLH

Lamp

VBLH

Lamp

VDDB

GNDB

Inverter

(Option)

Note2

VBLC

Note1

Metallic frame of lamp holder

Note1: Relations between GND (Signal ground), FG (Frame ground) and VBLC (Lamp low voltage terminal)

in the LCD module are as follows.

GND - FG Not connected

GND - VBLC Not connected

FG - VBLC Not connected

Note2: GND, FG and GNDB must be connected to customer equipment’s ground, and it is recommended that

these grounds are connected together in customer equipment.

DATA SHEET DOD-MD-0071 (6th edition)

6

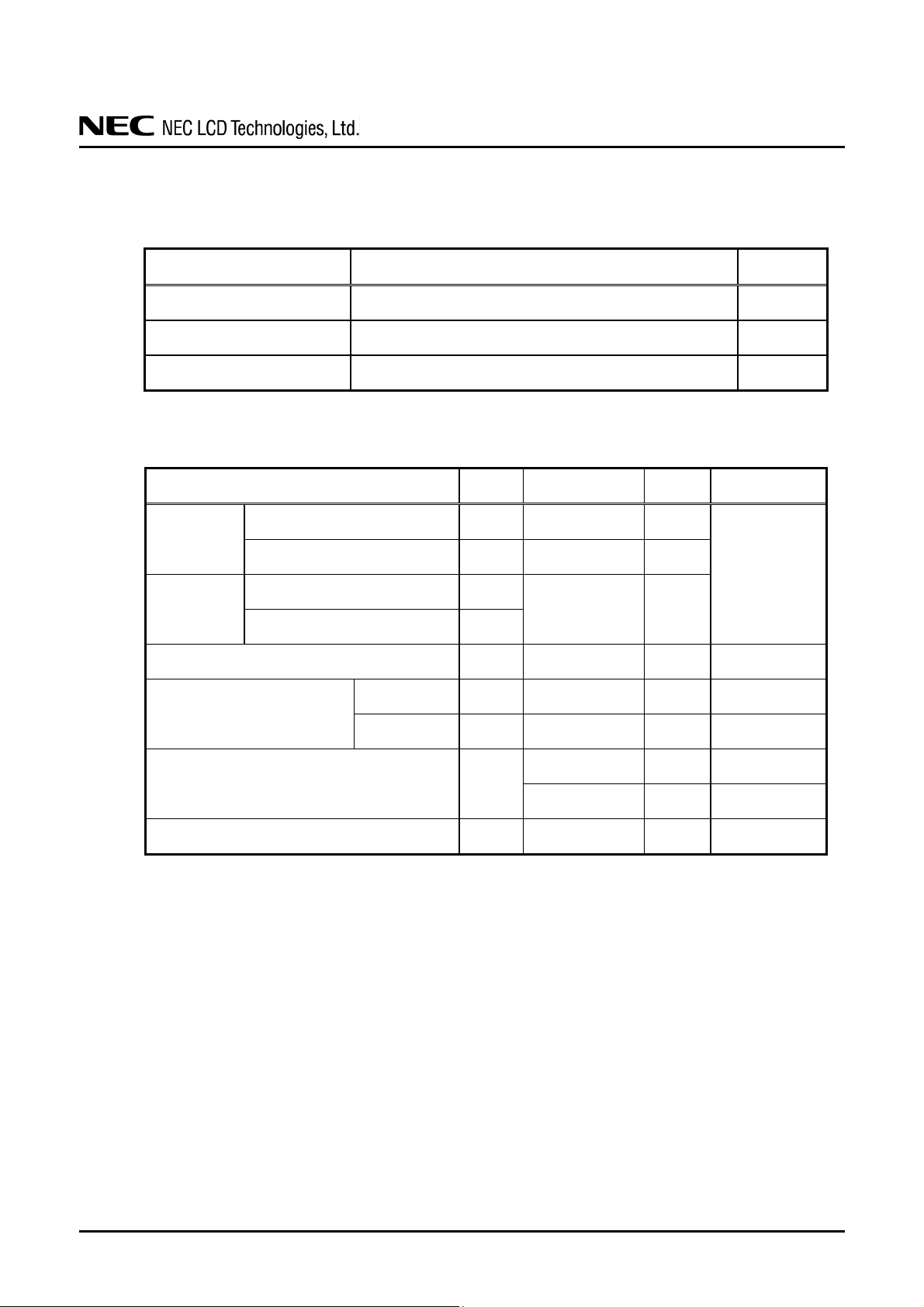

Page 7

4. DETAILED SPECIFICATIONS

4.1 MECHANICAL SPECIFICATIONS

Parameter Specification Unit

NL8060BC31-28D

Module size

Display area

Weight 730 (typ.), 760 (max.) g

Note1: See "7. OUTLINE DRAWINGS".

4.2 ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Rating Unit Remarks

Power supply

voltage

Input voltage

for signals

Operating temperature

LCD panel signal processing board VCC -0.3 to +4.0 V

Storage temperature Tst -20 to +80

280.0 ± 0.5 (W) × 210.0 ± 0.5 (H) × 13.0 (typ., D)

13.7 (max., D)

246.0 (H) × 184.5 (V)

Lamp voltage VBLH 1,800 Vrms

Display signals

Note1

Function signal

Note2

Front surface TopF -10 to +70

Rear surface TopR -10 to +70

VD

-0.3 to VCC+0.3 V

VF

°C

°C

°C

Note1 mm

Note1 mm

Ta = 25°C

-

Note3

Note4

Relative humidity

Note5

Absolute humidity

Note5

≤ 95

RH

≤ 85

AH

≤ 70

Note6

%

%

g/m

3

Note1: Display signals are D0+/-, D1+/-, D2+/- and CLK+/-.

Note2: Function signal is DPS.

Note3: Measured at center of LCD panel surface (including self-heat)

Note4: Measured at center of LCD module's rear shield surface (including self-heat)

Note5: No condensation

Note6: Water amount at Ta = 50°C and RH = 85%

40 < Ta ≤ 50°C

Ta ≤ 40°C

Ta > 50°C

DATA SHEET DOD-MD-0071 (6th edition)

7

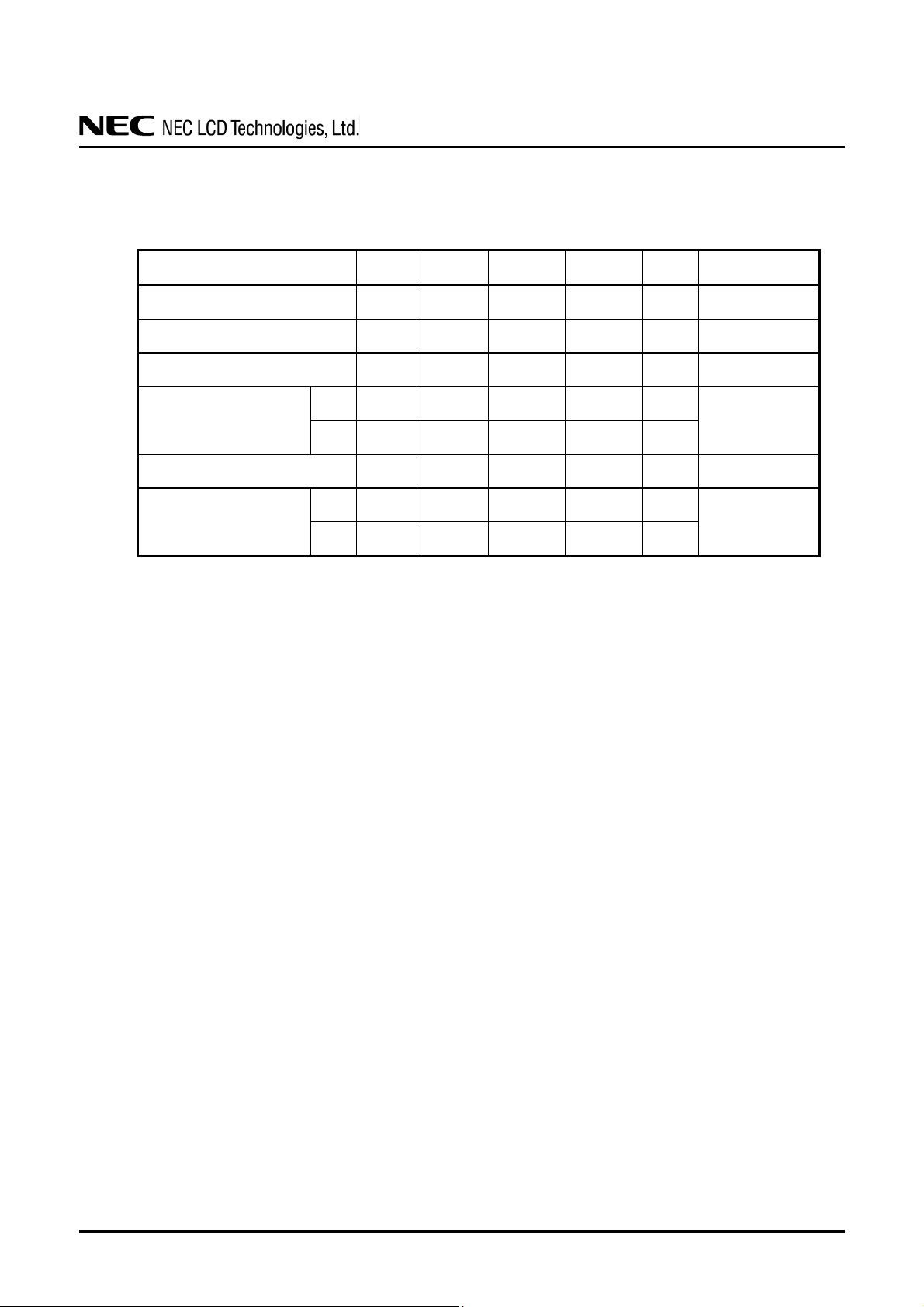

Page 8

4.3 ELECTRICAL CHARACTERISTICS

4.3.1 LCD panel signal processing board

Parameter Symbol min. typ. max. Unit Remarks

Power supply voltage VCC 3.0 3.3 3.6 V -

Power supply current ICC -

Permissible ripple voltage VRP - - 100 mVp-p for VCC

200

Note1

410

Note2

NL8060BC31-28D

(Ta = 25°C)

mA at VCC = 3.3V

Differential input threshold

voltage for LVDS receiver

Terminating resistance RT - 100 -

Input voltage for DPS

signal

High VTH - - +100 mV

Low VTL -100 - - mV

High VFH 2.0 - VCC V

Low VFL 0 - 0.8 V

Note1: Checkered flag pattern [by EIAJ ED-2522]

Note2: Pattern for maximum current

Note3: Common mode voltage for LVDS receiver

Ω

at VCM=1.2V

Note3

-

-

DATA SHEET DOD-MD-0071 (6th edition)

8

Page 9

4.3.2 Backlight lamp

Lamp current IBL 2.0 5.0 5.5 mArms

Lamp voltage VBLH - 570 - Vrms Note2, Note3

Lamp starting voltage VS

Lamp oscillation frequency FO 58 63 68 kHz Note6

Note1: This product consists of 2 backlight lamps, and these specifications are for each lamp.

Note2: The lamp voltage cycle between lamps should be kept on a same phase. "VS" and "VBLH"

Note3: The asymmetric ratio of working waveform for lamps (Power supply voltage peak ratio,

Note4: Th is product consists of 2 lamps. 2 lamps are contained in the 1 lamp hold er, and both lamps

Note5: The inverter should be designed so that the lamp starting voltage can be maintained for more

Note6: In case "FO" is not the recommended value, beat noise may display on the screen, because of

Note7: Method of lamp cable installation may invite fluctuation of lamp current and voltage or

NL8060BC31-28D

(Ta=25°C, Note1)

Parameter Symbol min. typ. max. Unit Remarks

at IBL=5.0mArms:

350cd/m

Note3, Note4

970 - - Vrms

1,410 - - Vrms

Ta = 25°C

Note2, Note3, Note5

Ta = -10°C

Note2, Note3, Note5

are the voltage value between low voltage side (Cold) and high voltage side (Hot).

power supply current peak ratio and waveform space ratio) should be less than 5 % (See the

following figure.). If the waveform is asymmetric, DC (Direct current) element apply into the

lamp. In this case, a lamp lifetime may be shortened, because a distribution of a lamp

enclosure substance inclines toward one side between low voltage terminal (Cold terminal)

and high voltage terminal (Hot terminal). When designing the inverter, evaluate asymmetric of

lamp working waveform sufficiently.

Pa

Sa

|Pa - Pb|

Pb

× 100 ≤ 5 %

0

Sb

Pb

|Sa - Sb|

Sb

× 100 ≤ 5 %

Pa: Supply voltage/current peak for positive, Pb: Supply voltage/current peak for negative

Sa: Waveform space for positive part, Sb: Waveform space for negative part.

are connected to 1 low voltage cable. Recommendation lamp current is 5.0mArms typical for

each lamp, and sum of 2 lamps is 10mArms typical. The lamp current should be measured by

high-frequency current meter at the low voltage terminal.

than 1 second. Otherwise the lamp may not be turned on.

interference between "FO" and "1/th". Recommended value of "FO" is as following

FO = × × (2n-1)

1 1

4 th

th: Horizontal cycle (See "4.9.2 Timing characteristics".)

n: Natural number (1, 2, 3 ⋅⋅⋅⋅⋅⋅⋅⋅)

asymmetric of lamp working waveform. When designing method of lamp cable installation,

evaluate the fluctuation of lamp current, voltage and working waveform sufficiently.

2

☆

DATA SHEET DOD-MD-0071 (6th edition)

9

Page 10

4.3.3 Power supply voltage ripple

This product works, even if the ripple voltage levels are beyond the permissible values as following

the table, but there might be noise on the display image.

Power supply voltage

NL8060BC31-28D

Ripple voltage Note1

(Measure at input terminal of power supply)

Unit

VCC 3.3V

≤ 100

Note1: The permissible ripple voltage includes spike noise.

4.3.4 Fuse

Parameter

Type Supplier

VCC FCC16202AB

Fuse

KAMAYA

ELECTRIC Co., Ltd

Rating

2.0A

32V

Fusing

current

4.0A Note1

Note1: The power supply capacity should be more than the fusing current. If it is less than the fusing

current, the fuse may not blow in a short time, and then nasty smell, smoke and so on may

occur.

mVp-p

Remarks

DATA SHEET DOD-MD-0071 (6th edition)

10

Page 11

4.4 POWER SUPPLY VOLTAGE SEQUENCE

4.4.1 LCD panel signal processing board

VCC

Note1

0V

Display signals*

Function signals

Note2

0V

0ms < t < 35ms

* These signals should be measured at the terminal of 100Ω resistance.

Note1: In terms of voltage variation (voltage drop) whi le VCC risi ng edge is below 3.0 V, a protection

circuit may work, and then this product may not work.

Note2: Display signals (D0+/-, D1+/-, D2+/- and CLK+/-) and function signal (DPS) must be Low or

High-impedance, exclude the VALID period (See above sequence diagram), in order to avoid

that internal circuits is damaged.

If some of display and function signals of this product are cut while this product is working,

even if the signal input to it once again, it might not work normally. VCC should be cut when

the display and function signals are stopped.

4.4.2 Inverter (Option)

Display and

function signals

Note1

VDDB

Note1: These are the display and function signals for LCD panel signal processing board.

Note2: The backlight should be turned on within the valid period of display and function signals, in

order to avoid unstable data display.

3.0V

ON

10µs≤ Tr < 50ms

Note2

VALID period

VALID period

NL8060BC31-28D

OFF

Toff ≥ 50ms

0ms < t < 35ms

ON

0.3V

☆

DATA SHEET DOD-MD-0071 (6th edition)

11

Page 12

4.5 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS

4.5.1 LCD panel signal processing board

CN1 socket (LCD module side): FI-SE20P-HFE (Japan Aviation Electronics Industry Limited (JAE))

Adaptable plug: FI-S20S (Japan Aviation Electronics Industry Limited (JAE))

Pin No. Symbol Signal Remarks

1 GND

Ground Note1

2 GND

3 DPS Selection of scan direction

4 GND

Ground Note1

5 GND

6 CLK+

Pixel clock Note3

7 CLK-

8 GND Ground Note1

NL8060BC31-28D

High: Reverse scan

Low or Open: Normal scan Note2

9 D2+

Pixel data Note3

10 D2-

11 GND Ground Note1

12 D1+

Pixel data Note3

13 D1-

14 GND Ground Note1

15 D0+

Pixel data Note3

16 D0-

17 GND

Ground Note1

18 GND

19 VCC

Power supply Note1

20 VCC

Note1: All GND and VCC terminals should be used without any non-connected lines

Note2: See "4.8 SCANNING DIRECTIONS".

Note3: Twist pair wires with 100Ω (Characteristic impedance) should be connected between LCD

panel signal processing board and LVDS transmitter.

Note4: See "4.5.4 Connection between receiver and transmitter for LVDS".

☆

DATA SHEET DOD-MD-0071 (6th edition)

12

Page 13

4.5.2 Backlight lamp

Attention: VBLH and VBLC must be connected correctly. Wrong connections will cause electric

shock and also break down of the product.

CN2 plug: BHR-04VS-1 (J.S.T Mfg. Co., Ltd.)

Adaptable socket: SM03 (7-D1) B-BHS-1-TB (LF) (SN),

SM03 (7-D1) B-BHS-1-TB (J.S.T Mfg. Co., Ltd.)

Pin No. Symbol Signal Remarks

1 VBLH High voltage (Hot) Cable color: Pink

2 VBLH High voltage (Hot) Cable color: Pink

3 N. C. - Keep this pin Open.

4 VBLC Low voltage (Cold) Cable color: White

4.5.3 Positions of plug and socket

CN2

High voltage (Hot)

4

2

1

Low voltage (Cold)

Caution label

Rear side

Barcode label Name plate

NL8060BC31-28D

1

20

CN1

Insert direction

DATA SHEET DOD-MD-0071 (6th edition)

13

Page 14

4.5.4 Connection between receiver and transmitter for LVDS

Note2

R0

R1

R2

R3

R4

R5

G0

G1

G2

G3

G4

G5

B0

B1

B2

B3

B4

B5

Note4

Vsync

DE

CLK

Host LCD module (Product)

TA0

TA1

TA2

TA3

TA4

TA5

TA6

TB0

TB1

TB2

TB3

TB4

TB5

TB6

TC0

TC1

TC2

TC3

TC4

TC5

TC6

CLK IN

TCLK+

TCLK-

TC+

TB+

TA+

GND

Note3

TC-

TB-

TA-

VCC

GND

DPS

LVDS transmitter

THC63LVDM83R or equivalent

Note1

Note1: Recommended transmitter THC63LVDM83R (THine Electronics Inc.) or equivalent

Note2: LSB (Least Significant Bit) – R0, G0, B0 MSB (Most Significant Bit) – R5, G5, B5

Note3: Twist pair wires with 100Ω (Characteristic impedance) should be used between LCD panel

signal processing board and LVDS transmitter.

Note4: Input signal to TC4 is not us ed inside the product, but do not keep TC4 open to avoid noise

problem.

10

11

12

13

14

15

16

17

18

19

20

NL8060BC31-28D

GND

1

GND

2

GND

3

DPS

4

GND

5

GND

6

CLK+

7

CLK-

8

GND

9

D2+

D2-

GND

D1+

D1-

GND

D0+

D0GND

GND

VCC

VCC

CN1

RCLK+

RCLK-

RC+

RC-

RB+

RB-

RA+

RA-

Receiver for LVDS

Equivalent of

THC63LVDF84B

LCD controller

LCD panel signal processing board

Signal

processor

VCC

DPS

DATA SHEET DOD-MD-0071 (6th edition)

14

Page 15

4.6 DISPLAY COLORS AND INPUT DATA SIGNALS

This product can display in equivalent to 262,144 colors in 64 gray scales. Also the relation between

display colors and input data signals is as the following table.

Display colors

Black

Blue

Red

Magenta

Green

Basic colors

Red gray scale

Green gray scale

Blue gray scale

Cyan

Yellow

White

Black

dark

bright

Red

Black

dark

bright

Green

Black

dark

bright

Blue

↑

↓

↑

↓

↑

↓

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

000000

000000

111111

111111

000000

000000

111111

111111

000000

000001

000010

:

:

111101

111110

111111

000000

000000

000000

:

:

000000

000000

000000

000000

000000

000000

:

:

000000

000000

000000

NL8060BC31-28D

Data signal (0: Low level, 1: High level)

000000

000000

000000

000000

111111

111111

111111

111111

000000

000000

000000

:

:

000000

000000

000000

000000

000001

000010

:

:

111101

111110

111111

000000

000000

000000

:

:

000000

000000

000000

000000

111111

000000

111111

000000

111111

000000

111111

000000

000000

000000

000000

000000

000000

000000

000000

000000

000000

000000

000000

000000

000001

000010

111101

111110

111111

:

:

:

:

:

:

DATA SHEET DOD-MD-0071 (6th edition)

15

Page 16

4.7 DISPLAY POSITIONS

The following table is the coordinates per pixel (See "4.8 SCANNING DIRECTIONS".).

C (0, 0)

R G B

C( 0, 0) C( 1, 0) ∙ ∙ ∙ C( X, 0) ∙ ∙ ∙ C(798, 0) C(799, 0)

C( 0, 1) C( 1, 1) ∙ ∙ ∙ C( X, 1) ∙ ∙ ∙ C(798, 1) C(799, 1)

∙

∙

∙

C( 0, Y) C( 1, Y) ∙ ∙ ∙ C( X, Y) ∙ ∙ ∙ C(798, Y) C(799, Y)

∙

∙

∙

C( 0, 598) C( 1, 598) ∙ ∙ ∙ C( X, 598) ∙ ∙ ∙ C(798, 598) C(799, 598)

C( 0, 599) C( 1, 599) ∙ ∙ ∙ C( X, 599) ∙ ∙ ∙ C(798, 599) C(799, 599)

4.8 SCANNING DIRECTIONS

The following figures are seen from a front view. Also the arrow shows the direction of scan.

Note1: Meaning of C (X, Y) and D (X, Y)

C (X, Y): The coordinates of the display position (See "4.7 DISPLAY POSITIONS".)

D (X, Y): The data number of input signal for LCD panel signal processing board

∙

∙

∙

∙

∙

∙

∙

∙ ∙ ∙

∙

∙

∙ ∙ ∙

∙

C (0, 0)

D (0, 0)

C (0, 599)

D (0, 599)

∙

∙

∙

∙

∙

∙

C (799, 0)

D (799, 0)

C (799, 599)

D (799, 599)

Figure1. Normal scan (DPS: Low or Open)

C (0, 0)

D (799, 599)

C (0, 599)

D (799, 0)

C (799, 0)

D (0, 599)

C (799, 599)

D (0, 0)

Figure2. Reverse scan (DPS: High)

∙

∙ ∙ ∙

∙

∙

∙ ∙ ∙

∙

Note1

Note1

NL8060BC31-28D

∙

∙

∙

∙

∙

∙

∙

∙ ∙ ∙

∙

∙

∙

∙

DATA SHEET DOD-MD-0071 (6th edition)

16

Page 17

4.9 INPUT SIGNAL TIMINGS

4.9.1 Outline of input signal timings

• Horizontal signal

Note1

DE (Data enable)

Display period

• Vertical signal

Note1

DE (Data enable)

Display period

Note1: This diagram indicates virtual signal for set up to timing.

Note2: See "4.9.3 Input signal timing chart" for numeration of pulse.

NL8060BC31-28D

Horizontal display period (thd)

Vertical display period (tvd)

1

2

34

600

Note2

DATA SHEET DOD-MD-0071 (6th edition)

17

Page 18

4.9.2 Timing characteristics

Parameter Symbol min. typ. max. Unit Remarks

Frequency 1/tc 34.0 38.362 40.0 MHz 26.067 ns (typ.)

CLK

DATA

Vsync

DE

CLK-DATA

Vsync-DE

timing

Horizontal

Vertical

(One frame)

CLK-DE

Duty - -

Rise time, Fall time -

Setup time - ns

Hold time - ns

Rise time, Fall time -

Pulse width tvp 1 2 - H

Setup time tvds 1 - - CLK

Hold time tvdh 1 - - CLK

Cycle th

Display period thd 800 CLK

Cycle tv

Display period tvd 600 H

Setup time - ns

Hold time - ns

Rise time, Fall time -

Note1: Definition of parameters is as follows.

tc = 1CLK, th = 1H

Note2: See the data sheet of LVDS transmitter.

NL8060BC31-28D

-

-

24.0 26.693 30.1

829 1,024 - CLK

16.1 16.683 17.2 ms

603 625 - H

-

ns

ns

µs

ns

Note2

Note2

-

37.463 kHz (typ.)

Note1, Note2

59.94 Hz (typ.)

Note1

Note2

☆

DATA SHEET DOD-MD-0071 (6th edition)

18

Page 19

4.9.3 Input signal timing chart

Horizontal timing

CLK

DATA

(R0-R5)

(G0-G5)

(B0-B5)

DE

Vertical timing

tvp

Vsync

DATA

(R0-R5)

(G0-G5)

(B0-B5)

DE

tvds

INVALID

INVALID

tvdh

tc

thd

1 2 599 600

tvd

tv

NL8060BC31-28D

INVALID1 2 799 800

th

INVALID

DATA SHEET DOD-MD-0071 (6th edition)

19

Page 20

4.10 OPTICS

4.10.1 Optical characteristics

Parameter Condition Symbol min. typ. max. Unit Remarks

Luminance

Contrast ratio

Luminance uniformity

White

Red

Chromaticity

Green

Blue

Color gamut

Response time

Right

Viewing angle

Left

Up

Down

θR = 0°, θL = 0°, θU = 0°, θD = 0°

θR = 0°, θL = 0°, θU = 0°, θD = 0°

θR

θR = 0°, θL = 0°, θU = 0°, θD = 0°

at center, against NTSC color space

White at center

White/Black at center

White

= 0°, θL = 0°, θU = 0°, θD = 0°

x coordinate Wx 0.283 0.313 0.343 -

y coordinate Wy 0.299 0.329 0.359 -

x coordinate Rx - 0.586 - -

y coordinate Ry - 0.345 - -

x coordinate Gx - 0.327 - -

y coordinate Gy - 0.518 - -

x coordinate Bx - 0.156 - -

y coordinate By - 0.145 - -

White to Black Ton - 8 10 ms

Black to White Toff - 25 30 ms

θU = 0°, θD = 0°, CR ≥ 10 θR

θU = 0°, θD = 0°, CR ≥ 10 θL

θR = 0°, θL = 0°, CR ≥ 10 θU

θR = 0°, θL = 0°, CR ≥ 10 θD

L 250 350 - cd/m

CR 300 600 - - Note3

LU - 1.25 1.40 - Note4

C 35 40 - %

Note1: These are initial characteristics.

Note2: Measurement conditions are as follows.

Ta=25°C, VCC=3.3V, IBL= 5.0mArms/lamp, Display mode: SVGA, Horizontal cycle =

1/37.463kHz, Vertical cycle = 1/59.94Hz, DPS= Low or Open: Normal scan

Optical characteristics are measured at luminance saturation after 20minutes from working the

product, in the dark room. Also measurement methods are as follows.

50cm

Photodetector (BM-5A)

LCD module

(Product)

1°

Note3: See "4.10.2 Definition of contrast ratio".

Note4: See "4.10.3 Definition of luminance uniformity".

Note5: These coordinates are found on CIE 1931 chromaticity diagram.

Note6: Product surface temperature: TopF = 28°C

Note7: See "4.10.4 Definition of response times".

Note8: See "4.10.5 Definition of viewing angles".

NL8060BC31-28D

(Note1, Note2)

60 70 60 70 35 45 45 55 -

2

-

Note5

Note6

Note7

°

°

Note8

°

°

DATA SHEET DOD-MD-0071 (6th edition)

20

Page 21

θ

①

②

4.10.2 Definition of contrast ratio

The contrast ratio is calculated by using the following formula.

Contrast ratio (CR) =

4.10.3 Definition of luminance uniformity

The luminance uniformity is calculated by using following formula.

Luminance uniformity (LU) =

The luminance is measured at near the 5 points shown below.

100

300

500

4.10.4 Definition of response times

Response time is measured, the luminance changes from "white" to "black", or "black" to "white" on

the same screen point, by photo-detector. Ton is the time it takes the luminance change from 90%

down to 10%. Also Toff is the time it takes the luminance change from 10% up to 90% (See the

following diagram.).

White

Luminance

Black

4.10.5 Definition of viewing angles

133

100%

90%

10%

0%

Left

Lower

Luminance of white screen

Luminance of black screen

Maximum luminance from ①

Minimum luminance from ①

400

③

④

Ton

Normal axis (Perpendicular)

θL

θU

θD

667

⑤

12 o’clock

Upper

R

NL8060BC31-28D

to ⑤

to ⑤

Toff

Right

DATA SHEET DOD-MD-0071 (6th edition)

21

Page 22

5. RELIABILITY TESTS

Test item Condition Judgement

High temperature and humidity

(Operation)

NL8060BC31-28D

① 60 ± 2°C, RH = 90%, 240hours

② Display data is black.

High temperature

(Operation)

Heat cycle

(Operation)

Thermal shock

(Non operation)

(Operation)

(Operation)

Vibration

(Non operation)

Mechanical shock

(Non operation)

ESD

Dust

① 70 ± 2°C, 240hours

② Display data is black.

① -10 ± 3°C…1hour

70 ± 3°C…1hour

② 50cycles, 4hours/cycle

③ Display data is black.

① -20 ± 3°C…30minutes

80 ± 3°C…30minutes

② 100cycles, 1hour/cycle

③ Temperature transition time is within

5 minutes.

① 150pF, 150Ω, ±10kV

② 9 places on a panel surface Note2

③ 10 times each places at 1 sec interval

① Sample dust: No. 15 (by JIS-Z8901))

② 15 seconds stir

③ 8 times repeat at 1 hour interval

① 5 to 100Hz, 19.6m/s2

② 1 minute/cycle

③ X, Y, Z direction

④ 120 times each directions

① 539m/ s2, 11ms

② ±X, ±Y, ±Z direction

③ 5 times each directions

No display malfunctions

Note1

No display malfunctions

No physical damages

Note1

Note1: Display and appearance are checked under environmental conditions equivalent to the

inspection conditions of defect criteria.

Note2: See the following figure for discharge points.

DATA SHEET DOD-MD-0071 (6th edition)

22

Page 23

6. PRECAUTIONS

6.1 MEANING OF CAUTION SIGNS

The following caution signs have very important meaning. Be sure to read "6.2 CAUTIONS" and

"6.3 ATTENTIONS", after understanding these contents!

NL8060BC31-28D

6.2 CAUTIONS

!

This sign has the meaning that customer will be injured by himself or the product will

sustain a damage, if customer has wrong operations.

This sign has the meaning that customer will get an electrical shock, if customer has

wrong operations.

This sign has the meaning that customer will be injured by himself, if customer has

wrong operations.

∗ Do not touch the working backlight. There is a danger of an electric shock.

∗ Do not touch the working backlight. There is a danger of burn injury.

∗ Do not shock and press the LCD panel and the backlight! There is a danger of breaking,

because they are made of glass. (Shock: To be not greater 539m/s

2

and to be not greater

11ms, Pressure: To be not greater 19.6 N (φ16mm jig))

☆

6.3 A TTENTIONS

!

6.3.1 Handling of the product

① Take hold of both ends without touching the circuit board when the product (LCD module) is picked

up from inner packing box to avoid broken down or misadjustment, because of stress to mounting

parts on the circuit board.

② Do not hook nor pull cables such as lamp cable, and so on, in order to avoid any damage.

③ When the product is put on the table temporarily, display surface must be placed downward.

④ When handling the product, take the measures of electrostatic discharge with such as earth band,

ionic shower and so on, because the product may be damaged by electrostatic.

⑤ The torque for product mounting screws must never exceed 0.294N⋅m. Higher torque might result

in distortion of the bezel.

⑥ The product must be installed using mounting holes without undue stress such as bends or twist (See

outline drawings). And do not add undue stress to any portion (such as bezel flat area). Bends or

twist described above and undue stress to any portion may cause display mura.

⑦ Do not press or rub on the sensitive product surface. When cleaning the product surface, use of the

cloth with ethanolic liquid such as screen cleaner for LCD is recommended.

DATA SHEET DOD-MD-0071 (6th edition)

23

Page 24

⑧ Do not push nor pull the interface connectors while the product is working.

⑨ Do not bend or unbend the lamp cable at the near part of the lamp holding rubber, to avoid the

⑩ If the lamp cable is attached on the metal part of the product directly, high frequency leak current

⑪ When not connecting FG of the LCD module to the customer's equipment ground, inverter noise

⑫ When handling the product, use of an original protection sheet on the product surface (polarizer) is

6.3.2 Environment

① Do not operate or store in high temperature, high humidity, dewdrop atmosphere or corrosive

② In order to prevent dew condensation occurring by temperature difference, the product packing

③ Do not operate in high magnetic field. Circuit boards may be broken down by it.

④ This product is not designed as radiation hardened.

6.3.3 Characteristics

The following items are neither defects nor failures.

① Response time, luminance and color may be changed by ambient temperature.

② Display mura, flicker, vertical seam or small spot may be observed depending on display patterns.

③ Optical characteristics (e.g. luminance, display uniformity, etc.) gradually is going to change

④ Do not display the fixed pattern for a long time because it may cause image sticking. Use a screen

⑤ The display color may be changed depending on viewing angle because of the use of condenser

⑥ Optical characteristics may be changed depending on input signal timings.

⑦ The interference noise between input signal frequency for this product's signal processing board

6.3.4 Other

① All VCC and GND terminals should be used without any non-connected lines.

② Do not disassemble a product or adjust variable resistors.

③ See "REPLACEMENT MANUAL FOR LAMP HOLDER SET", when replacing backlight lamps.

④ Pay attention not to insert foreign materials inside of the product, when using tapping screws.

⑤ Pack the product with original shipping package, in order to avoid any damages during

NL8060BC31-28D

damage for high voltage side of the lamp.

to the metal part may occur, then the brightness may decrease or the lamp may not be turned on.

may create video noise on the LCD screen.

recommended for protection of product surface. Adhesive type protection sheet may change color

or characteristics of the polarizer.

gases. Keep the product in packing box with antistatic pouch in room temperature to avoid dusts

and sunlight, when storing the product.

box should be opened after enough time being left under the environment of an unpacking room.

Evaluate the leaving time sufficiently because a situation of dew condensation occurring is

changed by the environmental temperature and humidity. (Recommended leaving time: 6 hours or

more with packing state)

depending on operating time, and especially low temperature, because the LCD has cold cathode

fluorescent lamps.

saver, if the fixed pattern is displayed on the screen.

sheet in the backlight.

and luminance control frequency of the inverter may appear on a display. Set up luminance control

frequency of the inverter so that the interference noise does not appear.

transportation, when returning the product to NEC for repair and so on.

DATA SHEET DOD-MD-0071 (6th edition)

24

Page 25

7. OUTLINE DRAWINGS

7.1 FRONT VIEW

NL8060BC31-28D

Unit: mm

Note1: The values in parentheses are for reference.

Note2: The torque for product mounting screws must never exceed 0.294N⋅m.

Note3: Mounting hole portions (4 pieces)

DATA SHEET DOD-MD-0071 (6th edition)

25

Page 26

7.2 REAR VIEW

Note1: The values in parentheses are for reference.

Note2: The torque for product mounting screws must never exceed 0.294N⋅m.

NL8060BC31-28D

Unit: mm

DATA SHEET DOD-MD-0071 (6th edition)

26

Loading...

Loading...