Page 1

FDl165

Flexible

Product

Disk

Drive

Description

NEe

Information

NEe

Systems,lnc.

819-000090-1001

4-82

Page 2

LIABILITY

DISCLAIMER

NEe

Information

accordance

Systems,

is

affected

tion,

other

are

cific

may

customer

factors.

considered

functional

vary.

Therefore,

the

suitability

is

not

warranted

with

Inc.

it

by

is

Systems,

the

terms

product

system

data

While

to

be

specification.

configuration,

and

NEC

compatible

implementation

the

customer's

of

a

product

by

NEC

First

Printing

Inc.

of

the

operator

Information

with

for

Information

-

products

applicable

Product

software,

control

of

Systems,

most

by

customers

responsibility

a

specific

Systems,

April

1982

are

warranted

NEC

the

Inc.

systems,

of

application

Inc.

Information

performance

the

applica-

system

among

products

the

the

product

to

determine

in

spe-

and

NEe

In~ormation

Lexington,

Printed

Copyright

5

Militia

1982©

Systems,

Drive

MA

in

U.S.A.

Inc.

02173

Page 3

CONTENTS

CHAPTER

1.1

1.2

GENERAL

FEATURES

1.2.1

1.2.2

1.2..3

1.2.4

1.2,,5

1.2.6

1.2.7

1.2.8

1.2.9

1.2.10

1.2.11

1.2.12

1.3

SPEC

1

GENERAL

.DESCRIPTION

••••••••

Microprocessor-Controlled

Diagnostics

Option

Variable

IFICATIONS

INFORMATION

••••••••••••••••••••••••••••

"

••••••••••••••••••••••••••••••

Compact

Loading/Ejection,

Size

and

Design

Interlocks,

•••••••••••••••

and

Sensors•••••••••••••••••••••••••••••••

Dc

Direct

Read/Write

Mic~o~ro?essor-Controlled

1 t 1on1 ng

Pos

Display

Door

Lock

Interface

Drive

Heads

Spindle

Motor

••••••••••••••••••••••

Head

•••••••••••••••••••••••••••

Head

LEOs

••••••••••••••••••••••••••

Solenoid

••••••••••••••••••••

••••••••'•••••••••••••••••••••

••••••.••

Loading

•••••••••••••••••••.•••••••

Selection

(Optional)

Frequency

••••••••••••••••••••••••••••

••••••••••••••••••••••

Oscillator

•••••••••••••••••••••••••••••••••

1-1

1-1

1-1

1-3

1-3

1-3

1-4

1-4

1-4

1-4

1-4

1-4

1-5

1-5

1-5

CHAPTER

2.1

2.2

PRELIMINARY

UNPACKING/REPACKING

2.2.1

2.2.2

2.3

SYSTEM

2.3.1

2.3.2

2.3.3

2.4

INSTALLATION

2.4.1

2.4.2

2.4.2.1

2.4.2.2

2

INSTALLATION

Unpacking

Repacking

REQUIREMENTS

Operating

Space

Power

Preinstal1ation

Drive

Terminator

Drive

INSPECTION

PROCEDURE

Procedure

Procedure

Environment

and

Weight

Requirements

PROCEDURE

Designation

Resistors..................

Identification

•••••••••••••••••••••••••

••••••••••••••••••

•••••••••••••••••••

•••••••••••••••••••

•••••••••••••••••

Data

•••••••••••••••••

••••••••••••••••••••

••••••••••.•••••••••••.••

Inspection............

••••••.•••••••.•••••

Selection

iii

(DX)...

2-1

2-1

2-1

2-1

.

2-3

2-3

2-3

2-4

2-4

2-4

2-4

2-5

2-5

Page 4

CONTENTS (cont'd)

Page

2.4.2.3

2.4.2.4

2.4.2.5

2.4.2.6

2.4.3

2.4.4

CHAPTER

3.1

3.2

3.3

DATA

SIGNAL

INPUT

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3.7

3.3.8

3.3.9

3.3.10

INTERFACE

3

INTERFACE

LEVELS

SIGNAL

Option

Diagnostic

Test

Tr

impots••••••••••••••••••••••••••••••

Mounting

Power

Selection

Pins

and

On

Testing

••••••••••••••••••••••

Plugs

(TP)

Wiring

(T2,

T3)

••••••••••••••••••••••••

•••••••••••••••••••

••••••••••••••••••••••

INFORMATION

CONNECTOR

DATA

••••••••••••••••••

••••••••••••••••••••••••••••••••••

FUNCTIONS

Drive

Select

Head Load

Step

(STP)

Direction

Side

Write

Write

Select

Gate

Data

Current

Reset

In

(FLR)

Use

••••••••••••••••••••••••••••••••

Changeover

•••••••••••••••••••••••••

1

to

4 (DXl

(HDL)

•••••••••••••••••••••••

••••••••••••••••••••••••••••

Select

(SSL)

(WGT)

(WDT)

(DIR)

••••••••••••••••

•••••••••••••••••••••

••••••••••••••••••••••

••••••••••••••••••••••

(LWC)

•••••••••••••••••••••••••••

•••••••••••••

to

DX4)

••••••

••••••••••••••

2-5

2-10

2-11

2-12

2-12

2-16

3-1

3-1

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-4

3-6

3-6

3-6

3.4

3.5

OUTPUT

3.4.1

3.4.2'

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

VFO

INTERFACE

3.5.1

3.5.2

3.5.3

3.5.4

SIGNAL

FUNCTIONS

Index

Track

Dual-Sided

Ready

File

Read

Unsafe

Data

Write

Disk

Change

SIGNAL

Modified

(MFM)

VFO

Synchronization

Standardized

Wi

ndow

••••••••••••••••••••••••

(IDX)

00

(ROy)

Protect

•••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••

(TKC)

••••••••••••••••••••••••

(TSD)

••••••••••••••••••••••

•••••••••••••••••••••••••••

(FUS)

(RDT)

(DCG)

FUNCTIONS

Frequency

•••••••••••••••••••••

•••••••••••••••••••••••

(PRT)

•••••••••••••••••••

•••••••••••••••••••••

•••••••••••••••••

Modulated

(SYC)

(WID)

Read

••••••••••••••••••••••••••

Data

iv

Mode

•••••••••••••

(SRO)

••••••••••

3-6

3-6

3-6

3-6

3-7

3-7

3-7

3-8

3-8

3-9

3-9

3-9

3-9

3-9

Page 5

CONTENTS (cont'd)

Page

3.6

Table

1-1

1-2

2-1

2-2

INTERFACE

3.6.1

3.6.2

3.6.3

3.6.4

3.6.5

3.6.6

Model FDl165

Model FDl165

Door Lock

Test

Pins

TIMING

Power

Drive

Step

Access

Write

Read

Plug

and

•••••••••••••••••••••••••••••••

On

Select

and

Sequence

••••••••••••••••••••••••••

Track

•••••••••••••••••••••

00

•••••••••••••••••••••

••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••

After

Step

•••••••••••••••••••••••

TABLES

Title

Capacity

Specifications

Combinations

Signals

•••••••••••••••••••••••

•••••••••••••••••

•••••••••••••••••

•••••••••••••••••••••••

3-10

3-10

3-10

3-10

3-10

3-11

3-12

Page

1-5

1-5

2-9

2-12

v

Page 6

ILLUSTRA

nONS

Figure

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

Title

Model

UnpaGking

Disk

Terminator

Location

on

Cable

Controller

Vertical

Horizontal

Perpendicular

Air

Cooling

Interface

Controller

Interface

Diagram

Data

Signal

Ass

Driver

Step

Write

Write

Index

Read

Disk

Read

Step

Access

FDl165

Drive

Flexible

Diagram

Dimensions

Resistor

and

Selection

Disk

•••••••••••••••••••••••••••

•••••••••••••••••••••••

and

Selection

Plug

PCB......................................

Connections

from

Disk

••••••••••••••••••••••••••••••••••

Installation

Installation

•••••••••••••••••••••••

•••••••••••••••••••••

Installation

Flow

Requirements

for

•••••••••••••••••••••••••••••••••••••

Cables

Between

Disk

••••••••••••••••••••••••••••••••••

••••••••

and

Control

Edge

ignments

and

Signal

Gate

Data

Signal

Data

Change

Data

and

Track

Timing

Connectors

~

••••••••••••••••••••••••••••

Cord

•.•••••••••••••••••••••••••••••••

Receiver

Timing

Signal

Signal

Timing

Signal

Signal

and

Window

00

•••••••••••••••••••••••••••••••

Physical

Interface

Connector

Circuits

••••••••••••••••••••••••••

Timing

Timing

••••••••••••••••••••

••••••••••••••••••••

•••••••••••••••••••••••••

Timing

•••••••••••••••••••••

Timing

Signal

Signal

Timing

Drive

Components.

Configuration

Drives

••••••••••••••••••

Natural

Drive

Location

Connector

Circuit

••••••••••••••••

•••••••••••••••••••

Timing

•••••••••••••

WriteTiming••••••••••••••••••••••••••••••••

Read

After

Step

Timing

••••••••••••••••••••••

Plug

to

Air

and

••••••••

••••••••••

1-2

2-2

2-3

2-

2-7

2-13

2-13

2-13

2-14

2-15

2-16

3-1

3-2

3-3

3-4

3-5

3-5

3-6

3-8

3-8

3-9

3-10

3-11

3-11

3-12

6

vi

Page 7

Page 8

Page 9

CHAPTER 1

GENERAL INFORMATION

This

Disk

face

planning

1.1

The

disk

disks.

format,

The

life

(MTBF)

1.2

The

ternal

document

Drive

information

systems.

GENERAL

Model

storage

wi

the

disk

drive

and

of

24,000

FEATURES

Model

controller

and

DESCRIPTION

FDl165

device

th

maximum

has

FDl165

transistor-transistor

supplied

the

disk

lamps

on

and

drive

the

front

describes

gives

in

Flexible

a

dual-sided

is

designed

a

field-proven

hours.

Flexible

(NEe

controlled

consist

panel

the

specification,

sufficient

Disk

that

uses

flexible

storage

capacity

for

Disk

~PD765

logic

externally.

of

a

(see

Model

single-

a

(TTL)

door

Figure

installation,

detail

Drive

long,

FDl165

is

or

disk

is

l.~

trouble-free

8-Inch

for

a

compact

evaluating

dual-sided

and

double-densi

million

and

mean-time-between-failures

Drive

is

is

operated

recommended)

interface.

Operator

handle

and

Dc

controls

READY

1-1).

Flexible

inter-

magnetic

flexible

bytes.

service

by

an

through

power

and

and

ty

ex-

a

is

on

BUSY

1.2.1

The

Drive

Compact

most

are

measures

mm)

pounds

wide,

(3.5

performance

interface

size,

one

the

two

conventional

remaining

Size

apparent

its

small

8.55

by

inches

13.20

kg)

,t

of

conventional

compatibility

disk

drives

space

and

features

size

inches

The

drive.

can

Design

(217.2

disk

with

can

If

be

of

and

be

used

the

light

mm)

(335.0

drive

units,

them.

mounted

only

1-1

Model

high,

one

to

weight.

mm)

has

and

Because

disk

store

FDl165

by

2.28

deep

all

maintains

in

the

drive

flexible

and

the

Flexible

The

inches

features

of

same

disk

weighs

media

its

space

is

mounted,

disks.

Disk

drive

(58.0

7.

and

and

small

7

as

Page 10

HEAD

LOAD

SOLENOID

Figure

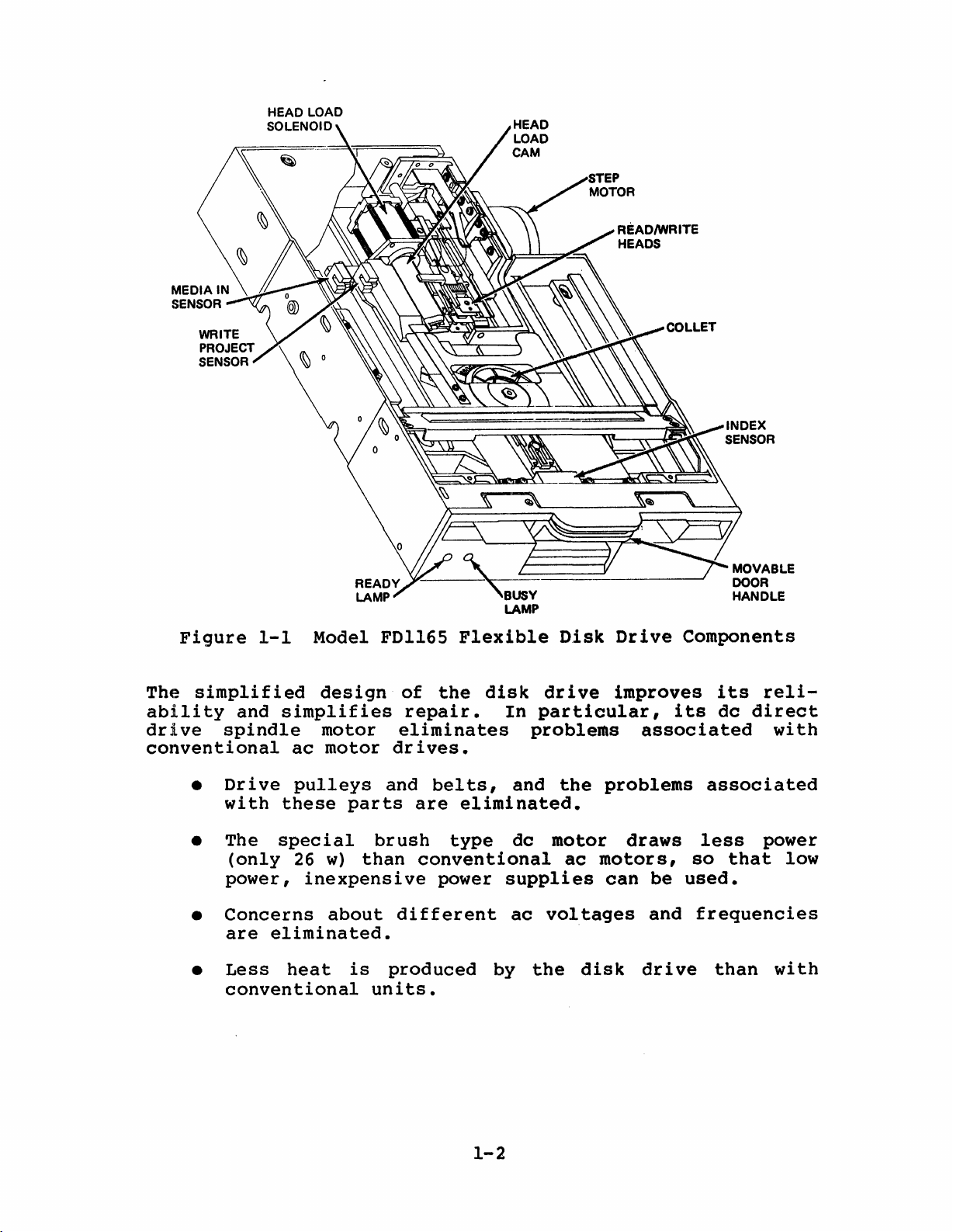

The

ability

drive

simplified

and

spindle

conventional

•

Drive

with

• The

(only

power,

•

Concerns

are

•

Less

conventional

1-1

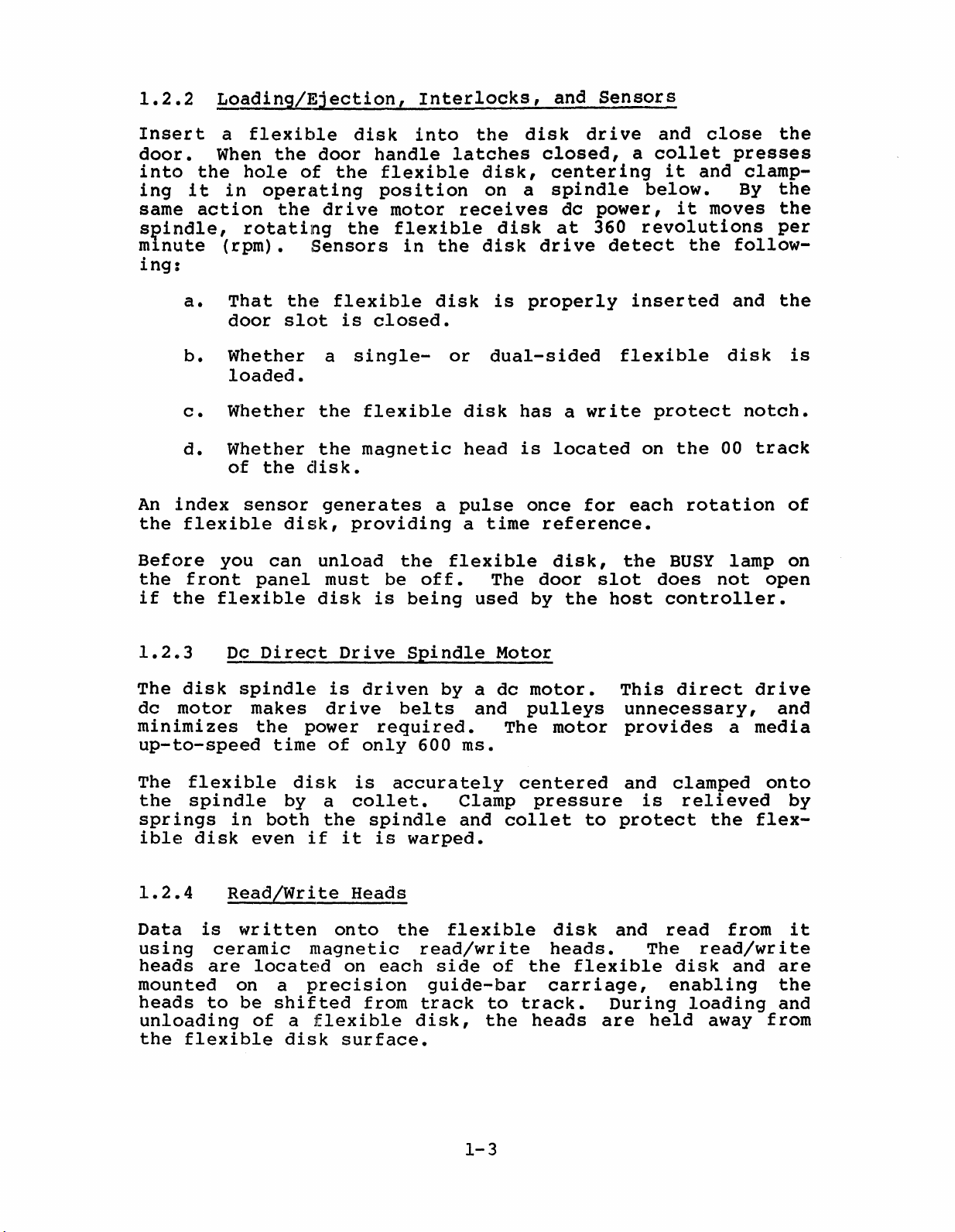

Model FDl165

design

simplifies

motor

ac

motor

pulleys

these

special

26

w)

inexpensive

about

eliminated.

heat

parts

brush

than

is

units.

Y---~=====~~--_-I

LAMP

Flexible

of

the

repair.

eliminates

drives.

and

bel

are

type

conventional

power

different

produced

disk

In

ts,

and

eliminated.

dc

supplies

ac

by

D.isk

drive

particular,

problems

the

problems

motor

ac

motors,

voltages

the

disk

Drive

improves

associated

draws

can

be

and

drive

Components

its

reli-

its

dc

direct

associated

less

so

power

that

used.

frequencies

than

with

low

with

1-2

Page 11

1.2.2

~oadin9/Ejection,

Interlocks,

and

Sensors

Insert

door.

into

ing

same

s~indle,

mlnute

When

the

it

action

a

flexible

hole

in

rotating

(rpm).

ing:

a.

That

door

b.

Whether

loaded.

c.

Whether

d.

Whether

o:f

An

index

the

flexible

Before

the

if

the

front

sensor

you

flexible

the

door

of

operating

the

Sensors

the

slot

the

the

the

disk.

disk,

can

unload

panel

disk

disk

handle

the

flexible

position

drive

motor

the

flexible

is

closed.

a

single-

flexible

magnetic

generates

providing

must

be

is

into

flexible

in

the

disk

or

a

the

flexible

off.

being

the

latches

disk,

on

receives

disk

disk

is

dual-sided

disk

head

pulse

a

time

The

used

disk

closed,

centering

a

spindle

dc

at

drive

properly

has

a

is

located

once

reference.

disk,

door

by

the

drive

power,

360

detect

write

for

slot

host

and

a

collet

it

below.

it

revolutions

inserted

flexible

protect

on

the

each

the

BUSY

does

controller.

close

presses

and

By

moves

the

follow-

and

disk

00

rotation

lamp

not

the

clamp-

the

the

per

the

is

notch.

track

of

on

open

1.2.3

The

disk

dc

motor

minimizes

up-to-speed

The

the

flexible

spindle

springs

ible

disk

1.2.4

Data

using

heads

is

ceramic

are

mounted

heads

to

unloading

the

flexible

Dc

Direct

spindle

makes

the

power

time

disk

by

in

both

even

if

Read/Write

written

magnetic

located

on a

be

of

precision

shifted

a

flexible

disk

Drive

is

driven

drive

of

only

is

a

collet.

the

it

Heads

onto

on

from

surface.

Spindle

bel

required.

600

accurately

spindle

is

warped.

the

read/write

each

guide-bar

track

disk,

by

a

ts

and

ms.

Clamp

and

flexible

side

Motor

dc

The

collet

of

to

the

motor.

pulleys

motor

centered

pressure

disk

heads.

the

flexible

carriage,

track.

heads

This

unnecessary,

provides

and

is

to

protect

and

The

During

are

held

direct

clamped

relieved

the

read

read/write

disk

enabling

loading

away

drive

a

media

flex-

from

and

and

onto

by

it

are

the

and

from

1-3

Page 12

1.2.5

Microprocessor-Controlled

Head

positioning

The

motor,

This

step

head

the

riage

1.2.6

When

structiori,

faces.

head

step

positioning

linked

arrangement

motor

posi

is

tioning

motor

1/2

track

to

the

provides

controlled

reliabili

shaft

on

the

Microprocessor-Controlled

the

disk

Head

it

loading

drive

lowers

microprocessor-controlled

reducing

creasing

1.2.7

Two

LEOs

ready

damage

flexible

Display

on

and

busy

the

to

disk

LEOs

front

states

the

(access)

carriage

1.8

flexible

logic

the

force

flexible

operating

panel

of

fast

by a

ty.

degrees,

circuit

heads

is

special

provide

the

disk

mechanism

by a

and

tensioned

accurate

microprocessor,

Each

pulse

which

disk.

Head

Loading

receives

onto

the

controlled

cam

disk

life

governs

surface,

and

a

visual

drive.

consists

command

moves a

a

head

flexible

by a

data

display

of

steel

access.

increasing

rotates

head/car-

load

disk

solenoid.

head

loading,

thereby

integrity.

a

belt.

of

step

The

in-

sur-

A

in-

the

1.2.8

The

during

loss

1.2.9

Signal

by a

Door Lock

door

certain

or

physical

Interface

and

50-pin

grounds)

quency

1.2.10

The

Oscillator

Diagnostics

disk

cuitboard

conditions.

lock

data

are

drive

(PCB)

solenoid

drive

lines

edge

all

diagnostics

Solenoid

operations,

damage

interface

card

connector.

operated

(VFO)

plugs

makes

to

the

at

option

that

it

flexible

TTL

requires

consist

can

impossible

thereby

disk.

with

the

The 21

levels.

another

of

movable

be

used

to

preventing

host

active

The

to

establish

remove a

controller

lines

Variable

three

printed

disk

data

is

(plus

Fre-

lines.

cir-

test

1-4

Page 13

1.2.11

The

FDl165

as

well

function

your

particular

scription

Option

is

as

drive

plugs

of

Selection

equipped

door

allow

needs.

these

with

and

you

features.

See

signal

busy

to

lamp

tailor

Section

function

function

the

2.4.2.3

disk

selection

plugs.

drive

for

a

to

full

plugs,

These

suit

de-

1.2.12

The

optional

troller

reliability

1.3

SPECIFICATIONS

Capacities

listed

and

performance

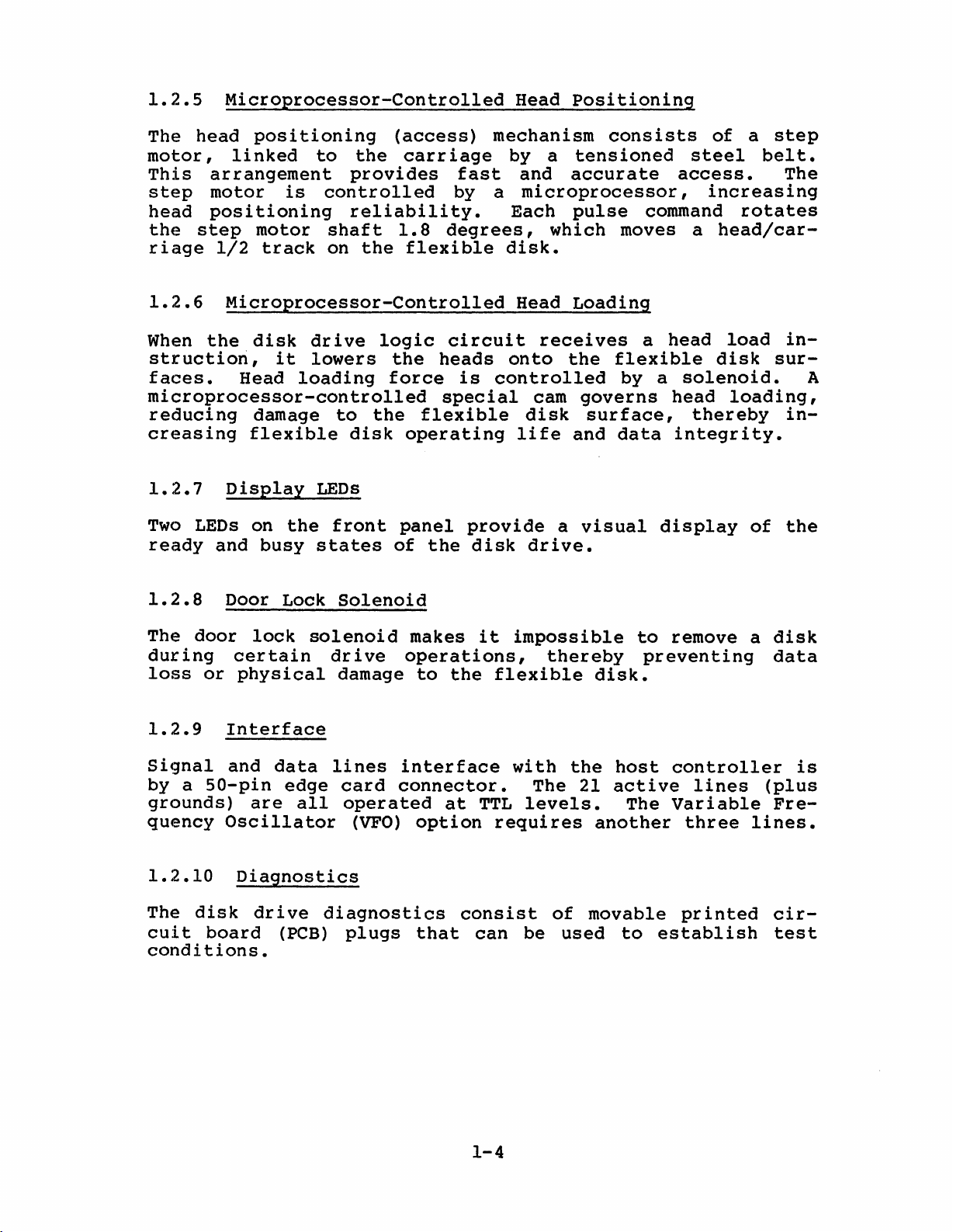

CAPACITY

(Bytes)

Per

diskette

Per

track

Per

sector

Sectors

track

Variable

more

in

Table

Table

per

of

for

Frequency

VFO

stable.

the

the

1-1.

makes

disk

Model

Mechanical,

Oscillator

the

This

drive.

FDl165

specifications

1-1

SINGLE-SIDED

SINGLE-DENSITY

24(;K

3328 3840 4096 3328

128 256 512 128

26

Model

284K

15

FD1l65

303K

8

interface

feature

Flexible

electrical,

are

listed

Capacity

DUAL-SIDED

SINGLE-DENSITY

493K 568K

3840 4096

26

(Optional)

signals

increases

606K 985K

256

15 8

Disk

environmental,

in

Table

(Formatted)

DOUBLE-DENSITY

512 256

6656 7680

26

to

the

the

overall

Drive

1-2.

DUAL-SIDED

1137K

512

15

con-

are

1212K

8192

1024

8

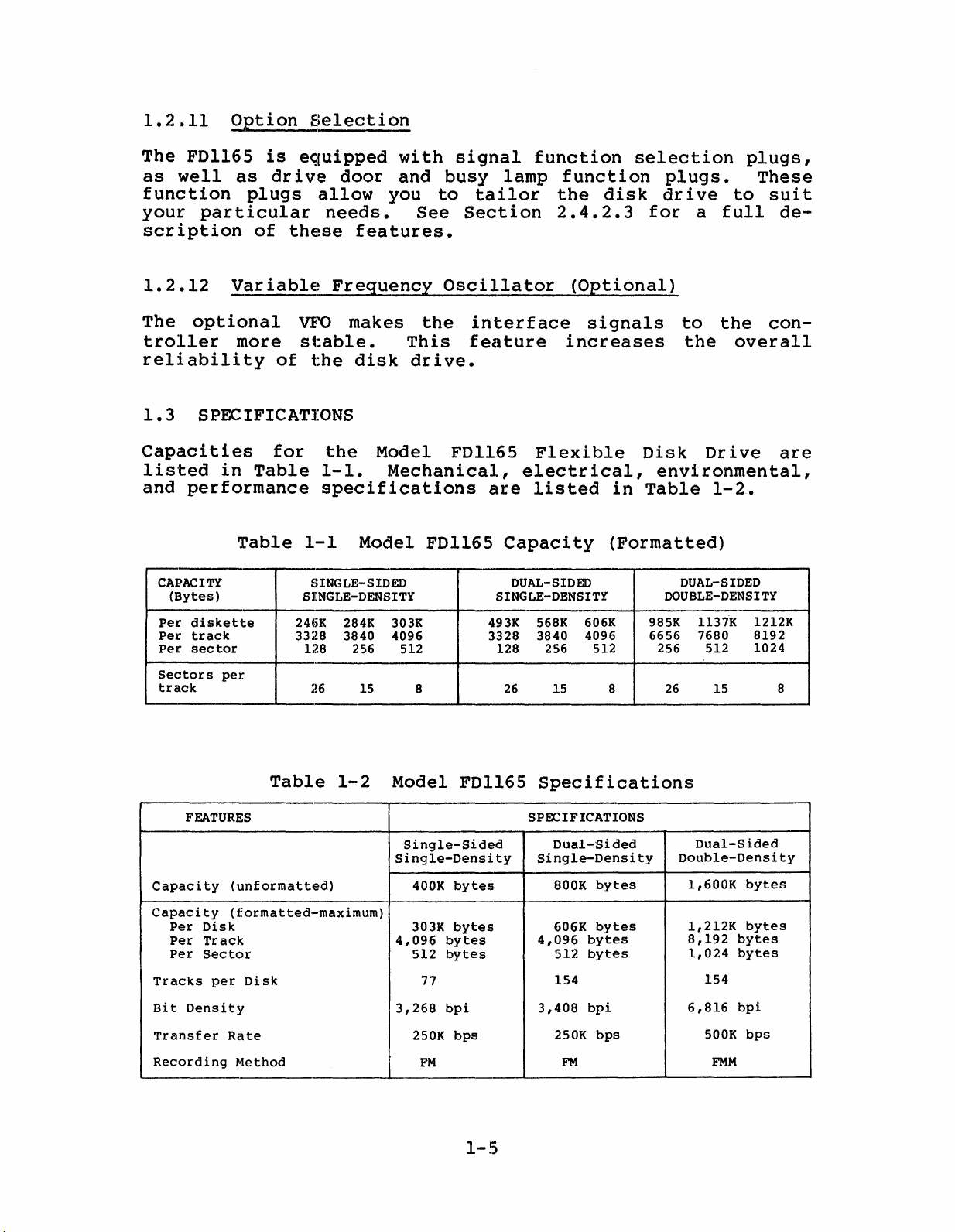

FEATURES

Capacity

Capacity

Per

Disk

Per

Track

Per

Sector

Tracks

Bit

Density

Transfer

Recording

Table

(unformatted)

(formatted-maximum)

per

Disk

Rate

Method

1-2

Model

Single-Sided

Single-Density

400K

303K

4,096

512

3,268

250K

FD1l65

bytes

bytes

bytes

bytes

77

bpi

bps

FM

1-5

Specifications

SPECIFICATIONS

Dual-Sided

Single-Density

bytes

800K

606K

512

154

250K

FM

bytes

bytes

bytes

bpi

bps

4,096

3,408

Dual-Sided

Double-Density

154

500K

FMM

bytes

bytes

bytes

bytes

bpi

bps

1,600K

1,212K

8,192

1,024

6,816

Page 14

Table

1-2

Model

FDl165

Specifications

(cont'd)

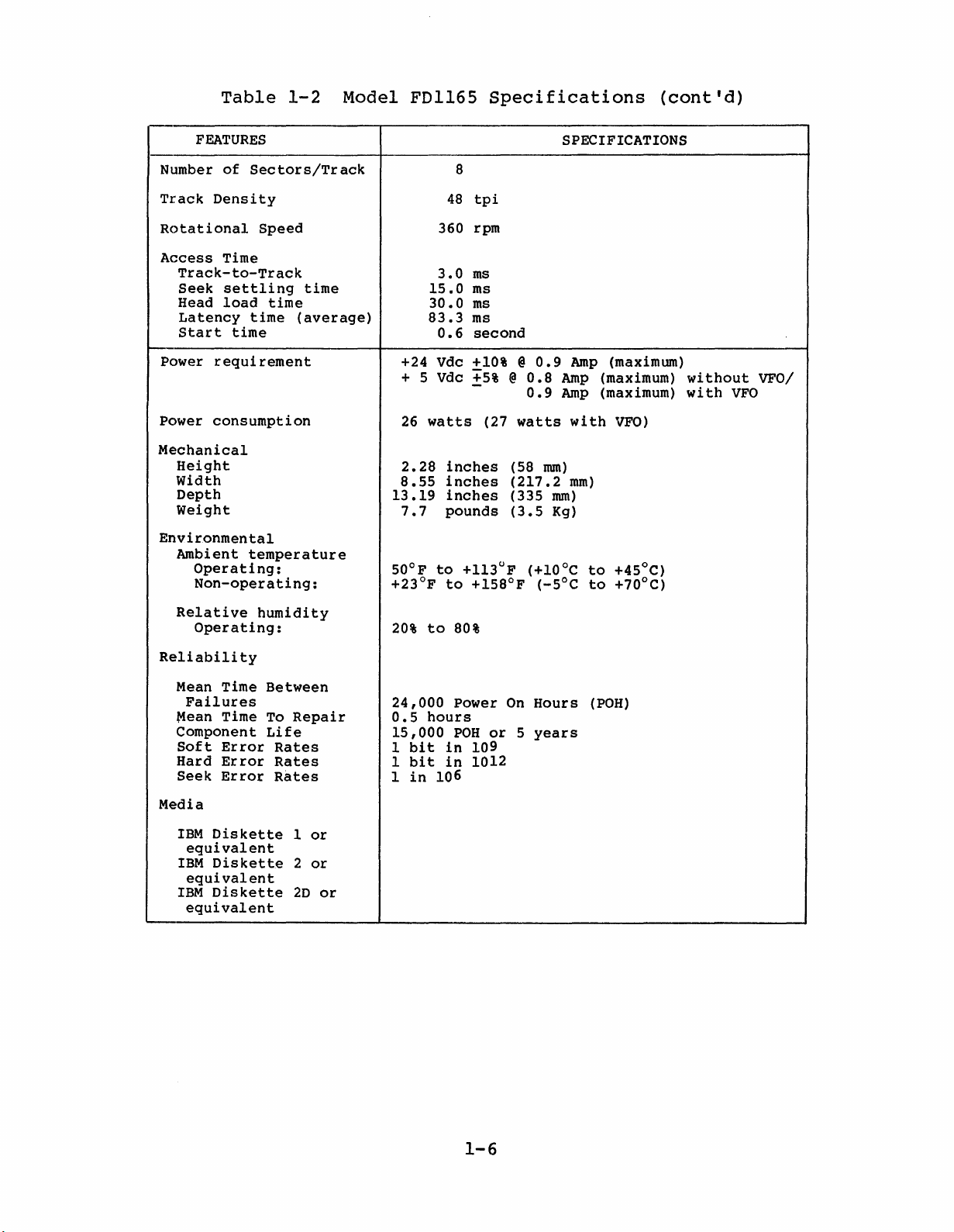

FEATURES

of

Number

Track

Rotational

Access

Track-to-Track

Seek

Head

Latency

Start

Power

Power

Mechanical

Height

Width

Depth

Weight

Environmental

Ambient

Operating:

Non-operating:

Sectors/Track

Density

Time

settling

load

time

time

requirement

consumption

temperature

Speed

time

time

(average)

83.3

+24 Vdc

+ 5 Vdc

26

watts

2.28

8.55

13.19

7.7

50°F

+23°F

8

48

tpi

360 rpm

3.0

ms

15.0

ms

30.0

ms

ms

0.6

second

+10%@0.9

+5%@0.8

(27

inches

inches

inches

pounds

to

+113°F (+10oC

to

+158°F

0.9

watts

(58

mm)

(217.2

(335

(3.5

(-5°C

SPECIFICATIONS

Amp

(maximum)

Amp

(maximum)

Amp

(maximum)

with

VFO)

mm)

mm)

Kg)

to

+45°C)

to

+70oC)

without

with

VFO/

VFO

Relative

Operating:

Reliability

Mean Time

Failures

~ean

Time

Component

Soft

Error

Hard

Error

Seek

Error

Media

IBM

Diskette

equivalent

IBM

Diskette

equivalent

IBM

Diskette

equivalent

humidity

Between

To

Repair

Life

Rates

Rates

Rates

1

or

2

or

2D

or

20%

24,000

0.5

15,000

1

bit

1

bit

1

in

to

80%

Power

hours

POH

in

in

106

On

or5years

109

1012

Hours

(POH)

1-6

Page 15

CHAPTER 2

INSTALLATION

This

the

2.1

Before

spect

age,

until

carton

2.2

This

drive.

2.2.1

To

unpack

these

future

chapter

Model

PRELIMINARY INSPECTION

unpacking

the

notify

the

is

UNPACKING/REPACKING

section

Unpacking

steps.

use.

tells

FD1l65

shipping

the

carrier's

undamaged,

the

Flexible

carrier

describes

Procedure

disk

Save

the

carton

you

Model

representative

follow

drive,

all

how

to

inspect,

Disk

for

immediately.

PROCEDURE

how

shipping

Drive.

FDl165

any

the

unpacking

to

unpack

refer

Flexible

damage.

Do

inspects

to

Figure

materials

unpack,

Disk

If

not

procedure.

and

repack

there

open

2-1

for

and

it.

install

Drive,

is

the

the

and

possible

dam-

carton

If

disk

follow

in-

the

2.2.2

To

repackage

cedure

a.

b.

c.

d.

e.

Repacking

in

Remove

package.

Slide

round.

Open

Remove

Inspect

the

Section

a

the

the

the

the

disk

tape

styrofoam

styrofoam

plastic

disk

Procedure

drive

2.2.1.

band

case.

film

drive

for

from

case

cover

for

reshipment,

2-1

out

any

around

of

the

from

shipment

cardboard

the

reverse

the

disk

damage.

shipping

sur-

drive.

the

pro-

Page 16

PLASTIC

FILM

COVER

Figure

2-1

Unpacking

2-2

Diagram

Page 17

2.3

SYSTEM

REQU:IREMENTS

This

and

2.3.1

Install

environment

(lOoe

maximum

Aim.

Kcal/h

2.3.2

The

perpendicular

servicing.

unit

section

power

Operating

the

to

ambient

Typical

(23.3

Space

disk

weighs

describes

requirements.

Environment

dislt

with

45°C)

Kcallh

and

drive

Refer

7.7

and

stray

heat

shelf

pounds

drive

an

with

Weight

is

mounting.

to

the

environmental,

in

any

ambient

relative

magnetic

dissipation

VFO).

Data

designed

Figure

(3.5

2-2

Kg).

clean,

temperature

humidity

field

by

the

for

vertical,

Provide

for

overall

space

relatively

of

of

20%

is

specified

disk

space

dimensions.

and

dust-free

50°F

dri

horizontal,

for

to

80%.

ve

cabling

to

weight,

ll3°F

as

4000

is

22.3

The

or

and

The

Figure

2-2

Disk

2-3

Drive

Dimensions

Page 18

2.3.3

Power

Requirements

Because

dc

source

~

SPECIFICATION

Voltage

Normal

Starting

Ripple

Transient

time

2.4

INSTALLATION

Perform

2.4.1

the

Current

voltage

the

disk

must

Current

response

following

be

Preinstallation

drive

does

supplied

+24

+24

0.75

0.9

Not

400

200

POWER

V

10%

+

A

A

greater

mVpp

ms

PROCEDURE

procedures

Inspection

as

not

include

follows.

SUPPLY

than

to

0.8

(Wi

0.8

(Without

Not

70

install

a

+5

A

thout

A

greater

mVpp

power

V

POWER

+5 V +

VFO)

VFO)

the

than

disk

supply,

SUPPLY

5%

0.9

A

(With

0.9

A

(With

drive.

a

VFO)

VFO)

2.4.2

If

more

troller

series

the

the

cedure

disk

each

DX4).

tion

a.

Inspect

indications

are

b.

Remove

c.

Insert

door

collet

binding.

ible

d.

Press

disk

Drive

than

and

from

terminating

last

uni

are

drive

disk

drive

Instructions

2.4.2.2.

for

tightly

the

a

flexible

handle

assembly

Turn

disk

rotates

the

is

ejected.

Designation

one

the

signal

a common

resistors

t

in

provided

is

connected

by

damage,

of

mated.

dummy

to

door

disk

the

in

an

for

problems.

flexible

disk

latch

engages

the

spindle

freely.

handle

drive

interface

controller

from

series.

section

to

addressable

this

loose

Check

disk

through

posi

tion,

the

and

is

connected

connectors

port

all

Instr

2.4.2.1.

a

single

number

procedure

parts,

flexible

and

check

(daisy

disk

uctions

or

that

from

the

the

door,

and

check

that

to

dr

ive

If

controller,

(DXl,

are

provided

other

all

connectors

unit.

press

check

disk

that

the

the

same

are

chain),

PCBs

for

this

more

DX2, DX3,

obvious

that

wi

the

flexible

wired

remove

except

than

identify

in

the

the

thout

flex-

con-

in

pro-

one

or

Sec-

2-4

Page 19

2.4.2.1

Terminator

Resistors

All

move

Do

more

disk

(RNI

in

a

not

are

served

allel

line

remove

in

the

and

these

system.

remove

as

disk

in

series

RNI

circuit.

2.4.2.2

When

DRIVE

that

in

only

SELECTION

dr

ive

a

system

number and

ately

(see

selected.

drives

RN2)

installed

resistors

these

by a

shown by

drives

and

Drive

one

as

dfLsk

DXI.

(four

insert

Figure

are

shipped

as

when

resistors

single

are

(daisy

RN2

controller

(A)

in

connected

chain)

from

each

Identification

drive

shorting

When

maximum),

the

shorting

2-3).

shown

only

Figure

is

plug

two

The

with

in

a

when two

to

as

shown

disk

Selection

used

(see

or

more

assign

plug

unit

terminator

Figure

single

or

but

are

2-4.

the

However,

controller

in

drive

except

(OX)

in

a

Figure

disk

each

for

that

is

resistor

2-3.

disk

drive

more

connected

(B)

of

system,

2-3)

dr

ives

one

a

unit

supplied

Do

not

is

disk

in

if

on a

Figure

the

last

insert

to

identify

are

different

appropri-

with

arrays

re-

used

drives

par-

two

or

common

2-4,

one

the

used

OX

DXI

2.4.2.3

The

Option

following

FDl165 PCB.

tion

3

HEAD

When

a

select

Drive

plied

RADIAL

When

the

you

of

for

ted

plugs

an

explanation

LOAD

you

select

by a Head r..oad

plug

Select

with

READY

you

disk

select

drive

select

the

drive

selected.

and

PLUG

position

HL

PLUG

plug

Selection

section

See

pins

(HL)

plug

signal

1

selected.

plug

i.s

position

select

Figure

and a

of

position

signal

from

(RX)

position

gated

signal.

describes

2-3

the

2,

head

by

2,

for

the

configuration

signals.

1,

head

f rom

the

load

the

controller.

1,

the

the

the

The

Drive

Ready

unit

option

location

load

con

action

Ready

signal

is

selection

chart.

troller.

is

Select

supplied

of

action

initiated

The

signal

signal.

is

on

the

See

selec-

Chapter

is

initi-

When

unit

is

sent

independent

with

the

you

by a

sup-

from

When

RX

1

2-5

Page 20

rerGl

us

RN

1 l

~

RV1

211i:i11

I

1~~X3

22

••

; 4

(-R-N-2-'

:

.

1

SS

2'·

RD

....

'1

1I::::!J

T3

RV

1RX22

E:::]1!!3

2

HL

e:m::J

2

FR1

T2

2as11BU2

,,,•.i

DRI

E!!I211:!:!!)2Dl

PRI

~21r:::::::J2

T1

l!I!I

•.••

TP I I I I I

G89G

DH

TPI

I I I I I I I

7131019121118

RX,Hl,DR,

PR,

Dl,

BU,

US,RD,

PINS

(SOLDER TYPE)

DH,

PLUGS

OX

PLUG

1E:).

2.

POS1

POS1

----1

[ID

RV3

DX3 DX4

3

1

•

CJ

•

• •

4

2

BS,FR,

PLUGS

T2,T3

PLUGS

1 3

POS1

2.

T3·BT2

•

•

•

2

E31

T2

•

CJ

4

2E3

T3Ej,.

POS2

·1

T3

T2

1

•

~

2

DX2

3

•

•

•

4

DX1

1

3

•

~

2

•

2

POS2

1 •

POS2

2----·1

•

•

4

E:)2

Figure

Location

2-3

Terminator

and

Selection

Resistor

Plug

2-6

and

Selection

Configuration

on

Plug

PCB

Page 21

SIGNAL

CABLES

FLEXIBLE

DiSK

DRIVE

CONTROLLER

DC

CABLES

SIGNAL

(

CABLES

I

FLEXIBLE

DRIVE

DISK

DX1*

I

V

(A)

PARALLEL

1

FLEXIBLE

DISK

DRIVE

DX2*

CONFIGURATION

FOUR DRIVES

V

FLEXIBLE

DISK

(MAXIMUM)

A

DRIVE

DX3*

V

FLEXIBLE

DISK

DRIVE

DX4*

\

,

FLEXIBLE

DISK

DRIVE

CONTROLLER

DC

CABLES

*MOUNTTERMINATOR

Figure

RESISTOR

2-4

FLEXIBLE

DISK

I

ARRAYS

Cable

DRIVE

DX1

(B)

RN1

AND

Connections

to

Controller

FLEXIBLE

DISK

DX2

SERIAL

RN2

FLEXIBLE

DRIVE

CONFIGURATION

DISK

from

DRIVE

DX3

Disk

FLEXIBLE

DISK

Drives

DRIVE

DX4

2-7

Page 22

SIDE SELECT

you

When

the

controller

position

mines

unit

the

selected.

uni

select

2,

disk

selects

t

PLUG

the

side.

side

selects

(SS)

plug

determines

Direction

If

position

the

O.

side

Direction

If

the

2.

1,

disk

Signal

Direction

The

the

side.

from

uni

Side

Signal

t

is

Select

When

the

level

Signal

supplied

signal

you

controller

select

is

level

high,

wi

is

th

from

plug

deter-

the

low,

SS 1

WRITE

When

Write

ing

you

Protect

if

is

FILE

When

function.

File

selected.

DOOR

The

different

occurs

from

door

function.

if

select

the

supplied

UNSAFE

you

LOCK

FDl165

the

PROTECT

you

Unsafe

lock

select

Protect

the

signal

flexible

select

PLUGS

combinations,

(see

disk

PLUG

signal

flexible

plug

to

with

PLUG

plug

When

three

Table

condition

you

function.

(DR, DL,

drive

(PR)

plug

position

the

disk

PR

1

(FR)

position

select

door

2-1).

when

consists

position

to

the

disk

controller

has

selected.

The

DH)

lock

determine

The

a

controller

has

2,

the

a wr i

1,

plug

function

flexible

door

1,

a wr i

te

you

position

unit

lock

of

the

te

disk

but

protect

is

when

a

lock

disk

and

protect

drive

allows

disable

supplied

plugs,

a

door

disk

condition

function

prevents

recording,

notch.

the

2,

you

which

lock

cannot

drive

notch.

sends

exists.

sends

a

The

File

enable

with

you

condition

be

or

record-

When

Write

even

uni

Unsafe

the

FR

use

removed

a

in

The

hold

a

t

2

•

DR

Plug

When

locks

Head

position

status,

Load

DR

1

you

select

when

Load

2,

that

status

selected.

Ready

status

the

are

is,

plug

status,

are

door

when

present.

position

present.

locks

Drive

2-8

1,

Drive

When

independently

Select

The

unit

the

Select

is

disk

you

status

supplied

drive

status,

select

of

and

door

and

plug

Ready

Head

with

Page 23

•

•

DL

Plug

For

and

DL

status

exist

DL

1,

door

When

pends

with

DH

Plug

a

In

plug

plug

you

DL

door

Use

determines

depends

as

long

is

lock

select

on

the

1

selected.

lock

signals

as

present.

hold

In

hold

on.

the

depends

plug

Use

condition

must

be

which

The

door

signal

When

position

signal.

signal

you

on

to

present

lock

that

select

the

Drive

2,

The

occur,

ini

the

hold

is

selected

door

uni

Drive

tially.

door

plug

Select

lock

t

lock

status

position

hold

is·

suppli

Select

The

hold

will

by

the

signal.

de-

ed

NO.

1

2

This

you

status.

the

selected.

PLUG

ID

DR

DL

DH

DR

DL

DH

plug

select

controls

plug

When

hold

Table

status.

2-1

PLUG,

POSITION

1 1

1

(hold

1

disable)

1 1

1

(hold

1

enable)

the

position

you

select

The

Door Lock

IN

USE

POSITION

door

uni

PLUG

1,

plug

t

Plug

Door

Drive

Load

Door

Door

Drive

Load

Door

and

lock

you

hold

disable

position

is

supplied

Combinations

EXPLANATION

lock

Select

or

lock

and

In

Use

lock

Select

lock

In

Use

status.

2,

you

wi

= Ready

and Head

=

Drive

=

Ready

and

=

Drive

the

th

and

Select

and

Head

Select

When

hold

enable

DH

1

3

DR

DL

DH

4

DR

DL

DH

1 2

1

1 Load

2

2

2

(disable)

2

2-9

Door

Drive

Door

lock

Select

lock

= Ready

=

and Head Load

and

Drive

and

Head

Select

Page 24

IN

USE

You

cannot

the

connections.

connect

signal

is

supplied

PINS

(US)

select

pin

1

when you

with

In

You

to

the

connect

USI

Use by

the

enable

center

pin

connected.

2

plug

the

pin.

to

method:

In

You

the

Use

disable

center

you

signal

pin.

must

when you

the

In

The

solder

Use

unit

READ

You

must

select

signal

the

Standardized

connect

RDI

connected.

BUSY

The

busy

busy

BS

2

• Busy

• Busy

DATA

PINS

solder

them by

when you

pin

LAMP

PLUGS

lamp

lamp

will

selected.

To

have

present,

To

have

is

present,

2

to

plugs

Lamp

Lamp

(RD)

the

the

connect

Read

the

(BU,

be

on.

on

the

busy

select

on

the

busy

select

connections

plug

method.

pin

Data

center

BS)

determine

The

During

Head Load

lamp on when a Head Load

BU2and

During

Drive

lamp

BU2and

1

to

signal

pin.

the

unit

BS

on when a

at

the

You

the

center

(for

The

unit

conditions

is

supplied

2.

Select

BS

1.

RD

enable

VFO

Drive

pins:

the

pin.

option)

is

supplied

under

with

Select

you

cannot

Read

You

enable

when you

which

BU

2

signal

signal

Data

with

the

and

is

• Busy

To

present,

2.4.2.4

Diagnostic

T2

and

T3.

the

center

AUTO

The

To

TAP

auto

select

a.

b.

Lamp

have

Diagnostic

tests

Normally

pin).

TEST

tap

the

auto

Turn

off

Connect

on

During

the

busy

Select

Plugs

are

test

consists

tap

the

diagnostic

In

lamp

BU1and

(T2,

performed

these

pins

test:

power.

pins

Use

on when

remove

T3)

by

of

T2

2-10

are

a

use

head

to

an

the

of

the

open

load/unload

the

center

In

Use

BS

plug.

diagnostic

(not

connected

signal

pin.

is

pins

to

action.

Page 25

c.

d.

Select

Turn

HL2and

on

the

connect

power

and

HL2

the

to

auto

ground.

tap

test

starts.

AUTO

The

to

track

the

AUTO

This

To

select

SEEK

auto

auto

a.

b.

c.

SEEK

test

a.

b.

c.

d.

TEST

seek

76

with

seek

Turn

off

Connect

Turn

on

AND

performs

the

Turn

off

Connect

Select

Turn

starts.

test

test:

the

diagnostic

the

TJ~P

auto

the

diagnostic

HL2

on

the

consists

the

power

TEST

both

seek

and

read/write

power.

and

auto

and

power.

connect

power

pin

tap

pins

and

of

the

seek

HL2

T3

test:

T2

the

a

seek

heads

to

auto

and

to

the

seek

and

T3

ground.

auto

action

unloaded.

center

test

auto

to

tap

the

seek

from

To

pin.

starts.

functions.

center

and

track

tap

0

select

pin.

test

HEAD

To

UNLOAD

delay

ground.

nored

pin

is

2.4G2.5

The

TP

2-2

G

facturing

the

With

when

open.

Test

numbers

Test

only.

DELAY

head

Tl

they

Pins

pins

(Tl)

shorted,

occur

and

not

unload

less

(TP)

the

listed

action

head

than

signals

load/unload

250

availale

in

'the

2-11

250

ms

table

ms,

apart.

are

are

short

pin

commands

Normally

listed

used

in

in

Tl

are

to

ig-

this

Table

manu-

Page 26

PIN

NUMBER

Table

2-2

Test

Pins

and

Signals

SIGNAL

2.4.2.6

There

the

write

tory

mines

justed

TP

TP8,

TP

TP

TP

TP

are

and

the

at

7

9

10

11

12

13

Trimpots

three

current.

should

speed

166.6

trimpots

These

never

of

the

±

0.5

Index

Analog

head

adjust

Index

Write

Track

Media

on

trimpots

be

adjusted

spindle

ms.

signal

signal

output.

CE,

signal

Protect

0

signal

detect

the

for

(differential)

Use

Azimuth,

for

signal

sensor

PCB.

are

in

motor.

dual-sided

to

check

or

Index

Single-sided

output

RVI

and

adjusted

the

field.

This

media

or

RV2

at

RV3

trimpot

of

burst.

media

determine

the

fac-

deter-

is

ad-

2.4.3

The

Mounting

disk

drive

peI'pendicular.

Figures

for

disk

air

cooling

sured,

Interface

For

to

Chapter

2-5,

adequate

drive

you may

cabling

further

air

is

is

details

3.

and

Wiring

can

be

Recommended

2-6,

and

flow

installed

necessary.

need

a

details

on

mounted

2-7.

are

in

If

forced

are

logic

vertically

mounting

Recommended

shown

the

in

standard

smooth

air

cooling

shown

in

lines

methods

Figure

air

Figures

in

the

or

horizontally

space

2-8.

manner,

flow

cannot

system.

connector,

are

shown

requirements

When

no

forced

be

2-9

and

2-10.

refer

and

in

the

en-

2-12

Page 27

,,--,

I \

KNOB

./'

/1/1/1//1111/1

\ J

..-'

" /

Figure

COLLET

SPINDLE MOTOR

Figure

2-5

ASSEMBLY

2-6

\ STEP MOTOR

Vertical

Horizontal

I I I

Installation

Installation

SPINDLE MOTOR

STEP

MOTOR

I

Figure

2-7

KNOB

" "

I I

\ /

'-

11111111/1/

Perpendicular

2-13

-

Installation

Page 28

AIR

FLOW

COUPLED BRACKET

20mm

20mm

/

~/

(A)

/

One

Disk

Drive

EXTERNAL

WALL

NOTE:

Figure

lotmmJ-~

AIR

FLOW SHOWN BY SOLID LINES

AIR

FLOW SHOWN BY BROKEN LINES

BY HOLES IN THE COUPLED BRACKET.

2-8

Air

+----.........--+--+-

(B)

Flow

Two

or

PASSES

Requirements

Four

PASSES

Disk

AROUND DISK DRIVES.

THROUGH DISK DRIVES

for

2-14

Drives

Natural

Air

Cooling

Page 29

CONTROLLER

SI<3NAL NAME

LOW

CURRENT

UNSAFE RESET

FILE

UNSAFE

TWO

SIDED

DISK CHANGE

SIDE SELECT

IN

USE

HEAD LOAD

INDEX

READY

VFO

SYNC·

DRIVE SELECT 1

DfUVE SELECT 2

DRIVE

SELECT 3

DfUVESELECT 4

DIRECTION SELECT

STEP

WRITE

DATA

WFUTE

GATE

TRACK

WRITE PROTECT

READ

MFM*

WINDOW*

00

DATA

10

12

14

16

18

2·0

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

PIN

NO.

2

4

6

8

DISK

DRIVE

SIGNAL

CONN.

SIGNAL

DC

GROUND

DC+5V

GROUND

FG

*SIGNALS USED

Figure

2-9

NAME

+24 V

ONLY

WHEN VFO OPTIONISINSTALLED.

Interface

and

Cables

Controller

Between

Disk

PIN

NO.

1

2

3

4

5

6

7

Drive

POWER

CONN.

2-15

Page 30

SIGNAL

CONNECTOR

Figure

2.4.4

After

all

connections,

a.

b.

POWER CONNECTOR

2-10

Power

Interface

On

you mount

Install

Check

motor

speed.

Use

to

whatever

exercise

operations,

Testing

the

then

a

for

starts

Connectors

disk

test

test

flexible

drive

using

abnormalities

and

brings

diagnostic

the

and

disk

repeated

POWER RECEPTACLE

Physical

and

select

this

test

drive

disk

and

the

through

general

and

note

disk

programs

head-positioning

Location

the

wiring,

procedure.

apply

that

spindle

write

are

Diagram

verify

dc

power.

the

drive

up

available

and

scans.

to

read

2-16

Page 31

CHAPTER 3

This

chapter

between

3.1

The

DATA

data

50-contact

disk

drive.

numbered

PCB,

and

component

signal

assignments

3-2.

describes

the

FDl165

INTERFACE

and

edge

The

contacts

the

odd-numbered

side

INTERF,ACE

Flexible

CONNECTOR

control

card

pins

of

connector

are

are

the

for

the

data

Disk

line

numbered 1

located

contacts

PCB,

this

INFORMA

and

control

Drive

DATA

interface

located

through

on

the

are

as

shown

connector

nON

interface

and

its

connects

on

the

50.

component

located

in

Figure

are

shown

controller.

through

PCB

side

on

The

of

even-

of

the

3-1.

in

Figure

lines

a

the

the

non.

The

3.2

All

fined

2 4 6 8 48

'""""""-,,------tll--------

3 5 7

Figure

SIGNAr~

data

as

and

follows.

True

False

LEVELS

control

=

Logic

-

Logic

3-1

LOGIC

Data

0

1

(low

(high

and

Control

interface

level)

level)

lines

..............

47

Interface

are

SIGNAL

o

to

+2.5

~-'

50_

49_

Connector

at

TTL

+0.4

to

CONTACT NUMBER

THE COMPONENTSIDE

CONTACT NUMBER

THE NON COMPONENT

SIDE

levels,

LEVEL

Vdc

+5.25

Vdc

ON

ON

de-

3-1

Page 32

NON COMPONENT

SIDE OF

PCB

COMPON

OF

PCB

ENTSIDE

GROUNDS

1~

3~

5~

7~

9~

11~

13~

15~

17~

19~

21~

23~

25~

27~

29~

31~

33~

35~

37~

39~

41

~

43~

45~.

47~

49~

CONTACT

NUMBERS

~

~

~

~

~

~

~

~

~

~

I§§§

~24

§§§J

§§§J

~30

~32

~34

~36

~38

~40

I§§§

~44

§§§J46

~48

~·50

2

4

6

8

10

12

14

16

18

20

22

26

28

42

SIGNAL

LOW CURRENT

UNSAFE RESET

FILE

(UNUSED)

TWO-SIDED

DISK CHANGE

SIDE SELECT

IN

HEAD

INDEX

READY

VFOSYNC

DRIVE

DRIVE

DRIVE

DRIVE

DIRECTION SELECT

STEP

WRITE

WRITE GATE

TRACK

WRITE PROTECT

READ

MFM

WINDOW **

NAME

UNSAFE *

*

USE

LOAD

*

*

**

SELECT 1 *

SELECT 2 *

SELECT 3 *

SELECT 4 *

DATA

00

DATA

**

Figure

Each

to

driver

the

provides

Each

receiver

controller

resistor.

trigger

shown

in

*SIGNALS

** SIGNALS USED

3-2

ENABLEDBYPLUGS

Signal

circuit

controlle~

is

a maximum

circuit

is

an

LSI

Lines

gate.

Figure

receiving

The recommended

3-3.

ONLY

WHEN VFO OPTIONISINSTALLED

Edge

delivering

an

sink

Cord

open

current

Connector

a

co~lector

of

receiving

gate

circui

at

t,

high

driver/receiver

3-2

signal

40

a

drive

terminated

Contact

from

type

rnA

at

speeds

the

of

SN7438,

the

signal

at

use

Assignments

disk

drive

which

low

level.

from

a ISO-ohm

a

Schmitt

circuits

the

are

Page 33

CONTROLLER

7438OREQUIVALENT

DRIVER

CIRCUIT

~

+5

V

MAXIMUM

TWISTED PAIR 6 m

FLAT

RIBBON 3 m

HIGH

II

CABLE LENGTH

SPEED

LINE

DISK DRIVE

+5V

+5V

I 7438

LSI

OR

EQUIVALENT

~

RECEIVER

CIRCUIT CIRCUIT

3.3

Descriptions

low.

3.3.1

These

disk

fective

To

the

to

shorting

INPUT

Drive

lines

drive

when

designate

desired

designate

plug

150 A

~

Figur(:~

SIGNAL

of

Select

select

is

its

terminal

the

selected

drive

each

a

specific

into

3-3

FUNCTIONS

disk

the

~\

Driver

disk

1

to

one

select

DXl

DXl

~ft~'thl

and

Receiver

drive

4 (DXl

to

four

and

drive,

to

disk

terminals

its

line

DX4

drive

input

to

DX4)

disk

input/output

goes

insert

on

signal

drives

a

the

as

(see

-'-I

Circuits

low.

shorting

PCB.

number

Figure

/I.

DRIVER

functions

in

a

lines

For

1,

2-3).

system.

are

plug

example,

insert

fol-

A

ef-

into

the

3.3.2

If

the

the

Head Load

disk

disk

drive

drive

to

(HDL)

is

ready,

initiate

a low

head

3-3

level

loading.

on

this

line

directs

Page 34

3.3.3

Step

(STP)

This

to

line.

going)

track.

shown

3.3.4

If

ternal

toward

trailing

line

track

in

STP----~U

DIR

carr

in

the

The

edge

heads

of

The

Figure

-1W~T-1

Direction

is

at

track.

the

internal

edge

ies

direction

each

repeti

3-4.

Figure

the

If

of

a

start

tion

Select

high

it

track.

the

pulse

pulse.

3-4

level,

is

STP

that

designated

to

move

One

rate

Step

(DIR)

at

the

The

signal.

and

u

the

moves

at

pulse

width

Signal

head

low

signal

by

the

level,

occurs

the

heads

the

leading

moves

of

T::

5 ms

W::

1

Il~.

Timing

moves

from

DIRECTION SELECT

the

this

heads

pulse

track

(positive

one

are

u

(MIN)

TO 2.5 ms

toward

the

Ips

the

head

before

ex-

moves

the

3.3.5

If

SSL

side).

nal

SSL

that

3.3.6

If

If

Data

signal

off,

tion

nals

chart

3.3.7

This

written

modified

side

this

the

is

the

can

Side

is

If

it

occurs

0

write

line

line

erased

level

SIDE SELECT

be

are

line

is

shown

Write

on

frequency

both

(WDT)

the

Select

high,

is

100

is

used

Gate

is

is

high,

from

goes

enabled

at

in

Data

flexible

(SSL)

it

low,

ps

in

(WGT)

low,

data

the

high.

only

the

Figure

(WDT)

supplies

modulated

selects

it

before

the

data

signal

high

disk

flexible

selects

the

single-sided

is

written

is

read

flexible

The

HEAD

can

when

3-5.

the

level.

the

in

(MFM)

side

READ/WRITE

from

disk

LOAD

be

WRITE

disk

frequency

1

to

the

changed,

The

drive

format

disk

(lower

disk.

the

for

signal

GATE

WRITE

modulated

(see

side

side).

operation.

flexible

flexible

560

with

ps

can

and

and

GATE

Figure

0

after

be

STEP

ERASE

data

(upper

disk.

turned

opera-

timing

(FM)

3-6).

Sig-

Note

disk.

sig-

to

the

be

or

3-4

Page 35

WGT

,

I

ERA

(INS

SE

SIGNAL.

IDE FDD)

T

1

T

2

~

NOTE: THE

WDT

(FM)

,

HEAD

SIGNAL

BE

ENABLED

Figure

LOAD

3-5

SIGNAL

IN THIS

TO1ma

INTERVAL.

Write

CANNOTBECHANGED,

T - 2 ps

W.. 0.15

CANNOTBETURNED

AND

THE

STEP OPERATION

Gate

(2T • 4

Signal

p.s

:t 12

ns)

:...--T

OFF,

--+

3

THE

SIDE SELECT

CANNOT

Timing

T1-100

T2-195ps

T3-

560/o&s

/O&S

(M

(M

AX)

AX)

WDT

(MFM) I

_---J

Figure

W

I-

T =2ps

W .. 0.15psTO

3-6

1

ps

Write

Data

3-5

(2T - 4 ps ± 12

Signal

ns)

Timing

Page 36

3.3.8

Current

Changeover

(LWC)

During

pensate

During

teristic

should

ternal

3.3.9

A low

Reset

FLR

3.3.10

A low on

lock

3.4

A

condition.

OUTPUT

description

lows.

WRITE

for

READ

of

be

high

tracks

resets

In

Use

this

operations,

high-densi

operations,

a

preamplifier.

in

external

(43

to

(FLR)

FILE

line

SIGNAL

of

FUNCTIONS

the

LWC

ty

LWC

76).

UNSAFE

instructs

functions

controls

records

changes

For

tracks

status.

the

WRITE

in

the

the

READ/WRITE

(00

to

disk

of

the

drive

output

current

internal

frequency

operation,

42) and low

to

hold

signals

to

comtracks.

charac-

LWC

in

in-

a

door

fol-

3.4.1

This

line

flexible

shown

3.4.2

When

TKC

3.4.3

This

line

and low

serted,

Index

(lOX)

(lOX)

disk

in

Figure

Track

is

00

low,

Dual-Sided

(TSD)

if

it

TSD

remains

signals

once

3-7.

(TKC)

the

(TSD)

is

is

lOX

the

every

head

high

rotation.

is

if

dual-sided.

high.

T - 166.7:l: 3.3

W-1

the

start

on

flexible

TO 3.5

the

If

ma

no

ms

point

The

zero

flexible

of

resulting

track.

disk

a

track

on

pulse

is

single~sided

disk

is

the

is

in-

Figure

3-7

Index

3-6

Signal

Timing

Page 37

3.4.4

Ready

(ROY)

When

following

3.4.5

A

operations.

It

•

• The

•

•

low

is

•

ROY

Dc

closed.

Rotational

more

detected

Only

is

File

FUS

active

WGT.WDT

is

low,

conditions.

power

flexible

than

side

single-sided.

Unsafe

indicates

This

for

is

the

any

The

within

active.

the

speed

70%

0

line

disk

supplied.

disk

of

of

speed

IDX

signal

has

(FUS)

an

been

alarm

is

of

the

WRITE

18

dri

ve

has

reset

been

the

and

four

selected

condition

following

DATA

s

is

flexible

the

or

to

high

signal

after

ready,

inserted

disk

disk

more

if

and

conditions.

WRITE

drive

times.

the

it

by

does

indicating

and

has

flexible

inhibits

the

FUR

not

GATE

the

reached

logic

signal.

appear

becomes

the

door

has

disk

write

•

•

•

3.4.6

This

the

signal

option

mitted

inserted

wavetrain

line

flexible

HDr:.WGT

ROY.WGT

WGT

.STP - The

Read

or

(see

only

the

on

is

Data

(RDT)

disk

Section

when

the

shown

-

The

LOAD

- The

is

the

STANDARDIZED

1

WRITE

is

WRITE

not.

STEP

WRITE

(ROT)

conveys

drive.

3.5.3).

the

RD

side.

in

Figure

not.

shorting

GATE

GATE

signal

GATE

signal-conditioned

This

READ

A

typical

3-8.

The

signal

signal

is

signal

line

DATA

READ

active

is

transmits

signal

DATA

plug

RDT

is

active

active

is

the

at

active.

data

the

used

signal

(See

conditioned

Figure

but

read

READ

for

is

but

same

the

2-3)

digital

HEAD

READY

time

from

DATA

VFO

trans-

is

3-7

Page 38

RDT

(FM)

w=200 ± 50

ROT

(MFM)

T =2

IJS

ns

T 1.5T 1.5T

~+

Figure

3-8

-+-

Read

Data

+-

Signal

Timing

w...-.-..

2T

~

3.4.7

This

WRITE

notch

3.4.8

This

flexible

selected.

line

signal

Write

is

PROTECT

prevents

Disk

Change

disk

The

Protect

high

notch

writing.

goes

has

time

DOOR

DRIVE

SELECT

(PRT)

when

and low

(DCG)

low

been

CLOSE

<P

to

changed

relationships

1~-O-PE-N--I_c_L_OS_E

the

flexible

if

signal

since

I

DISK

the

the

are

CHANGE

disk

disk

controller

the

disk

shown

does

has

in

a

drive

Figure

_

not

notch.

that

was

have

last

3-9.

a

A

the

DISK

CHANGE

Figure

<P

3-9

Disk

u

Change

3-8

Signal

Timing

Page 39

3.5

VFO

INTERFACE

SIGNAL

FUNCTIONS

The

scribed

3.5.1

This

The

3.5.2

This

VFO

synchronized.

3.5.3

This

ized

liably

READ

3-10.

is

functions

in

Modified

line

line

VFO

controller

circuit.

Standardized

line

by

the

read.

DATA

(Timing

passed

is

conveys

of

the

the

following

Frequency

is

low when

high

Synchronization

VFO

SIGNAL

until

when

signal

The

The

line

Read

STANDARDIZED

circuit