Navien NCB-20LHWE, NCB-23LHWE, NCB-28LHWE, NCB-33LHWE Operation Manual

These appliances are for use with natural gas or LPG.

(An LPG conversion kit is included with the boiler.)

Type : B23-B33-B53-C13-C33-C43-C53-C63-C83

Installation &

Operation

Manual

Keep this manual near this boiler for future reference

whenever maintenance or service is required.

WARNING

result, causing property damage or personal injury.

–

other appliance.

–

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliances.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call the National Gas Emergency Helpline on (Freephone) 0800 111999 or your gas

supplier from a neighbour’s phone. Follow the instructions received.

–

Installation and service must be performed by a Gas Safe registered installer, service agency or

the gas supplier.

Condensing System Boiler

Gas Model GC Number

Natural Gas

NCB-20LHWE

NCB-23LHWE

NCB-28LHWE

NCB-33LHWE

41-709-01

41-709-02

41-709-03

41-709-04

LPG

NCB-20LHWE

NCB-23LHWE

NCB-28LHWE

NCB-33LHWE

41-709-05

41-709-06

41-709-07

41-709-08

Contents

1. Safety Information 3

2. About the Boiler

7

2.1 Items Included 7

2.2 Accessories

7

2.3 Technical Data

8

2.4 Components

11

2.5 Dimensions

15

2.6 Operating Modes

16

2.7 Installation Procedure

17

3. Installing the Boiler 18

3.1 Choosing an Installation Location 18

3.2 Mounting the Boiler to the Wall

20

4. Installing the System Piping 21

4.1 Installing a Space Heating System 21

4.2 Installing a System Application

22

4.3 Connecting the Condensate Drain Line

22

4.4 Pressure Relief Valve

24

4.5 Filling the system

24

4.6 Testing the Water System

24

5. Connecting the Gas Supply 25

5.1 Gas Pipe Material 26

5.2 Propane Gas Installations (LPG)

26

5.3 Measuring the Inlet Gas Pressure

26

6. Flue System 28

6.1 Flue Terminal Positions 28

6.2 Selecting a Flue System

29

6.3 Coaxi

al Systems

30

6.4 Dual Duct Systems

31

6.5 Measuring Flue Length

33

6.6 Terminating the Flue

33

7. Setting the DIP Switches 34

7.1 PCB DIP Switches 34

7.2 Front Panel DIP Switches

34

8. Connecting Electrical Supplies 35

8.1 Accessing the Terminal Blocks 35

8.2 Connecting the Power Supply Cables

36

8.3 Setting the DIP Switches and Parameters for the

Terminal blocks 1 and 2

37

8.4 Terminal block 1 Connection

37

8.5 Terminal block 2 Connection

38

9. Wiring Examples for Dierent Applications 39

9.1 Connecting the Navien Smart Room Controller

(Optional)

39

9.2 Y Plan Applications

40

9.3 S Plan Applications 43

10. Installation Check list 44

11. Operating the Boiler

45

11.1 Turning the Boiler On or O 45

11.2 Adjusting the Temperature

45

11.3 Viewing Basic Information

46

11.4 Setting the Operation Mode

47

11.5 Setting the Parameters

48

11.6 Resetting the Boiler

55

12. Maintaining the Boiler 56

12.1 Cleaning the Boiler 56

12.2 Draining the Bo

iler 56

12.3 Cleaning the Return Adapter Filter

57

12.4 Protecting the Boiler from Freezing

57

12.5 Maintenance Schedules

58

13. Appendices 61

13.1 Gas Conversion 61

13.2 Cleaning the Heat Exchanger

67

13.3 Wiring Diagram

70

13.4 Ladder Diagram

71

13.5 Outdoor Temperature Sensor (Optional)

72

2 Contents

The following safety symbols are used in this manual. Read and

follow all safety instructions in this manual precisely to avoid

unsafe operating conditions, re, explosion, property damage or

personal injury.

DANGER

Indicates an imminently hazardous

situation which, if not avoided, could

result in severe injury or death.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in injury or death.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

DANGER

If you smell gas:

Do not try to light any appliances.

Do not touch any electrical switches or

use landline phones.

From a neighbour’s phone, call

your gas provider and follow their

instructions.

If you cannot reach your gas provider,

call the re department.

Do not return to your home until

authorised by your gas supplier or the

re department.

Do not use or store ammable

products, such as petrol, solvents, or

adhesives in the same room or area as

the boiler.

The boiler has a main burner ame that

can turn on at any time and can ignite

ammable vapours. Vapours from

ammable liquids can explode and

catch re, causing severe burns.

Vapours cannot be seen and are

heavier than air. They can travel long

distances along the ground and can be

carried from other rooms to the boiler’s

main burner ame by air current.

Keep all ammable products far

away from the boiler and store them

in approved containers. Keep the

containers closed tightly and out of the

reach of children and pets.

1. Safety Information

3Safety Information

4 Safety Information

WARNING

This appliance can be used by children

aged from 8 years and above and

persons with reduced physical, sensory

or mental capabilities or lack of

experience and knowledge if they have

been given supervision or instruction

concerning use of the appliance in a

safe way and understand the hazards

involved. Children shall not play with

the appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

WARNING

Do not store or use petrol or other

ammable liquids near this boiler.

Doing so may result in re or explosion.

Do not place combustibles, such as

newspapers or laundry, near the

boiler or ue system.

Doing so may result in a re.

Do not place or use hair sprays, spray

paints, or any other compressed

gases near the boiler or ue system,

including the ue termination.

Doing so may result in re or explosion.

Do not operate the boiler with the

front cover opened.

Doing so may result in re or carbon

monoxide (CO) poisoning, which may

result in property damage or personal

injury.

Do not operate this boiler without

proper ue system.

Doing so may result in re or carbon

monoxide (CO) poisoning, which may

result in property damage or personal

injury.

Do not touch the power cord or

internal components of the boiler

with wet hands.

Doing so may result in electric shock.

5Safety Information

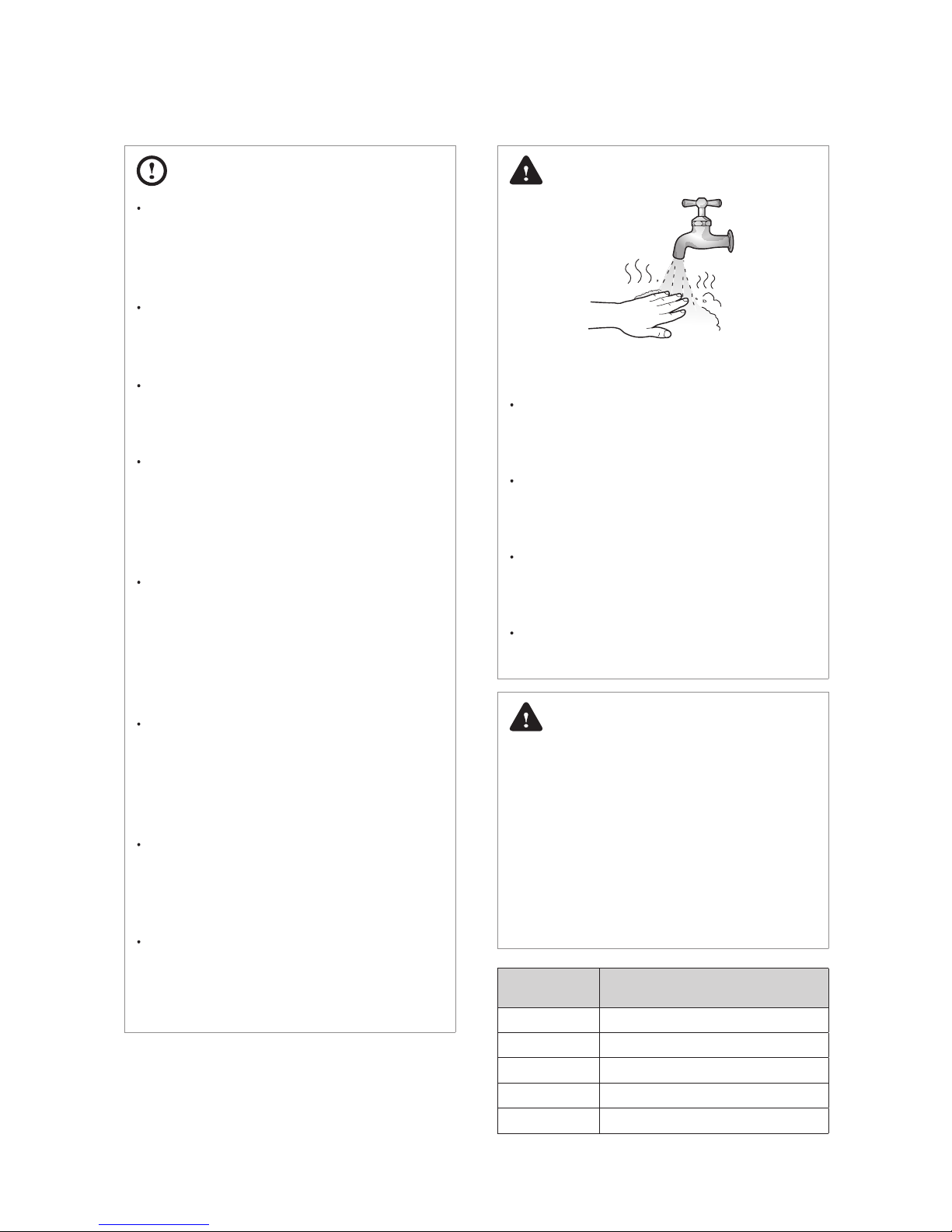

DANGER

HOT

BURN

To prevent burns:

Use the lowest operating temperature

setting necessary to provide

comfortably hot water.

If your household has children or

elderly or disabled residents, consider

using a lower temperature setting.

Read all the instructions in this

manual carefully before changing the

temperature setting.

Feel the water before using it on

children, the elderly, or the disabled.

DANGER

This boiler’s water temperature is set to

49°C at the factory for your safety and

comfort. Increasing the temperature

increases the risk of accidental scalding.

Water temperatures at or above 52°C

can cause instant scalding or severe

burns. Before you decide to change the

temperature setting, read the following

charts carefully.

Water

Temperature

Time in which a young child can suer a

full thickness (3rd degree) burn

70°C Less than 1 second

60°C 1 second

55°C 10 seconds

49°C 10 minutes

37°C Very low scald risk

CAUTION

Do not turn on the boiler unless

the water and gas supplies are fully

opened.

Doing so may damage the boiler.

Do not turn on the water if the cold

water supply shut-o valve is closed.

Doing so may damage the boiler.

Do not use this boiler for anything

other than its intended purpose, as

described in this manual.

Do not remove the front cover unless

the power to the boiler is turned o

or disconnected.

Failure to do so may result in electric

shock.

When servicing the controls, label all

wires prior to disconnecting them.

Failure to do so may result in wiring

errors, which can lead to improper or

dangerous operation. Verify proper

operation after servicing.

Do not use unapproved replacement

or accessory parts.

Doing so may result in improper or

dangerous operation and will void the

manufacturer’s warranty.

Do not place anything in or around

the ue terminals, such as a clothes

line, that could obstruct the air ow

in or out of the boiler.

This boiler has been approved for

use the UK and Ireland only.

Using the boiler in any other country

will void the manufacturer’s warranty.

2.1 Items Included

nstalling

the boiler. If it seems like there is a problem, do not use the boiler. Contact your supplier. Keep the included items out of the reach of

children, as they can be dangerous. When you no longer wish to use the boiler, disable any parts that could be potentially hazardous.

Installation & Operation

Manual, User’s Information

Manual

Boiler mounting plate

Boiler registration / Installers

Club Card

ErP Label

Wall mounting bracket Tapping screws & anchors Propane gas changing kit Electric cord

Pre-plumbing Kit Condensate trap hose

2.2 Accessories

The following optional accessories are available for the boiler:

Outdoor Temperature Sensor Smart Room Controller

2. About the Boiler

6 Safety Information

General Installation Guidelines

Navien ensures that this product contains no harmful

substances and that no harmful materials have been used in its

manufacture.

Current legislation must be taken into account on installing

this appliance, and it must be installed in a place with suitable

ventilation.

The boiler must be installed by an installer authorised by the

Ministry of Industry and it must be started up by an Ocial

Technical Assistance Service authorised by Navien.

The requirements included in the following regulations must be

observed on installing the boiler:

- The Gas Installation Regulation.

- The Technical Building Code.

- The Regulation for Heating Installations in Building.

- The Low Voltage Regulation.

Installing the system piping

The boiler is equipped with an internal relief valve. All systems

must be capable of sustaining pressure of up to 3 bar.

If the system pressure exceeds 2.65 bar at the maximum

heating temperature, an additional expansion vessel must be

installed on the central heating return.

The air vent is required in the system during lling.

CAUTION

The boiler is equipped with an internal

bypass valve. The internal bypass valve

is not intended to replace an external

bypass valve. An external automatic

bypass valve is required if a zone valve

has been connected to the system.

Gas Conversion

The boiler is congured for natural gas. If LPG conversion is

required, use the conversion kit supplied with the boiler.

The Codes of good practice and regulations refer to the

latest versions of the same.

The installation must also comply with the following European

Standards:

Standard Description

UNE-EN 13831:2008

Closed expansion vessels with

diaphragm.

UNE-EN 1856 Metal chimneys

UNE-EN 13384 Chimneys

UNE-EN 13779 Ventilation

UNE-EN ISO 16484 Building control systems.

UNE-EN 14336 Heating systems in buildings.

UNE-EN 15502-1

Gas-red heating boilers

Part 1: General Requirements and tests

UNE-EN 15502-2-1

Gas-red heating boilers

Part 2-1: Specic standard for type

C appliances and type B2, B3 and B5

appliances of a nominal heat input not

exceeding 1000 kW

UNE-EN 13203:2007 Domestic Hot Water

UNE-EN 303-7:2008 Heating boilers.

EC Conformity Declaration

0063

Navien, hereby declares that the boiler models:

NCB-20LHWE, NCB-23LHWE, NCB-28LHWE, NCB-33LHWE

to which this declaration refers, conform to and comply with

the essential requirements of the following applicable European

Standards and Directives.

Gas appliances dna 734 NE sdradnatS CE/241/9002 evitceriD :

EN 15502

Boiler Eciency: Directives 92/42/EEC and

93/68/EEC

Regulation (EN) No. 813/2013

Standards EN 15502

Low voltage: Directives 73/23/EEC and

93/68/EEC Standard EN 60335-1, EN 60335-2-30,

EN 60335-2-51, EN 50165

Electro-magnetic Compatibility: Directive 2004/108/EC

Standards EN 55014

Pressure Vessels: Directive 97/23/EEC

Navien, manufactures its products using a Quality Assurance

system in compliance with Standard EN-ISO 9001:2000.

2.1 Items Included

nstalling

the boiler. If it seems like there is a problem, do not use the boiler. Contact your supplier. Keep the included items out of the reach of

children, as they can be dangerous. When you no longer wish to use the boiler, disable any parts that could be potentially hazardous.

Installation & Operation

Manual, User’s Information

Manual

Boiler mounting plate

Boiler registration / Installers

Club Card

ErP Label

Wall mounting bracket Tapping screws & anchors Propane gas changing kit Electric cord

Pre-plumbing Kit Condensate trap hose

2.2 Accessories

The following optional accessories are available for the boiler:

Outdoor Temperature Sensor Smart Room Controller

2. About the Boiler

7About the Boiler

8

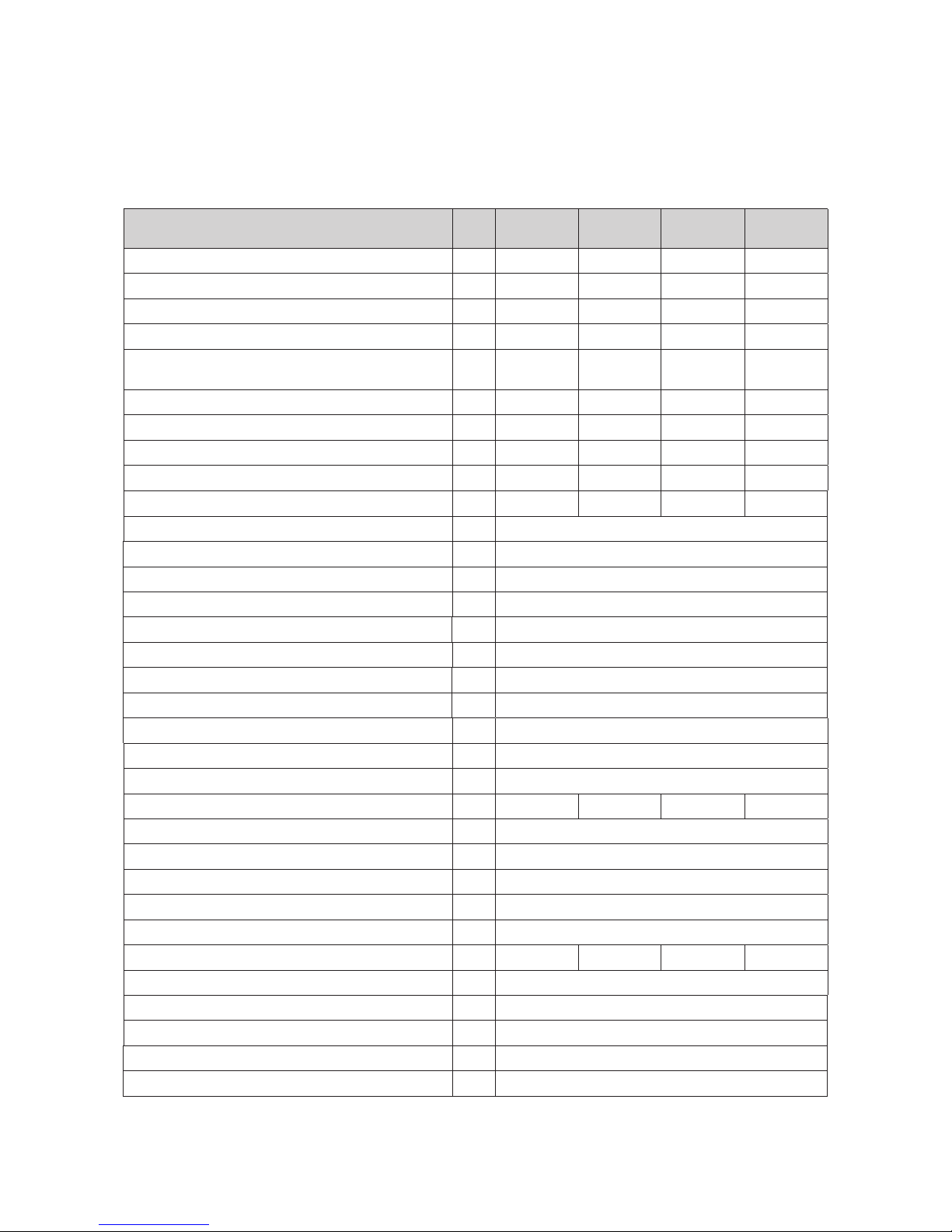

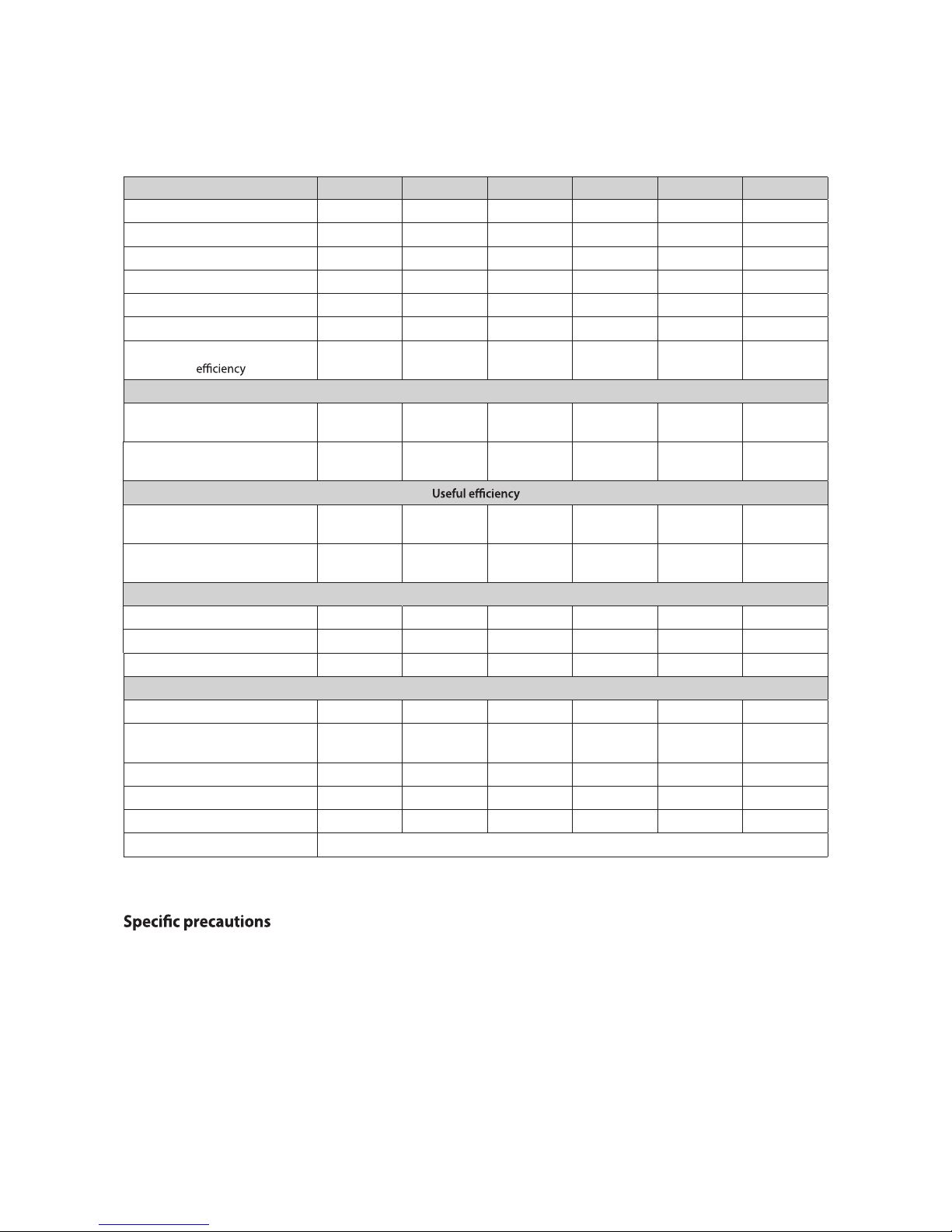

2.3 Technical Data

The following table lists the general specications for the boiler.

Specications Unit

NCB-

20LHWE

NCB-

23LHWE

NCB-

28LHWE

NCB-

33LHWE

Heat input range kW 20.0/4.2 24.0/4.2 29.0/5.1 34.0/4.0

Heat output range @ 80/60°C kW 19.5/3.9 23.4/3.9 28.3/4.9 33.2/3.8

Condensing heat output range @ 50/30°C kW 21.4/4.5 25.6/4.5 31.1/5.4 36.3/4.3

Full load eciency at Max./Min. output @ 80/60°C % 97.5/96.4 97.5/96.4 97.6/96.4 97.6/95.8

Full load eciency at Max./Min. output @ 50/30°C

(Condensing)

% 106.9/107.8 106.6/107.8 107.3/106.9 106.9/106.9

Partial load (30%) eciency with 47°C return temp. % 101.9 103.1 102.0 103.1

Partial load (30%) eciency with 30°C return temp. % 108.6 108.9 108.5 108.8

Heat loss through the case with burner switched on % 0.1 0.1 0.1 0.1

Heat loss through the chimney with burner switched on % 1.6 1.8 1.5 1.9

Seasonal eciency rate (SEDBUK 2009) - 89.0 89.1 89.0 89.1

NOx Classication - Class 5

Category - II2H3P

Type - Heating and instantaneous hot water production

Heat output adjustmen

t - Adjustable over entire Max./Min. output range

Type of heating installation - Close circuit

Max. heating operation pressure bar 2.5

Max. heating temperature °C 90

Adjustable heating temperature range °C 40-90

Expansion vessel volume l 6.0

Expansion vessel pre-charged pressure bar 1.0

Electrical power supply - 230 V/50 Hz

Nominal current A 0.6 0.6 0.62 0.62

Max. power consumption W 130

Appliance protection rating - IP X5D

Boiler mounting system type - Wall-mounted

Flue exhaust/Air intake system types - B23-B33-B53-C13-C33-C43-C53-C63-C83

Flue exhaust/Air intake system diameters mm Coaxial Ø60/100 and Ø80/125–Dual duct Ø80/80

Max. gas pipe pressure drop Pa 167 167 294 294

Max. horizontal coaxial length Ø60/100 m 20

Max. vertical coaxial length Ø60/100 m 21

Equivalent elbow length @ 90° Ø60/100 m 1.3

Equivalent elbow length @ 45° Ø60/100 m

1.0

Max. horizontal coaxial length Ø80/125 m 68

Unit

NCB-

20LHWE

NCB-

23LHWE

NCB-

28LHWE

NCB-

33LHWE

Max. vertical coaxial length Ø80/125 m 70

Equivalent elbow length @ 90° Ø80/125 m 2.2

Equivalent elbow length @ 45° Ø80/125 m 1.0

Equivalent length of adapter Ø60/100 => Ø80/125 m 0.5

Max. dual duct length Ø80/80 m 110

Equivalent elbow length @ 90° Ø80 m 2.2

Equivalent elbow length @ 45° Ø80 m 1.4

Hydraulic connection

diameter

Central Heating mm 22

DHW mm 15

Gas supply mm 22

Dimensions (Width x Depth x Height) mm 440 x 358 x 695 440 x 408 x 695

Total boiler weight (lift weight) Kg 36 36 40 40

About the Boiler

Unit

NCB-

20LHWE

NCB-

23LHWE

NCB-

28LHWE

NCB-

33LHWE

Max. vertical coaxial length Ø80/125 m 70

Equivalent elbow length @ 90° Ø80/125 m 2.2

Equivalent elbow length @ 45° Ø80/125 m 1.0

Equivalent length of adapter Ø60/100 => Ø80/125 m 0.5

Max. dual duct length Ø80/80 m 110

Equivalent elbow length @ 90° Ø80 m 2.2

Equivalent elbow length @ 45° Ø80 m 1.4

Hydraulic connection

diameter

Central Heating mm 22

DHW mm 15

Gas supply mm 22

Dimensions (Width x Depth x Height) mm 440 x 358 x 695 440 x 408 x 695

Total boiler weight (lift weight) Kg 36 36 40 40

9About the Boiler

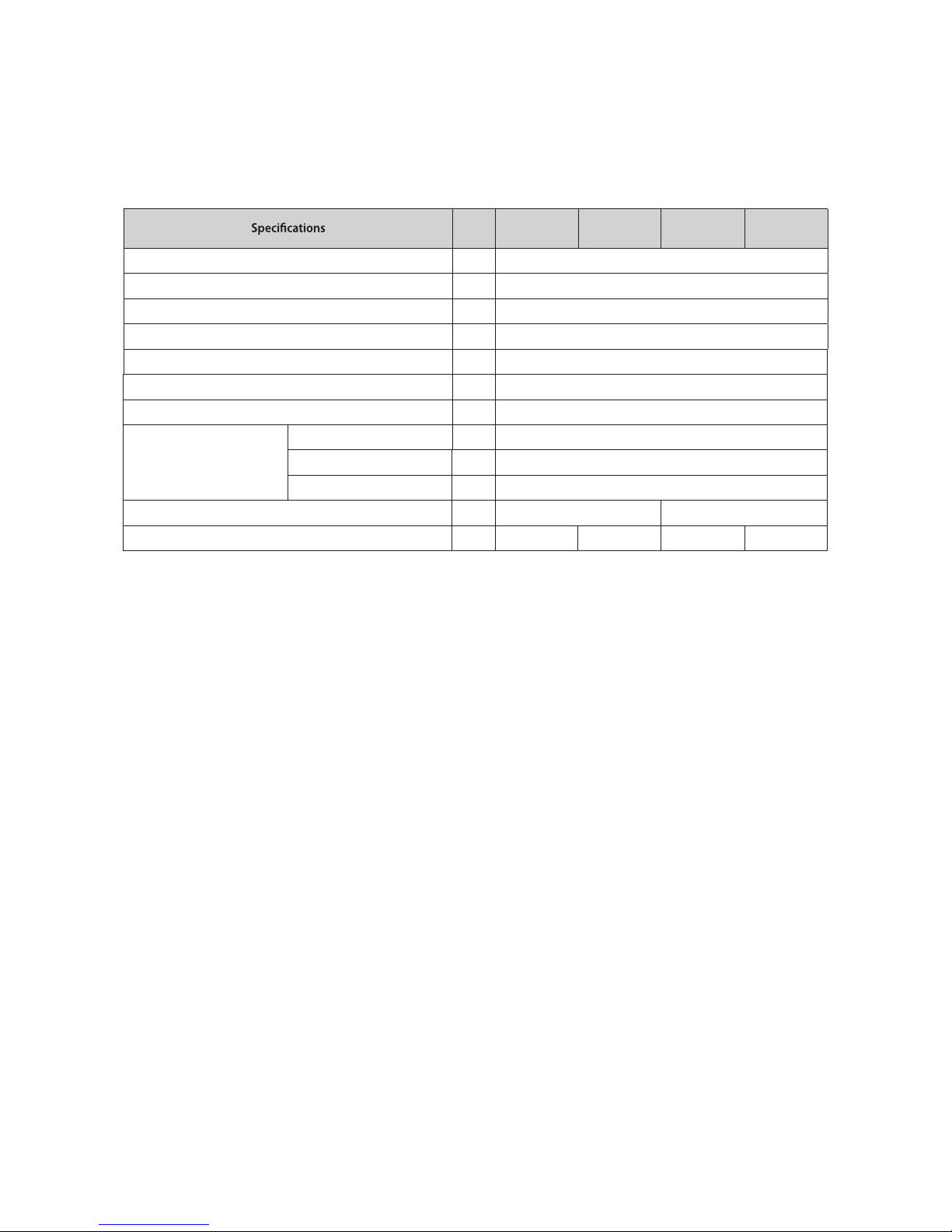

The following table lists the product information requirements (EU regulation No 811/2013 and No 813/2013)

KD Navien Symbol Unit NCB-20LHWE NCB-23LHWE NCB-28LHWE NCB-33LHWE

Condensing boiler YES YES YES YES

Low-temperature (**) boiler NO NO NO NO

B1 boiler NO NO NO NO

Cogeneration space heater NO NO NO NO

Combination heater NO NO NO NO

Rated heat output P

rated

kW 20 23 28 33

Seasonal space heating energy

η

s

% 92 93 93 93

Useful heat output

At rated heat output

and high-temperature regime (*)

P

4

kW 19.5 23.4 28.3 33.2

At 30 % of rated heat output

and low-temperature regime (**)

P

1

kW 6.5 7.8 9.4 11.1

At rated heat output

and high-temperature regime (*)

η

4

% 87.8 87.9 87.9 87.8

At 30 % of rated heat output

and low-temperature regime (**)

η

1

% 97.8 98.1 97.7 98.0

Auxiliary electricity consumption

At full load elmax kW 0.036 0.045 0.048 0.045

At part load elmin kW 0.014 0.015 0.016 0.016

In standby mode P

SB

kW 0.003 0.003 0.003 0.003

Other items

Standby heat loss P

stby

kW 0.080 0.080 0.084 0.084

Ignition burner power

consumption

P

ign

kW ----

Annual energy consumption Q

HE

GJ 37 43 52 57

Sound power level, indoors L

WA

dB 50 52 54 52

Emissions of nitrogen oxides NO

x

mg/kWh 36 38 30 37

Contact details

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return temperature (at heater inlet).

Read the user’s information and installation manual before the application is assembled, installed or maintained.

3000 Cathedral Hill, Guildford, Surrey, GU2 7YB

10 About the Boiler

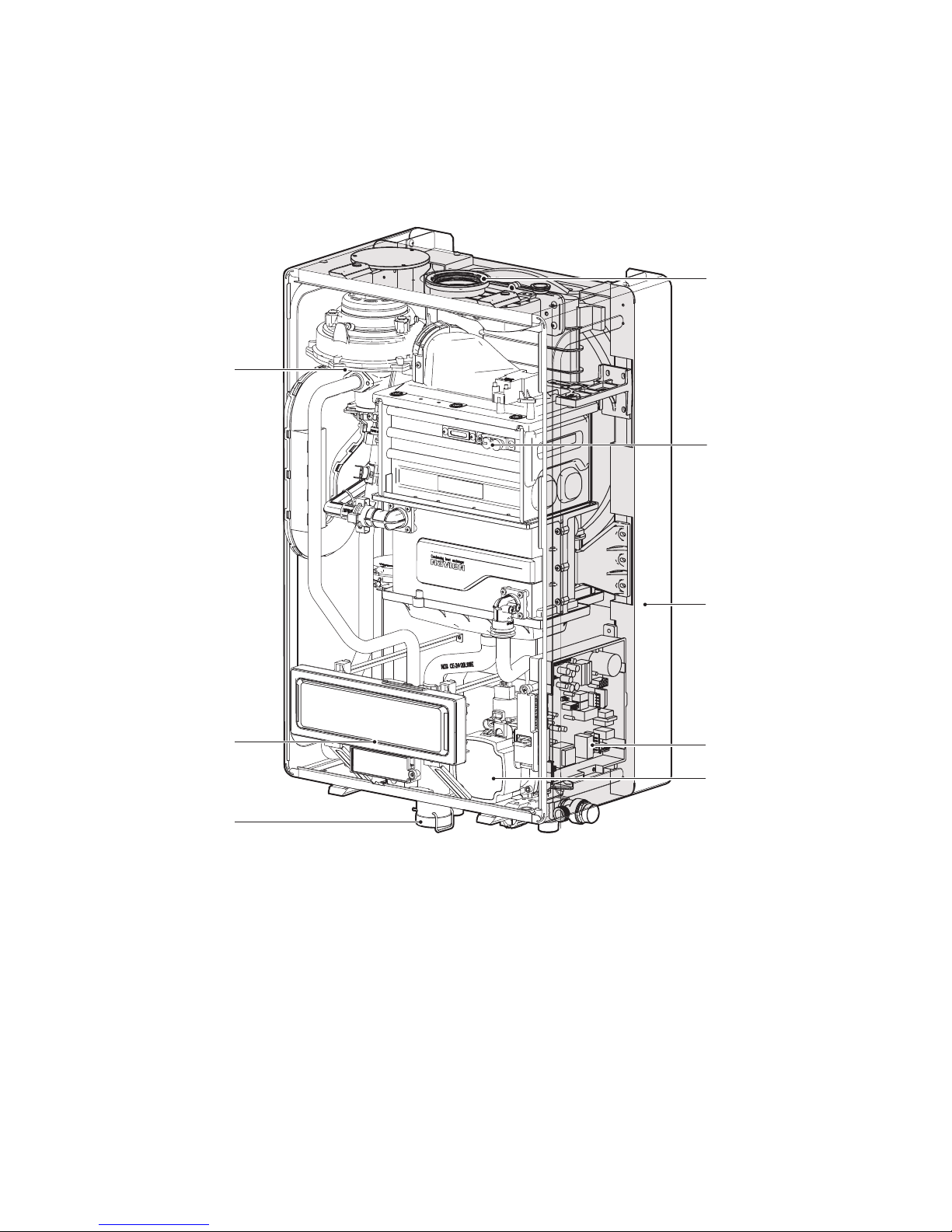

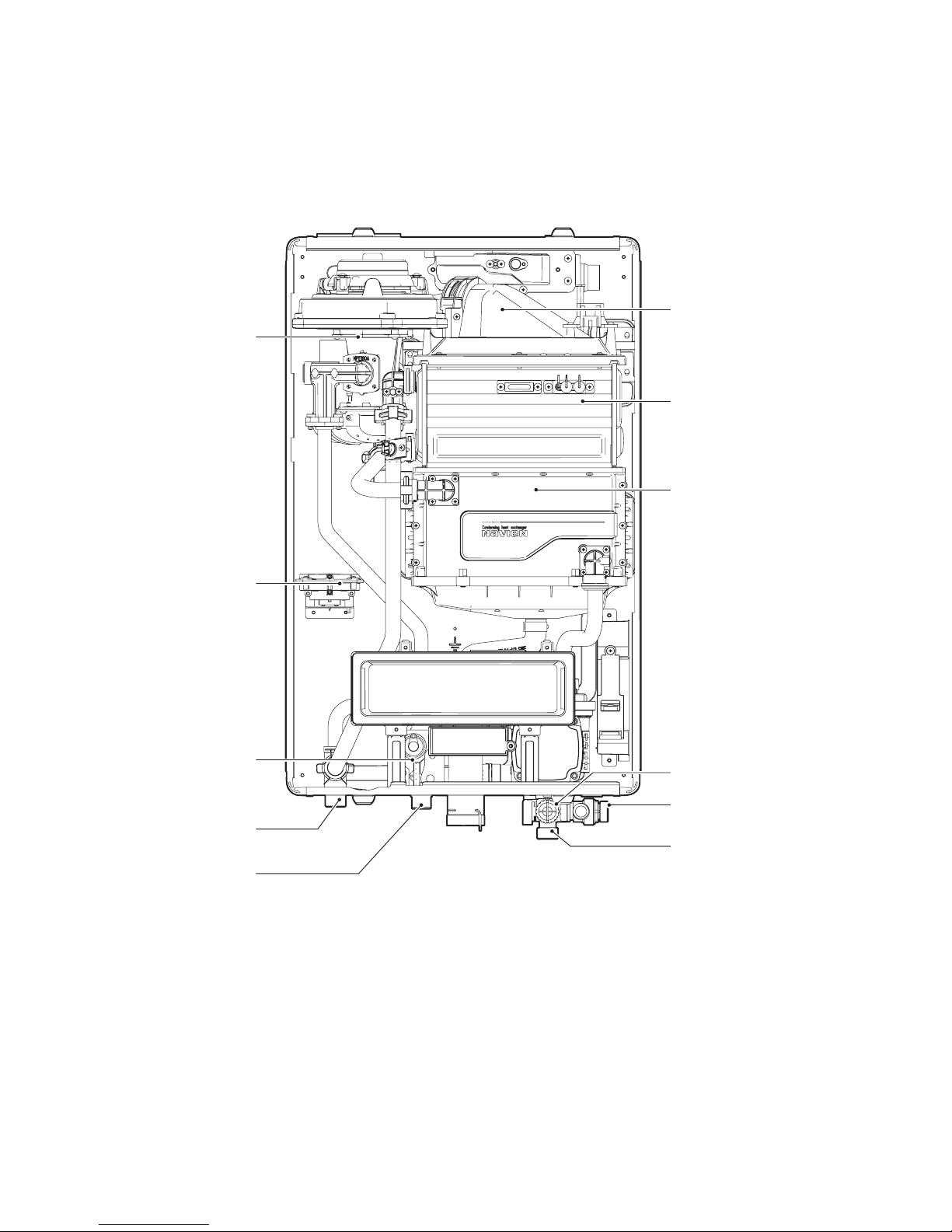

2.4 Components

The following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in

the Appendices.

Fan & Motor

Front Panel

Flue Duct

Ignitor & Flame Rod

Circulation Pump

Condensate Trap

Mounting Frame

PCB

NCB-20/23/28LHWE

11About the Boiler

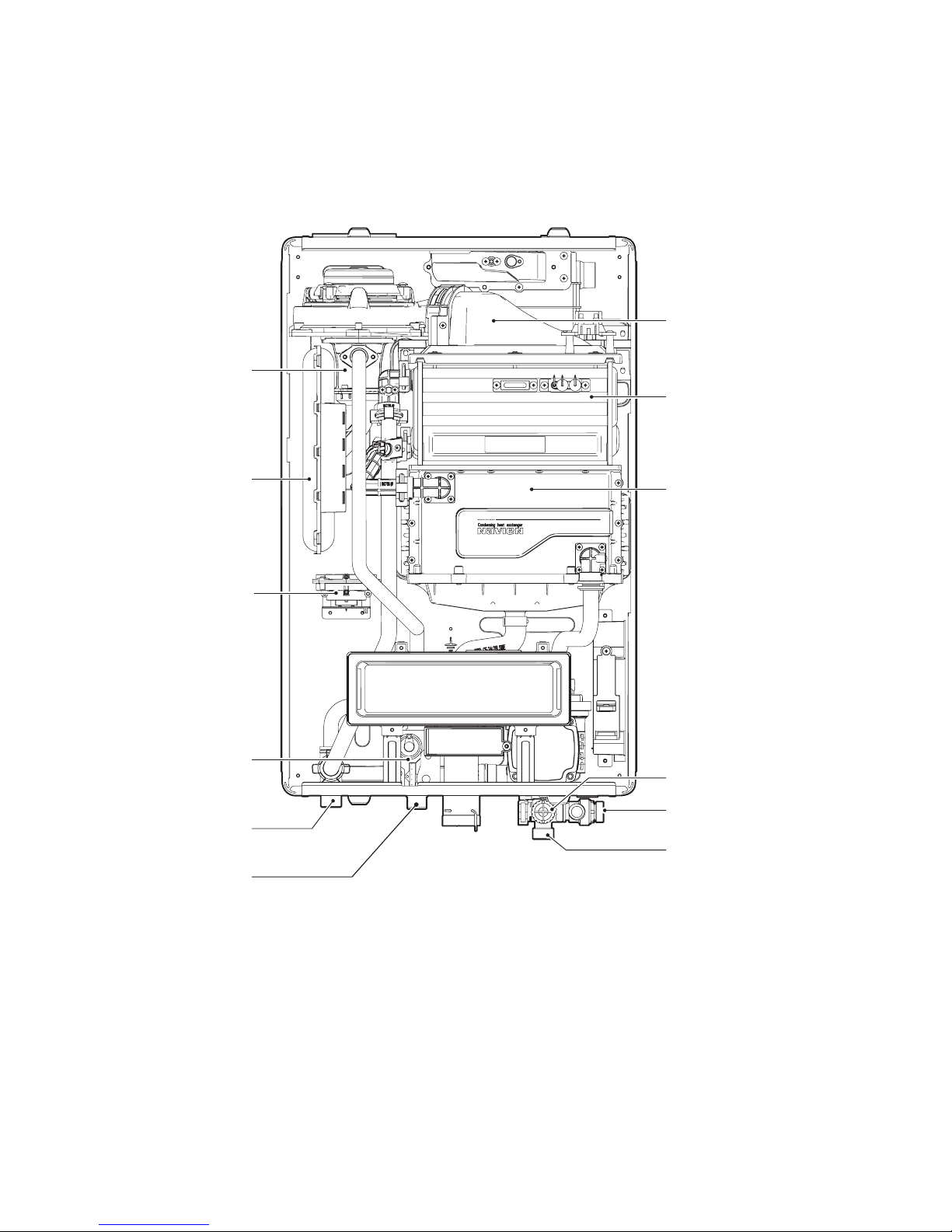

NCB-20/23/28LHWE

Single Venturi

Mixing Chamber

APS

Primary Heat Exchanger

Secondary Heat Exchanger

Return Adapter

Filter Assembly

Space Heating Return

Pressure Relief Valve

Space Heating Supply

Gas supply inlet

Gas Valve

Air Pipe

12 About the Boiler

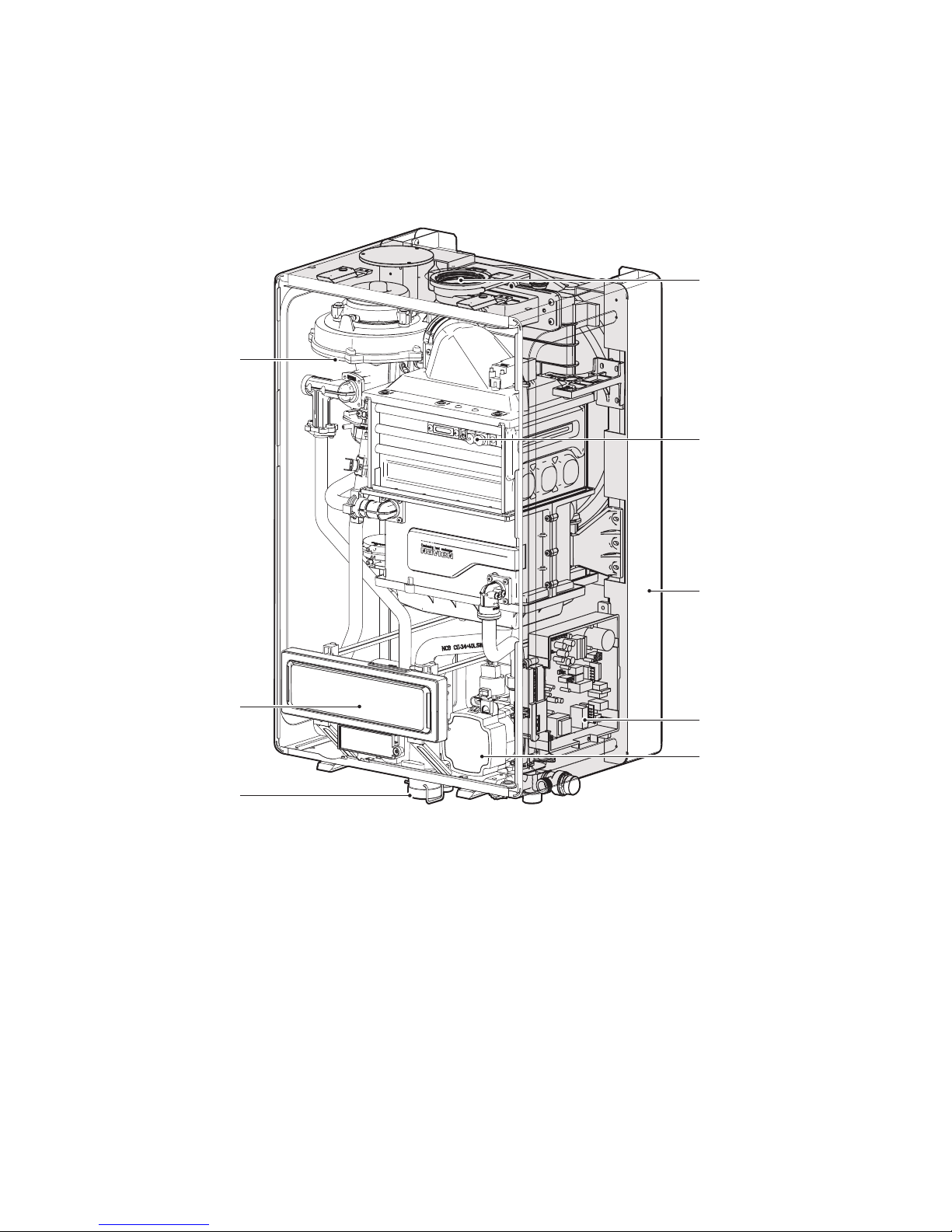

NCB-33LHWE

Fan & Motor

Front Panel

Flue Duct

Ignitor & Flame Rod

Circulation Pump

Condensate Trap

Mounting Frame

PCB

13About the Boiler

NCB-33LHWE

Dual Venturi

Mixing Chamber

Primary Heat Exchanger

Secondary Heat Exchanger

Return Adapter

Filter Assembly

APS

Space Heating Return

Pressure Relief Valve

Space Heating Supply

Gas supply inlet

Gas Valve

14 About the Boiler

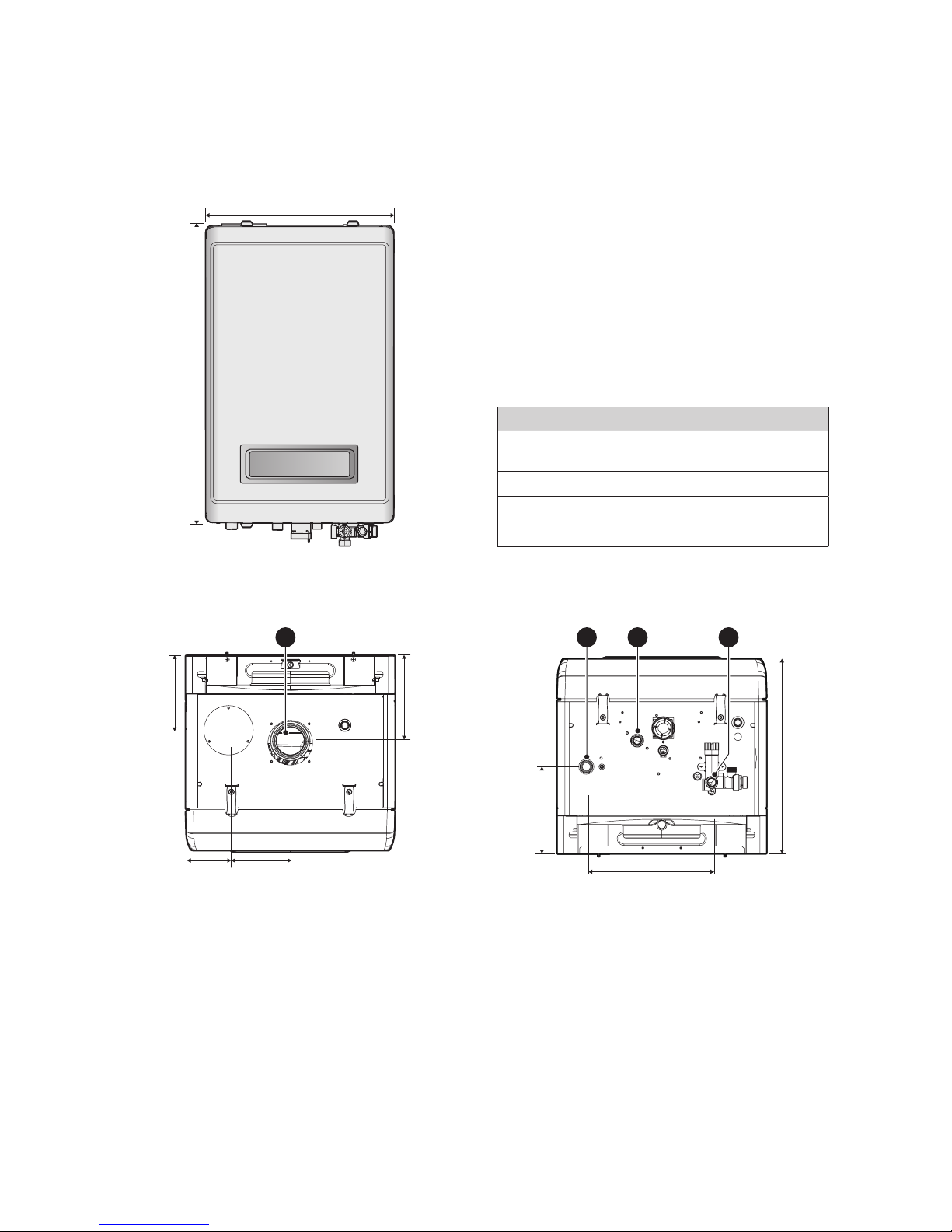

2.5 Dimensions

The following diagrams show the dimensions of the boiler and the table lists the supply connections.

695 mm

440 mm

Supply Connections

Description Diameter

A Flue exhaust/Air intake

Ø60/100,

Ø80/125

B Space heating supply 22 mm

C Gas supply inlet 22 mm

D Space heating return 22 mm

Overhead View

90 mm

157 mm

183 mm

130 mm

A

Bottom View

C

150 mm

D

*NCB-20LHWE/23LHWE: 358 mm

285 mm

-

408 mm*

B

15About the Boiler

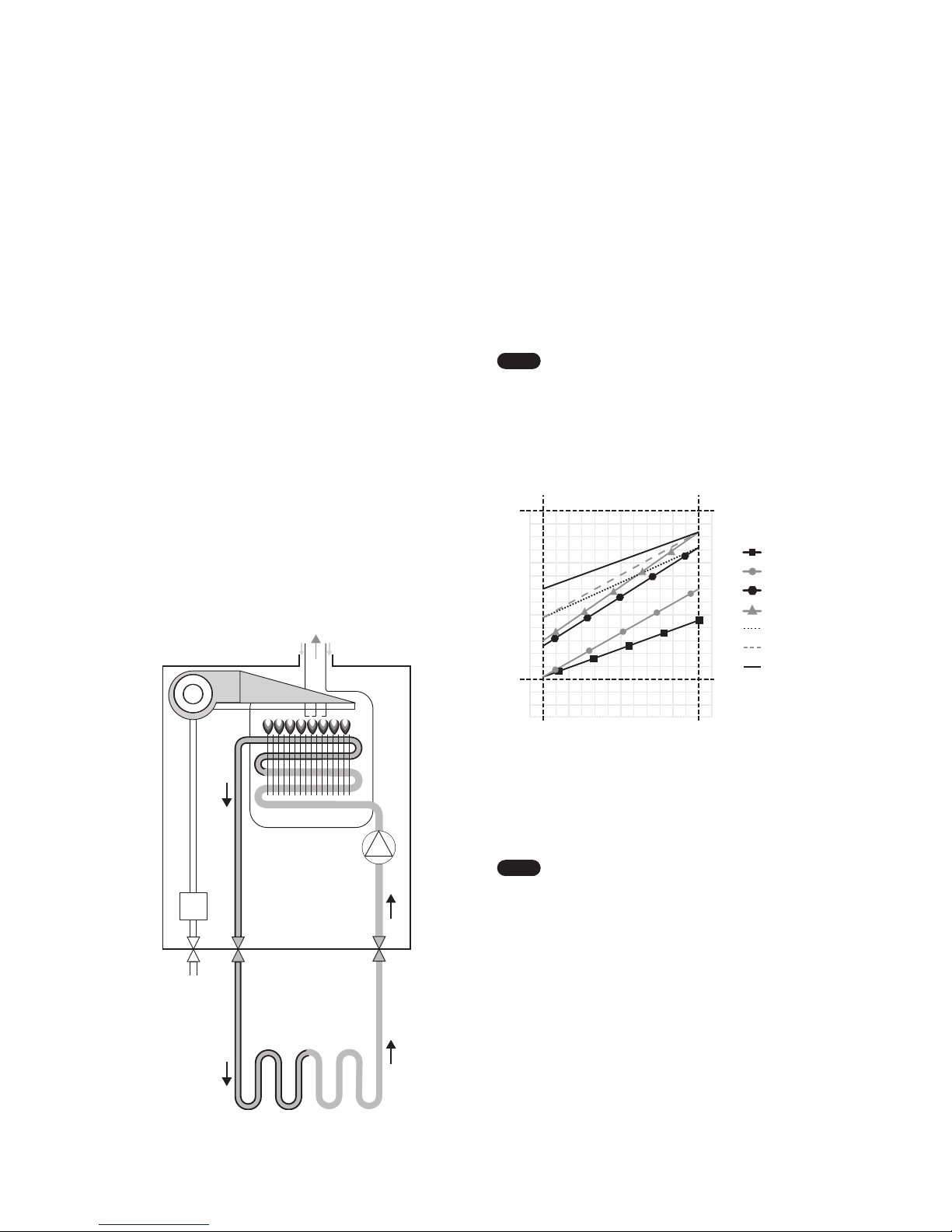

2.6.2 Operating According to Outdoor

Temperature Conditions

The Outdoor Reset Control feature may be used to enhance

energy eciency while maintaining optimal heating

performance. With the Outdoor Reset Control, the space heating

temperature setting automatically changes according to the

outdoor temperature and the current space heating system

application (system load).

You can congure the Outdoor Reset Control settings on the

front panel by entering the Special Parameter Setting mode.

Refer to “11.5 Setting the Parameters” on page 48.

Note

The Outdoor Reset Control feature requires

installation of an outdoor temperature sensor, and it

only works when the boiler is running in the normal

operation mode. It does not work when the boiler is

running in either the Minimum (MIN) or Maximum

(MAX) mode, or when the boiler’s front panel displays

a fault.

45 40 35 30 25 20 15 10 5 0 -5 -10 -15 -20 -25

185

194

176

167

158

149

140

131

122

113

104

95

86

77

68

59

50

113 104 95 86 77 68 59 50 41 32 23 14 5 -4 -13

°F

°C

85

90

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

°F °C

Absolute

MAX

Absolute

MIN

Outdoor

High MIN

Outdoor

Low MIN

High Mass Radiant

Low Mass Radiant

Cast Iron Baseboard

Custom

Radiator

Finned Tube Baseboard

Fan Coil

Space Heating Temperature Setting for the

Outdoor Reset Control Feature

The following tables list the default space heating temperature

range by system heat load and the applicable outdoor

temperature ranges.

Note

To connect the outdoor temperature sensor to the

boiler, carefully follow the connection instructions

provided in the “13.5 Outdoor Temperature Sensor

(Optional)” on page 72.

2.6 Operating Modes

2.6.1 Operating in Space Heating Mode

To operate the Space heating mode, press the Space heating

button on the front panel and select a heating temperature

setpoint higher than current heating temperature.

1. When the boiler detects a request for heating production

(from the installation’s room thermostat, for example), the

3-way valve goes to heating position and the circulating

pump starts up.

2. If the boiler water temperature is lower than the desired

temperature setpoint, the boiler ignites and heats up the

heating installation until the selected boiler temperature

is reached. The boiler’s electronic control modulates

the burner output to adapt to the installation’s heat

requirements at all times and so that the installation’s water

temperature remains constant. This prevents the installation

from overheating and reduces heat loss as much as possible.

3. When there is no further heating demand (e.g. when

the desired ambient temperature selected on the room

thermostat is reached), the burner is extinguished (if it was

ignited) and the circulation pump continues to run during

the post-circulation time (minimum 3 minutes), to protect

the boiler from overheating due to thermal inertia in the

installation.

Air InAir In

Exhaust

Gas

Blow Fan

Ignitor

Gas

Valve

Gas

Inlet

Flow

Out

CH

Return

Circulation

Pump

Heat

Exchanger

16 About the Boiler

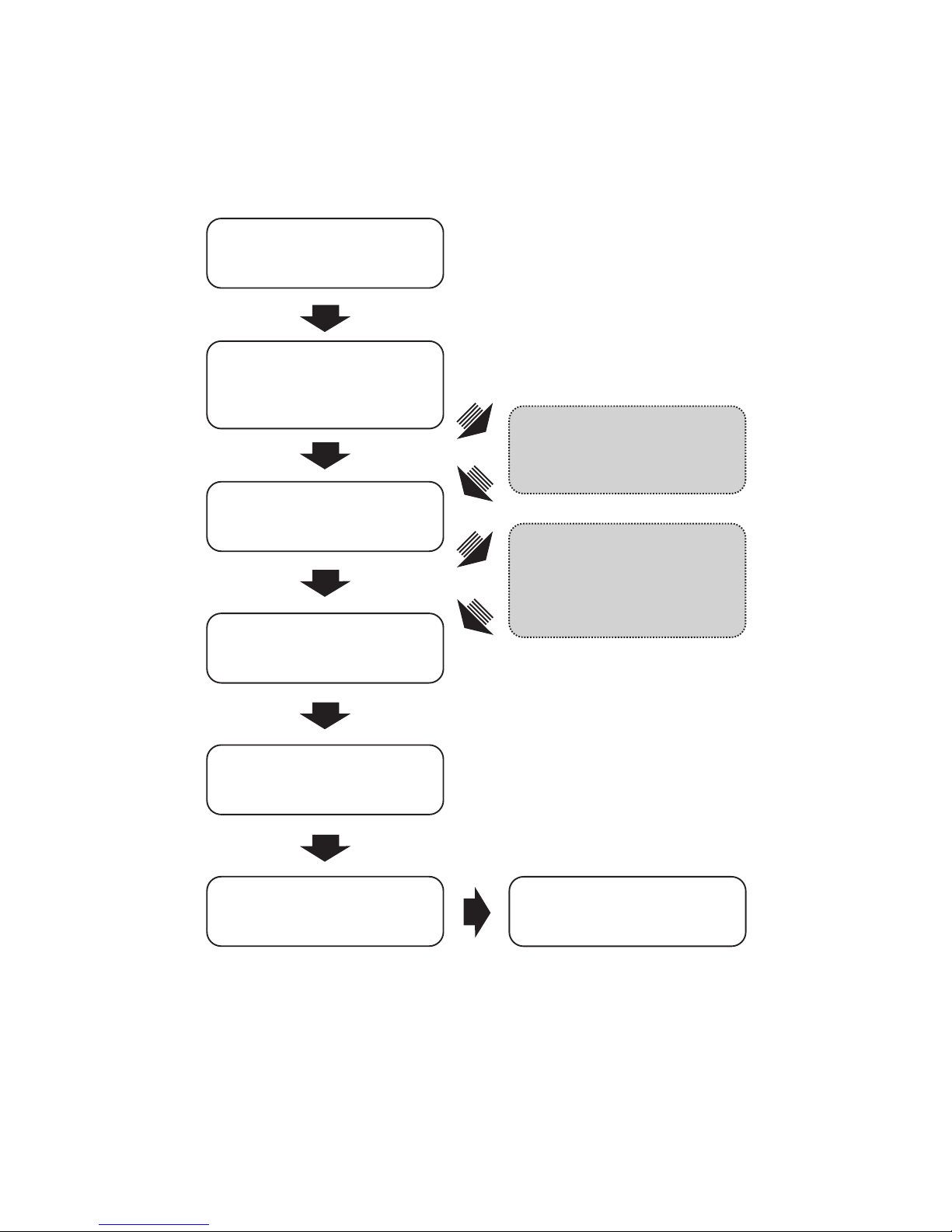

2.7 Installation Procedure

The ow diagram below provides a step-by-step description of the recommended procedure for clear, easy installation of the NCB LHWE

boiler in its nal location. A detailed description is given of the procedure in the sequenced sections below:

Wall-mounting

»

Gas connection

»

Electrical connections

»

DIP switch settings

»

Final check

»

Water and condensate

pipe connection

»

Flue gases exhaustion

system installation

(if necessary)

»

Gas changeover

(if necessary)

»

Boiler operation

»

p. 18

p. 21

p. 25

p. 35

p. 34

54 .p44 .p

p. 28

p. 61

17About the Boiler

3.1 Choosing an Installation Location

When choosing an installation location, you must ensure

that the location provides adequate clearance for the boiler,

adequate ueing and drainage options, and sucient access to

gas, water, and electrical supplies.

Carefully consider the following factors when choosing an

installation location:

Compliance Requirements

This boiler must be installed by qualied personnel in

compliance with the applicable Laws and Regulations.

In general, these Laws and Regulations are the Basic Gas

Installation Standards, the Heating, Air Conditioning and

Domestic Water Installation Regulation and all other local

regulations.

Access to Utilities

Water–the installation location should be near where the

domestic water supply enters the building.

Gas–the installation location should be near where the gas

supply enters the building.

Electricity–the installation location should be near where the

electrical supply enters the building.

Humidity and Contact with Water

When installing the boiler, avoid places with excessive humidity.

The boiler has electric gas ignition components. Water spray or

droppings can get inside the boiler and damage the ignition

system. The boiler must be installed in a way to ensure that

the gas ignition system components are protected from water

(dripping, spraying, rain, etc.) during operation and service.

If the boiler is installed in a very humid room (a shower room

or bathroom, for example), the Low Voltage regulation and

the Technical Building Code must be observed for correct

installation.

Proximity to Fixtures and Appliances

Install the boiler near xtures that deliver or use hot wat

er,

such as bathroom, kitchen, and laundry room faucets. Select

a location that minimises the water piping required between

major xtures. If the distances are long or if the user requires

“instant“ hot water, installation of a recirculation line which

circulates domestic hot water back to the boiler from the

furthest xture is recommended. Insulate as much of the hot

water supply and recirculation lines as possible. For more

information about the water supply, refer to "4.2 Installing a

System Application” on page 22.

Adequate Drainage

The boiler produces a signicant amount of condensate during

operation. This condensate must be removed from the boiler,

and suitably treated if national legislation so requires. The boiler

should be located near a suitable drain and where damage from

a possible leak will be minimal. Installing the boiler in a location

without a drain will void the warranty and Navien will not be

responsible for water damage that occur as a result. For more

information about condensate drainage, refer to “4.3 Connecting

the Condensate Drain Line” on page 22.

The boiler must be located in an area where leakage of the unit

or connections will not result in damage to the area adjacent

to the appliance or to lower oors of the structure. When such

locations cannot be

found, installation of an adequately drained

drain pan under the boiler is highly recommended. When

installing the drain pan, ensure that the installation does not

restrict combustion air ow.

Adequate Flue and Ventilation

The boiler must be installed in a suciently ventilated area with

openings directly to the outside of the building (as required by

the Gas Installations Regulation). The boiler must be located so

that the grilles of the premises are not obstructed and normal

boiler maintenance is possible even if installed between items

of furniture.

Select a location that requires minimal ue. Consider ue

restrictions caused by windows, doors, air intakes, gas meters,

foliage, and other buildings. For more information about ue

system, refer to “6. Flue System” on page 28.

To ensure adequate ue and ventilation, follow these guidelines:

Maintain proper clearances from any openings in the building.

Install the boiler with a minimum clearance of 300 mm above

an exterior grade or as required by local codes.

Do not enclose the ue termination.

Install the exhaust ue in an area that is free from any

obstructions, where the exhaust will not accumulate.

Do not install the boiler where moisture from the exhaust may

discolor or damage walls.

Do not install the boiler in bathrooms, bedrooms, or any

other occupied rooms that are normally kept closed or not

adequately ventilated.

The requirements and recommendations stipulated in the

Regulation for Heating Installations in Buildings (RITE) and any

other applicable legislation in this eld must be observed.

3. Installing the Boiler

18 Installing the Boiler

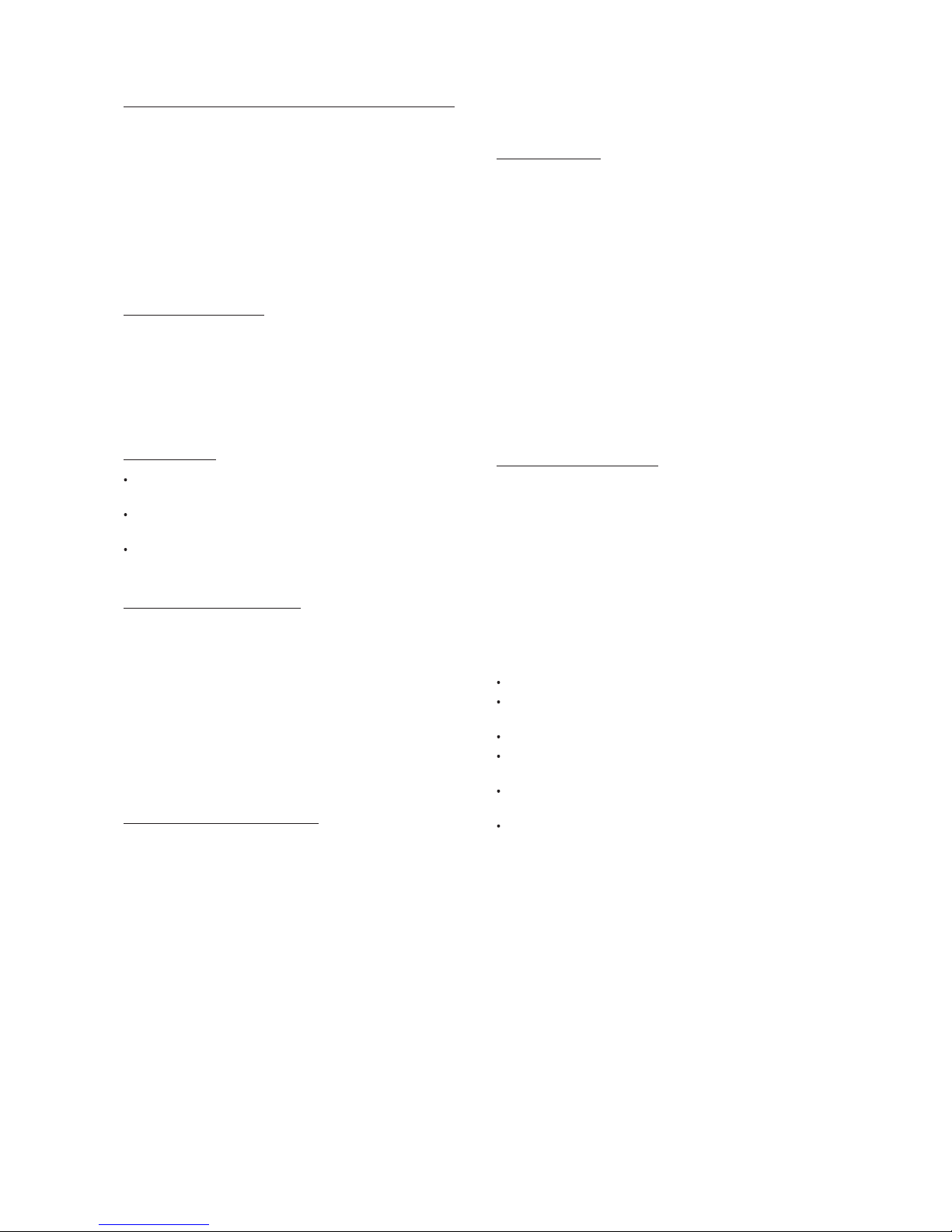

Clearance from: Indoor Installation

Top 250 mm minimum

Front 600 mm minimum

Bottom 200 mm minimum

Clean, debris and chemical-free combustion air

Do not install the boiler in areas where dust and debris may

accumulate or where hair sprays, spray detergents, chlorine,

or similar chemicals are used.

Do not install the boiler in areas where petrol or other

ammables are used or stored.

Ensure that combustible materials are stored away from

the boiler and that hanging laundry or similar items do not

obstruct access to the boiler or its ue system.

Adequate installation clearances

CAUTION

Do not install the boiler on carpeting.

Install the boiler in an area that allows for service and

maintenance access to utility connections, piping, lters,

and traps. Based on the installation location, ensure that the

following clearances are maintained:

Top

Bottom

Front

19Installing the Boiler

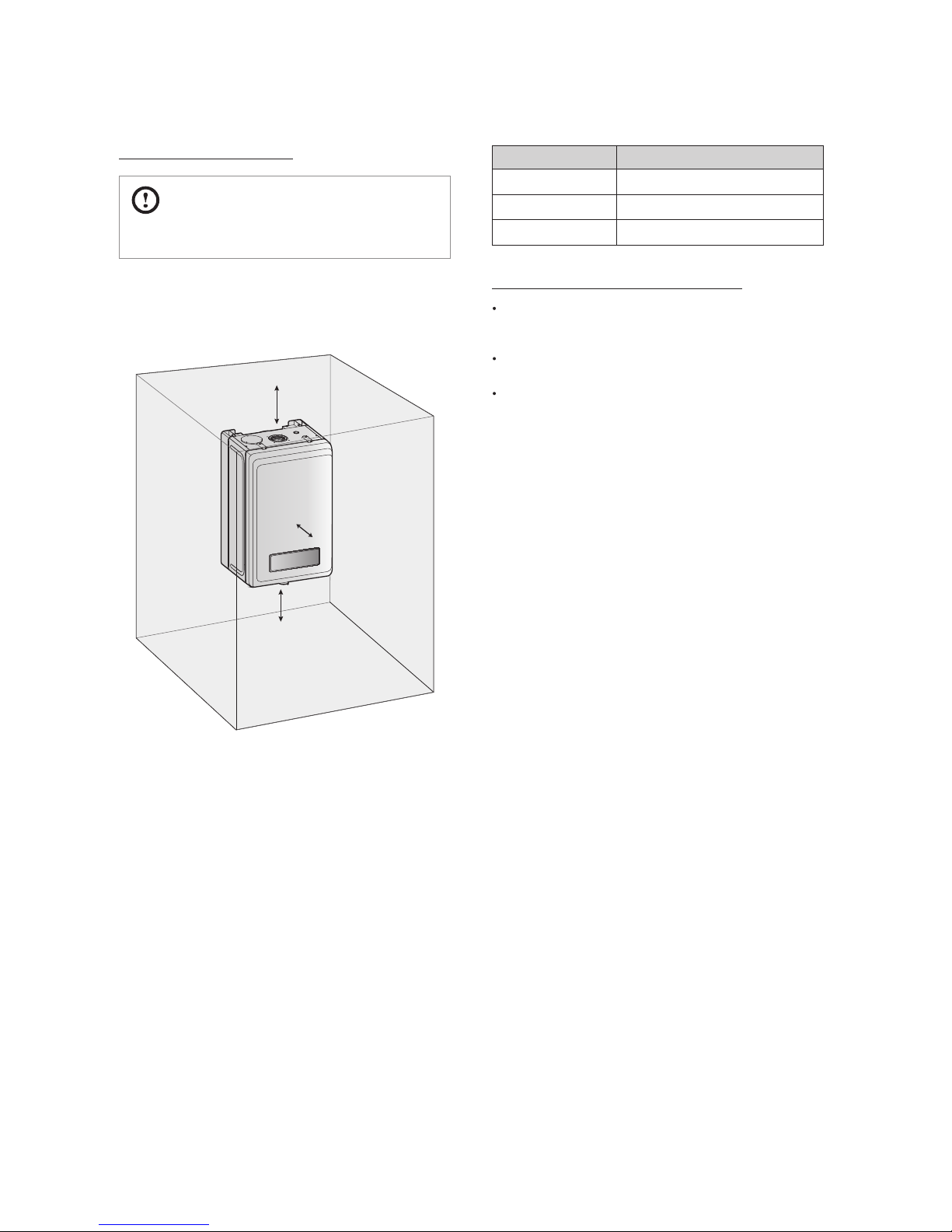

3.2 Mounting the Boiler to the Wall

Navien NCB LHWE boilers come with an upper mounting

bracket that is pre-drilled at 400 mm on center for easy

installation on standard wall studs. If the strength of the wall

is insucient or if the framing is non-standard or uneven,

reinforce the area before installing the boiler. Avoid installation

on common walls as the unit will make some operational noises

while it is running.

To mount the boiler to the wall:

1. Ax the bracket securely to the wall and ensure that it is

level and that it can support the weight of the boiler.

2. Align the grooves on the back of the boiler with the tongues

on the mounting bracket and hang the boiler on the

bracket.

When mounted with the mounting bracket, the boiler will

have a 16 mm clearance from the back of the wall.

WARNING

The boiler is heavy. Always lift the unit with assistance. Be

careful not to drop the boiler while lifting or handling it

to avoid bodily injury or damage to the unit.

Do not rest the boiler on the bottom end after removing

it from the shipping carton. Doing so may result in

excessive pressure on protruding pipes and result in

product damage. If you must put the boiler down, lay it

on its back or put it inside the protective shipping base.

DANGER

The boiler must be mounted on a suitable wall that can

support its weight and prevent explosion or re.

Do not install the boiler near paper or other ammable

objects.

Do not install the boiler near domestic waste.

The installation must be made by suciently qualied

technicians, authorised to do so. For correct installation, all

the requirements and recommendations described in the

Regulation for Heating Installations in Buildings (RITE) must

be complied with, together with all other national and/or local

regulations applicable at the time of installation. However, the

following recommendations must be complied with:

Before connecting the boiler hydraulically, the inside of the

pipes must be thoroughly cleaned, removing all sediment of

any type which could cause oxidation or damage to the heat

exchanger.

It is recommended to t shut-o valves to the heating

installation output and return pipes, to avoid having to drain

the installation when maintenance work is carried out on the

boiler.

Bleed the air from the boiler and heating installation. Ensure

there is no air in the heating circuit.

The NCB LHWE boiler is a condensing boiler, and it is

therefore essential for the condensate outlet to lead to a

drain, in compliance with all applicable national and/or local

regulations to this respect.

The boiler drain must not be located above a window, entry

door or other public point of access. Bear in mind that boiling

water or steam could come out when draining.

Draining must be done in a downward direction and towards

the walls.

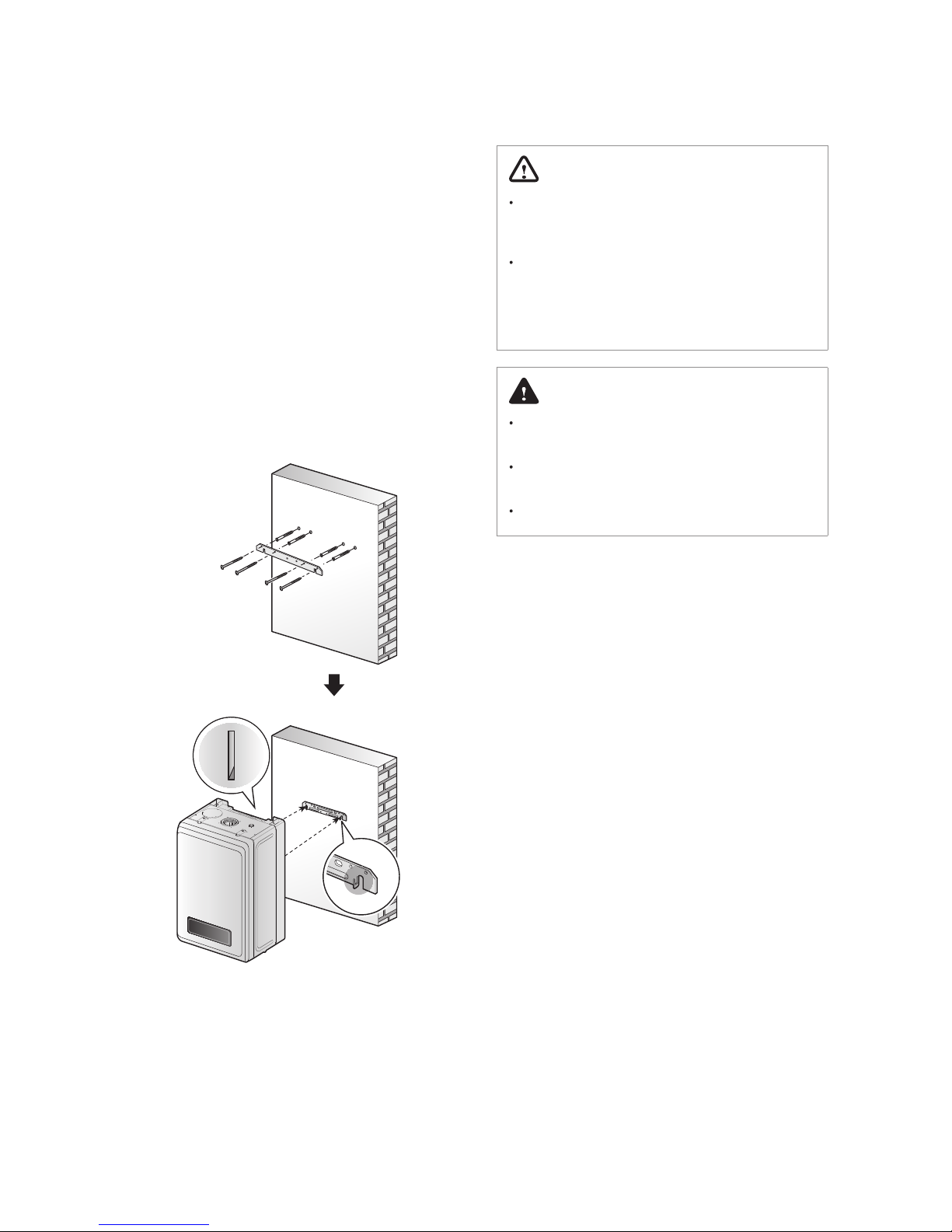

WARNING

Tighten the boiler water connections, taking care not

to damage them. Do not force the tube connections

excessively, as this could damage the connections and

cause leaks.

Any dirt in the tubes could reduce boiler eciency and

cause it to malfunction.

Any pipes exposed to the elements or which could freeze

in winter must be insulated with suitable insulating

material.

CAUTION

Failure to follow the instructions provided in this section will

void the warranty and may result in property damage, re

or serious injury.

4. Installing the System Piping

4.1 Installing a Space Heating System

The primary and secondary heat exchangers of the Navien

NCB LHWE boiler are designed to attain the highest level of

heat transfer in a compact design. To accomplish this, the

heating water ows through a series of tubes (secondary

heat exchanger) and nned tubes (primary heat exchanger),

designed to maximise the heat transfer area. To maintain the

ecient and reliable operation of the heat exchangers, and to

avoid heat exchanger failure, it is critical to ensure the rules and

guidelines in this section are followed.

CAUTION

The installation must be made by suciently qualied

technicians, authorised to do so.

For correct installation, all the requirements and

recommendations described in the Regulation for

Heating Installations in Buildings (RITE) must be

complied with, together with all other national and/or

local regulations applicable at the time of installation.

Refer to the following illustration for a typical heating piping

example for the boiler.

Union

CH Flow

CH Return

Bottom View

Floor Heating Circuit or

Heating Circuit (Radiator)

Heating Supply

Adapter

Heating Return

Adapter

When connecting the space heating system, follow these

guidelines:

Tighten the connection valves with care to avoid damage.

Test the boiler for proper space heating ow and inspect for

leaks.

20 Installing the Boiler

The installation must be made by suciently qualied

technicians, authorised to do so. For correct installation, all

the requirements and recommendations described in the

Regulation for Heating Installations in Buildings (RITE) must

be complied with, together with all other national and/or local

regulations applicable at the time of installation. However, the

following recommendations must be complied with:

Before connecting the boiler hydraulically, the inside of the

pipes must be thoroughly cleaned, removing all sediment of

any type which could cause oxidation or damage to the heat

exchanger.

It is recommended to t shut-o valves to the heating

installation output and return pipes, to avoid having to drain

the installation when maintenance work is carried out on the

boiler.

Bleed the air from the boiler and heating installation. Ensure

there is no air in the heating circuit.

The NCB LHWE boiler is a condensing boiler, and it is

therefore essential for the condensate outlet to lead to a

drain, in compliance with all applicable national and/or local

regulations to this respect.

The boiler drain must not be located above a window, entry

door or other public point of access. Bear in mind that boiling

water or steam could come out when draining.

Draining must be done in a downward direction and towards

the walls.

WARNING

Tighten the boiler water connections, taking care not

to damage them. Do not force the tube connections

excessively, as this could damage the connections and

cause leaks.

Any dirt in the tubes could reduce boiler eciency and

cause it to malfunction.

Any pipes exposed to the elements or which could freeze

in winter must be insulated with suitable insulating

material.

CAUTION

Failure to follow the instructions provided in this section will

void the warranty and may result in property damage, re

or serious injury.

4. Installing the System Piping

4.1 Installing a Space Heating System

The primary and secondary heat exchangers of the Navien

NCB LHWE boiler are designed to attain the highest level of

heat transfer in a compact design. To accomplish this, the

heating water ows through a series of tubes (secondary

heat exchanger) and nned tubes (primary heat exchanger),

designed to maximise the heat transfer area. To maintain the

ecient and reliable operation of the heat exchangers, and to

avoid heat exchanger failure, it is critical to ensure the rules and

guidelines in this section are followed.

CAUTION

The installation must be made by suciently qualied

technicians, authorised to do so.

For correct installation, all the requirements and

recommendations described in the Regulation for

Heating Installations in Buildings (RITE) must be

complied with, together with all other national and/or

local regulations applicable at the time of installation.

Refer to the following illustration for a typical heating piping

example for the boiler.

Union

CH Flow

CH Return

Bottom View

Floor Heating Circuit or

Heating Circuit (Radiator)

Heating Supply

Adapter

Heating Return

Adapter

When connecting the space heating system, follow these

guidelines:

Tighten the connection valves with care to avoid damage.

Test the boiler for proper space heating ow and inspect for

leaks.

21Installing the System Piping

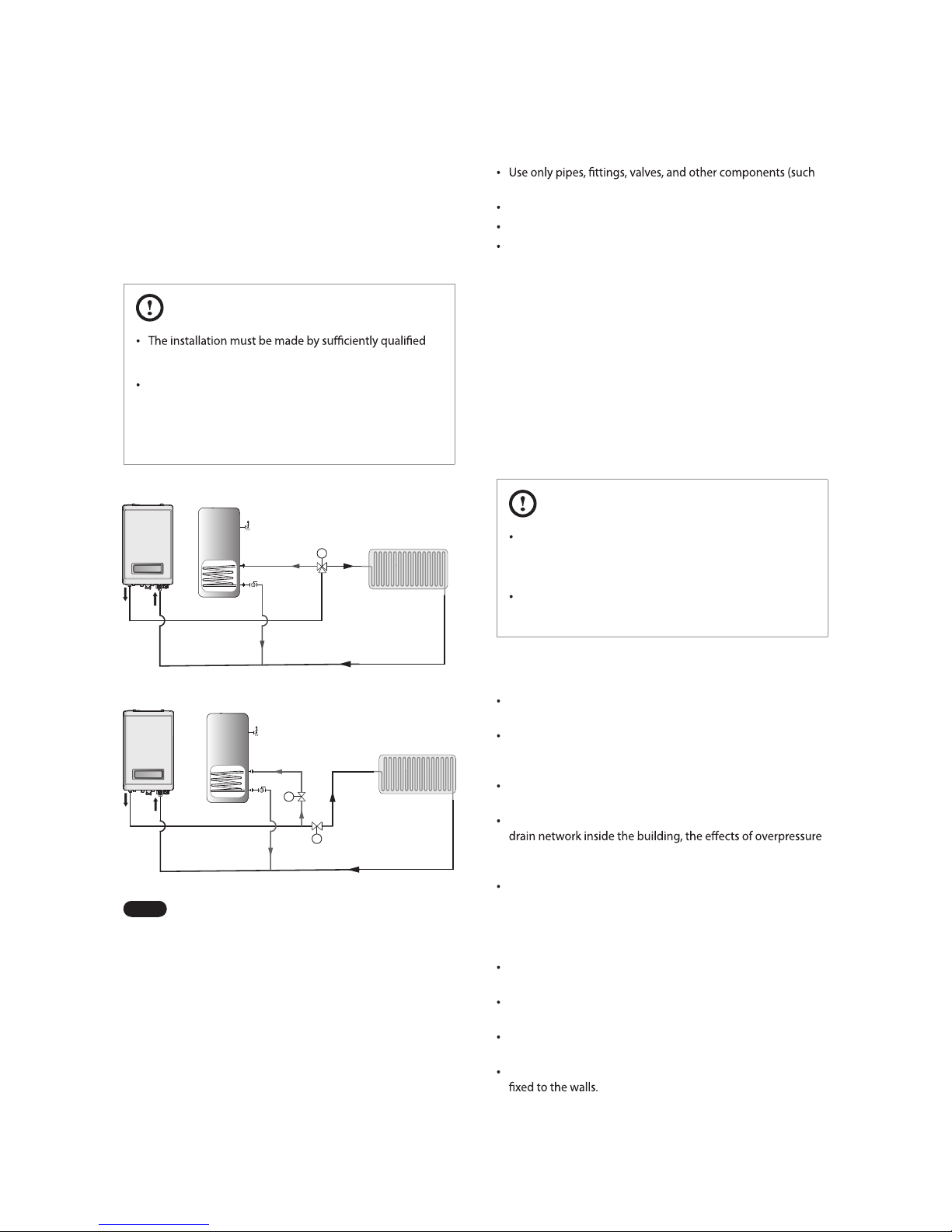

4.2 Installing a System Application

Refer to the following examples to properly implement a

system for space heating, DHW supply, or both. These examples

are provided to suggest basic guidelines when you installing

the boiler system. However, the actual installation may vary

depending on the circumstances, local building codes or

regulations.

CAUTION

technicians, authorised to do so.

For correct installation, all the requirements and

recommendations described in the Regulation for

Heating Installations in Buildings (RITE) must be

complied with, together with all other national and/or

local regulations applicable at the time of installation.

M

M

M

S Plan Layout

Y Plan Layout

Note

Refer to the “7. Setting the DIP Switches” and “11.5

Setting the Parameters” to control the boiler using the

external CH Controller and DHW Tank.

When installing the system, follow these guidelines:

as solder), that are approved for use in potable water systems.

Tighten the connection valves with care to avoid damage.

The external hydraulic bypass valve is required.

An additional expansion vessel must be installed to the

system in the central heating return.

4.3 Connecting the Condensate Drain

Line

The Navien NCB LHWE boiler creates condensation when it

operates. This condensation has an acidic pH of 3-5. Follow

all local codes and regulations when disposing of condensate

from the boiler. We recommend draining the condensate into

a laundry tub, as the alkali in laundry detergent will neutralise

the acid in the condensate. However, other suitable waste drain

locations may be used according to the local legislation.

CAUTION

Do not cap or plug the integrated condensate line. If

prevented from draining, condensate can damage the

boiler.

The condensate line must have a negative slope to drain

properly.

The requirements recommended for the condensate drain line

installation are as follows:

For correct condensate drain line installation, the tube must

have a minimum diameter of Ø21.5 mm.

The tube must be made of a material that can withstand

corrosion, e.g. PVC, PVC-U, ABS, PVC-C or PP. It must not be

made of metal.

For safety reasons, the end of the tube must be as close as

possible to the draining point.

When the condensate drainage is connected to a general

that could occur inside it must be taken into account,

installing suitable pressure release and ventilation elements.

The length of the tubes outside the building must be as short

as possible. They must also be installed with as much tilt as

possible. The tubes must be insulated if they are exposed

to extremly cold weather or blizzards. If the tubes are not

insulated, they must have a diameter of at least Ø32 mm.

The drain tube must have a minimum tilt of 2.5° downstream

of the boiler.

For tubes with Ø21.5 mm, the maximum permitted length is

3 metres.

If the appliance is installed in a non-heated premises, the tube

system must be treated as if it was an outdoor installation.

To prevent the risk of tripping, the outdoor tubes must be

22 Installing the System Piping

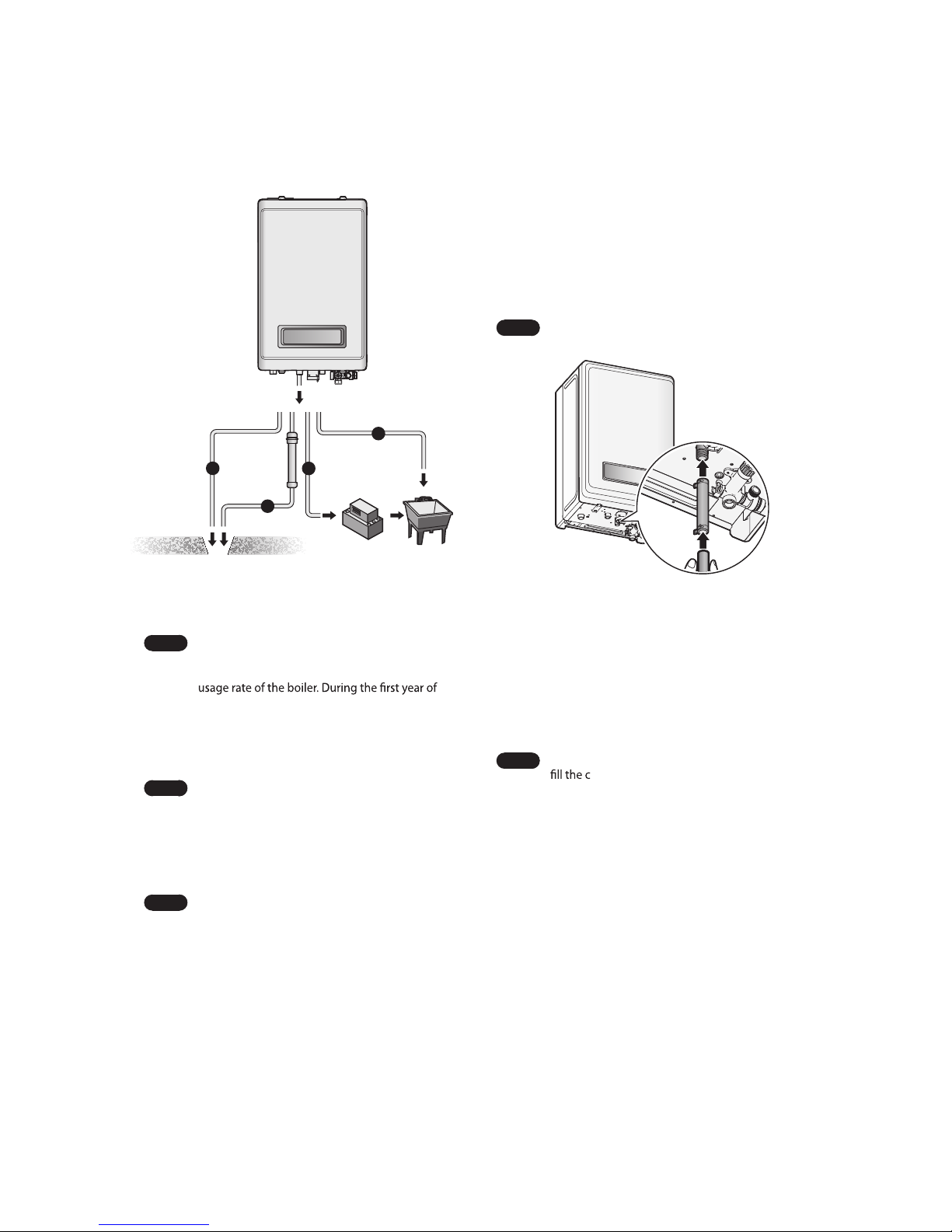

Before connecting the condensate drain, choose one of the

following disposal options:

a

b

c

d

a. From the boiler directly into an external drain.

b. From the boiler, through a neutralizing agent, and then

into an external drain.

Note

If you choose this option, the neutralizing agent

must be replaced periodically. Depletion of

the neutralising agent will vary, based on the

operation, the neutralizer should be checked

every few months for depletion and replaced as

needed.

c. From the boiler into a laundry tub.

Note

The bottom of the boiler must be higher than

the top of the laundry tub to use this option. The

condensate line must have a negative slope to

drain properly.

d. From the boiler into a condensate pump, and then into a

laundry tub.

Note

A pump can be used when there is a long

distance between the boiler and the laundry tub

or when the bottom of the boiler is lower than the

top of the laundry tub.

2. Place the free end of the drain line into an appropriate drain.

3. If you are using a condensate pump, ensure that the pump

allows for up to 3.78 LPH of drainage for each boiler in the

system.

4. If you are not using a condensate pump, ensure that the

drain line is pitched downward at a minimum slope of 6 mm

per 30 cm.

Note

Water must be poured into the exhaust connection to

ondensate trap.

To connect the condensate drain:

1. Connect a drain line to the condensate trap.

The condensate trap outlet will allow 21.5mm.

Use only corrosion-resistant material for the drain line,

such as PVC or CPVC. Do not reduce the size of the drain

line to less than 21.5mm.

The drain line can be connected to the condensate trap

using a condensate trap hose. The hose connection

must be secured with a hose clip.

Note

This hose is supplied along with the boiler.

23Installing the System Piping

4.4 Pressure Relief Valve

The requirements recommended for the pressure relief valve are

as follows:

The pressure relief valve is calibrated to be activated at a

maximum pressure of 3 bar, and all the pipes and connections

must therefore be able to withstand pressures of up to 3 bar.

Connect the pressure relief valve drain to a tube with a

diameter of at least Ø15 mm. It must tilt in a downstream

direction throughout its entire length, and the water must run

o to a suitable drain. It must be positioned so as not to cause

damage to cabling, electrical equipment or persons.

The drain must not be located above a window, entry door or

any other public access point. Bear in mind that boiling water

or steam could come out when draining.

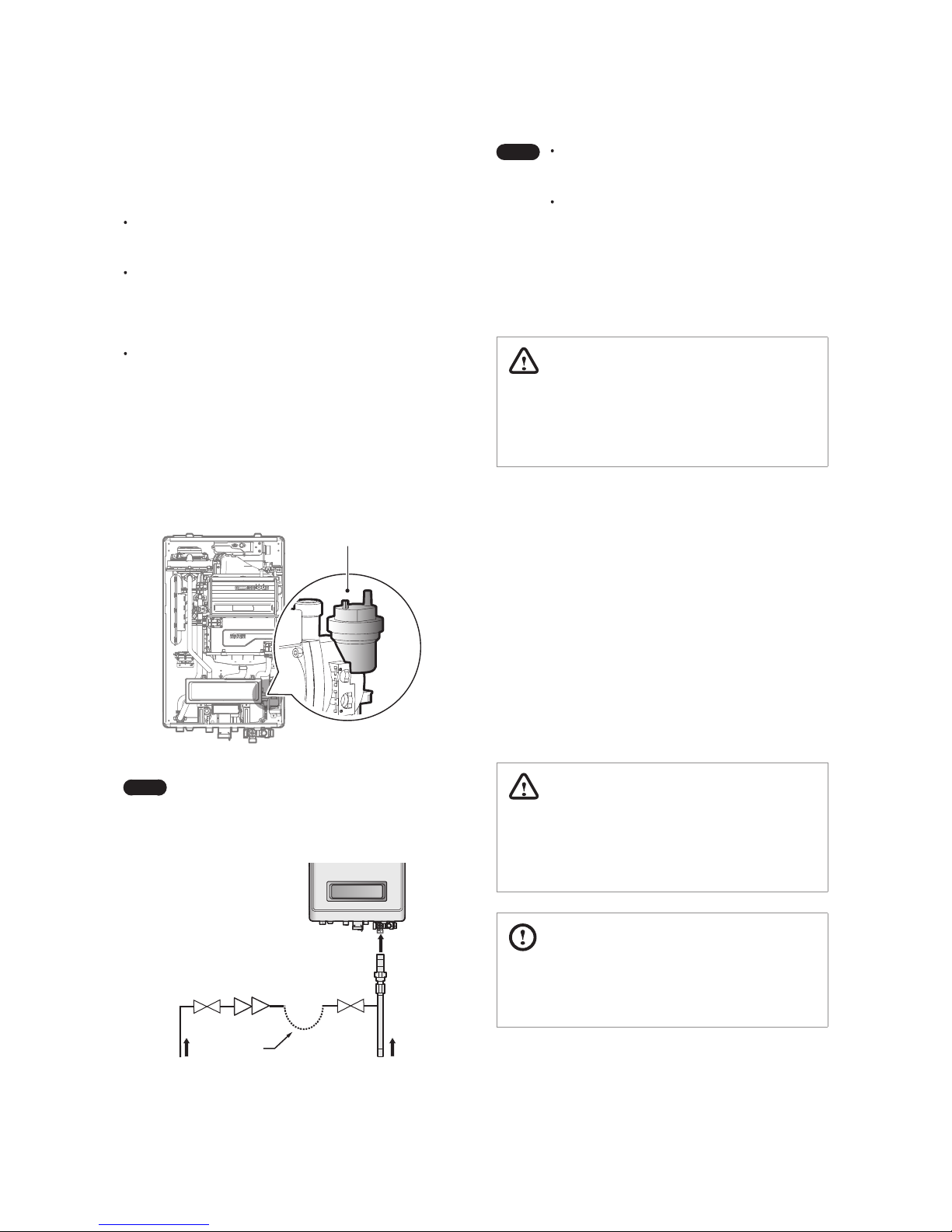

4.5 Filling the system

Before lling the boiler pipes, pull up the air ue cap to allow the

pipes to ll properly. Press the cap back in when the pipes are

full.

Air Flue Cap

Note

Ensure that the ue cap is tted before testing or

operating the system.

Refer to the following illustration for system ll.

Stop

Valve

Cold mains Inlet

Temporary

Loop

Space hating Return

Stop

Valve

Double

Check

Valve

Note

The system must be lled with approved

equipment and comply with all regulations for

system ll.

To perform an air purge after initially lling the

boiler pipes, the pump will run for 5 minutes and

20 seconds. The boiler will operate normally after

performing an air purge.

4.6 Testing the Water System

WARNING

Ensure that the boiler is full of water before ring the burner.

Operating the unit without lling it will damage the boiler.

Such damage is not covered by the warranty, and may result

in property damage or severe personal injury.

Perform a ll test after installing the boiler’s water system to

make sure that the system has been installed properly. Follow

the instructions below to perform a ll test on the water system.

1. Close the manual air ues and the boiler drain valve.

2. Fill the boiler. The correct pressure will vary with each

application.

3. If the pressure is lower than the minimum pressure set (1 bar

by default), error code E02 will appear on the display.

4. Fill the boiler with more water until the error message

disappears.

5. At initial ll and during boiler start

-up and testing, check

the system thoroughly for leaks. Repair any leaks before

proceeding further.

WARNING

Eliminate all system leaks. The continual introduction of fresh

makeup water will reduce boiler life. Minerals can build up in

the heat exchanger, reducing heat transfer, overheating the

heat exchanger and causing heat exchanger failure.

CAUTION

Before operating the boiler for the rst time, ensure that the

boiler system is lled with water. Purge the air inside the

system to avoid damage to the boiler.

WARNING

If a gas type other than the one specied on the boiler

reference plate is used, it could cause a re or even an

explosion.

It is important to ensure that the gas supply is suitable

for the type and capacity of the boiler.

Thoroughly check the seal and draining of the entire

installation, as a gas leak could cause serious damage.

DANGER

Gas leaks can cause explosions resulting in serious

personal and material damage.

Keep all doors and windows open while you are bleeding

the gas pipes and put out any cigarettes, ames or other

possible source of ignition.

For the installation of any type of gas, the installer must be

authorised by the Ministry of Industry and strictly follow the

applicable Gas Regulations. The gas installation must comply

with the Gas Installation Regulation.

However, the following recommendations must be complied

with, at the least:

Before installing the gas pipes, check the type of gas is

compatible with the boiler.

Check that the gas meter in the home can measure the rate of

gas supply required.

The gas pipe diameter is not determined by the boiler

connection. It should be calculated in accordance with its

length and consequently its pressure drop.

The pipes must be directly connected to the main gas supply

pipe, not connected in parallel to other gas appliances.

Check there are no leaks from the installation.

The gas supply company is solely responsible for connecting

the gas meter to the gas installation.

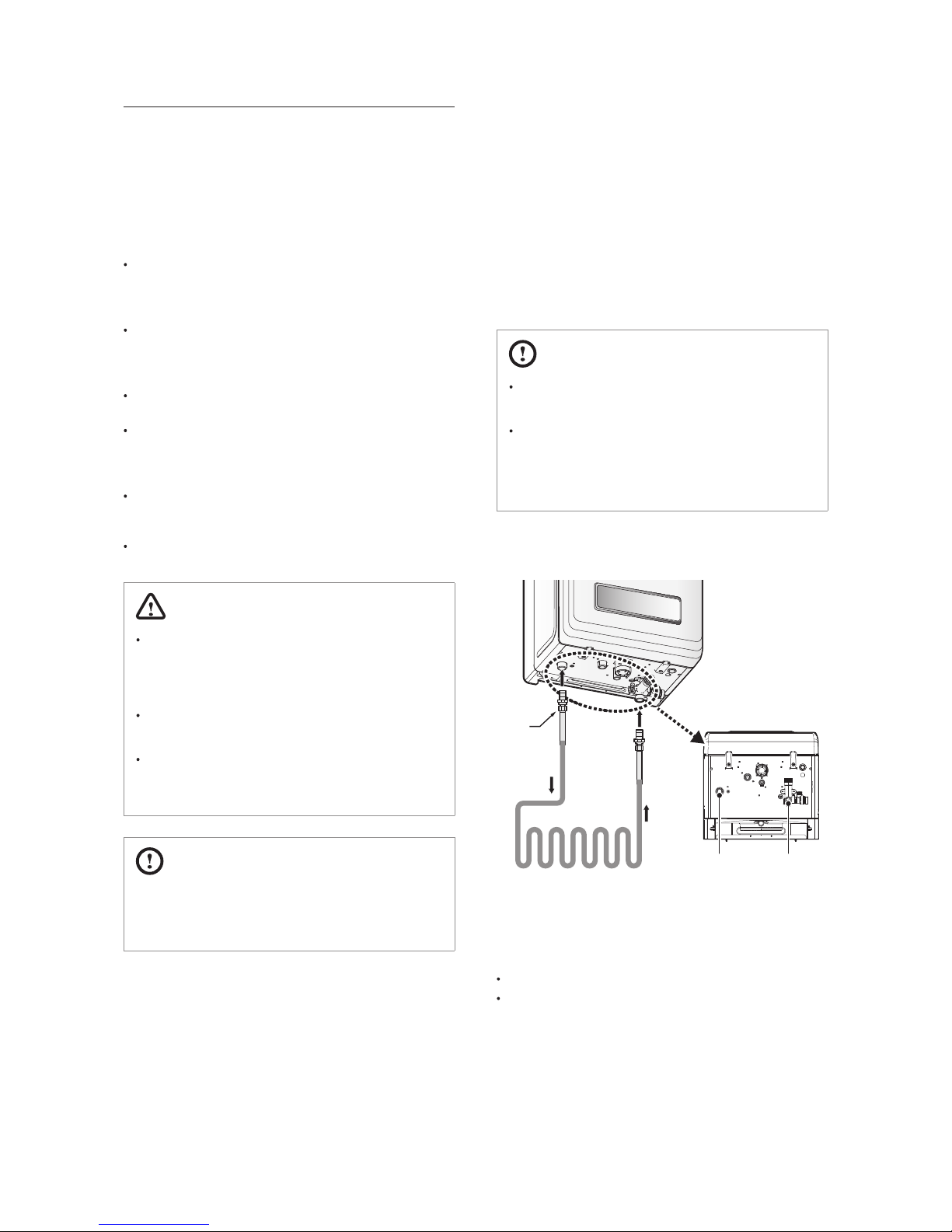

To connect the gas supply:

1. Connect the gas supply pope to the connection located on

the underside of the apliance.

2. After completing the gas installation, check there are no

leaks and bleed the air from all the pipes, following the

procedures described in the applicable standards to this

respect.

Gas Shuto Valve

Gas Supply

Union

Bottom View

Gas Inlet Adapter

Union

5. Connecting the Gas Supply

24 Installing the System Piping

Loading...

Loading...