Page 1

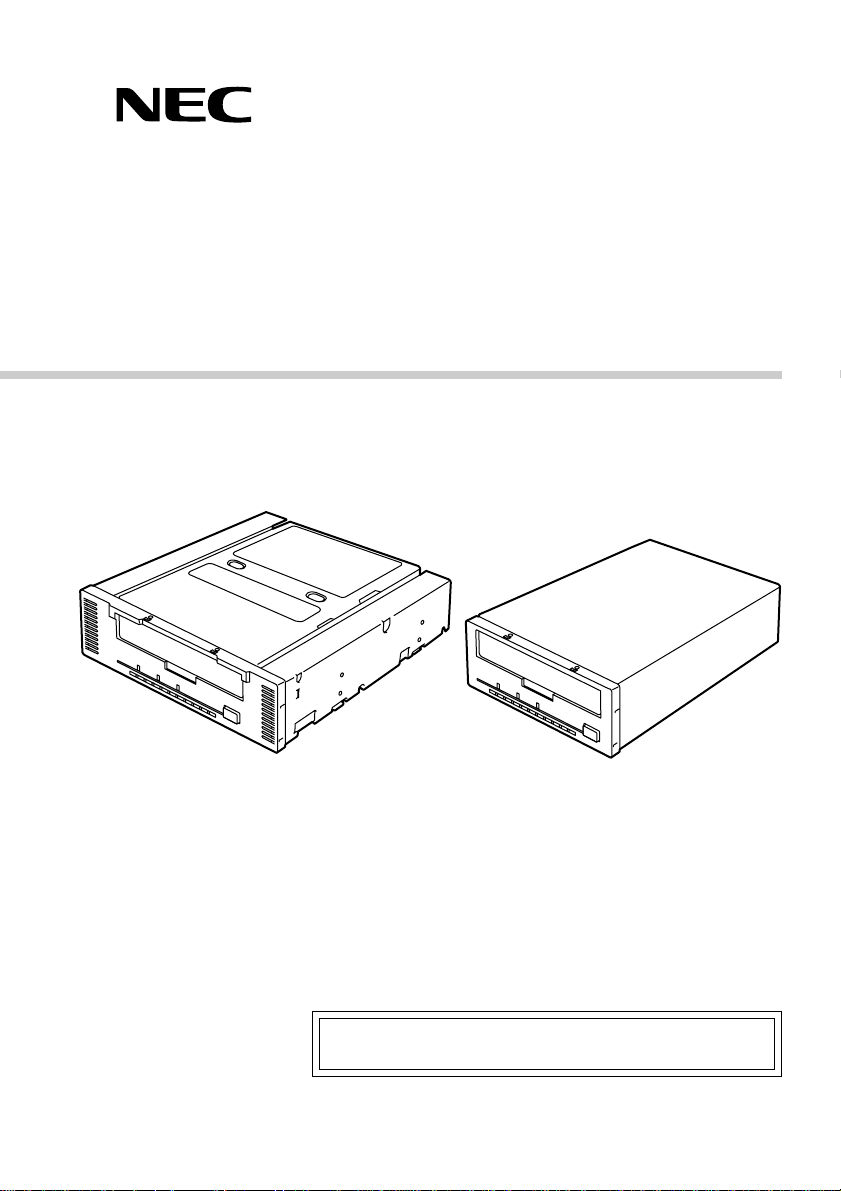

N8551-28F/N8151-44F

Built-In AIT

Instruction Manual

Make sure you read this manual before using the product.

After reading this manual carefully, store it in a safe place.

4-659-559-11(1)

Page 2

Trademarks

Microsoft, the logo of Microsoft and Windows NT are registered trademarks of the Microsoft

Corporation in the United States and other countries.

Advanced Intelligent Tape is a trademark of the Sony Corporation.

The company and product names contained in this manual are trademarks or registered trademarks

of the respective companies.

®

Windows NT 4.0 is an abbreviation of Microsoft

®

version 4.0 and Microsoft

Windows NT® Workstation network operating system version 4.0.

Windows NT® Server network operating system

Windows 2000 is an abbreviation for Microsoft® Windows® 2000 Professional, Microsoft

®

Windows® 2000 Server, and Microsoft® Windows® 2000 Advanced Server.

All names used in the sample applications are fictitious. They have no relation with any product,

party or individual names.

Remarks

(1) Reproduction of this document or portions thereof without prior approval is prohibited.

(2) The information contained in this document is subject to change at any time, without prior

notice.

(3) Reprinting or changing of this document without prior approval of NEC is prohibited.

(4) All efforts have been made to ensure that the contents of this manual are correct; however,

should any doubts arise, or errors or missed entries be detected, NEC would greatly appreciate

it if our dealers are informed about it.

(5) Please note that in no event shall NEC be liable for any damages whatever arising out of the

use of this device, regardless of item (4) above.

© NEC Corporation 2000

ii

Page 3

Keep this User’s Guide at hand for quick reference at anytime necessary.

Safety Consideration - Must Read -

Follow the instructions given in this User’s Guide for proper operations and safe use of the

device.

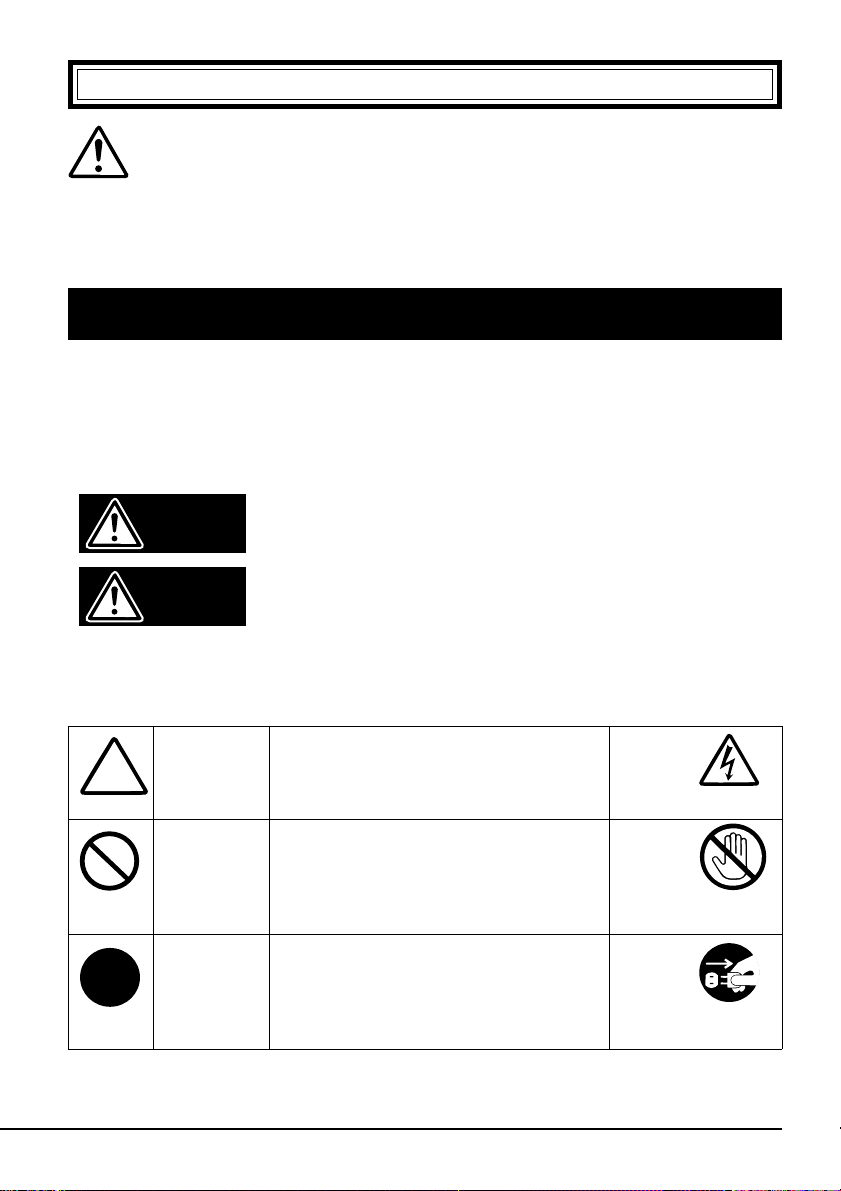

SAFETY INDICATIONS

This User’s Guide describes the device components with possible danger, hazards that

may be caused by ignoring warnings, and preventive actions against such hazards.

Components with possible danger are indicated with a warning label placed on or around

them. In the User’s Guide or warning labels, "WARNING" or "CAUTION" is used to

indicate a degree of danger. These terms are defined as follows:

Failure to heed this sign could result in serious

Warning

Caution

injury or death.

Failure to heed this sign could result in personal

in-jury or damage to properties.

Precautions and notices against hazards are presented with one of the follow-ing three

symbols. The individual symbols are defined as follows:

Attention

Prohibited

Action

Mandatory

Action

This symbol indicates the presence of a

hazard if the instruction is ignored. An

image in the symbol illustrates the

hazard type.

This symbol indicates prohibited

actions. An image in the symbol

illustrates a particular prohibited action.

This symbol indicates mandatory

actions. An image in the symbol

illustrates a mandatory action to avoid a

particular hazard.

(sample)

(Electric shock)

(sample)

(Do not

touch the part)

(sample)

(Disconnect the

power cord)

iii

Page 4

(Sample)

A symbol for

arousing attention

A content of

possible danger

A term indicating a

hazard level

Warning

Do not install the device while the power is turned on.

Unplug the AC power cord from the main power source when

installing/ uninstalling the device to/from basic processing unit

or connect it with the enclosure. Failure to follow this warning

may cause an electric shock.

SYMBOLS USED IN THIS USER’S GUIDE AND WARNING LABELS

Attention

Indicates that improper use

may cause an electric shock.

Indicates that improper use

may cause fingers to be caught.

Indicates that improper use

may cause fumes or fire.

Indicates a general notice or

warning that cannot be

specifically identified.

Prohibited Action

Indicates a general prohibited

action or warning that cannot

be specifically identified.

Do not touch unspecified parts

or units. Otherwise, burns or an

electric shock may be caused.

Mandatory Action

Unplug the power cord.

Otherwise, an electric shock or

fire may be caused.

iv

Do not disassemble, repair, or

modify the device. Otherwise,

an electric shock or fire may be

caused.

Indicates a general mandatory

action or warning that cannot

be specifically identified.

Page 5

SAFETY NO TES

This section provides several precautions to enable you to use the product safely and

correctly and to prevent injury and property damage. Read this section carefully to ensure

proper and safe use of the product. For symbols, see "SAFETY INDICATIONS" provided

earlier.

General Attention

Warning

Do not use the Built-in AIT if any smoke, odor, or noise is

present.

If smoke, odor, or noise is present, immediately turn off the

POWER switch and disconnect the power plug from the outlet,

then contact your sales agent. Using the Built-in AIT in such

conditions may cause a fire.

Keep needles or metal objects away from the Built-in AIT.

Do not insert needles or metal objects into ventilation holes in

the Built-in AIT. Failure to follow this warning may cause an

electric shock.

Caution

Keep water or foreign matter away from the Built-in AIT.

Do not let any kind of liquid (water etc.) or foreign matter

(e.g.,pins or paper clips) enter the Built-in AIT. Failure to follow

this warning may cause an electric shock, a fire, or a failure of

the Built-in AIT. When such things accidentally enter the Built-in

AIT, immediately turn off the power and disconnect the power

plug from the outlet. Do not disassemble the Built-in AIT. Contact

your sales agent.

v

Page 6

Attention to Power or Power Cord

Warning

Do not hold the DC cable with a wet hand.

Do not disconnect/connect the cable while your hands are wet.

Failure to follow this warning may cause an electric shock.

Caution

Do not install the device while the power is turned on.

Unplug the AC power cord from the main power source when

installing/ uninstalling the device to/from basic processing unit or

connect it with the enclosure. Failure to follow this warning may

cause an electric shock.

Insert the DC cable into the outlet as far as it goes.

Heat generation resulting from a halfway inserted DC cable

(imperfect contact) may cause a fire. Heat will also be generated

if condensation is formed on dusty blades of the halfway inserted

cable, increasing the possibility of a fire.

Do not connect the Built-in AIT by unspecified cabling.

Connecting or cabling with DC cable should be done in

accordance with the procedure specified in the User's Guide.

Unspecified connecting or cabling may cause an electric shock

or a fire.

Do not use any damaged power cord.

If the power cord is damaged, immediately replace it with a new

part of same type. Do not repair the damaged section for reuse.

Otherwise, the section repaired with vinyl tape or the like will be

overheated to cause an electric shock or a fire.

Use the authorized cable only.

Use only the specified cable when connecting the Built-in AIT

with a basic processing unit. Use of an unspecified cable or

connection by unspecified cabling may cause a fire.

vi

Page 7

Attention to Installing, Moving, Storing, Connection

Caution

Do not close the ventilation hole.

Do not close the ventilation hole in the front side of the Built-in

AIT. Otherwise, Its internal temperature will rise to cause

malfunctions or a fire.

Do not connect/disconnect the interface cables before

unplugging the power plug.

Before connecting/disconnecting the interface cables, disconnect

the power plug of the main power unit from the outlet. If the

power is off but the power plug is still connected, you may get an

electric shock.

Do not use the unspecified interface cables.

Use only the cable authorized by NEC and locate the device and

connector before connection. Use of an unauthorized cable or

displaced connection may cause a short circuit, resulting in a

fire.

When handling or connecting the interface cables, keep the

notes as follows:

• Do not tread on cables.

• Do not load on the cable.

• Insert the cable connector as far as it goes.

• Do not use damaged cables.

• Do not use damaged connectors.

• Make sure that screwing or the like be done firmly.

vii

Page 8

Attention to Handling or Maintenance

Warning

Do not disassemble, repair, or alter the Built-in AIT.

Never attempt to disassemble, repair, or alter the Built-in AIT on

any occasion other than described in this User's Guide. Failure

to follow this instruction may cause an electric shock or a fire as

well as malfunctions of the Built-in AIT.

Do not handle while the power plug is connected.

Before handling or cleaning the Built-in AIT, disconnect the

power plug of the main power unit from the outlet. If the power is

off but the power plug is still connected, you may get an electric

shock.

Caution

Insert the cables into the connectors as far as it goes.

Heat generation resulting from a halfway inserted cables or

Interface cables (imperfect contact) may cause a fire. Heat will

also be generated if condensation is formed on dusty blades of

the halfway inserted cable, increasing the possibility of a fire.

viii

Page 9

Attention to Operation

Do not insert your hands into the cartridge load

compartment.

Do not insert your hands into the cartridge load compartment.

Otherwise, the fingers will be caught/pinched by the Built-in AIT

to cause an injury.

Do not touch the Built-in AIT when it thunders.

If it starts thundering, do not touch any part of the Built-in AIT.

Failure to follow this warning may cause an electric shock or a

fire.

Keep away pets.

Keep away pets from the Built-in AIT. Insertion their hair or

excrements may cause a fire or an electric shock.

Do not use a cellular phone or a pager

Turn off the power of the cellular phone or a pager. Otherwise,

malfunction may be caused.

Warning

ix

Page 10

For Correct Operation

To operate the N8551-28F/N8151-44F Built-In AIT correctly, observe the following points. For

considerations on handling the AIT data cartridge, refer to the chapter “AIT Data Cartridge”.

• Set the N8551-28F/N8151-44F Built-In AIT’s SCSI ID so that it will not duplicate with SCSI

ID of other SCSI equipment.

→ Otherwise, an operation error will occur.

• When N8551-28F/N8151-44F Built-In AIT is a termination of the SCSI connection, set the

terminal resistance to ON using its DIP switch.

→ Otherwise, an operation error will occur.

• Do not turn off power of the basic processing unit when the BUSY LED on the front of the

Built-In AIT is ON or blinking.

→ This may cause a machine failure or damage of backup data.

• Do not use a portable phone near the Built-In AIT.

→ This may cause a machine failure.

• Do not store the Built-In AIT in a place exposed to direct sunlight.

→ The Built-In AIT may not be able to operate correctly.

• Do not store the Built-In AIT in a place subject to corrosive gas, chemicals or splash of chemi-

cals.

→ A Built-In AIT part may be deformed or damaged and may not be able to operate correctly.

• Do not store the Built-In AIT in a place subject to strong vibrations.

→ This may cause a machine failure.

• Do not put a thing on the Built-In AIT when using or storing it.

→ This may cause a machine failure.

• As the data cartridge set in the Built-In AIT, use our “AIT Data Cartridge (model: AIT2,

AIT1)”.

→ If you use a data cartridge of other manufacturer, a read/write error may occur.

• When cleaning the Built-In AIT, use our “AIT Cleaning Cartridge”.

→ If you use a cleaner of other manufacturer, a machine failure may occur.

x

Page 11

Others

Transfer to a third party

When you transfer (or sell) the N8551-28F/N8151-44F Built-In AIT to a third party, be sure to

include the instruction manual with the driver.

Disposal of consumed parts and equipment

For the disposal of the N8551-28F/N8151-44F Built-In AIT and its cartridge, observe the waste

disposal rules of your local government. For details, contact the local government office.

xi

Page 12

Introduction

Thank you for purchasing the N8551-28F/N8151-44F Built-In AIT.

The Built-In AIT will ensure smooth backup, application and management of your important data.

To maximize the N8551-28F/N8151-44F Built-In AIT functions, please read the instruction

manual carefully before use and fully understand how to handle the device.

xii

Page 13

Organization of the Instruction Manual

The instruction manual function as a guide that enables you to set up and use the N8551-28F/

N8151-44F Built-In AIT correctly. You can refer to this manual whenever you encounter a

question or problem during setup and daily operation.

The instruction manual consists of two chapters: the first covers the considerations on the safe use

of the Built-In AIT (setup, daily operation and maintenance) and the second covers the considerations on the safe use of the AIT data cartridge available on the Built-In AIT (operation and

maintenance).

Order of priority when the N8551-28F/N8151-44F Built-In AIT is used for the first time

When the Built-In AIT is being used first time, refer to the instruction manual in the following

sequence to perform the setup after unpacking the driver.

1. Check the contents in the package. ....................... Package Contents (→P. xv)

2. Learn the operational precaution. ......................... Safety Consideration (→ P. iii)

3. Learn the parts of the Built-In AIT ....................... Part Name and Function (→ P. 2)

4. Set before installation. .......................................... Setup (→ P. 4 to 7)

5. Install the driver in the basic processing unit........ Setup (→ P. 8 to 10)

6. Install the tape driver.* .......................................... Installing the tape driver (→ P. 11 to P. 13)

7. Learn how to handle the cartridge......................... AIT Data Cartridge (→ P. 19)

8. Set the cartridge. ................................................... Handling (→ P. 14)

9. Check the LED indication..................................... Handling (→ P. 16)

10. Clean the Built-In AIT. ......................................... Cleaning (→ P. 17)

* Required only when using Windows NT 4.0 NT backup, and Windows 2000 backup.

For details on data storage methods and settings, such as data save format, refer to

the instruction manual provided with the backup software.

xiii

Page 14

Symbols Used in This Text

The following symbols are used in this text to indicate cautions and notes concerning the operation

of this device. (Refer to the beginning of this document for an explanation of the symbols used for

safety-related cautions.)

Important

Hint

✎

This symbol indicates important information concerning the handling of the

device or the operation of the software.

Indicates useful information and operational help.

xiv

Page 15

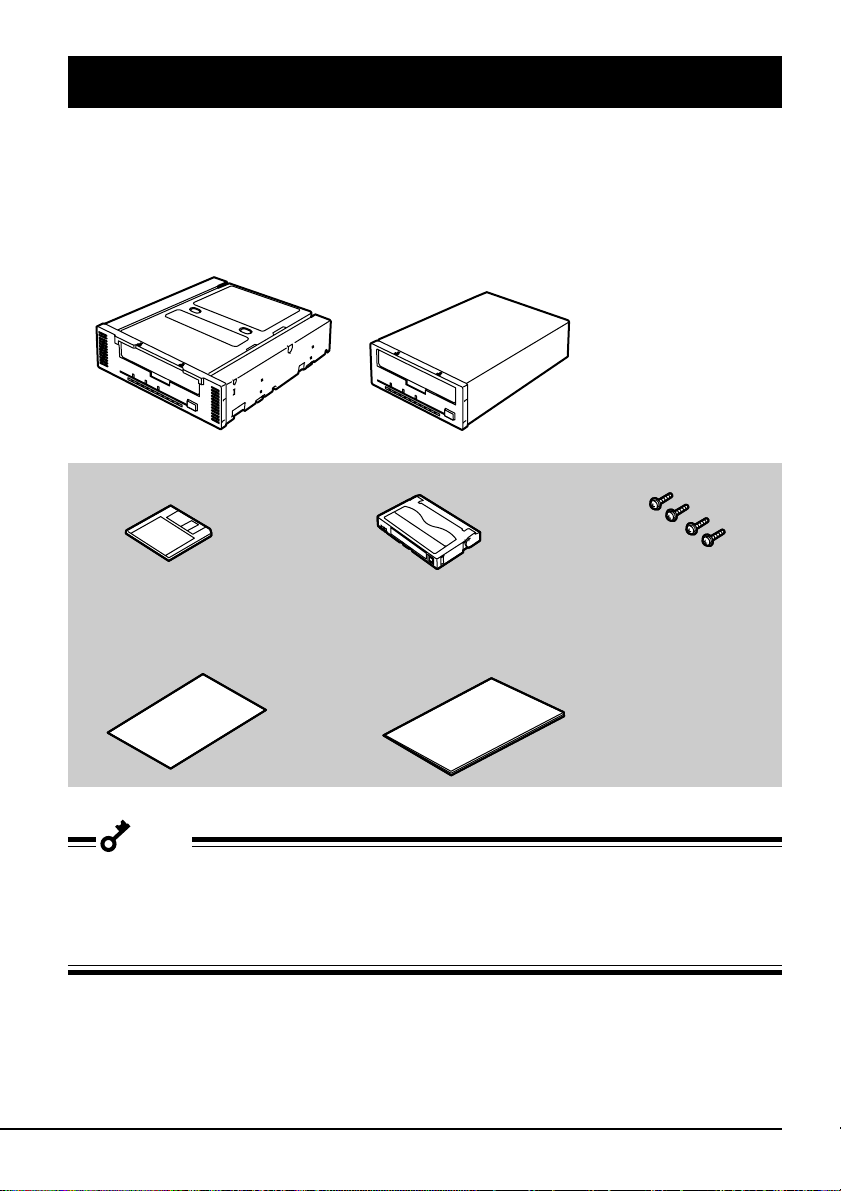

Package Contents

Many accessories are included with the Built-In AIT in the N8551-28F/N8151-44F Built-In AIT.

Verify the packed contents with the part list given below and ensure that all the components and

parts are present. Also, check that each item is undamaged. If a component or part is missing or

damaged, contact your dealer.

N8551-28F Built-In AIT

N8151-44F Built-In AIT

The following accessories are common to the N8551-28F and the N8151-44F.

Floppy disk (Device driver) Cleaning cartridge

Instructions on handling

the AIT unit

Instruction manual (this manual)

Screws (4)

Important

• Locking parts contained in the package or box will be required when removing the Built-In AIT

for transportation. Store them securely.

• Copy a backup from the provided floppy disk. Keep the provided floppy disk as the master disk

and use the backup disk in actual applications.

xv

Page 16

Table of Contents

Trademarks ............................................................... ii

Safety

Consideration

- Must Read -

Built-in AIT

SAFETY INDICATIONS ........................................ iii

SYMBOLS USED IN THIS USER’S GUIDE AND

WARNING LABELS ............................................ iv

SAFETY NOTES ..................................................... v

For Correct Operation.............................................. x

Others ..................................................................... xi

Transfer to a third party ..................................... xi

Disposal of consumed parts and equipment ...... xi

Introduction ............................................................ xii

Organization of the Instruction Manual................. xiii

Order of priority when the N8551-28F/N8151-

44F Built-In AIT is used for the first time.... xiii

Symbols Used in This Text .............................. xiv

Package Contents.................................................... xv

Features..................................................................... 1

Usable Cartridges ..................................................... 1

Part Name and Function ........................................... 2

Front.................................................................... 2

Rear ..................................................................... 2

Bottom ................................................................ 3

Setup ........................................................................ 4

Setting the Built-In AIT

- Setting with the jumper pins - ....................... 4

Setting the Built-In AIT

- Setting with the DIP switch - ........................ 6

Mounting on the basic processing unit ............... 8

Installing the tape device driver........................ 11

Handling ................................................................. 14

Setting the AIT data cartridge........................... 14

Ejecting the AIT data cartridge ......................... 15

LED indication.................................................. 16

Reading/writing data......................................... 16

Cleaning.................................................................. 17

Cleaning the read/write head ............................ 17

Cleaning the Built-In AIT................................. 18

xvi

Page 17

AIT Data Cartridge

Data Cartridge Part Name and Function................. 19

Operation, Storage and Transportation

Requirements........................................................ 20

Label ....................................................................... 20

Label paste position .......................................... 20

Precautions on entry to label............................. 21

Write-protect........................................................... 21

Precautions on Handling......................................... 22

Operational precautions .................................... 22

General precautions .......................................... 22

Usage Inhibition Standard ...................................... 23

Service Life ............................................................ 23

Storing Important Data ........................................... 24

Managing 3-generation Data .................................. 24

Data cartridge storage............................................. 24

xvii

Page 18

Page 19

Built-in AIT

This chapter explains setup, installation and daily operation of the N8551-28F/N8151-44F Built-In

AIT.

Features

This unit has the following features:

• You can record large amounts of data on the AIT1 and AIT2 data cartridges using AIT (Advanced Intelligent Tape) format.

• When the data compression function is used, an AIT2 (tape length: 230 m) data cartridge can

store 50 to 100 GB of data, an AIT1 (tape length: 230 m) data cartridge can store 35 to 70 GB of

data, and an AIT1 (tape length: 170 m) data cartridge can store 25 to 50 GB of data.

• The basic processing unit automatically determines whether data recorded on the AIT data

cartridges is compressed. It can also read data recorded on AIT data cartridges with conventional AIT drives.

*1

The compression rate for recorded data may differ depending on the user environment and

the type of data.

(When using an average compression rate of 2.)

Usable Cartridges

Please use Sony AIT data cartridges (AIT2 (tape length: 230 m), or AIT1 (tape length: 230 m),

(tape length: 170 m)) with this unit. Using other types of AIT data cartridges may cause read and

write errors.

Built-in AIT 1

Page 20

Part Name and Function

The Built-In AIT and magazine have the following parts and functions.

Important

The names and functions of each part of the N8551-28F and the N8151-44F and the setup

methods are identical. (Hereafter, the N8151-28F is used for the illustrations in this manual.)

Front

➀ Data cartridge slot

➀

➅ ➃ ➂ ➁

➄

A slot in which the AIT cartridge is set

(→ P. 14)

➁ Ventilation holes

(The N8151-44F does not have

ventilation holes.)

➂ EJECT button

Press this button when ejecting the

AIT cartridge from the Built-In AIT.

(→ P. 15)

➃ STATUS LED

An LED which shows the Built-In AIT

status. (→ P. 16)

➄ TAPE LED

An LED which shows the status of the

AIT data cartridge (→ P. 16)

➅ BUSY LED

An LED which shows the data

communication status (→ P. 16)

Rear

2 Built-in AIT

➀

➀ Fan

➁ Power connector

Connect the Built-In AIT’s built-in

power cable. (→ P. 9 )

➂ Jumper pin

Pins which set the Built-In AIT

(→ P. 4)

➃ SCSI connector

Connect the Built-In AIT’s built-in

SCSI cable. ( → P. 9 )

➁➃

➂

Page 21

Bottom

12345678

➀ DIP switch

Switches which set the Built-In AIT

ON

(→ P. 6 )

➀

Built-in AIT 3

Page 22

Setup

The procedure up to installation of the Built-In AIT to the “basic processing unit” is explained in

the following.

Setting the Built-In AIT - Setting with the jumper pins -

You can change the following settings with the jumper pins on the rear of the Built-In AIT.

• SCSI ID (factory-set to “ID4”)

• Parity function (factory-set to “Enabled”)

SCSI ID (pin 0 to 3 from right)

Unused (NC)

Parity (PD)

Hint

✎

Hint

✎

“With strap” means a status that the straps are attached to two pins. “Without strap” means a

status that no strap is attached to either pin or it is attached to one of two pins.

“Without strap” means that one strap is

attached to one of the two pins, or that

the strap has been removed altogether .

If you remove the strap, make sure you

store it in a safe place.

4 Built-in AIT

Page 23

Setting SCSI ID

Set SCSI ID which is used by the Built-In AIT. Use four jumper pins, pin 0 to pin 3, on the rear of

the Built-In AIT.

Pin 3 (Factory-set to “Without strap”)

Pin 2 (Factory-set to “With strap”)

Pin 1 (Factory-set to “Without strap”)

Pin 0 (Factory-set to “Without strap”)

Important

Check that the Built-In AIT’s SCSI ID is not duplicated with SCSI ID of other SCSI device.

SCSI ID Pin 3 Pin 2 Pin 1 Pin0

0 ✕✕✕✕

1 ✕✕✕❍

2 ✕✕❍✕

3 ✕✕❍❍

*1

4

5 ✕❍✕❍

6 ✕❍❍✕

*2

7

8 ❍✕✕✕

9 ❍✕✕❍

10 ❍✕❍✕

11 ❍✕❍❍

12 ❍❍✕✕

13 ❍❍✕❍

14 ❍❍❍✕

15 ❍❍❍❍

✕❍✕✕

✕❍❍❍

❍ : W ith strap

✕ : Without strap

*1

: Factory-set value

*2

: Do not set SCSI ID to ID7.

Built-in AIT 5

Page 24

Setting the parity function

Set the parity function using the leftmost jumper pin on the rear of the Built-In AIT.

The parity function is “Enabled” when setting “Without strap” (factory-set value). The parity

function is “Disabled” when setting “With strap”.

PD (Factory-set to “Without strap”)

Important

To improve reliability, set the parity function “Enabled” (Without strap).

Setting the Built-In AIT - Setting with the DIP switch -

The DIP switch on the bottom of the Built-In AIT enables you to change the following settings.

• Terminator Power (Terminator power supply) (Factory-set to ON)

• DC Control (1) (Data compression setting) (Factory-set to ON)

• DC Control (2) (Data compression setting) (Factory-set to OFF)

6 Built-in AIT

ON

12345678

Switches 1 to 4: Unused

Switch 5: Terminator Power

Switch 6: Unused

Switch 7: DC Control (1)

Switch 8: DC Control (2)

Page 25

Setting terminator power - Terminator Power -

Set whether terminator power is supplied to the SCSI bus or not.

Use Switch 5. Setting Switch 5 to ON (factory-set to ON) will

supply terminator power; setting Switch 5 to OFF will not supply

terminator power.

Important

When this unit is installed in the N8541-28F/N8141-28F device expansion unit, set this switch to

OFF if you want to use the slaved power control feature.

12345678

Setting data compression - DC Control (1) -

Set whether the Built-In AIT’s data compression function is enabled

or disabled.

Use Switch 7. Setting Switch 7 to ON (factory-set to ON) will

enable the data compression function; setting Switch 7 to OFF will

12345678

disable the terminator data compression function.

Setting data compression - DC Control (2) -

Set whether control of data compression from the backup software

is enabled or disabled.

Use Switch 8. Setting Switch 8 to ON will disable control of data

compression from the backup application; setting Switch 8 to OFF

(factory-set to OFF) will enable control of data compression from

the backup software.

12345678

ON

ON

ON

Built-in AIT 7

Page 26

Mounting on the basic processing unit

Caution

Turn off the power before installing or removing the device

Always be sure to turn off the main power and unplug the power cord from the

AC outlet before installing/removing this device or connecting any cables.

There is a risk of electric shock if this device in installed or removed or if any

cables are connected while the power cord is still plugged into an AC outlet.

The procedure for installing the drive in a server is as follows.

Hint

✎

Some servers require the rails to be used. For details on how to install the rails, refer to the

server's operating manual.

1 Install the N8551-28F/8151-44F Built-

In AIT as shown below.

Install in

either bay

8 Built-in AIT

Page 27

Important

• When using the rails, adjust their

mounting positions so that the front

cover of this device is aligned with

the front covers of the other

standard components (such as the

Use screws to secure

the upper rail.

Front cover

Rails

CD-ROM).

• Always use the screws that are provided with this device. The screws that

are provided with this device are millimeter screws (length: 5.0 mm; length

below washer: 3.5 mm). Using screws that are longer than the screws that

are provided with this device could result in damage to the device.

2 Connect the cables to the drive as

shown below.

3.5 mm

millimeter screw

DC power cable

(unused power

supply connector in

the computer)

SCSI interface cable

Important

• Confirm the SCSI ID and other settings before installation.

• The factory default setting of the SCSI ID is 4. Make sure this ID is not used by any other

device in the system.

• This unit does not have a built-in terminator. When connecting this unit to the last terminal of

the SCSI bus terminal, attach a terminator to the end of the SCSI cable.

3 Attach the cover to the basic processing unit. Plug the power cable to the outlet.

4 Turn on the basic processing unit.

Built-in AIT 9

Page 28

5 When the SCSI bus can be set on the side of the basic processing unit, set the following on the

Built-In AIT .

• Transfer rate : 40 MByte/second (max., synchronous)

• Data bus width : 16 bits (Ultra Wide SCSI, LVD/SE)

• DISCONNECT/RECONNECT function : Enable

For details, see the instruction manual provided with the basic processing unit.

Important

Set the maximum transfer rates as follows according to the number of devices connected to the

bus and the SCSI cable length.

SCSI ID

Ultra Wide SCSI 40 16 3 (-) 4

Ultra Wide SCSI 40 16 1.5 (-) 8

Ultra Wide SCSI 40 16 - (3) 16

Fast Wide SCSI 20 16 3 (3) 16

Wide SCSI 10 16 6 (3) 8

Maximum transfer Data bus Maximum cable

rate (Mbyte/s) width (bit) length (m) of devices

Single-ended (SCSI host +

(LVD*) number of

Maximum number

devices)

* When the SCSI host and all devices connected to the same bus are LVD-compatible.

10 Built-in AIT

Page 29

Installing the tape device driver

Install the tape device driver only when you want to use the Windows NT 4.0 backup (management

tool), or Windows 2000 backup (system tool).

Install the tape device driver in the basic processing unit. As the driver, use the provided floppy

disk. Prepare it beforehand.

For Windows NT 4.0 Users

1 Click [Start] button. Point [Setting] and click [Control Panel].

[Control Panel] dialog box appears.

2 Click [Tape Device] in [Control Panel].

[Tape Device] dialog box appears.

3 Click [Driver] tab.

4 Click [Add] button.

[Install Driver] dialog box appears.

5 Click the [Use Disk] button.

The [Install from floppy disk] dialog box is displayed.

6 Confirm that “A:\” is specified for the distributed file copy source (C):, and click the [Browse]

button.

The [Browse] dialog box appears.

7 Point to “WinNT4.0”, then click the [Open] button.

[NT4ait.inf] is displayed in the [Search Files] dialog box.

8 Confirm that “NT4ait.inf” is specified as the file name, then click the [Open] button.

9 Confirm that “A:\WinNT4.0” is specified for [Distributed file copy source (C)] and click the

[OK] button.

The [Installing Drivers] dialog box appears.

10 Click “Sony AIT Tape Drive (NT 4.0)” displayed in the [Tape Device] box, and click the [OK]

button.

The driver files are copied, then installation is completed.

Built-in AIT 11

Page 30

11 Restart the system.

Important

When using Windows NT backup, do not install any other backup software. If any other backup

software is installed, make sure you uninstall it. Further, when using backup software other than

Windows NT backup, make sure you delete “Sony AIT Tape Drive (NT 4.0)”.

Hint

✎

The tape device driver installed after restarting the system is enabled.

For Windows 2000 Users

1 Click the [Start] button, then point to [Settings] and click [Control Panel]. Then click [System].

The [System Properties] dialog box appears.

2 Click the [Hardware] tab, then click the [Device Manager] button.

The [Device Manager] dialog box appears.

3 Confirm that [SONY SDX-500C SCSI Sequential Device] is displayed under [Other devices],

and double click [SONY SDX-500C SCSI Sequential Device].

The [SONY SDX-500C SCSI Sequential Device Properties] dialog box is displayed.

4 Click the [Driver] tab, and click the [Update Driver] button.

The [Upgrade Device Driver Wizard] appears.

5 Click the [Next] button.

The [Install Hardware Device Drivers] screen appears.

6 Select [Search for a suitable driver for my device (recommended)], and click the [Next] button.

The [Locate Driver Files] screen appears.

Insert the floppy disk provided.

7 Place a checkmark in the [Floppy disk drives] checkbox, and click the [Next] button.

The basic processing unit starts searching for driver files.

12 Built-in AIT

Page 31

8 Confirm that [This wizard upgrades drivers for the following hardware device: SONY SDX-

500C SCSI Sequential Device] is displayed, and click the [Next] button.

The [Insert Disk] dialog box appears.

9 Click the [OK] button.

The driver is copied, then the [Files needs] dialog box appears.

10 Confirm that “A” is specified as the file copy source, and click the [Browse] button. Then

select sonyait2.sys, and click the [Open] button.

The screen returns to the [Files needs] dialog box.

11 Click the [OK] button.

The [Completing the Upgrade Device Driver Wizard] screen is displayed.

12 Click the [Finish] button.

Built-in AIT 13

Page 32

Handling

The following explains how to handle the N8551-28F/N8151-44F Built-In AIT.

Setting the AIT data cartridge

Important

• As the data cartridge to be set in the magazine, use our “AIT Data Cartridge (model: AIT2,

AIT1)”. If you use a data cartridge of other manufacturer, a read/write error may occur.

• While setting the data cartridge, do not turn off the basic processing unit. This may cause a

malfunction or damage data.

1 Turn on the basic processing unit.

Check that the driver’s STATUS

LED, BUSY LED and TAPE LED

go off.

2 Set the AIT data cartridge orienta-

tion as shown below and insert it

into the data cartridge slot.

By inserting the data cartridge to the

extent, it is automatically set in the

driver and the TAPE LED lights.

Important

When write-protect is enabled using the AIT data cartridge

write-protect plug so that you cannot write data in the data

cartridge, the STATUS LED lights.

STATUS LED

14 Built-in AIT

Write-protect plug (Sliding it up

write-protects the cartridge.)

(→ 21 page)

Page 33

Ejecting the AIT data cartridge

Check that the BUSY LED goes off.

Then, press the EJECT button. The

Built-In AIT starts rewinding the tape

(this may take a few minutes).

When the tape is completely rewound,

the data cartridge is automatically

ejected from the Built-In AIT.

Remove the data cartridge from the slot.

Important

• When the BUSY LED lights or is blinking, do not turn off the basic processing unit. This may

cause a malfunction or damage data.

• To avoid malfunction, do not transport this unit with the data cartridge installed.

Built-in AIT 15

Page 34

LED indication

Four LED on the Built-In AIT’s front side signal the status of the driver and the AIT data cartridge.

LED name Indication status Description

POWER LED OFF The Built-In AIT power supply is off.

ON The Built-In AIT power supply is on.

BUSY LED OFF –

ON Transmitting or receiving the data now

Blink The data is normally read/written from/to the

data cartridge set in the Built-In AIT.

TAPE LED OFF The data cartridge is not set.

ON The data cartridge is set.

Blink (at a given interval) The data cartridge is being set or ejected.

Blink (repeating a long ON

and a short ON)

STATUS LED OFF The data cartridge set in the Built-In AIT is

ON The data cartridge set in the Built-In AIT is

Blink (repeating a long ON

and a short OFF)

Blink (at a given interval) During the head cleaning, the cleaning

Blink (repeating a short ON

(once or twice) and a long ON)

The data cartridge set in the Built-In AIT is

deteriorated.

ready to write data.

not enabled to write data (write-protected).

The Built-In AIT head needs cleaning.

cartridge tape comes to the end.

The driver is broken.

Reading/writing data

To read/write the data from/to the AIT data cartridge, see the instruction manual provided with the

backup application.

16 Built-in AIT

Page 35

Cleaning

To keep the driver in the best condition, regular cleaning is required.

Cleaning the read/write head

When the STATUS LED is blinking (repeating a long ON and a short ON), clean the read/write

head within the driver.

Set the provided cleaning cartridge in the driver, following the procedure described in “Handling”

in “Setting the AIT Data Cartridge”.

When set in the Built-In AIT, the cleaning cartridge automatically starts cleaning the head.

After cleaning, the cleaning cartridge is automatically ejected (which requires about 35 seconds

after starting cleaning). Remove the cleaning cartridge.

Important

• Use our “AIT Cleaning Cartridge” to clean

the Built-In AIT. If you use a cleaner of other

manufacturer, a machine failure may be

caused.

• Do not touch the cleaning cartridge tape

surface or rewind the tape.

• You can use the cleaning cartridge for about

70 times. When the STATUS LED blinks (at a

given interval) during cleaning, the cleaning

cartridge tape comes to the end. (Eject the

cleaning cartridge tape and check that all the

tapes are wound around the right reel.)

Purchase a new cleaning cartridge tape.

Hint

✎

Before using the AIT data cartridges, you should clean the read/write head using the cleaning

cartridge once a week. (The cleaning frequency varies depending on the operating environment

(generation of dust and dirt) and the operation frequency. When using the Built-In AIT every day in

a typical office, a weekly cleaning is recommended.)

Built-in AIT 17

Page 36

Cleaning the Built-In AIT

If the Built-In AIT looks dirty, gently wipe its surface with soft cloth moistened with water or

detergent.

Important

Do not clean the Built-In AIT using chemicals such as benzine or thinner (volatile chemicals),

which may cause the unit to be deformed or discolored. For the same reason, do not spray

insecticide. If a chemical adheres to the driver surface, immediately wipe it with soft cloth

moistened with water.

18 Built-in AIT

Page 37

AIT Data Cartridge

This chapter explains how to handle the AIT data cartridge.

Data Cartridge Part Name and Function

Label paste position

Label paste position

Write-protect plug

Handle for insertion/ejection

(The same one is provided on

the opposite site.)

AIT Data Cartridge 19

Page 38

Operation, Storage and Transportation Requirements

■ Operation requirement

Temperature : 5 to 45 °C

Humidity : 20 to 80 % (The maximum temperature of wet bulb is 26 °C.)

Shelf time : If an AIT data cartridge is exposed to an environment other than

the operating or storage environment, expose it to the operating

environment for a longer time than the period when it is exposed to

other environment (for 8 hours at maximum) before use. The

temperature gradient is 10 °C/hour.

■ Storage requirement

Temperature : 5 to 32 °C

Humidity : 20 to 60 % (The maximum temperature of wet bulb is 26 °C.)

Storage condition : Store an AIT data cartridge in a protective case with cover. You

can place the case horizontally or vertically.

■ Transportation requirement

Temperature : -40 to 45 °C

Humidity : 5 to 80 % (The maximum temperature of wet bulb is 26 °C.)

Temperature gradient : 10 °C/hour

Transportation condition : Store an AIT data cartridge in a protective case. During transporta-

tion, pack the case so that force will not apply to the AIT data

cartridge.

Label

It is recommended that you should affix a label to each AIT cartridge to associate the AIT data

cartridge with the backup data for easier identification.

Label paste position

20 AIT Data Cartridge

Page 39

Precautions on entry to label

• To represent the data contained in the AIT data cartridge, use a label which can be easily

replaced and no adhesion trace is left.

• To change the label indication, do not erase it with an eraser but peel the old label and paste a

new one. (The INDEX labels are provided with the AIT data cartridge.)

• Pasting the label in the position specified in the previous section. To replace the label, peel the

old label and paste a new one.

• When using a label other than the specified INDEX label, its size should be the same as the

specified label.

• Enter the date when starting to use the cartridge in the provided INDEX label. It will help you

check the AIT data cartridge service life.

Write-protect

By setting the write-protect plug as

shown at right, the tape data can be

protected.

When you do not want to erase the

written data, set the plug to the “SAFE”

position (write disable). To enable write

to the tape, set the plug to the “REC”

position (write enable).

AIT2

Write enable Write disable

AIT1

Write enable Write disable

Write-protect plug

Write-protect plug

AIT Data Cartridge 21

Page 40

Precautions on Handling

Operational precautions

Before use

• If the AIT data cartridge is damaged, deformed or bent, do not use it.

• If the AIT data cartridge is exposed to an environment other than the operating or storage

environment, expose it to the operating environment for a longer time than the period when it is

exposed to other environment (for 8 hours at maximum) before use. If temperature is greatly

different between the storage site and the operating site, do not rush the cartridge into the

operating environment. Leave the AIT data cartridge in temperature of the operating site with

temperature gradient set to 10 °C/hour.

Mounting to the Built-In AIT

Set the cartridges as explained in “Setting the AIT data cartridge”. Close the empty protective case

firmly and store it in a place free of dust and dirt.

After use

Be sure to put the AIT data cartridge that you used in the protective case and store it in a place free

of dust and dirt. You can place it horizontally or vertically.

General precautions

• Do not touch a tape by hands. Do not

open or close the tape cover.

• Do not bring a substance which generate

magnetic close to the cartridge.

• Do not place the cartridge in a place

subject to direct sunlight or a place near a

heater.

• Do not apply strong shock.

• Avoid handling the cartridge while eating

or drinking. Take due consideration not

to adhere thinner or alcohol to the

cartridge.

Tape surface

Tape cover

• Insert the cartridge to the Built-In AIT gently and carefully.

22 AIT Data Cartridge

Page 41

Usage Inhibition Standard

If an AIT data cartridge that you are using is in the case below, you must replace it.

• When the AIT data cartridge is given a strong shock, for example, when falling, and damaged.

• When the recording surface is contaminated with liquid, such as soft drink, coffee and tea,

detergent, metal chips or cigarette ash.

Important

If you insert an AIT data cartridge in such a condition into the Built-In AIT, the read/write head or

the driver itself may be damaged or contaminated, causing a machine failure.

Also, if you insert a new AIT data cartridge into the Built-In AIT whose head is contaminated or

scratched and you do not know about it, the AIT data cartridge may be contaminated or damaged.

In this way, damage is expanding.

Service Life

The service life of the AIT data cartridge varies greatly depending on temperature and humidity in

the operating/storage environment, dust and dirt, and head abrasion condition.

You can judge its service life in the following sequence.

• Assign a management number to a new AIT data cartridge. Enter the number in the AIT data

cartridge label.

• Create the AIT data cartridge management book. Record the date when each AIT data cartridge

is used and estimate how many years and how often each cartridge is used.

• Examine the AIT data cartridge management book and index label regularly. Discard the

cartridges having low reliability, for example, those which generate write/read errors.

The tape magnetic layer is composed of chemicals and it becomes deteriorated as the time elapses.

Although the tape service life, which is determined by this deterioration, varies greatly depending

on the tape storage environment (humidity, temperature), the tape is generally serviceable for about

3 years since you purchase it.

AIT Data Cartridge 23

Page 42

Storing Important Data

When storing important data or programs, it is strongly recommended that you should prepare and

store the master tape and copy (backup) tape just in case.

Further, we recommend that you verify backup software when saving, and check saved data. For

details on verification, refer to the instruction manual for the backup software you are using.

By doing this, if one of the tapes causes a read error due to dust or dirt, you can recover the data

from the other tape. Thus, you can prevent loss of important data and programs.

Managing 3-generation Data

To store the data on the disk, you should manage the data in the three generations.

To manage the 3-generation data, use three tapes (A, B, C). On the first day, store the data on the

disk in tape A. On the second day, store the data in tape B. On the third day, store the data in tape

C.

This method allows you to protect your important data. For example, if tape C generates a read

error, you can use tape B to recover the data. If tape B generates a read error, you can use tape A

to recover the data.

Data cartridge storage

Always store data cartridges in a clean location under the specified storage conditions.

Enabling the write-protect feature is recommended when storing data cartridges.

When storing data cartridges for an extended period of time, data should be read periodically in

order to ensure that restoration from backup data is possible at all times.

Storing data cartridges in a different location from the system is recommended. If both master and

spare data cartridges are kept, storing each in a different location is recommended.

24 AIT Data Cartridge

Page 43

Specification

The N8551-28F/N8151-44F Built-In AIT has the following specification:

■ Performance

Memory capacity 50 Gbyte (In the compression mode: 100 Gbyte) when

using AIT2 Data Cartridge: tape length 230 m

35 Gbyte (In the compression mode: 70 Gbyte) when using

AIT1 Data Cartridge: tape length 230 m

25 Gbyte (In the compression mode: 50 Gbyte) when using

AIT1 Data Cartridge: tape length 170 m

The value in the compression mode is obtained when the

compression efficiency is X2.

The compression efficiency varies with the data pattern.

-17

Bit error code 10

Data transfer speed (TAPE) 6 Mbyte/second (in the non-compression mode)

Burst data transfer speed (SCSI) 40 Mbyte/second (max, synchronous)

Initialize time Less than 5 seconds

Load time Less than 14 seconds

Unload time Less than 20 seconds

Rewind time Less than 105 seconds

■ Environmental requirement

During operation Temperature: 5 °C to 35 °C

During non-operation Temperature: -40 °C to 70 °C

or less

Humidity: 20% to 80% (no dew condensation allowed)

Highest dry bulb temperature: 26 °C

Humidity: 10% to 90% (no dew condensation allowed)

■ Power supply specification

Voltage 5V±5% 12V±10%

Current (Typ.) 1.5A 0.4A

Current (Max.) 2.5A 1.2A

Specification 25

Page 44

■ Dimensions, weight

N8551-28F

41.2mm

149.0mm 162.0mm

N8151-44F

41.2mm

101.6mm 162.0mm

Weight 1.0 kg

Weight 0.75 kg

26 Specification

Page 45

Customer’s Application Sheet

Use this sheet as a note in which the information required for maintenance and management of the

N8551-28F/N8151-44F Built-In AIT.

Item Record

Basic processing unit model

name

Operating system (OS) (name,

version, service pack/batch

application)

Backup software (name,

version service pack/batch

application)

SCSI bus configuration (SCSI

ID/device on the same bus)

Built-In AIT installation

environment

Built-In AIT installation

environment (temperature,

humidity, dust)

Cartridge type (manufacturer,

EF model code)

Cleaning cartridge type

Cleaning cartridge usage

(method of managing cleaning

frequency, operation frequency

and starting month)

Cartridge usage (method of

managing cleaning frequency,

operation frequency and

starting month)

Cartridge management

Customer’s Application Sheet 27

Page 46

Page 47

N8551-28F/N8151-44F

Built-In AIT Operating Manual

First Edition, November 2000

Second Edition, August 2001

NEC Corporation

5-7-1 Shiba, Minato-ku, Tokyo

Tel. (03) 3454-1111 (Main switchboard)

©2000 NEC Corporation

No copying or modifying without permission of NEC Corporation.

The contents of this document may be changed without notice.

Page 48

Printed in Japan

Printed on recycled paper.

Loading...

Loading...