Page 1

FDI036A

PreJ

I

mIn

a..

, j

3.5-

FLOPPY

PRODUCT

806-520236-0

DISK

DESCRIPTION

REV.

~O

DRIVE

NEC

Corporation

Page 2

PROPRIETARY NOTICE

The

by

all

to

information

and

patent,

use,

therein,

others.

and

are'the

sales

except

proprietary

Specifications

introduction

and

property

proprietary

rights

to

The

foregoing

parts.

remain.subject

of

design

design

of

design,

thereto,

the

extent

improvements.

disclosed

NEe

rights

does

to

herein

Corporation.

manufacturing,

and

to

any

are

not

apply

change

were

article

expressly

to

vendor

to

allow

originated

NEC

reserves

reproduction

disclosed

granted

the

Copyright

NEC

Corporation

Printed

in

1985

Japan

~

- i -

Page 3

Edition

Description

1

Prepared

in

August

1985

-

ii

-

Page 4

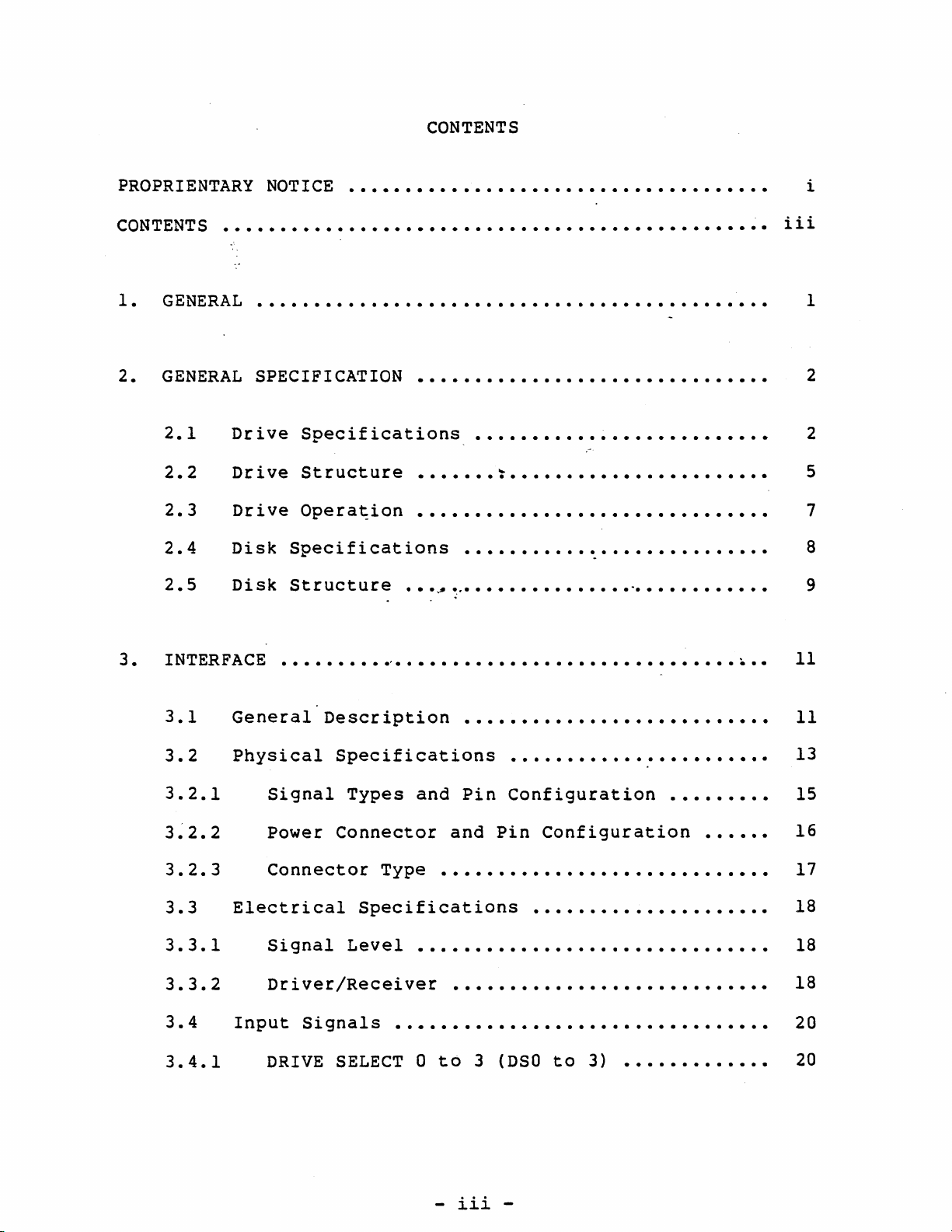

CONTENTS

PROPRIENTARY

CONTENTS

1.

GENERAL

GENERAL

2.

2.1

2.2

2.3

2.4

2.5

Drive

Drive

Drive

Disk

Disk

NOTICE

..............................

..............

...................................

SPECIFICATION

Specifications

Structure

Opera~ion

Specifications

Structure

...............................

.•••••••••

.............. ...............

...

...........................

..............

...

~~

~

i

iii

1

2

2

5

7

8

~

. 9

3.

INTERFACE

3.1

3.2

3.2.1

3~2.2

3.2.3

3.3

3.3.1

3.3.2

3.4

3.4.1

General

Physical

Electrical

Input

..........' .

Description

Specifications

Signal

Power

Connector

Signal

Driver/Receiver

DRIVE

Types

Connector

Type

Specifications

Level

Signals

SELECT

.................................

...........................

......................

.

and

Pin

Configuration

and

Pin

Configuration

......

.............................

.....................

.........................

...

............................

a

to

3

(DSO

to

3)

11

11

13

15

16

17

18

18

18

20

20

iii

Page 5

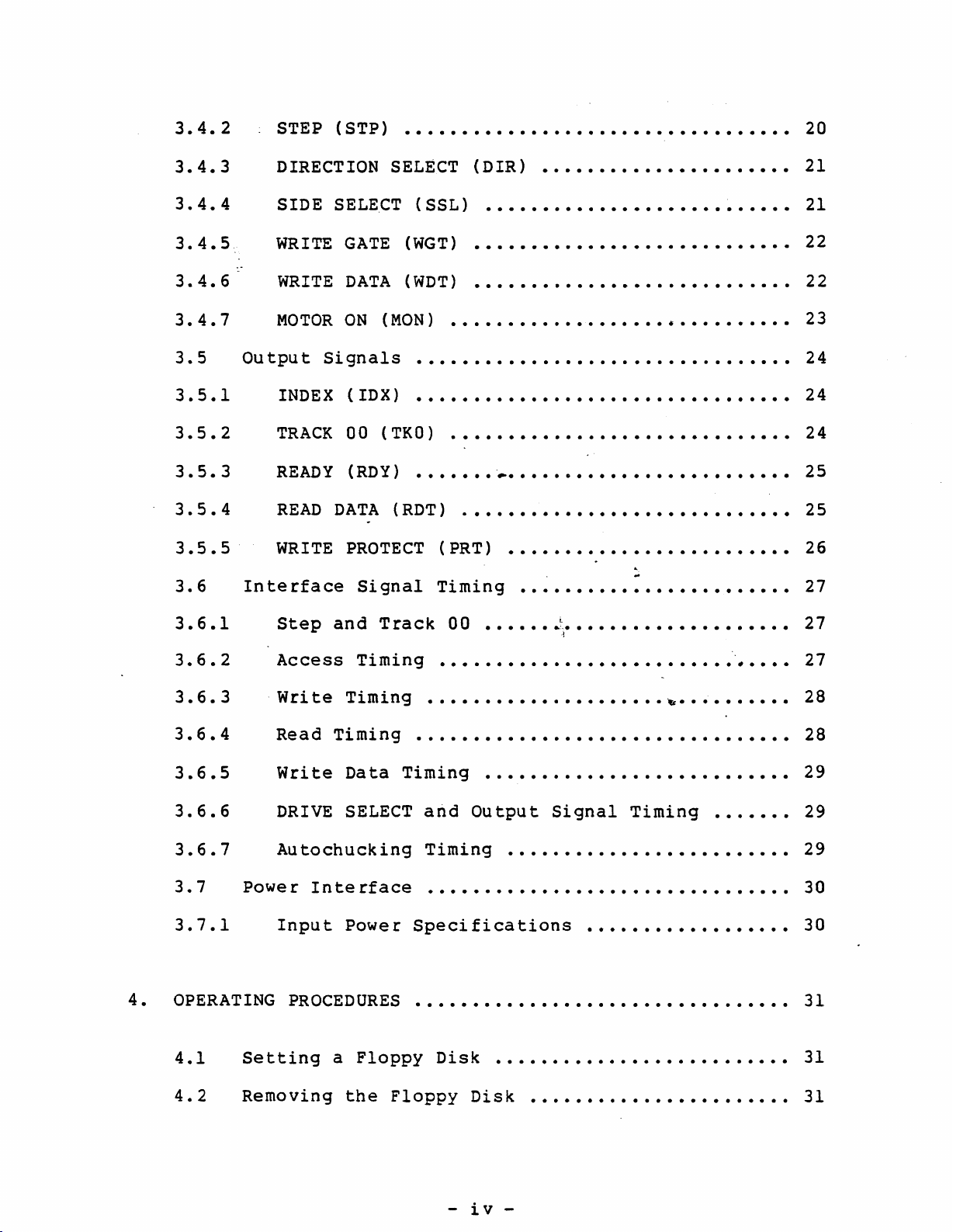

3.4.2

STEP (STP)

..................................

20

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.6

DIRECTION

SIDE

WRITE

WRITE

MOTOR

Ou

tputSignals

INDEX

TRACK

READY

READ

WRITE

Interface

SELECT

SELECT

GATE

DATA

ON

(MON)

(IDX)

00

(TKO)

(RDY)

DATA

PROTECT

(RDT)

Signal

......................

(SSL)

(WGT)

(WDT)

(DIR)

............................

............................

.

.............................

.................................

.

...

~

................

.

..........................

(PRT)

Timing

21

21

22

22

23

24

24

24

25

25

26

27

3.6.1

3.6.2

3.6.3

3.6.4

3.6.5

3.6.6

3.6.7

3.7

3.7.1

4.

OPERATING

4.1

Step

Access

Write

Read

Write

DRIVE

Autochucking

Power

Setting

Interface

Input

PROCEDURES

and

Track

Timing

Timing

Timing

Data

SELECT

Power

a

Floppy

00

........

•••••••••••.•••••••••

Timing

and

Timing

...............................

.

Specifications

...........................

Output

.........................

i.

:-

I

........

..

~.

Signal

Timing

..................

. .

.................................

Disk

.......................

27

.

27

28

28

29

29

29

30

30

31

31

4.2

Removing

the

Floppy

Disk

iv

31

Page 6

5.

4.3

EXTERNAL

Display

SHAPE

Lamp

AND

..................................

INSTALLATION

•••••••••••••••••••••

31

32

6.

5.1

5.2

5.3

PACKING

External

Installation

Recommended

AND

Shape

TRANSPORTATION

and

Fitting

•.•••.•••.•••••••.•••••••••••••••.

Air

Flow

•••••••••••••.•••••••••••.

Hole

Positions

•••..

32

33

34

35

- v -

Page 7

1.

GENERAL

The

FDl036

micro-floppy

disk

drive

is

a

double-sided

tracks

The

manual)

jacket

The

volume

per

Micro-floppy

used

with

FDl036

one

minifloppy

approximately

capacity.

micro-floppy

inch

(TPI).

disk

for

the

auto

shutter.

micro-floppy

fourth

disk

560

that

drives

g,

disk

(abbreviated

FDI036

disk

of

conventional

and

weights

yet

has

drive

is

contained

drive

a

comparable

with

as

has

only

disk

a

5-l/4

135

in

in

a

total

w

storage

this

hard

The

previous

short

slim

The

model

drive

brushless

it

consumes

The

low

In

this

is

abbreviated

depth

noise

manual

with

uses

DC

only

FD

(130

a

motor,

design

the

1035

series

mm).

thin

thickness

direct-driven

and

2.1

watts

assures

FDI036

as

FDD.

is

The

FD

by

due

of

micro-floppy

the

1036

(30

spindle

the

power

silent

short

series

mm).

with

low

power

(Typ).

operations.

disk

model

is

a

drive

with

the

design

-1-

Page 8

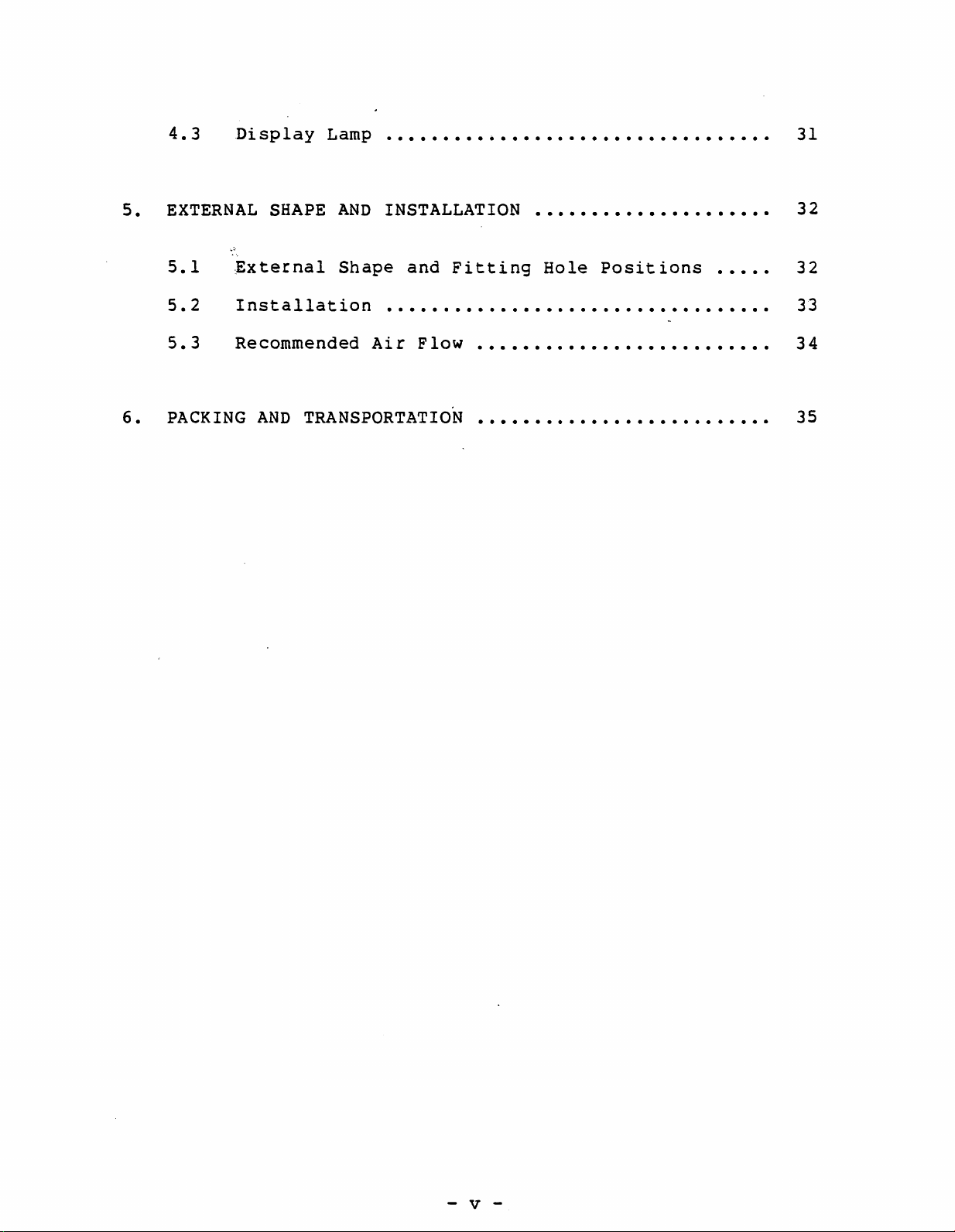

2.

•

GENERAL

SPECIFICATIONS

2.1

Drive

NO.

Recording

1

2

Capacity

Data

3

Maxim\D1

4

5

Tracks

Average

6

Seek

7

(Track-to-track)

8

Seek

Track

9

10

Start

Standard

11

external

dimensions

(NOTE

.-

--

specifications

Item

mode

Unformatted

Forma

transfer

bit

density

rotational

time

settling

density

time

3)

(NOTE

Width

Height

Depth

rate

time

ted

.

2)

(NOTE

speed

1)

Specification

MFM

1

640

250

8717

160

~

300

3

15

135

800

30

101.6

146

MAX

" ,

L

(1.2)

(4)

(5.75)

FM

0.5

320

125

4359

Unit

-

MB

kB

k-bit/sec.

BPI

rpm

ms

.,

ms

TPI

ms

\

(in)

mm

mm

(in)

mm

(in)

12

13

Weight

Operating

environment

condi-

tions

Temperat

Relative

h\D1idity

Max

im

1.DIl

wet-bulb

temperat

ure

ure

56

45

5

'"

20'"80

29.0

(woncondensing)

"-2-

gr

°C

iRH

°C

Page 9

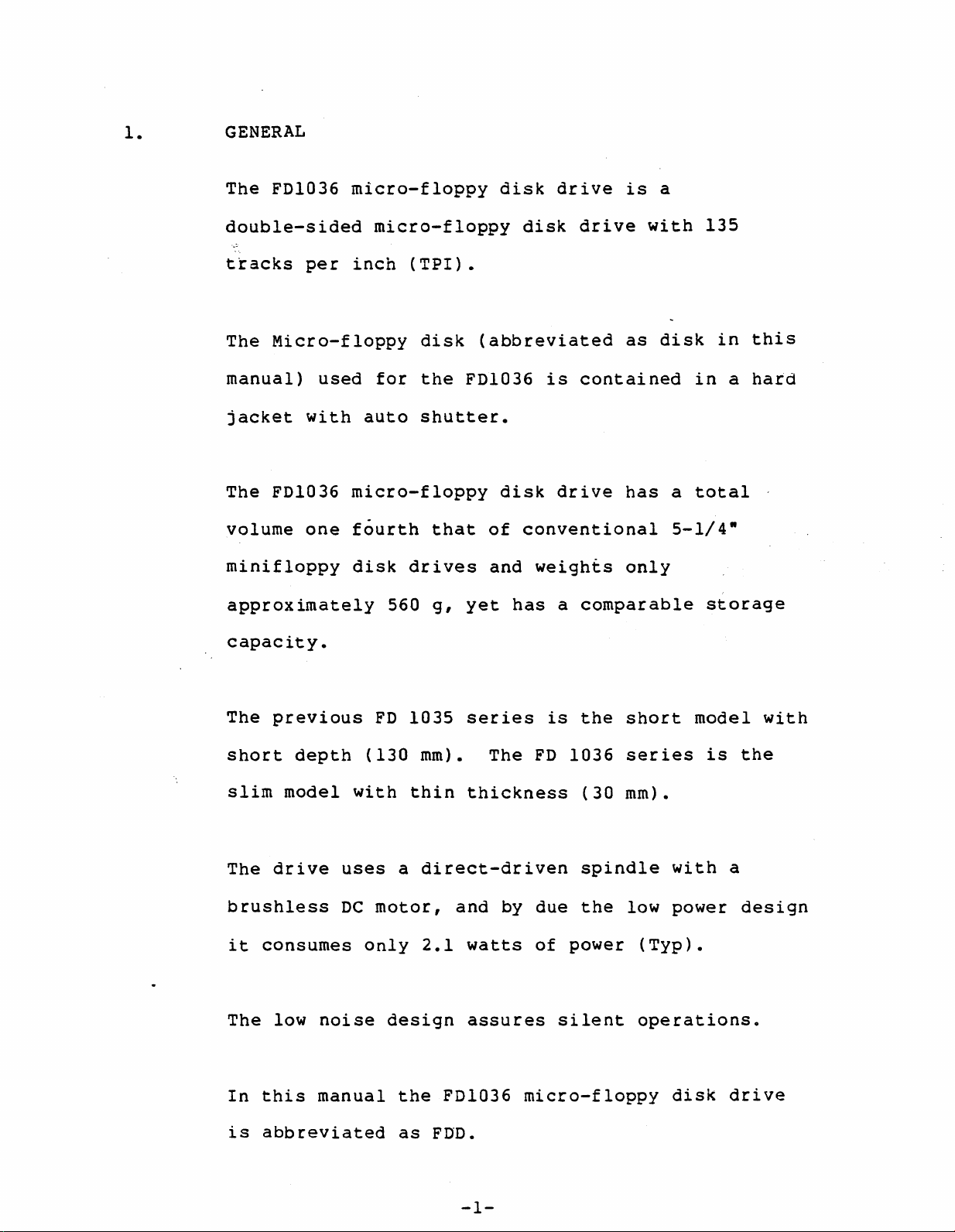

No

•.

Item

Specification

Unit

14

Power

supply

·Vo1tage

(V)

Start

(NOTE

up

4)

current

Steady-state

current

(NOTE

5)

requirement

15

16

17

Power

Heat

Reli-

dissipation

.".

output

ability

18

,"

Disk

life

+12

+5

MTBF

MTTR

Device

Soft

Hard

Seek

ratio

(NOTE

life

errors

errors

.

error

Less

60

0.3

0.26

6)

12000 (Under

~e

0.5

15000 poa

(De

10

or

10

10

3.0

than

condition)

sign

-9

(Not

less

-l.Z

_6

x 10

0.1

standard

or5years

life)

including

retry

6

90

200

2.1

1.8

2

attempts)

..

..

rnA

rnA

W

kcal/h

-

poa

h

Times/bit

Times/bit

Times/seek

Pass

count/

track

.

19

20

Disk

Drive

environment

Temperature

Relative

hunidity

M.ax

im

lU'It

wet-bulb

temPe

rat

ure

Largest

temperat

ure

Operating

4

tV

46

(39 "'115)

20

'" 80

29

(84)

20

(59)

Double

diskette

Non-operating

(Storage)

-20

(-4

10

40

sided

3.5"

specified

by

Transporting

(Packing)

'" 50

"'122)

-40

(-40

'" 90 5 '" 95

45.

(104) (113)

30

(86)

30

(86)

NEC

'" 60 '

"'140)

Unit

°C

(OF)

%RH

°C

(OF)

°C/h

(OF/h)

-3-

Page 10

No

.

Item

Specification

Unit

Allowable

vibration

(Except

resonance

point)

(NOTE

Allowable

shock

(Less

10

7)

ms)

at

than

NOTEl:

2:

3:

4:

0.5

(Less

100

Hz)

5

16

Time

Dimensions

bezel.

If

ON

than

sectors/track,

until

the

disk

signal

2

(Less

100

15

READY

not~nc1uding

is

than

Hz)

after

is

not

invalid.

256

inse

bytes/sector

2

(Less

100

40

MOTOR

that

rted

than

Hz)

-

ON

of

0 r

the

the

G

G

time

front

MOTOR

5:

6:

7:

When

Under

(1)

FDD

standard

Drive

time

(2)

Actual

time

(3)

Disk

ejection

(4)

(5)

Motor

Average

per

Excitation

is

in

service

(POH)

head

(R/W

insertion/

ON/OFF

use

disk

in

READY

use

load

time)

time

three

status.

,I

conditions

directions

8

h,Lday

0.5

h/day

25

times/day

300

times/day

2

h/day

(4

disks/day.drive)

one

R/W

test

8:

by

our

Between

FDD

SG

tester

and

-4-

FG:

for

0

90Kn (DC)

to

79

track

Page 11

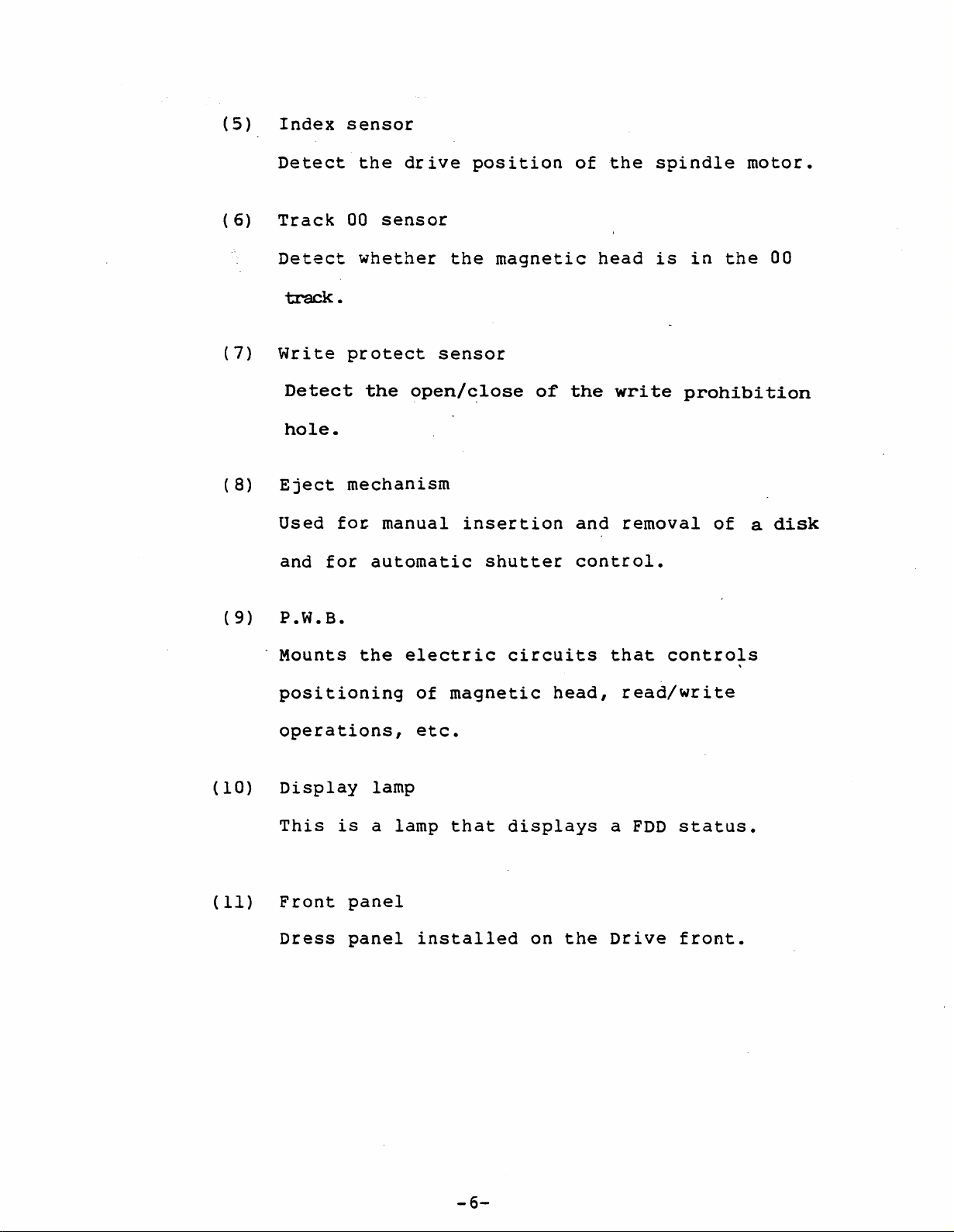

2.2

DRIVE

The

major

functions:

STRUCTURE

component

of

FDD

have

the

following

(1)

(2)

(3)

Base

Constructs

Spindle

Rotate

spindle

spindle

driving

Head

carriage

Contains

across

side

one

motor

the

motor.

with

pin.

a

the

is

the

frame.

assembly

~

The

a

magnet

assembly

pair

of

disk.

dislocated

directly

disk

and

magnetic

The

R/W

8

by

is

is

heads

gap

tracks

using

set

driven

of

inner

the

to

by

facing

the

DC

the

a

head

than

on

(4)

that

Step

Move

for

of

motor

the

head

the

head

carriage

position.

on

Assy

side

by

zero.

using

the

steel

belt

-5-

Page 12

(5)

Index

sensor

(6)

(7)

(8)

Detect

Track

Detect

track.

Write

Detect

hole.

Eject

Used

and

the

00

sensor

whether

protect

the

mechanism

fo~

manual

for

automatic

drive

the

sensor

open/close

insertion

position

magnetic

shutter

of

of

the

head

the

write

and

control.

spindle

is

removal

motor.

in

the

prohibition

of

a

00

disk

(9)

(10)

(11)

P.W.B.

Mounts

positioning

operations,

Display

This

Front

Dress

is

panel

panel

the

lamp

a

electric

of

etc.

lamp

installed

circuits

magnetic

that

displays

on

head,

the

that

controls

read/write

a

FDD

Drive

status.

front.

-6-

Page 13

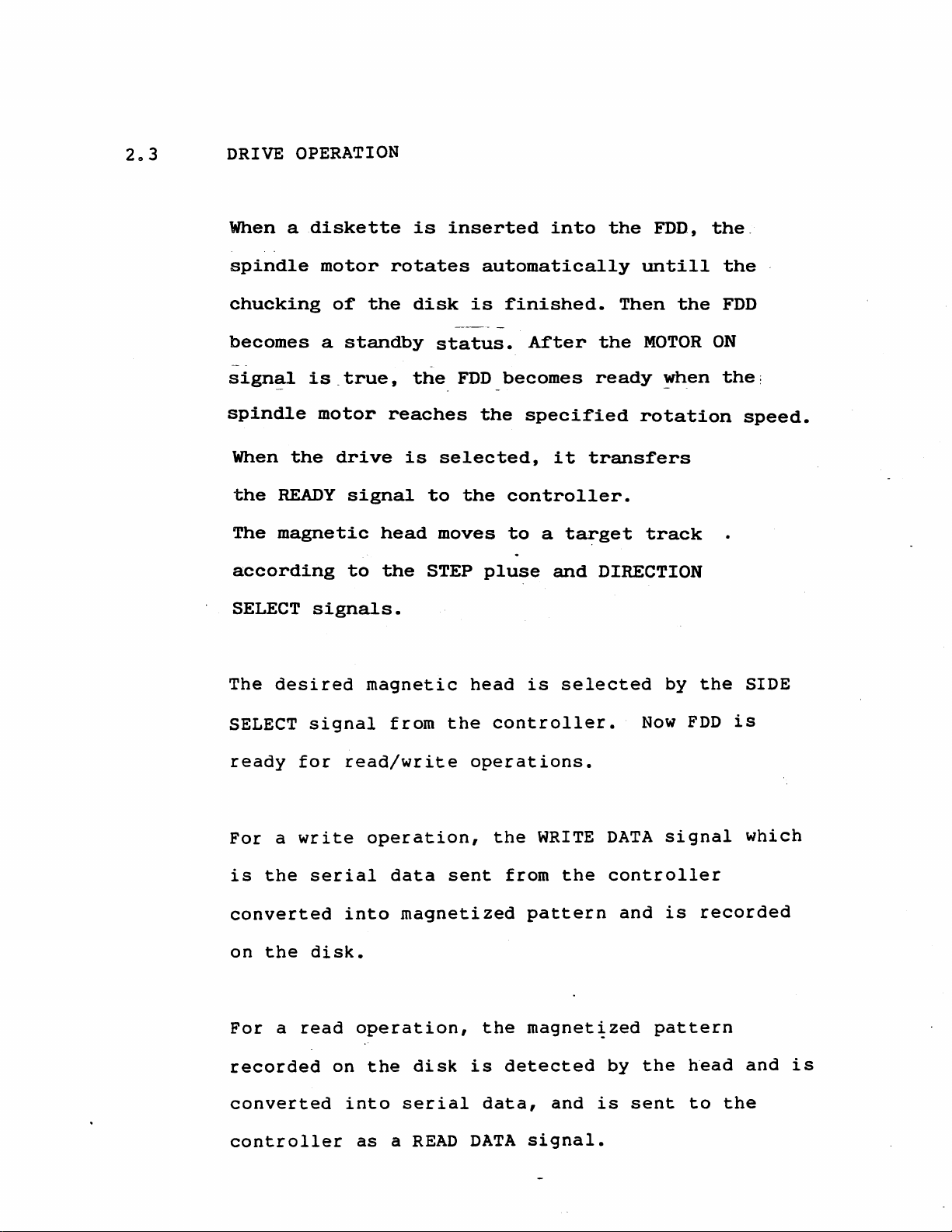

203 DRIVE OPERATION

When a

spindle

chucking

becomes

sign~l

spindle

When

the

READY

The

magnetic

according

SELECT

diskette

motor

a

is.true,

motor

the

signals.

of

the

standby

drive

signal

to

is

rotates

disk

the.

reaches

is

head

the

inserted

automatically

is

status.

FDD_becomes

the

selected,

to

the

moves

STEP

pluse

into

finished.

After

specified

it

controller.

to

a

target

and

the

FDD,

untill

Then

the

MOTOR

ready

~hen

rotation

transfers

track

DIRECTION

the

the.

the

FDD

ON

the:

speed.

The

desired

SELECT

ready

For

a

is

the

converted

on

the

For

a

recorded

converted

signal

for

write

serial

disk.

read

magnetic

from

read/write

operation,

data

into

operation,

on

the

into

head

the

operations.

sent

magnetized

disk

is

serial

is

controller.

the

WRITE

from

pattern

the

magnet~zed

detected

data,

and

selected

DATA

the

controller

by

is

and

sent

by

Now

signal

is

pattern

the

the

FDD

is

recorded

head

to

the

SIDE

which

and

is

controller

as

a

READ

DATA

signal.

Page 14

2.4

DISK SPECIFICATIONS

No.

1

2

3

4

5

6

7

Media

Prod

Number

uct

type

name

of

Recording

Number

per

Disk

of

disk

cartridge

Operating

environment

conditions

Item

disks

surfaces

total

size

Temperat

-

Relative

hunidity

Wet-bulb

temperature

Temperat

gradient

External

Magnetic

tracks

ure

ure

field

3.5-

double

specified

NEC

micro

10 '"

~

'1

20oC/h

4000

Specification

sided

by

NEC

floppy'_disk

90

x 94

60°C

8 tV

~.

29°C

MaximlDll

MaximlDll

(50

oersted)

A/m

(50

80%

-

\<

mediun

160

mm

'"

140°F)

RH

(84°F)

(36°F/h)

1

2

or

less

Note

Leave

minutes

the

in

environment

disk

the

at

drive

before

least

operating

use.

30

-8-

Page 15

2.5

DISK

STRUCTURE

The

floppy

withinside

disk

surface

polyethylene

magnetic

cloth

or

The

itself

and

dust.

disk

to

write-protect

The-disk

disk

of

is

which

protection.

terephthalate

layers.

protects

The

has

a

th~

hard

metal

spindle.

hole

construction

contained

liner

The

liner

the

jacket

hub

and

is

in

sheets

The

base

consists

disk

surfaces

is

made

wihch

The

hard

automatic'

shown

disk

is

in

a

hard

are

uses

coated

of

used

jacket

shutter.

Figure

jacket

provided

a

with

of

unwoven

from

ABS

to

scratch

resin.

secure

has

2.1.

for

a

-9-

Page 16

Figure

2.1

shows

the

disk

structure.

I.

Fig.

2.1

90

Disk

o

I

.I

Structure

-10-

Page 17

3.

INTERFACE

3.l

GENERAL

FDDIs

parallel

of

depends

daisy-chain

up

Signal

each

controller

(a)

FDD

to

FDD.

Parallel

may

Is

4

line

DESCRIPTION

be

connected

or

daisy-chain

which

on

dividual

FDDIs.

The

can

connection,

termination

basic

is

shown

connection

be

connected

system

FDD

in

to

its

controller

configuration.

and

controller.

each

controller

resistors

connection

Figure

3.i.

to

one

are

·controller

provided

to

the

in

The

can

either

number

For

control

on

Controller

Signal

Power

Signal

cable

cable

cable

.1

R

FDD

#0

I

maximum

R

FDD

il

length

R:

1 m

u

R

FDD'

#2

Terminating

resistor:

2K

R

FDD

#3

0

-11-

Page 18

(b)

Daisy

Chain

connection

.""

.0

Controller

Signal

cable

Signal

Power

-

total

cable

cable

\/

R

FDD

#0

I

length

...

maximum

\/

R

FDD

#1

I

R:

length

\/

R R

-

FDD

#2

Terminating

resistor

1 m

\

FDD

2K

#3

n

Fig.

3.1

Basic

Connection

Modes

~

-12-

Page 19

3.2

PHYSICAL SPECIFICATIONS

The

FDD

is

connected

to

its

controller

through

a

signal

terminal

connector

connector

is

provided

locations

and

a

for

are

power

frame

shown

connector.

ground.

in

Figure

A

The

3.2.

faston

-13-

Page 20

Power

plug

connector

Si

qnal

receptacle

connector

Signal

lu

connector

Fig.

3.2

Connector

Locations

-14-

Page 21

3.2.1

Signal

The

~ypes

following

and

shows

Pin

Configuration

the

signal

connector

pin

PWB

part

surface

configuration

~~""..MJ---!-~J--""--,,--,,,--,,~

Signal

MOTOR

IN

USE

ON

name

1

PIN

on

No.

Input

Input

the

I/O

FD

33

Signal

signal

signal

1036:

PIN

No.

.....

....c;.-,,--,-....c;.~M-"-"""'-..J-J

Pin

Nunber

~

';2

4

Pin

Nunber

1

3

Signal

Name

GND

GND

l~·

DRIVE·

SELECT

INDEX

DRIVE

DRIVE

DRIVE

SELECT

SELECT

SELECT

(MOTORON1)

MOTOR

ON

DIRECTION

STEP

WRI'lE

WRI'm

TRACK

WRITE

READ

SIDE

DATA

GATE

00

PROTECT

DATA

SELECT

READY

3

0

1

2/

SELECT

Input

Output

Input

Input

Input

Input

Input

Input

Input

Input

Output

Output

Output

signal

signal

signal

signal

signal

signal

signal

signal

signal

signal

signal

signal

signal

Inputsignal

Output

signal

6

8 7

10

12

14

11

13

16 15

18

20

22

24

26

28

30

32

34

17

19

21

23

25

27

29

31

33

5

~

GND

GND

9

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

.

-15-

Page 22

FG

and

SG

processing

as

follows:

3.2.2

SG

Impedance

R =

100

POWER

The

following

Te

kn

CONNECTOR

configuration:

R

rminator

(~

10%),

AND

shows

FG

C =

O.l~F

PIN

CONFIGURATION

the~power

Printed

circuit

+_

8400%%)

(

connector

board

pin

Fig.

Table

3.3

Pin

EB

EB

3

2

Connector

Connector

3.1

1

Power

Power

number

1

2

3

4 +12 V

EB

4

in

Supply

+5

Configuration

Pin

Assignments

voltage

V

DC

GND

GND

DC

.

-16-

Page 23

3.2.3

CONNECTOR

TYPE

Housinq:

Pins:

The

the

following

signal

equivalent

171822-4

170262-1

Power

pluq

connector

and

connector

by

Japan

connector

power

AMP.

Co.,

type

connections

types

Ltd.

may

are

recommended

for

also

be

the

FDD;

used.

Power

rece

for

connector

tacle

Signal

receptacle

connector

Si

qnal

lu

Socket:

PS-34SEN-D4Pl-1C-N

(closed-end

PS-34SEN-D4Pl-1D-N

(daisy-chain

both

by

Electronics

Co.,

Ltd.

or

equivalent

Cable:

3365-34

Sumitomo-3M,

or

equivalent

Fig.

type)

type)

Japan

Industry,

by

Co.,

3.4

connec

Aeronotic

NOTE

1

Ltd.

Connector

tor

Locations

and

Recommended

Models

-17-

Page 24

3.3

ELECTRICAL

SPECIFICATIONS

3.3.1

3.3.2

SIGNAL

All

the

TRUE

FALSE

LEVEL

the

input/output

following

=

Logical

=

Logical

DRIVER/RECEIVER

The

driver

controller

capable

which

is

of

obtaining

electrical

ftOft

Wlft

outputs

an

open

signals

(LOW

(HIGH

collector

sink

are

at

specifications:

level)

level)

signals

0,

+2.5

from

output

current

l

of

TTL

level

to

+0.4

to

+5.25

FDD

to

circuit

maximum 40

with

V

V

the

mA

at

from

gate'

LOW

level.

the

terminating

The

controller

receiver

to

with

FDD

2k

is

Ohm.

which

a

receives

Schmitt

signals

trigger

-18-

Page 25

·Con

troller

Cable

1.0

m

length

(Max.)

+5V

FDD

7438

equivalent

or

Driver

Receiver

Fig.

+5V

3.5

TiT

rf1

TiT

(MIN)

;;;-

Driver/Receiver

i7T

\h

m-

;;;-

Circuit

LS14

equivalent

7438

-equi

or

valent

Driver

Example

or

-19-

Page 26

3.4

Input

Signals

3.4.1

3.4.2

DRIVE

DRIVE

SELECT

SELECT

specified

level

selects

effective

FDD

is

specified

selection

STEP (STP)

Pulse

signal

direction

0

to

0

to

FDD.

the

the

input/output

plugs

which

specified

3

(DSO

3

are

signals

Setting

corresponding

by

shorting

a

to

3

on

moves

by

the

to3)

one

of

lines.

one

the

PWB.

the

magnetic

di~ection

for

DSO

FDD,

of

selecting

to

DS3

which

the

head

select

DX

to

makes

in

a

LOW

the

signal.

LOW

to

HIGH

head

input

moves

pulses.

conditions.

The

head

level

over

begins

of

as

Figure

this

many

moving

signal.

cylinders

3.6

shows

at

the

the

The

as

the

pulse

rising

magnetic

number

timing

from

of

-20-

Page 27

u U

u

3.4.3

DIRECTION

Signal

movement.

toward

toward

This

instructing

the

the

signal

JTJ_Tl

Fig.

SELECT

The

outer

inner

must

Tl:

T2:

3.6

HIGH

3 ms

0.8

STEP

(DIR)

the

level

tracks

tracks.

be

switched

_.I

min.

~s

~

Pulse

direction

indicates

and

2 ms

Specification

of

the

LOW

definitely

magnetic

the

direction

~level

o.all','S

head

indicates

3.4.4

before

STEP

SIDE

Signal

read.

the

This

the

the

signal.

SELECT

selecting

The

side

read/write

·0·

signal

trailing

(SSL)

HIGH

of

must

operation.

one

level

the

be

edge

of

disk

switched

(positive

the

selects

and

heads

the

the

100IIs

going)

used

magnetic

LOW

level

befor

for

of

the

write

head

selects

start

or

on

of

-21-

Page 28

3.4.5

WRITE

GATE

(WGT)

3.4.6

This

data

LOAD

signal

when

signal,

start

gone

to

WRITE

Pulse

the

disk.

to

LOW

head

of

changes

magnetization

writes

at

HIGH

switch

positioning,

HIGH

DATA

signal

level.

(WDT)

that

Every

level,

direction,

the

data

level.

the

for

supplies

time

write

on

th~

1 ms

the

when

Do

SIDE

data

signal

current

which

disk.

at

not

SELECT

after

changes

LOW

turn

this

to

be

changes

in

the

level

off

signal,

~ignal

written

from.

~agnetic

the

and

the

reads

HEAD

or

has

to

HIGH

direction

Figure

3.7

shows

the

WRITE

DATA

specification.

-22-

Page 29

WDT

(PM)

2Tl

WDT

(MFM)

Fig.

I.

Tl:4-

T2:

3.7

Tl:

T:

Tl

4

1.1s

0.lS'V2.S

1.5Tl

./.

lJS

0.15

WRITE

~

2.5

DATA

lJS

J

lJS

(2Tl:

Pulse

(2Tl:

8

8 lJS ±

Specification

1.1s±25

25

ns)

ns)

3.4.7

MOTOR

The

when

The

to

1.

*

2.

3.

NOTE: *

ON

spindle

the

following

rotate

Plug

Plug

Plug

0

(MON)

motor

disk

the

1:

Interface

2:

Interface

3:

Interface

mark

delivery.

rotates

is

inserted.

signals

spindle

indicates

on

the

motor.

pin

pin

pin

setting

by

making

MON

14

(DRIVE SELECT

16

(MOTOR

2

(MOTOR

this

plug

position

ON

ON

can

signal

0)

1 )

be

when

LOW

used

2)

-23-

Page 30

3.5

Output

Signals

3.5.1

INDEX

Signal

is

output

the

output

The

reading

reference.

(IDX)

for

INDEX

(lDX)

indicating

once

pulse

edge

every

revolution.

specification.

of

the

u u

t-::

the

origin

pulse

on

is

the

Figure

used

dis~.

as

3.8

a

-....1

Tl

=1'V8m.s

T2=200

This

shows

±3ms

3.5.2

TRACK

When

heads

This

track

step

Fig.

00

at

are

signal

00

motor.

3.8

(TKO)

LOW

on

sensor

INDEX

level,

track

is

generated

and

Pulse

this

·00·.

the

Specification

signal

by

(excitation)

indicates

the

signal

from

phase

that

of

the

the

the

-24-

Page 31

3.5.3

READY

(RDY)

Signal

This

selected,

ti)

(ii)

(iii)

(NOTE) When

indicating

signal

DC

A

The

reached

MOTOR

disk

goes

if

the

power

is

rotational

the

ON

that

to

following

is

supplied.

mounted.

90t

of

spindle

signal

LOW

speed

the

FDD

is

level,

conditions

of

specification.

motor

ready

when

(5V,

the

is

to

the

l2V)-

floppy

rotating

operate.

FDD

are

is

satisfied:

disk

by

has

the

3.5.4

READ

Data

string.

Figure

normally

DATA

read

3.9

(RDT)

from

shows

recorded

a

disk

the

data

which

READ

is

is

DATA

read.

shaped

signal

into

obtained

a

pulse

when

-25-

Page 32

Read

(FM)

data

(ROT)

Read

(MFM)

3.5.5

data

(ROT)

T3

I.

T3

T4

Fig.

WRITE PROTECT

If

a

inserted

disk

3.9

with

into

./.

4llS

IllS

READ

(PRT)

the

T

3

1.5

(Typ)

±500ns

DATA

its

drive,

.1

Signal

WRITE

Specification

PROTECT

the

PRT

hole

line

2T3

uncovered

goes

.I

is

low,

which

places

the

FDD

in

-26-

the

WRITE

PROTECT

state.

Page 33

3.6

Interface

Signal

Timing

3.6.1

3.6.2

Step

Step

Track

Access

and

(STP)

00

Track

(TKO)

timing

00

u

u

II

2•5

ms

(max.)

1

ms

(min.

:

)

Write"gate

Step

Direction

(DIR)

(STP)

(NOTE)

(WGT)

select

An

interval

between

changes.

step

of

pulses

at

-

0.8

:L

3

least

1.1s~2

ms

when

ms

18

ms

(NOTE)

18

IDS

the

L

(min.

)

-i

is

required

direction

,

0.8

(min.

1.1s

)

-27-

Page 34

3.6.3

Write

Timing

Step

Side

write

3.6.4

Step

(STP)

select

gate

(STP)

Read

(SSL)

(WGT)

Timing

18

IDS

(min)

100'

..

.

1.1S

-\

(min.

,

.

11

I

ms

(min.)

U

JK

)

18

ms

-...----I~~~

(min.)

Side

Write

Valid.

select

gate

read

(SSL)

(WGT)

data

100

1 ms

1.1S

(min.)

(min.)

Valid

-28-

Page 35

3.6.5

Write

Data

Timing

3.6.6

J.6.7

Write

write

DRIVE

The

valid

gate

data

SELECT

drive

500

active.

Autochucking

Power

supp~

- 5 V

12

V"

(WGT)

(WDT)

control

ns

---

and

Output

after

Timing

and

that·the

8

~S

Signal

status

(max.)

DRIVE

Timing

signals

are

SELECT

8 l.lS

become

line

(max".)

is

x

Disk

Spindle

Index

Spindle

X

is

in

internal

signal

l

of

Ready

the

...

Chucking

FDD.

-

Status

Completion

-29-

Page 36

3.7

POWER

INTERFACE

3.7.1

INPUT

....

Table

sequence

A

POWER

3.2

Table

Voltage

Current

(NOTE

Ripple

3.2

Item

1)

voltage

SPECIFICATIONS

shows

for

Activating

Average

seek

Average

read/write

Average

standby

the

each

Input

(NOTE

when

when

when

(NOTE

DC

DC

Power

6)

time

2)

power

power

Specifications

.. +12V power

+12V1:5%

350

mA

IDA

140

90

IDA

to

~t

Less

than

200mVp~p

specifications

is

not

needed.

+5V

+5V.±5%

140

160

,~

200

0.1

M 60'mA

or

less

100mVp-p

....

power

mA

mA

mA

or

for

,

less

FDD.

NOTE

1:

2:

3:

4:

5:

6:

This

is

This

Data

power

in

Write

If

power

moving

inner

returned

Do

not

supply

Including

FDD

includes

is

protected

supply

operation.

supply

the

side

to

turn

by

average

ON/OFF

carriage

for

track

on

the

ripple

the

is

1

and

relay,

comsuming

spike

in

spite

when

charged

to

track,

0

immediately.

off

etc.

voltage.

voltage.

FDD

the

the

the

current.

of

DC

is

after

outer

carriage

power

not

or

is

-30-

Page 37

4.

OPERATING

PROCEDURES

4.1

4.2

4.3

The

basic

power

Setting

(1)

Removing

(1)

(2)

Display

on/off,

Insert

the

Make

finished.

To

press

operating

A

Floppy

Eject

the

sure

eject

the

Lamp

disk

the

button

Floppy

the

the

Eject

procedures

setting

Disk

diskette

disk

write/read

diskette

pops

button.

and

slowly

out.

from

for

FDD

removal.

into

operation

the

include

the

drive,

of

slot

FDD

just

the

until

has

The

It

Display

comes

on

lamp

while

indicates

the

FDD

the

FDD

status.

is

selected.~

-31-

Page 38

5.

EXTERNAL

SHAPE

AND

INSTALLATION

5.1

External

Figure

positions

..

0

+I

"!

t"'l

...

o

..

+l

0

"!

+1

...

~

0\

0

...

5.1

Shape

shows

.

146:

1

r

'r

(

and

0

s

•

70±a·S

the

60::°·5

-

+

Fitting

external

..

31±0.S

)

-

~

::

21

--

Hole

to.slS

Positions

shape

.-~

.~

6;: o.s

:~.S

s

4:O·

..

+1

and

..

~

~

0

...

~

+1

0

C'l

Q/

r&I

~

..

~

i~

~

Q

fitting

.

6.3%0.5

~

;n

X

32:tlt

21.9:O·

-

hole

s

4-Rl.2

:/

I

I

II!

0

+I

\0

M

8-4t4-40UNC

(NO'l'E

NOTE

Fig.

1)

+

-.1

1:

5.1

'+"

I

""

The

External

""

metric

-

70:!:D.S

60%O·s

screw

Shape

31:

type

and

o.s

2l.:!:0.s

...

-]]I

II""

.J

...

..

-,~

_4

is

also

Fitting

...

\.;.

0

+I

r,-

LJ

8.6

Unit

[1IIlIl]

available.

Hole

,

t

±o-.s

r

Positions

-32-

Page 39

5.2

Installation

(1)

FDD

(a)

(b)

(c)

may

be

Vertical

Vertical

Horizontal

o

installed

in

the

following

manners:

a

.

(a)

Consider

that

from

installing

it

CRT,

the

may

location

be

power

it

(b)

protected

supply,

inside

of

CRT.

FDD

against

etc.,

in

the

the

especially

(c)

system,

noise

so

when

-33-

Page 40

5.3

Recommended

Air

Flow

(1)

(2)

Installing

~

--==-c::=.

/ , / " 3

..-.L

nO

I

U·

D \

\

/"

/

~~

Installing

/_--

1

~

_/

one

Ventilator

two

/

\~

FDD

FDDs

Ventilator

NOTE:

o

\

I

Appropriate

ambient

considerably.

cooling

temperature

is

required

around

FDD

if

rises

the

-34-

Page 41

6.

PACKING

AND_TRANSPORTATION

(1)

(2)

For

external

material

make

to

Make

shock

sure

FDD.

sure

used

no

during

packing,

in

the

direct

that

FDD

transportation.

either

carrying

shock

will

will

sustain

use

in

the

of

be

transmitted

no

excessive

packing

FDD

of

-35-

Loading...

Loading...