Page 1

N8551-26F/N8151-43F

Built-In DAT Users Guide

Note

• Please read this guide before using the drive.

• After reading it, keep this guide for future reference.

Page 2

Trademarks

Microsoft, the logo of Microsoft and Windows NT are registered trademarks of the Microsoft

Corporation in the United States and other countries.

Digital Data Storage is a trademark of the Sony Corporation.

The company and product names contained in this manual are trademarks or registered trademarks

of the respective companies.

®

Windows NT 4.0 is an abbreviation of Microsoft

®

version 4.0 and Microsoft

Windows NT® Workstation network operating system version 4.0.

Windows NT® Server network operating system

Windows 2000 is an abbreviation for Microsoft® Windows® 2000 Professional, Microsoft

®

Windows® 2000 Server, and Microsoft® Windows® 2000 Advanced Server.

All names used in the sample applications are fictitious. They have no relation with any product,

party or individual names.

Remarks

(1) Reproduction of this document or portions thereof without prior approval is prohibited.

(2) The information contained in this document is subject to change at any time, without prior

notice.

(3) Reprinting or changing of this document without prior approval of NEC is prohibited.

(4) All efforts have been made to ensure that the contents of this manual are correct; however,

should any doubts arise, or errors or missed entries be detected, NEC would greatly appreciate

it if our dealers are informed about it.

(5) Please note that in no event shall NEC be liable for any damages whatever arising out of the

use of this device, regardless of item (4) above.

© NEC Corporation 2000

ii

Page 3

Keep this User’s Guide at hand for quick reference at anytime necessary.

Safety Consideration - Must Read -

Follow the instructions given in this User’s Guide for proper operations and safe use of the

device.

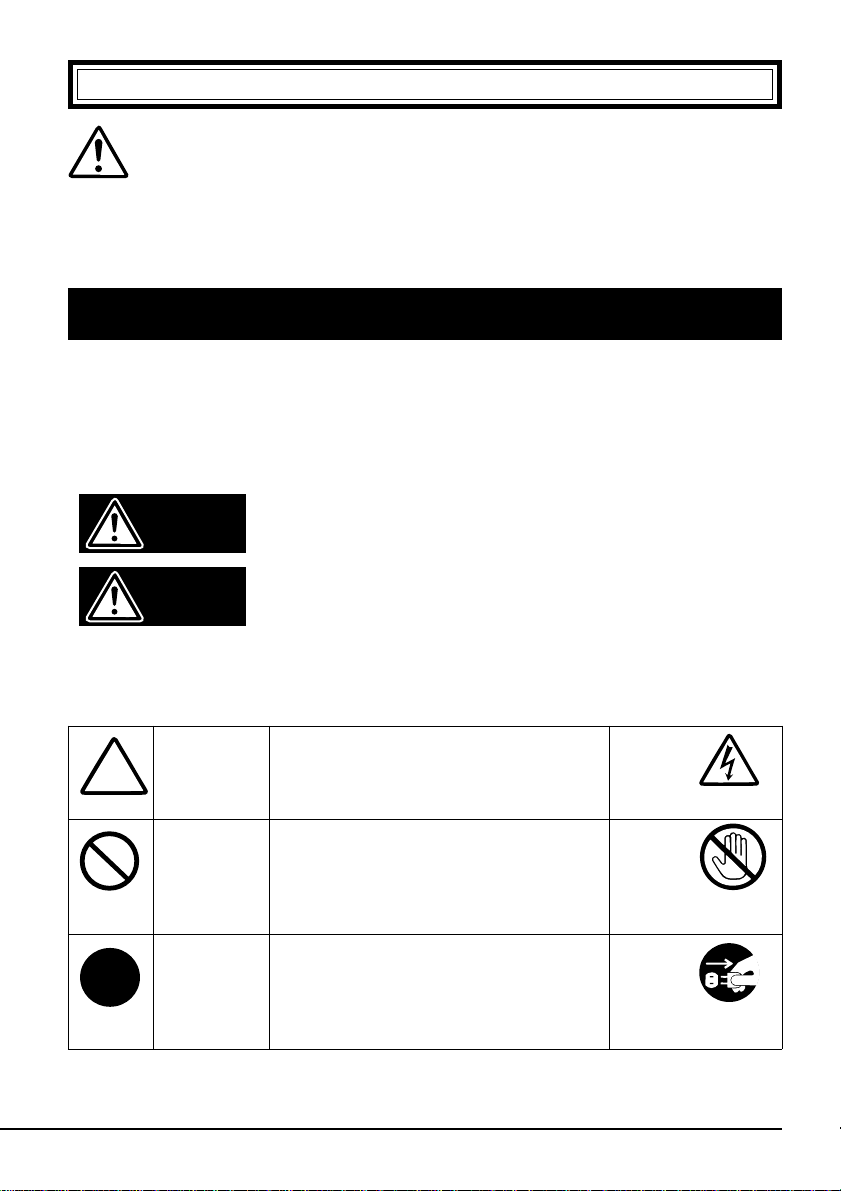

SAFETY INDICATIONS

This User’s Guide describes the device components with possible danger, hazards that

may be caused by ignoring warnings, and preventive actions against such hazards.

Components with possible danger are indicated with a warning label placed on or around

them. In the User’s Guide or warning labels, "WARNING" or "CAUTION" is used to

indicate a degree of danger. These terms are defined as follows:

Failure to heed this sign could result in serious

Warning

Caution

injury or death.

Failure to heed this sign could result in personal

in-jury or damage to properties.

Precautions and notices against hazards are presented with one of the follow-ing three

symbols. The individual symbols are defined as follows:

Attention

Prohibited

Action

Mandatory

Action

This symbol indicates the presence of a

hazard if the instruction is ignored. An

image in the symbol illustrates the

hazard type.

This symbol indicates prohibited

actions. An image in the symbol

illustrates a particular prohibited action.

This symbol indicates mandatory

actions. An image in the symbol

illustrates a mandatory action to avoid a

particular hazard.

(sample)

(Electric shock)

(sample)

(Do not

touch the part)

(sample)

(Disconnect the

power cord)

iii

Page 4

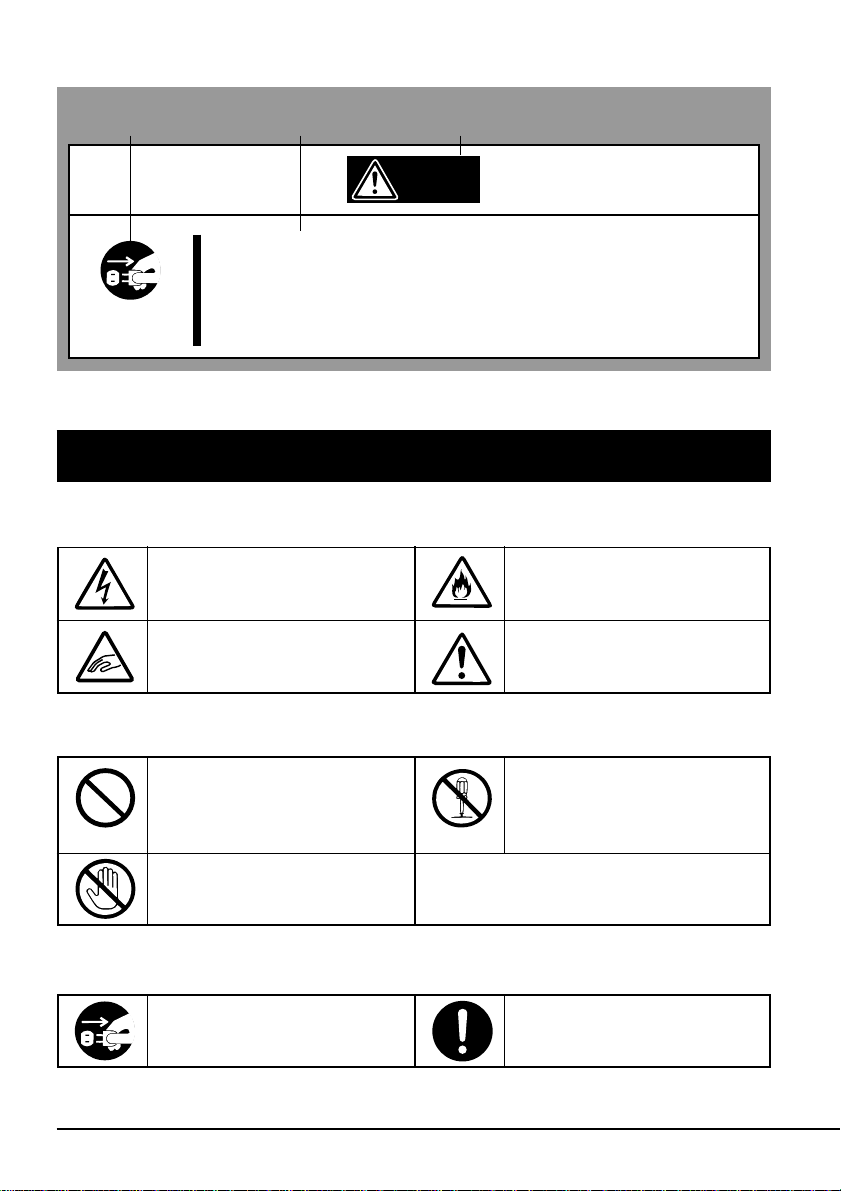

(Sample)

A symbol for

arousing attention

A content of

possible danger

A term indicating a

hazard level

Warning

Do not install the device while the power is turned on.

Unplug the AC power cord from the main power source when

installing/ uninstalling the device to/from basic processing unit

or connect it with the enclosure. Failure to follow this warning

may cause an electric shock.

SYMBOLS USED IN THIS USER’S GUIDE AND WARNING LABELS

Attention

Indicates that improper use

may cause an electric shock.

Indicates that improper use

may cause fingers to be caught.

Indicates that improper use

may cause fumes or fire.

Indicates a general notice or

warning that cannot be

specifically identified.

Prohibited Action

Indicates a general prohibited

action or warning that cannot

be specifically identified.

Do not touch unspecified parts

or units. Otherwise, burns or an

electric shock may be caused.

Mandatory Action

Unplug the power cord.

Otherwise, an electric shock or

fire may be caused.

iv

Do not disassemble, repair, or

modify the device. Otherwise,

an electric shock or fire may be

caused.

Indicates a general mandatory

action or warning that cannot

be specifically identified.

Page 5

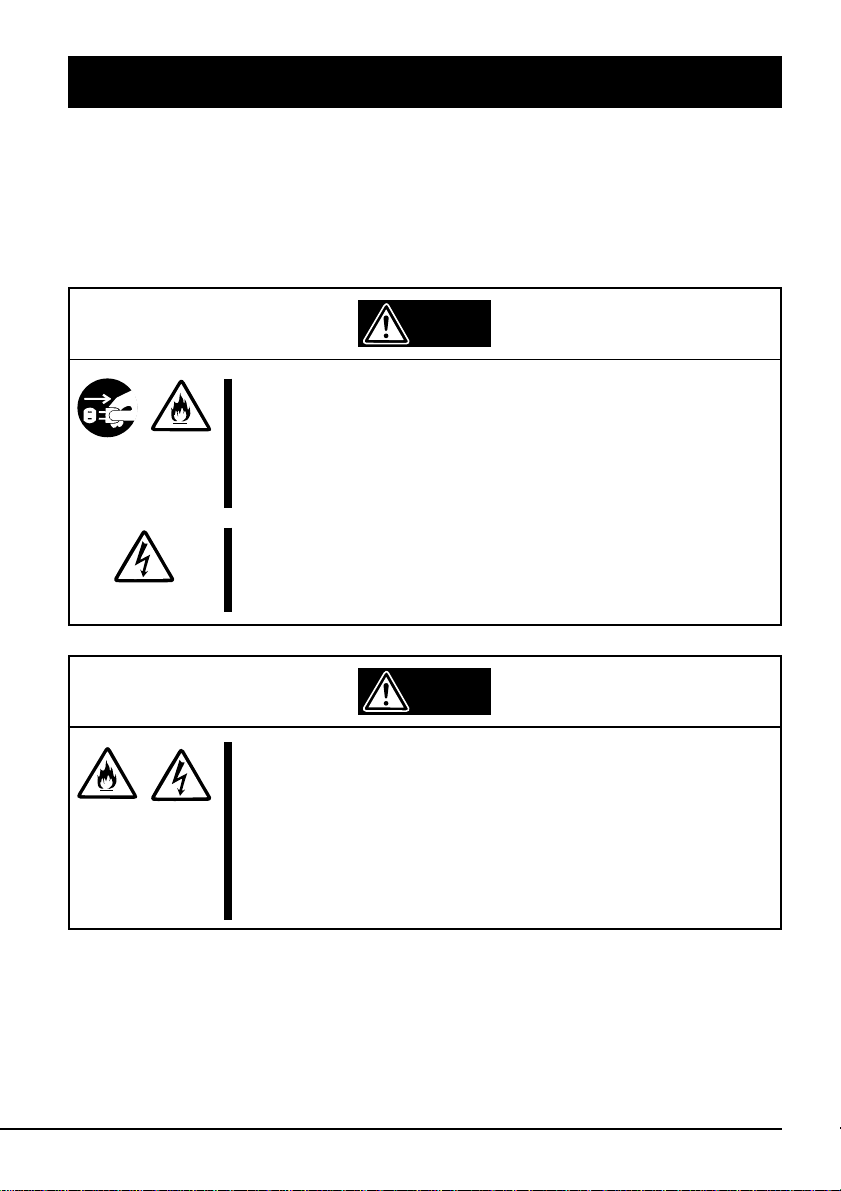

SAFETY NO TES

This section provides several precautions to enable you to use the product safely and

correctly and to prevent injury and property damage. Read this section carefully to ensure

proper and safe use of the product. For symbols, see "SAFETY INDICATIONS" provided

earlier.

General Attention

Warning

Do not use the Built-in DAT if any smoke, odor, or noise is

present.

If smoke, odor, or noise is present, immediately turn off the

POWER switch and disconnect the power plug from the outlet,

then contact your sales agent. Using the Built-in DAT in such

conditions may cause a fire.

Keep needles or metal objects away from the Built-in DAT.

Do not insert needles or metal objects into ventilation holes in

the Built-in DAT. Failure to follow this warning may cause an

electric shock.

Caution

Keep water or foreign matter away from the Built-in DAT.

Do not let any kind of liquid (water etc.) or foreign matter

(e.g.,pins or paper clips) enter the Built-in DAT. Failure to follow

this warning may cause an electric shock, a fire, or a failure of

the Built-in DAT. When such things accidentally enter the Built-in

DAT, immediately turn off the power and disconnect the power

plug from the outlet. Do not disassemb le the Built-in DAT.

Contact your sales agent.

v

Page 6

Attention to Power or Power Cord

Warning

Do not hold the DC cable with a wet hand.

Do not disconnect/connect the cable while your hands are wet.

Failure to follow this warning may cause an electric shock.

Caution

Do not install the device while the power is turned on.

Unplug the AC power cord from the main power source when

installing/ uninstalling the device to/from basic processing unit or

connect it with the enclosure. Failure to follow this warning may

cause an electric shock.

Insert the DC cable into the outlet as far as it goes.

Heat generation resulting from a halfway inserted DC cable

(imperfect contact) may cause a fire. Heat will also be generated

if condensation is formed on dusty blades of the halfway inserted

cable, increasing the possibility of a fire.

Do not connect the Built-in DAT by unspecified cabling.

Connecting or cabling with DC cable should be done in

accordance with the procedure specified in the User's Guide.

Unspecified connecting or cabling may cause an electric shock

or a fire.

Do not use any damaged power cord.

If the power cord is damaged, immediately replace it with a new

part of same type. Do not repair the damaged section for reuse.

Otherwise, the section repaired with vinyl tape or the like will be

overheated to cause an electric shock or a fire.

Use the authorized cable only.

Use only the specified cable when connecting the Built-in DAT

with a basic processing unit. Use of an unspecified cable or

connection by unspecified cabling may cause a fire.

vi

Page 7

Attention to Installing, Moving, Storing, Connection

Caution

Do not close the ventilation hole.

Do not close the ventilation hole in the front side of the Built-in

DAT. Otherwise, Its internal temperature will rise to cause

malfunctions or a fire.

Do not connect/disconnect the interface cables before

unplugging the power plug.

Before connecting/disconnecting the interface cables, disconnect

the power plug of the main power unit from the outlet. If the

power is off but the power plug is still connected, you may get an

electric shock.

Do not use the unspecified interface cables.

Use only the cable authorized by NEC and locate the device and

connector before connection. Use of an unauthorized cable or

displaced connection may cause a short circuit, resulting in a

fire.

When handling or connecting the interface cables, keep the

notes as follows:

• Do not tread on cables.

• Do not load on the cable.

• Insert the cable connector as far as it goes.

• Do not use damaged cables.

• Do not use damaged connectors.

• Make sure that screwing or the like be done firmly.

vii

Page 8

Attention to Handling or Maintenance

Warning

Do not disassemble, repair, or alter the Built-in DAT.

Never attempt to disassemble, repair, or alter the Built-in DAT on

any occasion other than described in this User's Guide. Failure

to follow this instruction may cause an electric shock or a fire as

well as malfunctions of the Built-in DAT.

Do not handle while the power plug is connected.

Before handling or cleaning the Built-in DAT, disconnect the

power plug of the main power unit from the outlet. If the power is

off but the power plug is still connected, you may get an electric

shock.

Caution

Insert the cables into the connectors as far as it goes.

Heat generation resulting from a halfway inserted cables or

Interface cables (imperfect contact) may cause a fire. Heat will

also be generated if condensation is formed on dusty blades of

the halfway inserted cable, increasing the possibility of a fire.

viii

Page 9

Attention to Operation

Do not insert your hands into the cartridge load

compartment.

Do not insert your hands into the cartridge load compartment.

Otherwise, the fingers will be caught/pinched by the Built-in DAT

to cause an injury.

Do not touch the Built-in DAT when it thunders.

If it starts thundering, do not touch any part of the Built-in DAT.

Failure to follow this warning may cause an electric shock or a

fire.

Keep away pets.

Keep away pets from the Built-in DAT. Insertion their hair or

excrements may cause a fire or an electric shock.

Do not use a cellular phone or a pager

Turn off the power of the cellular phone or a pager. Otherwise,

malfunction may be caused.

Warning

ix

Page 10

Contents

Trademarks ii

Safety Consideration - Must Read - iii

When Reading this Guide 1

Symbols Used in This Text .................................................................. 1

Package Contents 2

Packing Materials ............................................................................... 2

Unpacking........................................................................................... 2

Hardware Information 3

Part Names, Functions and Settings (SCSI ID, etc.) .......................... 3

Installing in the Server ........................................................................ 9

Server-Side Setup ............................................................................ 11

Using the N8551-26F/N8151-43F .................................................... 12

Cleaning ........................................................................................... 14

4 mm Data Cartridges 16

Cartridge Appearance ...................................................................... 16

Operating, Storage and Transporting Conditions.............................. 16

Labeling ............................................................................................ 17

Write Protection ................................................................................ 17

Handling Precautions ....................................................................... 18

Unusable Cartridges ......................................................................... 19

Cartridge Life .................................................................................... 19

Preserving Critical Data .................................................................... 20

Three-Generation Data Management............................................... 20

Data cartridge storage ...................................................................... 20

Appendix 21

Main Specifications........................................................................... 21

LED Indications ................................................................................ 22

Customer Problem Report Form ...................................................... 24

x

Page 11

When Reading this Guide

This users guide is the operating manual for the N8551-26F/N8151-43F

Built-In DAT. For information about server operation, please refer to the

server’s manual.

Symbols Used in This Text

The following symbols are used in this text to indicate cautions and notes

concerning the operation of this device. (Refer to the beginning of this

document for an explanation of the symbols used for safety-related

cautions.)

This symbol indicates important information concerning

Important

the handling of the device or the operation of the

software.

Hint

✎

Important

Please use only Sony 4 mm data cartridges (DDS 4, DDS 3, DDS 2,

DDS 1) with the N8551-26F/N8151-43F. Further only read operation is

assured when this DAT drive is used with DDS 1 cartridges. Using

cartridges made by other manufacturers could result in read and write

errors.

Indicates useful information and operational help.

When Reading this Guide 1

Page 12

Package Contents

Packing Materials

When moving the drive, use our original packing materials.

Unpacking

When unpacking, confirm that the following items are included.

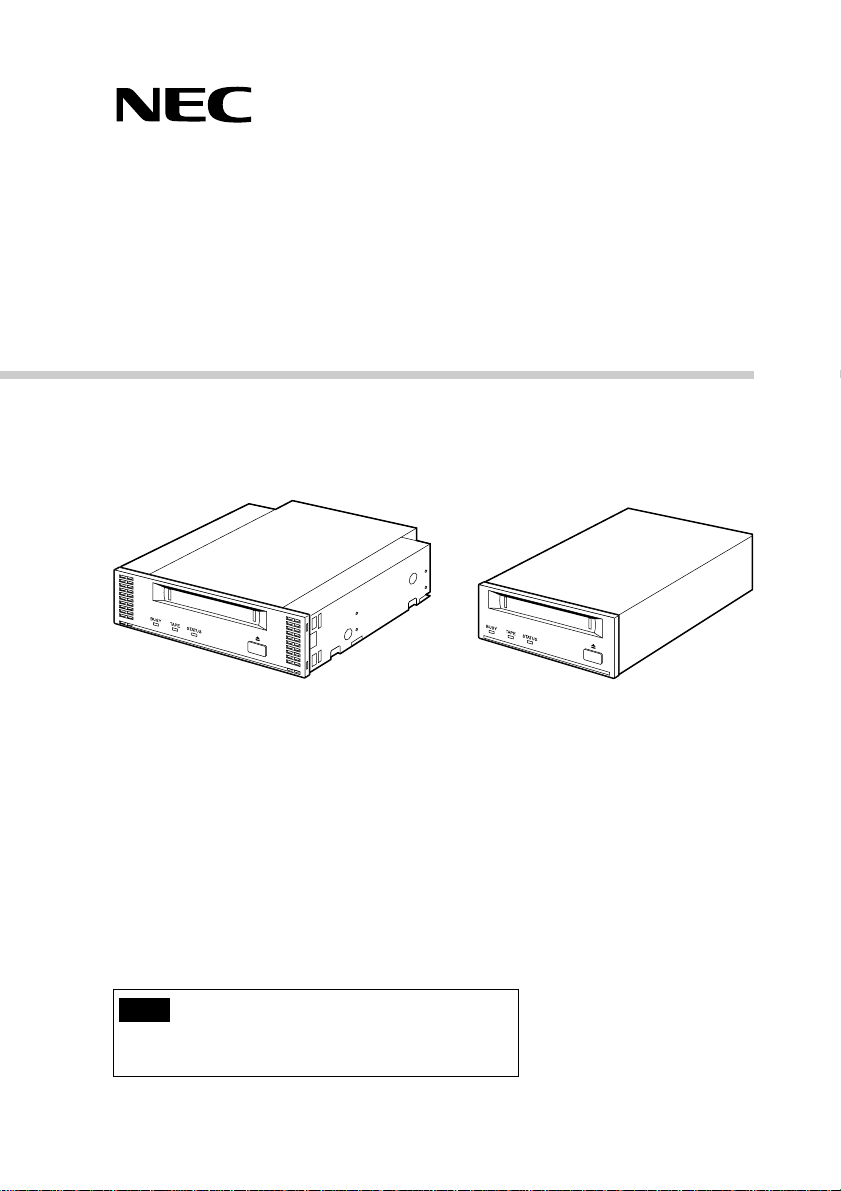

N8551-26F Built-In DAT N8151-43F Built-In DAT

The following accessories are common to the N8551-26F and the N815143F.

Cleaning Cartridge Users Guide (this booklet)

Four M3 Installation Screws Floppy Disk

• This Users Guide should always be kept together with the N8551-26F/

N8151-43F.

• Please follow any local regulations when disposing of the drive and

cartridges. Please contact the local authorities for details.

2 Package Contents

(SDT-11000 Driver for Windows NT 4.0)

DAT Handling Information

Page 13

Hardware Information

Part Names, Functions and Settings (SCSI ID, etc.)

Important

The names and functions of each part of the N8551-26F and the

N8151-43F and the setup methods are identical. (Hereafter, the N855126F is used for the illustrations in this manual.)

■ Front Panel

562134

14 mm Data Cartridge Slot

Insert a 4 mm data cartridge here. Refer to “Loading a Data Cartridge”

and “Removing a Data Cartridge” for details.

2BUSY LED

This LED is lit while data is transferring over the SCSI interface.

It blinks evenly during normal reading and writing to a data cartridge.

Never turn the power off and on while this LED is lit, as read or write

errors, or damage to the data cartridge, could result.

3TAPE LED

This LED is lit when a data cartridge is present in the drive, and blinks

under the following conditions:

When loading or unloading a cartridge Blinks evenly

When a worn cartridge is detected Blinks long-on/short-off

Hardware Information 3

Page 14

4STATUS LED

This LED is lit when the loaded data cartridge is write protected, and

blinks under the following conditions:

When cleaning is required Blinks long-on/short-off

During cleaning, at the end of the tape Blinks evenly

When the drive is damaged Blinks two-short/one-long

5EJECT Button

Press this button to eject the cartridge from the drive.

6Ventilation Holes

(The N8151-43F does not have ventilation holes.)

4 Hardware Information

Page 15

■ Bottom Cover

ON

345678

21

1

1DIP Switches

• Terminator power is set by switch 5 (factory default is ON).

• Data compression control setting 1 (DC Control 1) is set by switch 7

(factory default is ON).

• Data compression control setting 2 (DC Control 2) is set by switch 8

(factory default is OFF).

Switches 1 to 4: Reserved

Switch 5: Terminator Power

Switch 6: Reserved

Switch 7: DC Control 1

Switch 8: DC Control 2

345678

21

ON

Important

Normally, the factory default settings should not be changed.

Hardware Information 5

Page 16

Terminator Power Setting

ON

345678

21

This setting (DIP switch 5) enables or disables terminator power to the

SCSI bus. Terminator power is enabled when this switch is set to ON

(factory default).

Important

Set this switch to OFF when mounting this device on an N8541-28 or

N8541-28AF Device Expansion Unit.

Data Compression Control Setting (DC Control 1)

ON

345678

21

This setting (DIP switch 7) enables or disables control of the data compression function in the drive. The internal compression control function is

enabled when this switch is set to ON (factory default).

Data Compression Control Setting (DC Control 2)

ON

345678

21

This setting (DIP switch 8) enables or disables control of the compression

function by the backup application program. The backup program controls

the compression function when this switch is set to OFF (factory default).

6 Hardware Information

Page 17

■ Rear Panel

Hint

✎

1 2

3

SCSI ID (Pins 0 to 3, from right to left)

No connection (not used)

Parity Enable (PE)

Place any unused jumper straps

over the pin at one side, or retain in

a safe place.

In the following description, “jumpered” means that a jumper strap is

installed over two pins, and “not jumpered” means that a strap is

installed over only one pin, or not at all.

1Interface Connector

This is the SCSI signal connector for controlling the N8551-26F/

N8151-43F Built-In DAT.

2DC Connector (+5/+12 V)

This connector supplies power to the N8551-26F/N8151-43F Built-In

DAT by connecting a power cable in the server.

Hardware Information 7

Page 18

3Option Jumpers

The following settings are made by jumpers on the header on the rear

panel.

• SCSI ID (factory default setting is ID4)

• Parity function (factory default setting is enabled)

SCSI ID Setting

This setting determines the SCSI ID for this device. Header pin pairs 0 to 4

are used for this setting.

Pin pair 3 (factory default setting: not jumpered)

Pin pair 2 (factory default setting: jumpered)

Pin pair 1 (factory default setting: not jumpered)

Pin pair 0 (factory default setting: not jumpered)

Important

Confirm that the SCSI ID setting is different from all other connected

SCSI devices.

SCSI ID Pin pair 3 Pin pair 2 Pin pair 1 Pin pair 0

0 ××××

1 ×××Ο

2 ××Ο×

3 ××ΟΟ

4*

1

×Ο××

5 ×Ο×Ο

6 ×ΟΟ×

7*

2

×ΟΟΟ

8 Ο×××

9 Ο××Ο

10 Ο×Ο×

11 Ο×ΟΟ

12 ΟΟ××

13 ΟΟ×Ο

14 ΟΟΟ×

15 ΟΟΟΟ

Ο = jumpered

× = not jumpered

*1 Factory default setting

*2 Do not set to SCSI ID 7

8 Hardware Information

Page 19

Parity Setting

Caution

This setting enables and disables the parity function for this device. The

leftmost pin pair on the jumper header determines the setting: the parity

function is enabled when the jumper is present (factory default).

Important

Normally, this setting should not be changed from the factory default.

Installing in the Server

Turn off the power before installing or removing the

device

Always be sure to turn off the main power and unplug the

power cord from the AC outlet before installing/removing this

device or connecting any cables. There is a risk of electric

shock if this device is installed or removed or if any cables are

connected while the power cord is still plugged into an AC

outlet.

PE (factory default setting: jumpered)

The procedure for installing the drive in a server is as follows.

Hint

✎

Some servers require the rails to be used. For details on how to install

the rails, refer to the server's operating manual.

Hardware Information 9

Page 20

1 Install the N8551-26F/N8151-43F Built-In DAT as shown below.

Install in either bay

Important

• When using the rails, adjust their mounting positions so that the front

cover of this device is aligned with the front covers of the other

standard components (such as the CD-ROM).

Use screws to secure the upper rail.

Front cover

Rails

• Always use the screws that are provided with this

device. The screws that are provided with this

device are millimeter screws (length: 5.0 mm;

length below washer: 3.5 mm). Using screws that

are longer than the screws that are provided with

this device could result in damage to the device.

10 Hardware Information

3.5 mm

millimeter screw

Page 21

2 Connect the cables to the drive as shown below.

SCSI interface cable

Important

• Confirm the SCSI ID and other settings before installation.

• The factory default setting of the SCSI ID is 4. Make sure this ID is

not used by any other device in the system.

Server-Side Setup

Tape Device Driver Installation

How to install the SDT-11000 for Windows NT 4.0 with Service Pack 4

and higher:

1 Make sure that your DDS drive is properly connected to your computer

before you continue.

DC power cable

(unused power supply

connector in the computer)

2 Click on “Start”, select “Settings”, and select “Control Panel”.

3 From the Control Panel window, double-click on “Tape Devices”.

4 On “Install the Driver” window, click on “Have Disk...”

Otherwise, Select the Driver tab on the “Tape device” window and

select “Add(A)...”

5 Make sure the “Install the Driver” window appears.

6 Next click on “Have Disk...” and make sure that the floppy disk drive

path (A:\) is in the text field. Click on “OK”.

Hardware Information 11

Page 22

7 Make sure that “Sony 4mm DDS4 Tape” is shown on the “Driver

installation” window and click on “OK”.

8 On the “New SCSI tape device” window, click on “OK”.

9 On the “WindowsNT setup” window, type in “A:\” and click on

“Next”.

10Click on “OK” and eject the floppy Disk from your computer.

11Reboot the System.

Important

When NT backup is used, please do not install any other backup

program.

Uninstall NT backup before installing any other backup program. Also,

if using a backup program other than NT backup, delete the “NT 4.0

Sony SDT-11000 4mm DAT drive” .

Using the N8551-26F/N8151-43F

■ Loading a Cartridge

1 Insert a data cartridge in the direction shown in the following figure.

When inserted a certain distance, the cartridge loads automatically.

12 Hardware Information

Page 23

■ Unloading a Cartridge

Press the Eject button.

The cartridge ejects automatically.

• Up to 20 seconds may be needed to eject the cartridge (not including

rewind time).

• Do not move the machine while a cartridge is loaded.

→ Always eject the cartridge when moving the machine. Otherwise,

• Eject the cartridge before turning power off.

→ Turning power on while a cartridge is loaded can shorten the life

• Do not leave a cartridge sticking out of the insertion slot for a long

time.

→ The life of the cartridge may be shortened, or the drive may be

• Do not press the EJECT button while the BUSY LED is blinking.

→ Ejecting a data cartridge while the BUSY LED is blinking may

• If the cartridge is not ejected by pressing the EJECT button, you can

force ejection by holding the EJECT button for ten seconds. However

forcing ejection can damage the tape, so this should not be done

except in an emergency, and only after first turning the power off and

on to reboot.

Important

the drive or cartridge may be damaged by shock.

of the cartridge and cause backups to fail.

damaged.

destroy data stored on the tape.

Hardware Information 13

Page 24

Cleaning

■ Cleaning the Head

Cleaning is important to remove dirt buildup from the magnetic head that

accumulates from the operating environment and by normal tape usage.

When the head is dirty, reading and writing performance can be

degraded, and the life of the data cartridge can be shortened or the

tape ruined by scratching.

1 Load the supplied cleaning cartridge or the Cleaning Cartridge into the

2 Remove the cleaning cartridge and resume normal operation.

drive. Cleaning starts automatically, and the cleaning cartridge is

ejected after about 30 seconds.

Important

• The Cleaning Cartridge can be used about 50 times. If the STATUS

LED is blinking when finished cleaning, the cleaning cartridge has

reached the end of its useful life. (Refer to 4 STATUS LED under

the Part Names on page 4 for a description of this LED.

• If a cleaning cartridge is loaded which is no longer usable, it will not

eject automatically: press the EJECT button to remove it.

• Avoid touching the tape side of the cleaning cartridge with your

fingers, and do not rewind the cleaning tape in an attempt to reuse it.

14 Hardware Information

Tape side of cleaning tape

Page 25

■ Head Cleaning Frequency

Clean the head according to the amount of drive use, as shown below.

Usage Frequency Cleaning Frequency

One reel or less per day Weekly

Two to three reels per day Twice weekly

Four reels per day Daily

Hint

✎

• Whenever possible, clean the head before writing or reading.

• Clean before loading a new data cartridge.

• Even when not used, the head should be cleaned once each month.

Hardware Information 15

Page 26

4 mm Data Cartridges

Cartridge Appearance

Operating, Storage and Transporting Conditions

■ Operating Conditions

Temperature 10 to 35ºC

Humidity 20 to 80%

(at 26ºC wet-bulb temperature)

Standing If a data cartridge has been exposed to an

environment outside of the storage conditions,

allow the tape to stand in the operating environment for a longer period than that at which it

was outside of the conditions (up to 8 hours)

before use. The temperature slope is 10ºC per

hour.

■ Storage Conditions

Temperature 5 to 35ºC

Humidity 20 to 80%

Storage State Store 4 mm data cartridges in their protective

■ Transporting Conditions

Temperature –30 to +35ºC

Humidity 20 to 80%

Temperature slope 10ºC per hour

Transport State Store 4 mm data cartridges in their protective

16 4 mm Data Cartridges

(at 26ºC wet-bulb temperature)

case, with the cover closed. They may be stored

either horizontally or vertically.

(at 26ºC wet-bulb temperature)

case, enclosed in a sealed polyethelene bag.

Transport in a cardboard carton so as to prevent

applying pressure to the cartridges.

Page 27

Labeling

■ Label Attachment Location

Label

■ Writing Labels

• Labels indicating the contents of data cartridges should be removable,

without leaving behind adhesive.

• Do not erase a label to change the content information: replace the label.

(Index labels are supplied with each data cartridge.)

• When affixing a label, be careful to place it in the location shown above,

after completely removing any previous label.

• When using labels other than the supplied Index labels, make sure they

are the same size.

• The supplied Index labels include a place to write the date when a

cartridge is first used. Always write the date here, so you will be able to

determine the cartridge life.

Write Protection

Set the Write Protect tab as shown below right to protect tape contents.

Setting the tab as shown at the right prevents data already written on a tape

from being erased.

Setting the tab as shown at the left enables writing on the tape.

Write enabled Write disabled

4 mm Data Cartridges 17

Page 28

Handling Precautions

■ Usage Precautions

Before Using a Tape

• Do not use a data cartridge if appears to be damaged or warped.

• If a data cartridge has been stored in an environment outside of the

operating conditions, allow the tape to stand in the operating environment for a longer period than that at which it was outside of the conditions (up to 8 hours) before use. If the storage temperature is much

different from that of the operating location, the cartridge should be

allowed to acclimatize gradually, allowing about one hour per 10ºC

temperature difference, rather than changing the temperature suddenly.

When Loading in the Drive

Load the data cartridge according to the Loading a Cartridge paragraph.

When a cartridge is removed, place it in the protective case, close the cover

tightly, and store in a dust-free location.

After Use

Used data cartridges should always be stored in their protective cases in a

dust-free location. They can be stored either horizontally or vertically.

■ General Precautions

• Avoid touching the tape, or opening and closing the tape cover.

• Do not allow magnetic objects near the tape.

• Do not place in direct sunlight, or near a heater.

• Avoid subjecting cartridges to physical shock.

• Do not handle tapes while eating, drinking or smoking, and keep tapes

away from thinners and alcohol.

• When finished using, store tapes in their protective cases.

• Insert tapes into the drive carefully.

• Dirt and dust can easily damage the magnetic tape in 4 mm data

cartridges.

18 4 mm Data Cartridges

Page 29

Unusable Cartridges

In the following conditions, the data cartridge should be replaced.

• After a strong physical shock, such as from dropping, the cartridge may

be damaged.

• When the recording side has been soiled by contact with liquids such as

soda, coffee, tea or solvents, or with metallic powders or tobacco ash.

Remarks

If a data cartridge is inserted under the above conditions, the head or drive

may become damaged or contaminated, resulting in drive failure. Also, if a

new data cartridge is inserted afterwards, it is likely to become contaminated or ruined.

Cartridge Life

Data cartridges are subject to wear during every read and write operation.

Continuing to use a cartridge eventually leads to errors, and further use

could result in loss of stored data. Cartridges should therefore be replaced

periodically.

The useful life of a cartridge depends on the operating environment, but

the following table serves as an approximate guideline to cartridge life.

Usage Frequency Estimated Useful Life

Once per week One year

Two to three times per week Six months

Daily Three months

• The above estimates may be shortened by operating environment

conditions (temperature, humidity, dust, etc.)

To manage data cartridges for optimum useful life, we recommend the

following steps:

• Assign control numbers to new data cartridges, and write the numbers on

the labels.

• Maintain a tape control list, including the date of first use and the

expected useful life of each cartridge.

• Refer to the control list and tape labels to determine when cartridges are

reaching the end of their useful lives (or if read/write errors occur), and

remove them from use.

The chemical compounds that compose the magnetic layer of the tape will

deteriorate over time. The rate of this deterioration is greatly influenced by

the storage environment (temperature and humidity), so even if never used,

cartridges should be replaced about three years after purchase.

4 mm Data Cartridges 19

Page 30

Preserving Critical Data

To preserve critical data or programs, we recommend saving to two tapes:

a main and a sub copy.

Also, when writing the backup copies, we recommend confirming the copy

by using the verify function of the backup software. Please refer to the

documentation for the backup software regarding use of the verify

function.

By taking these steps, even if read errors are encountered as a result of dirt

or dust on the tape, the other tape can be used for data recovery, preventing

loss of critical data and programs.

Three-Generation Data Management

We recommend using a three-generation data management system for

backing up data saved on disk.

This system uses three tapes (call them A, B and C), with the disk data

saved in the order A-B-C as follows: disk data is saved to tape A on the

first day, tape B on the second day, and tape C on the third day.

With this system, if, for example, a read error was found on tape C, most

data could still be restored from tape B, and even if a read error was found

on tape B, important data could still be restored from tape A.

Data cartridge storage

Always store data cartridges in a clean location under the specified storage

conditions.

Enabling the write-protect feature is recommended when storing data

cartridges.

When storing data cartridges for an extended period of time, data should

be read periodically in order to ensure that restoration from backup data is

possible at all times.

Storing data cartridges in a different location from the system is recommended. If both master and spare data cartridges are kept, storing each in

a different location is recommended.

20 4 mm Data Cartridges

Page 31

Appendix

Main Specifications

■ Capabilities

Memory capacity 20 GB (40 GB compressed) using DDS 4

* The compressed capacity presumes 2x compression efficiency. Actual

compression efficiency depends on the data pattern.

Bit error rate 1 in 10

Data transfer rate 2.36 MB/s (uncompressed) using DDS 4

Burst data transfer speed (SCSI)

Initialization time Less than 1 s

Loading time Less than 24 s

Unloading time Less than 20 s

Rewinding time Less than 80 s

■ Environmental Conditions

Operation 10 to 35ºC 20 to 80% 26ºC non-condensating

Transport –30 to 40ºC 10 to 90% 26ºC non-condensating

Storage –5 to 40ºC 10 to 90% 26ºC non-condensating

12 GB (24 GB compressed) using DDS 3

4 GB (8 GB compressed) using DDS 2

–15

or less

14 MB/s (maximum asynchronous)

40 MB/s (maximum synchronous)

Ambient Temp. Relative Humidity Max. Wet-Bulb Temp.

■ DC Power Specifications

Voltage 5 V ±5% 12 V ±10%

Current 2.0 A 1.6 A

■ Size and Weight

N8551-26F

N8151-43F

101.6mm 149.8mm

41.2mm

149mm 149.8mm

Weight: Less than 0.91 kg

41.2mm

Weight: Less than 0.91 kg

Appendix 21

Page 32

LED Indications

Tape

status

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

or Fault

Drive

status

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

LED

DAT Drive

On-off

status

On or Off

Off

Off

Even blinking

On

***

Even blinking

Even blinking

***

On, off or

even blinking

On

***

***

On

On

Off

On

Even blinking

***

***

Long-on/

short-off

blinking

***

Long-on/

short-off

blinking

***

Meaning

• BUSY On = SCSI

active

• Data cartridge not

loaded.

• Data cartridge read/

write activity.

• Loading/unloading

cartridge.

• Data cartridge

loaded.

• Loaded cartridge is

write protected.

• The cleaning

cartridge is spent.

• Request cleaning.

• An error has

occurred on the

loaded data

cartridge that

exceeds the

specified media

warning threshold

(this is only a

warning—the data

cartridge is getting

old).

Remedy

Note: do not turn

power off in this LED

state.

Note: do not turn

power off in this LED

state.

Note: do not turn

power off in this LED

state.

Note: do not turn

power off in this LED

state.

• Load a new cleaning

cartridge. Do not

attempt to reuse a

spent cartridge.

• Load a cleaning

cartridge.

• If the same error is

indicated after

cleaning, use a new

data cartridge.

• Clean the head with a

new cleaning

cartridge. After

cleaning, if the same

error is indicated

when the data

cartridge is reloaded,

replace with a new

data cartridge (or just

use a new data

cartridge after

cleaning).

22 Appendix

Page 33

Tape

status

Normal

or Fault

Normal

or Fault

Fault

Drive

status

Normal

or Fault

Normal

or Fault

Fault

LED

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

BUSY

TAPE

STATUS

DAT Drive

On-off

status

Short-on/

long-off

blinking

***

***

***

Short-on/

long-off

blinking

***

***

***

Short-on

(twice)/longoff blinking

Meaning

• Awaiting reset.

• Awaiting eject.

• Device fault.

Remedy

• A data cartridge did

not eject after

pressing EJECT.

• The device hardware

may be damaged.

• Reset by turning the

power off and on. If

the same error

occurs after

rebooting, the drive

is damaged and must

be replaced.

• Eject the data

cartridge and load a

new cartridge. If the

error persists, the

drive is damaged and

must be replaced.

• The drive hardware

has failed.

• The drive must be

replaced. Also, the

data cartridge loaded

at the time of the

fault may be

damaged due to the

drive failure, so it

should be replaced

with a new cartridge.

The drive and

cartridge loaded at

the time this fault

occurs should not be

used.

*** indicates the LED conditions depends on the device status, but does not affect the

meaning or remedy.

Appendix 23

Page 34

Customer Problem Report Form

Use the following form to record information required for maintenance of

this drive.

Item Customer Notes

Server model name

Operating system (name,

version, service pack/patch

status)

Backup program (name,

version, service pack/patch

status)

SCSI Bus structure (devices

on same SCSI bus)

Installation environment

(temperature, humidity, dust

conditions, etc.)

Cartridge type

Cleaning cartridge type

Cleaning cartridge status

(cleaning frequency, times

used, control procedure for

usage introduction date, etc.)

Cartridge usage status

(usage times and control

procedure for usage

introduction date, etc.)

Cartridge control status

24 Appendix

Page 35

N8551-26F/N8151-43F

Built-In DAT Operating Manual

First Edition, May 2000

Second Edition, March 2001

Third Edition, September 2001

NEC Corporation

5-7-1 Shiba, Minato-ku, Tokyo

Tel. (03) 3454-1111 (Main switchboard)

©2000 NEC Corporation

No copying or modifying without permission of NEC Corporation.

The contents of this document may be changed without notice.

Page 36

Printed in Japan

Printed on recycled paper.

Loading...

Loading...