NBE Scotte 16kw, Scotte 24kw, Scotte 30kw, Opop 430, Opop 460 Installation And Operating Manual

...

Scotte/Opop

Installation and operating

Manual 16, 24 & 30kw

NORDIC BIO ENERGY LTD

Pellets Systems

CONTENTS

Section 1 ……….Legal requirements

• Planning and building control page 2

• Installation expertise page 2

Section 2 ……….Specification

• Description of Boiler & Manufacturers plate page 3

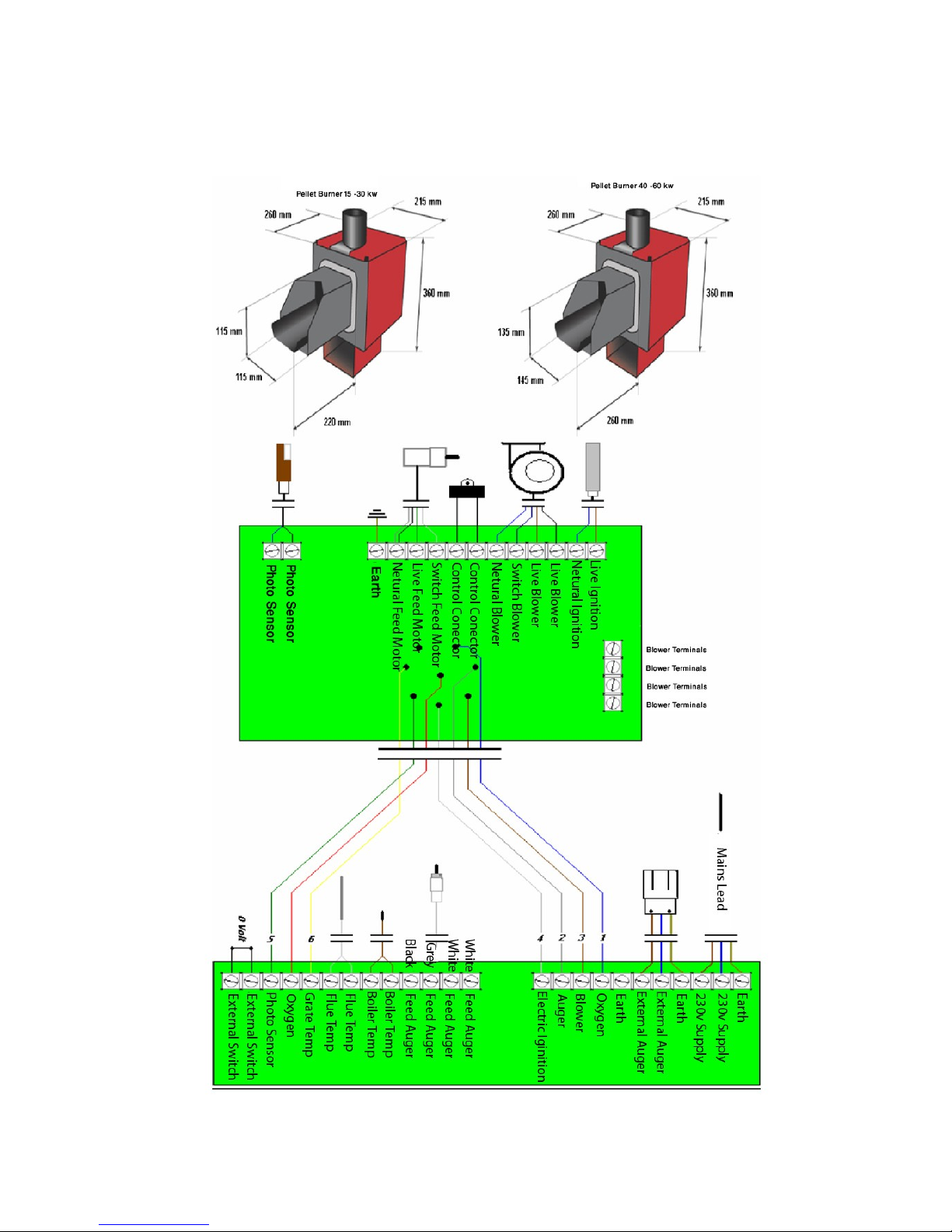

• Dimensions page 3 + 4

• Wiring diagram page 4

Section 3 ……….Assembly

• Fitting the burner into the boiler page 5

• Feed screw and pellet silo assembly page 5 + 6

Section 4 ……….Installation

• Boiler connection page 7

• Flue pipe connection page 7

Section 5 ……….Operating the burner

• First time start up page 8

• Adjusting the burner page 8

• Main menu on controller page 9

• Secondary menu on controller page 10

• Symbols and functions on controller page 10

Section 6 ……….Maintenance

• Cleaning the burner page 11

• Troubleshooting page 12

• Installation Examples page 13

• Health and Safety page 14

• Quick start guide page 15

Page 1

SECTION 1

Planning requirements.

If you are thinking of making any changes to your property, including installing a

form of renewable energy, you must apply to the Building Control Office at your

local council for approval.

Planning permission may or may not be required, depending on such factors as:

location, individual planning department, nature of scheme, neighbors' opinions,

visual impact and proximity to public through roads.

Before beginning any work we recommend that you contact your local planning

department to determine whether planning permission is required.

Building regulations.

- Any installation of a heating appliance, or modification to a chimney such as

relining, has to be carried out in accordance with. Building Regulations – Republic

of Ireland Part F – Ventilation Part J – Heat Producing Appliances (Article 41 in

N.Ireland Part J in England and Wales and F in Scotland). Building Control

Consent might also be needed for such work unless the work is carried out by a

qualified person as stated below. We recommend that all installation or design is

completed in accordance with British Standards, including BS 5410 , BS 4543, BS

4876, BS 1181 and BS 715.

Installer expertise.

All installation work should be undertaken by a person who is a member of an

approved competent person scheme as outlined in the COMPETENT PERSON

SELF-CERTIFICATION SCHEMES IN 2003 which can be found at.

http://www.odpm.gov.uk/index.asp?id=1131139

All appliances must be commissioned and failure to do so will

invalidate the

boiler/burner warranty.

Page 2

SECTION 2

Description of Boiler.

1 Supply to radiators, hot water tank etc.

2 Flue pipe/chimney connection.

3 Return from the radiators, hot

water tank etc

4 Thermostat pocket .

5 Emptying and filling of water to

the system.

Manufacturers plate and serial number.

Dimensions of boiler.

Opop boilers: table 1

Model number: 418 430 460 4120

Power kw 18 30 40 – 60 80 - 120

Height mm 865 865 1005 1305

Width mm 386 490 800 1000

Depth mm 533 533 720 920

Flue mm 130 145 160 180

Water content litres 26 35 56 105

Weight kg 160 200 245 335

Connections 1 ¼” 1 ¼” 1 ½” 2”

Page 3

Burner/ boiler type. Scotte / OPOP

Output 16/24/30 kW

Classification EN 303-5 3

Test pressure 4.0 Bar

Max. operational pressure 2.5 Bar

Water content 26 litres

Boiler weight 160 kg

Exit gas temperature, nominal load 115°C

Exit gas temperature, low load 66°C

Flue gas mass flow rate, nominal

load

37.7 kg/h

Flue gas mass flow rate, low load 18 kg/h

Waterside resistance, delta T = 20 °K 1.37 mbar

Waterside resistance, delta T = 10 °K 5.39 mbar

Operating temperature min. 35ûC

Max. temperature 90ûC

Efficiency 93.3 %

Power consumption 220 V

35 Watts

Manufacturer: NBE

Tel.:

DK 9830 Tårs

0045-96892630

Serial Number

Dimensions of burner and wiring diagram.

Page 4

Section 3

Assembly.

Fitting the burner unit.

1. seal with fire rope or heat resistant gasket sealer to the boiler via the

square hole located on side of boiler (left or right depending on

requirement).

2. mount the burner unit into flange and secure locking bolts

Fitting the feed screw.

1. fit one end of the thermoplastic hose to the top of the inlet tube on the

burner unit, and the other end of the thermoplastic hose to the outlet of

the feed screw.

2. mount the feed screw over the burner so the pellets can fall into the

burner effortlessly. The more the feed screw is mounted at an incline, the

less pellets it releases.

- adjust the control system according to the angle of incline. (see section 5,

operating the burner)

3. ensure the thermoplastic hose is angled enough so the pellets end up in

the burner, shorten the hose if needed.

Page 5

Pellet silo assembly.

The pellet silo…..

As the pellets that you put into the silo contain dust, you should empty the silo

completely from time to time. The more dust that is in the silo, the less pellets

the feed screw will release and the boiler will become unadjusted, leading to

inefficiency and possible breakdown.

How often the silo needs emptying completely, depends on the design of the silo

and the quality of the pellet fuel used.

Page 6

Section 4

Installation.

Power supply and connection.

230 volts 50Hz 10 Amp 60 Watts

Control is supplied via a priming circuit breaker,(high limit safety cutout stat)

which is mounted on the rear of the boiler (item 4, page 3). The temperature

sensor is mounted in the same immersion pocket as the priming circuit breaker or

a suitable place where the boiler temperature can be measured. Mount the power

to the control system via the priming circuit breaker so that the power is broken if

the temperature of the boiler exceeds 95 degrees in the event of a fault.

Flue pipe and chimney connections.

Use the correct flue size for boiler model (table 1, page 3).

Ensure adequate height of chimney to gain satisfactory draw and to prevent back

draft. A suitable cowl/rain cap/anti back draft must be fitted.

We recommend that a draft stabilizer is always mounted to the chimney.

The vent pipe should not be greater than 1 metre in length and should be

equipped with an access door.

The flue pressure of the chimney should be a minimum of 10 PA and be stable. A

flue fan may be required to assist the draft and secure stability.

Upon condensation of flue gases in the flue, a condensation trap should be

installed, or the valve in the rear flue of the boiler be opened, so that the flue gas

temperature is increased.

Page 7

Section 5

Starting the unit for the first time.

1. check all connections on burner, boiler, feed screw, flue, chimney and

power supply.

2. ensure that there are pellets at the inlet of the feed screw in the pellet

silo.

3. activate the forced feed operation by pressing the UP button on the

controller for 10 seconds and turn the mains power on at the same time.

4. when the feed screw has filled with pellets and they are falling into the

burner, turn the power off at mains.

5. The burner is started by switching the mains power on again. The control

box can be started/stopped by pressing the on/off button for 8 seconds.

6. The alarm is cancelled by pressing the DOWN button 2 times within 8

seconds.

To obtain the optimum efficiency from the burner and boiler, correct

adjustment is essential.

Please refer to section 5 on adjusting the burner and section 6 on

cleaning the burner.

Adjusting the burner.

For first time start up, refer to quick start guide on page 15.

The outputs for high and low loads are run by the control system in a 100 step

modulation and the changes between the different steps are made automatically.

Feed adjustments for high and low loads.

Wood pellets can vary (dust, pellet length etc.) so correct adjustment for fuel

economy and boiler efficiency are essential. The feed screw will supply the pellets

differently and will have an influence on the burn quality. It is necessary to open

the doors to the burner and look at the flame.

If the flame is fat – dark, possibly with black points, or the ash is black with

black pellets, fewer pellets are needed. Reduce steps 2 and 3 in the main menu.

If the flame is thin – little flame and like a sparkler, or the ash is light grey,

more pellets are needed. Increase steps 2 and 3 in the main menu.

* Correct burning adjustments normally produce a dark grey ash. *

The burner is intended for wood pellets between 6-8mm diameter.

If you are in any doubt then subscribe to a service contract. For further

information visit : www.nordjysk-bioenergi.dk

Page 8

Main menu on controller.

In order to adjust the burner press the SET button on the controller and

you will gain access to the main menu use

There are four adjustment options in this main menu.

1. Boiler temperature: *factory settings 60 degrees*

press the UP or DOWN buttons to reach the required

water temperature.

2. Feed screw in low load: * factory settings 5.6 *

press the UP or DOWN buttons to adjust the quantity

of pellets that corresponds to the blower speed. It is

important that this adjustment is correct in relation to

the speed of the blower. In the event of an incorrect

adjustment, the boiler will not run as economically and

there will also be the risk of a breakdown.

3. Feed screw in high load: * factory settings 33.6*

press the UP or DOWN buttons to adjust the quantity

of pellets that corresponds to the blower speed. It is

important that this adjustment is correct in relation to

the speed of the blower. In the event of an incorrect

adjustment, the boiler will not run as economically and

there will also be the risk of a breakdown.

4. Feed screw in pause firing: * factory settings 16.0*

pause firing enables the burner to keep lit and not to

have to use the electronic ignition every time more pellets

are required. Press the UP or DOWN buttons to adjust

the quantity of pellets the burner will use during pause

firing. Set as low as possible without the burner going out.

The burner fires every 5 minutes.

PLEASE USE PELLET TABLES TO SET

ABOVE MENUS 2,3,4

Secondary menu on controller.

To gain access to the secondary menu press and hold the SET button for

6 seconds.

A1.......The amount of fuel for stoking up at start Standard 32 sec.

A2.......Ignition Time Standard 10 min.

A3.......The effect of the electric ignition Standard 70 %.

A4.......Value photo sensor shall exceed before there is fire Standard 10 Lx

A5.......Total ignitions time 0000 H

A6.......Times the ignitions has ignited 0000 T

A7.......Blower at ignition Standard 15 %

B1……Amount of time the burner is allowed to be in pause firing Standard 0 min

B2……Fan in pause firing Standard 15 %.

B3……Start after pause, degrees below boiler setpoint Standard 5 C

B4……Time of blowing when turning to OFF Standard 5 min

C1……Oxygen control Standard 0 ( OFF )

C2……Calibrating sensor 0

C3……Time with low O2 before stopping pellets Standard 30 min

D1.......Times of starts each day Standard 0 x

D2.......Max running time on each start Standard 60 min.

D3.......First start 00.00 H

D4.......Clock, to be adjusted by user 00.00 H

E1…....Cleaning interval Standard 10 min.

E2........Cleaning time Standard 4 sec

E3…....Cleaning power Standard 30 %.

E4…....Minimum power on burner Standard 10 %.

E5........Maximum power on burner Standard 100 %.

E6........Sommer time, ( low output and more temp. Diff. ) Standard 0 ( OFF )

E7........Temperature difference over setpoint Standard 10 C

Off 2 power of burner off 1 is the watch off 3 internal switch

Other functions on the controller.

Forced feed screw operation – to start hold the UP button when switching on.

To stop press the DOWN button.

Shift between temperature and oxygen displays and smoke temperature –

press DOWN one time (only when connecting the oxygen program).

Section 6

Cleaning the burner.

Switch off the control system by pressing the DOWN button for 5 seconds.

Wait for approximately 5 minutes to allow the burner to cool down. When it

has cooled down completely it is ready for cleaning. Take the connector off

the burner, remove the shield and down pipe, and unscrew the burner unit off

the boiler. The parts can now be worked with for cleaning.

To ensure best boiler operation,

cleaning should be done frequently.

This guarantees the best fuel

efficiency. The better the boiler is

set up the longer the intervals

between cleaning.

The boiler …..

The boiler should be emptied from

ash and all of the surfaces should be

brushed in order to remove soot

particles. Pay particular attention to

ash in the exhaust deflector and the

flue pipe. The flue pipe does NOT

clean itself. You must do this yourself.

An old vacuum cleaner is the best

method for this.

The burner head …..

Remove the ash and any cinders from the unit.

Remove any pellet remains under the unit. Dry off the flame indicator.

Ensure that there is nothing in the blower.

Starting up after cleaning ….

Reassemble the burner and fit into boiler. Start the boiler by pressing the

DOWN button for 5 seconds and the system will start itself. Remember to put

the shield back into place so that the burner temperature will be measured

correctly.

Page 11

Trouble shooting.

PROBLEM CAUSE SOLUTION

ALARM, WARM DOWNPIPE,

SMOKE BLOW BACK

1. cinders/ash in the burner head

2. ash in the boiler, flue pipe and

chimney

3. flue deflector incorrectly mounted

4. lack of draught in the chimney

5. output kw to boiler is too high

6. thermal sensor defect

7. unfavorable draught

Clean the burner

Clean the boiler, flue pipe and chimney

Correct or remove the exhaust deflector plate

in the boiler

Insulate and raise the chimney

Decrease the output in HIGH LOAD

Change the thermal sensor

Change/correct your flue

ALARM, FAULT WITH

ELECTRIC IGNITION

1. flue grate is not positioned correctly

2. ash/cinders in the burn head

3. damp pellets

4. too few/many pellets for electric ignition

5. electric ignition incorrectly positioned

6. defective electric ignition

7. chimney draught too high

8. photo sensor defective/sooty

9. blower stopped

Check fitting of burner to boiler

Clean the burner

Change supplier/increase maintenance

Adjust the amount by approx + or – 1%

Place in the square holder

Change the electric ignition/lignite manually

Mount a draught regulator on the chimney

Clean/change the sensor

Clean the blower and check if it runs

ALARM, LOW BOILER

TEMPERATURE

The boiler temperature has not been above

35 degrees after 2 hours or has gone

below 35 degrees during operation

Too little output on the burner, adjust output

Check the feed / pellet supply and blower

Check the temperature sensor is on the boiler

ALARM CONNECTOR IS NOT

MOUNTED

1. the connector is not mounted correctly

2. dirt in the connector

3. sensor defective

Check the connector on the burner

Clean pellet debris/dust from the connector

Change the sensor (photo/thermal sensor)

No/ black display in the

control panel

1. the over-temperature safeguard on the

boiler has been knocked out

2. fuse blown in the control system

Reconnect the over-temperature safeguard

Change the fuse. Check for short circuits

The boiler triggers the mains

trip knockout switch

1. electric ignition defective

2. cables defective

Change the electric ignition/ignite manually

Check the cables and plug. Note the state the

boiler is in when the trip is engaged

The boiler goes out during

LOW LOAD/PAUSE and has a

thin flame

1. fuel supply unstable

2. pellets hang in the thermoplastic hose

Check the feed inlet for dust

Check the pellets for dust / moisture

Check the feed screw incline

Check the fall from feed screw to burner

Pellet consumption too

high / desired boiler

temperature not being

reached

1. burn incorrectly adjusted

2. chimney draught too high

3. flue deflector incorrectly adjusted

4. poor boiler efficiency and adjustment

5. burner output too high

Check that the ash is dark grey

Measure the chimney draught / mount a

draught regulator

Check boiler and flue deflector

Measure flue temperature and fix deflector

Decrease output on burner

Boiler and burner are sooty/

black

1. feed times too high

2. pause firing incorrectly adjusted

3. blower stopped

Adjust feed levels

Adjust flue deflector and chimney pressure

Clean blower

Cancel the alarm, turn off power then on again and hold DOWN button

for 8 seconds on controller.

Page 12

Installation Design Examples

1: Forward movement.

2: Return.

3: Flue connection.

4: Over-temperature safeguard with sensors.

5: Pump.

6: Safeguards set 2.5 bars.

7: Pressure expansion.

8: Return valve with remote sensors/

Tap.

9: Thermometer.

10:Return valve.

11:Taps.

12:Hot water containers.

13:Feed.

14:Cooling circuits intern.

15:Power 220 V 50 Hz 10 Amps.

16:Connector to pellet burner

Page 13

Health and Safety.

Pellet storage and supply

Pellet stores/bins installed inside buildings must be built with one hour fire

containment.

In case of an accident

If you find a person ill or unconscious near any fuel burning appliance, be

careful in case you also become a casualty. Open windows and doors immediately and

remove the casualty to fresh air.

If the casualty is unconscious, open their airway and check breathing. If

breathing has stopped, give artificial ventilation until breathing restarts and

then place in the recovery position. Seek medical advice immediately If you cannot

give artificial ventilation, get help really quickly - seconds could be vital.

Remove casualty to hospital.

Service and safety

Service Engineers are trained to ensure that your wood pellet burning

equipment works safely and efficiently. A list of Service Engineers in your

area is available from Green Energy Solutions. They will check that the burner is

properly adjusted, that there is a sufficient air supply that the flue is working properly.

Regular cleaning and de ashing must be carried out otherwise the warranty will be

null and void.

Scotte burners have been tested and approved for use in 28 EU countries and have

been awarded DS/EN 303.5 recognition and CE approval.

All these matters are important to ensure that your boiler operates safely and

efficiently.

In the unlikely event of a failure, refer to the trouble shooting section of this manual.

If fault persists turn all power from mains off and contact your dealer for advice.

Never attempt to disassemble or repair the burner yourself. Any unauthorised repairs

will invalidate the warranty.

Page 14

Quick Start

NBE Pellets Systems

adjust according to weight

1. The UP key is held in when connecting power the

DOWN key stops feed screw

2. Run pellets in a bucket for 15 min

Amount 360 sec. Pellets.(6 min)

Read the result on the back side

Put in the numbers in menu 2 – 3 – 4.

The feed screw is stopped on down key.

1.

2.

3.

4.

Put the connector on the burner again

If the burner isn’t starting, turn on / off

1.

2.

Quick Start 16kw

NBE Pellets Systems Estimating Table.

Quick Start

NBE Pellets Systems Estimating Table.

Quick Start

NBE Pellets Systems Estimating Table.

Loading...

Loading...