Page 1

SERVER MH4500

()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Page 2

xxx

Page 3

SERVER MH4500

()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Page 4

Proprietary Notice and Liability Disclaimer

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Computers Inc. and/or its licensors. NEC Computers Inc.

and/or its licensors, as appropriate, reserve all patent, copyright and other proprietary rights

to this document, including all design, manufacturing, reproduction, use, and sales rights

thereto, except to the extent said rights are expressly granted to others.

The NEC Computers Inc. product(s) discussed in this document are warranted in

accordance with the terms of the Warranty Statement accompanying each product.

However, actual performance of each such product is dependent upon factors such as

system configuration, customer data, and operator control. Since implementation by

customers of each product may vary, the suitability of specific product configurations and

applications must be determined by the customer and is not warranted by NEC Computers

Inc.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC Computers Inc. is prohibited.

Trademarks

Intel is a registered trademark of Intel Corporation.

MS-DOS is a registered trademark of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation.

All other trademarks belong to their respective owners.

PN: 456-00008-003

Copyright 1998, 1999, 2000

NEC Computers Inc.

15 Business Park Way

Sacramento, CA 95828

All Rights Reserved

NEC

Page 5

Contents

Proprietary Notice and Liability Disclaimer.....................................................................vii

Using This Guide........................................................................................................... viii

Text Conventions .............................................................................................................ix

Related Documents............................................................................................................x

Safety Notices..................................................................................................................xi

Safety Notices for Users Outside of the U.S.A. and Canada........................................xii

Care and Handling......................................................................................................... xiii

System Overview................................................................1-1

System Chassis Features................................................................................................ 1-3

Power Supplies......................................................................................................... 1-4

System Cooling........................................................................................................ 1-4

Peripheral Bays ........................................................................................................ 1-5

System Board Features.................................................................................................. 1-5

Pentium II Xeon Processor ....................................................................................... 1-7

System Memory ....................................................................................................... 1-7

I/O Expansion Slots.................................................................................................. 1-7

Real-Time Clock/Calendar....................................................................................... 1-8

BIOS........................................................................................................................ 1-8

IDE Controller.......................................................................................................... 1-8

SCSI Controllers ...................................................................................................... 1-9

Video Controller..................................................................................................... 1-10

Peripheral Controller.............................................................................................. 1-10

External Device Connectors.................................................................................... 1-11

System Board Management Controller (BMC)........................................................ 1-11

System Security Features............................................................................................. 1-11

Mechanical Locks and Monitoring.......................................................................... 1-11

Software Locks....................................................................................................... 1-11

Setting Up Your System .................................................... 2-1

Selecting a Site.............................................................................................................. 2-2

Unpacking the System................................................................................................... 2-3

Getting Familiar with the System................................................................................... 2-4

Installing the System......................................................................................................2-7

Connecting Peripherals.................................................................................................. 2-7

Connecting the Power Cords.......................................................................................... 2-7

Powering On the System................................................................................................ 2-8

Converting to a Rack Mount Server Unit..................................................................... 2-10

Equipment Rack Warnings and Cautions................................................................ 2-11

Converting the System Pedestal Unit...................................................................... 2-12

Preparing the Rack................................................................................................. 2-18

Installing the Rack Unit in the Rack........................................................................ 2-21

Contents iii

Page 6

Configuring Your System...................................................3-1

Using the BIOS Setup Utility......................................................................................... 3-3

Main Menu............................................................................................................... 3-4

Advanced Menu....................................................................................................... 3-6

Security Menu........................................................................................................ 3-10

Server Menu........................................................................................................... 3-12

Boot Menu............................................................................................................. 3-14

Exit Menu.............................................................................................................. 3-16

Using the Symbios SCSI Utility................................................................................... 3-16

Running the Symbios SCSI Utility.......................................................................... 3-16

Changing the Adapter and Device Configurations................................................... 3-17

Using the Optional RAID Controller............................................................................ 3-20

Factory Installed Controller .................................................................................... 3-20

Add-on Controller.................................................................................................. 3-20

DACCF Configuration Utility................................................................................. 3-21

Configuring System Board Jumpers............................................................................. 3-22

Moving System Board Jumpers.............................................................................. 3-23

Resetting the CMOS NVRAM................................................................................ 3-24

Clearing and Changing Passwords.......................................................................... 3-24

Upgrading Your System.....................................................4-1

Observing Static Precautions......................................................................................... 4-2

Preparing Your System for Upgrade.............................................................................. 4-3

Preparing the Equipment Log........................................................................................ 4-3

Removing the Access Cover.......................................................................................... 4-4

Installing the Access Cover.......................................................................................4-5

Opening the Subchassis and Electronics Bay.................................................................. 4-6

Closing the Subchassis and Electronics Bay.............................................................. 4-7

Upgrading the System Board......................................................................................... 4-8

Replacing the Real-time Clock Battery..................................................................... 4-8

Installing/Removing the Processor Cartridge........................................................... 4-10

Installing DIMM Modules...................................................................................... 4-14

Installing Option Boards.............................................................................................. 4-19

Installation Considerations...................................................................................... 4-20

Controller/Adapter Hardware Configurations.......................................................... 4-21

Installing an Option Board...................................................................................... 4-21

Removing an Option Board.................................................................................... 4-22

Installing Hard Disk Drives......................................................................................... 4-24

Installing an Optional SCSI Hard Disk Drive.......................................................... 4-25

Hot-Swapping a SCSI Hard Disk Drive.................................................................. 4-26

Installing Removable Media Devices........................................................................... 4-27

Installing a 5 1/4-Inch Media Device...................................................................... 4-28

Removing a 5 1/4-Inch Media Device..................................................................... 4-30

Solving Problems................................................................5-1

Static Precautions.......................................................................................................... 5-2

Troubleshooting Checklists............................................................................................ 5-2

Initial System Startup............................................................................................... 5-3

Running New Application Software.......................................................................... 5-4

After System Has Been Running Correctly............................................................... 5-4

iv Contents

Page 7

Additional Troubleshooting Procedures......................................................................... 5-5

Preparing the System for Diagnostic Testing.............................................................5-5

Monitoring POST..................................................................................................... 5-6

Verifying Proper Operation of Key System Indicators...............................................5-7

Confirming Loading of the Operating System ........................................................... 5-7

Specific Problems and Corrective Actions ..................................................................... 5-7

Power LED Does Not Light...................................................................................... 5-8

No Beep Code.......................................................................................................... 5-8

No Characters Appear on Screen .............................................................................. 5-8

Characters are Distorted or Incorrect......................................................................... 5-9

System Cooling Fan(s) Does Not Rotate................................................................... 5-9

Diskette Drive Activity LED Does Not Light.......................................................... 5-10

Hard Disk Drive Activity LED Does Not Light....................................................... 5-10

CD ROM Drive Activity Light Does Not Light....................................................... 5-11

Problems with Application Software....................................................................... 5-11

Press F2 Key to Enter Setup: Prompt Does Not Display.......................................... 5-11

Bootable CD-ROM Is Not Detected........................................................................ 5-13

Problems with the Network..................................................................................... 5-14

PCI Installation Tips.................................................................................................... 5-14

BIOS User’s Information............................................................................................. 5-15

Error and Status Messages...................................................................................... 5-15

Messages and Beep Codes...................................................................................... 5-17

POST Error Codes and Messages............................................................................ 5-21

System Cabling..................................................................A-1

Before You Begin..........................................................................................................A-2

Static Precautions..........................................................................................................A-2

Standard Configuration..................................................................................................A-2

Power Cabling..........................................................................................................A-3

Diskette Drive Data Cabling.....................................................................................A-3

SCSI Cabling............................................................................................................A-3

RAID Configuration......................................................................................................A-5

System Setup Utility...........................................................B-1

Creating SSU Diskettes.................................................................................................B-3

Running the SSU...........................................................................................................B-3

Customizing the SSU................................................................................................B-4

Launching a Task.....................................................................................................B-5

Resource Configuration Add-in (RCA) Window.......................................................B-6

Defining an ISA Board.............................................................................................B-7

Adding and Removing ISA Boards...........................................................................B-8

Modifying Resources................................................................................................B-8

Recommended Resource Settings.............................................................................B-9

System Resource Usage..........................................................................................B-11

Multiboot Add-in (MBA) Window.........................................................................B-11

Password Administration (PWA) Window..............................................................B-12

System Event Log (SEL) Window ..........................................................................B-12

Sensor Data Record (SDR) Manager Add-In Window............................................. B-13

Field Replaceable Unit (FRU) Manager Add-In Window ........................................B-14

Exiting the SSU...........................................................................................................B-14

Contents v

Page 8

Emergency Management Port...........................................C-1

How the EMP Works.....................................................................................................C-2

EMP Requirements and Configurations .........................................................................C-5

Setting Up the Server for the EMP.................................................................................C-6

System Management Submenu.................................................................................C-6

Console Redirection Submenu..................................................................................C-6

Main EMP Window.......................................................................................................C-7

Toolbar .................................................................................................................... C-7

Status Bar.................................................................................................................C-7

EMP Console Main Menu ........................................................................................C-8

Server Control Operations ........................................................................................C-8

Phonebook...................................................................................................................C-12

Management Plug-ins ..................................................................................................C-13

SEL Viewer............................................................................................................C-13

SDR Viewer...........................................................................................................C-14

FRU Viewer...........................................................................................................C-15

FRU and SDR Load Utility..........................................................................................C-16

When to Run the FRUSDR Load Utility................................................................. C-16

What You Need to Do............................................................................................ C-17

How You Use the FRUSDR Load Utility................................................................C-17

Cleaning Up and Exiting.........................................................................................C-21

Glossary

Equipment Log

vi C ont ents

Page 9

System Overview

Syst em Ch assis F eatures

System Board Features

System Security Features

1

Page 10

The MH4500 System is a modular, multiprocessing server based on the

Intel Pentium® II Xeon™ microprocessor. The combination of compute

performance, memory capacity, and integrated input/o ut put (I/O) provides a

high performance environment for many server market applications. These

range from large corporations supporting remote offices to small companies

looking to obtain basic connectivity capability such as file and print services,

email, web access, and web site server.

As application requirements increase, you can expand your server with

additional processors, memory, add-in boards, and peripheral devices (such as

tape devices and hard disk drives).

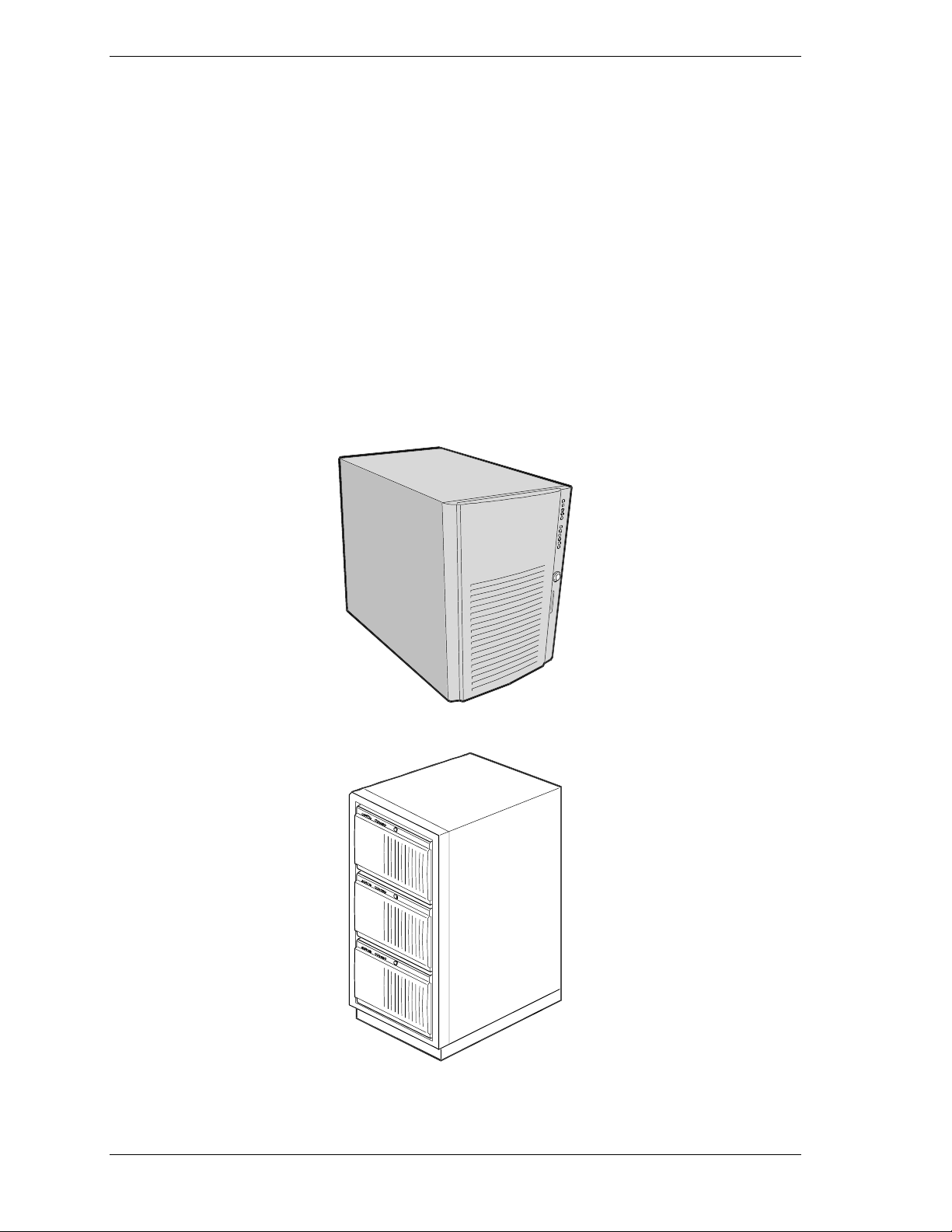

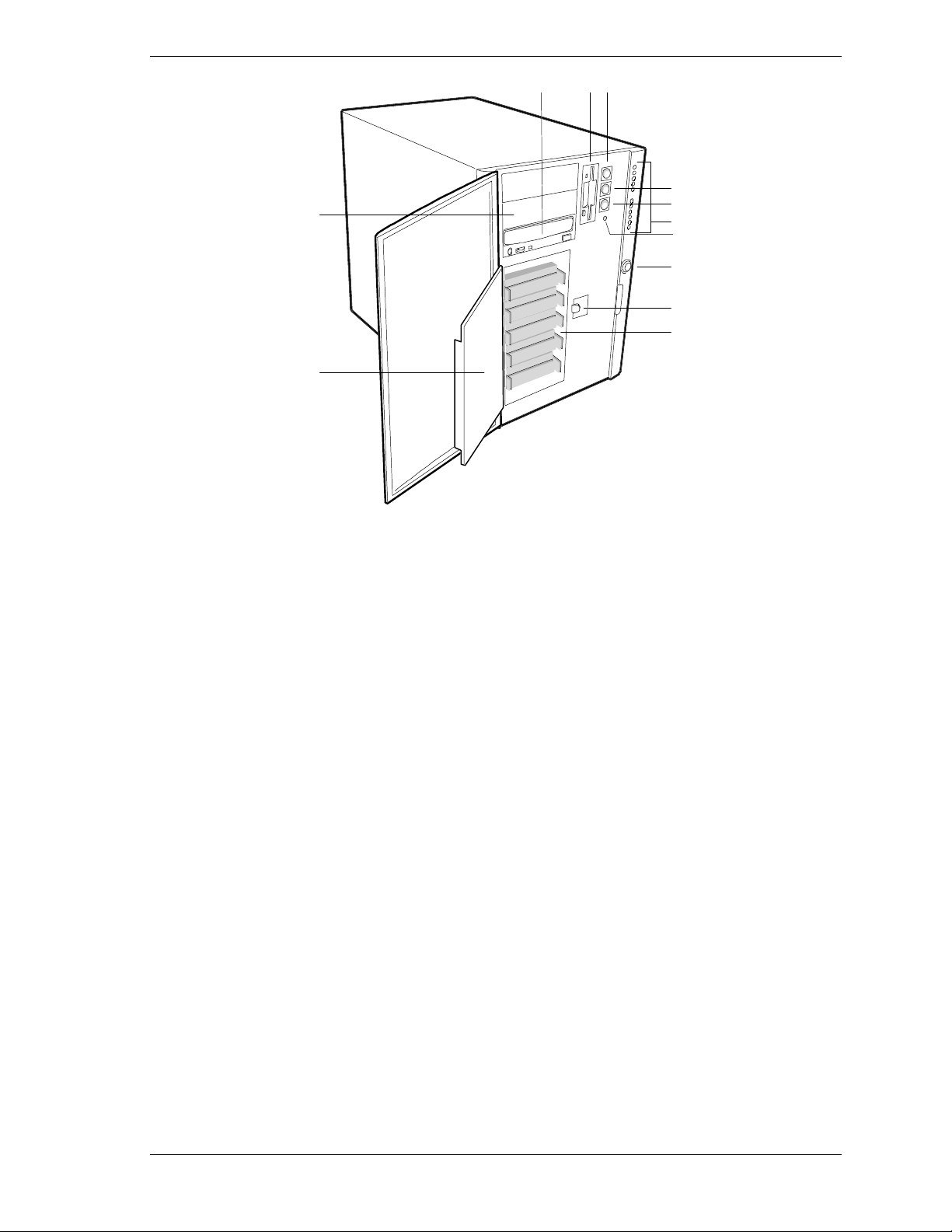

The server is available in two configurations: a stand-alone pedest al system and

a rack system. The pedesta l syste m can be converted to a rack-mounted system

using an optional rack mount kit. Both configurations use the same components

(except there is no outer covers on the rack unit). The following figures show

the pedestal system and a rack system mounted in a rack.

Rack Mounted Server System (three servers shown)

1-2 System Overview

Stand-A lon e Pedestal Server Sys t em

Page 11

Your server features the following major components:

up to four high-performance Pentium II Xeon pro cessors, each packaged

in a Single Edge Connector (S.E.C.) cartridge

integrated 512 KB or 1 MB secondary cache integrated in the S.E.C.

cartridge

128 MB to 4 GB of memory, using up to sixteen dual-inline memory

modules (DIMMs)

six PCI expansion slots for add-in boards (one slot shared with an ISA

slot; one slot for half-length PCI boards).

one half-length ISA expansion slot for add-in boards (shared with a PCI

slot)

onboard Cirrus Logic CL-GD5480 Super Video Graphics Array (SVGA)

controller

2 MB of video DRAM memory

onboard s ingle channel enhanc ed I DE cont r oller

onboard Symbio s SYM53C 810AE sing le channel na rrow S C SI contr oller

on the PCI-A bus providing a narrow SCSI interface for 5 1/4-inch

devices

onboard Symbios SYM53C896 dual-channel wide SCSI controller on the

PCI-B bus providing an ultra 2 wide SCSI interface for 3 1/2-inch

devices

1.44MB diskette drive

SCSI CD-ROM drive

six S C SI hot s wap ha rd disk d rive expansio n bays

SCSI single connecto r att achment ( S CA) compatible backplane that

provides continuous fast/w ide ultra 2 S CS I bus for access t o all ho t-swap

drive ba ys

three 5 1/4-inch bays for removable media devices

PS/2-compatible mouse and keyboard ports

VGA video port

one Universal Serial Bus (USB) port.

System Chassis Features

The system chassis is an easy-to-expand, fabricated metal struct ure housing the

power supplies, fans, expansion bays, system board, and supporting

components. A key feature o f the chassis is t he “swing-out” electronics bay and

subchassis modu les, allowing easy access to t he interior of the system.

System Overview 1-3

Page 12

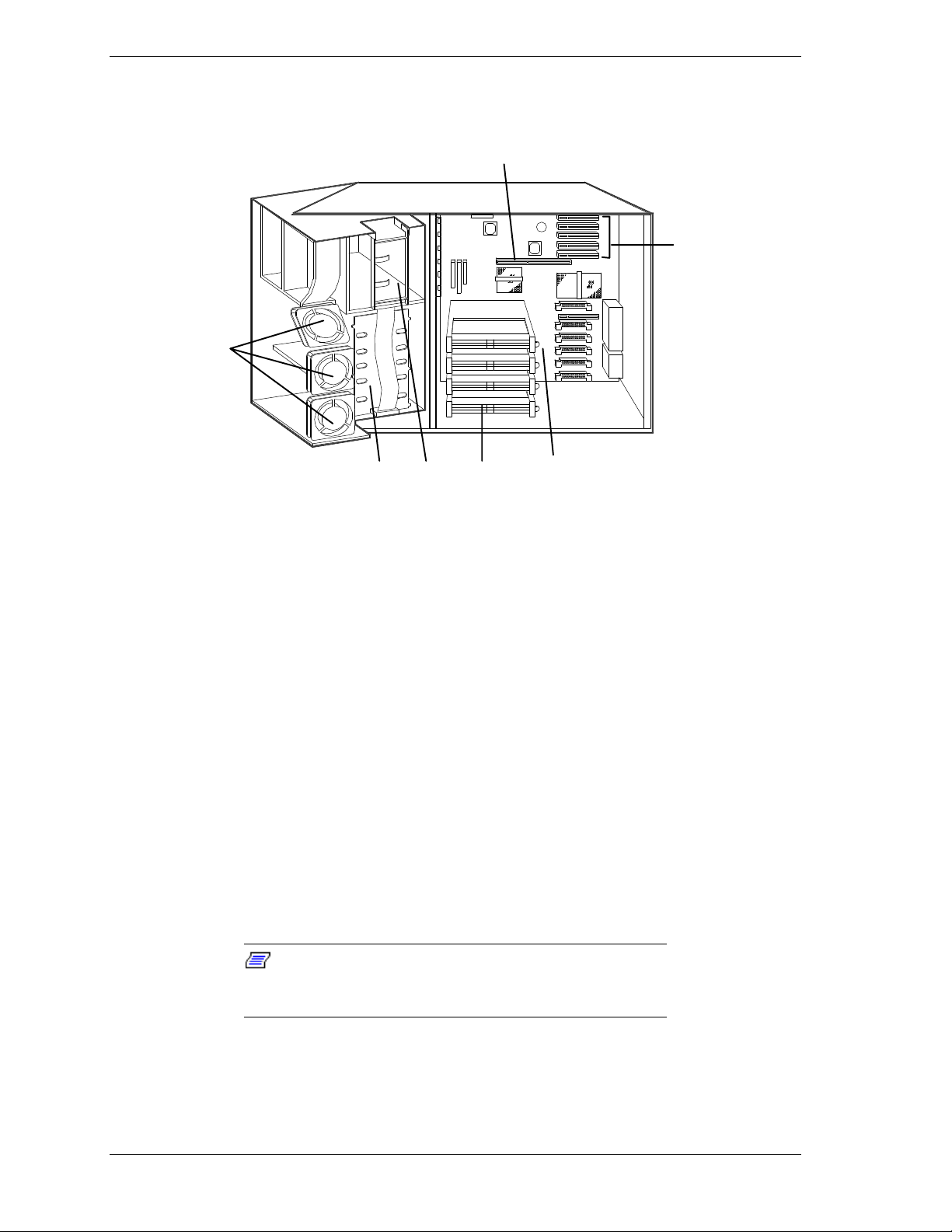

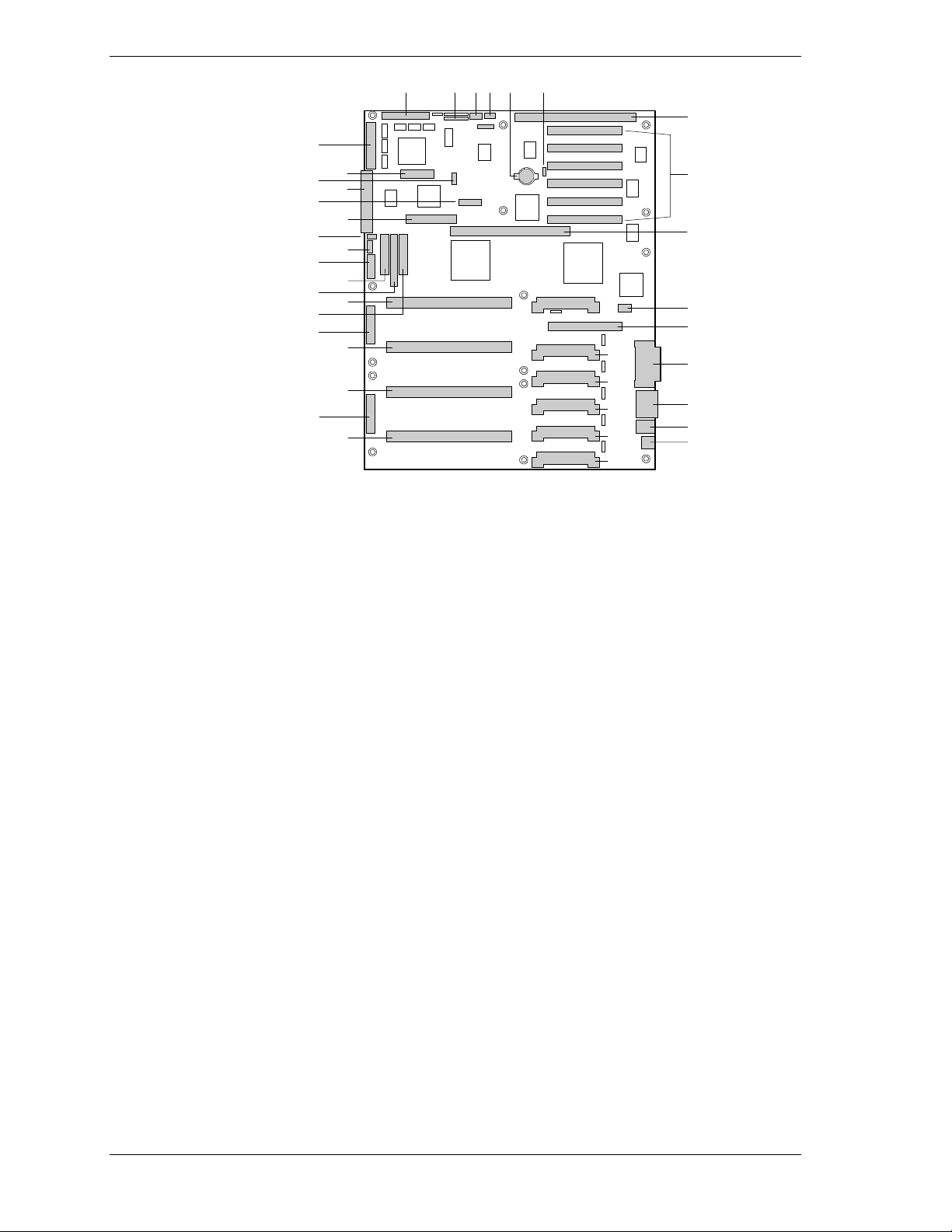

Several major syste m co mponent locations are shown in the fo llowing figure

and briefly described in the following paragraphs.

G

F

A

BC D E

A. Fans (8) E. System Board

B. SCSI Backplane F. Expansion Board Connectors

C. Removable Media Device Bays (3) G. Memory Module Connector

D. S.E.C. Processor Bays (4)

Power Supplies

Two 400 watt auto-voltage-sensing power supplies provide system power. Each

operates at 115 or 230 Vac at an operating frequency of 50/60 Hz. Both supplies

are designed to operate together during system operation. Both power supplies

comply w ith ex is ting emis sions standards and pro vid e s uff icie nt power for a

fully loaded system configuration. An optional third power supply can be added

to the system as a backup unit.

System Cooling

The chassis houses eight fans for cooling and airflow.

the chassis access cov er m ust be installed whenever the

system is running.

Note:

System Chassi s

To maintain proper system cooling and air flow,

1-4 System Overview

Page 13

Peripher al B ay s

The system supports a variety of standard PC AT-compatible peripheral devices.

The chassis includes the following peripheral bays:

3 1/2-inch front panel bay for mounting the standard 3 1/2-inch diskette

drive (supports 720 KB and 1.44 MB diskettes)

three 5 /14-inch removable media device front panel bays for mounting

one inch high 5 1/4-inch peripheral devices, including the standard SCSI

CD ROM drive.

Note:

recommended due t o cooli ng r estr aints and EMI

requirements.

six internal hard disk drive bays for mounting up to six, one inch high,

M

ounting a hard drive in the 5 1/4-inch bay is not

SCSI hot-swap hard disk drives.

System Board Features

The system board features processor and memory subsystems residing on the

board. The following figure shows the components on the system board. Brief

descriptions of the major components follow the figure.

System Overview 1-5

Page 14

MM

CDA E FB

G

LL

KK

JJ

II

HH

GG

FF

EE

DD

CC

AA

BB

P

Z

Y

X

W

V

Q

R

S

T

U

A. Wide SCSI B Connector U. VRM Connector for Processor 1

B. System Jumpers V. Processor 1, Slot 2 Connector

C. Hard Drive Input LED Connector W. Main Power Connector

D. System Speaker Connector X. Processor 2, Slot 2 Connector

H

I

J

K

L

M

N

O

E. Lithium Battery Y. Processor 3, Slot 2 Connector

F. Wake-on LAN Connector Z. Main Power Connector

G. ISA Slot AA. Front Panel Connector

H. PCI Slots B4, B3, B2, B1, A3, A2 BB. Processor 4, Slot 2 Connector

I. Memory Module Connector CC. IDE Connector

J. ICMB Connector DD. Diskette Drive Connector

K. PCI Slot A1 EE. Au xiliary Power Connector

L. Video and Parallel Port Connectors FF. USB Internal Header

M. Serial Port Connector GG. SMBus Connector

N. Keyboard and Mouse Connector HH. F16 Expansion Connector

O. USB Connector II. ITP Connector

P. VRM Connector for Processor 4 JJ. Narr ow SCSI Connector

Q. VRM Connector for Processors 4 and 3 KK. External IPMB Connector

R. VRM Connector for Processor 3 LL SMM Connector

S. VRM Connector for Processor 2 MM. Wide SCSI A Connector

T. VRM Connector for Processors 2 and 1

1-6 System Overview

System Board

Page 15

Pentium II Xeon Processor

The system board support s up to four Pentium II Xeon processo r s, each

packaged in a Single Edge Contact (S.E.C.) cartr idge. The cartr idge includes t he

processo r core with an integrated 16 KB primary (L1) cache; the secondary (L2)

cache; a thermal plate; and a back cover. T he processor implements the MMX™

technolog y and the processor’s numeric coprocessor signific antly increases the

speed of floating-point operations.

The processo r exter nal inter face operates at 100 MHz. The second-level cache is

located on the substrat e of the S.E. C. cart r idge. The cache inc ludes burst

pipelined synchronous st at ic RAM (BSRAM). T he L2 cache is offered in 512

KB and 1 MB configurations, with error correcting code (ECC) that operates at

half the core clock rate.

The processors are supported by one or more voltage regulator modules (VRM)

on the system board, with the number of VRMs dependent on t he number of

processors installed.

Each S.E.C cartridge connects to the system board through a 330-pin Slot 2

edge connector. The Slot 2 connectors are arranged in a vertical stack o f four on

the system board. The VRM modu les are located adjacent to the processors.

System Memory

S ystem m emory is mounted on a memory module that connects to t he system

board. The module contains sixteen 168-pin DIMM sockets arranged in four

banks. Up to 4 GB of EDO DIMM memory is supported, with 32 MB being the

minimum (the system ships with a minimum of 128 MB). The memory module

supports a 64/72 bit four-way-interleaved pathway to main memory on the

module and supports 4:1 interleaving.

System memory begins at address 0 and is continuous (flat addressing) up to the

maximum amount of DRA M installed (excep tion: s ys te m memory is

noncontiguous in the ranges defined as memory holes using configuration

registers). The system supports both base (conventional) and extended memory.

The system BIOS automatically detects, sizes, and initialize s the memory array,

depending on the type, size, and speed of the insta lled DIMMs. The BIOS

reports memory size and allocat ion to t he syst em via configuration register s.

The memory module connects to the system board through a 242-pin connector.

I/O Expansion Slots

The server's expansio n capab il it ies meet t he needs o f file and application servers

for high performance I/O by providing a combination of PCI local bus and ISA

connectors.

The system boar d has o ne full- le ngt h IS A bus connector. The co nnector shares a

chassis expansion slot with a PCI connector and supports half-length ISA

boards.

System Overview 1-7

Page 16

ISA features include:

bus speed up to 8.33 MHz

16-bit memory addressing

Type A transfers at 5.33 MB/seco nd

Type B transfers at 8 MB/ second

8- or 16-bit data transfers

Plug and Play ready.

The system board has two 32-bit PCI bus segments: PCI-A and PCI-B. The

segments provide seven PCI connectors, three on PCI-A and four on PCI-B.

PCI-A supports half-length boards only and PCI-B supports full-length boards.

One of the PCI-B connectors shares a chassis expansion slot with an ISA

connector.

PCI features include:

bus speed up to 33 MHz

32-bit memory addressing

5 V signaling environment

burst transfers of up to 133 Mbps

8-, 16-, or 32-bit data transfers

Plug and Play ready

parity enabled.

Real-Time Clock/Calendar

The real-time clock provides syste m clock/calendar information stored in a nonvolatile memory (NVRAM). The replaceable real-time clock battery provides

power backup for the real-time clock.

BIOS

A BIOS and Setup Utility are located in the Flash EP ROM on the system board

and include support for system setup and PCI/ISA Plug-and-Play autoconfiguration. A number of security, re liabilit y, and manageme nt featur es also

have been incorpor at ed to meet vita l server needs.

IDE Controller

The system includes a single channel enhanced IDE interface controller. The

controller has a primary co nnect or locat ed o n the system boar d that suppo rts a

master and a slave device.

1-8 System Overview

Page 17

The IDE controller featur es:

PIO and IDE DMA/bus master operations

Mod e 4 timings

transfer rates up to 22 MB/second

buffering for PCI/IDE burst transfers

master/slave I DE mo de.

SCSI Controllers

The system board contains two SCSI controllers: a narrow SCSI controller

(SYM53C810AE) on the PCI-A bus, and a dual-channel wide LVD/SE

(Ultra2/Ultra) SCSI controller (SYM53C896) on the PCI-B bus. The narrow

controller provides support for legacy 8-bit SCSI devices in the 5 1/4-inch drive

bays, including the factory inst alled SCSI CD-ROM dr ive . The wide c ontrolle r

drives one SCSI backplane and provides support for external expansion.

Internally, each wide channel is ident ical, capa ble o f operat ions using either

8- or 16-bit SCSI providing 10 MB/sec (Fast-10) or 20 MB/sec (Fast-20)

throughput, or 20 MB/sec (Ultra), 40 MB/sec (Ultra-wide) or 80 MB/sec

(40 MHz) (Ultra-2).

The SYM53C810AE (narrow) contains a high-performance SCSI cor e capable

of Fast 8-bit SCSI transfers in single-ended mode. It provides programmable

active negation, PCI zero wait-state bursts of faster than 110 MB/sec at 33 MHz,

and SCSI transfer rat es fro m 5 to 10 MB/sec. The narrow SCSI comes in a

100-pin rectangular plastic quad flat pack (PQFP).

The Sym53C896 (wide) contains a high-performance SCSI bus interface. It

supports SE mode with 8-bit (10 or 20 MB/sec) or 16-bit (20 or 40 MB/sec)

transfers and LVD mode with 8-bit (40 MB/sec) or 16-bit (80 MB/sec) transfers

in a 329-pin ball grid array (BGA) package.

Each controller has its own set of PCI configurat ion registers and SCSI I / O

registers. As a PCI 2.1 bus master, the SYM53C896 supports burst data

transfers on PCI up to the maximum rate of 132 MB/second using on-chip

buffers.

In the hot-swap bay, the system supports up to six, one-inch high SCSI hard disk

drives. Also, in the 5 1/4-inch bays, the system supports three SCSI or IDE

devices (the SCSI controller itself supports more devices, but the 5 1/4-inch bay

can only hold a maximum of three devices).

A wide SCSI cable provides two connecto r s for Ultra SCSI devices, one of

which is used for the SCSI backplane. However, S CSI devices do not need to

operate at the ultra transfer r ate. All drives on the bus must be Ultra-2 ( LVD) to

run at 80 MB/sec (40 MHz). The 5, 10, and 20 MHz operations can coexist on

the bus and each device interact s at its appro pr iate speed.

System Overview 1-9

Page 18

No logic, termination, or resistor loads are required to co nnect devices to the

SCSI controller other than terminat ion in the device at the end of the cable. The

SCSI bus is terminated o n t he system boar d with active terminators that can be

disabled.

Video Controller

The system has an onboard integrated Cirrus Logic CL-GD5480 64-bit highperformance SVGA subsystem that supports the following:

BIOS compatibility with VGA, EGA, CGA, Hercules Graphics, and

MDA

2 MB of 10 ns video random access memory (VRAM) video buffer

16-bit bus for high-speed displa y memor y access

hardware accelerated bit block transfers ( BITBLT)

display power management system

supports 100 Hz refresh, non-interlaced at 640x480, 800x600, 1024x768,

1240x1024, and 1600x1200 resolutions

displays up to 16 million colors at 640x480 and 800x600 resolutions,

64K colors at 1024x768 resolutions, and 256 colors at 1280x1024

resolutions.

Peripher al C o ntroller

The advanced integrated peripheral contro ller supports two serial ports, one

parallel port, diskette drive, PS/2-compatible keyboard and mouse, and

integrated Real Time Clock (RTC). The system provides the connector interface

for each port.

Serial Ports

Both serial ports ar e relocat able. E ach serial port can be set to one of four

different COM ports and can be enabled separately. When disabled, serial port

interrupts are available to add- in boards.

Parallel Port

One IEEE 1284-compatible 25-pin bidirectional EPP (supporting levels 1.7 and

1.9) parallel port is provided. BIOS programming enables the parallel port and

determines the port address and interrupt. When disabled, the interrupt is

available to add-in boards.

1-10 System Overview

Page 19

External Device Connectors

The external I/O connectors provide support for a PS/2 compatible mouse and a

keyboard, connector for VGA monitor, two serial port connectors, a parallel port

connector, and a USB connector.

System Board Management Controller (BMC)

Ser ver ma nagement is controlled by the Syste m Board Ma na gement Co ntroller

(BMC). The BMC and asso ciated circuits are power ed from a 5Vdc standby

voltage, which remains active when system power is switched off.

The BMC supports the Emergency Management Port (EMP) Console which

allows remote se rver management via a modem or direct con ne ction to a

manager system. Events monitored by the manager system include overtemperature and over-voltage co nd it ions, fan failure, o r chassis intrus io n.

Infor mation on the Emerg enc y M anagement Port (E M P) Console is inclu ded in

Appendix C, “Emergency M anag ement Port.”

System Security Features

To help prevent unauthor ized entr y or use of the syste m, the syst em includes a

three-po sit ion key lock/switch combination to permit selected access to the drive

bays. The system also includes Server Ma nagement software that monitors t he

chas s is int r u s io n mic r o sw it c h.

Mechanical Locks and Monitoring

The chassis intrusion micro switch is activated whenever the system’s access

cover is removed (pedestal system only). When the access cover is removed, the

switch tr ansmits an a larm signal to the system board, where server management

software processes the sig na l. The alarm syste m softwar e can be progr ammed t o

respond to an intrusion by powering down the system or by locking the

keyboard.

Software Locks

The BIOS Setup Utility and the Syste m Setup Utility (SSU) pro vide a number

of security features to pr event unautho r ized or accide nt al access to the system.

Once the security measures are enabled, access to t he system is allowed only

after the user enters the co rrect password(s). For example, t he SSU allows you

to:

enable the keyboard locko ut timer so t hat t he server requires a password

to reactivate the keyboard and mouse after a specified t ime-out per iod

(1 to 120 minutes)

set and enable administ r ato r and user passwords

set secure mode to prevent keyboard or mouse input and to prevent use of

the front panel reset and power switches

System Overview 1-11

Page 20

activate a hot-key combination to enter secure mode quickly

disable writing to the diskette dr ive when secure mode is set.

Further informat ion on the secur it y features is conta ined in

Chapter 3, “Configuring Your System.”

1-12 System Overview

Page 21

Setting Up Your System

Selecting a Site

Unpacking the System

Getting Familiar with the System

Installing the System

Connecting Peripherals

Connecting the Power Cords

Powering on the System

Converting to a Rack Mount Server Unit

2

Page 22

Your system ships as a st and-a lone, single ser v er pedestal unit or as a rack unit

ready to install in a rack. The pedestal system can also be convert ed to a rackmounted server unit using a rack conversion kit (not supplied). You can

purchase the kit from your dealer.

The information in this chapter pertains to bot h configurations. Where

differences occur bet ween configurat ions, they are noted.

Use this chapter to guide you in

selecting a site

unpacking the system

becoming familiar with the system

installing the syste m

connecting peripherals

connecting power cords

powering on the system

converting the system to a rack-mounted server unit.

Selecting a Site

The system operates r eliably in a t ypical o ffice en vironme nt . Choo se a site that

meets the following requirements.

Install the syste m near two or more grounded, three-pronged power

outlets, preferab ly on separ ate electrical circuits.

Note:

NEMA 5-15R outlets for 100-120 Vac or NEMA 6-15R

outlets for 200-240 Vac. For other international sites, this

means three-pronged power outlets applic able for the

electrical c ode of t he r egion.

Be sure the power service connec tion is through a properly

grounded outlet.

For the United States and Canada, this means

!

WARNING

The site must be clean, dust-free, and well vent ilated. Keep the front and

rear ventilation op enings free o f obstr u ctions and away from sources of

heat, vibration, or physical shock.

2-2 Setting Up Your System

Page 23

The site must be isolated from strong electromagnetic fields and electrical

noise produced by electrical devices such as air cond it ioners, large fans,

large electric motors, radio and TV transmitters, and high-frequency

security devices.

Provide at least eight inches (20.32 centimeter s) beh ind t he system and

three inches (eight centimeters) on each side of the syste m for prop er

cooling, airflow, and cable clearance.

Site the syste m so that it is easily accessible for system maintenance and

installation of system upgrades.

With the site selected, unpack and set up the system as described next.

Unpacking the System

!

WARNING

Your system weighs approximately 85 pounds (38.25 kg),

minimum confi gur ation. If your system contains optional

boards and peripheral devices, it may weigh up to 100

pounds (45.4 kg). To avoid per sonal injury, make sure you

have someone help you lif t or m ov e the system.

When you receive your syste m, inspect the shipping carton(s) pr ior to

unpacking. If the shipping carton(s) is damaged, note the damage, and if

possible, photograph it for reference.

After removing the cont ent s of the carton(s) , inspect for damage. If the contents

appear damaged, file a damage claim with the carrier immediately. Keep the

cartons and the packing materials.

Check that you have all the parts listed on the packing slip. If any are missing,

contact the dealer where you purchased the system.

Set the system where you can easily look at t he fro nt and rear. Take a few

minutes and become familiar with the system’s controls, indicators, and

connector s ( see “Getting Familiar with the S yst em,” next).

Setting Up Your System 2-3

Page 24

Getting Familiar with the System

Before setting up your system, you should become familiar with the system’s

features, such as the locat ion of your syst em's front and rear panel switches,

indicato r s, and connectors.

Front View

The following figure shows locations of controls and indicat ors on the front of

the system. A brief descr ipt ion of the cont rols and indicators follows the figure.

Note:

indicators are shown in t he following front and rear vi ew

figures. All controls and indicators shown on the stand-alone

unit are the same on the rack unit ex c ept f or orientation, as

the unit is mounted in the rac k on its side.

The stand-alone serv er unit and it s cont r ols and

2-4 Setting Up Your System

Page 25

ABC

D

L

E

F

G

H

I

J

K

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

CD-ROM Drive Standard, factory-installed CD-ROM Drive

Diskette Drive Standard, factory-installed 3 1/2-inch diskette drive.

Power On/Off Button Press to turn system DC power on or off.

Sleep/Service Button Press to put system in power saving mode or service

mode.

Reset Button Press to reset system.

Front Panel LEDs (starting at top)

Power On

Disk Bay Power On

Hard Disk Activity

Fan Failure

Power Supply Failure

Six Hard Drive LEDs

(labeled 0 - 5)

NMI Button Used for system troubleshooting by qualified technical

System Security Lock Key operated lock to prevent unauthorized access to

EMI Shield Lock Latches metal EMI shield door.

Internal Drive Bays Holds up to six 1” high SCSI hot-swap hard disk drives.

Metal EMI Shield EMI shield for SCSI hard drives.

When lit (green), DC power is present.

When lit (green), DC power is present at hard drive ba y.

When lit (green), hard disk drive i s in use.

When lit (yello w ) , a cooli ng fan has f ail ed.

When lit (yello w ) , a power supply ha s failed.

When lit (yello w ) , associated drive failed.

personnel only.

server controls.

L.

5 1/4-inch Expansion Drive Bay Holds up to three 5 1/4-inch devices, including the

factory-installed CD-ROM drive.

Front Features and Controls

Setting Up Your System 2-5

Page 26

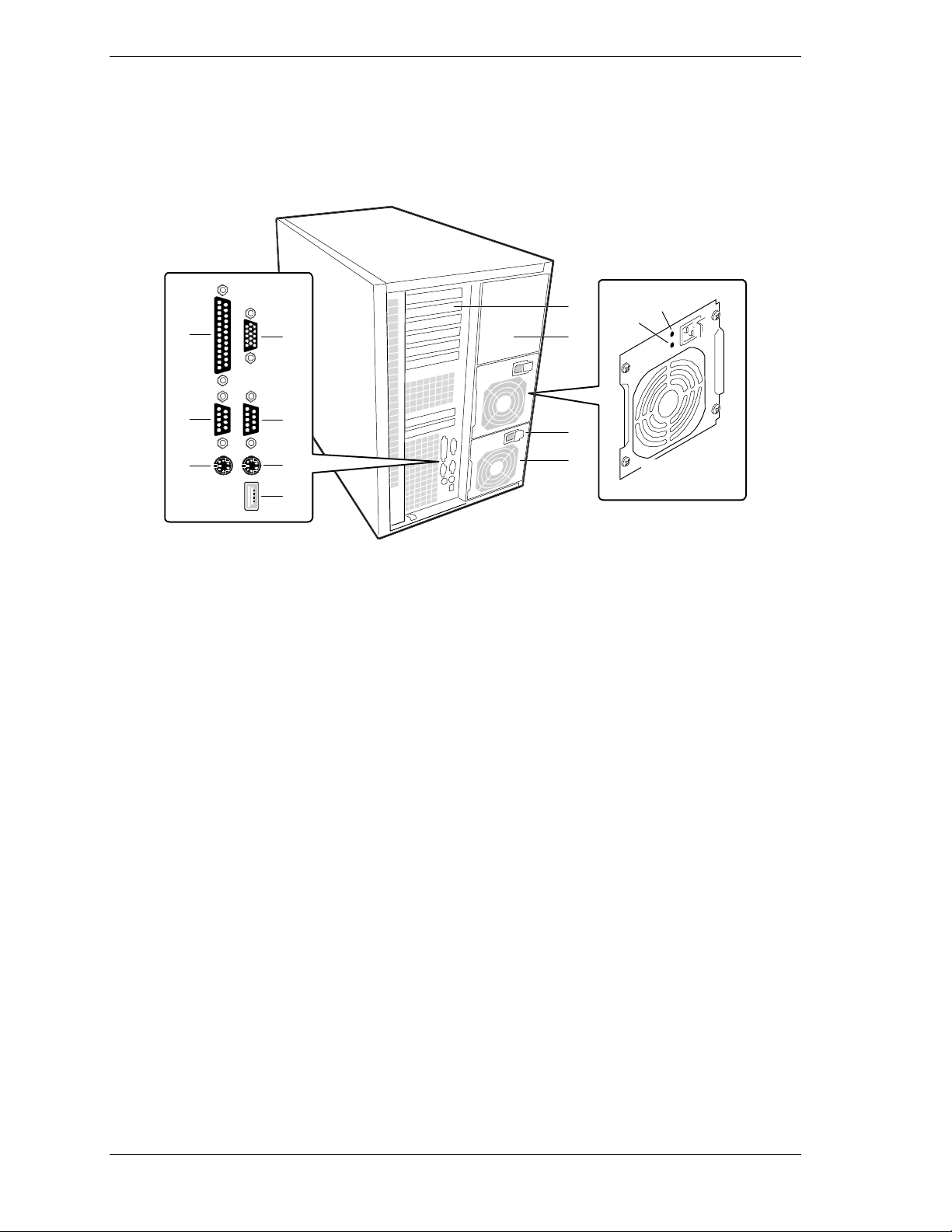

Rear View

The following figure shows the location of system controls, indicat ors, and

connectors on the rear of the system. The rack unit is similar except that it is

mounted in the rack on its side.

H

A

C

B

D

I

J

E

F

K

G

A.

Parallel Port Connector 25-pin parallel printer port connector.

B.

VGA Monitor Connector 15-pin monitor connector.

C.

Serial Port A (COM1) 9-pin serial COM1 port connector.

D.

Serial Port B (COM2) 9-pin serial COM2 port connector.

E.

Mouse Connector 6-pin PS/2-compatible mini-DIN mouse connector.

M

L

F.

Keyboard Connector 6-pin PS/2-compatible mini-DIN keyboard connector.

G.

USB Connector Single Universal Serial Bus connector.

H.

Expansion Slots 1 shared ISA/PCI slot, 1 ISA slot, and 6 PCI slots.

I.

Power Supply Bay Optional power supply bay for one backup power supply.

J.

AC Input Power Connector Supplies AC power to the power supply.

K.

Power Supply Fan Supplies cooling air to the power supply.

L.

Power Supply LED When lit, indicates AC power is available to power

M. Power Supply Failure LED When

2-6 Setting Up Your System

supply.

not

lit, indicates power supply failure.

Rear Features and Controls

Page 27

Installing the System

How you install the system depends on whether you have the stand-alone

pedestal unit or the rack-mounted unit. If you have the pedestal unit, install it at

your site and connect peripherals and power as explained next.

If you have the rack mounted unit, you need to install slide bars on the sides of

the unit before it can be installed in a standard E I A-compatible 19-inch

equipment rack. Yo u must also install rack extension brackets and slider

assemblies in the rack for the unit to mount on. See “Att aching the Outer Slide

Bars to the Chassis” and Pr epar ing the Rack” later in this chapt er for

procedures. Once your rack unit is in the rack, connect peripherals a nd power as

explained next.

Connecting Peripherals

If your system normally operates without a monitor, keyboard, or mouse (for

example, as a networ k server), you must install them to configure t he syst em.

You may remove them after running the System Setup Utility (SSU). For

information on running the SSU, refer to Appendix B of this User’s Guide.

Refer to the preceding figure and connect your keyboard, monitor, and mouse.

Connect any external peripheral de vices such as a pr inter by follow ing the

instructions included with the device.

!

CAUTION

System damage may result if the key boar d/mouse cable is

connected or disconnected when power is applied t o the

system.

Connecting the Power Cords

The system contains two 400-watt power supplies. Each power supply is

designed for automatic sensing of 115 or 230 Vac power, eliminating the need

for a line voltage selector switch. The power supplies operat e at a frequency of

50/60 Hz.

The system operates with both power supplies connect ed to po wer. Each power

supply is separately connected to a power source with its own power cord.

Connect each power cord as fo llows.

1.

Plug the female end of the AC power cord into its socket on the back of the

power supply.

You may need to slide the plug-lock away from the socket to allow

insertion of the plug into the socket.

Setting Up Your System 2-7

Page 28

To unplug the power cord, slide the lock away from the plug while

carefully pulling it out of the socket. Do not pull on the cord, only the

plug.

2. Plug the male end of the power cord into a wall-mounted power outlet.

Plug the male end of the power cord into an NEMA 5-15R outlet for

100-120 Vac.

Plug the male end of the power cord into an NEMA 6-15R outlet for

200-240 Vac.

If the power cords supplied with the system are not compatible with the AC wall

outlets in your r egion, obtain s uitable pow er cords that mee t the follow ing

criteria.

The power cord must be rated for the available AC voltage and have a

current rating that is at least 125% of the current rat ing of the system.

The power cord connector that plugs into the wall outlet must be

terminated in a grounding-type male plug designed for use in your region.

It must have certification marks showing cert ification by an agency

acceptable in your region.

The power cord connector t hat plugs into the syst em must be a n

IEC type CEE-22 female connector.

The power cord must be less than 1.8 meters (6.0 feet) long.

!

WARNING

Your system ships with two power cords, one for each power

supply. Do not attempt t o m odify or use the suppl ied AC

power cords if they are not the ex act type required.

Powering On the System

Power o n you r system as fo llows.

1. Make sure all external devices (monitor, keyboard, mouse) and power cords

are connected.

2. Make sure both AC power supply cords are connected to the system and

power outlets.

3. Power on the monitor and any other external devices.

4. Press the dc push-button power on/off switch on the front panel.

Verify that the dc power-on LED on the front panel is lit. If it is not lit,

ensure that the AC power cords are connected to funct ional AC power

sources.

2-8 Setting Up Your System

Page 29

Verify that the AC power-on and power supply failure LEDs on the

back of each power supply are lit. If the power supply failure LED is not

lit, ensure that the AC power cord is connected to a functional AC

power source.

!

WARNING

The DC push-button on/off switch on the front panel does

not turn off AC power. To turn off AC power, you must

unplug all power supply cords from either the power suppli es

or from the power sources.

without first turning off DC power

Do NOT turn off AC power

.

After a few seconds your s yst em begins the internal Power-On Self Tests

(POST). POST automat ica lly checks the system board, CP U modu le(s),

memory, keyboard, and most installed peripheral devices.

!

CAUTION

Always allow POST to complet e before powering down your

system.

!

CAUTION

The server management logic on your system board

monitors and logs system v oltage changes. When powering

down your system, you may experi enc e up to five seconds

delay from the time you pr ess the push-butt on power on/off

switch on the front panel and y our system poweri ng down.

This is normal system operat ion and is required by the

server management logic.

If you have problems powering on your system, refer to Chapter 5, “Solving

Pro blems , ” in this guide.

After you have successfully powered on your system, insert the

XPRESSBUILDER

E

follow the screen prompts to run E

CD ROM into the CD ROM drive, reboot t he syst em, and

XPRESSBUILDER

.

Setting Up Your System 2-9

Page 30

Converting to a Rack Mount Server Unit

You can convert a pedestal system to a rack mounted server unit using an

optional rack installat ion kit available from your dealer. The kit contains the

slide rails, bezel frame, and other hardware necessary for mounting the system

in an EIA-compatible 19-inch equipment r ack. Once you have the kit, use t he

following procedures to pr epar e the system for mount ing in a rack. You should

also follow any inst r uctions that may come with the k it.

Before starting the conversion, ensure that you have all the part s necessary for

the conversion (check t he pack ing slip t hat comes with t he rack inst allation kit).

You sho uld also obs e rve and impleme nt the fo llowing equipment rack warnings

and cautions.

2-10 Setting Up Your System

Page 31

Equipment Rack Warnings and Cautions

Observe and implement the following equipment rack war nings and cautions

before start ing t he co nvers ion.

!

WARNING

Anchor the Equipment Rack.

anchored to an unmov able support to prevent it from falling

over when one or more server s are extended in front of it on

slide assemblies. The anchors must be able to withstand a

force of up to 113 kg (250 lbs). You must also consider the

weight of any other dev ic e installed in the rack.

The equipment rack must be

Main AC Power Disconnect.

installi ng an AC power disconnect for the entir e rack unit.

This main disconnect m ust be r eadily ac c essible, and it must

be labeled as controlling power to the entire unit, not just to

the server(s).

Grounding the Rack Inst all at io n

electrical shock haz ar d, you must include a third wire saf ety

grounding conductor with the rack installati on. If server

power cords are plugged into AC outlets that are part of the

rack, then you must provide proper grounding for the r ac k

itself. If server power cords are plugged into wall AC outlets,

the safety groundi ng c onductor in each power cord provides

proper grounding onl y for the server. You must provide

additional, proper grounding for the rac k and other dev ic es

installed in it.

Overcurrent Protect ion.

line voltage source with up to 20 amperes of overcurr ent

protecti on. If the power system for the equipment r ack is

install ed on a branch cir c uit wit h m or e than 20 amper es of

protecti on, you m ust pr ov ide suppl em ental protection for the

server. If more than one server is installed in the rack, the

power source for each server must be from a separate

branch circuit. The over all current rating of a server

configured wit h thr ee power supplies is under 12 amperes.

You are responsible for

. To avoid a potential

The server is designed for an AC

!

CAUTION

Temperature

when install ed in an equipm ent rack, must not go below 5 °C

(41 °F) or rise above 35 °C (95 °F). Extr em e fluctuations in

temperature can c ause a variety of problems in your server.

Ventilation

airflow to the front of t he serv er to maintain proper cooling. It

must also include venti lation sufficient to exhaust a

maximum of 4,100 Btu' s per hour for the server. The rack

selected and the venti lation provided must be suitable to the

environment in whic h the server is used.

. The operating temperature of the server,

. The equipment rack must provide suffi ci ent

Setting Up Your System 2-11

Page 32

Converting the System Pedestal Unit

Converting your pedestal system to a rack mounted unit consists of:

removing the top and side covers

removing the bezel frame

installing a new bezel frame

inst a ll in g ha ndles

attaching slide rails to t he chassis

preparing the rack.

After the system unit is converted to a rack unit, install the unit in the rack (see

“Installing the Unit in the Rack” later in this chapter).

Removing the System Unit Covers

Remove the one piece syste m unit to p and side cover as fo llows.

1. Power down the syste m, discon nect any periphera l devices, and u nplug a ll

power cords.

2. At the back of the syste m unit, remove and save the screw from the top

cover (see the following figure).

Removing the Cover Screws

2-12 Setting Up Your System

Page 33

3. Grasp t he built-in handle on the back of the cover and, using an even pull,

slide the cover back about an inch u nt il it stops.

4. Pull the cover st r aight up and off the chassis. Set the cover aside.

5. Remove and save t he t wo screws holding the access (side) panel in place.

6. Grasp the built-in handle on t he back of the access panel a nd, us ing an even

pull, slide the cover back about an inch until it sto p s.

7. Pull the cover straight away fro m the chassis a nd set aside.

Replacing the Bezel Frame

The bezel frame must be replaced with a new bezel frame containing cutouts for

two chassis handles. Remove the bezel frame from the system unit and replace it

with a new bezel frame as follows.

1. Open the bezel door all the way to the left (as you face the unit) and lift the

door up slightly to free it from the bezel frame, then remove from the frame.

2. Remove the bezel frame by pressing its seven retaining tabs toward the

center of the chassis while pulling the frame away (see the fo llowing figure).

A.

B

A

Bezel Frame

B.

Frame Tabs (7)

Replacing the Bezel Frame

Setting Up Your System 2-13

Page 34

3. Install the new bezel frame by inserting the retaining tabs into their

correspond ing slot s on the chassis.

4. Install the bezel door by inserting the door onto the hinge pins on the

chassis. Shut t he bezel door.

Installing the Chassis Handles

Install the two chassis handles on the chass is a s follows.

Attaching the c hassis handles requires repositioning the

system unit on its side. The unit weighs between 85 pounds

(38 kg) and 100 pounds (45 kg), dependi ng on c onfiguration.

To avoid injury, mak e sure you hav e someone help you to

position the unit on it s side.

1. Turn the system unit o n its side, with the electronics bay facing up and the

front of the unit facing you.

2. Locat e the two rectangular cutouts in the bezel frame, one o n each side, and

the two threaded holes in each side of the chassis (see the following figure).

!

WARNING

3. Att ach t he handles, one to a side, to the chassis. Because of the bezel frame

configuration, the handles can only fit o ne way.

Align the two holes in the handle with the two threaded holes in the

chassis.

Fasten the handle in place w it h t wo scr ews fro m the k it.

Repeat for the second handle.

A

B

C

D

2-14 Setting Up Your System

Page 35

A. Bezel Frame

B. Rectangular Cutout

C. Chassis Handle

D. Screws

Attaching the Chassis Handles

Attaching the Outer Slide Bars to the Chassis

Note:

following procedure to attach the slide bars befor e m ounting

the unit in the rack. Observe all safety precauti ons,

warnings, and cautions noted throughout t his chapt er .

If you have a rack unit, you must use the

Each slide assembly cons ist s of a large outer bar, a center bar, and a small outer

bar. The large outer bar and the center bar attach to the rack unit. The small

outer bar attaches to the syste m chass is. As the slide assemb ly s hips as an

as sembl ed unit, you mu st remove the small outer bar from th e a sse mbly before

attaching to the chassis.

Remove the small outer bar from each slide asse mb l y and attach each bar to the

chassis as follows.

Position the slide assembly on a flat surface w ith t he sma l l outer bar down.

1.

Fully extend the three telescoping bars until they lock in place (see the

2.

following figure).

Setting Up Your System 2-15

Page 36

3. While press ing do wn on t he small outer bar safety latch (4 on the following

figure), pull the small out er bar out o f the assembly and set as ide for

installa tion on the c hass is .

Release the safety latch on the center bar (5 on the figure) and collapse

the large outer bar and center bar together.

Set the assembly aside for la ter installa tion in the rack.

4

1 2 3

5

1.

Large Outer Bar

2.

Center Bar

3.

Small Outer Bar

4.

Safety Latch on Small Outer Bar

5.

Safety Latch on Center Bar

Releasing the Small Outer Bar

2-16 Setting Up Your System

Page 37

4. Att ach each small o u ter bar to the chassis as fo llows.

Align the mounting holes in the bar to t he threaded ho les in the chassis

(see the following figure). The right angle end of the bar goes towar d t he

front of the chassis.

Secure the bar to the chassis with four scr ews from the kit.

1

2

4

3

1.

Threaded Holes in Ch assis

2.

Safety Latch

3.

Screw (1 of 4)

4.

Small Outer Bar (right angle end)

Attaching the Small Ou ter Bar to the Chassis

Setting Up Your System 2-17

Page 38

Prepari ng the Rack

Note:

following procedure to prepare the rack befor e m ounting the

unit in the rack. Observe all safety precautions, warnings,

and cautions noted thr oughout this chapter.

If you have a rack unit, you must use the

The converted syste m unit (or rack unit) mounts in a standard EIA-co mpat ible

19-inc h e quipment ra ck s imilar to that s hown in the following figure (shown

with three server units installed).

Typical Equipment Rack

Before you can mount the unit in the rack, you must insta ll a set of rack

extension brackets and slider ra ils to the rack. Do this as explained in the

following paragraphs.

Installing the Rack Extension Brackets

Install the four (two to a side) r ack ext ensio n bracket s on the rack as follows.

1. Determine where you want to install the server unit in the rack.

If the rack is empty, install the server unit in the bottom most position.

If there are units already installed, install your unit in the next empty

space from the bottom of the rack.

2. Remove a right-ang le ext ensio n bracket, two screws, and a bar nut fro m the

kit. The bar nut is a flat bar with four threaded holes.

2-18 Setting Up Your System

Page 39

3. Align the bracket behind the rack’s vertical edge and behind the mounting

holes in the vertical edge (see the following figure).

2

1

4

3

1.

Screw

2.

Rack Vertical Rail

3.

Bar Nut

4.

Right angle Extension Bracket

Installing the Extension Brackets

4. Deter mine where you want to attach the bracket on the rack’s vertical rail.

When determining where to attach t he bracket, be sure to allow space

for additional units.

Mark, with a pencil, the bracket to p and bottom hole locations on t he

rail.

5. Insert a screw through the marked top hole in the vertical rail and through

the top hole in the extension bracket.

6. Place a bar nut over the screw and loo se ly thread the screw into the bar nut.

7. Insert a screw through the marked bottom hole in the vertical rail and

extension bracket and loose ly thread the screw into the bar nut.

8. Insta ll the re maining t hree ext ension brackets, bar nuts, and screws.

Before insta lling, careful ly a lig n eac h bracket in exactly the same

vertical position as the first bracket.

After installing, check that the brackets ar e vertically alig ned and leve l

wit h eac h ot he r.

9. Tighten all the screws ho lding the brackets to the rack.

Installing the Slider Assemblies

Use the following procedure to inst all each slider assembly on the ext ensio n

brackets in the rack. Refer to the following figure while performing the

procedure.

Setting Up Your System 2-19

Page 40

1

22

4 6

3

2

5

4

2

6

2

1.

Back Extension Bracket

2.

8-32 Screw

3.

Flat Washer, Lock Washer, and 8-32 Nut

4.

Large Outer Bar

5.

Safety Latch on Center Bar

6.

Center Bar

7.

Front Extension Bracket

7

Installing the Slider Assembly

With the safety latch (5 o n the above figure) end of the slider assembly

1.

towards t he back of the rack, pr ess t he flat s ide o f the slider asse mb l y into

the U-shaped sections o f the previousl y installed extension

brackets (1 and 7).

Slide the slider assembly t owards the front of the rack until the end of the

2.

large outer bar (4) is flush with the end of the U-shaped section of the front

extension bracket (7).

Carefully slide t he center bar ( 6) towards the front of the rack until the

3.

oblong hole in the bar is over the first ho le in the large outer bar (4).

Insert a 8-32 screw through the oblong hole in the center bar, the ho le in

the large outer bar, and into the first hole in the front extension bracket.

Place a flat washer, lock washer, and a 8-32 nut on the screw and

loosely tighten.

2-20 Setting Up Your System

Page 41

4. Careful ly sl ide t he center bar (6 ) towar ds t he back of the rack unt il the

oblong hole in the bar is over the third hole from the front of the large outer

bar (4).

Insert an 8-32 screw through the oblong hole in the center bar, the ho le

in the large outer bar, and into the oblong slot in the front extension

bracket.

Place a flat washer, lock washer, and a 8-32 nut on the screw and

loosely tighten.

5. Secur e the back end of the large outer bar (4) to the back extension

bracket (1).

The end of the outer bar has four holes. T he extension bracket has two

holes and two elongated slots for fastening the bar.

Align two holes in the out er bar with a hole and slot in the bracket.

Which holes/slot s you use depends on the depth of the rack.

Insert an 8-32 screw through each of the two holes in the outer bar and

through the hole and slot in the extension bracket.

Place a flat washer, lock washer, and a 8-32 nut on each screw and

loosely tighten.

6. Check that the bars and brackets are pos itioned co r r ect ly in the rack.

7. Tighten all the screws holding the bars to the extension bracket s and rack.

Installing the Rack Unit in the Rack

Note:

following procedure to install the unit i n the rac k. Observe all

safety precautions, warnings, and cauti ons noted throughout

the procedures.

Install your converted unit (or rack unit) in the rack as follows.

If you have a rack unit, you must use the

Setting Up Your System 2-21

Page 42

!

WARNING

Anchor The Equipment Rack.

anchored to an unmov able support to prevent it from falling

over when one or more server s are extended in front of it on

slide assemblies. The anchors must be able to withstand a

force of up to 113 kg (250 lbs). You must also consider the

weight of any other dev ic e installed in the rack.

The equipment rack must be

Avoid Injury.

kg (85 lbs); the maximum confi gur ation weighs 45 kg (100

lbs). To avoid personal injury when installing the server,

have someone help you position the server in the rack.

Do not attempt to lift or mov e the server unit by the handles

on the power supplies.

1.

Pull the telescoping center bar (2 o n the following figure) out of each slider

The minimum server configurati on wei ghs 38

assembly on the rack unt il it locks in place.

2.

With someone helping you, use the handles on the sides of the rack unit to

lift and slide the unit into the slider asse mb l ies.

Align the small bars (1) attached to t he sides of the system unit with the

extended center bars (2).

Carefully slide t he server unit into the extended center bars until it stops.

Press in on the sa fety latches (4) on the small bars and care fu lly sl ide t he

server unit all the way into t he rack.

3.

Check that the server unit slides in and out of the rack. Grasp the two

handles on the sides of the unit and slowly pull the unit out and push it back

in.

4.

Connect all external perip herals and cables.

5.

Connect the two power supply cables to the back of the server unit and to a

power source.

6.

Power on the server unit.

2-22 Setting Up Your System

Page 43

2

3

1

4

2

1.

2.

3.

4.

Small Outer Bar

Center Bar

Large Outer Bar

Safety Latch

Installing the Server in the Rack

Setting Up Your System 2-23

Page 44

Page 45

Configuring Your System

Using the BIOS Setup

Using the Symbios SCSI Utility

Using the Optional RAID Controll er

Configuring Syst em B oard Jum pers

3

Page 46

This chapter describes t he Setup utilities that you can use to change your s yste m

configuration. The utilities described in this chapter include:

BIOS Setup Utility

Symbios SCSI Utility.

The BIOS Setup Utility is used to configure the system and any option boards

you may add . The B IOS Setup Utility is s tored in the system FL ASH memory.

You do not need a diskette to run the BIOS Setup Utility.

The Symb ios SCSI U tility is u s e d t o configur e the SCSI controller in you r

system, perform a SCSI disk format, or verify disk operation on the SCSI disk

drives. The utility is also used to configure any SCSI removable media devices

installed in your system. You do not need a diskette to run this utility as it is

accessible during system boot-up.

In addition, the following utilities are available for your use in configuring the

system. Informat ion on each utility is contained in the referenced appendix.

System Setup Utility (SSU) (see Appendix B, “System Setup Utility”)

Emergency Management Port (EMP) (see Appendix C, “Emergency

Mana gement Port ”)

FRUSDR Load Utility (see Appe nd ix C, “Emergency Management

Port”).

The System Setup Utility can be used to configure your system and any option

boards you may add t o your system. The SSU reads st o r ed syst em event

info rmatio n. App endix B c ontains info rma tion on the SSU.

The Emergency Management Port (EMP) is used for remote monitoring of the

server. The FRUSDR Load Utility can be used to update the field replacement

unit (FRU), sensor data record (SDR) and deskto p management interface (DMI)

flash components. Appendix C cont ains information on both ut ilities.

If your system is factory configured, you normally don’t need to run the SSU,

BIOS Setup, or Symbios SCSI Utility unless you want to change the password

or security features, add certain types of option boards or devices, or upgrade

your system board.

Also inc l u ded in t h is chapte r is information on se tting jumpers on the system

board for clearing

CMOS nonvolatile RAM (NVRAM)

Syste m passw ords.

3-2 Configuring Your System

Page 47

Using the BIOS Setup Utility

The BIOS Setup Utility is used to change system configuration parameters. Note

that many BIOS Setup parameters are also configurable with the SSU. However,

BIOS Setup Utility parameters that ar e sett able with the SSU are overwritten by

the SSU the ne xt t ime the SSU is run. The B IOS Set up Utility is resid ent in the

system Flash memory and does not r equire a disket te or an operating system

present to run.

You can access the BIOS Setup utility when you tur n on or reboot your system.

Use the following procedure to run the BIOS Setup Utility.

1. Power-o n o r reboot the system. The “Press <F2> to enter SETUP” message

displays.

2. Press F2. The B IOS Setup Utilit y s tart s and the M ain Menu is displa ye d.

The menu bar at the top of the Main Menu lists the following selections.

Menu Bar Selections

Menu Use

Main Use for b asic system confi gur atio n.

Adv anc ed Us e for sett ing the Advanced Feat ures available on your system.

Security Use to set User and Supervisor Passwords and Backup and Virus-

Check reminders.

Server Use for configuring Server Management features.

Boot Use to configure Boot Device priority.

Exit Exits current setup.

Use the arrow keys to select a menu or an ite m on a displayed menu. Press the

value keys (listed in the table below) to cycle through the allowable values for

the selected field. Use the Exit menu’s “Save Changes” selection to save t he

cur rent va lues on a ll the menus .

To display a submenu, posit ion the curso r on a selection that has a submenu and

press

. Selections with submenus are preceded by an arrow.

Enter

Refer to the following table for information on the keys you use with BIOS

Setup. These keys are also listed at the bottom of the Setup Menu.

Setup Menu Keys

Key Function in Setup Menu

F1 or Alt-H Get Help about an item.

ESC Exit t he cu r rent menu and r eturn to the previ ous menu.

Left or right arrow keys Move between menus.

Configuring Your System 3-3

Page 48

Key Function in Setup Menu

Up or dow n arr ow keys Move cursor up and down. The c ursor moves on l y to t he

- Select the p revi ous v alue for t he fi eld.

+ Select the n ext value for the fi eld.

F9 Load default configuration values for this menu.

F10 Sav e con f igurat ion values and exit.

Enter Execute command or Select submenu.

The following BIOS Setup Configuration tables show the default settings for the

BIOS Setup Utility. Recommended values are bold. The tables a lso pro vide a

space for you to record any changes you make to these set tings.

Main Menu

The follo wing table s hows the M ain M enu s e tt ings.

Setup Menu Keys

settings that you can change.

Main Me n u

Feature Choices Description Your Setting

System Time HH:MM:SS Sets the system time.

System Date MM/DD/YYYY Sets the system date.

Legacy Diskette A: Disabled

360KB

1.2 MB

720KB

1.44 MB

2.88 MB

Legacy Diskette B: Disabled

360KB

1.2 MB

720KB

1.44 MB

2.88 MB

Hard Disk Pre-delay Disabled

3, 6, 9, 12, 15, 21, or

30 seconds

Primary IDE Master Press Enter Refer to “Primary IDE Master and

Selects the diskette type.

Selects the diskette type.

Adds a delay before the first BIOS

access of a hard drive. Some hard

drives hang if accessed before they

initialize. The delay allows the drive

to initialize after power up, before

being accessed.

Slave Submenu. ”

Primary IDE Slave Press Enter Refer to “Primary IDE Master and

Slave Submenu. ”

Keyboard Features Press Enter Refer to “Keyboard Submenu.”

Processor Information Press Enter Information for al l process ors i s

3-4 Configuring Your System

Page 49

Main Me n u

Feature Choices Description Your Setting

described.

Language English (US)

Spanish, Italian

Fren ch , Germa n,

Japanese (Kanji)

Selects which language BIOS

disp la ys in.

Primary IDE Master and Slave Submenu

The following table shows t he sett ings for t he Primary IDE Master and Slave

submenu.

Primary IDE Master and Slave Submenu

Feature Choices Description Your Setting

Type Auto

None

CD-ROM

IDE Removable

ATAPI Removable

User

Cylinders 1 to 2048 Number of cylinders on drive. This

Auto allows the system to attempt

auto-detec ti on of t he drive t ype.

None informs the system to ignore

this drive.

Allows the manual entry of some

fields described below.

User allows the manual entry of all

fields described below.

field is changeable only for Type