Page 1

SolarMagic

TM

Weather Station

User Guide

Page 2

DISCLAIMER

The information, specifications, configurations and other technical information regarding the products

referenced herein are subject to change without notice. All the statements, technical information and

recommendations contained herein are believed to be accurate and reliable but National Semiconductor

Corporation makes no representations or warranties with respect to accuracy or completeness of the

contents of this User Guide. Users must take full responsibility for the application of any products

referenced herein. No license whether express, implied, arising by estoppel or otherwise, to any intellectual property rights is granted by this User Guide.

TO THE MAXIMUM EXTENT PERMITTED BY LAW, IN NO EVENT SHALL NATIONAL

SEMICONDUCTOR BE LIABLE TO BUYER, OR TO ANY PARTY CLAIMING THROUGH OR

UNDER BUYER, FOR ANY LOST PROFITS, LOSS OF DATA, INCREASED MANUFACTURING

COSTS, LOSS OF GOODWILL, OR FOR ANY INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY OR

CONSEQUENTIAL DAMAGES OF ANY KIND, ARISING OUT OF OR RELATED TO THE USE OF

THIS USER GUIDE, OR THE USE OF OR THE INABILITY TO USE ANY PRODUCT REFERENCED

HEREIN, EVEN IF NATIONAL SEMICONDUCTOR HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. NATIONAL SEMICONDUCTOR’S TOTAL CUMULATIVE LIABILITY SHALL BE

LIMITED TO THE AMOUNTS PAID BY BUYER TO NATIONAL SEMICONDUCTOR FOR THE

PRODUCTS ORDERED PURSUANT TO THE APPLICABLE PURCHASE ORDER. TO THE EXTENT

SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT

APPLY TO BUYER.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form by any means, electronic or mechanical, for any purpose, without the express

written consent of National Semiconductor Corporation.

National Semiconductor, the National Semiconductor logo, SolarMagic and MYPVDATA are trademarks

or registered trademarks of National Semiconductor Corporation. All other brand or product names

may be trademarks or registered trademarks of their respective holders.

Copyright© 2010 National Semiconductor Corporation

Page 3

WARRANTY

National Semiconductor Corporation (“Seller”) hereby warrants that the product for which this User Guide is

written (the “Equipment”) will comply in all material respects with Seller’s published specification for a period

of one (1) year from the date of shipment. For any material breach of the foregoing warranty, Seller’s sole and

exclusive obligation and buyer’s sole and exclusive remedy for breach of the foregoing warranty shall be, at

Seller’s option, to either repair, replace or issue credit for the nonconforming product, provided proof of purchase and written notice of non-conformance are received by Seller within the period noted above and Seller

confirms the alleged non-conformity. This warranty shall not apply to Equipment that Seller determines has

been, by buyer or otherwise, subject to unauthorized modification, improper installation, misuse, or use for any

reason other than electrical power monitoring of solar power equipment.

THIS WARRANTY EXTENDS TO BUYER ONLY AND NOT TO BUYER’S CUSTOMERS OR USERS OF

BUYER’S PRODUCTS OR SERVICES AND IS IN LIEU OF, AND SELLER EXPRESSLY DISCLAIMS, ALL

OTHER WARRANTIES, WHETHER EXPRESSED, IMPLIED, STATUTORY, INCLUDING BUT NOT

LIMITED TO ANY WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

TITLE AND NON-INFRINGEMENT. THIS WARRANTY SHALL NOT BE ENLARGED BY, AND NO

OBLIGATION OR LIABILITY SHALL AIRISE OUT OF, SELLER’S RENDERING OF TECHNICAL ADVICE

OR SERVICES IN CONNECTION WITH THE DELIVERY OF THE EQUIPMENT. TO THE EXTENT SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OF CERTAIN WARRANTIES, SOME OF THE

ABOVE EXCLUSIONS MAY NOT APPLY TO BUYER.

For further details please go to Seller’s website at: www.solarmagic.com

Page 4

Page 5

Contents

Chapter 1 ............................................................................................... Welcome 1

Chapter 2 ........................................................... About MYPVDATA® Services 4

Chapter 3 ............................................................................................... Planning 6

Contents

1.1 Important Safety Instructions .......................................................................................................................... 2

2.1 System Manager Overview ............................................................................................................................... 5

3.1 Enclosure .......................................................................................................................................................... 6

3.2 Sensors Overview ............................................................................................................................................. 7

3.3 Solar Irradiation Sensor .................................................................................................................................... 8

3.4 Wind Speed Sensor ........................................................................................................................................... 9

3.5 Wind Direction Sensor ...................................................................................................................................... 9

3.6 Ambient Temperature Sen sor ......................................................................................................................... 11

3.7 PV Cell Temperature Sensor ............................................................................................................................ 12

3.8 Reference Cell/Temperature Sensor ................................................................................................................ 12

3.9 Communication Module ................................................................................................................................. 13

Chapter 4 ........................................................................................... Installation 15

4.1 Standard Version ............................................................................................................................................ 15

Chapter 5 .................................................................................... Commissioning 21

5.1 Powering Up ................................................................................................................................................... 21

Chapter 6 ........................................................................................ Maintenance 22

Chapter 7 .................................................................................. Troubleshooting 24

6.1 Calibration ...................................................................................................................................................... 22

7.1 Technical Support ........................................................................................................................................... 24

i

Page 6

National Semiconductor • SolarMagic Weather Station User Guide

Appendix A ......................................................................... Reference Diagrams 27

ii

Page 7

Chapter 1 Welcome

C

ongratulations on your purchase of the SolarMagicTM weather

station. This instrument has been quality tested and approved

for providing accurate and reliable measurements. We are

confident that you will find the weather station to be a valuable asset

for your application. Should you require assistance, our technical staff

will be happy to help.

Chapter 1 • Welcome

Reading this entire manual is recommended for full understanding of

the use of this product.

Should you have any comments on the product or this manual, we will

be pleased to receive them:

National Semiconductor

2900 Semiconductor Drive

Santa Clara, CA 95051

Phone +1 (877) 765-6244

Fax +1 (866) 816-1201

Email: support@solarmagic.com

Web:

http://www.solarmagic.com

1

Page 8

National Semiconductor • SolarMagic Weather Station User Guide

Z

!

!

!

Z

Z

Z

1.1 Important Safety Instructions

This manual contains important safety instructions that should be

followed during the installation and maintenance of this product. To

reduce the risk of electrical shock, and to ensure the safe installation

and operation of this product, the following safety symbols have been

placed throughout this manual to indicate dangerous conditions and

important safety instructions.

WARNING:

A dangerous voltage or condition exists in this area. Use extreme caution when

performing these tasks.

CAUTION:

This procedure is critical to the safe installation or operation of the unit. Follow

these instructions closely.

NOTE:

This statement is important for best performance. Follow these instructions

closely.

CAUTION: Follow All Electrical Codes

All electrical work must be done in accordance with local, national, and/or

international electrical codes.

CAUTION: Read All Instructions

Before installing or using this device, read all instructions and cautionary markings

located in (or on) the products and the manual.

WARNING: Use Insulated Tools

To reduce the chance of short-circuits when installing or working with the

products use insulated tools.

WARNING: Remove Jewelry

Remove all jewelry while installing this system. This will greatly reduce the chance

of accidental exposure to live circuits.

WARNING: Stay Away from Live Wires

Make sure the weather station mast and sensor frame cannot get in contact with

live wires. This could cause serious injury, death or fire.

2

Page 9

Chapter 1 • Welcome

Z

!

WARNING: Do Not Install in Rain

Do not install or handle the SolarMagicTM DC Monitoring Combiner Box if it is wet or

raining.

CAUTION: Call if there is Damage

Contact us if the SolarMagic DC Monitoring Combiner Box enclosure is damaged or if its

contents are compromised.

3

Page 10

National Semiconductor • SolarMagic Weather Station User Guide

M

Chapter 2 About MYPVDATA®

Services

YPVDATA services is the web portal that provides access to

your SolarMagic system manager data. MYPVDATA services

are provided and hosted by National Semiconductor.

With focus on solar energy systems, National Semiconductor is the

leading provider of monitoring and management solutions for

photovoltaic (PV) systems. National Semiconductor recognizes the

importance of monitoring PV systems beyond just solar energy

production data. Detailed information is needed to utilize the system

to its full potential. By providing an enhanced web-based monitoring

and diagnostics solution, National Semiconductor addresses this

problem and safeguards your investment.

The system manager solution in conjunction with MYPVDATA

services brings the following benefits:

• Safeguard Your Investment and Maximize Your Return.

• Improved Efficiency.

• Lower Life Cycle Costs.

• Real-time and Historic Data Presented Using Web-based Devices.

• Alarm Functions Notify of a Decrease in Production and Device

Communication Failure.

• Remote Access to all Data Using Internet Technology.

4

Page 11

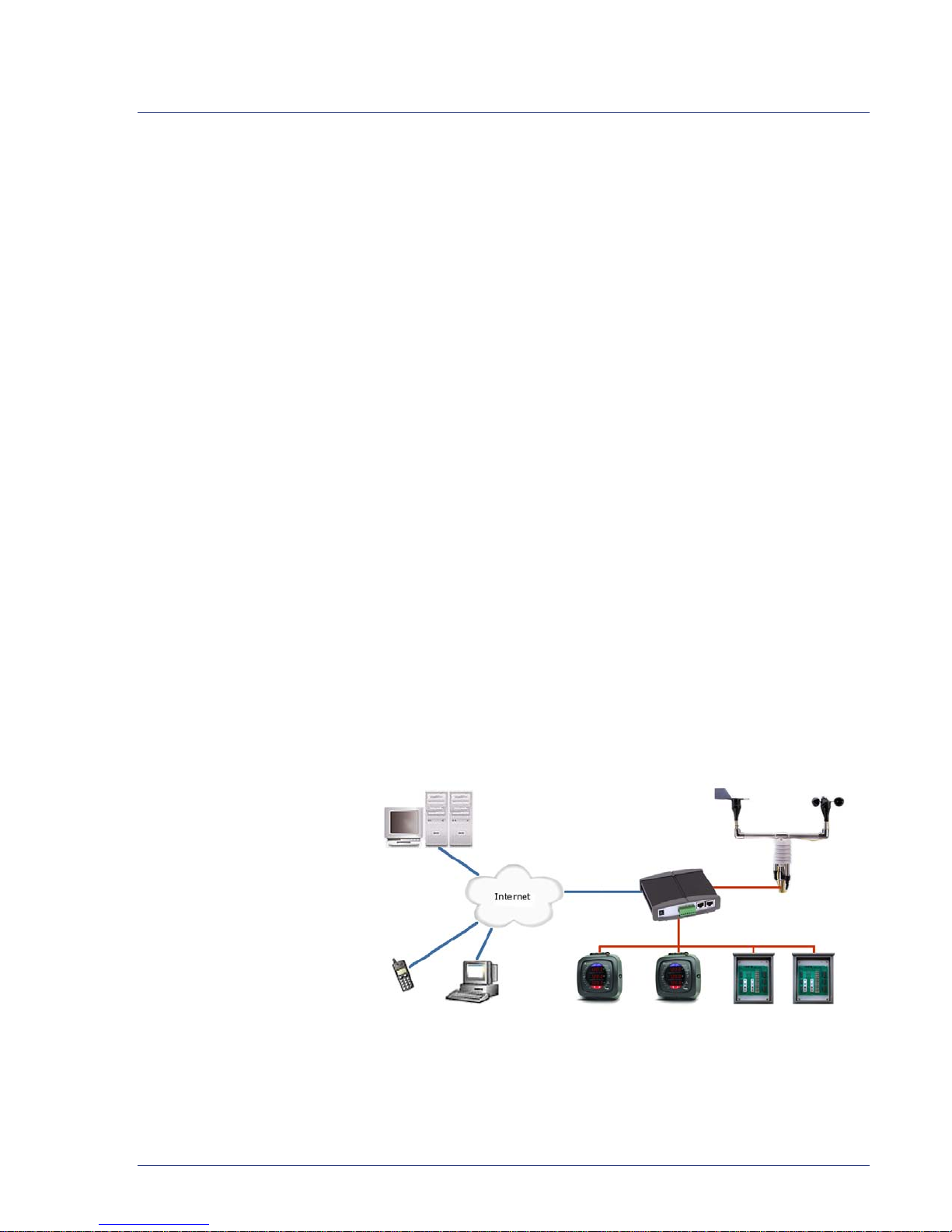

2.1 System Manager Overview

tem

Overview

The SolarMagic system manager is a lightweight Internet gateway and

data logger solution for remote data acquisition, which enables PV

system owners to benefit from advanced energy reports. The data

logger collects data from connected devices as energy meters, inverters

and weather stations, over the standard communications protocol

Modbus. System performance and energy information are logged into

a database on the Information Server, where it can be retrieved and

used for analysis via any standard web-browser enabled device by

logging in to the MYPVDATA site.

The system manager provides the following functions:

• AC Power Monitoring for Solar Production.

• Building Demand and Net Consumption Monitoring.

• Peak Demand Tracking.

• DC Monitoring to String Level.

Chapter 2 • About MYPVDATA® Services

Figure 2-1. Sys

• Real-time Power Values.

• Daily, Weekly and Monthly overviews.

• Local Data Storage Eliminates Need for Always-on Internet

Connection.

• Data Warehousing Facilitated on Internet Server.

• Web -based Presentation of Historical and Real-time Energy Data

in Graphs and Tables through MYPVDATA.com.

• Performance Alarming via Email and SMS.

5

Page 12

National Semiconductor • SolarMagic Weather Station User Guide

eather

Station Enclosure

Chapter 3 Planning

3.1 Enclosure

The SolarMagic weather station is housed in a painted galvanized steel

enclosure, suitable for outdoor mounting, type NEMA 4x. The

enclosure measures 10H x 8W x 4D.

Figure 3-1. W

3.1.2 Enclosure Specifications

• Type: 4-4x-12

• Material: 16 gauge painted galvanized steel

• Weight: 12lbs

• Size: 10”H x 8”W x 4”D

6

Page 13

3.2 Sensors Overview

Environmental sensors have many applications and therefore many

installation options. Where you locate the sensors for the weather

station is important in order to get accurate data. The sensors should

be located in a clear area on a level surface that represents the general

area of interest, and be away from obstructions such as buildings and

trees

All SolarMagic weather station weather sensors produce a 4–20mA

output signal. 4–20mA is an industrial standard signal for process

control monitoring. Most PLCs (Programmable Logic Controller) and

data acquisition systems accept this signal directly.

The communication module is already connected to the designated

input terminals on the input terminal block in the weather station. The

lead wires from the sensor will need to be connected to the input

terminals in the weather station enclosure. The weather station can be

installed up to 1000ft from the Data Logger and connects through a

twisted pair cable and RS-485 communication (National

Semiconductor recommends a size of stranded copper #18-22 twisted

pair with shielding and drain wire). The weather station also requires

24Vdc, which is typically sourced from the system manager

monitoring kit. The communication protocol is the widely spread

Modbus protocol.

Chapter 3 • Planning

The sensors are sampled continuously to provide real time data. Each

sensor draws between 4mA and 20mA depending on whether the

sensor is reading at the minimum or maximum of its range.

The weather station sensors include an assembly on a sturdy and

durable 1” OD stainless steel tube frame that can be mounted onto a

pre-existing base/mast or onto a tripod for upright installation. The

unit is designed for durability and endurance in harsh conditions. The

Solar Shield, a ventilated sun shield with high reflectiveness, low heat

retention, and low thermo conductivity, is provided as protection and a

mounting platform for the temperature sensor.

Choosing a proper installation location for weather sensors is

important to ensure accurate readings. For example, wind sensors

should not be installed too close to a building, as turbulence created by

the building can interfere with readings. To measure global irradiation

the solar irradiation sensor should be installed in direct sunlight on a

level surface (bubble level and leveling screws are included with

purchase) with similar sun exposure as the PV array.

7

Page 14

National Semiconductor • SolarMagic Weather Station User Guide

Solar

Irradiation Sensor

NOTE: Sensor Cable Length

Most sensors are shipped with a 25ft sensor lead cable. Make sure that the sensor

cables will reach. The sensor lead wires can be extended to a maximum length of

400ft if stranded #22AWG or larger wires are used.

If both the wind direction and wind speed sensors are purchased, the

weather station comes with a T-mounting bar with a 1" OD stainless

steel coupling unit and an Allen wrench to install the set screws during

installation. Individual wind sensors or solar irradiation sensors

include 1" stainless steel elbow couplers and an Allen wrench for the

set screws. The Solar Shield (with a stainless steel elbow coupler) can

be used for protection and easy installation of the Temperature and

Humidity sensors.

NOTE:

We recommend use of guy wires to support the weather sensor mast/base.

3.3 Solar Irradiation Sensor

The solar irradiation sensor or pyranometer is an instrument for

measuring solar irradiation from the hemispherical field of view

centered on the sensor. It measures the energy flux density of both

direct beam and diffuse sky irradiation passing through a horizontal

plane of known unit area.

Solar irradiation varies significantly among regions. Season and time

of day are major considerations, but surrounding terrain elevation,

man-made obstructions, and surrounding trees can also cause large

variations in locations with a small area.

Figure 3-2.

3.3.2 Solar Irradiation Sensor Specifications

• Output: 4–20mA

• Range: 0–1500 W/m2

• Accuracy: 1% of full scale

8

Page 15

• Operating Voltage: 10–36VDC

Speed

• Current Draw: Same as sensor output

• Warm Up Time: 3 seconds minimum

• Operating Temperature: –40°C to 55°C

• Size of Probe: 3" diameter × 1.5" high

• Weight: 0.25lb

3.4 Wind Speed Sensor

The wind speed sensor or anemometer produces a sine wave voltage

signal with a frequency that changes linearly with the wind speed. The

frequency is transformed into a 4–20mA sensor signal output.

Figure 3-3. Wind

Sensor

Chapter 3 • Planning

3.4.2 Wind Speed Sensor Specifications

• Output: 4–20mA

• Range: 0-100MPH

• Accuracy: 0.2MPH over the range 11 to 55MPH

• Operating Voltage: 10–36VDC

• Current Draw: Same as sensor output

• Warm Up Time: 3 seconds minimum

• Operating Temp: –40° to +55°C

• Size of Probe: 7" diameter × 8.5" long

• Weight: 1lb

3.5 Wind Direction Sensor

A wind direction sensor produces a ratio metric voltage signal. That

voltage signal is transformed into a 4–20mA sensor output signal.

9

Page 16

National Semiconductor • SolarMagic Weather Station User Guide

Wind Direction

Figure 3-4.

Sensor

3.5.2 Wind Direction Sensor Specifications

• Output: 4–20mA

• Range: 0 to 360° (352° electrical, 8° open)

• Accuracy: 1% of full scale

• Operating Voltage: 10–36VDC

• Current Draw: Same as sensor output

• Warm Up Time: 3 seconds minimum

• Operating Temp: –40° to +55°C

• Size: 8.5" diameter × 10 ½" long

• Weight: 1lb

3.5.3 Solar Shield

The solar shield is used to protect sensors, typically humidity and

temperature, from direct sunlight. Insert a sensor into one of the two

holes located on the underside of the shield. The shield provides a

friction lock so the sensors will not fall out. The sensors can be

removed by firmly twisting and pulling them out of the solar shield.

10

Page 17

Chapter 3 • Planning

Figure 3-5. Solar Shield

The shield comes with a stainless steel elbow that can be mounted on a

1” OD diameter tube. For best results ensure that the shield is mounted

vertically.

• Size: 4” diameter × 8 ½” long,

• Weight: 1 lb.

3.6 Ambient Temperature Sensor

Figure 3-5 shows the temperature sensor installed in the solar shield.

3.6.1 Ambient Temperature Sensor Specifications

• Output: 4–20mA

• Range: –50°C to 50°C

• Accuracy: ±0.2° F or ±0.1° C

• Operating Voltage: 10–36VDC

• Current Draw: same as sensor output

• Warm Up Time: five seconds minimum

• Operating Temperature: –50°C to 100°C

• Size of Probe: 0.75" diameter × 4.5" long

• Weight: 0.5lb

11

Page 18

National Semiconductor • SolarMagic Weather Station User Guide

PV Cell

Temperature Sensor

3.7 PV Cell Temperature Sensor

The PV Cell Temperature Sensor temperature sensor measures the

temperature of the aluminum heat sink located on the face.

Figure 3-6.

3.7.2 PV Cell Temperature Sensor Specifications

• Sensor Type: 100 Ohm Platinum Class A RTD

• Output: 4–20mA

• Range: –50° C to 85°C

• Accuracy: ±0.5° F or ±0.25°C

• Operating Voltage: 10–36VDC

• Current Draw: Same as sensor output

• Warm Up Time: 3 seconds minimum

• Storage Temperature: –55°C to 90°C

• Sensing Surface: 0.75” × 1.5” Aluminum

• Housing: 2.0W” × 1.1H” × 3.8L” ABS

• Weight: 13oz with 25’ of cable

3.8 Reference Cell/Temperature Sensor

The Reference Cell/Temperature sensor is a combination sensor with

an irradiation sensor via a temperature compensated mono-crystalline

silicon cell and a temperature sensor.

12

Page 19

Figure 3-7.

Reference

Cell/Temperature Sensor

Chapter 3 • Planning

3.8.2 Reference Cell/Temperature Sensor Specifications

• Solar Cell: Mono-crystalline Silicone (1.96in x 1.3in)

• Output: 4–20mA

• Range: –20° C to 70°C

• Irradiance Accuracy: +/- 5%

• Temperature Accuracy: +/- 2%

• Housing: 3.3W” × 1.5H” × 5.7L” Powder coated aluminum, IP65

• Weight: 8.8oz

3.9 Communication Module

The weather station includes a data acquisition module that provides

analog-to-digital conversion. The modules can be remotely controlled

using a set of commands, the Modbus RTU protocol. Communication

between the module and the SolarMagic Internet gateway / data logger

is via Modbus RTU over 2-wire RS-485 twisted pair. The weather

station module is set to 9600 baud in manufacturing for a more robust

communications network, and typically Modbus address 2.

3.9.1 Communication Module Specifications

The M-7017C is an 8-channel current input module.

• Channels: 8 current inputs

• Input Range: 4–20mA, ±20mA, or 0–20mA

13

Page 20

National Semiconductor • SolarMagic Weather Station User Guide

• Resolution: 16-bit

• Sample rate: Maximum 10 samples/second

• Bandwidth: 15.7Hz

• Accuracy: 0.1%

• Isolation: 3000VDC

• Indication LED Light For Power and Communication

• Communication: RS-485, Modbus RTU Protocol

• Power supply: 10–30VDC, 1.3W

14

Page 21

Chapter 4 Installation

!

4.1 Standard Version

4.1.1 Installing the SolarMagic Weather Station Enclosure

Chapter 4 • Installation

Mount the weather station enclosure out of direct sunlight in a

location where it will not be exposed to continuous water flow, snow

and ice build-up, and/or areas of extreme temperature. Install the

enclosure using the external enclosure mounting tabs.

The weather station enclosure may be mounted in a vertical (where the

door opens out) or a horizontal (where the door opens up) orientation.

Mount the weather station enclosure on the optionally supplied

base/mast or in its proximity.

CAUTION:

Drilling holes in the back plate is not recommended and will void the warranty.

For vertical installations, it is best to mount the enclosure directly to a

strut system, such as Uni-Strut. Both pieces of the strut system should

be at least 8" in length and be fastened to a stud bearing wall with (2)

1/4" lag bolts long enough to penetrate the stud at least 2.5". Fasten all

four corners of the enclosure to the strut with a 1/4"-20 X 3/4" bolt

(preferably stainless steal or galvanized), a 1/4" flat washer, and a 1/4"

channel nut.

4.1.2 Installing the optionally supplied Weather Sensors Mast

Mount the weather sensors on the frame using the provisions outlined

in the following sections. Secure the sensors to the frame with the set

screws using the supplied Allen wrench.

15

Page 22

National Semiconductor • SolarMagic Weather Station User Guide

!

Mount the base or mast for the weather station to a secure surface and

install guy wires if possible. It is very important to ground the mast or

base station for proper safety.

Attach the sensor frame to the base/mast.

4.1.3 Installing the Communication and Power

CAUTION: Turn Off Monitoring Panel

Before proceeding, make sure the power for the communication module and the

main Monitoring Panel (Internet Gateway / Data Logger) is switched off.

Connect the Modbus RS-485 communication cable (National

Semiconductor recommends a size of stranded copper #22AWG

twisted pair with shielding and drain wire) from the system manager

enclosure to one pair of the DATA+ and DATA– terminals. Connect

the shield drain wire to the shield terminal. Note this is not connected

to ground and the drain wire should only be connected to ground at

one point, typically in the system manager enclosure. The other pair of

Data + and Data – terminals is available for continuing the Modbus

data connection to another device.

Connect the weather station to the power supply using one pair of the

+Vs and GND terminals. The wire size for the 24Vdc power can be

determined using the specifications in the system manager User

Guide. The other pair of +Vs and GND terminals is available for

continuing the 24Vdc power connection to another device.

4.1.4 Installing the Weather Sensor Wires

Install your weather sensors so that they are easily accessible for

calibration purposes. You may need to clean, remove and/or reinstall

them in the future, so plan ahead!

NOTE: Sensor Cable Length

Most sensors are shipped with a 25ft sensor lead cable. Make sure that the sensor

cables will reach. The sensor lead wires can be extended to a maximum length of

400ft if stranded #22AWG or larger wires are used. If you extend or cut the sensor

wires, be sure to mark which sensor the wire is connected to.

Using a step bit or a 1/2" drill bit, drill one hole into the enclosure for

each sensor. Refer to the sensor references for recommended strain

relief placement. Using this order for the sensors will allow for cleaner

and easier wiring inside the enclosure.

16

Page 23

Figure 4-1.

Strain Relief

Connector

Z

Chapter 4 • Installation

NOTE:

After drilling through a powder coated enclosure, apply an anticorrosive solution

to reduce risk of corrosion. Allow the anticorrosive solution to adequately dry

before installing the strain relief connector. Be sure to completely remove all metal

filings from the interior and exterior of the enclosure using a vaccum cleaner

and/or brush.

Install one of the provided Sealcon strain relief connectors (size M12 X

1.5) for each sensor. Make sure that the gasket is properly inserted

between the connector and the outside of the enclosure and that the

fastener nut is firmly tightened down.

Connect the sensor to their respective input terminal in the enclosure,

See Appendix A for references. Make sure the polarity of the

conductors are marked and are connected to the proper terminals in

the enclosure.

4.1.5 Installing the Solar Irradiation Sensor

The sensor is a two-wire sensor using the red wire for power and the

black wire for the output signal.

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

Solar irradiation sensors should be mounted away from shadows,

reflective surfaces, and sources of light. Mounting the sensor on the

southernmost (for the northern hemisphere) part of the weather

station should minimize shading from the other weather station

sensors and hardware. The height the sensor is mounted is not critical

for the accuracy of the measurement. However, make sure it is

accessible to facilitate leveling, cleaning and calibration.

17

Page 24

National Semiconductor • SolarMagic Weather Station User Guide

Z

To m ea sure the module or array irradiation, ensure that the sensor is

placed on a level surface, use the alignment bolts to adjust the sensor

until it is level. Once the leveling alignment bolts are adjusted and

tightened then the irradiation sensor can be mounted at the same

angle and orientation as the PV modules. It is important the

irradiation sensor is mounted at the same angle and orientation in

order to determine the expected production of the PV system.

To measure global irradiation, mount the sensor on a level surface and

use the alignment bolts to adjust the sensor until it is level. Once the

leveling alignment bolts are adjusted, tighten them.

Remove the red cap to begin taking readings.

NOTE: Calibration

Calibration should be confirmed annually. Refer to Chapter 6 for calibration

procedures.

4.1.6 Installing the Wind Speed Sensor

The sensor is a two-wire sensor using the red wire for power and the

black wire for the output signal.

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

The sensor comes with a stainless steel elbow that can be mounted on

a 1” outside diameter tube. For best results ensure that the sensor is

mounted parallel to the ground surface located over open level terrain.

To measure the wind exposure of the PV array, National

Semiconductor recommends the wind sensor be installed in the

middle of the array at array height.

To measure the site wind conditions National Semiconductor

recommends the wind speed sensor be installed at a distance from

obstructions that is equal to five to ten times the height of nearby

buildings, trees, or other obstructions. For example if a parapet wall is

three feet higher than the wind sensor, then the wind sensor should be

installed 15 to 30 feet from the parapet wall.

The height over ground depends on the application and applicable

standards.

18

Page 25

4.1.7 Installing the Wind Direction Sensor

Z

Z

!

Z

The sensor is a two-wire sensor using the red wire for power and the

black wire for the output signal.

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

The ridge on the fixed portion of the sensor represents the 0° direction

of the sensor. Rotate the sensor so the ridge is aligns with the 0°

direction from a compass. The sensor comes with a stainless steel

elbow that can be mounted on a 1” outside diameter tube. For best

results ensure that the sensor is mounted parallel to the ground surface

located over open level terrain. National Semiconductor recommends

the wind direction sensor be installed near the wind speed sensor.

4.1.8 Installing the Ambient Temperature Sensor

The sensor is a two-wire sensor using the red wire for power and the

black wire for the output signal.

Chapter 4 • Installation

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

CAUTION:

Do not install the temperature sensor in direct sunlight.

For ambient temperature measurement applications the sensor should

be housed in a ventilated irradiation shield. To accurately measure the

ambient temperature we recommend that the sensor be no closer than

four times an obstruction’s height, at least 100ft. from large paved

areas, and located in an open level area that’s at least 30ft in diameter.

The open areas should be covered by short grass or, where grass does

not grow, the natural earth.

Avoid placing the sensor over rooftops, heat sources, high vegetation,

in shaded areas and areas that hold water.

4.1.9 Installing the PV Cell Temperature Sensor

The sensor is a two-wire sensor using the red wire for power and the

black wire for the output signal.

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

19

Page 26

National Semiconductor • SolarMagic Weather Station User Guide

!

Z

CAUTION:

Do not install the PV cell temperature sensor in direct sunlight.

Choose a PV module that will accurately model the average of the

panel temperature. Keep in mind that most PV modules on the edge

of an array are cooler because they have more air movement. After you

have chosen the correct module mark the appropriate location on the

back of the PV module to measure the PV cell temperature. This

location is typically under a PV cell and not the space between PV

cells.

For best operation, this sensor’s heat sink should be mounted flat

against the back of the solar panel. Mounting the sensor’s heat sink

over labels should be avoided if possible. A tube of silicone heat

transfer compound is provided with the sensor to ensure that the heat

sink is in proper contact with the solar panel and that the heat from

the panel is transferred efficiently to the sensor.

Apply an even coat of heat transfer compound to the surface of the

sensor as shown; making sure that the compound is a little bit higher

than the double stick tape. Use the alcohol pads provided with the

sensor to thoroughly clean the surface of the solar panel where the

sensor will be mounted. Allow this surface to dry completely before

mounting the sensor. Peel the backing from the adhesive tape and

press the sensor firmly against the solar panel. Tie the sensor cable to

the solar panel in a way that does not pull on the sensor.

20

4.1.10 Installing the Reference Cell/Temperature Sensor

The sensor is a four wire sensor using the red for power, black for

common/ground and orange and brown for the output signals.

WARNING: Do Not Connect When Energized

Do not connect the sensor wire if the communications module is energized.

The sensor has to brackets with each three M16 holes. Use at least one

M16 screw and washer at each bracket.

Mount the sensor in a location that best corresponds to your solar

installation. For recommendations, please contact National

Semiconductor Technical Support.

Page 27

Chapter 5 Commissioning

5.1 Powering Up

After all connections have been made, check the polarity of all wires

and connections to verify they are secured in the terminals and the

terminal screws are tight and connected to the proper terminals. If the

polarity of the wires is not correct, or they are connected to the wrong

terminals, you will not get weather data and may damage the sensors

or the communications module. After proper terminations have been

verified, it is ready to power on.

Chapter 5 • Commissioning

Turn on the power.

Verify the power LED is illuminated on the communication module.

Wait 15 minutes for the data to upload to the website and login to

MYPVDATA.com. Verify that the sensor readings on the MYPVDATA

site are available and accurate.

21

Page 28

National Semiconductor • SolarMagic Weather Station User Guide

Z

Chapter 6 Maintenance

The weather station sensors should be cleaned periodically. Sensors

can be cleaned using a damp cotton cloth.

NOTE: Do not submerge sensors

The sensors are water resistant, not waterproof.

6.1 Calibration

6.1.1 Temperature Sensor Calibration

Calibration should be confirmed annually.

To check the temperature sensor calibration you will need:

• 1 thermometer

• 3 containers of water

• 1 power supply

• 1 current meter

To calibrate the temperature sensor

Connect the sensor to the power supply and current meter in the

1

following way.

2 Attach the black wire to the positive input of the current meter.

3 Connect the ground terminal of the power supply to the ground of the

current meter.

4 Attach the red wire to the positive terminal of the power supply.

WARNING: Do Not Connect When Energized

Always connect the sensor with the power turned off.

22

Page 29

Chapter 6 • Maintenance

5 Fill a container of water with enough ice that it will not melt quickly.

6 Place the temperature sensor and thermometer into the container.

Turn on the power supply and the current meter. Let the sensor

stabilize for 30 minutes before taking any measurements.

7 Record the ice bath temperature, T

output current of the sensor, I

ICE

= _______, and record the

ICE

= _______.

8 Fill a container with enough warm water that it will not cool down

quickly.

9 Place the temperature sensor and thermometer into the container.

Turn on the power supply and the current meter. Let the sensor

stabilize for 30 minutes before taking any measurements.

10 Record the warm water temperature, T

the output current of the sensor, I

WARM

11 Calculate the relation between current and temperature:

a Calculate the current difference:

I

WARM

– I

= _______ = ∆I.

ICE

b Calculate the temperature difference:

T

c Calculate I

I

WARM

– T

WARM

– (∆I/∆T)(T

= _______ = ∆T.

ICE

B

WARM

) = _______ = IB.

d Calculate the low current value for the sensor:

(∆I/∆T) • (–50) + IB = _______ = I

HIGH

= _______, and record

WARM

= _______.

.

This current is the output current the sensor would produce if the

temperature were –50°C.

e Calculate the high current value for the sensor:

(∆I/∆T) • 50 + IB = _______ = I

LOW

.

This current is the output current the sensor would produce if the

temperature were 50°C.

12 Use these new current values calibrate the system that is monitoring

the sensor output.

23

Page 30

National Semiconductor • SolarMagic Weather Station User Guide

Chapter 7 Troubleshooting

Sensor reading incorrectly

Verify power source is supplying correct voltage.

1

2 Clean the sensor.

3 Confirm the sensor’s calibration.

4 Confirm the sensor is connected to the proper terminals.

7.1 Technical Support

For most efficient technical support please e-mail National

Semiconductor for technical support: support@solarmagic.com. Most

problems can be solved via email or call us at +1 (877) 765-6244.

When requesting technical support, please provide the following

information;

• Model #.

• Unit serial number.

• Site name and address, installer company name.

• Equipment purchaser name.

• Problem description.

Be prepared to describe the problem you are experiencing including

specific details of the application, installation, and any additional

pertinent information.

In the event that the equipment needs to be returned to the factory for

any reason, please call to obtain a RMA # (Return Material

Authorization). Do not return items without an RMA# displayed on

the outside of the package.

• Clean and decontaminate the sensor if necessary.

24

Page 31

Chapter 7 • Troubleshooting

• Include a written statement describing the problem(s).

• Insure your shipment; the warranty does not cover damage

incurred during transit.

• Send the package with shipping prepaid to our address at:

National Semiconductor

3875 Kifer Rd

Santa Clara, Ca 95051

25

Page 32

Page 33

Appendix A • Reference Diagrams

Appendix A Reference Diagrams

27

Page 34

National Semiconductor • SolarMagic Weather Station User Guide

A.1.1 Sensor Terminal Blocks

28

Page 35

A.1.2 Communications/Power Terminal Block

Appendix A • Reference Diagrams

29

Page 36

2900 Semiconductor Drive

Santa Clara, CA 95051

Phone 877-765-6244 Fax 866-816-1201

www.solarmagic.com

support@solarmagic.com

© 2010 National Semiconductor Corporation. National Semiconductor is a registered trademark and SolarMagic is a trademark of National Semiconductor Corporation. All

rights reserved. All other brand or product names are trademarks or registered trademarks of their respective holders.

Loading...

Loading...