USER MANUAL

2019-03 0.2

DECLARATION OF CONFORMITY

The manufacturer

Neatech.it

Via A. de Curtis 4/A, 80040, Cercola (NA), Italy

declares that

the wheelchair EVO 1

(reference code: S045)

other names: EVO-1, EVO 1, EVO-1 FWD, EVO-1 RWD, EVO 1 FWD, EVO 1 RWD,

PEGASUS EVO 1

satisfies the requirements laid down by the European Directive 93/42;

according to the criteria for classification of Annex IX of this Directive, it is classified as:

class I medical device

It also complies with the requirement of the harmonized standards:

UNI EN 12182 – Technical aids for disabled person

UNI EN 12184 – Electrically powered wheelchairs, scooters and their chargers - Requirements

and test methods

Index

1 PRODUCT INFORMATION ....................................................................................................... 1

2 PREPARATION FOR FIRST USE ................................................................................................ 2

2.1 Checks to be made on delivery ....................................................................................... 2

2.2 Unpacking ........................................................................................................................ 2

2.1 Software description ....................................................................................................... 3

3 ADJUSTMENTS ........................................................................................................................ 4

3.1 List of adjustments .......................................................................................................... 4

3.2 Seat depth ........................................................................................................................ 5

3.3 Backrest angle .................................................................................................................. 7

3.3.1 Adjunctive backrest angle adjustment ................................................................... 10

3.4 Armrest depth ............................................................................................................... 12

3.5 Armrest height ............................................................................................................... 15

3.6 Sidepad height ............................................................................................................... 17

3.7 Footplates height ........................................................................................................... 19

3.8 Footplates depth and angle ........................................................................................... 22

3.9 Calf support position ..................................................................................................... 25

3.10 Legrest angle .............................................................................................................. 28

3.11 Joystick position ......................................................................................................... 30

3.11.1 Standard support - Depth ...................................................................................... 30

3.11.1 Retractable support - Depth and height................................................................ 31

3.12 Default position .......................................................................................................... 32

4 USE OF THE PRODUCT .......................................................................................................... 33

4.1 Control system of the wheelchair ................................................................................. 39

4.1.1 VR2 60 A control system ......................................................................................... 39

4.1.2 Rnet 80 A control system ....................................................................................... 40

4.2 Manual brake release lever ........................................................................................... 42

4.3 Use as seat in a motor vehicle ....................................................................................... 43

4.3.1 Four points tie-down .............................................................................................. 50

4.3.2 Dahl engineering docking station ........................................................................... 52

4.4 Powered functions ......................................................................................................... 54

4.5 Main switch ................................................................................................................... 56

4.6 Battery charging ............................................................................................................ 57

4.7 Transport and storage ................................................................................................... 59

5 MAINTENANCE ..................................................................................................................... 60

5.1 Maintenance and cleaning ............................................................................................ 60

5.2 Controls to be performed on the product..................................................................... 61

5.3 Tire puncture ................................................................................................................. 62

5.3.1 User information .................................................................................................... 62

5.4 Wiring diagram .............................................................................................................. 67

5.4.1 Rnet ......................................................................................................................... 67

5.4.2 VR2 .......................................................................................................................... 68

5.5 Reuse ............................................................................................................................. 69

5.6 Spare parts ..................................................................................................................... 70

5.6.1 Antitip wheels ......................................................................................................... 75

5.6.2 Cover A.................................................................................................................... 77

5.6.3 Cover B .................................................................................................................... 79

5.6.4 Levers for cover ...................................................................................................... 81

5.6.5 Lever for motors ..................................................................................................... 82

5.6.6 Standard joystick support ....................................................................................... 83

5.6.7 Retractable joystick support ................................................................................... 85

5.6.8 Joystick .................................................................................................................... 87

5.6.9 Legrest actuator ...................................................................................................... 88

5.6.10 Footplates ............................................................................................................... 90

5.6.11 Footplate fixing system .......................................................................................... 94

5.6.12 Backrest actuator .................................................................................................... 98

5.6.13 Backrest support ................................................................................................... 100

5.6.14 Backrest pin .......................................................................................................... 102

5.6.15 Axis for angle adjustable backrest ........................................................................ 103

5.6.16 Armrest padding ................................................................................................... 104

5.6.17 Armrest support ................................................................................................... 106

5.6.18 Armrest fixing system ........................................................................................... 108

5.6.19 Armrest lower support ......................................................................................... 110

5.6.20 Sidepad ................................................................................................................. 112

5.6.21 Legrest support ..................................................................................................... 113

5.6.22 Lever for angle adjustable legrest ........................................................................ 116

5.6.23 Calf support .......................................................................................................... 118

6 SPECIFICATIONS .................................................................................................................. 121

6.1 Maximum user weight ................................................................................................. 122

6.2 Other provided information ........................................................................................ 123

6.3 Dimensions .................................................................................................................. 125

7 WARRANTY TERMS ............................................................................................................. 126

7.1 Serial number .............................................................................................................. 126

Symbols in this manual

WARNING

This symbol means presence of danger for the user or damage for the

product. Always follow instructions when this symbol is present.

PINCH HAZARD

This symbol means presence of pinch hazard.

ELECTRICAL WARNING

This symbol means presence of danger related to the presence of electrical

energy. Please pay special attention when this symbol is present.

INFORMATION

This symbol means general information intended to simplify or best explain

the use of the product.

CONTACT INFORMATION

This symbol means the need of contacting an authorized service center or

the manufacturer.

TEMPERATURE

The temperature of some surfaces may increase when the product is

exposed to external heat sources as direct sunlight.

TIPPING HAZARD

Tipping hazard is strongly reduced because of the design of the product

according to EN 12182.

In any case, please pay special attention during the adjustments and use of

the product to prevent any damage to the user or product itself.

Any transport on a slope greater than the maximum safety slope can be

dangerous.

Please don’t seat on armrests.

ANTI-TIP DEVICES

Using anti-tippers substantially reduces your risk of falling over, which can

cause serious injury. The Anti-Tippers will keep you from falling over, but

they will limit your ability to be pulled up curbs and some other maneuvers.

IT IS NOT POSSIBLE TO HAVE THIS WHEELCHAIR WITHOUT ANTITIP

DEVICES.

Center of balance of the wheelchair and so its stability cab be affected by:

• User position

• Us of a backpack

• Tilting of the seat

PINCH HAZARD

Make sure your feet do not hang up or get caught in the space between the

footrests. In general, make sure you have proper space in areas you will

travel through to minimize pinching or entrapment of body parts.

ELECTROMAGNETIC RADIATION DANGER

The behavior of the wheelchair while driving may be affected by

electromagnetic fields created by transceivers such as: Citizens band (CB)

radios, walkie-talkies, fire and police radios, cellular phones, lap-top

computers, commercial radio and television broadcast antennas. PLEASE

USE CAUTION in the presence of these devices.

Electromagnetic radiation can cause your chair, without warning, to:

• release its brakes

• move by itself

• move in unintended directions

If any of these occur, it could result in severe injury to you or others.

Electromagnetic radiation can damage the control system of your chair.

There is no way to know the effect on electromagnetic immunity if you add

accessories or modify this chair. Any change to your chair may increase the

risk related to electromagnetic radiation. Parts from other suppliers have

unknown electromagnetic properties. The wheelchair might disturb the

operation of devices in its environment.

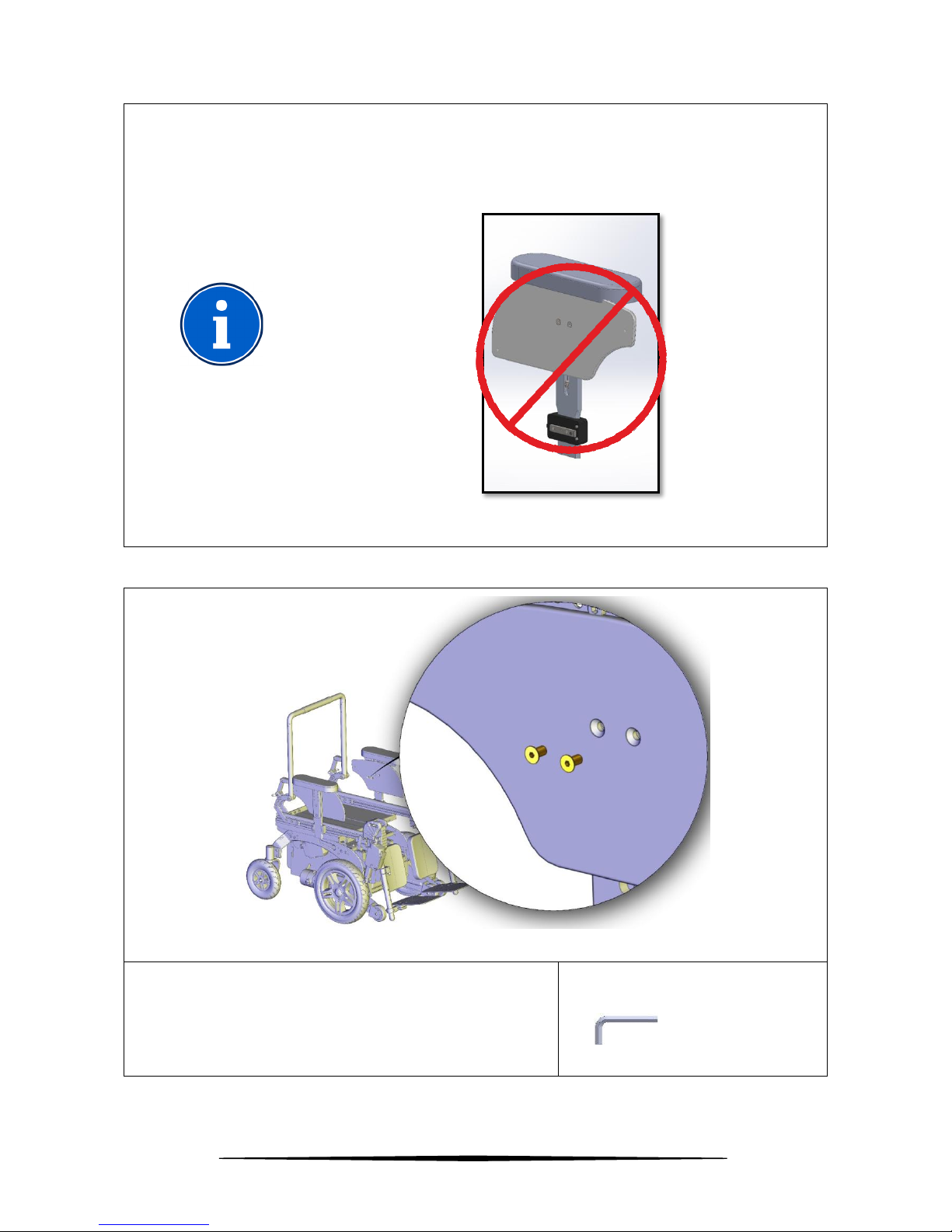

INFORMATION

For information on how to obtain information and instructions in a format

appropriate for use by visually impaired people please contact the

manufacturer.

Service manual is intended for technical personnel to maintain and repair wheelchairs. It is

important to follow the instructions contained in this manual in order to professionally work

with the product.

The qualified personnel who works with wheelchairs must comply with all provisions of

occupational safety and common sense in order to preserve his own safety.

The manufacturer declines all responsibility for any accidents occurring during the working with

the product.

WARNING: It is prohibited to use the product or its parts for any purpose other

than that indicated. For a correct use please follow the instructions given in this

manual. The manufacturer disclaims any responsibility for damages caused by

improper use of the product.

The manufacturer disclaims any responsibility for inappropriate selection of product model and

configuration.

Information in this manual may be subject to change without notice. All information, pictures and

specifications are based on the product details that were available at the time of preparation of this

document. They are representative examples and they are not intended to be exactly as the actual product.

MODIFICATIONS

Any unauthorized modification to the product may increase the risk of personal injury and damage to the

product itself. All modifications should be done by an authorized service center.

Do not use any unauthorized accessories or spare parts on the product. Do not use the product in

combination with other medical devices without first having considered any risk due to combination of

more products.

MANUFACTURER

For any need not expressly explained in this manual, please contact the manufacturer.

Neatech.it SRL

via A. de Curtis 4/A, 80040, Cercola (NA), Italy

www.neatech.it – info@neatech.it - +39 081 555 1946

INCIDENT REPORTING

If an incident occurs, please contact an authorized service center. For a list of authorized service center

please contact the manufacturer.

DISPOSING

This product and all its components can not be treated as household waste. For

more detailed information on how recycling and disposal this product contact your

local waste disposal service.

www.neatech.it

1/126

1 PRODUCT INFORMATION

Evo1 is a strong wheelchair, incredibly steady and made of high quality components for a

comfortable and safe driving performance anywhere you go.

Evo1 has a a minimal and well thought design, extremely compact and ideal for both indoor and

outdoor use, due to its small dimensions and the turning radius reduced to the minimum.

It is available with front or rear wheel drive and a wide range of options and alternative driving

systems.

The chassis is available in 2 sizes: small 49 cm and large 55 cm.

There is a choice of 16 colors, combinable so you can easily add a personal touch to the

wheelchair.

The modular seat structure is highly customizable, according to your own specific needs and it

can grow and develop together with the young user, with a wide range of interchangeable

support and positioning options.

Total wheelchair weight

Maximum user weight

MAX 125 kg

MAX 150 kg

Seat width

MIN 300 mm – MAX 460 mm

Batteries

Charger

Power module

Motors

2x 12 V 35 Ah / 2x 12 V 50 Ah

6 A

VR2 60 A / Rnet 80 A

2x 220 W

www.neatech.it

2/126

2 PREPARATION FOR FIRST USE

2.1 Checks to be made on delivery

• Check for the integrity of the original packaging.

• Check for any anomalies on shipping documents.

• Check for the functionality and integrity of the device in all its parts, at the time of delivery

or immediately thereafter, to ensure that no damage has resulted from a careless transport.

• Make sure the surface of the device is not damaged, scratched, bent, etc.

• Any fault or damage found must be immediately reported on the shipping documents and

promptly communicated to the shipper.

2.2 Unpacking

Inside the box there are:

• Evo1 wheelchair

• Documents and manual

• Charger

The wheelchair is delivered already mounted and ready to use. Before starting to use the

wheelchair please check if all described components are present. If not, please contact as soon

as possible the vendor.

PACKAGING DISPOSAL

To properly recycle the packaging materials follow instructions provided

by your local waste disposal service.

www.neatech.it

3/126

2.1 Software description

The wheelchair, according to specific configuration, can be equipped with Rnet system or VR2

system.

The software of the wheelchair can be categorized into these classes:

• Kernel software of power module.

There is no required access, modification or customization of this part of the software

In case a reprogramming of the wheelchair is required, please contact the

manufacturer to have instructions and the most suitable version of the

software.

In case of problems with this part of the software please contact the

manufacturer.

• Software parameters of the wheelchair.

This part of the software is made by the manufacturer. It is intended to assure driving and

seating function of the wheelchair. It is responsibility of the manufacturer to correct program

parameters regarding the structure of the wheelchair.

Qualified personnel of an authorized service center are able to customize this part of the

software to best fulfill single user requirements.

Programming must be conducted only by qualified personnel with indepth knowledge of the wheelchair and power module system.

Any change to this part of the software may result in a hazardous situation

for the user.

www.neatech.it

4/126

3 ADJUSTMENTS

3.1 List of adjustments

Type of operation

A

Operation intended to be performed by the user.

B

Operation intended to be performed by an assistant.

C

Operation intended to be performed by an authorized

service center.

Table 1

Adjustment

Type of operation

Seat depth

B - Assistant

Backrest angle

B - Assistant

Armrests depth

B - Assistant

Armrests height

B - Assistant

Sidepad height

B - Assistant

Footplates height

B - Assistant

Footplates angle and depth

B - Assistant

Joystick position

B - Assistant

Calf support position

B - Assistant

Legrest angle

B - Assistant

Table 2

www.neatech.it

5/126

3.2 Seat depth

WHEELCHAIR

SIZE

(A)

MIN

VALUE

(A)

MAX

VALUE

M1 - S045-V067

300 mm

420 mm

M2 - S045-V068

340 mm

460 mm

M3 - S045-V069

380 mm

440 mm

M3 - S045-V070

440 mm

500 mm

M4 – S045-V071

400 mm

460 mm

M4 – S045-V072

460 mm

520 mm

M5 – S045-V073

460 mm

520 mm

Table 3

WARNING

It is needed to set separately left and right seat depth. Always set them at

the same manner.

Average needed

time:

5 min

Difficulty level:

Easy

A

www.neatech.it

6/126

Figure 1

• Remove the backrest.

• Loosen the 6 screws shown in figure.

• Repeat operations for both left and right side of the

wheelchair.

• Set the backrest according to the desired seat depth.

• Tight again the 6 screws.

• Repeat operations for both left and right side of the

wheelchair.

• Mount again the backrest.

OPEN-END WRENCH

10 mm

www.neatech.it

7/126

3.3 Backrest angle

BACKREST

CONFIGURATION

(A)

POSSIBLE

VALUES

Angle adjustable with fixed

position

90° or 110°

95° or 115

100° or 120°

105° or 125°

110° or 130°

115° or 135°

Angle adjustable with

pistons

See section

3.3.1

Powered backrest

90° - 130°

WARNING

It is needed to set separately left and right backrest angle. Always set two

parts of backrest at the same manner.

Average needed

time:

5 min

Difficulty level:

Easy

Powered legrest

• Act on the joystick as described in section 4.1.

Angle adjustable with pistons

Use the lever located on the push bar to move the backrest.

A

www.neatech.it

8/126

Angle adjustable with fixed position

Figure 2

• Unscrew the 4 screws shown in figure.

• Repeat operations for both left and right side of the

wheelchair.

• Set the position of the hardware highlighted in

figure according to the desired backrest angle.

• Screw again screws.

• Repeat operations for both left and right side of the

wheelchair.

OPEN-END WRENCH

10 mm

www.neatech.it

9/126

ADDITIONAL ADJUSTMENT

After adjusted the angle of backrest as described above it is possible to

adjust of more 20° simply acting on the axis shown in figure.

Figure 3

www.neatech.it

10/126

3.3.1 Adjunctive backrest angle adjustment

WARNING

This section refers only to angle adjustable backrest with pistons.

WARNING

It is needed to set separately left and right backrest angle. Always set two

parts of backrest at the same manner.

Average needed

time:

5 min

Difficulty level:

Easy

BACKREST

CONFIGURATION

(A)

POSSIBLE

VALUES

Angle adjustable with

pistons

90° - 130°

95° : 130°

100° : 135°

105° : 135°

110° - 140°

120° - 145°

A

www.neatech.it

11/126

Figure 4

• Unscrew the 4 screws shown in figure.

• Repeat operations for both left and right side of the

wheelchair.

• Set the position of the hardware highlighted in

figure according to the desired backrest angle.

• Screw again screws.

• Repeat operations for both left and right side of the

wheelchair.

OPEN-END WRENCH

10 mm

www.neatech.it

12/126

3.4 Armrest depth

RANGE

It is not easy to provide a range for adjustment of armrests depth because

there are too many configuration and possibilities.

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right side.

Average needed

time:

<5 min

Difficulty level:

Easy

RANGE

Please be sure that the chosen position doesn't represent an obstacle.

Figure 5

www.neatech.it

13/126

Figure 6

• Loosen the lever shown in figure and remove the

armrest.

Figure 7

• Unscrew the lever shown in figure.

• Loosen the 2 screws shown in figure and set the

depth of armrest clamp as desired.

• Tighten again the 2 screws and put back the armrest.

ALLEN WRENCH

4 mm

www.neatech.it

14/126

ADDITIONA ADJUSTMENT

Moreover it is possible to adjust armrest depth unscrewing the 2 screws

shown in figure with a 4 mm allen wrench.

Figure 8

www.neatech.it

15/126

3.5 Armrest height

WHEELCHAIR

SIZE

(A)

MIN

VALUE

(A)

MAX

VALUE

S045-V401

200 mm

270 mm

S045-V402

260 mm

340 mm

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right armrest.

Average needed

time:

<5 min

Difficulty level:

Easy

SIDEPAD, JOYSTICK AND ARMREST HEIGHT

It is better to adjust first armrest height, then joystick and finally the

sidepad.

A

www.neatech.it

16/126

Figure 9

• Loosen the 2 screws shown in figure.

• Set the armrest according to the desired height.

• Tight again the 2 screws.

ALLEN WRENCH

4 mm

www.neatech.it

17/126

3.6 Sidepad height

RANGE

It is not easy to provide a range for adjustment of sidepad because there are

too many configuration and possibilities.

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right sidepad.

SIDEPAD, JOYSTICK AND ARMREST HEIGHT

It is better to adjust first armrest height, then joystick and finally the

sidepad.

Average needed

time:

<5 min

Difficulty level:

Easy

www.neatech.it

18/126

RANGE

Please be sure that the chosen position doesn't represent an obstacle for

armrest.

Figure 10

Figure 11

• Unscrew the 2 screws shown in figure and set the

position of sidepad as desired.

• Screw again the 2 screws.

ALLEN WRENCH

3 mm

www.neatech.it

19/126

3.7 Footplates height

LEGREST

CONFIGURATION

(A)

POSSIBLE

VALUES

Fixed angle

150 mm

175 mm

200 mm

225 mm

250 mm

275 mm

300 mm

325 mm

350 mm

375 mm

400 mm

Angle adjustable

150 mm

175 mm

200 mm

225 mm

250 mm

275 mm

300 mm

325 mm

350 mm

375 mm

Central mounted legrest

165 mm

185 mm

205 mm

225 mm

245 mm

265 mm

285 mm

305 mm

325 mm

345 mm

365 mm

385 mm

Powered legrest

255 mm

280 mm

305 mm

330 mm

355 mm

380 mm

A

www.neatech.it

20/126

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right legrest if you have splitted

footrest.

INFORMATION

With calf supports, it is possible that some footplates heights can't be

reached.

Average needed

time:

<5 min

Difficulty level:

Easy

Figure 12

• Unscrew the screw shown in figure with the allen

wrench while holding the nut behind with the open-

end wrench.

• Repeat the operation for both left and right side of

the wheelchair.

• Set the position of the footplate according to

desired height.

• Screw again the screws.

ALLEN WRENCH

5 mm

OPEN-END WRENCH

13 mm

www.neatech.it

21/126

Central mounted legrest

Figure 13

• Unscrew the screw shown in figure with the allen

wrench while holding the nut behind with the open-

end wrench.

• Set the position of the footplate according to

desired height.

• Screw again the screws.

ALLEN WRENCH

5 mm

OPEN-END WRENCH

13 mm

www.neatech.it

22/126

3.8 Footplates depth and angle

RANGE

It is not easy to provide a range for adjustment of footrests because there

are too many configuration and possibilities. In any case it is always possible

to choose between 3 different depth.

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right legrest if you have splitted

footrest.

Average needed

time:

<5 min

Difficulty level:

Easy

www.neatech.it

23/126

Angle adjustment

Figure 14

• Loosen the 2 screws shown in figure.

• Set the position of the footplate according to desired angle.

• Tighten again the screws.

ALLEN WRENCH

4 mm

Central mounted legrest

Figure 15

• Loosen the screw shown in figure to lower the footplate. Tighten

it to rise the footplate.

ALLEN WRENCH

4 mm

www.neatech.it

24/126

Depth adjustment

Figure 16

• Unscrew the 2 screws shown in figure.

• Set the position of the footplate according to desired depth.

• Screw again the screws.

ALLEN WRENCH

4 mm

Central mounted legrest

RANGE

It is not possible to perform this adjustment with central mounted legrest.

www.neatech.it

25/126

3.9 Calf support position

RANGE

It is not easy to provide a range for adjustment because there are too many

configuration and possibilities.

RIGHT AND LEFT SIDE

It is possible to adjust separately left and right side.

Average needed

time:

<5 min

Difficulty level:

Easy

Figure 17

• Unscrew the 2 screws shown in figure and set the

position of calf support as desired.

• Screw again the 2 screws.

ALLEN WRENCH

4 mm

www.neatech.it

26/126

ADJUNCTIVE ADJUSTMENT

Moreover it is possible to choose the angle of calf support simply by pulling

or pushing it.

Figure 18

Central mounted legrest

Figure 19

• Unscrew the screw shown in figure and set the

height of calf support as desired.

• Screw again the 2 screws.

ALLEN WRENCH

6 mm

www.neatech.it

27/126

Figure 20

• Loosen the screw shown in figure using a allen

wrench and a open-end wrench.

• Set the angle ad desired and tighten again the

screw.

ALLEN WRENCH

6 mm

OPEN-END WRENCH

13 mm

www.neatech.it

28/126

3.10 Legrest angle

LEGREST

CONFIGURATION

(A)

POSSIBLE

VALUES

Fixed angle

70°

Angle adjustable

20° - 90°

Central mounted

10° - 90°

Powered legrest

-15° - 80°

Angle adjustable

Average needed

time:

<1 min

Difficulty level:

Easy

Figure 21

• Loosen the lever shown in figure.

• Set legrest angle as desired.

• Tighten again the lever.

A

www.neatech.it

29/126

Powered legrest

• Act on the joystick as described in section 4.1.

PINCH HAZARD

Please pay special attention when moving legrest because there is the

possibility of trapping your or someone else fingers in legrest mechanism.

Figure 22

Central mounted legrest

Figure 23

• Loosen the lever shown in figure.

• Set legrest angle as desired.

• Tighten again the lever.

www.neatech.it

30/126

3.11 Joystick position

RANGE

It is not easy to provide a range for this because there are too many

configuration and possibilities.

Average needed

time:

<5 min

Difficulty level:

Easy

3.11.1 Standard support - Depth

Figure 24

• Unscrew the 2 screws shown in figure.

• Adjust the depth of the joystick as desired.

• Screw again the screws.

ALLEN WRENCH

5 mm

www.neatech.it

31/126

ADJUNCTIVE ADJUSTMENT

Moreover it is possible to adjust the angle of the joystick simply acting on

the two levers shown in figure.

Figure 25

3.11.1 Retractable support - Depth and height

Figure 26

• Unscrew the 2 screws shown in figure.

• Adjust the depth and the height of the joystick as

desired.

• Screw again the screws.

ALLEN WRENCH

5 mm

www.neatech.it

32/126

3.12 Default position

Default position means that all adjustable parts of the wheelchair are set in the most stable and

safe configuration

ADJUSTABLE PARTS

VALUE

NOTES

Seat angle

0°

Backrest angle

90°

Legrest angle

90°

Or minimum

Seat height

0 cm

Table 4

www.neatech.it

33/126

4 USE OF THE PRODUCT

WARNING

Do not operate the wheelchair if it is behaving abnormally or erratically.

The wheelchair may come to a sudden stop at any time during operation.

WARNING

Do not stand on the product. Always use caution when transferring in or out

of the seat. Every precaution should be taken to reduce the transfer

distance. Also be certain the wheel locks are engaged to prevent the wheels

from moving.

Do not let children use the wheelchair without supervision.

INFORMATION

The product is not intended to be dismantled. There are no parts of the

product expected to be handled during normal use of it

INFORMATION

Do not install, maintain or operate the product without reading all warnings

and this entire manual.

Always keep this manual in connection with the product.

INFORMATION

The wheelchair is designed for use mostly in indoor environments.

www.neatech.it

34/126

DRIVE WITH SEATING SYSTEM NOT IN DEFAULT POSITION

Seat tilt, backrest recline or legrest elevation may varies the center of

gravity of the system wheelchair + user and increase tipping risk.

Always drive at low speed when the seating system is not in the standard

position and use powered seating functions only on a flat horizontal

surface.

WARNING

Do not carry passengers on the wheelchair independently of the age of the

passenger. The wheelchair is not designed for weight training and is unsafe

for use as a seat while weight training. Do not lean over the top of the back

upholstery to reach objects from behind as this may cause the wheelchair

to tip over. Do not shift your weight or sitting position toward the direction

you are reaching as the wheelchair may tip over. Do not stand on the frame

of the wheelchair.

Some pathologies may limit your ability to use your wheelchair safely. Be

sure to consult with a doctor about your physical limitations.

Please practice your drive ability under the supervision of an assistant.

www.neatech.it

35/126

Dealing with uphill

When facing an uphill road it is recommended to set the seating system to default position. It is better to use

a drive profile with low speed.

Figure 27

Dealing with downhill

When facing a downhill road it is recommended to set the seating system to default position. It is better to

use a drive profile with low speed

Figure 28

MAX 6°

MAX 6°

www.neatech.it

36/126

WARNING

Don’t use the wheelchair up or down slopes with a gradient than indicated

in specifications of this manual.

Don’t use the wheelchair up or down ramps that are not equipped with

proper edge protection to prevent the wheelchair from falling down.

Don’t use the wheelchair down or up a hazardous incline if the surface is

covered with snow, ice or the surface is uneven.

WARNING

The stopping distance on slopes can be significantly greater than on level

ground

Dealing with side slopes

When facing with side slopes, always use the wheelchair with great caution and make sure the seating system

is in the default position.

Figure 29

Turning with the wheelchair

When turning with the wheelchair, always use great caution.

MAX 6°

www.neatech.it

37/126

Obstacle climbing

When facing with an obstacle, always use great caution and make sure the seating system is in

the default position. The wheelchair is able to climb an obstacle of 50 mm with a run up of

minimum 500 mm.

Figure 30

Driving in dark environments

Don't use the wheelchair in dark environments without lights turned on.

Pelvic belt

The wheelchair has the predisposition for a pelvic belt. Pelvic belt is only design to position the

user and not for any protection in case of accident.

Transfer into and out the wheelchair

Users transfer is recommended with the presence of an assistant. Don’t use footrests or

armrests as support. Always turn off the wheelchair before transfer.

www.neatech.it

38/126

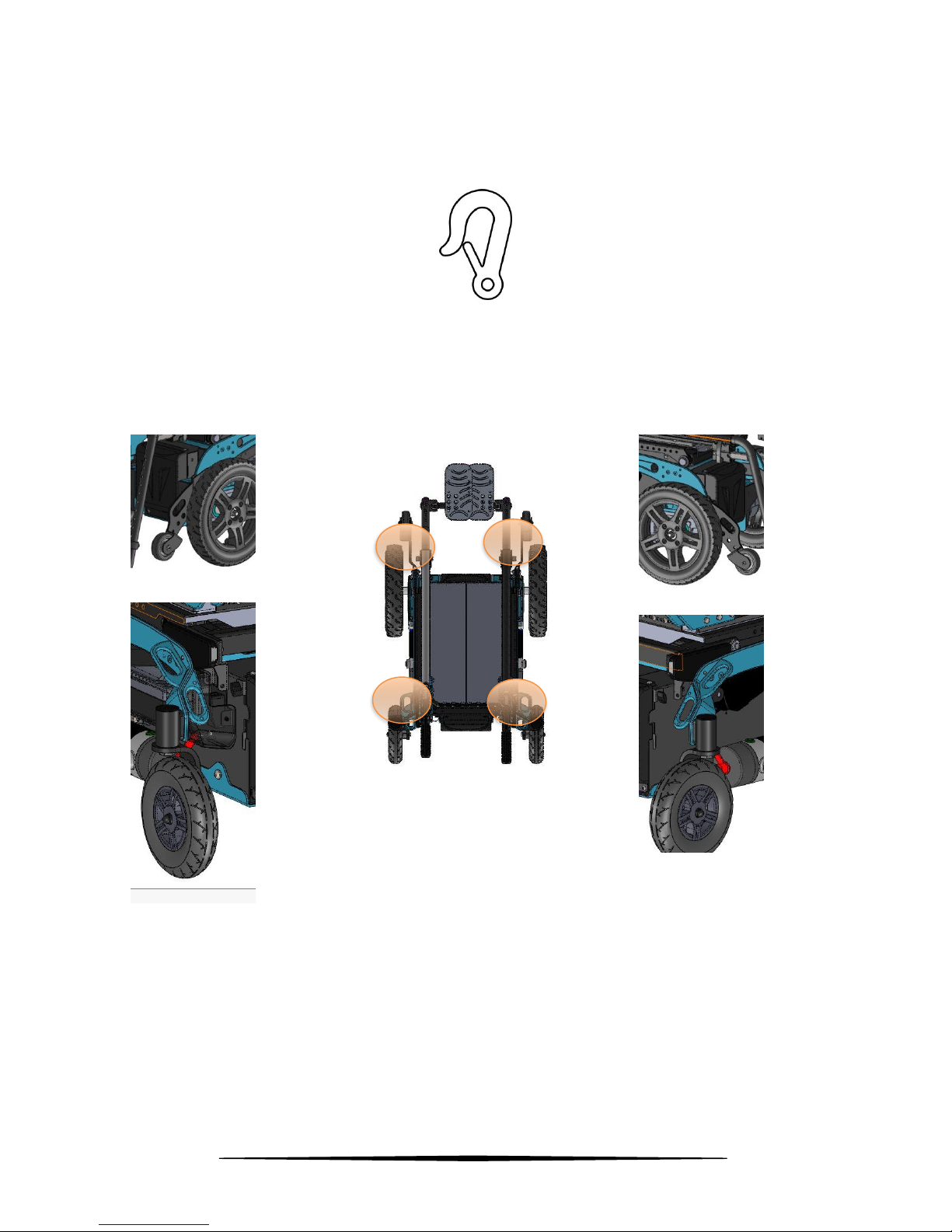

Lift of the wheelchair

Do not lift the wheelchair with a user on board. Do not lift the wheelchair grabbing the legrests.

If you really need to lift the wheelchair, it is suggested to grab it with the help of at least one

other people. Grab the wheelchair using the tie down shown in figure.

Figure 31

www.neatech.it

39/126

4.1 Control system of the wheelchair

It is possible to have the wheelchair with VR2 60 A control system or Rnet 80 A control system.

4.1.1 VR2 60 A control system

Figure 32

FUNCTION

DESCRIPTION

On-Off

Use this function to turn on and off the

wheelchair. Don't use this function to stop

the wheelchair unless it is an emergency.

Horn

MODE

Use this function to navigate between drive

and seat function.

Speed increase/decrease

www.neatech.it

40/126

4.1.2 Rnet 80 A control system

Figure 33

FUNCTION

DESCRIPTION

On-Off

Use this function to turn on and off the

wheelchair. Don't use this function to stop

the wheelchair unless it is an emergency.

Horn

MODE

Use this function to navigate all working

mode of the wheelchair. For example it is

possible to choose between drive and seat

function.

PROFILE

As default in the wheelchair they are saved

some different drive profile for the use indoor

and outdoor.

Use the function PROFILE to change different

types of profiles: they are sorted from the

more indoor ones to the more outdoor ones.

For each profile it is possible to change the

speed.

Speed increase/decrease

www.neatech.it

41/126

Activate at the same time the functions to increase and decrease speed to enter a configuration

menu.

FUNCTION

DESCRIPTION

Set time

Use this function to set the time shown on the

display.

Distance

Use this function to see total and partial

distance made with the wheelchair. It is also

possible to reset partial distance.

Backlight

It is possible to adjust backlights of the

screen.

Background

Use this function to choose the color of

background of the display.

www.neatech.it

42/126

4.2 Manual brake release lever

In case of necessity it is possible to manually move the wheelchair.

First of all, you have to turn off the wheelchair.

Then you can act on the release lever shown in Figure.

When the brakes are released. it is not possible to drive the wheelchair.

Figure 34

UNLOCKED

LOCKED

LOCKED

UNLOCKED

WARNING

When the brakes are released never use the wheelchair on a slope or a wet

surface.

Don’t operate the brake release without the presence of an assistant.

WARNING

The drive system should be re-engaged before an occupant is left

unattended or attempts to operate the wheelchair.

WARNING

Always act on both left and right manual release levers.

www.neatech.it

43/126

4.3 Use as seat in a motor vehicle

The wheelchair is designed to be secured facing forward when used as a seat in a motor vehicle and it

complies with the requirements of ISO 7176-19:2008.

It is possible to use four-point strap systems or the DAHL docking station.

Ease of access to, and maneuverability in, motor vehicle can be significantly affected by wheelchair size

and turning radius. Smaller wheelchairs or with a shorter turning radius will generally provide greater ease

of vehicle access and maneuverability to a forward- facing position.

Always use ISO 10542-1 approved Wheelchair Tiedown and Occupant Restraint Systems, which are

suitable for the weight of the wheelchair or Dahl docking.

Wheelchair users should transfer to the vehicle seat and use the vehicle-manufacturer-installed restraint

systems whenever it is feasible and the unoccupied wheelchair should be stored in a cargo area or secured

in the vehicle during the travel.

For the correct positioning of occupant belt restraints on the user, please consider following.

• The pelvic belt should be worn low across the front of the pelvis, so that the angle of the

pelvic belt is within the preferred zone of 30° to 75° to the horizontal, similar to that

shown in figure.

Figure 35

www.neatech.it

44/126

• Belt restraints should be adjusted as tightly as possible, consistent with user comfort.

• Belt should not be twisted during the use.

IMPROPER BELT RESTRAINT FIT

BELT RESTRAINTS MUST NOT BE HELD AWAY

FROM THE BODY BY WHEELCHAIR

COMPONENTS SUCH AS ARMRESTS OR

WHEELS

PROPER BELT RESTRAINT FIT

BELT RESTRAINTS SHOULD MAKE FULL

CONTACT WITH THE SHOULDER, CHEST AND

PELVIS AND PELVIC BELTS SHOULD BE

POSITIONED LOW ON THE PELVIS NEAR THE

THIGH ABDOMINAL JUNCTION

Figure 36

In order to mount pelvic belt on the wheelchair, firstly

mount the fixing plate as shown in figure.

Use socket head cap screw M6x10 and a 5 mm allen

wrench.

Repeat operation for both left and right side of the

wheelchair.

ALLEN WRENCH

5 mm

www.neatech.it

45/126

Figure 37

In order to mount chest belt on the wheelchair, firstly

mount the fixing plate as shown in figure.

Use socket head cap screw M6x10 DIN 912 and a 5 mm

allen wrench.

Repeat operation for both left and right side of the

wheelchair.

ALLEN WRENCH

5 mm

Figure 38

Moreover, chest belt must be fixed in the upper part of

the backrest. Firstly mount the fixing plate as shown in

figure.

Use hushroom head square neck bolt screw M5x16 DIN

603, M5 nut, and a 8 mm open-end wrench.

Repeat operation for both left and right side of the

wheelchair.

OPEN-END

WRENCH

8 mm

www.neatech.it

46/126

WARNING

The seating system must be set in the DEFAULT POSITION when used in a

motor vehicle. Particularly be sure that the seat is horizontal, legrest are

completely down and backrest is completely up. For more information see

section 3.12.

WARNING

Evo3 wheelchair has lots of configurations and accessories. The wheelchair

safety when used as a seat in a motor vehicle is assured by the

manufactured if the specific configuration is mentioned in the order form

and if all instructions in the manual are followed. Particularly it may exist

some options or accessories that are not compatible with the use of the

wheelchair as a seat in a motor vehicle, or it may exist some accessories

that require some precautions.

WARNING

If the backrest is with gas springs, when using the wheelchair as a seat in

a motor vehicle, it is necessary to lock the movement of the gas springs

with the locking system shown in the picture. Always repeat the operation

for the left and right side of the wheelchair. WARNING: Safety of

wheelchair and user can't be assured when the movement of gas springs

is not correctly locked while using the wheelchair as a seat in a motor

vehicle.

Figure 39

www.neatech.it

47/126

WARNING

The wheelchair complies with the requirements of ISO 7176-19:2008 and

has been designed and tested for use only as a forward-facing seat in a

motor vehicle.

Compliance with this standard does not preclude using the wheelchair

facing rearward in large accessible vehicles such as autobus.

WARNING

The wheelchair has been dynamically tested in a forward facing orientation

with the ATD restrained by both pelvic and shoulder belts.

WARNING

Both pelvic and shoulder belt should be used to reduce the possibility of

head and chest impacts with vehicle components.

WARNING

In order to reduce the potential of injury to vehicle occupants wheelchair

tray should be removed and secured separately in the vehicle.

WARNING

When possible other auxiliary wheelchair equipment should be either

secured to the wheelchair or removed from the wheelchair and secured in

the vehicle during travel, so that it does not break and cause injury to vehicle

occupants in the event of a collision.

www.neatech.it

48/126

WARNING

You should not use this product in a motor vehicle if your weight is less than

22 kg.

WARNING

Postural supports should not be relied on for occupant restraint in a moving

vehicle unless they are labelled as being in accordance with the

requirements specified in ISO 7176-19:2008.

WARNING

The wheelchair should be inspected by a manufacturer's representative

before reuse following involvement in any type of vehicle collision.

WARNING

Alterations or substitutions should not be made to the wheelchair

securement points or to structural and frame parts or components without

consulting the wheelchair manufacturer.

WARNING

Wheelchair has sealed type batteries. Never use different battery type when

used in a motor vehicle.

www.neatech.it

49/126

WARNING

Care should be taken when applying the occupant restraint to position the

seatbelt buckle so that the release button will not be contacted by

wheelchair components during a crash.

www.neatech.it

50/126

4.3.1 Four points tie-down

Use the tie down points marked with the symbol shown in figure.

Figure 40

Use the tie down points marked with the symbol shown in figure. Hook the wheelchair in 4

points: two in the front part and two in the rear part.

Figure 41

www.neatech.it

51/126

Tie down straps should form angles shown below.

PREFERRED ANGLES OF FRONT

WHEELCHAIR TIE DOWN STRAPS

Figure 42

PREFERRED ANGLES OF REAR WHEELCHAIR

TIE DOWN STRAPS

Figure 43

WARNING

Always use four tie down straps.

40°

60°

300

mm

25°

25°

45°

30°

10°

10°

300

mm

www.neatech.it

52/126

4.3.2 Dahl engineering docking station

WARNING

Please be sure that the vehicle is equipped with a fully working and

compatible Dahl docking system.

Figure 44

• To use the system, maneuver the wheelchair slowly and in a uniform direction over the

docking station. The lock plate under the wheelchair helps to guide the wheelchair into place

in the docking station. When the lock plate is fully engaged in the docking station, a spring-

action locking pin automatically secures the lock plate.

• The docking station is equipped with a control switch that indicates whether the lock plate

is correctly secured in the docking station. As soon as the lock plate comes into contact with

the locking pin, a warning tone will sound and the red led in the control panel will light up

until the lock plate is either fully engaged or else the wheelchair is removed from the docking

station. As an indication that the wheelchair is properly secured, the warning tone will cease,

the red diode in the control panel will go out and the green led will light up.

• When the wheelchair is correctly secured, the safety belt should be fitted and adjusted so

that it fits the user.

• UNLOCKING PROCEDURE. When the vehicle has been brought to a halt, remove the safety

belt. To unlock commence by driving the wheelchair forward to release pressure on the lock

pin and then press the red release button in the control panel. The locking pin will be

triggered/released for approx 5 seconds, after which the locking pin is automatically

locked/activated again. Do not attempt to reverse out the docking station until the red LED

on the control module, which indicates the unlock position, has been illuminated. Move the

wheelchair away from the docking station within this 5-second period.

www.neatech.it

53/126

WARNING

Attempting to reverse the wheelchair before the red LED has been

illuminated will result in blocking the docking station lock mechanism

which makes it impossible to reverse. If this happens repeat above

unlocking procedure.

Figure 45

CONTACT INFORMATION

For more information contact the manufacturer of the wheelchair or the

manufacturer of the docking station.

Dahl Engineering

Løvevej 3

DK-7700 Thisted

Tel. +45 96 18 00 77

https://dahlengineering.dk

sales@dahlengineering.dk

www.neatech.it

54/126

4.4 Powered functions

WARNING

Operating these functions changes the center of gravity and increases the

risk of tipping over.

Always drive in low speed when the seating system is not in the default

position. Use these functions only on horizontal plane.

To enter seating mode use MODE function of the joystick.

With VR2 system a led will turn on to indicate the seat function in use.

With Rnet system a wheelchair will appear on the screen of the joystick.

To select the desired function move the joystick left or right.

The number and the type of available function may change according to the specific

customization of each wheelchair.

MOVE UP

Move the joystick forward

while you are in seating mode

and the desired function is

selected

MOVE DOWN

Move the joystick rearward

while you are in seating mode

and the desired function is

selected

BACKREST

Move forward the backrest

Recline the backrest

LEFT LEGREST

Low left legrest

Elevate left legrest

www.neatech.it

55/126

RIGHT LEGREST

Low right legrest

Elevate right legrest

LEGRESTS BOTH

Low both legrests

Elevate both legrests

TILT

Move forward the seat

Tilt the seat

LIFT

Rise the seat

Lower the seat

www.neatech.it

56/126

4.5 Main switch

Use the main switch to connect and disconnect the batteries from the power module.

The switch also has the function of protecting the wheelchair from overloaded current and short

circuit.

OFF

ON

Figure 46

Figure is taken having the wheelchair on the front and shows the position ON and OFF of the

switch.

If the power chair suddenly stops, use the switch to connect again batteries to the power

module and turn on again the wheelchair. If the problem still continues, it means that there is

some electric fault.

If the switch operates, often this means that there is a major electrical

fault. The cause of fault should be checked carefully.

For more information, please contact the manufacturer.

www.neatech.it

57/126

4.6 Battery charging

In order to recharge batteries, use only the provided charger or one recommended by the

manufacturer. The manufacturer is not responsible for any damage to person or objects

resulting from the use of non-original product.

CHARGER SPECIFICATION

24 V -MIN 6 A MAX 10 A - Charge profile for AGM batteries

• Connect the power cord to a power supply 230 V.

• Connect the cable to the joystick as shown in Figure.

VR2

RNET

Figure 47

• When batteries are loaded unplug the power cord and the battery cable from the joystick.

RUNNING-IN PERIOD

Typically, batteries are able to offer 100% performance after about 15-20

cycles.

BATTERIES SPECIFICATION

Seat width from 300 mm to 360 mm: 24 V - 35 Ah - about 197x131x180 (h)

mm - about 11 kg

Seat width from 380 mm to 460 mm: 24 V - 50 Ah - about 198x166x171 (h)

mm - about 15 kg

www.neatech.it

58/126

WHEN AND HOW IT IS NECESSARY TO CHARGE BATTERIES?

It is very important to charge batteries every day, even if they are not

completely discharged. Each battery is subject to a normal self-discharge,

so batteries that are not used for long time will discharge by itself.

It is very important to don’t let batteries uncharged for long time.

It is very important to complete every cycle of charging

Charging time is influenced by multiple factors such as remaining battery

power, battery state of aging and temperature. However, the approximate

charging time is about 12 hours.

Battery charging should be done in well ventilated environments. Never

charge in bathroom or wet room.

When the charger is connected it is not possible to drive the wheelchair.

Don’t use the wheelchair during the charge.

SHOCK HAZARD

Check if charger requirements data matches with the network power

(voltage, frequency)

RELEASE DANGER

Any impact to the batteries could cause a loss of fluids. Please pay special

attention.

BATTERIES DISPOSAL

To properly recycle the batteries follow instructions provided by your local

waste disposal service.

www.neatech.it

59/126

4.7 Transport and storage

If you are not willing to use the wheelchair for a long period, keep it safe in a clean area and

away from heat.

If it is necessary to transport the wheelchair to facilitate operation follow these instructions.

It is possible to store the wheelchair in a place with a temperature between -20 °C and +45 °C.

• Turn off the wheelchair.

• Turn off the main switch. See section 4.5.

WARNING

If you transport the wheelchair with motors disengaged, the wheelchair is

free to move. This may result in a hazardous situation.

www.neatech.it

60/126

5 MAINTENANCE

Please remind that the wheelchair is intended exclusively for the carriage of seated people.

Below there are some precautions for the use of the wheelchair, which it is recommend to

follow, in order to ensure a safe use and a long duration.

Regular maintenance helps to keep intact the functionality and safety of the wheelchair.

Inadequate or lack of care and maintenance may cause a limitation of the warranty.

• Avoid prolonged contact of the wheelchair with water. It may cause oxidation of the metal

parts.

• Avoid long exposure of the wheelchair to direct sunlight.

WARNING

Any work on the wheelchair must be performed by an authorized service

center.

INFORMATION

It is not possible to perform any maintenance on batteries. It is only possible

to substitute them.

5.1 Maintenance and cleaning

To clean the wheelchair do not use high-pressure water spray devices. For plastic and metal

parts use a soft cloth dampened with mild detergent. For the upholstery, linings, seat and back

covers use warm water and mild detergent. Do not use stain removers, solvents, acids, etc.

www.neatech.it

61/126

5.2 Controls to be performed on the product

Type of operation

A

Operation intended to be performed by the user.

B

Operation intended to be performed by an assistant.

C

Operation intended to be performed by an authorized

service center.

Operation

Frequency

Type of operation

Check if motors are correctly

locked. See section 4.2.

Before each use

B - Assistant

Check that no wires are in the way

for the movements of the chair

Before each use

B - Assistant

Check the charge of batteries

Daily

A - User

Clean the wheelchair

Weekly

B - Assistant

Check if the pressure is the one

indicated on tires and in section 6

Traction wheels: 280 kPa; Castors:

250 kPa.

Weekly

B - Assistant

Check if the lever of the main

switch works correctly

Weekly

B - Assistant

Check tire usury

Monthly

B - Assistant

Check brake release lever

Monthly

B - Assistant

Check aging of batteries

Monthly

C - Service

www.neatech.it

62/126

5.3 Tire puncture

5.3.1 User information

Traction wheel

Figure 48

• Lift the wheelchair.

• Unscrew the 4 screws shown in figure.

• Remove the wheel.

ALLEN WRENCH

6 mm

www.neatech.it

63/126

Castors wheel

Figure 49

• Lift the wheelchair.

• Unscrew the nut shown in figure.

• Remove the castor.

OPEN-END WRENCH

10 mm

Contact an authorized service center for the repair or the substitution of the

damaged wheel. When the authorized service center gives you back the

repaired wheel or a new one, mount it following instructions in reverse

order.

www.neatech.it

64/126

Code

Description

Type of

operation

R045-0120A

Traction wheel Pneumatic Gray Ø320x58 mm

A

R045-0120B

Traction wheel Pneumatic Black Ø320x58 mm

A

R045-0121A

Tire of traction wheel gray Ø320x58 mm

B

R045-0121B

Tire of traction wheel black Ø320x58 mm

B

R045-0122

Tube of traction wheel Ø320 mm

B

R045-0131A

Castor Pneumatic gray Ø200 mm x 50 mm

A

R045-0131B

Castor Pneumatic black Ø200 mm x 50 mm

A

R045-0131C

Castor PU gray Ø200 mm x 50 mm

A

R045-0131D

Castor PU black Ø200 mm x 50 mm

A

R045-0132A

Tire of castor gray Ø200 mm x 50 mm

B

R045-0132B

Tire of castor black Ø200 mm x 50 mm

B

R045-0133

Tube for castor Ø200 mm x 50 mm

B

Table 5

Type of operation

A

Parts that can be bought at an authorized service center

and substitute autonomously

B

Parts that need to be substituted at an authorized service

center.

www.neatech.it

65/126

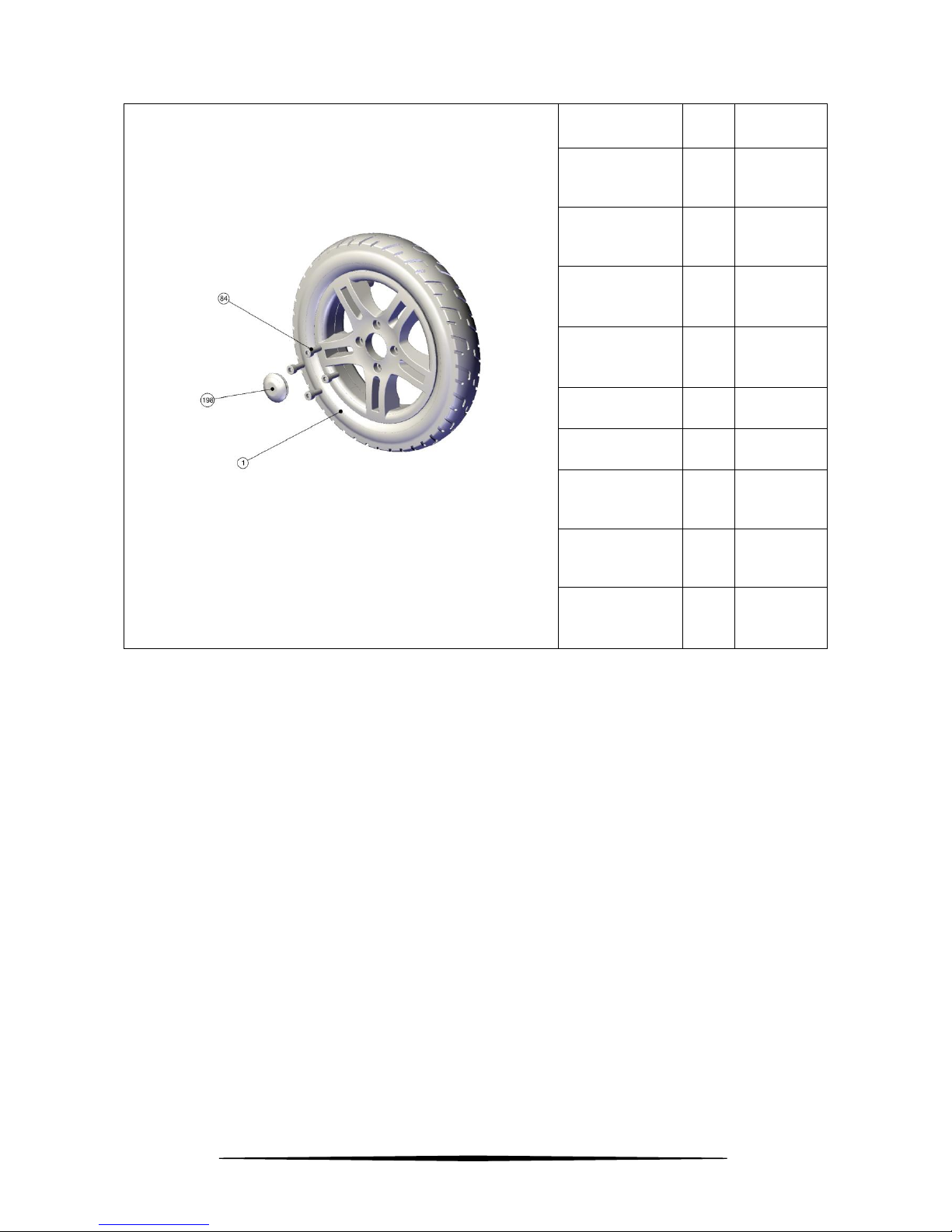

Figure 50

Code

ID

Quantity

R045-0120A

1A

tire

1

R045-0120B

1B

tire

1

R045-0120

1

rim

1

R045-0120

1

tube 1 R045-0120

198 1 R045-0120

84

4

R045-121A

1A

tire

1

R045-121B

1B

tire

1

R045-0122

1

tube

1

www.neatech.it

66/126

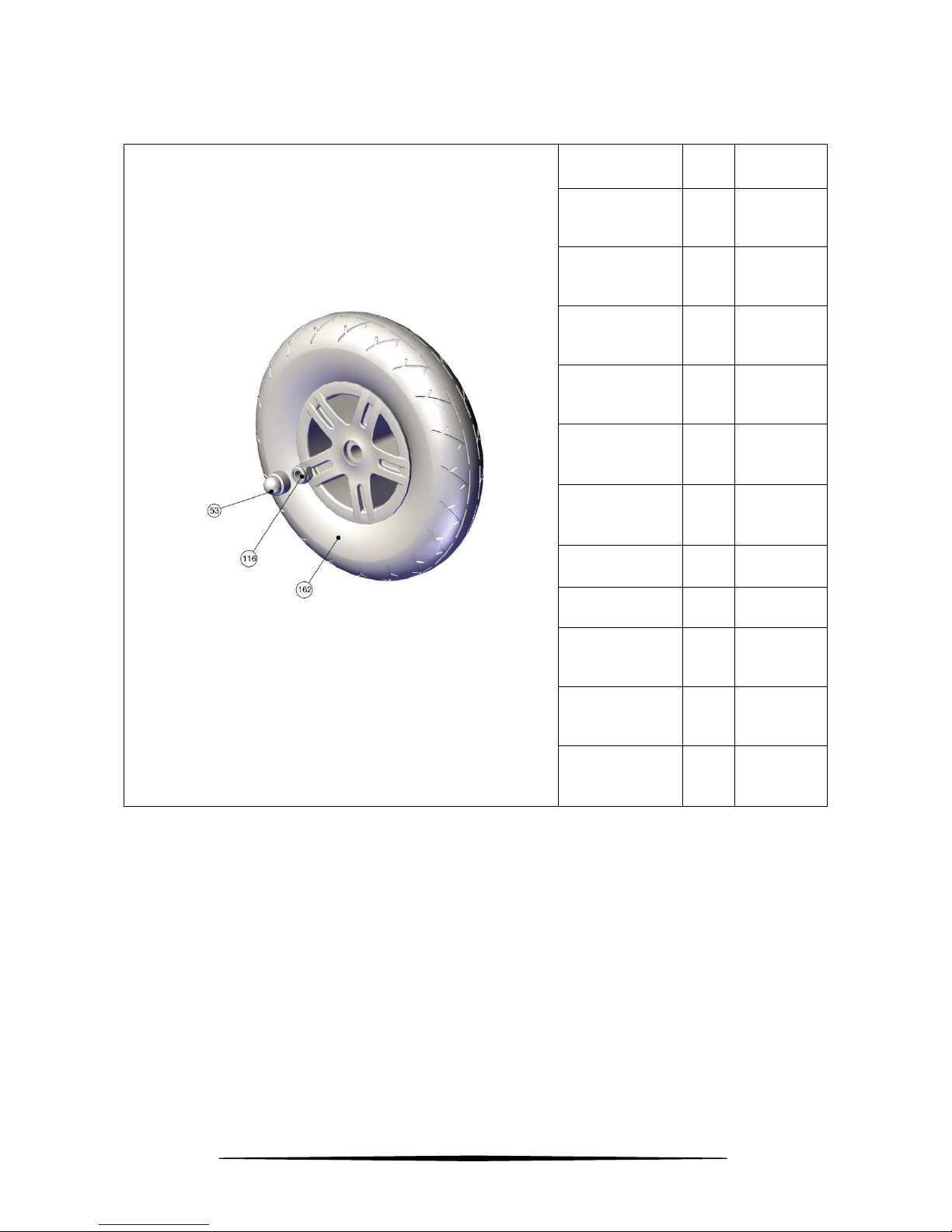

Figure 51

Code

ID

Quantity

R045-0131A

162A

tire

1

R045-0131B

162B

tire

1

R045-0131C

162C

tire

1

R045-0131D

162D

tire

1

R045-0131A

162

tube

1

R045-0131B

162

tube 1 R045-0131

53 1 R045-0131

116

1

R045-0132A

162A

tire

1

R045-0132B

162B

tire

1

R045-0133

162

tube

1

www.neatech.it

67/126

5.4 Wiring diagram

5.4.1 Rnet

Figure 52

www.neatech.it

68/126

5.4.2 VR2

Figure 53

www.neatech.it

69/126

5.5 Reuse

The product is suitable for reuse. Before dispensing it, the product must be cleaned, and

subjected to maintenance. The operating instructions are included in this manual and must also

be provided when the product is passed on.

WARNING

This operation must be performed only at an authorized service center.

www.neatech.it

70/126

5.6 Spare parts

Type of operation

A

Parts that can be bought at an authorized service center

and substitute autonomously

B

Parts that need to be substituted at an authorized service

center.

Table 6

Code

Description

Type of

operation

Notes

R045-0110A

Batteries 35 Ah

B

R045-0110B

Batteries 50 Ah

B

R045-0120A

Traction wheel Pneumatic Gray Ø320x58 mm

A

R045-0120B

Traction wheel Pneumatic Black Ø320x58 mm

A

R045-0121A

Tire of traction wheel gray Ø320x58 mm

B

R045-0121B

Tire of traction wheel black Ø320x58 mm

B

R045-0122

Tube of traction wheel Ø320 mm

B

R045-0131A

Castor Pneumatic gray Ø200 mm x 50 mm

A

R045-0131B

Castor Pneumatic black Ø200 mm x 50 mm

A

R045-0131C

Castor PU gray Ø200 mm x 50 mm

A

R045-0131D

Castor PU black Ø200 mm x 50 mm

A

R045-0132A

Tire of castor gray Ø200 mm x 50 mm

B

R045-0132B

Tire of castor black Ø200 mm x 50 mm

B

R045-0133

Tube for castor Ø200 mm x 50 mm

B

R045-0134

Fork B

www.neatech.it

71/126

R045-0135

Bearings

B

R045-0140

Antitip wheel

A

R045-0150

Cover A A

R045-0160

Cover B A

R045-0161

Levers for cover

A

R045-0170

Motors - couple

B

R045-0171

Lever for motors

A

R045-0180

Main switch

B

R045-0181

Lever for main switch

A

R045-0190A

Standard joystick support

A

R045-0190B

Retractable joystick support

A

R045-0200A

Joystick Rnet

A

R045-0200B

Joystick VR2

A

R045-0210A

Power module Rnet

B

R045-0210B

Power module VR2

B

R045-0220

Seat module Rnet

B

R045-0230

Charger A

R045-0313

Legrest actuator

A

R045-0320A

Footplates splitted - seat width 300 mm

A

R045-0320B

Footplates splitted - seat width 340 mm

A

R045-0320C

Footplates splitted - seat width 380 mm

A

R045-0320D

Footplates splitted - seat width 420 mm

A

R045-0320E

Footplates splitted - seat width 460 mm

A

www.neatech.it

72/126

R045-0320F

Footplate unique - seat width 300 mm

A

R045-0320G

Footplate unique - seat width 340 mm

A

R045-0320H

Footplate unique - seat width 380 mm

A

R045-0320J

Footplate unique - seat width 420 mm

A

R045-0320K

Footplate unique - seat width 460 mm

A

R045-0321A

Fixing system for footrest - LEFT side unique

footplate

A

R045-0321B

Fixing system for footrest - RIGHT or LEFT side

splitted footplates or RIGHT side unique

footboard

A

R045-0321C

Fixing system for footrest - central mounted

legrest

A

R045-0330A

Tilt actuator 30°

B

R045-0330B

Tilt actuator 45°

B

R045-0330C

Tilt actuator (with lift + 45° tilt system)

B

R045-0340

Lift actuator

B

R045-0360

Backrest actuator

A

R045-0371

Backrest support (4 pieces)

A

R045-0372

Gas spring for tilting - couple

B

R045-0373

Backrest pin

A

R045-0374

Axis for angle adjustable backrest

A

R045-0380

Padding for push handle

A

R045-0391

Armrest padding

A

R045-0392

Armrest support

A

R045-0393

Armrest fixing system

A

www.neatech.it

73/126

R045-0394

Lever for armrest

A

R045-0395A

Armrest lower support standard

A

R045-0395B

Armrest lower support high

A

R045-0396

Sidepad A

R045-0400

Legrest support

A

R045-0401

Lever for legrest

A

R045-0402A

Lever for angle adjustable legrest - standard

legrest

A

R045-0402B

Lever for angle adjustable legrest - central

mounted legrest

A

R045-0403

Plastic cover for powered legrest

B

R045-0404A

Calf support SMALL

A

R045-0404B

Calf support LARGE

A

R045-0404C

Calf support for central mounted legrest

SMALL

A

R045-0404D

Calf support for central mounted legrest LARGE

A

R045-0420

Gyroscope

B

Table 7

WARNING

The use of spare parts or accessories not approved by the manufacturer may

make the wheelchair unstable or uncontrollable.

For each order, always contact an authorized service center.

www.neatech.it

74/126

CONTACT INFORMATION

For any other part not described in this manual please contact the

manufacturer.

www.neatech.it

75/126

5.6.1 Antitip wheels

Average needed

time:

5 min

Difficulty level:

Easy

Figure 54

• Unscrew the screws shown in figure.

• Substitute the wheel.

• Screw the new screws.

SCREWDRIVER

www.neatech.it

76/126

Figure 55

Code

ID

Quantity

R045-0140

1 1 R045-0140

2

2

Code

Description

Type of

operation

Notes

R045-0140

Antitip wheel

A

www.neatech.it

77/126

5.6.2 Cover A

Average needed

time:

5 min

Difficulty level:

Easy

Figure 56

• Unscrew the 4 screws shown in figure.

• Substitute the cover.

• Screw the new screws.

ALLEN WRENCH

3 mm

www.neatech.it

78/126

Code

Description

Type of

operation

Notes

R045-0150

Cover A

A

Figure 57

Code

ID

Quantity

R045-0150

229

1

R045-0150

108

4

www.neatech.it

79/126

5.6.3 Cover B

Average needed

time:

5 min

Difficulty level:

Easy

Figure 58

• Unscrew the 4 screws shown in figure.

• Substitute the cover.

• Screw the new screws.

ALLEN WRENCH

3 mm

www.neatech.it

80/126

Code

Description

Type of

operation

Notes

R045-0160

Cover B

A

Figure 59

Code

ID

Quantity

R045-0160

367

1

R045-0160

366

4

R045-0161

365

2

www.neatech.it

81/126

5.6.4 Levers for cover

Average needed

time:

5 min

Difficulty level:

Easy

Figure 60

• Substitute the levers shown in figure.

Code

Description

Type of

operation

Notes

R045-0161

Levers for cover

A

www.neatech.it

82/126

5.6.5 Lever for motors

Average needed

time:

5 min

Difficulty level:

Medium

Figure 61

• Unscrew the screw shown in figure.

• Substitute the levers for motor.

• Screw the new screw.

ALLEN WRENCH

4 mm

Code

Description

Type of

operation

Notes

R045-0171

Lever for motors

A

Figure 62

Code

ID

Quantity

R045-0171

365

1

R045-0171

367

1

www.neatech.it

83/126

5.6.6 Standard joystick support

Average needed

time:

5 min

Difficulty level:

Easy

Figure 63

• Unscrew the 2 screws shown in figure.

• Remove the joystick.

ALLEN WRENCH

4 mm

Figure 64

• Unscrew the 2 screws shown in figure. Unscrew the 2

screws shown in figure.

• Substitute the joystick support.

• Mount the old joystick following instructions in

reverse order.

ALLEN WRENCH

5 mm

www.neatech.it

84/126

Code

Description

Type of

operation

Notes

R045-0190A

Standard joystick support

A

Figure 65

Code

ID

Quantity

R045-0190 A

76

1

R045-0190 A

107

2

R045-0190 A

114

2

R045-0190 A

336

1

R045-0190 A

337

1

R045-0190 A

338

1

R045-0190 A

339

1

R045-0190 A

340

1

R045-0190 A

341

1

R045-0190 A

342

1

R045-0190 A

348

1

www.neatech.it

85/126

5.6.7 Retractable joystick support

Average needed

time:

5 min

Difficulty level:

Easy

Figure 66

• Unscrew the 2 screws shown in figure.

• Remove the joystick.

ALLEN WRENCH

3 mm

Figure 67

• Unscrew the 2 screws shown in figure.

• Substitute the joystick support.

• Mount the old joystick following instructions in

reverse order.

ALLEN WRENCH

3 mm

www.neatech.it

86/126

Code

Description

Type of

operation

Notes

R045-0190B

Retractable joystick support

A

Figure 68

Code

ID

Quantity

R045-0190B

63

1

R045-0190B

64

1

R045-0190B

65

4

R045-0190B

107

2

R045-0190B

114

2

R045-0190B

118

8

R045-0190B

373

4

www.neatech.it

87/126

5.6.8 Joystick

Average needed

time:

5 min

Difficulty level:

Easy

Standard joystick support

Figure 69

• Unscrew the 2 screws shown in figure.

• Substitute the joystick.

ALLEN WRENCH

4 mm

Retractable joystick support

Figure 70

• Unscrew the 2 screws shown in figure.

• Substitute the joystick support.

ALLEN WRENCH

3 mm

www.neatech.it

88/126

Code

Description

Type of

operation

Notes

R045-0200A

Joystick Rnet

A

R045-0200B

Joystick VR2

A

5.6.9 Legrest actuator

Average needed

time:

5 min

Difficulty level:

Easy

Figure 71

• Remove the seegers shown in figure. Use a

screwdriver as a lever.

• Unplug cable of actuator.

• Substitute the actuator.

SCREWDRIVER

Code

Description

Type of

operation

Notes

R045-0313

Legrest actuator

A

www.neatech.it

89/126

Figure 72

Code

ID

Quantity

R045-0313

86

1

Loading...

Loading...