Page 1

NDA-24295

ISSUE 1

STOCK # 200773

®

Installation Manual

OCTOBER, 2000

NEC America, Inc.

Page 2

LIABILITY DISCLAIMER

NEC America, Inc. reserves t he right to change th e specifications, functions, or

features, at any time, without notice.

NEC America, Inc. has prepared this document for use by its employees and

customers. The information contained herein is the property of NEC America,

Inc. and shall not be reproduced without prior written approval from NEC

America, Inc.

NEAX

®

and D

term®

are registered trademarks of NEC Corporation.

Copyright 2000

NEC America, Inc.

Printed in the U.S.A

Page 3

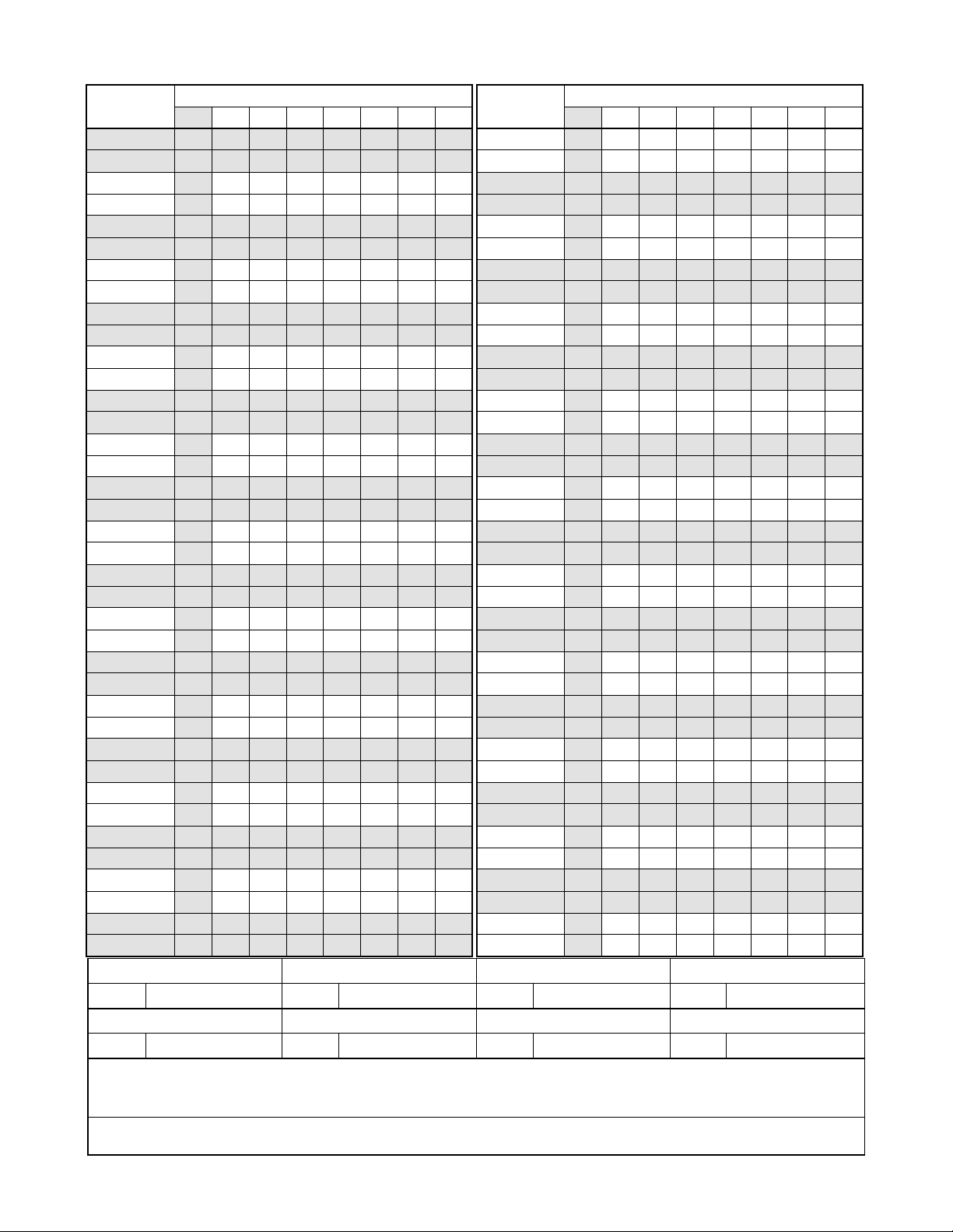

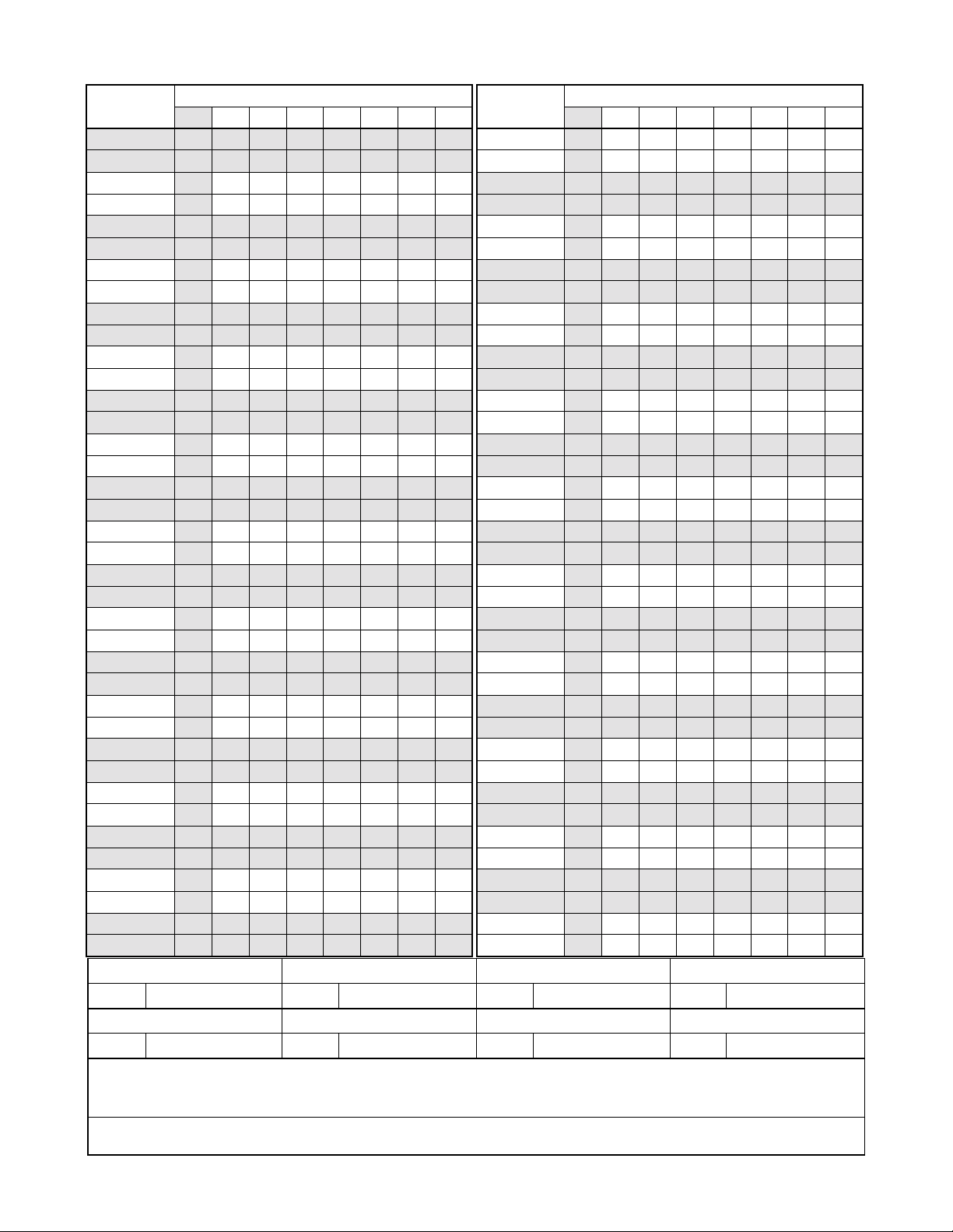

PAGE No.

i 1

ii 1

iii 1

iv

v 1

vi 1

vii 1

viii

ix 1

x 1

xi 1

xii

xiii 1

xiv 1

xv 1

xvi

xvii 1

xviii 1

xix 1

xx

1 1

2 1

3 1

4

5 1

6 1

7 1

8

9 1

10 1

11 1

12

13 1

14 1

15 1

16

17 1

18 1

DATE OCTOBER, 2000 DATE DATE DATE

DA TE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE N o.

19 1

20

21 1

22 1

23 1

24

25 1

26 1

27 1

28

29 1

30 1

31 1

32

33 1

34 1

35 1

36

37 1

38 1

39 1

40

41 1

42 1

43 1

44

45 1

46 1

47 1

48

49 1

50 1

51 1

52

53 1

54 1

55 1

56

12345678

1

1

1

1

1

1

1

1

1

1

ISSUE No.

NEAX2400 IPX

Installation Manual

Revision Sheet 1/6

NDA-24295

Page 4

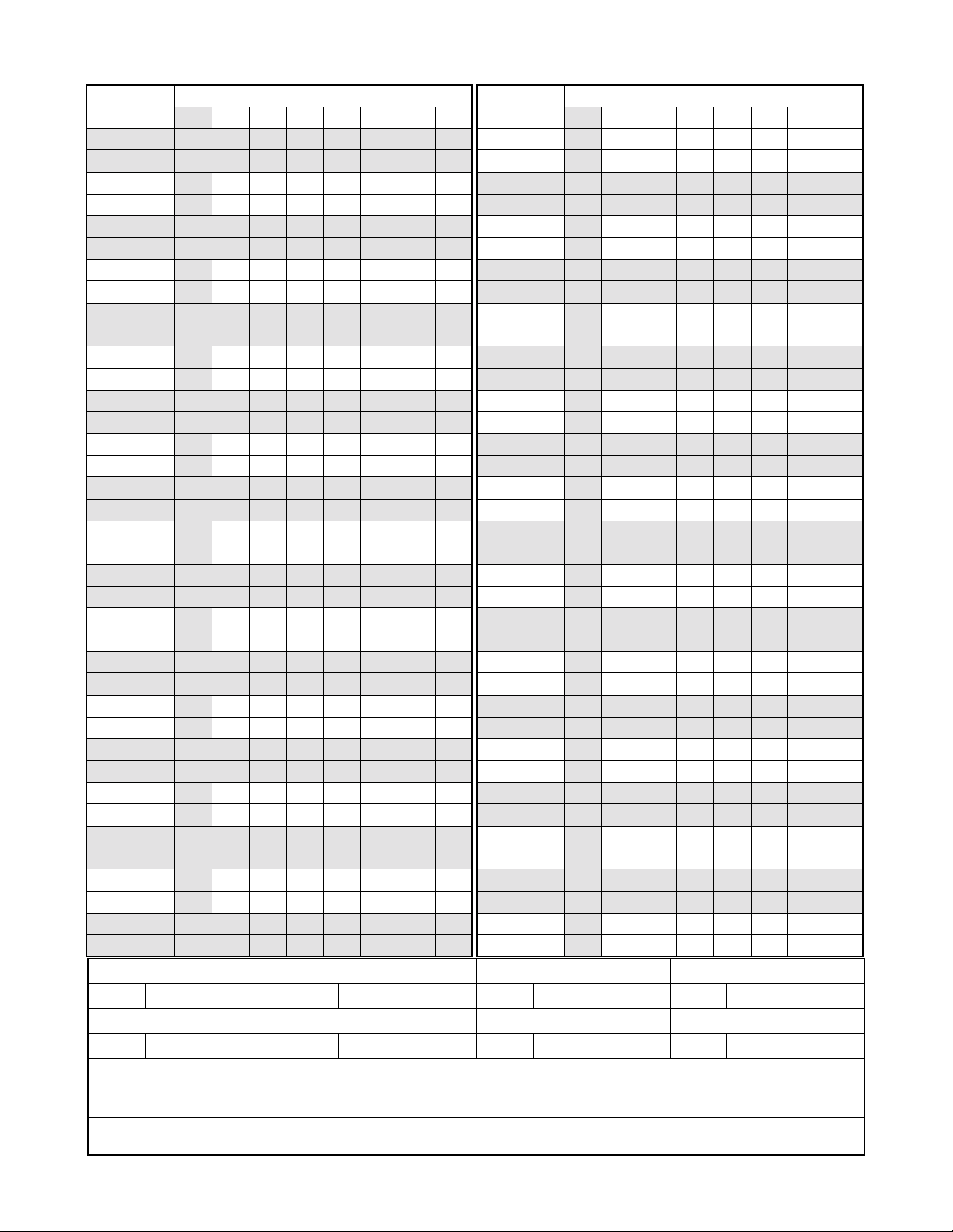

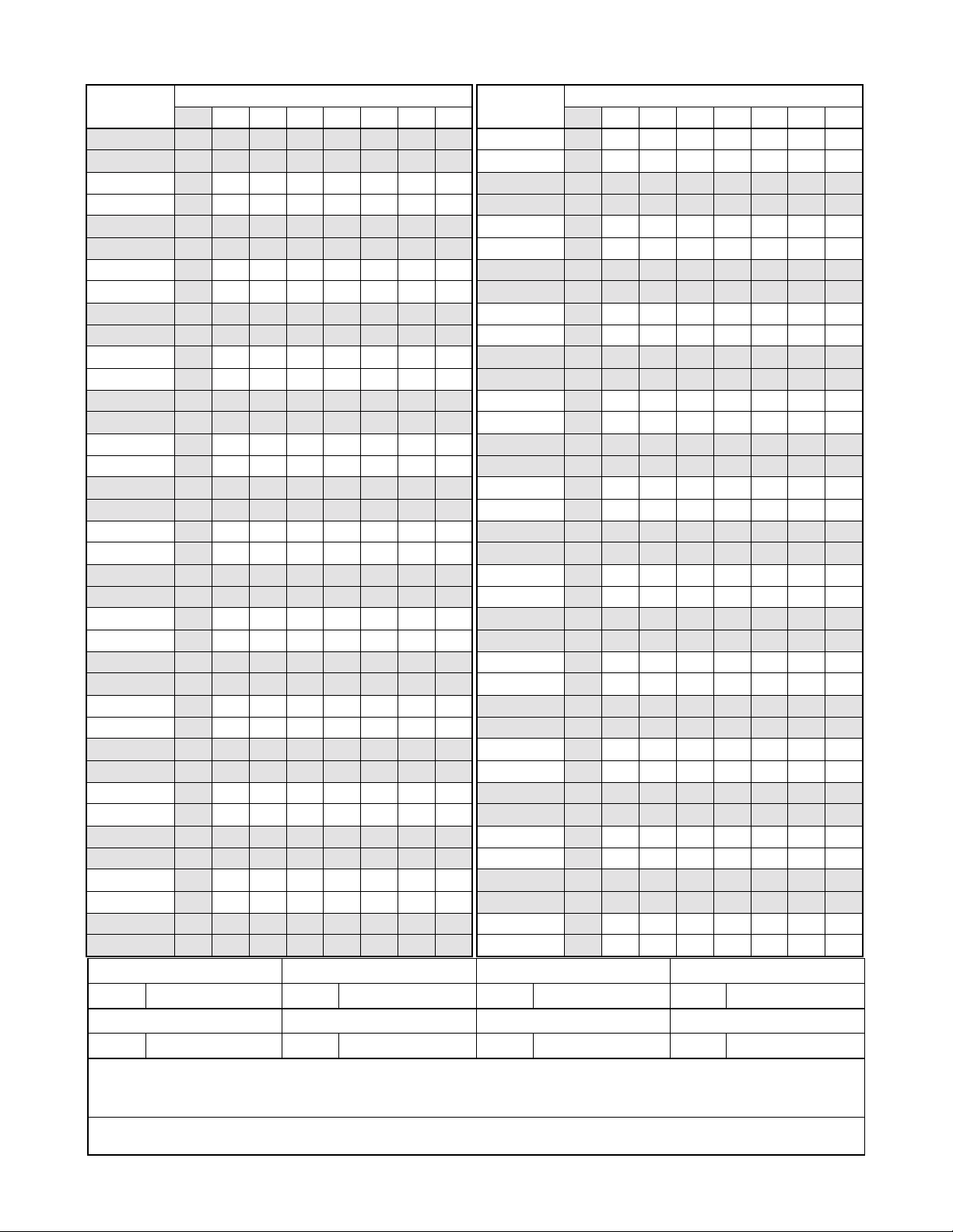

PAGE No.

57 1

58 1

59 1

60

61 1

62 1

63 1

64

65 1

66 1

67 1

68

69 1

70 1

71 1

72

73 1

74 1

75 1

76

77 1

78 1

79 1

80

81 1

82 1

83 1

84

85 1

86 1

87 1

88

89 1

90 1

91 1

92

93 1

94 1

DATE OCTOBER, 2000 DATE DATE DATE

DA TE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE N o.

95 1

96

97 1

98 1

99 1

100

101 1

102 1

103 1

104

105 1

106 1

107 1

108

109 1

110 1

111 1

112

113 1

114 1

115 1

116

117 1

118 1

119 1

120

121 1

122 1

123 1

124

125 1

126 1

127 1

128

129 1

130 1

131 1

132

12345678

1

1

1

1

1

1

1

1

1

1

ISSUE No.

NEAX2400 IPX

Installation Manual

Revision Sheet 2/6

NDA-24295

Page 5

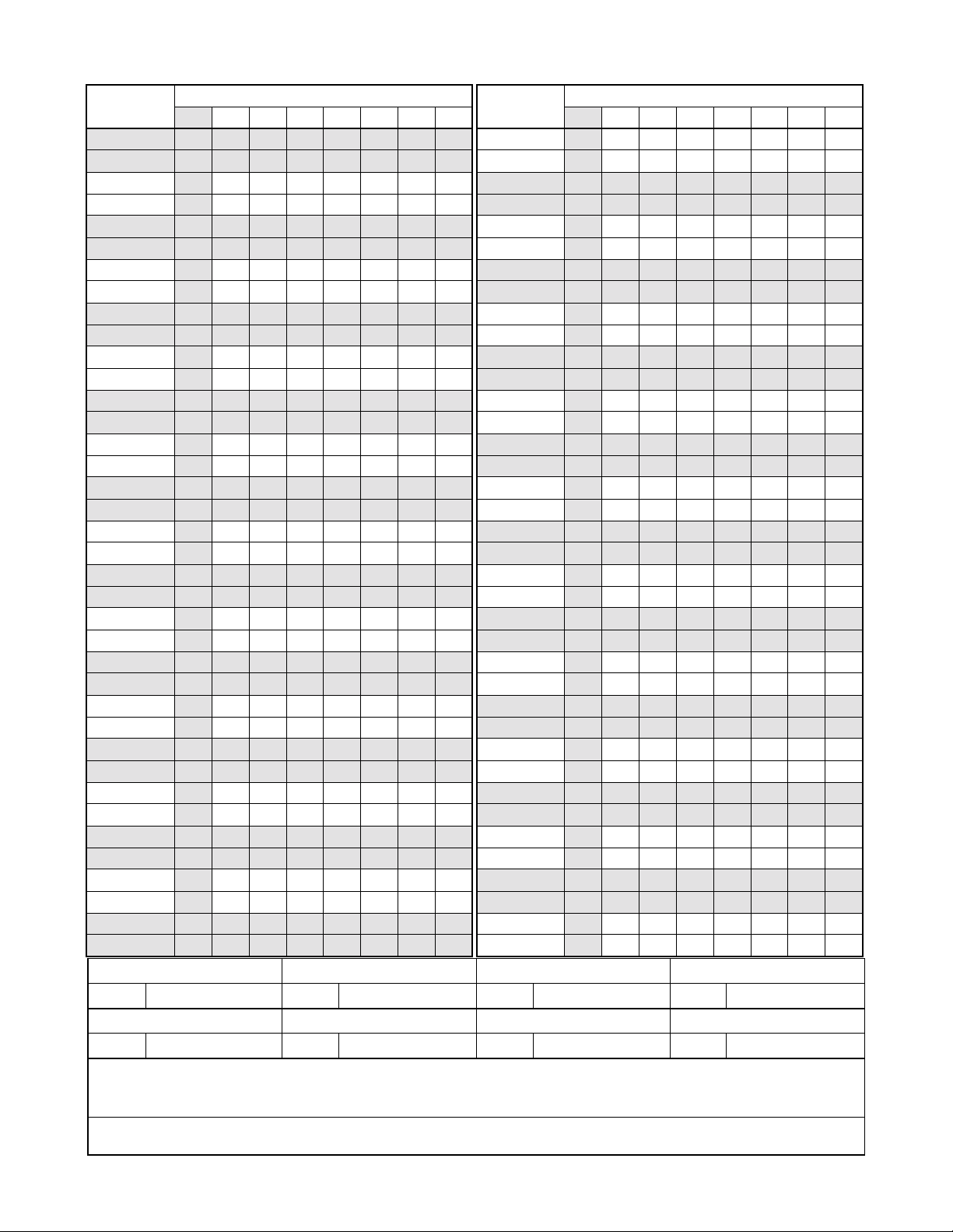

PAGE No.

133 1

134 1

135 1

136

137 1

138 1

139 1

140

141 1

142 1

143 1

144

145 1

146 1

147 1

148

149 1

150 1

151 1

152

153 1

154 1

155 1

156

157 1

158 1

159 1

160

161 1

162 1

163 1

164

165 1

166 1

167 1

168

169 1

170 1

DATE OCTOBER, 2000 DATE DATE DATE

DA TE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE N o.

171 1

172

173 1

174 1

175 1

176

177 1

178 1

179 1

180

181 1

182 1

183 1

184

185 1

186 1

187 1

188

189 1

190 1

191 1

192

193 1

194 1

195 1

196

197 1

198 1

199 1

200

201 1

202 1

203 1

204

205 1

206 1

207 1

208

12345678

1

1

1

1

1

1

1

1

1

1

ISSUE No.

NEAX2400 IPX

Installation Manual

Revision Sheet 3/6

NDA-24295

Page 6

PAGE No.

209 1

210 1

211 1

212

213 1

214 1

215 1

216

217 1

218 1

219 1

220

221 1

222 1

223 1

224

225 1

226 1

227 1

228

229 1

230 1

231 1

232

233 1

234 1

235 1

236

237 1

238 1

239 1

240

241 1

242 1

243 1

244

245 1

246 1

DATE OCTOBER, 2000 DATE DATE DATE

DA TE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE N o.

247 1

248

249 1

250 1

251 1

252

253 1

254 1

255 1

256

257 1

258 1

259 1

260

261 1

262 1

263 1

264

265 1

266 1

267 1

268

269 1

270 1

271 1

272

273 1

274 1

275 1

276

277 1

278 1

279 1

280

281 1

282 1

283 1

284

12345678

1

1

1

1

1

1

1

1

1

1

ISSUE No.

NEAX2400 IPX

Installation Manual

Revision Sheet 4/6

NDA-24295

Page 7

PAGE No.

285 1

286 1

287 1

288

289 1

290 1

291 1

292

293 1

294 1

295 1

296

297 1

298 1

299 1

300

301 1

302 1

303 1

304

305 1

306 1

307 1

308

309 1

310 1

311 1

312

313 1

314 1

315 1

316

317 1

318 1

319 1

320

321 1

322 1

DATE OCTOBER, 2000 DATE DATE DATE

DA TE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE N o.

323 1

324

325 1

326 1

327 1

328

329 1

330 1

331 1

332

333 1

334 1

335 1

336

337 1

338 1

339 1

340

341 1

342 1

343 1

344

345 1

346 1

347 1

348

349 1

350 1

351 1

352

353 1

354 1

355 1

356

357 1

358 1

359 1

360

12345678

1

1

1

1

1

1

1

1

1

1

ISSUE No.

NEAX2400 IPX

Installation Manual

Revision Sheet 5/6

NDA-24295

Page 8

PAGE No.

361 1

362 1

363 1

364

365 1

366 1

367 1

368

369 1

370 1

371 1

372

373 1

374 1

375 1

376

377 1

378 1

379 1

380

381 1

382 1

ISSUE No.

12345678

1

1

1

1

1

PAGE N o.

ISSUE No.

12345678

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

DATE OCTOBER, 2000 DATE DATE DATE

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

DA TE DATE DATE DATE

NEAX2400 IPX

Installation Manual

Revision Sheet 6/6

NDA-24295

Page 9

NDA-24295

ISSUE 1

OCTOBER, 2000

NEAX2400 IPX

Installation Manual

TABLE OF CONTENTS

Page

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

REGULATORY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1. REGULATORY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

2. FCC PART 15 REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3. FCC PART 68 REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3.1 Company Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3.2 Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3.3 Location of FCC Compliance Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4. DIRECT-INWARD DIALING (DID) CALLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

5. REGULATORY INFORMATION ON SINGLE-LINE ANALOG TELEPHONES. . . . . . . . . . . . . . . . . . . xix

6. HEARING AID COMPATIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

7. INDUSTRY CANADA CS-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

8. SAFETY LISTING/CERTIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

8.1 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

CHAPTER 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. HOW TO FOLLOW THE MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 How to Follow NAPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 How To Follow Trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Figure and Table Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Essential/Critical Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 2 INSTALLATION DESIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. ENVIRONMENTAL REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Temperature And Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Heat Generation From Switching Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. FLOOR SPACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. FLOOR LOAD REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5. EQUIPMENT ROOM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

NDA-24295 TABLE OF CONTENTS

Page i

Revision 1.0

Page 10

TABLE OF CONTENTS (CONTINUED)

Page

5.1 Floor Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3 Ceiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Lighting Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. POWER SUPPLY REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Main Source Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Current Consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Power Distribution Box Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7. MDF REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8. INSTALLATION TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9. SYSTEM ACCOMMODATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.1 Port Interface Module Configuration and Conditions for Configuration . . . . . . . . . . . . . . . . . . . 14

9.2 Circ uit Card Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.3 Preparation Of Trunking Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.4 Preparation Of Module Group Face Layout And Port Accommodation Diagram. . . . . . . . . . . . 26

9.5 Preparation Of Circuit Card Switch Setting Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10. INSTALLATION CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 AC Input, DC Power, And Ground Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.2 Cables Between The PBX And MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CHAPTER 3 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2. PRECAUTIONS BEFORE BEGINNING INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3. INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

NAP-200-001. Installation Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

NAP-200-002. Marketing, Leveling, and Drilling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1. WHEN SECURING THE PBX DIRECTLY ONTO THE FLOOR. . . . . . . . . . . . . . . . . . . . . . . . 42

2. WHEN SECURING THE PBX WITH THE SPECIAL STAND. . . . . . . . . . . . . . . . . . . . . . . . . . 45

3. WHEN SECURING PBX WITH FLOOR ELEVATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4. MARKING, LEVELING AND DRILLING FOR MDF, POWER EQUIPMENT, AND

PERIPHERAL EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

NAP-200-003. Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1. UNPACKING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2. INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

NAP-200-004. Installation of the Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1. INSTALLING THE BASE UNIT DIRECTLY ONTO THE FLOOR . . . . . . . . . . . . . . . . . . . . . . . 51

2. INSTALLING THE BASE UNIT USING A SPECIAL STAND . . . . . . . . . . . . . . . . . . . . . . . . . . 53

NAP-200-005. Mounting of Units and Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1. MOUNTING OF UNITS AND MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2. INSTALLATION OF FANU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3. PROCEDURE FOR FANU ON THE TOPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4. PROCEDURE FOR FANU IN THE FAN BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5. ATTACHING THE ADDITIONAL NOISE FILTER UNIT (NFILU) TO THE BASEU . . . . . . . . . 67

TABLE OF CONTENTS N DA-24295

Page ii

Revision 1.0

Page 11

TABLE OF CONTENTS (CONTINUED)

Page

NAP-200-006. Installation of Power Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

NAP-200-007. Installation of the MDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

NAP-200-008. Connection of Power and Ground Cables from the Power Equipment. . . . . . . . . . . . 72

1. CONNECTION OF THE POWER AND GROUND CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2. CONNECTION OF DC-DC CONVERTER FOR TELEPHONE SETS

EQUIPPED WITH MESSAGE WAITING LAMPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3. END JOINTING OF POWER AND GROUND CABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4. BRANCHING OF POWER CABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

NAP-200-009. Setting of Switch Positions and Mounting of Circuit Cards . . . . . . . . . . . . . . . . . . . . . 85

1. PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2. EXTRACTION OF MOUNTED CIRCUIT CARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3. MOUNTING OF CIRCUIT CARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4. SETTING OF SWITCH POSITIONS ON CIRCUIT CARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5. INSTALLATION OF CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

NAP-200-010. Internal Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

NAP-200-011. Inter-Frame Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

NAP-200-012. Front Cable Connections between Circuit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

NAP-200-013. Cable Running from the PBX to MDF, ATTCON, MAT, and SMDR. . . . . . . . . . . . . 186

1. CABLE RUNNING FROM THE PBX TO THE MDF AND ATTCON. . . . . . . . . . . . . . . . . . . . 187

2. CABLE RUNNING FROM THE PBX TO THE MAT AND SMDR . . . . . . . . . . . . . . . . . . . . . . 191

3. CONNECTIONS AT THE PBX SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4. CABLE TYING AT THE PBX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

5. TERMINATION OF THE CABLES BETWEEN THE PBX AND THE MDF

OR ATTCON ONTO THE CABLE SUPPORT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 194

NAP-200-014. Termination of Cables on MDF (Wire Accommodation of Each Cable) . . . . . . . . . . 199

NAP-200-015. Cable Termination and Cr os s Conn ec tion s from MD F to

Peripheral Equipment, C. O. Lines, and Tie Lines . . . . . . . . . . . . . . . . . . . . . . . . . . 200

1. CROSS CONNECTION OF STATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2. CROSS CONNECTION OF TRUNKS (C.O. LINES AND TIE LINES) . . . . . . . . . . . . . . . . . . 202

3. CROSS CONNECTIONS FOR PFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4. CROSS CONNECTION OF ALARM INDICATING PANEL AND MUSIC ON HOLD . . . . . . . 207

5. CROSS CONNECTIONS FOR TAS INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

6. CROSS CONNECTIONS FOR EXTERNAL SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

7. CONNECTION OF ANNOUNCEMENT MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

8. CONNECTION OF PAGING EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

9. CROSS CONNECTIONS FOR D

10.CROSS CONNECTIONS FOR DIGITAL INTERFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

NAP-200-016. Installation of the DESK CONSOLE and Cable Connection. . . . . . . . . . . . . . . . . . . 230

1. CABLE CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

2. CALCULATION OF THE DISTANCE BETWEEN THE ATI CIRCUIT

CARD AND MODULAR ROSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

3. MOUNTING OF HEADSET (OPTIONAL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

4. MOUNTING OF HANDSET (OPTIONAL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

5. CONNECTION OF RECORDING EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

6. 8-CORE LINE CABLE (INSTALLATION CABLE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

7. CONNECTION OF AC-DC ADAPTER (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

8. MOUNTING OF ADD-ON CONSOLE (FOR HOTEL SYSTEM). . . . . . . . . . . . . . . . . . . . . . . 250

9. MOUNTING OF ADD-ON CONSOLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

term

Series E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

NDA-24295 TABLE OF CONTENTS

Page iii

Revision 1.0

Page 12

TABLE OF CONTENTS (CONTINUED)

Page

10.CONNECTION OF AC-DC ADAPTER FOR ADD-ON CONSOLE (OPTIONAL) . . . . . . . . . . 257

11.CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

12.SELECTION OF CONFIGURATION ITEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

13.ASSIGNMENT OF CONFIGURATION DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

14.HEADSET/HANDSET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

15.HEADSET TYPE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

16.MUTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

17.REC CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

18.SUP CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

19.REC VOLUME ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

20.BLF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

21.HOLD/START/RELEASE/SWAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

22.UPDATING CONFIGURATION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

NAP-200-017. Installation of Maintenance Administration Terminal (MAT) and

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

1. INSTALLATION OF MAT AND CABLE CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

2. INSTALLATION OF MAT AND CABLE CONNECTION BY USING MODEM . . . . . . . . . . . . 275

3. INSTALLATION OF SYSTEM MESSAGE PRINTER AND CABLE CONNECTIONS . . . . . . 277

NAP-200-018. Connections of SMDR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

CHAPTER 4 SYSTEM STARTUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

2. PRECAUTIONS BEFORE BEGINNING SYSTEM STARTUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

3. SYSTEM STARTUP PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

NAP-200-019. Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

NAP-200-020. Program Install and Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

NAP-200-021. Assignment of Office Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

NAP-200-022. Check of Lamp Indications and System Messages . . . . . . . . . . . . . . . . . . . . . . . . . 299

NAP-200-023. Check of Alarm Lamps of the TOPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

CHAPTER 5 INSTALLATION TEST PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

1. HOW TO ENTER DATA IN THE TEST CHECK COLUMN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

2. BASIC CONNECTION TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

2.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

2.2 Basic Connection Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

NAP-200-024. Dial Tone Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

NAP-200-025. Station to Station Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

3. SYSTEM INITIALIZED TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

3.2 System Initialized Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

NAP-200-026. System Changeover Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

NAP-200-027. System Initialization Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

NAP-200-028. Circuit Card Initialization Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

4. PORT CONNECTION TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

4.2 Port Connection Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

TABLE OF CONTENTS N DA-24295

Page iv

Revision 1.0

Page 13

TABLE OF CONTENTS (CONTINUED)

Page

NAP-200-029. ORT (RST Card) Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

NAP-200-030. ATTCON (ATI Card) Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

NAP-200-031. Line (LC, ELC, DLC, Card) Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

NAP-200-032. Outgoing Trunk (COT, TLT, DTI Card) Connection Test . . . . . . . . . . . . . . . . . . . . . 329

NAP-200-033. Incoming Trunk (COT, TLT, DTI Card) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

NAP-200-034. Direct-In Termination Trunk (COT Card). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

NAP-200-035. SND (RST Card) Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

NAP-200-036. 3-party Conference Trunk Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

NAP-200-037. Connection Test-Announcement Trunk for Announcement Service. . . . . . . . . . . . . 337

NAP-200-038. Connection Test-Digital Announcement Trunk for Announcement Service . . . . . . . 338

NAP-200-039. Connection Test-Paging Trunk for Paging Access Service . . . . . . . . . . . . . . . . . . . 339

NAP-200-040. Connection Test-Paging Trunk for Paging Transfer Service. . . . . . . . . . . . . . . . . . . 340

NAP-200-041. Radio Paging Trunk (COT Card) Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . 342

NAP-200-042. Howler & Ringing Signal Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

5. OVERALL TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

5.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

5.2 Overall Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

NAP-200-043. Overall Test for C.O. Line Outgoing Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

NAP-200-044. Overall Test for C.O. Line Incoming Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

NAP-200-045. Overall Test of CCIS Tie Line Outgoing Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

NAP-200-046. Overall Test of CCIS Tie Line Incoming Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

NAP-200-047. Test of Connection and Alternate Routing to All Tie Lines . . . . . . . . . . . . . . . . . . . . 351

NAP-200-048. Test of Tandem Connection to Tie Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

NAP-200-049. PAD Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

CHAPTER 6 FAULT RECOVERY DURING TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

2. OUTLINE OF PROCEDURE FOR FAULT RECOVERY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

NAP-200-050. Abnormal Lamp Indications After System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . 358

NAP-200-051. Dial Tone Connection Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

NAP-200-052. Station to Station Connection Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

CHAPTER 7 WORK AFTER INSTALLATION TESTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

1. OFFICE DATA MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

1.1 Preservation of Office Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

2. PREPARATION OF TEST RESULT REPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

3. MOUNTING OF THE FRONT, SIDE, AND REAR COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

4. ATTACHMENT OF INTER-FRAME BRACKETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

5. SITE CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

NDA-24295 TABLE OF CONTENTS

Page v

Revision 1.0

Page 14

This page is for your notes.

TABLE OF CONTENTS NDA-24295

Page vi

Revision 1.0

Page 15

LIST OF

FIGURES

Figure Title Page

Figure 1-1 Example of NAP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1-2 Example of a Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 1-3 Static Caution Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1-4 3M

“

Model 8012 Portable Field Ser vic e Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-1 Heat Generation from Switching Equipment for the PBX . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2-2 Current Consumption of the PBX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-3 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2-4 Time Slot, Group Number Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2-5 Face Layout (Single IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2-6 Face Layout of IMG0 (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2-7 Location of Terminating Resistors on the TSWM Back Plane

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-8 Face Layout of IMG1 Front View (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-9 Face Layout of IMG2, 3 (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-10 Controlling Circuit Cards in LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-11 Controlling Circuit Cards in PIM 0 (Single IMG Configuration Only) . . . . . . . . . . . . . . . . . 23

Figure 2-12 Controlling Circuit Cards in PIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-13 Controlling Circuit Cards in TSWM (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . 25

Figure 2-14 DC Main Power Cable and Main Ground Cable (1- or 2-PIM System)

(Single IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-15 DC Main Power Cable and Main Ground Cable (3- or 4-PIM System)

(Single IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-16 DC Main Power Cable and Main Ground Cable (Multiple IMG Configuration) . . . . . . . . . 29

Figure 2-17 Calculation Method for Sectional Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 2-18 Outline of Cables from Module Group to the Outside . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 3-1 Scope of Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 3-2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 002-1 Locations of Base Unit Securing Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 002-2 Cable Hole on a Free-Access or Computer Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 002-3 Example of Special Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 002-4 Special Stand Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 002-5 Example of Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 004-1 Mounting the Base Unit Directly onto the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 004-2 Mounting the Base Unit on a Free-Access or Computer Floor . . . . . . . . . . . . . . . . . . . . . 52

Figure 004-3 Mounting the Base Unit on a Free-Access or Computer Floor via Elevation. . . . . . . . . . . 52

Figure 004-4 Setting the BASEU via Special Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 005-1 Procedure for Mounting Units and Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 005-2 Locations of FANU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 005-3 Mounting of FANU (on TOPU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 005-4 Attachment of FAN Fuse (PZ-M369) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 005-5 Cable Connections for FANU on TOPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 005-6 Connection of “FAN” Connector Cable (TOPU-PIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 005-7 Attachment of the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 005-8 Relocation of FANU and Insertion into FAN BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 005-9 FAN Cable Connections for FC0/FC1/FC2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 005-10 Cable Connections for FANU in FAN BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

NDA-24295 LIST OF FIGURES

Page vii

Revision 1.0

Page 16

LIST OF

Figure Title Page

Figure 005-11 Connection of “FAN” Connector Cable (FAN BOX-PIM) . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 005-12 Insertion of NFILU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 005-13 Attaching of NFILU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 005-14 Cabling Diagram of NFILU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 008-1 Detail of Cable Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 008-2 Detail of Cable Running (Multiple IMG Configuration). . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 008-3 Connection of Power and Ground Cables to Power Receiving Terminal . . . . . . . . . . . . . 75

Figure 008-4 Example Connection Diagram-DC-DC Converter for Message Waiting Lamps . . . . . . . . 77

Figure 008-5 Removal of Shorting Piece and Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 008-6 Placing the Clamp Terminal on the Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 008-7 Clamping Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 008-8 Stripped Length of Main and Branch Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 008-9 Inserting of Cables into Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 008-10 Clamping for Branch Jointing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 008-11 Taping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 008-12 Covering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 009-1 Removal of Card Stopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 009-2 Extraction of Circuit Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 009-3 Circuit Card Mounting (Partial Insertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 009-4 Removal of Front Panel and Top Cover from CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 009-5 Insertion of ISAGT and LANI Cards into CPR Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 009-6 Reattachment of CPR Top Cover and Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 009-7 Accommodation of New CPR into LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 009-8 Insertion of New HFD into CPR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 010-1 Locations of Connectors on the PIM Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 010-2 Locations of Connectors on the LPM Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 010-3 Location of Connectors on the TSWM Backplane (Multiple IMG Configuration). . . . . . . 105

Figure 010-4 Locations of Connectors on the Power Distribution Terminal Board (PZ-M371). . . . . . . 106

Figure 010-5 Power Cable Connections for 1-PIM System (Single IMG Configuration). . . . . . . . . . . . 107

Figure 010-6 Details on Power Cable Connections (for 1-PI M Sys tem) (Single IMG Configuratio n) . . 108

Figure 010-7 Power Cable Connections for 2-PIM System (Single IMG Configuration). . . . . . . . . . . . 110

Figure 010-8 Details on Power Cable Connections (for 2-PI M Sys tem) (Single IMG Configuratio n) . . 111

Figure 010-9 Power Cable Connections for 3-PIM System (Single IMG Configuration). . . . . . . . . . . . 113

Figure 010-10 Details on Power Cable Connections (for 3- PIM System) (Single IMG Configu ra tion) . . 114

Figure 010-11 Power Cable Connections for 4-PIM System (Single IMG Configuration). . . . . . . . . . . . 116

Figure 010-12 Details on Power Cable Connections (for 4- PIM System) (Single IMG Configu ra tion) . . 117

Figure 010-13 Power Cable Connection for IMG0 (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . 119

Figure 010-14 Power Cable Connection for IMG1 (1-PIM System) (Multiple IMG Configuration) . . . . . 121

Figure 010-15 Power Cable Connection for IMG1 (2-PIM System) (Multiple IMG Configuration) . . . . . 123

Figure 010-16 Power Cable Connection for IMG1 (3-PIM System) (Multiple IMG Configuration) . . . . . 125

Figure 010-17 Power Cable Connection for IMG1 (4-PIM System) (Multiple IMG Configuration) . . . . . 127

Figure 010-18 Power Cable Connection for IMG2/3 (1-PIM System) (Multiple IMG Configuration) . . . . 129

Figure 010-19 Power Cable Connection for IMG2/3 (2-PIM System) (Multiple IMG Configuration) . . . . 131

Figure 010-20 Power Cable Connection for IMG2/3 (3-PIM System) (Multiple IMG Configuration) . . . . 133

Figure 010-21 Power Cable Connection for IMG2/3 (4-PIM System) (Multiple IMG Configuration) . . . . 135

Figure 010-22 Bus Cable Connections for 1-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 137

Figure 010-23 Details on Bus Cable Connections (for 1-PIM System) (S ingle IMG Configuration) . . . . 138

Figure 010-24 Bus Cable Connections for 2-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 140

FIGURES

(CONTINUED)

LIST OF FIGURES NDA-24295

Page viii

Revision 1.0

Page 17

LIST OF

Figure Title Page

Figure 010-25 Details on Bus Cable Connections (for 2-PIM System) (S ingle IMG Configuration) . . . . 141

Figure 010-26 Bus Cable Connections for 3-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 143

Figure 010-27 Details on Bus Cable Connections (for 3-PIM System) (S ingle IMG Configuration) . . . . 144

Figure 010-28 Bus Cable Connections for 4-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 146

Figure 010-29 Details on Bus Cable Connections (for 4-PIM System) (S ingle IMG Configuration) . . . . 147

Figure 010-30 Internal Bus Cable Connection for IMG0 (Multiple IMG Configuration) . . . . . . . . . . . . . . 149

Figure 010-31 Internal Bus Cable Connection for IMG1 (1-PIM System)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 010-32 Internal Bus Cable Connection for IMG1 (2-PIM System)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 010-33 Internal Bus Cable Connection for IMG1 (3-PIM System)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 010-34 Internal Bus Cable Connection for IMG1 (4-PIM System)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 010-35 Internal Bus Cable Connec tio n for IMG 2/3 (2-P IM Sy st em)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 010-36 Internal Bus Cable Connec tio n for IMG 2/3 (3-P IM Sy st em)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 010-37 Internal Bus Cable Connec tio n for IMG 2/3 (4-P IM Sy st em)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 011-1 Inter-Frame ISA Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 011-2 Inter-Frame Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Figure 011-3 Inter-Frame Bus Cable Connection for IMG1-IMG2 (1-PIM System) . . . . . . . . . . . . . . . 165

Figure 011-4 Inter-Frame Bus Cable Connection for IMG1-IMG2 (2-PIM System) . . . . . . . . . . . . . . . 166

Figure 011-5 Inter-Frame Bus Cable Connection for IMG1-IMG2 (3-PIM System) . . . . . . . . . . . . . . . 168

Figure 011-6 Inter-Frame Bus Cable Connection for IMG1-IMG2 (4-PIM System) . . . . . . . . . . . . . . . 170

Figure 011-7 Inter-Frame Bus Cable Connection for IMG1-IMG3 (1-PIM System) . . . . . . . . . . . . . . . 172

Figure 011-8 Inter-Frame Bus Cable Connection for IMG1-IMG3 (2-PIM System) . . . . . . . . . . . . . . . 173

Figure 011-9 Inter-Frame Bus Cable Connection for IMG1-IMG3 (3-PIM System) . . . . . . . . . . . . . . . 175

Figure 011-10 Inter-Frame Bus Cable Connection for IMG1-IMG3 (4-PIM System) . . . . . . . . . . . . . . . 177

Figure 011-11 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . 179

Figure 011-12 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG2 . . . . . . . . . . . . . . . . . . . . . . . 181

Figure 011-13 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG3 . . . . . . . . . . . . . . . . . . . . . . . 183

Figure 012-1 Front Cable Connections between Circuit Cards for CCIS/ISDN . . . . . . . . . . . . . . . . . . 185

Figure 013-1 LT Cable Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 013-2 Cable Routing of Circuit Card Front Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 013-3 Example of Cable Tying Using Tie-Wrap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 013-4 Cable Support Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 013-5 Clamp Winding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 013-6 Termination of Installation Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 015-1 Cross Connection of Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 015-2 Cross Connection of Trunks (C.O. Lines and Tie Lines) . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 015-3 Mounting Locations of PFT (PA-M53) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Figure 015-4 Cross Connection for PFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Figure 015-5 Connection of Alarm Ind ic ati ng Pan el and Mus i c on Hold (Sin gle IMG C onfi guration) . . 208

Figure 015-6 Connection of Alarm Indicating Panel (Multiple IMG Configuration) (1/2) . . . . . . . . . . . . 210

Figure 015-7 Connection of Music on Hold (Multiple IMG Configuration). . . . . . . . . . . . . . . . . . . . . . . 211

Figure 015-8 Cable Connection Diagram for TAS (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

FIGURES

(CONTINUED)

NDA-24295 LIST OF FIGURES

Page ix

Revision 1.0

Page 18

LIST OF

FIGURES

(CONTINUED)

Figure Title Page

Figure 015-9 Outer View of External Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Figure 015-10 Connection of External Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Figure 015-11 Connection of Announcement Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 015-12 Connection of Paging Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Figure 015-13 Outer View of D

Figure 015-14 Cable Connection for D

term

Series E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

term

Series E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Figure 015-15 PLO Pin Assignments for Receiving Clock (Single IMG Configuration) . . . . . . . . . . . . . 224

Figure 015-16 PLO Pin Assignments for Receiving Clock (Multiple IMG Configuration) . . . . . . . . . . . . 225

Figure 015-17 Cable Connection Diagram for Accepting Synchronization Clocks

from an External High-Stability Oscillator (Single IMG Configuration). . . . . . . . . . . . . . . 226

Figure 015-18 Cable Connection Diagram for Accepting Synchronization Clocks

from an External High-S tab il ity O s ci ll ator ( Mult iple IM G Co n figuration) . . . . . . . . . . . . . 227

Figure 015-19 Cable Connection Diagram for Distributing Clock from a Digital Interface

(Single IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Figure 015-20 Cable Connection Diagram for Distributing Clock from a Digital Interface

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Figure 016-1 Outer View of Desk Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Figure 016-2 Cable Connection Diagram for Desk Console (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Figure 016-3 Cable Connection Diagram (When the Power Is Supplied from the PBX). . . . . . . . . . . . 234

Figure 016-4 Cable Connection Diagram (When Using Local Power Supply) . . . . . . . . . . . . . . . . . . . 236

Figure 016-5 Cable Connection Diagram for DESK CONSOLE Modular Block . . . . . . . . . . . . . . . . . . 237

Figure 016-6 Headset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 016 -7 Mounting of Handset (Left Side of DESK CONSOLE). . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Figure 016-8 Mo unting of Handset (Right Side of DESK CONSOLE) . . . . . . . . . . . . . . . . . . . . . . . . . 242

Figure 016-9 RECC Card Cable Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Figure 016-10 Three DESK CONSOLEs and One Recording Equipment . . . . . . . . . . . . . . . . . . . . . . . 246

Figure 016-11 Six DESK CONSOLEs and One Recording Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 016-12 8-core Line Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 016-13 Connection of AC-DC Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 016-14 Add-On Console Cable Connection Diagram (When the Power Is

Supplied from the PBX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Figure 016-15 Add-On Console Cable Connection Diagram (When Using Local Power Supply) . . . . . 251

Figure 016-16 Cable Connection Diagram for Add-On Console Modular Block . . . . . . . . . . . . . . . . . . . 252

Figure 016-17 Mounting of Add-On Console (Right Side of DESK CONSOLE). . . . . . . . . . . . . . . . . . . 253

Figure 016-18 Mounting of Add-On Console (Left Side of DESK CONSOLE) . . . . . . . . . . . . . . . . . . . . 255

Figure 016-19 Connection of AC-DC Adapter for Add-On Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 016-20 Displaying the Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Figure 016-21 Selecting a Configuration Item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Figure 016-22 Assigning Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 016-23 Updating Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Figure 017-1 Cabling of MAT when Using Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figure 017-2 Cable Connection Diagram for the MAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 017-3 Cabling of MAT Using Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Figure 017-4 Connection of System Message Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 017-5 Detail of RS-232C CA-(0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Figure 017-6 Detail of RS-232C CA-(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 017-7 Detail of RS-232C CA-(3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Figure 018-1 I/O Port Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

LIST OF FIGURES NDA-24295

Page x

Revision 1.0

Page 19

LIST OF

Figure Title Page

Figure 018-2 Cable Connection Diagram for the SMDR Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Figure 018-3 Connection of SMDR by Using MODEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 022-1 LED Indications in Normal Operation (Single IMG Configuration). . . . . . . . . . . . . . . . . . 300

Figure 022-2 LED Indications of IMG0 in Normal Operation (Multiple IMG Configuration). . . . . . . . . . 301

Figure 022-3 LED Indications of IMG1 in Normal Operation (Multiple IMG Configuration). . . . . . . . . . 302

Figure 022-4 LED Indications of IMG 2/3 in Normal Operation (example )

(Multiple IMG Configuration). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Figure 023-1 Alarm Lamps on the TOPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 5-1 Example of Entry to Test Check Column. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Figure 026-1 How to Perform a Control System Changeover (Single IMG Configuration). . . . . . . . . . 314

Figure 026-2 How to Perform a Control System Changeover (Multiple IMG Configuration). . . . . . . . . 314

Figure 026-3 LEDs and Switches on TSW/MUX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Figure 026-4 LEDs and Switches for System Changeover (Multiple IMG Configuration). . . . . . . . . . . 317

Figure 026-5 System Block Diagram (TSW and MUX) (Multiple IMG Configuration) . . . . . . . . . . . . . . 318

Figure 026-6 System Block Diagram (GT and Other Controlling Blocks)

(Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Figure 026-7 System Block Diagram (Speech Path) (Multiple IMG Configuration). . . . . . . . . . . . . . . . 320

Figure 027-1 System Initialization via ‘Start’ Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Figure 032-1 COT Test Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Figure 032-2 TLT Test Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Figure 032-3 DTI Test Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Figure 047-1 Combination of Tie Line Network and Public Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Figure 047-2 Tie Line Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Figure 048-1 Test of Tandem Connection to Tie Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Figure 049-1 Example of PAD Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Figure 049-2 Example of PAD Setting for CCIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Figure 7-1 Mounting of the Covers in a Full System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Figure 7-2 Mounting of the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Figure 7-3 Side Cover Mounting Method (BASEU+LPR+PIM0). . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Figure 7-4 Side Cover Mounting Method (PIM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Figure 7-5 Rear Cover Mounting Method (BASEU+LPR+PIM0). . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Figure 7-6 Rear Cover Mounting Method (PIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Figure 7-7 Rear Cover Mounting Method (FANU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Figure 7-8 Front Cover Mounting Method in a Full System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Figure 7-9 Front Cover Mounting Method (BASEU+LPR+PIM0) . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Figure 7-10 Front Cover Mounting Method (PIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Figure 7-11 Front Cover Mounting Method (FANU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Figure 7-12 Locations of Inter-frame Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Figure 7-13 How to Attach Inter-frame Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

FIGURES

(CONTINUED)

NDA-24295 LIST OF FIGURES

Page xi

Revision 1.0

Page 20

This page is for your notes.

LIST OF FIGURES NDA-24295

Page xii

Revision 1.0

Page 21

LIST OF TABLES

Table Title Page

Table 2-1 Temperature and Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2-2 Typical Installation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-3 Conditions for Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2-4 Controlling Circuit Cards in LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2-5 Controlling Circuit Cards in PIM 0 (Single IMG Configuration Only) . . . . . . . . . . . . . . . . . 23

Table 2-6 Controlling Circuit Cards in PIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2-7 Controlling Circuit Cards in TSWM (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . . 25

Table 2-8 Clamp Terminal Shape and Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 2-9 Selection of T-type Clamp Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2-10 Clamping Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 2-11 Calculation of Number of Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 002-1 Specification of Anchor Bolts-Sleeve Expansion Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 008-1 Stripped Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 010-1 Quick Reference Table (1/6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 010-2 Power Cable Connection for IMG0 (Single IMG Configuration). . . . . . . . . . . . . . . . . . . . 109

Table 010-3 Power Cable Connections for 2-PIM System (Single IMG Configuration). . . . . . . . . . . . 112

Table 010-4 Power Cable Connections for 3-PIM System (Single IMG Configuration). . . . . . . . . . . . 115

Table 010-5 Power Cable Connections for 4-PIM System (Single IMG Configuration). . . . . . . . . . . . 118

Table 010-6 Power Cable Connection for IMG0 (Multiple IMG Configuration) . . . . . . . . . . . . . . . . . . 120

Table 010-7 Power Cable Connecti on for IMG1 (1-PIM System) (Multiple IMG Con figuration) . . . . . 122

Table 010-8 Power Cable Connecti on for IMG1 (2-PIM System) (Multiple IMG Con figuration) . . . . . 124

Table 010-9 Power Cable Connecti on for IMG1 (3-PIM System) (Multiple IMG Con figuration) . . . . . 126

Table 010-10 Power Cable Connection for IMG1 (4 -PIM Sy s tem) (M ult iple IMG Co n figuration) . . . . . 128

Table 010-11 Power Cable Connection for IMG2/3 (1-PIM System) (Multiple IMG Configuration) . . . . 130

Table 010-12 Power Cable Connection for IMG2/3 (2-PIM System) (Multiple IMG Configuration) . . . . 132

Table 010-13 Power Cable Connection for IMG2/3 (3-PIM System) (Multiple IMG Configuration) . . . . 134

Table 010-14 Power Cable Connection for IMG2/3 (4-PIM System) (Multiple IMG Configuration) . . . . 136

Table 010-15 Bus Cable Connections for 1-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 139

Table 010-16 Bus Cable Connections for 2-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 142

Table 010-17 Bus Cable Connections for 3-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 145

Table 010-18 Bus Cable Connections for 4-PIM System (Single IMG Configuration). . . . . . . . . . . . . . 148

Table 010-19 Internal Bus Cable Connection for IMG0 (Multiple IMG Configuration) . . . . . . . . . . . . . . 150

Table 010-20 Internal Bus Cable Connection for IMG1 (1-PIM System) (Multiple IMG Configuration) . 151

Table 010-21 Internal Bus Cable Connection for IMG1 (2-PIM System) (Multiple IMG Configuration) . 153

Table 010-22 Internal Bus Cable Connection for IMG1 (3-PIM System) (Multiple IMG Configuration) . 155

Table 010-23 Internal Bus Cable Connection for IMG1 (4-PIM System) (Multiple IMG Configuration) . 157

Table 011-1 Inter-Frame ISA Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table 011-2 Inter-Frame Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Table 011-3 Inter-Frame Bus Cable Connection for IMG1-IMG2 (1-PIM System) . . . . . . . . . . . . . . . 165

Table 011-4 Inter-Frame Bus Cable Connection for IMG1-IMG2 (2-PIM System) . . . . . . . . . . . . . . . 167

Table 011-5 Inter-Frame Bus Cable Connection for IMG1-IMG2 (3-PIM System) . . . . . . . . . . . . . . . 169

Table 011-6 Inter-Frame Bus Cable Connection for IMG1-IMG2 (4-PIM System) . . . . . . . . . . . . . . . 171

Table 011-7 Inter-Frame Bus Cable Connection for IMG1-IMG3 (1-PIM System) . . . . . . . . . . . . . . . 172

Table 011-8 Inter-Frame Bus Cable Connection for IMG1-IMG3 (2-PIM System) . . . . . . . . . . . . . . . 174

Table 011-9 Inter-Frame Bus Cable Connection for IMG1-IMG3 (3-PIM System) . . . . . . . . . . . . . . . 176

Table 011-10 Inter-Frame Bus Cable Connection for IMG1-IMG3 (4-PIM System) . . . . . . . . . . . . . . . 178

Table 011-11 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG1 . . . . . . . . . . . . . . . . . . . . . . . 180

Table 011-12 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG2 . . . . . . . . . . . . . . . . . . . . . . . 182

NDA-24295 LIST OF TABL ES

Page xiii

Revision 1.0

Page 22

LIST OF TABLES (CONTINUED)

Table Title Page

Table 011-13 Inter-Frame Alarm Bus Cable Connection for IMG0-IMG3 . . . . . . . . . . . . . . . . . . . . . . . 184

Table 013-1 Cable Support Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

LIST OF TABLES NDA-24295

Page xiv

Revision 1.0

Page 23

SAFETY CONSIDERATIONS

IMPORTANT — SAVE THESE INSTRUCTIONS

(1) Never install telephone wiring during a lightning storm.

(2) Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

(3) Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

(4) Use caution when installing or moving telephone lines.

When using your telephone equipment, always follow basic safety precautions, such as the ones below,

to reduce the risk of fire, electric shock, and injury:

(5) Read and understand all instructions.

(6) Follow all warnings and instructions marked on the product.

(7) Disconnect this product from t he power source bef ore cleaning. Do not use liqui d cleaners or aerosol

cleaners. Use a damp cloth for cleaning.

(8) Do not use this product near water; for example , under water pi pes near a bath tub, sink, or laundry

tub, in a wet basement, or near a swimming pool.

(9) Do not place this product on an unstable cart, stand, or table. The product may fall, causing serious

damage to the product.

(10) Slots and openings in the cabinet and the back or bottom are provided for ventilation, to protect it

from overheating. These openings must not be blocked or covered. The openings should never be

blocked by placing the product on a rug, or other similar surface. This product should never be

placed near or over a radiator or heat register. This product should not be placed in a built-in

installation unless proper ventilation is provided.

(11) This product should be operated only from the type of power source indicated on the marking label.

If you are not sure of the type of power source avail able, consult with your local power company.

(12) Do not overload wall outl ets and ext ension cords as this can r esult in the risk of fire or electric shock .

(13) Never push objects of any kind into thi s product through cabi net slots as the y ma y touch dangerous

voltage points or short out par ts that could result in a risk of fire or electric shock. Never spill liquid

of any kind on the product.

NDA-24295 SAFETY CONSIDERATIONS

Page xv

Revision 1.0

Page 24

(14) To reduce the risk of electric shock, do not disassemble this product, but take it to a qualified

serviceman when some service or repair work is required. Open ing or remo ving co v ers ma y e xpose

you to dangerous voltages or other risks. Incorrect reassembly can cause electric shock when the

appliance is subsequently used.

(15) Unplug this product from the wall outlet and refer ser vicing to qualified service personnel under the

following conditions:

(a) When the power supply cord or plug is damaged or frayed.

(b) If liquid has been spilled into the product.

(c) If the product has been exposed to rain or water.

(d) If the product does not operate normally by following the operating instructions. Adjust only

those controls, that are co v ered b y the oper at ing instructions becaus e improper adj ustment of

other controls may result in damage and will often require extensive work by a qualified

technician to restore the product to normal operation.

(e) If the product has been dropped or the cabinet has been damaged.

(f) If the product exhibits a distinct change in performance.

(16) Avoid using a telephone (other than a cordless type) during an electrical storm. There may be a

remote risk of electric shock from lightning.

(17) Do not use the telephone to rep ort a gas leak in the vicinity of the leak.

SAFETY CONSIDERATIONS NDA-24295

Page xvi

Revision 1.0

Page 25

REGULATORY INFORMATION

1. REGULATORY REQUIREMENTS

The Federal C ommunic ations Commissi on (FCC) ha s establ ished rule s that pe rmit the N EAX2400 IPX to be

directly connected to the telephone network. A jack is provided on party lines or coin lines.

The telephone company may make changes in its technical operations and procedures. If such changes affect

the compatib ility o r use of the N EAX2 400 IPX, the tele phone compan y is requi red to gi ve adeq uate no tice of

the changes.

This equipment complies with the requirements in Part 15 of FCC Rules for a Class A computing device.

Operation of this equipme nt in a residentia l area may cause una cceptable int erference to ra dio and TV reception

requiring the operator to take whatever steps are necessary to corr ect this interference.

2. FCC PART 15 REQUIREMENTS

In compliance with FCC Part 15 Rules, the following statement is provided:

WARN ING

This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instruction manual,

may cause interference to radio communications. It has been tested and

found to comply with the limits for a Class A computing devic e pursuant to

Subpart J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when operated in a

commercial envi ronment. Operation of thi s e quipment in a residenti al area

is likely to cause interference in which case the user at his own expense will

be required to take whatever measures may be required to correct the

interference.

3. FCC PART 68 REGISTRATION

3.1 Company Notification

Before installing the NEAX2400 IPX to the telephone network, the telephone company must be provided with

the following:

• Your telephone number

• The FCC reg i stration numbers:

JAPAN USA

• PBX: AY5JPN-74906-PF-E AY5USA-74905-PF-E

• Hybrid: AY5JPN-74904-MF-E AY5USA-74913-MF-E

The Ringer Equivalence Number is 2.1B; the required USOC jacks are RJ21X, RJ2EX, and RJ2GX.

NDA-24295 REGULATORY INFORMATION

Page xvii

Revision 1.0

Page 26

3.2 Service Requirements

In the event of equipment malfunction, all repairs will be performed by NEC or an authorized distributor of

NEC. It is the responsibility of users requiring service to report the need for service to NEC or to one of their

authorized distributors.

If the equipment causes harm to the telephone network, the telephone company will notify you in advance that

temporary discontinu ance of servi ce may be requi red. I f adva nce not ice i s no t prac tical , the telep hone compa ny

will notify the customer as soon as possible. Also, you will be advised of your right to file a complaint with the

FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations, or procedures that affect the

operation of the equipment. If t his happen s, the t elephone company will provide advance notice i n order for you

to make necess ary modificat io ns in order to main tain uninterrupted service.

If trouble is experienced with this equipment, please contact NEC America, Inc.’s Oregon plant at (503) 6485000 for repair and/or warranty information. If the trouble is causing harm to the telephone network, the

telephone company may re quest tha t you remove t he equipment from the networ k until t he problem i s resolve d.

NO REPAIRS CAN BE DONE BY THE CUSTOMER.

3.3 Location of FCC Compliance Labels

Labels stating the NEAX2400 IPX FCC registration number and compliance with FCC Parts 15 and 68 are

attached to the Base Unit. If the unit is in a table-top configuration, the labels are located on the side of the

enclosure . The appear ance of the labels is as shown below:

NEAX2400 IMS-IP

Complies With Part 68 FCC Rules