Page 1

ND-24219

ISSUE 2

STOCK # 151980

®

1

Very Small Platform System Manual

NEAX2000 IVS Family of Products

AUGUST, 1998

NEC America, Inc.

Page 2

LIABILITY DISCLAIMER

NEC America, Inc. reserves the right to change the specifications,

functions, or features, at any time, without notice.

NEC America, Inc. has prepared this docum ent for use by its em ployees and customers. The information contained herein is the

property of NEC America, Inc. and shall not be reproduced without

prior written approval from NEC America, Inc.

NEAX and D

term

are registered trademarks of NEC Corporation.

Copyright 1998

NEC America, Inc.

Printed in U SA

Page 3

NDA-24219

ISSUE 2

AUGUST, 1998

NEAX1000 IVS

Very Small Platform System Manual

NEAX2000 IVS Family of Products

TABLE OF CONTENTS

LIST OF FIGURES

LIST OF TABLES

REGULATORY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Regulatory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

2. FCC Part 15 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

3. FCC Part 68 Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

3.1 Company Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

3.2 Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

3.3 Location of FCC Compliance Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

4. Direct-Inward Dialing (DID) Calls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

5. Regulatory Information on Single-Line Analog Telephones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

6. Hearing Aid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

7. Industry Canada CS-03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

8. Safety Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

8.1 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Page

vii

CHAPTER 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. PURPOSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. REFERENCE MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. HOW TO FOLLOW THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. SCOPE OF INSTALLATION PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 2 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. TRUNKING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. SYSTEM CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 PIM Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Installation Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. FUNCTIONAL OUTLINE OF EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Functional Outline of Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Functional Outline of Installation Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Functional Outline of Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 Control Circuit Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.2 Application Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.3 Line/Trunk Circuit Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NDA-24219 TABLE OF CONTENTS

Page i

Revision 2.0

Page 4

TABLE OF CONTENTS (CONTINUED)

Page

4. CIRCUIT CARD INSTALLATION CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Circuit Card Mounting Slots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHAPTER 3 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1. PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.1 Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2 Static Electricity Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3 Removing/Inserting Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2. PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

NAP-200

-001 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1. Unpacking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

-002 Marking and Drilling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1. CONFIRMING Equipment Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2. Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3. Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

-003 Installation of Main Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1. Wall-Mounting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2. 19-Inch Rack-Mounting Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3. DESKTOP Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4. AC Power Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

-004 PWR CA-A and BUS Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

-005 Connection of Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1. Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.1 Internal Battery Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

-006 Cable Running to MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1. MDF Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2. Cable Running to External MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

-007 Termination of Cables on MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1. Cable Connection to MDF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2. MDF Cross Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

-008 Switch Setting of Circuit Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1. Circuit Cards Switch Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

2. PN-CP03 (MP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3. PZ-PW86 (PWR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4. PZ-PW112 (PWR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5. PN-8COTM/8COTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

-009 Mounting Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

1. Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

-010 System Initialization and

System Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1. System Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.1 All Clear, Except LEN0000 CAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.2 Resident System Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2. System Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.1 CAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.2 MAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

2.3 Feature Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

TABLE OF CONTENTS NDA-24219

Page ii

Revision 2.0

Page 5

TABLE OF CONTENTS (CONTINUED)

Page

-011 Operation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1. Operation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

-012 Cleaning and Visual Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

1. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

2. Visual Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

-013 Mounting of Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

1. Mounting Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

CHAPTER 4 OFFICE DATA PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1. CUSTOMIZING DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.1 Data Programming Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.2 General Information on Customizing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.2.1 Numbering Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.2.2 Station Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

1.2.3 Trunk Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

1.2.4 Station Hunting Group Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

1.2.5 Call Pickup Group Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

1.2.6 Speed Calling-System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

1.2.7 Port Assignment Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

1.3 Customer Specification Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

1.3.1 Numbering Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

1.3.2 Station Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

1.3.3 Trunk Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1.3.4 Station Hunting Group Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

1.3.5 Call Pickup Group Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

1.3.6 Speed Calling-System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

1.4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.4.1 Port Assignment Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.4.2 Bay Face Layout for Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.4.3 Quantity Table for Circuit Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

NDA-24219 TABLE OF CONTENTS

Page iii

Revision 2.0

Page 6

LIST OF FIGURES

Figure Title Page

1-1 Installation Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Scope of Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-1 PBX Trunking Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2-2 PIM Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

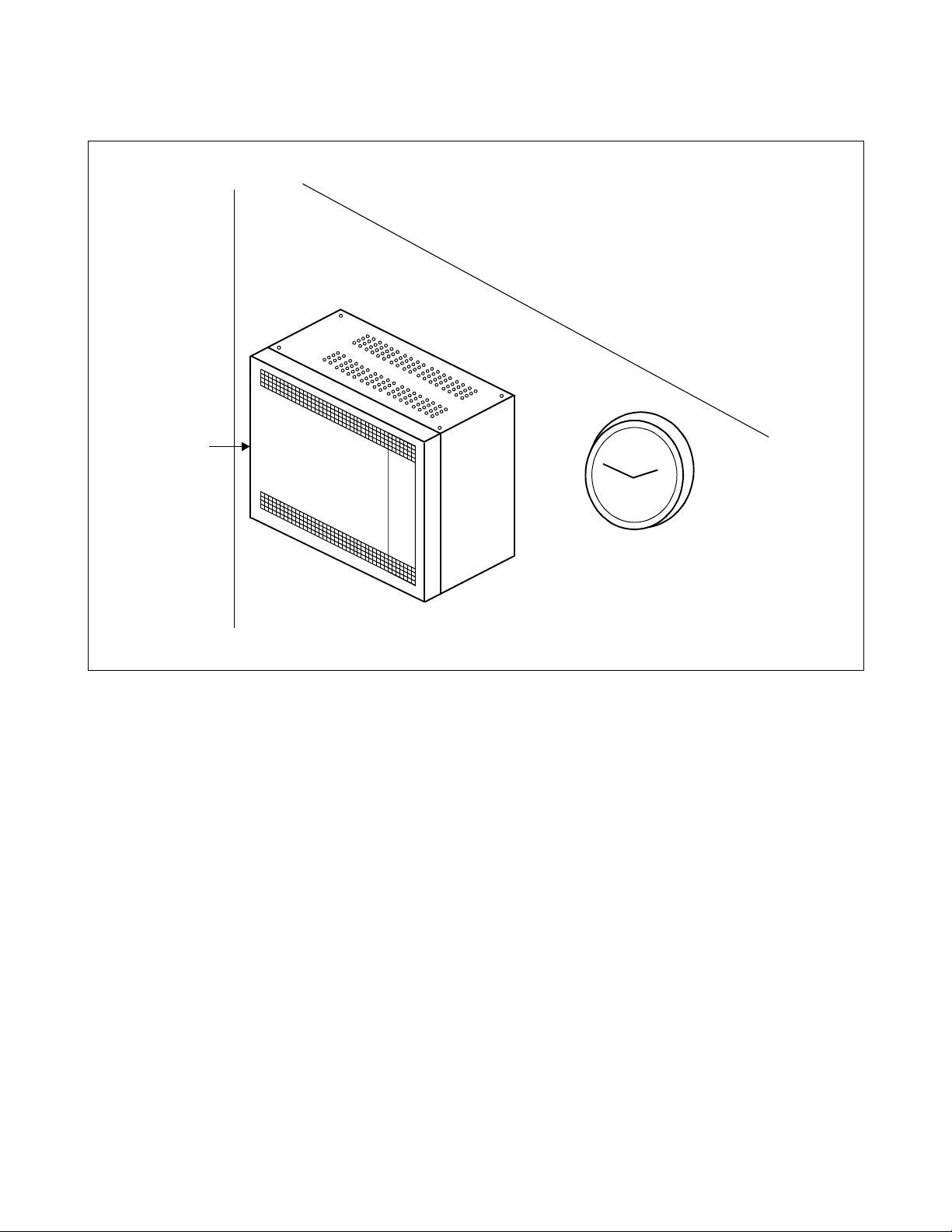

2-3 Wall-Mounting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

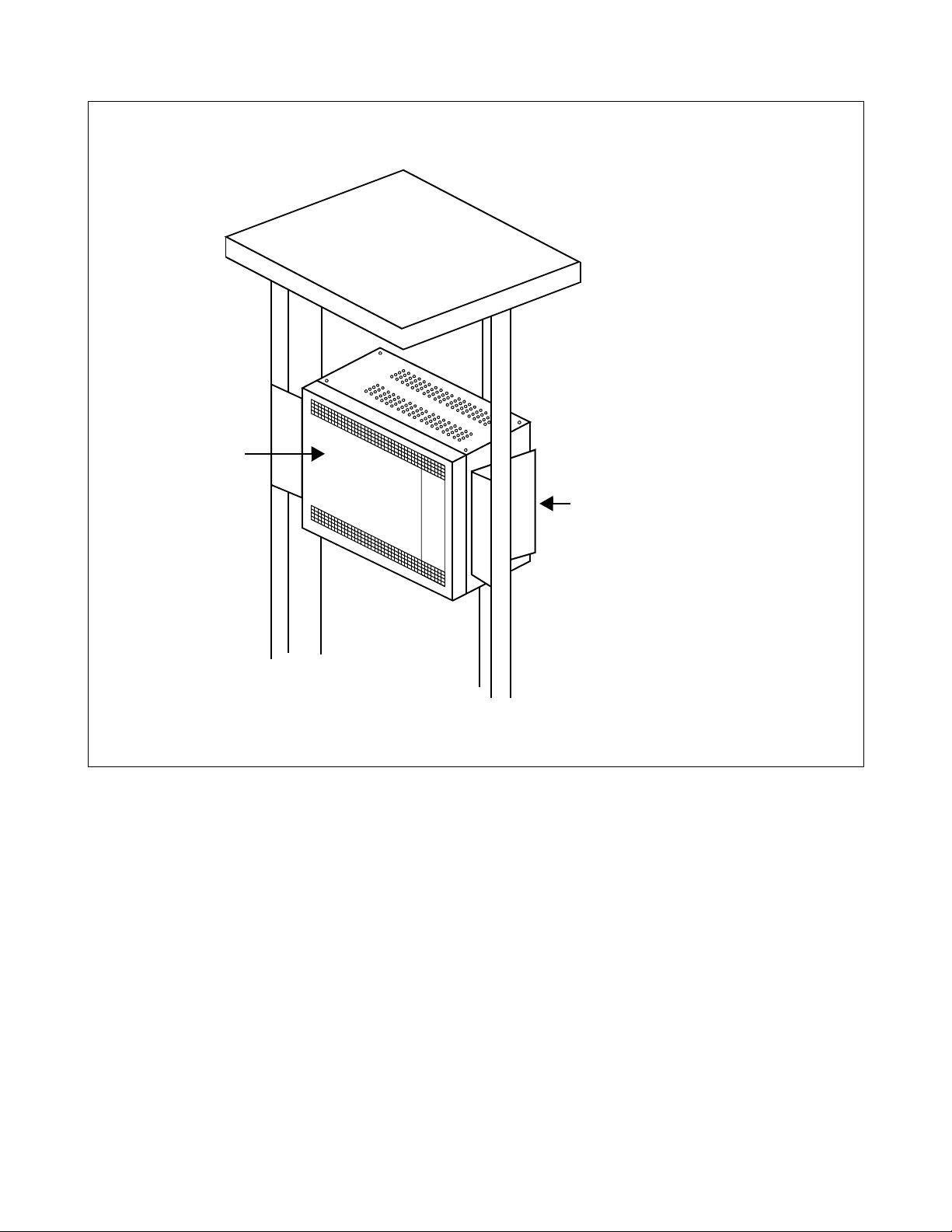

2-4 19-Inch Rack-Mounting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

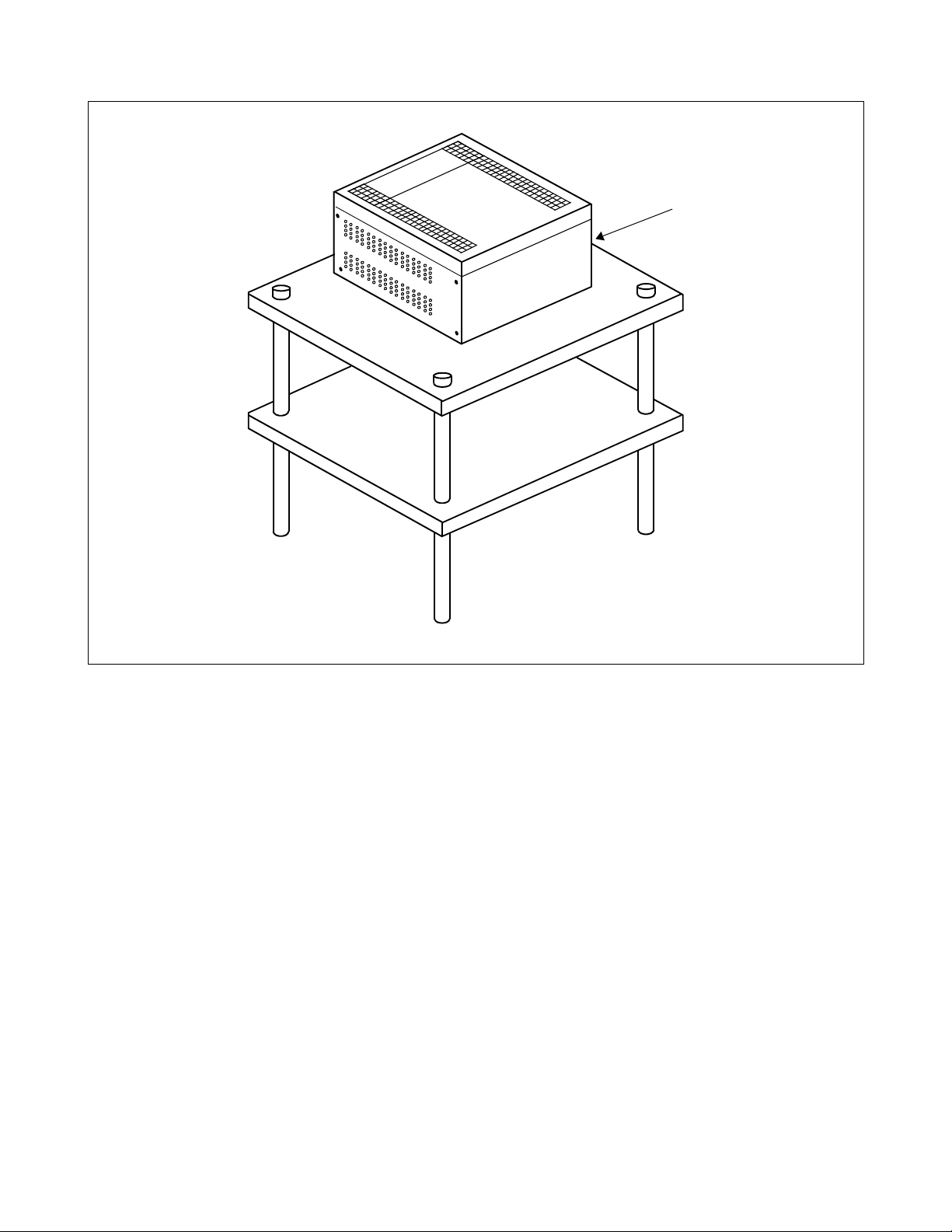

2-5 Desktop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-6 Circuit Card Mounting Slots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-1 Static Electricity Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-2 Procedure Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3 Static-Sensitive Caution Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

001-1 Unpacking Main Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

002-1 Wall Mounting Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

002-2 Installing Anchor Bolt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

003-1 Connection of PIMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

003-2 Screwing PIM to Wall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

003-3 Connecting Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

003-4 Connecting AC CORD to PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

003-5 Mounting PIM to 19-Inch Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

003-6 Connecting Rubber Foot to PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

003-7 Cable Connection on PZ-PW86/PW112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

003-8 PWR CNT CA-C Cable Connection between PIMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

003-9 AC Power Cable Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

004-1 Connection of PWR CA-A Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

004-2 Mounting BUS Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

005-1 Battery Replacement Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

005-2 Internal Battery Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

005-3 Internal Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

006-1 MDF Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

006-2 Cable Running to External MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

007-1 Card Slots and LTC Connectors Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

007-2 Location of Each LEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

007-3 LTC Connector Pin Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

007-4 MDF Cross Connection for 4 Line C.O. Trunk Card (PN-4COT). . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

007-5 MDF Cross Connection for 8 Line C.O. Trunk Card (PN-8COT). . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

007-6 MDF Cross Connection for 4W E&M Trunk Card (PN-2ODT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

007-7 MDF Cross Connection for 2W E&M Trunk Card (PN-2ODT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

007-8 MDF Cross Connection for 2 Line DID Trunk Card (PN-AUCA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

007-9 MDF Cross Connection for 4 Line DID Trunk Card (PN-4DITB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

007-10 MDF Cross Connection for Single Line Telephone (Standard Line) . . . . . . . . . . . . . . . . . . . . . . . . . 66

007-11 MDF Cross Connection for Single Line Telephone (Long Line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

007-12 MDF Cross Connection for Multiline Terminal/DSS Console (Standard Line). . . . . . . . . . . . . . . . . . 68

007-13 MDF Cross Connection for Multiline Terminal/DSS Console (Long Line) . . . . . . . . . . . . . . . . . . . . . 69

007-14 Mounting Handset Support to SN610 ATTCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

007-15 Jack Set Installation for SN610 ATTCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

007-16 SN610 ATTCON Switch Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

007-17 Cable Connection to SN610 ATTCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

007-18 MDF Cross Connection for SN610 ATTCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

007-19 MDF Cross Connection for Day/Night Mode Change by External Key . . . . . . . . . . . . . . . . . . . . . . . 76

007-20 External TAS Indicator Connection Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

LIST OF FIGURES NDA-24219

Page iv

Revision 2.0

Page 7

LIST OF FIGURES (CONTINUED)

Figure Title Page

007-21 MDF Cross Connection for TAS Indicator with Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

007-22 MDF Cross Connection for TAS Indicator with Battery (Ground Start) . . . . . . . . . . . . . . . . . . . . . . . 79

007-23 Paging Equipment Connection Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

007-24 MDF Cross Connection for Paging Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

007-25 External Tone Source Connection Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

007-26 MDF Cross Connection for External Tone Source Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

007-27 Connecting Tone Source Supplied with D.C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

007-28 MDF Cross Connection for External BGM Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

007-29 Cable Connection Between PN-TNTA and External BGM Sources . . . . . . . . . . . . . . . . . . . . . . . . . 88

007-30 PFT Connection Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

007-31 MDF Cross Connection for PFT (PN-AUCA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

007-32 PFT (PZ-8PFTA) Connection Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

007-33 Mounting PZ-8PFTA Card to PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

007-34 Connection of 25-Pair Cable and PZ-8PFTA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

007-35 PFT Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

007-36 MDF Cross Connection for PFT (PZ-8PFTA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

007-37 MDF Cross Connection for Alarm Display Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

007-38 Assembly of SN716 DESKCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

007-39 SN716 DESKCON Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

007-40 MDF Cross Connection with AC Adapter Power Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

007-41 MDF Cross Connection via PN-PW00 Power Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

007-42 Single Line Device Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

007-43 Message Center Interface Connection for VM00 to AP00. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

008-1 PN-CP03 (MP) Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

008-2 PZ-PW86 (PWR) Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

008-3 PZ-PW112 (PWR) Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

008-4 PN-8COT (COT) Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

009-1 PZ-PW86/PZ/PW112 Card Lamp Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

009-2 Mounting Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

009-3 Installing Card Stopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

0010-1 Connecting External Hold Tone Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

0010-2 MP Card Switch Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

013-1 Mounting Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4-1 Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

NDA-24219 LIST OF FIGURES

Page v

Revision 2.0

Page 8

LIST OF TABLES

Table Title Page

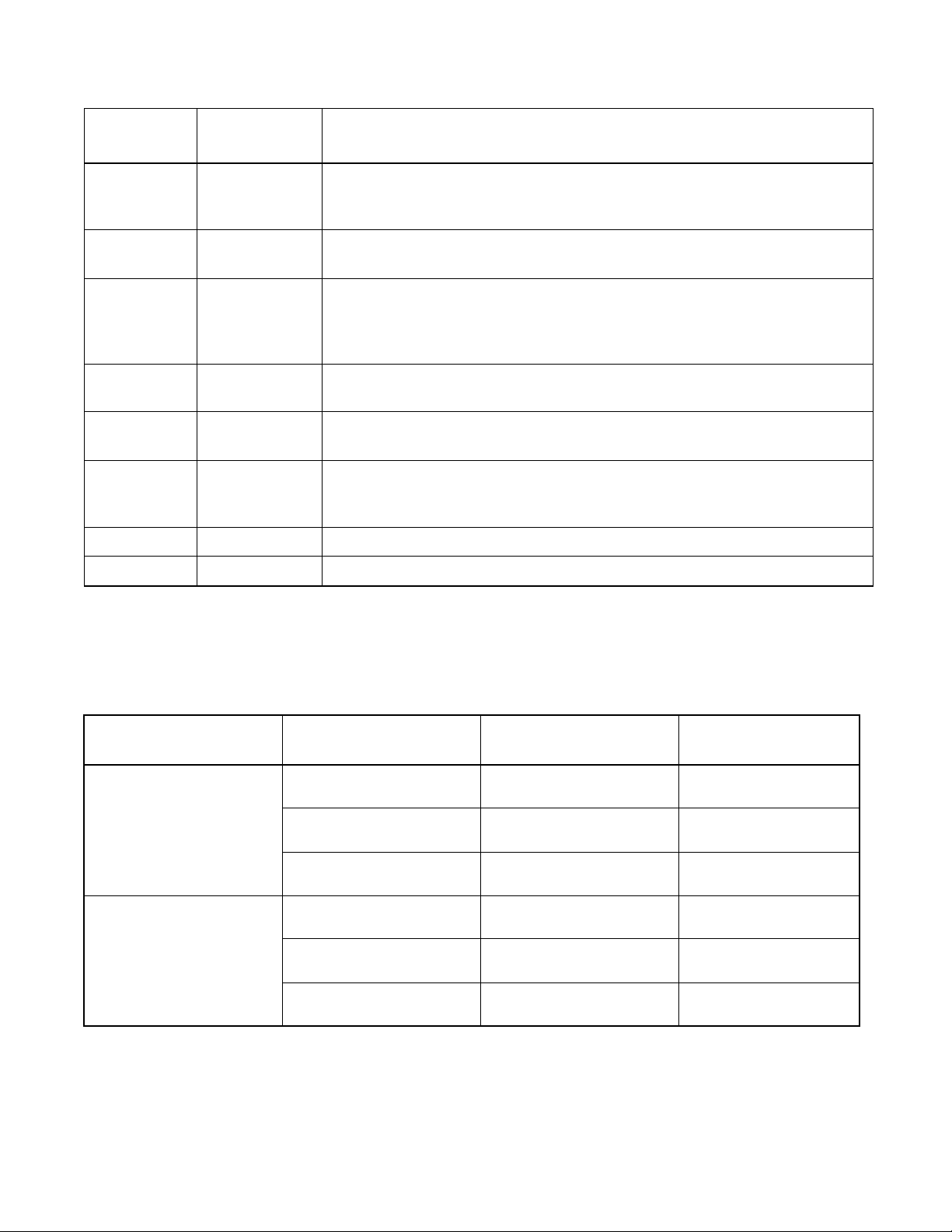

2-1 Symbols in Trunking Diagram Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2-2 Functional Outline of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 Functional Outline of Installation Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-4 Functional Outline of Control Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-5 Functional Outline of Application Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-6 Functional Outline of Line/Trunk Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-7 Line Condition of Each Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-1 Removing/Inserting Circuit Cards Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

003-1 Recommended Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

007-1 LTC Connector Accommodation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

007-2 LTC0 and LTC1 MDF Cross Connection Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

008-1 Control Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

008-2 Line/Trunk Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

008-3 PN-CP03 (MP) Card Lamp Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

008-4 PN-CP03 (MP) Card Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

008-5 PZ-PW86 (PWR) Card Lamp Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

008-6 PZ-PW86 (PWR) Card Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

008-7 PZ-PW112 (PWR) Card Lamp Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

008-8 PZ-PW112 (PWR) Card Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

008-9 PN-8COT (COT) Card Lamp Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4-1 Data Programming Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4-2 Port Assignment Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4-3 Numbering Plan Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4-4 Station Data Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4-5 Trunk Data Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4-6 Station Hunting Group Data Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4-7 Call Pickup Group Data Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4-8 Speed Calling-System Data Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4-9 Port Assignment Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

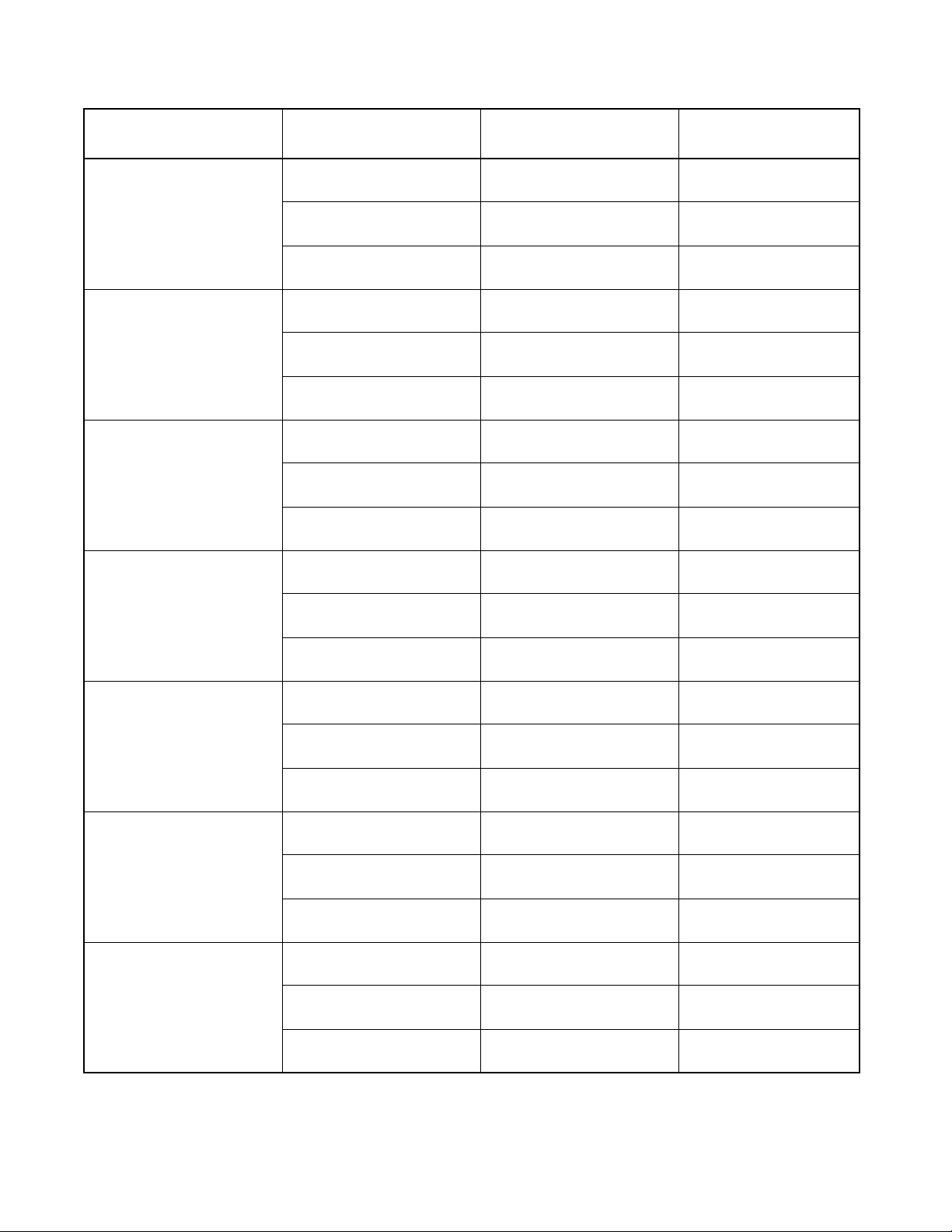

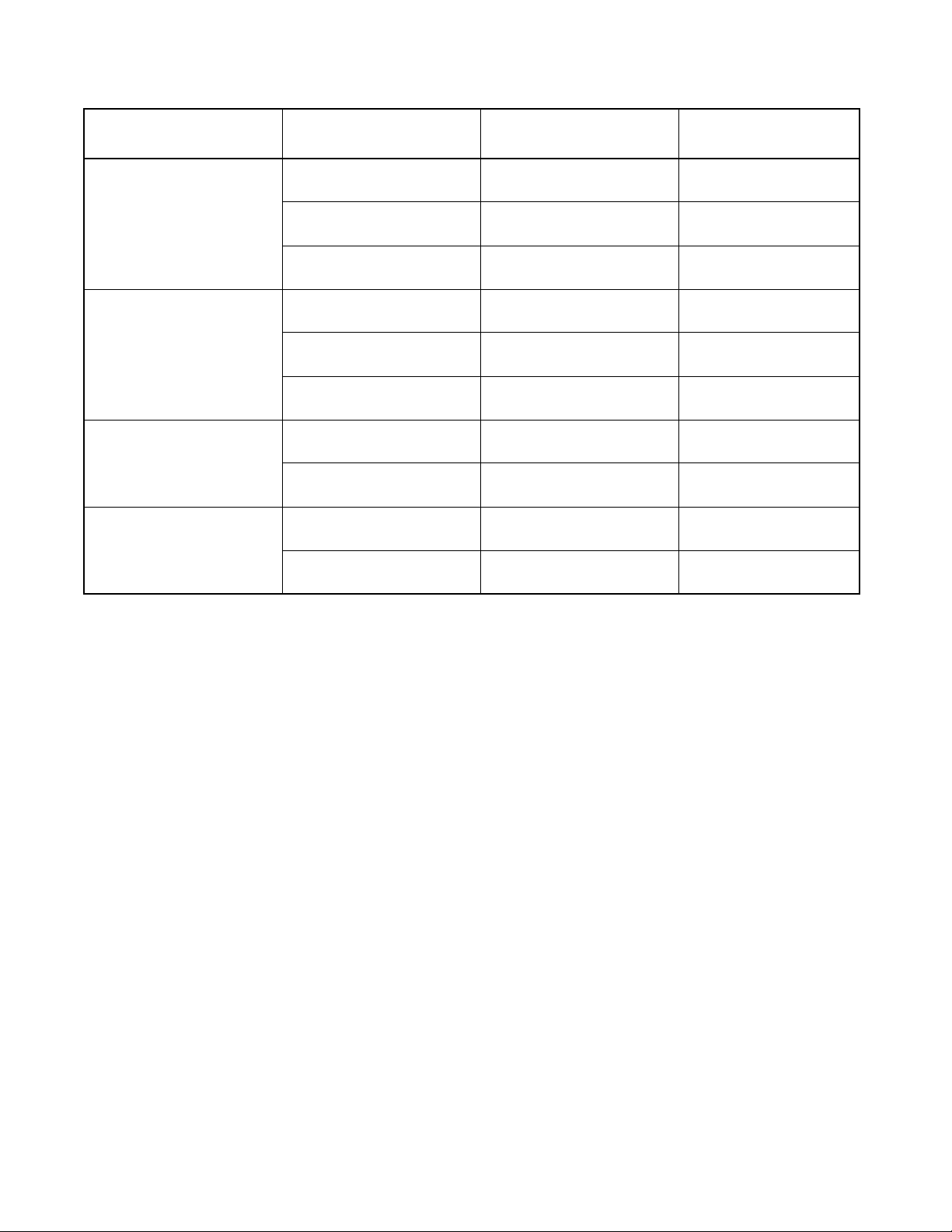

4-10 Quantity Table for Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4-11 Quantity Table for Line/Trunk Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

4-12 Quantity Table for Control Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

4-13 Quantity Table for Application Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

LIST OF TABLES

Page vi

Revision 2.0

NDA-24219

Page 9

REGULATORY INFORMATION

1. Regulatory Requirements

The Federal Commun ications Comm ission (FCC) has establi shed rules t hat permit the NEAX1000 IVS to b e direct ly connected to the telephone network. A jack is provided on party lines or coin lines.

The telephone company may make changes in its technical operations and procedures. If such changes affect the

compatibility or use of the NEAX1000 IVS, the telephone company must provide adequate notice of the changes.

This equipment compl ies with th e req uirements in Pa rt 15 of FCC Ru les f or a Cl ass A comput ing d e vice . Opera tion

of this equipment in a residential area may cause unacceptable interference to radio and TV reception requiring the

operator to take whatever steps are necessary to correct this interference.

2. FCC Part 15 Requirements

In compliance with FCC Part 15 Rules, the following statement is provided:

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instruction manual, may cause interference to radio communication s. It has bee n tested and found to comply wi th

the limits for a Cl ass A computing de vice pursuan t to Subpart J of Part 15 o f FCC

Rules, which a re designe d to pro vide reas onable p rotection against s uch inter ference when operated in a commercial environment. Operation of this equipment

in a residential area is likely to cause interference in which case the user at his

own expe nse wi ll be requi red t o tak e what e v er measur es may be req uired to cor rect the interference.

3. FCC Part 68 Registration

3.1 Company Notification

Before installing the NEAX1000 IVS to the telephone network, the telephone company must be provided with the

following:

• Your telephone number

• The FCC registration numbers:

JAP AN USA

PBX AY5JPN-20542-PF-E AY5USA-21582-PF-E

Hybrid AY5JPN-20543-MF-E AY5USA-21583-MF-E

Key system AY5JPN-20586-KF-E AY5USA-21584-KF-E

The Ringer Equivalence Number is 1.6B; the required USOC jacks are RJ21X, RJ2EX, and RJ2GX.

NDA-24219 REGULATORY INFORMATION

Page vii

Revision 2.0

Page 10

Note: Limitations on features exist if the system is registered as a KF system. Refer to Features and Specifications for details.

3.2 Service Requirements

In the eve nt of e quipment malfun ction, all repa irs will be perf orme d b y NEC or an a uthori zed di stri b utor of NEC. It

is the responsibility of users requiring service to report the need for service to NEC or to one of their authorized

distributors.

If the equipment ca uses har m to the te lephone netw ork , the tele phone compa n y wil l noti fy y ou in advance that temporary discontin uance of se rvice ma y be requi red. If adv ance noti ce is not pract ical, the telephone compan y will no tify the customer as soon a s possi ble. Al so, you wi ll be advis ed of y our ri ght to f ile a compla in t with the FCC i f you

believe it is necessary.

The telephone compan y may make changes in its facilities , equipment, operations, or procedures tha t a ffect the operation of the equipment. If this happens, the telephone company will provide advance notice in order for you to

make necessary modifications in order to maintain uninterrupted service.

If trouble is experienced with this equipment, please contact NEC America, Inc.’s Oregon plant at (503) 648-5000

for repair and/or warranty information. If the trouble is causing harm to the telephone network, the telephone company may request that you remove the equipment from the network until the problem is resolved.

NO REPAIRS CAN BE DONE BY THE CUSTOMER.

3.3 Location of FCC Compliance Labels

Labels stating the NE AX1000 IVS FCC re gistrat ion number and c ompliance wit h FCC Part s 15 and 68 are at tached

on the inside of the system’s front cover. Example of the labels are as follows:

“This equipment complies with the requirements in

Part 15 of FCC Rules for a Class A computing device.

Operation of this equipment in a residential area may

cause unacceptable interference to radio and TV reception requiring the operator to take whatever steps

are necessary to correct the interference.”

NEAX1000 IVS

Complies With Part 68 FCC Rules

FCC Registration Numbers : AY5USA-21582-PF-E

AY5USA-21583-MF-E

AY5USA-21584-KF-E

Ringer Equivalence : 1.6B

NEC America, Inc. MADE IN USA

4. Direct-Inward Dialing (DID) Calls

Allowing thi s equipmen t to be operat ed in suc h a manne r as to not pro vide f or pr oper ans wer supe rvi sion is a viola tion of Part 68 of the FCC’s rules.

PROPER ANSWER SUPERVISION IS WHEN:

(a) This equipment returns answer supervision to the PSTN when DID calls are:

• Answered by the called station

• Answered by the attendant

• Routed to a recorded announcement that can be administered by the CPE user

• Routed to a dial prompt

REGULATORY INFORMATION NDA-24219

Page viii

Revision 2.0

Page 11

(b) This equipment returns answer supervision on all DID calls forwarded to the PSTN. Permissible ex-

ceptions are:

• A call is unanswered

• A busy tone is received

• A reorder tone is received.

EQUAL ACCESS REQUIREMENTS

This equipment is capable of providing users access to interstate providers of operator services through the use of

access codes. Modification of this equipment by call aggregators to block access dialing codes is a violation of the

TElephone Operator Consumers Act of 1990.

5. Regulatory Information on Single-Line Analog Telephones

NEC single-line teleph ones comply with P art 68 of FCC Rules. On t he bottom of the e quipment is a la bel that state s,

among other informati on, the FCC registration number and ri nge r equivalence number (REN) for the equipment. If

requested, this information should be provided to the telephone company.

The equipment uses the following USOC jacks: RJ11C.

The equipment should be use d only behind a PBX or KTS. The REN is used to determine the quality of device tha t

may be connected to the telephone line. Excessive RENs on the tele phone line may result in the devices not ringing

in response to an incoming call. In most, but not all, areas, the sum of RENs should not exceed five (5.0). To be

certain of the number of de vi ces that ma y be connected to the line as de termin ed by the t otal RENs, conta ct the te lephone company to determine the maximum REN for the calling area.

6. Hearing Aid Compatibility

term

The D

terminals provi ded for the NEAX1000 IVS are hearin g aid compatibl e. FCC rules prohibi t the use of non -

hearing aid compatible telephones.

NEC-type single-line telephone sets used in conjunction with the NEAX1000 IVS are hearing aid compatible. If

other than NEC-type singl e-line telephone s ets are to be used with this system, ensur e that these are hearing aid compatible.

7. Industry Canada CS-03

Certification number: 140 5976A

Load Number of the equipment: 21

NOTICE: The Industry C anada label identifies certified equipment. The certificatio n means that the equipment

meets certain tel ecommunica tions netw ork p rotecti v e oper ational and safet y requir ements. The departmen t does no t

guarantee the equipment will operate to the user’s satisfaction.

Before install ing the equi pment, users should ens ure that i t is permi ssible to be connected to the f acilit ies of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. In

some cases, the company’s inside wiring asso ciate d with a sing le line individual service may be extende d by mean s

of a certified connector assembly (telephone extension cord). The customer should be aware that compliance with

the above conditions may not prevent degradation of service in some situations.

NDA-24219 REGULATORY INFORMATION

Page ix

Revision 2.0

Page 12

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or installations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request that the user disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone

lines, and internal metallic water p ipe syst em, if pres ent, are connected together. This prote ction may b e partic ularly

important in rural areas.

CAUTION 1:

Users should not attempt to make such connections themselves, but should contact the appropriate ele ctric inspection autho rity, or electrician, as appropriate.

CAUTION 2:

The act of monitoring or recording telephone conversations under certain circumstances may

violate federal or state statutes. Consultation with your legal counsel prior to engaging in such

practices would be advisable.

NOTICE: The Loa d Number assigned to e ach terminal de vice den otes the perce ntage of the total load to be connected to a telephone loop which is used by the device, to prevent overloading. The termination on a loop may consist

of any combination of devices subject only to the requirement that the total of the load numbers of all the devices

does not exceed 100.

8. Safety Certifications

This equipment has been listed by Underwriters Laboratories and found to comply with all the applicable requirements of the standard f or telephone equipment U.L. 1459. This equ ipme nt c ompl ies wit h CSA s tandard C 22.2 No.

225.

8.1 Safety Considerations

When using your telephon e equipment, basi c safety preca utions sho uld alway s be follo wed to reduce the ris k of fir e,

electric shock and injury, including the following:

(1) Never install telephone wiring during a lightning storm.

(2) Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

(3) Never touch un insulate d telep hone wi res or te rminals unless the telep hone li ne has be en dis connecte d at

the network interface.

(4) Use caution when installing or modifying telephone lines.

(5) Read and understand all instructions.

(6) Follow all warnings and instructions marked on the product.

(7) Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners.

Use a damp cloth for cleaning.

(8) Do not use this pr oduc t near water; for example, und er wa ter pipes near a bath tub, sink, or laund ry t ub, i n

a wet basement, or near a swimming pool.

(9) Do not place t his pro duct on a n unstabl e cart, stand, or table. The produc t may f all, ca using ser ious damag e

to the produ ct.

REGULATORY INFORMATION NDA-24219

Page x

Revision 2.0

Page 13

(10) Slots and openings in the cabinet and the back or bottom are provided for ventilation, to protect it from

overheatin g, these openings must not be blo cked or cove red. The openings should ne ver be blocke d by plac-

ing the product on a bed, sofa, rug, or other similar surface. This product should never be placed near or

over a radiator or heat register. This product should not be placed in a built-in installation unless proper

ventilation is provided.

(11) This product should be operated onl y from the typ e of po wer sou rce indi cated on the marking label. If you

are not sure of the type of power source available, consult with your local power company.

(12) This product normally connect ed wi th a three wire grounding type plug, a plug ha ving a third (grounding)

pin. This plug will onl y fit into a grounding type power outlet. This is a safety feature. If yo u ar e unable to

insert the pl ug into the outl et, cont act a n elect rician to repl ace your obsole te outl et. Do not defeat the saf ety

purpose of the grounding type plug.

(13) Do not allow anything to rest on the power cord. Do not locate this product where the cord will be abused

by persons walking on it.

(14) Do not overload wall outlets an d extension cords as this can result in the risk of fire or electric shock.

(15) Never push o bjects of any ki nd into this product t hrough cabi net slot s as the y may touch da ngerous v oltag e

points or short out part s that could r es ult in a risk of fire or electric shock. Ne ver spill liquid of an y k ind on

the product.

(16) To reduce the risk of electric shock, do not disassemble this product, but take it to a qualified serviceman

when some service or repair work is required. Opening or removing covers may expose you to dangerous

voltages or other risks. Incorrect reassembly can cause electric shock when the appliance is subsequently

used.

(17) Unplug this product from the wall outlet and refer servicing to qualified service personnel under the fol-

lowing conditions:

(a) When the power supply cord or plug is damaged or frayed.

(b) If liquid has been spilled into the product.

(c) If the product has been exposed to rain or water.

(d) If the product does not operate normally by following the operating instructions. Adjust only those

controls, that ar e co ve re d by the oper ating ins truct ions be cause i mpro per adj ust ment of o ther co ntrol s

may result in damage and will often require extensive work by a qualified technician to restore the

product to normal operation.

(e) If the product has been dropped or the cabinet has been damaged.

(f) If the product exhibits a distinct change in performance.

(18) A v oid using a te lephone (ot her than a cordless typ e) during an el ectrica l storm. There may be a remote risk

of electric shock from lightning.

(19) Do not use the telephone to report a gas leak in the vicinity of the leak.

NDA-24219 REGULATORY INFORMATION

Page xi

Revision 2.0

Page 14

This page is for your notes.

REGULATORY INFORMATION NDA-24219

Page xii

Revision 2.0

Page 15

CHAPTER 1 INTRODUCTION

1. PURPOSE

This manual explains the installation procedure for the NEAX1000 IVS (PBX) System.

2. REFERENCE MANUAL

During installation, refer to the NEAX2000 IVS manuals listed in Figure 1-1.

REFERENCE MANUALS

MAINTENANCE MANUAL

COMMAND MANUAL

CIRCUIT CARD MANUAL

DESCRIPTION

MAINTENANCE PROCEDURE

COMMAND DESCRIPTION

CIRCUIT CARD DESCRIPTION

CIRCUIT CARD MOUNTING CONDITIONS

SWITCH SETTING OF CIRCUIT CARD

Figure 1-1 Installation Reference Manuals

NDA-24219 CHAPTER 1

Page 1

Revision 2.0

Page 16

3. HOW TO FOLLOW THIS MANUAL

The Installation Procedure is shown by means of flowcharts with an NAP (NEC Action Procedure) Number. The

detail of the work for each step is described in corresponding NAP.

4. SCOPE OF INSTALLATION PROCEDURES

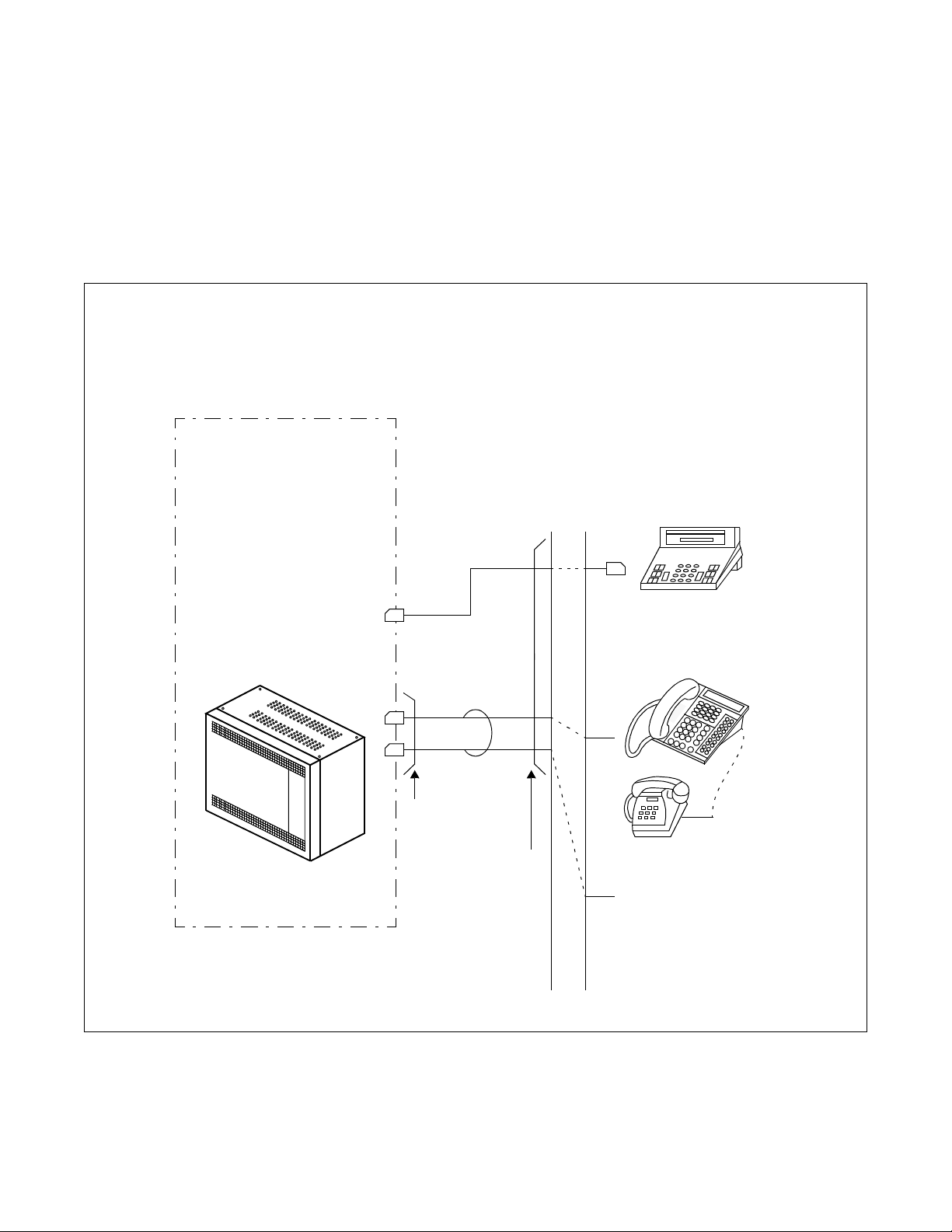

This manual covers the installation shown in Figure 1-2.

NAP-200-003:

INSTALLATION OF MAIN EQUI PMENT

NAP-200-007:

SWITCH SETTING OF CIRCUIT CARDS

NAP-200-008:

MOUNTING OF CIRCUIT CARDS

MDF

MDF CABLE

NAP-200-005:

CABLE RUNNING

TO MDF

NAP-200-006:

TERMINATION OF

CABLES ON MDF

Single Line Telephone

TO TAS INDICATOR, ALM

INDICATOR

Figure 1-2 Scope of Installation Procedures

SN610

ATTCON

or

DESKCON

Multiline Terminal

APR Adapter

CHAPTER 1 NDA-24219

Page 2

Revision 2.0

Page 17

CHAPTER 2 GENERAL INFORMATION

1. TRUNKING DIAGRAM

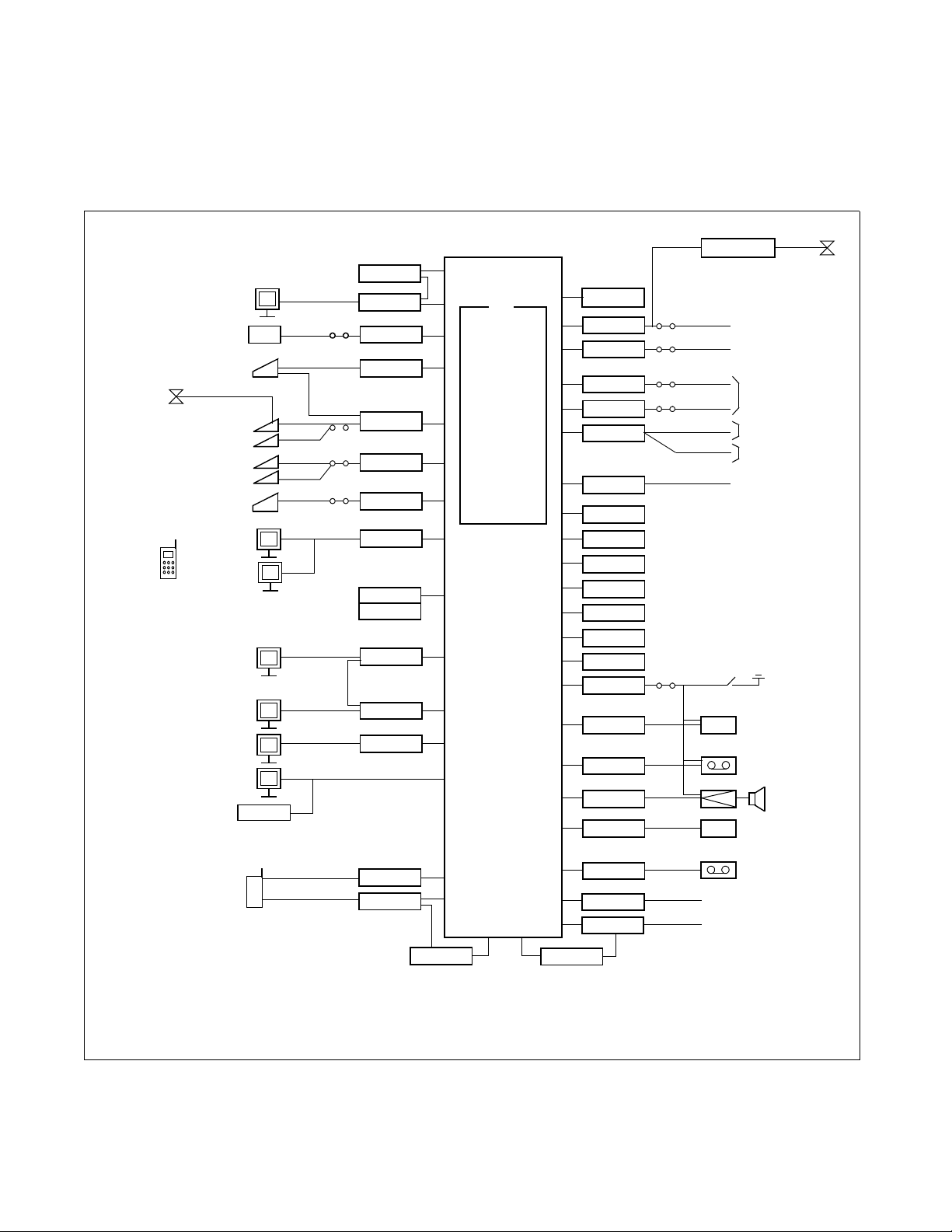

Figure 2-1 shows a typical trunking diagram for the PBX.

Single Line

Telephone

Multiline Terminal

Multiline Terminal

Wireless

PS

ISDN BRI

STATION

VOICE MA IL

SYSTEM

DESKCON

Via APR

DSS

Long Line DSS

SN610 ATTCON

SMDR

MCI

PC FOR OAI

and ACD-MIS

PC for OAI

DTE

MAT

From LC

(For Remote

Maintenance)

ZONE

TRANSCEIVER

MODEM

RS 232C

V.11

TCP/IP

V.11

RS-232C

Note 1

ICH

ILCA

LCD

PW00

DLCD/DLCJ

DLCB

DLCC

AP00

VM00

VM01

AP01

ETHER

DPC

RS 232C

PW00

CSIA

Note 2

MP

INCLUDING

SW

DTG

PBSND

16CFT

MLDT

PLO

MEM

MODEM

PBR

TNT

SMDR

RSTB-911

COT

AUC/DIT

ODT

ODT

DTI

BRT

CCH

DCH

PBR

DA T

PLO

MFR

CFT

DK

COT

COT

COT

COT/TNT

TNT

COT

COTG

PFT

6/10 PARTY CONFERENCE

8-PFT

C.O. LINE

DID LINE

2W E&M

4W E&M

ANNOUNCEMENT

MACHINE(*)

EXTERNAL HOLD TONE(*)

TIE LINE

DIGITAL LINK

ISDN (PRI)

NETWORK

ISDN (BRI)

NETWORK

KEY(*)

AMP(*)

SPEAKER(*)

(*)

EXTERNAL HOLD TONE(*)

ALL PSAP

ANALOG CALLER ID

CSH

RSTC

Note 3: An external Modem is no t required when the Built-In Modem on the MP is used.

Note 4: NEAX1000 may also be used as a Remote PIM.

Note 5: Customer provides equipment marked with (*).

Figure 2-1 PBX Trunking Diagram

NDA-24219 CHAPTER 2

Page 3

Revision 2.0

Page 18

Table 2-1 Symbols in Trunking Diagram Description

SYMBOL DESCRIPTION

AMP Amplifier for External Speaker

AP00 SMDR/MCI/PMS/Hotel Application Card KEY External Key

AP01 OAI Interface Card LCD/LCS Line Circuit Card

AUC Analog Universal Circuit Card

(Long Line Circuit, DID Trun k)

BGM External Music Source for Multiline

Terminal Back Ground Music Service

CCH Common Channel Handler Card MEM Main Memory

CFT 6/10-Party Conference Trunk Card MFR MF Receiver Trunk Card (TIANI)

COT C.O. Trunk Card MLDT Melody Trunk Card

COTG Analog Caller ID Trunk Card MODEM Modem

CSIA Zone Transceiver Line Card MP Main Processor Card

DAT Digital Announcement Trunk Card PF T Power Failure Transfer

DCH D -Channel Handler Card ODT OD Trunk Card (2/4 wire E&M)

DIT DID Trunk Card PBR PB Receiver Card

SYMBOL DESCRIPTION

ILCA BRI Station Line Card

(for Single Line Telephone)

MAT Maintenance Administration Terminal

MDF Main Distribution Frame

DK External Relay/Key Interface Card PBSND PB Sender

DLCD/DLCJ Digital Line Circuit Card

(for Multiline Terminal/DESKCON)

DLCB Digital Line Circuit Card

(for Multiline Terminal Long Line/

DESKCON)

DLCC Digital Line Circuit Card

(for SN610 ATTCON)

DPC Data Port Controller Card RSTC Register Card for Analog Caller ID

DSS DSS Console SMDR Station Message Detail Recording

DTI Digital Trunk Interface Card SW Time Division Switch

DTG Digital Tone Generator TNT Tone/Music Source Interface Card

ETHER Ethernet Control Card 16CFT 16 Circuit Three/Four Party Conference

FP Firmware Processor Card VM00 Digital VMS wit h 4-Digital Ports

ICH BRI Station Application Card VM01 4 additional Digital Ports

Note: Refer to NAP-200-008 and the Circuit Card Manual for details of circuit cards.

PLO Phase Lock Oscillator

PW00 Po wer Card for 2 Zone Transceivers or one

Attendant DeskCon

RSTB-911 Register/Sender E911

Trunk

CHAPTER 2 NDA-24219

Page 4

Revision 2.0

Page 19

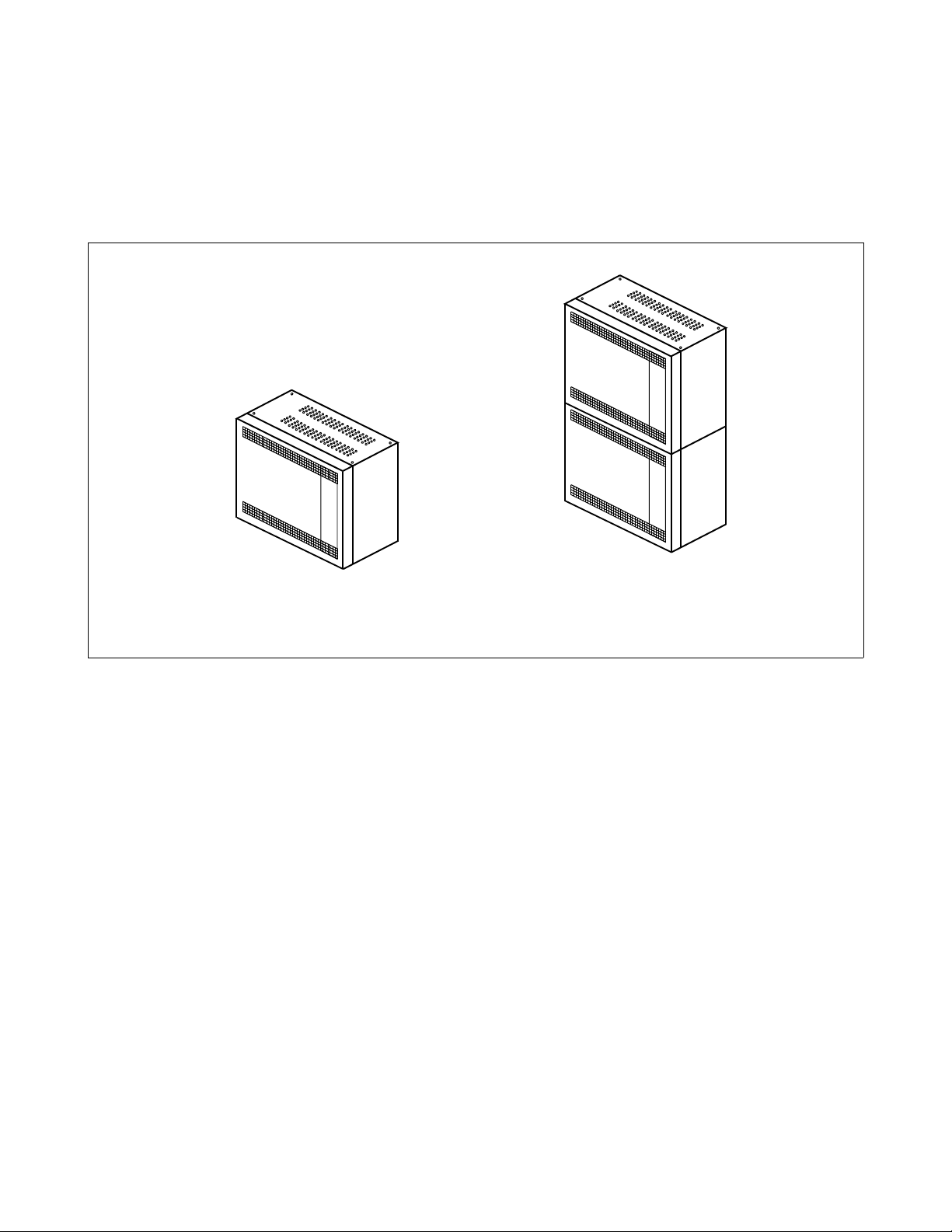

2. SYSTEM CONFIGURATIONS

2.1 PIM Configuration

The PBX system can accommodate a maximum of 48 ports per PIM. A maximum of 88 ports are available with a

two PIM configuration (PIM0 Slot LT08/AP4 used for PN-BS00).

TWO PIM CONFIGURATIONONE PIM CONF IGU RATION

Figure 2-2 PIM Configuration

NDA-24219 CHAPTER 2

Page 5

Revision 2.0

Page 20

2.2 Installation Methods

PIM

Figure 2-3 Wall-Mounting Installation

CHAPTER 2 NDA-24219

Page 6

Revision 2.0

Page 21

PIM

19”BRACKET (H)

Figure 2-4 19-Inch Rack-Mounting Installation

NDA-24219 CHAPTER 2

Page 7

Revision 2.0

Page 22

PIM

Figure 2-5 Desktop Installation

CHAPTER 2 NDA-24219

Page 8

Revision 2.0

Page 23

3. FUNCTIONAL OUTLINE OF EQUIPMENT

This section ex pla in s th e functional outline of the equipment (mod ule s, i nstallation hardware, circuit ca rd s) used in

the PBX.

3.1 Functional Outline of Modules

Table 2-2 shows the functional outline of the modules.

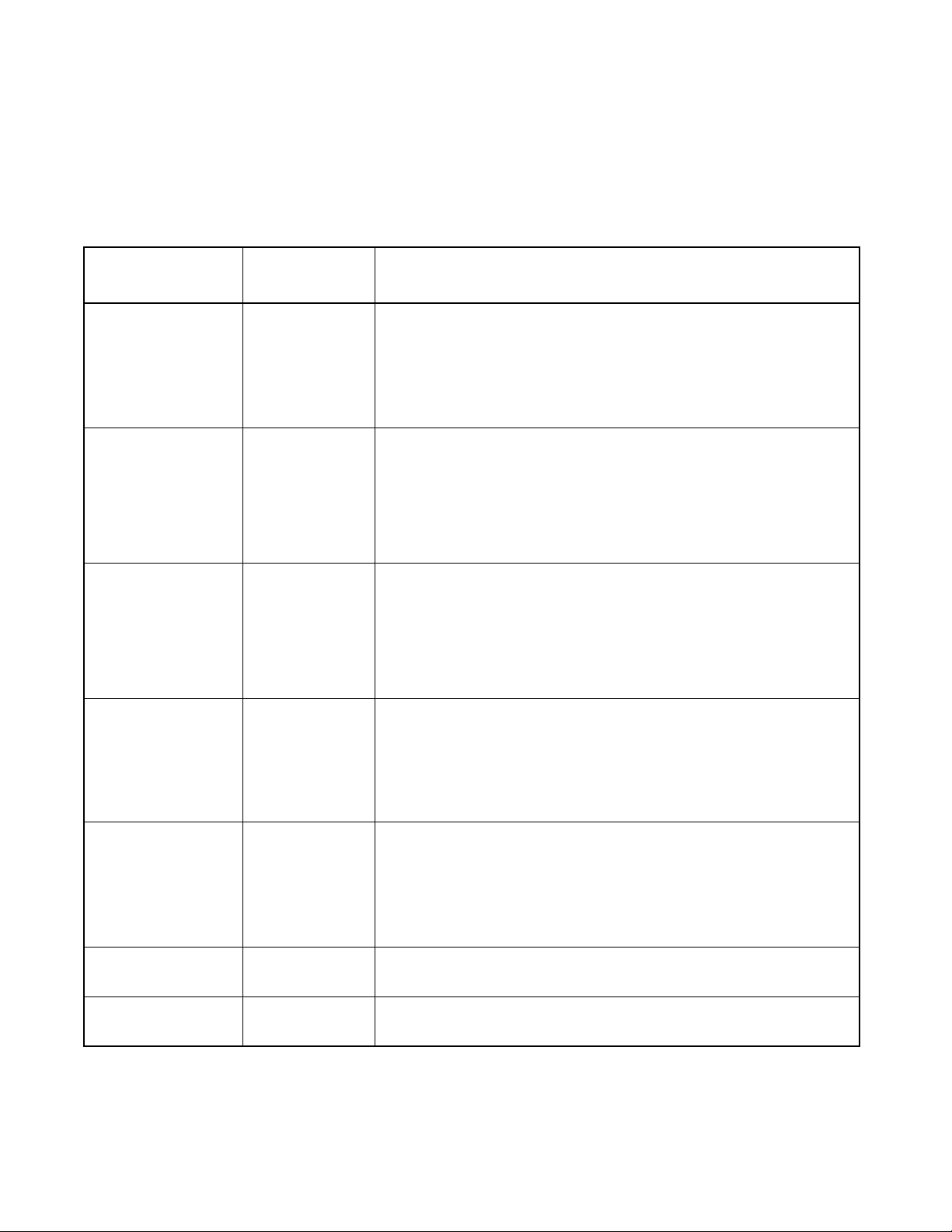

Table 2-2 Functional Outline of Modules

MODULES

SN1420 PIMAB-A PIM Port Interface Module (PIM)

FUNCTIONAL

NAME

FUNCTIONAL OUTLINE

A PIM provides 10 card slots for common control, Line/Trunk, and

Application Processor (AP) cards. It also houses a AC/DC Power Supply

and batteries for protection from short-term power interruption (standard).

T wo champ connectors for lin e/trunk (LTC0 to 1) and a connector for Power

(PWR) are located at the lower front side of the PIM.

A PIM provides a maximum of 9 card s l ots for line/trunk (LT) cards. At

maximum configuration, the system is comprised of 2 PIMs and it provides

88 physical ports (48 ports x 2) to MDF (PIM0 Slot LT8/AP4 used for PNBS00).

3.2 Functional Outline of Installation Hardware

Table 2-3 shows the functional outline of installation hardware.

Table 2-3 Functional Outline of Installation Hardware

INSTALLATION

HARDWARE

COVER PARTS TOP

19” BRACKET 19”

NDA-24219 CHAPTER 2

FUNCTIONAL

NAME

BOTTOM

COVER

BRACKET

FUNCTIONAL OUTLINE

Bottom Cover (includes Top Cover)

This hardware (bottom cover and top cover) is used for all NEAX1000

installations. A 4-rubber foot is required for desktop installation with PIM.

19-inch Bracket

The 19-inch bracket is sets of hardware to mount the PIM in IEC standard 19inch rack. One set of 19-inch bracket is required for PIM.

Page 9

Revision 2.0

Page 24

3.3 Functional Outline of Circuit Cards

3.3.1 Control Circuit Card

Table 2-4 shows the functional outline of each control circuit cards.

Table 2-4 Functional Outline of Control Circuit Cards

CARD NAME

PN-CP03 MP Main Processor Card

PZ-PW86 PWR Main Power Supply Card

PZ-PW112 PWR Main Power Supply Card

PN-BS00-B BS00 Bus Interface Card for PIM0

FUNCTIONAL

NAME

FUNCTIONAL OUTLINE

This card is equipped with Memory, TDSW (1024CH × 1024CH), 16-Line

CFT , DTMF Sender , Clock, PLO (recei ver mode 2 ports), R S-232C Ports (2

ports) for MAT/Built-in SMDR, modem for remote maintenance, and

Music-On-Hold tone source (Melody IC/TNT), 4-circuit PBR (for PB

calling or DID). This card is used on the basis of one per system.

Input: AC 120 V (50 Hz/60 Hz)

Output: –27 V (4.5 A), +5 V (7.5 A)

One card is mounted in PIM.

Note: This card does not provide ring generator or message wait volt-

age.

Input: AC 120 V (50 Hz/60 Hz)

Output: –27 V (3.5 A), +5 V (4.0 A)

One card is mounted in PIM.

Note: This card does not provide ring generator or message wait volt-

age.

This card is equipped with functions of driver/receiver of various signals,

functions of adjusting gate delay timing and cable delay timing, functions

of monitoring I/O Bus and PCM Bus, and functions of controlling power

supply. When the system consists of two PIMs, this card is mounted one in

PIM0

PN-BS01-B BS01 Bus Interface Card for PIM1

This card is equipped with functions of driver/receiver of various signals,

functions of adjusting gate delay timing and cable delay timing, functions

of monitoring I/O Bus and PCM Bus, and functions of controlling power

supply. When the system consists of two PIMs, this card is mounted one in

PIM1.

SPN-DAIB DAIB Firmware Processor-Bus Card—With T1

Used when installing PIM as a Remote PIM

SPN-DAIC DAIC Firmware Processor-Bus Card—With T1

Used when installing PIM as a remote PIM expanded to 43 ports.

CHAPTER 2 NDA-24219

Page 10

Revision 2.0

Page 25

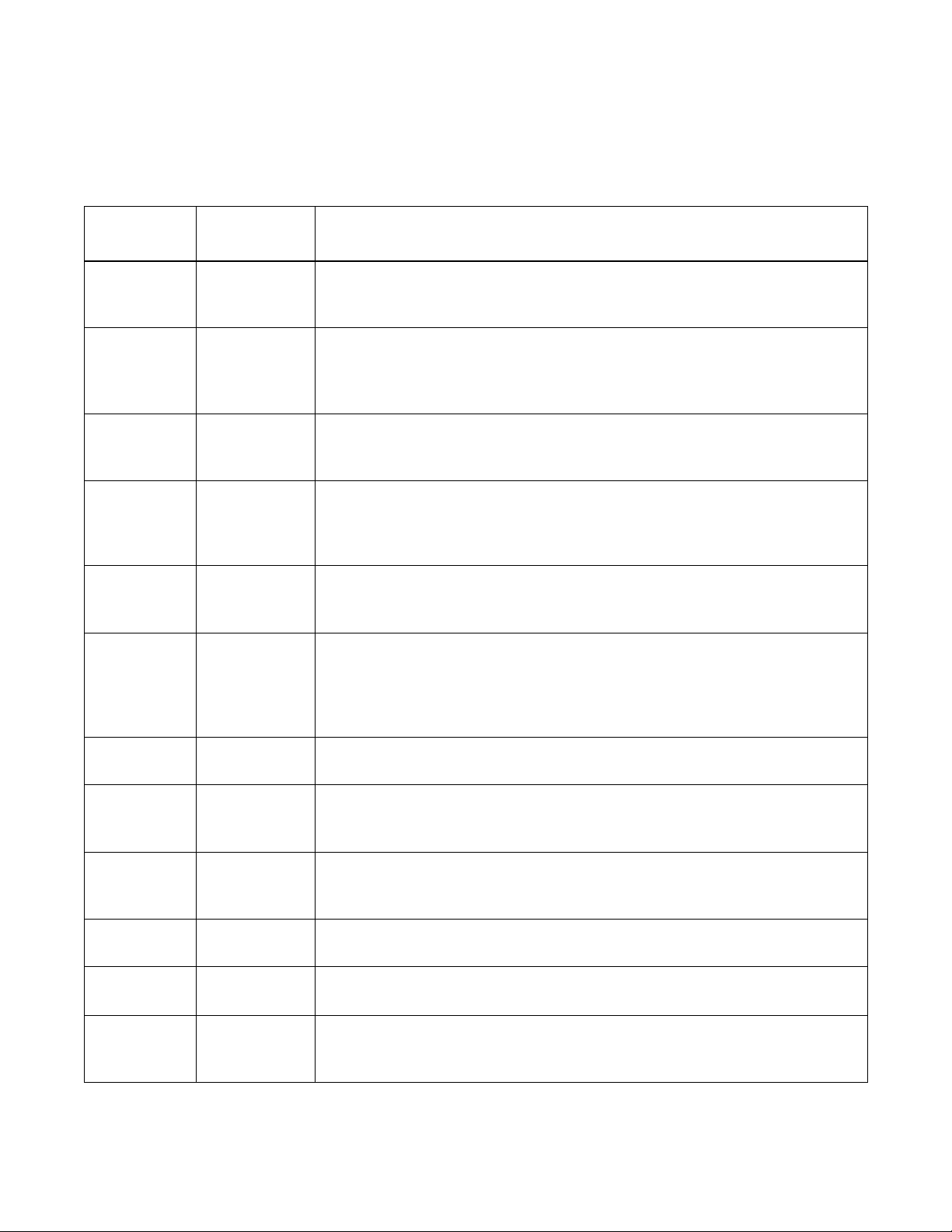

3.3.2 Application Circuit Cards

Table 2-5 shows the functional outline of each application circuit card.

Table 2-5 Functional Outline of Application Circuit Cards

CARD NAME

SPN-AP00-A AP00 Application Processor Card

SPN-AP01 AP01 Application Processor Card

SPN-BRTA BRI Basic Rate (2B+D) Interface Trunk Card (S/T Interface)

SPN-ME00 EXTMEM Memory Expansion Card

SPN-CC00 ETHER Ethernet Control Card

SPN-CK00 PLO Phase Locked Oscillator Card

FUNCTIONAL

NAME

FUNCTIONAL OUTLINE

This card is equipped with four RS-232C ports, and is used for SMDR, H/M Printer,

PMS functions and MCI. This card is used on the basis of one per system.

This card is equipped with one RS-232C port and one Ethernet interface port, and is

used for OAI function. Also, this card is used to expand authorization code and ACD.

This card is used on the basis of one per system.

This card has one circuit of Basic Rate interface and provides one 2-channel PCM

digital line.

This card is used with PN-AP00-A card for providing expansion memory.

This card can be equipped with an expansions SRAM card (1MB) as SMDR data

memory.

This card is used with the PN-AP01 card to accommodate the Ethernet, transmitting/

receiving a signal of TCP/IP protocol.

This card is a phase locked oscillator for providing a synchronized clock signal with the

network.

This card is used when the PBX is a master office or when the PBX requires two clock

supply routes and those frequencies differ.

SPN-24DTA/

SPN-24DTA-A

SPN-4RSTB MFR 4-line MF Receiver Trunk card

SPN-4RSTC CIR 4-line CALLER ID Receiver Trunk Card

SPN-SC00 CCH Common Channel Handler Card

SPN-SC01 DCH D-channel Handler Card

SPN-SC02 ICH ISDN-channel Handler Card

NDA-24219 CHAPTER 2

DTI Digital Trunk Interface (23B+D, 1.5 Mbps) Card

This card accommodates 24-channel, PCM digital lines.

This card is used for MF S ignaling on Digit al DID trunks. A max imum of four cards can

be provided per one system, including the PN-4RSTC card.

This card is used for CALLER ID (CLASS SM) on analog trunks. A maximum of four

cards can be provided per one system, including the PN-4RSTB card.

This card transmits/receives signals on the common signaling channel of No. 7 CCIS.

This card transmits/receives signals on the D channel of ISDN Primary Rate (23B+D).

This card provides the D channel signaling interface and controls an ILC (Layer 2 and

3). Provides signaling interface for two ILCA cards.

Page 11

Revision 2.0

Page 26

Table 2-5 Functional Outline of Application Circuit Cards (Continued)

CARD NAME

SPN-DAIA DAIA Firmware Processor Bus Card—With T1

SPN-4RSTB-

911

SPN-SC03 CSH Channel Handler for Zone Transceivers

SPN-SC03 ICH ISDN-BRI Channel Handler

FUNCTIONAL

NAME

Used in main system when connecting to Remote PIM SPN-DAIB.

MF-911 Provides MF signaling for Enhanced 911.

Provides D-channel signaling interface for four ILCA cards.

FUNCTIONAL OUTLINE

3.3.3 Line/Trunk Circuit Cards

Table 2-6 shows the functional outline of each line/trunk circuit card.

Table 2-6 Functional Outline of Line/Trunk Circuit Cards

CARD NAME

PN-2AMPA AMP 2-line Amplifier Trunk Card

FUNCTIONAL

NAME

FUNCTIONAL OUTLINE

This card equipped with the functions of Echo Canceller (EC), Automatic Gain

Controller (AGC) and Tone Disabler (TD).

PN-AUCA AUC 2-line Long-Line Circuit Card provided with the Power Failure Transfer (PFT) function

line resistance in the case of a long-line circuit: Max. 2500 ohms (incl us ive of the

internal resistance of the distant office equipment)

This card is internally equipped with a –48 V DC On-Bo a rd Power Supply.

This card can also be used as a 2-line Direct Inward Dialing trunk card.

PN-CFTA CFT Conference Trunk Card

Use of one card:Can control a conference of up to six participants.

Use of two cards:Can control a conference of up to ten participants.

PN-4COTB COT 4-line Central Office Trunk Card (ground-start/loop-start trunk) equipped with the

functions for loop detection, sending/d etecting ground on Ring/Tip wire

PN-4COTG COT 4-line Central Off ice T runk C ard (loop-start trunk) equi pped with the funct ions for loop

detection, receiving/sending the Caller ID (CLASS SM) signal

PN-8COTM COT 8-line Central Office Trunk Card (loop-start trunk only)

No loop disconnect detection is provided.

PN-8COTP COT 8-line Central Office Trunk Card (loop-start trunk only)

loop disconnect detection is provided.

PN-2CSIA CSIA 2-Line Zone Transceiver Card

PN-2DATA DAT 2-line Digital Announcement Trunk Card

Duration: Max. 60 seconds.

CHAPTER 2 NDA-24219

Page 12

Revision 2.0

Page 27

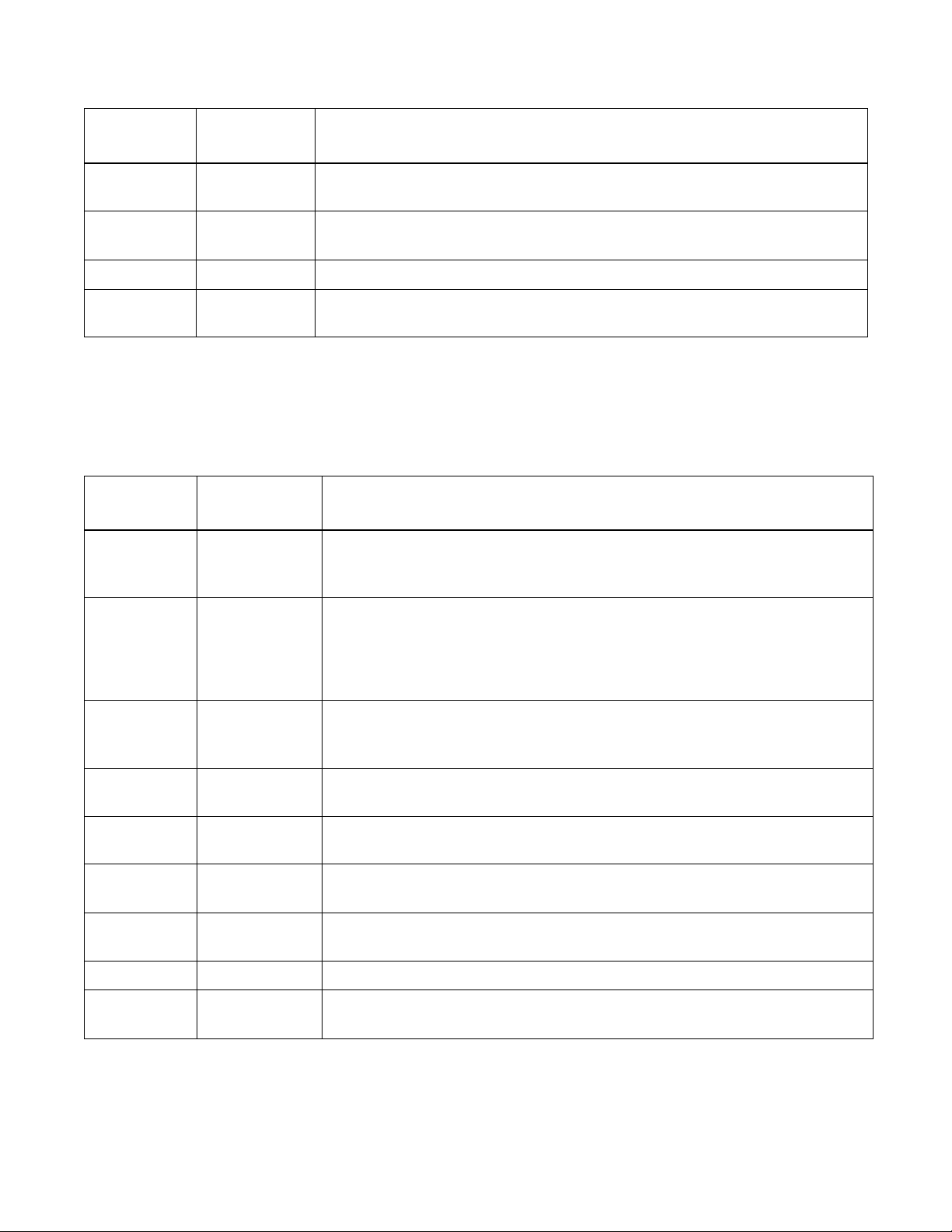

Table 2-6 Functional Outline of Line/Trunk Circuit Cards (Continued)

CARD NAME

PN-4DITB DIT 4-line Direct In-Dialing Trunk Card

PN-DK00 DK Circuit card for External Relay Control/External Key Scan

PN-4DLCA/

PN-4DLCM

PN-2DLCB/

PN-2DLCN

PN-2DLCC DLC 2-line Digital Line Circuit Card for Multiline Terminal Series II/SN610 Attendant

FUNCTIONAL

NAME

This card is equipped with the function for loop detection, sending reverse signal and

PB to DP signal conversion. This card is internally equipped with –48 V DC On-Board

Power supply.

This card is provided with eight circuits, and can provide the abov e-men tioned co ntrol

functions on a per circuit basis.

DLC 4-line Digital Line Circuit card for Multiline Terminal Series E/Elite/Series III/

ElectraPro/DSS Console (–27 V Version, 2-wire type) Note

This card is equipped with quick diagn ostics to detect short line conditions and the

normality (Synchronous/Asynchronous) of the terminal.

DLC 2-line Digital Line Circuit Card for Multiline T erminal Series E/Series III/DSS Console/

DESKCON (–48V Version, 2-wire type) Note

This card is equipped with quick diagn ostics to detect short line conditions and

normality (Synchronous/Asynchronous) of terminal. This card is internally equipped

with a –48 V DC On-Board Power Supply.

Console (–48 V Version, 4-wire type) Note

This card is equipped with quick diagn ostics to detect short line conditions and the

normality (Synchronous/Asynchronous) of the terminal. This card is internally

equipped with –48 V On-Board Power Supply.

FUNCTIONAL OUTLINE

PN-4DLCD/

PN-4DLCQ

PN-4DLCF DLC 4-line Digital Line Circuit Card for Multiline Terminal Series II/SN610 Attendant

PN-8DLCJ/

PN-8DLCP

PN-2DPCB DPC 2-line Data Port Controller Card

PN-2ILCA ILC 2-line ISDN Line Circuit Card

PN-4LCD-A LC 4-line Analog Line Circuit Card for single line telephones

DLC 4-line Digital Line Circuit Card exclusively used for Multiline T erminal Series E/Series

III/DSS Console/DESKCON (–27 V Version, 2-wire type) Note

This card is equipped with quick diagn ostics to detect short line conditions and the

normality (Synchronous/Asynchronous) of the terminal.

Console (–27 V Version, 4-wire type) Note

This card is equipped with quick diagn ostics to detect short line conditions.

DLC 8-line Digital Line Circuit Card for Multiline T erminal Series E/Series III/DSS Console/

DESKCON (–27 V Version, 2-wire type) Note

This card is used for the intra-office or inter-office digital data transmission on fixed

path connection. This card can acc ommodate a maximum o f two DTE with V.11 (X.21)

interface or V.24/V.28 (RS-232C) interface.

This card provides a physical interface to ISDN Terminals.

Loop resistance: Max. 600 ohms

This card is equipped with the function for control ling Message Waiting Lamp.

Each 4 circuits are equipped with momentary open function.

This card is equipped with quick diagn ostics to detect short and open line conditions.

This card is internally equipped with a +80 V DC-DC Power Supply circuit.

NDA-24219 CHAPTER 2

Page 13

Revision 2.0

Page 28

Table 2-6 Functional Outline of Line/Trunk Circuit Cards (Continued)

CARD NAME

PN-8LCS LC 8-line Analog Line Circuit Card for single-line telephones

PN-M03 M03 V.35 DTE Interface Card

PN-2ODTA ODT 2-line OD Trunk Card

PN-PW00 PWR Provides -48V power f or one DeskCon or two zone tran sceivers; maximum is 3 per

PN-8RSTA PBR 8-line DTMF Receiver Card

PN-TNTA TNT 2-line Tone/Music Source interface Card

PZ-VM00 4VM 4-Port Voice Mail Card (NEAX Mail AD-8)

PZ-VM01 4VMEXT 4-Port Expansion Card for AD-8 (VM00)

FUNCTIONAL

NAME

FUNCTIONAL OUTLINE

Loop resistance: Max. 600 Ω

This card is equipped with a controller for momentary open function.

This card is used together with the PN-2DPCB card to provide the V.35 interface.

This card can be used as either a 2-wire E&M trunk or a 4-wire E&M trunk, and is

internally equipped with a –48 V DC On-Board P ower Supply.

Both No. 0 and No. 1 circuits mu st be set to same purp ose (2-wire or 4-wire) in one card.

system; uses two card slots

This card can be used for a DTMF station line, DID or tie line.

This card is used for BGM or Music on Hold, and is equ ipped with tw o interface for an

external tone/music source.

Note: The cable length between the DLC and terminal varies depending on the type of terminal. For the line conditions

each terminal, refer to

TERMINAL TYPE CARD TYPE

DTP-8-1 PN-8DLCJ / 8DLCP

DTP-8D-1 PN-8DLCJ / 8DLCP

Table 2-7

Table 2-7 Line Condition of Each Terminals

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

.

CABLE LENGTH

(Cable 24AWG)

984ft. (300m) Note 1

984ft. (300m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

984ft. (300m) Note 1

984ft. (300m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

REMARKS

CHAPTER 2 NDA-24219

Page 14

Revision 2.0

Page 29

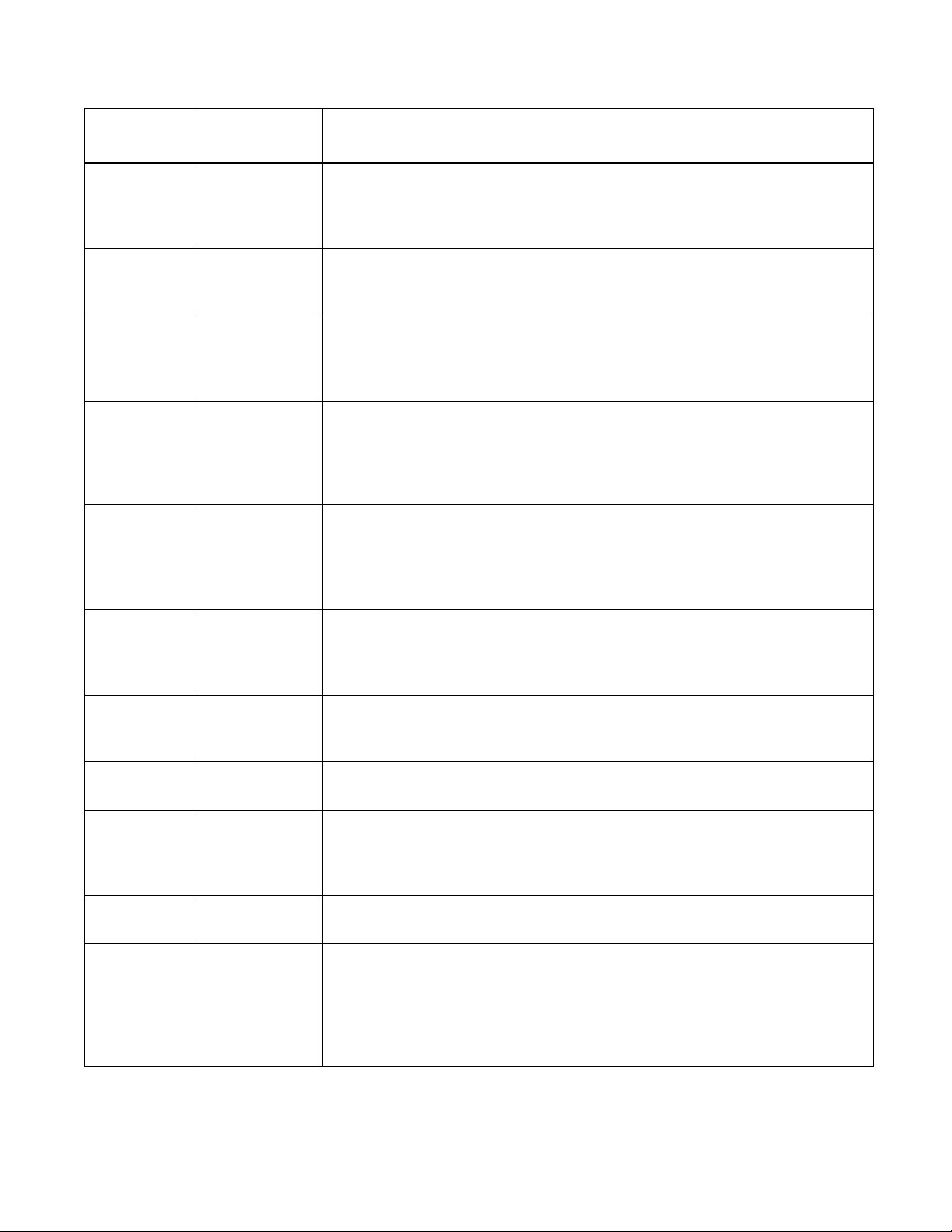

Table 2-7 Line Condition of Each Terminals (Continued)

TERMINAL TYPE CARD TYPE

DTP-16-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

DTP-16D-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

DTP-32-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

DTP-32D-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

DSS/BLF Console

Note 2

ETJ-8-1 PN-8DLCJ / 8DLCP

ETJ-16DC-1 PN-8DLCJ / 8DLCP

PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB / 2DLCN

(LONG)

CABLE LENGTH

(Cable 24AWG)

656ft. (200m) Note 1

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

656ft. (200m) Note 1

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

656ft. (200m) Note 1

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

656ft. (200m) Note 1

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

984ft. (300m) Note 1

984ft. (300m)

2788ft. (850m)

984ft. (300m) Note 1

984ft. (300m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

656ft. (200m) Note 1

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

REMARKS

NDA-24219 CHAPTER 2

Page 15

Revision 2.0

Page 30

Table 2-7 Line Condition of Each Terminals (Continued)

TERMINAL TYPE CARD TYPE

ETJ-16DD-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB

(LONG)

ETJ-24DS-1 PN-8DLCJ / 8DLCP

(STANDARD)

PN-4DLCD / 4DLCQ

(STANDARD)

PN-2DLCB

(LONG)

SN610 ATTCON PN-2DLCC

(LONG)

PN-4DLCF

(STANDARD)

DESKCON PN-4DLCD / 4DLCQ and

PW00 or AC Adapter

PN-8DLCJ / 8DLCP and

PW00 or AC Adapter

CABLE LENGTH

(Cable 24AWG)

656ft. (200m)

656ft. (200m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

492ft. (150m)

492ft. (150m)

[3937ft. (1200m)]

2788ft. (850m)

[3937ft. (1200m)]

3937ft. (1200m)

984ft. (300m)

1500ft. (457m)

1000ft. (304m)

REMARKS

Note 1

Note 1

Note 3

* The value in the [ ] shows the cable length when using the long line function.

Note 1: When using PN-8DLCJ or PN-8DLCP card, it is not available long line function.

Note 2: The DSS/BLF Console requires local AC/DC power supply.

Note 3: With AC/DC power at DESKCON 3000’ with 4DLCD

CHAPTER 2 NDA-24219

Page 16

Revision 2.0

Page 31

4. CIRCUIT CARD INSTALLATION CONDITIONS

4.1 Circuit Card Mounting Slots

Figure 2-6 shows circuit card mounting slots allocated in the PIM, on the basis of circuit card type.

Number of Ports Available per Slot

4-Port Card Mounted

8-Port Card Mounted

AD-8

uses

vacant

space

when

mounted

Slot 00

PWR0C

vacant

space

444444444

888880

00LT01LT02LT03LT04

LTC1

LTC0

(10 min. Internal Battery Back-Up Standard)

LT

/

AP0

1

05

LT

/

AP1

8018

06

07

LT

LT

/

AP2

AP3

/

08

LT

/

AP4

PWR0B

09

MP

/

BUS

P

W

R

LT01 - LT08 : Line/trunk circuit card mounting slots

• LT00 : No connection to MDF. When NEAXmail AD8 is mounted here, internal modem leads for AD8 are brought out on pins 25 & 50 of LTC1

cable for connection to single-line station or C.O. trunk.

• LT01 - LT04, LT06, LT08 : All line/trunk circuit cards can be mounted.

• LT05, LT07 : 4-port circuit cards that require cabling may be mounted only when 8port cards are not mounted in the slot to the left of them.

AP0 - AP5 : Application circuit card mounting slots

MP : PN-CP03 mounting slot

BUS : PN-BS00-B (Slot 08 on PIM0), PN-BS01-B (Slot 09 on PIM1) mounting slot

PWR : PZ-PW86/PW112 mounting slot

PWR0B : Connector for termination of ring generator when single-line card(s) are mounted. System

power supply does not supply ringing voltage

2

PWR0C : Connector for termination of PW91 Power for Zone Transceivers

1

When an 8-port card is mounted in Slot 04/06, Slot 05/07 can only be mounted with the following cards:

SPN-AP00 SPN-AP01 SPN-ME00 SPN-SC01

SPN-SC02 SPN-4RSTB SPN-4RSTB-911 SPN-4RSTC

SPN-CK00 SPN-CC00 PN-M03 SPN-SC03 (CSH)/(ICH)

2

It is re commended t hat an APR ad apter, which has a b uilt -in r ing g ener ator, be used in dual-por t mode t o

provide interface for single-line devices. APRs provide hookflash and disconnect signaling when 1800

series software or higher is used.

Figure 2-6 Circuit Card Mounting Slots

NDA-24219 CHAPTER 2

Page 17

Revision 2.0

Page 32

4.2 Installation Conditions

(20) The application circuit cards PN-BRTA and PN-24DTA-A cannot be mounted in slots AP1 or AP3 when

an 8-port card is mounted in Slot 04 or 06, since these slots share a connection to the MDF via the backplane.

(21) The application circuit ca rd t ype PN-CC00 can be mounted in any LT/AP slot, but it occupies two s lot po-

sitions; i.e. the slot immediately to its right must be vacant.

(22) PN-PW00 can be mounted in any LT/AP slot or LT slot, but it occupies tw o slots; i.e., the sl ot immediatel y

to its left must be vacant.

(23) AD8 (PN-VM00) can be mounted in any LT or LT/AP slot, but it occupies three slots; i.e., the two slots

immediately to its le ft must be vac ant. It i s recommended that LT00 be used when mounting the AD8 since

the vacant spac e to its left is specifically provided for this pu rpose and o nly LT00 brings lead s out for termination of the AD8 internal modem.

Note: The PN-CC00 must be mounted adjacent to its related PN-AP01 card, in order to allow the connection of cable type

48-TW-0.3 CONN CA between these cards.

CHAPTER 2 NDA-24219

Page 18

Revision 2.0

Page 33

CHAPTER 3 INSTALLATION PROCEDURE

1. PRECAUTIONS

1.1 Grounding Requirements

The system grounding must have a specific ground resistance and AC noise level, and is to be connected to a predetermined terminal in the PBX. Standard grounding requirements are as follows:

• Communication grounding: Less than 10 ohm

• Protective ground for PIM: Less than 10 ohm

Note: The AC ripple on these various grounds should be less than 0.5 Vp-p.

CAUTION:

Grounding circuit continuity is vital for safe operation of telecommunication equipment. Never

operate this equipment with the grounding conductor disconnected.

NDA-24219 CHAPTER 3

Page 19

Revision 2.0

Page 34

1.2 Static Electricity Guard

The installer must wear a grounded wrist strap to protect circuit cards from static electricity.

WHEN PLUGGING/UNPLUGGING A CIRCUIT CARD

•

PBX

FRAME GROUND SCREW

WRIST STRAP

CONNECT THE GROUND WIRE TO THE

FRAME EARTH OF THE EQUIPM ENT

.

• WHEN HOLDING A CIRCUIT CARD

NEVER TOUCH THE COMPONENTS

OR SOLDERED SURFACE WITH

BARE HANDS.

CARD FRONT

Figure 3-1 Static Electricity Guard

CHAPTER 3 NDA-24219

Page 20

Revision 2.0

Page 35

• WHEN MAKING A SWITCH SETTING ON A CIRCUIT CARD

CIRCUIT

CARD

• WHEN CARRYING A CIRCUIT CARD

CIRCUIT

CARD

Figure 3-1 Static Electricity Guard (Continued)

WEAR A WRIST STRAP AND PERFO RM

THE WORK ON A GROUNDED

CONDUCTIVE WORK SURFACE.

CONDUCTIVE

POLYETHYLENE

BAG

WHEN CARRYING A CIRCUIT

CARD AROUND, KEEP THE

CARD IN A CONDUCTIVE

POLYETHYLENE BAG.

NDA-24219 CHAPTER 3

Page 21

Revision 2.0

Page 36

1.3 Removing/Inserting Circui t Cards

When removing a circuit card from the PIM or when inserting a circuit card in the PIM, follow the procedure in

Table 3-1.

Table 3-1 Removing/Inserting Circuit Cards Procedure

PROCEDURE

CIRCUIT CARD

INSERT REMOVE

CONDITION

•PN-CP03 (MP)

• PZ-PW86 (PWR)

• PZ-PW112 (PWR)

•PN-PW00

• PN-AP00 (AP00)

• PN-ME00 (EXTMEM)

•PN-BRTA (BRT)

• PN-BS00-B (BS00)

• PN-BS01-B (BS01)

• PN-CK00 (PLO)

• PN-24DTA- A (DTI)

• PN-4RSTB (MFR)

•PN-4RSTC (CIR)

•PN-SC00 (CCH)

•PN-SC01 (DCH)

•PN-SC02 (ICH)

•PN-SC03 (ICH)

•PN-SC03 (CSH)

• PN-VM00

• PN-AP01 (AP01)

• PN-CC00 (ETHER)

Power off

↓

Insert

↓

Power on

Power off or

MB switch on

↓

Insert

↓

Power on or

MB switch off

Refer to the OAI System Manual.

Power off

Remove

Power on

Power off or

MB switch on

Remove

Power on

Always insert or remove these circuit cards

↓

↓

↓

↓

with power off to prevent damage to the card