Navien NR-180, NR-240A, NP-180, NP-180A, NP-210 Installation Manual

...

Gas Water Heater Operation

3

WARNING

If not followed this Installation Manual exactly, a fire or explosion may

result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or other appliance.

- WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch: do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Please return the “Installation Manual” to the customer after installing.

CAUTION

This product warranty is valid only used in the America and Canada but

automatically be voided for other countries. (for America and Canada

unit standard only)

Navien Gas Water Heater Operation

4

█

Installation Manual - Contents

Accessories Included with the Water Heater -------------------------- 3

Optional Accessories --------------------------------------- 4

Specifications -------------------------------------------------------------------- 5

Components & Dimensions Key Components : NR-A ----------------------------------- 6

Key Components : NP-A ----------------------------------- 7

Dimensions : NR-A,NP-A ---------------------------------- 8

Key Components : NR -------------------------------------- 9

Key Components : NP -------------------------------------- 10

Dimensions : NR, NP --------------------------------------- 11

Warnings Installation Warnings ---------------------------------------- 12

Rating Plate Getting Started ------------------------------------------------ 13

Check Rating Plate ------------------------------------------ 14

Location Selection Locating the Water Heater -------------------------------- 15

Mounting the Unit to the Wall ----------------------------- 16

Plumbing Plumbing and Water Connection Guidelines --------- 17

Water Piping Guidelines ----------------------------------- 18

Pressure Relief Valve -------------------------------------------------------------------- 19

Condensate Disposal Disposal of Condensate ----------------------------------- 20

Condensate Drain & Cleaning --------------------------- 21

Gas Piping Gas Piping Guidelines ------------------------------------- 22

Gas Supply Line Pressures ------------------------------- 22

Gas Piping Sizing Chart ----------------------------------- 23

Gas Pressure Testing Measuring Inlet Gas Pressure ---------------------------- 24

Venting Warning -------------------------------------------------------- 25

Venting Guidelines ------------------------------------------- 25

Contaminated Make-up Air Will Damage the Unit ---- 28

Exhaust Vent Pipe Materials ------------------------------- 28

Venting Clearances ------------------------------------------ 29

Allowable Vent Lengths ------------------------------------- 30

Vent Configuration Options -------------------------------- 31

Electrical Connections -------------------------------------------------------------------- 36

Remote Cotroller Installation -------------------------------------------------------------------- 37

PCB Board Settings -------------------------------------------------------------------- 38

Cascade Connection and Set-up Procedures ----------------------------------------------- 39

DIP Switch Settings -------------------------------------------------------------------- 45

Installation Checklist -------------------------------------------------------------------- 49

Factory Setting of DIP Switch ------------------------------------------------------------------ 56

Completing the Install -------------------------------------------------------------------- 56

Wiring Diagram -------------------------------------------------------------------- 57

Ladder Diagram -------------------------------------------------------------------- 61

Components Diagram & Parts List ------------------------------------------------------------- 65

CONTENTS

ACCESSORIES

Navien Gas Water Heater Installation

3

█

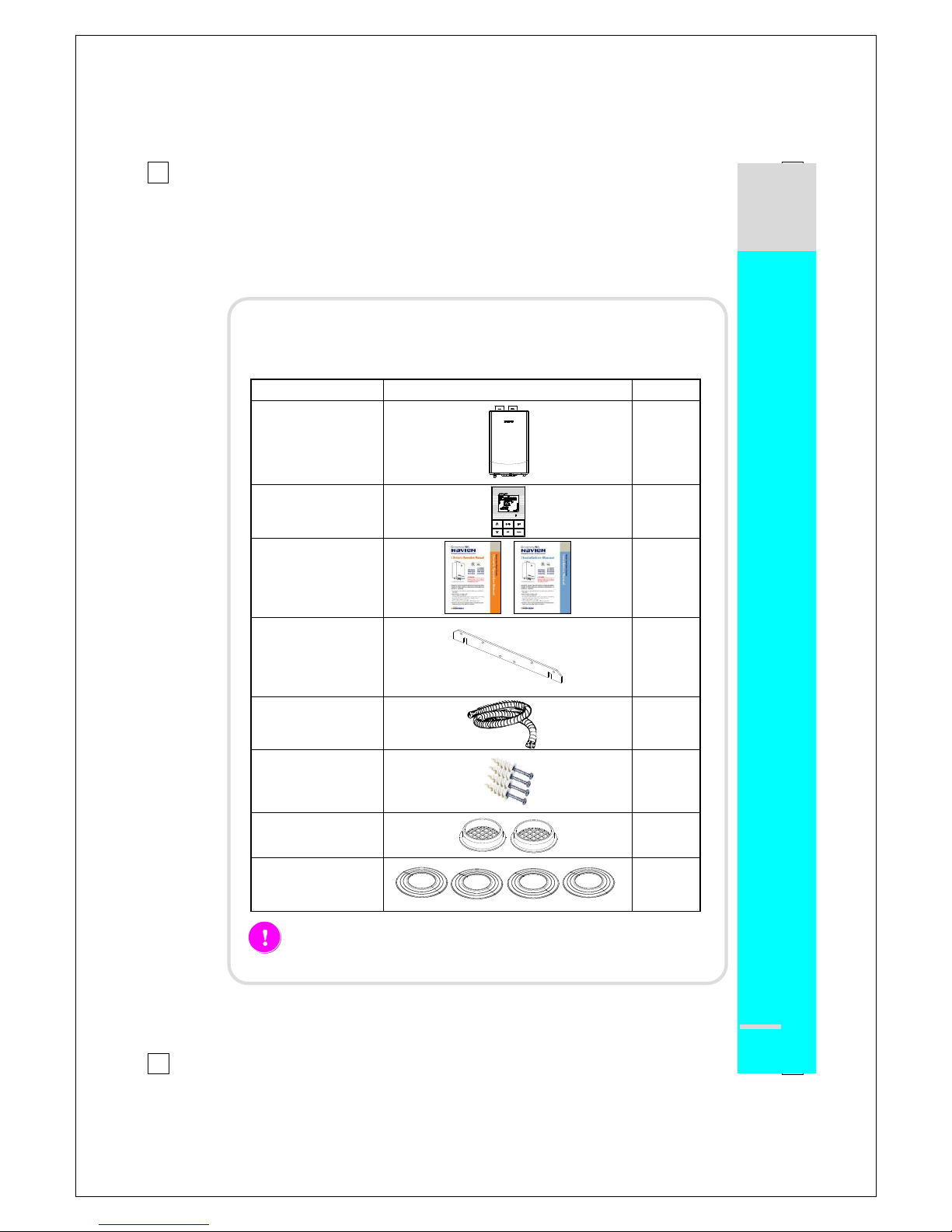

Accessories:

1. Included with the Water Heater:

Item

Description

Qty

Navien Gas

Water Heater

1

Remote Controller

1

Owner’s

Operation and

Installation

Manual

1

Wall Mounting

Bracket

1

Condensate Drain

Hose

1

Tapping Screws &

Anchors

4

Vent terminators

2

Wall Flanges

4

Check that you have received all of the above parts before installing

the Water Heater.

ACCESSORIES

Gas Water Heater Installation

4

█

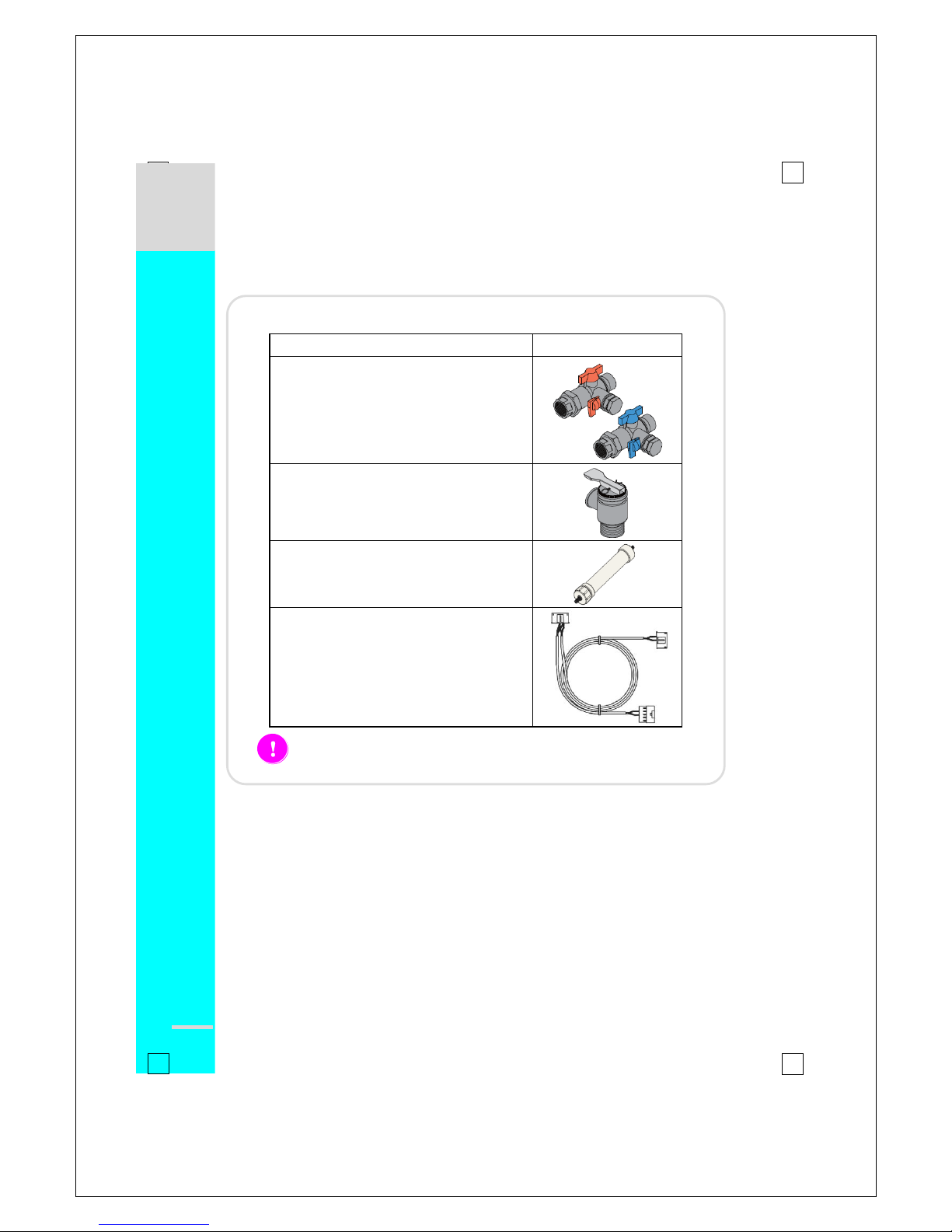

Optional Accessories:

A

2. Optional Accessories:

Item

Description

Navien Plumb Easy Valve Set

Navien Pressure Relief Valve

Navien condesate Neutralizer

Navien Ready-Link Communication Cable

Contact your Navien Water Heater supplier for optional accessories.

ACCESSORIES

Navien Gas Water Heater Installation

5

█

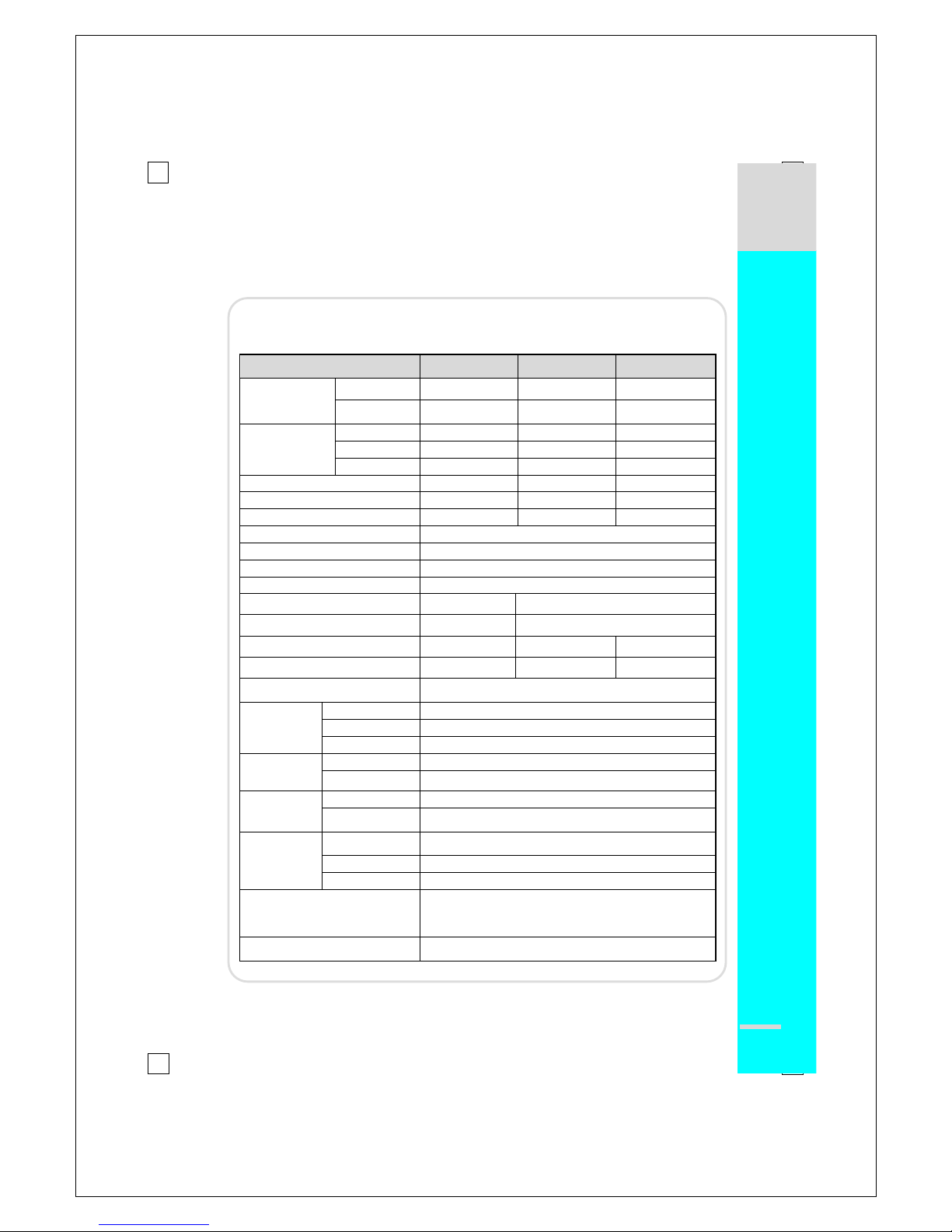

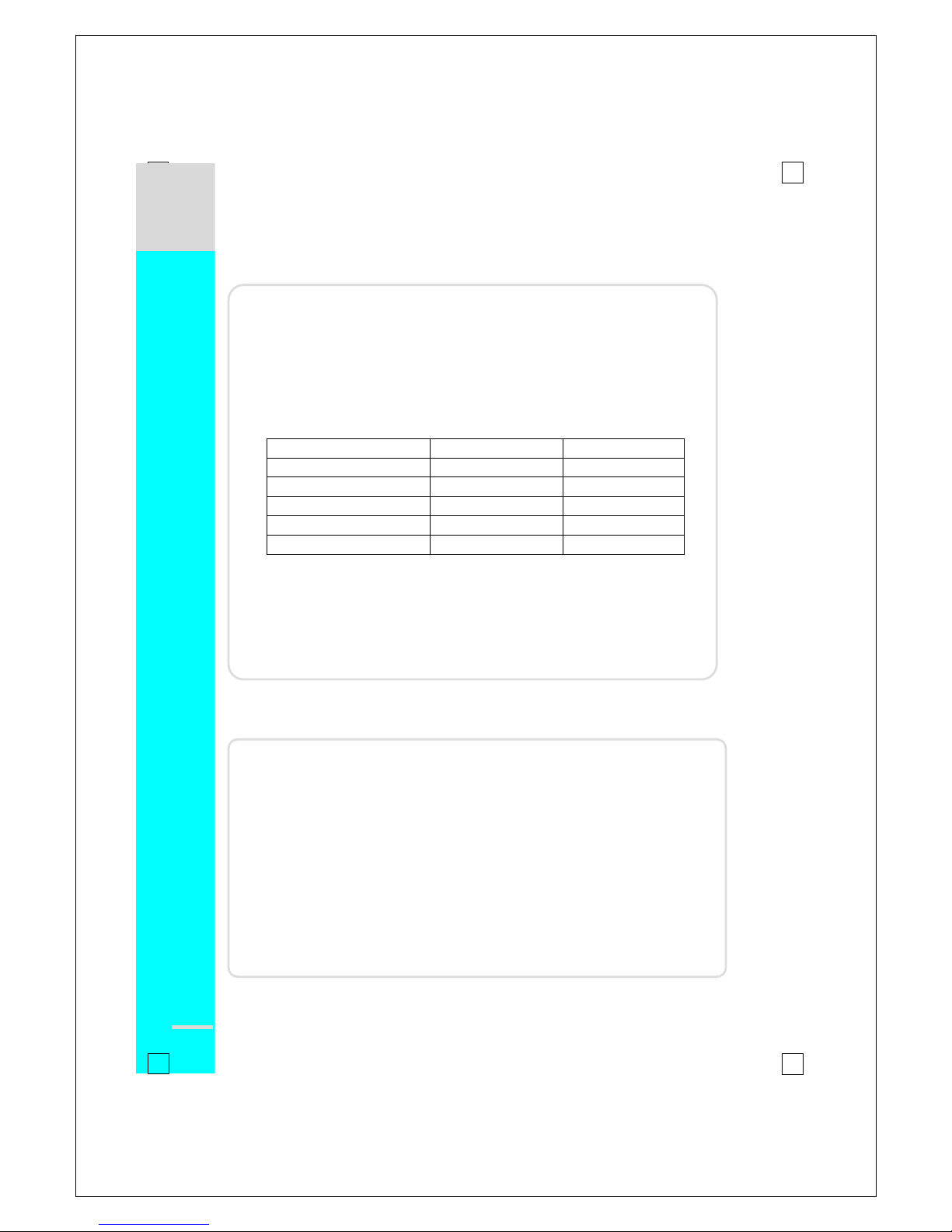

Specifications:

Please review these specifications before installation to confirm proper unit selection: As

Navien is dedicated to continuous product improvement, Navien reserves the right to

change specifications and/or design and/or discontinue any model or feature without

prior notice and without incurring obligations.

Item

NR-180(A)

NP-180(A)

NR-210(A)

NP-210(A)

NR-240(A)

NP-240(A)

Heat Capacity

(Input)

Natural Gas

Min: 15,000 Btuh

Max: 150,000 Btuh

Min: 17,000 Btuh

Max: 180,000 Btuh

Min: 17,000 Btuh

Max: 199,000 Btuh

Propane Gas

Min: 15,000 Btuh

Max: 150,000 Btuh

Min: 17,000 Btuh

Max: 180,000 Btuh

Min: 17,000 Btuh

Max: 199,000 Btuh

Heat Capacity

(Input)

35°F Rise

8.3 GPM

10.0 GPM

11 GPM

45°F Rise

6.5 GPM

7.7 GPM

8.6 GPM

77°F Rise

3.8 GPM

4.5 GPM

5.0 GPM

Dimensions

W17” x H28”x D14”

W17” x H28”x D15”

W17” x H28” xD15”

Weight NR-A, NP-A

77 lbs

86 lbs

86 lbs

Weight NR, NP

67 lbs

77 lbs

77 lbs

Installation Type

Indoor / Outdoor Wall-Hung

Venting Type

Forced Draft Direct Vent

Ignition

Electronic Ignition

Water Pressure (min-max)

15 – 150 PSI

Natural Gas Supply Pressure

(from source, Min ~ Max)

6”WC ~ 10.5” WC

5”WC ~ 10.5” WC

Propane Gas Supply Pressure

(from source, Min ~ Max)

9”WC ~ 13.5” WC

8”WC ~ 13.5” WC

Natural Gas Manifold Pressure

(min-max)

0.4”WC ~ 4.9” WC

0.4”WC ~ 3.5” WC

0.6”WC ~ 3.7” WC

Propane Gas Manifold Pressure

(min-max)

0.8”WC ~ 7.6” WC

0.8”WC ~ 5.9” WC

1.0”WC ~ 3.7” WC

Minimum Flow Rate

0 GPM for “A” models (no minimum flow rate requirement),

0.5 GPM for non-“A” models

Connection

Sizes

Cold Water Inlet

3/4” NPT

Hot Water Outlet

3/4” NPT

Gas Inlet

3/4” NPT

Power Supply

Main Supply

120VAC, 60Hz

Maximum Power

Consumption

200W (max 2A)

Materials

Casing

Cold Rolled Carbon Steel

Heat Exchangers

Primary Heat Exchanger: Stainless Steel

Secondary Heat Exchanger: Stainless Steel

Venting

Exhaust (ø3”)

ø3” PVC, ø3” CPVC, ø3” Special Gas Vent Type BH

(Class IIA (PVC) and Class I

Intake (ø3”)

PVC, CPVC, Galvanized Steel, Flex Aluminum, Flex, ABS,

Vent Clearances

0” to combustibles

Safety Devices

Flame Rod,Thermal Fuse(Overheat Cut Off device)

APS, GPS, Gas-Valve Operation Detector,

Ignition Operation Detector, Water Temperature High Limit Switch,

Exhaust Temperature High Limit Switch

Accessories

Remote Controller, Plumb Easy Valve Set,

Condensate Neutralizer, Ready-Link Communication Cable

SPECIFICATIONS

Gas Water Heater Installation

6

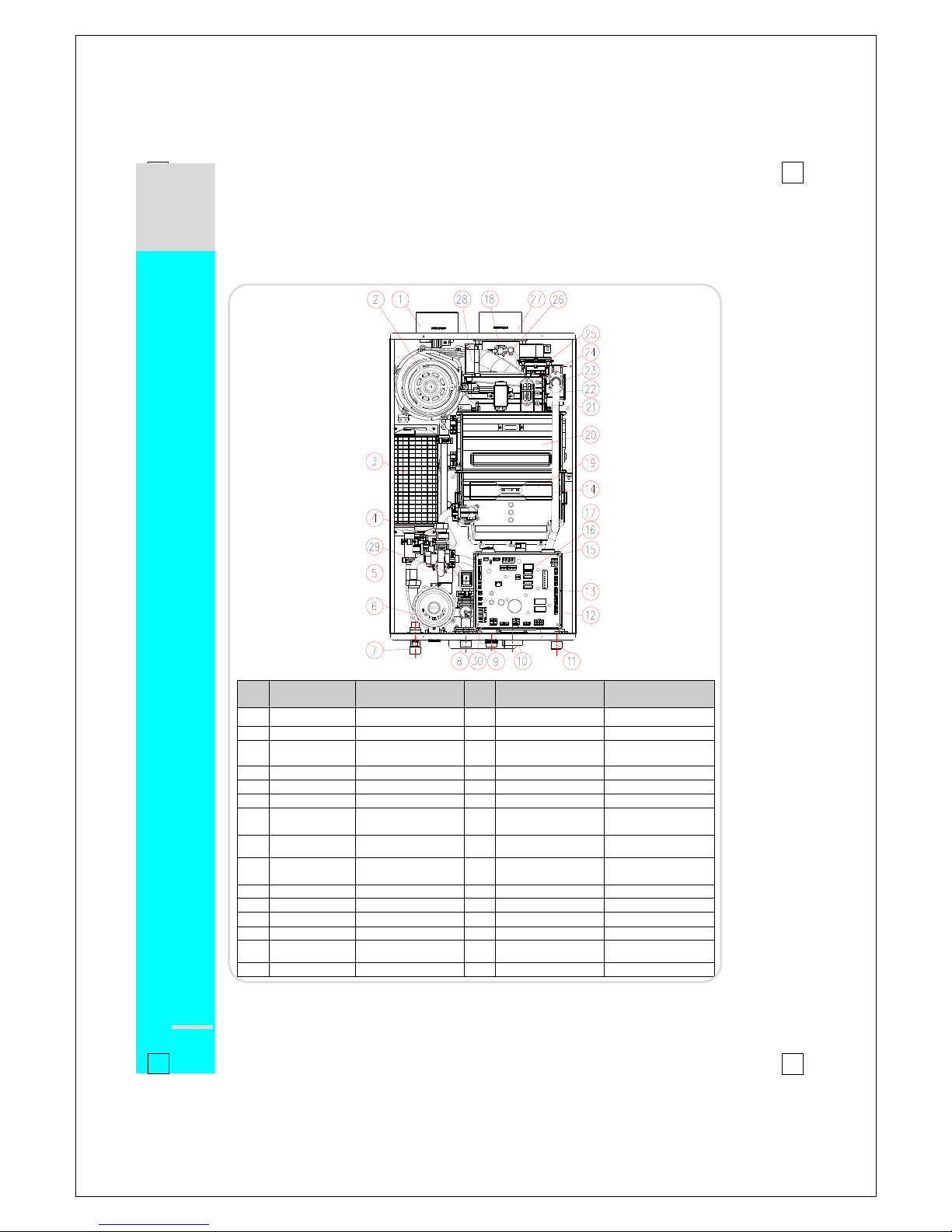

█

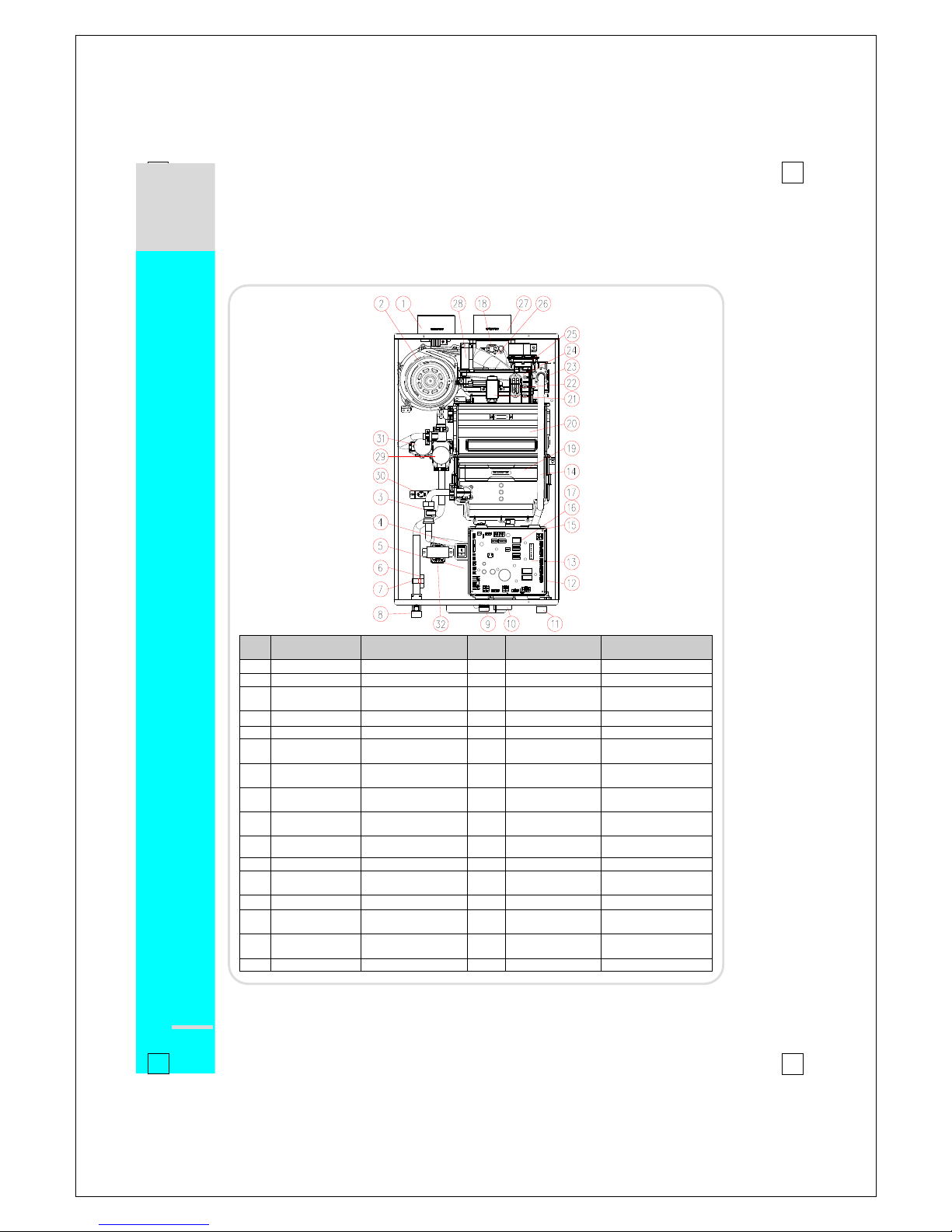

Key Components: NR-A

No

Description

Navien Part No.

No

Description

Navien Part No.

1

Intake Air Duct

BH2505400B

16

WAV

NCVM9EX00005

2

Fan Motor

NAFA9GLPCT01

17

Transformer

BH1205008A

3

Buffer Tank

PASNCWBFTANK_001

18

Exhaust Limit Switch

BH1401027A

4

Flow Sensor

BH1406004F

19

Secondary H/E

-

5

PCB Board

NACR1GS32410

20

Primary H/E

-

6

Circulation Pump

NAPU9GLPCT01

21

Ignition Transformer

BH1201041D

7

DHW Supply

Adapter

BH2507348B

22

APS Venturi

BH2501413A

8

3-Way Valve

BH2507467C

23

Manifold

PABCR180AMF_001

9

DHW Inlet

Adapter

BH2507469A

24

Burner

PABNCN30KDBN_003

10

Syphon

BH2507442C

25

APS

NASS9EX00009

11

Gas Inlet Adapter

BH2507396A

26

Exhaust Duct

BH2544004F

12

Main Gas valve

BH0901018A

27

Exhaust Pipe

BH2505401B

13

GPS Venturi

BH2507359B

28

Air Intake Guide

BH2543002C

14

Gas Pipe

BH2507509A

29

Power Switch

BH1426002A

15

GPS

NASS9EXGPS01

30

Water Leakage Detector

-

COMPONENTS & DIMENSIONS

O

U

T

I

N

Navien Gas Water Heater Installation

7

█

Key Components: NP-A

No

Description

Navien Part No.

No

Description

Navien Part No.

1

Intake Air Duct

BH2505400B

17

Transformer

BH1205008A

2

Fan Motor

NAFA9GLPCT01

18

Exhaust Limit Switch

BH1401027A

3

Buffer Tank

PASNCWBFTANK_001

19

Secondary H/E

-

4

Flow Sensor

BH1406004F

20

Primary H/E

-

5

PCB Board

NACR1GS32410

21

Ignition Trans

BH1201041D

6

Circulation Pump

NAPU9GLPCT01

22

APS Venturi

BH2501413A

7

DHW Supply

Adapter

BH2507348B

23

Manifold

PABCR180AMF_001

8

3-Way Valve

BH2507467C

24

Burner

PABNCN30KDBN_003

9

DHW Inlet Adapter

BH2507469A

25

APS

NASS9EX00009

10

Syphon

BH2507442C

26

Exhaust Duct

BH2544004F

11

Gas Inlet Adapter

BH2507396A

27

Exhaust Pipe

BH2505401B

12

Main Gas valve

BH0901018A

28

Air Intake Guide

BH2543002C

13

GPS Venturi

BH2507359B

29

Power Switch

BH1426002A

14

Gas Pipe

BH2507351A

30

Water Leakage

Detector

-

15

GPS

NASS9EXGPS01

31

WAV

NCVM9EX00005

16

2-Way Valve

BH0914002B

COMPONENTS & DIMENSIONS

O

U

T

I

N

Gas Water Heater Installation

8

█

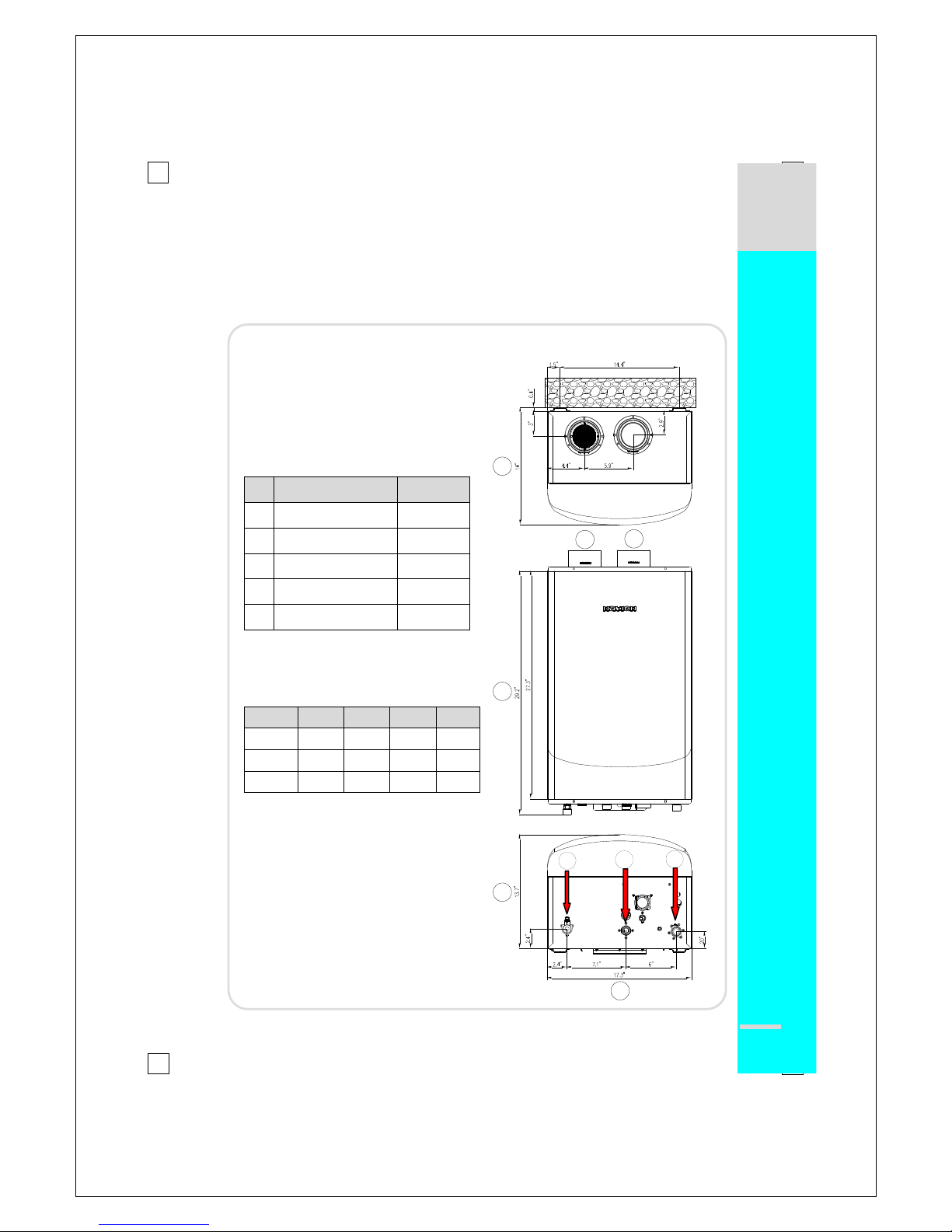

Dimensions: NR-A, NP-A

NR-A , NP-A

Description

Diameter A Exhaust

3” B Air Intake

3”

C

DHW Supply

¾”

D

Recirculation Inlet

¾”

E

Cold Water Inlet

¾” F Gas Inlet

¾”

NR-A , NP-A Type Dimensions

Model

① ② ③ ④ 180

14”

29.2”

13.7”

17.3”

210

15.2”

29.2”

14.9”

17.3”

240

15.2”

29.2”

14.9”

17.3”

COMPONENTS & DIMENSIONS

A

B

1

2

3

4

C

D

E

F

Navien Gas Water Heater Installation

9

█

Key Components: NR

No

Description

Navien Part No.

No

Description

Navien Part No.

1

Intake Duct

BH2505400B

17

Transformer

BH1205008A

2

Fan Motor

NAFA9GLPCT01

18

Exhaust Limit Switch

BH1401027A

3

Flow Sensor

BH1406004F

19

Secondary H/E

-

4

Power Switch

BH1426003A

20

Primary H/E

-

5

PCB Board

NACR1GS32401

21

Ignition Trans

BH1201041D

6

Heater

BH1501047B

22

APS Venturi

BH2501413A

7

Heater Clip

BH2507447A

23

Manifold

PABCR180AMF_001

8

DHW Supply Adapter

BH2507348B

24

Burner

PABNCN30KDBN_003

9

DHW Inlet Adapter

BH2507469A

25

APS

NASS9EX00009

10

Syphon

BH2507452C

26

Exhaust Duct

BH2544004F

11

Gas Inlet Adapter

BH2507396A

27

Exhaust Pipe

BH2505401B

12

Main Gas valve

BH0901018A

28

Air Intake Guide

BH2543002C

13

GPS Venturi

BH2507359B

29

Bypass Mixing Valve

AAVC9EXMIX01

14

Gas Pipe

BH2507351A

30

Freeze Protect Switch

BH1402001A

15

GPS

NASS9EXGPS01

31

Mixing Trans

BH1205013A

16

WAV

NCVM9EX00005

COMPONENTS & DIMENSIONS

Gas Water Heater Installation

10

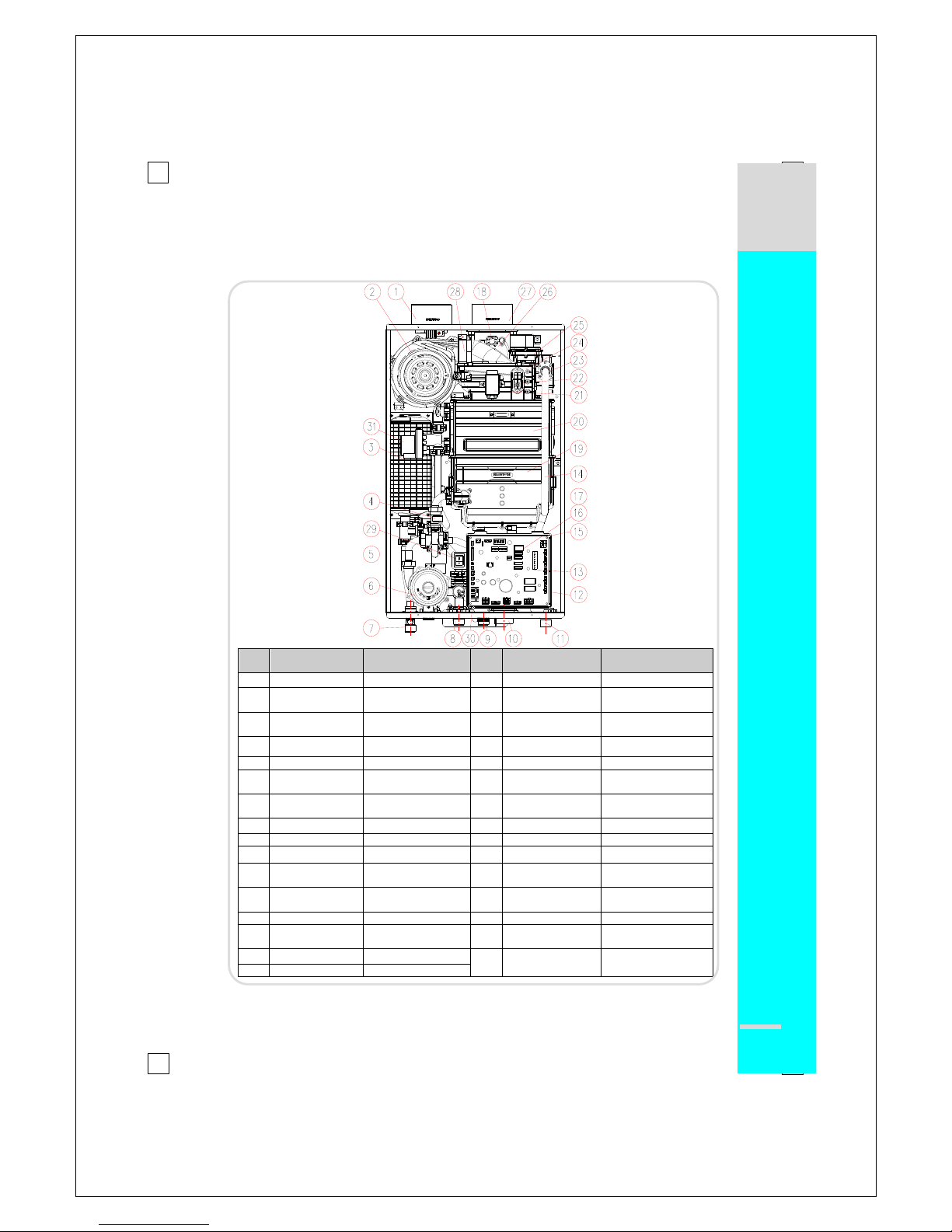

█

Key Components: NP

No

Description

Navien Part No.

No

Description

Navien Part No.

1

Intake Air Duct

BH2505400B

17

Transformer

BH1205008A

2

Fan Motor

NAFA9GLPCT01

18

Exhaust Limit Switch

BH1401027A

3

Flow Sensor

BH1406004F

19

Secondary H/E

-

4

Power Switch

BH1426003A

20

Primary H/E

-

5

PCB Board

NACR1GS32401

21

Ignition Trans

Bh1201041D

6

Heater

BH1501047B

22

APS Venturi

BH2501413A

7

Heater Clip

BH2507447A

23

Manifold

PABCR180AMF_001

8

DHW Supply

Adapter

BH2507348B

24

Burner

PABNCN30KDBN_003

9

DHW Inlet Adapter

BH2507469A

25

APS

NASS9EX00009

10

Syphon

BH2507452C

26

Exhaust Duct

BH2544004F

11

Gas Inlet Adapter

BH2507396A

27

Exhaust Pipe

BH2505401B

12

Main Gas valve

BH0901018A

28

Air Intake Guide

BH2543002C

13

GPS Venturi

BH2507359B

29

WAV

NCVM9EX00005

14

Gas Pipe

BH2507351A

30

Freeze Protect

Switch

BH1402001A

15

GPS

NASS9EXGPS01

31

Bypass Mixing Valve

AAVC9EXMIX01

16

2-Way Valve

BH0914002B

32

Mixing Trans

BH1205013A

Navien Gas Water Heater Installation

11

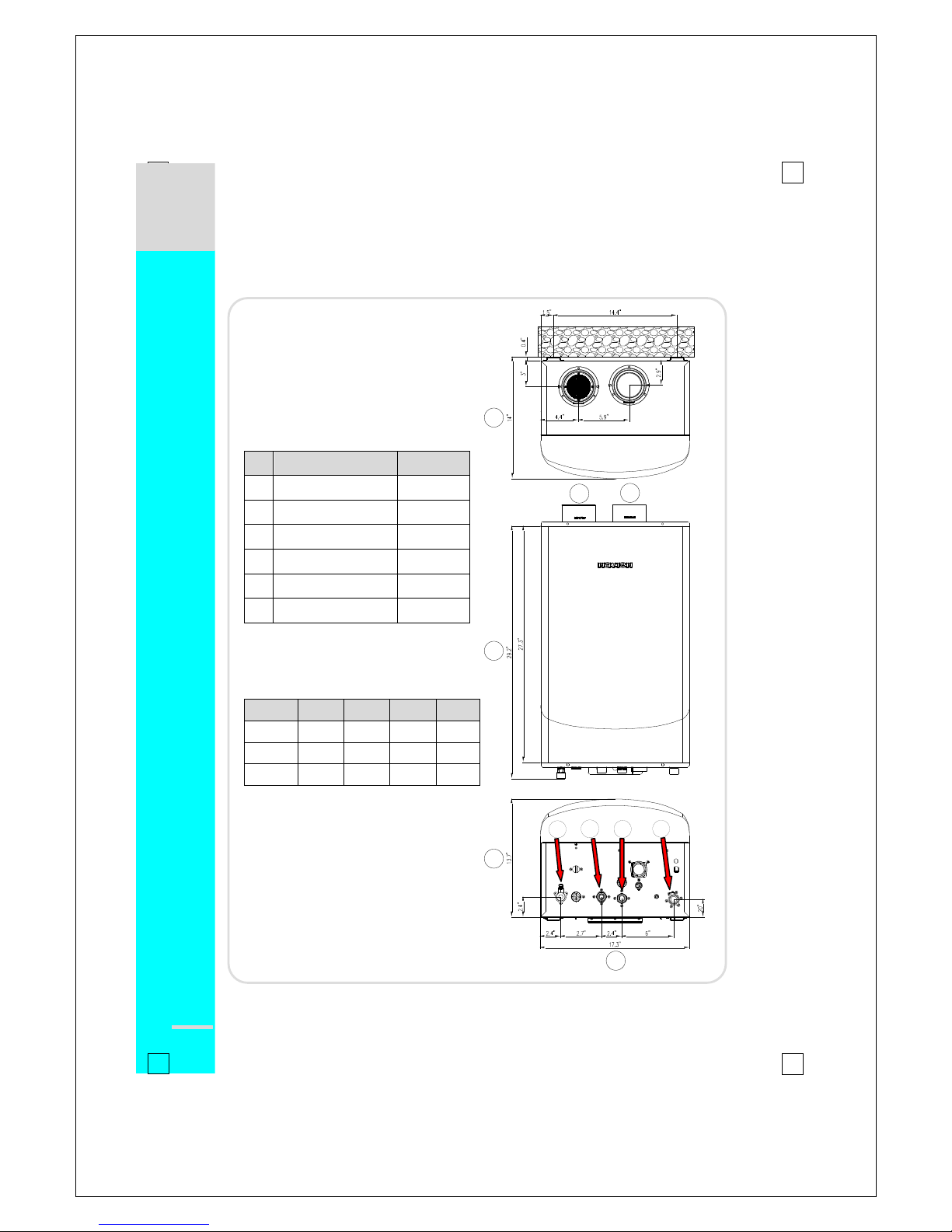

█

Dimensions: NR, NP

NR, NP

Description

Diameter

A

Exhaust

3”

B

Air Intake

3”

C

DHW Supply

¾”

D

Cold Water Inlet

¾”

E

Gas Inlet

¾”

NR, NP Type Dimensions

Model

① ② ③

④

180

14”

29.2”

13.7”

17.3”

210

15.2”

29.2”

14.9”

17.3”

240

15.2”

29.2”

14.9”

17.3”

COMPONENTS & DIMENSIONS

A

B

1

2

3

4

C

D

E

Gas Water Heater Installation

12

█

Installation Warnings:

Read all safety warnings in the “Owner’s Operation Manual”. The additional safety

issues outlined below must also be followed completely when installing this Navien

Water Heater:

1. This unit is designed for indoor installations. DO NOT operate this unit without the vent piping

connected. Exhaust gases must be completely expelled out of the building.

2. DO NOT use this appliance if any part has been underwater. Immediately call a qualified

service technician to inspect the appliance and replace any part of the control system and any

gas control which has been underwater.

3. Be sure not to reverse the water and gas connections as this may damage the gas valves.

4. Water temperature over 125°F can cause severe burns instantly or death from scalds. If the

proposed water heater outlet temperature is above 125°F, a thermostatically controlled mixing

valve (or a temperature limiting valve) for reducing point of use water temperature is

recommended to reduce the risk of scald injury. Contact a licensed plumber or the local

plumbing authority for further information.

5. The appliance should be located in an area where leakage within the unit or at its connections

will not result in damage to the surrounding area. Navien will not be responsible for any

damage resulting from leaking if adequate drainage is not provided.

6. DO NOT use this water heater for any purpose other than water heating and space heating.

7. If the water quality is known to have high acidity and/or high hardness, water treatment is

recommended to maintain full warranty. Consult the local water authority.

8. Protect against snow accumulation around the vent terminations. Ensure the exhaust vent

pipe and the intake airpipe remain clear from obstructions at all times.

9. DO NOT overtighten fittings as pipe and/or fitting damage may occur causing leakage.

10. DO NOT install water heater where subject to vibtations.

11. The vent for this appliance shall not terminate over public walkways, near soffit vents, crawl

space vents, or other areas where condensate or vapor could create a nuisance, hazard, or

cause property damage. The vent also should not terminate where condensate or vapor could

cause damage or could be detrimental to the operation of regulators, relief valves, or other

equipment.

12. For other than a direct vent appliance, the appliance must be located as close as possible to a

chimney or gas vent.

13. Should overheating occur or if the gas supply fails to shut off, turn off the manual gas control

valve to the appliance.

Follow all local codes and/or the most recent edition of the National Fuel Gas

Code (ANSI Z223.1/NFPA 54) in the USA or the Natural Gas and Propane

Installation Code in Canada (CAN/CGA B149.1).

Navien Gas Water Heater Installation

13

█

Getting Started:

CHECK THE RATING PLATE

Navien units come from the factory configured for use with either Liquid Propane (LP) or

Natural Gas (NG). Before starting the installation, check the rating plate located on

the backside of the front cover of the Water Heater to ensure the unit matches gas type,

gas pressure, water pressure and electrical supply. If the unit does not match

following requirements, do not install.

Be sure the gas type and electricity voltage

match the Rating Plate.

Use only the same gas type indicated on

the rating plate of the Navien Water Heater.

Using different gas type will cause

abnormal combustion and Water Heater

malfunction.

Be sure to use 120V AC, 60Hz, minimum

2A current. Using abnormally high or low

AC voltage may cause abnormal operation,

and may reduce the life expectancy of this

product.

If not certain, please contact Navien immediately.

Conversion of this unit from natural gas to propane or vise versa cannot be done in

the field. Please re-confirm gas type on the rating plate (left side of unit) before

installing. DO NOT attempt any field conversion; this will result in dangerous

operating conditions and will void all warranty.

Navien America Inc. is not liable for any property damage and/or personal

injury resulting from unauthorized conversions.

Gas Water Heater Installation

14

█

Check Rating Plate:

Sample Rating Plate

DO NOT install the Navien Water Heater in areas with excessively high humidity:

DO NOT install the unit in a location where

there is excessively high humidity such as

bathrooms, damp crawl space and other areas

such as this. This may cause the unit to

malfunction.

To avoid possible electrical shock, DO NOT

touch the internal components of the water

heater or the power cord with wet hands.

DO NOT splash excessive water on the Water

Heater or remote controller when cleaning: they

are water resistant, not water proof.

Rating Plate, *Plaque Signalétique

Automatic Instantaneous Water Heater,

*Chauffe-eau automatique instantané

Navien America Inc.

1371 Santa Fe Drive, Tustin, CA 92780

Tel: (714) 258 - 9005

Model No

. , *N de modèle

Type of Gas

, *Type de gaz

NR-180 NG *GAZ NATUREL

Max. Input Rating,

*Entrée GPL max.

Min. Input Rating,

*Débit calorifique max.

150,000 Btuh 15,000 Btuh

Recovery Rating,

*Calibre de recouvrement :

227 Gallons/Hour

, *gallons/heures

Max. Inlet Gas Pressure,

*Pression max. de gaz d’entrée

10.5 Inches W.C.

*pouces W.C.

Min. Inlet Gas Pressure, *Pression min. de gaz d’entrée

6.0 Inches W.C.

,*pouces W.C.

Manifold Pressure, *Pression d’admission

4.9 Inches W.C.

*po W.C.

Electrical Rating, *Régime nominal électrique

AC

*c.a.

120 Volts 60Hz Use less than 2 Amp,

*Utilise moins de 2A

Max. Water Pressure,

*Pression d’eau max.

150 Psi

*lb/po2

ANSI Z21. 10. 3b – CSA 4.3B-2004

RATING PLATE

Navien Gas Water Heater Installation

15

█

Locating the Water Heater:

Location selection may not necessarily affect the operation of the

Navien water heater but it will affect the customer’s experience and level

of satisfaction with the product. Understanding that each building is

different, the contractor will have to select the best location based on a

combination of the following factors:

1. Locate Navien Water Heater close to a drain where condensed water and possible

water leakage will not damage to surrounding areas. A significant amount of

condensed water will be produced each time the water heater is used. In addition,

as with any water heating appliance, the potential for leakage at some time in the

life of the product does exist. If there is no drain, Navien will not be responsible for

any water damage that may occur.

2. Locate where the domestic water supply comes into the building.

3. Locate where the gas supply comes into the building.

4. Locate the unit close to the main fixtures in the home (bathrooms, kitchen, laundry,

etc.). Select a location that minimizes the water piping distance between the major

fixtures. If the distances are long or an appliance needs “instant” hot water, Navien

recommends using its “A” models and running a recirculation line back from the

furthest fixture. Insulate as much of the hot water supply line and recirculation line

as possible.

5. Consider Venting Options: Select a location that minimizes the amount of venting

required. Consider venting restrictions from windows, doors, air intakes, gas meters,

neighbor’s houses, etc.

Maintain proper clearances from any openings in the building (see chart in

venting section).

Navien Water Heater requires a minimum clearance of 12 inches above the

exterior grade.

Do not install the water heater where moisture from the exhaust may cause

discoloration or damage to walls.

Install the exhaust vent so that there are no obstacles around the termination and

so that exhaust cannot accumulate.

Do not enclose the termination.

Do not install the water heater near vents for heating or cooling. A minimum of 4

feet (1.2m) should be maintained.

6. It is not recommended to install the Water Heater in bathrooms, bedrooms, any

occupied rooms normally kept closed, or in indoor areas without proper venting.

LOCATION SELECTION

Gas Water Heater Installation

16

█

Locating the Water Heater:

7. Select a location that ensures the unit will have sufficient and clean combustion air;

avoid installation where dust or debris will accumulate; avoid installation where

chemical agents (e.g., hair spray, spray detergent, chlorine, chemicals) are used.

8. If installing into a very tight space or corner, please ensure there is sufficient service

and maintenance access to all gas and water piping to ensure that regular

maintenance (such as cleaning the water filter, the air filter and the condensate trap)

will not become problematic.

Allow sufficient clearance:

Indoor Install

Outdoor Install

Top of Water Heater

Min. 9 inches

Min. 36 inches

Back of Water Heater

Min. 0.5 inches

Min. 0.5 inches

Front of Water Heater

Min 4 inches

Min. 24 inches

Sides of Water Heater

Min. 3 inches

Min. 3 inches

Bottom of Water Heater

Min. 12 inches

Min. 12 inches

9. DO NOT install in an area that contains or stores gasoline or other flammables.

10. Ensure that combustibles are clear of the immediate area. Ensure hanging laundry

or other such items will not impede the air movement into or out of the Water Heater

or its venting.

11. For commercial applications, avoid greasy fumes or a large amount of steam; take

measures to prevent the fumes and steam from entering in the equipment.

█

Mounting the Unit to the Wall:

1. All Navien units come with an upper mounting bracket pre-drilled at 16” on

center for easy installation on standard stud walls. Affix the bracket to the wall

securely, ensuring that it is level and that is can support the weight of the Water

Heater. If the strength of the wall is not sufficient, reinforce the area to prevent

any unsafe situations.

2. If the framing is not standard, reinforment of the wall is required or if installing

on an uneven surface, fasten ¾” plywood to the stud wall and then attach the

mounting brackets to the plywood.

3. When using the supplied mounting bracket, it creates a 5/8” clearance from the

back of the unit.

4. The upper bracket is installed on the wall and the Water Heater is then hung on

the bracket. On the back of the Water Heater at each of the top corners, there is

a hanger bracket on the back of the Water Heater that interlocks with a tab on the

wall mounting bracket.

▒

S

E

L

E

C

T

I

N

G

A

L

O

C

A

T

I

O

N

LOCATION SELECTION

Navien Gas Water Heater Installation

17

CAUTION

This Water Heater must only be used with the following water supply system conditions :

With clean, potable water free of corrosive chemicals, sand, dirt, of other contamintes.

With inlet water temperature above 32℉ (0℃), but not exceeding 140℉ (60℃).

Free of lime and scale deposits.

█

Plumbing:

Pipe Sizing

The water fittings on the Navien Water Heater are ¾”.

Although Navien’s water connections are ¾”, if the installation site has only ½” plumbing

throughout the building, it is NOT necessary to upsize the water lines to ¾” when installing a

single unit.

When installing multiple units to supply high volumes of hot water either in residential (multi-

head shower systems for example) applications or in commercial applications, the number of

Navien Water Heaters required and the header pipe sizing needs to be properly sized to meet

the total hot water demand. A water pressure of 40 PSI is recommended for each Water Heater

for proper operation of the Water Heaters. Consult the Navien website or call for further

information on sizing such applications.

Water Piping Guidelines

All pipes, pipe fittings, valves and other components, including solder, must be approved

for use in potable water systems.

The use of unions and manual shut off valves on both the cold water inlet and DHW outlet

are recommended.

The longer the piping, the longer it takes to get hot water to the fixtures. Make the hot

water piping system as short as possible.

To conserve water and energy, insulate all water piping especially the hot and recirculation

water lines. DO NOT cover the drain or pressure relief valve.

After the Water Heater has been installed, be sure to clean the inlet water filter located

within the cold inlet and then test the unit. The inlet water filter is there to prevent debris

from entering your heater. This will need to be cleaned periodically to maintain optimum

flow; See “draining the unit” and “cleaning the inlet water filter” procedures in the

maintenance section of the operation manual for instructions on these two procedures.

Space Heating

Piping and components connected to the Water Heater for the space heating application

shall be suitable for use with potable water.

The effect that toxic chemicals, such as used for boiler treatment, shall not be introduced

into the potable water used for space heating.

The effect that a water heater which will be used to supply potable wter shall not be

connected to any heating system or component(s) previously used with a nonpotable

water heating appliance.

Instructions that when the system requires water for space heating at temperatures higher

than required for other uses, a means such as a mixing valve shall be installed to temper

the water for those uses in order to reduce scald hazard potential. These instructions shall

include a piping diagram(s) for a typical installation.

PLUMBING

Gas Water Heater Installation

18

█

Plumbing:

Water Piping Guidelines

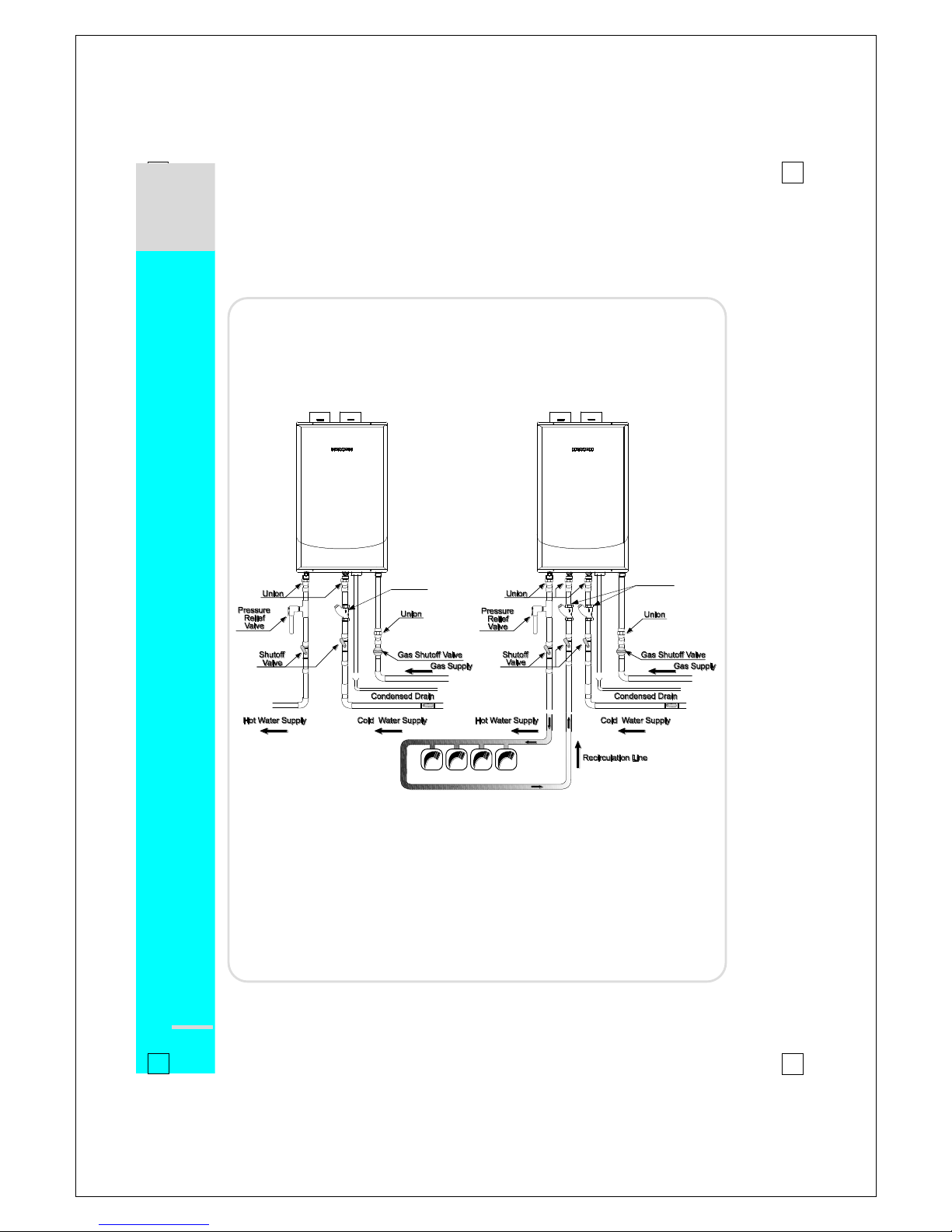

NR, NP Series NR-A, NP-A Series

NOTICE : If using mixing valves on the outlet, choose one which prevents cold water

pressure from overcoming hot water line pressure.

The flow rate of hot water may vary when more than two faucets(appliances,

fixtures, etc.) are being used simultaneously.

If a Water Heater is installed in a closed water supply system, such as one

having a backflow preventer in the cold water supply line, means shall be

provided to control thermal expansion. Contact the water supplier or local

plumbing inspector on how to control this situation.

PLUMBING

Y-Strainer

Y-Strainer

Navien Gas Water Heater Installation

19

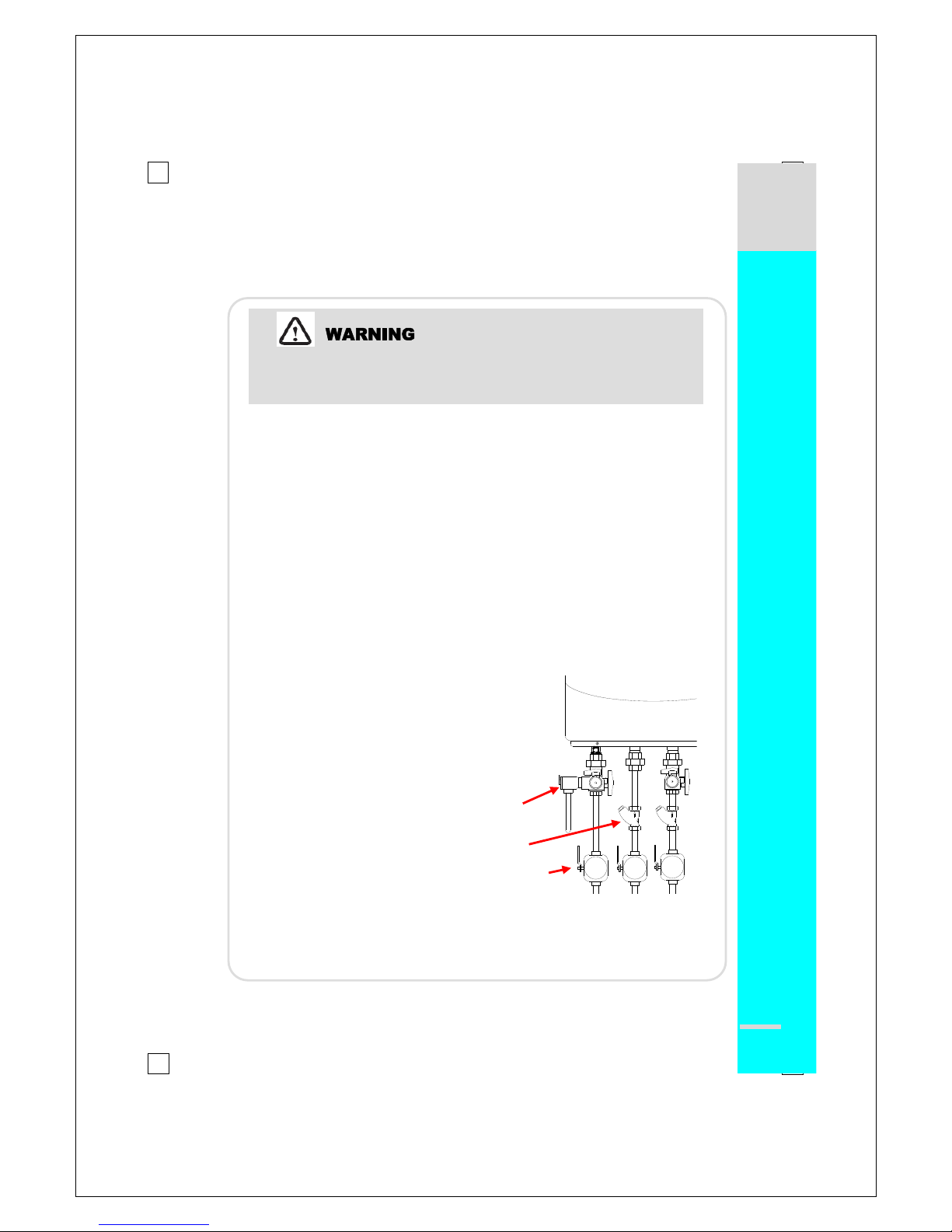

█

Pressure Relief Valve:

An approved ¾”, maximum 150 PSI pressure relief valve must be installed on the

hot water outlet, as close to the unit as possible. Please see below for more

information on approved pressure relief valves.

Each Navien Water Heater has a high-temperature shut off switch built in as a

standard safety feature (called a temperature high limit switch) therefore a “pressure

only” relief valve is required. This unit does not come with a pressure relief valve

but one must be installed on the hot water outlet.

The discharge capacity of the pressure relief valve must be at least equal to the

maximum pressure rating of the Water Heater.

The maximum input BTUH rating on the valve must be equal to or greater than the

maximum input BTUH rating of the Water Heater.

The discharge piping for the pressure relief valve must be directed so that the hot

water cannot splash on anyone or on nearby equipment. Attach the discharge tube

to the pressure relief valve and run the end of the tube to within 6" from the floor.

This discharge tube must allow free and complete drainage without any restrictions.

No reducing coupling or other restriction may be installed in the discharge line.

The following ¾”, maximum 150 PSI valves are

examples of valves approved for use with all

Navien products:

1. Wilkins P-1000A (Zurn Industries)

2. Conbraco 17-402-04

3. Watts Industries 3L(M7)

4. Cash Acme FWL-2 ¾”

Instructions for pressure, temperature and vacuum relief valves shall specify that no

valve is to be placed between the relief valve and the tank. The instructions shall specify

installation in such a manner that the discharge from temperature and pressure relief

valves will be conducted to a suitable place for disposal when relief occurs and that no

reducing coupling or other restriction be installed in the discharge line.

PRESSURE RELIEF VALVE

Failure to comply with the guidelines on installing the pressure relief valve

and discharge piping can result in personal injury, death or substantial

property damage.

Pressure

Relief Valve

Hot Rec Cold

Y-Strainer

Shut-off Valve

Gas Water Heater Installation

20

█

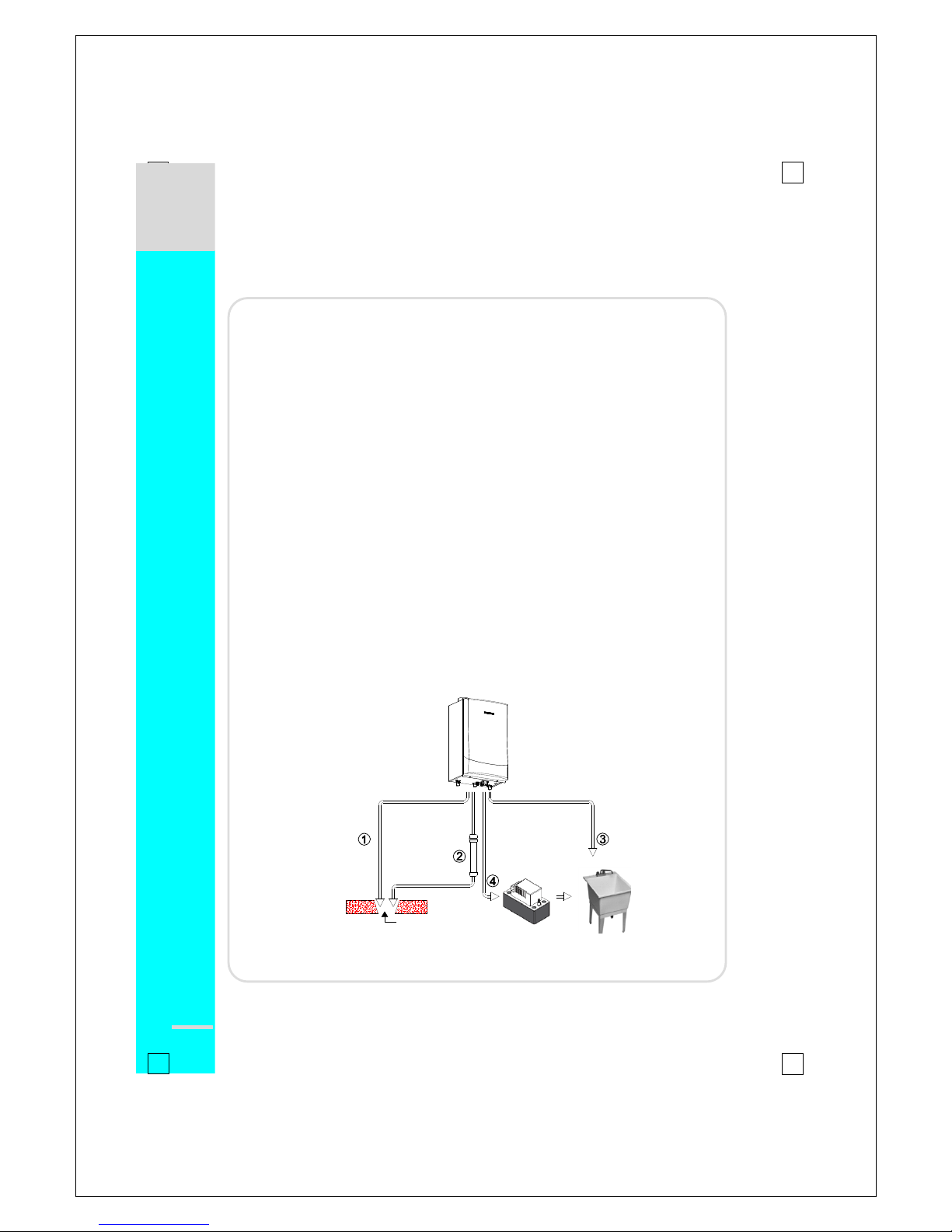

Disposal of Condensate:

▶ This Navien Water Heater is a high efficiency gas appliance that creates

condensation when it operates. Condensation has an acidic (pH) of approximately

3~4. Follow your local code with regards to the disposal of condensation. Here are

several options for the Disposal of Condensate (see diagram below):

① From Water Heater direct to drain.

② From Water Heater to neutralizer to drain.

③ From Water Heater to laundry tub (bottom of water heater must be above the

height of laundry tub; must have a negative slope to properly drain).

④ From Water Heater to condensate pump to laundry tub (for long distances

between water heater and laundry tub or when bottom of Water Heater is

installed below height level of laundry tub).

▶ All Navien’s NR & NP Series Water Heaters are condensing gas appliances. A

condensate trap comes factory installed inside each Water Heater.

▶ All condensate must be drained in accordance with all local regulations. Navien

recommends draining the condensate to a laundry tub as the alkalie in the

detergent from the washing machine will neutralize the acid in the condensation. If a

laundry tub is not close by, you may need to install a condensate pump to push the

condensate to the nearest laundry tub or consider installing a condensate

neutralizer so that you can release the neutralized (non-acidic) water into a regular,

nearby drain.

▶ If a neutralizer is installed, periodic replacement of the lime stone (or neutralizing

agent) will be required. The rate of depletion of the lime stone varies upon usage of

the water heater. During the first year of operation, please check the neutralizer

every few months for depletion. If you notice any depletion, order some

replacement neutralizer lime stone.

▶ Use only corrosion-resistant materials for the condensate drain lines such as ¾” ID

PVC pipe vinyl or plastic hose.

CONDENSATE DISPOSAL

Floor drain

Navien Gas Water Heater Installation

21

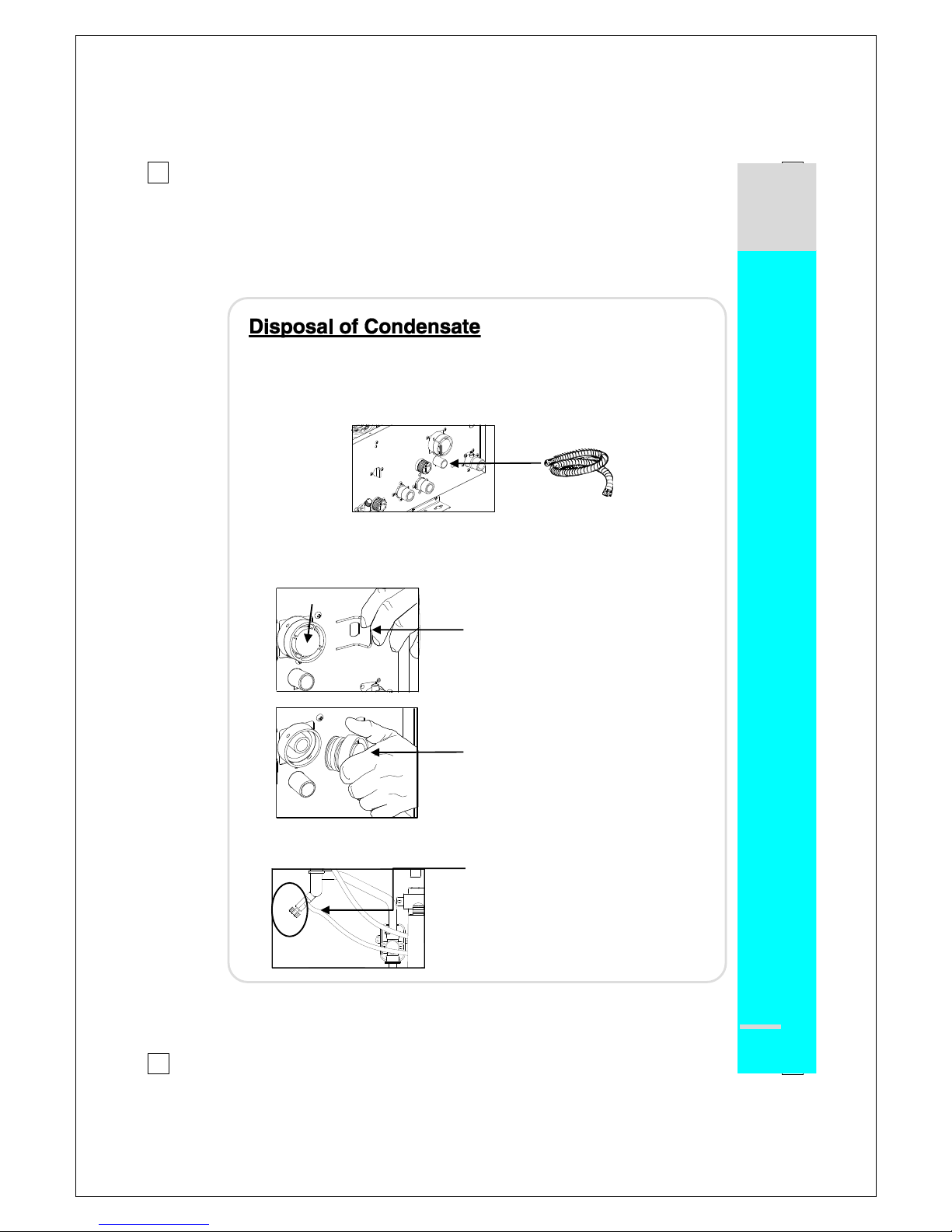

█

Condensate Drain & Cleaning:

A condensate drain tube is included with the Navien Water Heater. This tube

must be connected to the port at the bottom of the unit (see below). The end of

the tube should drain to a laundry tub or to a floor drain. If additional tubing is

required, any ¾” polyvinyl tubing should suffice.

Over time, blockage of the siphon by debris may occur; when the condensate

cannot be released, the water heater will go into error and will shut down. When

this occurs, the siphon must be cleaned. To clean, you will need a bucket to

collect any residual water. See figures below.

Remove retaining clip

Prepare bucket; twist and remove cap;

drain, clean out siphon and re-insert cap

and retaining clip.

Once the cap and clip have been re-inserted, the syphon must be re-filled. See

figure below.

Open the valve and water will begin to fill in

the syphon. Fill the siphon to the top and

then close the valve.

Open a hot water faucet; examine the

open end of the condensate drain line to

ensure no flue gases are exiting from that

pipe. If the flue gases are exiting,

immediately stop the unit and call Navien

for additional instructions.

CONDENSATE DISPOSAL

siphon

Gas Water Heater Installation

22

█

Gas Piping:

Navien recommends the Water Heater be the first appliance installed

downstream of the gas meter to ensure it will have sufficient gas supply.

Use the charts on the following pages to properly size the gas supply line.

The gas connection fitting on all Navien units is ¾”. DO NOT use less than ¾” piping.

When using flexible gas line, ensure the pipe’s inner diameter is sufficient to supply

the required BTUs, also ensure that the flexible line has no crimps or tight bends this

will restrict gas flow.

Install a manual gas shut-off valve on the gas supply line and the water heater.

When using rigid pipe, Navien recommends the installation of a union on the gas

supply pipe close to the water heater to facilitate any future maintenance and

service.

1. The minimum and maximum inlet gas pressures are:

Natural Gas Min. 5.0(6.0 : 180)” WC - Max. 10.5” WC

Propane Gas Min. 8.0(9.0 : 180)” WC - Max. 13.5” WC

2. Gas pressures over and above the specified ranges will result in adverse

performance and dangerous operating conditions, any damage resulting from

extreme gas supply pressures will not be covered by the limited warranty.

3. Until pressure testing of the main gas supply line is completed, ensure the gas line to

the Navien Water Heater is disconnected to avoid any damage to the Water Heater.

4. The appliance must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ psi (3.5 kPa);

5. The gas appliance and its gas connections must be leak tested before placing the

appliance in operation. Leaks can be found by using a gas leak detetion device or

by applying soapy water to all gas fittings. Should bubbles occur tighten those

connections and re-test.

6. Always purge the gas line for any debris before connecting to the Water Heater gas

inlet.

7. Never use an open flame to test for gas leaks, as property damage, personal injury,

or death could result.

GAS PIPING

Gas supply Line Pressures:

Navien Gas Water Heater Installation

23

█

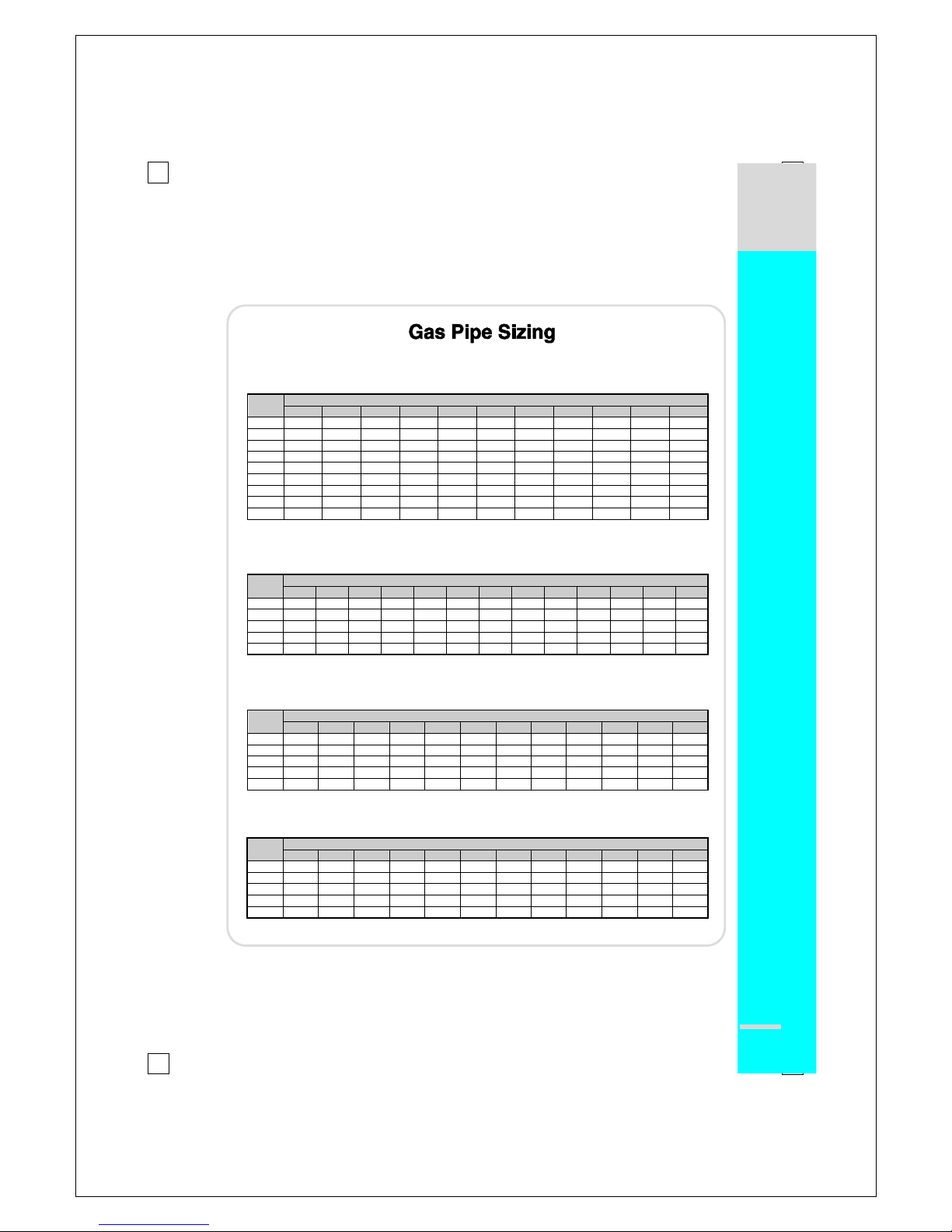

Gas Pipe Sizing Chart:

Maximum Natural Gas Delivery Capacity

in Cubic Feet (

ft3) per Hour (0.60 Specific Gravity, 0.5" WC Pressure Drop)

Pipe

Size

Length in Feet

10'

20'

30'

40'

50'

60'

70'

80'

90'

100'

125'

3/4"

363

249

200

171

152

138

127

118

111

104

93

1"

684

470

377

323

286

259

239

222

208

197

174

1 1/4"

1,404

965

775

663

588

532

490

456

428

404

358

1 1/2"

2,103

1,445

1,161

993

880

798

734

683

641

605

536

2"

4,050

2,784

2,235

1,913

1,696

1,536

1,413

1,315

1,234

1,165

1,033

2 1/2"

6,455

4,437

3,563

3,049

2,703

2,449

2,253

2,096

1,966

1,857

1,646

3"

11,412

7,843

6,299

5,391

4,778

4,329

3,983

3,705

3,476

3,284

2,910

3 1/2"

16,709

11,484

9,222

7,893

6,995

6,338

5,831

5,425

5,090

4,808

4,261

4"

23,277

15,998

12,847

10,995

9,745

8,830

8,123

7,557

7,091

6,698

5,936

Contact your gas supplier for BTU/ft3 rating. Use 1000 BTU/ft3 for simplied calculation.

Maximum Liquefied Propane Delivery Capacity

in Thousands of BTU/Hour (0.5" WC Pressure Drop)

Pipe

Size

Length in Feet

10'

20'

30'

40'

50'

60'

70'

80'

90'

100'

125'

150'

200'

3/4"

567

393

315

267

237

217

196

185

173

162

146

132

112

1"

1,071

732

377

323

286

259

239

222

208

197

174

252

213

1 1/4"

2,205

1,496

775

663

588

532

490

456

428

404

358

511

440

1 1/2"

3,307

2,299

1,161

993

880

798

734

683

641

605

536

787

675

2"

6,221

4,331

2,235

1,913

1,696

1,536

1,413

1,315

1,234

1,165

1,033

1,496

1,260

** For reference only. Please consult gas pipe manufacturer for actual pipe capacities.

Maximum Natural Gas Delivery Capacity with Corrugated Stainless Steel Pipe

in Cubic Feet (

ft3) per Hour (0.60 Specific Gravity, 0.5" WC Pressure Drop)

Pipe

Size

Length in Feet

10'

20'

30'

40'

50'

60'

70'

80'

90'

100'

150'

200'

3/4"

206

147

121

105

94

86

80

75

71

67

55

48

1"

383

269

218

188

168

153

141

132

125

118

94

82

1 1/4"

614

418

334

284

251

227

209

194

181

171

137

116

1 1/2"

1,261

888

723

625

559

509

471

440

415

393

320

277

2"

2,934

2,078

1,698

1,472

1,317

1,203

1,114

1,042

983

933

762

661

Maximum Liquefied Propane Delivery Capacity with Corrugated Stainless Steel Pipe

in Thousands of BTU/Hour ( 0.5" WC Pressure Drop)

Pipe

Size

Length in Feet

10'

20'

30'

40'

50'

60'

70'

80'

90'

100'

150'

200'

3/4"

325

232

191

166

149

136

126

118

112

106

87

76

1"

605

425

344

297

265

241

222

208

197

186

143

129

1 1/4"

971

661

528

449

397

359

330

307

286

270

217

183

1 1/2"

1,993

1,404

1,143

988

884

805

745

696

656

621

506

438

2"

4,638

3,285

2,684

2,327

2,082

1,902

1,761

1,647

1,554

1,475

1,205

1,045

** For reference only. Please consult gas pipe manufacturer for actual pipe capacities.

GAS PIPING

Referenced from Uniform Plumbing Code 1997

Gas Water Heater Installation

24

█

Measuring Inlet Gas Pressure:

Procedure to measure the inlet gas pressure:

1. Shut off the manual gas valve on the supply gas line.

2. Open a hot faucet. The unit should turn on and the gas in the gas

pipe line should purge. Leave the faucet on to keep the unit

running until the unit shuts down due to lack of gas supply.

Then shut off the hot faucet.

3. Remove the screw for the pressure port located on the gas

inlet of the Water Heater.

4. Connect a manometer to the pressure port and reset it to

zero.

5. Re-open the manual gas valve. Check to see that there are

no gas leaks.

6. Open multiple fixtures that have high flow rates (bathtub, showers, kitchen sink) to

ramp the Water Heater up to its maximum burn.

7. When the Navien Water Heater is at maximum burn, check the inlet gas pressure

reading on the manometer; it should read between 5.0” and 10.5” WC for Natural gas

between 8.0” to 13.5” WC for Liquid Propane.

8. The maximum inlet gas pressure must not exceed the value specified by the

manufacturer and the minimum value listed is for the purposes of input adjustment.

GAS PRESSURE TESTING

The Navien Water Heater cannot operate properly without sufficient inlet gas

pressure and volume. Below are instructions on how to check the inlet gas

pressure.

CAUTION

THIS IS ONLY TO BE DONE BY A LICENSED PROFESSIONAL.

Pressure test port on gas line

Loading...

Loading...