Navien NFB-175, NFB-200 Quick Installation Manual

1

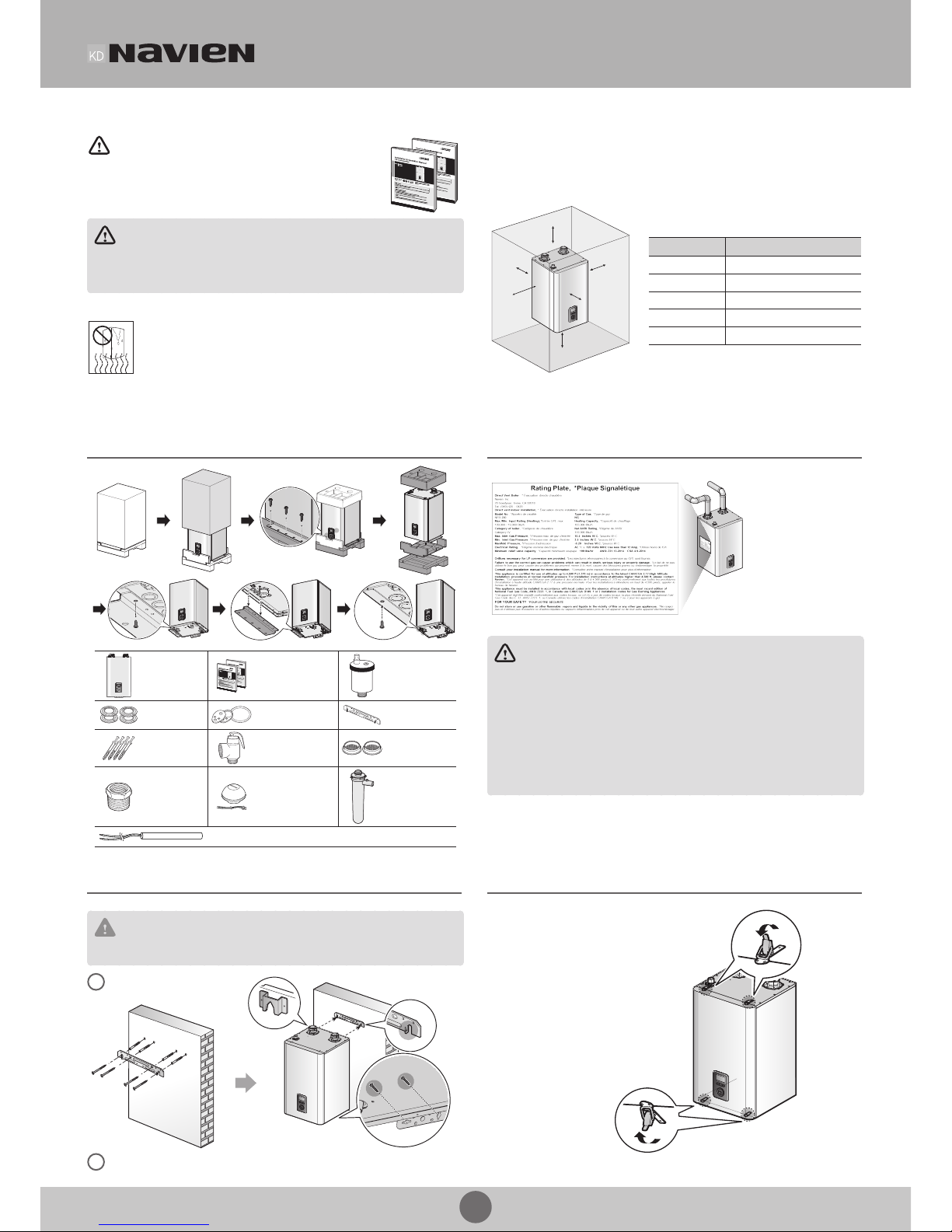

Unpacking

Navien

Condensing

Boiler

User’s Information

Manual, Installation

& Operation Manual

Air Vent

Wall Flanges Conversion Kit

Wall Mounting

Bracket

Tapping screws

and anchors

Pressure Relief Valve,

Heating

Vent Termination

Caps

Air Vent

Bushing

(

3

/4 in to 1/2 in)

Outdoor

Temperature Sensor

and Cable

Condensate Trap

System Temperature Sensor

Model

NFB-175/200

Quick Installation Guide

STEP 1 Before Installing

Read the Installation & Operation Manual before installing.

This product must be installed and serviced by a licensed plumber,

a licensed gas tter, or a professional service technician. Navien is

not liable for any damages or defects resulting from improper

installation.

WARNING

Follow all local codes and/or the most recent edition of the National Fuel Gas Code (ANSI

Z223.1/NFPA 54) in the USA, or the Natural Gas and Propane Installation Code in Canada

(CAN/CGA B149.1).

Safety

DO NOT install the boiler in areas with excessively high humidity.

Location Requirements

Select the best location on “Choosing an Installation Location” in the Installation &

Operation Manual.

Allowable minimum clearances

Top

Back

Side

Side

Front

Bottom

Clearance Indoor Installation

Top 9 in (229 mm) minimum

Back 0.5 in (13 mm) minimum

Front 4 in (100 mm) minimum

Sides 3 in (76 mm) minimum

Bottom 12 in (300 mm) minimum

STEP 2 Installing

Checking the Rating Plate

>

This boiler is congured

for Natural Gas from the

factory. If conversion to

Propane Gas in required,

the conversion kit supplied

with the boiler must be

used.

WARNING

· Before connecting the gas supply, determine the gas type and pressure for the boiler by

referring to the rating plate. Use only the same gas type indicated on the rating plate. Using a

dierent gas type will result in abnormal combustion and malfunction of the boiler. Gas

supplies should be connected by a licensed professional only.

· The appliance and its gas connection must be leak tested before placing the appliance in

operation.

· This boiler cannot be converted from natural gas to propane or vice versa without a Navien gas

conversion kit. Do not attempt a eld conversion of this boiler without a Navien gas conversion

kit. Doing so will result in dangerous operating conditions and will void the warranty.

Navien Inc. is not liable for any property damage and/or personal injury resulting from

improper conversions.

Mounting on the Wall

>

CAUTION

Do not install the boiler on dry walls without proper reinforcement.

Drill in the supplied anchor bolts

after considering where the vent

termination will be located.

1

Lift up the boiler, rest the unit on the hooks

provided on the wall bracket on the wall.

Secure the mounting bracket to the wall

with the tapping screws and anchors.

2

Removing the Front Cover

>

Unclasp the 4 buckles that x

the cover to the boiler, and then

remove the cover by lifting it

and pulling it outward

2

3

2

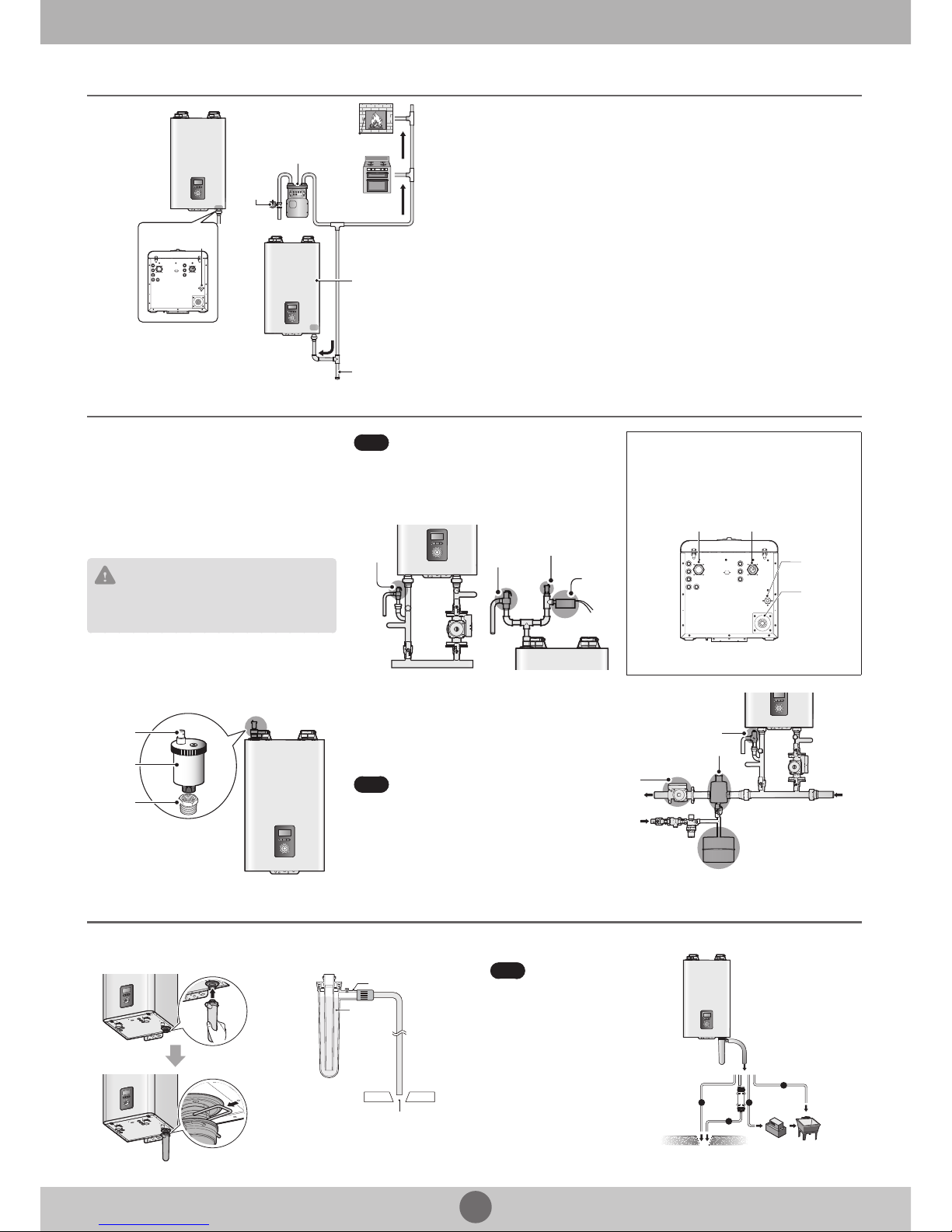

Gas Piping Connections

>

Water Piping Connections

>

Space Heating System

A pressure relief valve must be installed when installing pipings for

a heating system.

Install the included

3

/4 in, maximum 30 psi pressure relief valve on

the space heating supply.

An ASME approved HV pressure relief valve for space heating

system is supplied with the boiler.

You may install the pressure relief valve on the space heating supply

of the Navien Manifold System, or on the top connection along with

the air vent (and an external LWCO, if required).

CAUTION

Do not solder piping directly onto the water connections, as

the heat may cause damage to internal components. Use

threaded water connections only.

Note

Prior to connecting plumbing to the boiler, ush the

entire systemto ensure it is free of sediment, ux,

scale, debris or other impurities that may be harmful

to the system and boiler. During the assembly of the

heating system, it is important to keep the inside of

the piping free of any debris including construction

dust, copper burr, sand and dirt.

Pressure

Relief Valve

Pressure

Relief Valve

Air Vent

External

LWCO

Water Piping Connections

Space

Heating

Supply

Gas

Connection

Space

Heating

Return

Condensate

Outlet

System Fill Connection

Air Vent Cap

Air Vent

Air Vent

Bushing

The Navien NFB boilers have a top connection for an air vent. An air

vent must be installed to purge air from the boiler system.

When installing the air vent, install the air vent bushing between the

air vent and the top connection.

Before lling the boiler, remove the air vent cap to allow the system

to ll properly. Replace the cap when the system is full.

Note

Ensure that the vent cap is re-installed and the vent

screws on the system and boiler pumps are properly

tightened before testing or operating the system.

From

System

Expansion Tank

Make-up

Water

Pump

To system

Air Separator

Pressure Relief Valve

Gas Supply Line

Gas Inlet Adapter

Gas

Regulator

Gas supply

Bottom View

The boiler is

recommended

to be the rst

appliance to be

connected to

the gas supply

line.

Drip rig

The gas meter capacity

must be greater than

the total gas capacity of

connected appliances.

Example:

Gas meter

425 CFH

≥

Boiler

195 CFH

+

Furnace

58.8 CFH

+

Domestic gas stove

63.7CFH

* 1 CFH=1,020 Btuh

1

/2" rigid pipe can be used; refer to the sizing tables in the Installation & Operation

Manual for limitations. Avoid using 1/2" corrugated connectors or tubing as noise may

occur.

Condensate Drain Connection

>

A condensate drain pipe must be connected to the 1/2” condensate trap tting at the

bottom of the unit and water must be poured into the exhaust connection to ll the

condensate trap.

Condensate trap

Floor drain

Water

The end of the 1/2” (NPT) plastic piping should drain into a laundry tub or into a oor

drain.

Note

Do not submerge the end of

the pipe in water.

a

b

c

d

Direct to the external drain

To the

Drain via a

neutralizer

External drain

To the laundry tub

To the laundry tub

via a condensate pump

Loading...

Loading...