Page 1

ARP AVATAR PATCH PANEL

INSTRUCTION MANUAL

Page 2

Introduction

Thank you for purchasing an Avatar Patch Panel Kit! These instructions are intended to guide you through installing and using this kit.

Before we get started, let’s go over a few guidelines:

Never open the Avatar or perform any service on it when the unit is

plugged in to AC power. Take your time when drilling in to the front

panel and when making cuts to traces on the circuit boards. Careless

work can damage your instrument and diminish its resale value. This

work should be performed by persons experienced with electronics

and mechanical construction. This modication is considered advanced and should not be undertaken by the novice. Please consider

hiring a professional technician or engineer to do this work if you are

not comfortable. This kit will take 8-10 hours for an experienced tech-

nician to install

Kit Contents

• Polycarbonate Graphic Panel

• (2) Potentiometers

• Two Knobs (both black.)

• Heat Shrink Tubing

• (2) 50 pin IDC cables

• (2) PCBs, 1 x Left Panel, 1 x Right Panel

• (36) 1/8” Switching Jacks

• (36) 3/8” Mounting Nuts

• (1) 1M Resistor

• (2) 50-Pin IDC Connectors

Page 3

Tools Required For Installation

• Electric Drill

• 5/16” Drill Bit

• 3/8” Drill Bit

• Center Punch

• Wire cutters

• Wire strippers

• Solder

• Soldering Iron

• Dremel or Exact-O Knife

• 1/4”Socket Driver

• 3/8” Socket Driver

• Phillips Head Screwdriver

• Heat Gun or Hair Dryer

Positioning, Marking, and Drilling of Panel

The vinyl New England Analog adhesive panel overlay is used as a

template for marking and drilling the ARP Avatar front panel.

Line up the graphics horizontally and adjust vertically so the top edge

of the vinyl overlay just meets the orange front panel graphic under

the LFO Repeat switch. The bottom edge of the vinyl overlay should

be approximately 33mm from the bottom edge of the Avatar front

panel. Secure in position with removable tape taking care not to obstruct the holes in the overlay.

Accurately mark the center of the openings, remove the overlay, and

drill the VCO1 glide and VCO2 glide locations to 3/8” and all other

holes to 5/16”. Deburr the holes on both sides of the panel. If drilling

the panel by hand, cover the internal components adequately with a

dropcloth and use a sharp center punch to prep each drilling location

to minimize the drill bit wandering. If using a drill press, remove the

circuit boards from the front panel and remove the panel from the

case. Wooden spacer blocks will be needed under the panel to level it

while drilling.

Page 4

Figure 1A - Alignment of Overlay

Figure 1B - Alignment of Overlay

Page 5

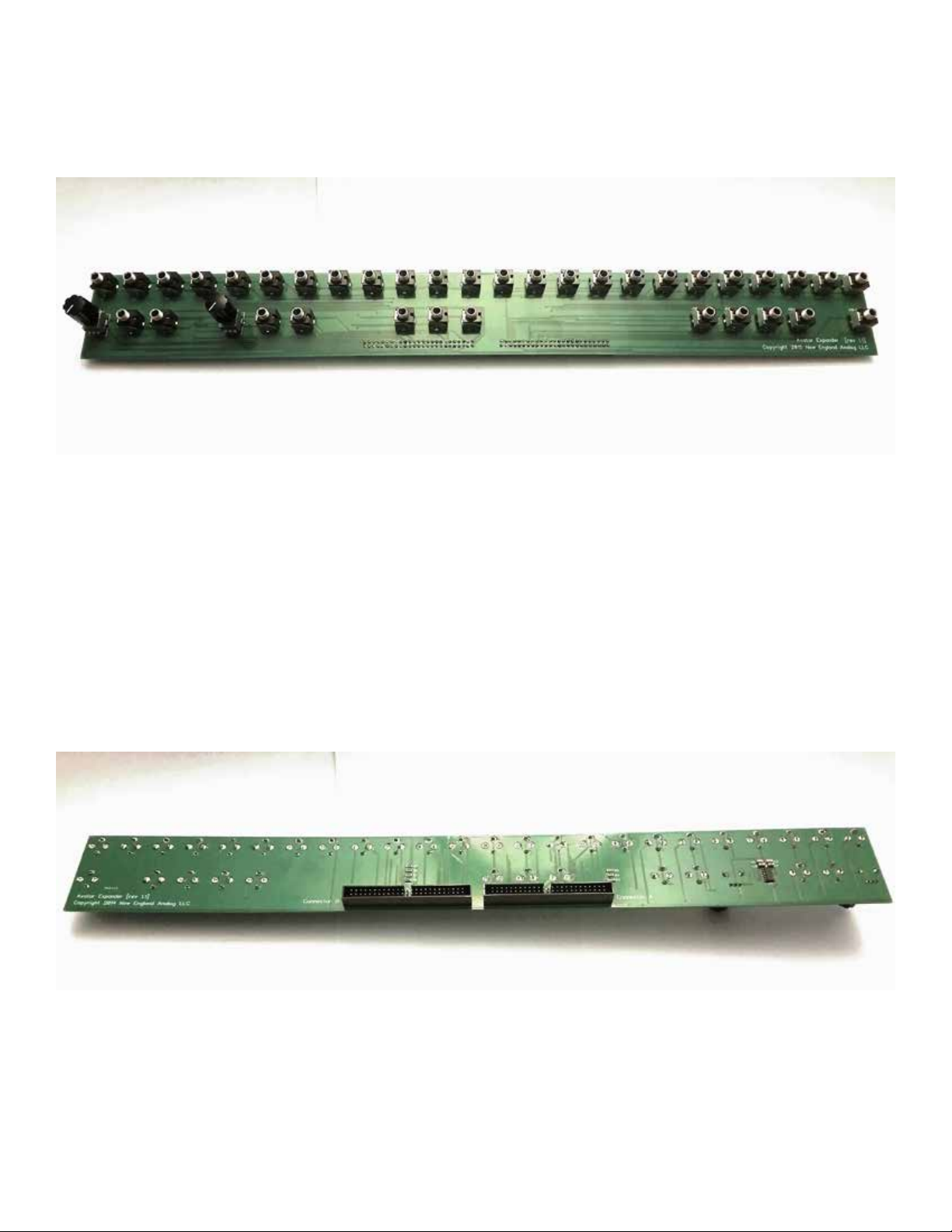

Assembled PCB (Top View)

Assembled PCB (Bottom View)

Page 6

Panel Mounting and PCB Mounting

Before afxing the vinyl overlay to the Avatar panel, dry t and verify

the alignment of the overlay, panel holes, and patch board hardware,

securing the jack hardware only loosely in place. Inaccurately drilled

panel holes may result in a slight buckling or misalignment of the

overlay which can be remedied by slightly enlarging the misaligned

holes. The vinyl overlay has a strong adhesive, so use care in afxing

it to the panel.

Attach the 36 1/8” switching jacks and pots to the top of the PCB.

Attach IDC connectors to the bottom of the PCB. Pay close attention

to the keying of the IDC connectors as well. Pin 1 is always marked

on the IDC header with either a 1 or a triangle pointing to pin 1. Make

sure you know which pin is pin 1 (brown wire) before you start wiring. IDC Header A is on the left side of the PCB (contains VCOs, S&H,

etc) and Header B is on the right side (VCF, VCA, Envelopes.)

Electrical Modications and Connections

Several conductive traces must be cut (electrically open) on the Avatar

circuit boards. This is best done with a rotary tool such as a Dremel

but can also be accomplished with a sharp utility or hobby knife.

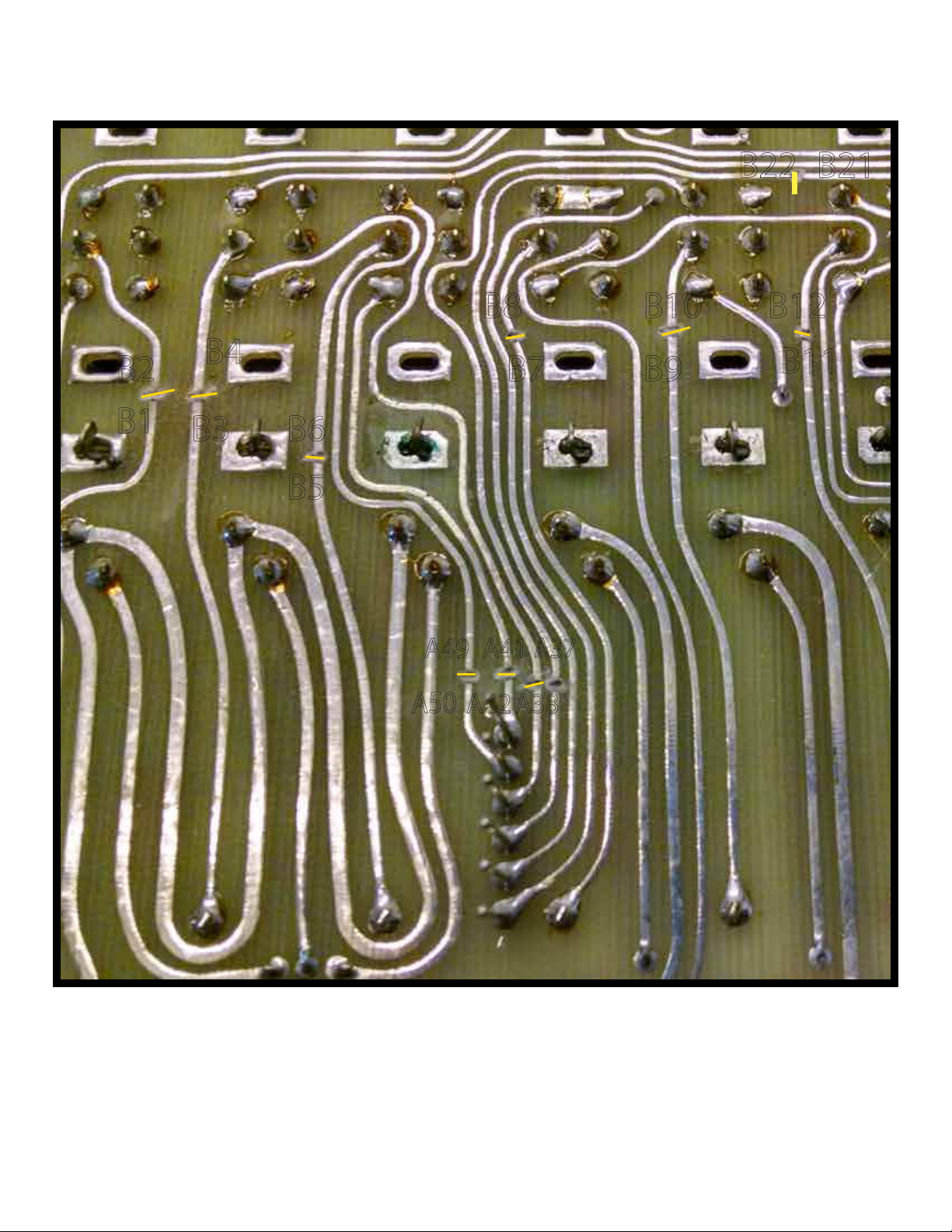

The following pages have diagrams of the circuit boards to be modi-

ed. There are certain conventions that must be followed when using

the diagrams. A cut to the PCB is indicated with a yellow line. Each

cut will require that a wire be tack soldered on to each side of the cut.

A trace that does not need to be cut, but still has a wire attached to it

will be indicated with a yellow dot. A wire will be needed on the oscillator board, and it is indicated by a purple line.

The diagrams have a letter and a number indicating which wires

should be soldered to each point. The letter A indicates that a wire is

on the left front panel PCB cable. The letter B indicates that the wire

is in the right front panel PCB cable. There are 50 wires on each cable. The red wire indicates pin 1. For example, A12 would mean wire

12 on the left front panel PCB cable. Trim the wires in the cables to

the lengths needed to reach the point on the PCB where they will be

soldered.

Page 7

A1

A2

A3

A4

A11

A12

A13

A15

A14

A16

Figure 2.

Board B Top Left

Page 8

A26

A31

A32

A28

A15

A16

A23

A24

A25

A27

A33

A34

Figure 3.

Board B Top Center

Page 9

Figure 4.

Board B Top Right

A30

Page 10

A5

A6

Wire

Figure 5.

Board B Bottom Left

A18

A17

Figure 6.

Board B Bottom Center

Page 11

A9, A10

A35, A36, A39

A40, A43, A44

A47, A48

A7, A8,

A19, A20

A21, A22

Figure 7.

Board B Bottom Right

Page 12

B21B22

B2

B1

B4

B3 B6

B5

A49

A50

B8 B10

A41

A42

B7

A37

A38

B9

B12

B11

Figure 8.

Board C Top Left

Page 13

B23,24

B19

B27,28

A45

B16

B15

B20

A46

B13,14,29,30,33,34,37-50

Figure 9.

Board C Top Center

Page 14

A26

A25

Figure 10.

Board C Top Right

Page 15

B18

B31

B17

Figure 11

Board C Bottom Left

Page 16

VCF Connections

When connecting the VCF portion of the patch panel to the

Avatar PCB, mote that a resistor must be removed, and two

wires of the IDE cable must be connected and soldered together.

Figure 11 has a yellow dotted box to indicate that the 1M resistor in the pcb above must be removed. This can be done

easily if you have a vacuum desoldering tool. We recommend

removing the solder from the PCB side and then using a wire

to gently poke the loose resistor from the mounting holes. Be

sure to recover the old resistor so it isn’t left in the chassis. If

you have removed board C, you can simply clip the resistor

out.

Once the resistor is removed, solder the 1M resistor to the

PCB as shown in gure 11. Attach wire B35 to the other end

of the resistor. Be sure to use some of the heat shrink tubing

included in the kit to prevent exposed metal and shorts.

Now, connect B32 to B36. This can be done using the wires or

simply by connecting those pins on the IDC header.

Reassembly and Testing

Be sure to test all of the functions on the patch panel and

check your work before reassembling the avatar. Take care

not to leave any metal shavings or loose debris in the case before closing.

You’re nished! Enjoy your newly expanded Avatar.

Loading...

Loading...