NCSPA Pipe Arches, Corrugated Steel Pipe, Structural Plate Installation Manual

Installation

Manual for

➤ Corrugated Steel Pipe

➤ Pipe Arches

➤ Structural Plate

NATIONAL CORRUGATED STEEL PIPE ASSOCIATION

08 InstallMan00

INSTALLATION MANUAL — NCSPA

The NCSPA Installation Manual is not a copyrighted publication.

If excerpted or copied, credit to the source would be appreciated.

* * *

The information contained in this Installation Manual is the

product of industry experience and practice. The methods used

to install corrugated steel pipe can affect both its effectiveness

and useful life. The situations described in this publication and

the suggested techniques for installation are general suggestions and guidelines intended to alert installers to the need for

careful review of on-site conditions. Each installation will

require its own individual evaluation. The statements or

descriptions provided herein are for general information only.

The National Corrugated Steel Pipe Association assumes no

responsibility for their use.

* * *

N

ATIONAL CORRUGATED STEEL PIPE ASSOCIATION

1255 Twenty-Third Street, NW, Suite 200

Washington, DC 20037-1174

Phone: 202/452-1700 • Fax: 202/833-3636

E-mail: csp@ncspa.org • Web: www.ncspa.org

TABLE OF CONTENTS

FOREWORD .............................................................................................. 3

BASIC PRINCIPLES FOR PROPER

CONSTRUCTION AND INSTALLATION............................................. 4

LOCATION................................................................................................. 5

EXCAVATION............................................................................................. 5

Embankment Condition.................................................................. 5

Trench Condition............................................................................ 5

Trench Width and Shape ................................................................ 6

PREPARING FOUNDATIONS................................................................. 7

Handling Poor Foundations............................................................ 7

Uneven Foundations....................................................................... 8

Soft Foundations............................................................................. 9

Pockets of Unstable Soil ................................................................ 9

Swampy Foundations................................................................... 10

Improved Foundations.................................................................. 10

Settlement Under High Fill Loads............................................... 10

Rock Foundations......................................................................... 11

Arch Foundations......................................................................... 11

ASSEMBLY............................................................................................... 12

Unloading and Handling .............................................................. 12

Connecting Bands ........................................................................ 12

Installing Connecting Bands ........................................................ 12

Typical Connecting Bands ........................................................... 14

Gaskets ......................................................................................... 16

Mastic........................................................................................... 17

Asphalt Coated Pipe..................................................................... 17

Paved-Invert Pipe.......................................................................... 17

Full Lined Pipe............................................................................. 18

Polymer Coated Pipe .................................................................... 18

Pipe Arch...................................................................................... 18

Field Coated Structural Plate Structures...................................... 18

Structural Plate Structures ............................................................ 18

Tools Required ............................................................................. 19

Erection ........................................................................................ 19

Long Span Structures................................................................... 21

Lifting Assistance......................................................................... 21

End Treatment.............................................................................. 21

Cut End......................................................................................... 22

CSP Installation Manual 1

08 InstallMan00

ASSEMBLY (continued)

Cut-Off Walls ............................................................................... 23

End Sections................................................................................. 24

Other End Finishes....................................................................... 24

Stream Diversion .......................................................................... 24

BACKFILLING ........................................................................................ 25

Backfill Material........................................................................... 25

Placing the Backfill...................................................................... 25

Pipe Arches................................................................................... 30

Arches........................................................................................... 30

Large Diameter Structures ........................................................... 32

Proper Material Placement........................................................... 32

Even Placement of Backfill.......................................................... 33

Shape Control............................................................................... 33

Multiple Installations.................................................................... 34

Long Span Structures................................................................... 35

Final Backfilling........................................................................... 35

COMPACTION EQUIPMENT............................................................... 35

Hand Compaction......................................................................... 35

Mechanical Compactors............................................................... 36

Roller Compactors........................................................................ 36

Vibrating Compactors .................................................................. 36

Hydraulic Compaction ................................................................. 36

Structure Protection ...................................................................... 36

Construction Loads ...................................................................... 37

Hydraulic Protection .................................................................... 38

SUMMARY............................................................................................... 40

SUBDRAINAGE ....................................................................................... 41

Underdrain Pipe............................................................................ 41

Flow Line ..................................................................................... 41

Preparing the Foundation ............................................................ 41

Assembly of Underdrain Pipe...................................................... 41

Proper Placement of Underdrain Pipe.......................................... 42

APPENDIX................................................................................................ 44

Culvert Grades and Outfall Treatment ......................................... 44

Length of Culverts........................................................................ 44

Skew Number............................................................................... 47

National Corrugated Steel Pipe Association 2

FOREWORD

This manual is intended for both the contractor and the engineer. It provides

practical information for the installation of corrugated steel pipe as storm

sewers or culverts. It also provides the necessary considerations for proper

design to achieve long term performance of the culvert or storm sewer.

Corrugated steel pipe with its high load carrying capacity, strong joints and

exceptional beam strength is installed more easily than other types of conduit. However, the correct installation procedures must be followed to insure

full investment value in the structure.

It is the intent of this manual to suggest ways and means of improving

installation practices. It is not intended to be used as a direct specification, but rather as a practical field guide for the installation of corrugated steel pipe, pipe arch and structural plate.

Too much emphasis cannot be placed on the necessity of adequate

compaction of backfill. Faulty compaction has led to more trouble with

pipe installations, flexible and rigid, than all other factors combined!

OSHA safety regulations and guidelines must be observed during all phases

of construction including foundation preparation, excavation, pipe handling,

assembly and backfilling.

Additional information is available in the AISI Handbook of Steel Drainage

and Highway Construction Products and ASTM Specifications A 798 and

A 807.

This manual uses dual units of measure with Imperial units shown first followed by metric units in parentheses. Complex drawings or tables may be

duplicated in metric.

CSP Installation Manual 3

BASIC PRINCIPLES FOR PROPER

CONSTRUCTION & INSTALLATION

Project plans and specifications provide the basic requirements for construction and installation. However, site conditions often vary from those anticipated during design. The contractor and construction engineer must recognize these variations. Often, alternate or additional construction considerations are necessary. The following guidelines provide specific considerations

and details for various conditions in a step-by-step construction sequence.

The following summary will appear again near the end of the manual.

However review it now as a basic outline of the steps required for a proper

installation:

1) Check alignment in relation to the plans as well as the

actual site conditions.

2) Make certain the pipe length(s), necessary appurtenances,

etc. are correct.

3) Excavate to the correct width, line and grade.

4) Provide a uniform, stable foundation—correct site conditions as necessary.

5) Unload, handle and store the pipe correctly.

6) Assemble the pipe properly—check alignment, follo w special procedures for the connecting bands, gaskets, and

other hardware used. (For structural plate structures,

achieve properly aligned plate laps, bolt torque, and

assembled dimensions.)

7) Use a suitable (granular) backfill material as required in

the plans and specifications.

8) Maintain proper backfill width.

9) Haunch the pipe properly.

10) Place and compact the backfill in 6 to 8 inches (150 to 200

millimeters) of thickness of compacted lifts.

11) Install the necessary end treatment quickly to protect the

pipe and your efforts.

12) Protect the structure from heavy construction equipment

loads, other heavy loads and hydraulic forces.

4 National Corrugated Steel Pipe Association

LOCATION

Before installing any drainage structure, it is best to first recheck the planned

alignment and grade (position and percent of slope) of the pipe in relation to

the topography of the site. Even when complete construction plans are supplied, a careful examination of the site should be made.

EXCAVATION

Embankment Condition

The only excavation typically required for an embankment condition is to

remove the topsoil, muck and organic matter and prepare a stable foundation

at the proper elevation and grade.

Trench Condition

Most storm sewers are installed in trenches. Although pipes can be easily

installed in a trench, there are some general guidelines that should be followed.

All trench excavation should proceed only after OSHA and other safety

requirements are met. Trench excavation normally proceeds in the upgrade

direction. Most trenching equipment is more efficiently operated in this manner, and pipe sections are also more easily joined when progressing in this

direction. If excavated spoil is to be used as backfill, it should be stockpiled

at a safe distance from the edge of the trench. As a general rule, when trench

walls are unsupported, the distance from the trench edge to the toe of the

stockpiled material should not be less than one-half the depth of the trench.

When trench walls are protected by some form of sheeting or shoring, a safe

minimum distance between the trench edge and stockpiled material must still

be maintained, but will vary with soil and bracing types.

Care should always be exercised in the operation of equipment in the vicinity of an open trench. Operated too close to the trench, equipment weight and

vibration may collapse the trench walls. The three phases of construction in

a trench (excavation, pipe installation, and backfilling) should be scheduled

in close sequence with each other. An open trench is dangerous and vulnerable to accidents. An open excavation can result in damage to the project

under construction. The two main hazards that must always be considered in

trenching work are:

➤ Stability of trench walls; and

➤ W ater that may accumulate in the trench resulting from seepage and

surface runoff.

CSP Installation Manual 5

T o minimize accidents and losses resulting from trenching operations the following procedures should be followed:

➤ Begin excavation only when installation of pipe can immediately

follow.

➤ Protect trench walls to insure their stability throughout the con-

struction period.

➤ Follow procedures that will keep the trench free of seepage and sur-

face waters.

➤ Excavate the trench at the same rate as pipe installation with a min-

imum distance, as dictated by safety, separating the two operations.

➤ Backfill the trench as soon as practicable after pipe installation.

Trench Width and Shape

The width and shape of the trench should be as shown on the plans. Any

change should be approved by the Engineer.

Generally, the trench width will be specified as 12 to 48 inches (300 to 1200

millimeters) wider than the pipe. However, it must be wide enough to allow

the critical lower quadrants of the pipe to be properly backfilled (haunched).

Figure 16 provides guidelines about minimum spacing between multiple

structures. These same guidelines can be used to provide the necessary width

between the pipe and trench wall to adequately place typical backfill. Lesser

spacing may be used with slurries and other backfill materials that do not

require mechanical compaction.

6 National Corrugated Steel Pipe Association

PREPARING FOUNDATIONS

Foundation requirements should be detailed on the plan sheets. However,

field conditions often vary requiring special attention and alterations that are

discovered only during excavation. Any alterations should first be approved

by the Engineer.

Although corrugated steel drainage structures can experience some uneven

settlement without disjointing or breaking, they should be placed on a firm,

uniform foundation for best performance and long service life.

All storm sewers and culverts must be installed with the area under the

haunches well compacted and all voids filled.

For corrugated steel pipe, the most popular method of preparing the foundation is by excavating to a flat surf ace and then carefully tamping the fill under

the haunches of the pipe. Proper backfill density can be achieved by compacting the soil with a wooden pole, 2 x 4, or the smaller sizes of pneumatic

tampers to eliminate all voids under the structure. See Figure 1 for typical

methods of bedding corrugated steel structures and the 2 x 4 description.

This “flat foundation” technique works well except for larger pipe-arches

and horizontal ellipses. The vee-shaped bedding technique for these structures is shown in Figure 12.

All pipe must be placed on stable earth or fine granular foundation. Never

install them on sod, frozen earth or on a bed that contains large boulders or

rock. When poor foundations with low bearing strength are encountered,

investigate the possibility of a change in pipe location. Otherwise, it may be

necessary to stabilize the poor foundation by a method described in the next

section.

Care must be taken to prevent water leaking through the fill or along the

pipe. When granular materials have been added for bedding, the ends of the

fill should be sealed against infiltration. This can be done by bedding the

ends in well compacted clay or by adding some type of end treatment such

as an end section or a cut off wall.

Handling Poor Foundations

If poor or non-uniform foundations are encountered, they must be treated

correctly to assure satisfactory results. The critical factor is to achieve uniformity along the pipe with a tendency for the foundation to yield under the

pipe in relation to alongside the pipe.

CSP Installation Manual 7

Uneven Foundations

When the excavated grade line reveals both soft and hard spots, the foundation must be changed to make it as uniform as possible. Sometimes hard

spots can be excavated below grade and replaced with softer material.

Alternatively, it may be more economical to excavate the entire foundation

slightly below grade line and replace it with suitable, uniform material. In

any event, any abrupt changes from hard to soft foundation must be avoided.

8 National Corrugated Steel Pipe Association

Figure 1. Methods for attaining proper compaction under haunches of CSP

and pipe-arch.

*Note: When tamping with a 2 x 4, the designation of 2 x 4 will remain in

usage as a descriptive expression without conversion to metric. It

represents an approximate lumber cross-section of 40 by 90 millimeters.

Soft Foundations

When soft, unstable material is encountered at the foundation level, it must

be excavated below the flow line grade and backfilled to grade with sand,

gravel, crushed stone or other suitable material. The zone of select material

must be adequate to support the pipe and backfill. When unexpected materials are encountered, consult the Engineer.

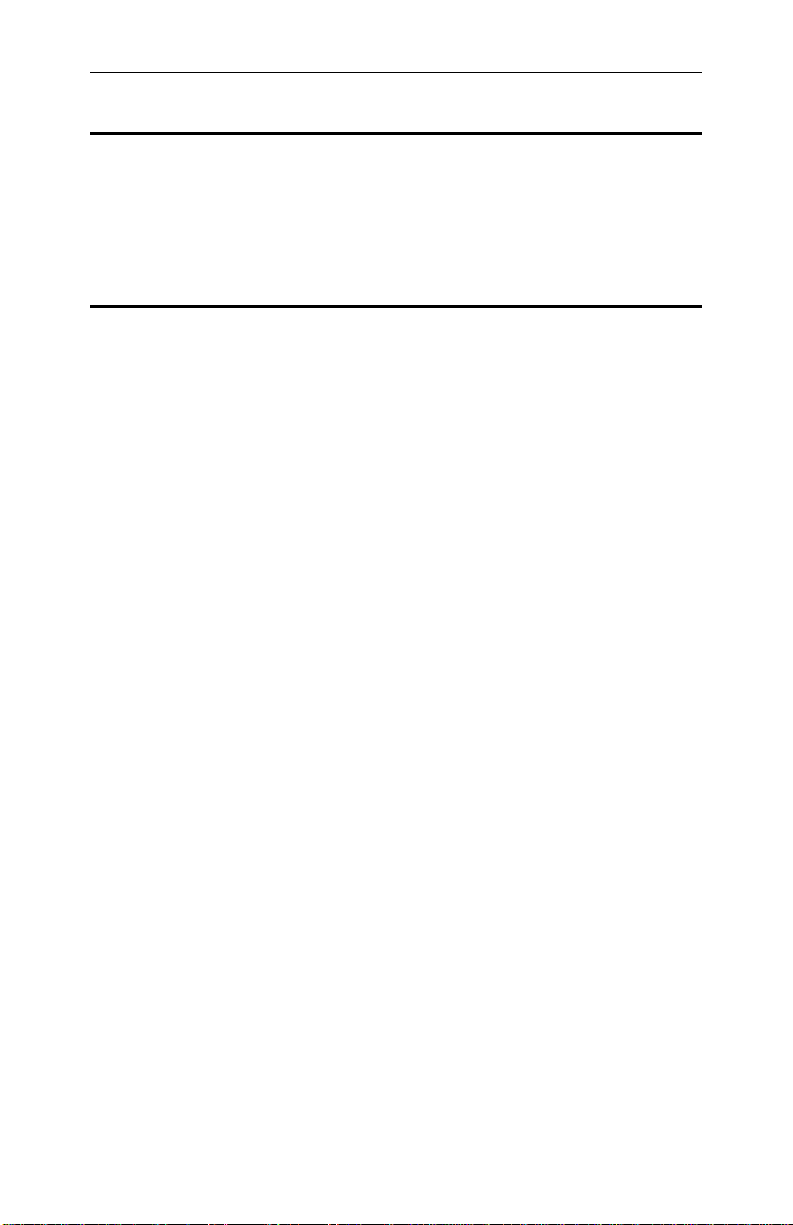

Pockets of Unstable Soil

If unstable foundation material is in small pockets, it is best to excavate all

of the poor foundation and replace it with suitable backfill material.

Frequently, a relatively thin mat of granular material will provide satisfactory support, but it may be necessary to replace v ery soft foundations to a depth

great enough to support not only the pipe, but also the hea vier backf ill placed

beside it.

CSP Installation Manual 9

Figure 2.

Direction of desired relative movement shown by arrows.

Treatment for Soft Foundations

Swampy Foundations

Corrugated steel pipe must not be placed in direct contact with pipe bents or

concrete cradles that are installed to help provide a foundation. Such supports, if used, should be built with a flat top and covered with an earth cushion. In this way the flexible structure can develop side support without concentrating the load at any point.

Improved Foundations

(soft, uneven, unstable or swampy)

Whenever a foundation is stabilized by using a coarse granular material, consideration of the bedding and backfill material becomes even more important. Fine materials can migrate into coarser materials and geotextile separators are often required to prevent this migration.

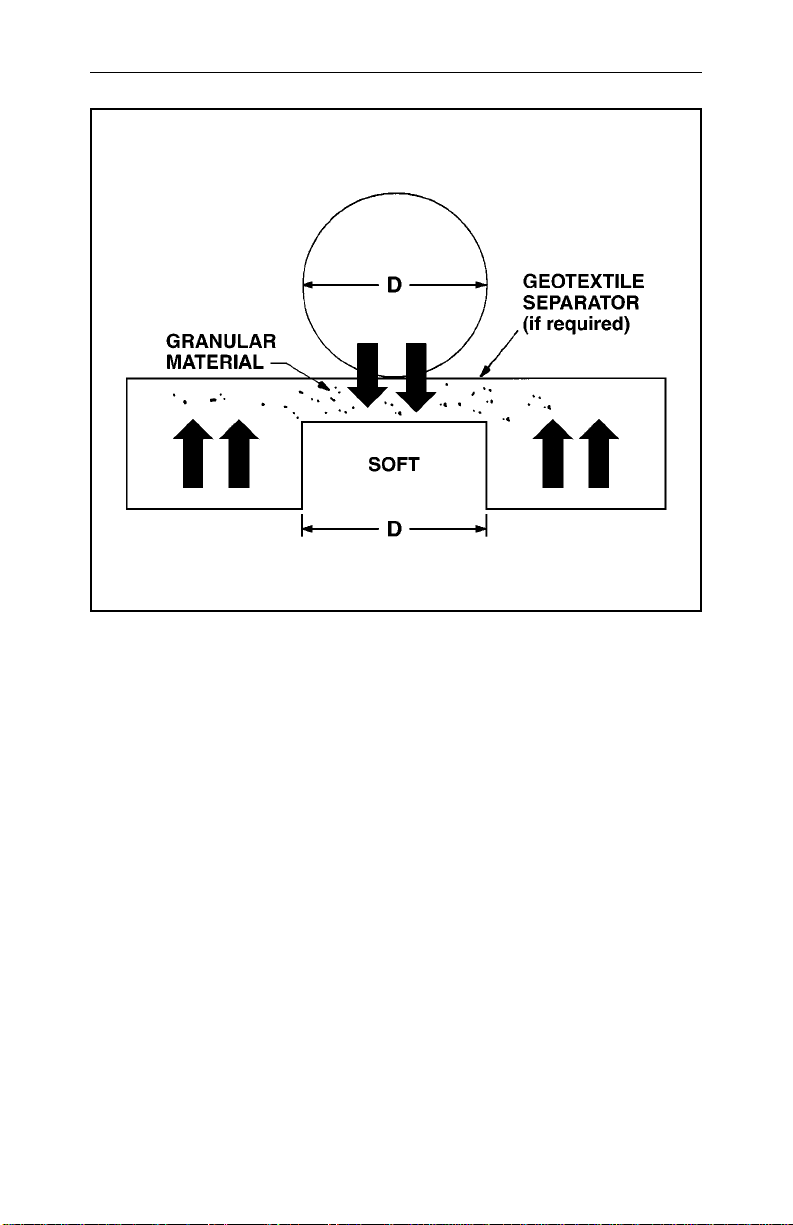

Settlement Under High Fill Loads

(camber for embankment installations)

Cambering the center part of the foundation will compensate for unequal settlement under the weight of heavy embankments. This assures proper grade

after settlement and prevents the structure from sagging in the middle as the

foundation consolidates. Generally, sufficient camber can be obtained by

installing the upstream half of the pipe on a flat grade and the downstream

half on steeper than normal grade as shown in Figure 3. If camber is considered necessary based on foundation soil conditions, the amount of camber

10 National Corrugated Steel Pipe Association

Figure 3. Correct method of cambering pipe to compensate for unequal settle-

ment under high fills. Should be in accordance with procedure given

in the AISI Handbook of Steel Drainage and Highway Construction

Products.

must be determined by a qualified soils engineer. If the pipe is setting on

cushioned rock or other adequate strength foundation, no camber is necessary, as settlement will be minor.

Be careful not to raise the center of the pipe above the inlet, as this will pocket water in the pipe.

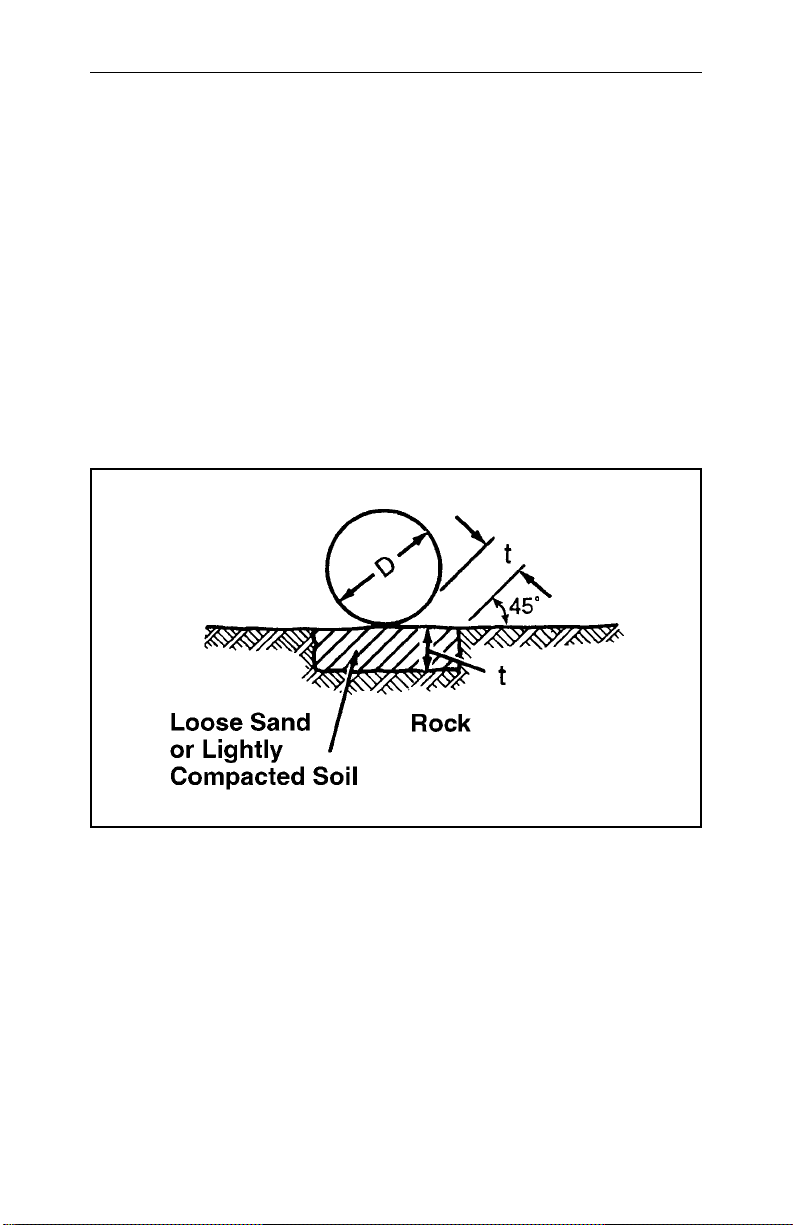

Rock Foundations

Rock encountered in the foundation must be removed to provide more than

the minimum bedding thickness underneath the bottom of the structure.

Excavate wide enough to av oid any possibility of the pipe resting on rock and

provide access to adequately haunch the pipe as shown in Figure 4. The e xcavated area is then backfilled with compacted,granular soil to cushion the pipe.

Arch Foundations

Arches differ from other structural plate structures in that they are generally

erected on concrete foundations. The key way or unbalanced channel in

which the arch rests must be accurately built to the proper line, grade and

spacing for easy assembly of the plates. The unbalanced channels must be

carefully located to insure that the holes correctly align with those in the

plates to permit bolting. They must be properly oriented (angled) to receive

the plate.

CSP Installation Manual 11

Figure 4. Method of handling rock foundations. t = 1/2 inch (13 millimeters) per

foot (.30 meter) of fill over pipe,with 24 inches (.60 meter) the maximum.

ASSEMBLY

Unloading and handling

Pipe must never be dumped directly from a truck bed while unloading.

Although corrugated steel drainage structures withstand normal handling

they should be handled with reasonable care. Dragging the pipe at any time

may damage the coatings. Also avoid striking rocks or hard objects when

lowering pipe into trenches.

Since corrugated steel pipes are relatively light weight, they can be handled

with light equipment. Use of slings is recommended to properly handle the

pipe.

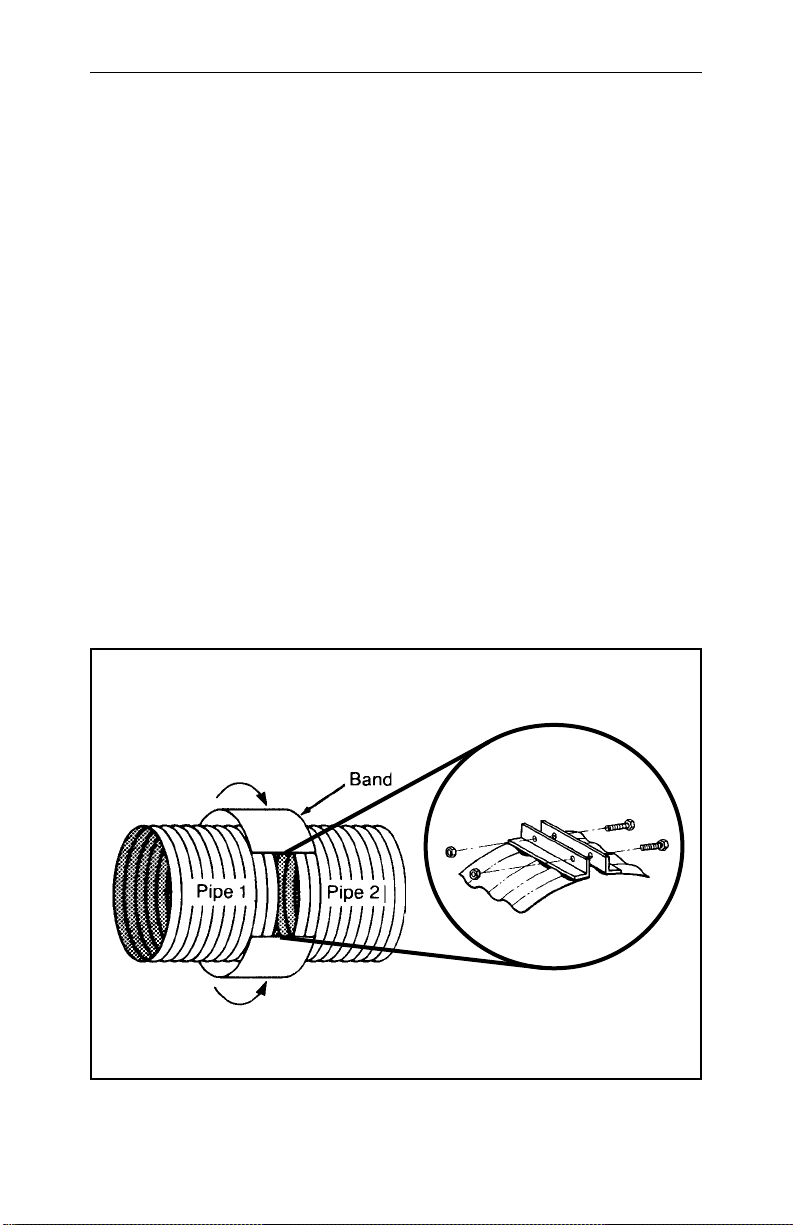

Connecting Bands

The usual method of joining two or more lengths of pipe or pipe arch is by

steel connecting bands. The bands engage the ends of each pipe section. They

are placed to overlap each pipe section equally. The corrugations on the band

must fit into the corrugations of each pipe. Tightening of bolts draws the

band tightly around the adjacent ends of pipe lengths, providing an integral

and continuous structure.

One piece bands are used for most installations of smaller sizes of pipe.

“Two-piece” bands are used on larger diameter pipe and when installation

conditions are difficult. “Rods and Lugs” are used on levees, aerial sewers

and similar installations where bands that provide tighter and stronger joints

are essential.

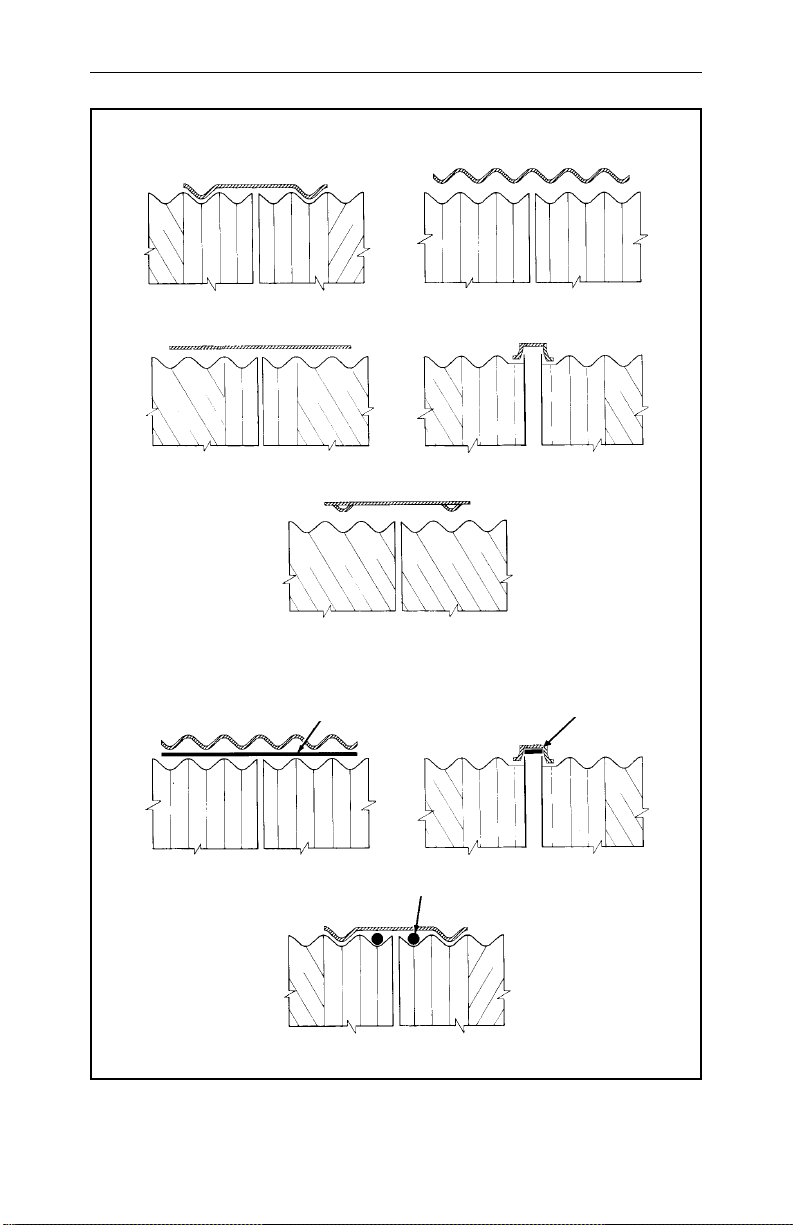

Typical bands, and their method of installation, are illustrated in Figures 4A

to 4E. Specially fabricated bolted, welded or riveted connectors can be supplied for use in jacking and for special or unusual conditions. If the pipe ends

have been match marked by the fabricator, then they must be installed in the

proper sequence.

Installing Connecting Bands

During the construction of a corrugated steel pipe system, care must be giv en

to the assembly of joints to control both infiltration and exfiltration. Both

processes will have an effect upon backfill materials since soil particle

migration can occur. This is particularly true when fine “rained soils (fine

sands and silts) are present in the backfill material. When necessary, a gasket, a geotextile wrap,or both can also be used to control infiltration of fines.

12 National Corrugated Steel Pipe Association

Bands are put into position at the end of one section of pipe with the band

open to receive the next section. The next section is brought against or to

within 1 inch (25 millimeters) of the first section. After checking to see that

connecting parts of both band and pipe sections match, that the interior of

bands and exterior of pipe are free of dirt, stones, etc., bolts are inserted and

tightened.

To speed the coupling operation, especially for large diameter structures, a

cinching device will help draw the band up tight. Special coupling devices

can be used to fit over the connecting bands and quickly draw them together. Advantage of these devices is that they permit faster hand-tightening of

the bolts, so that a wrench is needed only for final tightening.

On large diameter pipe and asphalt coated pipe, merely tightening bolts will

not assure a tight joint, due to the friction between the band and the pipe

ends. In such installation, tap the band with a mallet to take up the slack as

the band is tightened.

The wrench used to tighten coupling bands may be a deep socket or ratchet

wrench for greater speed.

CSP Installation Manual 13

Figure 4A. Typical connecting band is wrapped around the joint and drawn

together.

Band Angle Connector

14 National Corrugated Steel Pipe Association

Figure 4B. Standard and Gasketed couplers for corrugated steel pipe.

Standard Couplers

Gasketed Couplers

Semi-Corrugated (Hugger) Corrugated (Annular)

Corrugated (Annular)

Sleeve Gasket Mastic or Gasket

O-Ring

Semi-Corrugated (Hugger)

Hat

Flat Hat

Universal*

*Unless a dimple fills

each corrugation

valley, a suitable

gasket or geotextile

wrap is required

Loading...

Loading...