NEC FD1165 Maintance Manual

FDl165

Flexible

Disk

Maintenance

Drive

Manual

NEe

Info,mation

NEe

Systems,lnc.

819-000090-2001

10-82

LIABILITY

DISCLAIMER

NEe

Information

accordance

Systems,

is

affected

tion,

other

customer

factors.

compatible

mentation

Therefore,

application

warranted

This

time

may

manual

of

have

Systems,

features,

without

NEC

Information

use

by

tained

produced

from

NECIS.

Inc.

by

by

pr

inting,

been

Inc.

or

notice.

NECIS

herein

in

with

the

product

by

system

data

While

with

most

customers

the

suitability

must

NECIS.

is

as

updated

reserves

specifications

Systems,

employees

is

whole

Systems,

terms

configuration,

and

systems,

be

determined

complete

however,

the

property

or

in

Inc.

of

the

specification.

operator

NECIS

products

the

of

the

product

of

and

the

since

the

right

of

Inc.

and

has

customers.

of

part

without

products

applicable

control

specific

a

product

by

the

factual

information

that

time.

to

its

prepared

NECIS

are

Product

software,

of

are

may

vary.

customer

as

change

products

The

and

prior

warranted

NEC

Information

performance

the

the

system

considered

functional

for

a

and

possible

in

this

NEC

Information

the

at

this

document

information

shall

written

applica-

among

to

imple-

specific

is

at

manual

functions,

any

not

time,

be

approval

in

be

not

the

for

con-

re-

First

NEe

Printing

Copyright

Information

5

Militia

Lexington,

Printed

-

October

1982©

Systems,

Drive

MA

in

U.S.A.

1982

Inc.

02173

FEDERAL

COMMUNICATIONS

INTERFERENCE

COMMISSION

STATEMENT

RADIO

FREQUENCY

Although

require

Model

This

unit

limits

disk

FCC

FDl165.

for

specifications

are

designed

interference

Manufacturer's

to

Prevent

Manufacturer's

The

ing

user

and

1.

must

operating

Operate

manufacturer's

2.

Ensure

grounded

plied

rating,

has

a

Radio

drives

been

Class

for

to

provide

in

a

residential

Instructions

Freguency

Instructions

observe

this

the

that

wall

with

as

the

type

B

computing

Subpart

the

device:

equipment

instructions

the

outlet

the

unit

subsystem

following

tested

J

of

reasonable

installation.

and

Interference

following

in

unit

and

is

ond

device

Part

User's

strict

:is

that

used

type

components

statement

found

in

accordance

15

of

to

protection

Responsibilities

precautions

accordance

for

the

plugged

the

and

not

applies

comply

FCC

Rules,

against

in

model.

into

a

power

modified.

do

to

with

with

install-

with

properly

cord

not

the

the

the

which

such

the

sup-

3.

4.

5.

Ensure

factory

Make

affect

Rules.

Properly

state

that

installed

no

modification

its

maintain

of

repair.

the

meeting

unit

cover

the

is

set

to

the

equipment

ii

i.

always

on

the

equipment

specified

the

operated

unit.

limits

in

a

with

which

would

of

satisfactory

the

the

User's

The

ar

ising

ment

ference

determined

encouraged

following

others

user.

Responsibility

user

under

1.

2.

3.

4.

If

these

the

following

1.

has

from

his

to

by

to

measures.

not

mentioned

Change

antenna.

Change

Change

Change

a

ttempts

Line

the

ultimate

harmful

contiol.

radio

turning

try

in

in

in

in

devices:

isolation

radio-frequency

or

television

the

to

correct

All

are

orientation

orientation

location

equipment

are

unsuccessful,

transformers

responsibility

If

this

equipment

the

of

these

exclusively

of

of

equipment.

power

emissions

equipment

reception,

off

interference

responsibili

at

of

the

the

equipment.

source.

install

to

correct

does

and

the

receiving

from

cause

which

on,

by

ties

expense

one

the

one

or

problems

equip-

inter-

can

user

of

the

and

of

device

all

any

the

be

is

of

2.

3.

If

necessary,

experienced

gestions.

by

the

Federal

to

Identify

This

Office,

"Note:

to

is

interest

has

booklet

stop

causing

been

Line

Electro-magnetic

Washi'ngton,

The

operating

filters

the

radio/television

The

to

corrected."

user

Communications

and

is

operator

harmful

stop

user

Resolve

available

his

opera

shielding

should

may

D.C.

interference

of

find

Radio-TV

from

20402,

a

computing

device

tion

consult

technician

the

until

following

Commission

the

u.s.

Stock

upon

and

the

the

dealer,

for

to

Interference

Government

No.

device

finding

004-000-00345-5.

it

is

interference

additional

booklet

be

helpful~

may

that

in

be

the

NEC

Problems."

the

or

sug-

prepared

"How

Printing

required

device

public

problem

an

iv

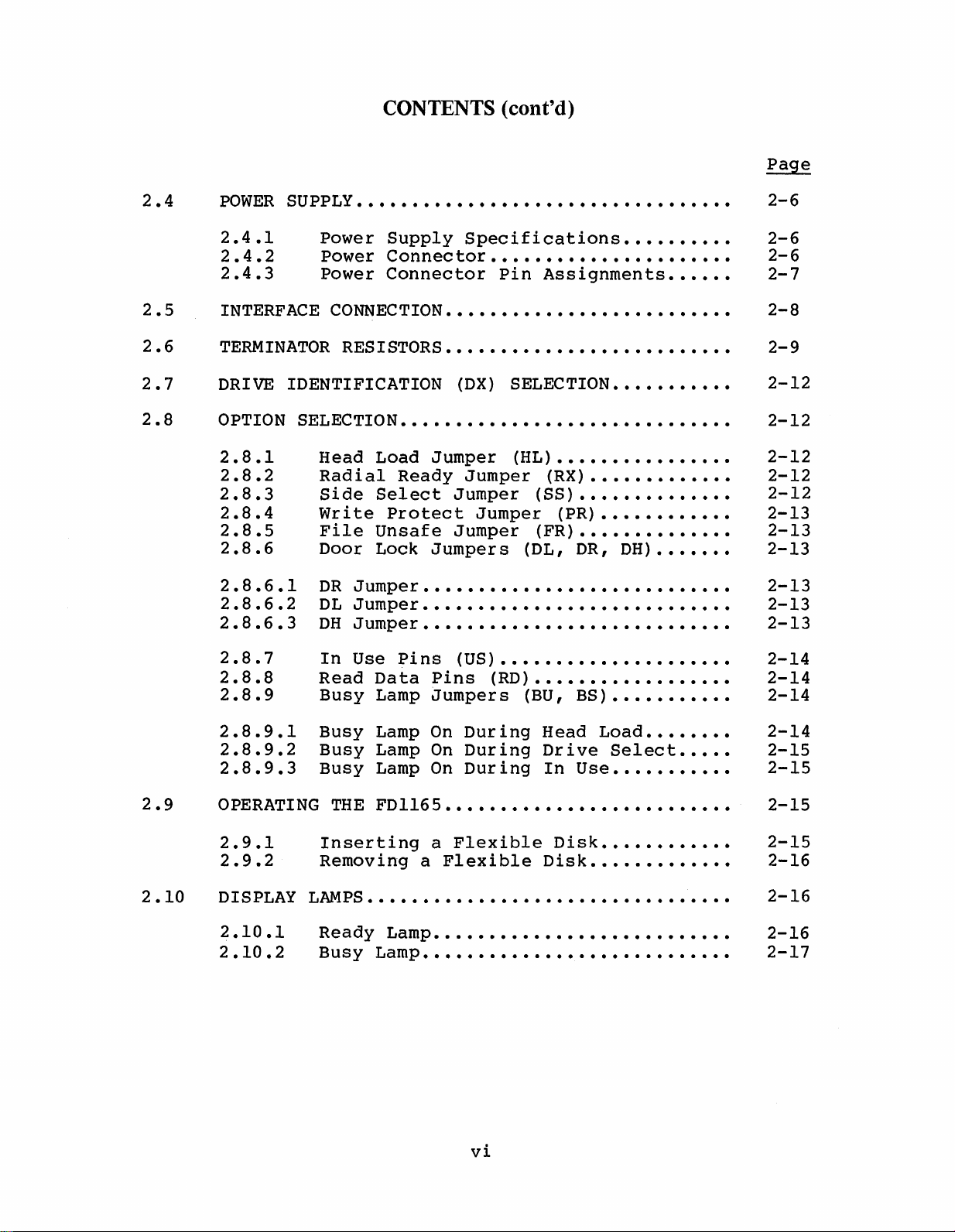

CONTENTS

CHAPTER

1.1

1.2

1

GENERAL

DESC.RI

CONSTRUCTION

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.2.10

1.2.11

1.2.12

1.2.13

1.2.14

1.2.15

1.2.16

1.2.17

1.2.18

PTION•••••••••••••••••••••••••••••••••••

Base

Spindle

Dc

Carriage

Stepping

Head

Pop-Up

Index

00

Write

Media-In

Collet

Printed

Variable

,(Optional)

Display

Front

Movable

Door

INFORMATION

AND

FEATURES

Frame

Direct

Load

Sensor

Track

Protect

Panel

Lock

•••••••••••••••••••••••••••

Assembly

Drive

Read/Write

Motor

Cam

Feature

•••••••••••••••••••••••••

Sensor

Sensor

Assembly

Circuit

Frequency

Lamps

••••"•••·••••••••••••••••••

Door

Solenoid

••••~••••••••••••••••

•••••••••••••••••••••

Spindle

•••••••••••••••••••••••

Assembly

•••••••••••••••••••••••

••••••••••••••••••••••

Sensor

••••••••••••••••••••••

••••••••••••••••••••••

Board

Oscillator

••••••••••••••••••••••••

Handle

••••••••••••••••••

•••••••••••••••••••

Motor

Assembly

•••••••••••••••

•••••••••••••••••

(PCB)

••••••••

Heads

••••••••••

•••

1-1

1-2

1-2

1-2

1-3

1-3

1-3

1-3

1-4

1-4

1-4

1-4

1-4

1-4

1-4

.

1-4

1-5

1-5

1-5

1-5

1.3

CHAPTER

2.1

2.2

2.3

SPECIFICATIONS

2 INSTALLATION

PRELIMINARY INSPECTION .

UNPACKING

2.2.1

2.2.2

2.2.3

ENVIRONMENTAL

2.3.1

2.3.2

2.3.3

AND

Unpacking

Repacking

Preinsta11ation

Operating

Space

Mounting

••••••••••••••••••••••••••••••••

AND

OPERATION

REPACKING

Procedure

Procedure

REQUIREMENTS

Environment

and

Weight

•••••••••••••••••••••••••••••

•••••••••••••••••••••••

••••••••••••••••••

••••••••••••••••••

Inspection

••••••••••••••••••••

••••••••••••••••

Data

v

••••••••••••••••

•••••••••••

1-5

2-1

2-1

2-1

2-1

2-3

2-3

2-3

2-3

2-3

CONTENTS (cont'd)

Page

2.4

2.5

2.6

2.7

2.8

POWER

2.4.1

2.4.2

2.4.3

INTERFACE

TERMINATOR

DRIVE

OPTION

2.8.1

2.8.2

2.8.3

2.8.4

2.8.5

2.8.6

2.8.6.1

2.8.6.2

2.8.6.3

SUPPLy

Power

Power

Power

IDENTIFICATION

SELECTION

Head Load

Radial

Side

Write

File

Door

DR

DL

DH

••••••••••••••••••••••••••••••••••

Supply

Connec

Connector

CONNECTION

RESISTORS

••••••••••••••••••••••••••••••

Ready

Select

Protect

Unsafe

Lock

Jumpe r

Jumper

Jumper

Specifications

tor

••••••••••••••••••••••

Pin

Assignments

••••••••••••••••••••••••••

••••••••••••••••••••••••••

(DX)

Jumper

Jumper

Jumper

Jumpers

••••••••••••••••••••••••••••

••••••••••••••••••••••••••••

••••••••••••••••••••••••••••

SELECTION

(HL)

Jumper

Jumper

(RX)

(SS)

(FR)

(DL, DR,

••••••••••

••••••

•••••••••••

••••••••••••••••

•••••••••••••

••••••••••••••

(PR)

••••••••••••

••••••••••••••

DH)

•••••••

2-6

2-6

2-6

2-7

2-8

2-9

2-12

2-12

2-12

2-12

2-12

2-13

2-13

2-13

2-13

2-13

2-13

2.9

2.10

2.8.7

2.8.8

2.8.9

2.8.9.1

2.8.9.2

2.8.9.3

OPERATING

2.9.1

2.9.2

DIS

PLAY

2.10.1

2.10.2

LAMPS

In

Use

Rea

d Da

Busy

Busy

Busy

Busy

Inserting

Removing

Ready

Busy

Lamp

Lamp

Lamp

Lamp

THE

FDl165

•••••••••••••••••••••••••••••••••

Lamp

Lamp

Pins

taP

(US)

•••••••••••••••••••••

ins(RD)

Jumpers

On

During

On

During

On

During

••••••••••••••••••••••••••

a

Flexible

a

Flexible

•••••••••••••••••••••••••••

••••••••••••••••••••••••••••

• • • • • • • • • • • • • • • • • •

(BU,

BS)

Head Load

Drive

In

Use

Disk

Disk

•••••••••••

••••••••

Select

•••••••••••

••••••••••••

•••••••••••••

•••••

2-14

2-14

2-14

2-14

2-15

2-15

2-15

2-15

2-16

2-16

2-16

2-17

vi

CONTENTS (cont'd)

CHAPTER

3.1

3.2

3.3

3.4

3

INTERFACE

BASIC

OPE:RATIONAL

ELECTRICAL

3.2.1

3.2.2

3.2.3

INPUT

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3.7

3.3.8

3.3.9

3.3.10

OUTPUT

SIGNALS

SIGNALS

INFORMATION

DESCRIPTION

INTERFACE

Signal

Levels

Driver/Receiver

Interface

Lines

••••••••••••••••••••••••••••.••••

Drive

Head Load

Step

Direction

Side

Write

Write

Low

File

In

(STP)

Select

Write

Unsafe

Use

Select

(HDL)

•••••••••••••••••••••••••••

Select

Gate

Data

Current

(USE)

•••

•••••

.....................

••.•••••••••••••••••••••

Circuits

•••••••••••••

••••••••••••••••••••••

1

Through

4 (DSXl

••••••••••••••••••••••

(SSL)

(WGT)

(WDT)

Reset

•••

(DIR)

••••••••••••••••••••

•••••••••••••••••••••

•••••••••••••••••••••

It

•••••••••••••••••••••

•••••••••••••••

(LWC)

(FUR)

••••••••••••••

••••••••••••••

.

................

to

4).

3-1

3-2

3-2

3-2

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3.5

3.6

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

VFO

INTERFACE

3.5.1

3.5.2

3.5.3

3.5.4

INTERFACE

3.6.1

3.6.2

3.6.3

3.6.4

3.6.5

3.6.6

Index

Tr

ack

(IDX) .

00

Dual-Sided

Ready

File

Read

Write

(ROY)

Unsafe

Data

Protect

DiskChan

SIGNALS

Modified

(MFM)

VFO

••••••••••••••••••••••••••••••

Synchroni

Standardized

Wi

ndow

TIMING

Power

Drive

Step

Access

Wr

i

te

Read

(WID)

••••••••••••••••••••••••

On

Select

and

•••••••••••••••.•••••••••••••••

.••••••••••••••••••••••••••••••••

(TKO)

(TSD)

•••••••••••••••••••••

••••.~•••••••••••••••••••••

(FUS)

••••••••••••••••••••

(ROT)

ge

(PRT)

(DCG)

••••••••••••••••••

••••••••••••••••••••

•••••••••••••••••••••••••

Frequency

zation

Read

Modulation

(SYC)

Data

(SRD)

Mode

••••••••••••

•••••••••

•••••••••••••••••••••••••

Sequence••••••••••••••••••••

•••••••••••••••••••••••••

Track

00

••••••••••••••••••••

3-6

.

3-7

3-7

3-7

3-7

.

3-8

3-8

3-8

3-9

3-9

3-9

3-9

3-9

3-10

3-10

3-10

3-10

3-11

.

3-11

3-12

vii

CONTENTS (cont'd)

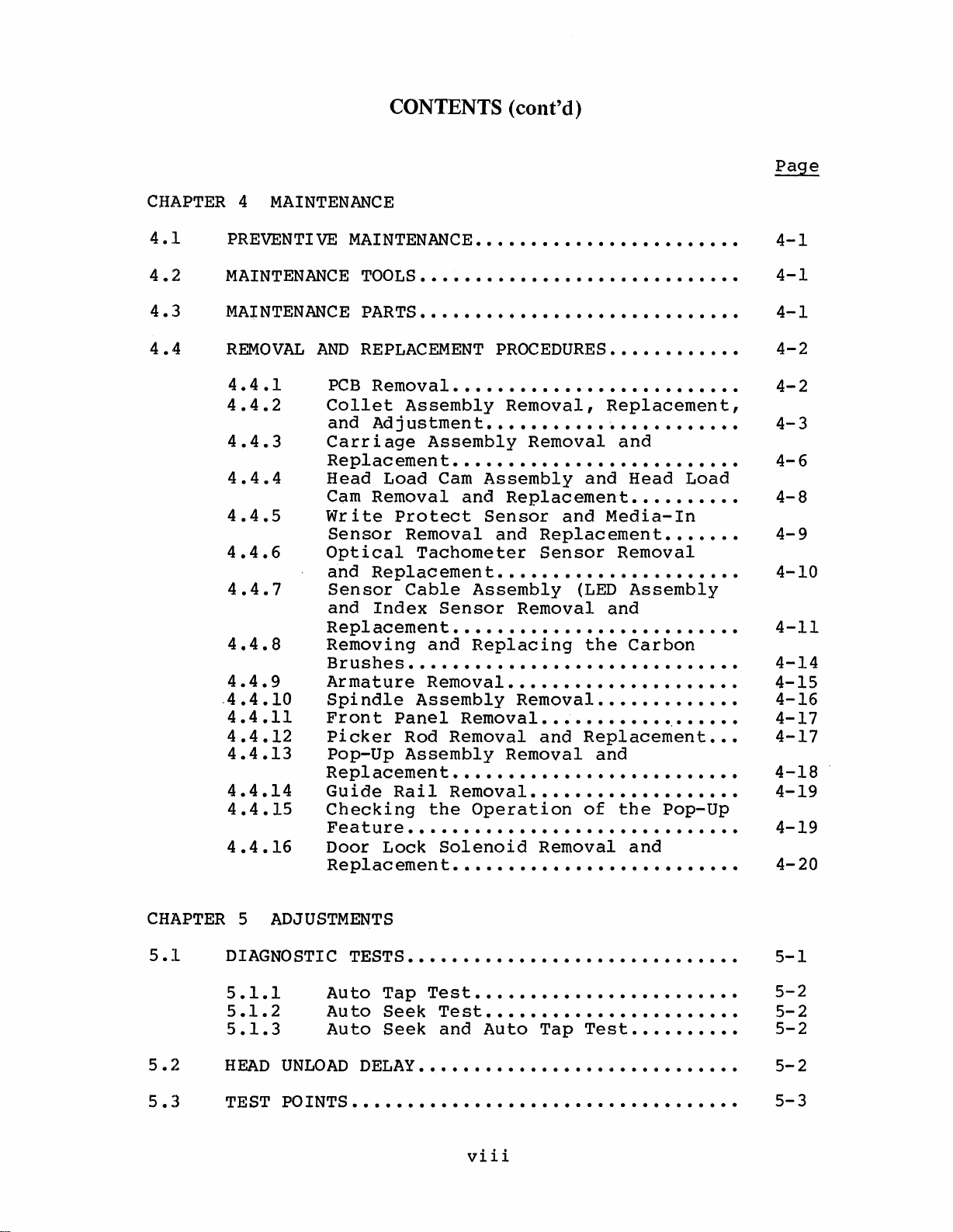

CHAPTER

4.1

4.2

4.3

4.4

4

MAINTENANCE

PREVENTI

VE

MAINTENANCE

MAINTENANCE

REMOVAL

4.4.1

4.4.2

AND

PCB

Collet

and

4.4.3

Carriage

Replac

4.4.4

4.4.5

Head Load

C~m

Write

Sensor

4.4.6

Optical

and

4.4.7

Sensor

and

Replacement

4,,4.8

Removing

Brushes

4.4.9

.4

.4.10

4.4.11

4.4.12

4.4.13

Armature

Spindle

Front

Picker

Pop-Up

Replacement

4.4.14

4.4.15

Guide

Checking

Feature..............................

4.4.16

Door Lock

Replacement..........................

MAINTENANCE

TOOLS

PARTS

•••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••

REPLACEMENT

Removal

••••••••••••••••••••

Assembly

Adj

ustment••••••••••••••

Assembly

ement

••••••••••••••••••••••••••

Cam

Removal

and

Protect

Removal

Tachometer

Replacement

Cable

Index

Sensor

••••••••••••••••••••••••••

and

••••••••••••••••••••••••••••••

Removal

Assembly

Panel

Rod

Removal

Removal

Assembly

••••••••••••••••••••••••••

Rail

Removal

the

Solenoid

••••••••••••••••••••••••

PROCEDURES

Removal,

Removal

Assembly

Replacement

Sensor

and

and

Replacement

Sensor

••••••••••••

Replacement,

and

and

Head

••••••••••

Media-In

Removal

•.••••••••••••••••••••

Assembly

Removal

Replacing

(LED

the

Assembly

and

Carbon

•••••••••••••••••••••

Removal

•••••••••••••

••••••••••••

and

Replacement

Removal

and

•••••••••••••••••••

Operation

of

Removal

the

and

"

"

••••••••

•••••••

,

•••••

Pop-Up

•••••

Load

•••

4-1

4-1

4-1

4-2

4-2

4-3

4-6

4-8

4-9

4-10

4-11

4-14

4-15

4-16

"

4-17

4-17

4-18

4-19

4-19

4-20

CHAPTER

5.1

5.2

5.3

5

ADJUSTMENTS

DIAGNOSTIC

5.1.1

5.1.2

5.1.3

HEAD

TEST

UNLOAD

PO

INTS

TESTS

Auto

Auto

Auto

DELAy

•••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••

Tap

Test

Seek

Seek

••••••••••••••••••••.•••

Test

and

•••••••••••••••••••••••

Auto

••••••••••

viii

Tap

"""""""

Test

II

" " " " " • " • "

.•••••••••

5-1

5-2

5-2

5-2

••

5-2

5-3

CONTENTS (cQnt'd)

5.4

5.5

5.6

CHAPTER

CHAPTER

ADJUSTMENTS

FLEXIBLE DISK

5.4.1

Head

Adj'ustment•••••••••••••••••••••••••••

5.4.2

5.4.3

O'l"HER

5.5.1

Azimuth

Index

ADJUSTMENTS

LED

and

5.5.2

5.5.3

00

Write

Adjus

5.5.4

TRIM

6

ILLUSTRATED

7

SCHEMATIC

POTS

Head

••••.-•••••••••••

AND

CHECKS

USING

THE

•••••••••••••••••••••••••••••••••

Radial

Check

Alignment

Alignment

Check

••••••••••••••••••••••••

Check

or

••••••••••••••••

Assembly/Index

Adjustment

Track

Sensor

Protect

•••••••••••••••••••••••

Sensor

Assembly

Check

or

Check

tment•••••••••••••••••••••••••••

Load

Check

PARTS

••••••••••••••••••••••

~

••••••••••••••••••••

BREAKDOWN

ALIGNMENT

or

Adjustment

~

••••••••••••

Check

Adjustment

or

••

••

5-3

5-4

5-6

5-7

5"'8

5-8

5-9

5-10

5

.....

10

5-11

ix

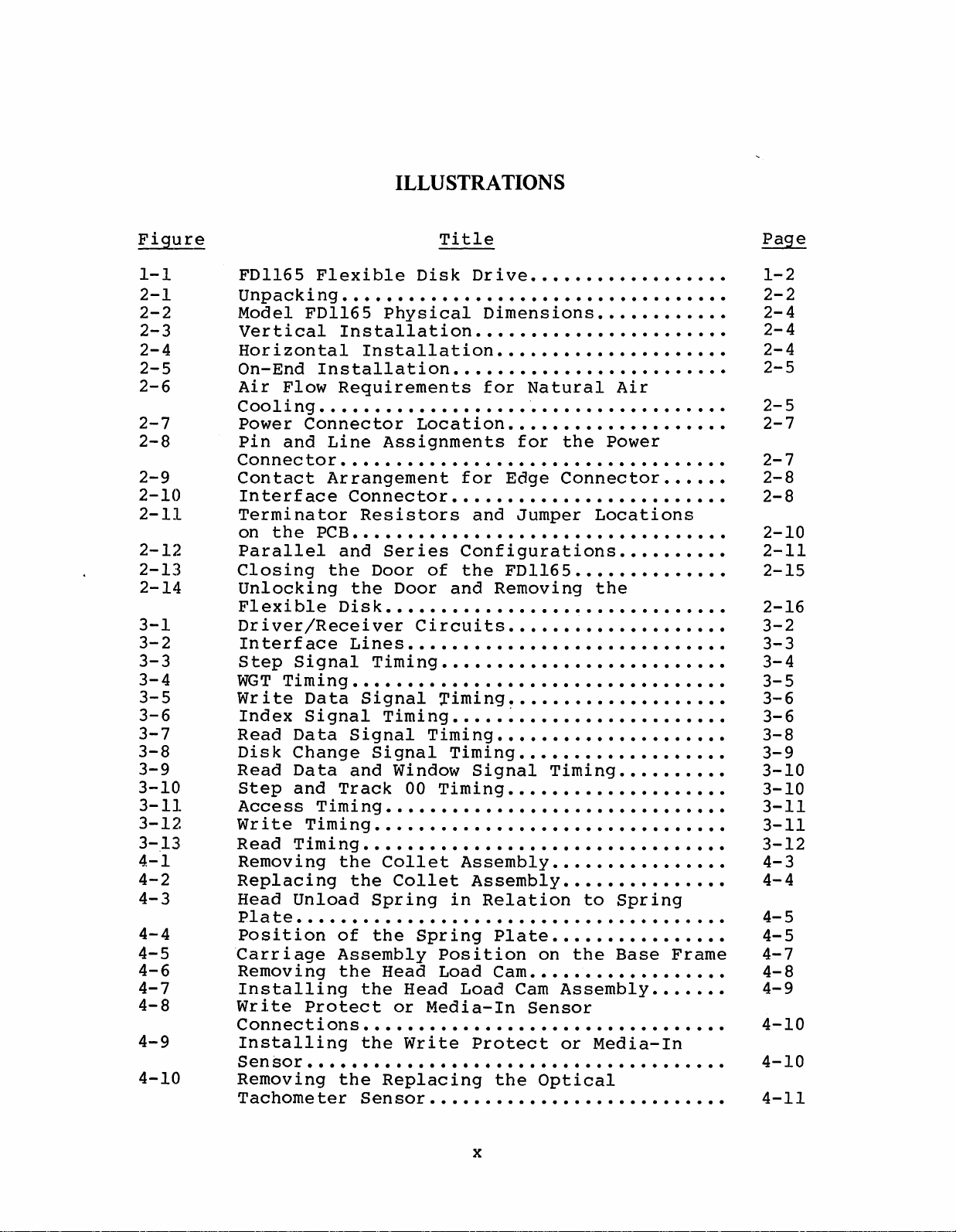

ILLUSTRATIONS

Figure

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

Title

FDl165

Unpack

Model

Vertical

Horizontal

On-End

Air

Cool

Power

Pin

Connec

Contact

In

terf

Terminator

on

Parallel

Closing

Unlocking

Fle'xible

Dr i ve r/Rec

Interface

Step

WGT

Write

Index

Read

Disk

Read

Step

Acce

Write

i ng

FDl165

Flow

i ng

Connector

and

tor

ace

the

Signal

Timing

Data

Signal

Data

Change

Data

and

Flexible

••••••••••••••••••••••••••••.••••••

Installation

Installation

Installation

Requirements

•••••••••••••••••••

Line

•••••••••••••••••••••••••••••••••••

Arrangement

Connector

Resistors

PCB

•••••••••••••••.•••••••••••••.••••

and

the

the

Disk

e i ver Ci r

Lines

••••••••••••••••••••••••••••••••••

Signal

Signal

and

Track

Disk

Physical

Drive

••••••••••••••••••

Dimensions

.••••••••••••••••••.•••

•••••••••••••••••••••

•••••••••••••••••••••••••

for

Natural

'

••••••••••••••••••

Location

Assignments

••••••••••••••••••.•

for

for

Edge

the

Connector

•••••••••••••••••••••••••

and

Jumper

Series

Door

Door

Configurations

of

the

FDl165

and

Removing

••••••••••••••

•••••••••••••••••••••••••••••••

cui

t s • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••.••••••••.

Timing

Timing

Signal

Window

••••••••••••••••••••••••••

Ximing

••••••••••••••••••••

•••••~•••••••••••••••••.•

Timing

00

Timing

Timing

••••••••••••••••.•.••

•.•••••••.•••••••••

Signal

Timing

••••••••••••••••••••

ssTiming•••••••••••••••••••••••••••••••

Timing

••••••••.••••••••••••••••••••.••

••••••••••••

Locations

the

ReadTiming••••••••••••••.••••••••••••••••••

Removing

Replacing

Head

Plate

Unload

Position

Carriage

Removing

Installing

Write

the

the

of

Assembly

the

Protect

Collet

Collet

Spring

the

Spring

Head Load

the

Head Load

or

Media-In

Assembly

Assembly

in

Relation

Plate

position

Cam

••••••••••••••••

•••••••••••••••

to

••••••••••••••••

on

the

••••••••••••••••••

Cam

Assembly

Sensor

Connections.................................

Installing

the

Write

Protect

or

Media-In

Sensor......................................

Removing

Tachometer

the

Sensor

Replacing

•••••••••••••••••••••••••••

the

Optical

Air

Power

••••••••••

••••••••••

Spring

Base

•••••••

••••••

Frame

Page

1-2

2-2

2-4

2-4

2-4

2-5

2-5

2-7

2-7

2-8

2-8

2-10

2-11

2-15

2-16

3-2

3-3

3-4

3-5

3-6

3-6

3-8

3-9

3-10

3-10

3-11

3-11

3-12

4-3

4-4

4-5

.

4-5

4-7

4-8

4-9

4-10

4-10

4-11

x

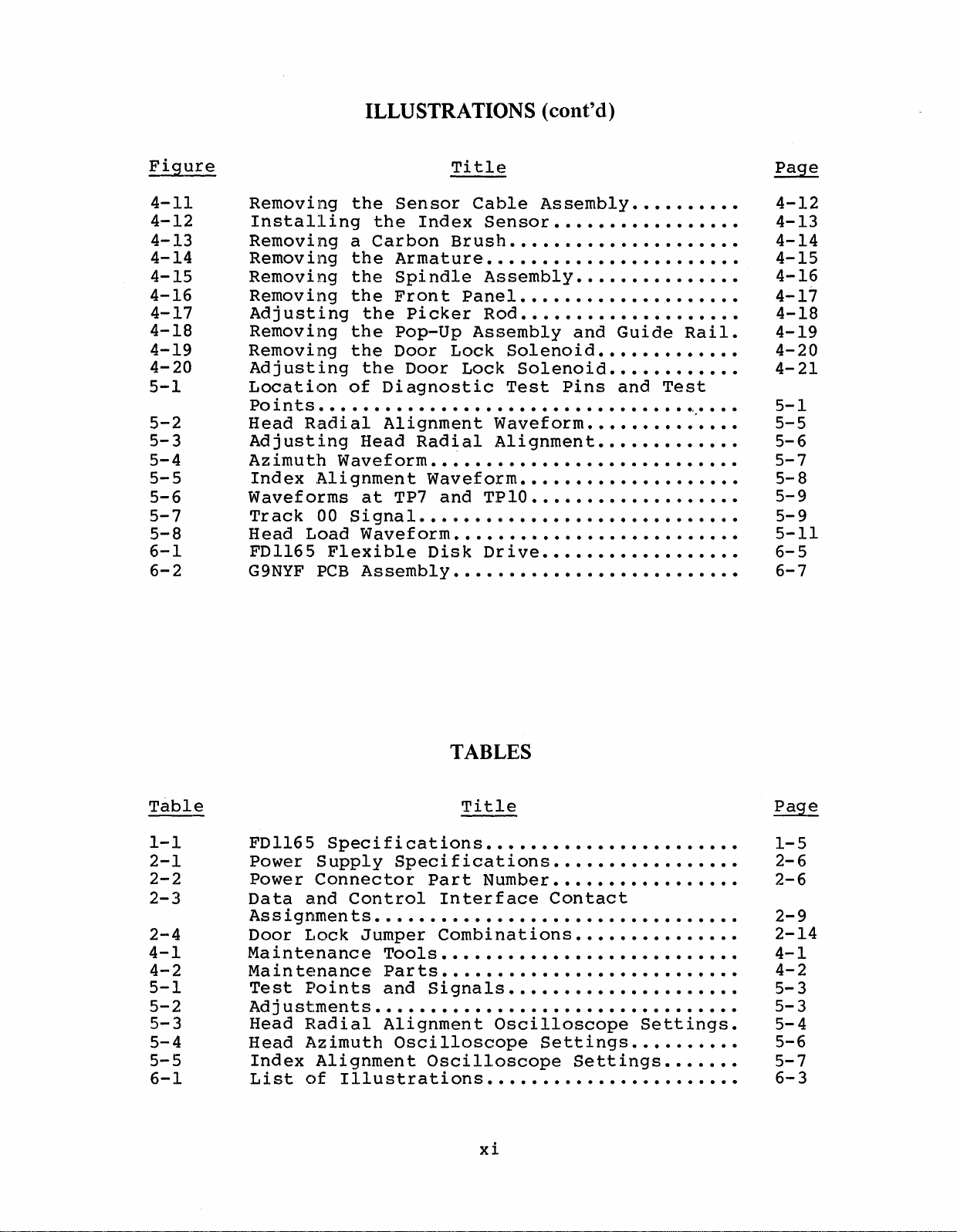

ILLUSTRATIONS (cont'd)

Figure

4-11

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

6-1

6-2

Removing

Installing

Removing

Removing

Removing

Removing

Adjusting

Removing

Removing

Adjusting

Location

Points

Head

Adjusting

Azimuth

Index

Waveforms

Track

Head

FDl165

G9NYF

Radial

Alignment

00

Load

Flexible

PCB

the

Sensor

the

a

Carbon

the

Armature

the

Spindle

the

Front

the

Picker

the

Pop-Up

the

Door

the

Door

of

Diagnostic

Alignment

Head

Waveform

at

TP7

Signal

Waveform

Assembly

Title

Cable

Index

Radial

••~•••••••••••••••••••••••••

Waveform

•••••••••••••••••••••••••••••

Disk

Sensor

Brush

•••••••••••••••••••••••

Assembly

Panel

Rod

Assembly

Lock

Lock

Waveform

and

TP10

••••••••••••••••••••••••••

Drive

••••••••••••••••••••••••••

Assembly

•••••••••••••••••

•••••••••••.•••••••••

•••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

and

Solenoid

Solenoid

Test

Alignment

••••••••••••••••••••

•••••••••••••••••••

••••••••••••••••••

•••••••••••••

••••••••••••

Pins

••••••••••••••

•.••••••••••.

••••••••••

Guide

and

Test

Rail.

Page

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

4-21

.

5-1

5-5

5-6

5-7

5-8

5-9

5-9

5-11

6-5

6-7

Table

1-1

2-1

2-2

2-3

2-4

4-1

4-2

5-1

5-2

5-3

5-4

5-5

6-1

TABLES

Title

FDl165

Power

Power

Data

Ass

Door

Maintenance

Maintenance

Test

Adj

Head

Head

Index

List

Specifications

Supply

Connector

and

ignments•••••••••••••••••••••••••••••••••

Lock

Points

ust.ments

Radial

Azimuth

Alignment

of

Illustrations

Specifications

Part

Control

Jumper

Tools

Parts

and

•••••••••••••••••••••••••••••••••

Alignment

Interface

Combinations

Signals

Oscilloscope

Oscilloscope

•••••••••••••••••••••••

Number

••••••••••••••••••••••.••••

••••••.••••••••••••••••••••

•••••••••••••••••••••

Oscilloscope

•••••••••••••••••••••••

xi

••••••••••.••••••

••••••••••••.••••

Contact

•••••••••••••••

Settings

Settings

••••••••••

Settings.

•••..••

1-5

2-6

2-6

2-9

2-14

4-1

4-2

5-3

5-3

5-4

5-6

5-7

6-3

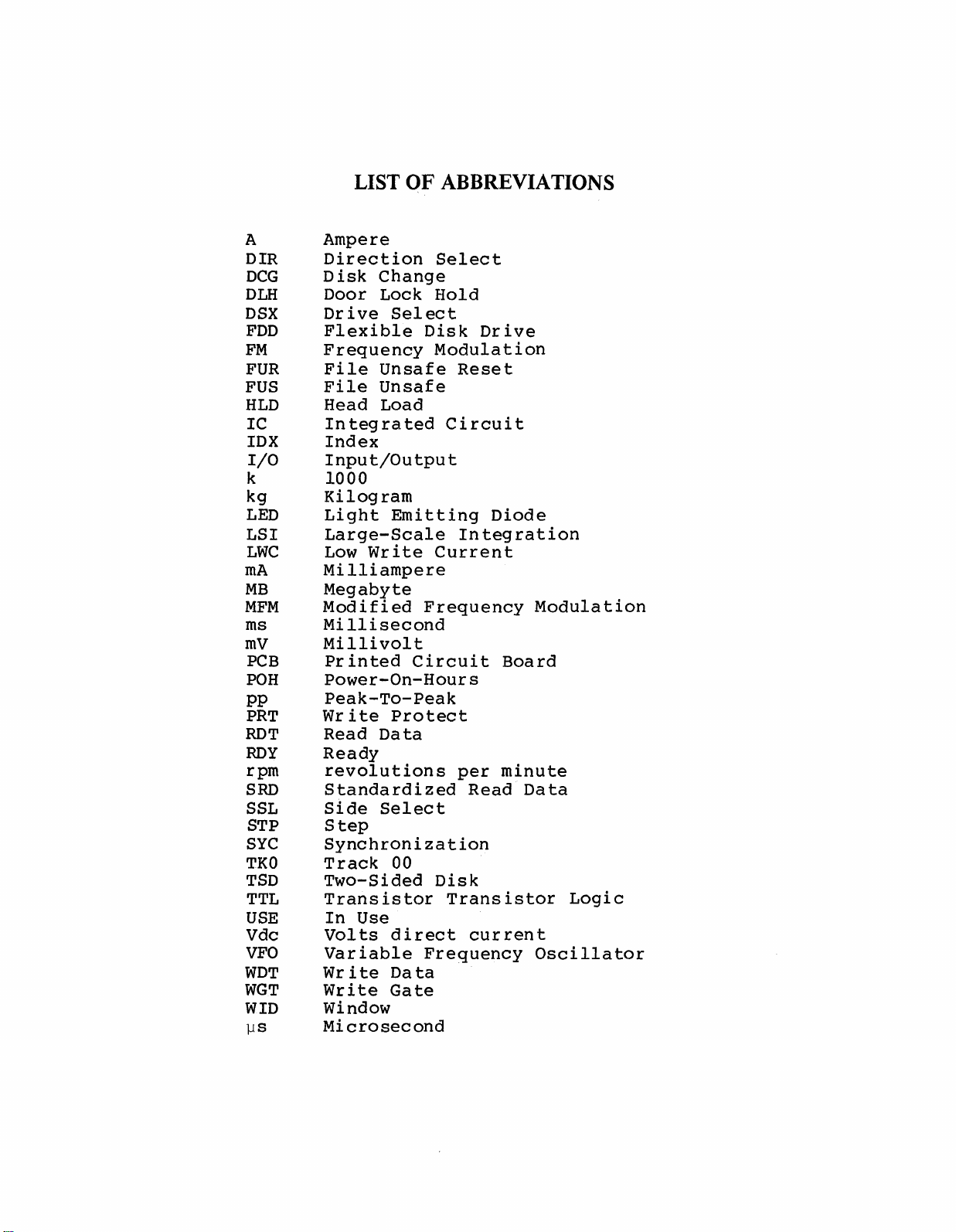

LIST OF ABBREVIATIONS

A

DIR

DCG

DLH

DSX

FDD

FM

FUR

FUS

HLD

IC

IDX

I/O

k

kg

LED

LSI

LWC

rnA

MB

MFM

ms

mV

PCB

POH

pp

PRT

ROT

ROY

rpm

SRO

SSL

STP

SYC

TKO

TSD

TTL

USE

Vdc

VFO

WDT

WGT

WID

~s

Ampere

Direction

Disk

Door

Change

Lock

Drive

Flexible

Frequency

File

File

Head

Unsafe

Unsafe

Load

Integrated

Select

Hold

Select

Disk

Modulation

Circuit

Index

Input/Output

1000

Kilogram

Light

Emitting

Large-Scale

Low

Write

Current

Milliampere

Megabyte

Modified

Frequency

Millisecond

Millivolt

Printed

Circuit

Power-On-Hours

Peak-To-Peak

Write

Read

Protect

Data

Ready

revolutions

Standardized

Side

Select

Step

Synchronization

Track

Two-Sided

Transistor

In

Volts

Variable

Write

Write

00

Disk

Transistor

Use

direct

Frequency

Data

Gate

Window

Microsecond

Drive

Reset

Diode

Integration

Modulation

Board

per

minute

Read

Data

current

Oscillator

Logic

CHAPTER 1

GENERAL INFORMATION

This

FDl165

and

chapter

parts

8-Inch

of

the

fications.

1.1

The

disk

or

the

ette

DESCRIPTION

Model

storage

FDl165

device

double-density

disk

that

drive

is

double-density

million

The

size

(2l7.2

inches

The

larger,

most

and

disk

bytes

apparent

light

rom)

high,

(335.0

drive

conventional

interface-compatible

measures

two

disk

conventional

one-half

drives

drive.

gives

Flexible

disk

Flexible

depends

used.

format,

(MB).

features

weight.

rom)

deep

has

can

an

drive

that

flexible

wi

by

2.28

all

units,

with

the

be

overall

Disk

uses

on

th

a

the

The

and

the

height

mounted

description

in

Disk

disks.

the

Drive,

detail,

Drive

single-

type

describes

or

The

and

dual-sided

maximum-storage

of

the

Model

disk

inches

weighs

drive

(58.0

only

features

and

~hem.

of

is

Because

'conventional

in

the

of

the

and

is

lists

a

compact

the

dual-sided,

storage

format

flexible

capacity

of

disk

capacity

FDl165

measures

rom)

7.7

and

are

8.55

wide

pounds

performance

media-compatible

the

Model

disk

same

space

the

features

speci-

magnetic

single-

the

is

its

inches

by

(3.5

FDl165

drives,

as

Model

of

disk-

and

1.6

small

13.20

kg).

of

and

one

a

The

Model

~PD765

(TTL)

supply

(for

the

motor)

FDl165

is

recommended)

interface.

that

TTL)

(see

must

and

Section

is

supply

microprocessor-controlled

mizes

(stepping

extremely

head

and

motor)

accurate

media

is

operated

The

+24

also

head

by

an

external

through

disk

and

Vdc

1.2.3).

head

wear.

drive

(for

a

Transistor

requires

control

the

The

loading

The

dc

disk

head

microprocessor-controlled

positioning.

1-1

Transistor

an

two

vol

direct

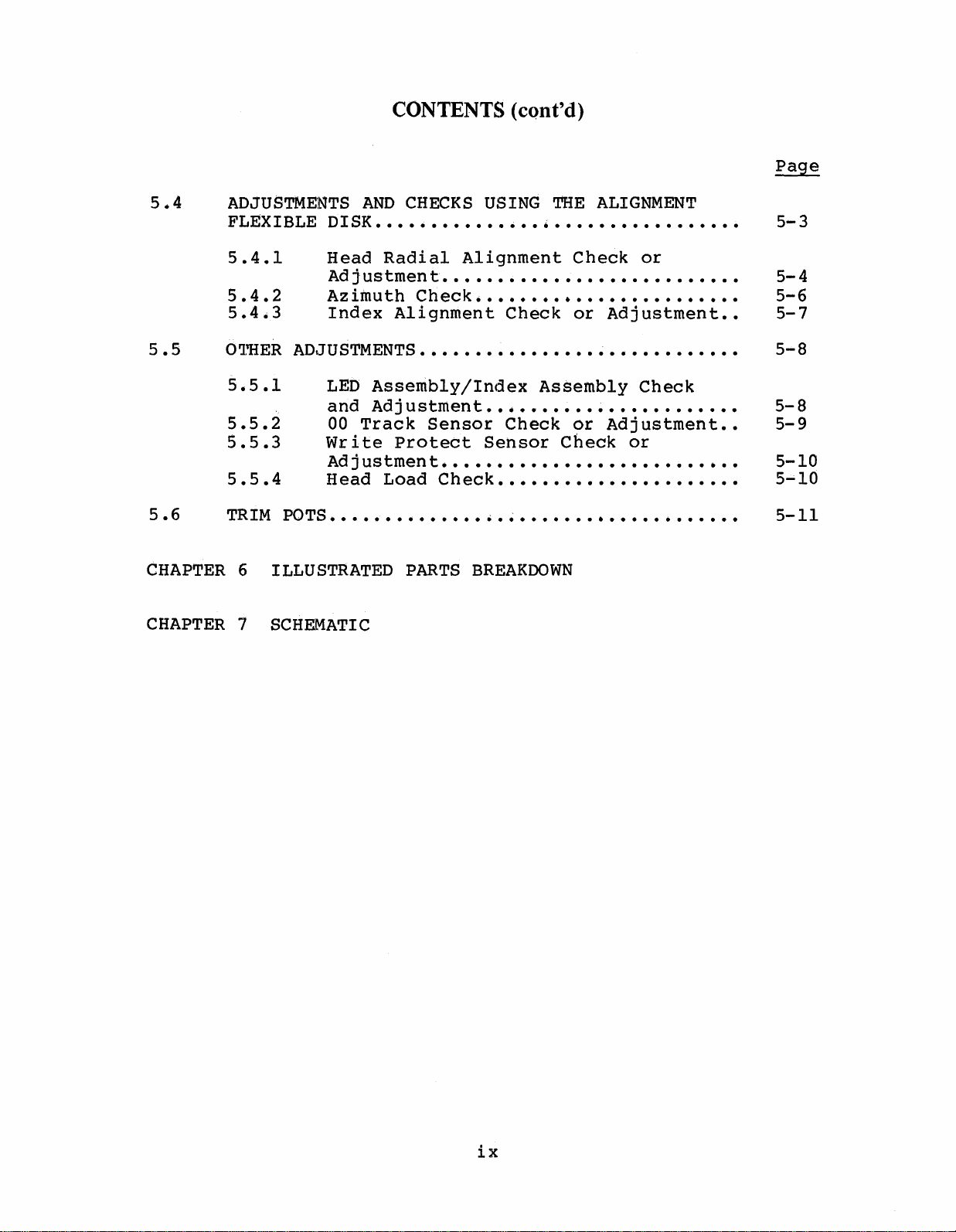

drive

mechanism

position

controller

external

tages,

drive

features

that

mechanism

+5 Vdc

spindle

to

(NEC

Logic

power

a

mini-

ensure

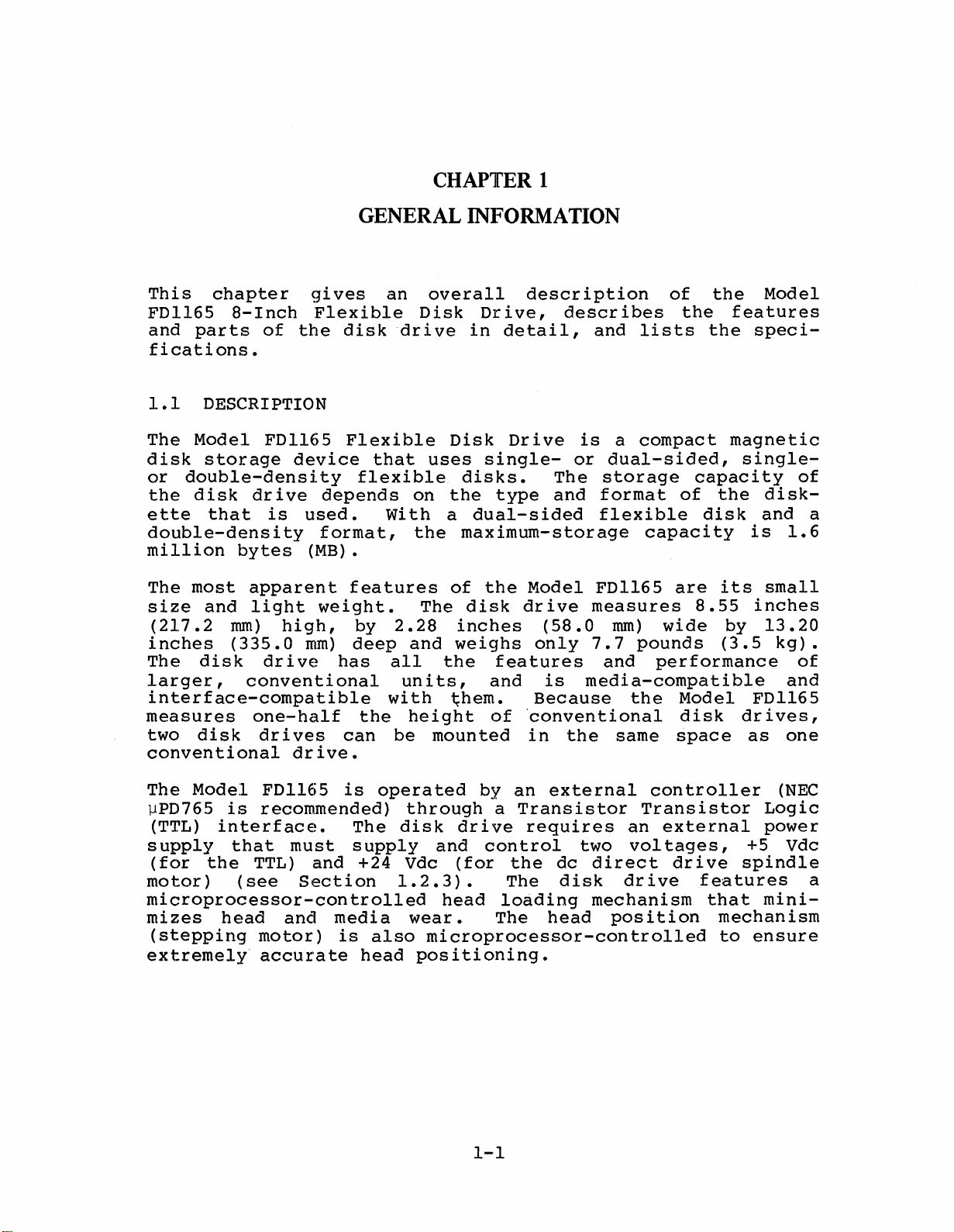

1.2

CONSTRUCTION

AND

FEATURES

This

and

Figure

this

section

explains

1-1

section.

describes

the

to

identify

HEAD LOAD

SOLENOID

features

the

construction

of

the

the

assemblies

various

that

of

the

assemblies.

are

Model

described

FDl165

See

in

1.2.1

The

base

assemblies

1.2b2

The

spindle

drive

minu

and

te

Figure

Base

frame

of

Spindle

rotates

(rpm).

Frame

is

the

Assembly

assembly

1-1

disk

the

FDl165

the

drive.

supports

flexible

metal

Flexible

form

the

disk

1-2

that

flexible

at

Disk

supports

360

Drive

disk

in

revolutions

the

the

sub-

disk

per

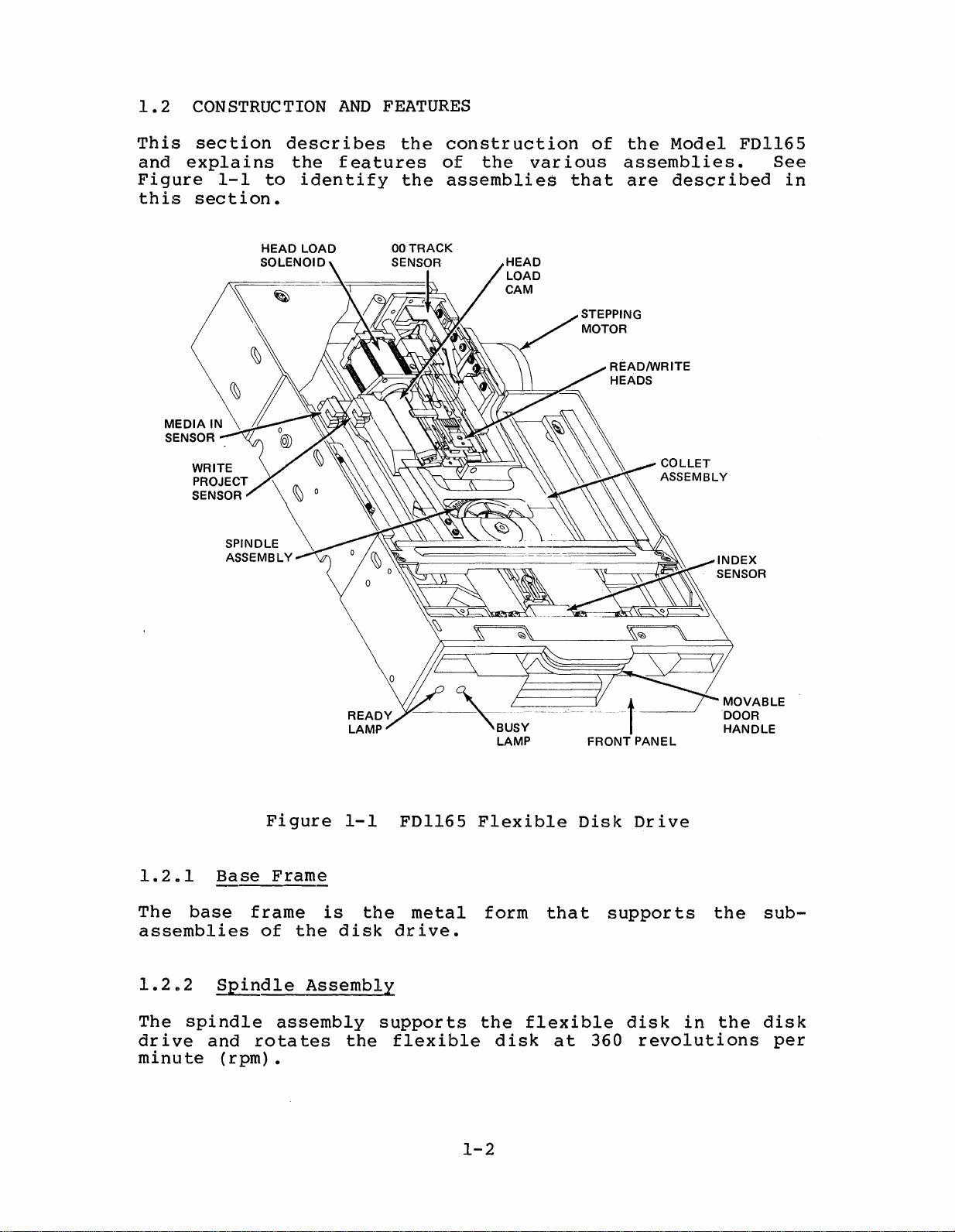

1.2.3

Dc

Direct

Dtive

Spindle

Motor

The

assembly.

associated

The

1.2.4

The

allowing

read

carriage

During

are

dc

•

•

•

•

spindle

read/write

from

held

direct

This

with

The

motor

inating

The

motor

be

The

concerns

The

un

Carr!

used.

its.

data

it.

assembly

the

away

motor

s.

motor

motor

motor

age

loading

drive

dc

motor

conventional

does

the

problems

consumes

Low-power,

uses

about

generates

has

Read/Write

heads

to

be

written

The

read/write

that

of

from

the

motor

not

direct

voltages

an

up-to-speed

touch

shifts

a

flexible

surface

(not

eliminates

ac

motor

use

drive

associated

less

inexpensi

Assembly

each

current,

and

less

to

the

heads

the

of

power

shown)

the

drives.

pulleys

ve

frequencies.

heat

time

Heads

side

heads

disk,

the

of

flexible

are

flexible

rotates

with

than

power

so

part

from

the

problems

or

these

conventional

that

than

of

700

the

flexible

disk

of

track

read/write

disk.

the

belts,

suppli

there

conventional

that

parts.

ms.

and

a

precision

to

spindle

elim-

es

are

disk,

to

track.

heads

are

ac

can

no

be

1.2.5

The

the

arrangement

each

shaft

carriage

1.2.6

The

heads

by

flexible

Stepping

stepping

carriage

pulse

rotates

Head

head

onto

a

microprocessor.

1/2

load

disk

motor,

assembly

provides

the

1.8

track

Load

the

and

Motor

stepping

degrees.

on

Cam

cam

flexible

reduces

under

with

fast

motor

the

Assembly

assembly

disk

This

wear

microprocessor

a

tensioned

and

flexible

receives,

This

(rotary

with

action

of

accura

action,

disk.

a

the

te

solenoid)

force

prevents

read/write

control,

steel

data

the

in

that

stepping

turn,

belt.

access.

lowers

is

controlled

damage

heads.

positions

This

motor

moves

to

For

the

the

the

1-3

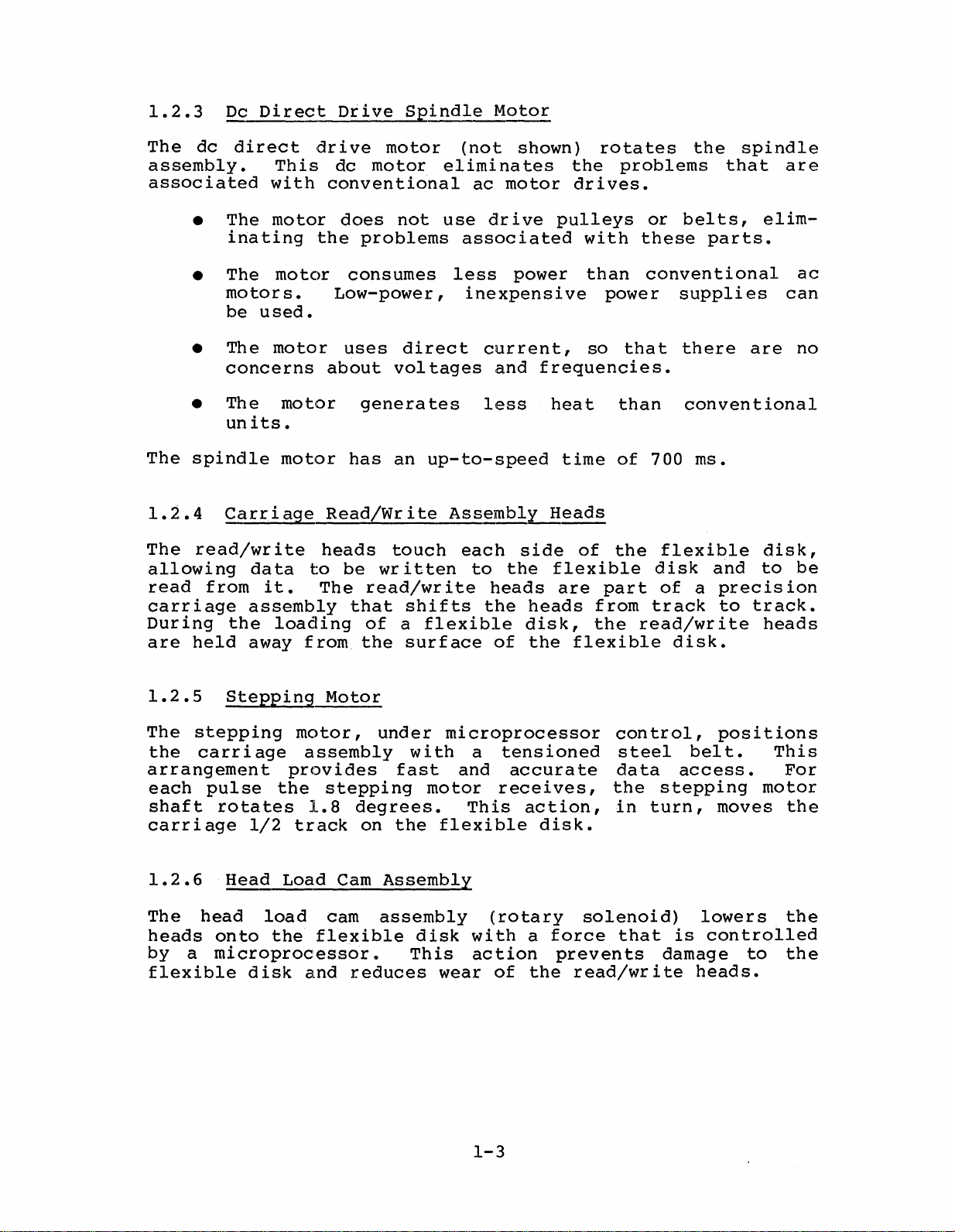

1.2.7

Pop-Up

Feature

For

the

drive

the

from

1.2.8

The

that

Model

sided

1.2.9

The

the

1.2.10

The

a

write

notch,

the

easy

pop-up

when

flexible

the

Index

index

senses

FDl165

and

00

00

Track

00

track

Write

write

the

write

removal

feature

the

disk

sensor

the

dual-sided

Track

protect

protect

write

function

door

disk

drive.

Sensor

has

Sensor

sensor

(track

Protect

notch

of

the

ejects

is

protrudes

is

index

a

dual

flexible

detects

0,

sensor

function

operation

flexible

opened.

a

combination

position

index

side

Sensor

detects

on

the

is

disk

the

flexible

After

approximately

of

sensor

disks.

when

the

0).

the

flexible

disabled.

is

enabled.

from

ejection,

LED

the

to

read/write

presence

disk.

the

disk

1/2

and

flexible

detect

If

no

disk

from

the

inch

drive,

the

edge

(13

phototransistor

disk.

both

or

If

notch

single-

head

absence

there

exists,

is

disk

mm)

The

is

of

at

of

a

1.2~11

The

media-in

in

the

1.2012

The

the

collet

spindle

1.2.13

The

PCB

circuits

1.2.14

The

the

optional

interface

creasing

Media-In

disk

Collet

assembly

Printed

(not

of

Variable

the

sensor

drive.

Assembly

when

shown)

the

Variable

signals

overall

Sensor

detects

holds

the

door

Circuit

supports

disk

drive.

Frequency

reliability

the

the

is

closed.

Board

the

Oscillator

Frequency

to

the

presence

flexible

(PCB)

electronic

Oscillator

controller

of

(Optional)

the

disk

of

disk

a

drive

(VFO)

more

drive.

flexible

in

position

stable,

and

PCB

disk

on

logic

makes

in-

1-4

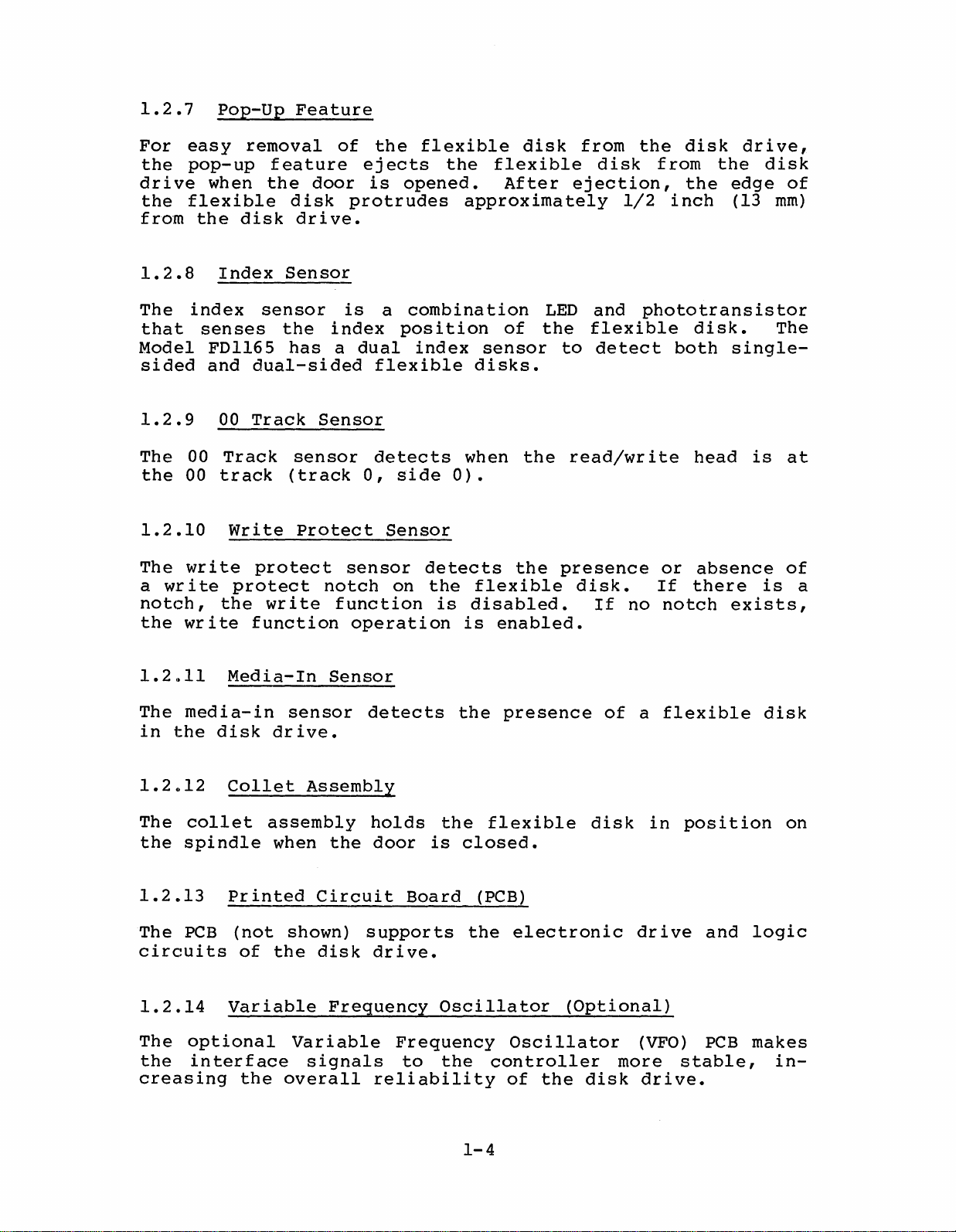

1.2.15

Displ~Lamps

Two

lamps

ready

1.2.16

The

front

attractive

1.2.17

The

movable

assembly.

1.2.18

The

door

remove

theieby

flexible

1.3

SPECIFICATIONS

on

and

busy

Front

Movable

Door

lock

the

preventing

disk.

the

front

states

Panel

panel

holds

appearance

Door

door

Lock

Solenoid

solenoid

flexible

of

for

Handle

handle

disk

data

panel

the

the

,when

(not

provide

disk

display

the

during

loss

front

closed,

shown)

or

a

drive.

lamps

of

makes

certain

physical

visual

the

engages

and

disk

it

drive

display

provides

drive.

the

impossible

operations,

damage

of

collet

to

the

an

to

the

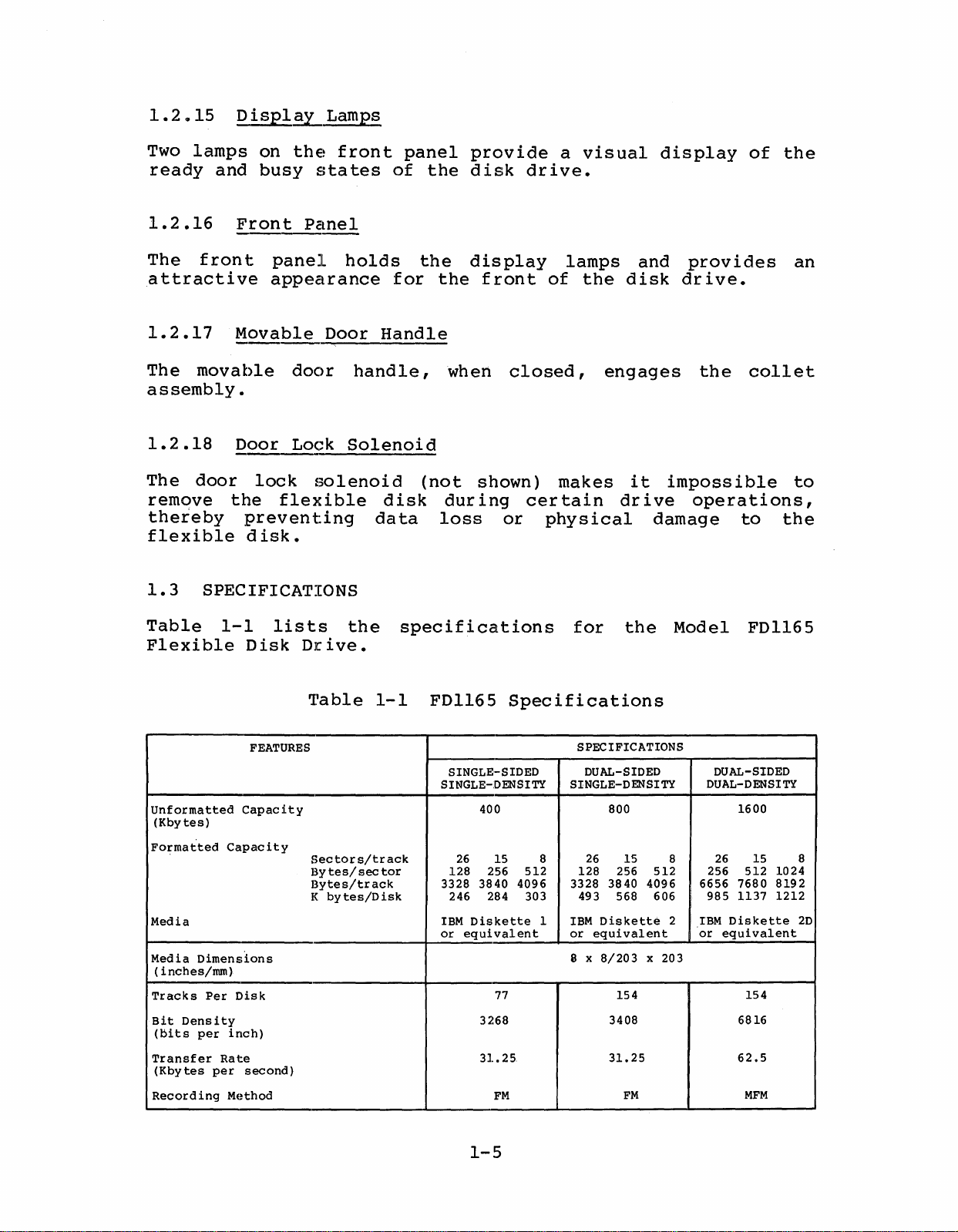

Table

Flexible

Unformatted

(Kbytes)

Formatted

Media

Media

Dimensions

(

inches/rom)

Tracks

Bit

Density

(bits

per

Transfer

(Kbytes

Recording

1-1

Capacity

Per

Rate

per

Disk

FEATURES

Capacity

Disk

inch)

second)

Method

lists

Drive.

the

Table

Sectors/track

By

tes/

by

sec

tes/D

Bytes/track

I<

specifications

1-1

tor

isk

FDl165

SINGLE-SIDED

SINGLE-DENSITY

128 256

3328 3840 4096 3328 3840 4096 6656 7680

246 284 303

IBM

or

400

26

15 8

Diskette

equivalent

77

3268

31.25

FM

for

Specifications

SPECIFICATIONS

DUAL-SIDED

SINGLE-DENSITY

800

512

26

128 256 512

493

1

IBM

or

8 x

Diskette

equivalent

8/203

3408

31.25

the

15

568 606

x 203

154

FM

Model

DUAL-DENSITY

8

256 512

985

IBM

2

or

FDl165

DUAL-SIDED

1600

15 8

26

equivalent

1024

8192

1137 1212

Diskette

154

6816

62.5

MFM

20

1-5

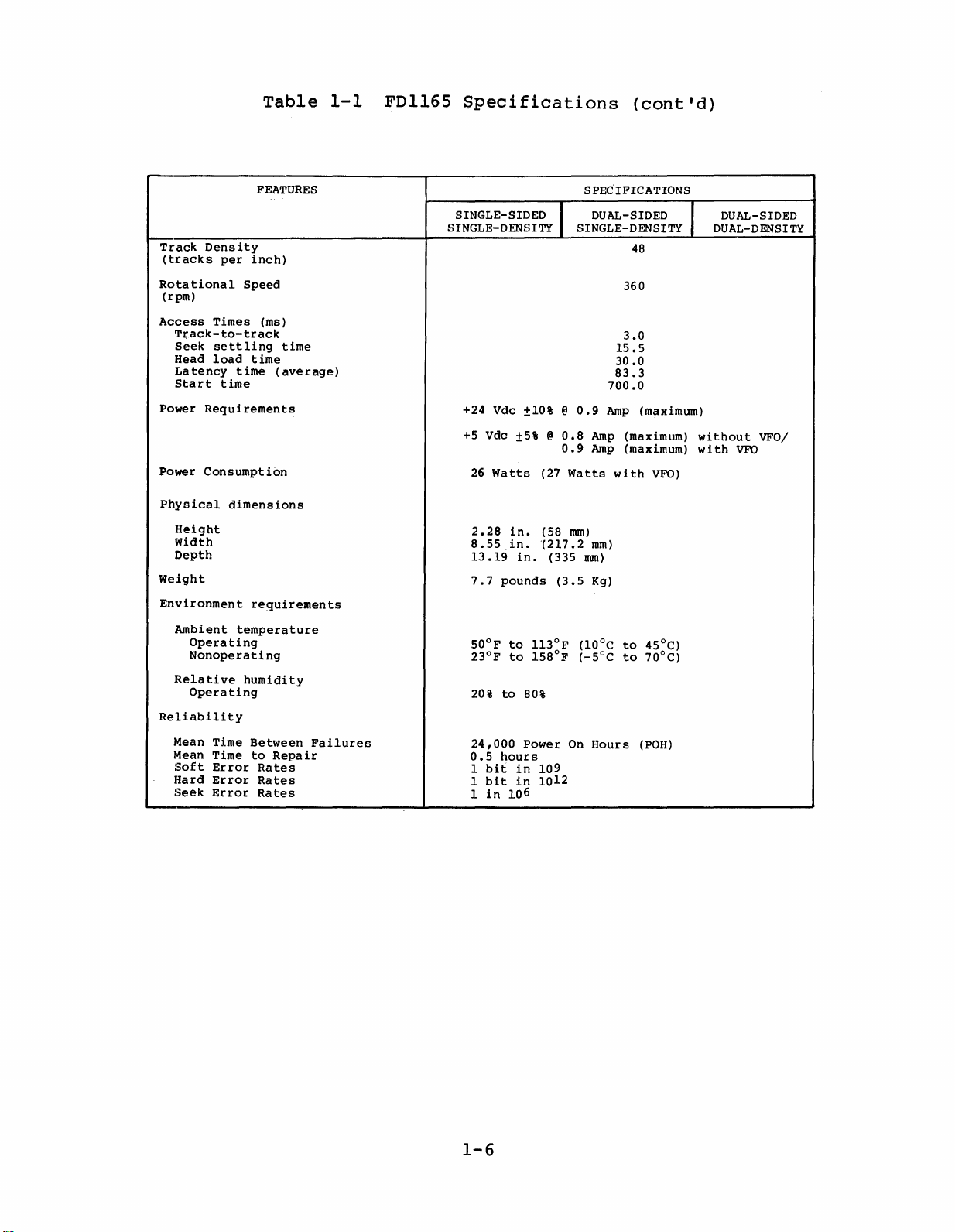

Table

1-1

FDl165

Specifications

(cont'd)

FEATURES

Track

Density

(tracks

Rotational

(rpm)

Access

Power

Power

Physical

Weight

Environment

Reliabili

per

inch)

Speed

Times (ms)

Track-to-track

Seek

settling

Head

load

Latency

Start

Requirements

Consumption

Height

Width

Depth

Ambient

Operating

Nonoperating

Relative

Operating

Mean Time

Mean TimetoRepair

Soft

Hard

Seek

time

time

time

dimensions

requirements

temperature

humidity

ty

Between

Error

Error

Error

Rates

Rates

Rates

time

(average)

Failures

SINGLE-SIDED I

SINGLE-DENSITY

+24 Vdc

+5

26

2.28

8.55

13.19

7.7

50°Fto113°F

23°Fto158°F

20%to80%

24,000

0.5

1

1

1

Vdc

Watts

pounds

hours

bit

bit

in

±10%@0.9

±5%@0.8

(27

in.

(58

in.

(217.2

in.

Power

in

109

in

1012

106

SPECIFICATIONS

DUAL-SIDED

SINGLE-DENSITY

83.3

700.0

Amp

Amp

0.9

Amp

Watts

with

rom)

mm)

(335

rom)

(3.5

Kg)

(10°C

(-5°C

On

Hours

48

360

3.0

IS

.5

30.0

(maximum)

(maximum)

(maximum)

VFO)

to

45°C)

to

70°C)

(POH)

DUAL-SIDED

I

DUAL-DENSITY

without

with

VFO

VFO/

1-6

CHAPTER 2

This

and

Disk

2.1

Before

carton

ch~pter

operating

Drive.

PRELIMINARY INSPECTION

you

for

immediately.

tiveof

aged,

'the

unpack

instructions

2.2

This

UNPACKING

section

FDl165.

INSTALLATION

gives

instructions

unpack

damage.

Do

carrier

the

(see

AND

describes

unpacking

the

If

not

disk

Section

REPACKING

Model

there

open

inspects

drive

unpacking

AND

and

for

the

2.2~1).

the

FDl165,

is

damage,

carton'

it.

by

OPERATION

installation

ModelFDl165

inspect

notify

until

If

the

following

and

repacking

the

carton

information

the

the

representa-

is

the

unpacking

the

Flexible

shipping

carr

undam-

Model

ier

2.2.1

To

unpack

following

sible

a.

b.

c.

d.

e.

2.2.2

To

repack

cedure

Unpacking

the

procedure.'

use

in

Remove

age.

Slide

sleeve.

Open

Remove

Insp~ct,

Repacking

the

in

Section

Procedure

Model

reshipment.

the

tape

'

the

the

styrofo~m

the

plastic

the

Procedure

Model

2.2.1.

FDl165,

Save

band

styrofoam

disk

drive

FDl165

refer

all

case.

film

for

to

shipping

from

around

case

cover

for

any

reshipment,

Figure

out

from

shipment

rna

.

the

of

2-1

ter

ialsfor

shipping

the

the

reverse

and

cardboard

disk

damage.

use

pack-

drive.

t~e

the

pos-

pro-

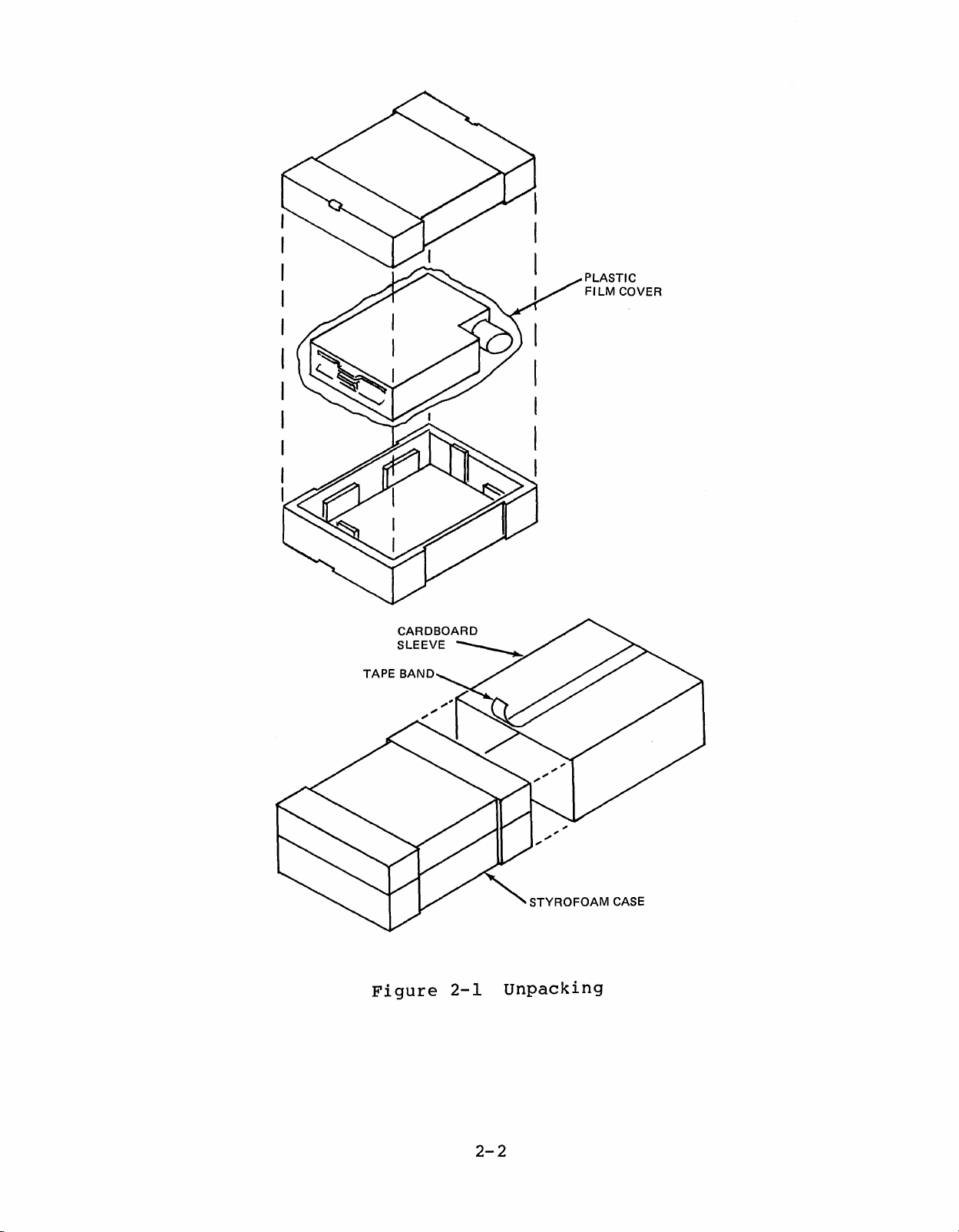

PLASTIC

FILM

COVER

Figure

2-1

Unpacking

2-2

2.2~3

Preinstallation

Inspection

After

unpacking

procedures.

a.

b.

c.

a.

2.3

This

for

disk

2.3.1

The

dust-free

to

The

(Aim)

per

ENVIRONMENTAL

section

the

drive,

Operatinq

disk

113°F

maximum

•

Hour

Inspect

other

Remove

Insert

flexible

Press

ible

disk

Model

and

drive

environment

(10°C

stray

Typical

(Kcal/h)

the

the

obvious

the

dummy

a

flexible

disk

the

door

is

REQUIREMENTS

descr

ibes

FDl165,

shows

Environment

can

to

45°C)

magnetic

hea

(23.3

Model

dis

k

drive

indications

flexible

locks

handle

ejected.

the

gi

ves

recommended

be

installed

with

and

t

diss

ipation

Kcal/h

FDl165,

disk

in

required

space

an

relative

field

for

of

disk

through

place

and

mounting

in

ambient

is

is

with

perform

damage,

problems.

and

make

opera

and

any

humidity

4000

22.3

VFO).

loose

from

the

the

door

close

sure

that

ting

weight

methods.

clean,

temperature

of

Amperes

Ki

logram

the

following

parts,

unit.

until

the

door.

the

environment

da

ta

rela

20%

per

for

tively

of

to

Calor

the

flex-

the

50

° F

80%.

meter

ies

or

2.3.2

The

unit

servicing.

of

the

2.3.3

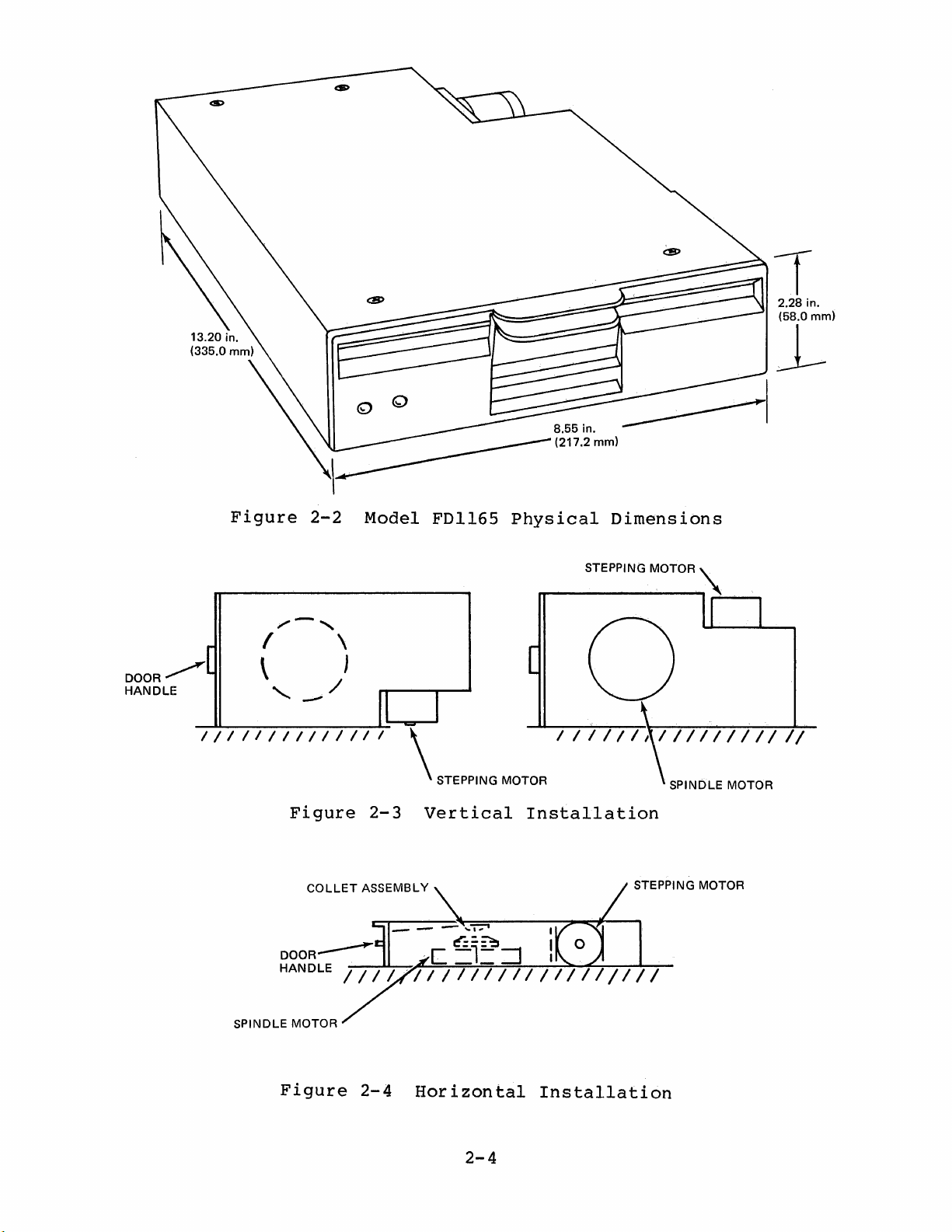

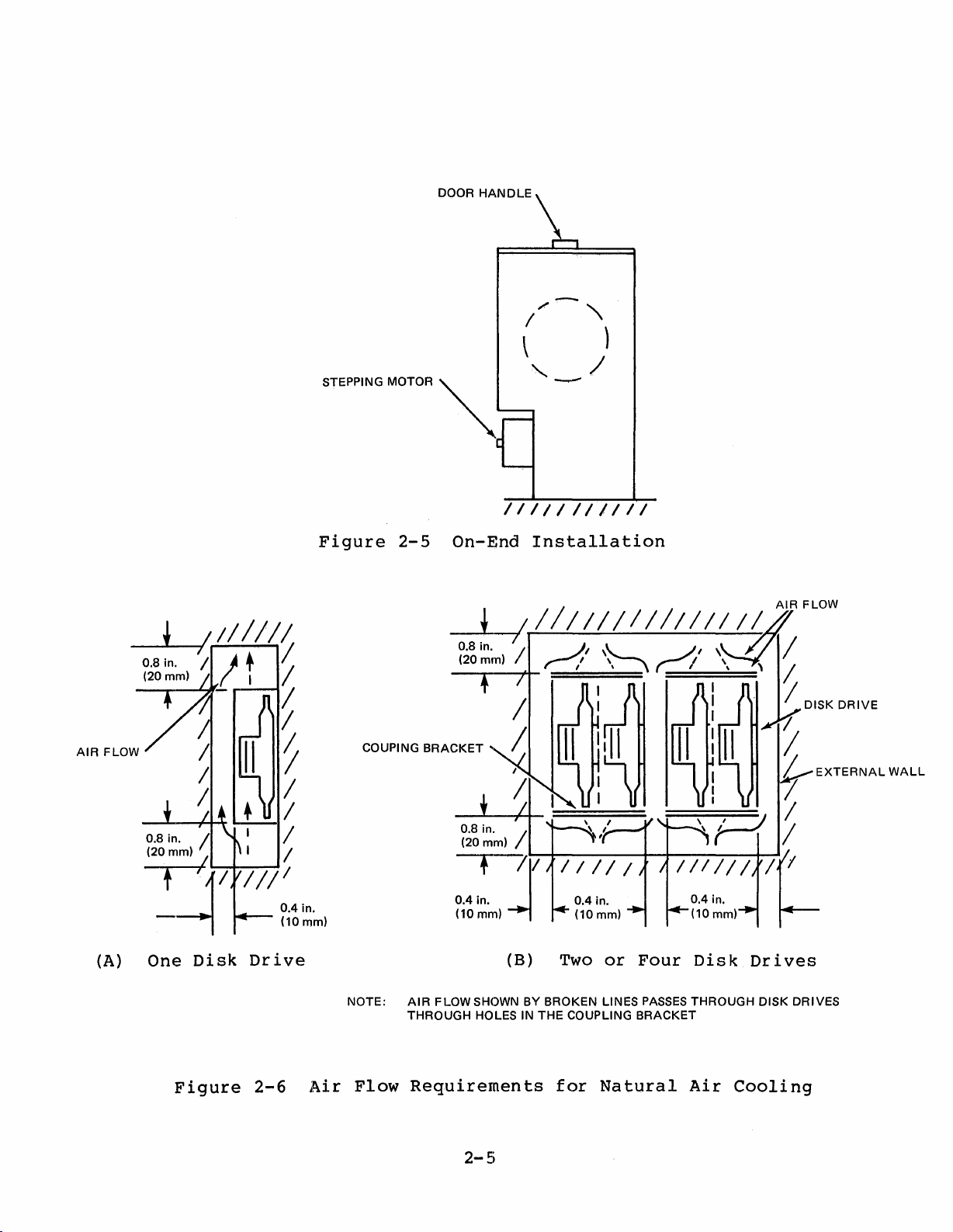

The

disk

on-end.

mounting

adequate

mended,

flow

cannot

needed.

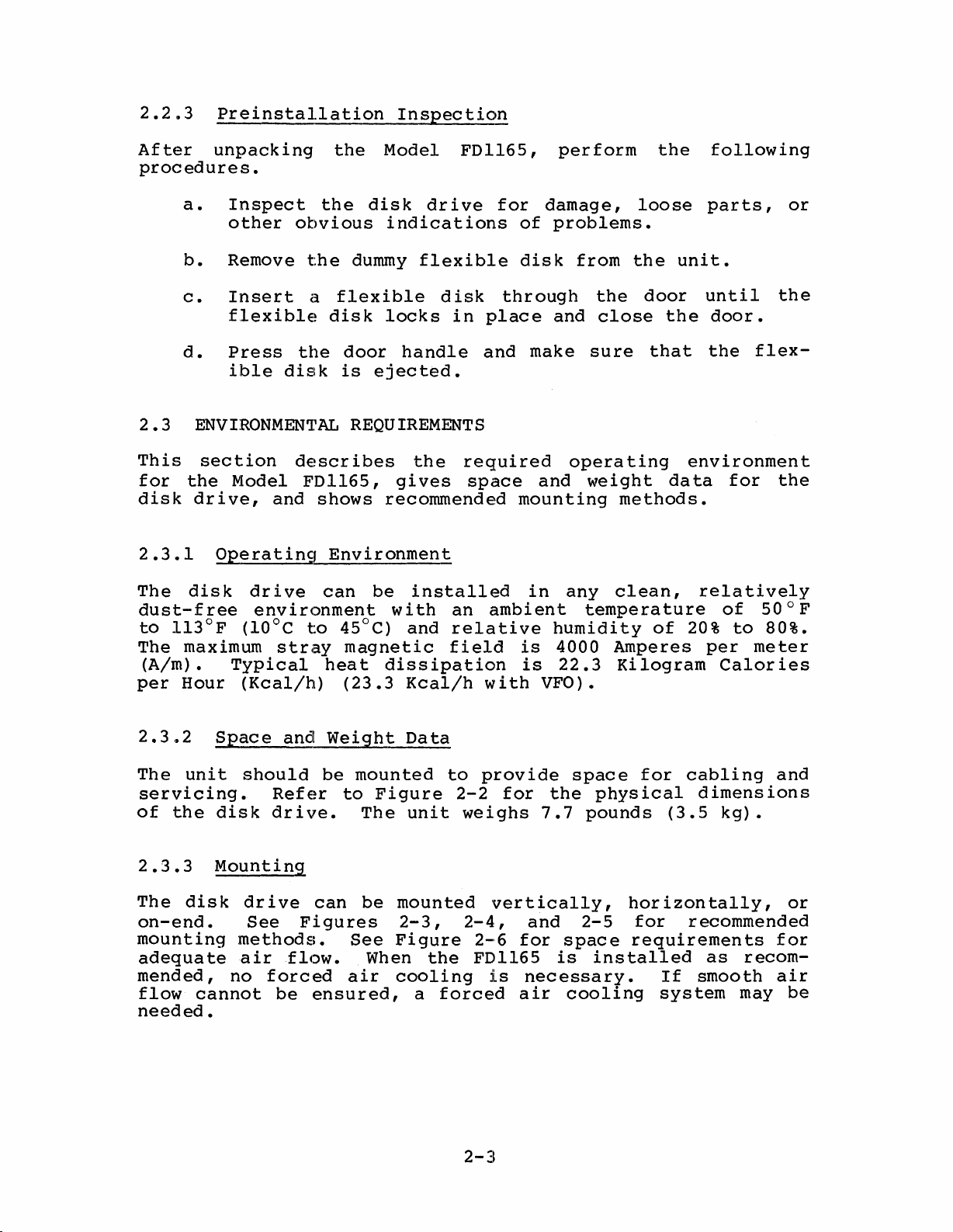

Space

should

Refer

disk

drive.

Mounting

drive

See

methods.

airflow.

no

forced

be

and

can

Figures

ensured,

Weight

be

mounted

to

The

be

See

air

Figure

mounted

Figure

When

cooling

Data

unit

2-3,

a

to

the

forced

provide

2-2

weighs

vertically,

2-4,

2-6

FDl165

is

2-3

for

the

7.7

and

for

necessary.

air

space

pounds

2-5

space

is

installed

cooling

for

physical

horizontally,

for

requirements

cabling

dimensions

(3.5

kg).

recommended

as

If

smooth

system

and

for

recom-

air

may

or

be

Figure

{ \

/-,

2-2

Model

FDl165

Physical

Dimensions

DOOR~

HANDLE

///1/1//1111//

\ J

'-

--/

Figure

COLLET

SPINDLE MOTOR

Figure

\

2-3

ASSEMBLY

2-4

111/11,1//////////

STEPPING MOTOR SPINDLE MOTOR

Vertical

Horizontal

Installation

STEPPING MOTOR

Installation

2-4

DOOR

HANDLE

AIR

~///I//

0.8. in.

(20mm)

FLOW

_L---+-+--\o

~f

0.8

(20mm)

/!

-~/

'-~_I

in. I I /

///:'41n.

-----i

+

I

I /

STEPPING MOTOR

Figure

II

/

'!

/

/

(10 mm)

2-5

COUPING

~

On-End

BRACKET

0.8

(20mm)

0.4

(10 mm)

/ / / / / /

Installation

in. /

i.~.

7~1/

II

-I:------+~--f__

---I

/ / /

(A)

One

Disk

Figure

Drive

2-6

Air

NOTE:

Flow

(B)

AIR

FLOW SHOWNBYBROKEN LINES

THROUGH HOLES IN THE COUPLING

Requirements

2-5

Two

for

or

Natural

Four

PASSES

BRACKET

Disk

THROUGH DISK DRIVES

Air

Drives

Cooling

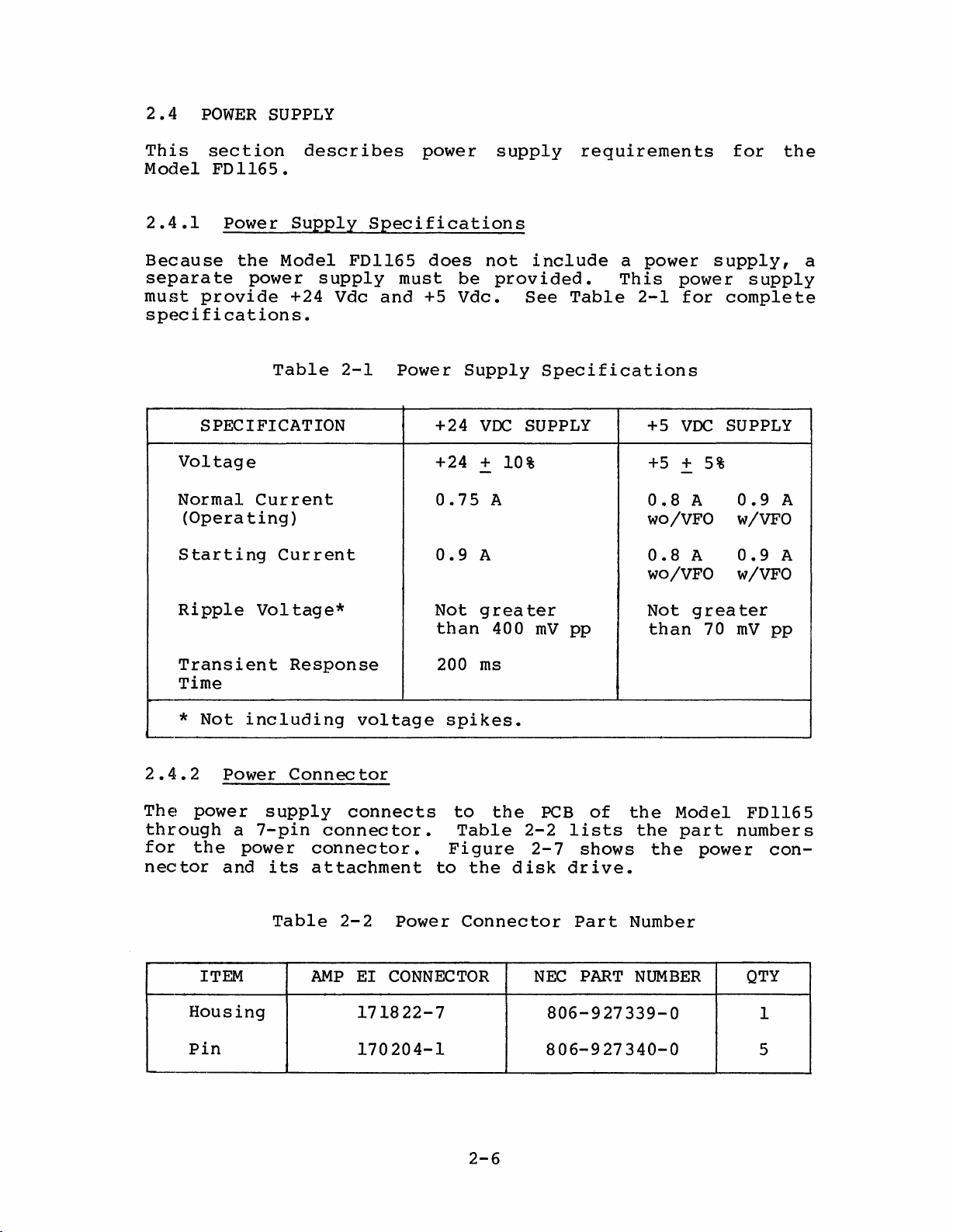

2.4

POWER

SUPPLY

This

Model

2.4.1

Because

separate

must

specifications.

section

FDl165.

Power

the

power

provide

SPECIFICATION

Voltage

Normal

(Opera

Starting

ting)

describes

Supply

Model

+24

Table

Current

Current

FDl165

supply

Vdc

2-1

power

Specifications

does

must

and

Power

+5

+24

+24

0.75

0.9

be

Vdc.

Supply

supply

not

VDC

+

-

A

include

provided.

See

Specifications

SUPPLY +5

10%

A

requirements

a

power

This

Table

2-1

+5

0.8

wO/VFO w/VFO

0.8

wO/VFO

supply,

power

for

VDC

+

5%

-

A

A

for

complete

SUPPLY

0.9

0.9

w/VFO

the

supply

A

A

a

Ripple

Transient

Time

*

2.4.2

The

through

for

nector

Housing

Pin

Not

Power

power

the

and

ITEM

Vol

including

supply

a

7-pin

power

its

Table

tage*

Response

voltage

Connector

connects

connector.

connector.

attachment

2-2

AMP

EI

171822-7

170204-1

Not

greater

than

200

ms

spikes.

to

Table

Figure

to

the

Power

CONNECTOR

Connector

400

the

mV

pp

PCB

2-2

lists

2-7

disk

drive.

Part

NEC

806-927339-0

806-927340-0

of

shows

PART

Not

than

the

Model

the

part

the

Number

NUMBER

greater

70

mV

numbers

power

pp

FDl165

con-

QTY

1

5

2-6

POWER

CONNECTOR --.......

!PCB

....

2.4.3

The

Figure

pin

DC

POWER

SUPPLY

Figure

Power

Connector

assignments

2-8.

SIGNAL

+24

GROUND

+5VDC

GROUND

FG

VDC

NAME

2-7

for

Power

Pin

Assignments

the

Connector

power

Location

connector

PIN

are

NUMBER

1

2

3

4

5

6

7

shown

POWER

CONNECTOR

in

Figure

2-8

Pin

and

Line

Assignments

Connector

2-7

for

the

Power

2.5

INTERFACE

CONNECTION

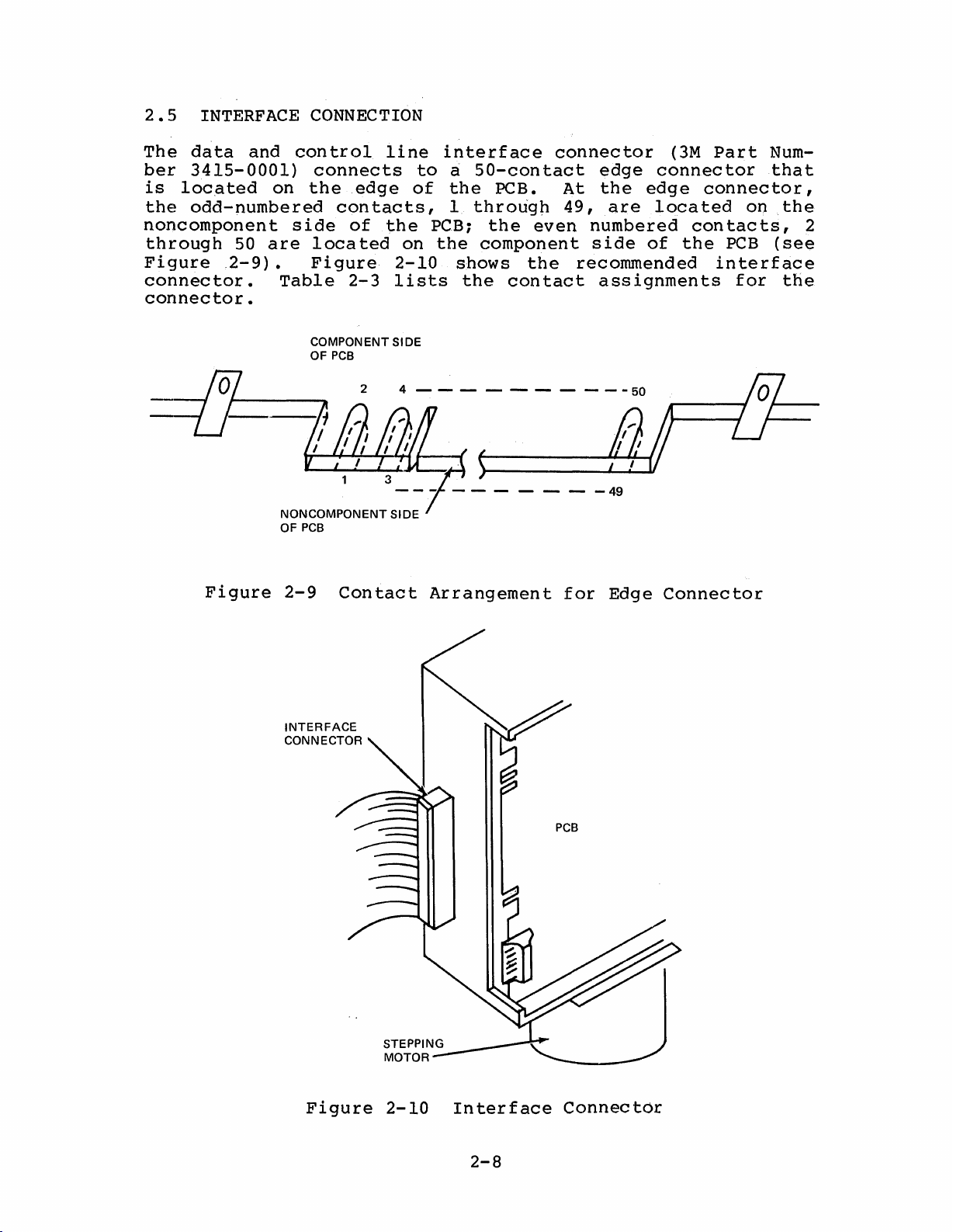

The

data

ber

3415-0001)

is

loca

the

odd-numbered

and

ted

noncomponent

through

Figure

50

.2-9).

connector.

connector.

Figure

control

connects

on

the

edge

contacts,

side

are

of

located

Figure

Table

NONCOMPONENT SIDE

OF

PCB

2-9

2-3

COMPONENT SIDE

OF

PCB

24----------50

Contact

line

to

of

the

PCB;

on

the

2-10

lists

Arrangement

interface

~

50-contact

the

PCB.

1

through

the

component

shows

the

even

the

contact

- - -

connector

edge

At

the

49,

are

numbered

side

recommended

assignments

-49

for

Edge

(3M

connector

edge

connector,

located

contacts,

of

the

Connector

Part

Num-

that

on

PCB

interface

for

the

2

(see

the

INTERFACE

CONNECTOR

Figure

2-10

Interface

2-8

PCB

Connector

Table

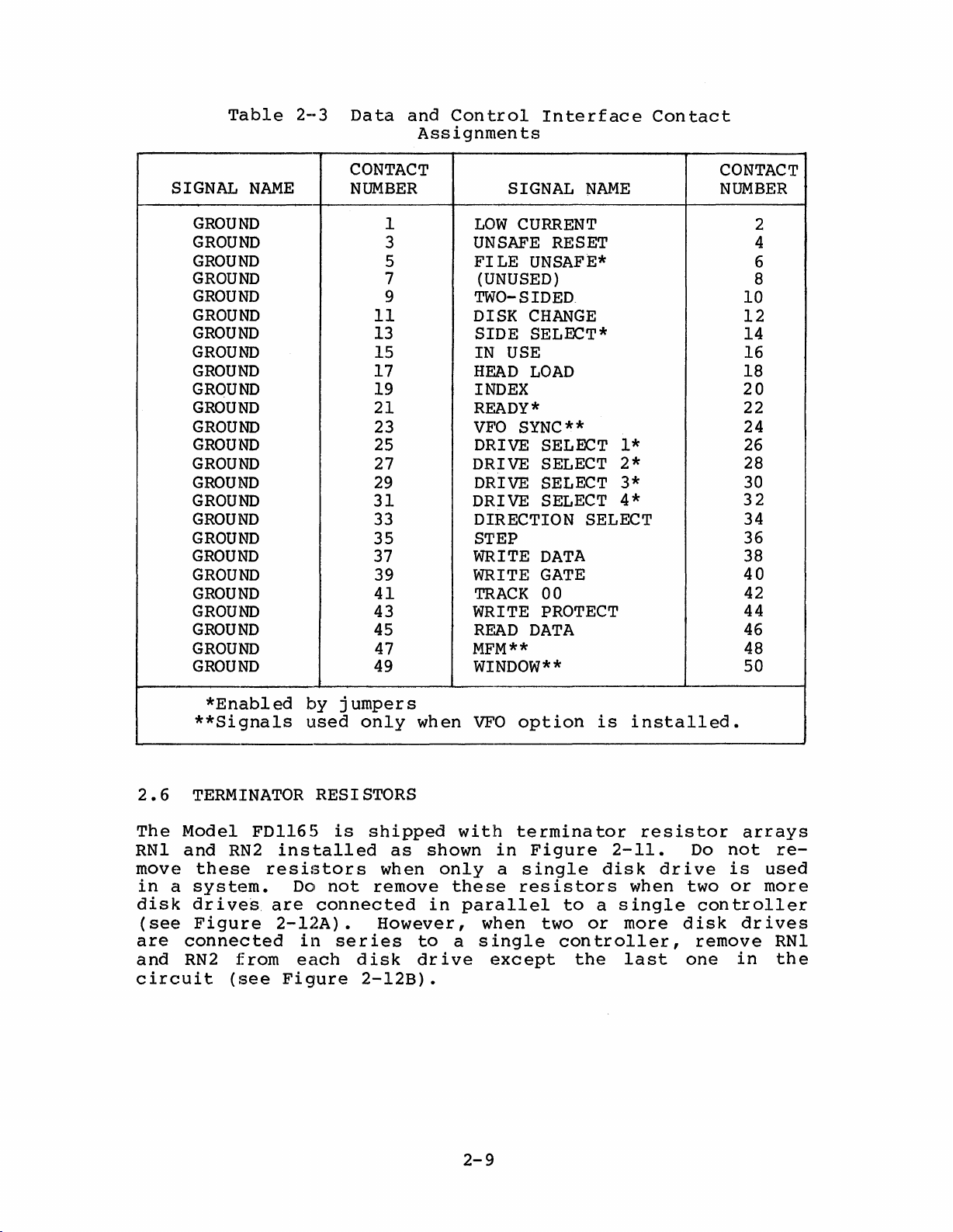

2-3

Data

and

Control

Assignments

Interface

Contact

SIGNAL

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

NAME

CONTACT

NUMBER

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

49

SIGNAL

LOW

CURRENT

UNSAFE

FILE

UNSAFE*

NAME

RESET

(UNUSED)

TWO-SIDED

DISK

SIDE

CHANGE

SELECT*

IN USE

HEAD

LOAD

INDEX

READY

VFO

DRIVE SELECT

DRIVE SELECT

*

SYNC**

1*

2*

DRIVE SELECT 3*

DRIVE SELECT

4*

DIRECTION SELECT

STEP

WRITE

WRITE

TRACK

DATA

GATE

00

WRITE PROTECT

READ

DATA

MFM**

WINDOW**

CONTACT

NUMBER

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

2.6

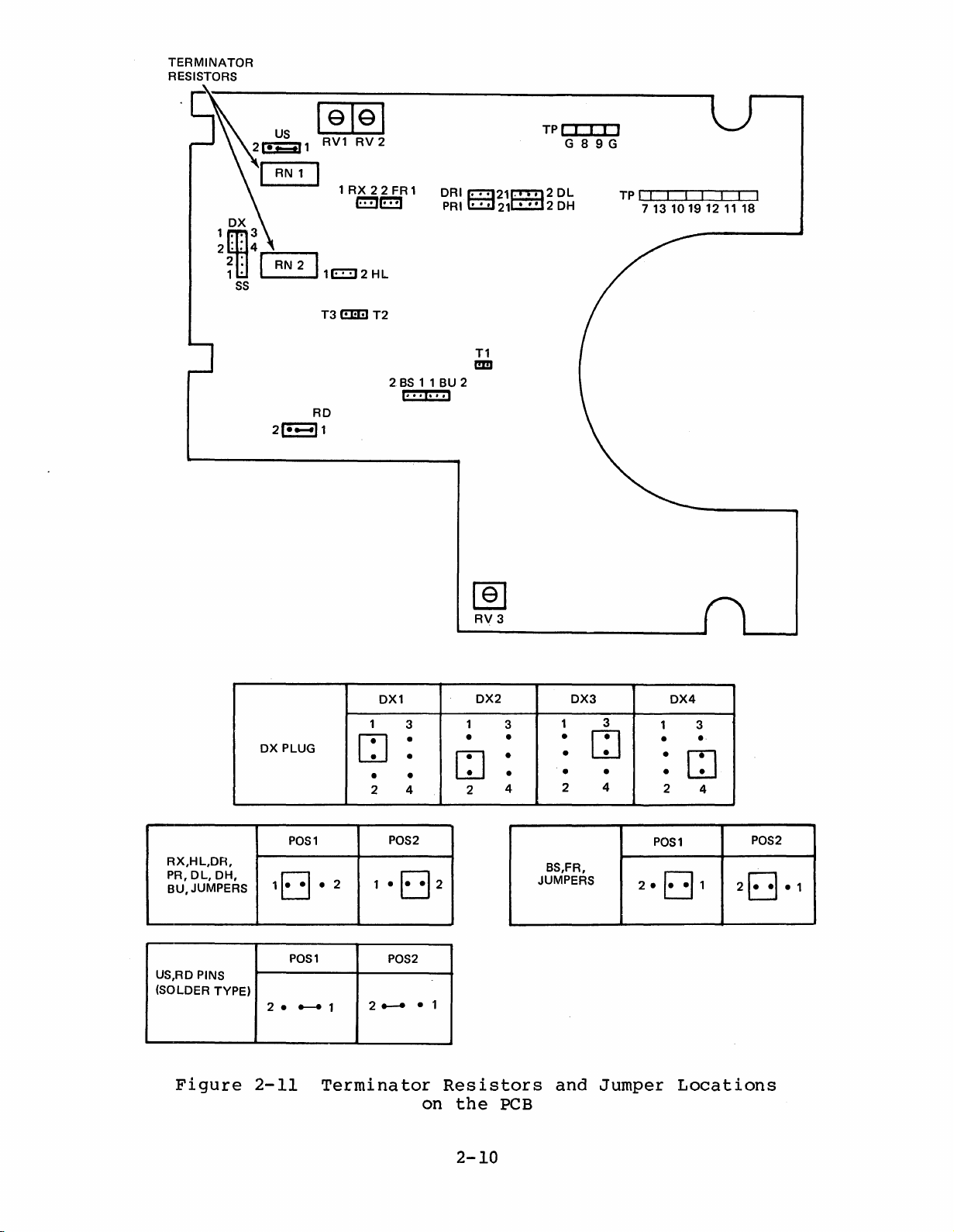

The

RNI

move

in

a

disk

(see

are

and

circuit

*Enabled

**Signals

TERMINATOR

Model

and

these

FDl165

RN2

resistors

system.

drive~

are

Figure

connected

RN2

from

(see

by

used

RESISTORS

installed

Do

not

connected

2-12A).

in

each

Figure

jumpers

only

is

shipped

when

remove

However,

ser

ies

disk

2-12B).

as

when

shown

only

in

to

dr

ive

VFO

with

these

parallel

when

a

single

except

option

terminator

in

Figure

a

single

resistors

two

to

con

is

a

or

troller,

the

installed.

2-11.

disk

when

single

more

last

resistor

drive

disk

one

arrays

Do

not

is

two

or

controller

drives

remove

in

re-

used

more

RNI

the

2-9

TERMINATOR

RESISTORS

~

RV1

RV

2

1

RX22FR 1 DRI

I:!!J~

2 I

RN

__

---I

1E::!J 2 Hl

T3

(!E!I

T2

2BS1 1 BU 2

~21C!!!l2

PRIE::il21o:::::J

T1

I!ID

TPI I I I I

G89G

DL

2 0 H

TP I I I I I

7 13

10191211

I I I

18

RX,HL,DR,

PR,

DL,

BU,JUMPERS

US,RD PINS

(SOLDER TYPE)

DH,

OX PLUG

POS1

1Ej

POS1

2.

~

[§]

RV

3

2

DX2

1

•

CJ

3

•

•

•

4

DX1

1

3

•

~

2

•

1

•

•

•

2 4 2

POS2

1 •

Ej

POS2

2~

• 1

DX3

3

1

•

CJ

•

• • •

4

2

BS,FR,

JUMPERS

2.

DX4

1 3

•

•

2

POS1

E3

•

CJ

4

1

2Ej

POS2

.1

Figure

2-11

Terminator

Resistors

on

the

2-10

PCB

and

Jumper

Locations

Loading...

Loading...