Navien NCB-24LSWE, NCB-28LSWE, NCB-34LSWE, NCB-40LSWE Service Manual

Service

Manual

Service Support

Options for service support include:

●

Technical Assistance Service (TAS). A list of official TAS providers is available at

http://www.navienuk.com. Contact a TAS for all warranty claims.

●

The technician or company that installed your boiler.

●

A registered service provider.

When you contact a TAS, please have the following information available.

●

Model

number

●

Serial

number

●

Date of

●

Installation location and

●

Error code information from the front display panel if available

purchase

Condensing Combi Boiler

type

KD Navien Co.,Ltd

Version: 1.0 (Oct. 19. 2015)

Condensing Combi Boiler

Service

Manual

Model

NCB-24LSWE

NCB-28LSWE

NCB-34LSWE

NCB-40LSWE

Keep this manual near the boiler for future reference.

WARNING

The safety information contained in this manual is important. Not following the

safety precautions may cause a fire or explosion and result in property damage,

injury, or death.

-

Do not store or use gasoline or other flammable liquid or vapour near this or any other appliance.

-

WHAT TO DO IF YOU SMELL GAS

●

Do not use any appliances.

●

Do not turn on any electrical devices or circuits. Do not use a phone inside the building.

●

Call your gas supplier from a phone outside the building. Follow the gas supplier’s instructions.

●

If you cannot reach your gas supplier, call the fire service.

-

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

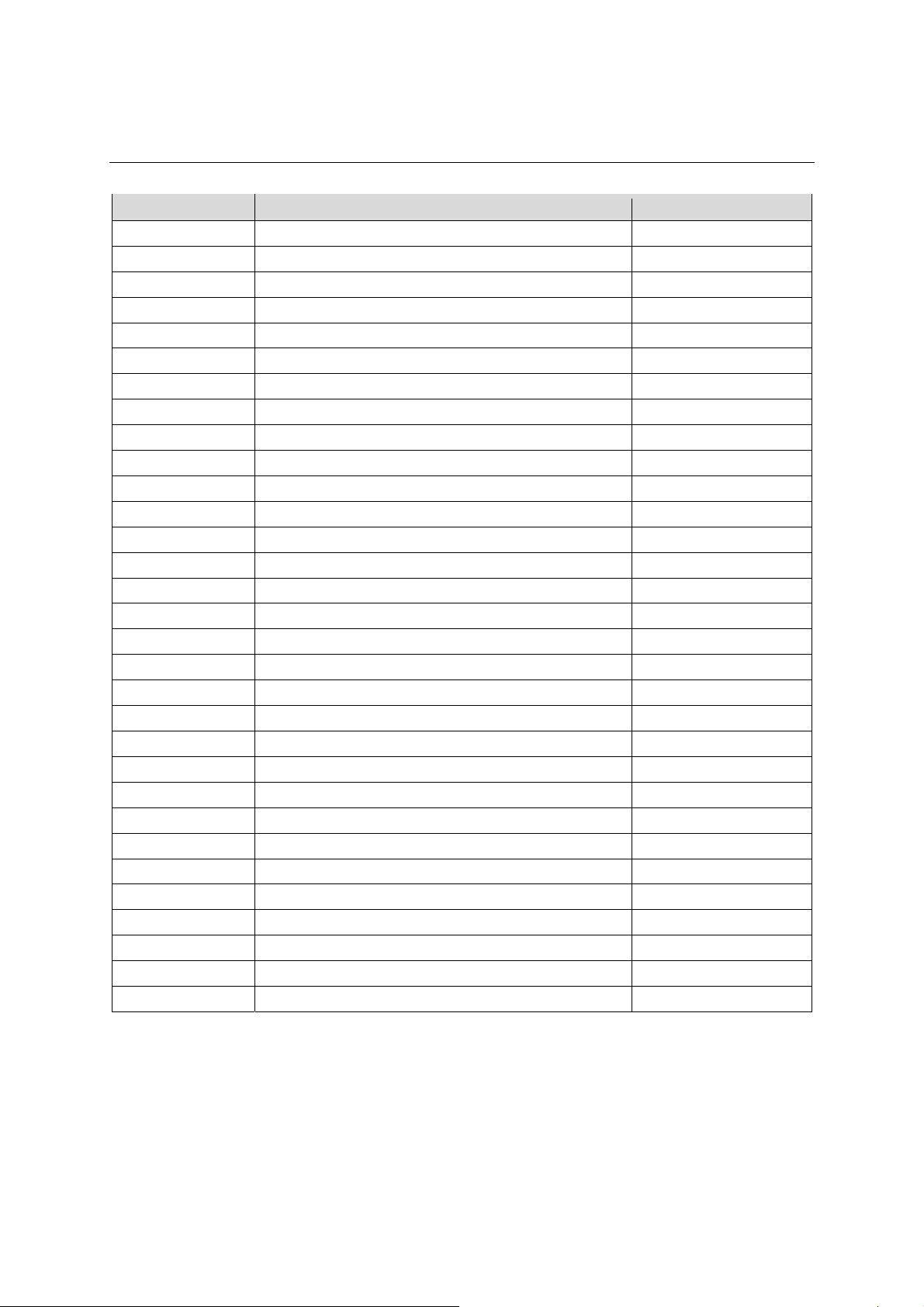

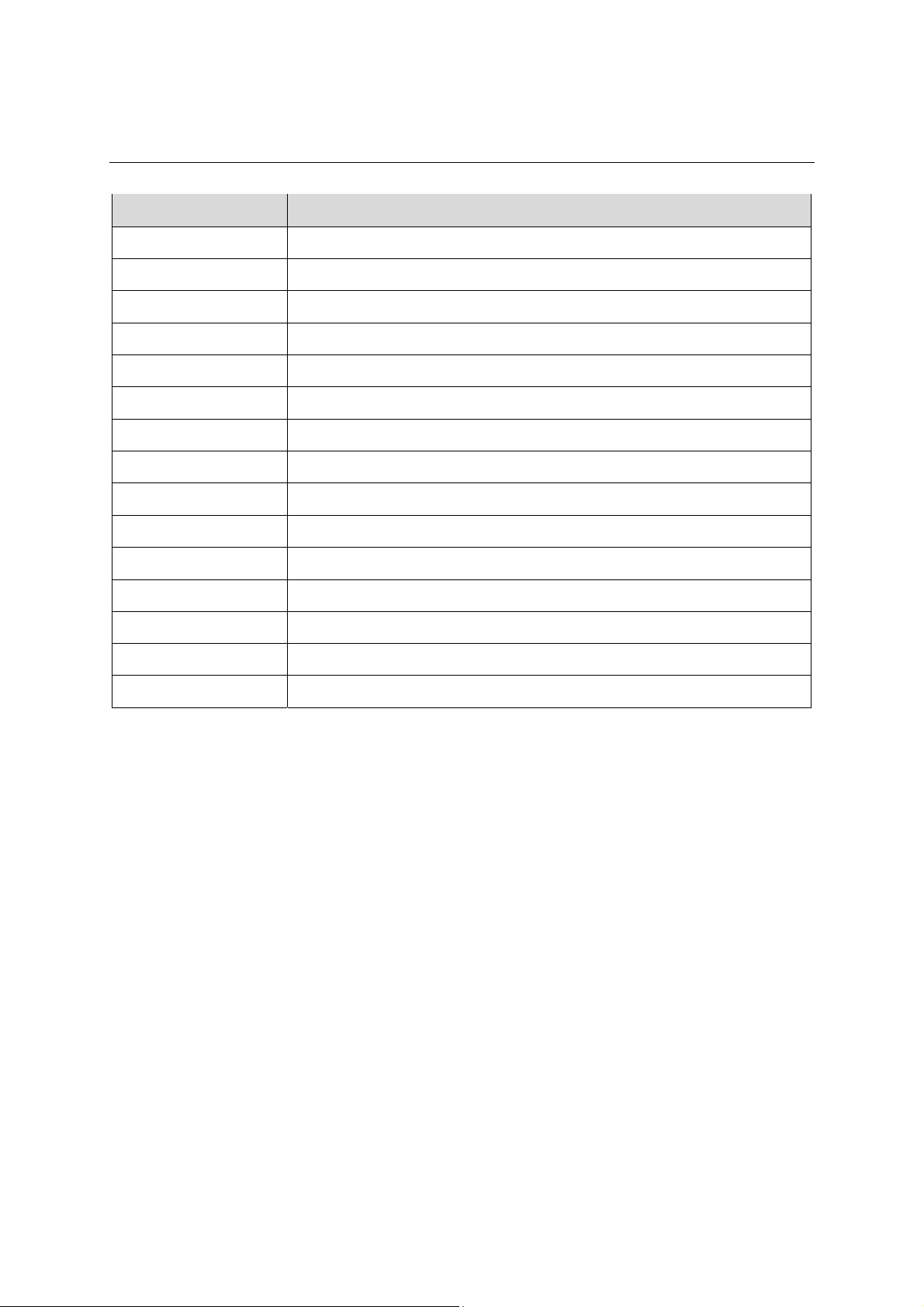

Revisions

Version Description of changes Date

1.00 First issue Mar. 12, 2015

Version 1.0

NCB Service Manual 1

Contents

1. Safety Information 5

1.1 Safety Definitions 5

1.2 Safety Symbols 5

1.3 Instructional Symbols 5

1.4 Safety Precautions 5

2. Product Information 12

2.1 Product Information 12

2.2 Components 13

3. Technical Data 17

3.1 General Specifications 17

3.2 Dimensions 19

4. System Details 20

4.1 Setting the DIP Switches 20

4.1.1 PCB DIP Switches 20

4.1.2 Front Panel DIP Switches 21

4.2 Measuring the Incoming Gas Pressure 21

4.3 Gas Conversion 23

4.4 The Front Panel 30

4.4.1 LCD Display 30

4.4.2 Buttons 31

4.4.3 Turning the Boiler ON or OFF 33

4.4.4 Normal Operation 33

4.4.5 Displaying and resetting errors 35

4.4.6 Adjusting the Space Heating Temperature set point 35

4.4.7 Adjusting the DHW Temperature 36

4.4.8 Viewing Basic Information 37

4.4.9 Displaying Error History 39

4.4.10 Displaying Service Information 40

4.4.11 Service Status Information 43

4.4.12 Parameter Setting Mode 45

4.4.13 Resetting The Boiler (Factory Reset) 56

4.5 Version Display 57

4.6 Heat Demand 57

4.7 Error Codes 57

4.8 Electrical Diagnostic Contacts and Wiring Diagram 58

4.9 Key Component Descriptions 60

4.9.1 PCB 60

4.9.2 High Temperature Limit Switch 61

4.9.3 Thermistor 62

4.9.4 Fan Motor 63

4.9.5 Flame Rod Assembly 64

4.9.6 Ignition Transformer 65

4.9.7 APS 66

4.9.8 Main Gas Valve 67

4.9.9 Burner (to be revised) 68

4.9.10 Flow Sensor (to be revised) 69

4.9.11 Primary Heat Exchanger 70

4.9.12 Secondary Heat Exchanger 71

4.9.13 DHW Heat Exchanger 72

4.9.14 Circulation Pump 73

4.9.15 3 Way Valve 74

4.9.16 Water Pressure Sensor 75

4.9.17 Dual venturi 76

4.9.18 Expansion tank 77

5.2.2 Error 003 84

5.2.3 Error 004 90

5.2.4 Error 012 91

5.2.5 Error 016 94

5.2.6 Error 030 96

5.2.7 Error 046 98

5.2.8 Error 047 98

5.2.9 Error 060 99

5.2.10 Error 109 101

5.2.11 Error 110 103

5.2.12 Error 205 104

5.2.13 Error 218 106

5.2.14 Error 302 108

5.2.15 Error 352 109

5.2.16 Error 353 110

5.2.17 Error 407 111

5.2.18 421Error 113

5.2.19 515Error 115

5.2.20 517Error 116

5.2.21 594Error 116

5.2.22 615Error 116

5.2.23 740Error 117

5.2.24 782Error 118

5.3 Troubleshooting guide by symptom 119

5.3.1 Noise 119

5.3.2 Water Temperature Issue 120

5.3.3 Circuit breaker operation 121

6. Replacement of Parts 122

6.1 Replacement Procedure 122

6.2 Components Replacement Instructions 123

6.2.1 PCB 123

6.2.2 Fuse 123

6.2.3 Fan Motor (Combustion Air) 123

6.2.4 Flame Rod 124

6.2.5 Ignition Transformer 125

6.2.6 APS 126

6.2.7 Main Gas Valve 126

6.2.8 Condensate Trap 127

6.2.9 Circulation Pump 128

6.2.10 Flow Sensor 128

6.2.11 3-way Valve 129

6.2.12 Water Pressure Sensor 129

6.2.13 DHW Heat exchanger 130

6.2.14 Expansion tank 130

7. Components Diagram and Part List

7.1 Case Assembly 131

7.2 Burner Assembly 132

7.3 H-Ex Assembly 133

7.4 Waterway Assembly 134

7.5 Gas Assembly 135

7.6 Fan Assembly 136

8. Inspection and Maintenance Schedule 137

8.1 Annual Servicing 137

8.2 Maintenance Report 137

8.3 Maintenance Schedules 137

8.4 Inspection Report 137

131

5. Troubleshooting 78

5.1 Error Code Classification 78

5.2 Error Code List and Actions 79

5.2.1 Error 001 82

2 NCB Service Manual

Version 1.0

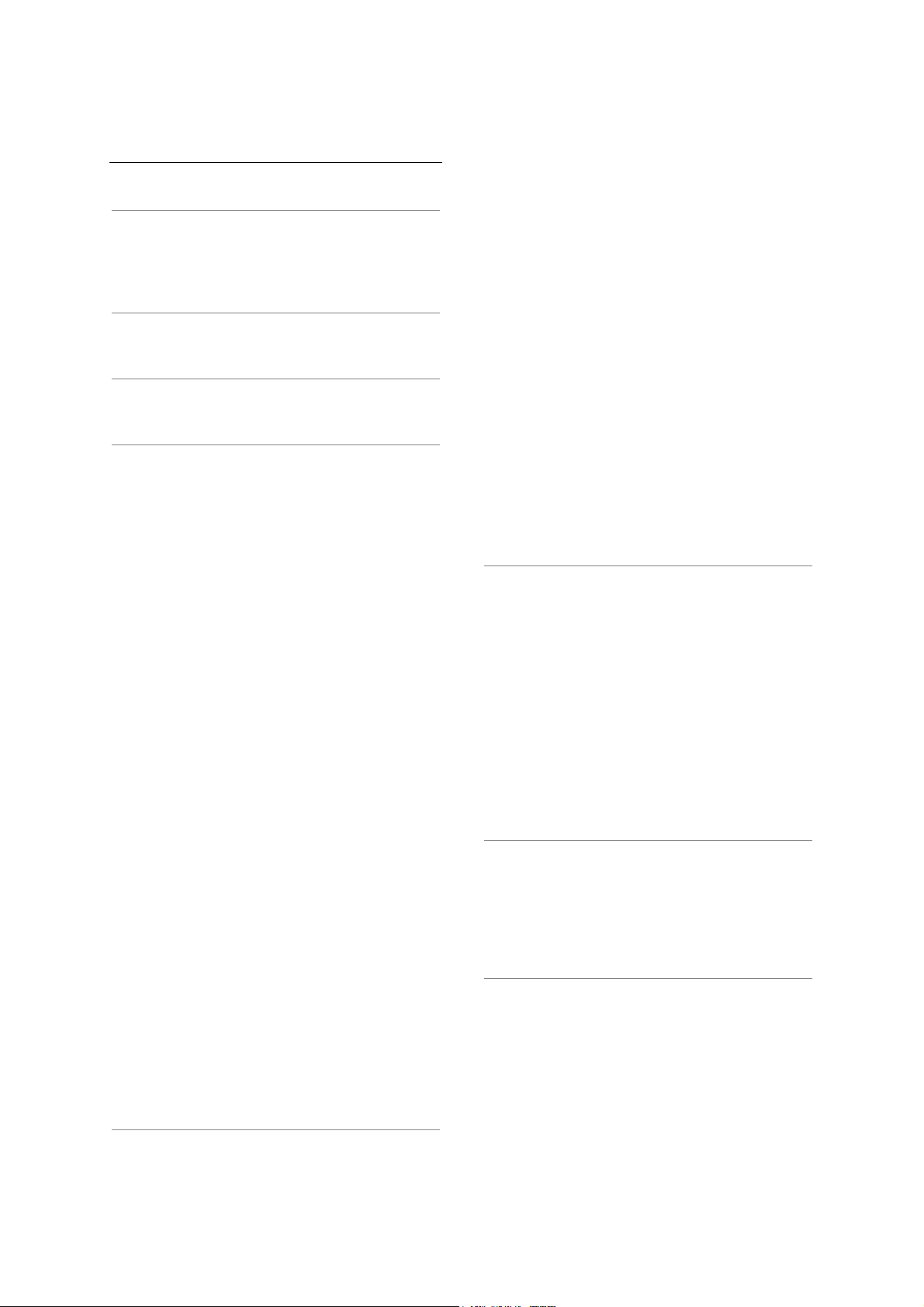

Navien Warranty

Warranty Period

Navien products come with a limited warranty covering. The

warranty covers labour, parts, and the heat exchanger. The

warranty period starts from the date of original installation.

The date of original installation must be advised to Navien,

and if requested, proof of the original installation date must

also be provided to Navien. When the product is installed in

a new installation, the warranty period will start from the

date the end-user takes responsibility for the property.

Product Warranty Period

NCB Series Boiler

(Residential use, single dwelling)

Warranty Claim Procedure

To obtain warranty repair service, the end user or

homeowner must contact the original installer of the Navien

product. If the original installer is unknown, the end user or

homeowner can contact the Navien Technical Department

at

0844–332-2323

warranty service.

. Proof of purchase is required to obtain

Warranty Service

At its option, Navien will replace the defective component

(part(s) or heat exchanger), in accordance with the terms of

this Limited Warranty, if it fails in normal use and service

during the Applicable Warranty Period identified above. The

replacement component must be Navien original factory

component. Navien, at its sole discretion, may replace the

product with a new or refurbished product of comparable

quality and design. The replacement component or product

will be warranted only for the unexpired portion of the

original component’s Applicable Warranty Period. Payment

for labour in completing the warranty service is subject to

Navien’s prior written approval and shall be subject to

Navien’s schedule of approved labour allowances.

Warranty Exclusions

Navien’s Limited Warranty shall be void in the event of an

occurrence of any of the following:

Improper installation, failure to install in strict compliance

with the Installation Manual procedures, installed by a

non-licensed installer, and installation in violation of

applicable rules, laws or building codes.

Product purchased through the internet, other ecommerce channels, or any installer that obtained the

Product from a supplier or distributor not authorised by

Navien.

3 years

Failure to perform regular maintenance, misuse,

operation at settings other than those recommended or

specified, non-compliance with instructions or guidelines

set forth in the User’s Operation Manual.

Modification or alteration of the Product in any manner,

including but not limited to, removal of any component

or part, addition of any non-approved components,

relocating or moving the Product from its original

installation site, or any accidental or intentional damage

to the Product.

Installation in commercial or multi-unit dwelling

applications or for non-recommended uses.

Any damage caused by local adverse conditions including

but not limited to hard water deposits, lime or mineral

build-up, operating in corrosive atmospheric elements.

Damage or caused by gas flow issues, electrical surges,

flooding, fire, abnormal external temperature, and any

other cause of damage not directly caused by a

manufacturing defect.

Installer’s failure to fully comply with the Warranty Service

and Return Policy procedures previously provided to

Installer and as is available on Navien’s website. Such

policies include but are not limited to the Installer’s failure

to first contact Navien Technical Support while in front of

the product for purposes of trouble shooting the

identified problem or issue.

Performance problems caused by improper sizing of the

boiler, the gas supply line, the flue connection,

combustion air openings, electric service voltage, wiring,

fusing or any other components, parts or specifications.

Improper conversion from natural gas to LP gas or LP gas

to natural gas or attempt to operate with a type of gas

not specified for the boiler.

Any damage, malfunction or failure caused by abuse,

negligence, alteration, accident, fire, flood, freezing, wind,

lightning and other acts of God.

Operating, using or storing the boiler in a corrosive or

contaminated atmosphere or environment.

Operating the boiler at water temperatures outside the

factory calibrated temperature limits and/or exceeding

the maximum setting of the high limit control.

Operating the boiler when it is not supplied with potable

water at all times.

Subjecting the heat exchanger to pressures or firing rates

greater or lesser than those shown on the rating plate.

Removal or alteration of the rating plate.

Version 1.0

NCB Service Manual 3

Abbreviations and Definitions

Abbreviation Definition

NCB-CE General name for NCB-24LSWE, NCB-28LSWE, NCB-34LSWE, and NCB-40LSWE products

NG Natural Gas

LP Propane Gas

AP Air Pressure

APS Air Pressure Sensor

DHW Domestic Hot Water

FM Fan Motor

GARC Gas Air Ratio Control

LPM Litre Per Minute

MGV Main Gas Valve

RPM Revolutions per Minute

PCB Printed Circuit Board

EMI Electromagnetic Interference

HTL High Temperature Limiter

LWCO Low Water Cut Off

4 NCB Service Manual

Version 1.0

1. Safety Information

1.1 Safety Definitions

The following safety symbols are used in this manual. Read

and follow all safety instructions in this manual to avoid

unsafe operating conditions, fire, explosion, property

damage, personal injury, or death.

1.2 Safety Symbols

DANGER

Indicates an imminently hazardous

situation which, if not avoided, could

result in severe injury or death.

WARNING

Indicates a potential hazardous

situation which, if not avoided, could

result in injury or death.

CAUTION

Indicates an imminent hazardous

situation which, if not avoided, may

result in minor or moderate injury.

1.3 Instructional Symbols

IMPORTANT

Warns of a risk of damage and

environmental pollution.

NOTE

Indicates additional information that

is important but not related to

personal injury or property damage.

1.4 Safety Precautions

DANGER

FLAMMABLE MATERIALS

Keep the area around the boiler clear

and free from flammable materials.

DO NOT place flammable liquids

such as oil or gasoline, near the

boiler.

DO NOT place combustibles such

as newspapers and laundry, near

the boiler or the flue system.

Version 1.0

DO NOT place or use hair spray or

paint aerosols or any other type of

aerosol can near the boiler or the

flue system (including the flue

termination).

DO NOT place anything in or

around the flue terminations that

could obstruct the air flow in and

out of the boiler, such as a clothes

line.

NCB Service Manual 5

DANGER

FLAMMABLE VAPOUR

Vapours from flammable liquids can

explode and cause fire resulting in

death or severe burns.

Do not use or store flammable

products such as gasoline, solvents,

or adhesives in the same room or

area near the boiler.

Store flammable products far away

from the boiler in approved

containers, with the lid tightly

closed, and out of the reach of

children.

The boiler’s main burner ignites

automatically at various intervals

and may ignite flammable vapours.

Flammable vapour is invisible, is

heavier than air, and can travel

long distances at floor level.

Dangerous concentrations of

flammable vapour can be moved

by air flow from other rooms

towards the main burner flame.

DANGER

WHAT TO DO IF YOU SMELL GAS

It is important that these instructions

are followed exactly to avoid fire or

explosion, property damage,

personal injury, or loss of life.

DO NOT OPERATE THE BOILER.

DO NOT CREATE ANY SOURCES OF

IGNITION

DO NOT OPERATE ANY FAUCETS.

Smell around the appliance area for

gas. Ensure to smell close to the floor

because gas is heavier than air and

will settle on the floor.

Do not smoke.

Extinguish all open flames.

Do not use appliances of devices

that generate sparks.

Do not operate light switches or

use electrical equipment.

Do not use a phone inside the

building.

Open the windows and doors.

Keep people away from the danger

zone.

Close the gas shutoff valve.

Observe the gas supplier’s safety

instructions posted on the gas

meter.

As soon as possible call the gas

supplier from outside of the

building. Follow the gas supplier’s

instructions.

If you cannot contact your gas

supplier, call the emergency

services. Notify your plumbing or

heating contractor when you are

outside of the building.

6 NCB Service Manual

Version 1.0

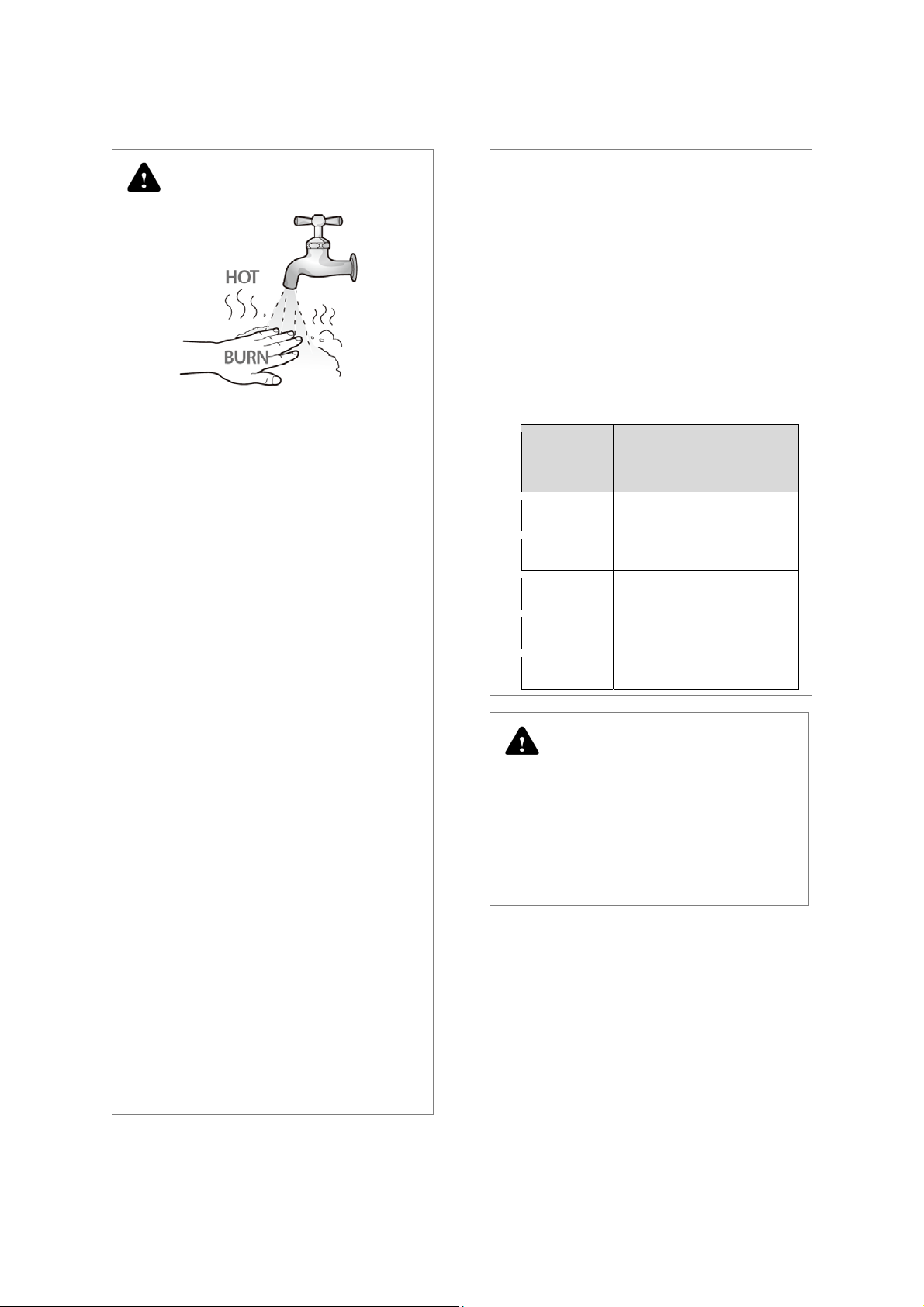

DANGER

HOT WATER TEMPERATURE

SETTING

Water temperatures at or above

52°C can cause instant severe

burns or scalding that can result in

serious injury or death.

Households with small children, or

disabled or elderly people, may

require a temperature setting of

49°C or lower for a safer water

temperature.

TO PREVENT BURNS

For your safety and comfort, the

default water temperature setting

is 49°C. Increasing the temperature

increases the risk of accidental

burns or scalds. Water temperature

at or above 52°C can cause instant

scalding, severe burns, or death.

Before you change the

temperature setting, read the

following table carefully.

Water

Temperature

70 ℃

60 ℃

55 ℃

49 ℃

37 ℃

Time for a young child to

receive full thickness (third

degree) burns

Less than 1 second

1 second

10 second

10 minutes

Very low risk of scalding

Use the lowest operating

temperature setting that provides

a comfortable water temperature.

If the household has children, or

elderly or disabled residents, use a

lower temperature setting.

Read all instructions in this manual

carefully before changing the

temperature setting.

Check the water temperature

before allowing children, or elderly

or disabled people to use it.

Contact a registered plumber or

your local plumbing authority for

more information.

DANGER

INSTALLATION REQUIREMENTS

Installation method may affect

how the boiler is serviced. Read all

related information in the

“Installation Manual”.

Version 1.0

NCB Service Manual 7

DANGER

IMPORTANT SAFETY PREAUTIONS

Read the safety information before

operating or servicing Navien

boilers.

Confirm the location of the gas

shut-off valve. During servicing,

close the manual shut-off valve if

the boiler overheats or is subjected

to fire, flood, physical damage or

other similar conditions.

DO NOT turn on the boiler unless

the water and gas supplies are

connected and supplied.

DO NOT turn on the boiler if the

main water supply valve is closed.

Ensure the boiler’s power supply is

isolated before removing the front

cover.

WARNING

GAS TYPE and POWER SUPPLY

This default gas supply

configuration for this boiler is

Natural Gas. If it is converted to

Propane Gas, the conversion kit

supplied with the boiler must be

used.

The power supply must be 230

VAC, 50 Hz. Voltages that are

abnormally high or low may affect

operation and reduce the life of the

boiler.

If the gas or power supplies do not

match the specifications do not

connect the boiler. Contact Navien

for assistance.

Label all wires prior to

disconnection. Wiring errors can

cause improper and dangerous

operation. Test and verify that the

boiler operates safely and correctly

after it is serviced or repaired.

Incorrect adjustments,

modifications, servicing or

maintenance can cause property

damage, personal injury, or death.

To prevent scalding, always check

the hot water temperature when

servicing is completed.

DO NOT change the water

temperature while the boiler is in

use.

DO NOT use parts other than those

specified for the boiler.

DO NOT allow children to operate

or handle the unit.

8 NCB Service Manual

Version 1.0

WARNING

Isolate the gas supply if the

boiler is damaged.

Identify the location of the gas

shut off valve and ask a qualified

technician to demonstrate how to

close the valve. If the boiler is

damaged due to overheating, fire,

flood, or any other reason, close

the shut off valve and do not

operate the boiler until it has been

inspected by a qualified

technician.

DO NOT store or use gasoline or

other flammable liquids near the

boiler.

Doing so may result in fire or

explosion.

DO NOT place combustibles,

such as newspapers or laundry,

near the boiler or flue system.

Doing so may result in a fire.

DO NOT operate the boiler with

an open front cover.

Doing so may result in fire or

carbon monoxide (CO) poisoning

and may result in property

damage, personal injury, or death.

DO NOT operate this boiler

without proper flue system.

Doing so may result in fire or

carbon monoxide (CO) poisoning

and may result in property

damage, personal injury, or death.

Inspect the flue termination and

air intake supply at least annually

to ensure proper operation of the

boiler. Turn off and discontinue

using the boiler if any of the flue

pipes, flue elbows, or intake pipes

are damaged, have loose

connections, or has signs of

corrosion or heat damage.

DO NOT touch the power cord or

internal components of the

boiler with wet hands.

Doing so may result in electric

shock.

DO NOT place or use hair spray

or paint aerosols, or any other

compressed gases near the

boiler or flue system, including

the flue termination.

Doing so may result in fire or

explosion.

Version 1.0

NCB Service Manual 9

CAUTION

Do not attempt to repair or

replace any part of the boiler

unless it is specifically

recommended in this manual.

For repairs not covered in this

manual, contact a qualified

technician or a licensed

professional. Incorrect

adjustments, modifications,

servicing, or maintenance may

cause property damage, personal

injury, or death and will void the

warranty.

Do not allow children to operate

or access the boiler.

Doing so may result in property

damage or personal injury.

Do not change the water

temperature while the boiler is

being used.

Doing so may result in personal

injury.

DO NOT turn on the boiler unless

the water and gas supplies are

connected and supplied Doing

so may damage the boiler.

DO NOT use hot water inside the

installation when the main water

supply shut-off valve is closed.

Doing so may damage the boiler.

DO NOT use the boiler for

purposes other than those

described in this manual.

DO NOT remove the front cover

unless the power to the boiler is

turned off or disconnected.

Failure to do so may result in

electric shock.

When servicing the control

circuits, label all wires prior to

disconnecting them.

Failure to do so may result in

wiring errors and lead to improper

or dangerous operation.

Do not use unauthorised

replacement parts or

accessories.

Doing so may result in improper or

dangerous operation and will void

the manufacturer’s warranty.

Do not place anything in or

around the flue terminals, such

as a clothes line, that can

obstruct the air flow in or out of

the boiler.

If the boiler overheats or the gas

supply fails to shut off, isolate

the gas at the boiler’s main

valve.

Do not use this appliance if any

part has been covered by water.

Contact a qualified service

technician to inspect the appliance

to verify the boiler is safe to

operate and to replace any

damaged parts.

10 NCB Service Manual

Version 1.0

General Installation

Navien guarantees that no

have been used

All current and local laws and regulations must

the boiler. The boiler must

when

adequately

The boiler must

ventilated area.

Guidelines

harmful

substances or materials

in the manufacture of this product.

be

be

installed

installed

by registered installers

in

an

be observed

.

Commissioning of the boiler must be performed by a

Navien authorised TAS

The requirements included

be

observed

must

-

Gas installation r

-

Technical building c

- Building h

eating installation regulations

.

on

installing the

egulations.

odes.

in

the following regulations

boiler:

.

- Elec tric a l regulations.

The latest version of the regulations and codes

of

practice must be applied to the installation methods

The installation must also comply with the

European

Standards listed in the table below:

Standard Description

UNE-EN

13831:2008

Closed expansion vessels with

diaphragm.

UNE-EN 1856 Metal chimneys

EC

Conformity

Declaration

Navien, hereby declares that the boiler

NCB-24LSWE, NCB-28LSWE, NCB-34LSWE,

which this declaration refers, conform

to

with

the essential requirements

models:

NCB-40LSWE

to

and comply

of

the following applicable

European

Standards and

Gas appliances

Directives.

: Directive 2009/142/EC Standards

EN

437

and EN 15502

Boiler Efficiency

: Directives 92/42/EEC

93/68/EEC Standards

Low voltage

.

Electro-magnetic Compatibility

Pressure Vessels

Navien, manufactures

Assurance

: Directives 73/23/EEC

Standard

EN

system

EN

60335-1,

60335-2-51,

: Directive

in

97/23/EEC

its

products using a Quality

compliance with Standard EN-ISO

EN 50165

and

EN 15502

and

93/68/EEC

EN 60335-2-30,

: Directive

2004/108/EC

Standards

EN 55014

9001:2000.

UNE-EN 13384 Chimneys

UNE-EN 13779 Ventilation

UNE-EN ISO 16484 Building control systems.

UNE-EN 14336 Heating systems in buildings.

UNE-EN 15502-1

Gas-fired heating boilers

Part 1: General Requirements and

Gas-fired heating boilers

Part 2-1: Specific standard for type C

UNE-EN 15502-2-1

appliances and type B2, B3 and B5

appliances of a nominal heat input

not exceeding 1000kW

UNE-EN

13203:2007

UNE-EN 3037:2008

Domestic Hot Water

Heating boilers.

Version 1.0

NCB Service Manual 11

2. Product Information

2.1 Product Information

The NCB series gas boiler is a fully modulating gas appliance which has a built-in circulation pump and air vent. It provides central

heating and domestic hot water. Depending on the heat capacity, three models are available with different ratings: 24 kW, 28 kW,

34kW, and 40 kW.

Model Maximum Space Heating Input Maximum DHW INPUT

NCB-24LSWE 20.0 kW 24.0 kW

NCB-28LSWE 24.0 kW 28.0 kW

NCB-34LSWE 29.0 kW 34.0 kW

NCB-40LSWE 34.0 kW 40.0 kW

By default, the boiler assigns system priority to DHW supply.

The NCB Series boiler has a built-in circulation pump, 3-way valve assembly, flow sensor, DHW plate heat exchanger and, a

safety valve (or relief valve). A separate heating expansion vessel is required.

Internal freeze protection and an electronic control unit are incorporated inside the boiler. The boiler is compatible with all

brands of standalone room thermostats and various sets of relay contacts can be used with the boiler.

12 NCB Service Manual

Version 1.0

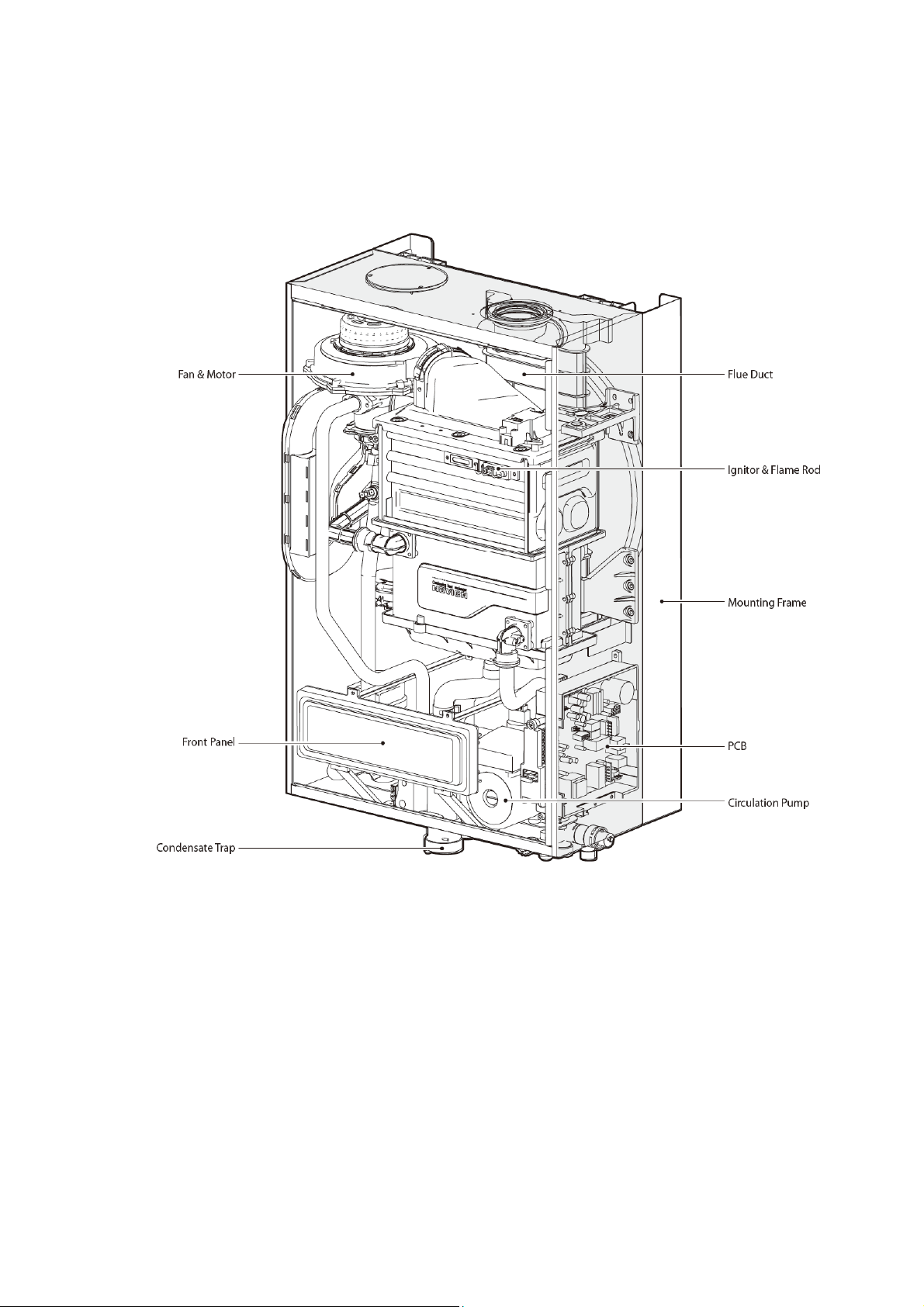

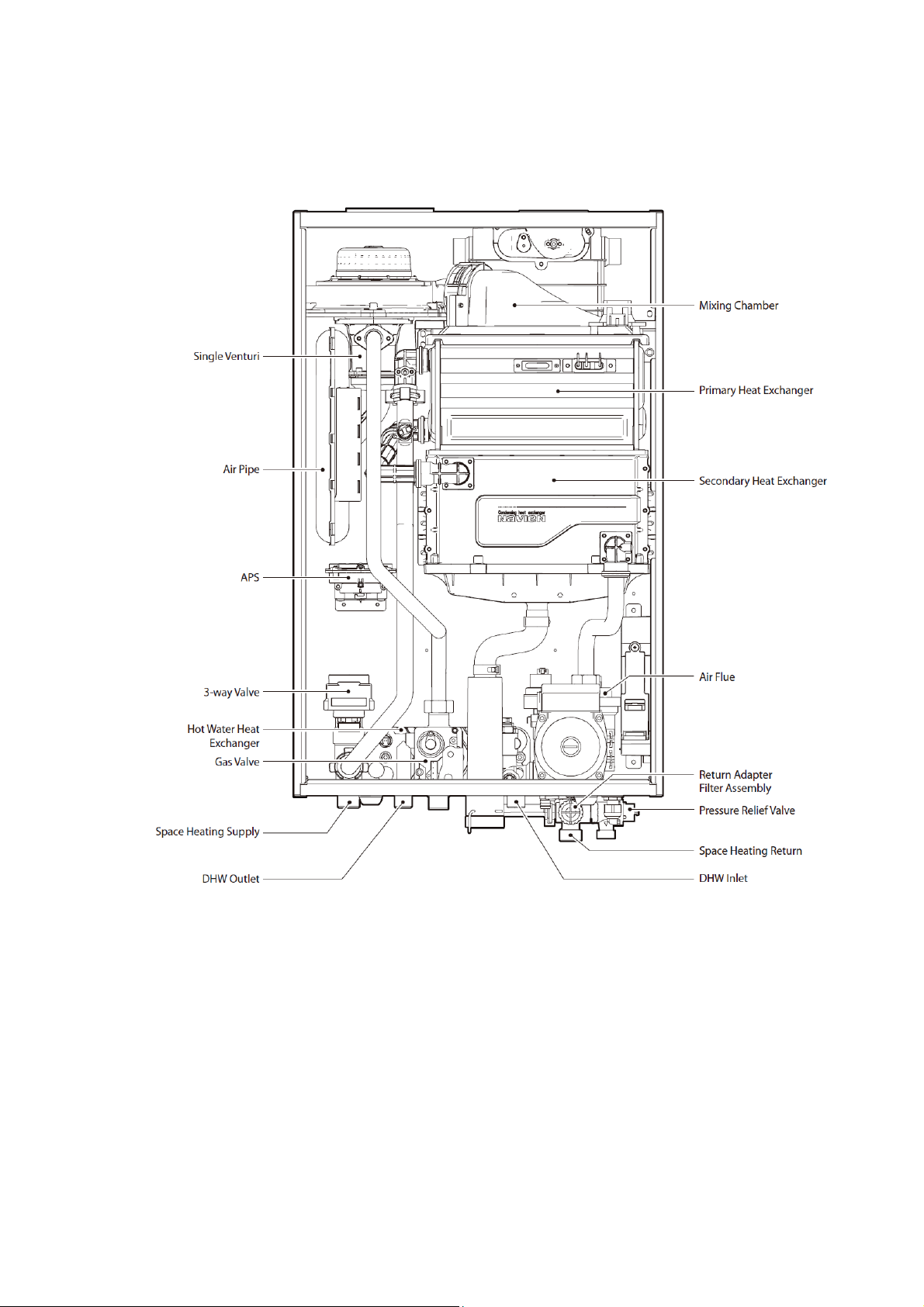

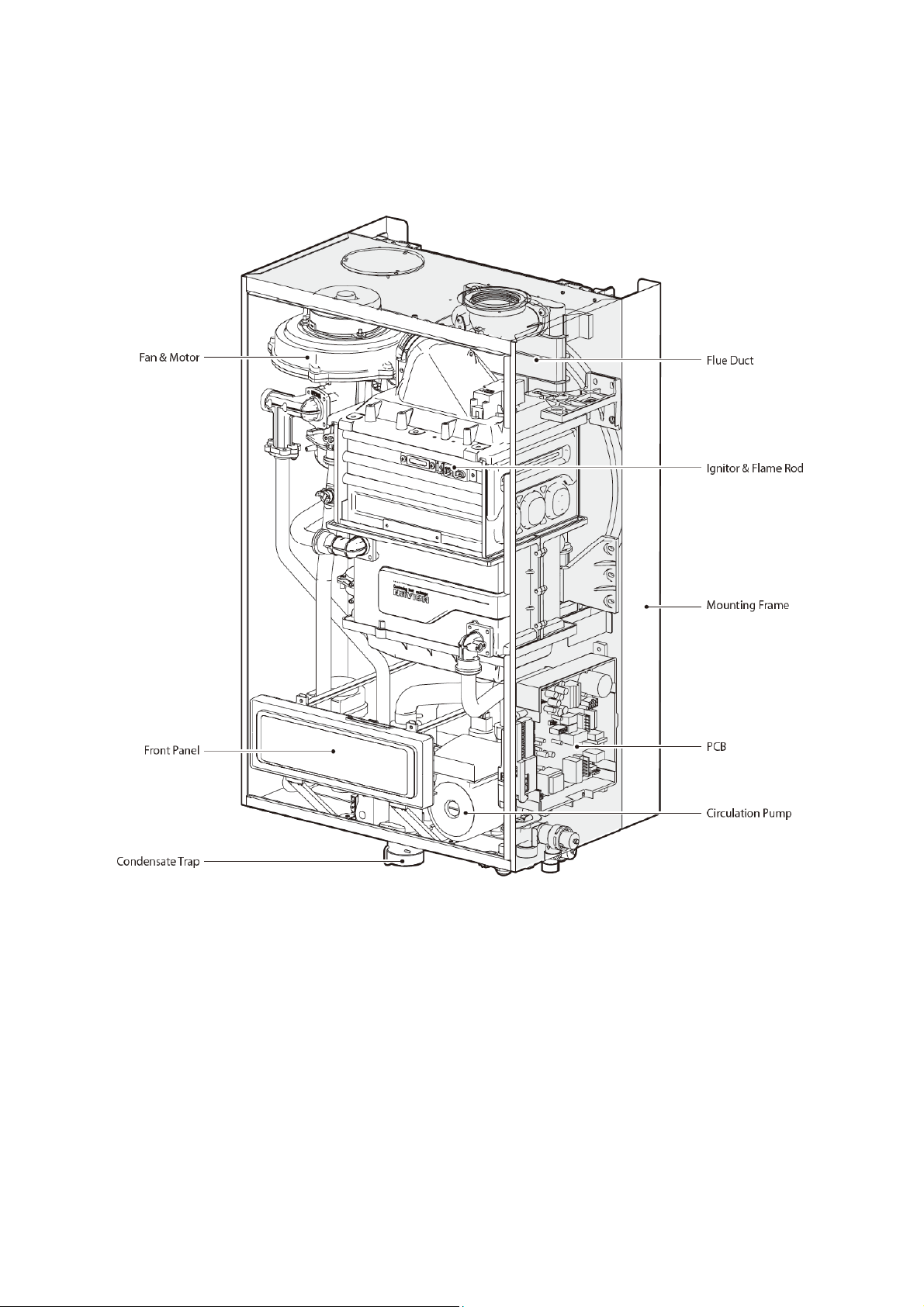

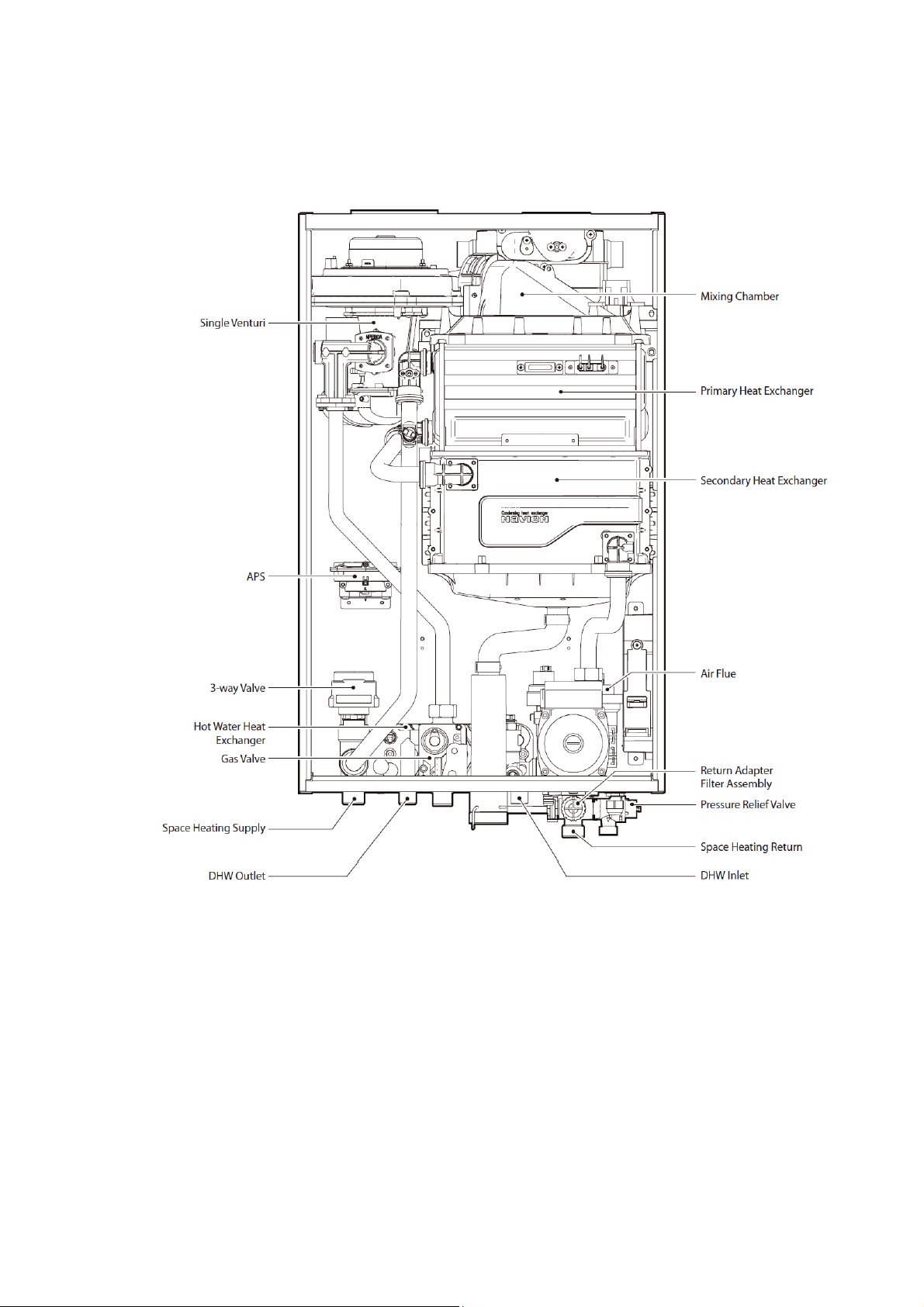

2.2 Components

The following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are

included in the appendices.

NCB-24/28/34LSWE

Version 1.0

NCB Service Manual 13

NCB-24/28/34LSWE

14 NCB Service Manual

Version 1.0

NCB-40LSWE

Version 1.0

NCB Service Manual 15

NCB-40LSWE

16 NCB Service Manual

Version 1.0

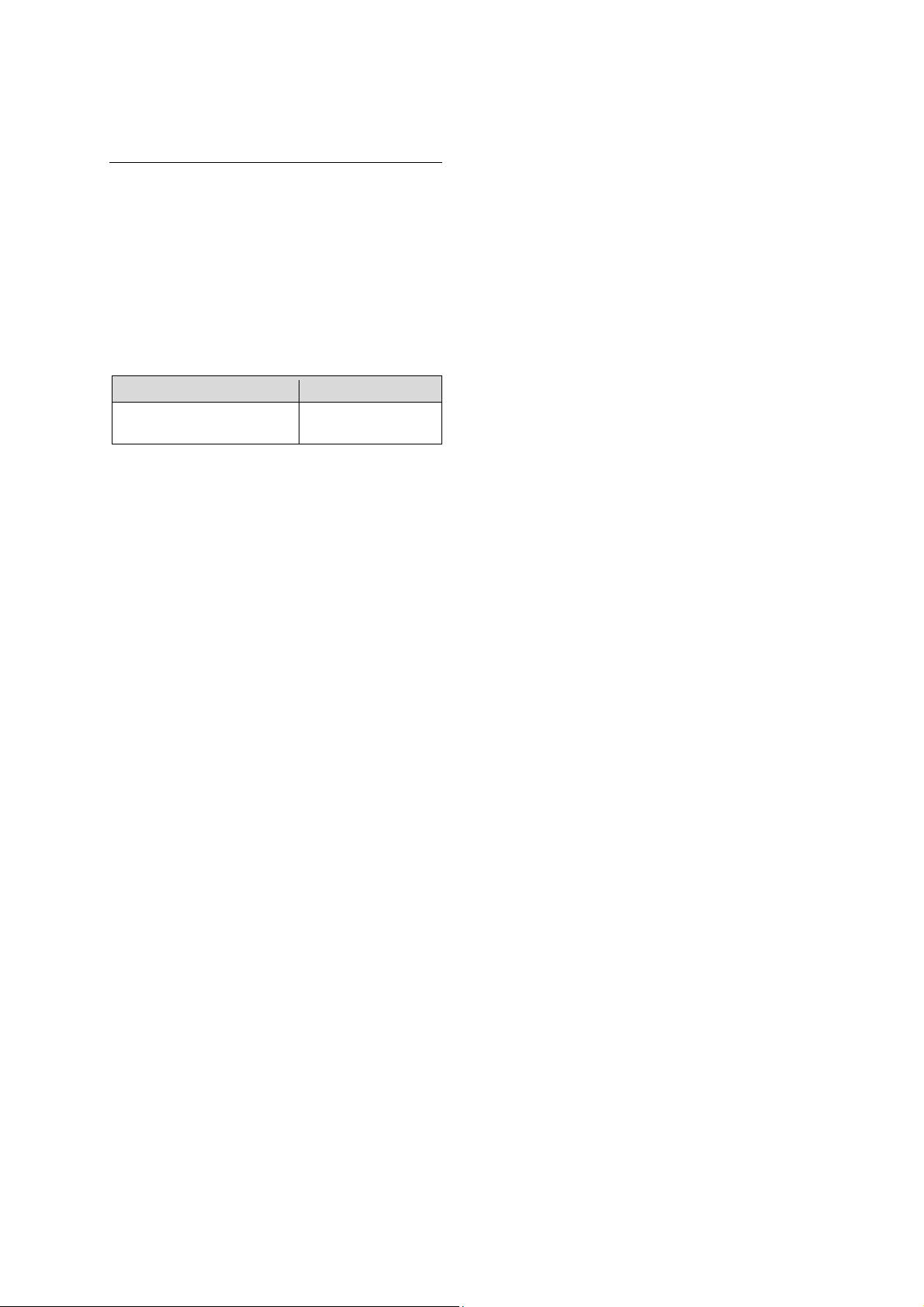

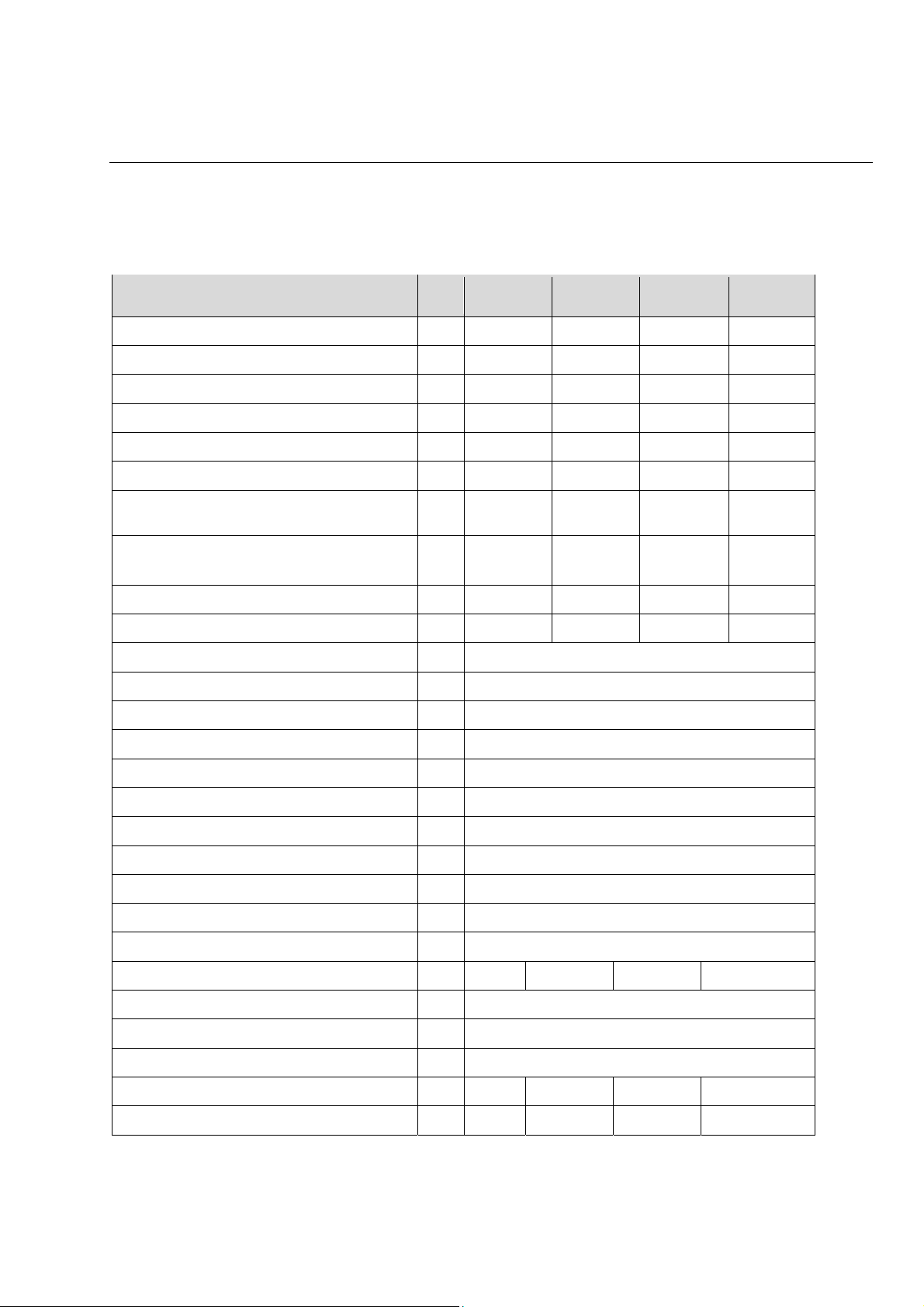

3. Technical Data

3.1 General Specifications

The table below lists the boiler’s general specifications.

Specification Unit

Heating capacity (max/min)

NCB-

24LSWE

kW 20.0/4.2 24.0/4.2 29.0/5.1 34.0/4.0

NCB-

28LSWE

NCB-

34LSWE

NCB-

40LSWE

DHW heat capacity (max/min)

Heating output (max/min) at 80/60°C

DHW output (max/min)

Condensing heating output (max/min) at 50/30°C

Full output load efficiency (max/min), at 80/60°C

Full output load efficiency (max/min), at 50/30°C

(condensation)

Partial load (30%) efficiency, at 30°C return

temperature

Heat Loss via the casing with burner switched on

Heat Loss via the chimney with burner switched on

Seasonal efficiency rate (SEDBUK rating)

NOx class

Category

Type

Heating output adjustment

Type of heating installation

kW 24.0/4.2 28.0/4.2 34.0/5.1 40.0/4.0

kW 19.5/4.0 23.3/4.2 28.4/4.9 33.2/3.8

kW 20.0/4.0 24.0/4.0 34.0/5.0 40.0/4.0

kW 21.4/4.5 25.5/4.5 31.1/5.5 36.2/4.3

% 97.7/96.4 97.2/96.4 97.9/96.4 97.5/95.8

% 106.9/107.8 106.3/107.8 107.3/107.9 106.6/107.9

% 108.3 108.3 108.6 108.8

% 0.1 0.1 0.1 0.1

% 1.6 1.8 1.5 1.9

- A

- 5

- II2H3P

- Heating and instantaneous hot water production

- Adjustable over entire max/min output range

- Closed circuit

Maximum heating pressure

Maximum heating temperature

Adjustable heating temperature range

Expansion vessel volume

Expansion vessel pre-load

Minimum DHW pressure

Minimum DHW flow

Maximum DHW pressure

Adjustable DHW temperature range

Specific flow (T=25°C)

Specific flow (T=30°C)

Version 1.0

bar 2.5

°C 90

°C 40-90

l 6. 0

bar 1

bar 1.0 1.2 1.4 1.4

l/min 2.0

bar 10

°C 30–65

l/min 13.8 16.1 19.5 22.9

l/min 11.5 13.4 16.2 19.1

NCB Service Manual 17

Specification Unit

Specific flow for kitchens (T=45°C)

NCB-

24LSWE

NCB-

28LSWE

NCB-

34LSWE

NCB-

40LSWE

l/min 7.6 8.9 10.8 12.7

Electrical supply

Nominal current

Electrical maximum rating

Electrical protection

Boiler mounting method

Flue exhaust/Air intake system types

Flue exhaust/Air intake system diameters

Max. horizontal coaxial pipe length Ø60/100

Max. vertical coaxial pipe length Ø60/100

Equivalent elbow length at 90° Ø60/100

Equivalent elbow length at 45° Ø60/100

Max. horizontal coaxial pipe length Ø80/125

Max. vertical coaxial pipe length Ø80/125

Equivalent elbow length at 90° Ø80/125

Equivalent elbow length at 45° Ø80/125

Equivalent length of adapter Ø60/100 => Ø80/125

- 230 V / 50 Hz

A 0.6 0.62

W 130

- IP X5D

- Wall-mounted

- B23-B33-B53-C13-C33-C43-C53-C63-C83

mm Coaxial Ø60/100 and Ø80/125–Dual duct Ø80/80

m 20

m 21

m 1.3

m 1

m 68

m 70

m 2.2

m 1

m 0.5

Max. dual duct length Ø80-Ø80

Equivalent elbow length at 90° Ø80

Equivalent elbow length at 45° Ø80

m 110

m 2.2

m 1.4

Heating mm 22

Hydraulic connection diameter

DHW mm 15

Gas inlet mm 22

Dimensions (width x depth x height)

Weight

mm 440 x 350 x 695 440 x 380 x 695

kg 38 42

18 NCB Service Manual

Version 1.0

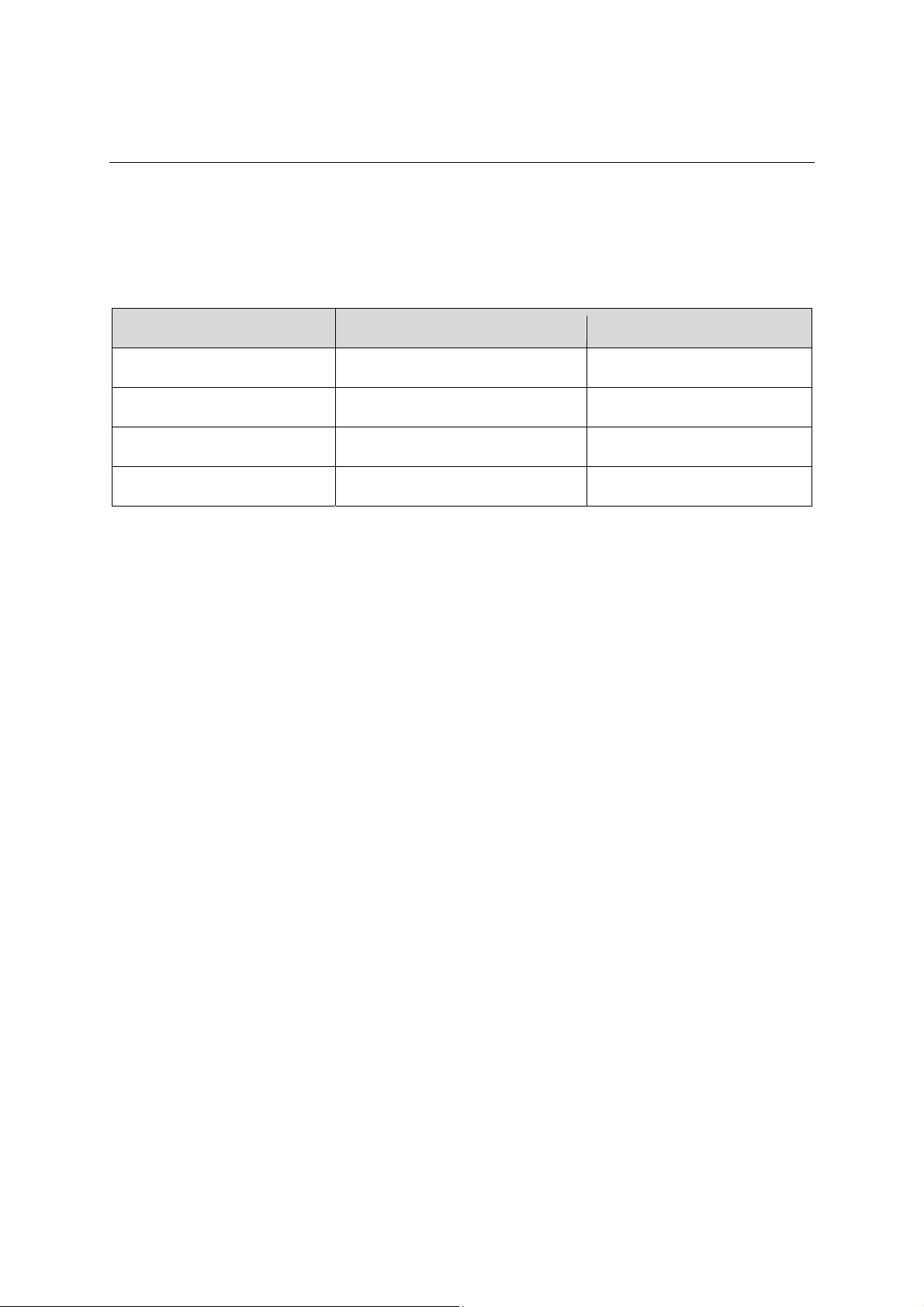

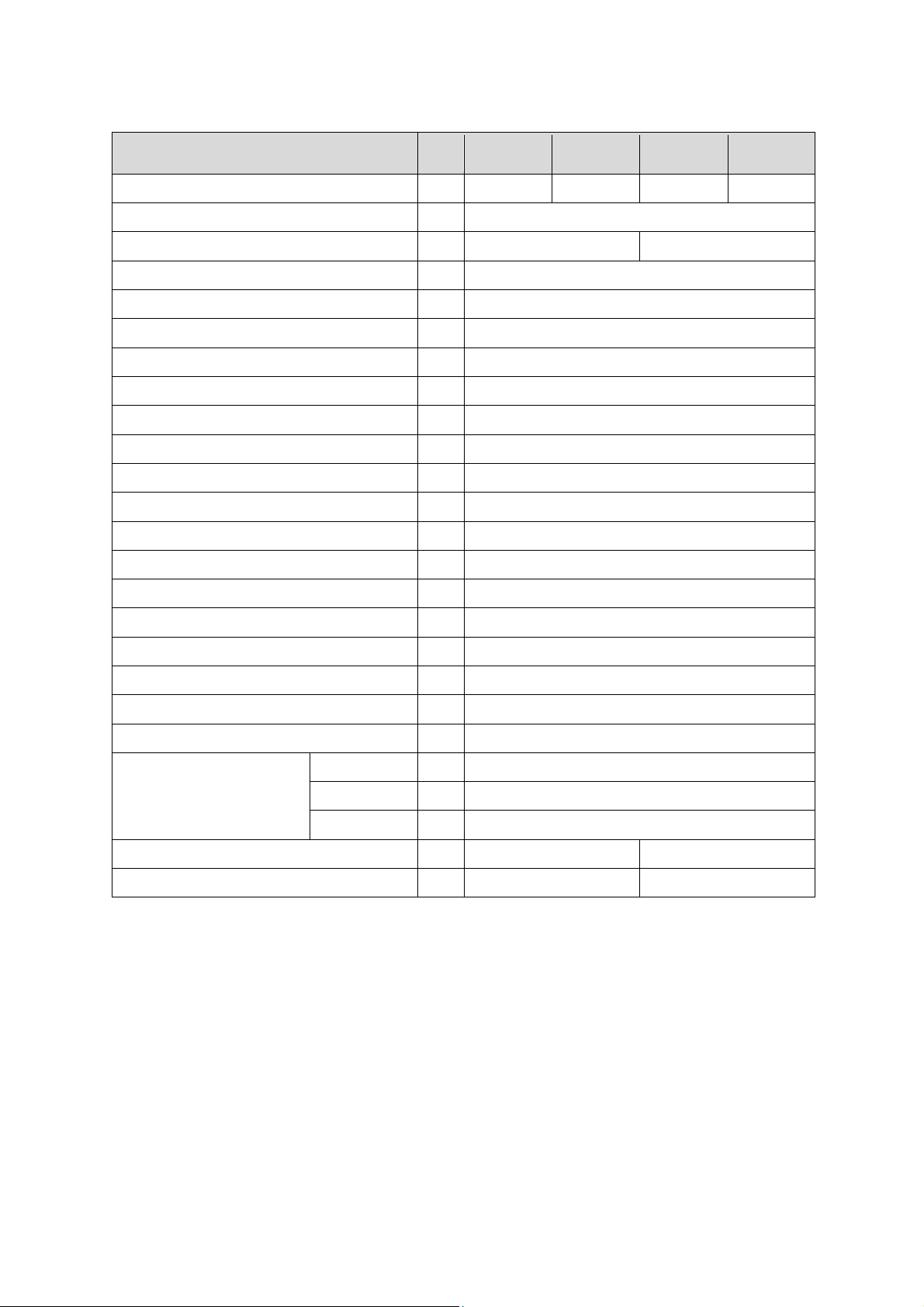

3.2 Dimensions

The following diagrams show the dimensions of the boiler. The table below lists the pipe diameters for various connection points.

Supply Connection Pipe Diameters

Overhead View

Re

A

B

C

D

E

F

Description Diameter

Flue exhaust/Air intake

Space heating supply 22 mm

Hot water outlet (DHW) 15 mm

Gas supply inlet 22 mm

Cold water inlet (DHW) 15 mm

Space heating return 22 mm

60 mm/100 mm,

80 mm/125 mm

Supply Connections

Version 1.0

* NCB-24LSWE/28LSWE: 350 mm

NCB-34LSWE/40LSWE: 380 mm

NCB Service Manual 19

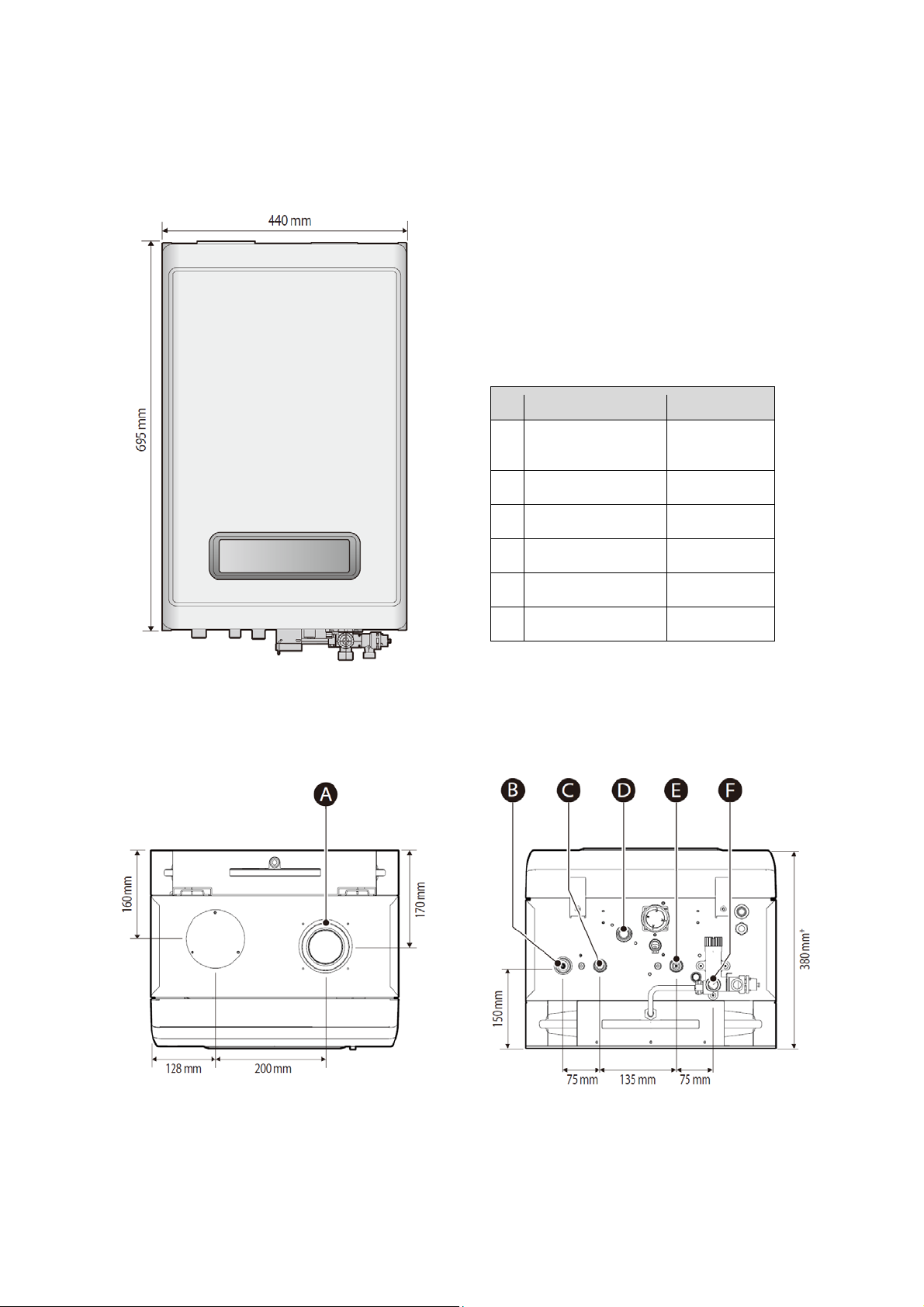

4. System Details

4.1 Setting the DIP Switches

CAUTION

Do not remove the front cover

unless the power supply is turned

off or disconnected.

may result in electric shock.

The boiler has two sets of DIP switches on the main circuit

board (PCB) and two sets of DIP switches on the front

panel. DIP switches are used to control the boiler’s

functions. Set the DIP switches as required based on the

installation.

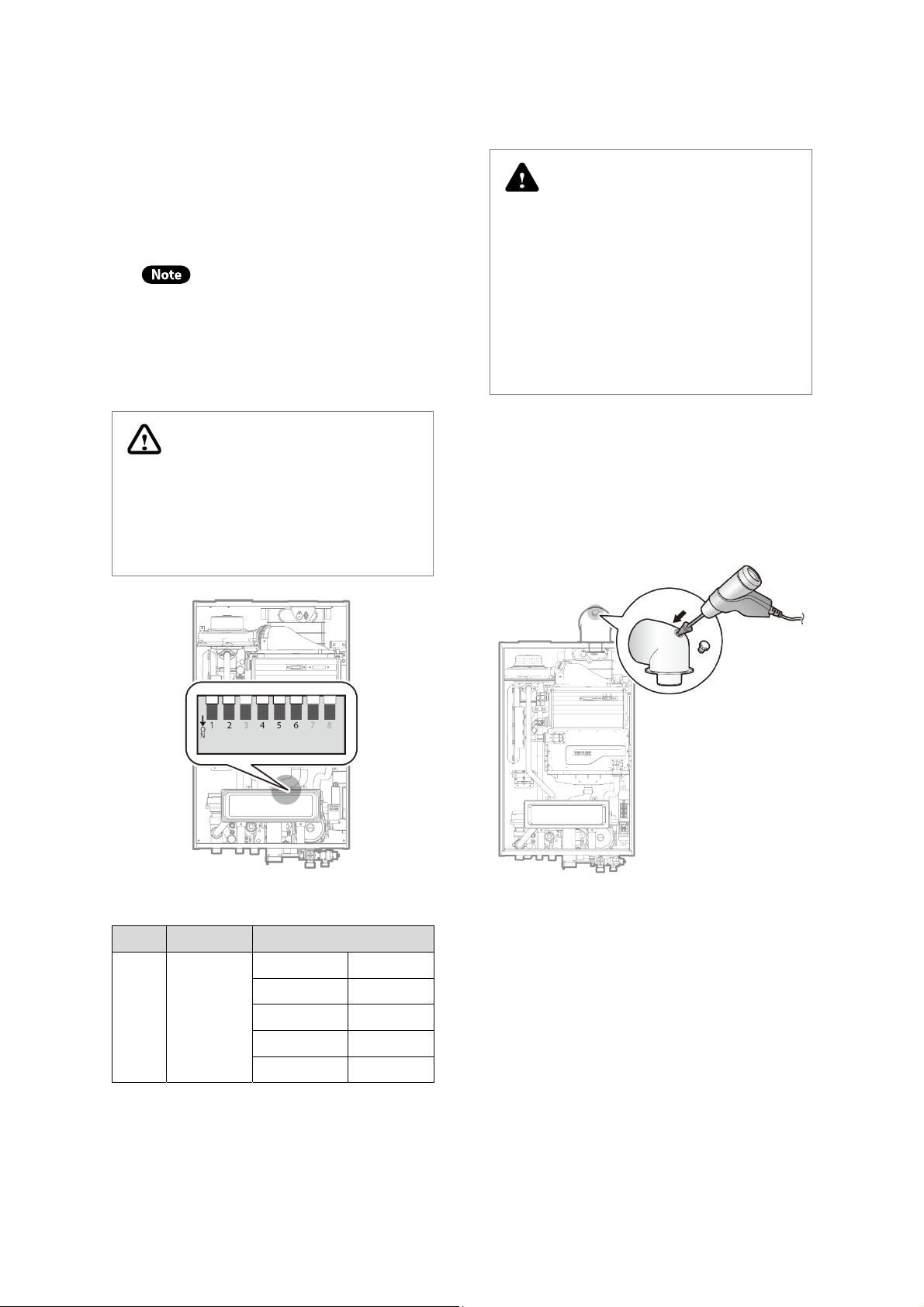

4.1.1 PCB DIP Switches

Setting the Circuit Board DIP Switches (8-way)

Failure to do so

Switch Function Setting

Normal operation 1-OFF, 2-OFF

1 & 2

3 & 4 Capacity

Operation

status

24/28/34

LSWE

40LSWE

24/28/34

LSWE

40LSWE

24/28/34

LSWE

40LSWE

DHW

MAX

DHW 2-

stage

MAX

MIN

1-stage

MIN

Heating

MAX

Heating

2-stage

MAX

24LSWE 3-OFF, 4-OFF

28LSWE 3-ON, 4-OFF

34LSWE 3-OFF, 4-ON

1-ON, 2-OFF

1-OFF, 2-ON

1-ON, 2-ON

The DIP switches on the circuit board configure the boiler’s

model and gas settings. These configurations are set at the

factory and should not be changed. The following tables

describe the functions of the DIP switches and their

settings.

40LSWE 3-ON, 4-ON

5

6 & 7 Region Europe 6-OFF, 7-OFF

Burner

type

Bekaert 5-ON

Alantum 5-OFF

Eg.) DIP Switch On/Off

20 NCB Service Manual

Version 1.0

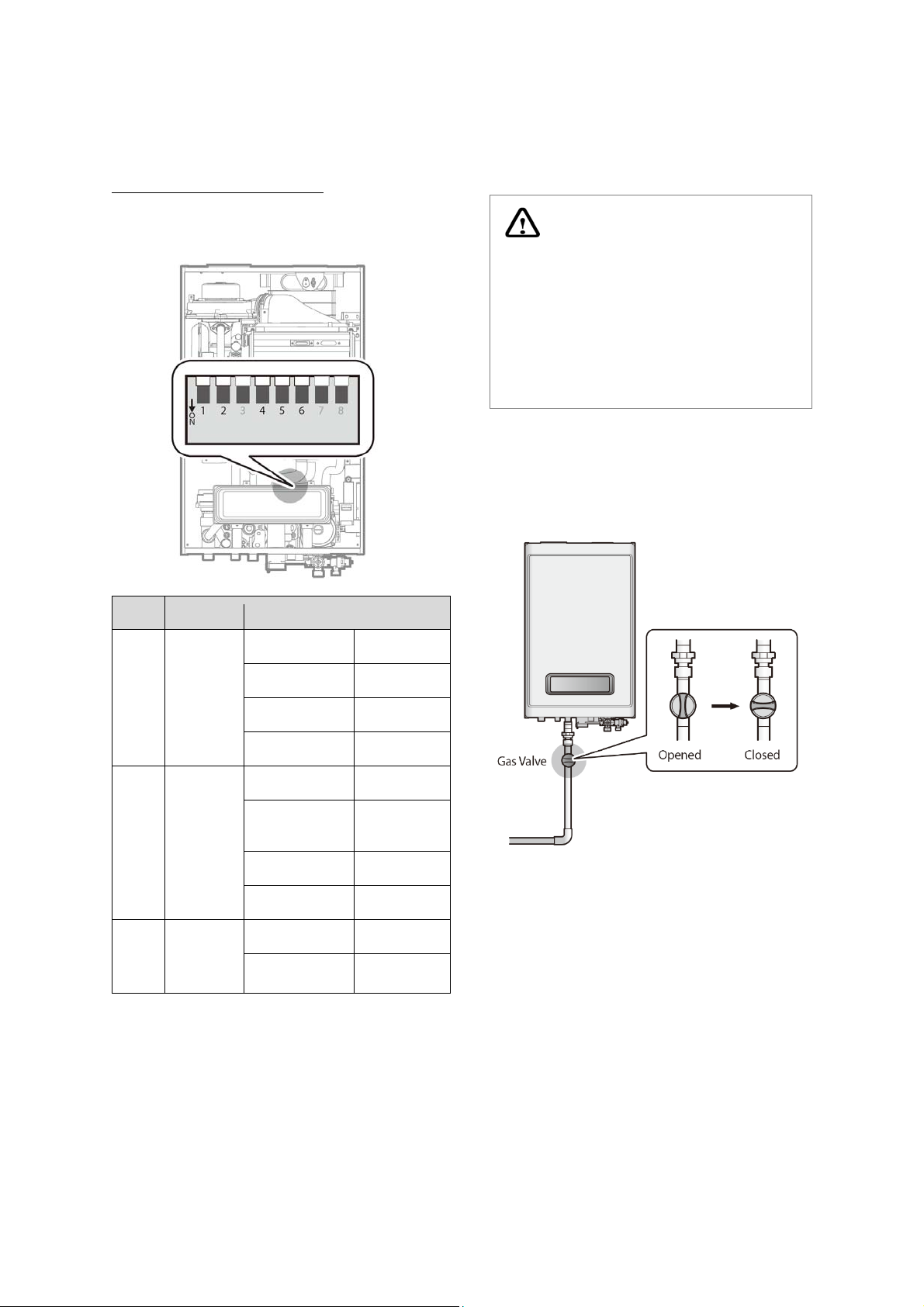

4.1.2 Front Panel DIP Switches

T

Setting the Front Panel DIP Switches

The DIP switch on the front panel configures the fuel

selection, source of the heat demand, and the temperature

control standard.

4.2 Measuring the Incoming Gas

Pressure

WARNING

The boiler does not function

correctly if there is insufficient

incoming gas pressure. Measuring

the inlet gas pressure should be

performed by a registered technician

only.

Switc

1 & 2

4 & 5

6

Function Setting

G20 (LNG) 1-OFF, 2-OFF

Fuel

selection

Heat

demand

Temperatu

re control

standard

G25, G27(LNG) 1-OFF, 2-ON

G30 (LPG) 1-ON, 2-OFF

G31 (LPG) 1-ON, 2-ON

Panel 2-OFF, 3-OFF

OpenTherm

Remote Control

hermostat 2-OFF, 3-ON

Panel 4-ON, 5-ON

Supply Water 1-OFF

Return Water 1-ON

2-ON, 3-OFF

* The incoming gas pressure must be between 17 mbar and 25

mbar for natural gas and between 25 mbar and 35 mbar for

liquefied propane.

To measure the incoming gas pressure:

1.

Shut off the manual gas valve on the gas supply line.

2.

Open a hot water tap. The boiler should turn on and

the gas in the gas supply line will be purged.

Leave the faucet on until the boiler shuts down due

3.

to the absence of gas, and then turn off the hot

water tap.

Version 1.0

NCB Service Manual 21

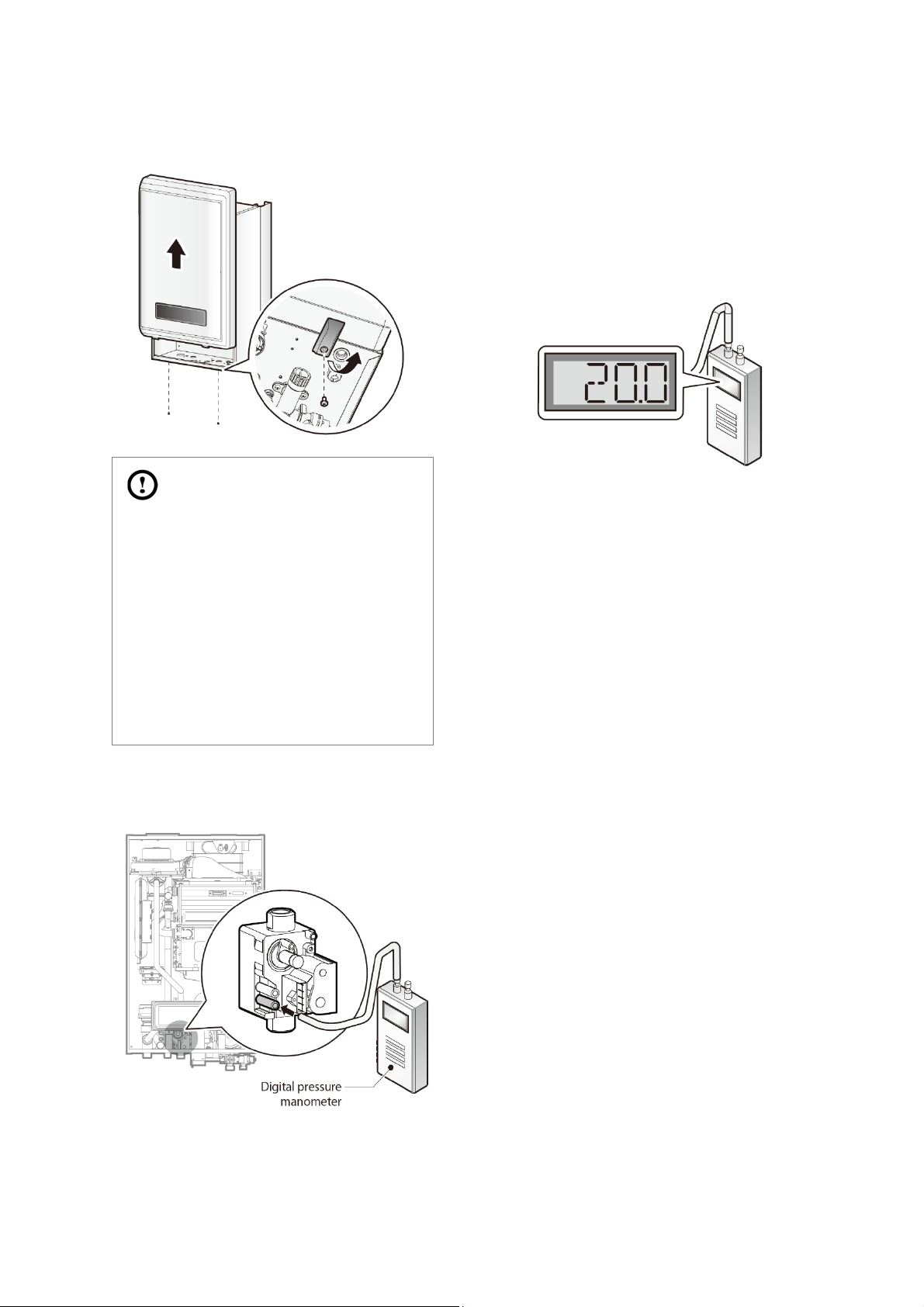

4. Remove the boiler’s front cover by loosening the 4

Phillips head screws securing it to the case.

Open multiple hot water outlets that that have high

7.

flow rates, such as bathtub taps and shower mixers,

to allow the boiler to operate at its maximum firing

rate.

When the boiler reaches the maximum firing rate,

8.

check the inlet gas pressure reading on the

manometer. The gas pressure must be within the

operating range listed in the specifications on page

17.

CAUTION

Ensure that no cables obstruct the

PCB assembly before inserting it in

position. If the assembly is stuck, do

not force it. Doing so may damage

the cables and result in serious

malfunction.

Check again to ensure that no cables

or any other parts obstruct the PCB

before proceeding.

5.

Loosen the screw indicated in the figure below and

connect a manometer to the pressure port. Reset the

manometer to zero before use.

Re-open the manual gas valve and check for leaks.

6.

22 NCB Service Manual

Version 1.0

4.3 Gas Conversion

This default gas supply configuration for this boiler is

Natural Gas. If it is converted to Propane Gas, the

conversion kit supplied with the boiler must be used.

Included Items:

Gas orifice specifications

Model NG LP

NCB-24LSWE Ø5.7 Ø4.5

WARNING

This conversion kit must be installed

by a qualified service agent*. All

conversions must be performed in

accordance with all applicable laws

and regulations. The information in

these instructions must be followed

to minimise the risk of fire or

explosion and to prevent property

damage, personal injury, or death.

The service agent is responsible for

the correct installation of the kit. The

conversion is not proper and

complete until the operation of the

converted appliance is checked as

specified in the manufacturer’s

instructions supplied with the kit.

* A qualified service agent is any individual, firm, corporation or

company who either in person or through a representative is

engaged in and is responsible for the connection, installation,

repair, or servicing of gas equipment or accessories. Qualified

service agents are experienced in gas appliance work,

familiar with all safety precautions, and has comply with all

applicable laws and regulations.

NCB-28LSWE Ø5.7 Ø4.5

NCB-34LSWE Ø5.9 Ø4.55

NCB-40LSWE Ø4.8/Ø6.05 Ø3.8/Ø4.7

Table 1. Orifice sizes

Gas pressure and conversion kit labels

Procedure:

1. Turn off the gas and water supplies to the boiler.

2. Use a Phillips screwdriver to remove the two screws

(one at the left bottom and one at the right bottom)

from the front cover assembly to gain access to the

internal components. Refer to Figure 1 for an

illustration of the front cover on the unit.

Tools r

equired:

Phillips screwdriver

Flathead screwdriver

4 mm (5/32 in ) Allen wrench

Combustion analyzer or dual port manometer

Gas leak detector

Version 1.0

Figure1. B LSWE Series front cover

Remove the front cover and place it in a safe location

3.

to prevent accidental damage.

4.

Label all of the PCB wires.

5. Disconnect all wires from the PCB.

NCB Service Manual 23

6. Loosen the four screws indicated in the illustration

below.

Remove the PCB

7.

assembly.

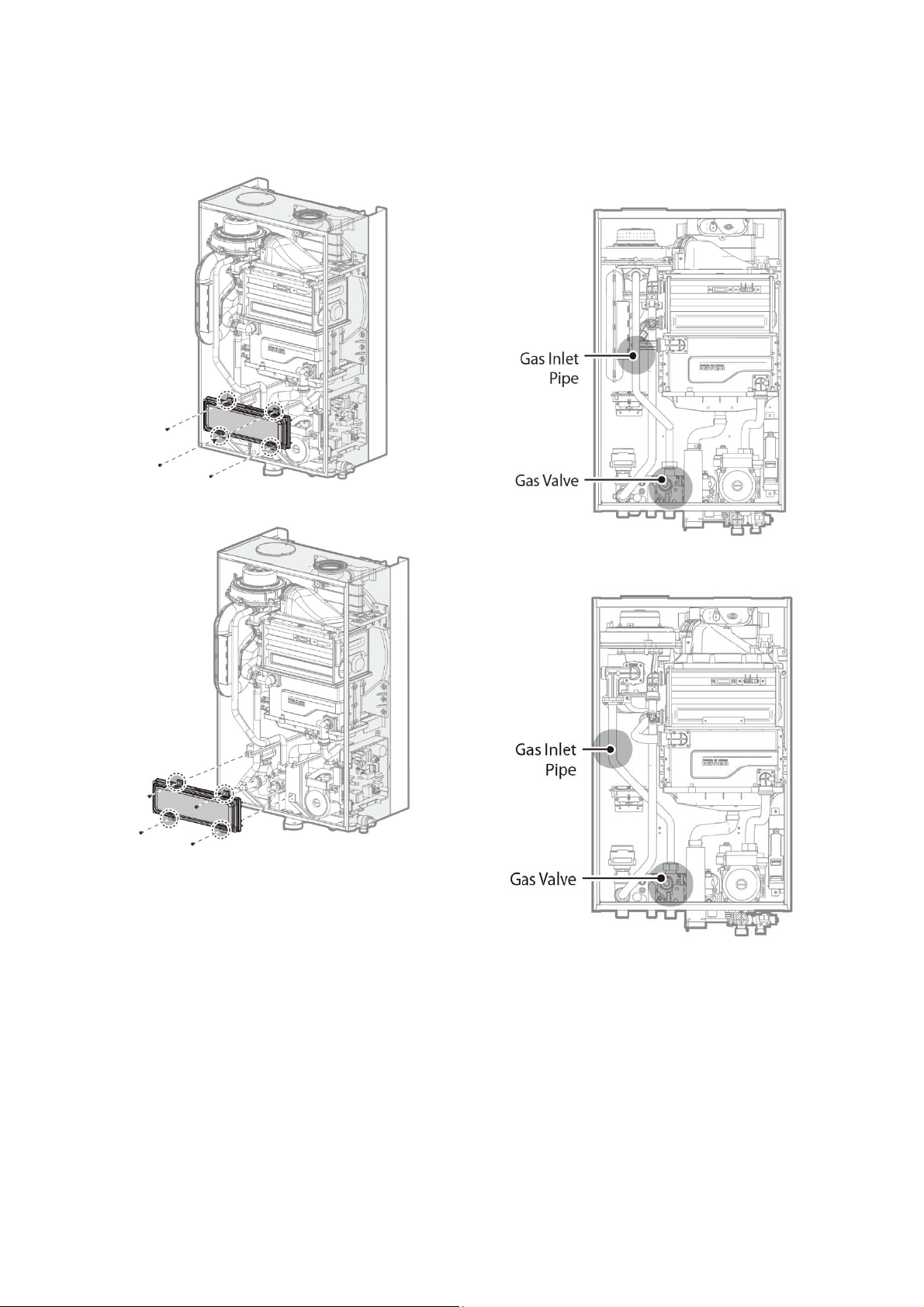

With the internal components exposed, locate the

8.

inlet

gas

unit

pipe and the gas valve

as

shown

in

Figure 2-1 and Figure

in

the middle

2-2.

Figure 2-1. NCB-24/28/34LSWE Internal Components

of

the

Figure 2-2. NCB-40LSWE Internal Components

24 NCB Service Manual

Version 1.0

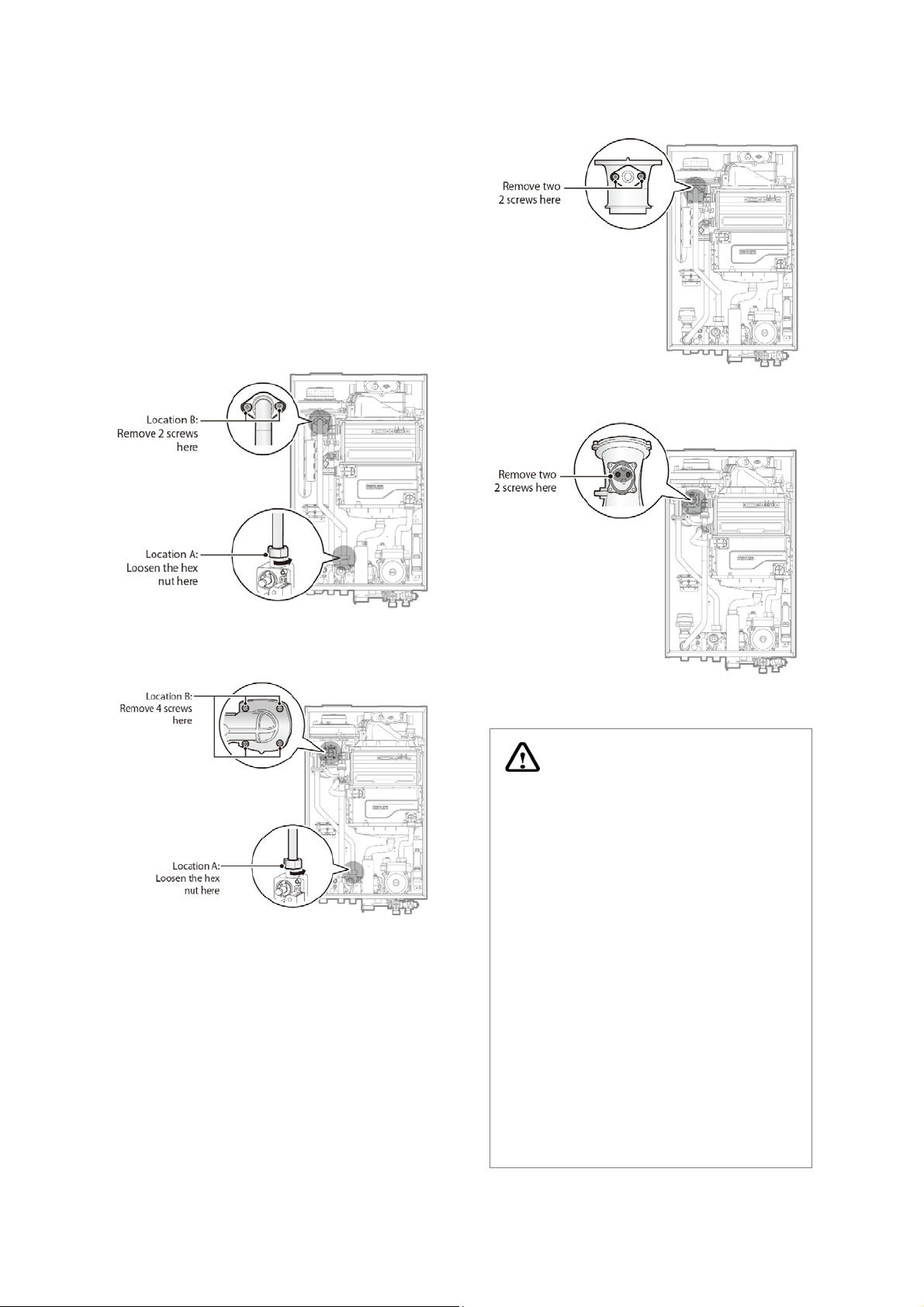

9.

Loosen the hex nut at location A - the connection

above the gas valve where it connects to the pipe

(refer to Figure 3-1 and Figure 3-2). When the hex nut

is loosened, carefully separate the pipe from the gas

valve.

Detach the gas inlet pipe from the gas valve and

10.

locate B - the connection above the gas valve where

it is attached to the fan motor assembly. Carefully

remove the two screws (four screws for NCB40LSWE) using a Phillips screwdriver. Then, pull the

gas inlet pipe out from the fan assembly to access

the gas orifice.

Figure 4-1. Access to Gas Orifice in Fan Assembly

(NCB-24/28/34LSWE)

Figure 3-1. Detaching Gas Inlet Pipe from

Gas Valve and Fan Motor Assembly (NCB-24/28/34LSWE)

Figure 3-2. Detaching Gas Inlet Pipe from

Gas Valve and Fan Motor Assembly (NCB-40LSWE)

When the gas orifice is exposed, remove the two screws

that hold it in place. Remove the orifice from its housing

and prepare the new LP orifice for installation.

Figure 4-2. Access to the gas orifice in fan assembly

(NCB-40LSWE)

WARNING

DO NOT adjust or attempt to

measure the outgoing gas pressure.

The gas valve is factory-set for the

correct

is

propane and does not require field

adjustment.

Attempting to adjust or measure

the gas valve outlet pressure

could result in damage to the

valve or other property, serious

personal injury, o r death

NCB LSWE

configured for

installations

outlet pressure. This setting

suitable

for

natural gas

boilers

are shipped

natural gas

ONLY.

and

. Navien

Version 1.0

NCB Service Manual 25

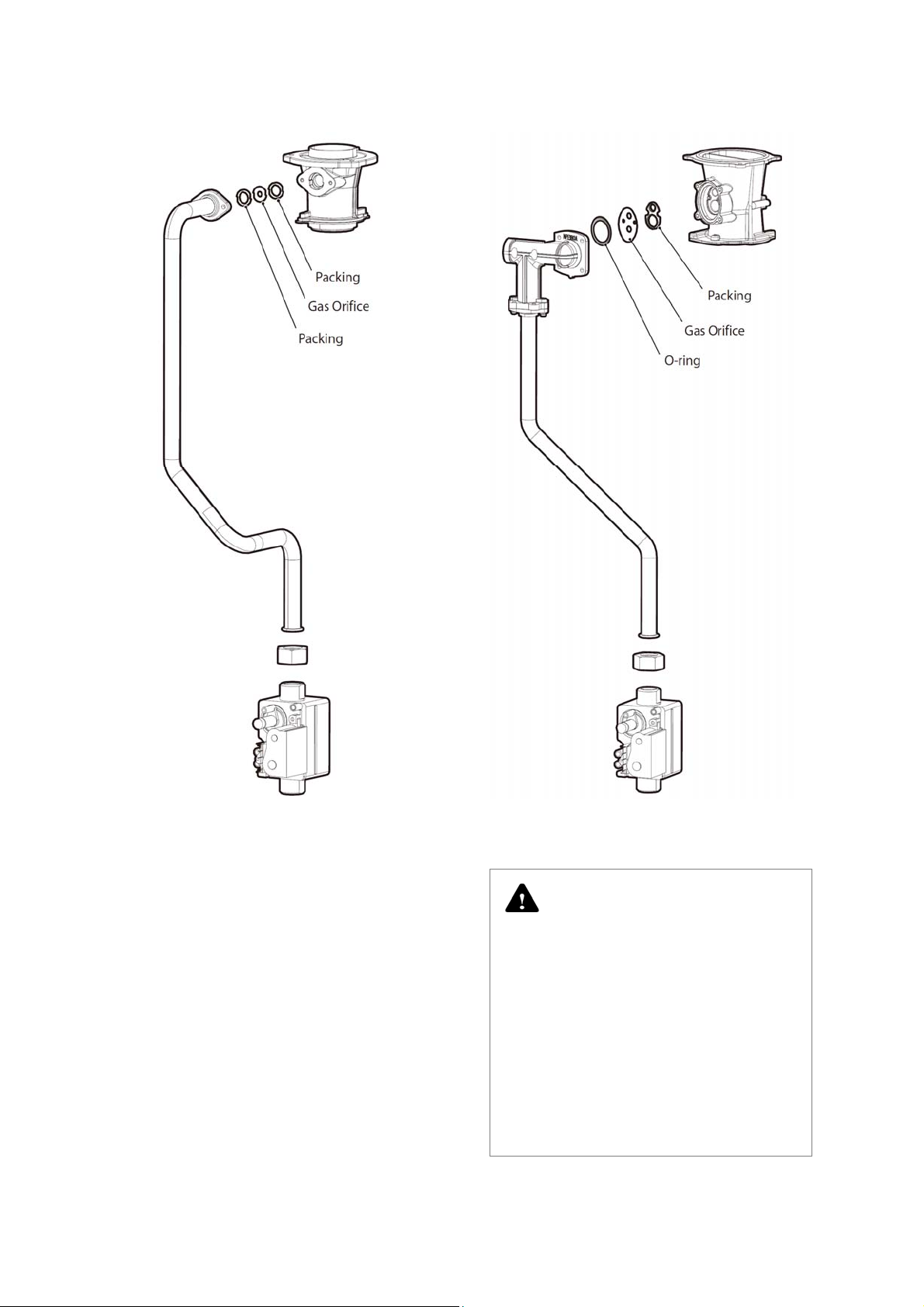

Figure 5-1. Exploded View of Gas Pipe Assembly

(NCB-24/28/34LSWE)

Figure 5-2. Exploded View of Gas Pipe Assembly

(NCB-40LSWE)

DANGER

See Figure 5-1. Inspect the O-ring

each time the connection between

the venturi and gas valve inlet

adapter is disassembled. The O-ring

must always be installed and also

must not be damaged. A missing Oring will cause a gas leak and can

result in serious personal injury or

fatality.

26 NCB Service Manual

Version 1.0

Replace the orifice with the new LP gas orifice. Ensure that

the orifice is seated properly inside the port before

proceeding to the next step.

11.

Reinstate the gas inlet pipe to its original position

and replace all of the screws and ensure all

connections are secure.

over tighten th e sc rews

DO NOT

components

12.

Refer to the labels carefully and then connect all the

wires.

13. Change the front panel Dip Switch settings for the

new gas type.

may be damaged

as

or cracked

WARNING

DANGER

When a gas conversion is performed,

ensure the front panel DIP switches

are set for the correct gas type.

.

Failure to properly set the DIP

switches can cause carbon

monoxide poisoning and result in

serious personal injury or death.

14. Turn on the gas and supply water to the boiler.

15.

Measure and adjust the gas/air ratio.

Ensure that you have turned off the

power to the boiler before opening

the front cover and accessing the DIP

switches

Figure 6. Set the DIP switches

Switch Function Setting

G20 (LNG) 1-OFF, 2-OFF

G25, G27(LNG) 1-OFF, 2-ON

1 & 2 Gas type

Table 1. The DIP Switch Setting by Fuel Selection

G30 (LPG) 1-ON, 2-OFF

G31 (LPG) 1-ON, 2-ON

G20 (LNG) 1-OFF, 2-OFF

Option 1. Combustion analyser (recommended)

Loosen the screw, rotate the plate, and then

a.

remove the gasket to access the emissions

monitoring port as shown in Figure 8.

b.

Insert the analyser into the port (Figure 8).

Figure 7. Insert the Analyser

Version 1.0

NCB Service Manual 27

Model

NCB-24LSWE

NCB-28LSWE

NCB-34LSWE

NCB-40LSWE

(CO2 values at high flame settings must be within 0.5% and

CO2 values for low flame settings must be within 0.3% of

Fully open several hot water outlet fittings and

c.

set the boiler to operate at Stage 1MIN mode.

Measure the CO2 value at the low flame setting. If the CO2

value is not within 0.5% of the value listed in Table 2, adjust

the gas valve set screw. If set screw adjustment is required,

locate the screw as shown in Figure 9. Use a 4 mm (5/32 in)

Allen wrench and turn the set screw no more than 1/4 turn

clockwise to increase or anticlockwise to decrease the CO

value.

Gas Type

G20

Max

% CO

9.27%

G31

10.40%

G20

9.20%

G31

10.42%

G20

9.10%

G31

10.30%

G20

9.20%

G31

10.50%

Table 2. CO2 Value

the values listed.)

Refer to page 55 for information about

selecting operating modes.

Min

% CO

8.78%

10.00%

8.65%

10.00%

8.50%

9.90%

8.70%

10.40%

2

d. Fully open several hot water outlet fittings and

set the boiler to operate at 2-stage MAX mode

(refer to page 55). Measure the CO2 value at a

high flame setting. If the CO2 value does not

match the values listed in Table 2 at a high flame

setting, do not adjust the gas valve. Check that

the orifice is the correct specification.

DANGER

Improper gas valve settings can

cause property damage, serious

personal injury, or death.

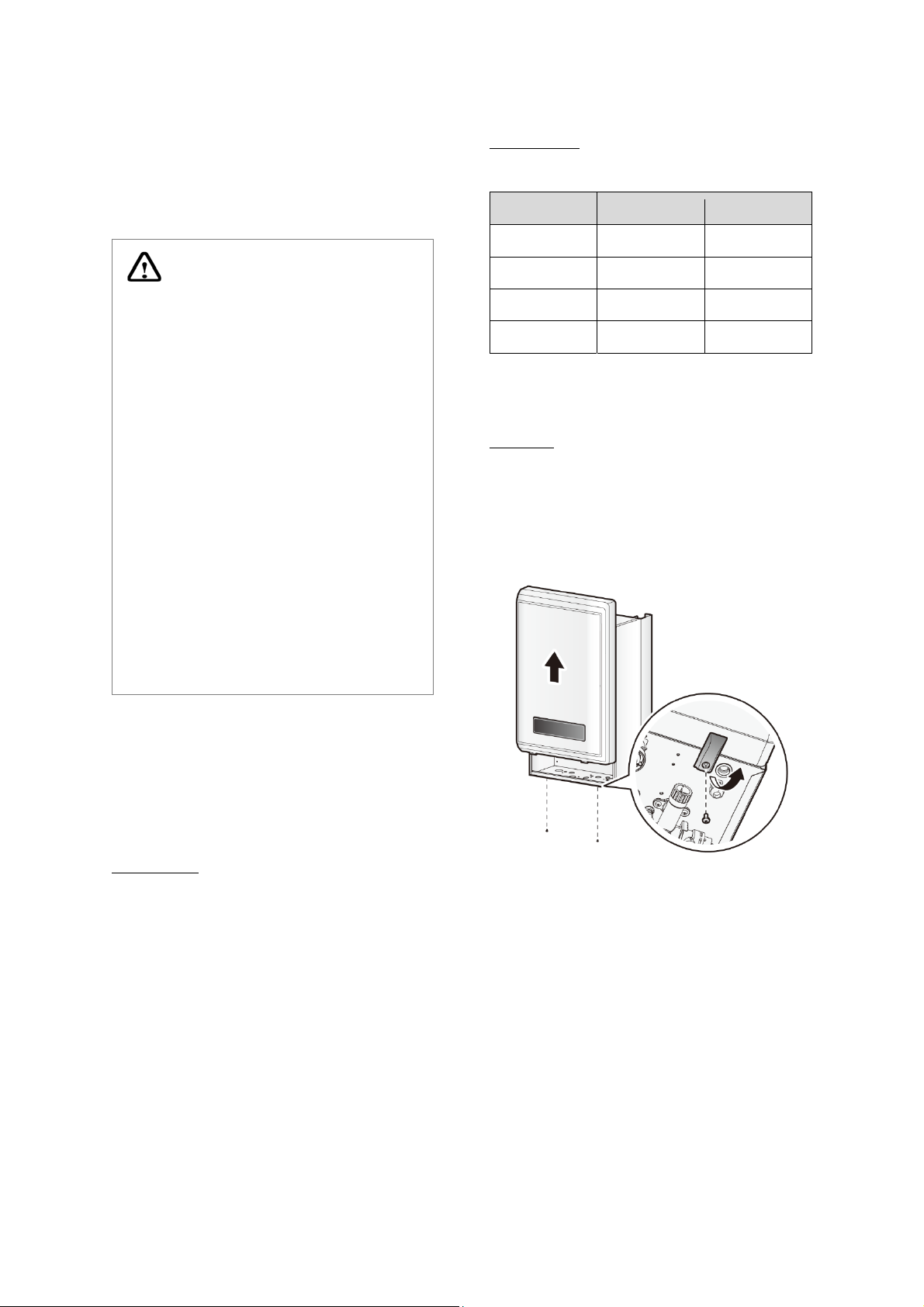

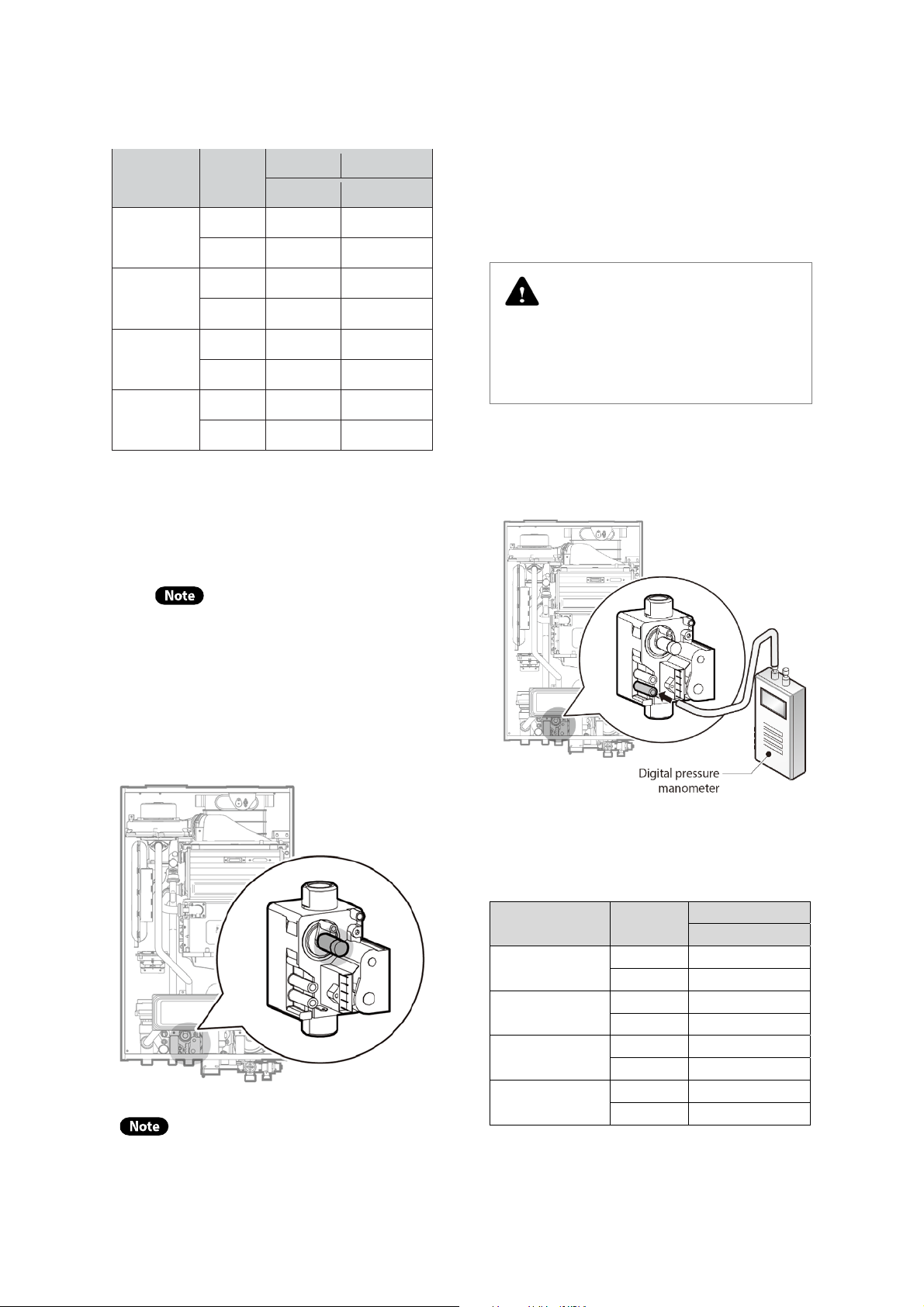

Option 2. Digital manometer

a.

Open the offset pressure port by loosening the

screw two turns. The location of the offset port is

shown in Figure 10.

Figure 9. Digital pressure manometer connection

b. Connect a manometer to the offset pressure port.

For dual port manometers, use the positive

pressure side.

Model Gas Type

NCB-24LSWE

NCB-28LSWE

NCB-34LSWE

Figure 8. Set screw location

The set screw is located behind a

removable cover. To access the set screw,

loosen the screws and remove the cover.

28 NCB Service Manual

NCB-40LSWE

Table 3. Minimum offset values

G20 8 ± 1

G31 4 ± 1

G20 8 ± 1

G31 4 ± 1

G20 8 ± 1

G31 4 ± 1

G20 8 ± 1

G31 4 ± 1

Minimum Offset

Pa

Version 1.0

Loading...

Loading...