Navien NCB-150E, NCB-180E, NCB-210E, NCB-240E Operation Manual

WARNING

If the information in these instructions is not followed exactly, a re or explosion may result, causing

property damage, personal injury or death.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other

appliance.

What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service agency or the gas supplier.

The installation must conform with local codes or, in the absence of local codes, the National Fuel Gas Code,

ANSIZ223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Code.

H

NSF/ANSI 372

Keep this manual near this boiler for future reference whenever

maintenance or service is required.

* The wetted surface of this product contacted by consumable water contains less than

one quarter of one percent (0.25%) of lead by weight.

Installation & Operation Manual

NCB-E Condensing Combi-Boilers

Model

NCB-150E

NCB-180E

NCB-210E

NCB-240E

2

Requirements for the State of Massachusetts

NOTICE BEFORE INSTALLATION

This appliance must be installed by a licensed plumber or gas fitter in accordance with the Massachusetts Plumbing and Fuel Gas

Code 248 CMR Sections 2.00 and 5.00.

IMPORTANT: In the State of Massachusetts (248 CMR 4.00 & 5.00)

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment,

the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery backup is

installed on the floor level where the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the

services of qualified licensed professionals for the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery backup may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision cannot be met at the time of completion of installation, the owner shall have a

period of thirty (30) days to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery

operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of

eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less than onehalf (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of

248 CMR 5.08(2)(a)1 through 4.

Contents 3

Contents

Safety Information 4

1. About the Boiler

7

1.1 Items Included 7

1.2 Accessories 7

1.3 Specifications

8

1.4 Components

10

1.5 Dimensions 12

1.6 Rating Plate

13

2. Installing the Boiler 14

2.1 Choosing an Installation Location 14

2.2 Mounting the Boiler to the Wall 16

3. Installing the System Piping 17

3.1 Installing a Space Heating System 17

3.2 Installing a Domestic Hot Water (DHW) System

20

3.3 Connecting the Condensate Drain

23

3.4 System Fill Connection

26

3.5 Testing the Water System

27

3.6 Examples of System Applications 27

4. Installing a Cascading System 32

4.1 Connecting Water Supplies 32

4.2 Connecting the Communication Cables 33

4.3 Configuring the Communication Settings

33

5. Connecting the Gas Supply 35

5.1 Gas Pipe Sizing Tables 37

5.2 Measuring the Inlet Gas Pressure 38

6. Venting the Boiler 40

6.1 Selecting a Vent Type 40

6.2 Selecting Vent Pipe Materials 44

6.3 Measuring Vent Length

45

7. Setting the DIP Switches 48

7.1 PCB DIP Switches 48

7.2 Front Panel Dip Switches 49

8. Connecting the Power Supply 50

9. Installation Check list

51

10. Operating the Boiler

54

10.1 Turning the Boiler On or Off 54

10.2 Adjusting the Temperature

54

10.3 Viewing Basic Information 55

10.4 Setting the Operation Mode

56

10.5 Setting the Parameters 56

10.6 Resetting the Boiler

63

11. Appendixes 64

11.1 Gas Conversion 64

11.2 Wiring Diagram

70

11.3 Ladder Diagram 71

11.4 Component Assembly Diagrams and Parts Lists

72

11.5 Outdoor Temperature Sensor (Optional)

80

11.6 Outdoor Reset Control (Available with Optional

Outdoor Temperature Sensor)

80

4 Safety Information

The following safety symbols are used in this manual. Read and

follow all safety instructions in this manual precisely to avoid

unsafe operating conditions, fire, explosion, property damage,

personal injury, or death.

DANGER

Indicates an imminently hazardous situation which, if not

avoided, could result in severe injury or death.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in property damage.

DANGER

If you smell gas:

Ɣ

Do not try to light any appliance.

Ɣ

Do not touch any electrical switches or use landline phones.

Ɣ

From a neighbor’s phone, call your gas provider and follow

their instructions.

Ɣ

If you cannot reach your gas provider, call the fire

department.

Ɣ

Do not return to your home until authorized by your gas

supplier or the fire department.

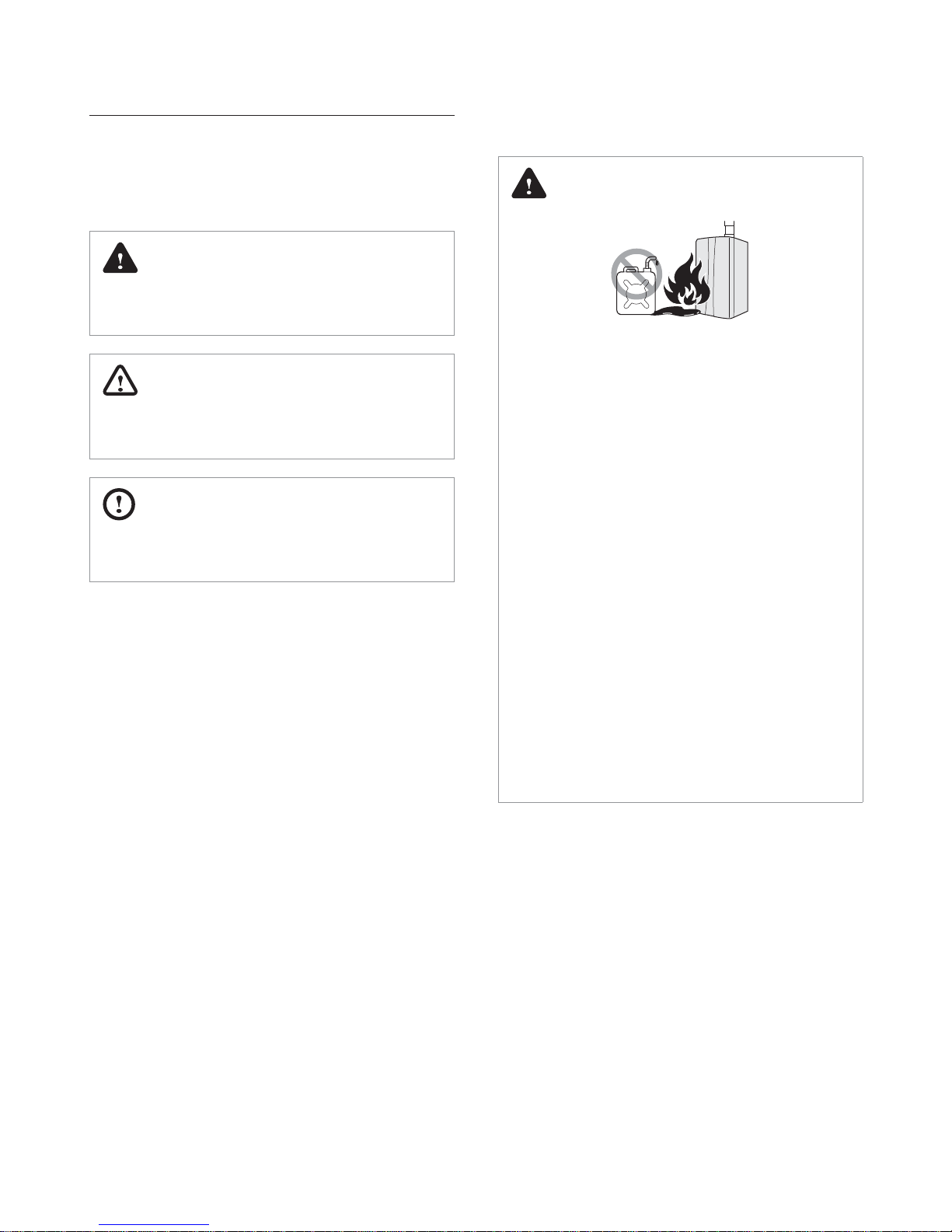

Do not use or store flammable products, such as gasoline,

solvents, or adhesives in the same room or area as the

boiler.

Ɣ

The boiler has a main burner flame that can turn on at

any time and can ignite flammable vapors. Vapors from

flammable liquids can explode and catch fire, causing death

or severe burns.

Ɣ

Vapors cannot be seen and are heavier than air. They can

travel long distances along the ground and can be carried

from other rooms to the boiler’s main burner flame by air

current.

Ɣ

Keep all flammable products far away from the boiler and

store them in approved containers. Keep the containers

closed tightly and out of the reach of children and pets.

Safety Information

Safety Information 5

CAUTION

Ɣ

Do not turn on the boiler unless the water and gas

supplies are fully opened.

Doing so may damage the boiler.

Ɣ

Do not turn on the water if the cold water supply shutoff valve is closed.

Doing so may damage the boiler.

Ɣ

Do not use this boiler for anything other than its

intended purpose, as described in this manual.

Ɣ

When servicing the controls, label all wires prior to

disconnecting them.

Failure to do so may result in wiring errors, which can lead to

improper or dangerous operation. Verify proper operation

after servicing.

Ɣ

Do not use unapproved replacement or accessory parts.

Doing so may result in improper or dangerous operation

and will void the manufacturer’s warranty.

Ɣ

Do not place anything in or around the vent terminals,

such as a clothes line, that could obstruct the air flow in

or out of the boiler.

Ɣ

This boiler has been approved for use in the USA and

Canada only.

Using the boiler in any other country will void the

manufacturer’s warranty.

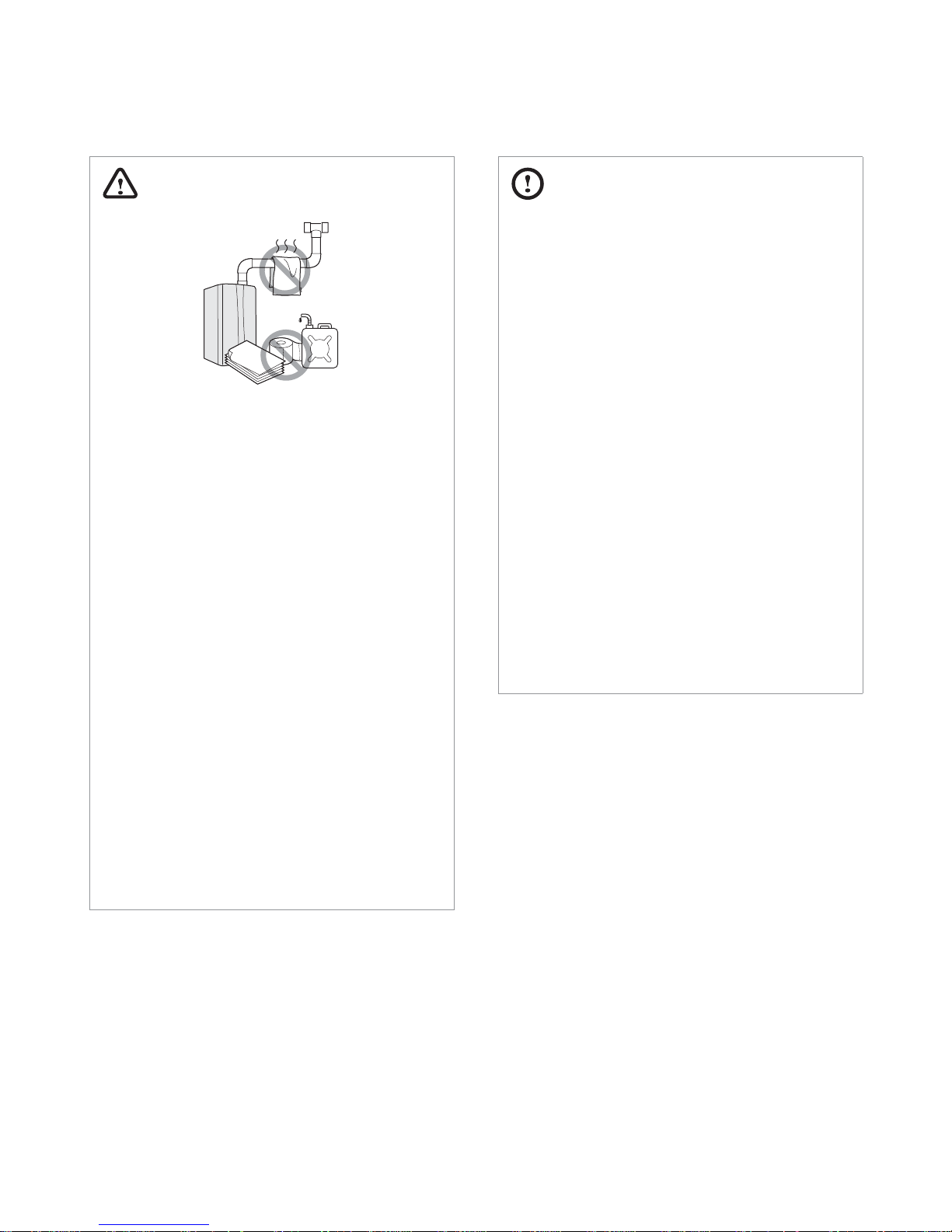

WARNING

Ɣ

Do not store or use gasoline or other flammable liquids

near this boiler.

Doing so may result in fire or explosion.

Ɣ

Do not place combustibles, such as newspapers or

laundry, near the boiler or venting system.

Doing so may result in a fire.

Ɣ

Do not place or use hair sprays, spray paints, or any other

compressed gases near the boiler or venting system,

including the vent termination.

Doing so may result in fire or explosion.

Ɣ

Do not remove the front cover unless the power to the

boiler is turned off or disconnected.

Failure to do so may result in electric shock.

Ɣ

Do not operate the boiler with the front cover opened.

Doing so may result in fire or carbon monoxide (CO)

poisoning, which may result in property damage, personal

injury, or death.

Ɣ

Do not operate this boiler without proper venting.

Doing so may result in fire or carbon monoxide (CO)

poisoning, which may result in property damage, personal

injury, or death.

Ɣ

Do not touch the power cord or internal components of

the boiler with wet hands.

Doing so may result in electric shock.

6 Safety Information

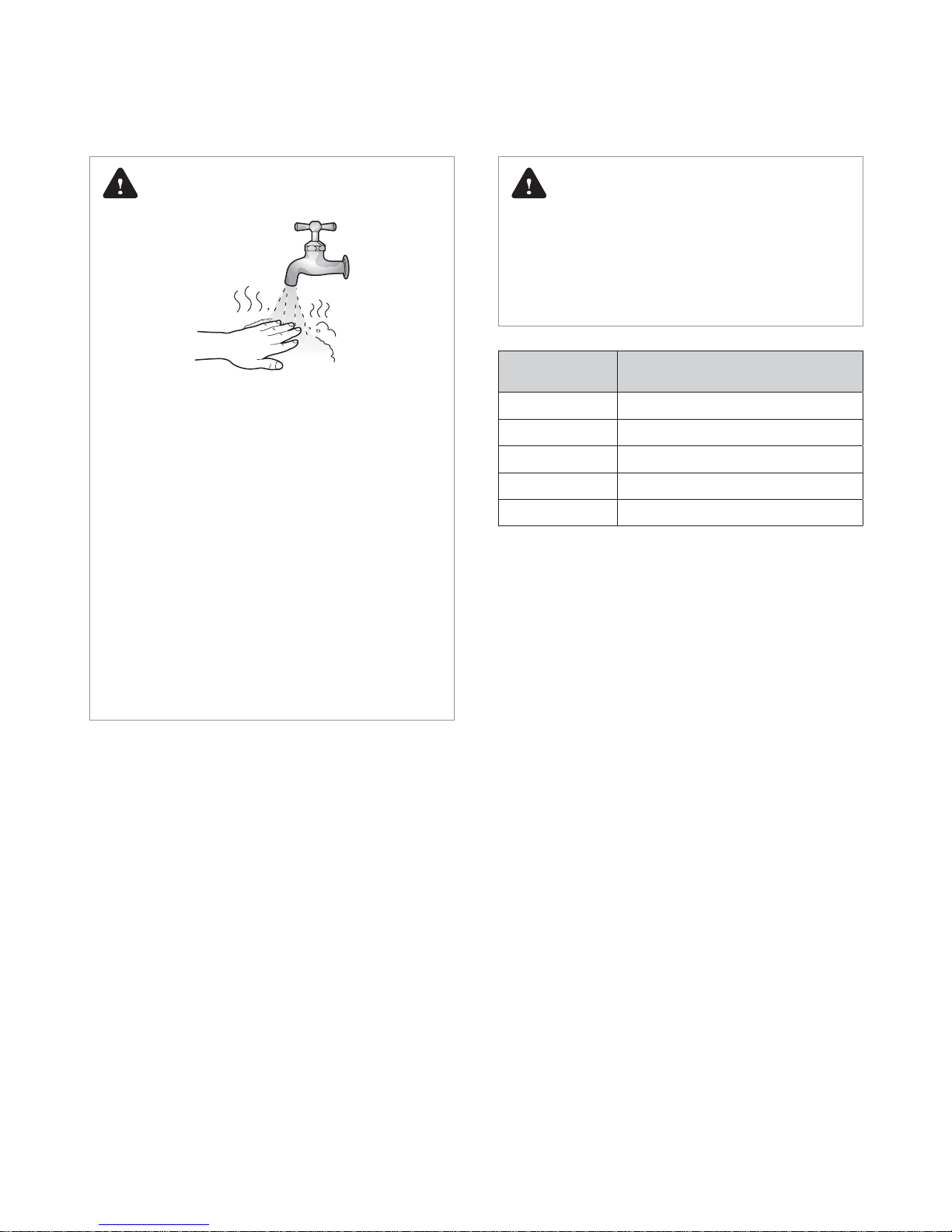

DANGER

This boiler’s water temperature is set to 120°F (49°C) at the

factory for your safety and comfort. Increasing the temperature

increases the risk of accidental scalding. Water temperatures at

or above 125°F (52°C) can cause instant scalding, severe burns,

or death. Before you decide to change the temperature setting,

read the following charts carefully.

Water

Temperature

Time in which a young child can suffer a

full thickness (3rd degree) burn

160°F (70°C) Less than 1 second

140°F (60°C) 1 second

130°F (55°C) 10 seconds

120°F (49°C) 10 minutes

100°F (37°C) very low scald risk

DANGER

HOT

BURN

To prevent burns:

Ɣ

Use the lowest operating temperature setting necessary to

provide comfortably-hot water.

Ɣ

If your household has children or elderly or disabled

residents, consider using a lower temperature setting.

Ɣ

Read all the instructions in this manual carefully before

changing the temperature setting.

Ɣ

Feel the water before using it on children, the elderly, or the

disabled.

Ɣ

If it is necessary to set the water temperature above 125°F

(52°C), consider installing a thermostatically-controlled

mixing valve or temperature-limiting valve. Contact a

licensed plumber or your local plumbing authority for more

information.

About the Boiler 7

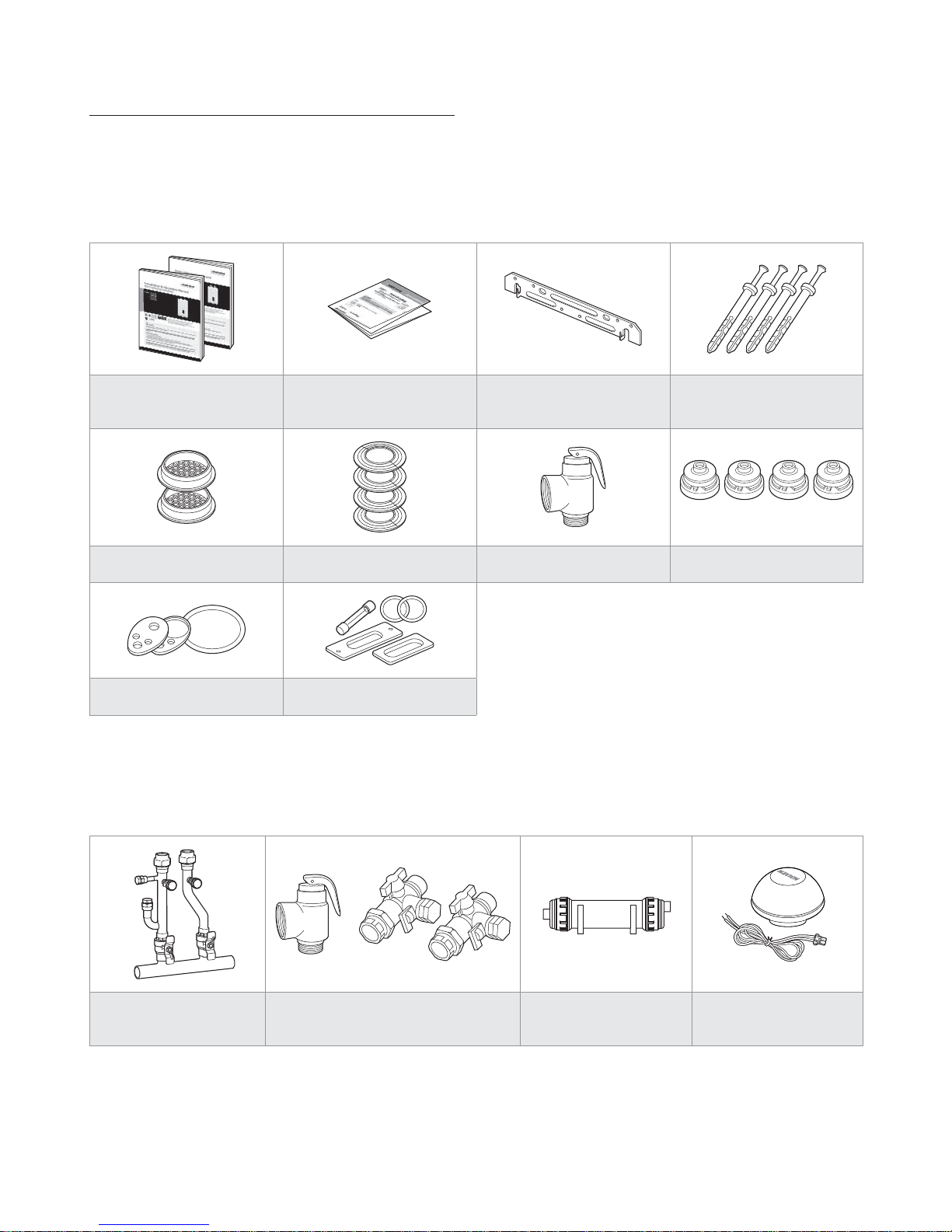

1.1 Items Included

When you open the box, you will find the following items with the boiler. Check the box for each of the following items before installing the

boiler.

Installation & Operation Manual,

User’s Information Manual

Quick Installation Manual Wall Mounting Bracket Tapping Screws & Anchors

2 in Vent Termination Caps 2 in Wall Flanges Pressure Relief Valve, Heating Flow Restrictors

Conversion Kit Spare Parts

1.2 Accessories

The following optional accessories are available for the boiler:

Navien Manifold System

Plumb Easy Valve Set

(Pressure Relief Valve, DHW)

Condensate Neutralizer

Outdoor Temperature

Sensor with Cable

1. About the Boiler

8 About the Boiler

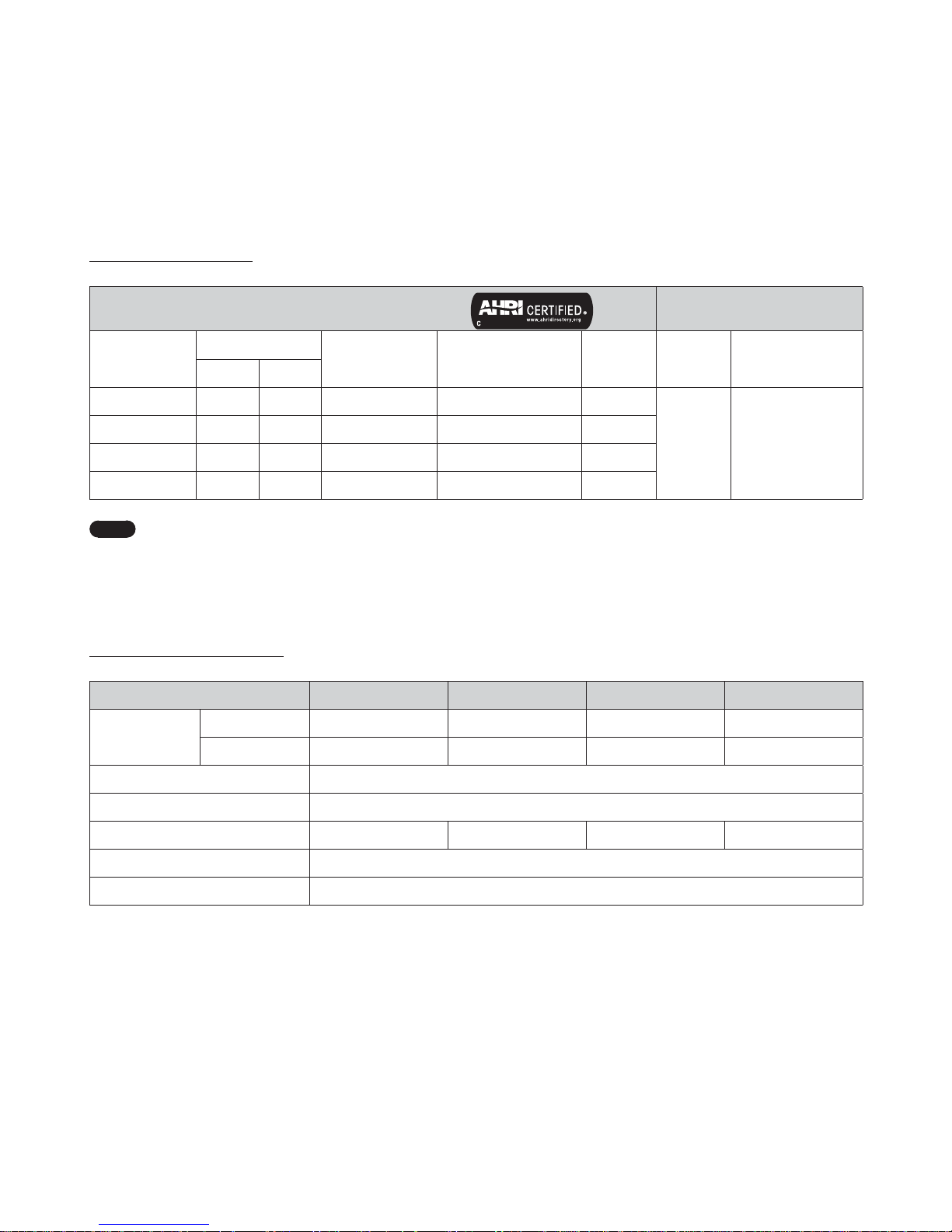

1.3 Specifications

The following tables list the specifications for the boiler. Additional specifications about water, gas, electric, and air supplies (venting) appear in

the Installation section.

Space Heating Specifications

Navien Combination Boiler

Space Heating Ratings

Other Specifications

Model Number

1

Heating Input, MBH

Heating Capacity

2

,

MBH

Net AHRI Rating Water3,

MBH

AFUE

2

, %

Water

Pressure

Water Connection

size (Supply, Return)

Min Max

NCB-150E 12 60 56 49 95

12-30 psi 1 in NPT

NCB-180E 14 80 75 65 95

NCB-210E 18 100 94 82 95

NCB-240E 18 120112 97 95

Note

1. Ratings are the same for natural gas models converted to propane use.

2. Based on U.S. Department of Energy (DOE) test procedures.

3. The net AHRI water ratings shown are based on a piping and pickup allowance of 1.15. Consult Navien before selecting a boiler

for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping

system, etc.

Domestic Hot Water Specifications

Item NCB-150E NCB-180E NCB-210E NCB-240E

Input Ratings

Min 12,000 BTU/H 14,000 BTU/H 18,000 BTU/H 18,000 BTU/H

Max 120,000 BTU/H 150,000 BTU/H 180,000 BTU/H 199,900 BTU/H

Water Pressure 15-150 psi

Minimum Flow Rate 0.5 GPM (1.9 L/m)

Flow Rate 77°F (43°C) Temp. Rise 3. GPM 3.4 GPM 4.0 GPM 4.5 GPM

DHW Supply Connection Size

3

/4 in NPT

Cold Water Input Connection Size

3

/4 in NPT

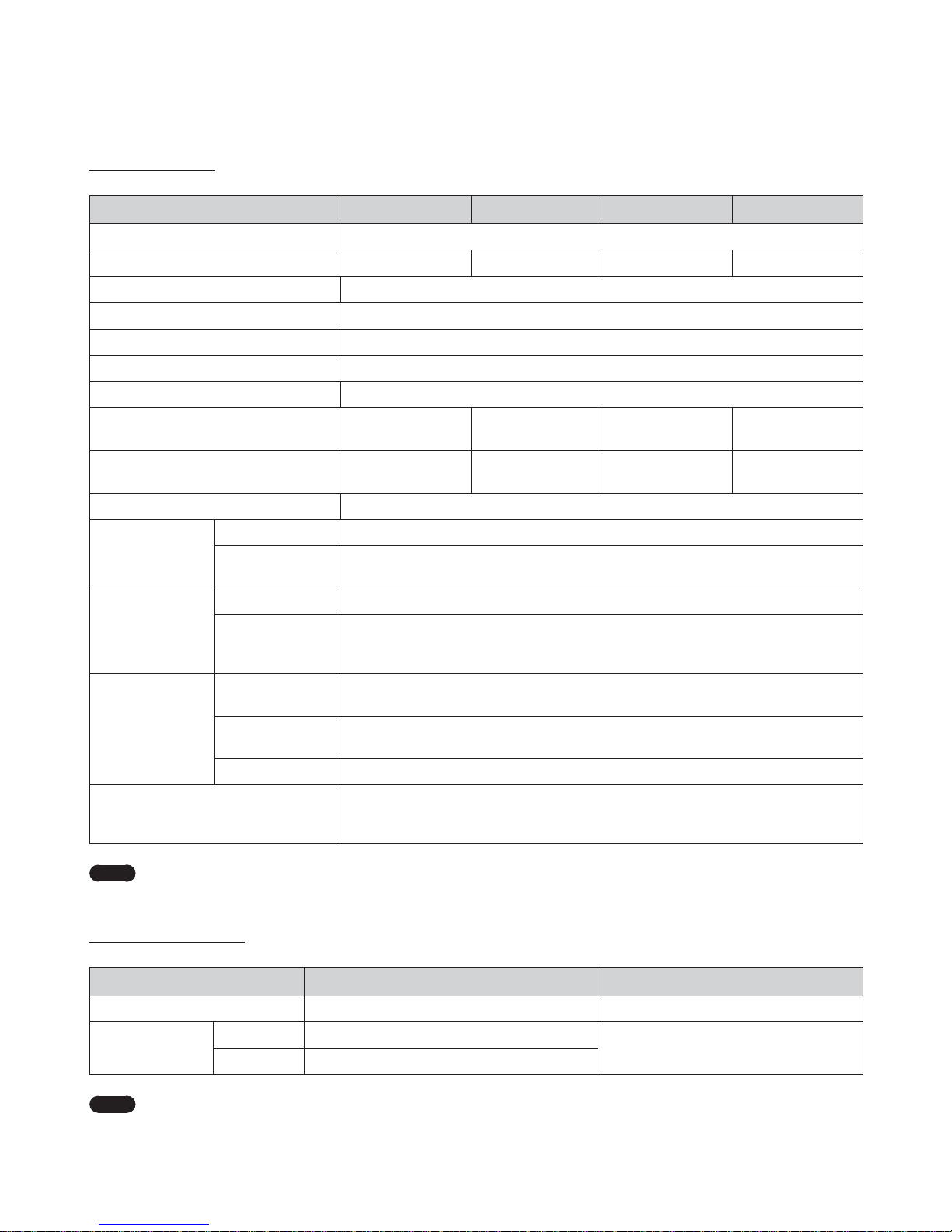

About the Boiler 9

General Specications

Item NCB-150E NCB-180E NCB-210E NCB-240E

Dimensions 17 in (W) x 28 in (H) x 13 in (D)

Weight 66 lbs (30 kg) 74 lbs (34 kg) 84 lbs (38 kg) 84 lbs (38 kg)

Installation Type Indoor Wall-Hung

Venting Type Forced Draft Direct Vent

Ignition Electronic Ignition

Natural Gas Supply Pressure (from source) 3.5 in-10.5 in WC

Propane Gas Supply Pressure (from source) 8.0 in-13.5 in WC

Natural Gas Manifold Pressure (min/max)

-0.09 in WC /

-0.34 in WC

-0.07 in WC /

-0.66 in WC

-0.05 in WC /

-0.36 in WC

-0.06 in WC /

-1.20 in WC

Propane Gas Manifold Pressure (min/max)

-0.04 in WC /

-0.30 in WC

-0.07 in WC /

-0.66 in WC

-0.10 in WC /

-0.66 in WC

-0.03 in WC /

-0.98 in WC

Gas Connection Size

3

/4 in NPT

Power Supply

Main Supply 120V AC, 60Hz

Maximum Power

Consumption

200W (max 2A)

Materials

Casing Cold-rolled carbon steel

Heat Exchangers

Primary Heat Exchanger: Stainless Steel

Secondary Heat Exchanger: Stainless Steel

Domestic Water Heat Exchanger: Stainless Steel

Venting

Exhaust

2 in or 3 in PVC, CPVC, Polypropylene

2 in or 3 in Special Gas Vent Type BH (Class III, A/B/C)

Intake

2 in or 3 in PVC, CPVC, Polypropylene

2 in or 3 in Special Gas Vent Type BH (Class III, A/B/C)

Vent Clearances 0 in to combustibles

Safety Devices

Flame Rod, APS, Gas Valve Operation Detector, Ignition Operation Detector, Water

Temperature High Limit Switch,

Exhaust Temperature High Limit Sensor

Note

This unit may be installed at elevations up to 10,100 ft (3,078 m) for use with Natural Gas, and up to 4,500 ft (1,370 m) for use with

Propane.

Temperature Setting Range

Item Temperature Setting Range Remarks

DHW 89°F-140°F (30°C-60°C)

Space Heating

Supply 120°F-180°F (48.5°C-82°C)

Finned Tube Baseboard (Default)

Return 101°F-147°F (38°C-63.5°C)

Note

For more information about space heating temperature setting range, refer to “Types of Heat Load” on page 58.

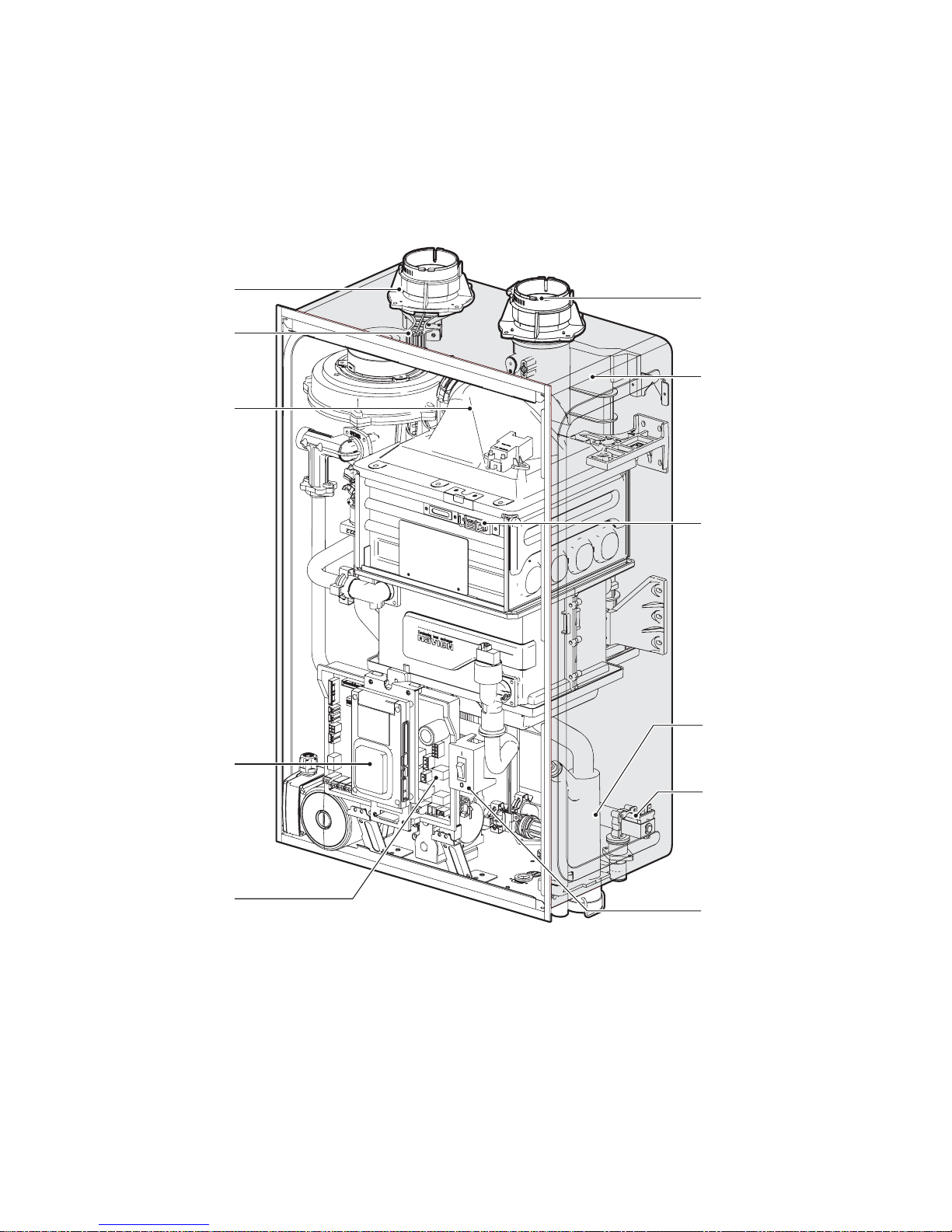

10 About the Boiler

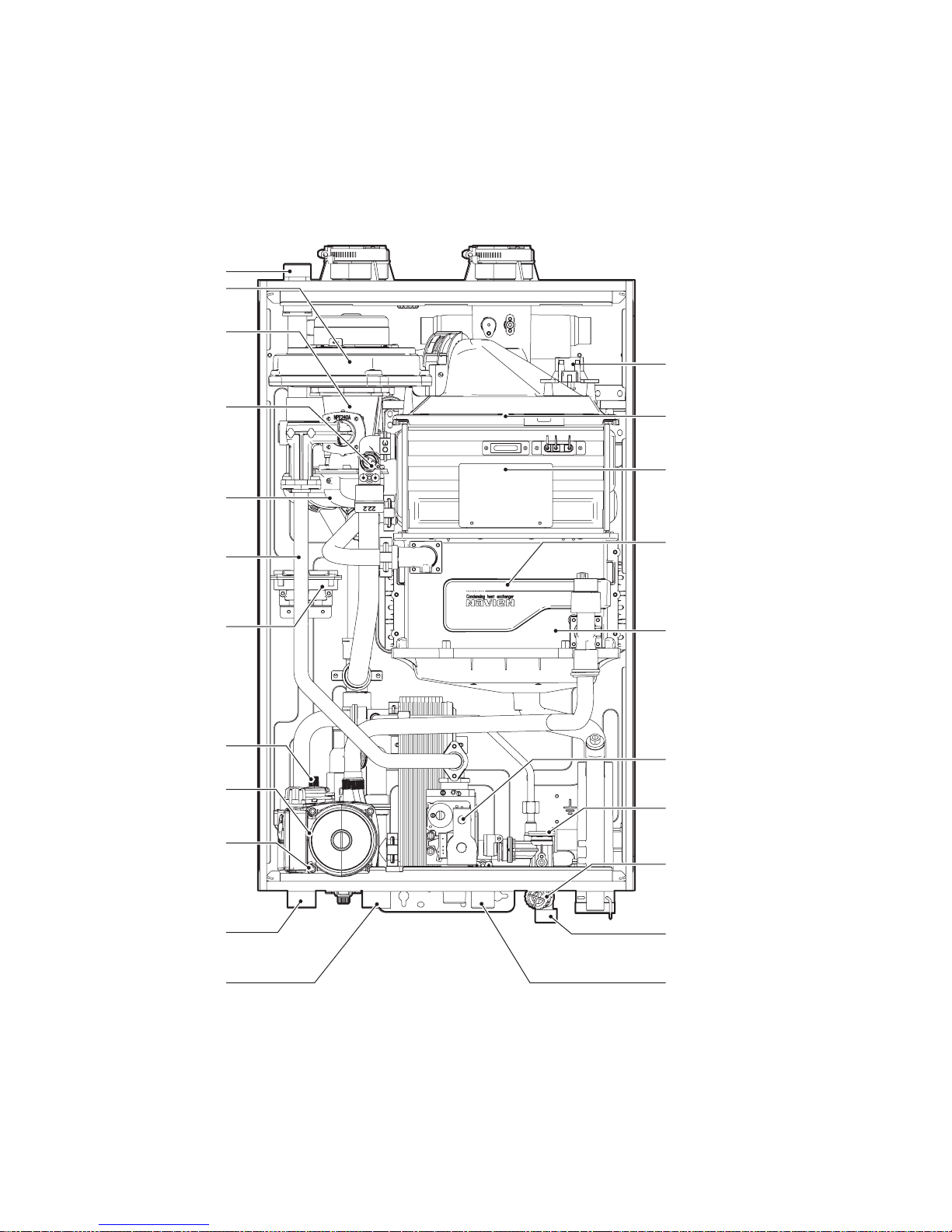

1.4 Components

The following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the

Appendixes.

Intake Air

Air Filter

Mixing Chamber

Front Panel

Exhaust

Flue Duct

Ignitor & Flame Rod

Auto Feeder

(Make-up water)

Condensate Trap

PCB

Power Switch

About the Boiler 11

Air Vent

Fan & Motor

Ignition Transformer

Dual Venturi

Premix Burner

Air Pipe

Primary Heat Exchanger

Gas Pipe

Secondary Heat Exchanger

Circulation Pump

Flow Sensor

Pressure Sensor (LWCO)

3-Way Valve

DHW Inlet Filter

(with built-in flow restrictor)

Space Heating

Supply

DHW Inlet

Space Heating

Return

DHW Outlet

Gas Valve

APS

High Limit Switch

Pressure Relief Valve Adapter

12 About the Boiler

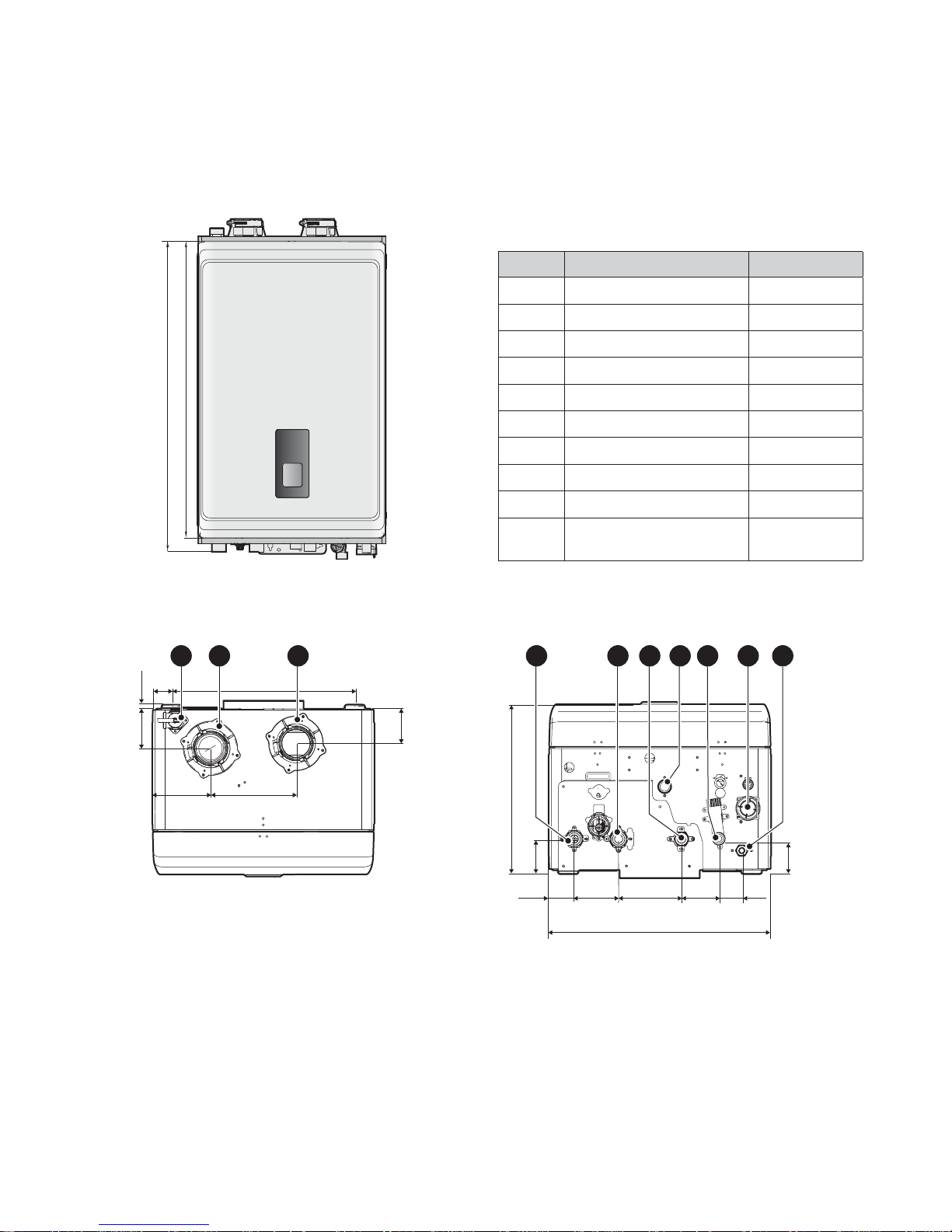

1.5 Dimensions

The following diagrams show the dimensions of the boiler and the table lists the supply connections.

27.4" (695mm)

28.8” (731mm)

Supply Connections

Description Diameter

A Pressure Relief Valve Adapter

3

/4 in

B Air Intake 2 in

C Exhaust Gas Vent 2 in

D Space Heating Supply 1 in

E Space Heating Return 1 in

F Hot Water Outlet (DHW)

3

/4 in

G Gas Supply Inlet

3

/4 in

H Cold Water Inlet (DHW)

3

/4 in

I Condensate Outlet

1

/2 in

J

Auto Feeder Inlet (Make-up

Water)

1

/2 in

Overhead View

3” (77 mm)

6.7” (170 mm)

4.5” (115 mm)

0.4“ (10 mm)

1.5”

(38 mm)

14.3” (364 mm)

2.6” (67 mm)

A

B C

Supply Connections

13“ (330 mm)

3.5”

(88 mm)

4.8”

(123 mm)3”(76 mm)

1.8”

(46 mm)

2”

(50 mm)

17.3” (440 mm)

2.4” (61 mm)

3.0” (77 mm)

D F J

E

H

IG

About the Boiler 13

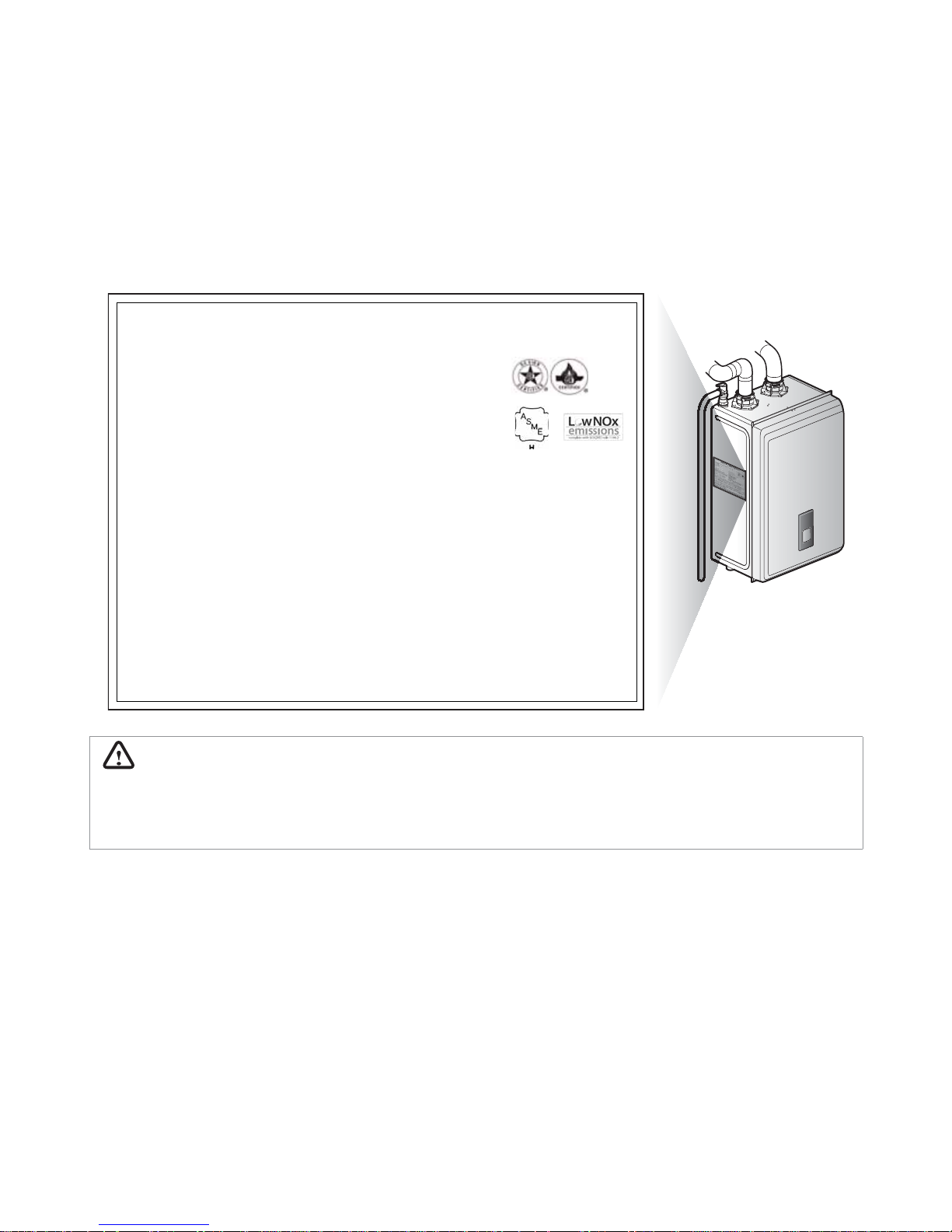

1.6 Rating Plate

The Navien NCB-E boilers come from the factory configured for use with Natural Gas (NG). Before starting the installation, check the rating

plate located on the side of the boiler to ensure that the boiler matches the gas type, gas pressure, water pressure, and electrical supply

available in the installation location. If the boiler does not match each of these ratings, do not install the boiler. If conversion to Propane

Gas is required, the included gas conversion kit must be used. Refer to “11.1 Gas Conversion” for details.

Rating Plate, *Plaque Signalétique

Combination Boiler *Chaudière combinaison

Navien, Inc.

20 Goodyear, Irvine, CA 92618

Tel: 1-800-519-8794

Direct vent indoor installation, * Évacuation directe installation intérieure

Model No., *Numéro de modèle Type of Gas, *Type de gaz

NCB-240E NG

Max. Input Rating (DHW),*Entrée GPL max. Min. Input Rating,*Débit calorifique max.

199,900 Btu/h 18,000 Btu/h

Max. Input Rating (Heating),*Entrée GPL max. Heating Capacity, *Capacité de chauffage

120,000 Btu/h 112,000 Btu/h

Category of boiler, *Catégorie de chaudière Net AHRI Rating, *Régime de AHRI

Category IV 97,000 Btu/h

Max. Inlet Gas Pressure, *Pression max. de gaz d’entrée 10.5 Inches W.C. *pouces W.C.

Min. Inlet Gas Pressure, *Pression min. de gaz d’entrée 3.5 Inches W.C. *pouces W.C.

Manifold Pressure, *Pression d’admiss

ion -1.20 Inches W. C. *pouces W.C.

Electrical Rating, *Régime nominal électrique AC *c.a. 120 Volts 60Hz Use less than 2 Amp, *Utilise moins de 2A

Minimum relief valve capacity, *Capacité minimaum soupape. 189 lbs/hr ANSI Z21.13b-2014 · CSA 4.9b-2014

Orifices necessary for LP conversion are provided. *Les injectures nécessaires à la conversion au GPL sont fournis.

Failure to use the correct gas can cause pro

blems which can result in death, serious injury or property damage. *Le fait de ne pas

utiliser le bon gaz peut causer des problèmes qui peuvent mener à la mort, causer des blessures graves ou endommager la propriété.

Consult your installation manual for more information. *Consultez votre manuel d’installation pour plus d’information.

This appliance is certified for use at altitudes up to 4,500 ft (1,370 m) in accordance to the latest CAN/CGA 2.17-High Altitude

Installation procedures at normal manifold pressure. For installation instructions at altitudes higher than 4,500 ft, please contact

Navien. *Cet appareil est certifié pour une utilisation à des altitudes de 0 à 4,500 pieds (1,370 m) conformément aux toutes les procédures

d’installation à haute altitude CAN/CGA 2.17 à une pression normale. Pour les installations à élévations en haut de 4,500 pieds, appeler le

bureau de Navien.

This appliance must be installed in accordance with local codes or in the absence of local codes, the most recent edition of

National Fuel Gas Code, ANSI Z223. 1, in Canada use CAN/CGA B149. 1 or 2 installation codes for Gas Burning Appliances.

*Cet appareil doit être installé conformément aux codes locaux, ou

s’il n’y a pas de codes locaux, la plus récente version du National Fuel

Gas Code des É.-U., ANSI Z223. 1, au Canada utilisez les codes d’installation CAN/CGA B149. 1 ou 2 pour les appareils à gaz.

FOR YOUR SAFETY *POUR VOTRE SÉCURITÉ

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other gas appliances. *Ne rangez

pas et n'utilisez pas d'essence ou d'autres liquides ou vapeurs inflammables près de cet appareil ou de tout autre appareil électroménager.

WARNING

Ensure that the gas type and power source specifications match what is listed on the rating plate. Using a different gas type will cause

abnormal combustion and boiler malfunction. Using abnormally high or low AC voltage may cause abnormal operation, and may reduce

the life expectancy of the product.

This appliance complies with the requirements of SCAQMD Rule 1146.2 for NOx emissions of 14 ng/J or 20 ppm at 3% O

2

.

14 Installing the Boiler

2.1 Choosing an Installation Location

When choosing an installation location, you must ensure that the

location provides adequate clearance for the boiler, adequate

venting and drainage options, and sufficient access to gas, water,

and electrical supplies. Carefully consider the following factors

when choosing an installation location:

Compliance Requirements

Ɣ

Local, state, provincial, and national codes, laws, regulations, and

ordinances.

Ɣ

National Fuel Gas Code, ANSI Z223.1-latest edition.

Ɣ

Standard for Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1, when required.

Ɣ

National Electrical Code.

Ɣ

For Canada only: B149.1 Installation Code, CSA C22.1 Canadian

Electrical Code Part 1 and any local codes.

Access to Utilities

Ɣ

Water – the installation location should be near where the

domestic water supply enters the building.

Ɣ

Gas – the installation location should be near where the gas

supply enters the building.

Ɣ

Electricity – the installation location should be near where the

electrical supply enters the building.

Humidity and Contact with Water

When installing the boiler, avoid places with excessive humidity.

The boiler has electric gas ignition components. Water spray or

droppings can get inside the boiler and damage the ignition

system. The boiler must be installed in a way to ensure that the gas

ignition system components are protected from water (dripping,

spraying, rain, etc.) during operation and service.

Adequate Drainage

The boiler produces a significant amount of condensate during

operation. The boiler should be located near a suitable drain and

where damage from a possible leak will be minimal. Installing

the boiler in a location without a drain will void the warranty and

Navien will not be responsible for water damages that occur as a

result. For more information about condensate drainage, refer to

“3.3 Connecting the Condensate Drain” on page 23.

The boiler must be located in an area where leakage of the unit or

connections will not result in damage to the area adjacent to the

appliance or to lower floors of the structure. When such locations

cannot be found, installation of an adequately drained drain pan

under the boiler is highly recommended. When installing the drain

pan, ensure that the installation does not restrict combustion air

flow.

Adequate Venting and Ventilation

Select a location that requires minimal venting. Consider venting

restrictions caused by windows, doors, air intakes, gas meters,

foliage, and other buildings. For more information about venting,

refer to “6. Venting the Boiler” on page 40.

To ensure adequate venting and ventilation, follow these

guidelines:

Ɣ

Maintain proper clearances from any openings in the building.

Ɣ

Install the boiler with a minimum clearance of 12 in (300 mm)

above an exterior grade or as required by local codes.

Ɣ

Maintain a minimum clearance of 4 ft (1.2 m) from heating and

cooling vents.

Ɣ

Do not enclose the vent termination.

Ɣ

Install the exhaust vent in an area that is free from any

obstructions, where the exhaust will not accumulate.

Ɣ

Do not install the boiler where moisture from the exhaust may

discolor or damage walls.

Ɣ

Do not install the boiler in bathrooms, bedrooms, or any other

occupied rooms that are normally kept closed or not adequately

ventilated.

Proximity to Fixtures and Appliances

Install the boiler near fixtures that deliver or use hot water, such

as bathroom, kitchen, and laundry room faucets. Select a location

that minimizes the water piping required between major fixtures.

If the distances are long or if the user requires “instant“ hot water,

installation of a recirculation line which circulates domestic hot

water back to the boiler from the furthest fixture is recommended.

Insulate as much of the hot water supply and recirculation lines as

possible. For more information about the water supply, refer to "3.2

Installing a Domestic Hot Water (DHW) System” on page 20.

2. Installing the Boiler

Installing the Boiler 15

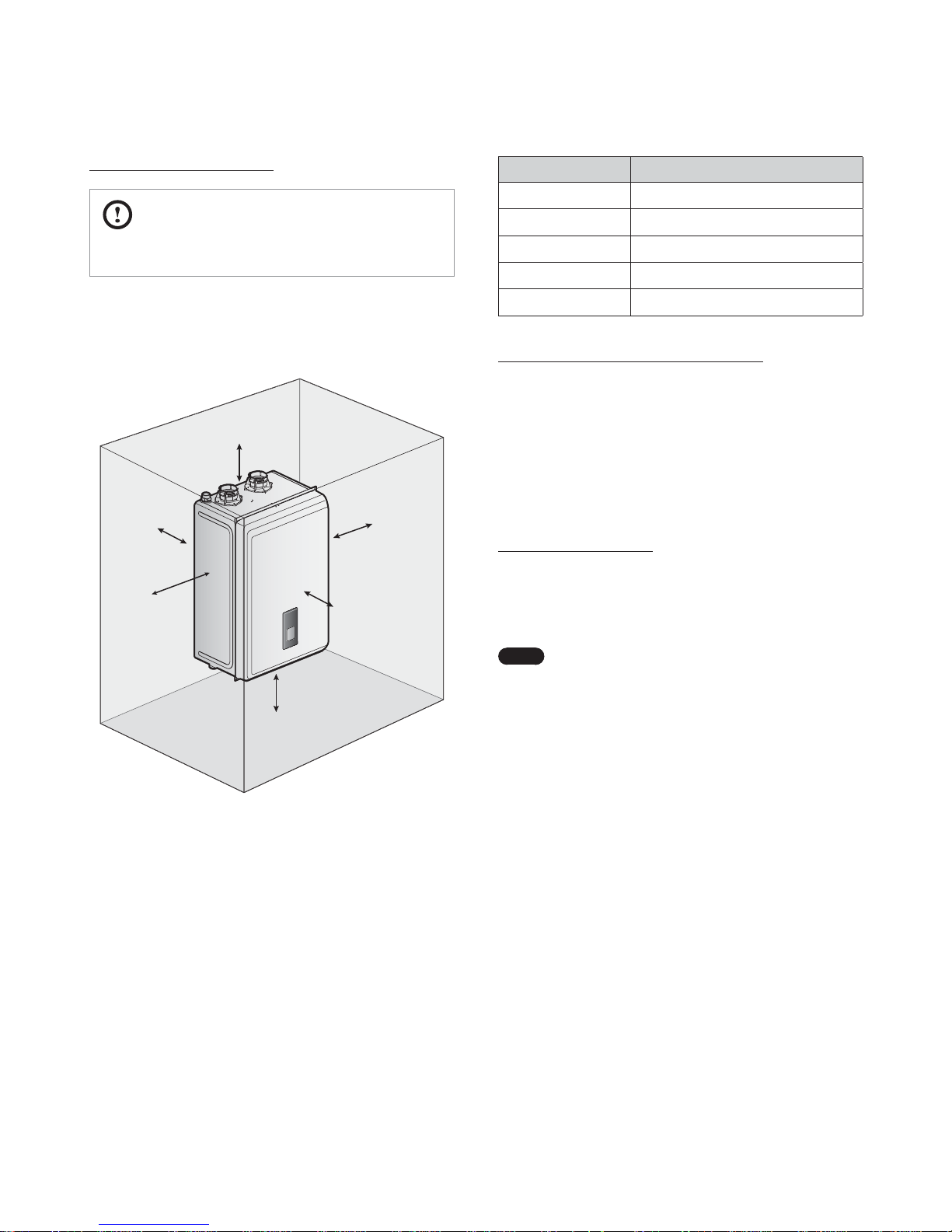

Clearance from: Indoor Installation

Top 9 in (229 mm) minimum

Back 0.5 in (13 mm) minimum

Front 4 in (100 mm) minimum

Sides 3 in (76 mm) minimum

Bottom 12 in (300 mm) minimum

Clean, debris and chemical-free combustion air

Ɣ

Do not install the boiler in areas where dust and debris may

accumulate or where hair sprays, spray detergents, chlorine, or

similar chemicals are used.

Ɣ

Do not install the boiler in areas where gasoline or other

flammables are used or stored.

Ɣ

Ensure that combustible materials are stored away from the

boiler and that hanging laundry or similar items do not obstruct

access to the boiler or its venting.

High Elevation Installations

This boiler may be installed at elevations up to 10,100 ft (3,078 m)

for use with natural gas (NG), and up to 4,500 ft (1,370 m) for

use with liquefied petroleum (LP). Refer to "7. Setting the DIP

Switches" on page 48 for the appropriate altitude setting.

Note

Above 2,000 ft (610m), the boiler will derate by 4% for

each 1,000 ft (300 m) of altitude gain.

Adequate installation clearances

CAUTION

Do not install the boiler on carpeting.

Install the boiler in an area that allows for service and maintenance

access to utility connections, piping, filters, and traps. Based on

the installation location, ensure that the following clearances are

maintained:

Top

Back

Side

Bottom

Front

Side

16 Installing the Boiler

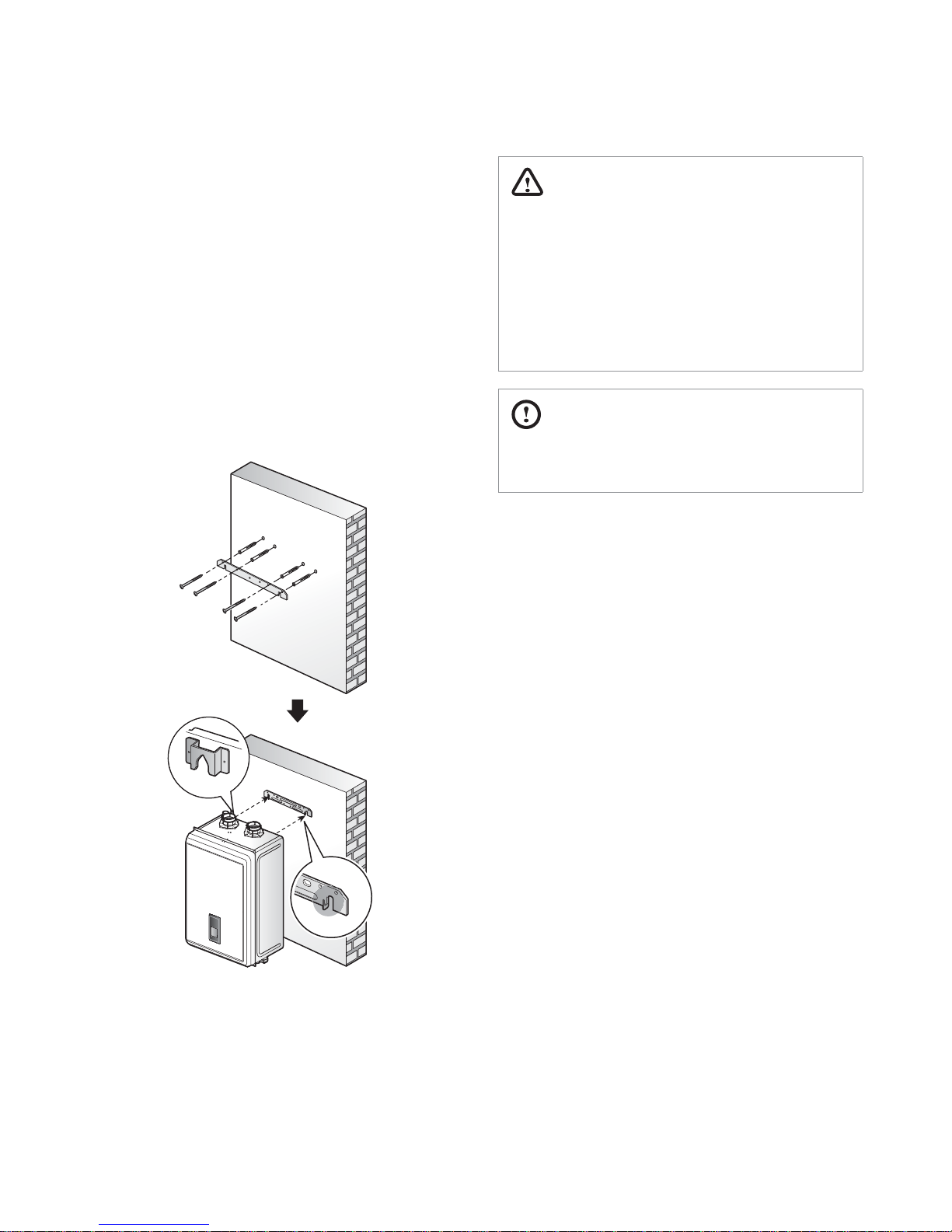

2.2 Mounting the Boiler to the Wall

Navien NCB-E boilers come with an upper mounting bracket that

is pre-drilled at 16 in (400 mm) on center for easy installation on

standard wall studs. If the strength of the wall is insufficient or if

the framing is non-standard or uneven, reinforce the area before

installing the boiler. Avoid installation on common walls as the unit

will make some operational noises while it is running.

To mount the boiler to the wall:

1. Affix the bracket securely to the wall and ensure that it is level

and that it can support the weight of the boiler.

2. Align the grooves on the back of the boiler with the tongues

on the mounting bracket and hang the boiler on the bracket.

When mounted with the mounting bracket, the boiler will

have a

5

/8 in (16 mm) clearance from the back of the wall.

WARNING

Ɣ

The boiler is heavy. Always lift the unit with assistance. Be

careful not to drop the boiler while lifting or handling it to

avoid bodily injury or damage to the unit.

Ɣ

Do not rest the boiler on the bottom end after removing it

from the shipping carton. Doing so may result in excessive

pressure on protruding pipes and cause product damage.

If you must put the boiler down, lay it on its back or put it

inside the protective shipping base.

CAUTION

Do not mount the boiler to dry wall that has not been

reinforced.

Installing the System Piping 17

Prior to connecting plumbing to the boiler, flush the entire system

to ensure it is free of sediment, flux, solder, scale, debris or other

impurities that may be harmful to the system and boiler. During

the assembly of the heating system, it is important to keep the

inside of the piping free of any debris including construction and

copper dust, sand and dirt.

For retrofits, all system piping including radiators, must be cleaned

of all build-up including sludge and scale. All systems, old and new,

must be cleaned to remove flux, grease and carbon residue. Navien

recommends cleaning the boiler system with cleaning products

specially formulated for boiler systems. For retrofit applications

with heavy limescale and sludge deposits, a heavier duty cleaner

may be required. For information on performing the cleaning,

follow the instructions included with the boiler system cleaner

products.

WARNING

Failure to rid the heating system of the contaminants listed

above will void your warranty and may result in premature

heat exchanger failure and property damage.

3.1 Installing a Space Heating System

The primary and secondary heat exchangers of the Navien NCB-E

boiler are designed to attain the highest level of heat transfer in

a compact design. To accomplish this, the heating water flows

through a series of tubes (secondary heat exchanger) and finned

tubes (primary heat exchanger), designed to maximize the heat

transfer area. To maintain the efficient and reliable operation of the

heat exchangers, and to avoid heat exchanger failure, it is critical to

ensure the rules and guidelines in this section are followed.

CAUTION

Failure to follow the instructions provided in this section will

void the warranty and may result in property damage, fire,

serious injury or death.

3. Installing the System Piping

3.1.1 Guidelines for a Space Heating Installation

Read and follow the guidelines listed below to ensure safe and

proper installation of a boiler heating system.

Freeze Protection for a Space Heating System

Ɣ

Freeze protection products may be used for the space heating

system. Freeze protection for new or existing systems requires

specially formulated glycol , which contains inhibitors to prevent

the glycol from attacking the metallic system components.

Ɣ

Before using freeze protection products, ensure that system

fluid contains proper glycol concentration and the inhibitor level

is appropriate. Navien recommends against exceeding a 35%

concentration of glycol.

Ɣ

When using the freeze protection products, the system must

be tested at least once a year, and as recommended by the

manufacturer of the glycol solution.

Ɣ

When using the freeze protection products, allowance should be

made for expansion of the glycol solution.

Ɣ

Freeze damage is not covered by the warranty.

WARNING

For systems requiring freeze protection, use only inhibited

propylene glycol, specially formulated for hydronic heating

systems; use of other types of antifreeze may be harmful to the

system and will void the warranty.

System Pressure

Ɣ

The Navien NCB-E boiler is intended solely for use in pressurized

closed loop heating systems operating with 12-30 psi water

pressure at the boiler outlet. To obtain the minimum system

design pressure, follow the piping diagrams illustrated in this

section.

Ɣ

The Navien NCB-E boiler’s space heating system is not approved

for operation in an “open system”, thus it cannot be used for

direct potable water heating or to process heating of any kind.

18 Installing the System Piping

Oxygen Elimination

This boiler may only be installed in a pressurized closed-loop

heating system, free of air (oxygen) and other impurities. To avoid

the presence of oxygen, ensure all of the air is removed from

the system during commissioning via strategically placed and

adequately sized air removal devices, located throughout the

heating system.

Note

Ɣ

The Navien NCB-E boiler has a built-in air vent on top

of the internal circulator to efficiently remove the air in

the space heating system.

Ɣ

See the examples of system application at the end of

this section detailing the installation location of the

air removal device, in case an additional air removal

device is required for a specific application.

WARNING

Ɣ

Immediately repair any leaks in the system plumbing to

avoid the addition of make-up water; make-up water

provides a source of oxygen and minerals that may lead to

heat exchanger failure.

Ɣ

Failure to follow these instructions will result in poor

performance, unnecessary wear of system components and

premature failure.

3.1.2 Essential Elements in a Space Heating System

Low Water Cut Off (LWCO) Device

Internal LWCO

The Navien NCB-E boiler is equipped with a factory-installed,

pressure-sensing type low water cutoff (LWCO) device. The

minimum operation pressure for this device is 7.3 psig.

Note

Ɣ

The boiler performs water replenishment

automatically when the built-in water pressure sensor

detects insufficient water level in the boiler system.

Ɣ

If the water replenishment is not completed after

5 minutes, error code E351 is displayed on the front

panel requiring a manual boiler reset.

Refer to local codes to determine if a LWCO device is required

for your system and ensure that the built-in device meets the

requirements. Install a backflow preventer in the make-up water

line to the unit if required by local codes.

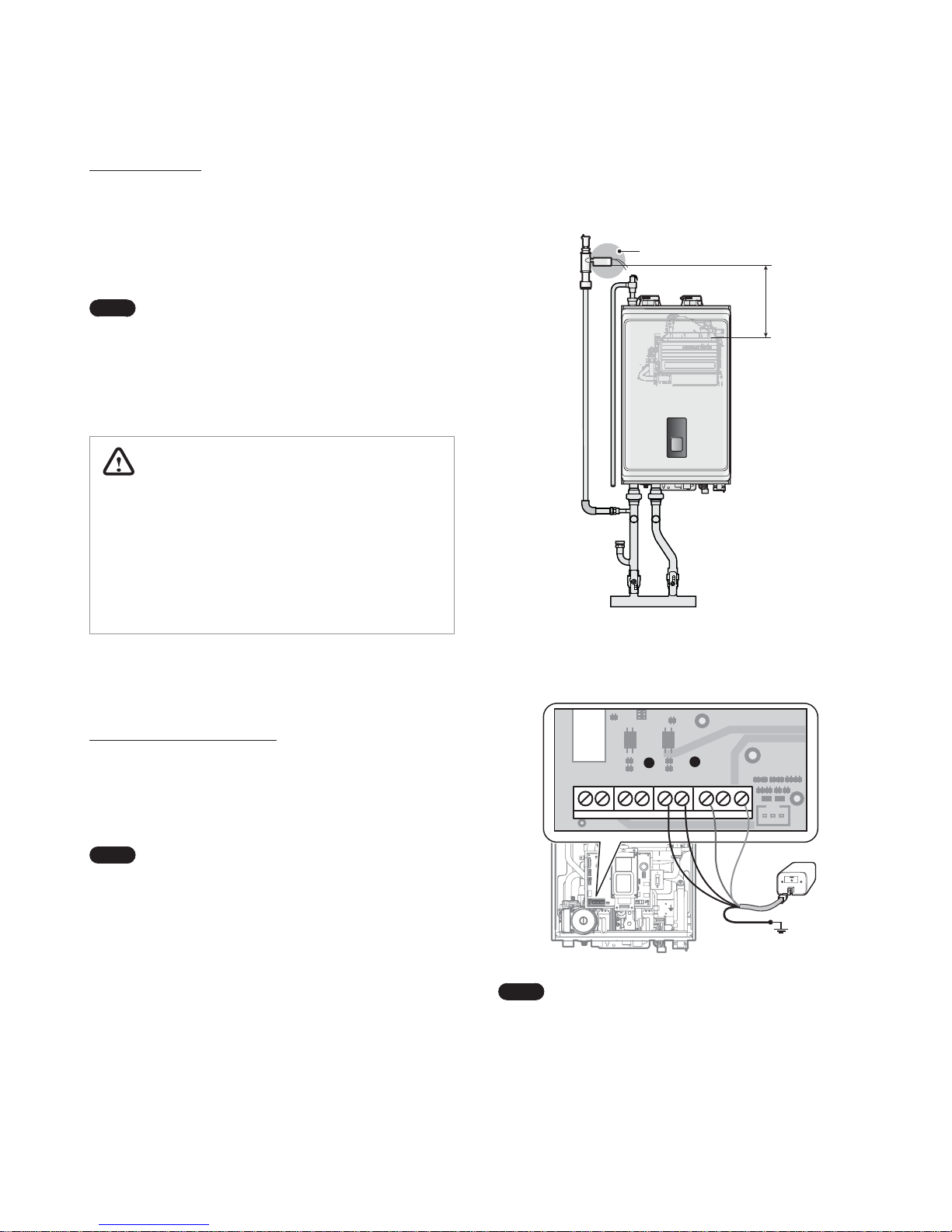

External LWCO

Install a separate LWCO device if required by local codes. The

following figure illustrates an example of typical LWCO installation.

External LWCO

6" (152 mm) min.

The external LWCO must be installed at least 6 in (150 mm) above

the top of the heat exchanger. Refer to the following diagram for

typical wiring connections of the LWCO to the boiler PCB.

CN23 CN10 CN24 CN25

Common Hot

Note

Ɣ

Remove the factory installed jumper on the LWCO

terminals (CN24) prior to connecting the LWCO.

Ɣ

The boiler supplies 24 VAC at the LWCO power

terminals (CN25).

Installing the System Piping 19

Backflow Preventer

Install a backflow preventer valve in the make-up water supply to

the unit as required by local codes.

Expansion Tank

An expansion tank must be installed in the space heating piping

to prevent excessive pressure from building in the system. See the

examples of system application at the end of this section for the

installation location. Refer to the expansion tank manufacturer’s

instructions for additional details.

Follow the guidelines below when installing an expansion tank.

Ɣ

Connect an air separator to the expansion tank only if the air

separator is located on the suction side of the system circulator.

Ɣ

Navien NCB-E boiler is equipped with an auto-feeding water

connection and motorized feeding valve. Therefore, installation

of additional system water fill connection is not necessary in

most cases.

Ɣ

If an additional water fill connection is required for a specific

use, install the water fill connection at the same location as the

expansion tank’s connection to the system.

Ɣ

When replacing an expansion tank, consult the expansion tank

manufacturer’s literature for proper sizing.

Ɣ

For diaphragm expansion tanks, always install an automatic air

vent on the top side of the air separator to remove residual air

from the system.

Isolation Valves and Unions

Ɣ

Full port ball valves are required for the boiler system. Failure

to use full port ball valves could result in a restricted flow rate

through the boiler.

Ɣ

Check valves are recommended for installation. Failure to install

check valves could result in a reverse flow condition during

pump(s) off cycle.

Ɣ

Unions are recommended for unit serviceability.

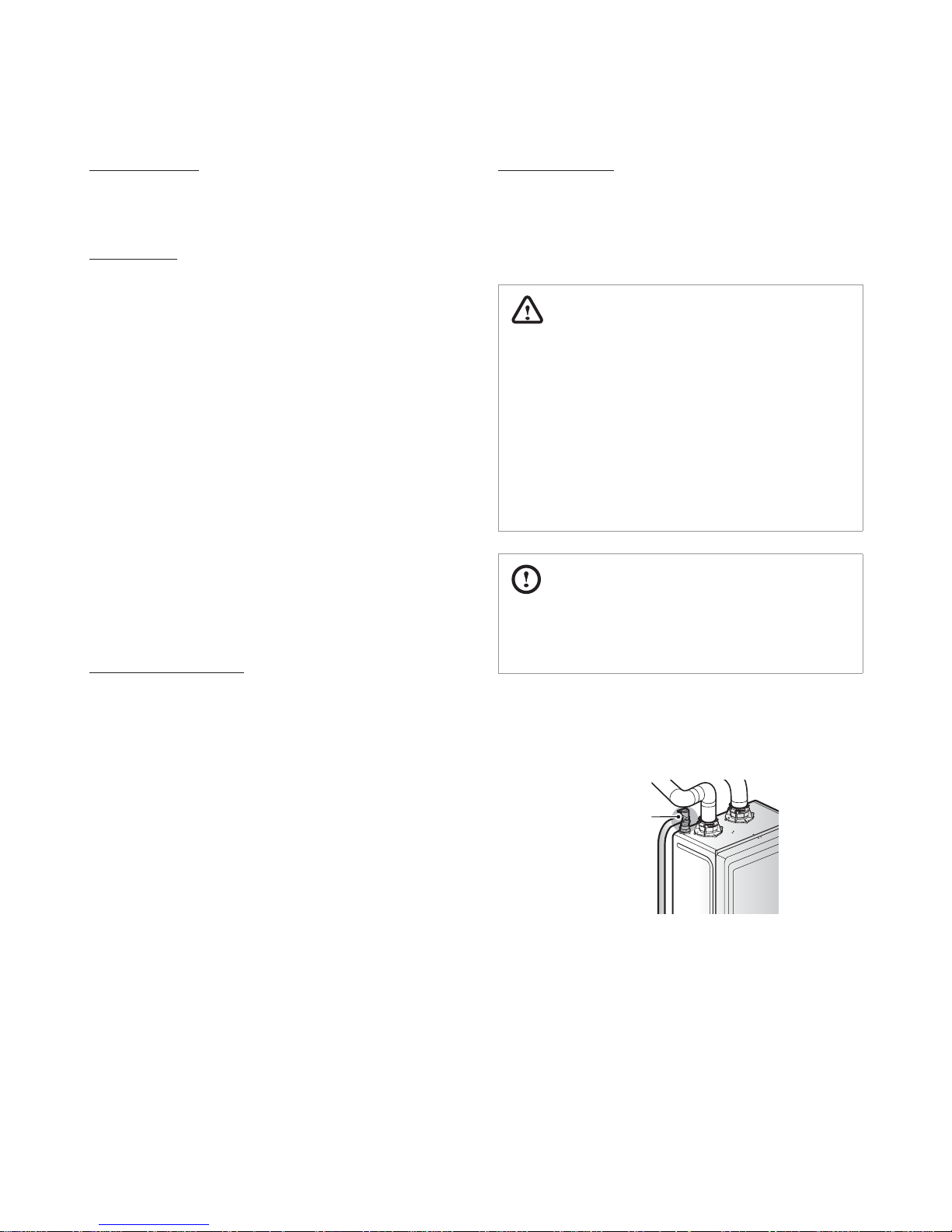

Pressure Relief Valve

To complete the space heating system installation, you must install

a

3

/4 in, maximum 30 psi pressure relief valve to the pressure relief

valve adapter located on the top side of the NCB-E boiler. An ASME

approved HV pressure relief valve for space heating system is

supplied with the boiler.

WARNING

Ɣ

Installing the pressure relief valve improperly may result

in property damage, personal injury, or death. Follow all

instructions and guidelines when installing the pressure

relief valve. The valve should be installed only by a licensed

professional.

Ɣ

The pressure relief valve must be installed vertically to the

pressure relief valve adapter on the top side of the boiler,

as shown in the example below, with the drain pipe outlet

exiting the side of the pressure relief valve horizontally and

elbowing down.

CAUTION

Install the pressure relief valve as close to the boiler as possible.

No other valve should be installed between the pressure relief

valve and boiler.

Refer to the following illustration and install a pressure relief valve

to the pressure relief valve adapter located on the top corner of the

NCB-E boiler. Conbraco Watts M330-M1 pressure relief valve (

3

/4 in,

HV, Max 30 psi) is provided with the boiler.

Pressure

Relief Valve

20 Installing the System Piping

When installing the pressure relief valve, follow these guidelines:

Ɣ

Ensure that the valve’s discharge capacity is equal to or greater

than the maximum pressure rating of the boiler’s space heating

system.

Ɣ

Ensure that the maximum BTU/H rating on the pressure relief

valve is equal to or greater than the maximum input BTU/H

rating of the boiler.

Ɣ

Direct the discharge piping of the pressure relief valve so

that hot water does not splash on operator, or any nearby

equipment.

Ɣ

Attach the discharge line to the pressure relief valve and run the

end of the line to within 6-12 in (150-300 mm) of the floor.

Ɣ

Ensure that the discharge line allows for free and complete

drainage without restriction. Do not install a reducing coupling

or other restrictions on the discharge line.

If the relief valve discharges periodically, this may be due to

thermal expansion caused by expansion tank waterlogging or

undersizing. Do not plug the relief valve.

3.1.3 Space Heating System Piping

When connecting the space heating system, follow these

guidelines:

Ɣ

Tighten the connection valves with care to avoid damage.

Ɣ

After installing the boiler, clean the strainer for space heating

return. Then, test the boiler for proper space heating flow and

inspect for leaks. Instruct the boiler owner that the strainer must

be cleaned periodically to maintain proper space heating water

flow.

The Navien manifold system (optional) allows for easy separation

of the Boiler-Primary loop from the System-Secondary loop(s).

Refer to the following illustration for a typical water piping

example with a Navien manifold system.

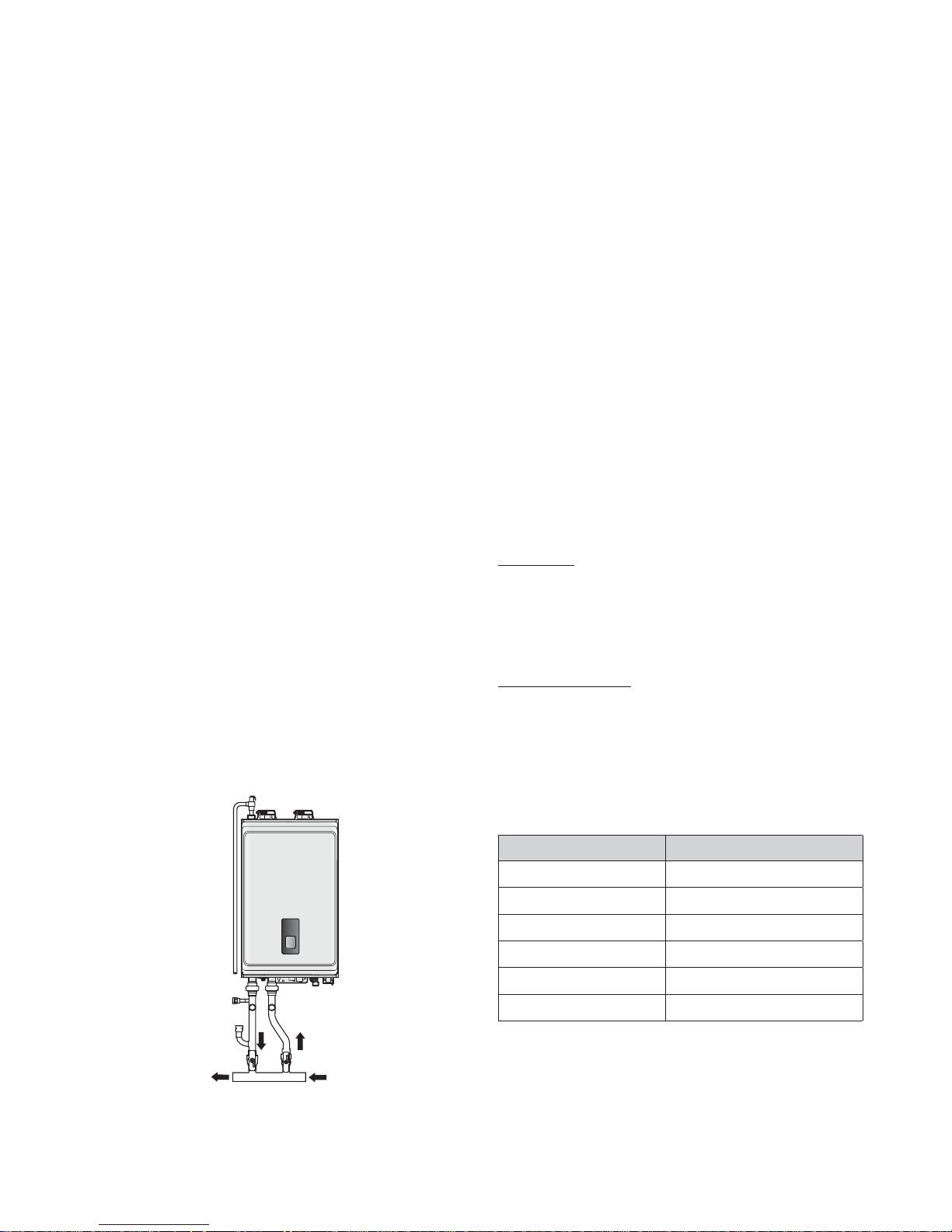

Space Heating

Return

Space Heating

Supply

3.2 Installing a Domestic Hot Water (DHW)

System

The Navien NCB-E boiler provides domestic hot water continuously

when flow is sensed by the flow sensor. This method is the most

efficient means of heating water by allowing the boiler to operate

at a lower return water temperature by minimizing standby losses,

thus increasing combustion efficiency.

3.2.1 Guidelines for a DHW System

With its multi-purpose design, the Navien NCB-E boiler provides

hot water on demand. This means that the boiler produces DHW

only when the user demands it.

The boiler recognizes a DHW demand when the flow sensor

detects a DHW flow of approximately 0.5 GPM or greater. Once

the flow sensor detects the flow, the boiler immediately goes into

DHW mode regardless of the status of the space heating system.

Read and follow the guidelines listed below to ensure safe and

proper installation of a boiler heating system.

Scald Hazard

Hotter water increases the risk of scald injury. There is a hot water

scald potential if the DHW temperature is set too high. Be sure

to follow the adjustment instructions in the boiler’s operation

manual.

About the DHW Quality

Proper maintenance of the boiler is required to ensure that your

DHW meets EPA quality standards. The following table shows the

maximum contaminant levels allowed, based on the EPA National

Secondary Drinking Water Regulations (40 CFR Part 143.3). If you

suspect that your water is contaminated in any way, discontinue

use of the DHW and contact an authorized technician or licensed

professional.

Contaminant Maximum Allowable Level

Total Hardness Up to 200 mg/l (12 grains/gallon)

Aluminum 0.05 to 0.2 mg/l

Chloride Up to 250 mg/l

Copper Up to 1.0 mg/l

Iron Up to 0.3 mg/l

Manganese Up to 0.05 mg/l

Installing the System Piping 21

Contaminant Maximum Allowable Level

pH 6.5 to 8.5

Sulfate Up to 205 mg/l

Total Dissolved Solids (TDS) Up to 500 mg/l

Zinc Up to 5 mg/l

Navien is not responsible for plugging of the domestic system by

scaling or accumulation of dirt; suitable steps shall be taken by the

installer and user to avoid water quality related issues.

Freeze Protection

Navien recommends heat tracing and insulating the DHW water

pipes. Pipe enclosures may be packed with insulation for added

freeze protection. Freeze damage is not covered by the warranty.

3.2.2 Essential Elements in a DHW System

DHW Heat Exchanger

The DHW heat exchanger installed inside the Navien NCB-E boiler

has been tested and certied in accordance with IAPMO standard

PS 92-2010.

Drain and Isolation Valves

Install drain and isolation valves on the inlet and outlet of the

DHW heat exchanger, so it can be ushed free of possible build-up

caused by dirt or hard water.

DHW Filter

The Navien NCB-E boiler has built-in DHW lter at the entrance of

the cold water inlet. Clean the lter periodically to ensure that the

lter is not obstructed creating disturbance in the ow. Failure to

protect the ow sensor from dirt and debris will cause the boiler to

malfunction.

Flow Restrictor (pressure regulator)

A ow restrictor is used to avoid excessive ow at the faucets. The

Navien NCB-E boiler has a built-in ow restrictor at the cold water

inlet adapter to limit the overall ow of domestic hot water. Follow

the instructions below when installing a ow restrictor:

CAUTION

Do not operate the boiler without the ow restrictor installed.

Refer to the ow restrictor specications and install an

appropriate valve for proper operation.

All Navien NCB-E boilers are shipped from the factory with three

ow restrictors included for dierent ow rates. Each ow restrictor

allows for a specied amount of water to ow through the unit. A

ow restrictor valve is pre-installed at the cold water inlet adapter

(at the tip of the cold water inlet lter).

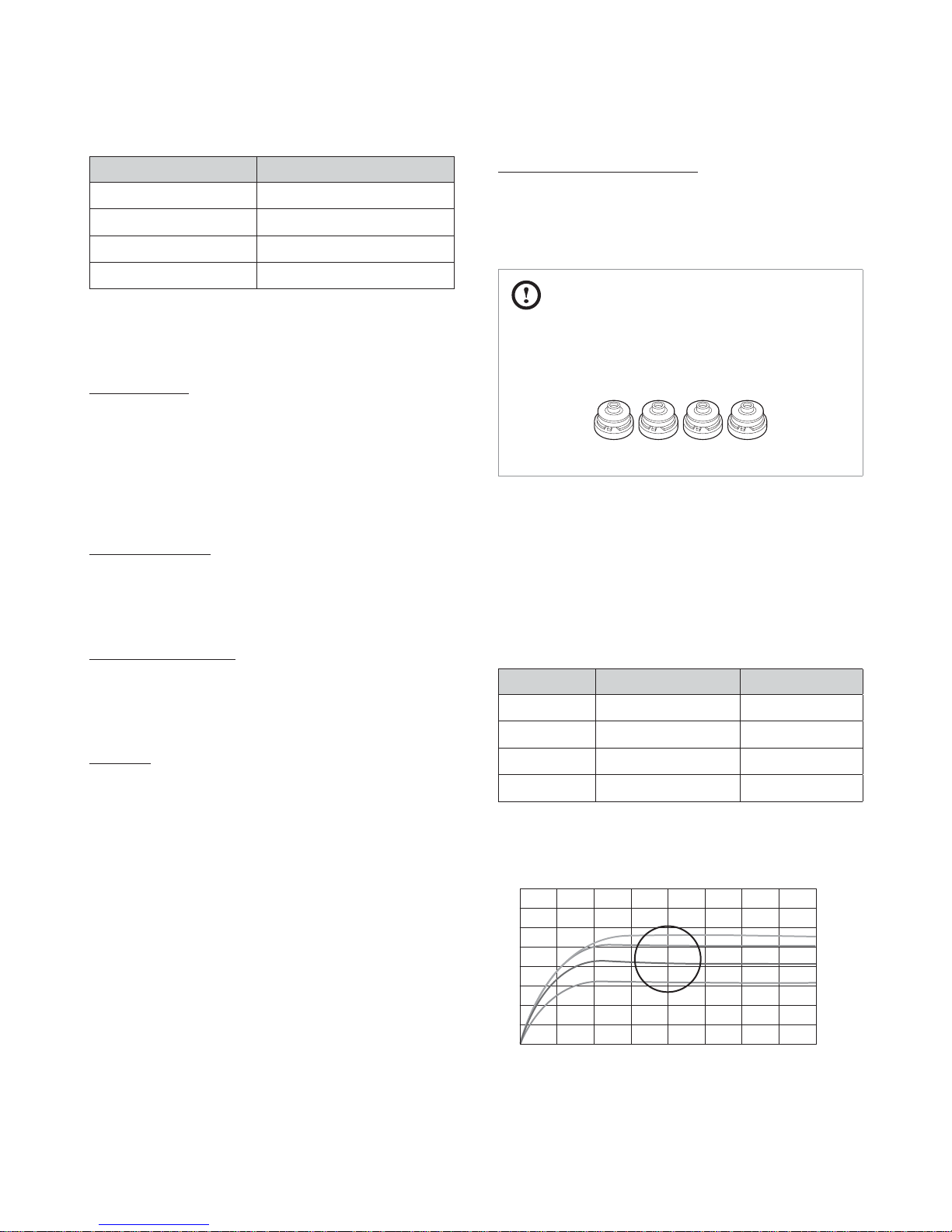

The ow restrictors are color coded for easier identication. Refer

to the table below for detailed specication. Factory-installed ow

restrictors and specications are as follows:

Valve color Applied Model Specication*

Orange NCB-240E, pre-installed 5.6 GPM

Yellow NCB-210E, pre-installed 5.0 GPM

Blue NCB-180E, pre-installed 4.0 GPM

Pink NCB-150E, pre-installed 3.2 GPM

* Flow rate in GPM, as factory tested with 56 psi water pressure.

The following graph describes the water ow rate (in GPM) and

water pressure (in psi) specications for each ow restrictor.

Orange

Yellow

Blue

Pink

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 14 28 42 56 71 85 99

113

22 Installing the System Piping

If necessary, replace the factory-installed flow restrictor with one

that satisfies your flow requirements. Follow these instructions to

replace the flow restrictor.

1. Locate the cold water inlet adapter on the bottom of the unit.

2. Turn the knob counterclockwise to remove the water inlet

filter. The flow restrictor is attached at the tip of the filter

assembly.

3. Remove the current flow restrictor and replace it with one that

provides an appropriate flow rate.

Pressure Relief Valve for DHW

To complete the installation of the DHW system, you must install

an approved

3

/4 in, maximum 150 psi pressure relief valve on

the hot water outlet. The Navien NCB-E boiler has a built-in high

temperature shut off switch, so install a “pressure only“ relief valve.

WARNING

Ɣ

Installing the pressure relief valve improperly may result

in property damage, personal injury, or death. Follow all

instructions and guidelines when installing the pressure

relief valve. The valve should be installed only by a licensed

professional.

Ɣ

The pressure relief valve must be installed at the boiler outlet

and in the vertical position, as shown in the example below,

with the drain pipe outlet exiting the side of the pressure

relief valve horizontally and elbowing down.

The DHW pressure relief valve is not supplied, but is required.

The following examples are pressure relief valves approved for use

with the boiler:

Ɣ

Wilkins P-1000A (Zurn Industries)

Ɣ

Conbraco 17-402-04

Ɣ

Watts Industries 3L (M7)

Ɣ

Cash Acme FWL-2, 3/4 in

Cold Water InletDHW Supply

Pressure

Relief Valve

CAUTION

Install the pressure relief valve as close to the boiler as possible.

No other valve should be installed between the pressure relief

valve and boiler.

Installing the System Piping 23

When installing pressure relief valve, follow these guidelines:

Ɣ

Ensure that the valve’s discharge capacity is equal to or greater

than the maximum pressure rating of the boilers DHW system.

Ɣ

Ensure that the maximum BTU/H rating on the pressure relief

valve is equal to or greater than the maximum input BTU/H

rating of the boiler.

Ɣ

Direct the discharge piping of the pressure relief valve so

that hot water does not splash on operator, or any nearby

equipment.

Ɣ

Attach the discharge line to the pressure relief valve and run the

end of the line to within 6-12 in (150-300 mm) of the floor.

Ɣ

Ensure that the discharge line allows for free and complete

drainage without restriction. Do not install a reducing coupling

or other restrictions on the discharge line.

Ɣ

If the relief valve discharges periodically, this may be due to

thermal expansion in a closed water supply system. Contact the

water supplier or local plumbing inspector on how to correct the

situation. Do not plug the relief valve.

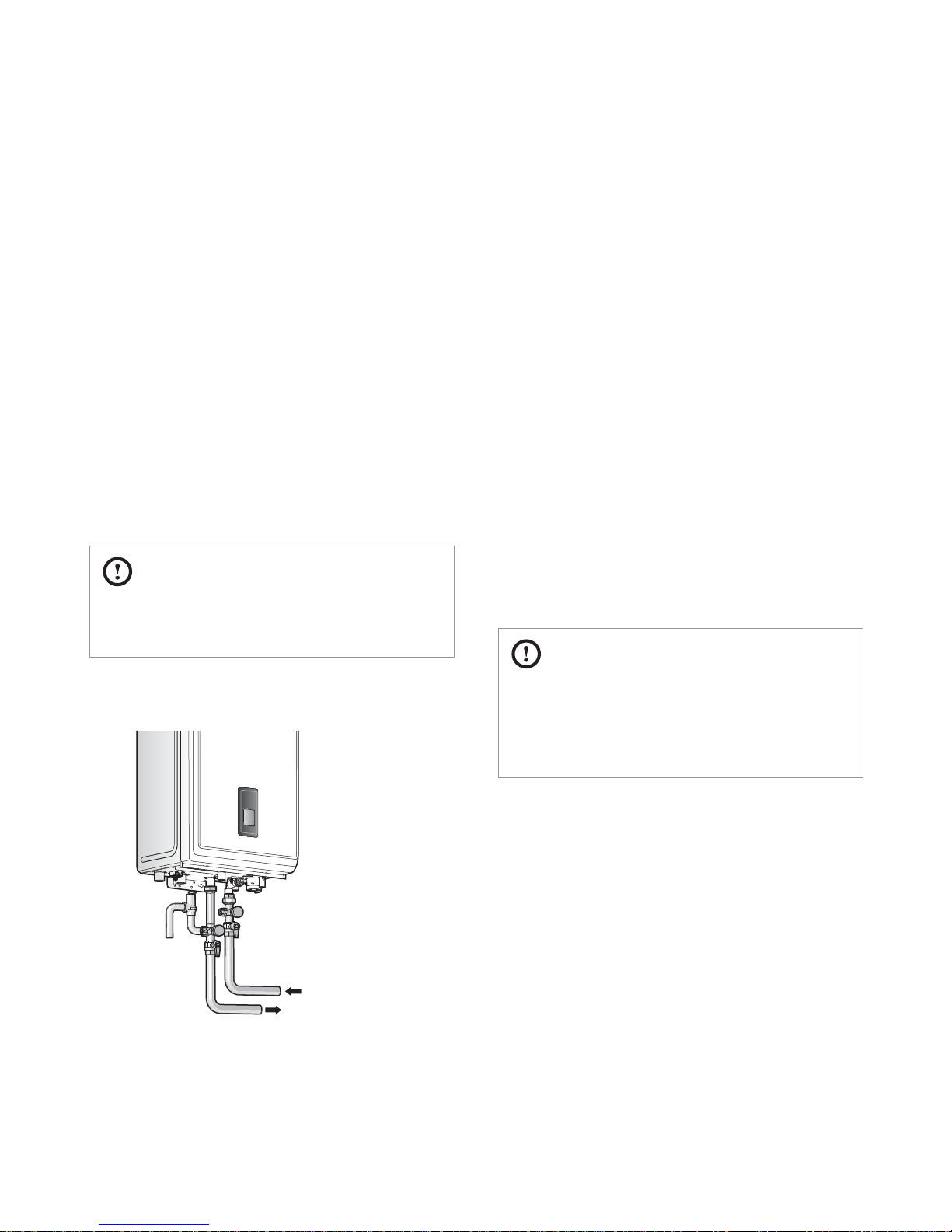

3.2.3 DHW System Piping

CAUTION

To comply with ASME or CRN requirements, an additional high

temperature limitation device may be needed. Consult your

local code requirements to determine if this device is required.

Refer to the following illustration for a typical DHW piping example

for the boiler.

DHW Supply

Cold Water Supply

When installing the DHW system, follow these guidelines:

Ɣ

Use only pipes, fittings, valves, and other components (such as

solder), that are approved for use in potable water systems.

Ɣ

Tighten the connection valves with care to avoid damage.

Ɣ

Navien recommends using unions and manual shut-off valves

on the cold water inlet and DHW outlet.

Ɣ

Keep the hot water piping system as short as possible, to deliver

hot water to the fixtures more quickly.

Ɣ

To conserve water and energy, insulate the DHW supply and

DHW recirculation lines (if applicable). Do not cover the drains or

pressure relief valves.

Ɣ

After installing the boiler, clean the cold water inlet filter.

Then, test the boiler for proper DHW supply and inspect for

leaks. Instruct the boiler owner that the filter must be cleaned

periodically to maintain proper DHW flow.

3.3 Connecting the Condensate Drain

The Navien NCB-E boiler creates condensation when it operates.

This condensation has an acidic pH of 3-5. Follow all local codes

and regulations when disposing of condensate from the boiler.

We recommend draining the condensate into a laundry tub,

as the alkali in laundry detergent will neutralize the acid in the

condensate. However, other suitable waste drain locations may be

used according to the local codes.

CAUTION

Ɣ

Do not cap or plug the integrated condensate line. If

prevented from draining, condensate can damage the boiler.

Ɣ

The condensate line must have a negative slope to drain

properly.

24 Installing the System Piping

Before connecting the condensate drain, choose one of the

following disposal options:

a. From the boiler directly into an external drain

b. From the boiler, through a neutralizing agent, and then

into an external drain

Note

If you choose this option, the neutralizing agent

must be replaced periodically. Depletion of

the neutralizing agent will vary, based on the

usage rate of the boiler. During the first year of

operation, the neutralizer should be checked

every few months for depletion and replaced as

needed.

c. From the boiler into a laundry tub.

Note

The bottom of the boiler must be higher than

the top of the laundry tub to use this option. The

condensate line must have a negative slope to

drain properly.

d. From the boiler into a condensate pump, and then into a

laundry tub.

Note

A pump can be used when there is a long

distance between the boiler and the laundry tub

or when the bottom of the boiler is lower than the

top of the laundry tub.

To connect the condensate drain:

1. Connect a drain line to the

1

/2 in fitting at the bottom of the

boiler.

Use only corrosion-resistant material for the drain line, such as

PVC or CPVC. Do not reduce the size of this fitting or the drain

line to less than

1

/2 in.

NPT / in

2. Place the free end of the drain line into an appropriate drain.

3. If you are using a condensate pump, ensure that the pump

allows for up to 2 GPH of drainage for each boiler in the

system.

4. If you are not using a condensate pump, ensure that the drain

line is pitched downward at a minimum slope of

1

/4 in per foot.

Installing the System Piping 25

3.3.1 Condensate Neutralizer Kit

WARNING

Ɣ

To avoid damaging the appliance, the neutralizer inlet and

discharge must be lower than the condensate drain.

Ɣ

Do NOT allow exhaust flue gases to vent through the

neutralizer. Leakage can cause injury or death from carbon

monoxide.

Ɣ

The connection between the appliance and the neutralizer

must be installed to prevent the backflow of condensate

into the appliance.

Ɣ

Do not connect more than one appliance to the neutralizer.

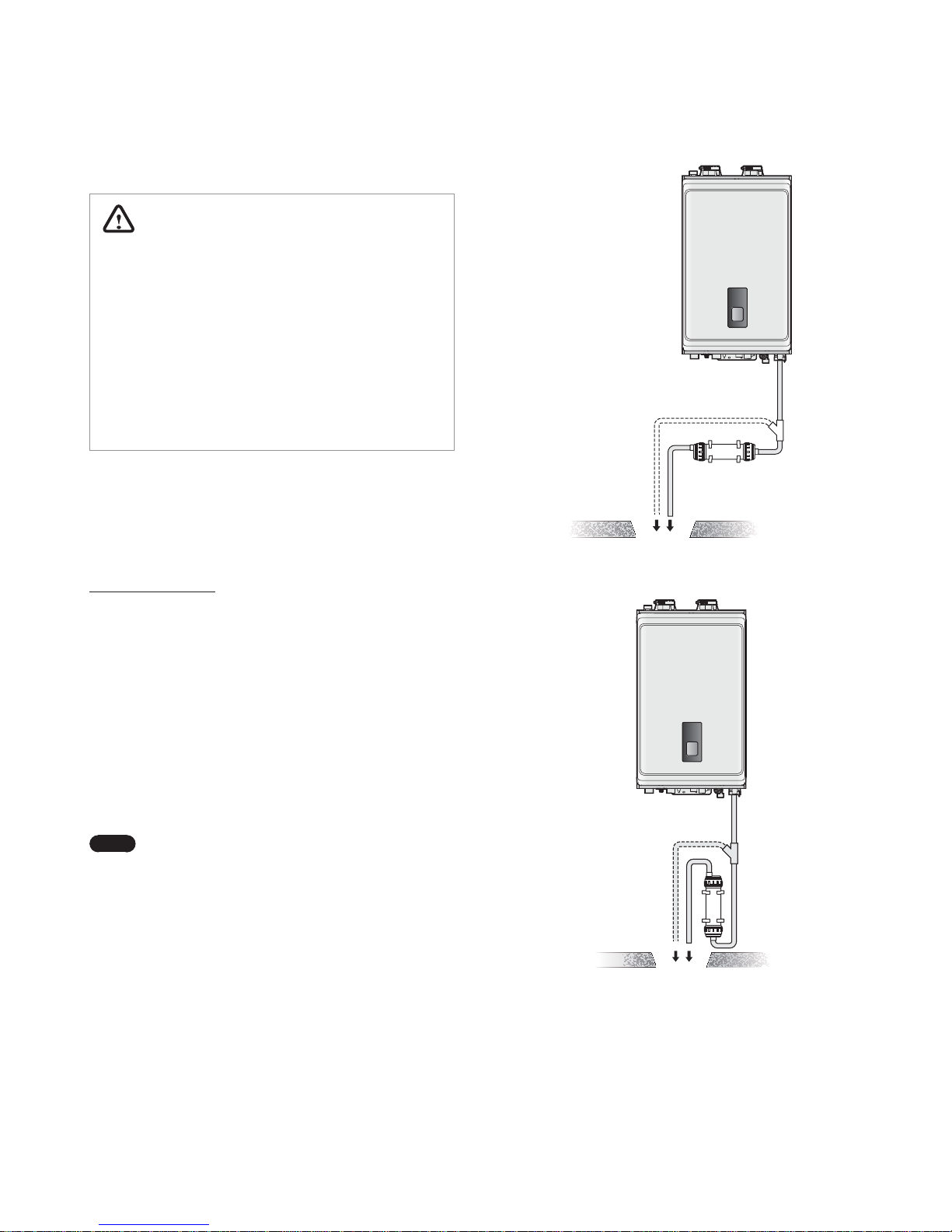

If option 'b' is selected for condensate disposal, the Navien

condensate neutralizer kit is recommended. The condensate from

the appliance flows through the neutralizing media and increases

the pH of the condensate. An increased pH prevents corrosion of

the installation's drainage system and the public sewer system.

Installation guidelines

Ɣ

The inlet has a center connection port and the outlet has an

offset connection.

Ɣ

Install the neutralizer on the wall or the floor and secure it using

the brackets supplied with the kit.

Ɣ

If the neutralizer is installed horizontally, rotate the neutralizer to

position the outlet at the highest point (Figure 1).

Ɣ

If the neutralizer is mounted vertically, ensure that the outlet is

higher than the inlet (Figure 2).

Ɣ

Ensure that the condensate runs freely to the drain.

Ɣ

Ensure all connections are made to prevent the backflow of

condensate. Use corrosion resistant piping and secure all piping

to prevent movement.

Note

Do not install condensate piping in areas where the

temperature drops below freezing point. Protect

piping in high pedestrian areas from damage and

vibration.

Ɣ

For increased safety when the condensate drain blocks, install

a Y-fitting. Connect the Y-fitting as shown in the installation

diagram and ensure that the condensate runs freely to the drain.

Ɣ

Ensure that the discharge connection is accessible. Access to

the discharge connection is required for maintenance and pH

testing.

Ɣ

If there is insufficient gradient for drainage, install a drainage

pump designed for boiler and water heater condensate removal.

Optional

overflow bypass

Figure 1. Horizontal installation

Optional

overflow bypass

Figure 2. Vertical installation

Loading...

Loading...