Medium-sized gas boiler

29

1. Precautions for safety--------------------------------------30

2. Outside drawing of the boiler ----------------------------31

3. Safe and correct installation method --------------------34

4. Electric wiring installation --------------------------------37

5. Gas piping installation-------------------------------------39

6. Heating and hot water piping installation --------------41

7. Exhaust / Intake vent installation ------------------------47

8. Temperature controller installation ---------------------- 52

9. Check points for test operation---------------------------53

10. Electric wiring diagram --------------------------------- 55

11. Specifications------------------------------------------------56

※

This installation manual is subject to change without notice for quality improvement.

Table of

contents

Medium-sized gas boiler

30

Precautions for safety

The instructions provided in this installation manual include important

information for safe use of this product. Failure of complying with

those instructions may result in death, severe injury, or tremendous loss

of property.

The instructions for safe use are classified into ‘Danger’, ‘Warning’,

‘Caution’

by the degree of danger, which respectively contains the

following meaning.

Violation of instructions may cause a seriously dangerous

situation such as death or a severe injury

Violation of instructions may cause a potentially dangerous

situation such as death or severe injury.

Violation of instructions may cause a potentially dangerous

situation such as a light or half-serious injury.

Violation of instructions may cause a situation such as a

property loss, product malfunction, or deteriorated performance.

1) The symbols provided in the product and the installation manual contains the

following meaning.

This symbol implies that “precautions” shall be taken against a possibility of a

personal injury under a specific condition.

This symbol implies that a “prohibition” shall be made against a possibility

of a personal injury or a property loss under a specific condition.

This symbol implies that the instructions shall be complied with.

2) The warnings and cautions specified in the installation manual do not include all

the possible safety precautions to be taken for using the product. Consequently,

utmost care shall be taken for safety during use of the product.

1

Medium-sized gas boiler

31

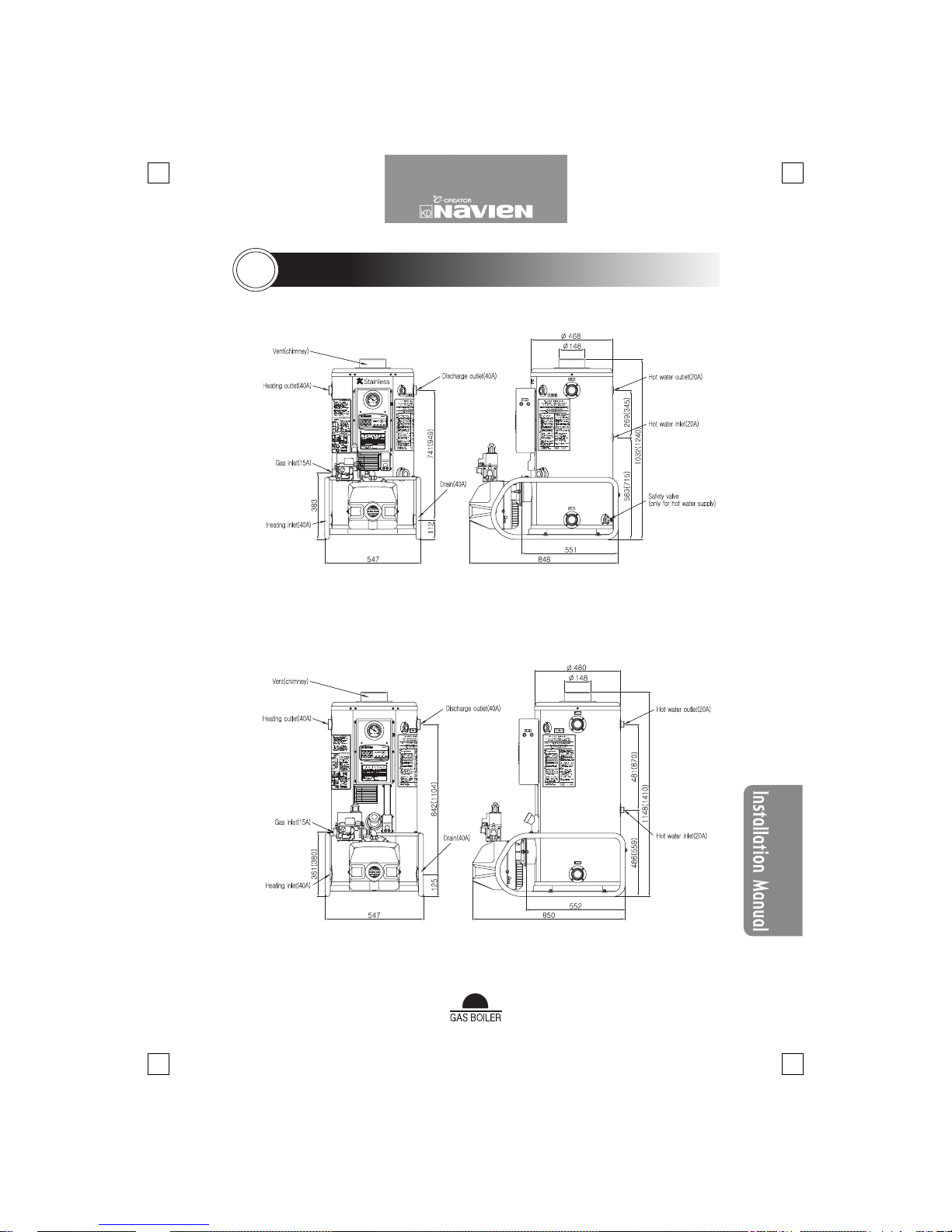

Outside drawing of the boiler

Model no.:

KDB-535GTD, GTS, GTG

※

The sizes in the blank “( )” are applied to the model no..

※

A dedicated boiler (GTS, GTG) is not supplied with the hot water inlet and outlet on the rear of

the boiler.

Model no.:

KDB-535GPD, GPS

※

The sizes in the blank “( )” are applied to the model no.

※

A dedicated boiler (GPS) is not supplied with the hot water inlet and outlet on the rear of the

boiler.

2

Medium-sized gas boiler

32

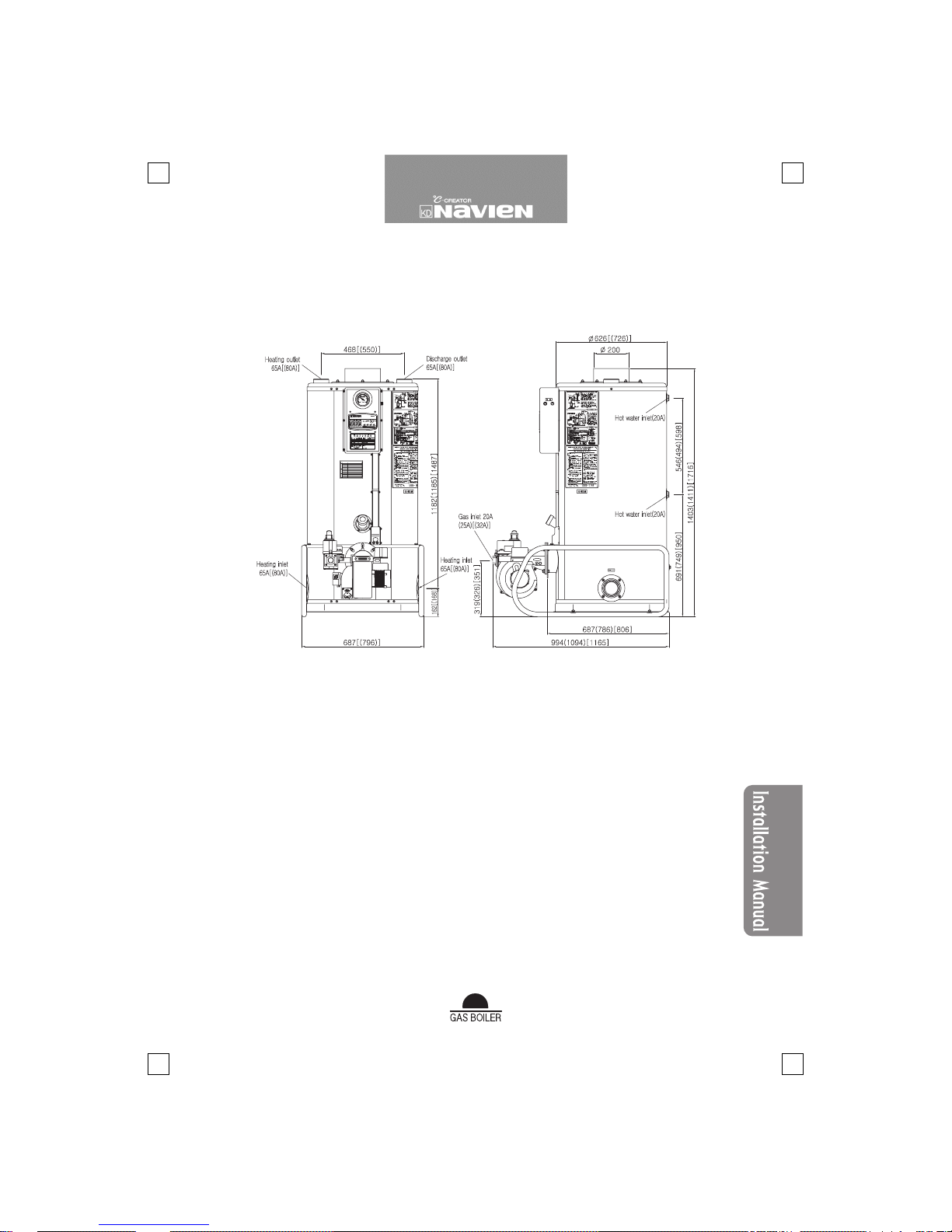

Model no.:

KDB-735GTD, GTS, GTG

※

The sizes in the blank “( )” are applied to the model no..

※

A dedicated boiler (GTS, GTG) is not supplied with the hot water inlet and outlet on the rear of

the boiler.

Model no.:

KDB-735GPD, GPS

※

The sizes in the blank “( )” are applied to the model no.

※

A dedicated boiler (GPS) is not supplied with the hot water inlet and outlet on the rear of the

boiler.

Medium-sized gas boiler

33

Model no.:

KDB-1035GPD, GPS, GPG

1535GPD, GPS, GPG

2035GPD, GPS, GPG

※

The sizes in the blank “( )” are applied to the model no. 1535, and those in the bracket “[ ]” are to the

model no. 2035GPD, GPS, GPG.

※

A dedicated boiler (GPS, GPG) is not supplied with the hot water inlet and outlet on the rear of the

boiler.

Medium-sized gas boiler

34

Safe and correct installation method

After completion of installation, be sure to return the user’s (installation) manual to the user.

Be sure to check the gas to be used in the

installation place, prior to installation.

Use of the gas, other than the one specified on the

name plate on the front of the boiler, may result

in a fire or explosion.

Be sure to check the power supply gas to be

used in the installation place, prior to

installation.

The power supply, if higher or lower than the one

specified on the front of the boiler, may cause a fire.

After reading the following instructions, install the product in a safe and correct way as

specified in the instructions.

Never install the boiler in a place with

inflammable objects.

Highly inflammable materials, such as volatile

oil or alcohol, may cause a fire during ignition of

the boiler.

Install the boiler in a boiler room free froml

the impact of rain and wind.

Incomplete combustions, resulting from rain and

wind, may eventually lead to a carbon oxide

poisoning.

3

Before installation

Selection of the installation place

Medium-sized gas boiler

35

Never install the boiler in a moist or enclosed

place such as a bathroom, a toilet.

Incomplete combustion, caused by oxygen

deficiency, may lead to a carbon oxide poisoning.

Installation in the above place may also cause

earlier product malfunctions.

Never install the product with corrosive gas

such as ammonia, chlorine, sulfur, acids.

Corrosive gas may damage the boiler and cause

incomplete combustion, eventually leading to a

carbon oxide poisoning.

Never install the boiler in the following areas.

Do not install the boiler near the electric equipment.

Do not install the boiler in an uneven or unstable place.

Do not install the boiler in a place with highly combustible materials.

Do not install the boiler in a place inadequate for safe gas piping installation.

Do not install the boiler in a place with special chemical agents

(generating combustible or corrosive gas).

Do not install the boiler in a place where it is difficult to get access to the

stairway or the exit for escaping.

Do not install the boiler in a place which is not well drained.

Do not install the boiler below the shelf with unstable objects.

Do not install the boiler in a place where it is difficult to conduct

maintenance of the boiler after installation.

Do not install the boiler in a place with noise and air pollution.

Do not install the boiler in a place where the wind generated from a vent, a

range, and a hood have an impact on the air intake and exhaust.

Do not install the boiler in a place which is not well-ventilated.

Do not install the boiler in a place with strong wind.

Do not install the boiler in a place where it is difficult to install the

chimney pipe (chimney).

Be sure to install the boiler in a sufficient place for check up and repair of

the boiler.

A space of more than 1m shall be provided in front of the boiler, in order to

perform maintenance and checks.

Other considerations

Medium-sized gas boiler

36

Install the boiler on the surface with a structure capable of enduring the load of the boiler (weight). (Refer to the

specifications presented in the user’s manual.)

Install the boiler in a horizontal, upright position so that the boiler does not lean toward one side.

Installation shall be made for the front side of the boiler to face forward.

Install the boiler to be fixed on the floor, in order to prevent vibration during operation.

Sufficient light shall be provided with the boiler room in order to help to observe the boiler equipment by sight

and offer the after-sales service for the equipment.

Be sure to install the boiler in the dedicated boiler room. (The boiler room shall be designed so that the gas

emitted from the boiler does not flow into the living room, and the wall between the boiler room and the

living room shall be made of the fireproof materials, except for the entrance / exit door.)

The dedicated boiler room shall not be equipped with the ventilating fan which causes the negative pressure (the

pressure lower than the atmosphere pressure).

The dedicated boiler room shall not be equipped with the exhaust duct of the gas range (hood) which leads to air

flowing in and out of the living room and the kitchen.

Installation of the boiler shall not be made nearby the place for storage and treatment of the combustible or

inflammable objects. A sufficient space shall be provided for boiler installation as presented in the following

figure, in order to perform the control, combustion, check-ups and repair of the boiler.

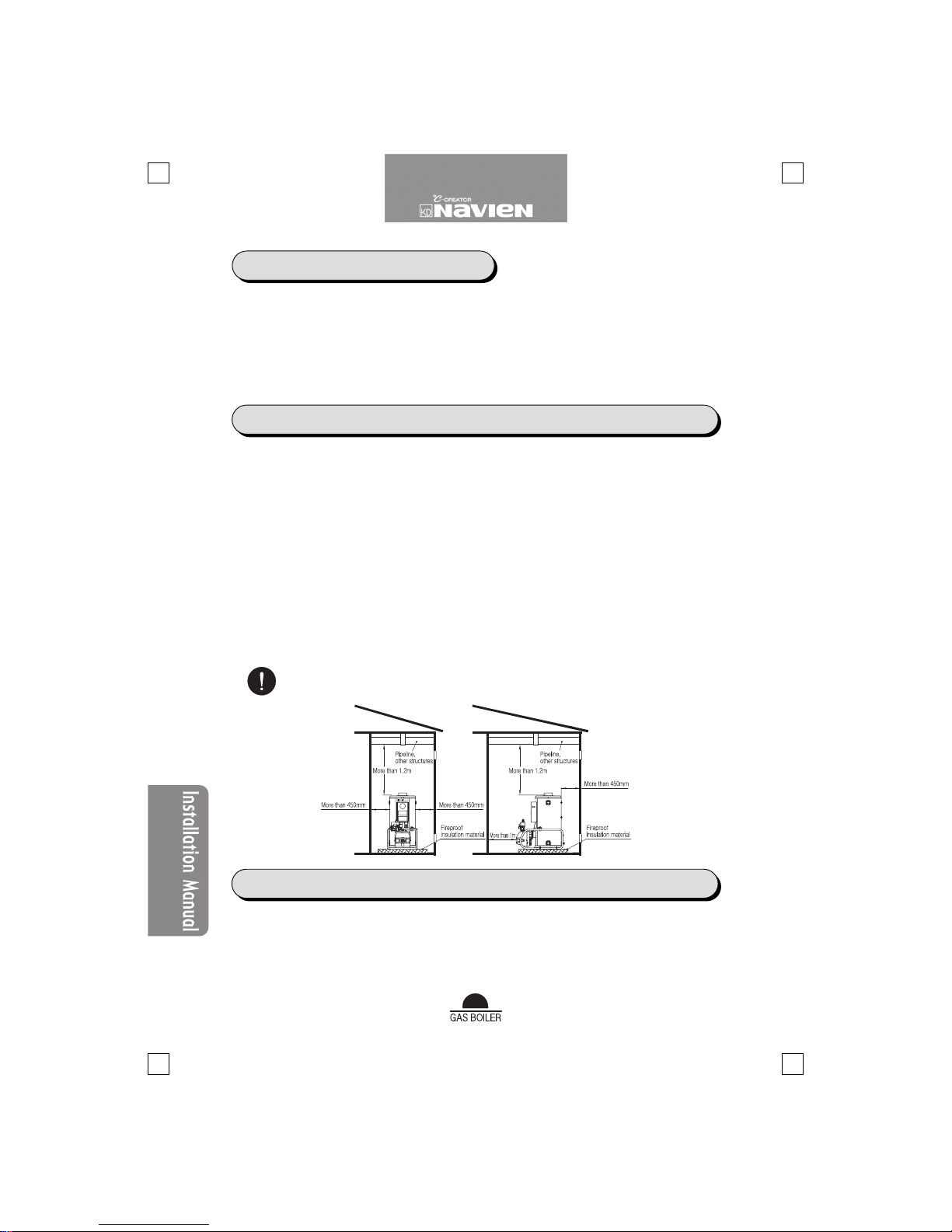

The top of the boiler body shall be kept at least 1.2m away from the structures such as the ceiling and the piping.

The boiler body shall be kept at least 450mm away from other structures such as the wall and the piping on the side of the

boiler.

The front of the boiler shall be kept more than 1m away from the structures in front of the wall.

The boiler shall be kept away from the nearby combustible objects, as illustrated in

the following figure.

Appropriate facilities such as the casing shall be equipped with the boiler to prevent the rain from permeating into

the boiler.

The waterproof treatment shall be applied to the exposed insulation materials or lagging.

Proper measures shall be taken to protect the water pipe outside the boiler from getting frozen.

Proper measures shall be taken for boiler combustion to be protected against snow, rain and wind.

Precautions for boiler installation in a dedicated boiler room

Boiler installation method

Precautions for installation of the boiler in the outdoors

Medium-sized gas boiler

37

Electric wiring installation

The electric wiring installation shall be

performed to comply with the power supply of

the product.

The power supply, if higher or lower than the one

specified on the name plate on the front of the

boiler, may cause a fire.

Do not connect the power supply to the boiler until the

electric wiring installation is completed.

With the power supply on, the electricity flowing through the

boiler may cause an electric shock.

Install the power outlet in a place free from the

impact of rain and moisture.

Electric leakage, possibly resulting from rain and

moisture, may cause a fire.

4

Medium-sized gas boiler

38

Never make a ground connection to the lightning

rods and the gas pipe.

Ground connection to the lightning rod may result in a boiler

malfunction.

Ground connection to the gas pipe may result in an explosive

accident.

Be sure to use the magnet switch for connection of the

circulation pump with more than 1.5kW.

The boiler may malfunction, without the magnet switch.

Install the electric wiring as presented in the electric wiring drawing in the installation manual.

Install the dedicated power outlet for the boiler, with a length of less than the effective length of

the power cord. Installation shall be made for the power outlet not to get in contact with the drain

valve of the boiler.

Use the power outlet with a cover attached, and install the outlet at more than 300m above

ground level.

If the power outlet is not provided with a cover, install the outlet in a place free from the impact

of rain or moisture, or in the waterproof box or the indoor distribution box.

Never install a switch onto the power cord, nor use the power outlet with a switch attached. (The

boiler does not operate, when the switch is set at off.)

A ground connection shall be installed, if not, on the side of the power outlet.

The wires of the room temperature controller shall be connected through the insulation pipe with

a thickness of more than 4mm. The insulation pipe shall be installed and concealed with an

upper gradient toward the indoors.

The wires of the circulation pump, connected to the controller, shall not be

short-circuited.

Correct electric wiring installation

Medium-sized gas boiler

39

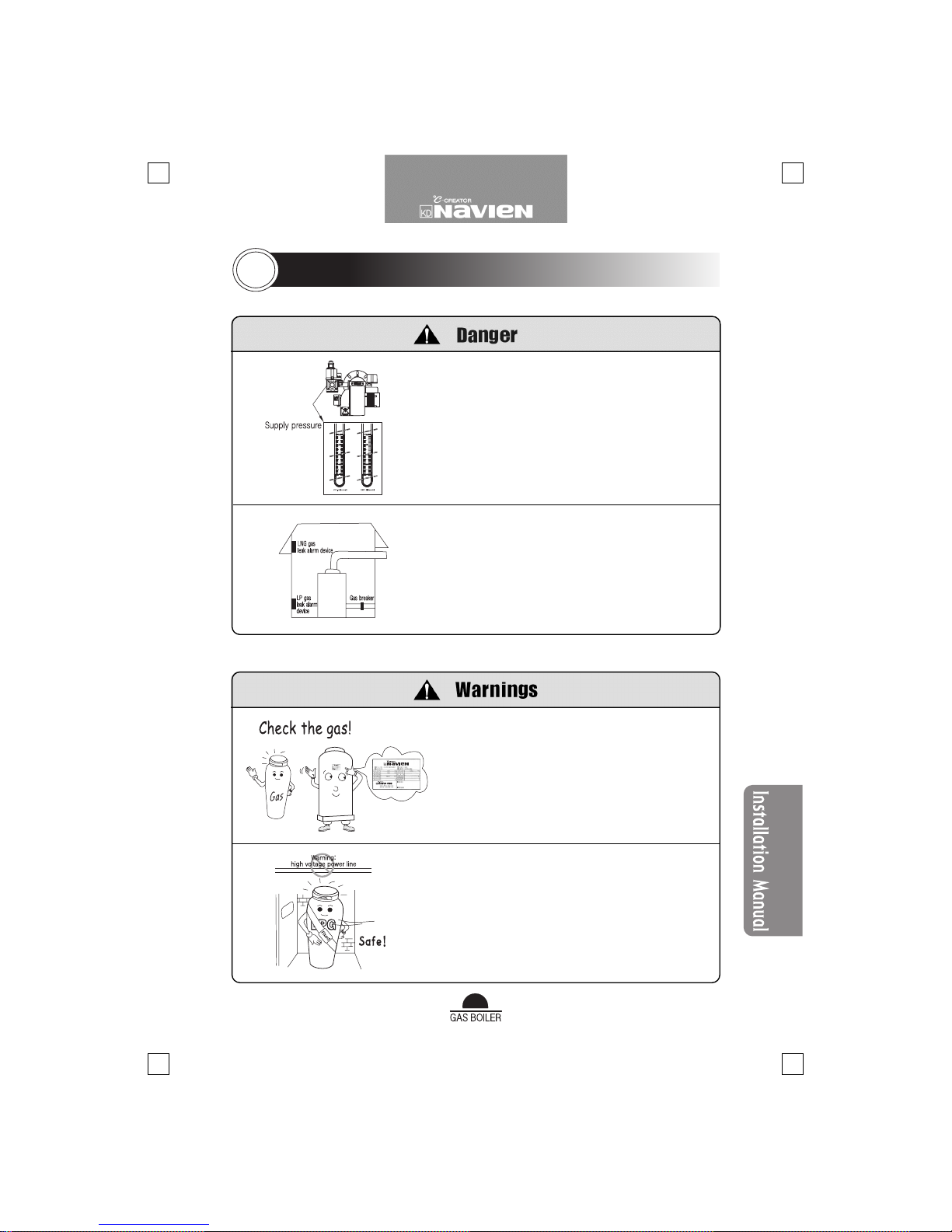

Gas piping installation

Be sure to perform the gas leak test after gas pipe

installation, replacement of the burner, or the

supply pressure or head pressure test.

Retention of the leaked gas, combined with static electricity or

spark, may cause a fire

In preparaion for the unexpected gas leak, be sure

to install the gas leak alarm device and the gas

breaker in the boiler room.

Retention of the leaked gas, combined with static electricity

or spark, may cause a fire

Be sure to check the gas to be used for the product

prior to gas piping installation.

Use of the gas, other than the one specified on the name plate

on the front of the boiler, may cause incomplete combustion,

eventually leading to a fire or explosive ignition.

Install the gas holder, if used, in the well-ventilated

outdoor without above ground high voltage power

line. The gas holder shall be fixed not to fall down

on the ground.

If the gas holder falls down or gets in contact with the high

voltage power line, an explosive accident may occur.

5

Medium-sized gas boiler

40

The gas piping installation shall be performed by the gas

company and the gas piping installation company.

1

Refer to the “Specifications” presented in this installation

manual, with regard to the connection size.

2

Use the metal pipe or the metal flexible pipe which

passed a gas appliance test for gas piping. When LP gas

is used, never install the fuse cock, and be sure to install

the gas middle valve. (Installation of the fuse cock may

cause a boiler malfunction.)

3

The following shall be kept in mind, when using LP gas.

The domestic low pressure regulator, appropriate for the

indicated gas consumption, shall be used as the LP gas

regulator.

2 or more vessels with a weight of 50kg shall be installed

to be used for the LP gas vessel. (Connect the twin valve

to simultaneously supply the gas from 2 vessels.)

※

The vessels with a small capacity may result in gas loss

for lack of vaporization volume, which may cause a

boiler malfunction.

4

Be sure to connect the gas pipe directly to the main

pipe. Never connect the gas pipe in common with

other gas appliances.

5

A

separable union connection or a nut connection

shall be made on the connection points.

6

The gas pipe shall be installed with its surface

exposed to the outside. However, the copper pipe, the

stainless steel pipe, or other pipes made of heat- and

corrosion-resistant materials without connection

joints (except for welding joints) may be buried for

installation.

7

Be sure to install the gas leak alarm device and the

gas breaker in the boiler room.

LP gas: lower than the boiler

(300mm above the ground level)

LNG : higher than the boiler

Medium-sized gas boiler

41

The piping materials shall comply with the Korea Standard.

Gas pipe

Carbon steel pipe for fuel gas piping, Copper or copper alloy pipe,

Metal flexible pipe which passed the gas appliance test

Heating pipe Copper or copper alloy pipe+Insulation, XLPE pipe+Insulation

Hot water

pipe

Copper or copper alloy pipe+Insulation, XLPE pipe+Insulation

Items

Distance from the gas pipe

Flue pipe & chimney 300mm or more

Electric switch, Power outlet 300mm or more

Electricity meter, Safety cutout 600mm or more

Wire 150mm

Size of the pipe Interval

13mm or less To fix every 1m

13mm~33mm To fix every 2m

33mm or more To every 3m

Piping materials

Piping installation

Fixing the pipe

Medium-sized gas boiler

42

Heating and hot water piping installation

The exposed pipes shall be heat insulated with the

insulation material.

The exposes pipes may get frozen in the winter.

If the water supply pipe is frozen, the hot water is not

supplied. When the heating pipe has run out of water, the

water is not supplemented. Consequently, the boiler can

not operate normally.

Fix the parts of the boiler pipes with appropriate tools,

prior to piping installation.

Do not exert excessive force on the pipe during the

installation, Damages on the parts may cause a water leak.

Be sure to use the insulation flange on the heating

inlet and outlet in case of installation of the copper

pipe (the hot water inlet and outlet for a boiler

dedicated for hot water supply).

Failure to use the insulation flange may cause rapid

corrosion (rusty water).

We do not take the responsibility of the problems arising from

failure to use the insulation flange.

Do not use water, other than the tap water, for the

boiler.

Salt content in the sea water or spa water may accelerate

corrosion and shorten the life of the boiler.

We do not take the responsibility of the problems caused by

using water, other than the tap water.

Install the pipes as illustrated in the standard pipe

drawing.

Failure to install the pipe as illustrated in the standard

piping drawing may deteriorate the efficiency of the

boiler and the circulation of the heating water, which

may result in a boiler malfunction.

6

Medium-sized gas boiler

43

A separable union connection or a nut connection shall be performed on the connection points.

The piping materials shall comply with the Korea Standard.

Do not use the metals with different electric potentials to install the piping in the

dedicated boiler for hot water supply, (For example, do not install the copper pipe in the

iron boiler.) which may cause galvanic corrosion, eventually generating rusty water.

Do

not

use the rubber hose for the faucet, when installing the piping.

Be

sure

to remove foreign objects inside the pipe prior to the piping installation.

Install the piping correctly for the water supply, the hot water supply, the heating, and

the drain.

The

heating

pipe shall be equipped with the heating strainer.

If the

water

supply pressure exceeds the allowable working pressure specified on the

name plate, be sure to install the depressurizing valve.

Proper

measures

shall be taken against a water leak through a water leak test for the

entire piping after completion of installation.

The entire pipelines, except for the gas pipe, shall be provided with heat insulation to

protect against getting frost, after completion of installation. (Especially, care shall

be taken for the water supply and the hot water pipes.)

Be sure to install the pressure release pipe for installation of the boiler. If it is

impossible to install the pressure release pipe, the safety valve, operating below the

maximum allowable working pressure of the boiler, shall be installed.

(The maximum allowable working pressure of the boiler is presented in the

“Specifications”.)

Never install the valve and the check valve in the pipeline where the pressure release

pipe or the safety valve is installed.

Select the boiler expansion tank, if necessary, with a capacity suitable for the boiler

in use.

Do not use the water inlet for the purpose of the drain, and vice versa.

If the water is supplied to the boiler from the rooftop water tank, be sure to install the

water supply pipe in the auxiliary tank, separate from the rooftop water tank, for

water supply to the boiler.

Install the pipes as illustrated in the standard pipe drawing.

Precautions for piping installation

Considerations in common

Medium-sized gas boiler

44

Model no. : KDB-535, 735 GTD, GTS

KDB-535, 735, 1035, 1535, 2035 GPD, GPS

Open piping system

- Be sure to comply with the instructions presented in the “Considerations in common”.

- Be sure to install the air vent valve in the distributor.

- The return water distributor shall be installed below the heating inlet on the boiler.

- The pressure release pipe shall be installed to exceed 25A.

- Never supply the water with a pressure higher than the maximum allowable working

pressure of the boiler specified on the name plate, nor connect the water pipe directly

for the piping.

- The reverse flow of the heating water into the expansion tank, while operating or

stopping the circulation pump, results from too much air in the pipe. (Open the valve in

the distributor one by one and remove the air from the pipe, while operating the

circulation pump.)

- The expansion tank shall be installed at least 1.5m above the heat dissipation surface in

case of the upward type, and at least 1.5m above the top of the boiler in case of the

downward type.

- The piping installation shall be performed not to mix the heating water and the hot

water.

Closed piping system

- Be sure to comply with the instructions presented in the “Considerations in common”.

- Be sure to install the strainer, the depressurizing valve, the check valve, and the closed

expansion tank, in order to directly connect the boiler to the water pipe.

- Be sure to install the depressurizing valve and the check valve in the water supply pipe.

- Install the air vent on top of the heat dissipation surface to facilitate air vent.

- Be sure to install the strainer in the water supply pipe, in order to prevent metal and

foreign objects from flowing into the water supply pipe.

- Be sure to install the safety valve.

- Be sure to install the closed expansion tank with an appropriate capacity.

Precautions for the piping installation for the combi boiler for

heating and hot water supply / the dedicated boiler for heating

Medium-sized gas boiler

45

Composition

1. Body

2. Cap

3. Cap gasket

4. Strainer screen

Features:

The device is to remove foreign objects in the boiler and the heating pipeline.

1. Prevention of corrosion in the pipe: The portion of accumulated foreign objects inside the pipe

gets corroded first. Accordingly, the foreign objects shall be strained to prevent corrosion.

2. Extension of the boiler life: The accumulated foreign objects obstruct heat transfer, and the

accumulated portion is overheated, which shortens the life of the boiler. Consequently, the

foreign objects shall be strained to extend the boiler life.

3. Protection of main equipment: The heating circulation pump, the valve, and other equipment

are protected from being damaged by foreign objects.

Installation method

1. Install the strainer in the direction of the heating water flow, as indicated in the body of the

heating strainer.

2. You may install the strainer in a horizontal or vertical direction, as desired.

3. Install the valves on each end of the heating strainer, in order to prevent the heating water

from draining during cleaning of the strainer.

4. The pocket shall be installed to face the ground surface, and a sufficient space shall be

provided for cleaning the strainer.

The method of cleaning (Removal of foreign objects)

1. Close the valves on each side of the strainer, to

completely shut off the heating water.

2. Open the cap to remove the foreign objects on the

strainer screen.(! Caution: Care shall be taken against

a burn, possibly caused by the heating water.)

3. After cleaning, check if there is a leak of the heating

water. Then, open the valve to use the strainer.

4. The heating strainer shall be cleaned periodically. At

the beginning of use, foreign objects usually remain

in the pipe, which shall be cleaned out.

STRAINER

Medium-sized gas boiler

46

Model no.: KDB-535, 735 GTG

KDB-1035, 1535, 2035 GPG

Open piping system

- Be sure to comply with the instructions presented in the “Considerations in common”.

- Never supply the water with a pressure higher than the maximum allowable working

pressure of the boiler specified on the name plate, nor connect the water pipe directly

for the piping.

- Be sure to use the coated piping material and the stainless piping material for the

dedicated boiler for hot water supply.

- The pressure release pipe shall be installed to exceed 25A.

- The expansion tank shall be installed at least 1.5m above the maximum height of the

hot water pipe in case of the upward type, and at least 1.5m above the top of the boiler

in case of the downward type.

- When installing the hot water storage tank, connect the hot water outlet to lower part (inlet)

of the hot water tank, and the hot water inlet to the upper part (outlet) of the hot water tank.

- Use the connection wire to the circulation pump of the boiler to install the hot water

storage tank separately.

- If the water pressure is too low, attach an additional pump to the hot water outlet.

- When attaching an additional pump, be sure to install the pressure switch (S/W) and the

check valve. (Do not connect them to the wire of the circulation pump of the boiler.)

Closed piping system

- “Be sure to comply with the instructions presented in the “Considerations in common”.

- Be sure to install the strainer, the depressurizing valve, the check valve, the safety valve,

and the closed expansion tank, in order to directly connect the boiler to the water pipe.

- Be sure to use the coated piping material and the stainless piping material for the dedicated

boiler for hot water supply.

- Be sure to install the depressurizing valve and the check valve in the water supply pipe.

- Install the air vent on top of the hot water supply pipe to facilitate air vent.

- Be sure to install the safety valve.

- Be sure to install the closed expansion tank with an appropriate capacity.

- When installing the hot water storage tank, connect the hot water outlet to lower part (inlet)

of the hot water tank, and the hot water inlet to the upper part (outlet) of the hot water tank.

-

Use the connection wire to the circulation pump of the boiler, in order to install the hot

water storage tank separately.

- If the water pressure is too low, attach an additional pump to the hot water outlet.

-

When attaching an additional pump, be sure to install the pressure switch (S/W) and the

check valve. (Do not connect them to the wire of the circulation pump of the boiler.)

Precautions for the piping installation for the

dedicated boiler for hot water supply

Medium-sized gas boiler

47

Exhaust / Intake vent installation

Installation of the exhaust and intake chimney

pipe (chimney) shall be performed in a specified

method.

Incorrect installation of the exhaust and intake

chimney pipe (chimney) may lead to an exhaust

gas poisoning.

The connection points of the exhaust and intake

pipes shall be free from any leakage.

The exhaust gas, if flowing into the indoors, may

cause carbon oxide poisoning.

The air intake or the exhaust vent shall be

installed in the outdoors or a well-ventilated

place where the exhaust gas emitted from the

vent does not flow into the indoors.

The exhaust gas, if flowing into the indoors, may

cause carbon oxide poisoning.

Be sure to install the air intake and the exhaust

vent.

Failure of ventilation may lead to incomplete

combustion due to oxygen deficiency, which may

eventually result in carbon oxide poisoning.

The boiler of the forced exhaust type (FE) can

not employ the multiple exhaust ducts.

The reverse flow of the exhaust gas may cause

carbon oxide poisoning.

7

Medium-sized gas boiler

48

The horizontal section of the chimney pipe shall

be installed to be inclined downward at an angle

of 5°, to prevent the condensed water or rain

from flowing in reverse into the boiler.

Flow of the condensed water or rain into the

boiler may deteriorate the performance of the

boiler and shorten the life of the boiler.

r

■ The exhaust duct type of the forced exhaust type (FE) boiler: the single exhaust type, the

chamber type, the shared exhaust type

■

The total length of the exhaust duct shall be kept to 10m or less, and the curved parts to 3

segments or less. (except for the curve on the edge point of the exhaust duct)

■ The connection size of the exhaust duct shall comply with the specifications. (Refer to the

specifications.)

■ Care shall be taken to prevent the middle part of the exhaust duct from getting narrower. The

exhaust duct shall be installed to keep the radius of the curved part at maximum as possible.

■ The exhaust duct shall be heat insulated with the non-flammable insulation material.

Installation of the chimney pipe for the forced exhaust type (FE) boiler

Medium-sized gas boiler

49

■

The exhaust duct shall be made of the stainless steel (pipe) or the heat- and corrosion-

resistant metal.

■

The exhaust duct shall be connected, if necessary, to the boiler tightly not to be pulled

out or shaken.

■

If the exhaust duct passes through the combustible wall or the ceiling made of

combustible material, the exhaust duct shall be heat insulated with a non-flammable

material with a thickness of more than 20mm, and kept at least 50mm away from the

wall or the ceiling. In addition, the exhaust duct, if passing through the ceiling, shall be

equipped with the inspection hole.

■

The exhaust duct shall be installed as a single unit, if possible. Never use the exhaust

duct in common with the heaters of the natural exhaust type or those using other fuel

(briquette, petroleum).

■

The air intake shall be provided in a well-ventilated place such as the outdoors, into

which the exhaust gas emitted from the exhaust duct does not flow.

(

※

Make sure that failure of air intake and ventilation causes oxygen deficiency,

eventually leading to incomplete combustion.)

■

Bore holes in the wall to install the vent on the upper side of the wall and the air intake

on the lower side, to facilitate ventilation.

■

The effective cross-sectional area of the air intake or the vent shall be larger than that of

the exhaust duct.

■

The bird protection net shall be installed on top of the exhaust duct so that birds, mice or

objects with a diameter of more 16mm can not go into the exhaust duct.

■

A space of more than 300mm shall be provided between the top of the exhaust duct and

the outer wall surface, if non-flammable.

If the exhaust duct is to be installed and concealed into the ceiling, the connection points

shall be securely connected to prevent exhaust gas leakage. Then, wind a non-flammable

material, other than the metal, around the connection points.

Finish the connection points using the heat resistant silicon (except for the plaster bandage).

Install the inspection hole to check and repair the exhaust pipe in a dark side.

In order to extend the exhaust pipe, install one hanger at least every 900mm and tighten the

installed hangers securely. (in case of the pipe extension with a length of more than 1m)

Incorrect installation of the exhaust pipe may cause deteriorated performance of the

product as well as a disaster. Consequently, the installation shall be performed in

accordance with this manual.

Installation of the chimney pipe

Medium-sized gas boiler

50

Combi boiler for heating and hot water supply-

“

Open expansion tank”

Standard piping drawing

Combi boiler for heating and hot water supply-

“

Closed expansion tank”

Medium-sized gas boiler

51

Dedicated boiler for hot water supply

“

Closed expansion tank”

Medium-sized gas boiler

52

Installation of the temperature controller

■ Install the temperature controller on the wall of the room to be provided with

frequent indoor heating.

The temperature controller shall be installed 1.2m to 1.5m above the floor, with

sufficient air circulation.

■ Do not install the controller in a place nearby the frequently opened door, or

where cold wind blows, or under direct sunlight, or easily accessible by children.

(The example of the installation place, ● : Temperature controller

1. Connect 2 temperature controller wires from the boiler to 2 wires on the rear side

of the temperature controller securely.

2. Fix the bracket of the temperature controller onto the desired position on the wall,

or into the holes of the wall outlet using a bolt.

3. Install the temperature controller by hanging the connection wire onto the

bracket carefully in the desired direction.

Note : Do not exert excessive force while connecting the wire, and secure the bolt tightly. Pushing the

temperature controller upward will separate the temperature controller and the bracket. If the cover of

the wire peels off or the terminal connection is inferior, the temperature controller may not function

normally. Consequently, care shall be taken for the insulation treatment of the temperature controller.

8

Installation place

Installation method

Medium-sized gas boiler

53

Check points for test operation

1) Check if the boiler is installed correctly.

① Check if the floor surface is made of strong and flat non-flammable materials

such as concrete and if the surrounding area is also made of non-flammable

materials.

② Check the air intake and vent in the boiler room.

③ Check if the boiler room is provided with a drain, and if the boiler is equipped

with the drain valve.

④ Check if the boiler and the pipeline are heat insulated to prevent frost damage.

⑤ Check if the flue pipe is correctly installed.

⑥ Check if rain does not permeate through the penetration portion of the exhaust

pipe.

⑦ Check if the boiler is evenly installed.

⑧ Check if there is water leakage near the piping connection joint.

⑨ Check if there is any leakage near the gas pipe connection joint.

⑩ Check if the boiler room is equipped with the gas leak alarm device and the gas

breaker.

- The location of installation of the gas leak alarm device

LNG : 300mm from the ceiling

LPG : 300mm from the floor

⑪ Check if the fuel is the same as the gas specified on the name plate of the boiler.

⑫ Check if the pressure release pipe or the safety valve are installed in the boiler.

⑬ Check if the ground wire is connected. (If the ground connection is made on the

fuel pipe or the lightning rod, change the position.)

9

Medium-sized gas boiler

54

1) Open the water supply valve to supplement water in the boiler.

The water supply pressure shall be kept to less than the allowable working pressure,

specified on the name plate of the boiler.

- Upon completion of water supplement, the makeup water lamp on the controller

goes out.

2) Connect the boiler to the power supply.

Do not touch the power cord with wet hands.

3) Push the power switch of the boiler controller to on.

4) Open the valve on the fuel line.

5) Set the room temperature controller S/W at the operation mode.

6) After ignition of the boiler, check the combustion mode and the heating

circulation mode.

① Set the temperature on the temperature controller → Set the room temperature

controller button (High speed, Temperature, Time) at ON → Operation of the

burner fan → Check the gas pressure → Check the wind pressure →

Operation of the ignition transformer → Open the 1

st

and 2nd gas valve →

Ignition → Flame detection → Combustion → ON/OFF in accordance with

the temperature setting (operation of the circulation pump)

② Check if the boiler stops operation and the circulation pump is operating, by

adjusting the temperature controller from the boiler controller.

7) Press the “Hot water” button on the room temperature controller (DR-1), in

order to check if the circulation pump stops operation and hot water is supplied.

8) Press the “Outside” button on the room temperature controller to check if the

boiler stops operation.

Test operation

Medium-sized gas boiler

55

Electric Wiring Diagram

10

Medium-sized gas boiler

56

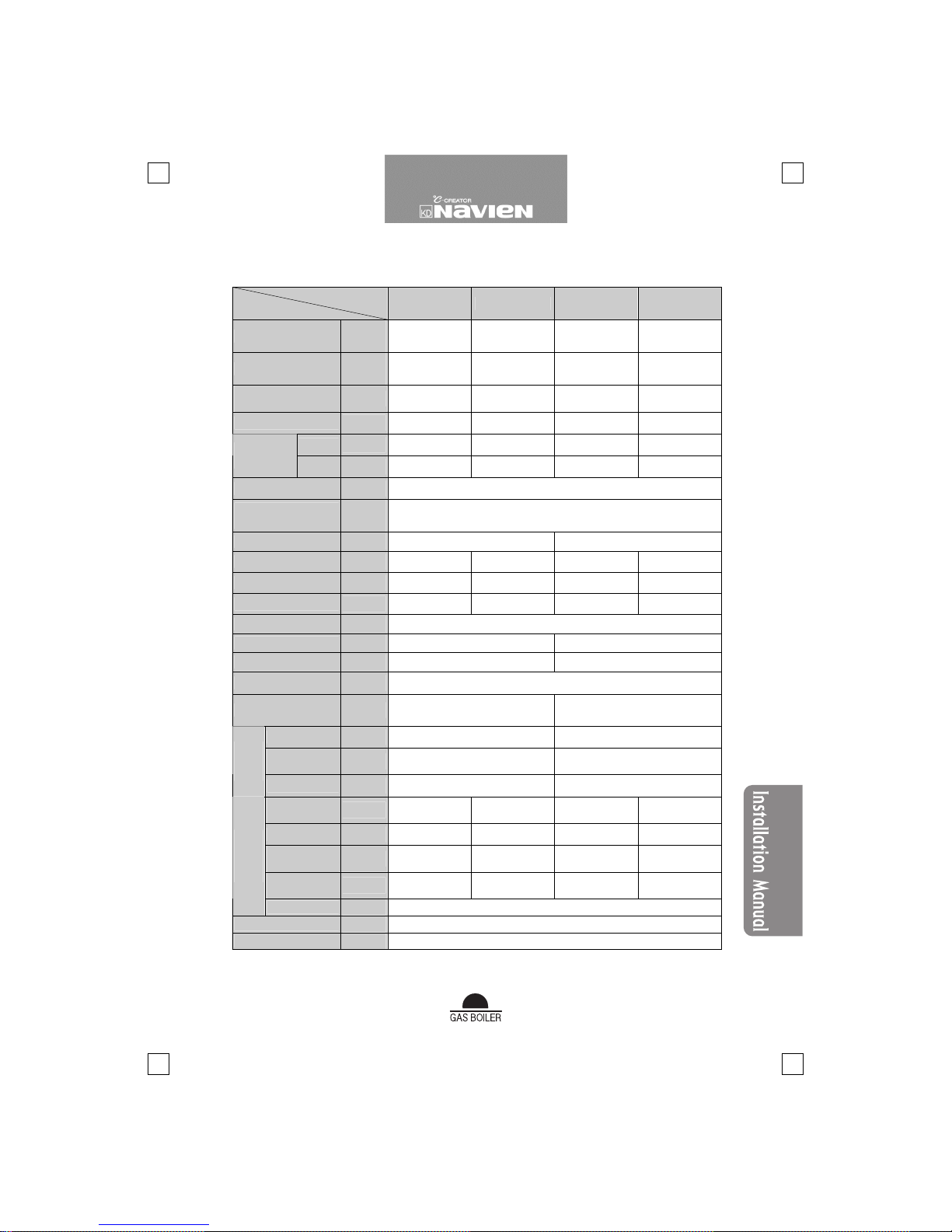

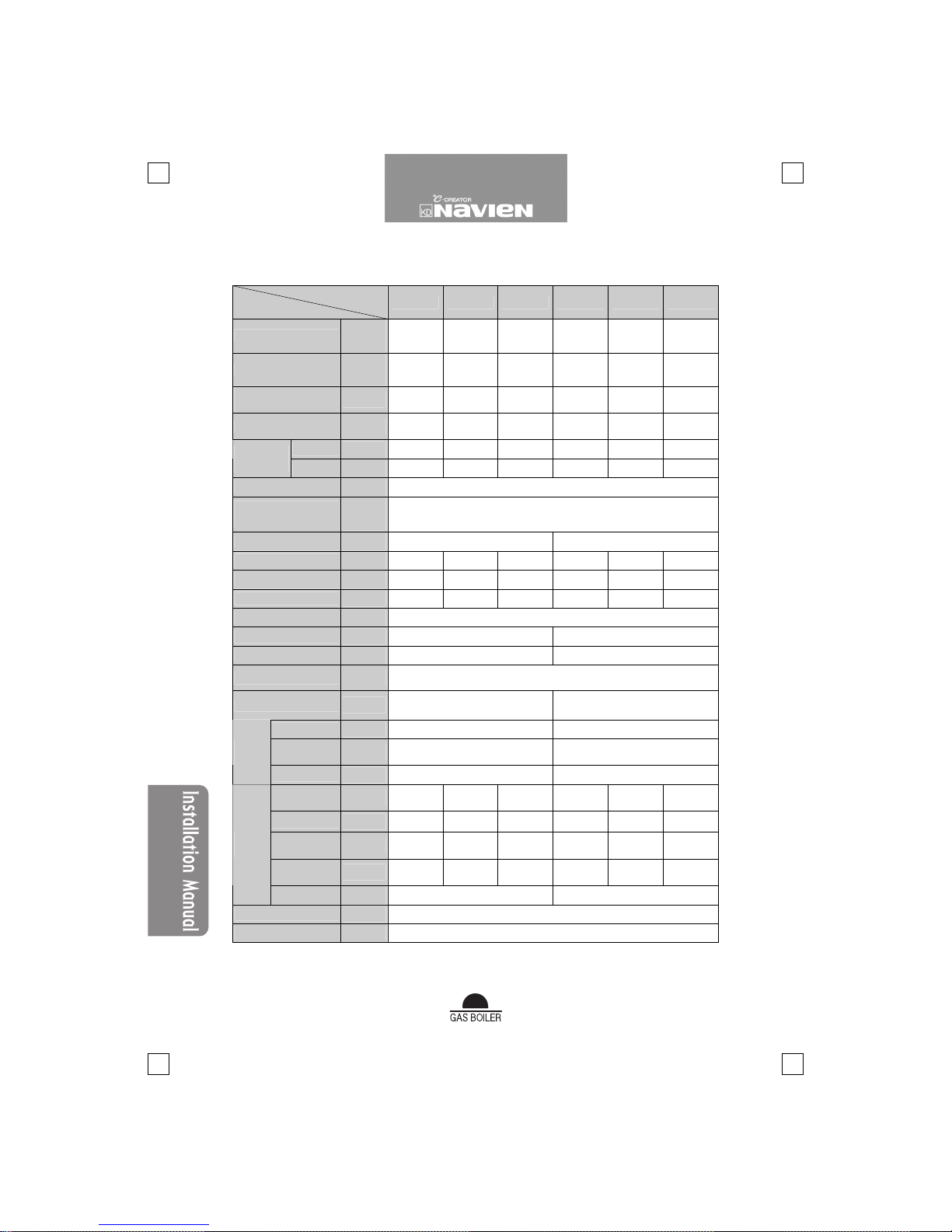

Specifications

1) Stainless boiler

Model no.

Classification

535GTD 535GTS 535GTG 735GTD 735GTS 735GTG

Heating output

kcal/h

(kW)

50,000

(58.1)

50,000

(58.1)

-

70,000

(81.3)

70,000

(81.3)

-

Hot water output

kcal/h

(kW)

50,000

(58.1)

-

50,000

(58.1)

70,000

(81.3)

-

70,000

(81.3)

Hot water supply

capacity (△ 40℃)

ℓ

/min

21 - 21 29 - 29

Purpose

Combi

Heating

only

Hot water

only

Combi

Heating

only

Hot water

only

LNG

%

92.3 92.2 92.2 92.6 92.8 92.8

Efficieny

(Total)

LPG

%

92.3 92.2 92.2 92.6 92.8 92.8

Fuel

City gas (13A), LP gas

Maximim allowable

working pressure

kgf/cm

2

(MPa)

3.5 (0.343)

Heat transfer area

m2

1.96 2.78

Heating area

m2

100 100 - 140 140 -

Volume of pipe water ℓ

40 46 46 60 68 68

Weight

kg

100 93 93 110 102 102

Power supply

1φ, 220V, 50Hz

Burner Model no.

KPG-50A KPG-70A

Power consumption

W

143 208

Gas pressure

mmH2O

LN gas : 200

+

50

-

100

, LP gas : 280±50

Fuel consumption

LNG : 61,000kcal/h(70.9kW)

LPG : 5.1kg/h(70.9kW)

LNG : 84,000kcal/h(97.6kW)

LPG : 7kg/h(97.6kW)

Width

Ng mm

547 547

Depth +

Burner

mm

848 837

size

Height

mm

1,032 1,240

Heating inlet

·

Outlet

A

40 40 - 40 40 -

Drain

A

40 40 40 40 40 40

Discharge

outlet

A

40 40 40 40 40 40

Hot water

inout·Outlet

A

20

-

40 20 - 40

Piping

size

Gas inlet

A

15

Chimney size

φ

148

Exhaust gas

℃

250 or less

※

The specifications presented in this manual is subject to change without notice for quality improvement.

11

Medium-sized gas boiler

57

2) Steel boiler

Model

Classification

535GPD 535GPS 735GPD 735GPS

Heating output

kcal/h

(kW)

50,000

(58.1)

50,000

(58.1)

70,000

(81.3)

70,000

(81.3)

Hot water output

kcal/h

(kW)

50,000

(58.1)

-

70,000

(81.3)

-

Hot water supply

capacity (△

40℃)

ℓ

/min

21

-

29 -

Purpose

Combi Heating only Combi Heating only

LNG

%

92.6 92.7 92.8 92.8

Efficiency

(Total)

LPG

%

92.6 92.7 92.8 92.8

Fuel

City gas (13A), LP gas

Maximum allowable

working pressure

kgf/cm

2

(MPa)

3.5 (0.343)

Heat transfer area

m2

2.34 3.10

Heating area

m2

100 100 140 140

Volume of pipe water

ℓ

56 63 72 85

Weight

kg

151 146 180 173

Power supply

1φ, 220V, 50Hz

Burner Model no.

KPG-50A KPG-70A

Power consumption

W

143 208

Gas pressure

mmH2O

LP gas: 280±50, LNG : 200

+50

-100

Fuel consumption

LNG : 61,000kcal/h(70.9kW),

LPG : 5.1kg/h(70.9kW)

LNG : 84,000kcal/h(97.6kW),

LPG : 7kg/h(97.6kW)

Width

mm

547 547

Depth +

Burner

mm

850 838

Prod

uct

size

Height

mm

1,148 1,410

Heating inlet

·

outlet

A

40 40 40 40

Drain

A

40 40 40 40

Discharge

outlet

A

40 40 40 40

Hot water

inlet·outlet

A

20

-

20 -

Pipi

ng

size

Gas inlet

A

15

Flue size

φ

148

Exhaust gas

℃

250 or less

※

The specifications presented in this manual is subject to change without notice for quality improvement.

Medium-sized gas boiler

58

3) Steel boiler

Model

Classifications

1035GPD 1035GPS 1035GPG 1535GPD 1535GPS 1535GPG

Heating Output

kcal/h

(kW)

100,000

(116.2)

100,000

(116.2)

-

150,000

(174.4)

150,000

(174.4)

-

Hot water Output

kcal/h

(kW)

100,000

(116.2)

-

100,000

(116.2)

130,000

(151.1)

-

150,000

(174.4)

Capacity of hot water

supply (△

40℃)

ℓ

/min

42 - 42 54 - 63

Purpose

Combi

Heating

only

Hot water

only

Combi

Heating

only

Hot water

only

LNG

%

91.2 91.2 91.2 91.5 91.5 91.5

Efficiency

(Total)

LPG

%

91.2 91.2 91.2 91.5 91.5 91.5

Fuel

Citygas (13A), LP gas

Maximum allowable

working pressure

kgf/cm

2

(MPa)

3.5 (0.343)

Heat transfer area

m2

3.32 4.77

Heating area

m2

662 662 - 992 992 -

Volume of pipe water

ℓ

135 148 148 173 188 188

Weight

kg

267 248 248 390 370 370

Power supply

1φ, 220V, 50Hz

Burner Model no.

KPG-100A KPG-150A

Power consumption

W

224 232

Gas pressure

mmH2O

LP gas: 280±50, LNG : 200

+50

-100

Fuel consumption

LNG : 124,000kcal/h(144.1kW)

LPG : 10.3kg/h

(144.1kW)

LNG : 178,000kcal/h(206.9kW)

LPG : 14.8kg/h(206.9kW)

Width

mm

687 796

Depth

+

Burner

mm

994 1,094

Product

Size

Height

mm

1,403 1,411

Heating inlet

·

outlet

A

65 65 - 80 80 -

Drain

A

65 65 65 80 80 80

Discharge

outlet

A

65 65 65 80 80 80

Hot water

inlet·outlet

A

20

-

65 20 - 80

Piping

size

Gas inlet

A

20 25

Flue size

φ

200

Exhaust gas

℃

250 or less

※

The specifications presented in this manual is subject to change without notice for quality improvement.

Medium-sized gas boiler

59

4) Iron boiler

Model

Classification

2035GPD 2035GPS 2035GPG

HeatingOutput

kcal/h

(kW)

200,000

(232.5)

200,000

(232.5)

-

Hot waterOutput

kcal/h

(kW)

130,000

(151.1)

-

200,000

(232.5)

Hot water supply

capacity (△

40℃)

ℓ

/min

63 - 83

Purpose

Combi Heating only Hot water only

LNG

%

92.0 92.0 92.0

Effici

ency

(Total)

LPG

%

92.0 92.0 92.0

City gas (13A), LP Gas

Maximum allowable

working pressure

kgf/cm

2

(MPa)

3.5 (0.343)

Heat transfer area

m2

6.46

Heating area

m2

1323 1323 -

Volume of pipe water

ℓ

237 255 255

Weight

kg

475 450 450

Power supply

1φ, 220V, 50Hz

Burner

Model no.

KPG-200A

Power consumption

W

366

Gas pressure

mmH2O

LP gas: 280±50, LNG : 200

+50

-100

Fuel consumption

LNG : 24Nm3/h, 252,000kcal/h(293.0kW), LPG : 21kg/h

Width

mm

796

Depth +

Burner

mm

1,165

Product

size

Height

mm

1,716

Hot water

inlet·outlet

A

80 80 -

Drain

A

80 80 80

Discharge

outlet

A

80 80 80

Hot water

inlet·outlet

A

20

-

80

Piping

size

Gas inlet

A

32

Flue size

φ

200

Exhaust gas

℃

250 or less

※

The specifications presented in this manual is subject to change without notice for quality improvement.

Medium-sized gas boiler

60

MEMO

Medium-sized gas boiler

61

MEMO

Medium-sized gas boiler

62

MEMO

Medium-sized gas boiler

63

MEMO

Medium-sized gas boiler

64

MEMO

Loading...

Loading...