Page 1

Series

*855-900672- - AB*

456-01796-000

PN# 456-01796-000

N8406-026

10GbE インテリジェントスイッチ(L3)ユーザーズガイド

10Gb Intelligent L3 Switch User’s Guide

2008 年 7 月(第1版)

July 2008 (1st Edition)

855-900672- - A

456-01796-000

Page 2

Page 3

■N8406-026 構成品

品名

数量

備考

10GbE インテリジェントスイッチ(L3)

1

N8406-026

ユーザーズガイド

1

本書

ソフトウェアマニュアル CD

1

CD-ROM

保証書

1

構成品一覧表

本製品は以下の品目で構成されています。確認してください。

Page 4

■N8406-026 Packaging List

Items

Quantity

Notes

10Gb Intelligent L3 Switch

1

N8406-026

User’s Guide

1

This guide

Software manual CD

1

CD-ROM

Warranty

1

This warranty is available only for using in Japan.

Do not use it in any other than Japan.

Packing List

This product is shipped with the following items, verify package contents:

Page 5

ご注意

1. 本書の内容の一部または全部について、許可なく複製・転載・翻訳・他形式・メディアへの変

換等を行うことは、禁止されています。

2. 本書の内容については、将来予告なしに変更することがあります。

3. 本書の内容については、万全を期して作成いたしましたが、万一お気付きの点や、ご不明の点

がありましたら、販売店または弊社までご連絡ください。

4. 本製品を運用した結果の影響については、上記 3 項にかかわらずいかなる責任も負いかねます

ので、ご了承ください。

5. 本書は、本体装置の操作に熟知した管理者、または保守員向けに記載されております。本体装

置の取り扱いや、各種 OS の操作、その他一般的かつ、基本的な事柄につきましては記載を省い

ておりますのであらかじめご了承ください。

NEC Corporation 2008

日本電気株式会社の許可無く、本書の複製・改変などを行うことはできません。

◆ 情報処理装置等電波障害自主規制協議会(VCCI)表示

Page 6

この装置は、情報処理装置等電波障害自主規制協議会(VCCI)の基準に基づ

くクラス A 情報技術装置です。この装置を家庭環境で使用すると電波妨害を

引き起こすことがあります。

この場合には使用者が適切な対策を講ずるよう要求されることがあります。

Page 7

Note

1. No part of this guide may be reproduced, transmitted, translated in any form, or converted to

medias without prior written permission

2. The contents of this guide are subject to change without prior notice.

3. All efforts have been made to ensure the accuracy of all information in this guide. If you find any

part unclear, incorrect, or omitted in this guide, contact your service representative.

4. The company assumes no liability arising from the use of this product, nor any liability for

incidental or consequential damage arising from the use of this guide regardless of 3 above.

5. This guide is created for the manager or the maintenance person who is well informed about the

operation of this device. Note that the basic information, such as the operation procedures of the

device and OS, is omitted.

6. This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction guide, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own

expense.

NEC Corporation 2008

No part of this guide may be reproduced or changed in any form without prior written permission of NEC

Corporation.

CE Statement

Warning: This is a Class A product. In domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures (EN55022).

Canadian notice

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

BSMI Statement

Page 8

Page 9

目次

目次

使用上のご注意-必ずお読みください- ......................................................................... i

安全に関わる表示について .............................................................................................................. i

本書で使用する記号とその内容 ..................................................................................................... iii

安全上のご注意 ............................................................................................................................... v

はじめに ..................................................................................................................... 1

本書について .............................................................................................................. 1

本文中の記号について ................................................................................................................... 1

関連マニュアル .......................................................................................................... 2

装置の概略 ................................................................................................................. 2

機能概要 ........................................................................................................................................ 2

各部の名称と役割 ................................ ................................ ................................ .......................... 5

ランプについて .............................................................................................................................. 7

本製品のポート構成について ........................................................................................................ 8

ブレード収納ユニット内における CPU ブレードと本製品のつながり ....................................... 10

ネットワークケーブルついて ...................................................................................................... 12

設置 .......................................................................................................................... 13

取り付け手順 ............................................................................................................................... 13

取り外し手順 ............................................................................................................................... 16

設定方法 ................................................................................................................... 20

トラブルシューティング .......................................................................................... 24

仕様 .......................................................................................................................... 27

Page 10

Table Of Contents

Table of Contents

Precautions for Use........................................................................................... xi

Safety Indications .................................................................................................................. xi

Symbols Used in This User’s Guide .................................................................................xii

安全注意事項 ................................................................................................................................ xiii

Precautions for Safety.........................................................................................................xvi

Introduction ....................................................................................................... 29

About this guide ................................................................................................ 29

Text Conventions .................................................................................................................. 29

Repurchasing This Guide.................................................................................................... 29

Additional references ...................................................................................... 30

Product Overview ............................................................................................. 30

Features .................................................................................................................................... 30

LED.............................................................................................................................................. 34

Number of ports .................................................................................................................... 35

Connection with CPU Blade ............................................................................................... 37

Network Cables ...................................................................................................................... 38

Installation ......................................................................................................... 39

Installation Procedure ........................................................................................................ 39

Removal Procedure .............................................................................................................. 40

Configuration ..................................................................................................... 45

Troubleshooting ................................................................................................ 48

Specification ................................................................................................ ....... 50

Page 11

本書は、必要なときすぐに参照できるよう、お手元に置いておく

ようにしてください。「使用上のご注意」を必ずお読みください。

使用上のご注意-必ずお読みください-

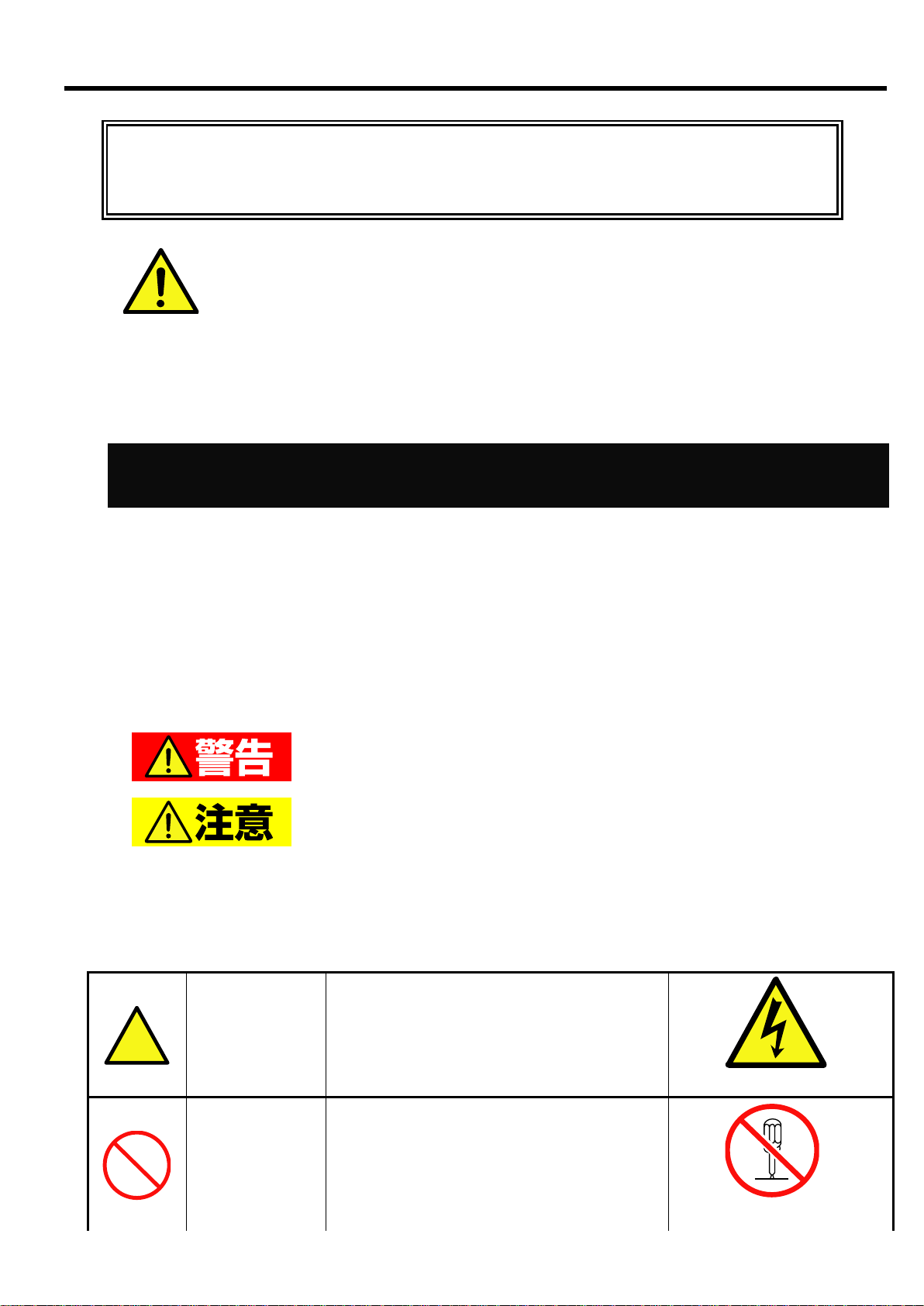

安全に関わる表示について

人が死亡する、または重傷を負うおそれがあることを示します。

火傷や怪我などを負うおそれや、物的損害を負うおそれがあるこ

とを示します。

注意の喚起

この記号は、危険が発生するおそれがあ

ることを表します。記号の中の絵表示は

危険の内容を図案化したものです。

(例)

(感電注意)

行為の禁止

この記号は行為の禁止を表します。記号

の中や近くの絵表示は、してはならない

内容を図案化したものです。

(例)

(分解禁止)

使用上のご注意(Japanese)

本製品を安全に正しくご使用になるために必要な情報が記載されています。また、本文中の名称については

ユーザーズガイドの「各部の名称と機能」の項をご参照ください。

本製品を安全にお使い頂くために、本書の指示に従って操作してください。

本書には、ご使用時に本製品のどこが危険でどのような危険に遭うおそれがあるか、どうすれば危険を避け

られるかなどについて記載されています。

本書では危険の程度を表す言葉として、「警告」と「注意」という用語を使用しています。

それぞれの用語は次の意味を持つものとして定義しています。

危険に対する注意・表示は次の 3 種類の記号を使って表しています。それぞれの記号は次のような意味を持

つものとして定義しています。

i

Page 12

行為の強制

この記号は行為の強制を表します。記号

の中の絵表示は、しなければならない行

為の内容を図案化したものです。危険を

避けるためには、この行為が必要です。

(例)

(プラグを抜け)

使用上のご注意(Japanese)

ii

Page 13

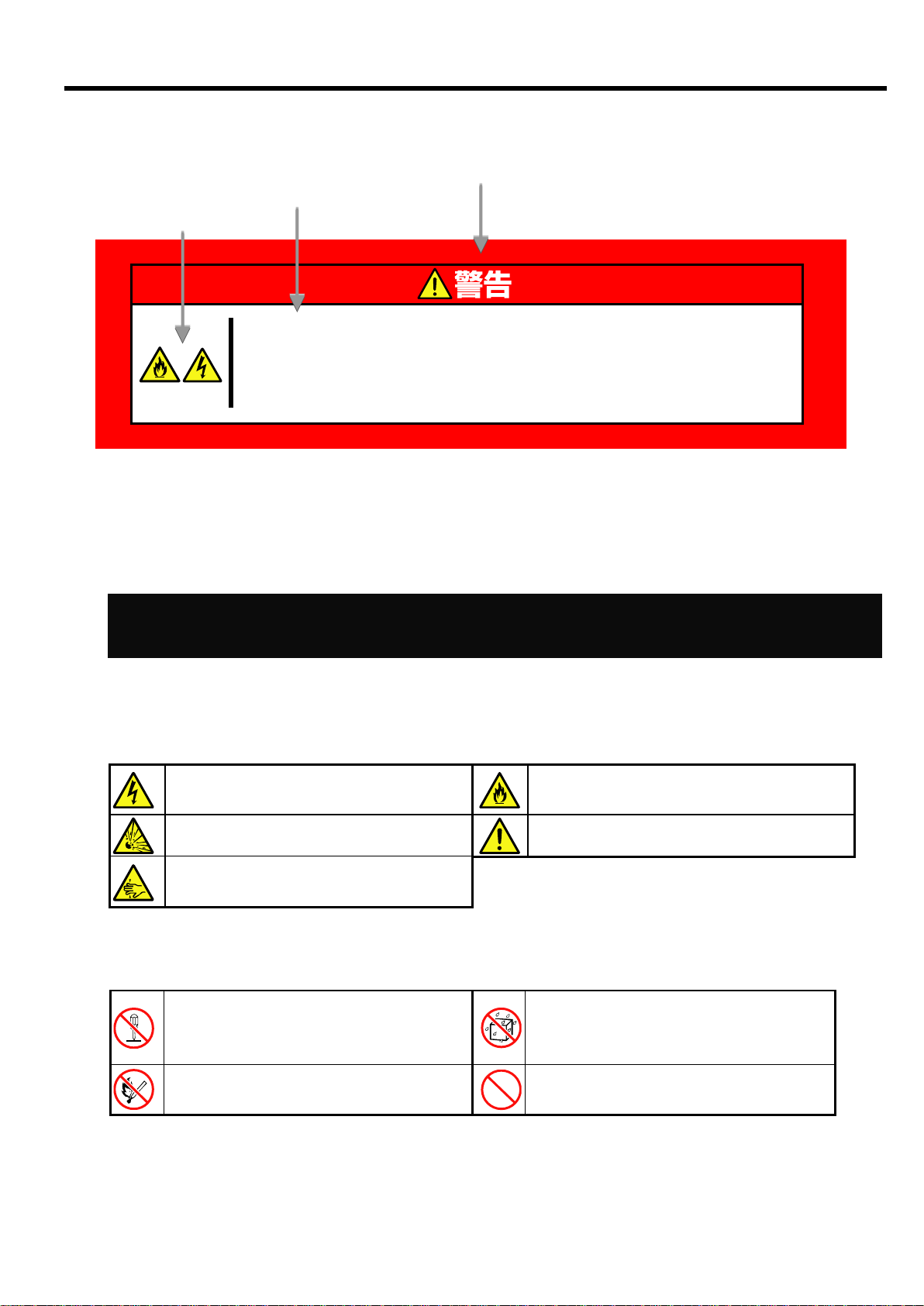

危険の程度を表す用語

危険に対する注意の内容

注意を促す記号

指定以外のコンセントに差し込まない

指定の電圧で、指定のコンセントをお使いください。

指定以外の電源を使うと火災や漏電の原因となります。

本書で使用する記号とその内容

感電のおそれのあることを示します。

発煙または発火のおそれがあることを示しま

す。

破裂のおそれがあることを示します。

特定しない一般的な注意。警告を示します。

指が挟まれて怪我をするおそれがあるこ

とを示します

本装置を分解・修理・改造しないでくださ

い。感電や火災のおそれがあります。

水や液体がかかる場所で使用しないでくだ

さい。水に濡らすと感電や発火のおそれが

あります。

火気に近づけないでください。発火するお

それがあります。

特定しない一般的な禁止を示します。

使用上のご注意(Japanese)

注意の喚起

行為の禁止

行為の強制

iii

Page 14

ブレード収納ユニットの電源プラグをコ

ンセントから抜いてください。火災や感電

のおそれがあります。

特定しない一般的な使用者の行為を指示

します。説明に従った操作をしてくださ

い。

使用上のご注意(Japanese)

iv

Page 15

安全上のご注意

人命に関わる業務や高度な信頼性を必要とする業務には使用しない

本製品は医療機器・原子力設備や機器、航空宇宙機器・輸送設備や機器など、人命に

関わる設備および高度な信頼性を必要とする設備などには使用しないでください。

これらの設備に本製品を使用した結果、人身事故、財産損害などが生じても当社はい

かなる責任も負いかねます。

煙や異臭、異音がしたまま使用しない

万一、煙、異臭、異音などが生じた場合は、直ちにブレード収納ユニットの電源コー

ドをコンセントから取り外してください。その後、お買い求めの販売店または保守サ

ービス会社にご連絡ください。そのまま使用すると火災の原因となります。

針金や金属片を差し込まない

本製品に金属片や針金などの異物を差し込まないでください。感電の危険があります。

光線を直視しない(N8406-027 10GbE XFP モジュール装着時)

オプションのN8406-027 10GbE XFPモジュールは、通信にクラス1 レーザ光線を使用

しています。

このレーザ光線は、人体への影響はほとんどありませんが、動作中はXFPモジュールの

ポートをのぞきこまないでください。光ファイバケーブルを接続していない場合は必

ず付属の防塵カバー(ゴムキャップ)をはめてコネクタ端子を保護してください。

装置内に水や異物を入れない

本製品に水などの液体、ピンやクリップなどの異物を入れないでください。火災や感

電、故障の原因となります。もし入ってしまったときは、すぐにブレード収納ユニッ

トの電源を OFF にして、電源コードをコンセントから抜いてください。分解しない

で、販売店または保守サービス会社にご連絡ください。

使用上のご注意(Japanese)

本製品を安全にお使い頂くために、ここで説明する注意事項をよく読んで理解し、安全に活用してください。

記号の説明については「安全に関わる表示について」( i ページ)の説明を参照してください。

一般的な注意事項

v

Page 16

使用上のご注意(Japanese)

vi

Page 17

ブレード収納ユニット内部に手を入れない

ブレード収納ユニットに装置を取り付け/ 取り外しをする際には、ブレード収納ユ

ニット内に手を入れないでください。感電するおそれがあります。また、ブレード収

納ユニットに取り付けられているカバーは装置の取り付けなど必要な場合を除いて

取り外さないでください。

指定以外の場所で使用しない

本製品は、専用の「ブレード収納ユニット」に搭載して使用します。ブレード収納

ユニット以外やその他の筐体(ケース)に取り付けて使用しないでください。火災

や感電の原因となります。

通気口をふさがない

装置にある通気口をふさがないでください。装置内部の温度が上がり、火災の原因

となるおそれがあります。

指定以外のインタフェースケーブルを使用しない

インタフェ-スケーブルは、適合するものを使用し、接続する装置やコネクタを確

認した上で接続してください。指定以外のケーブルを使用したり、接続先を誤った

りすると、ショートにより火災を起こすことがあります。

また、インタフェ-スケーブルの取り扱いや接続について、次の注意をお守りくだ

さい。

破損したケーブルコネクタを使用しない

ケーブルを踏まない

ケーブルの上にものを載せない

ケーブルの接続がゆるんだまま使用しない

破損したケーブルを使用しない

腐食性ガスの存在する環境で使用または保管しない

使用上のご注意(Japanese)

設置・移動・保管・接続に関する注意事項

vii

Page 18

腐食性ガス(二酸化硫黄、硫化水素、二酸化窒素、塩素、アンモニア、オゾンなど)

の存在する環境に設置し、使用しないでください。

また、ほこりや空気中に腐食を促進する成分(塩化ナトリウムや硫黄など)や導電

性の金属などが含まれている環境へも設置しないでください。装置内部のプリント

板が腐食し、故障および発煙・発火の原因となるおそれがあります。

もしご使用の環境で上記の疑いがある場合は、販売店または保守サービス会社にご

相談ください。

使用上のご注意(Japanese)

viii

Page 19

分解・修理・改造はしない

本製品を分解したり、修理・改造を行ったりしないでください。感電や火災の危険が

あります。

中途半端に取り付けない

インタフェースケーブルは確実に取り付けてください。中途半端に取り付けると接

触不良を起こし、発煙や発火の原因となるおそれがあります。

ペットを近づけない

本製品にペットなどの生き物を近づけないでください。排泄物や体毛が装置内部に

入って火災や感電の原因となります。

近くで携帯電話や PHS、ポケットベルを使わない

本製品のそばでは携帯電話やPHS、ポケットベルの電源をOFF にしておいてくださ

い。電波による誤動作の原因となります。

本製品を廃棄する場合は各自治体の条例に従ってください

詳しくは、各自治体にお問い合わせください

本製品を他人に譲渡する場合は、本書および添付品すべてを必ず一緒に渡

運用中の注意事項

廃棄・譲渡に関する注意事項

使用上のご注意(Japanese)

お手入れ・内蔵機器の取り付けに関する注意事項

運用中の注意事項

廃棄・譲渡に関する注意事項

ix

Page 20

してください。

使用上のご注意(Japanese)

x

Page 21

Precautions for Use

-Be sure to read this section -

Safety Indications

Indicates the presence of a hazard that may result in death or serious

personal injury if the instruction is ignored.

Indicates the presence of a hazard that may cause minor personal injury,

including burns, or property damage if the instruction is ignored.

Attention

This symbol indicates the

presence of a hazard if the

instruction is ignored. An image in

the symbol illustrates the hazard

type.

Example

(Electric hazard)

Prohibited

action

This symbol indicates prohibited

actions. An image in the symbol

illustrates a particular prohibited

action.

Example

(Do not disassemble)

Mandatory

action

This symbol indicates mandatory

actions. An image in the symbol

illustrates a mandatory action to

avoid a particular hazard.

Example

(Unplug)

Keep this User’s Guide at hand for quick reference

at anytime necessary.

Be sure to read this section carefully.

CAUTION

WARNING

Precautions for Use

The following includes information necessary for proper and safe operation of the product.

See the "Product Overview" chapter for the term in this guide.

Follow the instructions in this User's Guide for your safety to use this product.

The server contains components with possible danger, hazards that may cause by ignoring warnings, and

preventive actions against such hazards.

The words “WARNING” and “CAUTION” are used to indicate the degrees of danger.

These terms are defined as follows:

This guide uses the following three types of symbols to give indications and precautions against a danger.

They are defined as follows:

xi

Page 22

Term indicating a degree of danger

Description of a danger

Symbol to draw attention

Do not plug the power cord in a nonconforming outlet

Use a wall outlet with specified voltage and power type.

Otherwise, there is a risk of a fire or current leakage.

Symbols Used in This User’s Guide

Indicates that improper use may cause an

electric shock.

Indicates that improper use may cause fumes

or fire.

Indicates that improper use may cause

explosion.

Indicates a general notice or warning that

cannot be specifically identified.

Indicates that improper use may cause

fingers to be caught.

Do not disassemble, repair, or modify this

product. Otherwise, there is a risk of an

electric shock or fire.

Keep the product away from water.

Otherwise, there is a risk of an electric

shock or ignition.

Never put this product close to fire.

Otherwise, there is a risk of an ignition.

Indicates a general prohibited action.

Unplug the power cord of Blade

Enclosure. Otherwise, an electric shock or

fire may be caused.

Indicates a mandatory action that cannot

be specifically identified. Make sure to

follow the instruction.

WARNING

Precautions for Use

Attentions

Prohibited actions

Mandatory actions

xii

Page 23

安全注意事項

WARNING

表示如不遵守該指示,可能引發人員傷亡。

CAUTION

表示如不遵守該指示,可能發生燒傷等身體損傷或造成物質損失。

表示該處可能發生危險。符號為危險內容的圖案。(注意)

表示禁止行為。符號中或其附近的圖案為禁止行為內容。(禁止行為)

表示強制行為。符號中的圖案為強制必須做的行為內容。即為避免危險必需的

行為。(強制行為)

注意符號

表示危險程度的用語

CAUTION

注意高溫。

本產品關閉電源後,內置硬碟等內部設備仍然處於高溫狀態。請在充

分冷卻之後進行拆裝。

禁止行為的提示符號(有

可能沒有此類提示)

危險提示內容

Precautions for Use

安全標示

請參考本用戶指南中的指示以安全使用NEC SIGMABLADE系列伺服器。

本用戶指南說明了設備何處有危險、危險類型、如何避免危險等。在設備可預計到的危險之處或其附近貼有警告標籤。

用戶指南及警告標籤中,根據危險程度不同,使用“警告”、“注意”等詞,含義如下:

對危險的提示表示有如下三種符號,具體含義如下所述:

(用戶指南中範例)

xiii

Page 24

表示有觸電的危險。

表示有因高溫而負傷的危險。

表示有手指等被夾住的危險。

表示有冒煙或者著火的危險。

表示非特定的一般的提醒警告。

表示有因雷射導致失明的危險。

表示有爆炸的危險。

表示有受傷的危險。

表示非特定的一般禁止。

不要觸摸指定區域。有觸電或著火的危險。

不要用濕手觸摸。有觸電的危險。

遠離火源。有著火的危險。

遠離液體。如果沾到液體,有觸電或著火的危險。

請不要對本設備進行拆卸、修理、改造。有觸電和發生火災的危險。

請將本設備的電源插頭從伺服器上拔下。有發生火災和觸電的危險。

對非特定的一般使用者的行為進行指示。請按照說明進行操作。

Precautions for Use

注意

本書及警告標籤中使用的符號

禁止行為

強制行為

xiv

Page 25

Precautions for Use

注意: 本產品通過多餘的硬體模組提供硬體容錯性能。但是這並不表示能夠保證完全容錯。

如,在以下情況下可能發生宕機:

– 軟體發生致命故障。

– 多餘硬體雙方均發生故障,不能運行。

– 時鐘產生器線路或內部連接背板等非多餘元件發生致命故障。

– 切斷了整個系統的AC電源

xv

Page 26

Precautions for Safety

Do not use the product for services where critical high availability

may directly affect human lives.

The product is not intended to be used with or control facilities or devices concerning

human lives, including medical devices, nuclear facilities and devices, aeronautics

and space devices, transportation facilities and devices; and facilities and devices

requiring high reliability. NEC assumes no liability for any accident resulting in

personal injury, death, or property damage if the product has been used in the above

conditions.

Do not continue to use the equipment if you detect smoke, odor, or

noise

If the equipment emits smoke, odor, or noise, immediately unplug the power cord of

Blade Enclosure. Then, contact your service representative. Continuing to use the

product in such condition may cause a fire.

Do not insert a wire or metal object

Do not insert a wire or metal object into this product.

There is a risk of an electric shock.

Avoid direct look into the laser beam. (When N8406-027 installed)

The N8406-027 10GbE XFP module, optional product, uses class-1 laser beam for

communication.

This laser beam has little impact on the human body. However, do not look into the

XFP module port during operation. Keep any vacant LC connector covered with a

dust cover (rubber cap) when you do not use it or when you transport it.

Keep water or foreign matter away from the equipment.

Do not let any form of liquid (water etc.) or foreign matter (e.g., pins or paper clips)

enter the equipment. Failure to follow this warning may cause an electric shock, a

fire, or a failure of the equipment. When such things accidentally enter the equipment,

immediately turn off the power of Blade Enclosure and unplug the power cord. Then,

contact your service representative.

CAUTION

WARNING

Precautions for Use

This section provides precautions for using this product safely. Read this section carefully to ensure proper

and safe use of the server. For symbol meanings, see “Safety Indications” on page xi.

General Precautions

xvi

Page 27

Do not put your hand inside Blade Enclosure.

When you are installing/removing the product in/from the Blade Enclosure, do not put

your hand inside the Blade Enclosure. Doing so may cause an electric shock. Do not

remove the cover from the Blade Enclosure unless you are installing the device in it.

Use the product only in the specified places

This product should be installed in the dedicated Blade Enclosure for its use. Do not

install the product in a chassis other than the Blade Enclosure. Failure to follow it

may result in fire and/or electric shock to occur.

Do not block the air openings

Do not block the air openings. When they are blocked, the internal temperature will

raise and may cause a fire.

Do not use any unauthorized interface cable.

Use only interface cables authorized by NEC and locate a proper device and

connector before connecting a cable. Using an authorized cable or connecting a

cable to an improper destination may cause a short circuit, resulting in a fire.

Also, observe the following notes on using and connecting an interface cable.

Do not use any damaged cable connector.

Do not step on the cable.

Do not put any object on the cable.

Do not use the equipment with the loose interface cable connection.

Do not use any damaged cable.

Do not use the equipment in the place where corrosive gases exist.

Make sure not to locate or use the equipment in the place where corrosive gases

(sulfur dioxide, hydrogen sulfide, nitrogen dioxide, chlorine, ammonia, ozone, etc)

exist.

Also, do not set it in the environment where the air (or dust) includes components

accelerating corrosion (ex. sulfur, sodium chloride) or conductive metals.

There is a risk of a fire due to corrosion and shorts of an internal printed board.

CAUTION

WARNING

Precautions for Use

Precautions for Installation, Relocation, Storage and Connection

xvii

Page 28

Do not disassemble, repair, or modify the product yourself

Do not disassemble, repair, or modify this product. Doing so may cause an electric

shock or a fire. Do not put the product close to fire, or immerse it in water. Doing so

may cause an explosion. If the product does not function normally, contact your

service representative.

Make sure to complete device installation

Securely connect the interface cables. Loose connection may cause fuming or

ignition.

Keep animals away from the product

Keep animals away from the product. Their discharges or fur may enter the

equipment and cause a fire or electric shock.

Do not use cellular phones, PHSs, and pagers around the product

Do not use cellular phones, PHSs and pagers around the product. Radio interference

may cause malfunctioning of the product.

Follow the ordinances by your local government when you are disposing the

product. Contact the local government for more information.

When you transfer this product to a third party, make sure to provide all items that

come with the product, including this guide.

CAUTION

WARNING

Precaution on operation

Precaution on disposing or transferring

Precautions for Use

Precautions for Cleaning and Handling of Internal Devices

Precaution on operation

Precaution on disposing or transferring

xviii

Page 29

(Japanese)

本文中の記号について

装置の取り扱いや、ソフトウェアの操作で守らなければならない事柄

や、特に注意すべき点を示します。

装置やソフトウェアを操作する上で確認しておく必要がある点を示し

ます。

知っておくと役立つ情報や、便利なことを示します。

はじめに

このたびは、「N8406-026 10GbE インテリジェントスイッチ(L3)」をお買い求めいただき、誠にありがとうござい

ます。

本製品の持つ機能を最大限に引き出すためにも、ご使用になる前に本書をよくお読みになり、装置の取り扱いを

十分にご理解ください。

本書について

本書は、本製品を正しくセットアップし、安全に使用できるようにするための手引きです。製品のセットアップ

を行うときや製品の取り扱いがわからないときなどにご利用ください。

本書は常に製品のそばに置いて いつでも見られるようにしてください。

本書では巻頭で示した安全に関わる注意記号の他に、3 種類の記号を使用しています。

これらの記号と意味をご理解になり装置を正しくお取り扱いください。

1

Page 30

機能概要

(Japanese)

関連マニュアル

本製品の設定方法につきましては、添付 CD-ROM に収められている以下のドキュメントを参照してください。

・ 10GbE インテリジェントスイッチ(L3) アプリケーションガイド

・ 10GbE インテリジェントスイッチ(L3) コマンドリファレンスガイド(AOS)

・ 10GbE インテリジェントスイッチ(L3) コマンドリファレンスガイド(ISCLI)

・ 10GbE インテリジェントスイッチ(L3) ブラウザベースインタフェースリファレンスガイド

装置の概略

この章では本製品の機能概要について説明します

本製品は、SIGMABLADE 用のインテリジェント・レイヤ 3 スイッチです。ブレード収納ユニットのスイッチモジュー

ルスロットに装着して使用します。

CPU ブレード向けのポートとして内部に 16 ポート、外部ポートには 10Gbps 対応のイーサネットポートを 4 ポート装

備しています。外部ポートは、N8406-027 XFP モジュールを装着することにより光ファイバでの接続が可能となります。

■サポート機能

・ルーティングプロトコル

- スタティック

- RIP v1, v2

- OSPF

・VRRP

・VLAN

- ポートベース VLAN

- タグベース VLAN (802.1q)

・スパニングツリー

- Spanning Tree Protocol (802.1D)

- Rapid Spanning Tree Protocol (802.1w)

- Multiple Spanning Tree Protocol (802.1s)

・リンクアグリゲーション (ポートトランク機能)

- スタティック

- LACP

・Uplink Failure Detection (トランクフェールオーバ機能)

・QoS

・ジャンボフレーム (最大 9K)

・ポートミラーリング

・IGMP スヌーピング (v1,v2,v3)

2

Page 31

・NTP クライアント

・DNS クライアント

・Syslog

・SNMP v1,v2c,v3

・RMON (グループ 1,2,3,9)

(Japanese)

3

Page 32

(Japanese)

・HTTP/HTTPS サーバ

・TELNET サーバ/クライアント

・SSH/SCP (公開鍵認証/パスワード認証)

・TFTP/FTP クライアント

・BOOTP/DHCP クライアント

・ユーザ認証機能

- RADIUS クライアント

- TACACS+

・802.1x 認証

・管理インタフェース

- コマンドラインインタフェース (以下 CLI と略します)

以下の 2 通りのコマンド形式から選択

* AOS ・・・コマンド構造がメニューベース

AOS のコマンドリファレンスガイドを参照してください。

* ISCLI ・・・コマンド構造がツリーベース

ISCLI のコマンドリファレンスガイドを参照してください。

- ブラウザベースインタフェース (BBI)

Web ブラウザを通しての管理インタフェースです。

詳細は BBI のリファレンスガイドを参照してください。

4

Page 33

各部の名称と役割

名称

機能

1.ID ランプ

装置を識別するためのランプ

2.STATUS ランプ

本製品の状態を表示するランプ

電源 ON 後 5 分以上経っても緑色に変わらない場合は、保守サービス会社に連絡して

ください。

3.イジェクタ

本製品をブレード収納ユニットへ着脱するときの操作レバー

4.シリアルポート

(コンソールポート)

ローカルコンソール接続用ポート(DB-9)。

ご使用になるにはオプションのシリアルケーブル(K410-84(05))が必要です。

5.アップリンクポート

(XFP モジュールスロット)

本スロットに N8406-027 XFP モジュール(別売)を装着することにより、ブレード収納

ユニットの外部のネットワーク機器に接続できます。CPU ブレードとは、本製品に内

蔵しているレイヤ 3(L3)スイッチングチップを介して接続されます。

本スロットの下部に表示される数字はポート番号に対応しています。

6.LINK ランプ

LAN ポートの LINK 状況を示すランプ

消灯

リンクダウン

点灯(グリーン:緑色)

リンク確立

7.ACT ランプ

LAN ポートのデータの送受信状況を示すランプ

点滅

データの送受信

8.RESET スイッチ

本製品をリセットするスイッチ

このリセットにより本スイッチが再起動します。保存していない設定情報は

失われます。また、一時的に相手装置とのリンクが切断されます。

本製品はブレード収納ユニットの電源の状態と連動して動作します。本製品には電源O

N/

OFFスイッチはありません。

N8406-026

1

2

3

4 5 6 7 8

■ N8406-026

(Japanese)

5

Page 34

(Japanese)

6

Page 35

(Japanese)

ランプについて

STATUS ランプの状

態

意味

対処方法

緑色に点灯

正常に動作しています

-

消灯

電源が OFF になっています

-

アンバー(橙色)に点滅

次の異常を検出しました

温度異常

内蔵 CPU の異常 等

ブレード収納ユニット(SIGMABLADE-M)

では SIGMABLADE モニターに異常内容

が表示されます。詳細は EM カードのユー

ザーズガイドを参照してください。エラー

種別によっては保守サービス会社に連絡

してください。

スイッチモジュールインタ

フェースミスマッチ

ブレード収納ユニット(SIGMABLADE-M)

では SIGMABLADE モニターに

「SWMn IFmiss Alm」が表示されます。「ブ

レード収納ユニット内における CPU ブレードと

本製品のつながり」(10 ページ)を確認して、

CPU ブレードのインタフェース種別(FC

または LAN)と本製品のインタフェース種

別が一致しているか確認してください。

ID ランプの状態

意味

青色に点灯または点滅

操作対象であることを管理ソフトウェアなどにより設定された

消灯

上記以外

STATUS ランプ

本製品やブレード収納ユニットが正常に動作している間は STATUS ランプが緑色に点灯します。STATUS ランプ

がアンバー(橙色)に点灯または点滅しているときは、システムに何らかの異常が発生したことを示します。異常を

示しているときは保守サービス会社に連絡してください。

ID ランプ

操作対象の製品であることを識別するためのランプ。

複数台の装置の中から、特定の装置を識別したいときに使用できます。

メンテナンスの時などに、このランプを点灯させておくと、対象装置を間違えずに作業することができます。

7

Page 36

本製品のポート構成について

インタフェース名

ポート

番号

速度

説明

内部インタフェース

CPU ブレードポート

1~16

10Gbps

CPU ブレード接続専用のポートです。各ポートが、

ブレード収納ユニットのブレードスロットに実装さ

れる各 CPU ブレードに接続します。また、ブレード

収納ユニットにより接続が異なります。詳細は「ブ

レード収納ユニット内における CPU ブレードと本製品のつ

ながり」(10 ページ)を参照してください。

マネジメントポート

17

10/100Mbps

ブレード収納ユニット内部の管理用 LAN に接続す

るためのポートです。他のポートとは VLAN を分離

しており通信できません。管理専用でお使いくださ

い。ご使用の際はブレード収納ユニットの外部ポー

トから接続します。詳細はブレード収納ユニットの

ユーザーズガイドを参照してください。

外部インタフェース

アップリンクポート

(XFP モジュールスロット)

18~21

10Gbps

外部ネットワークへの接続用のイーサネットポート

です。N8406-027 XFP モジュールを接続して使用し

ます。

シリアルポート

(コンソールポート)

-

9600bps

ローカルコンソール接続のポートです。コネクタ形

状は DB-9 です。

CPU ブレードポート(Port1~16)、アップリンクポート(Port18~21)は初期設定で VLAN1

に属しています。

(Japanese)

本製品のポート構成と内部での接続を以下に示します。

本製品のインタフェースは大きく分けて内部インタフェースと外部インタフェースがあります。

8

Page 37

port

18

スイッチモジュール外部

Ethernetインタフェース

(アップリンクポート)

シリアルポート

(コンソールポート)

port

1

port

16

C PU ブレードへ

port

17

収納ユニット内部

管理用LA N へ

N 8 4 0 6 -0 2 6

10G b E インテリジェントスイッチ(L 3 )

外部インタフェース

内部インタフェース

EM カードへ

10/100Mbps

10Gbps

固定

C P U ブレードポート

制御用

C P U

制御用

インタフェース

レイヤ3 (L 3 )

スイッチングL S I

マネジメントポート

port

21

XFP モジュールスロット

10Gbps

【N8406-026 10GbE インテリジェントスイッチ(L3)の内部/外部ポートの構成図】

(Japanese)

9

Page 38

ブレード収納ユニット内における CPU ブレードと本製品のつな

がり

C PUブレード

(Express5800/120Bb-6)

標準LAN

メザニン拡張

スロット1

(Type-1専用)

メザニン拡張

スロット2

(Type-1,2共用)

ポート2

ポート1

ポート2

ポート1

ポート2

ポート1

スロット5 、スロット6 へ

本製品と接続されません

S IG M A B L A D E -M の場合

…スロット5 、スロット6 へ

S IG M A B L A D E -H の 場合

…スロット7 、スロット8 へ

本製品と接続されません

本製品と接続されません

本製品と接続されません

スイッチモジュールスロット5

スイッチモジュールスロット3

スイッチモジュールスロット1

スイッチモジュールスロット6

スイッチモジュールスロット4

スイッチモジュールスロット2

本スロットで本製品は使用できません

本スロットで本製品は使用できません

スイッチモジュールスロット1

スイッチモジュールスロット3

スイッチモジュールスロット5

スイッチモジュールスロット7

スイッチモジュールスロット2

スイッチモジュールスロット4

スイッチモジュールスロット6

スイッチモジュールスロット8

本スロットで本製品は使用できません

本スロットで本製品は使用できません

SIGMABLADE-M

SIGMABLADE-H

ブレード収納ユニット背面

(Japanese)

ブレード収納ユニット内での CPU ブレードと本製品のつながりを示します。

本製品をブレード収納ユニットに搭載するにあたって参考にしてください。

メザニン拡張スロット 2 へ N8403-024 10GbE 接続ボードを装着して接続されます。

ブレード収納ユニットのスイッチモジュールスロット番号

10

Page 39

(Japanese)

11

Page 40

ネットワークケーブルついて

コネクタ

LC コネクタ

ケーブルタイプ

マルチモードファイバ(MMF)ケーブル

ケーブル長

最大 300 メートル

光ファイバケーブルの取り付けについては、ケーブルフォーミングや取り扱う

上での専門知識が必要ですので、保守サービス会社に依頼してください

光ファイバケーブルは慎重かつ丁寧に扱うよう注意してください。

光ファイバケーブルの曲げ半径は「最低でも50mm」は確保してください

ケーブルのコネクタは無理に押し込まないでください、各コネクタは正しい向

き、正しい角度で差し込まないと接続できません。

正しく差し込んだ時は強い力を入れなくてもスムーズに差し込めるようになっ

ています。うまく差し込めないときには無理矢理差し込まずにもう一度コネク

タの向きを確認してください。

ケーブル装着時にコネクタ及びコンタクトに座曲等の損傷、ゴミの付着、汚れ

のないことを確認してください

誤配線のないようにケーブルの仕様と接続先のコネクタを確認してください。

コネクタを床などに落下させ破損させないように取り扱いに注意してくださ

い。また、コネクタを床上に引きずりゴミなどを付着させないようにしてくだ

さい。

ケーブルを装着した状態で、コネクタ部やケーブル部に無理な力を掛けないで

ください。また、ケーブルを踏んだり、重いものを載せたりして変形させない

でください。

強く押し込むと光ファイバケーブル端面に傷が付いて光の出力が低下し、動作

不良の原因となることがあります。

(Japanese)

次の仕様を満たすケーブルをご使用ください

12

Page 41

取り付け手順

1

取り付けるスイッチモジュールスロット

のブランクパネルおよびサポートステー

を取り外す。

2

本製品のイジェクタのストッパーをはず

し、イジェクタを開く

イジェクタ

ストッパー

3

本製品のイジェクタを開いたまま、ゆっく

りとていねいにブレード収納ユニットに

差し込む。

①

②

設置

ブレード収納ユニットへの本製品の取り付け方法について説明します。

詳しくはブレード収納ユニットのユーザーズガイドをご覧になってください。

(Japanese)

13

Page 42

4

イジェクタをストッパーがロックされる

まで押し込み、ブレード収納ユニットに固

定する。

ブレード収納ユニット

ストッパー

(Japanese)

14

Page 43

・ ブレード収納ユニットに本製品を取り付けられないときは、いったん本製品を取り外

してから取り付けなおしてください。無理な力を加えると破損するおそれがあります

ので注意してください。

・ 本製品の取り付け・取り外し方法はブレード収納ユニットにより異なりますので必ず

ブレード収納ユニットのユーザーズガイドをお読みください。

・ 本製品はブレード収納ユニットの電源の状態と連動して動作します。電源供給されて

いるブレード収納ユニットに本製品を取り付けると、本製品にもすぐに電源供給され

稼動開始します。そのため、本製品を実装するスイッチモジュールスロットに接続さ

れる CPU ブレード側のポートが、オプションの 10GbE 接続ボードであることを十分

ご確認の上、本製品を取り付けてください。

・ 本製品には電源ON/OFFスイッチはありません。

・ 本製品の取り付け後、約 10 秒で STATUS ランプが緑色に点灯します。

(Japanese)

15

Page 44

取り外し手順

1

本製品のストッパーをはずし、イジェクタ

を開いてロックを解除する。

2

本製品のイジェクタを手前に軽く引いて

ください。

3

本製品のイジェクタを開いたまま、本製品

をしっかりと持ってゆっくりと引き出す。

ブレード収納ユニット

イジェクタ

ストッパー

・ 本製品をスイッチモジュールスロットから取り外し、再度取り付ける場合は 30 秒以

上時間をおいて取り付けてください。

・ ブレード収納ユニットのスイッチモジュールスロットに、本製品ならびにその他のス

イッチモジュールを搭載しない場合は、スイッチモジュールスロットにブランクパネ

ルを取りつけて運用してください。

・ ブレード収納ユニットのブランクパネルの取り付け方法は、ブレード収納ユニットの

ユーザーズガイドを参照してください。

(Japanese)

本製品の取り外しについて説明します。

詳しくはブレード収納ユニットのユーザーズガイドをご覧になってください。

16

Page 45

(Japanese)

XFP モジュール取り付け/取り外し手順

光線を直視しない

N8406-027 10GbE XFPモジュールは、クラス1 レーザ光線を使用して通信します。このレーザ光線は、

人体への影響はほとんどありませんが、光ファイバケーブルを接続していない場合は必ず付属の防塵

カバー(ゴムキャップ)をはめ、コネクタ端子を保護してください。また、動作中はXFPモジュールのポ

ートをのぞきこまないでください。

取り付け手順

1

XFP モジュールに装着している防塵カバーを外す。

2

XFP モジュールの XFP コネクタを 10GbE イン

テリジェントスイッチ(L3)の XFP モジュールス

ロットに差し込み、「カチッ」と音がするまでし

っかりと差し込む。

N 8 40 6-0 26

1 0 G b E イン テリジェントスイッチ(L 3 )

X F P

モジュール

X F P モジュールスロット

XFP モジュールを取り付けた状態で保管または輸

送する場合、ホコリ等からLCコネクタを保護する

ため、必ず XFP モジュールに添付されている「防

塵カバー」を取り付けてください。

異物の付着等により XFP モジュールの光出力/光感

度が低下し、使用不能となる場合があります。

XFP モジュールを XFP スロットに挿入する際に

は、まっすぐに挿入し、無理な力をかけないでくだ

さい。無理に斜めに挿入すると本製品や XFP モジ

ュールが破損することがあります。

防塵カバー

XFPモジュール

XFP モジュールスロットに接続するN8406-027 10GbE XFPモジュールの取り付けと取り外し手順について説明し

ます。

17

Page 46

イジェクタを倒さずに XFP スロットの奥

まで「カチッ」と音がするまでしっかり

と差し込んでください。

イジェクタを倒して挿入した場合、リン

クしても接触不良により通信エラーが発

生することがあります。

(Japanese)

18

Page 47

取り外し手順

1

光ファイバケーブルを外し、XFP モジュール

のイジェクタを下ろす。

N 8 4 0 6 -0 2 6

1 0 G b E インテリジェントスイッチ(L 3 )

X F P モジュール

レバーを倒す

2

レバーをつまんで図中の矢印方向に引き抜

く

N 8 4 0 6 -0 2 6

1 0 G bE インテリジェントスイッチ(L 3 )

取り出し方向

光ファイバケーブルの取り付けについては、ケーブルフォーミングや取り扱う上での

専門知識が必要ですので、保守サービス会社に依頼してください

(Japanese)

19

Page 48

通信速度

9600 bps

データ長

8 ビット

パリティ

なし

ストップビット

1 ビット

フロー制御

なし

・ シリアルポートコネクタには専用回線を直接接続することはできません。

・ コマンドラインインタフェースには、AOS と ISCLI の2つのモードがあります。ど

ちらかのモードを選択して使用してください。デフォルト設定では AOS で起動しま

す。

・ 本製品では、EM カードからのシリアルインタフェース接続はサポートしていません。

そのため、CONNECT SWITCH (SIGMABLADE-H)、connectswitch (SIGMABLADE-M)

コマンドによる、EM カードからのシリアルコンソール接続はできません。

(Japanese)

設定方法

本製品はシリアルポート経由でローカルコンソールにログインするか、ネットワーク経由でリモートコンソール

にログインして設定することができます。

・ローカルコンソール接続

本製品のシリアルポートと管理用コンソール間をシリアルケーブルで接続します。本製品のコマンドラインイ

ンタフェースにアクセスし、ログインプロンプトが表示されます。なお、ケーブルはオプションのシリアルケ

ーブル(K410-84(05))が必要です。また、管理用コンソールには VT-100 準拠の通信ソフトウェアが必要です。

通信ソフトウェアは下表の通り設定してください。

・リモート接続

ネットワーク経由のリモート接続をするためには、本装置に IP アドレスを設定する必要があります。設定した

IP アドレスに対して telnet や Web ブラウザを通して接続し、CLI/BBI にアクセスすることができます。

IP アドレスは以下の方法で設定することができます。

- DHCP による自動設定 (工場出荷時)

- 手動設定

・DHCP による自動設定

20

ブレード収納ユニットに搭載された EM カードが DHCP サーバとなっており、本装置のマネジメントネッ

トワーク側のインタフェースに IP アドレスが割り当てられます。DHCP サーバで割り当てる IP アドレス

Page 49

(Japanese)

>> # /cfg/sys/dhcp disable

Current DHCP: enabled

New DHCP: disabled

(DHCP クライアントを Disable)

>> # /cfg/l3/if 250

(インタフェース 250 を選択)

>> IP Management Interface 250# addr 192.168.12.90

Current IP address: 0.0.0.0

New pending IP address: 192.168.12.90

Pending new subnet mask: 255.255.255.0

(インタフェース 250 に IP アドレスを設定)

>> IP Management Interface 250# ena

(インタフェース 250 を Enable)

>> IP Management Interface 250# ../gw 254

(ゲートウェイ 254 を選択)

>> Default management gateway 254# addr 192.168.1.2

Current IP address: 0.0.0.0

New pending IP address: 192.168.1.2

(ゲートウェイ 254 に IP アドレス設定)

>> Default management gateway 254# ena

(ゲートウェイ 254 を Enable)

>> Default management gateway 254# apply

(変更した設定を適用)

>> Default management gateway 254# save

(Flash に保存)

Router>enable

(Privileged EXEC mode に移行)

Router#configure terminal

(Global Configuration mode に移行)

Router(config)#no system dhcp

(DHCP クライアントを Disable)

Router(config)#interface ip 250

(Interface IP Configuration mode に移行)

Router(config-ip-if)#ip address 192.168.12.90 255.255.255.0

(IP アドレスを設定)

Router(config-ip-if)# enable

(インタフェース 250 を Enable)

Router(config-ip-if)# exit

(Global Configuration mode に戻る)

Router(config)# ip gateway 254 address 192.168.1.2

(ゲートウェイ 254 に IP アドレスを設定)

Router(config)# ip gateway 254 enable

(ゲートウェイ 254 を Enable)

Router(config)# copy running-config startup-config

(Flash に保存)

・ DHCP サーバから IP アドレスが得られない場合、本製品のローカルコンソールに接

続し、手動で設定してください。手動での設定方法については、下記の「手動設定」

を参照してください。

・ ブレード収納ユニット内のマネジメント LAN ネットワークには、本製品の Port17 が

接続されています。

・ ブレード収納ユニットのマネジメント LAN ポートの接続・設定方法は、EM カードも

しくはブレード収納ユニットのユーザーズガイドを参照してください。

の設定は EM カードにて行います。詳細は EM カードもしくはブレード収納ユニットのユーザーズガイド

を参照してください。

・手動設定

ローカルコンソールで本装置に接続し IP アドレスを設定します。以下のコマンド例を参照して設定してくだ

さい。

AOS CLI の場合

ISCLI の場合

21

Page 50

・ 本製品のマネジメントネットワーク側に IP アドレスとデフォルトゲートウェイを手

動で設定する場合、インタフェース 250 とゲートウェイ 254 に設定してください。

・ dhcp 有効時、IP アドレスを手動設定しても DHCP サーバから IP アドレスが割り当

てられた場合、DHCP サーバで割り当てられた IP アドレスが優先されます。手動で

設定する場合、dhcp を無効にしてください。

(Japanese)

22

Page 51

(Japanese)

ユーザアカウント

説明

パスワード

(デフォルト)

User

スイッチの統計情報やステータス情報の表示のみ行うことができま

す。設定の変更はできません。工場出荷時有効です。

user

Oper

スイッチの設定を変更することができますが、本製品をリセットする

とその変更は解除されます。工場出荷時無効で、パスワードはありま

せん。

-

admin

すべての設定を行うことができます。

admin

・ セキュリティ観点からパスワードをデフォルト値から変更することを推奨致します。

ユーザのアクセス権

本製品には 3 つのアクセスレベルがあります。各アクセスレベルのデフォルトユーザ名、パスワードは下表の通

りです。工場出荷時状態では、コマンドラインインタフェースのログオン時、パスワードのみ要求されます。エ

ンドユーザアカウントを設定し有効にすると、コマンドラインインタフェースでユーザ名とパスワードを要求さ

れます。

23

Page 52

(Japanese)

トラブルシューティング

ここでは本製品を搭載して発生しうるトラブルについて、その対処方法を説明します。

解決しない場合は保守サービス会社に連絡してください。

ブレード収納ユニットに本製品を着脱できない

ブレード収納ユニットのスロットに異物が入っていないか確認してください

本製品の取り付け方向が正しいか確認してください

本製品が使用できない

「ブレード収納ユニット内における CPU ブレードと本製品のつながり」(10 ページ)を参照して、本

製品、CPU ブレード上の標準 LAN またはメザニン拡張スロット、ケーブルそれぞれの位置が正しい

か確認してください。

本製品がブレード収納ユニットにしっかりと接続されていることを確認してください。

本製品を含めシステムに電源が供給されていることを確認してください。

STATUS ランプがアンバー点灯する/グリーン点灯しない

本製品が正しく取り付けられているか確認してください。

本製品を取り付け時 STATUS ランプが点灯しない場合、いったんブレード収納ユニットから取り外

し、再度取り付けをしてください。

ブレード収納ユニット(SIGMABLADE-M)では SIGMABLADE モニターに異常内容が表示されます。詳

しくは EM カードのユーザーズガイドをご覧になり、エラー種別によっては保守サービス会社に連

絡してください。

24

ローカルコンソールが使用できない

指定のクロスケーブルを使用しているか確認してください。

ローカルコンソールの通信設定が正しいか確認してください。

本製品を含めシステムに電源が供給されていることを確認してください。

Page 53

(Japanese)

リモートコンソールが使用できない

本装置からリモートコンソールに至るまでの経路を確認してください。

IP アドレスなどの設定が正しいか確認してください。

本製品を含めシステムに電源が供給されていることを確認してください。

25

Page 54

(Japanese)

リンクが確立しない(LINK/ACT ランプが点灯しない)

ケーブルが正しく取り付けられているか確認してください。

お使いのケーブルの仕様が「ネットワークケーブルついて」(12 ページ)に準拠したものか確認して

リンクパートナー(スイッチ等)の通信モードが自動認識または速度/Duplex 設定が本装置と等しく

CPU ブレードで正しいドライバを使用しているか確認してください。

リンクパートナー側装置について問題がないか、リンクパートナー側のエラーログなどを確認して

EM カードよりスイッチモジュール縮退回復トラップが通知される

ください

なっていることを確認してください

ください。

EM カードでトラップ通知を有効にしている状態で、ブレード収納ユニット(SIGMABLADE-M)に本製

品を取り付けた時、もしくは本製品を実装したブレード収納ユニット(SIGMABLADE-M)の電源を供

給した時、EM カードよりスイッチモジュール縮退回復のトラップが通知されます。特に問題はあり

ませんので、そのまま使用してください。

CPU ブレードでネットワークアダプタのチーミングを構成したが動作しない

チーミングを外して、個々のインタフェースで動作することを確認してください。

チーミング設定時のみ動作しない場合は、チーミング設定内容及び通信相手までの NW 構成が正し

い状態であることを確認してください。

「アダプタフォルトトレランス」(AFT)を使用する場合、ネットワークアダプタを接続するポートの

スパニングツリーを off にして使用してください。

以上の項目を確認したにもかかわらず、問題が解決しない場合は、本製品に何らかの故障が発生している可能性

が考えられます。保守サービス会社または本製品をお買い求めの販売店までお問い合わせください。

26

Page 55

製品名

10GbE インテリジェントスイッチ(L3)

型番

N8406-026

インタフェース

10GBase-SR(Port1-16, 18-21(XFP モジュールスロット))

10Base-T/100Base-TX(Port17)

コネクタ

XFP モジュールスロット

ポート数

16 ポート(CPU ブレードポート)

1 ポート(マネジメントポート)

4 ポート(アップリンクポート)

消費電力

70W

環境条件

温度(℃)

湿度(%)

10~35

20~80

ただし、結露なきこと

サイズ(mm)

2スロット幅

387(W) x 268(D) x 28(H)

重量(Kg)

2.72

仕様

(Japanese)

27

Page 56

Page 57

(English)

Text Conventions

IMPORTANT:

Items that are mandatory or require attention when using this product

NOTE:

Helpful and convenient piece of information

Repurchasing This Guide

Introduction

Thank you very much for purchasing our 10Gb Intelligent L3 Switch. To maximize the functionality of this product,

please read this guide carefully and follow the instructions for proper handling.

About this guide

This guide describes how to handle and use this product properly.

Keep this guide at hand for your future reference.

This guide is intended for technically qualified personnel with sufficient knowledge such as network

configuration.

The following conventions are used throughout this guide. For safety symbols, see “Safety Indications” provided

earlier.

Contact your service representative if you lost this guide.

29

Page 58

Features

(English)

Additional references

Detailed information about how to configure this product is described in the reference guides listed below. These

guides are contained in the attached CD-ROM.

・ 10Gb Intelligent L3 Switch Application Guide

・ 10Gb Intelligent L3 Switch Command Reference Guide (AOS)

・ 10Gb Intelligent L3 Switch Command Reference Guide (ISCLI)

・ 10Gb Intelligent L3 Switch Browser-based Interface Reference Guide

Product Overview

The features of this product are briefly described below.

The N8406-026 10Gb Intelligent L3 Switch is a Switch Module for the Blade Enclosure. The Switch Module is used

to connect the CPU Blade with the external network through the Ethernet port. The Switch Module has 16 ports

dedicated to CPU Blade, 4 uplink ports, and one port dedicated to management network. Four uplink ports can be

fiber using N8406-027 XFP modules.

■Supported technologies

・ Routing protocl

- static

- RIP v1, v2

- OSPF

・ VRRP

・ VLAN

- Port-based VLAN

- Tagged VLAN

・ Spanning Tree

- Spanning Tree Protocol (802.1D)

- Rapid Spanning Tree Protocol (802.1w)

- Multiple Spanning Tree Protocol (802.1s)

・ Link aggregation (Port trunking)

- static

- LACP

・ Uplink Failure Detection (Trunk failover feature)

・ QoS

・ Jumbo frames (up to 9216 bytes)

・ Port mirroring

・ IGMP Snooping (v1, v2, v3)

・ NTP client

・ DNS client

・ Syslog

・ SNMP v1, v2c, v3

・ RMON (Group 1,2,3,9)

30

Page 59

(English)

31

Page 60

(English)

・ HTTP/HTTPS server

・ Telnet server/client

・ SSH/SCP

・ TFTP/FTP client

・ BOOTP/DHCP client

・ User authentication

- RADIUS

- TACACS+

・ Port security based on 802.1x authentication

・ Management interface

- Command Line Interface (CLI)

This switch provides two CLI modes. You can set the switch to use either CLI mode.

- AOS ...... menu-based command structure

Refer to the Command Reference Guide (AOS).

- ISCLI ...... tree-based command structure

Refer to the Command Reference Guide (ISCLI)

- Browser-based Interface (BBI)

BBI provides access to the management of the switch through your Web browser. Refer to

the Browser-based Interface Reference Guide.

32

Page 61

Description

Name

Description

1. ID LED

The LED is intended to identify the Switch Module in the Blade Enclosure. The LED is lit

by software command.

2. STATUS LED

Indicates the Switch Module status.

Contact your service representative if it does not go on green in five minutes after the

Blade Enclosure is powered on.

3. Ejector

Use this lever to install or remove a Switch Module in/from the Blade Enclosure.

4. Serial Port

Used as a DB-9 management serial port.

5. Uplink port

(XFP module slot)

XFP module connectors for optional fiber uplink

6. LINK LED

Indicate the link status of each LAN port.

Off

Link not established

On (Green)

Link established

7. ACT LED

Indicate the activity of each LAN port.

Flash (Green)

Data being transmitted or received

8. RESET Switch

Press this switch to restart the Switch Module.

Pressing the RESET switch reboots this Switch Module, loses the configuration

data not to save in the flash memory, and temporarily disconnects

communication with the network.

NOTE: The Switch Module works with the Blade Enclosure. It does not

have a POWER switch.

1

2

3

4 5 6

7

8

N8406-026

(English)

33

Page 62

LED

STATUS LED

Description

Action

On (Green)

The Switch Module is operating

normally.

-

Off

The power is turned off.

Turn on the power.

Flash (Amber)

The following errors have been

detected.

- Abnormal temperature

- Processor error or other

components error

When installed in the Blade Enclosure (6U), an

error message is displayed on the

SIGMABLADE monitor.

Refer to the User’s Guide of the EM Card.

Switch Module interface

mismatch

When installed in the Blade Enclosure (6U),

“SWMn Ifmiss Alm” (n: slot number) is displayed

on the SIGMABLADE monitor. See page 37

“Connection with CPU Blade”, and make sure

the location of the Mezzanine Card in the CPU

Blade and the Switch Module.

Refer to the User’s Guide of the Blade

Enclosure.

ID LED

Description

On or Flash in blue

Management software has specified the Switch Module.

Off

Other than the above

(English)

STATUS LED

The STATUS LED goes on green when the Switch Module operates normally. When the LED is lit or flashing in

amber, it indicates that the Switch Module has failed. The following table lists indications of the STATUS LED,

descriptions, and actions to take. If an error occurs, contact your service representative.

ID LED

The ID LED is intended to identify a specific Switch Module in the Blade Enclosure when more than one Switch

Modules are installed. Making this LED being lit can help the maintenance work to identify the faulty device.

When the recognized command is received from the management software such as NEC ESMPRO/Server

Manager, the LED goes on or flashes in blue.

34

Page 63

Number of ports

Category

Port number

Speed

Description

Internal interface

CPU Blade

1-16

10Gbps

The ports dedicated to the CPU Blade. Each port

connects with each CPU Blade installed the

Blade Slot in the Blade Enclosure. The

connection is difference between the Blade

Enclosures. Refer to page 37 “Connection with

CPU Blade”.

Management network

17

10/100Mbps

The port dedicated to management network. Port

17 is isolated from the other ports by using

VLAN. Use port 17 for managing the Switch

Module. To connect the management interface,

connect the port in the Blade Enclosure. For

more information, see the Blade Enclosure

User’s Guide.

External interface

Uplink

(XFP module slot)

18-21

10Gbps

Uplink ports using optional N8406-027 XFP

modules

Serial port

-

9600bps

DB-9 management serial port

NOTE: By default, VLAN 1 is the default VLAN, and all ports except Port

17 are assigned to it.

The following table lists the ports.

(English)

35

Page 64

port

18

Serial Port

(Console port)

port

1

port

16

To CPU Blade

port

17

Connected to

management network

In Blade Enclosure

N8406-026

10Gb Intelligent L3 Switch

External interface

Internal interface

10/100Mbps

10Gbps fixed

CPU

Layer 3

Switching LSI

port

21

Uplink ports

XFP module slots

10Gbps

(English)

10Gb Intelligent L3 Switch internal and external ports connection diagram

36

Page 65

Connection with CPU Blade

CPU Blade

(Express5800/120Bb-6)

on-board LAN

Mezzanine

slot1

(Type-1)

Mezzanine

slot 2

(Type-1,2)

Port1

Port2

Port1

Port2

Port1

To Switch Module slot 5, slot 6

Not connect

Port2

Not connect in Blade Enclosure(6U)

To Switch Module slot 7, slot 8

in Blade Enclosure(10U)

Not connect

Not connect

Not connect

Switch Module slot 6

Switch Module slot 5

Switch Module slot 4Switch Module slot 3

Switch Module slot 2

Switch Module slot 1

Not Available

Not Available

Switch Module slot 1

Switch Module slot 3

Switch Module slot 5

Switch Module slot 7

Switch Module slot 2

Switch Module slot 4

Switch Module slot 6

Switch Module slot 8

Not Available

Not Available

Blade Enclosure (6U)

Blade Enclosure (10U)

Rear View

The following figure shows the network connection diagram between CPU Blades and Switch Modules.

(English)

Switch Module slot number in Blade Enclosure

37

Page 66

Network Cables

Connector

LC connector

(when N8406-27 10GbE XFP module installed)

Type of Cable

Multimode Fiber (MMF) cable

Cable Length

(max.)

300m

IMPORTANT:

・ Contact your service representative for placing optical fiber cables.

Experts must place the cables.

・ Handle optical fiber cables carefully.

・ Keep more than 50 mm by a bending radius when you bend a optical

fiber cable.

・ Install the cable to the XFP connector straight. Do not force to install the

calbe to avoid damage it.

・ Make sure that the connector of the cable is clean and is not

damaged.

・ Make sure that your cable meets specifications for the use of the XFP

module.

・ Do not come into contact with contamination.

・ Do not give any impact or pressure to the cable and its connector. Do

not step on the cable or put something heavy on it.

(English)

Your network cables must have the following specifications:

38

Page 67

Installing Switch Module

1

Remove the slot cover and divider.

2

Open the ejector of 1Gb Intelligent L3

Switch.

Ejector

3

With the ejector being opened, insert the

Switch Module into the Blade Enclosure.

4

Close the ejector to fix the Switch Module

to the Blade Enclosure.

The Switch Module is locked and fixed.

①

②

Installation

Refer to the Blade Enclosure User’s Guide for details.

(English)

39

Page 68

IMPORTANT:

・ The Switch Module works with the Blade Enclosure. The Switch

Module is powered on as soon as it is installed in the powered Blade

Enclosure. Therefore, make sure that the ports connected with the

Switch Module are only the ports of NIC on the CPU Blade. Then,

install the Switch Module in the Blade Enclosure.

・ Do not hold the ejector to install the Switch Module in the Blade

Enclosure. Hold the Switch Module itself and insert it into the Switch

Module slot. Inserting the Switch Module with the ejector being held,

the ejector may be damaged or disengaged from the Switch Module.

It may cause the personal injury if the Switch Module drops.

NOTE:

・ The Switch Module does not have a POWER switch.

・ The STATUS LED goes on green after the period of about 10

seconds from installing the Switch Module in the powered Blade

Enclosure.

Removing Switch Module

1

Open the ejector of 1Gb Intelligent L3

Switch to unlock.

2

Pull the ejector a little.

3

With the ejector being open, firmly hold the

Switch Module and slowly pull out from the

Blade Enclosure.

Blade Enclosure

Ejector

IMPORTANT:

・ Install the Switch Module in the Blade Enclosure after the period of 30

seconds or longer has passed from removing it from the powered

Blade Enclosure.

・ Install the Slot Cover to the empty slot and secure it with a screw, if

the Blade Enclosure is used with the Switch Module being removed.

(English)

Refer to the Blade Enclosure User’s Guide for details.

40

Page 69

NOTE: For the information how to install the Slot Cover, see the Blade

Enclosure User’s Guide.

(English)

41

Page 70

Installing and Removing XFP Module

IMPORTANT:

・ Attach the dust covers to all vacant LC connectors to protect them

from contamination, if you store or transport the Switch Module

which the XFP modules are installed.

・ Optical power and sensitivity may be lower and cause malfunction

by coming into contact with contamination.

・ Install the XFP module to the XFP module slot straight. Do not force

to install it to avoid damage the module.

Dust cover

XFP Module

Avoid direct look into the laser beam.

The N8406-027 10GbE XFP Module is classified as a Class 1 Laser Product. A class 1

laser will not be harmful to the human body. However, do not look directly into the XFP

module port during operation. Keep any vacant LC connector covered with a dust cover

(rubber cap) when you do not use it or you transport it.

Installing XFP Module

1

Remove the dust cover attached to the XFP module.

2

Insert the XFP module to the XFP

module slot in the Switch Module.

N 8 4 0 6 -0 2 6

X F P m od u le

X F P m od u le slo t

NOTE: Insert the XFP module to the XFP module slot without pulling

down the lever. If you insert with the lever pulled down, a communication

failure may occur.

WARNING

(English)

The following is described how to install and remove N8406-027 10GbE XFP Module in and from N8406-026 10Gb

Intelligent L3 Switch.

42

Page 71

(English)

43

Page 72

Removing XFP Module

1

Remove the optical fiber cable, and pull

down the XFP module lever.

N 8 4 0 6 -0 2 6

X F P m o d u le

P u ll do w n th e lev e r

2

Hold the lever and pull the XFP module

straight.

N 8 4 0 6 -0 2 6

IMPORTANT:

・ Contact your service representative for placing optical fiber cables.

Experts must place the cables.

(English)

44

Page 73

(English)

Baud rate

9600

Data bits

8

Parity

None

Stop bits

1

Flow control

None

IMPORTANT: A leased line cannot be connected to the Serial Port

directly.

NOTES:

・ The command line interface has 2 modes, AOS CLI and ISCLI. You

can set the Switch Module to use either CLI mode. By default, the

mode is AOS CLI.

・ Serial interface is not connected between this switch module and the

EM card. Therefore It is not available to connect from the Enclosure

Manager by using "CONNECT SWITCH" command on Blade

Enclosure(10U) or "connectswitch" command on Blade

Enclosure(6U).

Configuration

The Switch Module can be configured locally using the Serial Port or remotely using the Ethernet ports.

Connection via Serial Port

Use a serial cable (with a female DB-9 connector) to connect between a management console (such as a personal

computer) and the Serial Port. A communication software conformed to VT100 terminal emulation is required. Set

the parameters of communication software as shown in the table below.

45

Page 74

NOTES:

・ If the IP address cannot be obtained from the DHCP server, access

the local console of the Switch Module and assign the IP address

manually. Refer to “Manual assignment” below. After assigning the IP

address, then access the Switch Module via network.

・ Port 17 of the Switch Module is connected with the management

network in the Blade Enclosure.

・ Refer to the Blade Enclosure User’s Guide and the EM Card User’s

Guide about how to connect or configure the Enclosure Management

LAN port.

>> # /cfg/sys/dhcp disable

Current DHCP: enabled

New DHCP: disabled

(Disable dhcp)

>> # /cfg/l3/if 250

(Select IP interface 250)

>> IP Management Interface 250# addr 192.168.12.90

Current IP address: 0.0.0.0

New pending IP address: 192.168.12.90

Pending new subnet mask: 255.255.255.0

(Assign IP address for the Interface)

>> IP Management Interface 250# ena

(Enable IP interface 250)

>> IP Management Interface 250# ../gw 254

(Select default gateway 254)

>> Default management gateway 254# addr 192.168.1.2

Current IP address: 0.0.0.0

New pending IP address: 192.168.1.2

(Assign IP address for a router)

>> Default management gateway 254# ena

(Enable default gateway 254)

>> Default management gateway 254# apply

(Apply the configuration)

>> Default management gateway 254# save

(Save the configuration)

Router>enable

(Enter Privileged EXEC mode)

Router#configure terminal

(Enter Global Configuration mode)

Router(config)#no system dhcp

(Disable dhcp)

Router(config)#interface ip 250

(Enter Interface IP Configuration mode)

Router(config-ip-if)#ip address 192.168.12.90 255.255.255.0

(Assign IP address for the Interface)

Router(config-ip-if)# enable

(Enable IP interface 250)

Router(config-ip-if)# exit

(Exit to Global Configuration mode)

Router(config)# ip gateway 254 address 192.168.1.2

(Assign default gateway 254)

Router(config)# ip gateway 254 enable

(Enable default gateway 254)

Router(config)# copy running-config startup-config

(Save the configuration)

IMPORTANT:

・ When assigning an IP address and default gateway for the

management interface manually, assign them to interface 250 and

Gateway 254, respectively.

・ When enabled dhcp of the Switch Module, the IP address obtained

(English)

Connection via Network

To connect to this Switch Module via network, you need to assign an IP address to it. You can access the

browser-based interface or the command line interface in the switch througn a telnet application or Web browser

by using the assigned IP address.

IP address is configured by the following.

- Assignment by DHCP (by default)

- Manual assignment

- Assignment by DHCP

By default, the management network interface on the Switch Module is set up to obtain its IP address from the

DHCP server on the Enclosure Manager Card. You can configure the IP address in the EM Card. For more

information, see the EM Card User’s Guide and the Blade Enclosure User’s Guide.

- Manual assignment

You can assign the IP address by connecting to the Switch Module via the local console. Refer to the following

examples, you can configure them.

AOS CLI

ISCLI

46

Page 75

(English)

from the DHCP server overrides the static IP address. When

assigning the IP address manually, disable the dhcp.

User account

Description

Password

(Default)

user

The user can view all the Switch Module status information and statistics,

but cannot make any configuration changes to the Switch Module. The

user account is enabled by default.

user

oper

The operator manages all functions of the Switch Module, but these

changes will be lost when the Switch Module is rebooted/reset. By

default, the operator is disabled and has no password.

-

admin

The administrator has complete access to all menus, information, and

configuration commands on the Switch Module. The admin account is

enabled by default.

admin

NOTE: It is recommended that you change the passwords after initial

configuration.

User access levels

The Switch Module provides three levels for user access. The default user names/passwords for each access level

is listed in the following table.

47

Page 76

(English)

Troubleshooting

This section describes the action to be taken at an occurrence of trouble. If the Switch Module still fails to operate,

contact your service representative.

Fails to insert or remove the Switch Module.

1. Make sure that there is no foreign object inside the Switch Module slot.

2. Make sure that you have installed the Switch Module in the right direction.

A switch module does not work.

1. See “Connection with CPU Blade” (page 37) to make sure that the Switch Module, slot for onboard

LAN or mezzanine card, and cable connections are correctly installed in the Blade Enclosure.

2. Make sure that you have properly installed the Switch Module in the Blade Enclosure.

3. Make sure that power is supplied throughout the system, including the Switch Module.

The STATUS LED goes on amber, not green.

1. Make sure that the Switch Module has been installed properly.

2. If the STATUS lamp does not go on when installing the Switch Module, remove the Switch Module

from the Blade Enclosure, and then install it again.

3. When installed in the Blade Enclosure (6U), an error message is displayed on the SIGMABLADE

monitor. Refer to the User’s Guide of the EM Card. Or, contact your service representative according

to the error type indicated.

The local console is disabled.

1. Make sure that the cross cable used for connection is the specified one.

2. Make sure that the communication parameters for the local console are properly specified.

3. Make sure that power is supplied throughout the system, including the Switch Module.

The remote console is disabled.

1. Make sure that the connection between the Switch Module and the remote console is correct.

2. Make sure that the remote console is properly configured including an IP address.

3. Make sure that power is supplied throughout the system, including the Switch Module.

Fails to establish a link. (The LINK/ACT LED indicator does not turn on.)

1. Make sure that the cable has been connected properly.

2. See "Network Cables" (page 38) to make sure that your cable meets the specification required.

3. Make sure that the communication mode of link partners (e.g. switch) is set for Auto Negotiation or

1000Mbps/Full Duplex.

4. Make sure that you are using a correct driver in the CPU Blade.

5. Confirm the error logs on the link partner side.

Switch Module Reduce Recovered trap is notified by the EM card.

1. When installing the Switch Module in the Blade Enclosure or powering on the Blade Enclosure that

contains the Switch Module while the trap notification is enabled in the EM card, Switch Module

Reduce Recovered trap is notified by the EM card. This does not cause any trouble, and you can

48

Page 77

(English)

continue operation.

Network adapter Teaming feature of the CPU Blade does not work.

1. Once the teaming adapter is removed, make sure that each interface is available.

2. Make sure that the teaming is correctly configured and the network is correctly deployed, if it is not

available only by using the teaming feature.

3. Turn off Spanning Tree Protocol on the port connected to the network adapter when using "Adapter

Fault Tolerance" (AFT).

49

Page 78

Product name

10Gb Intelligent L3 Switch

Product code

N8406-026

Interface

10GBase-SR (Port 1-16, 18-21(XFP module slot))

10Base-T/100Base-TX (Port 17)

Connector

XFP module slot

Port

16 ports

1 port

4 ports

(for CPU Blade)

(for management)

(for uplink)

Power consumption

70W Max

Environmental requirements

Temperature

10 to 35 ℃

Humidity

20 to 80 % RH (no condensation)

External dimensions

387(W) x 268(D) x 28(H) mm

Weight

2.72 kg

(English)

Specification

50

Page 79

Page 80

N8406-026

10GbE インテリジェントスイッチ(L3)ユーザーズガイド

10Gb Intelligent L3 Switch User’s Guide

2008 年 7 月 (第 1 版)

July 2008 (1st Edition)

日本電気株式会社

NEC Corporation

東京都港区芝 5 丁目 7 番 1 号

TEL(03)3454-1111(大代表)

7-1 Shiba 5-Chome, Minato-Ku

Tokyo 108-8001, Japan

このマニュアルは再生紙を使用しています

This guide is made from recycled paper.

855-900672- - A

*855-900672- - AB*

456-01796-000

PN# 456-01796-000

Loading...

Loading...