ATU-HP

Automatic

Antenna Tuning

Unit

Technical Instruction Manual

Issue 2.0 .........................06 October 2011

Nautel Limited

10089 Peggy's Cove Road,

Hackett's Cove, NS, Canada B3Z 3J4

T.+1.902.823.2233 F.+1.902.823.3183

info@nautel.com

U.S. customers please contact:

Nautel Inc.

201 Target Industrial Circle, Bangor ME 04401

T.+1.207.947.8200 F.+1.207.947.3693

info@nautel.com

e-mail: support@nautel.com

www.nautel.com

© Copyright 2011 NAUTEL. All rights reserved.

Warranty

by Nautel Limited/Nautel Inc. (herein after referred to as Nautel)

Nautel Limited/Nautel Incorporated, hereinafter referred to as Nautel, guarantees all mechanical and electrica l par ts of

the equipment for a period of thirteen months from date of shipment.

1. A "Part Failure" shall be deemed to have occurred when the part has become defective, or does not have the

characteristics required for the specified equipment performance:

(a) When the equipment is operated within the design parameters, and

(b) When the equipment is installed and adjusted according to Nautel's prescribed procedures as stated in

2. Nautel shall provide replacements for all "Parts" at no cost to the Customer when they become defective during

3. In the event that a "Part" fails during the warranty period and causes damage to a sub-assembly that cannot be

4. Where warranty replacements or repair are provided under items 2 or 3, Nautel will pay that part of the shipping

5. Warranty replacement parts and repair, which are provided under items 2 or 3, shall be guaranteed for a period

6. Nautel will not assume responsibility fo r any ch ar ges incurr ed by ot her t han Na ute l employ ee s.

7. Nautel shall have the privilege of investigating whether failures have been caused by factors beyond its control.

8. Nautel shall in no event be liable for any consequential damages arising from the use of this equipment.

9. When requesting a warranty repair/replacement, please provide complete and accurate information. Observe

10. When ordering spare/replacement parts, please provide complete and accurate information. Refer to the parts

the instruction manual.

the warranty period, and upo n the ret urn of the de fect ive par t.

readily repaired in the field, the entire sub-assembly so damaged may be returned to Nautel for repair. The

repairs will be made without charge to the Customer.

costs incurred in returning the part/assembly t o t he C u sto mer .

of ninety days from date of shipment or until the end of the original warranty period, whichever occurs later.

the instructions regarding 'Equipment Being Returned to Nautel' on page two of this warranty and provide the

information requested.

list of the Repair manual for ordering info rmat ion. Provid e as mu ch of the inf orma tio n requ este d for 'E quip ment

Being Returned to Nautel' on page two of this warranty as is practical. The information identified by an asterisk

is the minimum required.

Nautel Limited Nautel Inc.

10089 Peggy's Cove Road 201 Target Industrial Circle

Hackett's Cove NS Canada B3Z 3J4 Bangor ME USA 04401

T. 1.902.823.2233 F. 1.902.823.3183 T. 1.207.947.8200 F. 1.207.947.3693

24hr. Answering Service 1.902.823.3900

Customer Service Notice

A ‘Technical Assistance’ and ‘Plug-in Module Exchange’ service is available to Nautel users.

ATU-HP Technical Instruction Manual Oct.06.11

Factory Support

TECHNICAL ASSISTANCE

Nautel's field service department provides telephone technical assistance on a 24 hour, seven days a week basis.

Requests by other media (facsimile or e-mail) will be responded to the next working day if rece ived after Nautel's normal

working hours. Contact the appropriate field service centre from the following:

U.S.A. customers use: Nautel Incorporated Telephone 207-947-8200 (24 hours)

201 Target Industrial Circle Facsimile 207-947-3693

Bangor, Maine 04401

All other customers use: Nautel Limited Telephone 902-823-3900 (24 hours)

10089 Peggy’s Cove Road, Facsimile 902-823-3183

Hackett’s Cove, NS, Canada E-Mail support@nautel.com

B3Z 3J4 Web www.nautel.com

MODULE EXCHANGE SERVICE

In order to provide Nautel customers with a fast and efficient service in the event of a problem, Nautel operates a

factory rebuilt, module exchange service which takes full advantage of the high degree of module redundancy in

Nautel equipment. This module exchange service is operated from Nautel’s factory in Bangor, Maine and Hackett’s

Cove, Nova Scotia. These two locations allow us to provide a quick turn around service to keep our customers on

the air. During the transmitter’s warranty period, up to thirteen months from shipment, repair and exchange of

modules is at no charge to the customer. When the warranty has expired, a charge of 80% of the list price for all

exchanged modules is made. If the faulty module is returned to Nautel within 30 days, a credit is issued reducing

this charge by one half to 40% of the list price. U.S.A. customers are required to contact our Bangor, Maine facility.

Canadian and overseas customers should contact our Nova Scotia, Canada facility.

EQUIPMENT BEING RETURNED TO NAUTEL

All equipment being returned to Nautel and all requests for repairs or replacements should be marked 'field return' and

addressed to the appropriate Nautel facility.

Complete and accurate information regarding the equipment being returned will ensure prompt attention and will

expedite the dispatch of replacements. Refer to the nameplate on the transmitter and/or the appropriate

module/assembly to obtain name, type, part and serial number information. Refer to the parts list of this manual or the

appropriate service instruction manual for additional ordering information.

The following information should accompany each request:

* Model of Equipment

* Serial number of Equipment

* Name of Part/Assembly

Serial number of Part/Assembly

* Complete reference designation of Part/ Asse mbly

* Nautel's part number of Part/ Assemb ly

* OEM's part number of Part/Assembly

Number of hours in Use

Nature of defect

* Return shipping address

* Denotes minimum information required to order spare/replacement parts

ATU-HP Technical Instruction Manual Oct.06.11

Safety

Symbols

General definitions of safety symbols used on equipment or in manuals.

DANGER – HIGH VOLTAGE

Indicates dangerous voltages (in excess of 72 V), capable of causi ng a fatal

electrical shock, are present on or near parts bearing this label.

GROUND (EARTH)

Used with wiring terminals to indicate the terminal must be connected to

earth ground before operating equipment. If power is supplied without

grounding the equipment, there is a risk of receiving a severe or fatal

electrical shock. Also used on electrical schematics to indicate a part that is

connected to earth ground.

GROUND (PROTECTIVE or SAFETY)

Used with protective (safety) conductor terminals to indicate the terminal

must be connected to ground before operating the equipment. If power is

supplied without grounding the equipment, there is a risk of receiving a

severe or fatal electrical shock.

ELECTROSTATIC SENSITIVE

Indicates a part or assembly is or contains devices that are electrostatic

sensitive. To prevent damage to these devices, ensure the handling

procedures outlined in this manual are observed.

WARNING

CAUTION

NOTE

A WARNING denotes a hazard. It identifies an operating procedure,

condition, etc. which, if not strictly observed or adhered to, could result in

injury or death to personnel. Throughout the technical manual, a

WARNING shall immediately precede the text to which it applies.

A CAUTION denotes a hazard. It identifies an operating procedure,

condition, etc., which, if not strictly observed or adhered to, could result in

damage to, or destruction of the equipment. Throughout the technical

manual, a CAUTION shall immediately precede the text to which it

applies.

A NOTE denotes important information pertaining to an operating

procedure, condition, statement, etc., which is essential to highlight. A

NOTE may precede or follow the text to which it applies.

ATU-HP Technical Instruction Manual Oct.06.11

Safety

Toxic Hazard Warning

There are devices used in this equipment containing beryllium oxide ceramic,

which is non-hazardous during normal device operation and under normal device

failure conditions. These devices are specifically identified in the equipment

parts list(s).

DO NOT

HAZARDOUS IF INHALED. Unserviceable devices should be disposed of as

harmful waste.

cut, crush or grind devices because the resulting dust may be

ATU-HP Technical Instruction Manual Oct.06.11

Contents Page

1 GENERAL INFORMATION

1.1 INTRODUCTION 1-1

1.2 FACTORY SUPPORT 1-1

1.3 PURPOSE AND SCOPE OF MANUAL 1-1

1.4 PURPOSE OF EQUIPMENT 1-1

1.5 MECHANICAL DESCRIPTION 1-1

1.6 TECHNICAL SUMMARY 1-2

1.7 TEST EQUIPMENT AND SPECIAL TOOLS 1-2

2 PREPARATION FOR USE AND INSTALLATION

2.1 INTRODUCTION 2-1

2.2 PREPARATION FOR USE 2-1

2.2.1 Mounting Considerations 2-1

2.2.2 Environmental Considerations 2-1

2.2.3 Proximity to Transmitter 2-1

2.2.4 Antenna Structure 2-1

2.2.5 Customer Required Interfacing 2-5

2.2.5.1 RF Output Feed Cable 2-5

2.2.5.2 Remote Control/Monitor Wiring 2-5

2.2.5.3 RF Input Cable 2-5

2.2.5.4 Ac Power Cable 2-5

2.2.5.5 Ground Connection 2-5

2.2.6 Pre-Startup User Determined Information 2-6

2.2.6.1 Carrier Frequency 2-6

2.2.6.2 Antenna Capacitance 2-6

2.2.7 Parts Supplied by Nautel 2-7

2.2.8 Test Equipment 2-7

2.2.9 Available Options 2-7

2.2.9.1 Solar Shield 2-7

2.2.9.2 Frequency Agile Capacitor Kit 2-7

2.2.9.3 Series Resistor 2-7

2.3 UNPACKING 2-7

2.4 INSTALLATION 2-10

2.5 SYSTEM TURN-ON/TUNING PROCEDURE 2-10

2.5.1 Adjusting the Spark Gap 2-26

2.6 INCREASING ANTENNA BANDWIDTH 2-28

3 OPERATING INSTRUCTIONS

3.1 INTRODUCTION 3-1

3.2 EMERGENCY SHUTDOWN 3-1

3.3 CONTROLS AND INDICATORS 3-1

ATU-HP Technical Instruction Manual Oct.06.11

Contents Page

4 TESTING AND ADJUSTMENT

4.1 INTRODUCTION 4-1

4.2 OPERATING PRECAUTIONS 4-1

4.3 FUNCTIONAL TESTS 4-1

4.3.1 General 4-1

4.3.2 Initial Settings 4-1

4.3.3 Manual Check of Tuning Drive 4-2

4.3.3.1 Inductive Tuning Motor 4-2

4.3.3.2 Resistive Tuning Motor 4-2

4.3.4 Initial Check of RF Tuning and

Automatic Operation 4-3

4.3.5 Final Tuning of RF Circuits 4-4

4.4 NON-STANDARD ADJUSTMENTS 4-5

4.4.1 Antenna Current Meter Calibration 4-5

5 MAINTENANCE AND TROUBLESHOOTING

5.1 GENERAL 5-1

5.2 SCHEDULED MAINTENANCE 5-1

5.2.1 Cleaning the ATU-HP 5-1

5.2.2 Checking Hardware 5-1

5.3 CORRECTIVE MAINTENANCE 5-1

5.3.1 Replacing a Failed Fan 5-2

5.3.2 Checking/Replacing the Inductive

Tuning Motor 5-2

5.3.3 Checking/Replacing the Resistive

Tuning Motor 5-3

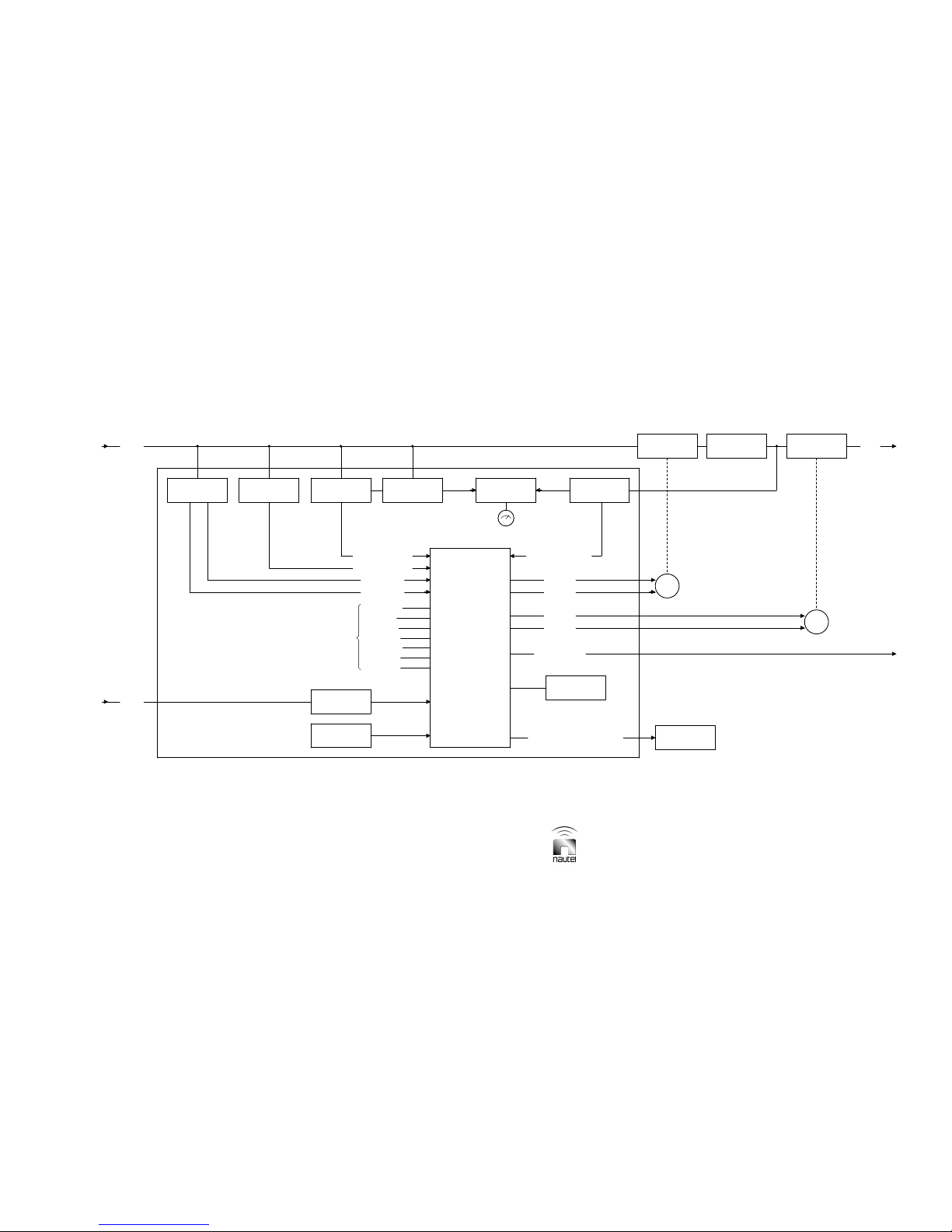

6 THEORY OF OPERATION

6.1 INTRODUCTION 6-1

6.2 ANTENNA TUNING UNIT OVERVIEW 6-1

6.2.1 ATU Control PWB 6-1

6.2.1.1 Power Supplies 6-1

6.2.1.2 Servo Probe 6-1

6.2.1.3 Forward/Reflected Power Probe 6-1

6.2.1.4 Input Voltage and Current Probes 6-1

6.2.1.5 Microcontroller 6-2

6.2.1.6 Antenna Current Probe 6-2

6.2.2 Matching Transformer/Current Probe 6-2

6.2.4 Tuning Coils 6-2

6.2.3 Resistive Matcher/Capacitor PWB 6-2

ATU-HP Technical Instruction Manual Oct.06.11

Contents Page

6.2.5 Tuning Drive Motor 6-2

6.3 DETAILED CIRCUIT DESCRIPTIONS 6-5

6.3.1 Servo Probe 6-5

6.3.2 Forward/Reflected Power Probe 6-5

6.3.3 Power Supplies 6-5

6.3.4 Current/Voltage Samples 6-6

6.3.5 Antenna Current Probe 6-6

6.3.6 Microcontroller Control 6-6

6.3.6.1 Analog Inputs 6-6

6.3.6.2 Digital Inputs 6-7

6.3.6.3 Digital Outputs 6-8

6.3.7 Serial Communications (RS485) 6-9

6.3.8 Motor Limit Control 6-9

7 PARTS INFORMATION

7.1 INTRODUCTION 7-1

7.2 REFERENCE DESIGNATIONS LISTS 7-1

7.3 COLUMN CONTENT EXPLANATION 7-1

7.3.1 Ref Des Column 7-1

7.3.2 Description Column 7-1

7.3.3 Nautel # Column 7-1

7.3.4 Vendor # Column 7-1

7.3.5 OEM Code Column 7-2

7.4 OEM CODE TO MANUFACTURER

CROSS-REFERENCE 7-2

7.4.1 Manufacturer’s Index 7-2

7.5 COMMON ABBREVIATIONS/ACRONYMS 7-2

8 WIRING INFORMATION

8.1 INTRODUCTION 8-1

8.2 WIRING LISTS NOT PROVIDED 8-1

8.3 PRINTED WIRING PATTERNS 8-1

8.4 WIRE COLORS 8-1

8.5 WIRING LISTS PROVIDED 8-1

9 ELECTRICAL SCHEMATICS

9.1 INTRODUCTION 9-1

9.2 COMPONENT VALUES 9-1

9.3 GRAPHIC SYMBOLS 9-1

9.4 LOGIC SYMBOLS 9-1

ATU-HP Technical Instruction Manual Oct.06.11

Contents Page

9.5 REFERENCE DESIGNATIONS 9-1

9.6 UNIQUE SYMBOLOGY 9-1

9.6.1 Type of Inputs/Outputs 9-1

9.6.2 Logic Level/Convention 9-1

9.7 IDENTIFICATION OF SCHEMATIC

DIAGRAMS 9-1

9.8 STRUCTURE OF SCHEMATICS 9-2

9.9 LOCATING THE SCHEMATIC DIAGRAM(S)

FOR A FUNCTIONAL BLOCK 9-2

9.10 LOCATING A PART/ASSEMBLY IDENTIFIED

ON A SCHEMATIC 9-2

10 MECHANICAL DRAWINGS

10.1 INTRODUCTION 10-1

10.2 LOCATING ASSEMBLY DETAIL DRAWINGS 10-1

10.3 CONTENT OF MECHANICAL DRAWINGS 10-1

List of Tables

1-1 Recommended Site Test Equipment and Special Tools 1-3

2-1a Frequency Dependent Capacitors for DGPS Applications 2-8

2-1b Frequency Dependent Capacitors for Low Power NDB Applications 2-8

2-1c Frequency Dependent Capacitors for High Power NDB Applications 2-9

2-1d Capacitors Ordering Information 2-9

2-2 Tuning Coil Inductance Values (μH) 2-11

2-3 T1 Matching Transformer 50 Ohm Connections 2-16

2-4 Determining ‘R Match’ 2-17

2-5 T1 Taps vs Resistance Ratio 2-17

2-6a Loading Coil (DGPS) Series Connection (500-136 μH) 2-20

2-6b Loading Coil (DGPS) Parallel Connection (135-20 μH) 2-21

2-6c Loading Coil (NDB Low Power) Series Connection (2700-640 μH) 2-22

2-6d Loading Coil (NDB Low Power) Parallel Connection (639-50 μH) 2-23

2-6e Loading Coil (NDB High Power) Series Connection (1200-300 μH) 2-24

2-6f Loading Coil (NDB High Power) Parallel Connection (299-25 μH) 2-25

2-7 T2 Taps vs Series Resistance 2-31

3-1 ATU Control/Monitor PWB Controls and Indicators 3-3

7-1 Manufacturer’s Index 7-3

8-1 Wiring Lists Provided 8-1

8-2 Wiring List – ATU-HP – Automatic Antenna Tuning Unit 8-2

9-1 Electrical Schematics 9-2

10-1 Mechanical Drawings 10-1

ATU-HP Technical Instruction Manual Oct.06.11

Contents Page

List of Figures/Drawings

1-1 ATU-HP Automatic Antenna Tuning Unit 1-2

2-1 Typical Site Layout 2-2

2-2 Examples of Typical Installations (Sheet 1 of 2) 2-3

2-2 Examples of Typical Installations (Sheet 2 of 2) 2-4

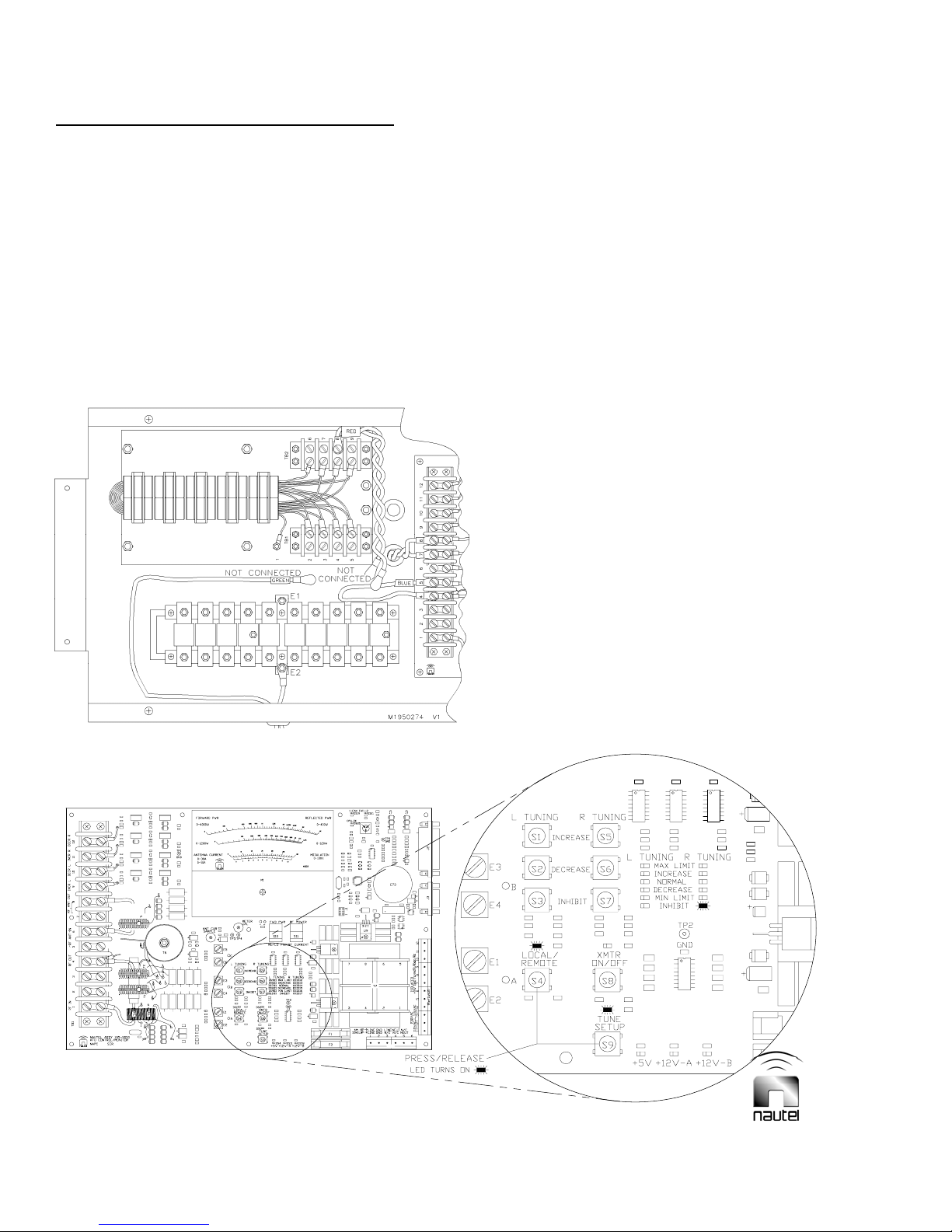

2-3 ATU-HP – Customer Interface Connections 2-6

2-4 Initial RF Wiring Connections 2-12

2-5 ATU Control/Monitor PWB – Pushbutton Switches and LEDs 2-12

2-6 Flow Diagram – Loading Coil Tuning 2-13

2-7 Post-Inductive Tuning RF Wiring Connections 2-14

2-8 Flow Diagram – Determining Antenna Resistance 2-15

2-9 Post-Resistive Tuning RF Wiring Connections 2-16

2-10 Variometer Positioning within Loading Coil L1A 2-18

2-11 Variable Matching Transformer 2-19

2-12a Loading Coil (DGPS) Series Connection (500-136 μH) 2-12

2-12b Loading Coil (DGPS) Parallel Connection (135-20 μH) 2-13

2-12c Loading Coil (NDB Low Power) Series Connection (2700-640 μH) 2-14

2-12d Loading Coil (NDB Low Power) Parallel Connection (639-50 μH) 2-15

2-12e Loading Coil (NDB High Power) Series Connection (1200-300 μH) 2-16

2-12f Loading Coil (NDB High Power) Parallel Connection (639-20 μH) 2-17

2-13 Peak Antenna Voltage Versus Spark Gap Setting 2-26

2-14a Flow Diagram – Adding Antenna Series Resistance (DGPS) 2-29

2-14b Flow Diagram – Adding Antenna Series Resistance (NDB) 2-30

2-15 Partial View of Series Resistance Transformer T2 Taps 2-31

2-16 ATU-HP – Dimensional Information and Mounting Options 2-32

3-1 Part of ATU Control/Monitor PWB A1 (NAPC144

6-1 Block Diagram of ATU-HP Automatic Antenna Tuning Unit 6-3

SD-1 Electrical Schematic – ATU-HP Automatic Antenna Tuning Unit

(NAT40

SD-2 Electrical Schematic – ATU Control/Monitor PWB (NAPC144

(Sheet 1 of 2) SD-2

SD-3 Electrical Schematic – ATU Control/Monitor PWB (NAPC144

(Sheet 2 of 2) SD-3

MD-1 Assembly Detail –ATU-HP Automatic Antenna Tuni ng Unit

(NAT40

MD-2 Assembly Detail – ATU Control/Monitor PWB (NAPC144

A) SD-1

A) MD-1

A/01) 3-2

A/01)

A/01)

A/01) MD-2

ATU-HP Technical Instruction Manual Oct.06.11

Release Control Record

Issue Date Reason

2.0 06 October 2011 Release 2 of product (NAT40A)

ATU-HP Technical Instruction Manual Oct.06.11

ATU-HP

TECHNICAL INSTRUCTION MANUAL

Section 1 GENERAL INFORMATION

1.1 INTRODUCTION

The ATU-HP – Automatic Antenna Tuning

Unit:

• Provides automatic tuning and

impedance matching between an

antenna and a 50 ohm feeder cable

from a DGPS (750 W – 3,000 W) or

NDB (500 W or 1000/2000 W)

transmitter.

• Automatically compensates for both

antenna system reactance changes

and resistance changes.

• Can be serially connected to its

associated transmitter, allowing a

variety of control/monitoring features,

including stabilization of the antenna

current by adjusting the associated

transmitter’s power level.

• Operates in the LF/MF band (190 kHz

to 550 kHz).

Options include a sunshield for use in

environments with high temperatures, and

a resistor assembly to allow for increased

bandwidth in high Q antenna systems.

1.2 FACTORY SUPPORT

Nautel provides after sales factory

support. Technical assistance is available

on a 24 hour, seven days a week basis. A

factory service facility for repair of

modules/assemblies is also available.

Refer to the Factory Support portion of the

Warranty pages at the front of this manual

for additional information.

1.3 PURPOSE AND SCOPE OF

MANUAL

This Technical Instruction manual

provides the information required to

install, operate and maintain the

equipment.

1.4 PURPOSE OF EQUIPMENT

The ATU-HP interfaces and impedance

matches the RF output of a transmitter to

an antenna. Two servomechanisms

automatically maintain a well matched

condition when either the antenna

reactance or resistance changes. Through

a serial interface, the transmitter’s output

power can be controlled to provide

antenna current stability. Remote control

facilities are incorporated to allow

unattended operation from a remote

location.

1.5 MECHANICAL DESCRIPTION

The ATU-HP (see Figure 1-1) is housed in

an all-weather cabinet suitable for outdoor

installation close to the antenna. Electrical

interconnection is made via cables that

enter the cabinet through sealed

connectors located on the side. The ac

input wiring is terminated on terminal

blocks located on the ATU control/monitor

PWB (A1), which is located behind the

cabinet’s front cover. The remote wiring

terminates on either terminal blocks or a

9-pin D-sub connector also located on A1.

The cabinet is assembled from heavy

gauge aluminium alloy and is fitted for

rear or base mounting. There is a

weather–tight, removable cover on the

front of the cabinet, which permits access

to the ATU-HP. It is removed by

unfastening the three pull-down latches on

each side of the cabinet. The cabinet

ATU-HP Technical Instruction Manual Page 1-1

Section 1 General Information Issue 2.0

contains a loading coil assembly, lightning

arrestor spark gap, insulated RF feedthrough connector, a variable matching

transformer assembly, temperature

sensor, two cooling fans, a PWB/chassis

that contains the electronic circuitry and a

matching transformer and tuning

capacitors. The electrical wiring access

holes are fitted with liquid tight connectors

which can be tightened to ensure rodents,

dirt and moisture do not enter the cabinet.

1.6 TECHNICAL SUMMARY

An equipment brochure, containing a

technical summary, is provided with this

manual.

1.7 TEST EQUIPMENT AND

SPECIAL TOOLS

Table 1-1 lists the test equipment and

special tools that are required to operate

and maintain the ATU-HP.

Figure 1-1 – ATU-HP- Automatic Antenna Tuning Unit

Page 1-2 ATU-HP Technical Instruction Manual

Issue 2.0 Section 1 General Information

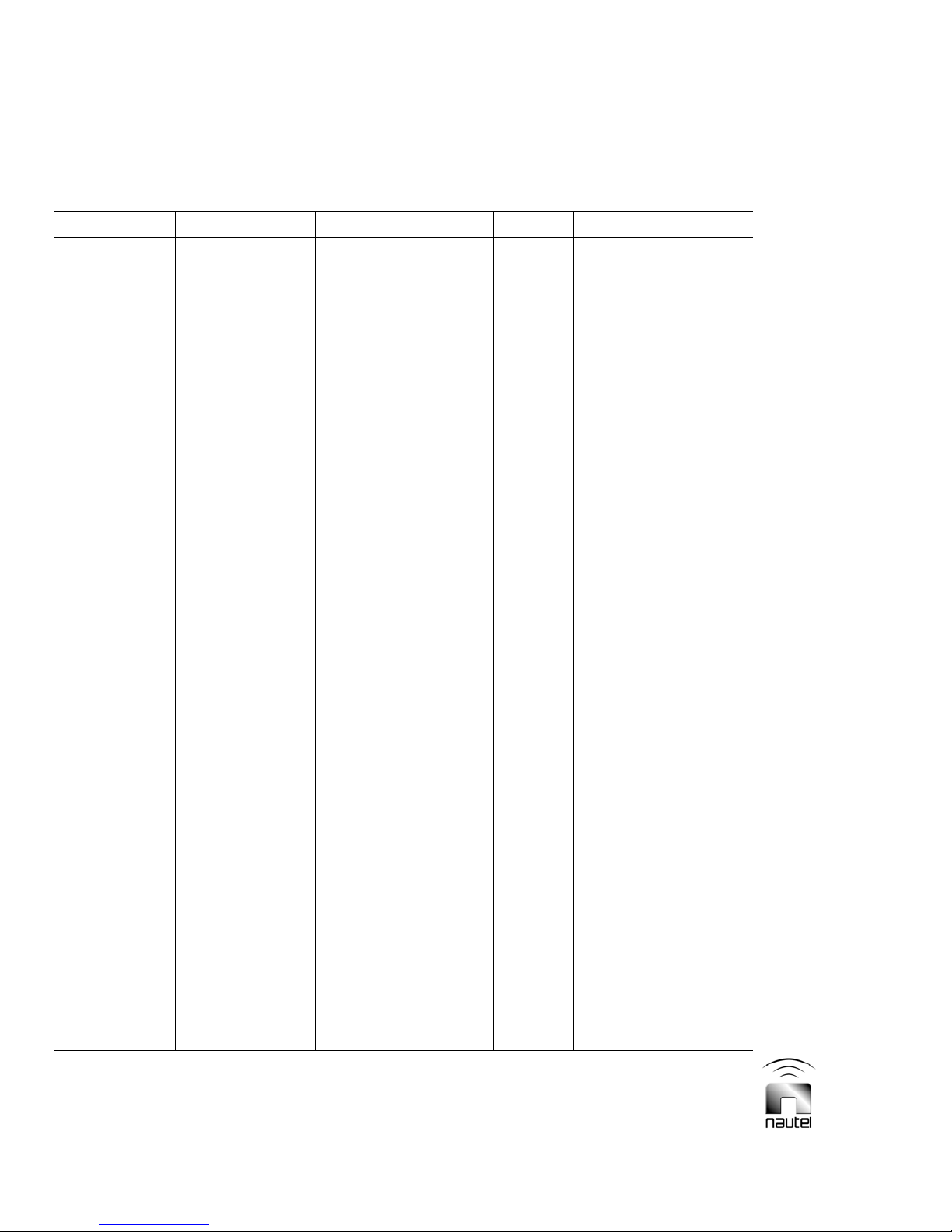

Table 1-1: Recommended Site Test Equipment and Special Tools

NOMENCLATURE

Dummy Load 50 ohms, rated for twice rated

Digital Multimeter

Ac Voltmeter HP400E Testing and

Oscilloscope Tektronix Model T922 Testing and

Current Probe Nautel Part # 195-9131

Standard Electronic Tool

Kit

Standard Wrenches 1/4 inch and 1/2 inch sizes Spark gap

Hex-Head Allen Key M3 size Tuning motor

Handheld Calculator Various Calculating

PART/MODEL NUMBER OR TYPE

(EQUIVALENTS MAY BE USED)

transmitter power

3 1/2 digit, ac and dc volts (10 MΩ

input), ohms and amps, ±0.5% accuracy,

Beckman 3010

Contact Nautel if required

Various size screwdrivers and nut-

drivers

APPLICATION

'Off-air' testing

Testing and

maintenance

maintenance

maintenance

Antenna Current

Meter Calibration

Miscellaneous

maintenance

adjustment and RF

feed cable

connection.

maintenance or

replacement.

resistance ratios

ATU-HP Technical Instruction Manual Page 1-3

Section 1 General Information Issue 2.0

ATU-HP

TECHNICAL INSTRUCTION MANUAL

Section 2 PREPARATION FOR USE AND INSTALLATION

2.1 INTRODUCTION

This section contains pre-installation and

installation information required in

unpacking, installing and preparing the

ATU-HP antenna tuning unit for use.

NOTE

Failure to comply with these

recommendations and instructions could

void the manufacturer’s warranty. Please

review Nautel’s warranty terms for more

information.

2.2 PREPARATION FOR USE

Sites should be prepared to receive the

ATU prior to its delivery and/or installation.

The following must be taken into

consideration when preparing new sites

and should be used as the evaluating

criteria at existing sites. Nautel

recommends that all requirements be

incorporated to ensure optimum reliability

and performance.

2.2.1 Mounting Considerations

The ATU should be installed as close to

the vertical (radiating) section of the

antenna as is practical. It may be rear

mounted on a grounded part of an antenna

structure or a wall or base mounted. Refer

to Figure 2-16 for external and mounting

dimensions for both mounting options. The

base of the ATU must be located at a

higher elevation than any possible snow

accumulation, to allow maintenance and to

prevent the possibility of water

accumulation.

Nautel ships the ATU-HP with brackets

installed for rear mounting.

2.2.2 Environmental

Considerations

Refer to Figure 2-16 for environmental

considerations for the ATU, such as

operating temperature, altitude and weight.

2.2.3 Proximity to Transmitter

The practice of locating the ATU and

transmitter within a single building beneath

the antenna is not recommended. It is

extremely difficult to provide adequate

shielding to prevent feedback between the

high RF field of the antenna and the low

signal level circuits of the transmitter.

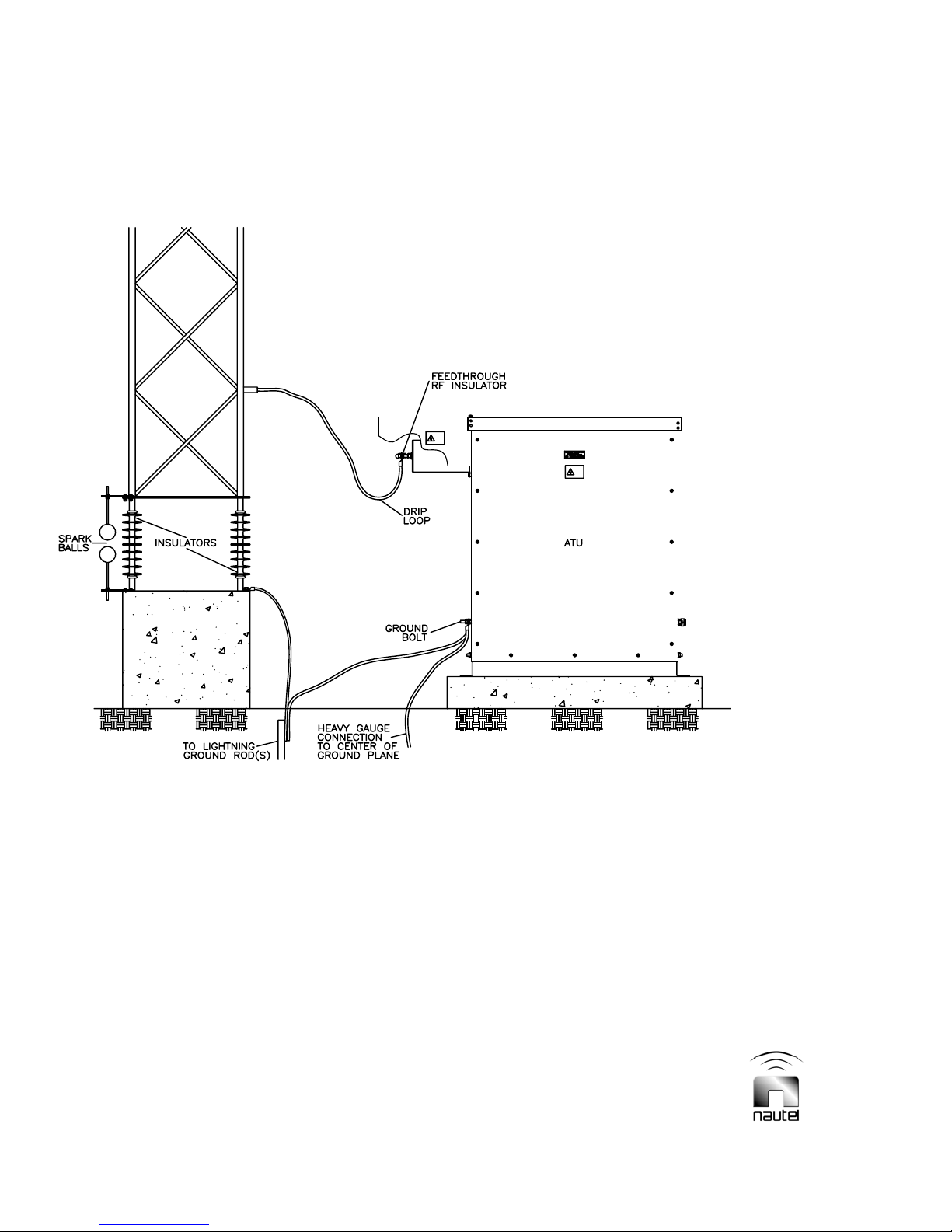

2.2.4 Antenna Structure

The ground plane should be arranged

symmetrically around the antenna's vertical

(radiating) section. Refer to Figure 2-1 for a

typical site layout. Refer to Figure 2-2 for

various interconnection scenarios between

the antenna and ATU. In the case of Figure

2-2 (a), a down lead insulator is shown

which is used to keep the downlead under

tension. This insulator is necessary to

minimize movement of the downlead and

to relieve any mechanical strain from the

ATU feed-through insulator. The downlead

should be positioned at least two feet away

from the ATU or any other grounded metal

structure to minimize antenna capacitance

change due to wind induced movement of

the downlead.

NOTE

ATU-HP Technical Instruction Manual Page 2-1

Section 2 Preparation for Use and Installation Issue 2.0

Figure 2-1 – Typical Site Lay out

Page 2-2 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

Figure 2-2 – Examples of Typical Installations (Sheet 1 of 2)

(a)

T Antenna

ATU-HP Technical Instruction Manual Page 2-3

Section 2 Preparation for Use and Installation Issue 2.0

(b)

Vertical

Tower

Antenna

Figure 2-2 – Examples of Typical Installations (Sheet 2 of 2)

Page 2-4 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

2.2.5 Customer Required

Interfacing

The following paragraphs describe the

connections that must be made to the ATU

by the customer. For ease of installation, it

is recommended that wiring and applicable

connectors are on site prior to unpacking/

installing the ATU. Figure 2-3 illustrates the

ATU-HP’s interface.

2.2.5.1 RF Output Feed Cable

The method by which the ATU output (J2)

connects to the antenna is critical because

of the high voltage, current and impedance

levels at this interface. The antenna feed

RF cable connects to the feed-through/

insulator located at the top left of the ATU

cabinet. This cable must be of adequate

diameter to avoid corona discharge, must

not contain sharp bends and should have

sufficient length to permit a drip loop at the

feed-through/insulator. Refer to Figure 2-2

(a) or (b) for a typical downlead connection.

2.2.5.2 Remote Control/Monitor Wiring

The ATU-HP can interface with a Nautel

Vector series DGPS or NDB transmitter

using RS-485 serial communication.

Connections are made via a cable that

passes through a liquid-tight connector in

the side of the cabinet, to the ATU control/

monitor PWB (9-pin D connector J3 or

2.2.5.3 RF Input Cable

A suitably rated, good quality, 50 Ω RF

coaxial cable should be used to

interconnect the ATU-HP and the

transmitter. The RF input connection is

made to N connector J3 at the side of the

ATU-HP cabinet. Where practical, it is

recommended that the cabling between the

transmitter and ATU-HP be installed

underground (i.e., suitable for direct earth

burial). The only penalty for long distances

between the ATU-HP and the transmitter is

the cost of the cable and the power loss in

the coaxial feeder cable. This loss is

typically 0.1 dB/100 m for a good quality,

1/2-inch diameter cable.

2.2.5.4 AC Power Cable

The ac power connection is made via a

cable that passes through one of the liquidtight connectors on the side of the ATU-HP

cabinet to TB2 of ATU control/monitor

PWB A1 (see ac power options in Figure

2-3). The ac power cable should conform

to local electrical codes. The ac power for

the ATU-HP should be provided on a

dedicated circuit from the service

entrance. Facilities to disconnect this

service should be provided. Ac power

requirements for obstruction lighting, etc.,

should be individually supplied by branch

circuits from the service entrance panel.

terminals TB3-6 though TB3-10). The cable

should be shielded and suitable for direct

earth burial, to be installed underground

between the transmitter and ATU-HP. The

RS-485 specification limits the cable length

to a maximum of 4000 ft. (1220 m).

The following pin-out and terminal

assignment applies:

+5V A1J3-1 or A1TB3-6

Ground A1J3-2 or A1TB3-7

TX/RX A1J3-3 or A1TB3-8

The ATU-HP is configured to operate from

one of three ac power sources:

115 V ac, single-phase, 0.25 A max.

230 V ac, single-phase, 0.15 A max.

230 V ac, split-phase, 0.15 A max.

2.2.5.5 Ground Connection

A ground cable (6 AWG minimum) must be

connected between the centre of the

antenna ground plane and the ground lug

located on the bottom, left-hand side of the

ATU-HP cabinet. This ground cable should

TX/RX A1J3-4 or A1TB3-9

DE/RE A1J3-5 or A1TB3-10

be continuous and low resistance to ensure

efficient operation.

NOTE

ATU-HP Technical Instruction Manual Page 2-5

Section 2 Preparation for Use and Installation Issue 2.0

AC INPUT CONFIGURATION, CUSTOMER CONNECTION

Figure 2-3 – ATU-HP Automatic Tuning Unit – Customer Interface Connections

The ground lug should also connect to

ground rod(s) that provide a low

impedance path to ground for lightning

protection.

2.2.6 Pre-Startup User

Determined Information

The following user determined information

will minimize the start-up time of the ATUHP. It should be determined and recorded

prior to equipment installation.

2.2.6.1 Carrier Frequency

Determine/record the carrier frequency

assigned to the associated transmitter.

2.2.6.2 Antenna Capacitance

Determine/record the approximate antenna

capacitance from antenna design records

or by measurement. A Nautel technical

paper entitled ‘NDB Antennas’ may be

used to estimate antenna capacitance.

Page 2-6 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

2.2.7 Parts Supplied By Nautel

An ancillary parts kit is provided with each

ATU-HP. The ancillary parts are provided

to ensure the initial installation is not

delayed because of a lost or missing part.

They are not intended to be long-term

maintenance spares. An itemized listing of

the ancillary parts kit is included in its

packing list.

2.2.8 Test Equipment

The test equipment and special tools

required to install and maintain the

ATU-HP are listed in Table 1-1.

2.2.9 Available Options

There are several options available for the

ATU-HP automatic antenna tuning unit.

Each option is described below to assist

the user in selecting the final configuration

for the system.

2.2.9.1 Solar Shield

A solar shield (Nautel Part # 195-9090,

shown in Figure 2-16) is available to

assist in reducing the temperature of the

ATU-HP due to solar radiation. If

purchased, the solar shield will be factory

installed.

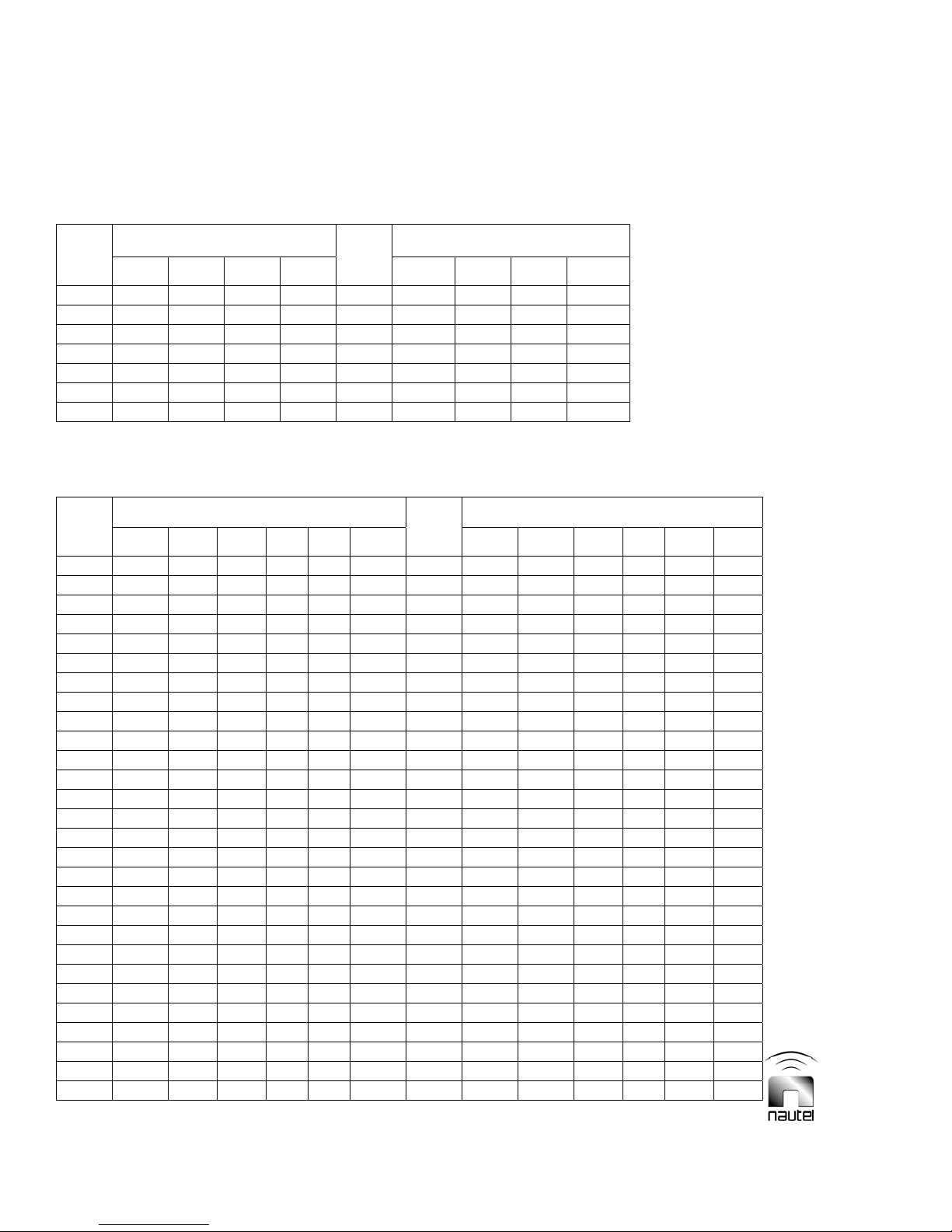

2.2.9.2 Frequency Agile Capacitor Kit

A capacitor kit (Nautel Part # 195-9094 or

-01 through -03) is available to allow

frequency agility. In addition to frequency

dependency, the capacitor values and

quantities are also dependent on the

tuning coils installed in the ATU, which are

determined by the associated transmitter.

Refer to either Table 2-1a for DGPS

applications, Table 2-1b for low power

(500 W) NDB applications or Table 2-1c

for high power (1,000/2,000 W) NDB

applications to determine the particular

values and quantities used for a given

operating frequency. Refer to Table 2-1d

to cross-reference the capacitor value to

the Nautel part number for ordering

purposes.

2.2.9.3 Series Resistor Kit

An external series resistor kit (Nautel Part

# 195-9054) is available to assist in

improving the bandwidth of the ATU-HP.

The resistance is adjustable via tap

settings on a matching transformer, also

provided. The external series resistor is

factory installed on a solar shield (see

paragraph 2.2.9.1), which is included with

this kit.

2.3 UNPACKING

The ATU-HP is packed in a wooden crate,

fully assembled. A packing list, on the

outside of the crate, provides a detailed

listing of crate contents. All shipments

should be inspected for transit damage

prior to acceptance. Open the crate and

remove the contents as follows:

CAUTION

The ATU-HP (without solar shield option)

weighs 111 pounds. At least two people, or

sufficient mechanical assistance, should be

available to unpack the ATU-HP.

(a) Position the crate in a clear area that

will permit extraction of the ATU-HP

without risk of damage to the unit or

injury to personnel.

(b) Stand the crate upright as marked on

the side of the crate.

(c) Remove the crate panel identified as

the front using a screwdriver (battery

powered is recommended).

(d) Remove any small packages, as

identified in the packing list, that are

located between the ATU-HP cabinet

and the packing crate.

(e) Extract the ATU-HP from the crate.

ATU-HP Technical Instruction Manual Page 2-7

Section 2 Preparation for Use and Installation Issue 2.0

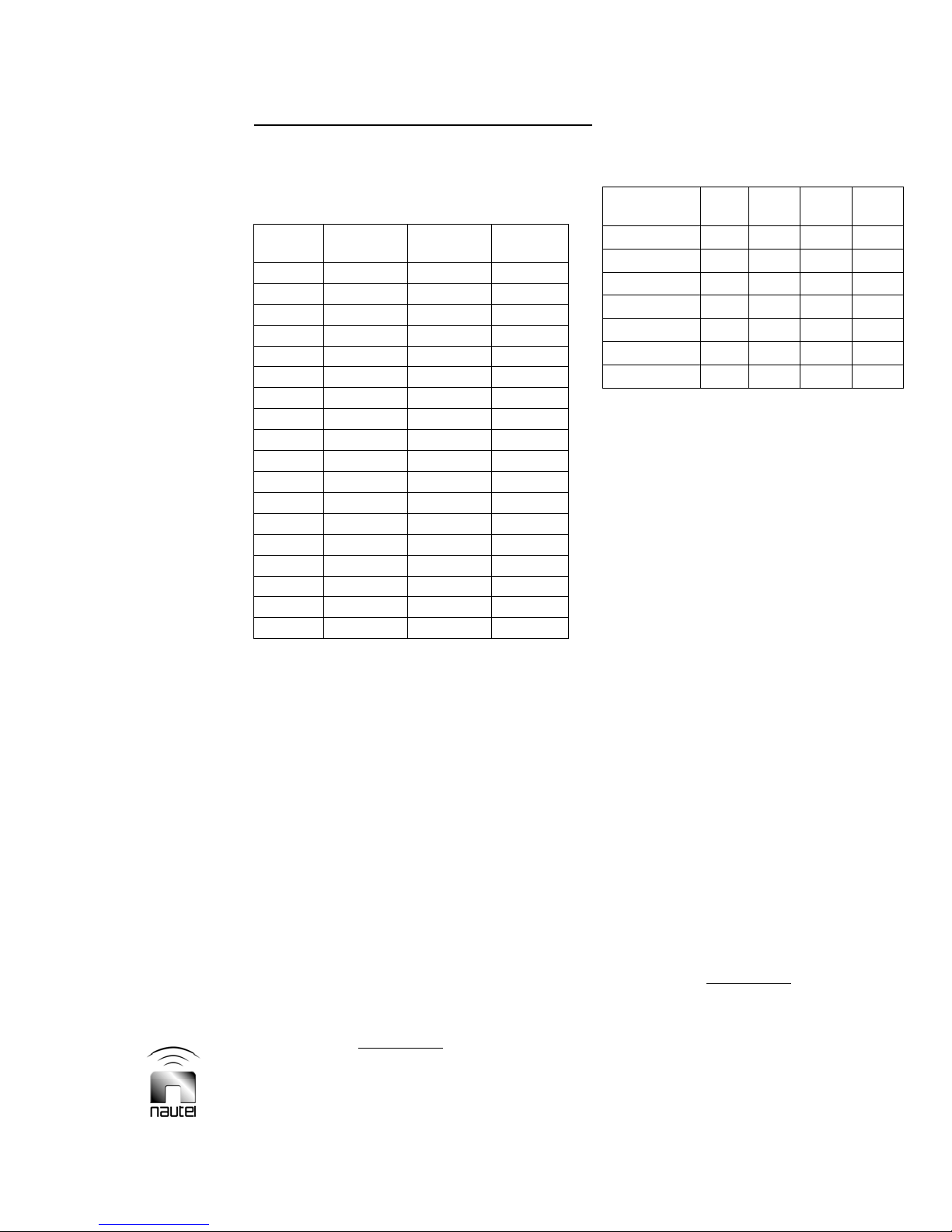

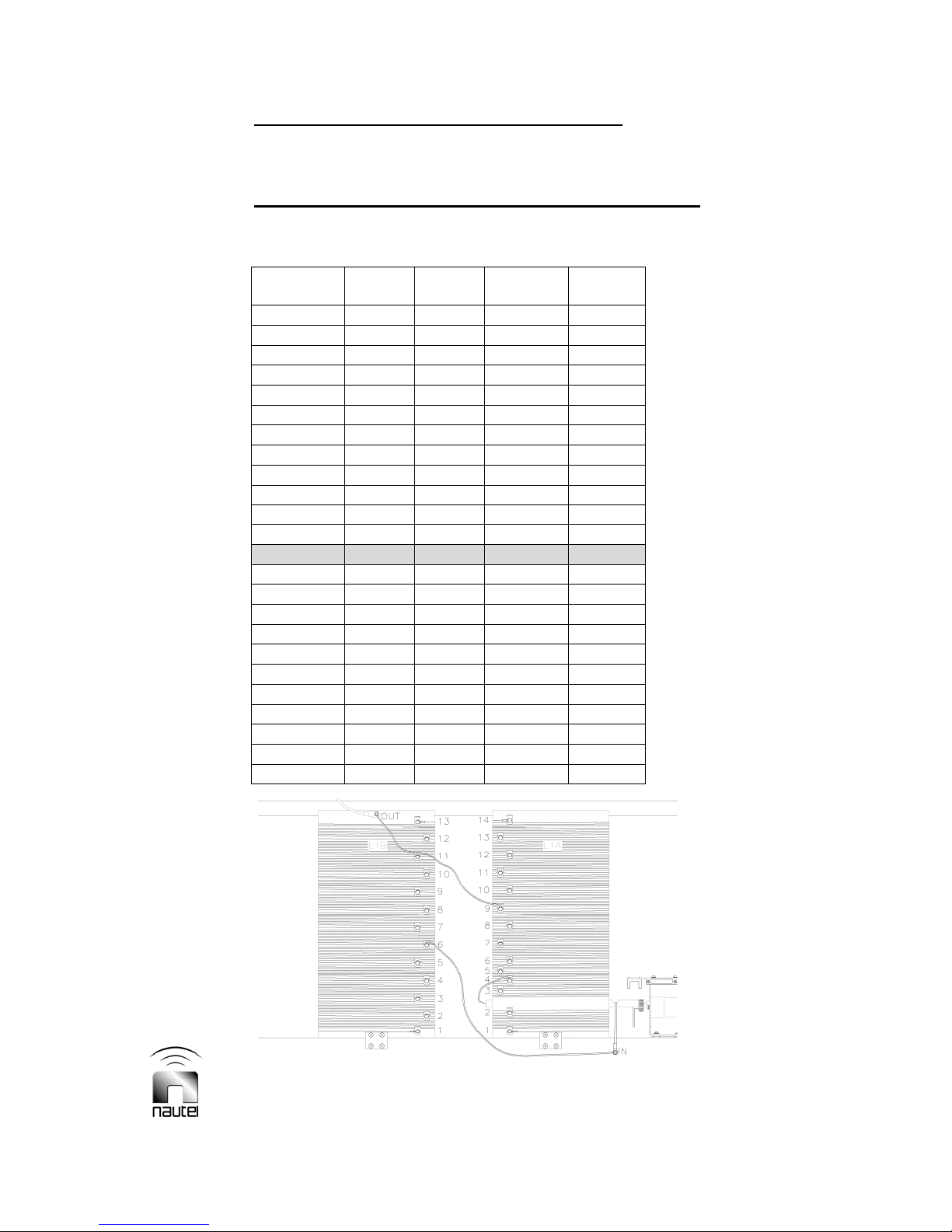

Table 2-1a: Frequency Dependent Capacitors for DGPS Applications

(from Nautel Part # 195-9094 capacitor kit)

FREQ

(kHz)

280 4 - - - 317 3 - - 1

285 3 1 1 1 324 3 - - -

290 3 1 1 - 440 1 1 - 1

295 3 1 - 1 458 1 1 - -

300 3 1 - - 47 8 1 - 1 1

305 3 - 1 1 502 1 - 1 -

310 3 - 1 - 529 1 - - 1

Capacitors (pF) and qty Capacitors (pF) and qty

1750 875 430 218

FREQ

(kHz)

1750 875 430 218

Table 2-1b: Frequency Dependent Capacitors for Low Power NDB Applications

(from Nautel Part # 195-9094-02 capacitor kit)

FREQ

(kHz)

200 1 1 1 1 1 1 268 1 1 1

202 1 1 1 1 1 272 1 1

203 1 1 1 1 1 276 1 1

205 1 1 1 1 280 1

207 1 1 1 1 1 285 1 1 1 1 1

208 1 1 1 1 290 1 1 1 1

210 1 1 1 1 295 1 1 1 1

212 1 1 1 300 1 1 1

214 1 1 1 1 1 305 1 1 1 1

216 1 1 1 1 311 1 1 1

218 1 1 1 1 317 1 1 1

220 1 1 1 324 1 1

222 1 1 1 1 331 2 1 1 1

224 1 1 1 338 2 1 1

227 1 1 1 346 2 1 1

229 1 1 355 2 1

231 1 1 1 1 1 364 2 1 1

224 1 1 1 1 374 2 1

236 1 1 1 1 385 2 1

239 1 1 1 397 2

242 1 1 1 1 410 1 1 1 1

245 1 1 1 424 1 1 1

248 1 1 1 440 1 1 1

251 1 1 458 1 1

254 1 1 1 1 478 1 1 1

257 1 1 1 502 1 1

261 1 1 1 530 1 1

264 1 1

7000 3500 1750 875 430 218

Capacitors (pF) and qty Capacitors (pF) and qty

FREQ

(kHz)

7000 3500 1750 875 430 218

Page 2-8 ATU-HP Technical Instruction Manual

Issue 2.0 Section 1 Preparation for Use and Installation

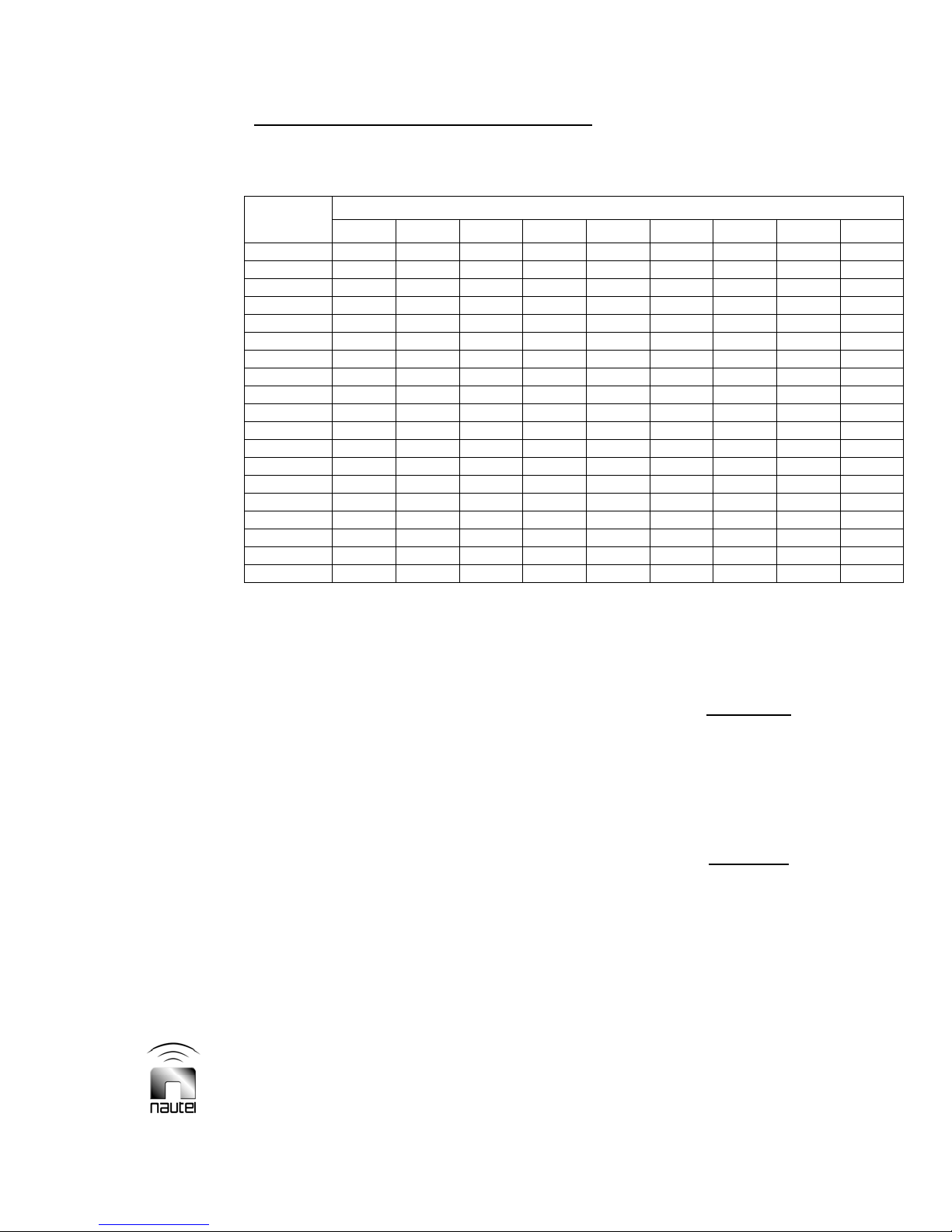

Table 2-1c: Frequency Dependent Capacitors for High Power NDB Applications

(from Nautel Part # 195-9094-01 capacitor kit)

FREQ

(kHz)

200 7 1 1 1 268 4 1 1

202 7 1 1 - 272 4 1 -

203 7 1 1 276 4 1

205 7 1 - 280 4 -

207 7 1 1 285 3 1 1 1

208 7 1 - 290 3 1 1 -

210 7 1 295 3 1 1

212 7 - 300 3 1 -

214 6 1 1 1 305 3 1 1

216 6 1 1 - 311 3 1 -

218 6 1 1 317 3 1

220 6 1 - 324 3 -

222 6 1 1 331 2 1 1 1

224 6 1 - 338 2 1 1 -

227 6 1 346 2 1 1

229 6 - 355 2 1 -

231 5 1 1 1 364 2 1 1

224 5 1 1 - 374 2 1 -

236 5 1 1 385 2 1

239 5 1 - 397 8

242 5 1 1 410 7 1

245 5 1 - 424 7

248 5 1 440 6 1

251 5 - 458 6

254 4 1 1 1 478 5 1

257 4 1 1 - 502 5

261 4 1 1 530 4 1

264 4 1 -

Capacitors (pF) and qty Capacitors (pF) and qty

1750 875 430 218

Table 2-1d: Capacitor Ordering Information

Capacitor Value

(pf)

109 195-9004-08

218 195-9004-06

430 195-9004-07

875 195-9004-02

1750 195-9004-03

3500 195-9004-04

7000 195-9004-05

Nautel Part #

FREQ

(kHz)

1750 875 430 218

ATU-HP Technical Instruction Manual Page 2-9

Section 2 Preparation for Use and Installation Issue 2.0

2.4 INSTALLATION

Secure the ATU-HP in its final position and

connect user interface cabling as follows:

NOTE

All electrical input connections, from

external sources, are made through cable

entrance holes in the side of the cabinet.

Refer to Figure 2-3 to locate these holes

and all other customer interface points.

(a) Mount the ATU-HP in its final position

by securing the two rear mounting

angles to a support. If base mounting

is preferred, remove the front cover to

gain full access to the mounting

angles. Using Figure 2-16 as a guide,

reinstall the angles for base mounting.

Ensure hardware is properly oriented

and tight. Do not reinstall the front

cover at this time.

(b) Ensure the transmitter is turned off.

WARNING

Extremely high, potentially lethal, RF

voltages are

present in the ATU-HP

when an RF input is being applied. Use

extreme caution near the tuning coils.

(c) If the ATU-HP is being used in

conjunction with a Nautel Vector

series transmitter, route the remote

control/monitor wiring through the

appropriate liquid-tight connector to

the ATU control/monitor PWB (A1) as

detailed in paragraph 2.2.5.2.

(d) Install the RF input cable between the

associated transmitter’s RF output

and the ATU-HP. The RF input

connector (J3) is located on the lower,

right-hand side of the cabinet. See

paragraph 2.2.5.3 for details.

(e) Connect the grounding cable from the

antenna ground plane and the lightning

ground rod(s) to the ground stud on the

lower, left-hand side of the ATU-HP

cabinet. Ensure paragraph 2.2.5.5 has

been completed.

(f) Connect the antenna RF feed cable to

the feed-through insulator (J2). Ensure

the requirements of paragraph 2.2.5.1

are met. Ensure the centre conductor

of the insulator does not rotate while

securing the RF feed cable. Verify nuts

are tight.

(g) Route the ac power cable through the

appropriate liquid-tight connector to

TB2 of the ATU control/monitor PWB

(A1). Ensure the requirements of

paragraph 2.2.5.4 are met. Refer to

Figure 2-3 to determine the specific

connections for your ac service.

(h) Install wire link(s) (minimum 18 AWG)

on appropriate terminals of TB3 (see

Figure 2-3):

• 115 V ac Link 1 to 2; Link 3 to 4

• 230 V ac Link 2 to 3

(i) Connect ATU control/monitor PWB

jumper wires A, B and C (Figure 3-1)

for the desired A1M1 meter scales:

• Forward Power

0 – 4,000 W: jumper B to E3

0 – 1,200 W: jumper B to E4

• Reflected Power

0 – 400 W: jumper A to E1

0 – 120 W: jumper A to E2

• Antenna Current

0 – 10 A: jumper C to E5

0 – 30 A: jumper C to E6

(j) Verify the proper capacitors are

installed on the capacitor bank. Refer

to Table 2-1a for DGPS applications,

Table 2-1b for low power (500 W)

NDB applications or Table 2-1c for

high power (1,000/2,000 W) NDB

applications to determine the values

and quantities used for a given

operating frequency.

Page 2-10 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

Stage 1 of Tuning Procedure

Initial Setting of L Tuning Taps (LOCAL control, TUNE SETUP on)

Table 2-2: Tuning Coil Inductance Values (μH)

ANTENNA

CAP (pF)

200

300

400

500

600

700

800

900

1000

1200

1400

1600

1800

2000

2250

2500

2750

3000

3500

190 200 250 300 350 400 450 500 550

3508 3166 2026 1407 1034 792 625 507 419

2339 2111 1351 938 689 528 417 338 279

1754 1583 1013 704 517 396 313 253 209

1403 1267 811 563 414 317 250 203 167

1169 1055 675 469 345 264 208 169 140

1002 905 579 402 295 226 179 145 120

877 792 507 352 258 198 156 127 105

780 704 450 313 230 176 139 113 93

702 633 405 281 207 158 125 101 84

585 528 338 235 172 132 104 84 70

501 452 289 201 148 113 89 72 60

439 396 253 176 129 99 78 63 52

390 352 225 156 115 88 69 56 47

351 317 203 141 103 79 63 51 42

312 281 180 125 92 70 56 45 37

281 253 162 113 83 63 50 41 33

255 230 147 102 75 58 45 37 30

234 211 135 94 69 53 42 34 28

200 181 116 80 59 45 36 29 24

2.5 INITIAL TURN-ON/TUNING

PROCEDURE

The tuning procedure is divided into three

stages:

1. Initial setting of L tuning taps

2. Determining antenna resistance

3. Final setting of L and R tuning taps

Check the top of each of the following

pages to determine the stage number and

other applicable information.

(a) Determine the approximate loading coil

inductance by entering the data

recorded for operating frequency (see.

2.2.6.1) and antenna capacitance (see.

2.2.6.2) into Table 2-2.

(b) Enter the inductance from step (a) into

the appropriate Table 2-6 (a-f), noting

the application and inductance range

for each. Determine the initial loading

coil tap settings. If the inductance was

not determined, use the shaded value

in the appropriate series connection

table (e.g., 215 μH in Table 2-6a).

FREQUENCY (kHz)

(c) Tap the loading coils L1A and L1B for

the settings determined in step (b).

See the appropriate Figure 2-12 (a-f)

for examples.

Use extreme caution near the tuning

coils. Extremely high RF voltages, that

may arc many inches of air breakdown

path

and cause severe RF burns, are

present when an RF input of any level

is applied to the ATU-HP.

Wires connecting to tuning coil taps must

be dressed in a manner that will prevent

them from coming in contact with any part

of the coils other than the tap connecting

points. Arcing that may result in damage

to the coils and/or loss of tuning may

occur.

WARNING

CAUTION

ATU-HP Technical Instruction Manual Page 2-11

Section 2 Preparation for Use and Installation Issue 2.0

Stage 1 of Tuning Procedure

Initial Setting of L Tuning Taps (LOCAL control, TUNE SETUP on)

Paragraph 2.5 continued

(d) Gain access to the ATU-HP’s control

circuitry, by removing the transparent

cover across the front of the cabinet,

noting it is secured by four screws, two

on either side of the cabinet.

(e) Configure the RF wiring at the ATU

control/monitor PWB’s terminal block

(A1TB1) and the matching transformer

T1

terminal blocks (T1-TB1 and T1-TB2)

as shown in Figure 2-4. Disconnect

wiring from capacitor bank as

necessary.

(f) Turn on the ATU-HP’s ac power

supply. On ATU control/monitor PWB

A1, press the LOCAL/REMOTE (S4)

and TUNE SETUP (S9) so that the

LOCAL and TUNE SETUP LEDs turn

on. See Figure 2-5.

Figure 2-4 - Initial RF Wiring Connections

A1TB1

Figure 2-5 - ATU Control/Monitor PWB – Pushbutton Switches and LEDs

Page 2-12 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

Stage 1 of Tuning Procedure

Initial Setting of L Tuning Taps (LOCAL control, TUNE SETUP on)

Paragraph 2.5 continued

(g) With the ATU-HP connected to both

the transmitter and the antenna

system, turn on the transmitter (use

CW mode for NDB transmitters) and

set its output power for 100 W

(maximum).

TUNE LOADING

COILS

Turn transmitter on

Wait for L TUNING -

NORMAL, MAX

LIMIT or MIN LIMIT

LED to turn on.

(h) Using the flow diagram illustrated in

Figure 2-6, tune the ATU-HP loading

coils. Disregard the status of the R

TUNING LEDs on the ATU control/

monitor PWB during this procedure.

Turn transmitter

off. Increase

inductance to next

higher setting as

per appropriate

Table 2-6 (a–f).

L TUNING R TUNING

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

Check L TUNING

LEDs on PWB

Which L

TUNING

LED is

on?

L TUNING R TUNING

LOADING COILS

TUNED

L TUNING R TUNING

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

Turn transmitter

off. Decrease

inductance to next

lower setting as

per appropriate

Table 2-6 (a-f).

Figure 2-6 - Flow Diagram – Loading Coil Tuning

ATU-HP Technical Instruction Manual Page 2-13

Section 2 Preparation for Use and Installation Issue 2.0

Stage 2 of Tuning Procedure

Determining Antenna Resistance (LOCAL control, TUNE SETUP on)

T1

A1TB1

Figure 2-7 – Post-Inductive Tuning RF Wiring Connections

Paragraph 2.5 continued

(i) Turn transmitter off. Configure the RF

wiring between the ATU control/

monitor PWB’s terminal block

(A1TB1) and the matching

transformer terminal blocks (T1-TB1

and T1-TB2) as shown in Figure 2-7,

noting the blue wire should be

terminated on T1-3 and the red wires

should be terminated on A1TB1-5 and

A1TB1-6.

(j) Using the flow diagram illustrated in

Figure 2-8, determine the antenna

resistance by selecting the T1 tap

settings that provide minimum reflected

power. View reflected power on the

ATU control/monitor PWB’s meter,

noting switch A1S10 must be set to

REFLD PWR and switch A1S11 must

be set to RF POWER.

Page 2-14 ATU-HP Technical Instruction Manual

Issue 2.0 Section 1 Preparation for Use and Installation

Forward power must be maintained at the

same level when determining the reflected

power. After each tapping of T1, allow the

loading coils to retune (i.e., L TUNING NORMAL LED turned on).

(k) When step (j) is complete, use Table

2-3 to determine the antenna system

resistance associated with the T1

connections that provided minimum

reflected power.

NOTE

Stage 2 of Tuning Procedure

Determining Antenna Resistance (LOCAL control, TUNE SETUP on)

Turn transmitter off.

Change taps on T1 to

next higher antenna

resistance as per

Table 2-3.

DETERMINE ANTENNA

RESISTANCE

Turn transmitter on

Wait for L

NORMAL LED to

turn on (motor

stops)

Turn transmitter off.

Change taps on T1 to

next lower antenna

resistance as per

Note reflected power level

Table 2-3

on meter

If a DECREASE

adjustment has already

been made, discontinue

loop and proceed as if

NORMAL

L TUNING R TUNING

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

L TUNING R TUNING

Which R

TUNING

LED is on?

L TUNING R TUNING

Note reflected power level

on meter

ANTENNA RESISTANCE

DETERMINED

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

MAX LIMIT

INCREASE

NORMAL

DECREASE

MIN LIMIT

INHIBIT

If an INCREASE,

adjustment has already

been made, discontinue

loop and proceed as if

NORMAL

Figure 2-8 - Flow Diagram – Determining Antenna Resistance

ATU-HP Technical Instruction Manual Page 2-15

Section 2 Preparation for Use and Installation Issue 2.0

Stage 3 of Tuning Procedure

Final Setting of L and R Tuning Taps (LOCAL control, TUNE SETUP off)

Table 2-3: T1 Matching Transformer 50 Ohm Connections

Antenna System Resistance (Ω) T1

Connections

In (Blue wire) 3 6 5 4 6 3 5 6 5 3 6 4 5 6 3 4 5 6

Out (Red wire) 7 8 8 8 9 8 9 2 2 9 3 2 3 4 2 3 4 5

Paragraph 2.5 continued

(l) Press the ATU control/monitor PWB’s

TUNE SETUP switch so that its

associated LED and the R TUNING –

INHIBIT LED turn off.

Ensure the transmitter is off when

making adjustments on the ATU-HP.

Lethal voltages are present when any

level of RF is applied to the ATU-HP.

2 3 4 5.6 7 8 9 12.5 16 18 20 22 25 28 32 35 37 39

(m) Turn off the t ra n sm i t t e r. C onfigure the

RF wiring between the ATU control/

monitor PWB’s terminal block

(A1TB1) and the matching

transformer terminal blocks (TB1 and

TB2) as shown in Figure 2-9.

WARNING

Reconnect blue wire to capacitor bank.

(n) Using Table 2-4, select the nearest

operating frequency and determine

the ‘R match’ value.

T1

Figure 2-9 - Post-Resistive Tuning RF Wiring Connections

The termination points for

the T1 INPUT (green) and

T1 OUTPUT (red) wires,

determined in steps (n)

through (u), can be on either

of T1’s terminal blocks.

A1TB1

Page 2-16 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

Stage 3 of Tuning Procedure

Final Setting of L and R Tuning Taps (LOCAL control, TUNE SETUP off)

Paragraph 2.5 continued

Table 2-4: Determining ‘R Match’

Freq.

(kHz)

190 16.9 370 64.2

200 18.8 380 67.7

210 20.7 390 71.4

220 22.7 400 75.1

230 24.8 410 78.9

240 27.0 420 82.8

250 29.3 430 86.7

260 31.7 440 90.8

270 34.2 450 95.0

280 36.8 460 99.3

290 39.5 470 103.6

300 42.2 480 108.1

310 45.1 490 112.6

320 48.0 500 117.3

330 51.1 510 122.0

340 54.2 520 126.9

350 57.5 530 131.8

360 60.8 535 134.3

R Match

(Ω)

Freq.

(kHz)

R Match

(Ω)

(o) Divide the ‘R match’ value from step

(n) by the antenna resistance from

step (k) (from Table 2-3). For

example, if R match = 48.0 Ω and

antenna resistance = 4 Ω, the

resistance ratio will be 12.0.

(p) Enter the resistance ratio from step (o)

into Table 2-5 (or closest possible

option) to determine the input (green

wire) and output (red wire) taps for T1.

(q) Connect the green T1-Input (

and the red T1-Output (

IN) wire

OUT) wire to

the taps determined in step (p).

(r) Turn on the transmitter and allow

sufficient time for the loading coils and

the variable resistive matcher to tune.

WARNING

Ensure the transmitter is off when

making adjustments on the ATU-HP.

Lethal voltages are present when any

level of RF is applied to the ATU-HP.

ATU-HP Technical Instruction Manual Page 2-17

Section 2 Preparation for Use and Installation Issue 2.0

Table 2-5: T1 Taps vs Resistance Ratio

T1 Taps IN

OUT

6 5 4 3

5 1.31 - - -

4 1.78 1.36 - -

3 2.56 1.96 1.44 1.0

2 4 3.06 2.25 1.56

9 7.11 5.44 - 2.78

8 16 12.25 9 6.25

7 64 49 36 25

(s) If an L TUNING – MAX LIMIT or MIN

LIMIT LED turns on, turn off the

transmitter and tap the tuning coils for

the next closest inductance value in

the appropriate Table 2-6 a-f. Use the

next higher inductance value for a

MAX LIMIT indication and the next

lower inductance value for a MIN

LIMIT indication respectively.

(t) If an R TUNING – MAX LIMIT or MIN

LIMIT LED turns on, turn off the

transmitter and tap for the next closest

resistance ratio in Table 2-5. Use the

next lower resistance ratio tap for a

MAX LIMIT indication and the next

higher resistance ratio for a MIN

LIMIT indication. Repeat step (r).

(u) When no L T UNING or R TUNING –

MAX LIMIT or MIN LIMIT LEDs occur,

the ATU-HP is tuned. The NORMAL

LEDs should turn on.

(v) Check the position of the variometer

inside the bottom of loading coil L1A,

noting it is behind the ATU-HP’s

protective cover, which also supports

the ATU control/monitor PWB.

WARNING

Ensure the transmitter is off when

making adjustments on the ATU-HP.

Lethal voltages are present when any

level of RF is applied to the ATU-HP.

perp

Stage 3 of Tuning Procedure

Final Setting of L and R Tuning Taps (LOCAL control, TUNE SETUP off)

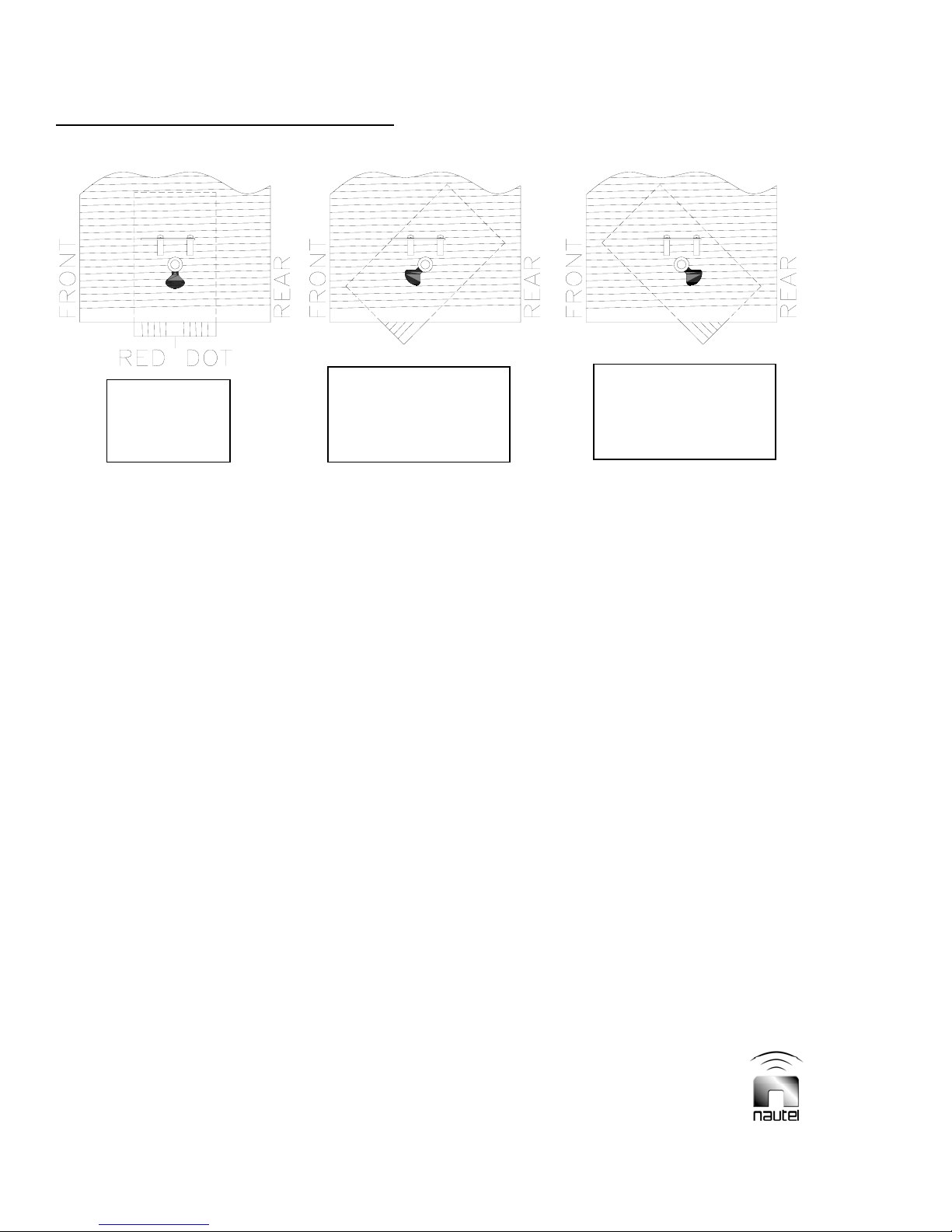

Figure 2-10 - Variometer Positioning within Loading Coil L1A (shown from tuning motor B1 view)

A

Optimum tune.

Variometer

endicular

Tap loading coils L1A and

L1B for next higher

inductance value as per

appropriate Table 2-3 (a-f).

B

Tap loading coils L1A and

L1B for next lower

inductance value as per

appropriate Table 2-3 (a-f).

C

(w) Ensure the largest adjustment range

is provided for the loading coils. If the

variometer position is:

- perpendicular, as depicted in Figure

2-10 A, the variometer is in the

optimum position and no further

adjustment is required.

- shifted as depicted in Figure 2-10 B,

turn off the transmitter and tap the

loading coils (L1A and L1B) for the

next higher inductance value as per

the appropriate Table 2-6 (a-f). Turn

the transmitter back on, allow the ATU

to tune and then recheck the

variometer’s position. If the variometer

is further away from perpendicular,

return to the previous loading coil

taps.

- shifted as depicted in Figure 2-10 C,

turn off the transmitter and tap the

loading coils (L1A and L1B) for the

next lower inductance value as per

the appropriate Table 2-6 (a-f). Turn

the transmitter back on, allow the

ATU-HP to tune and then recheck the

variometer’s position. If the variometer

is further away from perpendicular,

return the loading coils to their

previous tap(s).

(x) Ensure the largest adjustment range

is provided for the variable matching

transformer. If the inner coil is:

- centered, as depicted in Figure 2-11,

the variable matching transformer is in

the optimum position and no further

adjustment is required.

- closer to the ‘MAX LIMIT’ (see Figure

2-11), adjust T1’s input and output

taps for the next lower resistance

ratio as per Table 2-5. Turn the

transmitter back on, allow the ATU to

tune and then recheck the variable

matching transformer’s position.

Repeat if necessary to achieve

optimum position. If the variable

matching transformer is further off

centre, return to the previous T1 taps.

- Closer to the ‘MIN LIMIT’ (see Figure

2-11), adjust T1’s input and output

taps for the next higher resistance

ratio as per Table 2-5. Turn the

transmitter on, allow the ATU-HP to

tune and then recheck the variable

matching transformer’s position.

Repeat if necessary to achieve

optimum position. If the variable

matching transformer is further off

centre, return to the previous T1 taps.

Page 2-18 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

Stage 3 of Tuning Procedure

Final Setting of L and R Tuning Taps (LOCAL control, TUNE SETUP off)

Figure 2-11 - Variable Matching Transformer (shown centred, optimum tuning)

(y) Adjust the transmitter for the desired

operating power level.

(z) For DGPS applications

: If excessive

reflected power is measured, but the

L and R TUNING - NORMAL LEDs

are on, it is likely that the antenna

bandwidth is too narrow for the

radiated signal. The antenna

bandwidth may be increased by

increasing the antenna system

resistance using Nautel’s Series

Resistor Kit (optional), as detailed in

paragraph 2.6.

(aa) For NDB applications

MCW mode): If excessive reflected

power prevents the desired mod

depth from being achieved, reduce

the carrier level as needed or increase

the antenna system resistance using

Nautel’s Series Resistor Kit (optional),

as detailed in paragraph 2.6.

(bb) Adjust the ATU-HP’s spark gap (see

paragraph 2.5.1).

(transmitter in

ATU-HP Technical Instruction Manual Page 2-19

Section 2 Preparation for Use and Installation Issue 2.0

All Stages of Tuning Procedure

DGPS Applications

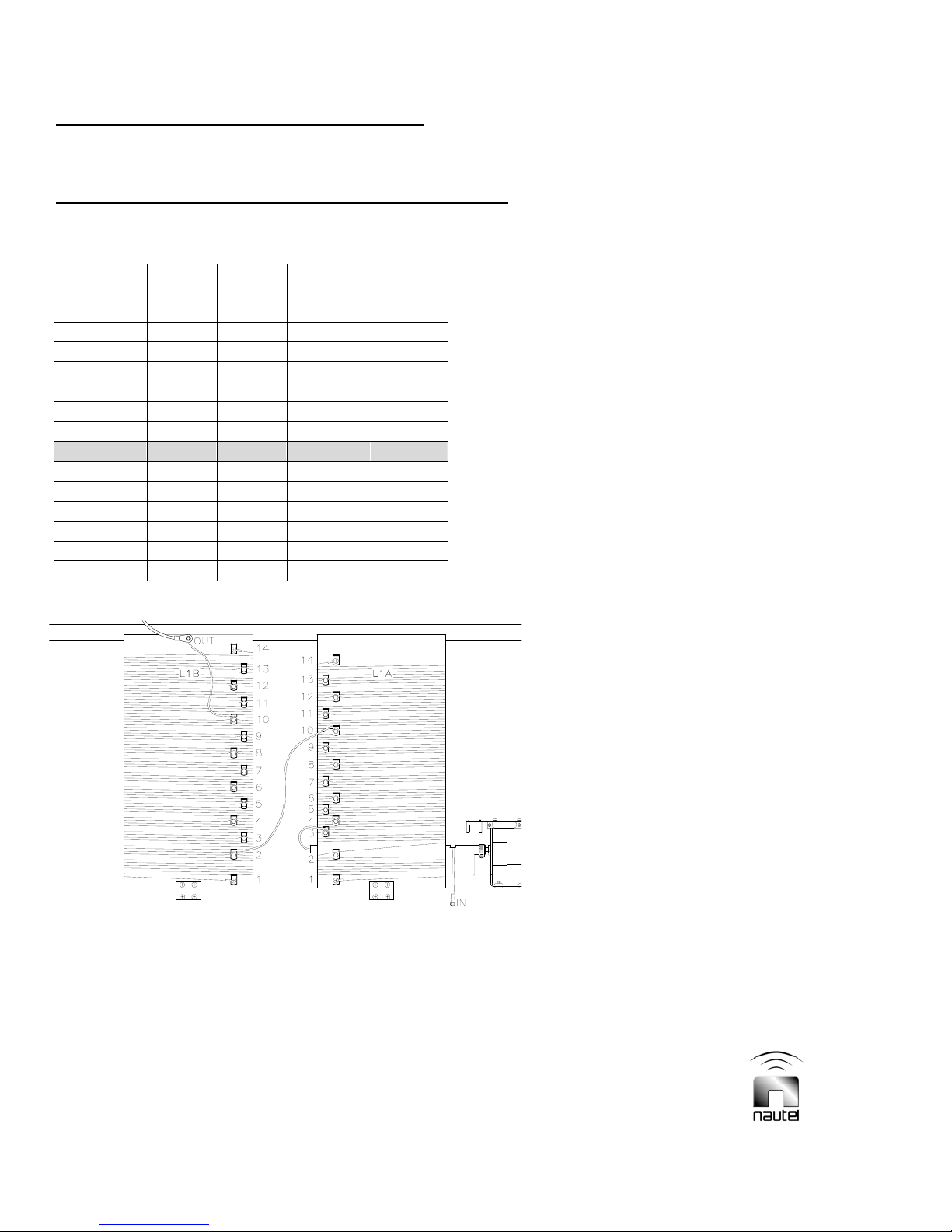

Table 2-6a: Loading Coil (DGPS) Series Connection (500-136 μH)

Inductance

(μH)

480 1 13 1 12

460 1 13 1 11

440 1 13 1 10

390 1 11 1 10

350 1 10 1 9

320 1 11 2 9

275 2 11 2 9

250 2 10 2 9

235 2 10 2 8

215 2 9 2 8

195 2 9 2 7

180 3 8 2 8

164 3 8 2 7

145 3 8 2 6

L1A

input

L1A

output

L1B

input

L1B

output

Figure 2-12a: Loading Coil (DGPS) Series Connection (500-136 μH)

(215 μH shown)

Page 2-20 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

All Stages of Tuning Procedure

DGPS Applications

Table 2-6b: Loading Coil (DGPS) Parallel Connection (135-20 μH)

Inductance

(μH)

125 2 13 1 12

110 2 12 1 11

100 2 11 1 10

90 2 10 1 9

80 2 12 4 10

70 3 10 3 9

65 3 10 3 8

58 3 11 5 9

53 3 9 5 9

46 4 8 2 6

40 4 8 3 6

36 5 7 1 7

32 5 7 2 5

26 5 6 2 6

23 3 5 4 5

L1A

input

L1A

output

L1B

input

L1B

output

Figure 2-12b: Loading Coil (DGPS) Parallel Connection (135-20 μH)

(90 μH shown)

ATU-HP Technical Instruction Manual Page 2-21

Section 2 Preparation for Use and Installation Issue 2.0

All Stages of Tuning Procedure

Low Power NDB Applications

Table 2-6c: Loading Coil (NDB Low Power) Series Connection (2700-640 μH)

Inductance

(μH)

2500 1 14 1 13

2350 1 14 1 12

2250 1 14 1 11

2100 1 14 1 10

2000 1 14 2 10

1850 1 14 3 10

1750 1 12 2 10

1625 1 12 2 9

1375 1 11 3 9

1160 2 10 3 9

1050 2 10 3 8

875 3 10 4 8

775 3 8 4 9

700 4 10 5 8

650 4 9 5 9

L1A

input

L1A

output

L1B

input

L1B

output

Figure 2-12c: Loading Coil (NDB Low Power) Series Connection (2700-640 μH)

(1375 μH shown)

Page 2-22 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

All Stages of Tuning Procedure

Low Power NDB Applications

Table 2-6d: Loading Coil (NDB Low Power) Parallel Connection (639-50 μH)

Inductance

(μH)

620 1 14 1 13

580 1 13 1 13

555 1 13 1 12

520 1 12 1 12

460 1 11 2 12

400 1 11 2 10

370 1 11 2 9

340 1 10 3 10

300 1 10 3 9

290 2 10 4 10

260 2 9 4 10

230 2 9 4 9

200 4 9 6 11

190 5 9 3 8

170 4 8 6 11

150 5 8 4 9

135 5 8 4 8

130 3 8 7 10

110 3 7 7 10

100 4 7 6 9

90 5 6 6 12

80 5 6 6 10

70 5 6 6 9

60 3 5 7 9

L1A

input

L1A

output

L1B

input

L1B

output

Figure 2-12d: Loading Coil (NDB Low Power) Parallel Connection (639-50 μH)

(200 μH shown)

ATU-HP Technical Instruction Manual Page 2-23

Section 2 Preparation for Use and Installation Issue 2.0

All Stages of Tuning Procedure

High Power NDB Applications

Table 2-6e: Loading Coil (NDB High Power) Series Connection (1200-300 μH)

Inductance

(μH)

1150

1050

950

840

730

680

630

580

530

480

450

400

350

310

L1A

input

1 14 1 14

1 13 1 13

1 12 1 12

1 11 1 11

2 11 1 10

2 10 1 10

2 10 1 9

3 10 2 10

3 10 2 9

3 9 2 9

4 10 3 9

4 9 3 9

4 9 4 9

4 8 4 9

L1A

output

L1B

input

L1B

output

Figure 2-12e: Loading Coil (NDB High Power) Series Connection (1200-300 μH)

(580 μH shown)

Page 2-24 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

All Stages of Tuning Procedure

High Power NDB Applications

Table 2-6f: Loading Coil (NDB High Power) Parallel Connection (299-25 μH)

Inductance

(μH)

290

260

235

220

205

190

180

165

150

135

120

110

95

90

80

70

60

55

50

40

35

33

30

29 4 6 7 9

26 4 5 7 9

L1A

input

1 14 1 14

1 13 1 13

1 12 1 12

2 13 2 12

2 12 2 12

2 12 2 11

2 11 2 11

2 11 2 10

2 10 2 10

3 10 3 10

3 10 3 9

3 9 3 9

3 9 4 9

4 9 4 9

4 8 4 9

5 8 4 9

5 8 5 9

5 6 2 9

5 6 4 9

4 5 5 9

4 5 6 9

4 7 7 9

5 7 7 9

L1A

output

L1B

input

L1B

output

Figure 2-12f: Loading Coil (NDB High Power) Parallel Connection (299-25 μH)

(110 μH shown)

ATU-HP Technical Instruction Manual Page 2-25

Section 2 Preparation for Use and Installation Issue 2.0

(kV)

Peak

Antenna

Voltage

100

80

60

40

20

10

8

6

4

2

1

.01 .02 .04 .1 .2 .4 1 2

Gap Length (Inches)

Figure 2-13 Peak Antenna Voltage Versus Spark Gap Setting

2.5.1 Adjusting the Spark Gap

Adjust the ATU-HP’s spark gap as follows:

IA is the current recorded from step (a)

X

is the reactance from step (c).

L

(a) Record the antenna current on the

ATU control/monitor PWB’s meter.

Set switch A1S11 to RF CURRENT.

(b) Turn the transmitter off.

(c) Calculate the ATU-HP reactance (X

using the following formula:

X

= 0.00628ƒcL

L

ƒ

is the operating frequency (in kHz)

c

L is the inductance (in μH) (use value

selected from the appropriate Table

2-6 (a-f).

(d) Calculate the peak ATU-HP output

voltage (V

DGPS: V

NDB: V

) using either:

PK

= 1.414 IA XL

PK

= 1.414 IA XL (1+Mod %/100)

PK

)

L

Ensure the transmitter is off when

making adjustments on the ATU-HP.

Lethal voltages are present when any

level of RF is applied to the ATU-HP.

(e) Enter the graph shown in Figure 2-13

with the peak antenna voltage

calculated in step (d) and determine

the spark gap length (in inches).

(f) Set the spark ball gap for the length

determined in step (e).

(g) Turn on the transmitter at the desired

power level and ensure no arcing of

the spark gap.

(h) Install ATU-HP covers.

WARNING

Page 2-26 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

This Page Intentionally Left Blank

ATU-HP Technical Instruction Manual Page 2-27

Section 2 Preparation for Use and Installation Issue 2.0

2.6 INCREASING ANTENNA

BANDWIDTH

If it is necessary to increase antenna

system bandwidth, as determined in

paragraph 2.5, step (z) for DGPS

applications or step (aa) for NDB

applications, incorporate the Nautel’s

Series Resistor Kit, if provided, as follows:

NOTE

The series resistor kit is factory installed if

purchased with the ATU-HP. The kit is

user-installed, using a separate

Information Sheet document, if purchased

after ATU-HP installation.

Adding series resistance will reduce the

reflected power level, but will reduce

antenna current.

WARNING

It is recommended that additional safety

precautions against accidental RF input

application be taken when working in

the vicinity of the tuning coils.

Connect grounding clip (located near

the RF input) to the RF input.

(a) Using Figure 2-14a (for DGPS

applications) or Figure 2-14b (for NDB

applications), determine the additional

series resistance by selecting the T2

tap settings that provide acceptable

reflected power. View reflected power

on the ATU control/monitor PWB’s

meter, noting switch A1S10 must be

set to REFLD PWR and switch A1S11

must be set to RF POWER.

Page 2-28 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

(

–

p (x)

DGPS Applications

ADDING SERIES RESISTANCE

With transmitter

operating in MSK

mode at desired

power level, note

reflected power on

meter

Turn transmitter off.

Change taps on T2 to

add resistance as per

Table 2-7. Turn

transmitter on.

Wait for L TUNING -

NORMAL and R

TUNING – NORMAL

LEDs to turn on

motors stop)

Is the R

TUNING–

MAX LIMIT

LED on?

NO

YES

NO YES

Turn transmitter

off. Change taps

on T1 to next

higher resistance

ratio as per Table

2-5. Turn

transmitter on.

Is reflected

power

acceptable?

Repeat para.

2.5, ste

NO

Note T2 tap settings.

Note variable matching

transformer position

(see Figure 2-12)

Is variable

matching

transformer near

optimum

position?

YES

ATU-HP

TUNED

Figure 2-14a - Flow Diagr am

ATU-HP Technical Instruction Manual Page 2-29

Section 2 Preparation for Use and Installation Issue 2.0

Adding Antenna Series Resistance (DGPS Applications)

(

p (x)

NDB Applications

ADDING SERIES RESISTANCE

Turn transmitter off.

Change taps on T2 to

add resistance as per

Table 2-7. Turn

transmitter on.

Wait for L TUNING -

NORMAL and R

TUNING – NORMAL

LEDs to turn on

motors stop)

NO YES

Turn on transmitter, in

CW mode, and set to

desired power level.

Set transmitter to

operate in MCW

mode. Increase the

modulation to the

desired level.

Can mod depth

be achieved

with acceptable

reflected power

level?

Repeat para.

2.5, ste

NO

Note T2 tap settings.

Note variable matching

transformer position

(see Figure 2-12)

Is variable

matching

transformer near

optimum

position?

Is the R

TUNING–

MAX LIMIT

LED on?

Figure 2-14b - Flow Diagr am – Adding Antenna Series Resistance (NDB Applications)

Page 2-30 ATU-HP Technical Instruction Manual

Issue 2.0 Section 2 Preparation for Use and Installation

NO

YES

Turn transmitter

off. Change taps

on T1 to next

higher resistance

ratio as per Table

2-5. Turn

transmitter on.

YES

ATU-HP

TUNED

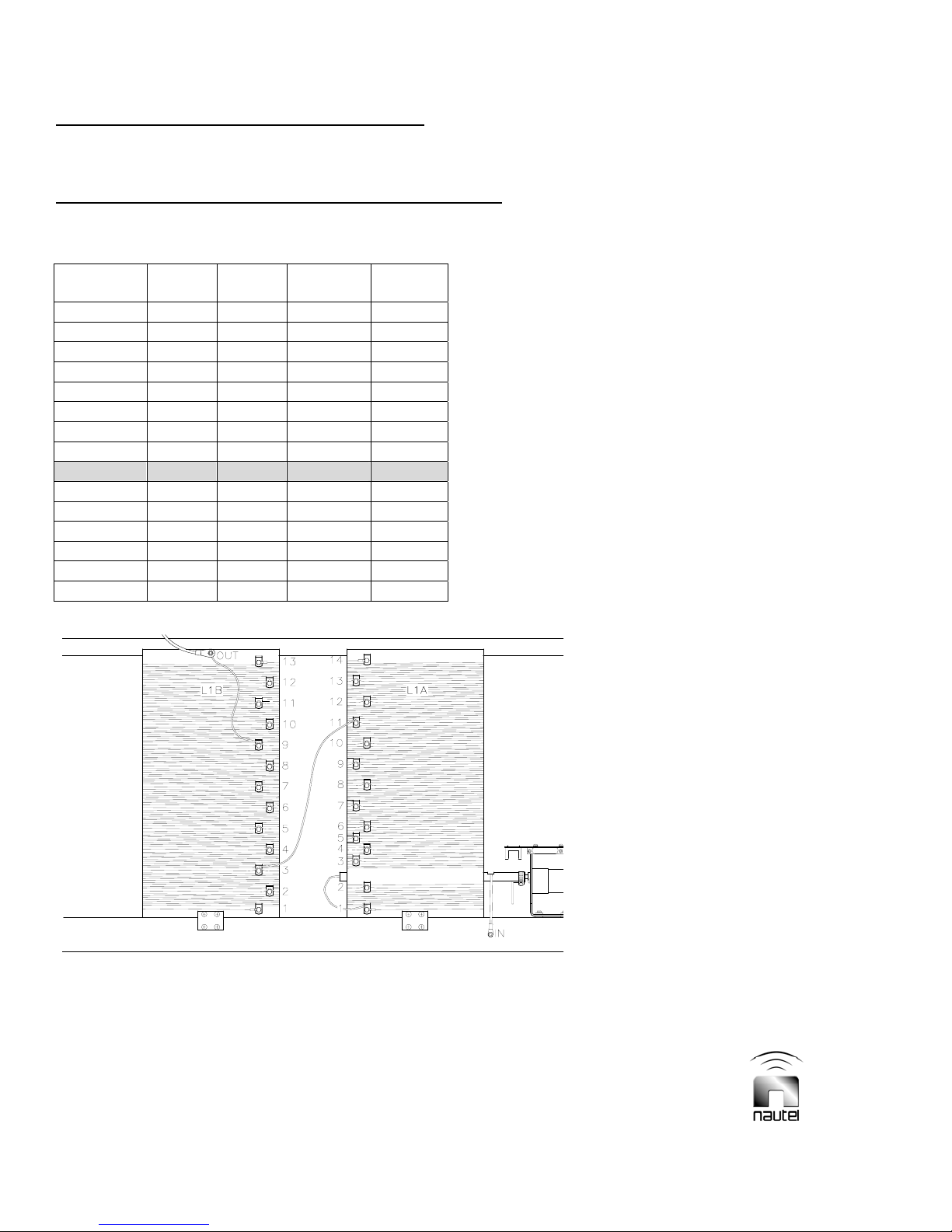

Table 2-7: T2 Taps vs Series Resistance

T2 Tap Settings

Series

Resistance

(Ω)

0 1 1 3 1

0.8 7 1 6 1

1.0 7 1 5 1

1.4 7 1 4 1

2.0 7 1 3 1

3.1 8 1 6 1

4.1 8 1 5 1

5.6 8 1 4 1

(terminated on positions 1 through 9 as in Fig. 2-16)

Wires

terminating on

A1TB1-7/8 (A)

Wire terminating

on L1A-input (B)

Core connection

from external

load resistor

Shield connection

from external

load resistor

Figure 2-15 Partial View of Series Resistance Transformer T2 Taps

(shown connected to provide an additional 0.8 Ω series resistance)

ATU-HP Technical Instruction Manual Page 2-31

Section 2 Preparation for Use and Installation Issue 2.0

ATU-HP Technical Instruction Manual Page 2-32

Section 2 Preparation for Use and Installation Issue 2.0

Figure 2-16 ATU-HP – Dimensional Information and Mounting Options

ATU-HP

TECHNICAL INSTRUCTION MANUAL

Section 3 OPERATING INSTRUCTIONS

3.1 INTRODUCTION

This section provides the information required

to place the ATU-HP in operation. The

ATU-HP will normally be unattended during

use. The following instructions are intended

for persons involved in testing or

maintenance of the equipment.

WARNING

Use extreme caution near the tuning

coils. Extremely high RF voltages, that

may arc many inches of air breakdown

path

and cause severe RF burns, are

present when an RF input of any level is

applied to the ATU-HP.

3.2 EMERGENCY SHUTDOWN

There are no special procedures to be

observed if an emergency shutdown is

required. Remove RF input by having

transmitter's RF output turned off or by

disconnecting RF input coaxial cable from RF

input connector J3.

.

3.3 CONTROLS AND INDICATORS

All of the controls and indicators for the

automatic antenna tuning unit are located on

the ATU control/monitor PWB (A1). Figure

3-1 and Table 3-1 identify and describe the

controls and/or indicators on the ATU

control/monitor PWB. It is recommended the

operator/maintainer be familiar with the ATU

controls and indicators before placing the

ATU-HP into service and/or attempting to

perform fault diagnostics.

NOTE

On some assembly detail drawings,

numbered callouts are provided to crossreference the control/indicator to the

description table.

The names used in the PANEL MARKING

column of the controls and indicators tables

are intended to be the closest possible

representation to the item’s label/silkscreen.

ATU-HP Technical Instruction Manual Page 3-1

Section 3 Operating Instructions Issue 2.0

M1

R10

Q9

Q5

ECB

CR5

R11

R12

R13

Q10

Q6

ECB

CR6

R14

R15

R16

Q11

Q7

ECB

CR7

R17

R18

R19

Q12

Q8

ECB

CR8

R20

R21

2

CR13

1

CR14

CR15

CR16

T6

T2

2 1

1

2

4 3

431

2

T3

6

R22

T5

5

CR9

CR10

CR17

CR18

CR19

CR11

CR12

CR20

CR21

CR22

CR23

CR24

CR25

CR26

CR27

CR28

DS20 R70 R51 S10 S11

DS19

DS21

FAN FAIL12

DS19 DS21

R118

CPU OK

C6

R29

C7

R30

GND

TP1

C8

R31

C9

R32

M1

CR38

R109

R110

CR39

CR40 CR43

R111

R23

R24

R25

R26

METER

R72

ANT CUR

SAMPLE

C21

C19

R51

R49

R57

CR32

R56

C20

R74

C18

R39

CR30

R81

R50

R48

R55

R46

R70

R73

C23

R71

TP4TP5

C22

E5

C

E6

INCREASE

CAL

R28R33

R42

R27

C10

C11

4

R38

R47

CR31

R40

R45

CR29

C12

C14

C15

R43

R44

C16

C13

C17

E3

S2

R52

R63

R62

R64

E4

E1

R34

R53

R41

R54

E2

DECREASE

B

S3

INHIBIT

R66

R67

R68

LOCAL/ XMTR

REMOTE

A

+-

C79

R TUNINGL TUNING

R94

S5S1

R95

R96

L TUNING R TUNING

DS5

S6

DS6

DS7

DS8

DS9

S7

DS10

R83

R76

R77

R78

R79

R87

R84

R88

R85

R89

DS2DS1

R90

ON/OFF

S8S4

R80R69

DS3

SETUP

TUNE

R91R86

R92

S9

+5V

RF POWERFWD PWR

S10 S11

RF CURRENTREFLD PWR

C24 C29 C31

U1

U2

R97

R98

R99

NORMAL

INHIBIT

TP2

GND

DS12

DS13

DS14

DS15

DS16

DS17

C30

U3

+12V-B+12V-A

MAX LIMIT

INCREASE

DECREASE

MIN LIMIT

C25

C26

C27

C28

R93

DS4

C40

123

U5

CR34

U4

C36

C37

R102

R103

R105

R104

R106

R107

CR35

CR36

C38

CR37

C32

C33

C39

C34

C35

C41

4

123

U6

4

F1

R101R100

DS18DS11

F2

DS20

R119

R114

R115

C50

C51

R116

R117

C55

CR41

R120

C47

R121

C48

CR42

C49

U8

C44 C43

Y1

C46 C45

R112

CR44

CR45

R113

C52

CR46

CR47

C53

C42

U7

R108

J1

1

C54

4

78 65

34 21

SPLIT

SINGLE

R123

R124

R122

R130

C56

C62

U11

CR48

CR51

CR49

CR52

CR50

CR53

+

C58

C59

U10

C60

L5

C61

C63

C57

CR54

321

U9

T7

LINE

LINE

123

R125

R126

Q13

R127

R128

Q14

R129

C64

GND

LINE NEUT N/C

GND

Q15 Q16

CR55

CR56

C67

R141

TP3

GND

R134

R135

R136

R137

R138

R139

R140

C73

C74

U15

C65

R131

R132

C66

R133

N/C NEUTN/C

456

TB2

R142

R143

R144

R145

C68

C69

C70

C71

C72

CR59

CR60

C75

R152

1

R153

R154

R155

R156

R148

R149

R150

R151

C76

R157

C78

C80

L7

C77

R147

U12U13

CR57

CR58

J2

L6

1

J3

R146

R158

U14

TX/RX TX/RX DE/RE

GND

ISOLATED

+5V

TB3

230VAC

115VAC 115VAC

123456789101112

A - C

S1 – S9

DS1 – DS3

Fig. 3-1 - Part of ATU Control/Monitor PWB A1 (NAPC144

Page 3-2 ATU-HP Technical Instruction Manual

Issue 2.0 Section 3 Operating Instructions

DS4

DS11

DS18

A/01)

DS5 – DS10

DS12 - DS17

F1

F2

Table 3-1: ATU Control/Monitor PWB Controls and Indicators

REF DES

A1DS1

A1DS2

A1DS3

A1DS4

A1DS5

A1DS6

A1DS7

A1DS8

A1DS9

A1DS10

A1DS11

A1DS12

ATU-HP Technical Instruction Manual Page 3-3

Section 3 Operating Instructions Issue 2.0

PANEL

MARKING

LOCAL/REMOTE

XMTR OFF

TUNE SETUP

+5V

L TUNING – MAX

LIMIT

L TUNING –

INCREASE

L TUNING –