NCR RealScan 7875-7000, RealScan 7875-8000 Installation Manual

RealScan 7875-7000/8000

Installation Guide

AIP-00342

Release C

Aug 16, 2007

Information Products

RSD-Atlanta

16044

NCR RealScan 7875-7000/8000 Installation Guide

The program products described in this book are licensed products of NCR Corporation. It is the

policy of NCR to improve products as new technology, components, software, and firmware

become available. Therefore, NCR reserves the right to change specifications without prior

notice. All features, functions, and operations described herein may not be marketed by NCR in

all parts of the world. Therefore, before using this document, consult your NCR representative or

NCR office for information that is applicable and current.

NOTE: Connection of EPOS/PC terminals to weighing or measuring devices requires

governmental approval before the connected devices can by placed into service for retail trade.

Before connecting any NCR device to a retail weighing or measuring system contact the NCR,

Weights and Measures Coordinator, Retail Atlanta to authenticate that NCR Certificates of

Conformance/Approval are not infringed.

06/03 AIP-00342 Release B

2 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Contents

Contents..........................................................................................................................................3

Revision Record..............................................................................................................................5

Obtaining Additional Information..................................................................................................5

Obtaining Technical Assistance......................................................................................................6

System Components .......................................................................................................................7

NCR Components......................................................................................................................7

Sensormatic Components...........................................................................................................7

Step 1 – Verify and Prepare the Checkstand ..................................................................................8

Checkstand Cutout – RealScan 7875-7000/8000......................................................................8

Service Clearance.......................................................................................................................9

Item Diverter..............................................................................................................................9

Ventilation Requirements.........................................................................................................10

Electrical Wiring to the Checkstand ........................................................................................11

Specific Checkstand Modifications..........................................................................................12

Sensormatic Equipment ...........................................................................................................12

Step 2 – Connect the Components................................................................................................13

Install Sensormatic Antenna ....................................................................................................13

Connect Sensormatic Cables....................................................................................................14

Connect Remaining Components.............................................................................................15

Set the Communications Protocol Switch................................................................................16

Step 3 – Sensormatic Deactivation Setup.....................................................................................17

Power up the System................................................................................................................17

Specific Function Programming ..............................................................................................18

Step 4 – Install RealScan 7875.....................................................................................................19

Install RealScan 7875...............................................................................................................19

Align the RealScan 7875 to the Checkstand............................................................................20

Step 5 – Calibrate the Scale..........................................................................................................22

Set Scale AC Voltage Frequency.............................................................................................22

Exercise the Scale ....................................................................................................................22

Access the Calibration Switch .................................................................................................23

Calibrate the Scale ...................................................................................................................24

Verify the Calibration ..............................................................................................................24

Secure the Calibration Switch..................................................................................................26

Step 6 – Set Program Parameters..................................................................................................27

Setting the Program Parameters...............................................................................................27

Step 7 – Check the Scanner Operation .........................................................................................28

Scan Sample Tags....................................................................................................................28

Check Sensormatic Deactivation System.................................................................................29

Call Sensormatic......................................................................................................................29

Operating the Scanner...................................................................................................................30

AIP-00342 Release B 06/03

3 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Operating the Scale.......................................................................................................................31

Operating the Sensormatic Deactivation System..........................................................................32

Normal Operation ....................................................................................................................32

Manual Deactivation................................................................................................................33

Cleaning the RealScan 7875......................................................................................................... 34

Correcting Scanner Problems .......................................................................................................35

Correcting Scale Problems............................................................................................................36

Isolating Sensormatic Problems....................................................................................................37

Voice Messages........................................................................................................................37

Tones........................................................................................................................................37

Programming Worksheets.............................................................................................................38

1 0 – Communications Protocol...............................................................................................38

1 1 – Good Read Tone.............................................................................................................38

1 2 – Timers.............................................................................................................................39

1 3 – Bar Codes - 1 ..................................................................................................................39

1 4 – Bar Codes - 2 ..................................................................................................................40

1 5 – Bar Codes - 3 ..................................................................................................................41

1 7 – Bar Codes - 4 ..................................................................................................................41

1 8 – Bar Codes - 5 ..................................................................................................................42

1 6 – Label Identifiers..............................................................................................................42

2 0 – RS-232 Parameters - 1 ....................................................................................................43

2 1 – RS-232 Parameters - 2 ....................................................................................................43

2 2 – RS-232 Prefix Byte.........................................................................................................44

2 3 – RS-232 Terminator Byte.................................................................................................44

2 4 – RS-232 Communications Options...................................................................................44

3 0 – Scale Parameters.............................................................................................................45

3 2 – Miscellaneous Parameters...............................................................................................45

3 6 – Dual Cable Interface Options..........................................................................................45

ASCII Code Chart....................................................................................................................46

Appendix A – Pan-Oston PO-2 ....................................................................................................47

Appendix B – Pan-Oston PO-2.....................................................................................................48

Appendix C – Pan-Oston PO-4.....................................................................................................49

Appendix D – Regulatory Information.........................................................................................50

Federal Communications Commission (FCC) Radio Frequency Interference Statement.......50

Voluntary Control Council for Interference (VCCI) Radio Frequency Interference Statement50

Canadian Department of Communications Radio Frequency Interference Statement............50

Scale Regulatory......................................................................................................................51

Declaration of Conformity.......................................................................................................52

Laser Safety .............................................................................................................................53

06/03 AIP-00342 Release B

4 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Revision Record

Date Issue Pages Remarks

05/13/03 A 1 though 54 First Printing

06/02/03 B 12, 17, 29, 33 Updated to latest Sensormatic requirements

8/16/2007 C 20 Updated scale alignment section

Obtaining Additional Information

Order Number Title

497-0001843 NCR RealScan 7875 Installation/Owner Guide

B005-0000-1085 NCR RealScan 7875 User Guide

B005-0000-1086 NCR RealScan 7875 Repair Guide

BST0-2121-74 NCR Scanner Programming Tags

BD20-1074-A NCR Scanner/Scale Interface Programmer's Guide

Web Sites

• http://inforetail.AtlantaGA.NCR.COM

(NCR only)

• http://www.info.NCR.COM (Anyone)

Online Order

• Connect System (NCR only)

Phone Order

• 800-543-2010 (US area)

• 622-3727 (VOICEplus)

• 44-181-242-5350 (International)

Fax Order

• 937-445-6245 (US area)

44 (0) 20 8 242 5355 (International)

Other Information Products

How To Obtain Information Products

E-Mail

• IP136695@exchange.DaytonOH.ncr.COM

(US area)

• M0500005@exchange.UnitedKingdom.NC

R.COM (International)

Mail Order

• NCR Corporation IPP-Dayton

1529 Brown St.

IPP EMD-2

Dayton, OH 45479

USA

• NCR Corporation

915 High Road

North Finchley

London N12 0HN United Kingdom

AIP-00342 Release B 06/03

5 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Technical assistance is available as follows.

• Technical assistance in the United States: 1-800-262-7782

• Technical assistance in other countries: call your local NCR office

• To order parts: 1-800-438-7830

Note: If you find any defective parts during installation of a new scanner, contact the Customer

Satisfaction Hotline at one of the following.

• Phone: 1-800-528-8658 (USA)

• Phone: 770-623-7400 (International)

• E-mail: CustomerSat.Retail@NCR.com

Obtaining Technical Assistance

06/03 AIP-00342 Release B

6 of 56

NCR RealScan 7875-7000/8000 Installation Guide

System Components

NCR Components

Following are the required NCR components.

• NCR RealScan 7875-7000/8000

• Power Supply with Power Cord

• Interface Cable – appropriate for host terminal

• Sensormatic Communications Cable – 1416-C841-030

The RealScan 7875 is shipped with Shipping Spacers that must be removed before installing the

unit.

Sensormatic Components

Following are the required Sensormatic components.

• Sensormatic ScanMax

• Sensormatic ScanMax

Shipping Spacers (2)

TM

Pro Controller – ZBSMPRO – with software version 6.6 or higher

TM

NS Pro Antenna – ZBSMPNS

20790

AIP-00342 Release B 06/03

7 of 56

NCR RealScan 7875-7000/8000 Installation Guide

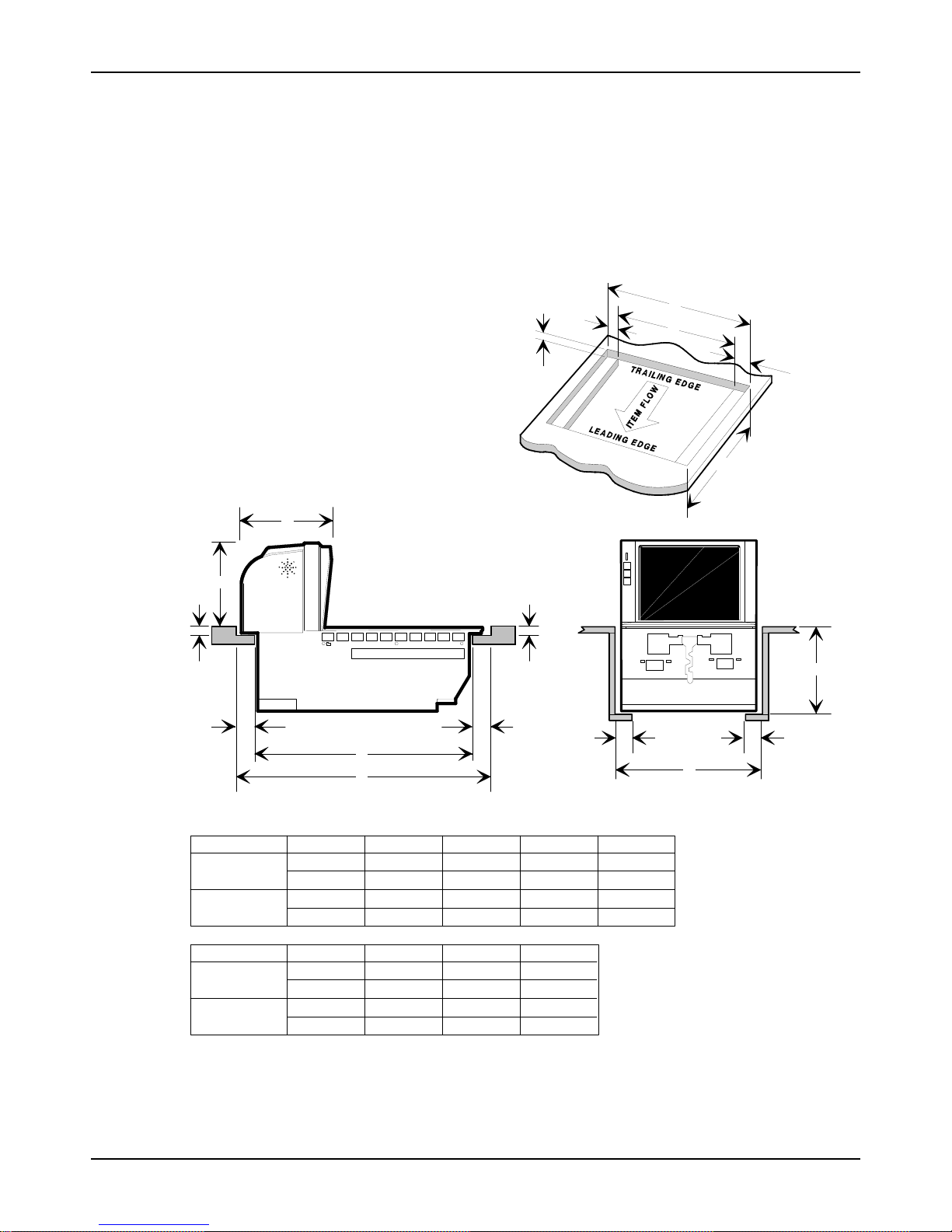

Checkstand Cutout –

RealScan 7875-7000/8000

Step 1 – Verify and Prepare the

Checkstand

I

H

D D

C C

E

B

C

D

*

F

No electronics under RealScan 7875

B

E

C

A

G

F

A

7875-7200

Scanner

7875-8200

Scanner/Scale

7875-7200

Scanner

7875-8200

Scanner/Scale

11 5/8 in.

29.51 cm

12 1/16 in.

30.63 cm

1 3/8 in.

3.49 cm

1 3/8 in.

3.49 cm

06/03 AIP-00342 Release B

8 of 56

ABCD E

20 1/16 in.

50.95 cm

20 1/16 in.

50.95 cm

FG

7 1/8 in.

18.1 cm

7 1/8 in.

18.1 cm

1 3/8 in.

3.49 cm

1 3/8 in.

3.49 cm

HI

7 3/8 in.

18.73 cm

7 1/4 in.

18.42 cm

3/8 in.

0.95 cm

1/2 in.

1.27 cm

7 1/4 in.

18.42 cm

7 1/4 in.

18.42 cm

17 5/16 in.

43.97 cm

17 5/16 in.

43.97 cm

Note:

Note:

*

Recommended shelf to catch

RealScan 7875 if dropped

during installation.

Dimension A for a 7875-7200

includes a spacer along each side

of the unit so that it fits an existing

7870-2000 cutout.

Dimension H includes a

Produce Guard.

20551

NCR RealScan 7875-7000/8000 Installation Guide

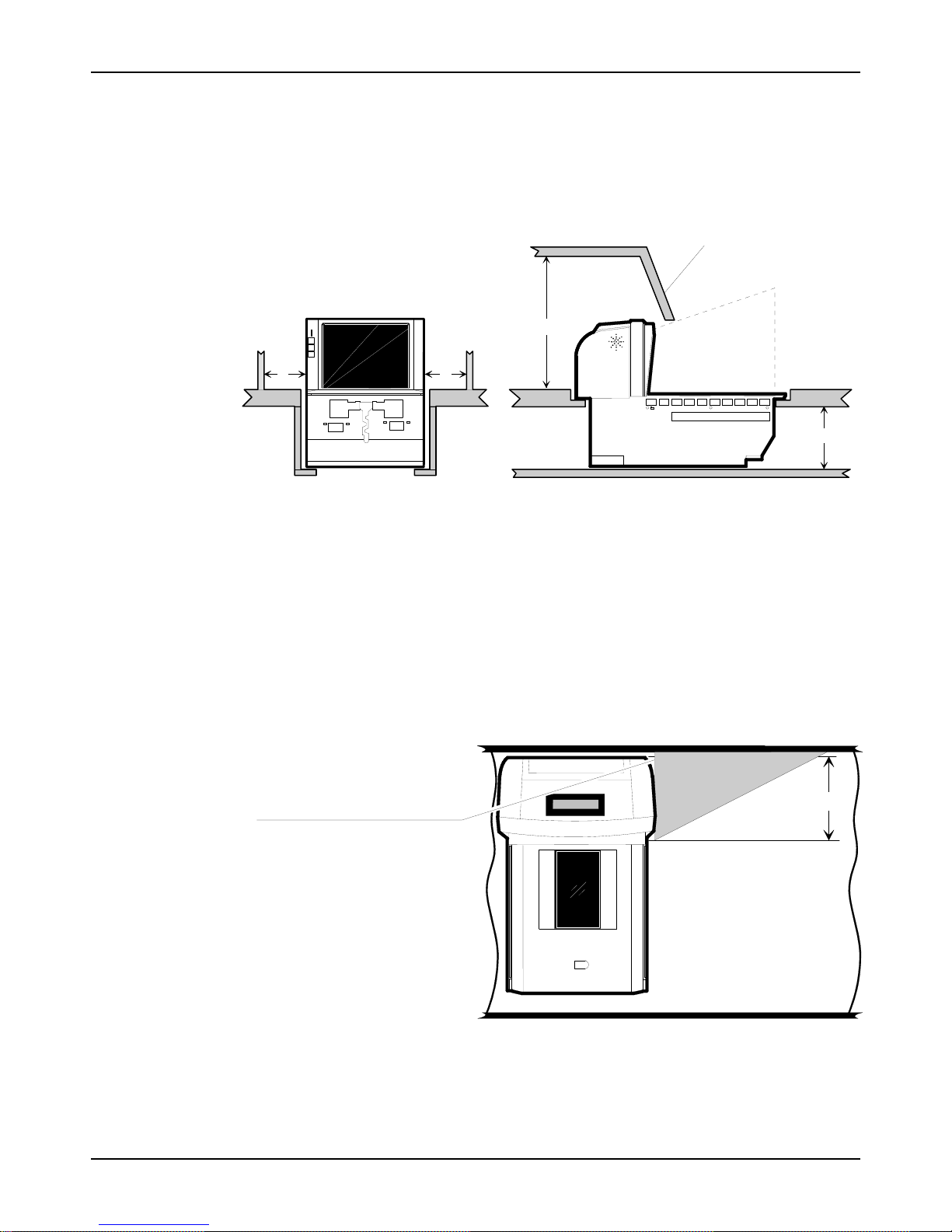

Service Clearance

Mounting surface for keyboard must be

removable for the following.

• Servicing the unit.

• Removing the 7875-8000 Produce Guard.

• Replacing the vertical window.

B

Item Flow Area

A A

C

Item Diverter

A = 20.3 cm (8 in.) minimum if checkstand structure is not removable for servicing.

2.5 cm (1 in.) minimum if checkstand structure is removable for servicing.

B = 35.6 cm (14 in.) minimum if checkstand structure is not removable for servicing.

17.8 cm (7 in.) minimum if checkstand structure is removable for servicing.

C = 18.1 cm (7 1/8 in.) minimum clearance to closest checkstand panel.

The NCR 7875-7000/8000 must not be supported by a bottom panel.

RealScan 7875-8000 units with a Produce Guard must have enough clearance to remove

Note:

the Produce Guard for cleaning. The dimensions given here satisfy these requirements.

Item Diverter

(Must be removable to service

Scanner/Scale in checkstand)

20784

7.25 in. (18.4 cm)

Note: The Item Diverter is not used in most self-checkout installations.

AIP-00342 Release B 06/03

14957

9 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Ventilation Requirements

The RealScan 7875 is designed to operate without an exhaust fan in the checkstand; however,

there must be adequate convection airflow. The ambient temperature inside the checkstand

cannot be higher than 40° C (104° F). Also, the ambient temperature inside the checkstand

cannot be higher than 7° C (12.6° F) above the ambient temperature outside the checkstand. For

example, if the ambient temperature outside the checkstand is 24.4° C (76° F), the ambient

temperature inside the checkstand cannot be greater than 31.4° C (88.6° F). If the checkstand

contains other heat producing equipment, you may need to use forced air to keep the temperature

within the specified range. However, air coming into or leaving the checkstand MUST NOT

enter or exit past the RealScan 7875.

06/03 AIP-00342 Release B

10 of 56

NCR RealScan 7875-7000/8000 Installation Guide

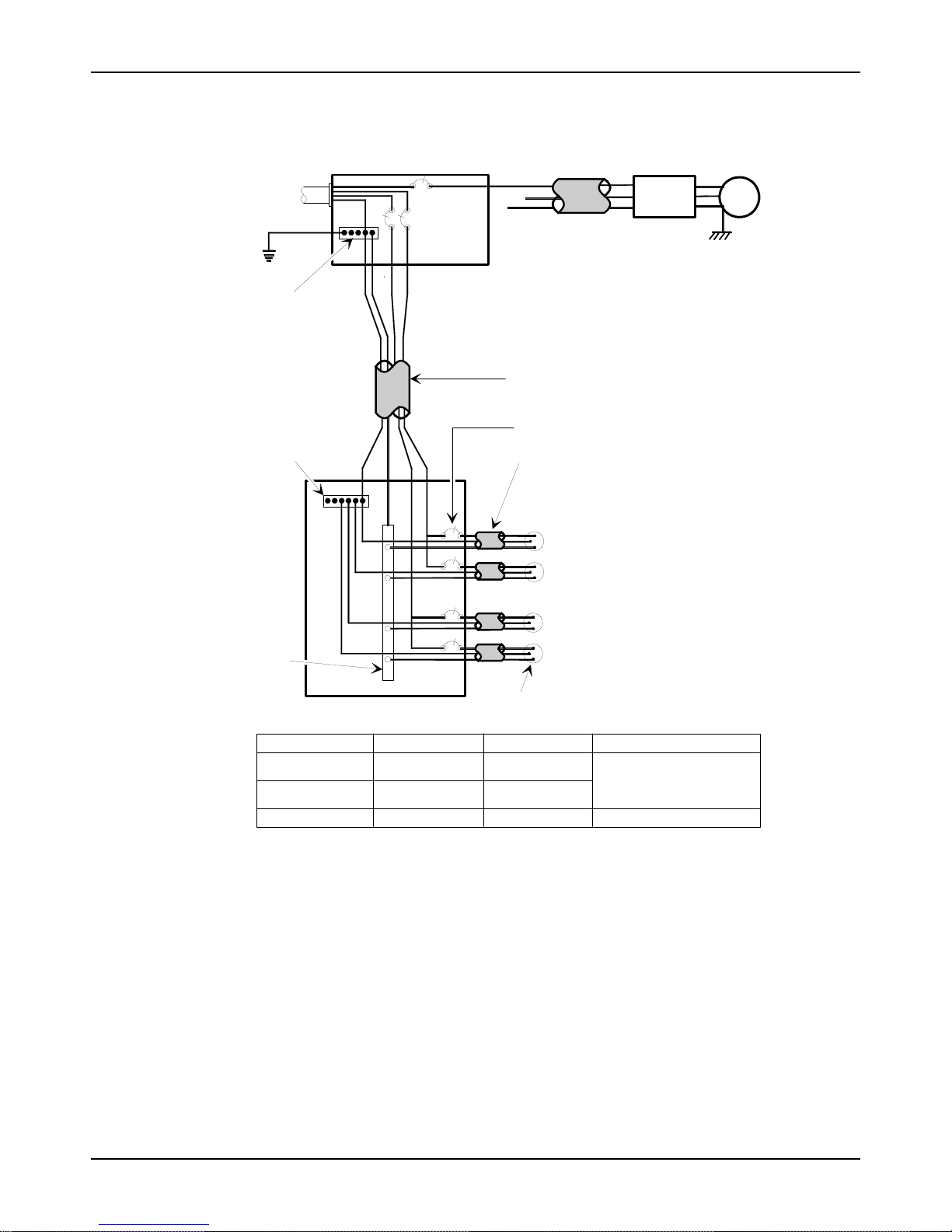

Electrical Wiring to the Checkstand

Input

Voltage

Neutral and

Ground Bus

Isolated/Insulated

Ground Bus

Neutral

Bus

Main Service

L2

Distribution Panel

Panel

L1

L3

Belt Control

N

G

Circuit A: Checkstand

Note:

Isolated Ground Receptacles

Conduit

The electrical wiring must meet all

electrical codes, laws, and regulations.

Feeder wiring and insulated ground from

main service panel to distribution panel

to be run in metal conduit.

Circuit Breakers

NCR circuits should be run in

separate metal Conduits.

NCR circuits must be dedicated to

Note:

NCR equipment or other logically

connected electronic equipment

(modems, DAA, bridges, etc.)

Circuit B: Terminal

Circuit C: Scanner/Scal e

Receptacle should be easily

accessible and near the

Scanner/Scale

Lighting

Misc. Equip.

Checkstand

Frame

Belt

Motor

Installation Type

U.S., Canada, &

Japan

International

European

Note: The RealScan 7875 outlet in the checkstand must be connected to a circuit breaker switch.

This switch must be located close to the operator and is used as the On/Off switch for the

RealScan 7875.

AIP-00342 Release B 06/03

Input Voltage L1, L2 Circuit Breakers

100Vac to 120Vac

220Vac to 240Vac

220Vac

100Vac to 120Vac

220Vac to 240Vac

220Vac

Standard single-pole; value

determined by type of device

branch and by electrical code.

European double-pole.

R0121

11 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Specific Checkstand Modifications

A few checkstands require some modification. Appendices are included for these different types

of checkstands. If modifications are needed, refer to the appendix that matches your installation.

After making any necessary modifications, continue to step 2 on the next page.

• Appendix A – Pan-Oston PO-2

• Appendix B – Pan-Oston PO-3

• Appendix C – Pan-Oston PO-4

Sensormatic Equipment

• Plug the power cord of the Sensormatic ScanMaxTM Pro into an ac outlet not dedicated to

POS equipment. Plug into an unswitched ac outlet with less than 0.5Vac between neutral

and ground. Electrical Primary input: 100-120/200-240Vac, 50-60 Hz ±5%, 1Arms

maximum.

• Do Not connect through generator or Uninterruptible Power Supply (UPS).

• Keep the power cord and antenna cable away from cash drawers and other items whose

operation may pinch or otherwise damage them. Failure to do so can damage equipment or

injure people nearby.

• Do not plug or unplug ANY Sensormatic ScanMax

• If mounting the controller to the sidewall of a counter, its cable connectors cannot face up.

• Deactivator Interacting with Other Devices: Isolate ScanMax Pro controller from neon

signs, motors, computers, cash registers, terminals, or data communications equipment.

Computer monitors, TVs, switching power supplies and neon displays can affect deactivator

operation. Keep the Sensormatic ScanMax

whenever possible.

• Environmental: Operating temperature 0 to 40°C (32° to 104°F) / Non-operating

temperature -40° to 70°C (-40° to 158°F)

TM

Pro Controller cables with power on.

TM

NS Pro Antenna away from these devices

06/03 AIP-00342 Release B

12 of 56

NCR RealScan 7875-7000/8000 Installation Guide

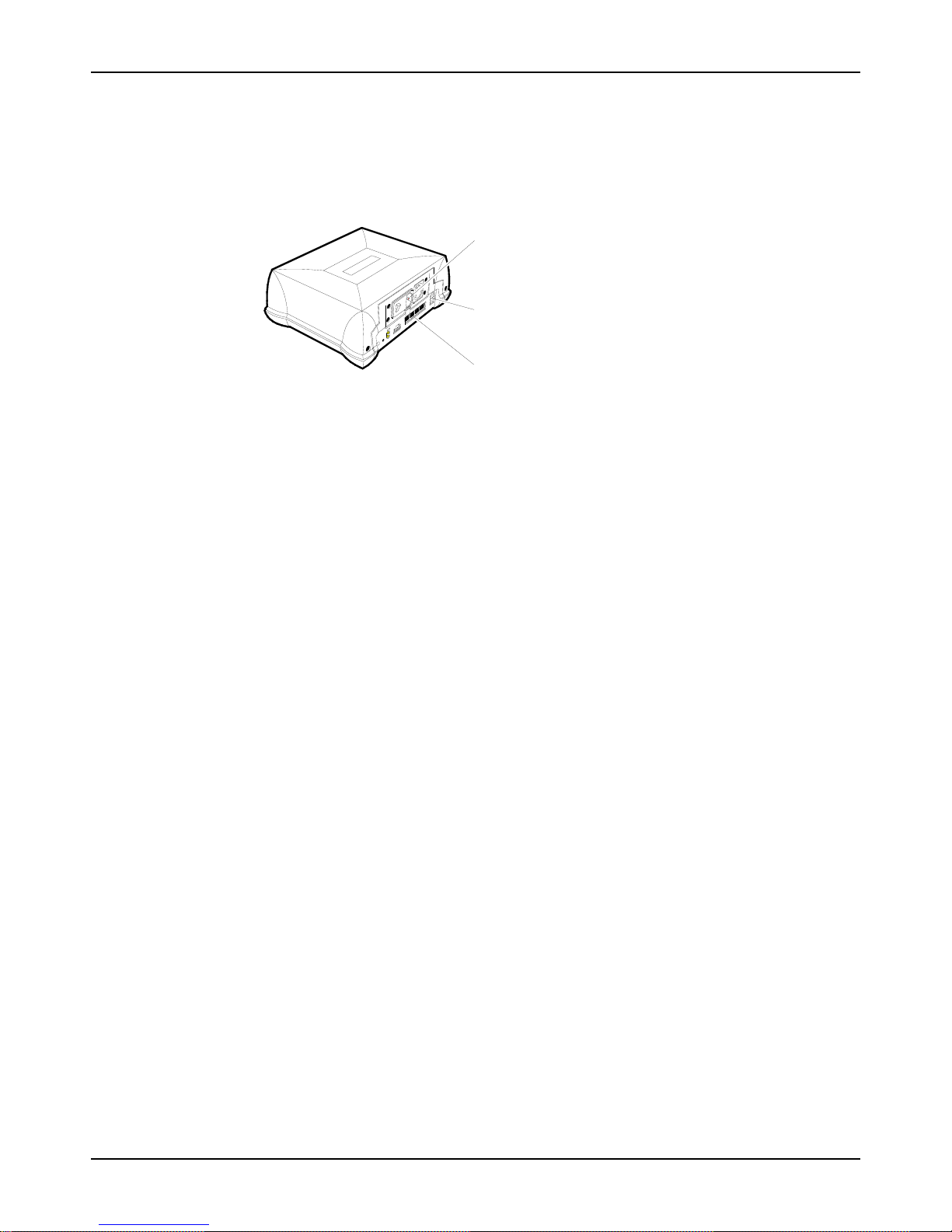

Step 2 – Connect the

Components

AC Power Connector

Antenna Connector

Locate the Sensormatic ScanMax

spilled liquids cannot contact it.

Install Sensormatic Antenna

Note: The Sensormatic ScanMaxTM NS Pro Antenna is very heavy; do not to drop it in the

scanner.

The Sensormatic ScanMax

7875. It should always be placed on the trailing side. If the installation is setup to scan from

right-to-left, put the Sensormatic Antenna on the left side of the scanner as shown in the

illustration.

1. Feed the Sensormatic Antenna Cable through the large hole in the front of the Mounting

Bracket (bucket). This must be the hole on the side where you are installing the antenna.

Note: Depending on the checkstand configuration, you may have to slide the back of the

Antenna under the Produce Guard if one is included. The Antenna must not interfere with

Produce Guard movement.

2. Carefully place the Sensormatic Antenna in position, setting it on the Sub Plate.

3. Route the Sensormatic Antenna Cable down through the slot in the front of the Mounting

Bracket (bucket).

TM

Communications Connector (POS)

TM

Pro Controller inside the checkstand in a position where

NS Pro Antenna can be positioned on either side of the RealScan

20588

AIP-00342 Release B 06/03

13 of 56

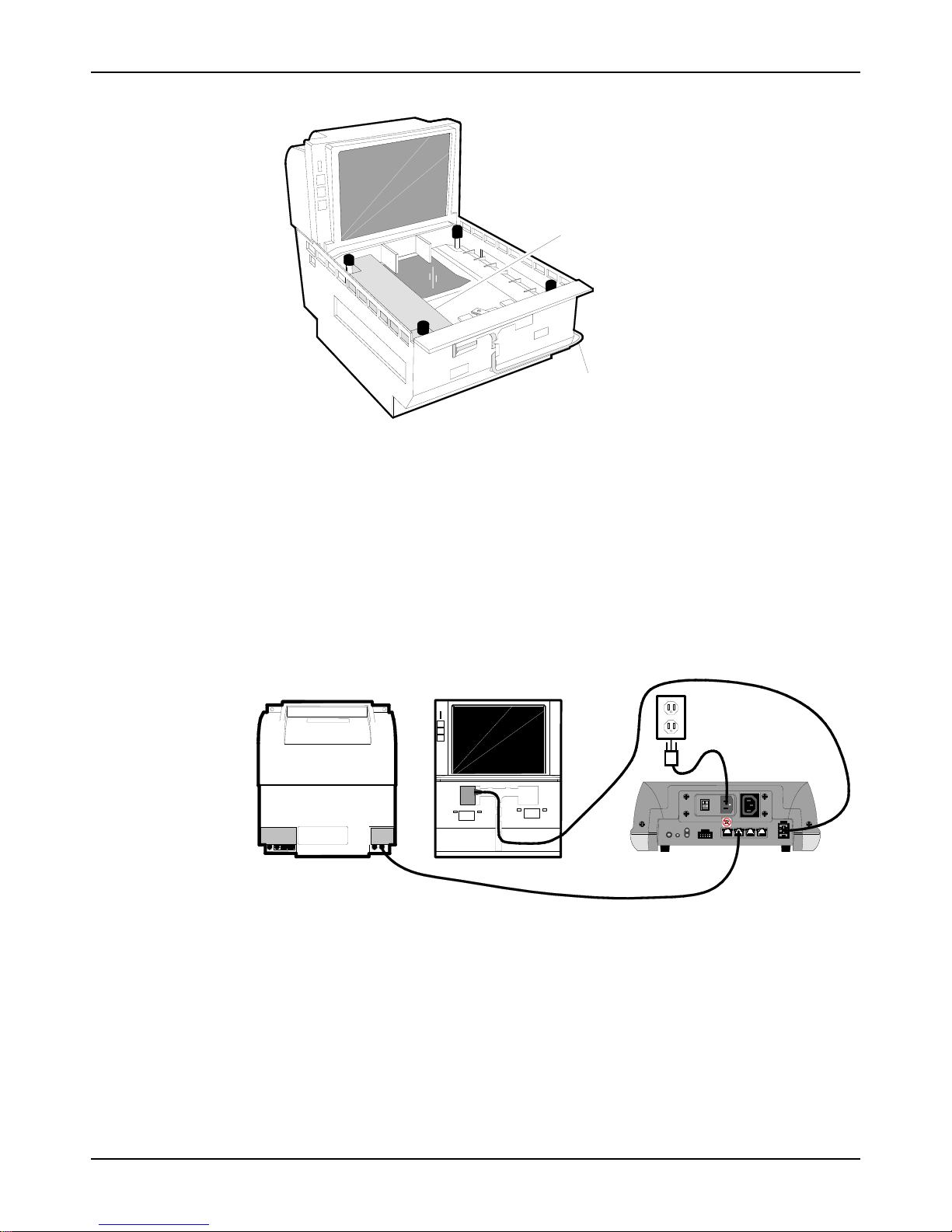

NCR RealScan 7875-7000/8000 Installation Guide

Connect Sensormatic Cables

Sensormatic Antenna

Sensormatic Antenna Cable

20574

The Sensormatic Antenna Cable and the Sensormatic Communications Cable go between the

RealScan 7875 and the ScanMax

TM

Pro Controller. Be sure to route these cables through the

cutout in the checkstand.

1. Connect the Sensormatic Antenna Cable to the Antenna connector on the ScanMax

TM

Pro

Controller.

2. Connect one end of Sensormatic Communications Cable to one of the RS-232 Peripheral

Ports on the RealScan 7875 and the other end to the POS connector on the ScanMax

TM

Pro

Controller.

RealScan 7875

Sensormatic

Antenna

Cable

PROGSTATUS

Sensormatic

Communications Cable

AC

Power

Cord

MNS

BCAN I/O POS SERVICE REMOTE ANTENNAEXPANSIONBR

ScanMax™

Pro Controller

20592

06/03 AIP-00342 Release B

14 of 56

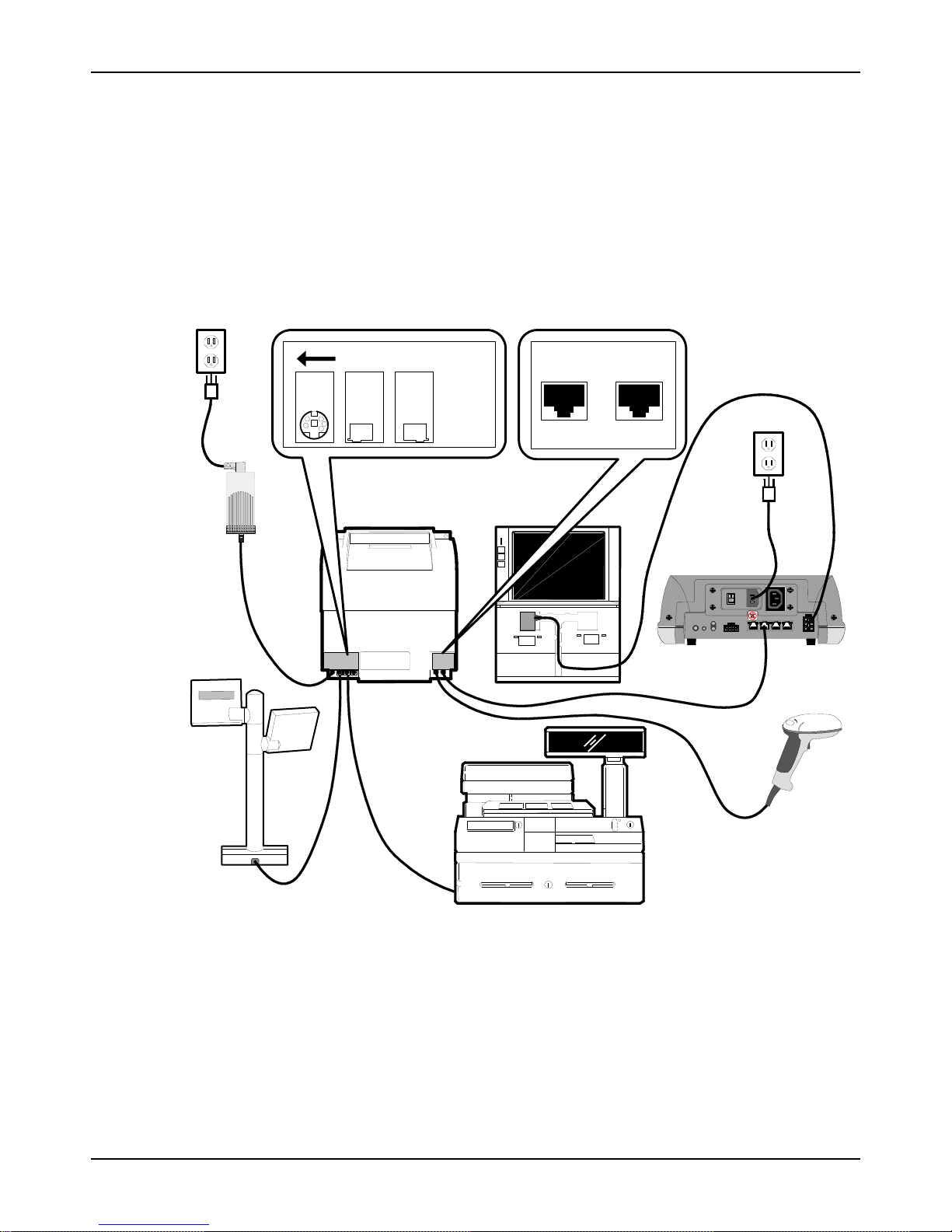

NCR RealScan 7875-7000/8000 Installation Guide

Connect Remaining Components

Locate the NCR RealScan 7875 Power Supply in position in the checkstand where spilled liquid

cannot contact it. The system configuration may also include a Remote Display and an RS-232

peripheral such as a hand-held scanner. The following illustration shows how all cables are

connected. Be sure to route these cables properly through the checkstand. After all cables are

connected, plug in the NCR RealScan 7875 and the Sensormatic ScanMax

Power Cords to supply power to the units.

TM

Pro Controller

AC

Power

Cord

Power

Supply

DC

Power

Cable

Remote

Display

Check switch settings

C

R

E

D

W

O

P

Y

E

T

A

X

L

A

O

P

M

M

S

E

I

A

R

D

5

V

5

Interface

Cable

R

E

N

N

A

C

S

RealScan 7875

DUAL PERIPHERAL PORTS

PORT 1 PORT 2

Sensormatic

Communications Cable

Host

Terminal

Sensormatic

Antenna

Cable

MNS

PROGSTATUS

AC

Power

Cord

BCAN I/O POS SERVICE REMOTE ANTENNAEXPANSIONBR

Sensormatic

ScanMax™

Pro Controller

RS-232

Peripheral

AIP-00342 Release B 06/03

20553

15 of 56

NCR RealScan 7875-7000/8000 Installation Guide

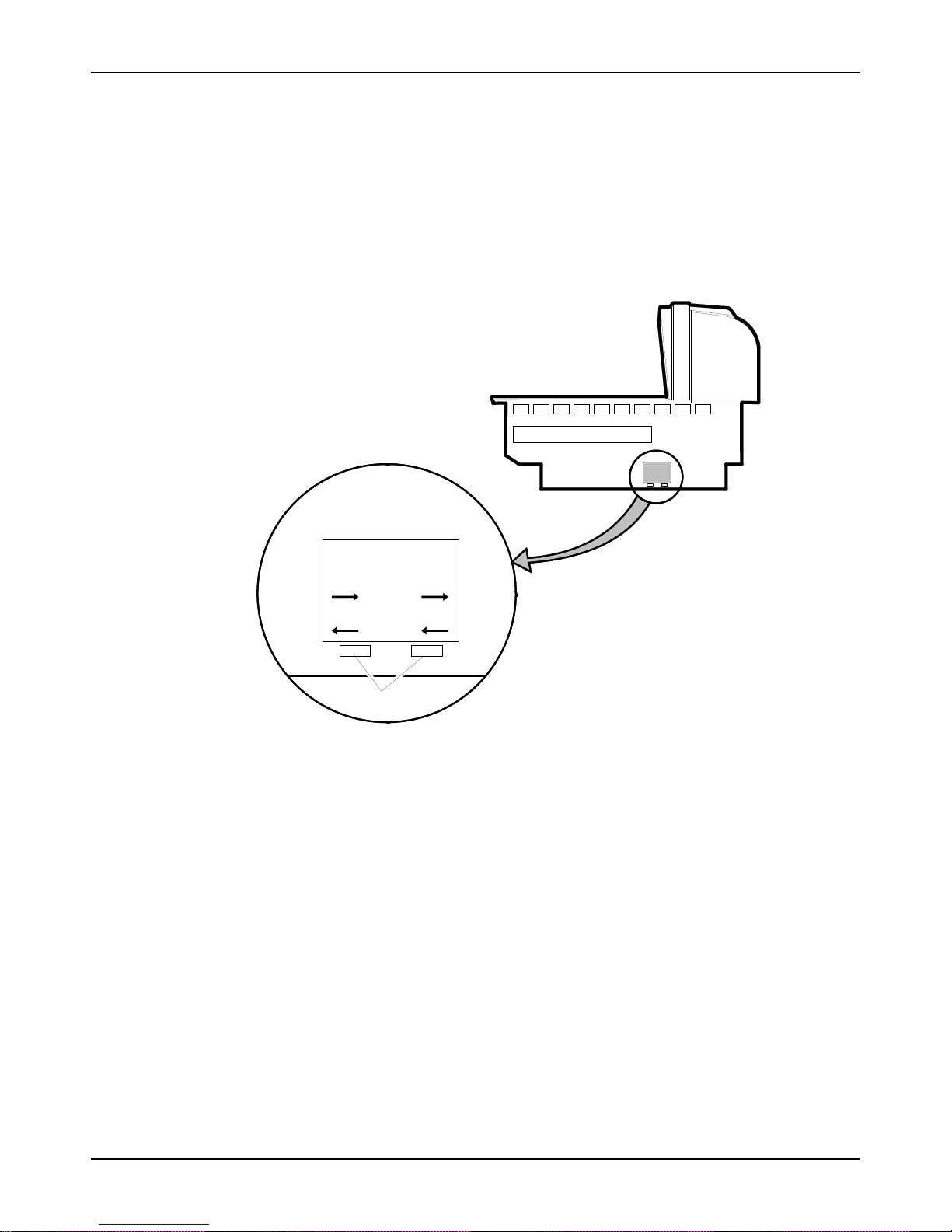

Set the Communications Protocol Switch

Before setting the RealScan 7875 into the cutout in the checkstand, verify that the

Communications Protocol Switch is properly set. Single cable units have one switch, dual cable

units have two. The switches are located on the Interface Board and you can access them

through holes in the side of the unit. For RS-232 communications, both switches must be toward

the front (operator side) of the unit. For all other communication protocols, both switches must

be toward the back (customer side) of the unit.

AUX PO RT/

DATACHKR

DATACHKR OCIA/IBM

Make sure power is

off before changing

switch setting

RS-232 RS-232

SCANNER

Switches

20789

06/03 AIP-00342 Release B

16 of 56

NCR RealScan 7875-7000/8000 Installation Guide

Step 3 – Sensormatic

Deactivation Setup

Power up the System

Note: Refer to the Sensormatic ScanMax™ Pro Controller documentation for additional

information about setting up the controller.

1. Turn on the NCR RealScan 7875. When the RealScan 7875 is first turned on, all the

Sensormatic parameters should be at their default settings.

• RealScan 7875 Scan tone delay until deactivation = Enabled

• RealScan 7875 Deactivation button = Disabled

• RealScan 7875 Clicking = Enabled

The RealScan 7875 should give the voice message EAS Offline if the Sensormatic

ScanMax

2. Turn on the Sensormatic ScanMax

factory with default settings for proper operation.

3. After the RealScan 7875 and the Sensormatic ScanMax

for about 15 seconds, the RealScan 7875 should give the voice message EAS Online.

Note: Voice message EAS Online must be given before you can continue. If voice message

EAS Online is not given, turn off the power to all components. Check all cable connections

then repeat this procedure starting at step 1. If voice message EAS Online is still not given

and the Red Status Indicator is flashing rapidly, scan the Reset programming tag. If the

status given is still EAS Offline, follow instructions on the Sensormatic Card – Before You

Call About… The problem may be a bad Antenna cable.

4. Position a Hard Tag over the top of the RealScan 7875. As you move the Hard Tag, the

RealScan 7875 should start clicking when the tag moves within 4 inches of the center of the

Top Plate. If the clicking sound is not generated, scan the Reset programming tag, then go

to step 3. If the second attempt fails, call for help. Refer to Obtaining Technical Assistance.

TM

Pro Controller is still turned off. Also, the Red Status Indicator flashes rapidly.

TM

Pro Controller. This system is programmed at the

TM

Pro Controller have both been on

AIP-00342 Release B 06/03

17 of 56

Loading...

Loading...