Navien NCB-150E, NCB-180E, NCB-210E, NCB-240E Service Manual

Getting Service

If your boiler requires service, you have several options for getting service:

●

Contact Technical Support at 1-800-519-8794 or on the website: www.navienamerica.com.

For warranty service, always contact Technical Support first.

●

Contact the technician or professional who installed your boiler.

●

Contact a licensed professional for the affected system (for example, a plumber or electrician).

When you contact Technical Support, please have the following information at hand:

●

Model number

●

Serial number

●

Date purchased

●

Installation location and type

●

Error code, if any appears on the front panel display.

Navien, Inc.

800.519.8794

www.Navien.com

20 Goodyear lrvine, CA 92618

Service Manual

NCB-E Condensing Combi Boiler

THE LEADER IN CONDENSING TECHNOLOGY

Version: 1.4 (Oct 26, 2015)

WARNING

If the information in these instructions is not followed exactly, a fire or explosion may result, causing

property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

●

Do not try to light any appliance.

●

Do not touch any electrical switch; do not use any phone in your building.

●

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

●

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

The installation must conform with local codes or, in the absence of local codes, the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Code.

When applicable, the installation must conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 and/or CAN/CSA Z240 MH Series, Mobile Homes.

H

NSF/ANSI 372

Keep this manual near this boiler for future reference

whenever maintenance or service is required.

* The wetted surface of this product contacted by consumable water contains less than

one quarter of one percent(0.25%) of lead by weight.

Service Manual

NCB-E Condensing Water Heaters

Model

NCB-150E

NCB-180E

NCB-210E

NCB-240E

Revisions 3

Version Description of changes Date

1.00 First Issue October/27/2013

1.10 Cascade information addition January/03/2014

1.20 E001 information addition, E205 information revision June/12/2014

1.30 AFUE Change November/24/2014

1.40 NCB-150E,180E,210E and 240E Model Added September/30/2015

1.10 Reviewed BY :

1.20 Reviewed BY : Paek Ji Ho

Revisions

Version 1.4

4 NCB-E Service Manual

1. Safety Information 10

1.1 Safety Definitions 10

1.2 Safety Symbols

10

1.3 Symbols Used in the Instructions

10

1.4 Safety Precautions

10

2. Product Information 14

2.1 Product Information 14

2.2 Components

15

3. Technical Data 17

3.1 General Specifications 17

3.2 Dimensions

19

4. System Details 20

4.1 Setting the DIP Switches 20

4.1.1 Setting the DIP Switches 20

4.2 Measuring the Inlet Gas Pressure 22

4.2.1 Gas Pipe Sizing Tables

(Referenced from 2012 National Fuel Gas Code)

24

4.3 Gas Conversion 26

4.4 The Front Panel

32

4.4.1 Icons and Digital Display 32

4.4.2 Buttons

33

4.4.3 Turning the Boiler On or Off

35

4.4.4 Normal Operation

35

4.4.5 Error Display and RESET

37

4.4.6 Adjusting the Space Heating Temperature

37

4.4.7 Adjusting the DHW Temperature

38

4.4.8 Viewing Basic Information (For Homeowner)

39

4.4.9 Error occurrence history display

41

4.4.10 Information display (for servicer)

42

4.4.11 Special Parameter mode

47

4.4.12 Resetting the Boiler (Factory Reset)

57

4.4.13 Cascade Protocol Settings

57

4.4.14 Cascade Set-up Procedure

58

4.4.15 Cascade Set-up Procedure for NP/NR Series Models

58

4.5 Version Display 59

4.6 Error Codes

59

4.7 Ladder Diagram

60

4.8 Electrical Diagnostic Point & Wiring Diagram

61

4.9 Key Components Description 64

4.9.1 PCB 64

4.9.2 High Limit Switch

65

4.9.3 Thermistor

66

4.9.4 Fan Motor

67

4.9.5 Flame Rod Assembly

68

4.9.6 Ignition Transformer

69

4.9.7 APS

70

4.9.8 Main Gas Valve

71

4.9.9 Burner

72

4.9.10 Flow Sensor

73

4.9.11 Primary Heat Exchanger

74

4.9.12 Secondary Heat Exchanger

75

4.9.13 DHW Heat Exchanger

76

4.9.14 Circulation Pump

77

4.9.15 3-Way Valve

78

4.9.16 Water Pressure Sensor

79

4.9.17 Auto feeder Valve

80

4.9.18 Dual Venturi

81

5. Troubleshooting 82

5.1 Error code classification 82

5.2 Error Code List

83

5.1.1 001Error 86

5.2.2 003Error

89

5.2.3 004Error

95

5.2.4 012Error

97

5.2.5 016Error

101

5.2.6 030Error

103

5.2.7 046Error

105

5.2.8 047Error

105

5.2.9 060Error

106

5.2.10 109Error

108

5.2.11 110Error

110

5.2.12 205Error

112

5.2.13 218Error

114

5.2.14 351Error

116

5.2.15 352Error

118

5.2.16 353Error

119

5.2.17 407Error

120

5.2.18 421Error

122

5.2.19 439Error

124

5.2.20 515Error

126

5.2.21 517Error

127

5.2.22 594Error

127

5.2.23 615Error

127

5.2.24 740Error

128

5.2.25 777Error

129

5.2.26 782Error

130

5.3 Troubleshooting guide by symptom 131

5.3.1 Noise 131

5.3.2 Water Temperature Issue

132

5.3.3 Circuit breaker operation

133

Contents

Contents 5

6. Replacement of Parts 134

6.1 Replacement Procedure 134

6.2 Components Replacement Instructions

134

6.2.1 PCB 134

6.2.2 Fuse

135

6.2.3 Fan Motor (Combustion Air)

135

6.2.4 Flame Rod

136

6.2.5 Ignition Transformer

137

6.2.6 APS

137

6.2.7 Main Gas Valve

138

6.2.8 Condensate Trap

139

6.2.9 Flow Sensor

140

6.2.10 Circulation Pump

141

6.2.11 3-way Valve

142

6.2.12 Water Pressure Sensor

143

6.2.13 Space Heating Strainer

143

6.2.14 Auto Feeder Valve

144

6.2.15 DHW Heat exchanger

144

7. Components Diagram and Part List 145

7.1 Case Assembly 145

7.2 Burner Assembly

146

7.3 Waterway Assembly (NCB)

148

7.4 Waterway Assembly (NCB-E)

150

7.5 Fan (Gas) Assembly

152

8. Inspection and Maintenance Schedule 154

8.1 Annual Servicing 154

8.2 Maintenance Report

154

8.3 Maintenance Schedules

154

8.4 Inspection Report

154

Version 1.4

6 NCB-E Service Manual

Requirements for the State of Massachusetts

This appliance must be installed by a licensed plumber or gas fitter in accordance with the Massachusetts Plumbing and Fuel Gas Code 248

CMR Sections 2.00 and 5.00.

IMPORTANT: In the State of Massachusetts (248 CMR 4.00 & 5.00)

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment,

the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back‐up is

installed on the floor level where the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the

services of qualified licensed professionals for the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back‐up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision cannot be met at the time of completion of installation, the owner shall have a

period of thirty (30) days to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery

operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight

(8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment.

The sign shall read, in print size no less than one‐half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of

248 CMR 5.08(2)(a)1 through 4.

7

Warranty Exclusions

Navien’s Limited Warranty shall be void in the event of an

occurrence of any of the following:

●

Improper installation, failure to install in strict compliance with

the Installation Manual procedures, installed by a non-licensed

installer, and installation in violation of applicable rules, laws or

building codes.

●

Product purchased through the internet, other e-commerce

channels, or any installer that obtained the Product from a

supplier or distributor not authorized by Navien.

●

Failure to perform regular maintenance, misuse, operation at

settings other than those recommended or specified, noncompliance with instructions or guidelines set forth in the User’s

Operation Manual.

●

Modification or alteration of the Product in any manner,

including but not limited to, removal of any component or

part, addition of any non-approved components, relocating

or moving the Product from its original installation site, or any

accidental or intentional damage to the Product.

●

Installation in commercial or multi-unit dwelling applications or

for non-recommended uses.

●

Any damage caused by local adverse conditions including but

not limited to hard water deposits, lime or mineral build-up,

operating in corrosive atmospheric elements.

●

Damage or caused by gas flow issues, electrical surges, flooding,

fire, abnormal external temperature, and any other cause of

damage not directly caused by a manufacturing defect.

●

Installer’s failure to fully comply with the Warranty Service and

Return Policy procedures previously provided to Installer and

as is available on Navien’s website. Such policies include but

are not limited to the Installer’s failure to first contact Navien

Technical Support while in front of the product for purposes of

trouble shooting the identified problem or issue.

●

Performance problems caused by improper sizing of the boiler,

the gas supply line, the venting connection, combustion air

openings, electric service voltage, wiring, fusing or any other

components, parts or specifications.

●

Improper conversion from natural gas to LP gas or LP gas

to natural gas or attempt to operate with a type of gas not

specified for the boiler.

●

Any damage, malfunction or failure caused by abuse,

negligence, alteration, accident, fire, flood, freezing, wind,

lightning and other acts of God.

●

Operating, using or storing the boiler in a corrosive or

contaminated atmosphere or environment.

●

Operating the boiler at water temperatures outside the factory

calibrated temperature limits and/or exceeding the maximum

setting of the high limit control.

●

Operating the boiler when it is not supplied with potable water

at all times.

●

Subjecting the heat exchanger to pressures or firing rates

greater or lesser than those shown on the rating plate.

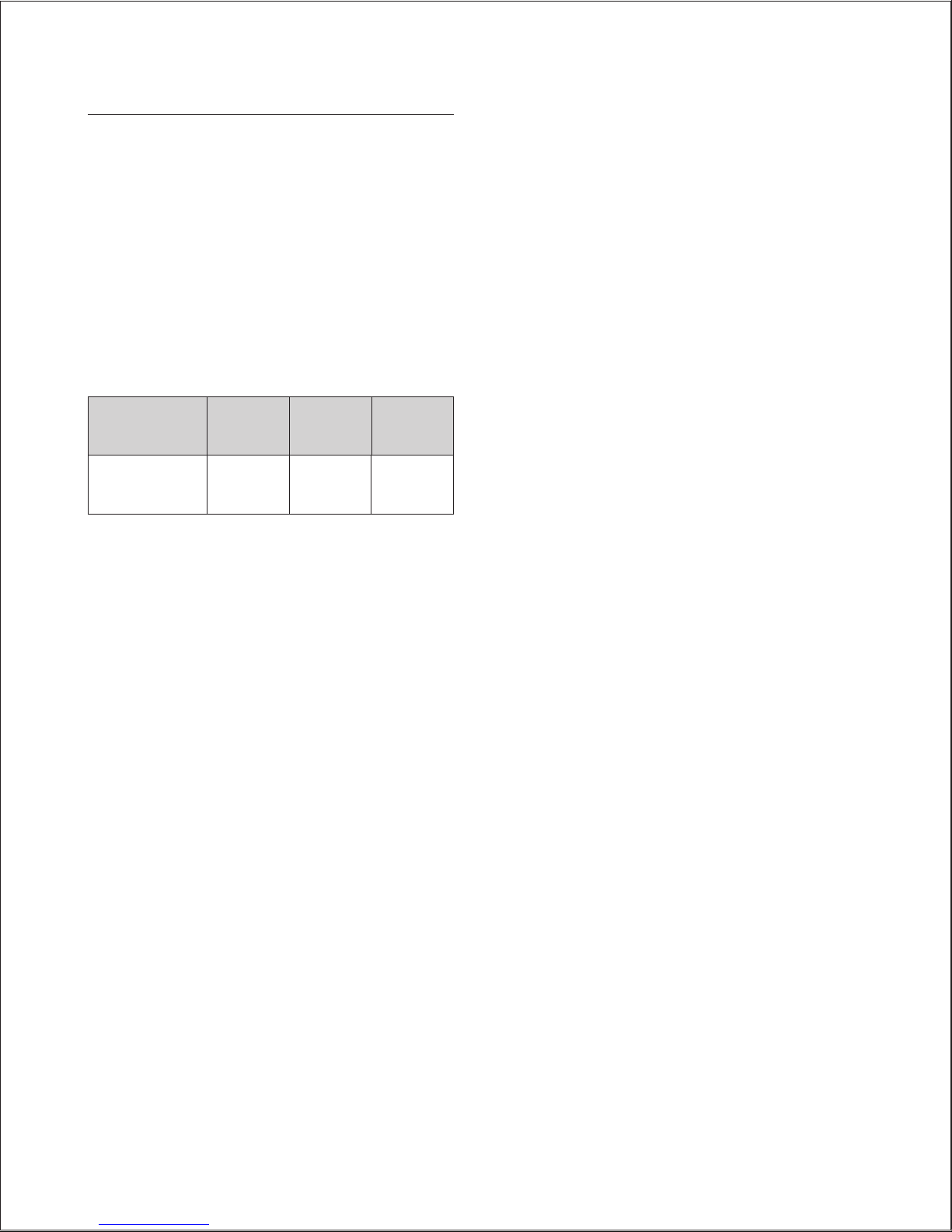

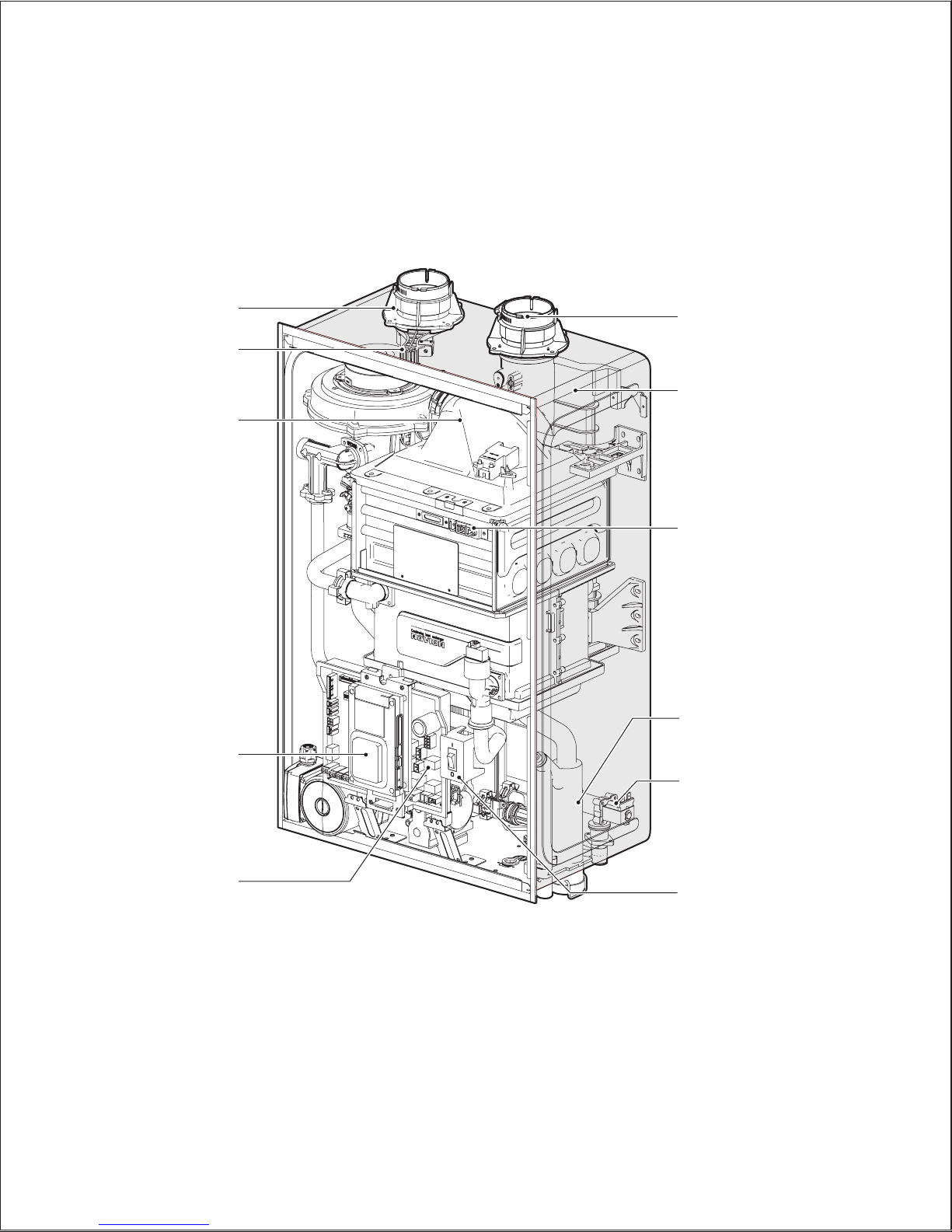

Warranty Period

Navien products come with a limited warranty covering labor,

parts and the heat exchanger. The following warranty periods

begin to run from the date of original installation. The date of

original installation must be provided to Navien, and upon request,

proof of the original installation date must also be provided to

Navien. When the product is installed in a new construction, the

commencement date shall be dated upon which the end-user

takes title to the property.

APPLICABLE WARRANTY PERIOD

Product

Labor

Warranty

Parts

Warranty

Heat

Exchanger

Warranty

NCB-E Series Boiler

(Single Family

Residential Use)

1 Year 5 Years 10 Years

Warranty Claim Procedures

To obtain warranty repair service, the end user or homeowner

must contact the original installer of your Navien product. If the

original installer cannot be identified, the end user or homeowner

may contact Navien’s Technical Administration Department at

(800) 519-8794. Proof of purchase is required to obtain warranty

service.

Warranty Service

At its option, Navien will replace the defective component (part(s)

or heat exchanger), in accordance with the terms of this Limited

Warranty, if it fails in normal use and service during the Applicable

Warranty Period identified above. The replacement component

must be Navien original factory component. Navien, at its sole

discretion, may replace the product with a new or refurbished

product of comparable quality and design. The replacement

component or product will be warranted only for the unexpired

portion of the original component’s Applicable Warranty Period.

Payment for labor in completing the warranty service is subject

to Navien’s prior written approval and shall be subject to Navien’s

schedule of approved labor allowances.

Navien Warranty

Version 1.4

8 NCB-E Service Manual

●

Installation at any location outside the United States and

Canada.

●

Removal or alteration of the rating plate.

Rating Plate, *Plaque Signalétique

Combination Boiler *Chaudière combinaison

Navien, Inc.

20 Goodyear, Irvine, CA 92618

Tel: 1-800-519-8794

Direct vent indoor installation, * Évacuation directe installation intérieure

Model No., *Numéro de modèle Type of Gas, *Type de gaz

NCB-240E NG

Max. Input Rating (DHW),*Entrée GPL max. Min. Input Rating,*Débit calorifique max.

199,900 Btu/h 18,000 Btu/h

Max. Input Rating

(Heating),*Entrée GPL max. Heating Capacity, *Capacité de chauffage

120,000 Btu/h 112,000 Btu/h

Category of boiler, *Catégorie de chaudière Net AHRI Rating, *Régime de AHRI

Category IV 97,000 Btu/h

Max. Inlet Gas Pressure, *Pression max. de gaz d’entrée 10.5 Inches W.C. *pouces W.C.

Min. Inlet Gas Pressure, *Pression min. de gaz d’entrée 3.5 Inches W.C. *pouces W.C.

Manifold Pressure, *Pression d’admiss

ion -1.20 Inches W.C. *pouces W.C.

Electrical Rating, *Régime nominal électrique AC*c.a. 120 Volts 60Hz Use less than 2 Amp, *Utilise moins de 2A

Minimum relief valve capacity, *Capacité minimaum soupape. 189 lbs/hr ANSI Z21.13b-2014 · CSA 4.9b-2014

Orifices necessary for LP conversion are provided. *Les injectures nécessaires à la conversion au GPL sont fournis.

Failure to use the correct gas can cause pro

blems which can result in death, serious injury or property damage.*Le f ait de ne pas

utiliser le bon gaz peut causer des problèmes qui peuvent mener à la mort, causer des blessures graves ou endommager la propriété.

Consult your installation manual for more information.*Consultez votre manuel d’installation pour plus d’information.

This appliance is certified for use at altitudes up to 4,500 ft (1,

370 m) in accordance to the latest CAN/CGA 2.17-High Altitude

Installation procedures at normal manifold pressure. For installation instructions at altitudes higher than 4,500 ft, please contact

Navien. *Cet appareil est certifié pour une utilisation à des altitudes de 0 à 4,500 pieds (1,370 m) conformément aux toutes les procédures

d’installation à haute altitude CAN/CGA 2.17 à une pression normal

e. Pour les installations à élévations en haut de 4,500 pieds, appeler le

bureau de Navien.

This appliance must be installed in accordance with local codes or in the absence of local codes, the most recent edition of

National Fuel Gas Code, ANSI Z223. 1, in Canada use CAN/CGA B149. 1 or 2 installation codes for Gas Burning Appliances.

*Cet appareil doit être installé conformément aux codes locaux, ou

s’il n’y a pas de codes locaux, la plus récente version du National Fuel

Gas Code des É.-U., ANSI Z223. 1, au Canada utilisez les codes d’installation CAN/CGA B149. 1 ou 2 pour les appareils à gaz.

FOR YOUR SAFETY *POUR VOTRE SÉCURITÉ

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other gasappliances. *Ne rangez

pas et n'utilisez pas d'essence ou d'a

utres liquides ou vapeurs inflammables près de cet appareil ou de tout autre appareil électroménager.

Other Terms: This Limited Warranty is subject further to the terms

and conditions set forth herein and as may be further specified

in the Terms and Conditions page located on Navien’s website at

www.navienamerica.com. WITH THE EXCEPTION OF THIS LIMITED

WARRANTY, NAVIEN DISCLAIMS ANY OBLIGATION OR LIABILITY

WITH RESPECT TO THE PRODUCTS OR THEIR SALE AND USE, AND

NAVIEN NEITHER ASSUMES NOR AUTHORIZES THE ASSUMPTION

OF, ANY OBLIGATION OR LIABILITY IN CONNECTION WITH THE

PRODUCTS. THIS DISCLAIMER INCLUDES ANY OTHER WARRANTIES,

EXPRESS, IMPLIED OR STATUTORY RESPECTING THE PRODUCTS

OR ANY PARTS OR COMPONENTS THEREOF, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. Navien’s total liability

for any claim arising hereunder shall not exceed the purchase

price which you paid for the Product. NAVIEN SHALL NOT IN ANY

EVENT BE LIABLE FOR INDIRECT, SPECIAL, CONSEQUENTIAL OR

LIQUIDATED DAMAGES OR PENALTIES, INCLUDING CLAIMS FOR

LOST REVENUE, PROFITS OR BUSINESS OPPORTUNITIES, EVEN IF

NAVIEN HAD OR SHOULD HAVE HAD ANY KNOWLEDGE, ACTUAL

OR CONSTRUCTIVE, OF THE POSSIBILITY OF SUCH DAMAGES.

9

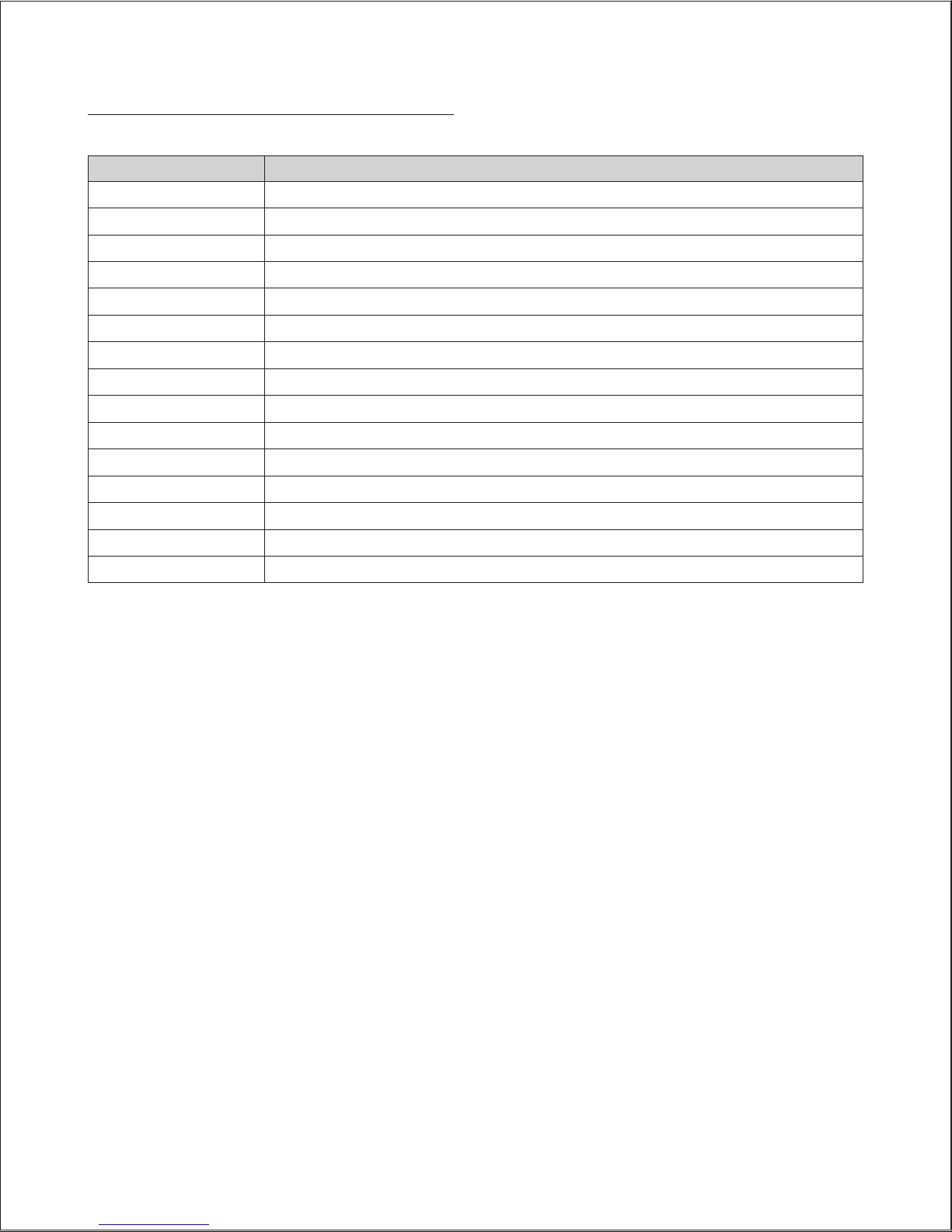

Abbreviation Definition

NCB-E General name of NCB-180E, NCB-210E, and NCB-240E

NG Natural Gas

LP Propane Gas

AP Air Pressure

APS Air Pressure Sensor

DHW Domestic Hot Water

FM Fan Motor

GARC Gas Air Ratio Control

GPM Gallons Per Minute

MGV Main Gas Valve

RPM Revolutions Per Minute

PCB Printed Circuit Board

EMI Electromagnetic Interface

HTL High Temperature Limiter

LWCO Low Water Cut Off

Abbreviations and Definitions

Version 1.4

10 NCB-E Service Manual

1.1 Safety Definitions

The following safety symbols are used in this manual. Read and

follow all safety instructions in this manual precisely to avoid unsafe

operating conditions, fire, explosion, property damage, personal

injury, or death.

1.2 Safety Symbols

DANGER

Indicates an imminently hazardous situation which, if not

avoided, could result in severe injury or death.

WARNING

Indicates a potential hazardous situation which, if not avoided,

could result in injury or death.

CAUTION

Indicates an imminent hazardous situation which, if not

avoided, may result in minor or moderate injury.

1.3 Symbols Used in the Instructions

The following symbols are used throughout the instructions to

bring attention to important information concerning the appliance.

IMPORTANT

Warns of a risk of damage and environmental pollution

NOTE

Indicates additional information that is important but not

related to personal injury or property damage.

1.4 Safety Precautions

DANGER

FLAMMABLE MATERIALS

Keep the area around the boiler clear and free from flammable

materials.

●

DO NOT place flammable liquids such as oils or gasoline, etc.

near the boiler.

●

DO NOT place combustibles such as newspapers and

laundry etc. near the boiler or the venting system.

●

DO NOT place or use hair spray, spray paint or any other type

of spray can near the boiler or the venting system (including

the vent termination).

●

DO NOT place anything in or around the vent terminations

that could obstruct the air flow in and out of the boiler such

as a clothes line.

DANGER

FLAMMABLE VAPORS

Vapors from flammable liquids will explode and catch fire

causing death or severe burns.

Do not use or store flammable products such as gasoline,

solvents or adhesives in the same room or area near the boiler.

●

Keep flammable products: far away from the boiler in

approved containers, tightly closed, and out of children’s

reach.

●

Boiler has a main burner flame: which can come on at any

time, and may ignite flammable vapors.

●

Vapors: cannot be seen, are heavier than air, go a long way

on the floor and can be carried from other rooms to the

main burner flame by air currents.

1. Safety Information

Safety Information 11

DANGER

HOT

BURN

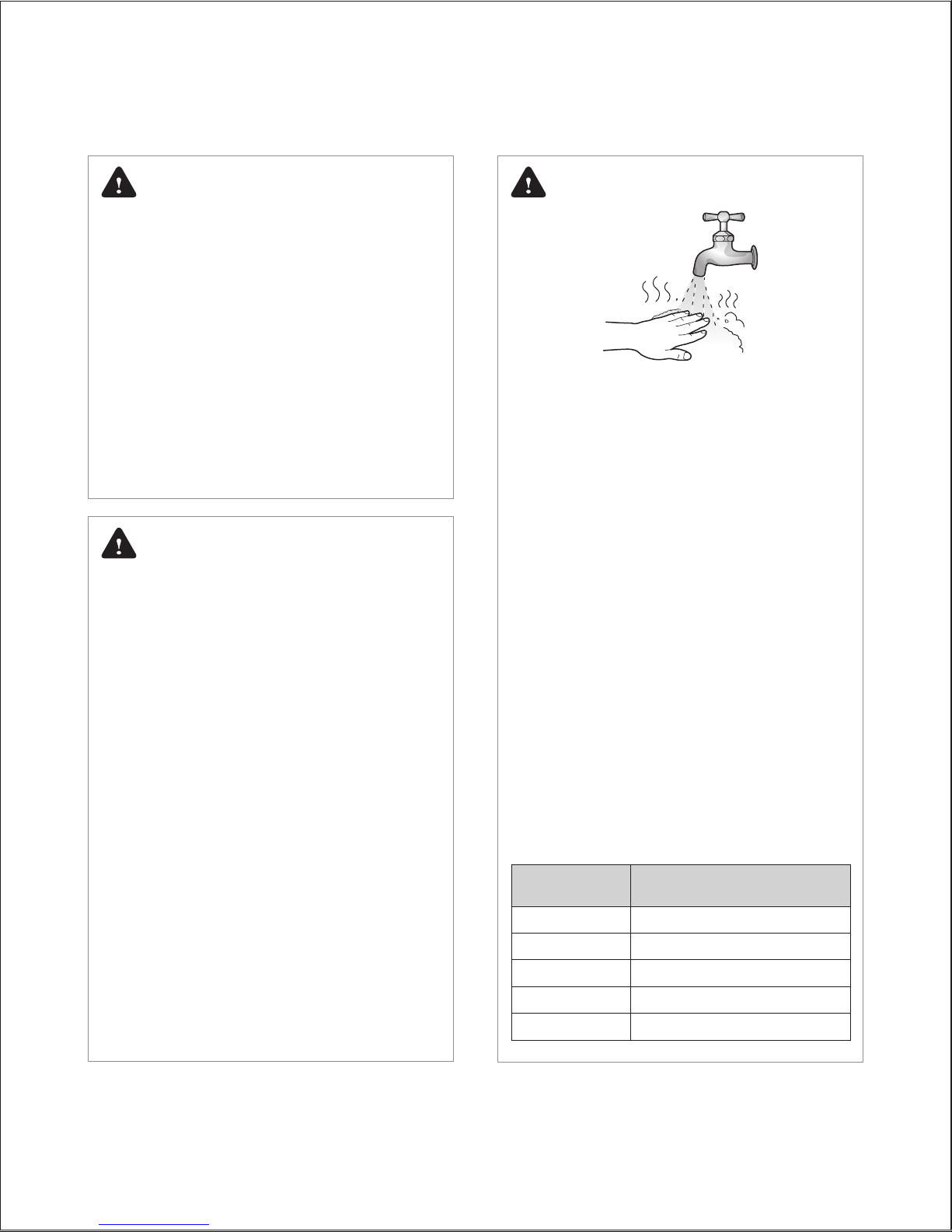

HOT WATER TEMPERATURE SETTING

●

Water temperatures at or above 125°F (52°C) can cause

severe burns instantly or death from scalds.

●

Households with small children, disabled, or elderly persons

may require 120 °F (49°C) or lower temperature setting to

prevent contact with “HOT” water.

TO PREVENT BURNS

●

Use the lowest operating temperature setting necessary to

provide comfortably-hot water.

●

If your household has children or elderly or disabled

residents, consider using a lower temperature setting.

●

Read all the instructions in this manual carefully before

changing the temperature setting.

●

Feel the water before using it on children, the elderly, or the

disabled.

●

Contact a licensed plumber or your local plumbing authority

for more information.

●

This boiler’s water temperature is set to 120°F (49°C) at

the factory for your safety and comfort. Increasing the

temperature increases the risk of accidental scalding. Water

temperatures at or above 125°F (52°C) can cause instant

scalding, severe burns or death. Before you decide to change

the temperature setting, read the following charts carefully.

Water Temperature

Time in which a young child can suffer

a full thickness (3rd degree) burn

160°F (70°C) Less than 1 second

140°F (60°C) 1 second

130°F (55°C) 10 second

120°F (49°C) 10 minutes

100°F (37°C) very low scald risk

DANGER

COMPROMISED VENTING SYSTEM

●

Failure to follow the Venting Section of the installation

manual may result in unsafe operation of this boiler. To

avoid the risk of fire, explosion or asphyxiation from carbon

monoxide, never operate the boiler unless it is properly

vented to the outside and has an adequate air supply for

proper operation.

●

Be sure to inspect the vent termination and the air intake

pipe annually to ensure safe operation of the boiler.

●

Immediately turn off and do not use the boiler if any of the

vent pipes, vent elbows and/or the boiler are:

-

damaged in any way;

-

separated at a joint,

-

cracked or show evidence of corrosion, rusting or

melting.

DANGER

WHAT TO DO IF YOU SMELL GAS

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal

injury or loss of life.

DO NOT OPERATE THE BOILER.

DO NOT OPERATE ANY FAUCETS.

Smell all around the appliance area for gas. Be sure to smell

next to the floor because some gas is heavier than air and will

settle on the floor.

●

Do not smoke.

●

Extinguish any open flames and sparks.

●

Do not operate light switches or electrical equipment

switches.

●

Do not use any phone in your building.

●

Open the windows and doors.

●

Close the gas shutoff valve.

●

Keep people away from the danger zone.

●

Observe the safety regulations of your local gas supplier,

found on the gas meter.

●

Immediately call your gas supplier from the outside of the

building. Follow the gas supplier’s instructions.

●

If you cannot reach your gas supplier, call the fire department.

●

Notify your plumbing/heating contractor from the outside

of the building.

Version 1.4

12 NCB-E Service Manual

WARNING

GAS TYPE and AC VOLTAGE

This boiler is configured for Natural Gas from the factory. If

conversion to Propane Gas is required, the conversion kit

supplied with the boiler must be used.

●

Be sure to use 120 VAC, 60 Hz, minimum 2 A current. Using

abnormally high or low AC voltage may cause abnormal

operation, and may reduce the life expectancy of this

product.

If the unit does not match requirements, do not service,

please contact Navien immediately.

WARNING

GAS CONVERSION

The conversion kit shall be installed by a qualified service

agency* in accordance with Navien America’s instructions and

all applicable codes and requirements of the authority having

jurisdiction. The information in these instructions must be

followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or death. The qualified

service agency is responsible for the proper installation of

this kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified in

the manufacturer’s instructions supplied with the kit.

* A qualified service agency is any individual, firm, corporation

or company which either in person or through a representative

is engaged in and is responsible for the connection, utilization,

repair or servicing of gas utilization equipment or accessories;

who is experienced in such work, familiar with all precautions

required, and has complied with all of the requirements of the

authority having jurisdiction.

In Canada: The conversion shall be carried out in accordance

with the requirements of the provincial authorities having

jurisdiction and in accordance with the requirements of the

CAN‐B149.1 and CAN1‐B149.2 Installation Code.

Navien America Inc. is not liable for any property damage

and/or personal injury resulting from unauthorized

conversions.

DANGER

INSTALLATION REQUIREMENTS

●

Installation conditions may affect how the boiler is serviced.

Read all related information in the “Installation Manual”.

●

The Boilers must be installed according to all local and state

codes or, in the absence of local and state codes, the most

recent edition of the “National Fuel Gas Code (ANSI Z223.1/

NFPA 54)” in the USA or the “National Gas and Propane

Installation Code (CAN/CSA B 149.1)” in Canada.

●

Massachusetts code requires this boiler to be installed in

accordance with Massachusetts Plumbing and Fuel Gas

Code 248 CMR Section 2.00 and 5.00.

DANGER

IMPORTANT SAFETY PREAUTIONS

●

Read and understand this safety information before

operating or servicing this Navien Boiler.

●

Confirm the location of the gas shut-off valve. Close the

manual shut-off valve if the Navien Boiler ever becomes

subjected to overheating, fire, flood, physical damage or any

other such damaging condition during servicing.

●

DO NOT turn on the boiler unless water and gas supplies are

fully opened.

●

DO NOT turn on the boiler if the cold water supply shut-off

valve is closed.

●

Make certain power to the boiler is “OFF” before removing

the front cover for any reason.

●

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

●

Improper adjustment, alteration, service or maintenance

can cause property damage, personal injury, or death.

●

To prevent scalding, always check the temperature of the

hot water after servicing.

●

DO NOT attempt to change the water temperature while

someone is using the boiler.

●

DO NOT use parts other than those specified for this

equipment.

●

DO NOT operate the boiler if you feel something is wrong

with the unit.

●

DO NOT allow children to operate or otherwise handle the

unit.

Safety Information 13

CAUTION

●

Do not attempt to repair or replace any part of the boiler,

unless it is specifically recommended in this manual.

For all other service, contact an authorized technician or

licensed professional. Improper adjustments, alterations,

service, or maintenance may lead to property damage,

personal injury, or death and will void your warranty.

●

Do not operate the boiler if you feel something is wrong

with it.

Doing so may result in product damage or personal injury.

●

Do not allow children to operate or access the boiler.

Doing so may result in product damage or personal injury.

●

Do not attempt to change the water temperature while

the boiler is being used.

Doing so may result in personal injury.

●

Do not turn on the boiler unless the water and gas

supplies are fully opened.

Doing so may damage the boiler.

●

Do not turn on the water if the cold water supply shutoff valve is closed.

Doing so may damage the boiler.

●

Do not use this boiler for anything other than its

intended purpose, as described in this manual.

●

Do not remove the front cover unless the power to the

boiler is turned off or disconnected.

Failure to do so may result in electric shock.

●

When servicing the controls, label all wires prior to

disconnecting them.

Failure to do so may result in wiring errors, which can lead to

improper or dangerous operation.

●

Do not use unapproved replacement or accessory parts.

Doing so may result in improper or dangerous operation

and will void the manufacturer’s warranty.

●

Do not place anything in or around the vent terminals,

such as a clothes line, that could obstruct the air flow in

or out of the boiler.

●

This boiler has been approved for use in the USA and

Canada only.

Using the boiler in any other country will void the

manufacturer’s warranty.

●

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas valve to the appliance.

●

Do not use this appliance if any part has been under

water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

WARNING

●

Shut off the gas supply if the boiler is damaged.

Have your installer or plumber show you the location of the

gas shut off valve and demonstrate how to close the valve.

If the boiler is damaged as a result of overheating, fire, flood,

or any other reason, close the manual shut off valve and do

not operate the boiler again until it has been inspected by a

qualified technician.

●

Do not store or use gasoline or other flammable liquids

near this boiler.

Doing so may result in fire or explosion.

●

Do not place combustibles, such as newspapers or

laundry, near the boiler or venting system.

Doing so may result in a fire.

●

Do not place or use hair sprays, spray paints, or any other

compressed gases near the boiler or venting system,

including the vent termination.

Doing so may result in fire or explosion.

●

Do not operate the boiler with the front cover opened.

Doing so may result in fire or carbon monoxide (CO)

poisoning, which may result in property damage, personal

injury, or death.

●

Do not operate this boiler without proper venting.

Doing so may result in fire or carbon monoxide (CO)

poisoning, which may result in property damage, personal

injury, or death. Inspect the vent termination and air intake

supply annually to ensure proper operation of the boiler.

Turn off and discontinue use of the boiler if any of the vent

pipes, vent elbows, or intake pipes are damaged in any way,

separated at a joint, or show evidence of corrosion, rusting,

or melting.

●

Do not touch the power cord or internal components of

the boiler with wet hands.

Doing so may result in electric shock.

Version 1.4

14 NCB-E Service Manual

2.1 Product Information

Navien features the NCB-E series gas boiler with a built-in

Circulation Pump and Air vent. This appliance is fully modulating

and provides central heating and domestic hot water. Depending

on the heat capacity, each model is divided into three types; 150E,

210E and 240E.

Model

Maximum

Space Heating

Input

Maximum

DHW

Input

NCB-150E 60,000 BTU/H 120,000 BTU/H

NCB-180E 80,000 BTU/H 150,000 BTU/H

NCB-210E 100,000 BTU/H 180,000 BTU/H

NCB-240E 120,000 BTU/H 199,900 BTU/H

The appliance always gives priority to DHW supply.

Navien features the NCB-E series boiler with a built-in Circulation

pump and 3-Way valve assembly, Flow sensor, DHW plate heat

exchanger and safety valve(or relief valve). A separate heating

expansion vessel is required.

Internal freeze protection and an electronic control unit are

incorporated within the boiler. Any standalone room thermostat or

set of contacts can be used with the boiler.

2. Product Information

Product Information 15

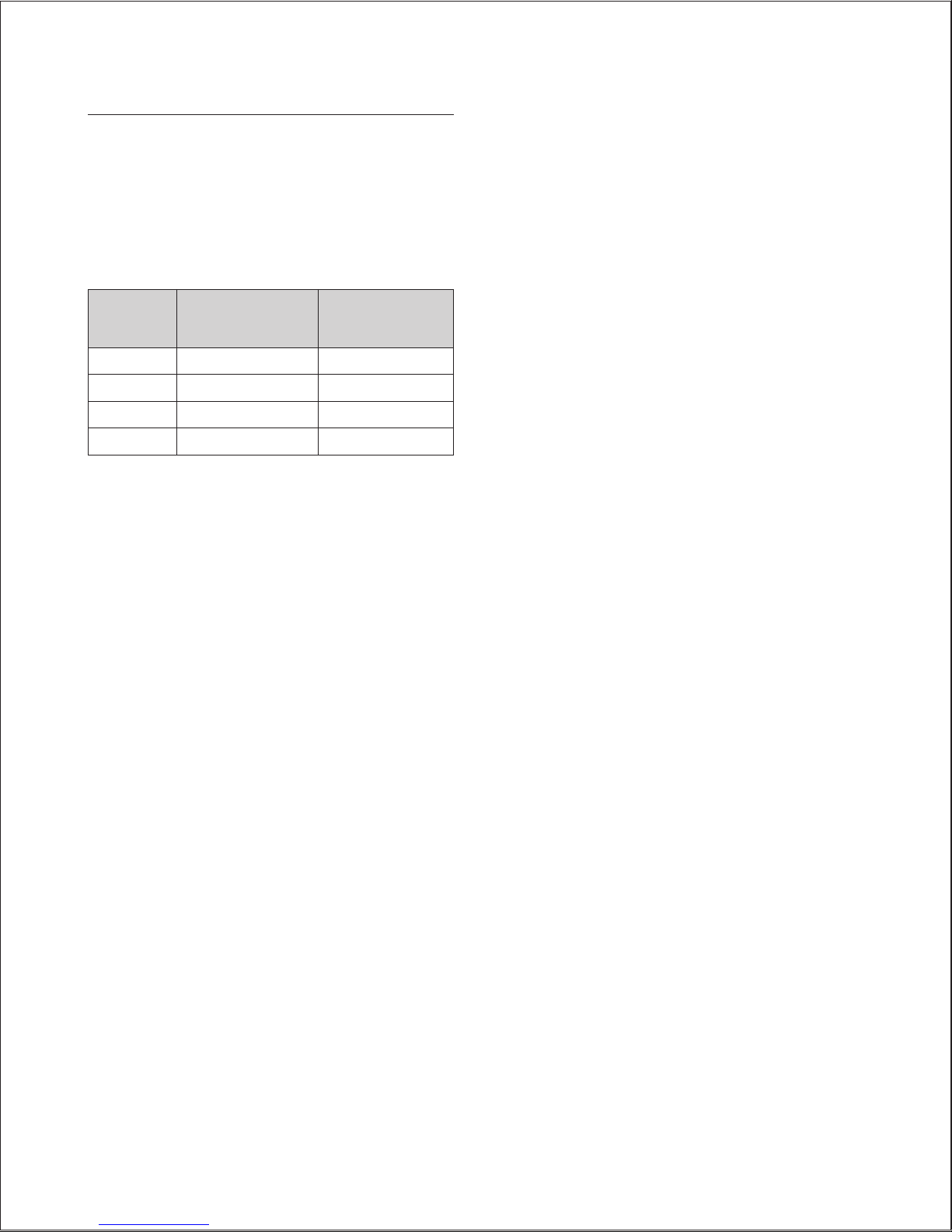

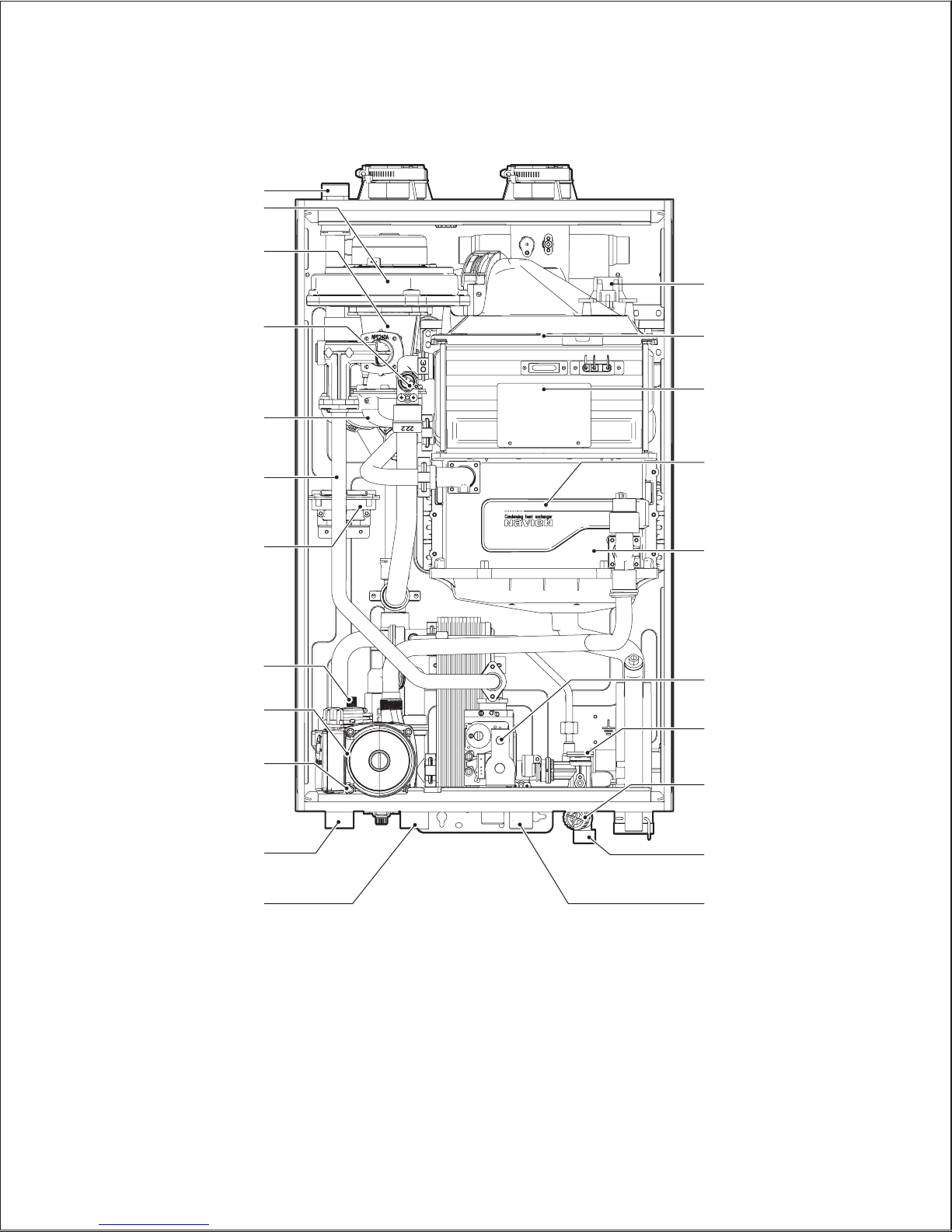

2.2 Components

The following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the

Appendixes.

Intake Air

Exhaust

Flue Duct

Igniter & Flame Rod

Condensate Trap

Auto Feeder

(Make-up water)

Power Switch

Air Filter

Mixing

Chamber

Front Panel

PCB

Version 1.4

16 NCB-E Service Manual

Pressure Relief Valve Adapter

Fan & Motor

Dual Venturi

High Limit Switch

Air Pipe

Gas Pipe

APS

Air Vent

Circulation Pump

3-Way Valve

Space Heating Supply

Space Heating Return

Ignition Transformer

Premix Burner

Primary Heat Exchanger

Secondary Heat

Exchanger

Pressure Sensor

(LWCO)

Gas Valve

Flow Sensor

DHW Inlet Filter

(with built-in flow

restrictor)

DHW Inlet

DHW Outlet

Technical Data 17

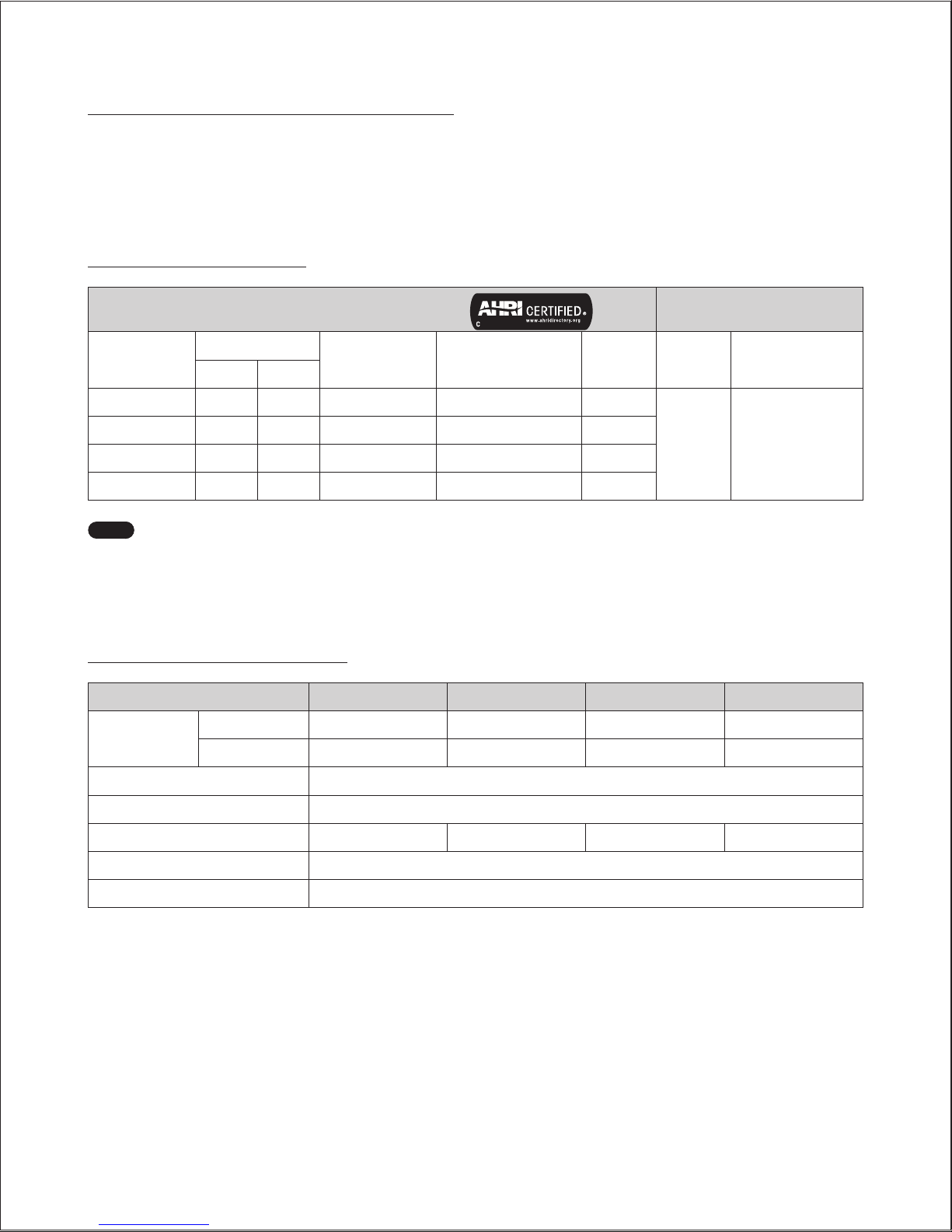

3.1 General Specifications

The following table lists the specifications for the boiler. Additional specifications about water, gas, electric, and air supplies (venting) appear in

the Installation section.

Space Heating Specifications

Navien Combination Boiler

Space Heating Ratings

Other Specifications

Model Number

1

Heating Input, MBH

Heating Capacity

2

,

MBH

Net AHRI Rating Water3,

MBH

AFUE

2

, %

Water

Pressure

Water Connection

size (Supply, Return)

Min Max

NCB-150E 12 60 56 49 95

12-30 psi 1 in NPT

NCB-180E 14 80 75 65 95

NCB-210E 18 100 94 82 95

NCB-240E 18 120 112 97 95

Note

1. Ratings are the same for natural gas models converted to propane use.

2. Based on U.S. Department of Energy (DOE) test procedures.

3. The net AHRI water ratings shown are based on a piping and pickup allowance of 1.15. Consult Navien before selecting a

boiler for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping

system, etc.

Domestic Hot Water Specifications

Item NCB-150E NCB-180E NCB-210E NCB-240E

Input Ratings

Min 12,000 BTU/H 14,000 BTU/H 18,000 BTU/H 18,000 BTU/H

Max 120,000 BTU/H 150,000 BTU/H 180,000 BTU/H 199,900 BTU/H

Water Pressure 15-150 psi

Minimum Flow Rate 0.5 GPM (1.9 L/m)

Flow Rate 77°F (43°C) Temp. Rise 3.1 GPM 3.4 GPM 4.0 GPM 4.5 GPM

DHW Supply Connection Size

3

/4 in NPT

Cold Water Input Connection Size

3

/4 in NPT

3. Technical Data

Version 1.4

18 NCB-E Service Manual

General Specifications

Item NCB-150E NCB-180E NCB-210E NCB-240E

Dimensions 17 in (W) x 28 in (H) x 12 in (D)

Weight 66 lbs (30 kg) 74 lbs (34 kg) 84 lbs (38 kg) 84 lbs (38 kg)

Installation Type Indoor Wall-Hung

Venting Type Forced Draft Direct Vent

Ignition Electronic Ignition

Natural Gas Supply Pressure (from source) 3.5 in-10.5 in WC

Propane Gas Supply Pressure (from source) 8.0 in-13.5 in WC

Natural Gas Manifold Pressure (min/max)

-0.09 in WC /

-0.34 in WC

-0.07 in WC /

-0.66 in WC

-0.05 in WC /

-0.36 in WC

-0.06 in WC /

-1.20 in WC

Propane Gas Manifold Pressure (min/max)

-0.04 in WC /

-0.30 in WC

-0.07 in WC /

-0.66 in WC

-0.10 in WC /

-0.66 in WC

-0.03 in WC /

-0.98 in WC

Gas Connection Size

3

/4 in NPT

Power Supply

Main Supply 120V AC, 60Hz

Maximum Power

Consumption

200W (max 2A)

Materials

Casing Cold-rolled carbon steel

Heat Exchangers

Primary Heat Exchanger: Stainless Steel

Secondary Heat Exchanger: Stainless Steel

Domestic Water Heat Exchanger: Stainless Steel

Venting

Exhaust

2 in or 3 in PVC, CPVC, Polypropylene

2 in or 3 in Special Gas Vent Type BH (Class III, A/B/C)

Intake

2 in or 3 in PVC, CPVC, Polypropylene

2 in or 3 in Special Gas Vent Type BH (Class III, A/B/C)

Vent Clearances 0 in to combustibles

Safety Devices

Flame Rod, APS, Gas Valve Operation Detector, Ignition Operation Detector, Water

Temperature High Limit Switch,

Exhaust Temperature High Limit Sensor

NOTE

This unit may be installed at elevations up to 10,100 ft (3,078 m) for use with Natural Gas, and up to 4,500 ft (1,370 m) for use with Propane.

Technical Data 19

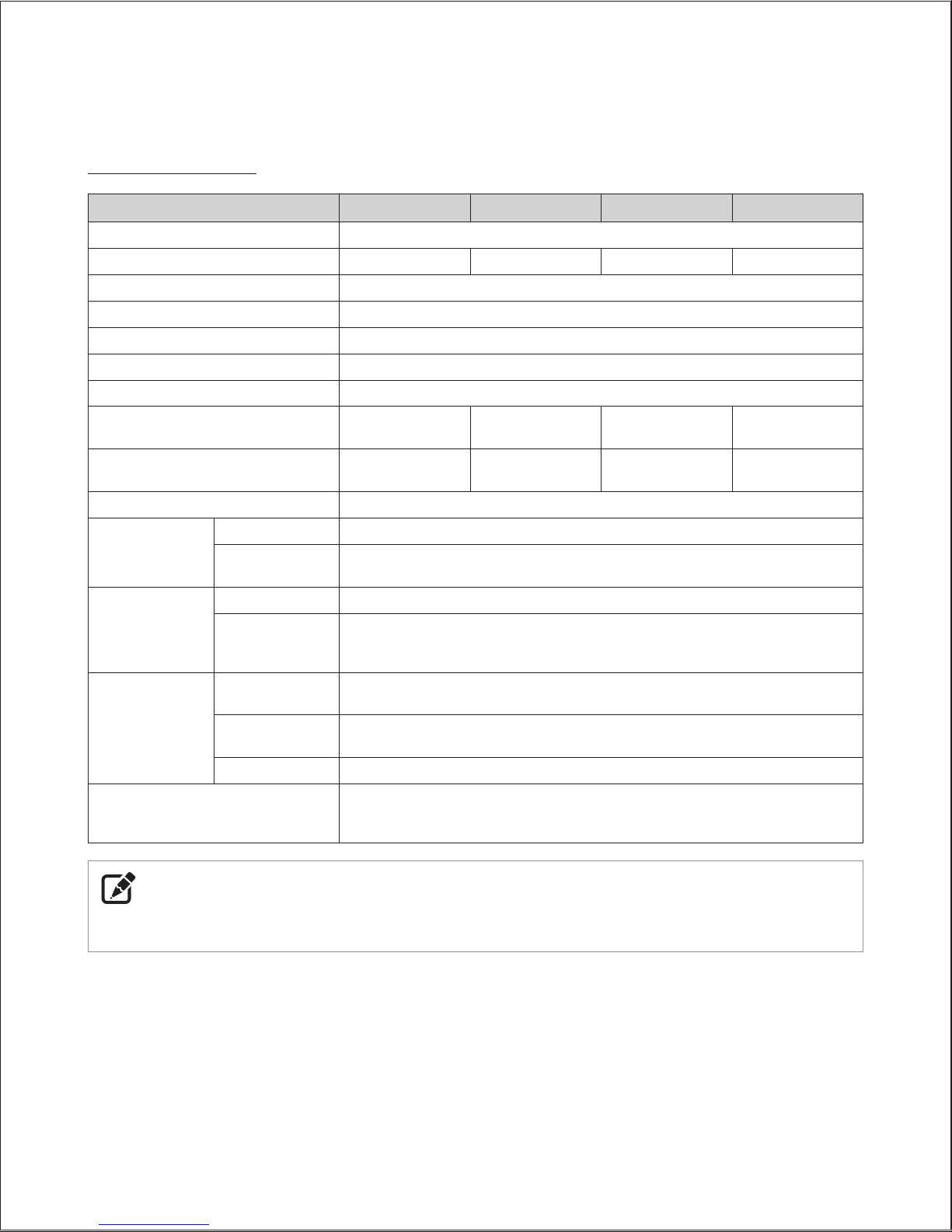

3.2 Dimensions

The following diagrams show the dimensions of the boiler and the table lists the supply connections.

27.4" (695mm)

28.8” (731mm)

Supply Connections

Description Diameter

A Pressure Relief Valve Adapter

3

/4 in

B Air Intake 2 in

C Exhaust Gas Vent 2 in

D Space Heating Supply 1 in

E Space Heating Return 1 in

F Hot Water Outlet (DHW)

3

/4 in

G Gas Supply Inlet

3

/4 in

H Cold Water Inlet (DHW)

3

/4 in

I Condensate Outlet

1

/2 in

J

Auto Feeder Inlet (Make-up

Water)

1

/2 in

Overhead View

3” (77 mm)

6.7” (170 mm)

4.5” (115 mm)

0.4“ (10 mm)

1.5”

(38 mm)

14.3” (364 mm)

2.6” (67 mm)

A

B C

Supply Connections

12“ (306 mm)

3.5”

(88 mm)

4.8”

(123 mm)3”(76 mm)

1.8”

(46 mm)

2”

(50 mm)

17.3” (440 mm)

2.4” (61 mm)

3.0” (77 mm)

D F J

E

H

IG

Version 1.4

20 NCB-E Service Manual

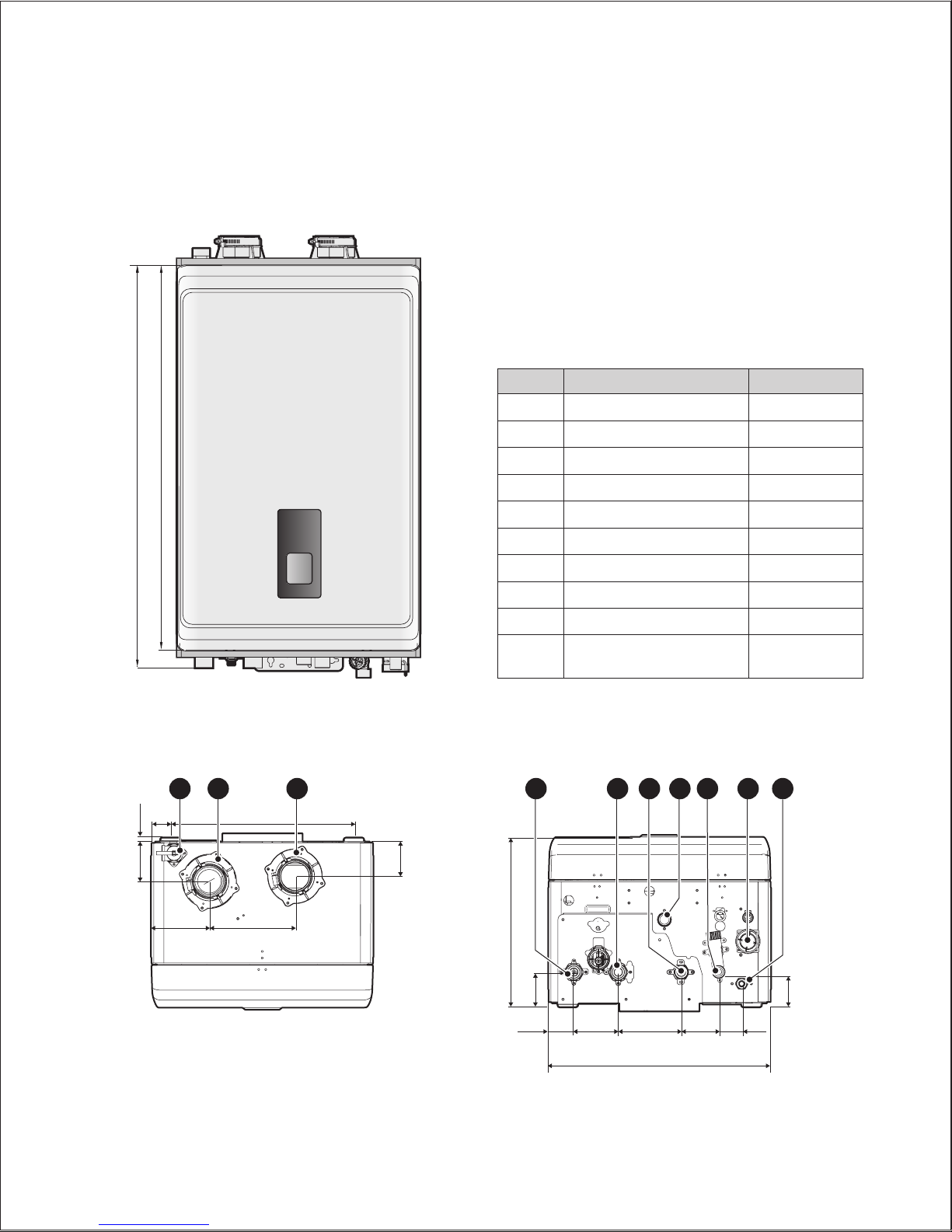

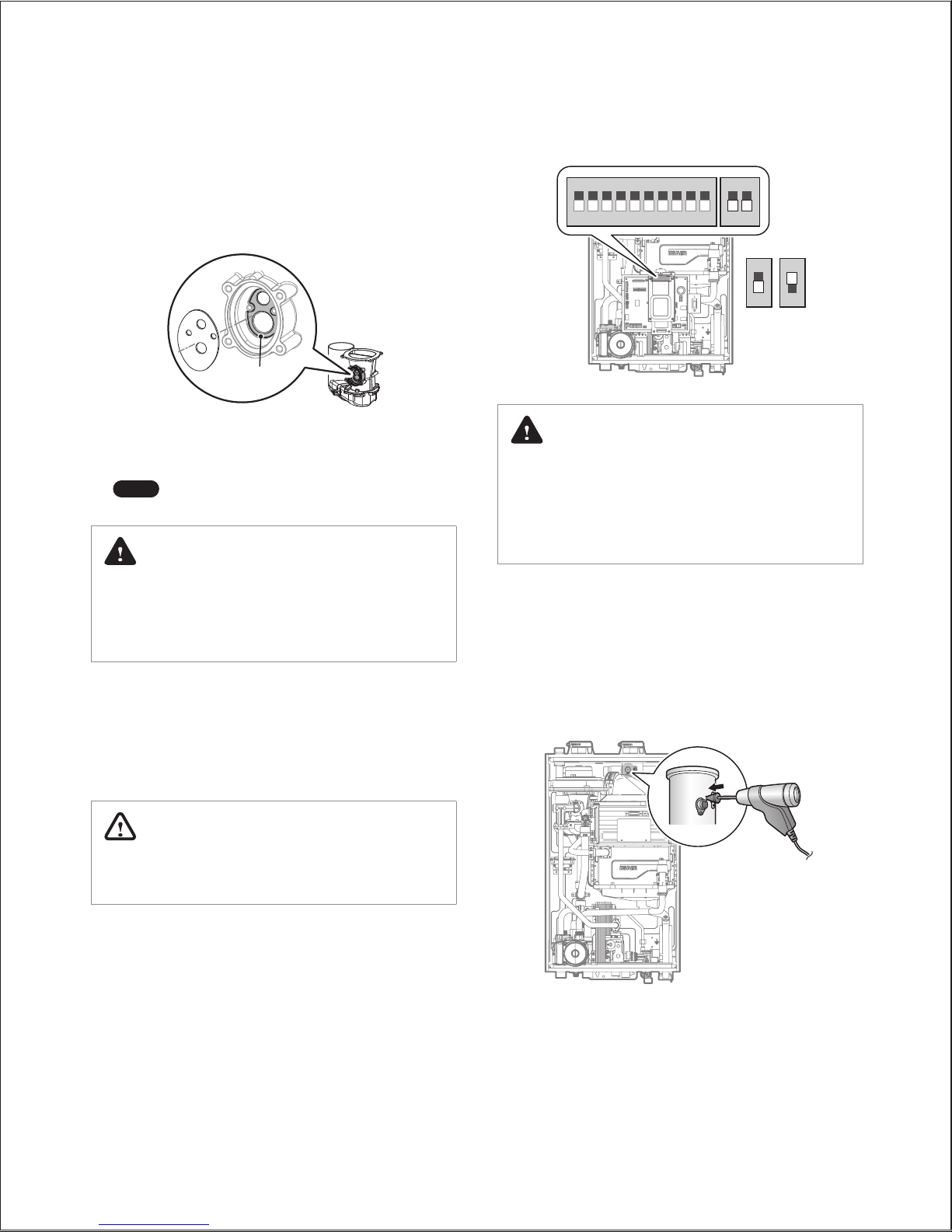

4.1 Setting the DIP Switches

CAUTION

Do not remove the front cover unless the power to the

boiler is turned off or disconnected. Failure to do so may

result in electric shock.

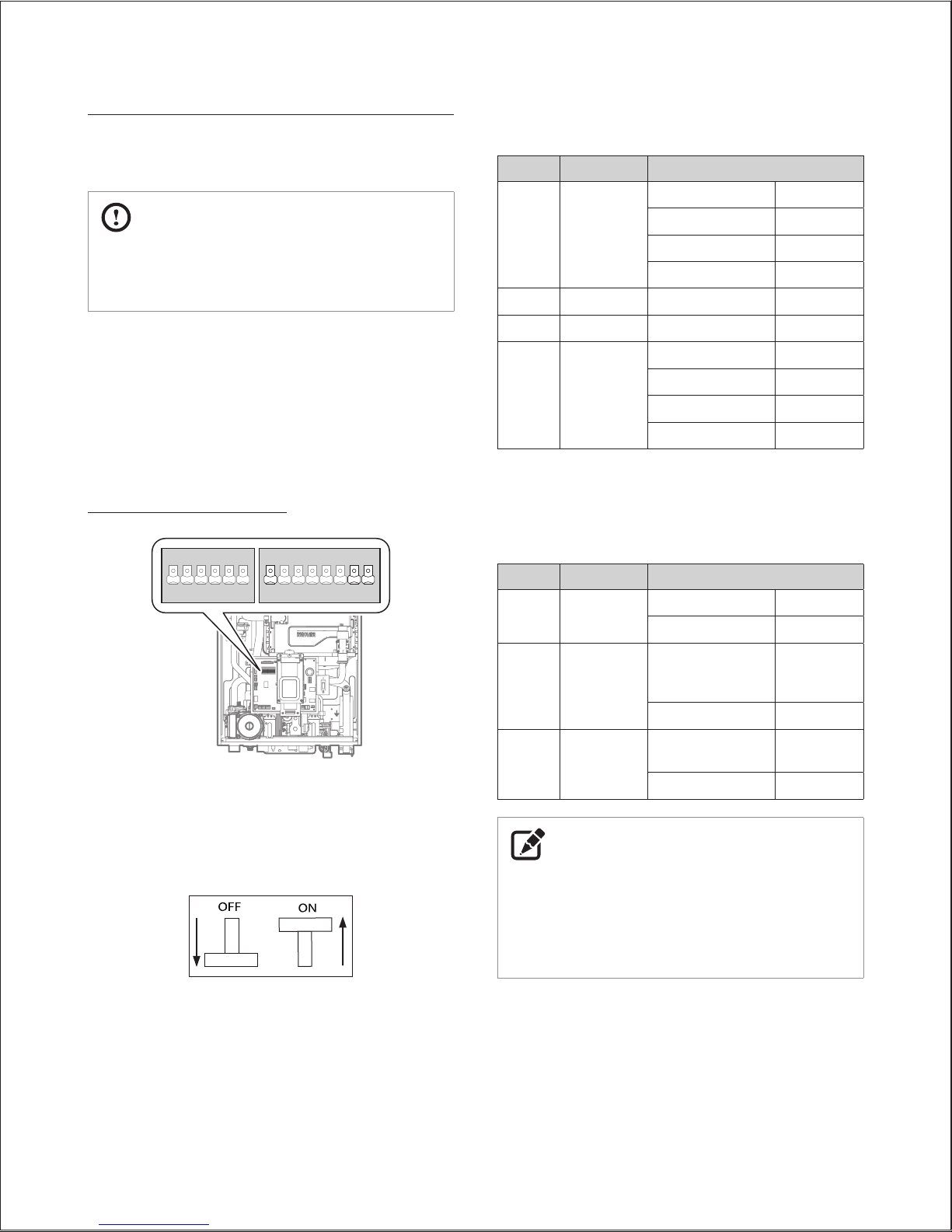

The boiler has two DIP switch locations: on the main circuit board

(PCB) and on the front panel. Each location has two sets of DIP

switches that control the functionality of the boiler. Set the DIP

switches appropriately, based on the installation environment and

the gas type.

4.1.1 Setting the DIP Switches

Circuit Board DIP Switches

1 2 3 4 5 6ON1 2 3 4 5 6 7 8

ON

●

Set of DIP Switches 1 (Set of 6)

The DIP switches 1 on the circuit board configure the boiler’s

model and gas type settings. These configurations are set at the

factory and should not be changed. The following tables describe

the functions of the DIP switches and their settings.

Ex) DIP Switch On/Off

Switch Function Setting

1 & 2

Operation

Status

Normal 1-OFF, 2-OFF

Forced Max (2 stage) 1-ON, 2-OFF

Forced Min (1 stage) 1-OFF, 2-ON

1 Stage Max 1-ON, 2-ON

3 Reserved - -

4 Reserved - -

5 & 6

Capacity

select

NCB-150E 5-ON, 6-ON

NCB-180E 5-OFF, 6-OFF

NCB-210E 5-ON, 6-OFF

NCB-240E 5-OFF, 6-ON

●

Set of DIP Switches 2 (Set of 8)

The DIP SW 2 on the circuit board configures additional features at

the time of installation, such as temperature control modes.

Switch Function Setting

1

Temperature

Control

Return Water 1-ON

Supply Water 1-OFF

7

Thermostat

or Zone

Controller

Unused (Permanent

space heating

demand)

7-ON

Used 7-OFF

8

Exhaust

Thermostat

Temperature Limit

Unused (CPVC)

8-ON

Setting (PVC) 8-OFF

NOTE

●

When PCB DIP switch #8 on DIP switches 2(set of 8), the

boiler does not operate without an exhaust thermostat

installed.

●

When you set PCB switch #8 on DIP switches 2(set of 8) to on,

ensure that CPVC piping is used for exhaust venting.

4. System Details

System Details 21

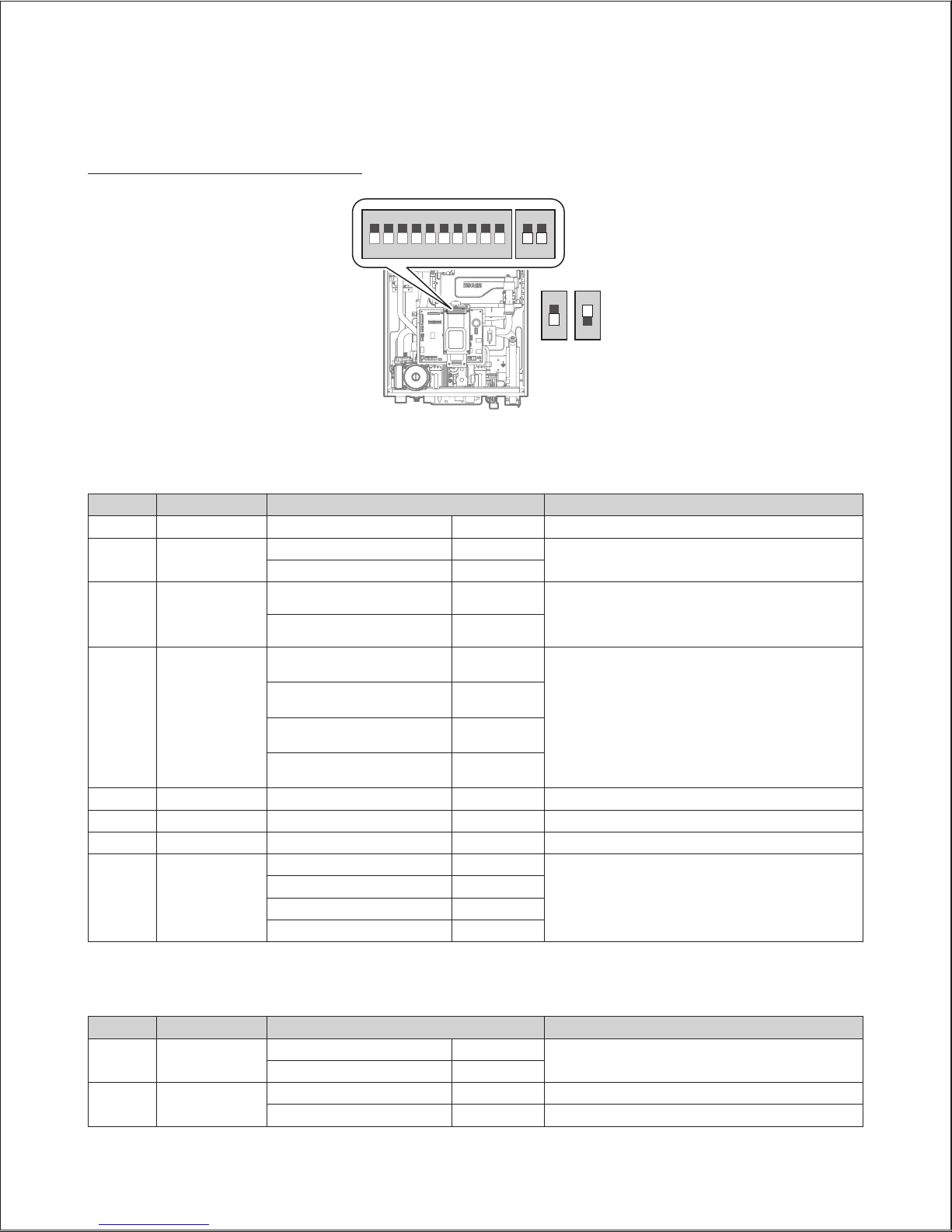

Setting the Front Panel DIP Switches

1 2 3 4 5 6 7 8 9 10

1 2

ON ON

2

ON

NG LP

2

ON

●

Set of DIP Switches 1 (Set of 10)

The DIP SW 1 on the front panel configures the temperature unit, well pump, and high altitude settings.

SW1 NO. Application Setting Remarks

1 Reserve

2 Temperature Unit

°C (Celsius) 2-ON

°F (Fahrenheit) 2-OFF

3 Well Pump

Well Pump ON 3-ON Well Pump Mode

These settings are to be used with well system when an

external pump is wired to the boiler.Well Pump OFF 3-OFF

4 & 5 High Altitude

0-1,999 ft (0-609 m) 4-OFF, 5-OFF

High Altitude

Above 2,000 ft (610 m), the boiler will de-rate by 4% for

each 1,000 ft (305 m) of altitude gain.

This boiler may be installed at elevations up to 10,100

ft (3,078 m) for use with Natural Gas and 4,500 ft (1,370

m) for use with Propane. To use the boiler at a specific

altitude, the DIP switches should be set as described

above.

2,000-5,399 ft (610-1,645 m) 4-ON, 5-OFF

5,400-7,699 ft (1,646-2,346 m) 4-OFF, 5-ON

7,700-10,100 ft (2,347-3,078 m) 4-ON, 5-ON

6 Reserve

7 Reserve

8 Reserve

9 & 10 Lime Alarm

Off 9-OFF, 10-OFF

Cascade system only

(Front Panel: after V1.2)

6 Months Alert 9-ON, 10-OFF

12 Months Alert 9-OFF, 10-ON

12 Months Alert 9-ON, 10-ON

●

Set of DIP Switches 2 (Set of 2)

The DIP SW 2 on the front panel configures the gas type setting.

SW1 NO. Application Setting Remarks

1 Cascade vent

Common Vent 1-OFF

Cascade system only

(Front Panel: after V1.2)

Individual Vent 1-ON

2 Gas type

Natural Gas 2-OFF

Propane Gas 2-ON

Version 1.4

22 NCB-E Service Manual

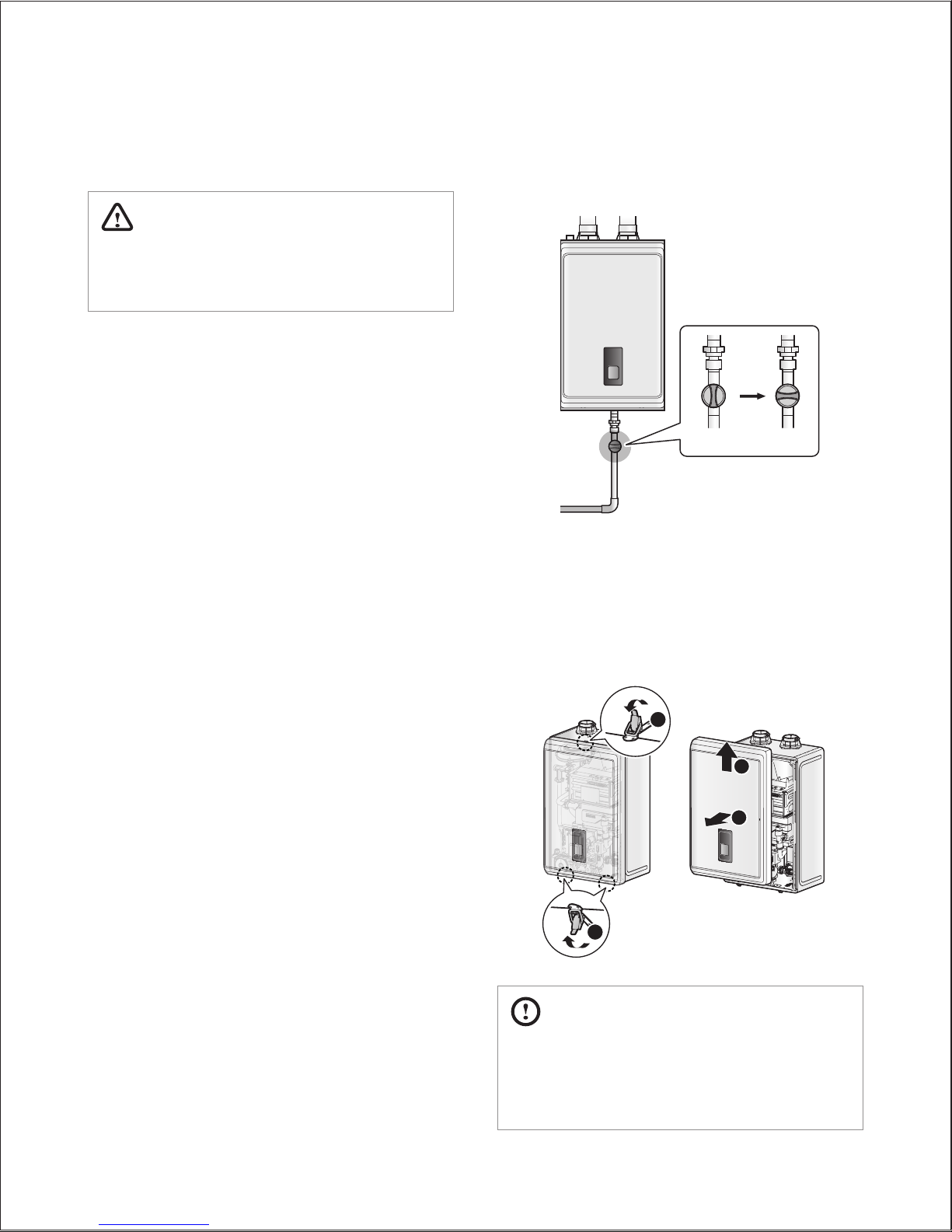

To measure the inlet gas pressure:

1. Shut off the manual gas valve on the gas supply line.

Gas Valve

Opened Closed

2. Open a hot water faucet. The boiler should turn on and the gas

in the gas supply line will be purged.

3. Leave the faucet on until the boiler shuts down due to a lack of

gas supply, and then turn off the hot water faucet.

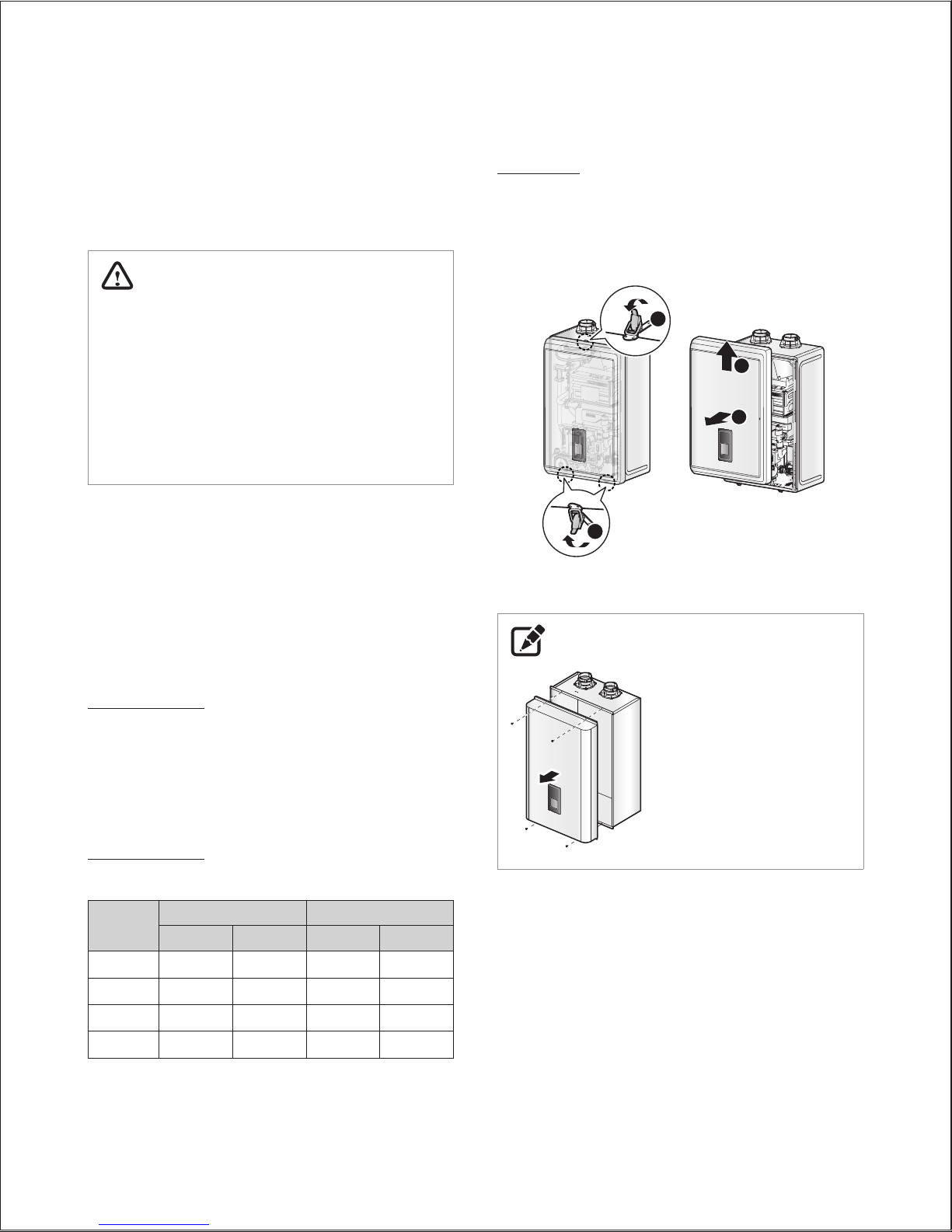

4. Unclasp the 3 buckles that fix the cover to the boiler, and then

remove the cover by lifting it and pulling it outward.

1

1

2

3

CAUTION

Ensure that no cables are in the way before folding down the

PCB assembly. If the assembly is stuck, do not force it. Doing

so may damage the cables and result in serious malfunctions.

Check again to ensure that no cables or any other parts are in

the way before you proceed.

4.2 Measuring the Inlet Gas Pressure

WARNING

The boiler cannot function properly without sufficient inlet

gas pressure. Measuring the inlet gas pressure should be

performed by a licensed professional only.

●

The inlet gas pressure must be maintained between 3.5” and

10.5” WC for natural gas and between 8.0” and 13.5” WC for

liquefied propane.

●

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psi (3.5 kPa).

●

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

System Details 23

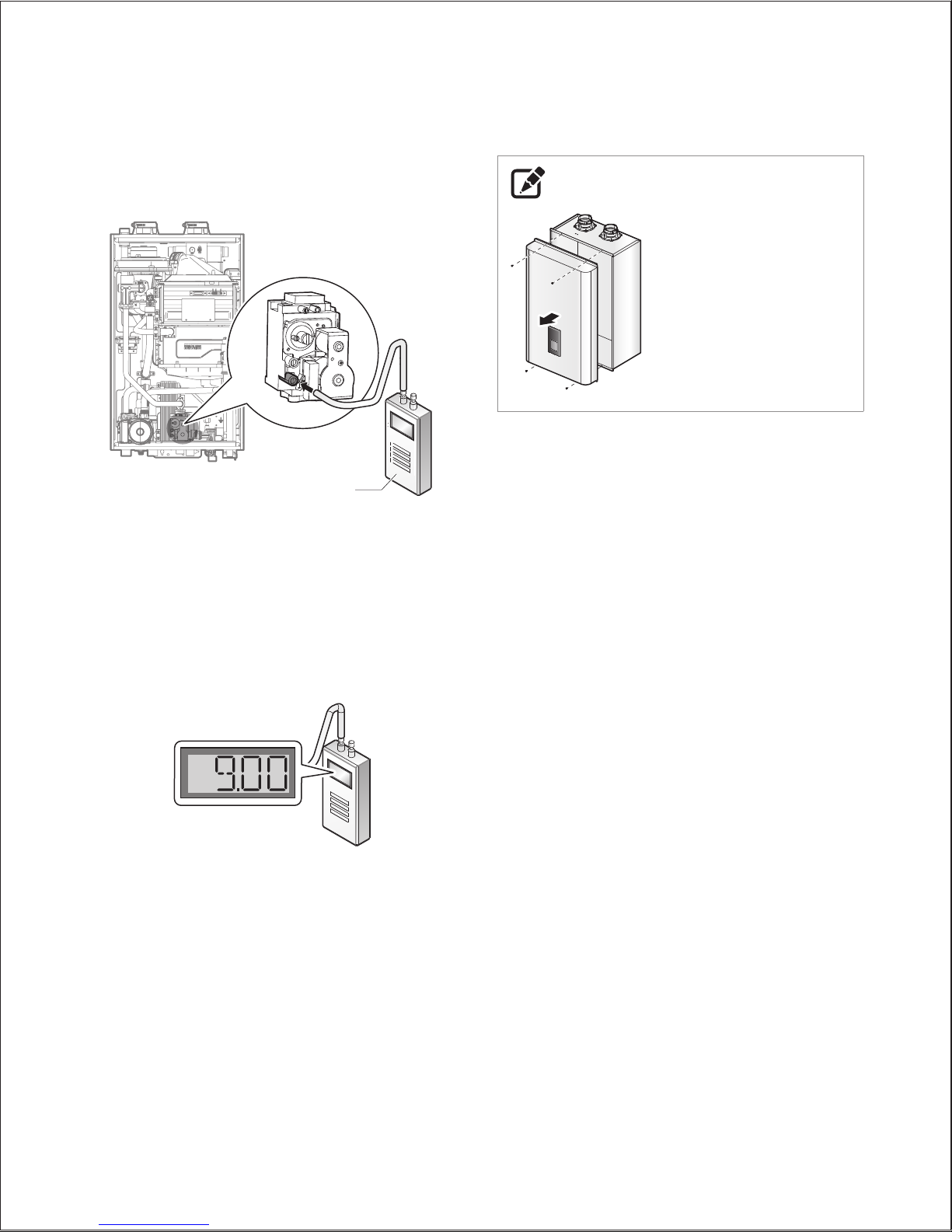

NOTE

For NCB series, remove

the boiler front cover by

loosening the 4 Phillips head

screws securing it to the

case.

5. Loosen the screws indicated in the figure below and connect a

manometer to the pressure port. Reset the manometer to zero

before use.

Digital pressure

manometer

6. Re-open the manual gas valve and check for leaks.

7. Open multiple fixtures that have high flow rates, such as

bathtub and shower faucets, to ramp the boiler up to its

maximum firing rate.

8. When the boiler reaches its maximum firing rate, check the

inlet gas pressure reading on the manometer. The gas pressure

must fall within the ranges specified on page 18.

Version 1.4

24 NCB-E Service Manual

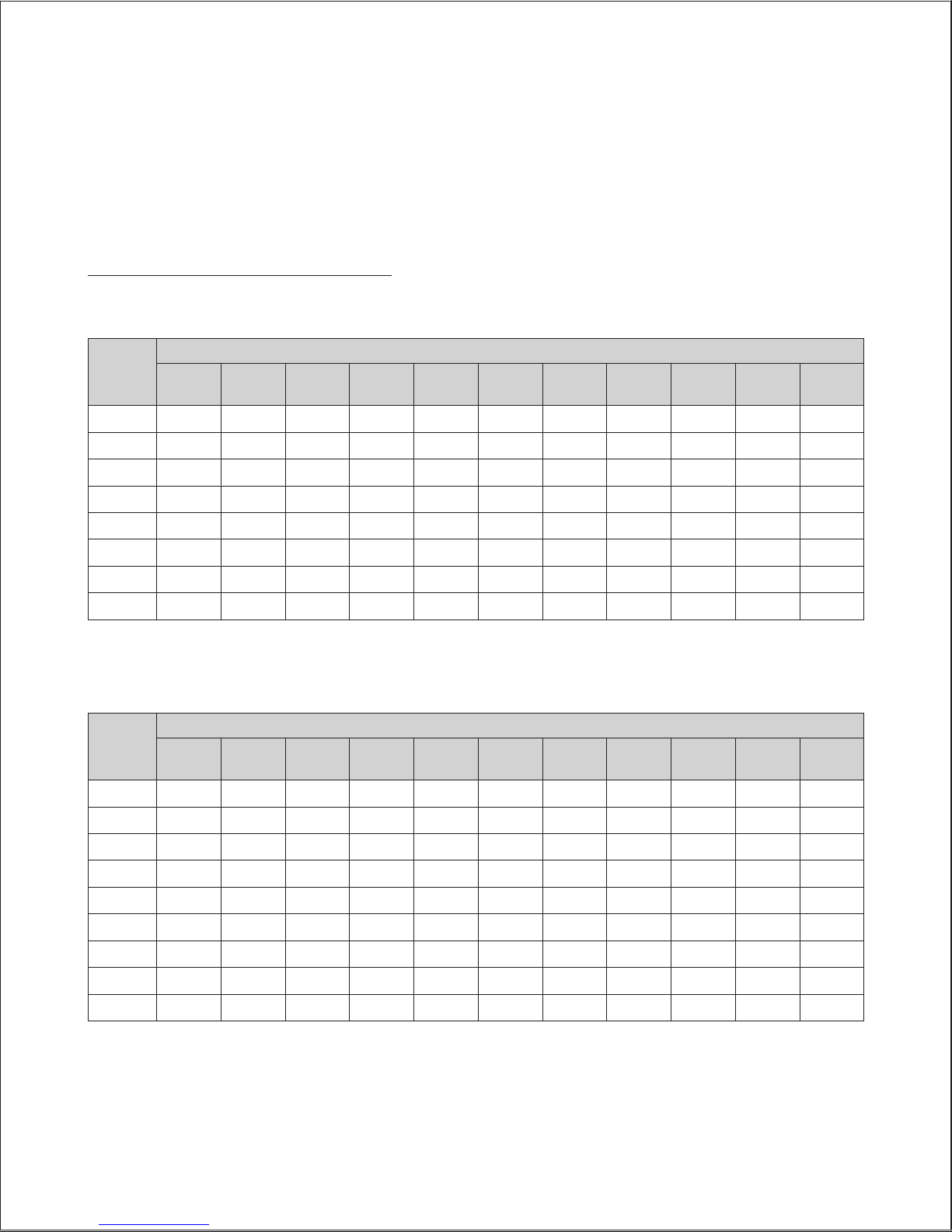

4.2.1 Gas Pipe Sizing Tables (Referenced from 2012 National Fuel Gas Code)

These tables are for reference only. Please consult the gas pipe manufacturer for actual pipe capacities.

Maximum Natural Gas Delivery Capacity

in Cubic Feet (ft3) per Hour (0.60 Specific Gravity; 0.5” WC Pressure Drop). Contact your gas supplier for BTU/ft3 ratings. Use 1,000 BTU/ft3 for

simplified calculations. This table is recommended for supply pressures less than 6” WC.

Pipe Size

Length (including fittings)

10'

(3m)

20'

(6m)

30'

(9m)

40'

(12m)

50'

(15m)

60'

(18m)

70'

(21m)

80'

(24m)

90'

(27m)

100'

(30m)

125'

(38m)

3/4" 360 247 199 170 151 137 126 117 110 104 92

1" 678 466 374 320 284 257 237 220 207 195 173

1 1/4" 1,390 957 768 657 583 528 486 452 424 400 355

1 1/2" 2,090 1,430 1,150 985 873 791 728 677 635 600 532

2" 4,020 2,760 2,220 1,900 1,680 1,520 1,400 1,300 1,220 1,160 1,020

2 1/2" 6,400 4,400 3,530 3,020 2,680 2,430 2,230 2,080 1,950 1,840 1,630

3" 11,300 7,780 6,250 5,350 4,740 4,290 3,950 3,670 3,450 3,260 2,890

4" 23,100 15,900 12,700 10,900 9,660 8,760 8,050 7,490 7,030 6,640 5,890

in Cubic Feet (ft

3

) per Hour (0.60 Specific Gravity; 3.0” WC Pressure Drop). Contact your gas supplier for BTU/ft3 ratings. Use 1,000 BTU/ft3 for

simplified calculations. This table is recommended for supply pressures of 6” WC or greater.

Pipe Size

Length (including fittings)

10'

(3m)

20'

(6m)

30'

(9m)

40'

(12m)

50'

(15m)

60'

(18m)

70'

(21m)

80'

(24m)

90'

(27m)

100'

(30m)

125'

(38m)

1/2" 454 312 250 214 190 172 158 147 138 131 116

3/4" 949 652 524 448 397 360 331 308 289 273 242

1" 1,787 1,228 986 844 748 678 624 580 544 514 456

1 1/4" 3,669 2,522 2,025 1,733 1,536 1,392 1,280 1,191 1,118 1,056 936

1 1/2" 5,497 3,778 3,034 2,597 2,302 2,085 1,919 1,785 1,675 1,582 1,402

2" 10,588 7,277 5,844 5,001 4,433 4,016 3,695 3,437 3,225 3,046 2,700

2 1/2" 16,875 11,598 9,314 7,971 7,065 6,401 5,889 5,479 5,140 4,856 4,303

3" 29,832 20,503 16,465 14,092 12,489 11,316 10,411 9,685 9,087 8,584 7,608

4" 43,678 30,020 24,107 20,632 18,286 16,569 15,243 14,181 13,305 12,568 11,139

System Details 25

Maximum Liquefied Propane Delivery Capacity

in Thousands of BTU/H (0.5” WC Pressure Drop)

Pipe Size

Length (including fittings)

10'

(3m)

20'

(6m)

30'

(9m)

40'

(12m)

50'

(15m)

60'

(18m)

80'

(24m)

100'

(30m)

125'

(38m)

150'

(45m)

175'

(53m)

200'

(60m)

250'

(76m)

1/2" 291 200 160 137 122 110 101 94 89 84 74 67 62

3/4" 608 418 336 287 255 231 212 197 185 175 155 140 129

1" 1,150 787 632 541 480 434 400 372 349 330 292 265 243

1 1/4" 2,350 1,620 1,300 1,110 985 892 821 763 716 677 600 543 500

1 1/2" 3,520 2,420 1,940 1,660 1,480 1,340 1,230 1,140 1,070 1,010 899 814 749

2" 6,790 4,660 3,750 3,210 2,840 2,570 2,370 2,200 2,070 1,950 1,730 1,570 1,440

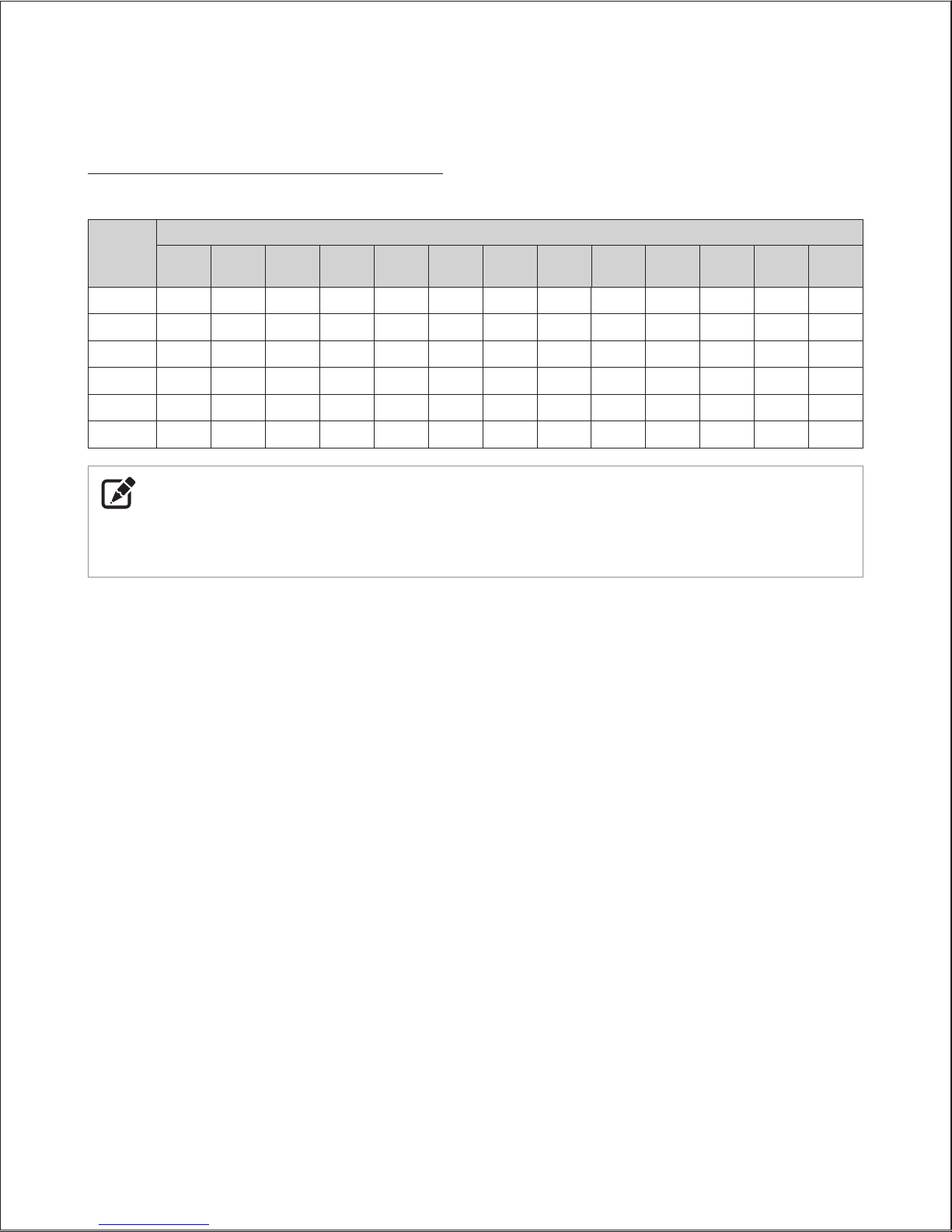

NOTE

●

For installations using CSST (flexible) gas piping, please refer to the sizing charts provided by the manufacturer.

●

The use of single-stage regulators are recommended. Dual-stage regulators could cause operational issues with the boiler.

Version 1.4

26 NCB-E Service Manual

Procedure:

1. Turn off both gas and water supply to the boiler.

2. Unclasp the 3 buckles that fix the cover to the boiler, and then

remove the cover by lifting it and pulling it outward. See Figure

1 for illustration of the front cover on the unit.

1

1

2

3

Figure 1. NCB-E Series Front cover

NOTE

For NCB series, remove

the boiler front cover by

loosening the 4 Phillips head

screws securing it to the

case.

3. Once the front cover is removed, place it in a safe location to

prevent accidental damage.

4. Label all the wires on the PCB.

5. Disconnect all the wires.

4.3 Gas Conversion

This boiler is configured for Natural Gas from the factory. If

conversion to Propane Gas is required, the conversion kit supplied

with the boiler must be used.

WARNING

This conversion kit shall be installed by a qualified service

agency* in accordance with Navien’s instructions and all

applicable codes and requirements of the authority having

jurisdiction. The information in these instructions must be

followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or death. The qualified

service agency is responsible for the proper installation of

this kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified in

the manufacturer’s instructions supplied with the kit.

* A qualified service agency is any individual, firm, corporation or company

which either in person or through a representative is engaged in and

is responsible for the connection, utilization, repair or servicing of gas

utilization equipment or accessories; who is experienced in such work,

familiar with all precautions required, and has complied with all of the

requirements of the authority having jurisdiction.

In Canada: The conversion shall be carried out in accordance with

the requirements of the provincial authorities having jurisdiction

and in accordance with the requirements of the CAN‐B149.1 and

CAN1‐B149.2 Installation Code.

Tools Required:

●

Phillips Screwdriver

●

Flathead Screwdriver

●

5

/32 in or 4mm Allen Wrench

●

Combustion Analyzer or Dual Port Manometer

●

Gas Leak Detector

Included Items:

●

Gas Orifice (refer to below table)

Model

NG LP

1STAGE 2STAGE 1STAGE 2STAGE

NCB-150E Ø5.10 Ø5.80 Ø4.10 Ø4.50

NCB-180E Ø4.80 Ø5.95 Ø3.80 Ø4.70

NCB-210E Ø6.10 Ø6.30 Ø4.50 Ø4.80

NCB-240E Ø6.10 Ø6.30 Ø4.50 Ø4.80

Table 1. Orifice Size

●

Gas Pressure and Conversion Kit Number Labels

System Details 27

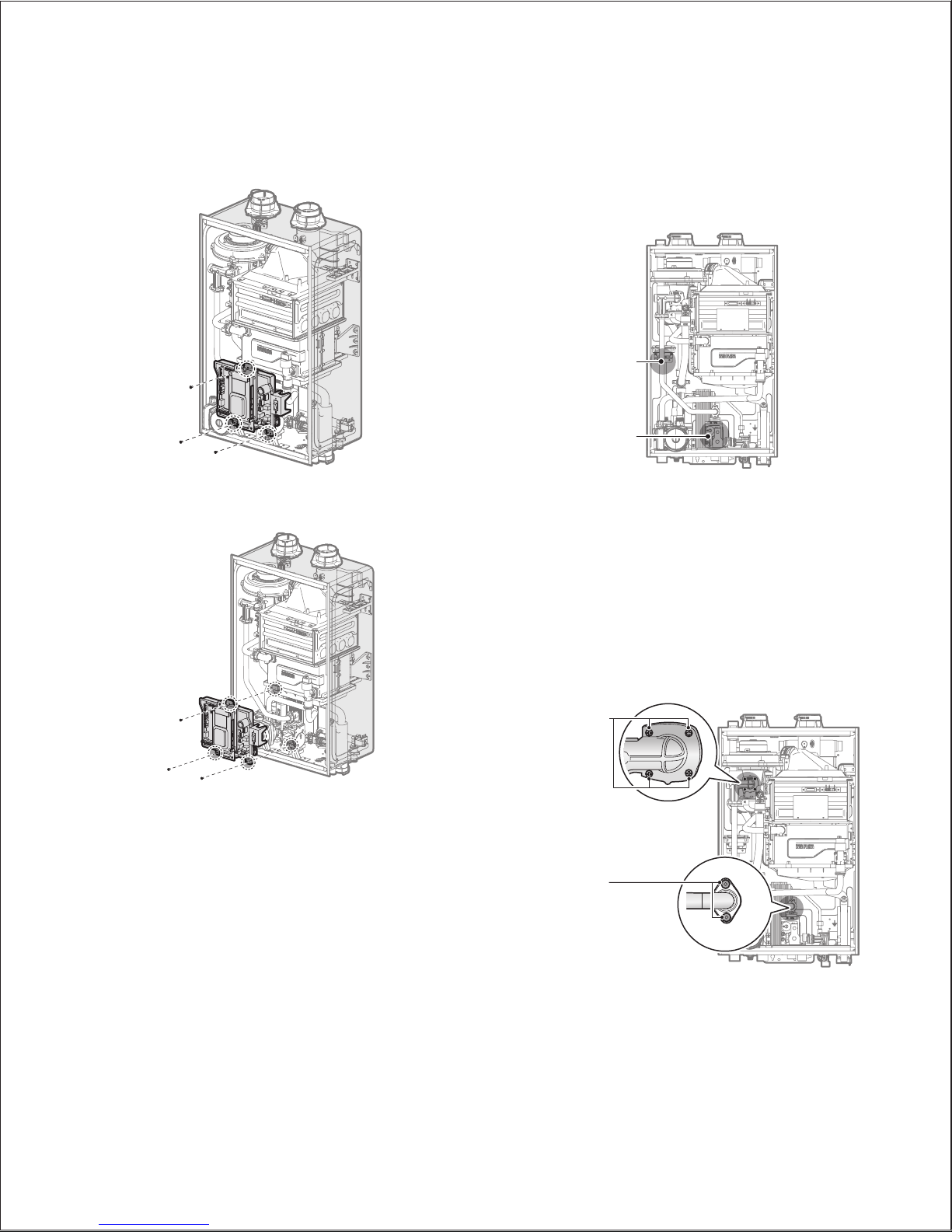

8. With the internal components exposed, locate the gas inlet

pipe and the gas valve in the middle of the unit, as shown in

Figure 2.

Gas Valve

Gas Inlet

Pipe

Figure 2. NCB-E Series Internal Components

9. Use a Phillips screwdriver to remove the two screws at location

A - the connection below the gas valve where it connects

to the pipe. See Figure 3 for reference. Once the screws are

removed, carefully separate the pipe from the gas valve.

10. Once the gas inlet pipe is detached from the gas valve, find

location B - the connection above the gas valve where it is

attached to the fan motor assembly. Carefully remove the four

screws by hand using a Phillips screwdriver and pull the gas

valve away from the fan assembly to access the gas orifice.

Location B: Remove

4 screws here

Location A: Remove

2 screws here

Figure 3. Detaching Gas Valve from

Gas Inlet Pipe and Fan Motor Assembly

6. Loosen the three screws indicated in the figure.

7. Remove the PCB assembly.

Version 1.4

28 NCB-E Service Manual

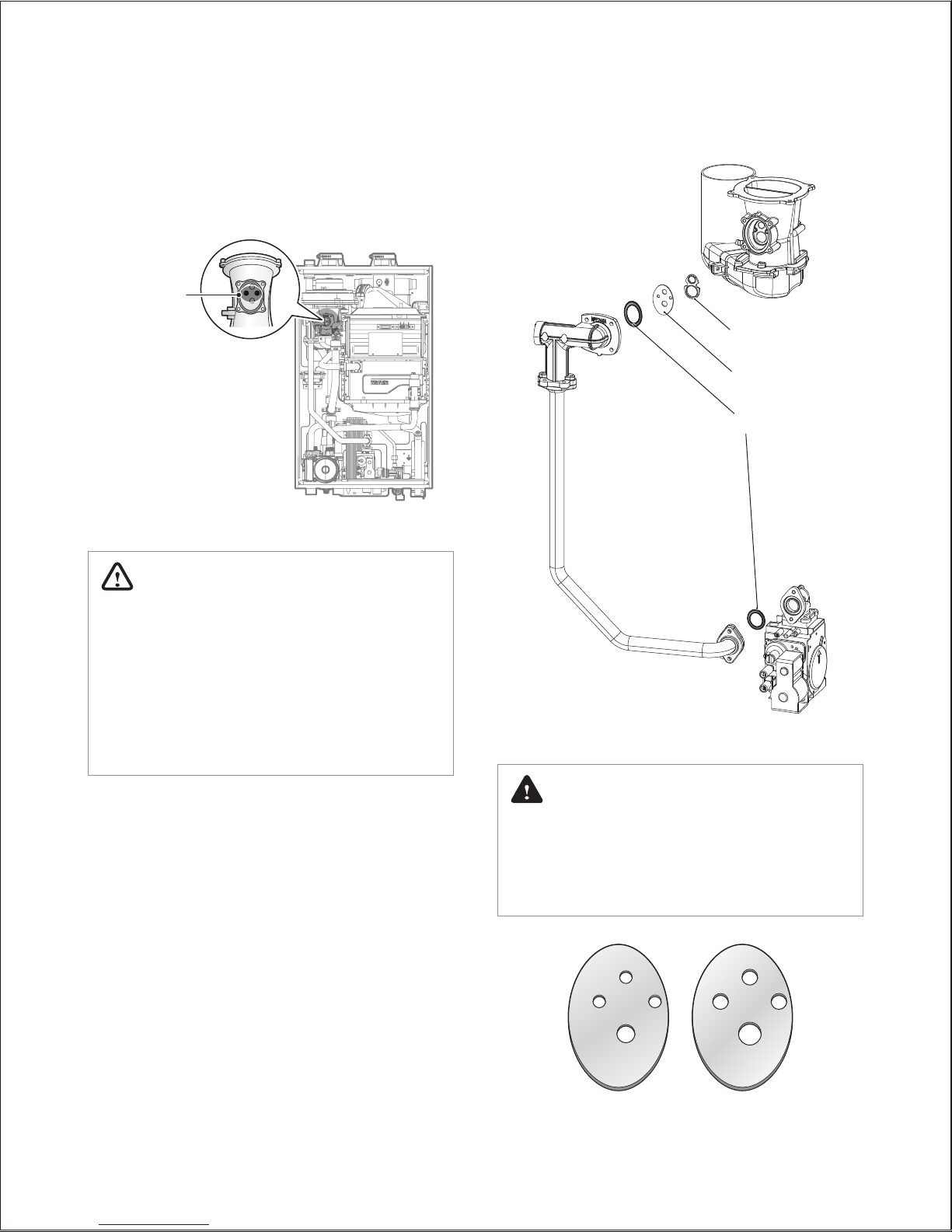

O-ring

Gas Orifice

Packing

Figure 5. Exploded View of Gas Pipe Assembly

DANGER

See Figure 5. Inspect the O-ring between the gas valve and

gas valve inlet adapter whenever they are disassembled.

The O-ring must be in good condition and must be installed.

Failure to comply will cause a gas leak, resulting in severe

personal injury or death.

240LP 240NG

Figure 6. Orifice Identification

11. Once the Gas Orifice is exposed, remove the two screws that

hold the part in place. Remove the Gas Orifice from its housing

and prepare the new Gas Orifice for the LP conversion for

installation.

Remove two

2 screws here

Figure 4. Access to Gas Orifice in Fan Assembly

WARNING

●

DO NOT adjust or attempt to measure gas valve outlet

pressure. The gas valve is factory-set for the correct outlet

pressure. This setting is suitable for natural gas and propane,

requiring no field adjustment.

●

Attempting to alter or measure the gas valve outlet pressure

could result in damage to the valve, causing potential severe

personal injury, death or substantial property damage.

Navien NCB-E boilers are shipped ready to fire natural gas

ONLY.

System Details 29

12. Remove the Gas Orifice, ensure that the packing is properly

seated inside the port, and then install the new Gas Orifice for

use with LP gas. Ensure that the Orifice is properly seated on

the packing inside the port before proceeding to the next step.

Packing

13. Replace the gas inlet pipe to its original position and use all

screws to secure all connections.

Note

Do not overtighten as this may damage or crack

the components.

DANGER

Inspect the O-ring between the gas valve and gas valve inlet

adapter whenever they are disassembled. The O-ring must be

in good condition and must be installed. Failure to comply will

cause a gas leak, resulting in severe personal injury or death.

14. Place the PCB assembly back on to the boiler and tighten the

three screws.

15. Check the labels carefully and then connect all the wires.

16. Set the front panel Dip Switch to change the gas type. For LP,

set Dip Switch 2 #2 to On. For NG, set DIP SW2 #2 to Off.

WARNING

Ensure that you have turned off the power to the boiler before

accessing the DIP switches.

1 2 3 4 5 6 7 8 9 10

1 2

ON ON

2

ON

NG LP

2

ON

DANGER

●

When conversion is required, be sure to set the front panel

DIP switches according to the supply gas type.

●

Failure to properly set the DIP switches could cause carbon

monoxide poisoning, resulting in severe personal injury or

death.

17. Turn on the gas and water supply to the boiler.

18. Measure and adjust the gas/air ratio.

Option 1. Using Combustion Analyzer (recommended)

a. Loosen the screw, rotate the plate and remove the gasket

to access the emissions monitoring port as shown in

Figure 7.

b. Insert the analyzer into the port (Figure 7).

Figure 7. Insert the Analyzer

Loading...

Loading...