Page 1

PART NO. 599910588

•

SERVICE MANUAL

COLOR MONITOR

MultiSync

LCD1550V

MODELS LCD1550V-1 (B)/-BK(B)

This model changed a LCD panel (manufactured by Hannstar) from the original model.

Use the applicable service manual which surely confirms the model number of the

NAME PLATE, INSTRUCTION.

Refer to the page which the point of view of the model number is mentioned in.

• Model number : LA-15R02 / LA-15R02-BK

Maintenance is performed by the original service manual (Part No.

599910571).

Model number : LA-15R02-1 / LA-15R02-1-BK

Maintenance is performed using this service manual.

NEC-MITSUBISHI ELECTRIC VISUAL SYSTEMS CORPORATION

JUNE 2002

200206

08109741

08109742

Page 2

The SERVICE PERSONNEL should have the appropriate technical training, knowledge and experience

necessary to:

• Be familiar with specialized test equipment, and

• Be careful to follow all safety procedures to minimize danger to themselves and their coworkers.

To avoid electrical shocks, this equipment should be used with an appropriate power cord.

This equipment utilized a micro-gap power switch. Turn off the set by first pushing power switch. Next,

remove the power cord from the AC outlet.

To prevent fire or shock hazards, do not expose this unit to rain or moisture.

This symbol warns the personnel that un-insulated voltage within the unit may have sufficient

magnitude to cause electric shock.

This symbol alerts the personnel that important literature concerning the operation and

maintenance of this unit has been included.

Therefore, it should be read carefully in order to avoid any problems.

WARNING

PRODUCT SAFETY CAUTION

1. When parts replacement is required for servicing, always use the manufacturer's specified replacement.

2. When replacing the component, always be certain that all the components are put back in the place.

3. As for a connector, pick and extract housing with fingers properly since a disconnection and improper

contacts may occur, when wires of the connector are led.

4. Use a proper screwdriver. If you use screwdriver that does not fit, you may damage the screws.

Page 3

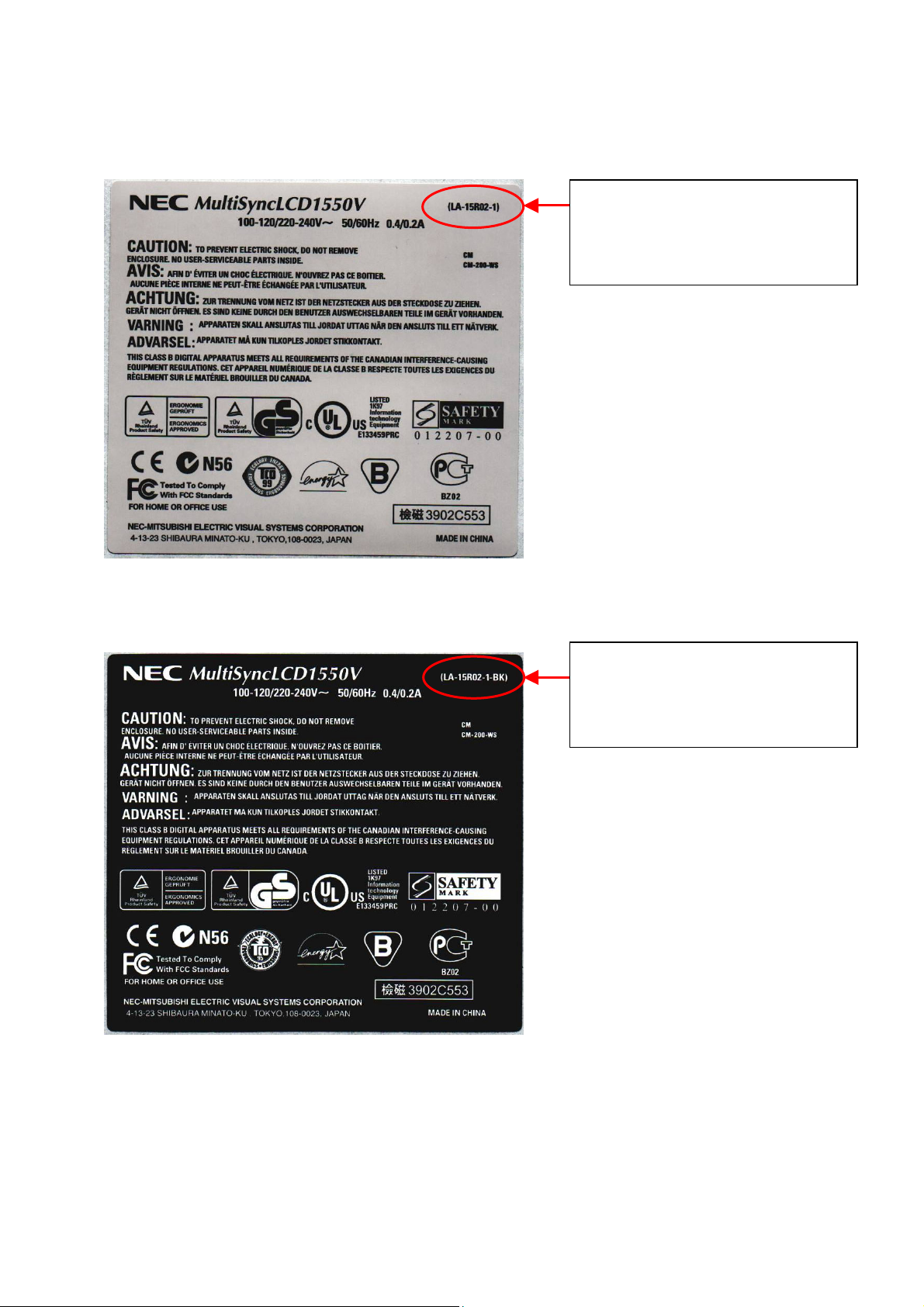

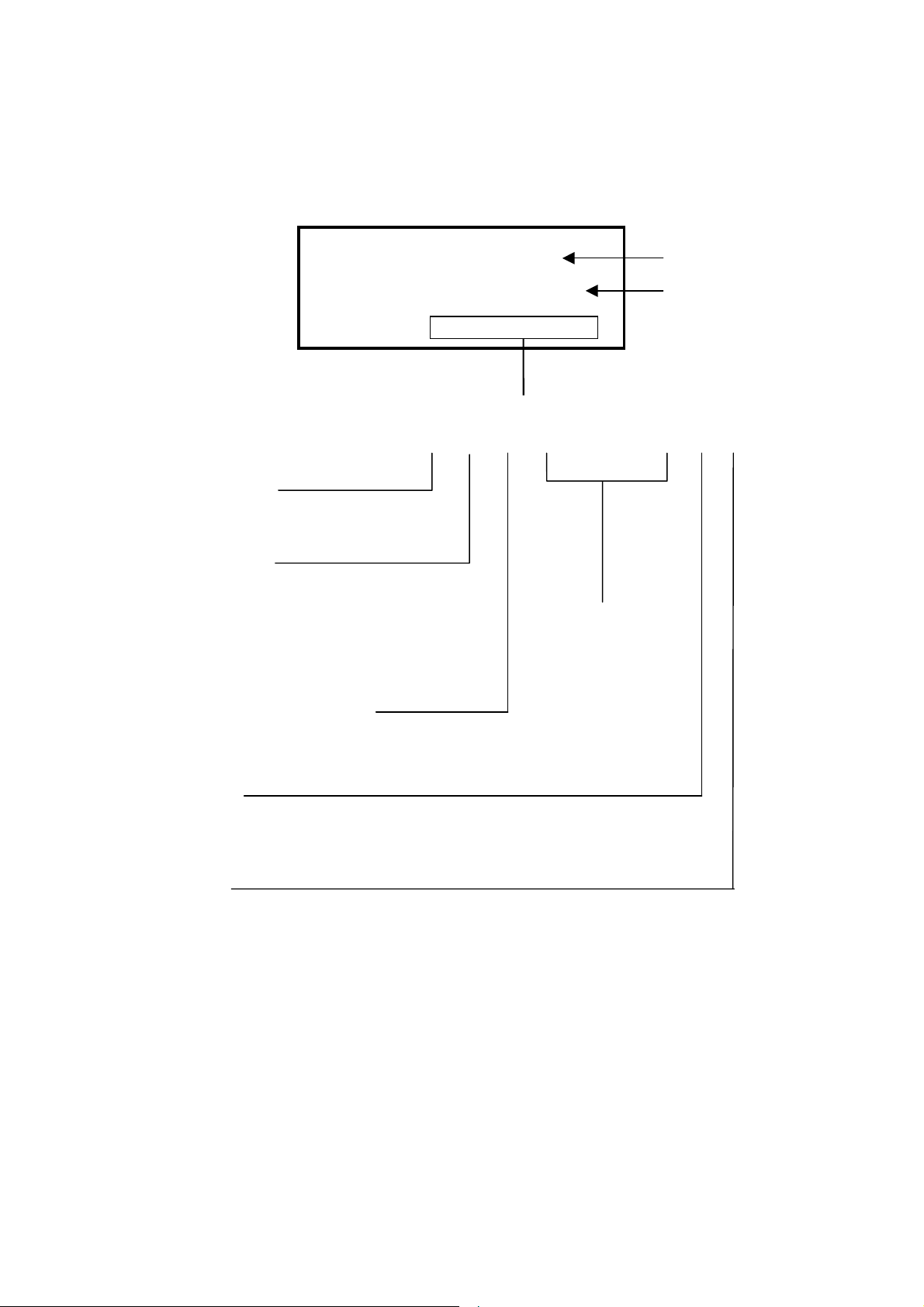

Point of view of the model number

NAME PLATE, INSTRUCTION (White model)

NAME PLATE, INSTRUCTION (Black model)

Model number

Original model: LA-15R02

Hannstar LCD model: LA-15R02-1

Model number

Original model: LA-15R02-BK

Hannstar LCD model: LA-15R02-1-BK

Page 4

CONTENTS

USER'S MANUAL ------------------------------------------------------------------- 1-1

SERIAL NUMBER INFORMATION --------------------------------------------- 2-1

DISASSEMBLY ----------------------------------------------------------------------- 3-1

ADJUSTMENT PROCEDURES -------------------------------------------------- 4-1

INSPECTION --------------------------------------------------------------------------- 5-1

TROUBLE SHOOTING ------------------------------------------------------------- 6-1

CIRCUIT DESCRIPTION ----------------------------------------------------------- 7-1

Page No.

REPLACEMENT PARTS LIST --------------------------------------------------- 8-1

BLOCK DIAGRAM ------------------------------------------------------------------- 9-1

SCHEMATIC DIAGRAMS -------------------------------------------------------- 10-1

Page 5

USER'S MANUAL

MultiSync LCD1550V

User’s Manual

UÏivatelská pfiíruãka

Bedienerhandbuch

Οδηγίες Χρήσης

Manual del usuario

Manuel Utilisateur

Manuale utente

Gebruikershandleiding

Podr´cznik u˝ytkownika

Руководство пользователя

Kullan∂c∂ Klavuzu

1-1

Page 6

Declaration

Declaration of the Manufacturer

We hereby certify that the colour monitor

MultiSync LCD1550V (LA-15R02)

MultiSync LCD1550V (LA-15R02-BK)

MultiSync LCD1550V (LA-15R02-1)

MultiSync LCD1550V (LA-15R02-1-BK)

is in compliance with

Council Directive 73/23/EEC:

Council Directive 89/336/EEC:

and marked with

– EN 60950

– EN 55022

– EN 61000-3-2

– EN 61000-3-3

– EN 55024

NEC-Mitsubishi Electric Visual Systems, Corp.

MS Shibaura Bldg., 13-23,

Shibaura 4-chome,

Minato-Ku, Tokyo 108-0023, Japan

1-2

Page 7

TCO’99

This is a translation of the original English TCO'99 document.

MultiSync LCD1550V White Model (LA-15R02 and LA-15R02-1)

Congratulations! You have just purchased a TCO’99

approved and labeled product! Your choice has

provided you with a product developed for

professional use. Your purchase has also contributed

to reducing the burden on the environment and also

to the further development of environmentally

adapted electronics products.

Why do we have environmentally labelled computers?

In many countries, environmental labelling has become an established

method for encouraging the adaptation of goods and services to the

environment. The main problem, as far as computers and other

electronics equipment are concerned, is that environmentally harmful

substances are used both in the products and during the manufacturing.

Since it has not been possible for the majority of electronics equipment

to be recycled in a satisfactory way, most of these potentially damaging

substances sooner or later enter Nature.

There are also other characteristics of a computer, such as energy

consumption levels, that are important from the viewpoints of both the

work (Internal) and natural (external) environments. Since all methods of

conventional electricity generation have a negative effect on the

environment (acidic and climate-influencing emissions, radioactive

waste, etc.), it is vital to conserve energy. Electronics equipment in

offices consume an enormous amount of energy since they are often left

running continuously.

What does labelling involve?

This product meets the requirements for the TCO’99 scheme which

provides for international and environmental labelling of personal

computers. The labelling scheme was developed as a joint effort by the

TCO (The Swedish Confederation of Professional Employees), Svenska

Naturskyddsforeningen (The Swedish Society for Nature Conservation)

and Statens Energimyndighet (The Swedish National Energy

Administration).

1-3

Page 8

The requirements cover a wide range of issues: environment,

ergonomics, usability, emission of electrical and magnetic fields, energy

consumption and electrical and fire safety.

The environmental demands concern restrictions on the presence and

use of heavy metals, brominated and chlorinated flame retardants,

CFCs (freons) and chlorinated solvents, among other things. The

product must be prepared for recycling and the manufacturer is obliged

to have an environmental plan which must be adhered to in each

country where the company implements its operational policy. The

energy requirements include a demand that the computer and/or

display, after a certain period of inactivity, shall reduce its power

consumption to a lower level in one or more stages. The length of time

to reactivate the computer shall be reasonable for the user.

Labelled products must meet strict environmental demands, for

example, in respect of the reduction of electric and magnetic fields,

physical and visual ergonomics and good usability.

Environmental Requirements

Flame retardants

Flame retardants are present in printed circuit boards, cables, wires,

casings and housings. In turn, they delay the spread of fire. Up to thirty

percent of the plastic in a computer casing can consist of flame

retardant substances. Most flame retardants contain bromine or chloride

and these are related to another group of environmental toxins, PCBs,

which are suspected to give rise to severe health effects, including

reproductive damage in fisheating birds and mammals, due to the

bioaccumulative* processes. Flame retardants have been found in

human blood and researchers fear that disturbances in foetus

development may occur.

TCO’99 demand requires that plastic components weighing more than

25 grams must not contain flame retardants with organically bound

chlorine and bromine. Flame retardants are allowed in the printed circuit

boards since no substitutes are available.

Lead**

Lead can be found in picture tubes, display screens, solders and

capacitors. Lead damages the nervous system and in higher doses,

causes lead poisoning.

TCO’99 requirement permits the inclusion of lead since no replacement

has yet been developed.

1-4

Page 9

Cadmium**

Cadmium is present in rechargeable batteries and in the

colourgenerating layers of certain computer displays. Cadmium

damages the nervous system and is toxic in high doses.

TCO’99 requirement states that batteries, the colourgenerating layers of

display screens and the electrical or electronics components must not

contain any cadmium.

Mercury**

Mercury is sometimes found in batteries, relays and switches, Mercury

damages the nervous system and is toxic in high doses.

TCO’99 requirement states that batteries may not contain any Mercury.

It also demands that no mercury is present in any of the electrical or

electronics components associated with the display unit.

CFCs (freons)

CFCs (freons) are sometimes used for washing printed circuit boards.

CFCs break down ozone and thereby damage the ozone layer in the

stratosphere, causing increased reception on Earth of ultraviolet light

with consequent increased risks of skin cancer (malignant melanoma).

The relevant TCO’99 requirement; Neither CFCs nor HCFCs may be

used during the manufacturing and assembly of the product or its

packaging.

* Bio-accumulative is defined as substances which accumulate within

living organisms.

** Lead, Cadmium and Mercury are heavy metals which are

Bioaccumulative.

To obtain complete information on the environmental criteria document,

order from:

TCO Development Unit

SE-114 94 Stockholm

SWEDEN

FAX Number: +46 8 782 92 07

E-mail (Internet): development@tco.se

You may also obtain current information on TCO’99 approved and

labelled products by visiting their website at:

http://www.tco-info.com/

1-5

Page 10

TCO’95

This is a translation of the original English TCO'95 document.

MultiSync LCD1550V Black Model (LA-15R02-BK and LA-15R02-1-BK)

Congratulations! You have just purchased a TCO’95

approved and labeled product! Your choice has

provided you with a product developed for

professional use. Your purchase has also

contributed to reducing the burden on the

environment and also, to the further development of

environmentally adapted electronics products.

Why do we have environmentally labelled computers?

In many countries, environmental labelling has become an established

method for encouraging the adaptation of goods and services to the

environment. The main problem, as far as computers and other

electronics equipment are concerned, is that environmentally harmful

substances are used both in the products and during the manufacturing.

Since it has not been possible for the majority of electronics equipment

to be recycled in a satisfactory way, most of these potentially damaging

substances sooner or later enter Nature.

There are also other characteristics of a computer, such as energy

consumption levels, that are important from the viewpoints of both the

work (Internal) and natural (external) environments. Since all methods of

conventional electricity generation have a negative effect on the

environment (acidic and climate-influencing emissions, radioactive

waste, etc.), it is vital to conserve energy. Electronics equipment in

offices consume an enormous amount of energy since they are often left

running continuously.

What does labelling involve?

This product meets the requirements for the TCO’95 scheme which

provides for international and environmental labelling of personal

computers. The labelling scheme was developed as a joint effort by the

TCO (The Swedish Confederation of Professional Employees),

Naturskyddsforeningen (The Swedish Society for Nature Conservation)

and NUTEK (The National Board for Industrial and Technical

Development in Sweden).

The requirements cover a wide range of issues: environment,

ergonomics, usability, emission of electrical and magnetic fields, energy

consumption and electrical and fire safety.

1-6

Page 11

The environmental demands concern restrictions on the presence and

use of heavy metals, brominated and chlorinated flame retardants,

CFCs (freons) and chlorinated solvents, among other things. The

product must be prepared for recycling and the manufacturer is obliged

to have an environmental plan which must be adhered to in each

country where the company implements its operational policy. The

energy requirements include a demand that the computer and/or

display, after a certain period of inactivity, shall reduce its power

consumption to a lower level in one or more stages. The length of time

to reactivate the computer shall be reasonable for the user.

Labelled products must meet strict environmental demands, for

example, in respect of the reduction of electric and magnetic fields,

physical and visual ergonomics and good usability.

TCO’95 is a co-operative project between TCO (The Swedish

Confederation of Professional Employees), Naturskyddsforeningen

(The Swedish Society for Nature Conservation) and NUTEK

(The National Board for Industrial and Technical Development in

Sweden).

Environmental Requirements

Brominated flame retardants

Brominated flame retardants are present in printed circuit boards,

cables, wires, casings and housings. In turn, they delay the spread of

fire. Up to thirty percent of the plastic in a computer casing can consist

of flame retardant substances. These are related to another group of

environmental toxins, PCBs, which are suspected to give rise to similar

harm, including reproductive damage in fisheating birds and mammals,

due to the bio-accumulative* processes. Flame retardants have been

found in human blood and researchers fear that disturbances in foetus

development may occur.

TCO’95 demand requires that plastic components weighing more than

25 grams must not contain organically bound chlorine and bromine.

Lead**

Lead can be found in picture tubes, display screens, solders and

capacitors. Lead damages the nervous system and in higher doses,

causes lead poisoning.

TCO’95 requirement permits the inclusion of lead since no replacement

has yet been developed.

1-7

Page 12

Cadmium**

Cadmium is present in rechargeable batteries and in the

colourgenerating layers of certain computer displays. Cadmium

damages the nervous system and is toxic in high doses.

TCO’95 requirement states that batteries may not contain more than

25 ppm (parts per million) of cadmium. The colourgenerating layers of

display screens must not contain any cadmium.

Mercury**

Mercury is sometimes found in batteries, relays, switches, and back-light

systems, Mercury damages the nervous system and is toxic in high

doses.

TCO’95 requirement states that batteries may not contain more than

25 ppm (parts per million) of mercury. It also demands that no mercury

is present in any of the electrical or electronics components concerned

with the display unit, except the back-light system.

CFCs (freons)

CFCs (freons) are sometimes used for washing printed circuit boards

and in the manufacturing of expanded foam for packaging. CFCs break

down ozone and thereby damage the ozone layer in the stratosphere,

causing increased reception on Earth of ultraviolet light with consequent

increased risks of skin cancer (malignant melanoma).

The relevant TCO’95 requirement; Neither CFCs nor HCFCs may be

used during the manufacturing of the product or its packaging.

* Bio-accumulative is defined as substances which accumulate within

living organisms.

** Lead, Cadmium and Mercury are heavy metals which are

Bioaccumulative.

To obtain complete information on the environmental criteria document,

order from:

TCO Development Unit

SE-114 94 Stockholm

SWEDEN

FAX Number: +46 8 782 92 07

E-mail (Internet): development@tco.se

You may also obtain current information on TCO’95 approved and

labelled products by visiting their website at:

http://www.tco-info.com/

1-8

Page 13

English

âesky

Deutsch

Ελληνικά

Español

Français

Italiano

Nederlands

Polski

Русский

Türkçe

1-9

Page 14

WARNING

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS UNIT TO RAIN

OR MOISTURE. ALSO, DO NOT USE THIS UNIT’S POLARIZED PLUG WITH AN

EXTENSION CORD RECEPTACLE OR OTHER OUTLETS UNLESS THE PRONGS

CAN BE FULLY INSERTED.

REFRAIN FROM OPENING THE CABINET AS THERE ARE HIGH VOLTAGE

COMPONENTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

CAUTION

RISK OF ELECTRIC SHOCK • DO NOT OPEN

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER

CAUTION

Caution:

When operating the MultiSync LCD1550V with a 220-240V AC power source in Europe,

use the power cord provided with the monitor.

In the UK, a BS approved power cord with a moulded plug has a Black (five Amps) fuse

installed for use with this equipment. If a power cord is not supplied with this equipment

please contact your supplier.

When operating the MultiSync LCD1550V with a 220-240V AC power source in

Australia, use the power cord provided with the monitor.

For all other cases, use a power cord that matches the AC voltage of the power outlet

and has been approved by and complies with the safety standard of your particular

country.

(OR BACK). NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

This symbol warns user that uninsulated voltage within the unit may have

sufficient magnitude to cause electric shock. Therefore, it is dangerous to make

any kind of contact with any part inside this unit.

This symbol alerts the user that important literature concerning the operation

and maintenance of this unit has been included. Therefore, it should be read

carefully in order to avoid any problems.

English

E

NERGYSTAR

is a U.S. trademark.

As an E

determined that this product meets the E

NERGYSTAR

The E

IBM PC/XT/AT, PS/2, MCGA, VGA, 8514/A and XGA are registered trademarks of

International Business Machines Corporation.

Apple and Macintosh are registered trademarks of Apple Computer Inc.

Microsoft and Windows are registered trademarks of the Microsoft Corporation.

NEC is a registered trademark of NEC Corporation.

All other trademarks or registered trademarks are property of their respective owners.

®

NERGYSTAR

Partner, NEC-Mitsubishi Electronics Display of America, Inc. has

emblem does not represent EPA endorsement of any product or service.

NERGYSTAR

guidelines for energy efficiency.

English-1

1-10

Page 15

Contents

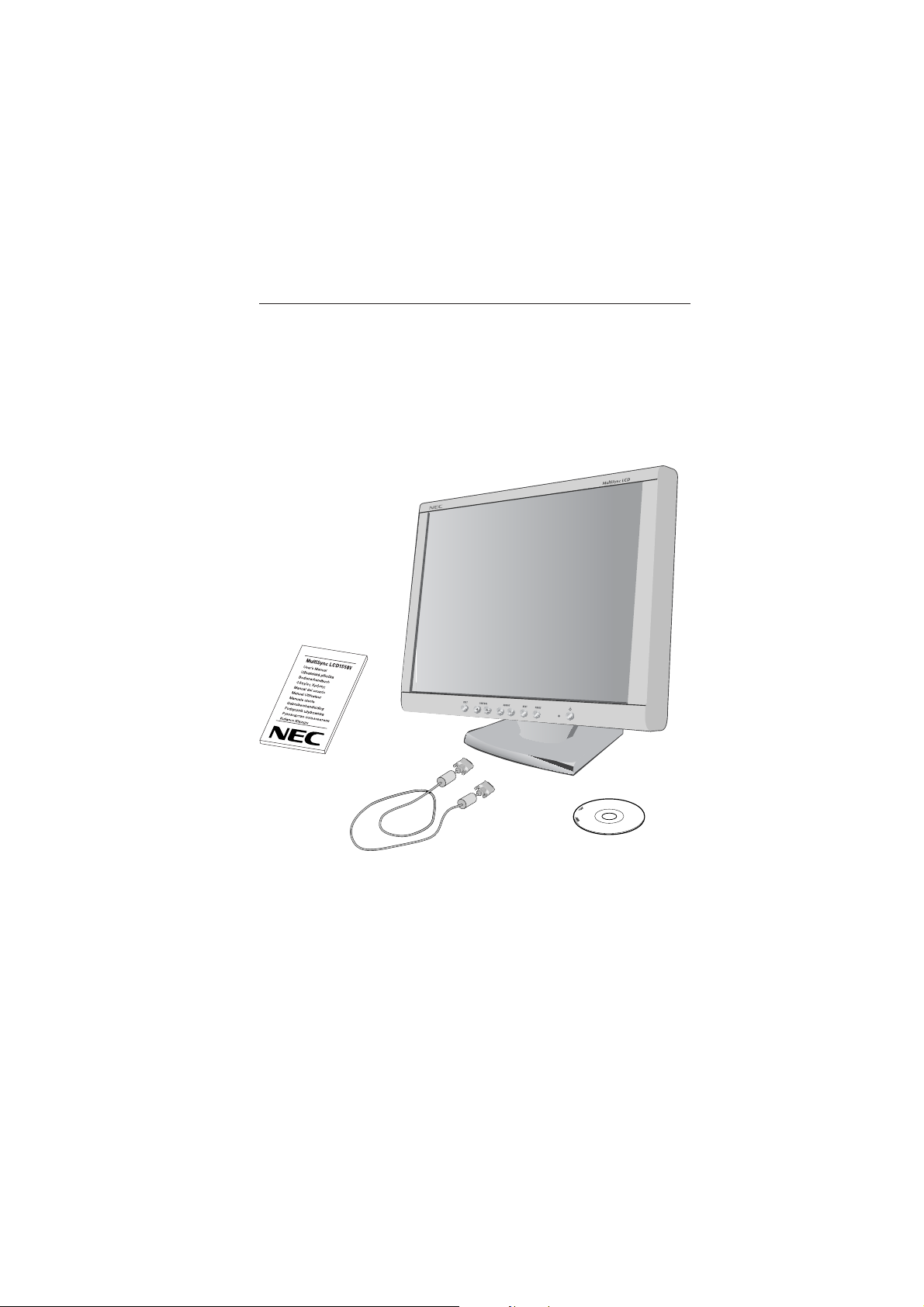

Your new NEC MultiSync LCD monitor box* should contain the following:

• MultiSync LCD1550V monitor with tilt base

• Power Cord(s)

• Video Signal Cable

• User’s Manual

• CD ROM (includes complete User’s Manual in PDF format). To see

the User’s Manual, Acrobat Reader 4.0 must be installed on your PC.

1550V

* Remember to save your original box and packing material to transport

or ship the monitor.

English-2

1-11

Page 16

Quick Start

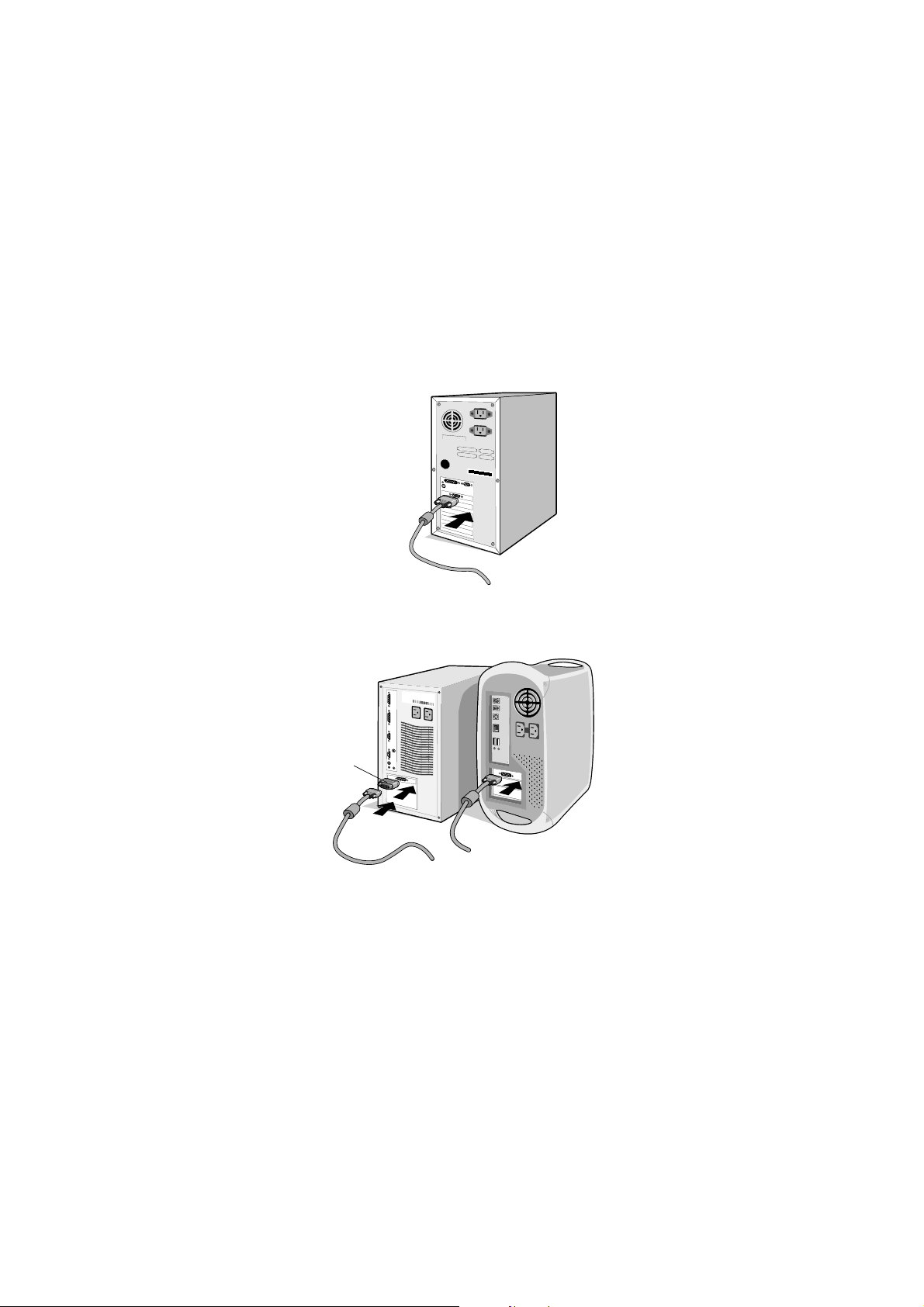

To attach the MultiSync LCD monitor to your system, follow these

instructions:

1. Turn off the power to your computer.

2. Remove connector cover and cable cover.

3. For PC: Connect the 15-pin mini D-SUB of the appropriate

signal cable to the connector for the display card in your system

(Figure A.1). Tighten all screws.

For Mac: Connect the MultiSync LCD1550V Macintosh cable

adapter to the computer (Figure B.1). Attach the 15-pin mini D-SUB

end of the appropriate signal cable to the MultiSync LCD1550V

Macintosh cable adapter (Figure B.1). Tighten all screws.

4. Connect the 15-pin mini D-SUB of the video signal cable to the

appropriate connector on the back of the monitor (Figure C.1). Place

the Video Signal Cable under Clip B.

5. Connect one end of the power cord to the MultiSync LCD Series

monitor and the other end to the power outlet. Place the video signal

cable and AC power cord under the clips (Figure C.1). Replace

connector cover and cable cover.

NOTE: Adjust the position of the cable under the clips to avoid damage

for cable or monitor.

NOTE: Please refer to Caution section of this manual for proper

selection of AC power cord.

English

6. The Vacation Switch on the right side of the monitor must be turned

on (Figure D.1). Turn on the monitor with the Power Button and the

computer.

NOTE: The Vacation Switch is a true on/off switch. If this switch is on

the OFF position, the monitor cannot be turned on using the

front button DO NOT switch on/off repeatedly.

7. No-touch auto adjust automatically adjusts the monitor to optimal

settings upon initial setup for most timings. For further adjustments,

use the following OSM controls:

• Auto Adjust Contrast

• Auto Adjust

English-3

1-12

Page 17

Refer to the Controls section of this User’s Manual for a full description

of these OSM controls.

NOTE: If you have any problems, please refer to the Troubleshooting

section of this User’s Manual.

Figure A.1

Macintosh

Cable

Adapter

(not included)

Figure B.1

English-4

1-13

Macintosh G3

and G4 do not

need a

Macintosh cable

adapter

Page 18

Figure C.1

V

0

5

5

1

Connector cover

English

Cable cover

Clip B

Power Button

Vacation Switch

Figure D.1

Tilt

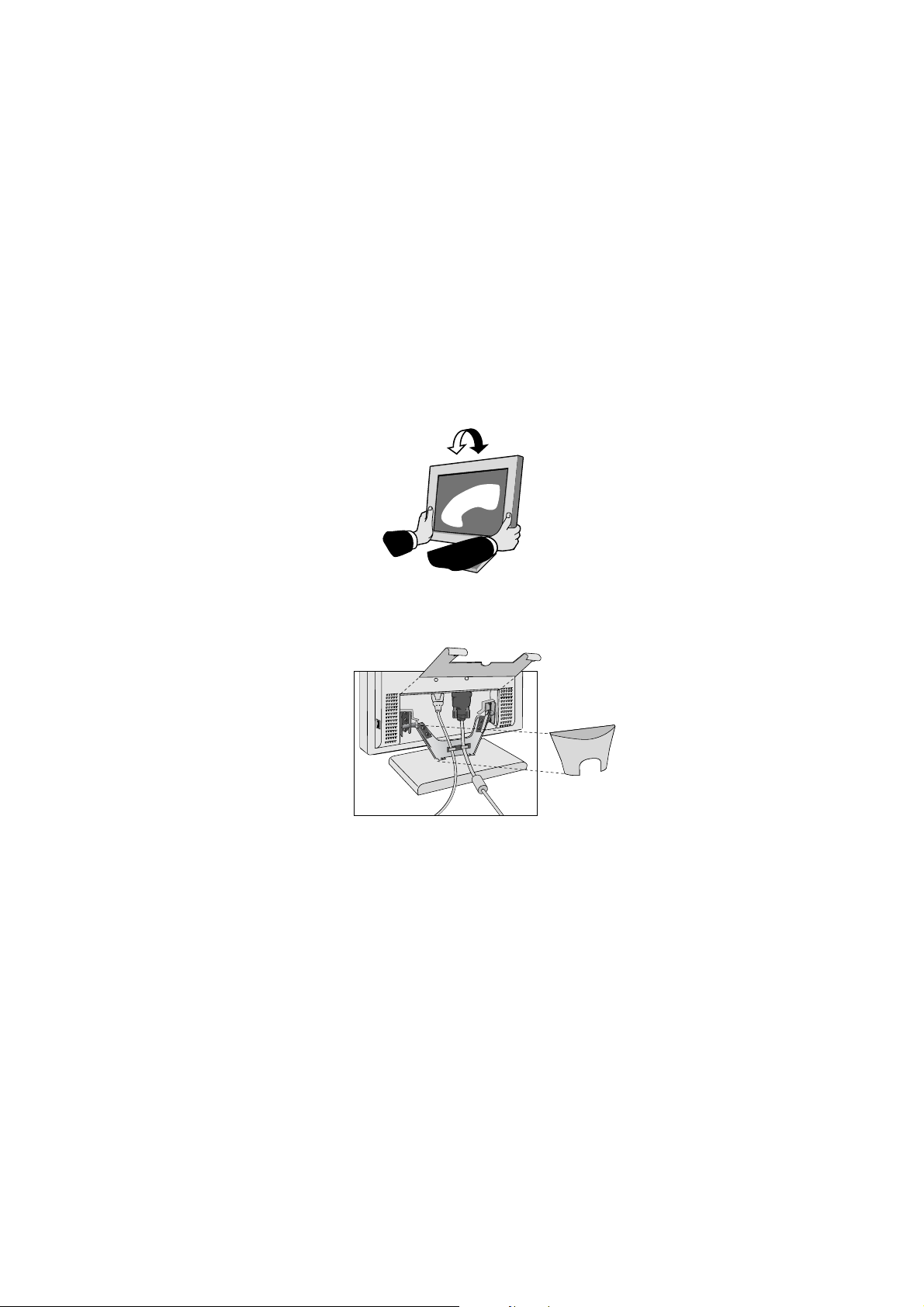

Grasp both sides of the monitor screen with your hands and adjust the

tilt as desired (Figure TS.1).

Remove Monitor Stand for Mounting

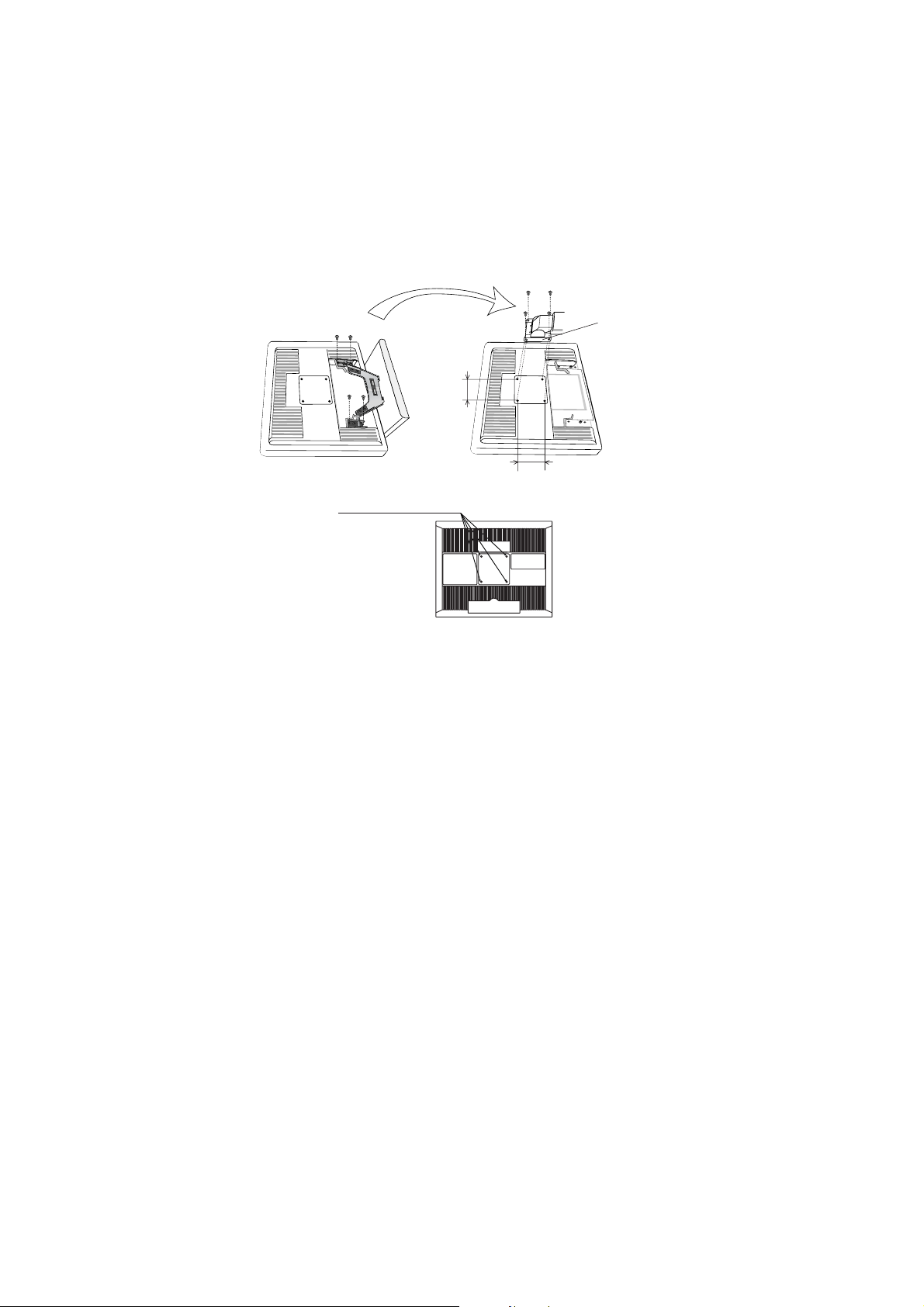

To prepare the monitor for alternate mounting purposes:

1. Remove the connector cover and cable cover (Figure R.1).

2. Disconnect all cables.

3. Place monitor face down on a non-abrasive surface (Figure R.2).

English-5

1-14

Page 19

4. Remove the 4 screws connecting the monitor to the stand and lift off

the stand assembly (Figure R.2) the monitor is now ready for

mounting in an alternate manner.

5. Connect the AC cord and signal cable to the back of the monitor

(Figure R.3).

6. Reverse this process to reattach stand.

NOTE: Use only VESA-compatible alternative mounting method.

Figure TS.1

Figure R.1

English-6

1-15

Page 20

English

Non-abrasive

surface

Figure R.2

Figure R.3

7. This LCD monitor is designed for use with a flexible arm. Please use

the attached screws (4pcs) when mounting. To meet the safety

requirements the monitor must be mounted to an arm which

guaranties the necessary stability under consideration of the weight

of the monitor. The LCD monitor shall only be used with an approved

arm (e.g. GS mark).

English-7

1-16

Page 21

Replace screws

75 mm

75 mm

Thickness of bracket (arm)

2.0 ~ 3.2 mm

Tighten all screws

4 SCREWS (M4)

(MAX depth: 8.5 mm

If use other

screw, check

depth of hole.

)

Weight of LCD assembly: 3.2kg (MAX)

English-8

1-17

Page 22

Controls

OSM (On-Screen-Manager) Controls

The OSM controls on the front of the monitor function as follows:

To access OSM press any of the control buttons (

, , -, +, NEXT).

English

Control

EXIT

CONTROL

ADJUST -/+

NEXT

RESET

NOTE: When RESET is pressed in the main and sub-menu, a warning

window will appear allowing you to cancel the RESET function

by pressing the EXIT button.

Menu

Exits the OSM controls.

Exits to the OSM main menu.

Moves the highlighted area left/right to select control

/

menus.

Moves the highlighted area up/down to select one of the

controls.

Moves the bar left/right to increase or decrease the

adjustment.

Activates Auto Adjust function.

Enter the sub menu.

Moves the highlighted area of main menu right to select

one of the controls.

Resets the highlighted control to the factory setting.

Brightness/Contrast Controls

BRIGHTNESS

Adjusts the overall image and background screen

brightness.

CONTRAST

Adjusts the image brightness in relation to the

background.

AUTO ADJUST

Adjusts the image displayed for non-standard

video inputs.

English-9

1-18

Page 23

Auto Adjust

Automatically adjusts the Image Position, the H. Size

and Fine setting.

Position Controls

LEFT/RIGHT

Controls Horizontal Image Position within the display

area of the LCD.

DOWN/UP

Controls Vertical Image Position within the display area

of the LCD.

H. SIZE

Adjusts the horizontal size by increasing or decreasing

this setting.

FINE

Improves focus, clarity and image stability by increasing

or decreasing this setting.

Colour Control Systems

Five colour presets select the desired colour setting.

Each colour setting is adjusted at the factory.

R,G,B

Increases or decreases Red, Green or Blue colour

depending upon which is selected. The change in colour

will appear on screen and the direction (increase or

decrease) will be shown by the bars.

Tools

OSM POSITION

You can choose where you would like the OSM control

image to appear on your screen. Selecting OSM

Location allows you to manually adjust the position of

the OSM control menu left, right, down or up.

English-10

1-19

Page 24

OSM TURN OFF

The OSM control menu will stay on as long as it is use.

In the OSM Turn Off submenu, you can select how long

the monitor waits after the last touch of a button to shut

off the OSM control menu. The preset choices are 10,

20, 30, 45, 60 and 120 seconds.

OSM LOCK OUT

This control completely locks out access to all OSM

control functions. When attempting to activate OSM

controls while in the Lock Out mode, a screen will

appear indicating the OSM controls are locked out.

To activate the OSM Lock Out function, press

and hold down simultaneously. To de-activate the OSM

Lock Out, press

simultaneously.

, then and hold down

, then

RESOLUTION NOTIFIER

This optimal resolution is 1024 x 768. If ON is selected,

a message will appear on the screen after 30 seconds,

notifying you that the resolution is not at 1024 x 768.

FACTORY PRESET

Selecting Factory Preset allows you to reset all OSM

control settings back to the factory settings. The RESET

button will need to be held down for several seconds to

take effect. Individual settings can be reset by

highlighting the control to be reset and pressing the

RESET button.

English

Information

DISPLAY MODE

Indicates the current display resolution and frequency

setting of the monitor.

MONITOR INFO.

Indicates the model and serial numbers of your monitor.

English-11

1-20

Page 25

OSM Warning

OSM Warning menus disappear with Exit button.

NO SIGNAL: This function gives a warning when there

is no signal present. After power is turned on or when

there is a change of input signal or video is inactive, the

No Signal window will appear.

RESOLUTION NOTIFIER: This function gives a

warning of use with optimized resolution. After power is

turned on or when there is a change of input signal or

the video signal doesn’t have proper resolution, the

Resolution Notifier window will open. This function can

be disabled in the TOOL menu.

OUT OF RANGE: This function gives a

recommendation of the optimized resolution and refresh

rate. After the power is turned on or there is a change of

input signal or the video signal doesn’t have proper

timing, the Out Of Range menu will appear.

CHECK CABLE: This function will advise you to check

all Video Inputs on the monitor and computer to make

sure they are properly connected.

English-12

1-21

Page 26

Recommended Use

Safety Precautions and Maintenance

FOR OPTIMUM PERFORMANCE, PLEASE NOTE

THE FOLLOWING WHEN SETTING UP AND

USING THE MULTISYNC LCD COLOUR MONITOR:

• DO NOT OPEN THE MONITOR. There are no user serviceable parts

inside and opening or removing covers may expose you to dangerous

shock hazards or other risks. Refer all servicing to qualified service

personnel.

• Do not spill any liquids into the cabinet or use your monitor near water.

• Do not insert objects of any kind into the cabinet slots, as they may

touch dangerous voltage points, which can be harmful or fatal or may

cause electric shock, fire or equipment failure.

• Do not place any heavy objects on the power cord. Damage to the cord

may cause shock or fire.

• Do not place this product on a sloping or unstable cart, stand or table, as

the monitor may fall, causing serious damage to the monitor.

• Do not place any objects onto the monitor and do not use the monitor

outdoors.

• The inside of the flourescent tube located within the LCD monitor

contains mercury. Please follow the bylaws or rules of your municipality

to dispose of the tube properly.

Immediately unplug your monitor from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

• When the power supply cord or plug is damaged.

• If liquid has been spilled, or objects have fallen into the monitor.

• If the monitor has been exposed to rain or water.

• If the monitor has been dropped or the cabinet damaged.

• If the monitor does not operate normally by following operating

instructions.

• Do not bend power cord.

• Do not use monitor in high temperatured, humid, dusty, or oily areas.

• Do not cover vent on monitor.

• If monitor is broken, do not come in contact with the liquid crystal.

• If glass is broken. Handle with care.

English

English-13

1-22

Page 27

• Allow adequate ventilation around the monitor so that

heat can properly dissipate. Do not block ventilated

openings or place the monitor near a radiator or other

CAUTION

• For optimum performance, allow

20 minutes for warm-up.

• Adjust the monitor height so that the top of

the screen is at or slightly below eye level.

Your eyes should look slightly downward

when viewing the middle of the screen.

• Position your monitor no closer than 40 cm

and no further away than 70 cm from your

eyes. The optimal distance is 53 cm.

• Rest your eyes periodically by focusing on

an object at least 6 m away. Blink often.

• Position the monitor at a 90° angle to windows and other light sources to

minimize glare and reflections. Adjust the monitor tilt so that ceiling lights

do not reflect on your screen.

• If reflected light makes it hard for you to see your screen, use an

antiglare filter.

• Clean the LCD monitor surface with a lint-free, non-abrasive cloth. Avoid

using any cleaning solution or glass cleaner!

• Adjust the monitor’s brightness and contrast controls to enhance

readability.

• Use a document holder placed close to the screen.

• Position whatever you are looking at most of the time (the screen or

reference material) directly in front of you to minimize turning your head

while you are typing.

heat sources. Do not put anything on top of monitor.

• The power cable connector is the primary means of

detaching the system from the power supply. The

monitor should be installed close to a power outlet which

is easily accessible.

• Handle with care when transporting. Save packaging for

transporting.

CORRECT PLACEMENT AND ADJUSTMENT OF

THE MONITOR CAN REDUCE EYE, SHOULDER

AND NECK FATIGUE. CHECK THE FOLLOWING

WHEN YOU POSITION THE MONITOR:

English-14

1-23

Page 28

• Avoid displaying fixed patterns on the monitor for long periods of time to

avoid image persistence (after-image effects).

• Get regular eye checkups.

Ergonomics

To realize the maximum ergonomics benefits, we recommend the following:

• Use the preset Size and Position controls with standard signals.

• Use the preset Colour Setting.

• Use non-interlaced signals with a vertical refresh rate between

60-75 Hz.

• Do not use primary colour blue on a dark background, as it is difficult to

see and may produce eye fatigue to insufficient contrast.

English

English-15

1-24

Page 29

1-25

Printed in Taiwan

HD67NM55101

Page 30

Serial Number Information

r

)

Refer to the serial number information shown below.

Manufactured Year :

( Last digit )

Manufactured Month :

January to September 1 to 9

October X

November Y

December Z

Panel Code: A ~ Z (Hannstar panel)

EX.) SERIAL NUMBER LABEL

Model Name : LCD1550V-1

: LCD1550V-1-BK

SERIAL NO. :

g g g g g g g g g

Serial Number(4-digit)

(sequential numbe

at production month,

0001-9999

(White model)

(Black model)

Reference: 0~9 (LG panel)

Factory Code:

Compal Taiwan factory ...... “I”

Compal China factory ...... “T”

Control Code:

A, B

2-1

Page 31

DISASSEMBLY

g Before you disassemble the set, turn off power and pull out the power plug.

g Use the proper screwdriver. If oversize or undersize screwdriver is used, screws may be damaged.

g Assembly is the opposite process of disassembly.

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION CABINET COLOR

1 FANM5522100 79PP0619 CONNECTOR COVER NM5522 AB White

1 FANM5522200 79PP0694 CONNECTOR COVER NM5522 AB Black

2 FANM5524100 79PP0589 CABLE COVER White

2 FANM5524200 79PP0607 CABLE COVER ASSY(BK-A) Black

3 --- --- SL-CPIMS*4*12*15BF ---

1

3

2

3

3 3

3-1

Page 32

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION CABINET COLOR

4 FANM5516100 79PP0587 CABINET BACK ASSY White

4 FANM5516200 79PP0606 CABINET COVER ASSY(BK-A) Black

5 --- --- #2CPITS*3*12*3AF White

5 --- --- #2CPITS*3*12*3KF Black

4

5

5

3-2

Page 33

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION

6 --- --- CPIMS(CUP)*3*6*3AF

7 --- --- SCREW SPECIAL

8 --- --- SHIELD PCB ASSY

6

8

7

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION

5 --- --- #2CPITS*3*12*3AF

9 454A5267001 79PP0584 PCBA KEY/B VK-530 LNM555G

CN1

9

5

5

5

3-3

Page 34

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION CABINET COLOR

6 --- --- CPIMS(CUP)*3*6*3AF --10 461A7367004 79PP0860 FIRMWARE CTRL/B VL-543 LN White

10 461A7367005 79PP0868 FIRMWARE CTRL/B VL-543 LN Black

CN2

CN3

J2

6

10

J1

SYMBOL CODE(Compal) CODE DESCRIPTION CABINET COLOR

6 --- --- CPIMS(CUP)*3*6*3AF --11 --- --- SPECIAL WASHER 4*8*15BF --26 --- --- CFIMS*3*6*3KF --12 453A7367001 79PP0801 PCBA POWER/B VP-543 LNS55 --13 453A7567001 79PP0802 PCBA INVERTER/B VI-543 LN --14 DC020149900 79PP0806 H-CON SET NS555 P802-SW White

14 DC020150000 79PP0855 H-CON SET NS555 P802-SW B Black

J951

P804

6

P803

13

J901

12

J911

14

11

P802

2

3-4

Page 35

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION CABINET COLOR

5 --- --- #2CPITS*3*12*3AF --16 FANM5515100 79PP0586 CABINET FRONT ASSY White

16 FANM5515200 79PP0605 CABINET FRONT ASSY(BK-A) Black

5

16

SYMBOL CODE(Compal) CODE(NMV) DESCRIPTION

17 --- --- CPIMS*2.5**4*3AF

17

17

3-5

Page 36

SYMBOL CODE(Compal) CODE DESCRIPTION

18 AC600022900 79PP0804 LCD HSD150SX84-B 15" HANNSTAR

27 NBX40000300 79PP0808 FFC 40P G P0.5 PAD=0.5 71

27

27

18

SYMBOL CODE(Compal) CODE DESCRIPTION CABINET COLOR

19 --- --- HINGE L --20 --- --- HINGE R --21 FANM5523100 79PP0620 STAND FRONT NM5523 ABS+PC White

21 FANM5523200 79PP0695 STAND FRONT NM5523 ABS+PC Black

22 --- --- BRACKET HINGE --23 FANM5517100 79PP0618 BASE ASSY NM5517 ABS+PC M White

23 FANM5517200 79PP0693 BASE ASSY-NEC NM5517 ABS+ Black

24 --- --- SL-CPIMS*4*8*15BF --25 --- ---- SL-CPIMS*4*16*15BF ---

19

20

21

24

22

25

23

3-6

Page 37

ADJUSTMENT PROCEDURES

TABLE OF CONTENTS

Page

1. Application --------------------------------------------------------------------------------------------- 2-2

2. Adjustment conditions ------------------------------------------------------------------------------ 2-2

2.1 Time for adjustment ------------------------------------------------------------------------------- 2-2

2.2 Measuring instruments, jigs, and tools ------------------------------------------------------- 2-2

2.3 Power-supply voltage ----------------------------------------------------------------------------- 2-2

2.4 Aging -------------------------------------------------------------------------------------------------- 2-2

3. Set adjustments -------------------------------------------------------------------------------------- 2-3

3.1 Power ON -------------------------------------------------------------------------------------------- 2-3

3.2 Factory mode --------------------------------------------------------------------------------------- 2-4

3.3 Factory reset and auto contrast ---------------------------------------------------------------- 2-8

4. VG-829 Setting Method --------------------------------------------------------------------------- 2-10

2-1

Page 38

1. Application

This adjustment specification shall be applied to the adjustment of the LCD1550V (LA-15R02-1) /

LCD1550V-BK (LA-15R02-1-BK).

2. Adjustment conditions

2.1 Time for adjustment

Adjustment of a unit to be adjusted shall be carried out only at the time of the adjustment of the set as a whole.

2.2 Measuring instruments, jigs, and tools

The measuring instruments, jigs, and tools required at the time of the adjustment of the unit to be adjusted shall

be as specified below.

a. A signal generator that can generate an output of signal timing produced by the adjusted (*) VG-829 or

specified in [4. Setting method for the VG-829.] In this case, however, this signal generator shall be

capable of displaying all white and all black as a screen display pattern.

* The word “adjusted” shall mean that the amplitude of each signal R, G, B, which is output from the signal

generator, is maintained at 0.7Vp-p ± 0.05V when a load of 75Ω is connected.

b. D-SUB 15-pin signal cable

c. Video signal cable

2.3 Power-supply voltage

INPUT : 100Vac ~ 240Vac ±10%, 47~63Hz

2.4 Aging

Not required.

2-2

Page 39

3. Set adjustments

r

3.1 Power ON

1) Insert the AC power cable in a wall outlet, or press the POWER key thereafter. Confirm that the LED is lit

in amber (or that an OSM of [NO SIGNAL] is displayed).

* The product shall be regarded as an NG item unless the LED is lit in amber even when the AC power cable

is inserted in a wall outlet or the POWER key is pressed.

2) Enter an input of Signal 20. Confirm that the LED is lit in green.

* The product shall be regarded as an NG item unless the LED is lit in green at that time.

3) Press the NEXT. ADJUST or Control key, and confirm that an OSM is displayed in the LCD screen.

Information

Supplementary description

The horizontal and vertical frequency values

displayed involve the errors of ±2kHz fo

horizontal and ±2kHz for vertical.

Indicate the Input signal timing mode.

Resolution /Frequency

4

(right) : No Function

3(left) : No Function

+ (plus) : No function

- (minus) : No function

NEXT : Change tag to next right direction

RESET : No function.

EXIT : Jump to main menu

Press RESET + 3 + 4 at the same time under the condition of the above OSM to enter Factory mode.

2-3

Page 40

3.2 Factory mode

Mention the contents of the service menu letter

Warning message

How to enter Service mode

1. Open Information menu (Signal information)

2. Press “3”+”4”+”RESET”

3. Indicate warning message

4. Press Next then enter Service mode

Or Press EXIT to close OSM menu

OSM Flame is CYAN

Color of frame

Service: Cyan

How to use Service mode

Page1:

The page can check user’s HOURS RUNNING and system total’s HOURS RUNNING.

1. Press “NEXT” to move cursor on HOURS RUNNING.

2. Press “3 (LEFT)” + “RESET” at the same time can check HOURS RUNNING.

3. Press “3 (LEFT)” or “4 (RIGHT)” to move cursor on FACTORY PRESET.

4. Press “RESET” + “4 (RIGHT)” can reset all function to initial (include user’s HOURS RUNNING

and AUTO INFORMATION).

2-4

Page 41

Page2:

The page can adjust RGB offset and gain.

3

1. Press

2. Press “+” or “-“ can auto balance.

How to exit Service mode

Press exit key and then close OSM menu (Service mode)

When turn off monitor in Service mode, it should exit from Service mode.

If unplug a power cord in Service mode, it should exit from Service mode too.

: Hours Running

or 4 to move cursor on AUTO GAIN or AUTO OFFSET.

Indicate On time and Off mode (power save) time(hours, minutes).

There are two timers.

The one can be cleared and the other cannot be cleared.

Following Key operation changes the timer indication.

Select Hours Running item

RIGHT+ RESET: Indicate timer which can be cleared

LEFT+ RESET: Indicate timer which cannot be cleared

LEFT+RIGHT+RESET : Timer is cleared

The indicated number should be changed every 5minutes.

On mode time xxxH xxM

Off Mode time xxxH xxM

2-5

Page 42

Page 3

: F/W ver Indicate F/W version

: Auto ADJUST COUNT

Indicate total time that Auto Adjustment (Contrast, Auto adjust) is executed.

Value should be cleared by factory reset in Service mode menu.

: OSM Menu Change

Bar or Number of User menu should be selected in Factory mode menu.

: Factory Preset in Factory mode

When proceed key is pushed at Factory preset, Hours running and auto count is cleared.

2-6

Page 43

Page 4

In this page, it is possible to modify the display style of the OSM menu.

1) Press the 3 (left) key or the 4 (right) key to adjust the cursor to the DESTINATION, MODEL TYPE,

DESIGN, or the VCO TYPE.

2) When the + or - key is pressed, each display style is changed.

DESTINATION (The OSM menu for each destination is changed.)

0: Overseas : Shipment setting

1: (Reserve)

2: Domestic

MODEL TYPE (The MODEL name of MONITOR INFO. is changed.)

B : LCD1550V : Shipment setting

BK : LCD1550V BK : Shipment setting

M3X : RDT153X

DESIGN (The adjusting value displayed is modified into a bar or a numeral.)

BAR: The adjusting value is displayed in a bar. : Shipment setting

DBG: The adjusting value is displayed in numerals. (Debug)

VCO TYPE

CAL : Shipment setting

FIX : (For evaluation)

When finishing the factory mode:

1) When the EXIT key is pressed, the OSM menu (factory mode) is closed and the factory mode is

finished.

2) If the monitor power supply is turned off in the factory mode, the factory mode is finished.

3) Even when the power cord plug is pulled out of the wall outlet in the factory mode, the factory mode

is also finished.

2-7

Page 44

3.3 Factory reset and auto contrast

1) To display information of OSM on LCD screen.

2) Press “RIGHT” + “LEFT” + “RESET” key at same time.

3) LCD screen display warring message.

4.1) Press “exit” key will exit factory mode.

4.2) Press “NEXT” key will enter factory mode.

5) When enter factory mode and move make to FACTORY PRESET.

6) Press “PLUS” or “MINUS” key and will clear HOURS RUNNING, AUTO INFORMATION and EEPROM etc.

2-8

Page 45

7) Move make to item 2 and change input video pattern to gray scale.

8) Move make to AUTO GAIN and AUTO OFFSET.

9) Press “PLUS” or “MINUS” key can adjust RGB offset and gain.

10) Exit factory mode press “exit” key.

2-9

Page 46

4. VG-829 Setting Method

Signal VG-829

Mode

H

V

OUTPUT

PAT SEL

CHARA

PATTERN

GRAY Direction:0 L0:0 L1:17 L2:34 L3:51 L4:68 L5:85 L6:102 L7:127

DOT CLOCK [MHz] 78.75

TOTAL [DOT]

DISP [DOT]

SYNC PULSE [DOT] 96

BACK [DOT] 176

HDstrat [DOT] 0

HDwidth [DOT] 0

INTERLACE NON

TOTAL [H] 800

DISP [H] 768

SYNC PULSE [H] 3

BACK PORCH [H] 28

EQPfp [H] 0

EQPbp [H] 0

SERRATION [H] OFF

EDP [H] OFF

VDs [H] 0

VBf [H] 0

OUTPUT MODE ANALOG

NRZ/RZ NRZ

CV

HS POS

VS POS

CS NEG

HD NEG

VD NEG

RGB POS

HT POS

C NEG

VIDEO 0.70V

Set-up 0.00V

Sync 0.30V

Format

Code

Font

Cell

1312

1024

GRAY

1

82

16*16

16*16

L8:143 L9:159 LA:175 LB:191 LC:207 LD:223 LE:239

LF:255

20

2-10

Page 47

INSPECTION

1. Inspection of PLUG & PLAY communication and OSM "MONITOR INFORMATION" for model name/ serial number

1.1 A construction of System

This system should be connected as shown below.

PROGRAM

P ART No. 599910552

Signal Generator

R G B H V

AUTO ADJ I/F JIG

Part No. 599910401 (120V) (For A ver.)

Part No. 599910402 (220V) (For B ver.)

D-sub to D-Sub 15pin Signal Cable

1.2 Input Signal

Horizontal synchronization frequency : No specified.

Vertical synchronization frequency : No specified.

1.3 Programs required

PNP.EXE

PNP.INI

Program D isk

PC

Printer Cable

08109741.MDL

EDID550V.TXT

5-1

Page 48

1.4 Operational procedures

1. Start PNP.EXE from DOS mode or DOS pronto of Windows.

2. Operation key assignment

• Determine the operation mode with the F1 ~ F9 and ESC keys.

F1: (Select Model) Setting file changeover for respective models.

F4: (Read) EDID data for reading.

F5: (Write Input 1) It is not used in this model.

F8: (Write Input 2) EDID data is written in.

F9: (Write ALL) It is not used in this model.

ESC: (EXIT) End of program.

3. Press the F1 key and enter an input of setting file for the related model. Press the Enter key.

File name Model

08109741 LCD1550V

4. Writing and inspection procedures

a. Press the F8 key (Write Input 2).

b. Since the screen is changed over to the one that waits for an input of serial number, examine the serial

number of the set, enter it from the keyboard, and press the Enter key.

The message of the screen:

Model Name "LCD1550V"

Input serial number (Enter only: Use previous number)

c. EDID data writing and inspection

According to the screen commands, make connections for the connectors and change over the

signals.

The message of the screen:

Input 1 File 1 set V 42Hz N (Hit any key)

Notes: This message does not need to be followed. The D-SUB connector is connected and

arbitrary signals a received.

When the Enter key is pressed, the write and inspection of EDID data are performed.

d. Upon normal completion, a screen display is presented "OK".

e. Serial number writing for the OSM “MONITOR INFORMATION”.

* The signal cable of equipment is connected with a signal generator.

* It goes into the factory mode and returns to the user mode, without carrying out anything.

* A Display “MONITOR INFORMATION.” of the OSM, and confirm that the model name

(LCD1550V or LCD1550V BK) and serial number have been correctly written.

5-2

Page 49

1.5 EDID data file

The EDID data file text is shown below. When you write or inspect EDID for this monitor, the following table

can be used.

file name : EDID550V.TXT

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 FF FF FF FF FF FF 00 38 A3 C6 65 01 01 01 01

00

25

0B

10

*1)

1E 50 54 BF EE 00 01 01 01 01 01 01 01 01 01 01

20

01 01 01 01 01 01 C3 1E 00 20 41 00 20 30 10 60

30

13 00 30 E4 10 00 00 1E 00 00 00 FD 00 37 4B 1F

40

3C 08 00 0A 20 20 20 20 20 20 00 00 00 FC 00 4E

50

45 43 20 4C 43 44 31 35 35 30 56 0A 00 00 00 FF

60

00 31

70

Note 1: address 10h Week of manufacture = Month of manufacture × 4

Note 2: address 11h Year of manufacture - 1990

01 03 08 1E 17 78 EA 7E A5 A0 58 4E 96 25

*2)

35 30 30 30 30 31 49 41 0A 20 20 20 00 49

*3)

Table 1.5 Data list

*4)

Notes 3: address 71h ~ 7Dh Serial Number (ASCII coded)

If less than 13 char, terminate with 0Ah and fill the rests with 20h.

Note 4: address 7Fh Checksum

The sum of entire 128 byte shall be equal to 00h.

5-3

Page 50

2. External inspection on the LCD module

Inspection condition is approximately 15-50cm

Viewing angle is normal to the LCD panel.

Ambient temperature is in the room temperature.

Ambient illumination is 300-500Lux.

Display characteristics

Defect type Criteria

Dark / Bright Spot

Circular Foreign Material

Visual defect

D: Diameter

N: Number

W: Horizontal width

L: Vertical high

Electrical defect

N: Number

Bright or Dark Line

Foreign Material

Polarizer / Linear Scratch

Polarizer – bubble / Peeling

Maximum Allowable Defect

Count All Types

Bright Dot Random

Bright Dot 2 Adjacent

Dark Dot Random

Dark Dot 2 Adjacent

Dark Dot 3 or More Adjacent N=0

Total Bright and Dark Dots

Minimum Distance Between Bright Dots

Minimum Distance Between Dark Dots

Minimum Distance Between Bright Dots

and Dark Dots

0.2mm≤D<0.5mm

N≤4

0.05mm≤W<0.2mm

0.3mm≤L≤3mm

N≤4

0.01mm≤W<0.2mm

1.0mm≤L≤10mm

N≤3

0.15mm≤D<0.25mm

N≤4

N≤7

N≤4

N≤2

N≤4

N≤3

N≤4

≥15mm

≥10mm

≥10mm

5-4

Page 51

Note(1): Bright dot defect description

Two adjacent

Type2

Note(2): Dark dot defect description

Two adjacent

Type2 Type3

Note(3): Dark dot defect description

Type1

Type3

Type1

Three adjacent

Type1

Type2 Type3 Type4

5-5

Page 52

Not(4): Minimum distance between dot defect

Bright dot to bright dot

<15mm

NG

Dark dot to dark dot

<10mm

NG

Bright dot to dark dot

<10mm

NG

Note(5): “Average Diameter” description

Dusts would be judged by “Average Diameter” under vertical high ≥0.1mm and horizontal width ≥0.1mm

condition.

Average Diameter D=(a+b)/2

b

a

5-6

Page 53

3. Safety Tests

Perform the following inspection tests in accordance with the standards set forth in Common Electrical

Safety Inspection Standards for Information Processing Device & Office Equipment (DSQS-009-103).

Destination : World wide

Applicable Regulations : UL1950, CSA C22.2 No 950 (C-UL), DHHS, TUV (EN60950), CE, PTB

Classification : Class I device (with safety ground), movable

Ratings : AC 100-240V, 50/60Hz,

Unless otherwise specified, rating voltage is 240V.

3.1 Ground Continuity

( It is applied to the PSU built-in set. )

Perform the test at the points indicated below and make sure that the ground continuity values are within

the prescribed range. (This test is to be performed before the electric strength test.)

1) The Ground Line of inlet shall be satisfied indicated below.

a) The color of Ground Line is spiral of green and yellow.

b) The Ground Line is connected at specified point on the chassis base with specified screw.

2) Measurement Point- Between the ground terminal of power supply cord and the chassis Screw

The standard for a decision : Less than 0.1ohm. ( Input current 25A)

3.2 Electric Strength

( It is applied to the PSU built-in set. )

Perform the tests at the points indicated below and make sure that there is no dielectric breakdown or

flashing.

Measurement Points

Make measurements between the power supply terminals (other than the ground terminal) and each

of the following points : (See note below.)

Signal cable connector shell

Chassis base

Note : The two terminals other than the ground terminal (power supply cord) must be shorted out.

The standard for a decision : Less than 10mA. ( Input voltage 1500V AC )

5-7

Page 54

3.3 Leakage Current

( It is applied to both the PSU built-in set and the set with AC adapter. )

Perform the tests at the points indicated below and make sure that the leakage current is within the

prescribed range. (This test must be performed after the electric strength test.)

Measurement Points

Make measurements between the terminals of AC inlet (other than the ground terminal) and each of

the following points :

Signal cable connector shell

Chassis base

Note : Power switch status ; "ON" and "OFF" condition.

The standard for a decision : Less than 1.5 mA. ( Input voltage 255V AC (60Hz))

Measurement condition : The leakage ammeter builds in the resistor of 1500 ohm, and uses a thing

with the bypass condenser of 0.15uF.

3.4 Insulation Resistance

( It is applied to the PSU built-in set. )

Perform the tests at the points indicated below and make sure that the insulation resistance is within the

prescribed range. (This test must be performed after the electric strength test.)

Measurement Points

Make measurements between the power supply terminals (other than the ground terminal) and each

of the following points : (See note below.)

Signal cable connector shell

Chassis base

Note : The two terminals other than the ground terminal (Power supply cord) must be shorted out.

The standard for a decision : More than 30Mohm. (Input voltage 500V DC)

5-8

Page 55

TROUBLE SHOOTING

TABLE OF CONTENTS

1. No display of screen (Screen is black, color of LED is amber) ------------------------- 6-2

2. Nothing displays on screen (Screen is black, color of LED is green) ----------------- 6-3

3. Checking the back light unit --------------------------------------------------------------------- 6-6

4. Abnormal screen ---------------------------------------------------------------------------------- 6-7

5. No OSM display ----------------------------------------------------------------------------------- 6-9

6. Abnormal Auto adjustment ---------------------------------------------------------------------- 6-10

7. Abnormal plug and play operation ------------------------------------------------------------ 6-11

7.1 Abnormal DDC2 ---------------------------------------------------------------------------------- 6-11

8. Checking the interface circuit of sync signal ------------------------------------------------ 6-12

8.1 Checking the control circuit of horizontal sync pulse ------------------------------------ 6-12

Page

8.2 Checking the control circuit of vertical sync pulse --------------------------------------- 6-13

9. Checking the resolution change IC movement --------------------------------------------- 6-14

10. No power on -------------------------------------------------------------------------------------- 6-15

11. Checking the operation of CPU --------------------------------------------------------------- 6-16

6-1

Page 56

1. No display of screen (Screen is black, color of LED is amber)

Y

Does OSM display when you

push “NEXT, Adjust or Control”

button.

When a signal isn't being inputted, it is indicated with "NO SIGNAL".

It is indicated with "OUT OF RANGE" at the time of the frequency that it

can't be distinguished.

NO

Proceed section 4 “No OSM

display”.

ES

Check if the sync signal from Computer is output

and if the video cable is connected normally.

NG

OK

Proceed section 9 “Checking the resolution

change IC movement”.

Input the sync signal of computer, or

change the cable.

6-2

Page 57

2. Nothing displays on screen (Screen is black, color of LED is green)

g

)

Does computer output RGB

video si

Check OSM menu is displayed on screen

when you push the “NEXT, Adjust or

Control” key.

Is backlight lit?

NG

OK

nals?

NG

OK

NG

Refer to section 3

“Checking the backlight unit.

Check the video cable for failure.

Check the host for output signal with all black only.

1) Change pattern of video signal output on the host.

2) Reconnect the video cable.

3

Change the video cable.

Check if the LCD video signal cable is connected

between the MAIN board and LCD module.

OK

Proceed section 4

“Abnormal screen“.

OK

Next page

NG

Failure point

The cable is disconnected.

6-3

Page 58

Continue

Is 5V-source voltage provided to pins 1 and 2 of J2 in

MAIN board.

OK

NG

Is 5V-source voltage provided to pins 1

and 2 of P803 in SW REG board.

OK

Failure point

J2 cable pulled out or disconnected

Is a dot clock being outputted under the condition that a

LCD module is connected to CN2 and CN3 pin 26?

NG

OK

Check the STH pulse of negative polarity is

output on CN2 pin 29 at TTL level.

OK

NG

Check the STV1 and STV2 of negative

polarity are ouput on CN2 pin 35, 36.

NG

OK

NG

Failure point

Error in SW REG board.

Failure point

1) U3 failure.

2) Printed wire broke between

U3 and CN2, CN3 pin26.

3)L10, R63, L11 or R64 failure

Failure point

1) U3 failure.

2) Printed wire broke between

U3 and CN2 pin 29.

3) R68 or L14 failure

Failure point

1) U3 failure.

2) Printed wire broke between

U3 and CN2 pin 35, 36.

3)R72, R73, L18 or R25 failure

next page

6-4

Page 59

Continue

Check the LOAD, POL, REV, CPV, OE of positive

polarity are ouput on CN2 pin 30, 31, 32, 37, 38.

NG

OK

Check the data signal output on CN3 and CN2 R, G,

B data pin.

NG

OK

Failure point

1) U3 failure.

2) Printed wire broke between U3 and

CN3 pin 30, 31, 32, 37, 38.

3)R69, 70, 71, 74, 75, L15,16, 17, 20

or L21 failure

Failure point

1) U3 failure.

2) Printed wire broke between

U3, CN2 and CN3 data line.

Failure point

The cable broke between CN2, CN3 and LCD module.

6-5

Page 60

3. Checking the back light unit

Is 12V-source voltage provided

to pins 1 and 2 of P804 in SW

REG board?

OK

Is 12V-source voltage provided

to pins 1 and 2 of J901 in

inverter board?

OK

Check the ON/FF signal of equal “H” at J901 pin3?

OK

Check F901 open

NG

NG

NG

Error in SW REG board.

Failure point

Inverter cable disconnection.

1) u-p failure

2) printed wire broke between u-p trace to P804 pin3

OK

NG

1) Inverter cable disconnection.

2) C915, C955 open

Failure point

F901 failure. Replace the

inverter board

NG

Failure point

Failure point

6-6

Page 61

4. Abnormal screen

p

Check the R, G, B video signal from computer

in

ut on D-Sub R,G,B connector.

OK

Check the R,B,G input signals on U3 pin 17, 24,

30,respectively that their level is 0.7Vp-p

maximum.

OK

OK

Is the pulse of the TTL level being out put to

CN2 and CN3 from the data line of U3?

OK

Check the negative STH sync pulse output to

CN2 pin 29 from U13 pin 92 at TTL level.

OK

Check the negative STV1 and STV2 sync pulse

output to CN2 pin35 from U3 pin 83, 84 at TTL

level.

OK

NG

NG

NG

NG

NG

Check the positive sync pulse output LOAD,

POL, REV, CPV, OE to CN2 pin 30, 31, 32, 37,

38 from U3 pin 91, 90, 85, 82 at TTL level.

OK

NG

Next Page

Failure point

1) No R, G and B video signal output from host

computer. Check computer.

2) Video signal cable disconnection.

Failure point

In the case of the Red signal. (A Green and

Blue signal is the same path, too.)

Printed wire broke between D-Sub(R,G,B) and

U3 pin 17,24,30.

Failure point

Printed wire broke between U3 data line and

CN2,CN3.

Failure point

Printed wire broke between U3 pin 92 and CN2

pin 29.

Failure point

Printed wire broke between U2 pin 35, 36 and

CN2 pin 25, 36.

Failure point

Printed wire broke between U3 pin 91, 90, 85,

82, 81 and CN2 pin 30, 31, 32, 37, 38.

6-7

Page 62

Continue

Check the CPH clock output to CN2 and CN3

pin 26 from U3 pin 123 at TTL level.

NG

OK

Proceed section 9 “Checking the resolution

change IC movement”.

Failure point

Printed wire broke between U3 pin 123

and CN2, CN3 pin 26.

6-8

Page 63

5. No OSM display

p

Check the output of pulse from U3 pin105 ~118 and pin 124 ~ 140

when

ress NEXT, ADJUST or CONTROL key.

NG

OK

Proceed section 9 “Checking the resolution

change IC movement”

Printed wire broke between U3 pin105 ~ 118, 124 ~

140 and CN2, CN3.

6-9

Page 64

6. Abnormal Auto adjustment

Check the input of pulse from U3 pin 49 ~ 61, 67 ~75.

OK

Proceed section 9 “Checking the resolution change IC movement”.

NG

Check the output of pulse from U6 pin 3, 4, U7 pin 3, 4, 7, 8, 13, 14, 17, 18.

OK

NG

1) Printed wire broke between U6 pin 2, 5 and U8 pin 2, 30.

2) Printed wire broke between U7 pin 2, 5, 6, 9, 12, 15, 16, 19 and

U8 pin 13~15, 17 ~ 21.

Check the output of

pulse from U3 pin

49 ~ 61, 67 ~75

Failure point

OK

Failure point

(1) Printed wire broke between

U6 pin 3,4 and U3 pin 49,

50.

(2) Printed wire broke

between U7 pin 3, 4, 7, 8,

13, 14, 17, 18 and U3 pin

51 ~ 58, 67 ~ 75.

6-10

Page 65

7. Abnormal plug and play operation

7.1 Abnormal DDC2

Confirm the output of serial data on U9 pin 6 synchronize

SCLK at TTL level.

OK

1) The host machine isn't communicating in DDC2 mode.

2) The video cable may have failed or may not to have

connections for DDC.

3) Between U19 pin 6 and CN1 pin 15 may have failed.

4) Cable failure.

NG

Failure point

U9 failure.

Failure point

6-11

Page 66

8. Checking the interface circuit of sync signal

8.1 Checking the control circuit of horizontal sync pulse

Check the horizontal sync signal on U1 pin 1 at TTL

level.

OK

Check the hovizuntal sync signal on U3 pin 206 a

TTL level.

OK

Procees section 9 “Checking the resolution change

IC movement”

NG

NG

Failure point

1) No separate sync or composite sync

output by host. (Confirm the host,

output the sync signal.)

2) Video cable may have failed.

3) Printed wire broke between CN1 pin

13 and U13 pin 30.

4) R10, R38, L14, R74 open.

5) U12 failure.

Failure point

U3 failure

6-12

Page 67

8.2 Checking the control circuit of vertical sync pulse

Check the vertical sync signal on U1 pin 11

at TTL level.

NG

OK

1) No separate sync output signal from the host.(Check the

2) Video cable may have failed.

3) Printed wire broke between CN1 pin 14 and U1 pin 11.

4) R10 open.

5) U1 failure

Proceed section 9 “Checking the resolution

change IC movement”.

Failure point

host.)

6-13

Page 68

9. Checking the resolution change IC movement

Is there +3.3V supply on U3 pins 65, 76, 86, 121, 143, 157, 167, 198, 193, 183, 179, 175, 188.

Is there +2.5V supply on U3 pins 5, 7, 10, 11, 12, 15, 18, 21, 22, 25, 28, 31, 35, 36, 42, 63, 76,

88, 119, 141, 159, 162, 163, 166, 169, 170, 189, 190, 196.

OK

Is 14.318MHz clock input to U3 pin 3, 4 at

TTL level.?

OK OK

Proceed section 11 "Checking the

operation of CPU"

NG

NG

Is 14.318MHz clock output from Y1 at TTL

level.?

Failure point

Y1 failure

Proceed section 11 "Checking the

operation of CPU"

6-14

Page 69

10. No power on

Check the +12V power provided from SW REG

board.

Check the +5V power from SW REG board.

OK

Is LED turned on in amber momentarily when

power button is pushed.

OK

Proceed section 11 "Checking the operation of

CPU".

OK

NG

NG

NG

Failure point

SW REG board failure.

Failure point

SW REG board failure.

Failure point

SW REG board failure.

6-15

Page 70

11. Checking the operation of CPU

Is there +5.0V supply on U8 pin 32.

OK

OK

NG

Printed wire broke between output J2 pin1, 2 and U8

power supply pin 32.

Is 14.318MHz clock input to U3 pin 3, 4 at TTL level?

NG

Failure point

Y1 failure.

Failure point

U3 failure.

Failure point

6-16

Page 71

CIRCUIT DESCRIPTION

TABLE OF CONTENTS

Page

1. Power Circuit ------------------------------------------------------------------------------------- 7-2

1.1 Power input block ------------------------------------------------------------------------------ 7-2

1.2 Power control block --------------------------------------------------------------------------- 7-2

2. Microcomputer Control Circuit ---------------------------------------------------------------- 7-2

2.1 Clock circuit ------------------------------------------------------------------------------------- 7-2

2.2 Microcomputer port circuit ------------------------------------------------------------------- 7-2

2.3 PIO (General-purpose port) ----------------------------------------------------------------- 7-2

3. Input Image Enlargement Display Circuit -------------------------------------------------- 7-3

3.1 Jag-D ---------------------------------------------------------------------------------------------- 7-3

4. EEPROM Control Circuit ---------------------------------------------------------------------- 7-3

4.1 Data memory ------------------------------------------------------------------------------------ 7-3

5. Auto-adjuster circuit control ------------------------------------------------------------------- 7-3

5.1 Video level adjusting function --------------------------------------------------------------- 7-3

7-1

Page 72

1. Power Circuit

1.1 Power input block (Circuit diagram: SW REG board)

A power supply for internal 12V and 5V are gained from the power connector through the voltage

supervisory circuit.

1.2 Power control block

1.2.1 Basic power control

SW REG board is used to generate the system power. It have built in PWM controllers to provide two

voltage output, one is provided for microprocessor or other TTL level IC (+5V) etc., the other one is provided

for the power of inverter (+12V). These two supply power used the same oscillation frequency, the same

start-up circuit, and the same protection circuit, so they can avoid the interference each other.

1.2.2 3.3V power control (Circuit diagram: MAIN Board P.4/5)

The U11,U10 are DC converter for the 3.3V power system. It output fixed 3.3V. The U16 is a DC converter

for 2.5V power system. It out fixed 2.5V.

3.3V power are fed to S9050,and panel. 2.5V power is only fed to S9050.

1.2.3 LCD panel 3.3V power control (Circuit diagram: MAIN Board P.5/5)

Panel power control used Q6 and U15 from S9050(pin_94) PENVDD.

When the PENVDD stays at the high level, the Panel voltage is 3.3V .

When the PENVDD stays at the low level, the Panel voltage is 0V .

(Circuit diagram:

MAIN Board)

2. Microcomputer Control Circuit

2.1 Clock circuit (Circuit diagram: MAIN Board P.3/5)

The Y1 is a crystal the microcomputer. It generates an output of 14.318MHz.

2.2 Microcomputer port circuit (Circuit diagram: MAIN Board P.3/5 and P.1/5)

S9050 has an embedded Microcontroller link to U8 Flash Rom.

2

2.2.1 I

2.2.2 S9050 and Flash ROM communication buses

C buses

U3 (PIN40) (GPIO2) SDDAT Serial data

U3 (PIN39) (GPIO1) SDCLK Serial clock

2

This is an I

U3 (PIN75) MCAD0

U3 (PIN74) MCAD1

U3 (PIN73) MCAD2

U3 (PIN72) MCAD3

U3 (PIN71) MCAD4

U3 (PIN70) MCAD5

U3 (PIN69) MCAD6

U3 (PIN68) MCAD7

U3 (PIN67) MCA8

U3 (PIN57) MCA9

U3 (PIN56) MCA10

C serial communication bus and is used for R or W data communication of U2 and U9.

U3 (PIN55) MCA11

U3 (PIN54) MCA12

U3 (PIN53) MCA13

U3 (PIN52) MCA14

U3 (PIN51) MCA15

U3 (PIN50) MCAD16

U3 (PIN49) MCAD17

U3 (PIN61) CS0#

U3 (PIN60) MCWR#

U3 (PIN59) MCRD#

7-2

Page 73

2.3 PIO (General-purpose port) (Circuit diagram: MAIN Board P.3/5)

2.3.1 Key scan status

U3 GPIO20 (pin 203) Key2-1 and GPIO 17 (pin 80) Key1-2 output pulses continuously. If Keys are pressed,

microcomputer will detect U3 signal to judge which key is pressed.

2.3.2 D-sub cable status signal

U3 GPIO5 (PIN96) CABLE-DETECT

This is an IN/OUT supervisory signal for the D-sub cable.

It is set at the low level when the cable is connected.

2.3.3 LED control

U3 GPIO3 (PIN41) LEDY

U3 GPIO19 (PIN78) LEDG

These signals are used for the LED lighting control.

When GPIO3 is high the LEDY lit and GPIO19 is low the LEDG lit.

3. Input Image Enlargement Display Circuit

3.1 S9050 (Circuit diagram: MAIN Board P.1/5)

The S9050 (U3) is controlled through the internal microcomputer.

The S9050 is provided with the analog interface D-SUB (CN1) and the digital interface.

4. EEPROM Control Circuit

4.1 Data memory (Circuit diagram: MAIN Board P.3/5)

The display control data are held by the EEPROM (U9). These display control data are accessed through

the IIC bus of the microcomputer.

5. Auto-adjuster circuit control

5.1 Video level adjusting function

Functions of VIDEO RAM are also used for the automatic contrast adjustment (video level adjustment).

For the microcomputer, a maximum value of the entered one screen or the level data in the specified area

can be used.

This readout value is used for the black level setting and white level setting (contrast setting) for the VIDEO

amplifier.

7-3

Page 74

REPLACEMENT PARTS LIST

)

V

The components specified for Model LCD1550V-1(B

SYMBOL Part No for Compal Part No forNM

*** ICS ***

U1 SA074140400 79PP0843 S IC SN74LVC14 SOP-14 INV

U10 SA011170300 79PP0842 S IC APL1117-33VC-TR SOTU11 SA010840200 79PP0841 S IC AIC1084-33CE TO252-3

U12 SA744066000 79PP0484 SM IC 74HC4066D SOP-14 AN

U13 SA011170200 79PP0626 IC APL1117-25 SOT-223 2.5

U14 SA011170200 79PP0626 IC APL1117-25 SOT-223 2.5

U15 SB923050000 79PP0846 S TR SI2305DS-T1 1P SOT-2

U2 SA024210300 79PP0627 IC EE 128X8 SOP-8 24LC21A

U3 SA090500000 79PP0844 S IC S9050-100 QFP-208

U4 SA007810010 79PP0840 FS781 BZB SOP-8 SPREAD CL

U5 SA008100300 79PP0625 IC LM810M3X-4.38 SOT-23

U6 SA7437382T2 79PP0845 S IC 74HCT373 (SSOP-20)

U7 SA7437382T2 79PP0845 S IC 74HCT373 (SSOP-20)

U8 SA002610000 79PP0839 S IC EPROM PLCC-32 MX26C1

U800 AB008170000 79PP5290 IC LTV-817M-B DIP-4 PHOTO

U801 AB038420404 79PP5021 IC KA3842A DIP-8 PWM

U802 AB0043101T3 79PP5289 IC KA431Z TO-92 REGULATOR

U9 SA024160008 79PP0359 IC EE 16K SO-8 C

U901 SA097410000 79PP0632 IC BA9741F SOP-16 PWM

DESCRIPTION

*** TRANSISTORS ***

Q1 SBX012400T0 79PP0058 TR DTC124EK (SOT-23)

Q2 SBX012400T0 79PP0058 TR DTC124EK (SOT-23)

Q3 SB7700200T5 79PP0189 TR 2N7002

Q4 SB1103600T3 79PP0055 TR 2SA1036K (SOT-23)

Q5 SB7700200T5 79PP0189 TR 2N7002

Q6 SBX012400T0 79PP0058 TR DTC124EK (SOT-23)

Q801 BB527610001 79PP5310 TRANSISTOR 2SK2761-01MR 1

Q802 BB3014500T7 79PP0735 TR HTL145 NPN TO-92

Q803 BB30945P1T5 79PP5028 TRANSISTOR 2SC945-P

Q804 BC9T169D0T7 79PP5323 SCR BT169D TO-92

Q901 SB3241100T8 79PP0057 TR 2SC2411K (SOT-23)

Q902 SB8A12400T1 79PP0635 TR DTA124EK (SM)

Q911 SB3241100T8 79PP0057 TR 2SC2411K (SOT-23)

Q912 SB8A12400T1 79PP0635 TR DTA124EK (SM)

Q913 SB3467200T3 79PP0634 TR 2SC4672 (SOT-89)

Q914 SB3467200T3 79PP0634 TR 2SC4672 (SOT-89)

Q915 SB7700200T5 79PP0189 TR 2N7002

Q916 SB934570000 79PP0636 TR SI3457DV-T1 1P TSOP-6

Q951 SB3241100T8 79PP0057 TR 2SC2411K (SOT-23)

Q952 SB8A12400T1 79PP0635 TR DTA124EK (SM)

8-1

Page 75

SYMBOL Part No for Compal Part No forNM

V

DESCRIPTION

Q953 SB3467200T3 79PP0634 TR 2SC4672 (SOT-89)

Q954 SB3467200T3 79PP0634 TR 2SC4672 (SOT-89)

Q955 SB7700200T5 79PP0189 TR 2N7002

Q956 SB934570000 79PP0636 TR SI3457DV-T1 1P TSOP-6

*** DIODES ***

BD801 BC3BP08M100 79PP0814 DIO (BR) 2KBP08M PANJIT

D1 SC10QS041T4 79PP0061 DIODE EC10QS04

D2 SC10QS041T4 79PP0061 DIODE EC10QS04

D3 SC4LZ56B0T5 79PP0380 ZENER DIODE RLZ5.6B(LL-34

D4 SC4LZ56B0T5 79PP0380 ZENER DIODE RLZ5.6B(LL-34

D5 SC4LZ56B0T5 79PP0380 ZENER DIODE RLZ5.6B(LL-34

D6 SC4LZ56B0T5 79PP0380 ZENER DIODE RLZ5.6B(LL-34

D801 BC1PS1010T0 79PP0832 DIO PS1010R DO-41 PANJIT

D802 BC1PS1040T0 79PP0833 DIO PS104R DO-41 PANJIT

D803 BC11N4148T8 79PP0258 DIODE 1N4148

D804 BC11N4148T8 79PP0258 DIODE 1N4148

D805 BC11N4148T8 79PP0258 DIODE 1N4148

D806 BC11N4148T8 79PP0258 DIODE 1N4148

D841 BC1ER100200 79PP0736 DIODE ER1002F T0-220F

D842 BC1SB5600N0 79PP0813 DIO SB560-F17 DO-201AD P2