Page 1

OWNER’S MANUAL

FOR

AR-15 COMBO TOOL

FOR USE ON AR-15, M16, M16A1, M16A2, AND M4

READ ALL INSTRUCTIONS CAREFULLY BEFORE

USING ON ANY FIREARM.

PATENT PENDING

Page 2

CAUTION: ALWAYS PRACTICE SAFE

FIREARMS HANDLING!

BE SURE THAT THE FIREARM IS

UNLOADED

BEFORE PERFORMING

ANY OF THE FOLLOWING

PROCEDURES!

BE SURE THAT THE FIREARM IS

POINTED IN A SAFE DIRECTION AT

ALL TIMES!

ALWAYS FOLLOW THE INSTRUCTIONS

OF THE MANUFACTURER TO AVOID

INJURY OR DAMAGE TO THE

FIREARM!

IF YOU ARE UNSURE ABOUT ANY OF

THE FOLLOWING PROCEDURES SEEK

ASSITANCE FROM A QUALIFIED

PROFESSIONAL!

(1)

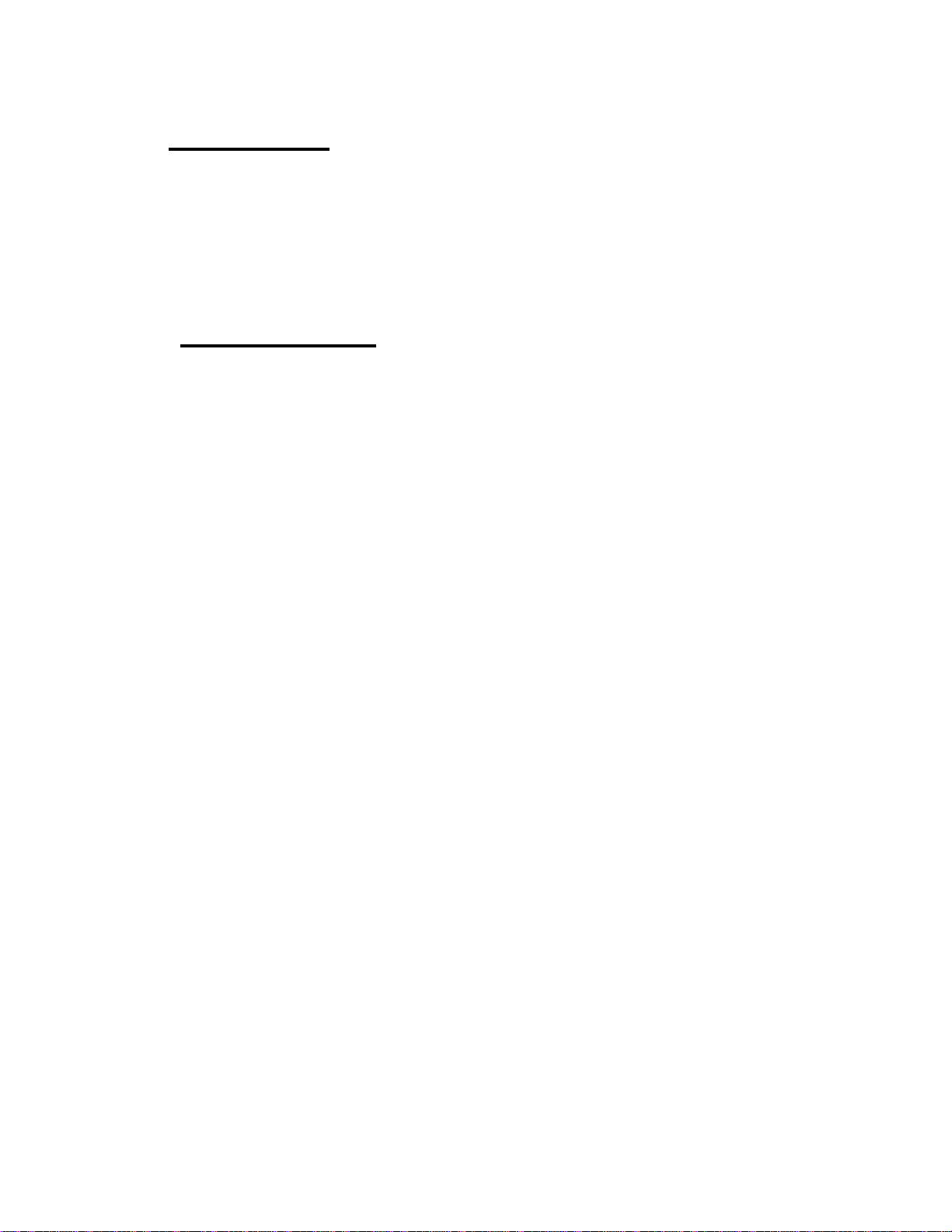

A2 Front Sight Post Wrench

Page 3

The A2 front sight post wrench has 4 pins, and is used to adjust the front

sight post up and down. To use, simply unfold the tool handle, and extend

the A2 front sight post wrench to its outer most position until you feel it lock

into place. Close the tool handle completely. You can now make

adjustments using the wrench. Follow all of the manufacturer’s instructions

for adjusting your particular rifle’s sights. Line up the 4 pins with the sight

post’s 4 holes. Carefully push down and rotate left or right to adjust sight

post for elevation.

(2)

Page 4

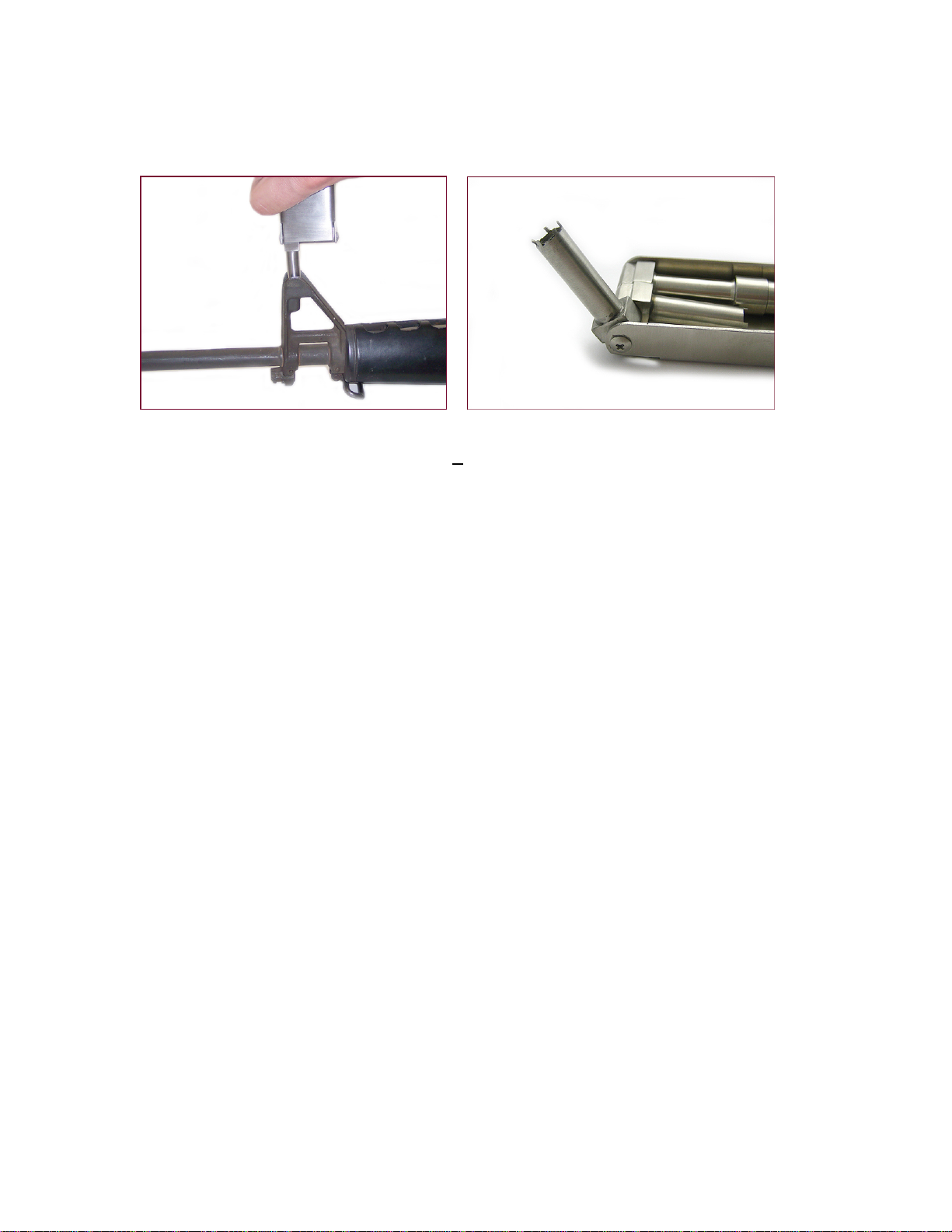

A1 Front Sight Post Wrench

The A1 front sight post wrench has 5 pins, and is used to adjust the front

sight post up and down. To use, simply unfold the tool handle, and extend

the A1 front sight post wrench to its outer most position until you feel it lock

into place. Close the tool handle completely. You can now make

adjustments using the wrench. Follow all of the manufacturer’s instructions

for adjusting your particular rifle’s sights. Line up the 5 pins with the sight

post’s 5 holes. Carefully push down and rotate left or right to adjust sight

post for elevation.

(3)

Page 5

A1 REAR SIGHT TOOL

The A1 rear sight tool will help you adjust for windage to zero your rifle.

To use, extend the rear sight tool until it locks into place. Close the handle

completely. Next, line up the 5 pins on the tool with the 5 holes on the rear

sight adjuster (that is on your AR-15 or M16 handle). Push the tool inward

to release the rear sight locking pin, and rotate the adjuster to move the

aperture left or right.

(4)

Page 6

RECEIVER PIN PUNCH

The receiver pin punch is a necessary tool for field stripping your rifle. To

use, extend the larger sized punch until it locks into place. Close the handle

completely. Set your rifle up in a gun vise or other secure platform so that it

will not be damaged. Line up the punch with the pin on your rifle and

carefully push through until the pin starts to come out. Pull the pin all the

way out on the other side making sure that the lower and upper receivers are

secure. You will now be able to continue field stripping your rifle.

(5)

Page 7

BOLT CARRIER CARBON SCRAPER

The bolt carrier carbon scraper is designed to remove the carbon build up in

the rear space of the bolt carrier that the bolt fits in. To use this tool, first

unfold the tool handle and extend the carbon scraper until you feel it lock

into place. Then, close the tool handle. Next, follow the firearm

manufacturer’s instructions for removing the bolt carrier. Once you have the

bolt carrier stripped down you can carefully insert the scraper. Be sure that

the scraper is properly aligned into the bolt carrier to prevent damage.

Lightly push tool in, and turn the scraper clockwise ONLY. Turning the

scraper counter clockwise can damage the firearm and the tool. Once the

carbon has been loosened it can be removed with a cleaning patch or

cleaning swab.

(6)

Page 8

BORE CLEANING CABLE AND BRUSH

This tool is designed to clean the bore of your rifle. Begin the take down

procedure according to the manufacturer’s instructions. Next, remove the

bore cable from the side pouch. Next, unscrew the bore brush from the

threaded rod attached to the tool. Extend this rod until it locks into place.

Close the tool handle and attach the cable to the threaded rod securely. Use

a bore guide to prevent damage to the breach and chamber surfaces. Run the

cable down the barrel from the breach to the muzzle and attach the patch tip

to the end. Pull a few solvent soaked patches through the barrel using this

method. Remove the patch tip, and run the cable down the barrel from the

breach again. Attach the solvent soaked bore brush and pull through as

many times as needed in order to loosen fouling build-up. Run dry patches

through to remove fouling. Repeat this process as many times as necessary

until the dry patches come out clean.

(7)

Page 9

BOLT CARRIER GAS KEY CLEANING BRUSH

Your bore brush can also be used as a bolt carrier gas key cleaning brush.

Open the tool handle, and extend the bore brush until it locks into place.

Close the tool handle completely. Carefully insert the solvent soaked brush

into the gas key as far as it will go, and turn clockwise to loosen fouling

build-up. Remove fouling using pipe cleaners. Repeat as necessary until

pipe cleaners come out clean.

(8)

Page 10

BOLT ASSEMBLY PIN PUNCH

The bolt assembly punch can be used to remove various pins on your rifle

such as the extractor pin. To use, extend the smaller punch until it locks into

place. Close the handle completely. Be sure to securely hold the bolt in

place and also be certain that the pin will not be damaged as it protrudes

from the other end. Line the punch up with the pin and carefully push it out.

Once the pin starts to protrude from the other side you can then pull it out.

Always make sure that the punch properly fits the pin that you are using it

on as not to damage the pin, bolt assembly pin hole, or the tool itself.

(9)

Page 11

BOLT ASSEMBLY CLEANING BRUSH

Your bore brush can also be used as a bolt assembly cleaning brush. To use,

extend the cleaning brush until it locks into place. Close tool handle

completely. Refer to manufacturer’s instructions for proper disassembly of

bolt. Carefully insert brush into bolt and rotate to loosen fouling. Use a pipe

cleaner to remove loosened fouling. Be careful to clean only as necessary to

prevent damage to the bolt.

(10)

Page 12

BROKEN SHELL EXTRACTOR

This tool will help you clear a broken shell case that is lodged in your barrel.

To use, remove the entire shell extractor unit (3 pieces) from the base of the

tool handle. Be sure that all 3 pieces are still attached and that the extractor

pin is not tight so it does not cause the end to flare. Lock the action of your

rifle in the open position. Next, drop the shell extractor tool into the

chamber (pin side towards the muzzle) and close the action. Cycle the

action to remove the broken shell extractor with the broken shell attached.

Repeat if necessary. Unscrew the inner pin to remove the broken shell

casing from the extractor tool.

(11)

Page 13

A4/M4 COLLPASIBLLE STOCK WRENCH

This 3 prong wrench is designed to remove and install A4 and M4

collapsible stocks. To use, open tool handle and rotate 180 degrees until the

handle is closed and the wrench is extended. Line up the prongs with the

indentations on the stock’s castle nut. Then slide the wrench over the castle

nut. Follow the firearm manufacturer’s instructions for proper removal and

installation of the stock.

(12)

Page 14

LARGE FLAT-HEAD SCREW DRIVER

The large flat head screw driver can be used for various tasks on your rifle.

It can be used to remove or install the pistol grip, butt stock, and swivel

sling. It can also be used as a carbon scraping tool. Use extreme care when

removing carbon from rifle components. Scraping with to much pressure

can cause damage to rifle surfaces. To use, extend the screw driver until it

locks into place, then close the tool handle completely. Use as necessary to

remove flat head screws and for scraping.

(13)

Page 15

THE AR-15 COMBO TOOL

IS PATENT PENDING AND A TRADE MARK OF

NcSTAR

FOR TECHNICAL ASSISTANCE CALL 1-866-NcSTAR-8

(1-866-627-8278)

WWW.NCSTAR.COM

Loading...

Loading...