Page 1

LP3945/LP3946

Battery Charge Management System

LP3945/LP3946 Battery Charge Management System

October 2003

General Description

The LP3945 and LP3946 are complete charge management

systems that safely charge and maintain a Li-Ion battery or a

four-cell Ni-MH (LP3945 only) battery pack. The LP3945

offers the flexibility of programming charge current, battery

regulation voltage (4.1V/4.2V), battery type (Li-Ion/Ni-MH),

and End Of Charge (EOC) termination through the use of I

interface. On the LP3946, these parameters are programmed at the factory per customer specification.

The pass transistor, charge current sensing resistor and

charge current setting resistors are all integrated inside the

LP3945 and LP3946. This eliminates the use of external

components and significantly reduces design time and board

space.

The LP3945 and LP3946 operate in four modes: prequalification, constant current, constant voltage and maintenance modes. The LP3945 features Ni-MH charging mode

as well. The charger has under-voltage and over-voltage

protection as well as an internal 5.6 hr timer to prevent

overcharging the battery. There are two open drain outputs

for status indication.An internal amplifier readily converts the

charge current into a voltage. Also, the charger can operate

in an LDO mode providing up to 1 Amp to the load.

2

Features

n Integrated pass transistor

n Does not require external charge current setting or

sensing resistors

2

n I

C interface (LP3945 only) — programmable charge

current, EOC current and battery regulation voltage

C

n Near-depleted battery preconditioning

n Built-in 5.6 hour timer

n Under voltage and over voltage lockout on adaptor

n Charge status indicators

n Charge current monitor analog output

n LDO mode operation can source 1 amp

n Continuous over current/temperature protection

Key Specifications

n 1% charger voltage accuracy over 0˚C ≤ TJ≤ 85˚C

n 4.5V to 6.0V input voltage range

n LLP package power dissipation: 2.7W at T

Applications

n Cellular phones

n PDAs

n Digital cameras

n USB powered devices

n Programmable current sources

= 25˚C

A

Typical Application Circuit

20066502

20066501

© 2003 National Semiconductor Corporation DS200665 www.national.com

Page 2

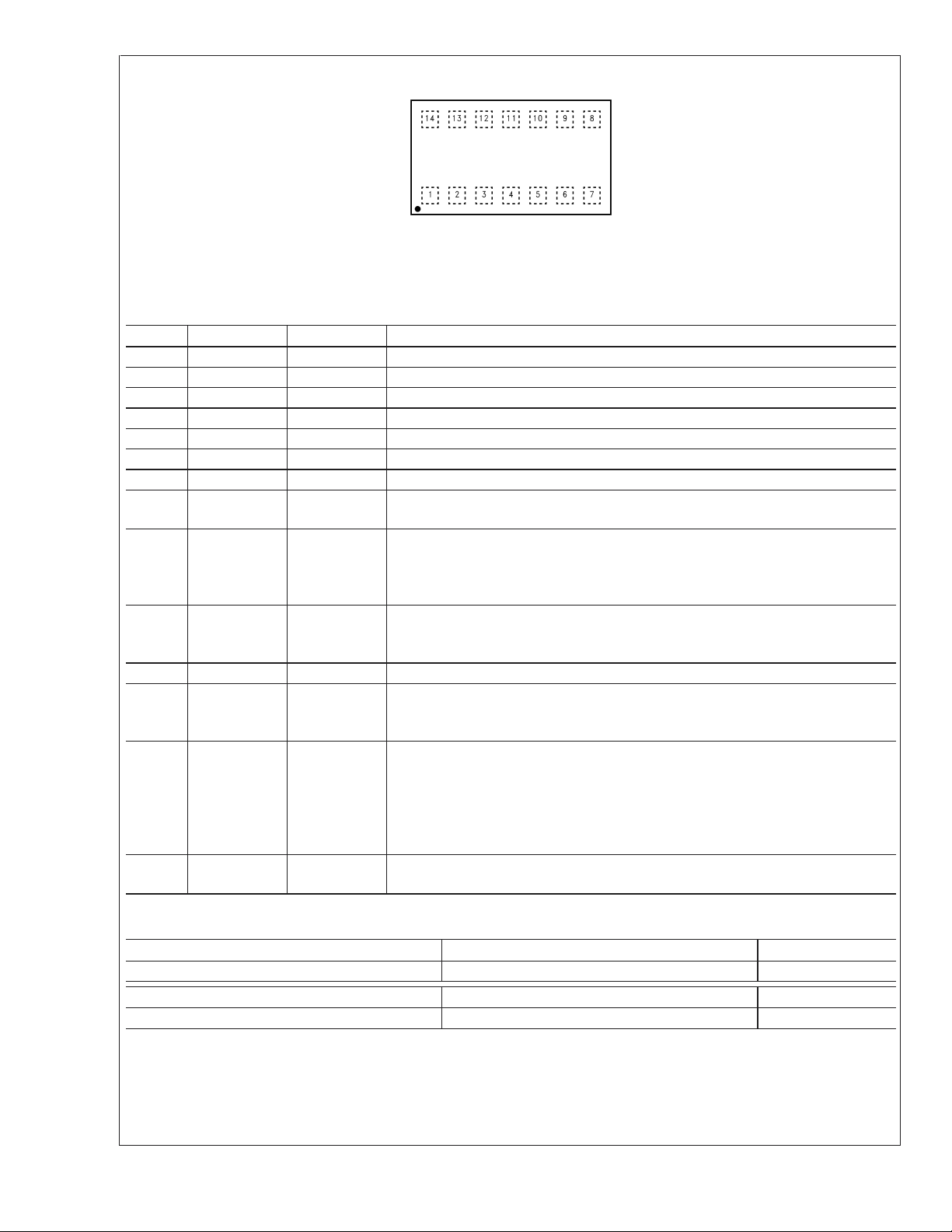

LP3945/LP3946 LLP14 Package Drawing

LP3945/LP3946

(TOP VIEW)

20066503

See NS Package Number LDA14A

LP3945/LP3946 Pin Description

Pin # LP3945 LP3946 Description

1 EN EN Charger Enable Input. Internally pulled high to CHG-IN pin.

2 SCL GND Serial Interface Clock Input for LP3945. Ground in LP3946.

3 SDA GND Serial Interface DATA Input/Output for LP3945. Ground in LP3946.

4 BATT BATT Battery supply input terminal. Must have 10 µF ceramic capacitor to GND.

5V

6VB

BG

SENSE

7 GND GND Digital Ground

8 Diff-Amp Diff-Amp Charge current monitoring differential amplifier output. Voltage output representation

9 BIPB BIPB Battery in Place Bar. Input signal to indicate presence/absence of the battery.

10 EOC EOC Active Low Open Drain Output to drive Green LED. Active when wall adaptor is

11 GND GND Analog Ground

12 CHG CHG Active Low Open Drain Output to drive Red LED. Active when wall adaptor is

13 StopModeEN StopModeEN For normal operation, this pin must be left floating. Pulling this pin to ground will

14 CHG-IN CHG-IN Charger input from a regulated, current limited power source. Must havea1µF

V

VB

BG

SENSE

Bandgap Voltage Reference (1.225V). Factory test point. Must be left floating.

Battery Voltage Sense connected to the + terminal of the battery.

of the charge current.

Internally pulled high to CHG-IN. Pulled low by the Battery ID resistor. Absence of

the ID resistor (BIPB signal high) indicates no battery. Pulling BIPB pin high sets the

device to LDO mode.

connected and battery is fully charged. Regardless of the battery chemistry, this

signal is available whenever a battery is attached.

connected and battery is being charged. Regardless of the battery chemistry, this

signal is available whenever a battery is attached.

bypass the 5.6 Hrs safety timer in constant current mode. See "StopModeEN PIN"

Section for more detail.

WARNING! Disabling the timer is not a recommended operating condition

since it disables the safety timer function. User must provide protection

against continuously charging a defective battery.

ceramic capacitor to GND.

Ordering Information

LP3945 supplied as 1000 units Tape and Reel LP3945 supplied as 4500 units Tape and Reel Package Marking

LP3945ILD LP3945ILDX L00011B

LP3946 supplied as 1000 units Tape and Reel LP3946 supplied as 4500 units Tape and Reel Package Marking

LP3946ILD LP3946ILDX L00030B

The LP3946 has default values of I

Semiconductor Sales Office.

www.national.com 2

=500mA, V

CHG

=4.1V and EOC=0.1C. For other default options, please contact National

BATT

Page 3

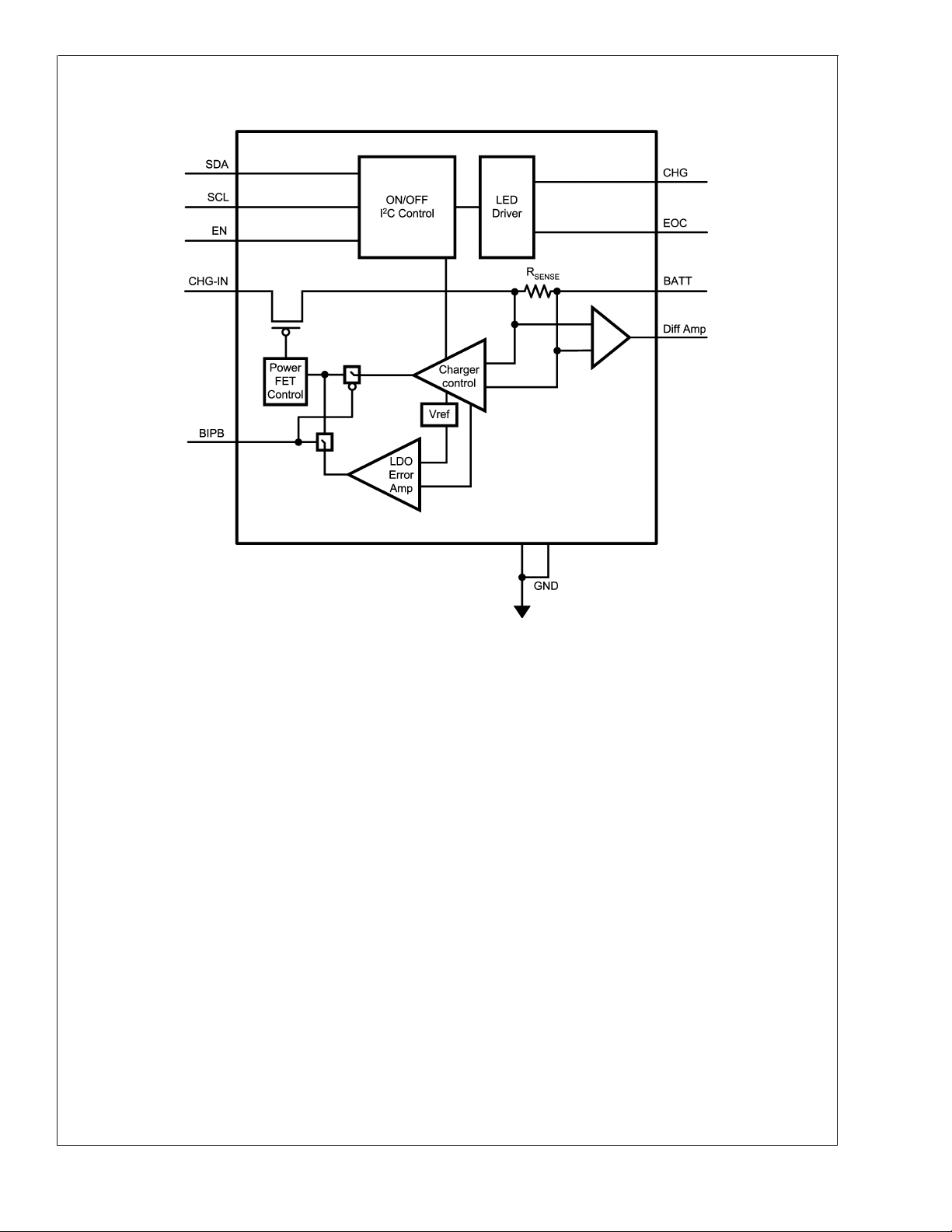

Block Diagram

LP3945/LP3946

LP3945 Functional Block Diagram

20066530

www.national.com3

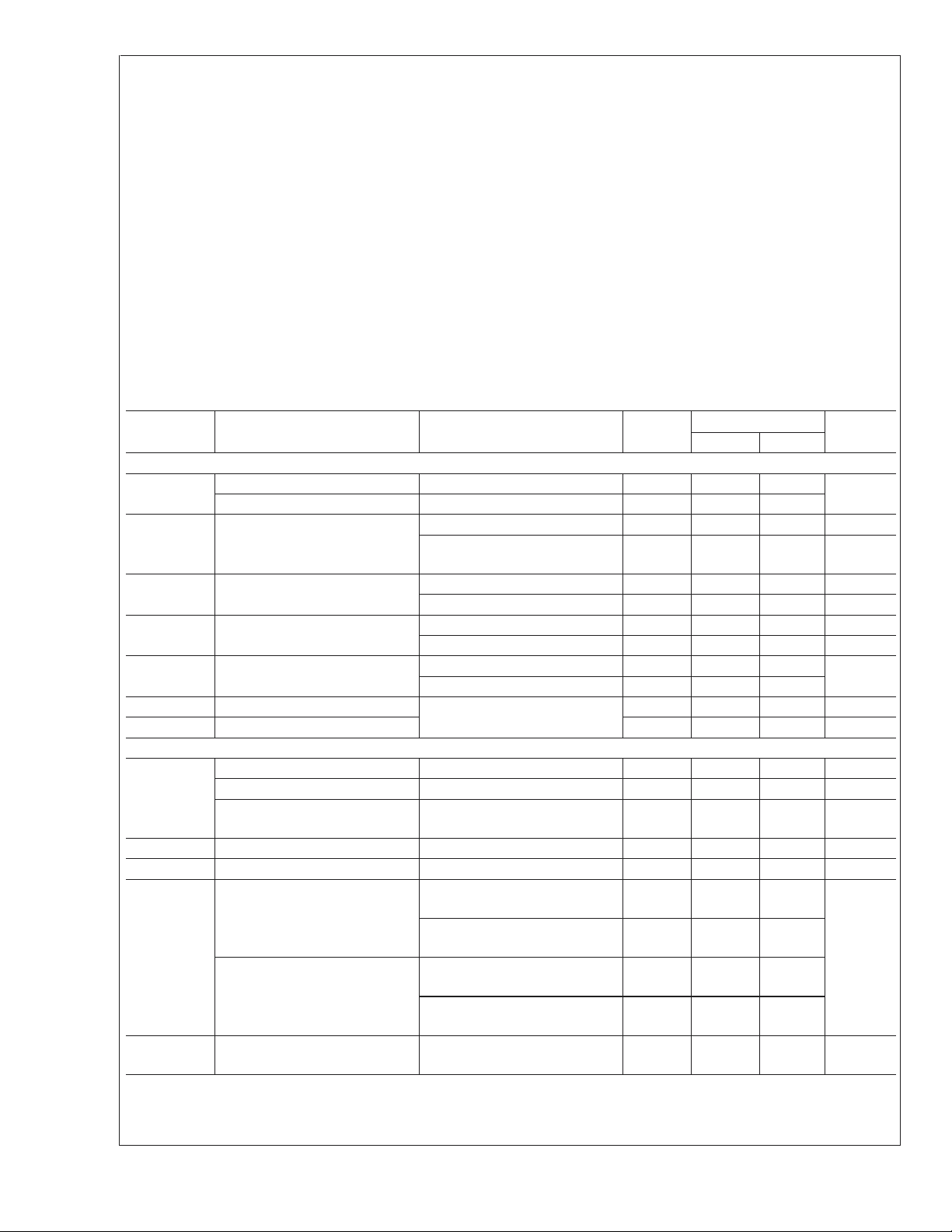

Page 4

Absolute Maximum Ratings (Notes 1,

2)

If Military/Aerospace specified devices are required,

ESD (Note 4)

Human Body Model

Machine Model

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

LP3945/LP3946

CHG-IN −0.3V to +6.5V

BATT, VB

CHG, EN, BIPB, StopModeEN −0.3V to +6V

Junction Temperature 150˚C

Storage Temperature −65˚C to +150˚C

Power Dissipation (Note 3) 1.76W

, SDA, SCL, EOC,

SENSE

Operating Ratings (Notes 1, 2)

CHG-IN 3.0V to 6.0V

EN, BIPB, StopModeEN 0V to (V

Junction Temperature, T

Operating Temperature, T

Thermal Resistance, θ

Maximum Power Dissipation

(TA= 85˚C, (Note 5) ) 1.08W

Electrical Characteristics

Unless otherwise noted, V

mal type apply for T

= −40˚C to +85˚C. (Notes 6, 7, 8)

T

J

= 25˚C. Limits appearing in boldface type apply over the entire junction temperature range for operation,

J

Symbol Parameter Conditions Typical

V

SUPPLY

CC

V

CHG-IN

I

BATT

V

OK−TSHD

V

UVLO−TSHD

V

OVLO−TSHD

Input Voltage Range 4.5 6

Operating Range Battery Connected 4.5 6

Battery Leakage Current

Adapter OK Trip Point (CHG-IN)

Under Voltage Lock-out Trip

Point

Over Voltage Lock-out Trip Point

Thermal Shutdown Temperature

Thermal Shutdown Hysteresis 20 ˚C

BATTERY CHARGER — Li ION MODE (MODE = LOW)

Fast Charge Current Range 500 950 mA

I

CHG

Fast Charge Current Accuracy −10 +10 %

Programmable Charging Current

Step

I

PRE-CHG

I

EOC

Pre-Charge Current V

End Of Charge Current Accuracy For I

Battery Regulation Voltage

(For 4.1V Cell) (Default State)

V

BATT

Battery Regulation Voltage

(For 4.2V Cell)

V

CHG-Q

Full Charge Qualification

Threshold

CHG-IN

= 5V, V

BATT

= 4V, C

V

CHG-IN

= 1µF, C

CHG-IN

≤ 4V 2 20 µA

EOC = Low, adaptor connected,

V

= 4.1V

BATT

V

CHG-IN-VBATT

V

CHG-IN-VBATT

V

V

V

V

(Rising) 4.15 3.8 4.5 V

CHG-IN

(Falling) 3.95 3.6 4.3 V

CHG-IN

(Rising) 5.9

CHG-IN

(Falling) 5.7

CHG-IN

(Note 7)

=2V 50 65 mA

BATT

= 0.1C, 0.15C or 0.2C +20 −20 %

EOC

T

= 0˚C to +85˚C

J

I

CHARGE

T

I

CHARGE

T

I

CHARGE

T

I

CHARGE

V

= 10 mA, Mode = Low

= −40˚C to +85˚C

J

= 10 mA, Mode = Low

= 0˚C to +85˚C

J

= 10 mA, Mode = Low

= −40˚C to +85˚C

J

= 10 mA, Mode = Low

Rising, Transition from

BATT

Pre-Charge to Full Current

= 10µF. Typical values and limits appearing in nor-

BATT

(Rising) 60 mV

(Falling) 50 mV

200V

+0.3V)

CHG-IN

J

A

JA

Min Max

−40˚C to +125˚C

−40˚C to +85˚C

Limit

37˚C/W

Units

50 150 µA

160 ˚C

50 mA

4.1 4.059 4.141

4.1 4.038 4.162

4.2 4.158 4.242

4.2 4.137 4.263

3.0 V

2kV

V

V

V

www.national.com 4

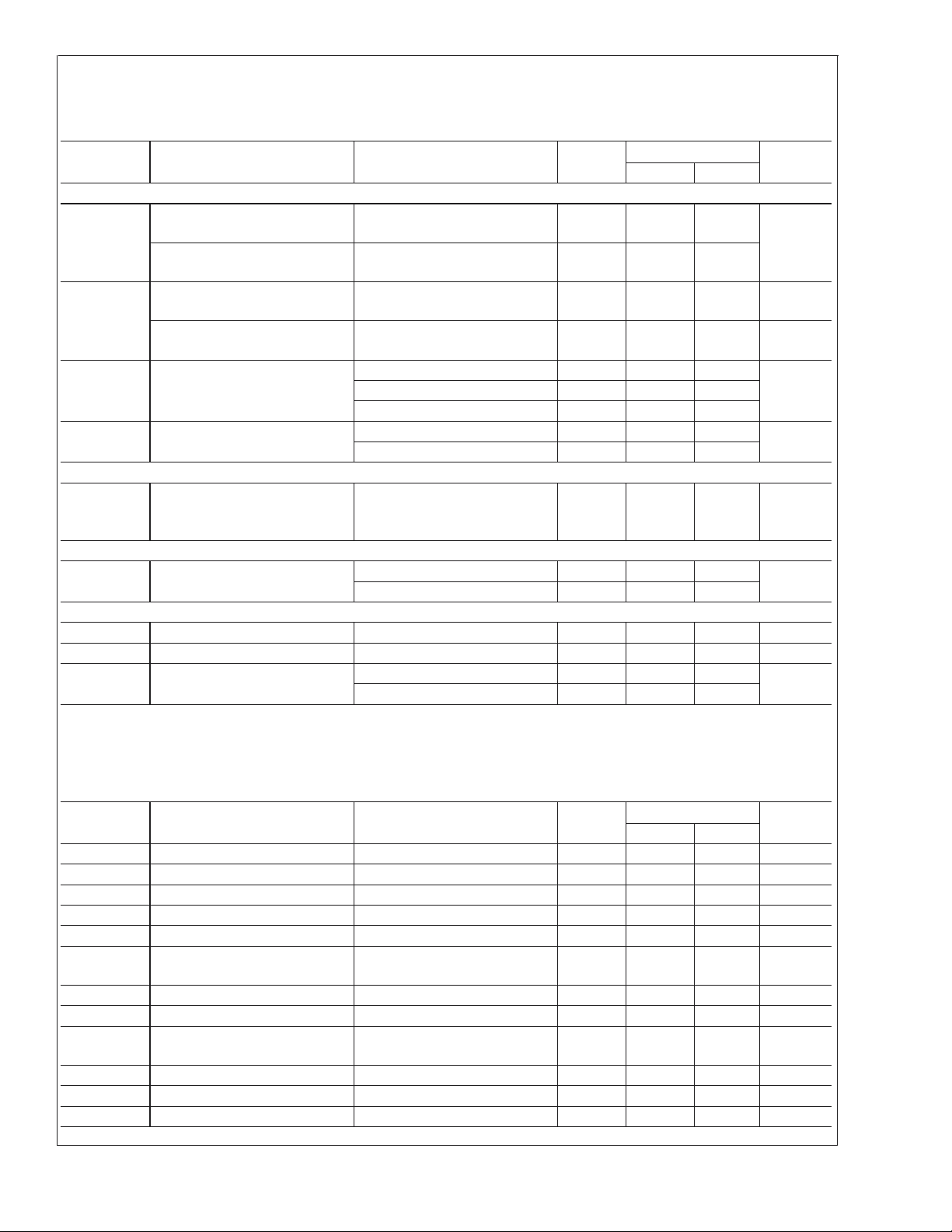

Page 5

Electrical Characteristics (Continued)

Unless otherwise noted, V

mal type apply for T

= −40˚C to +85˚C. (Notes 6, 7, 8)

T

J

= 25˚C. Limits appearing in boldface type apply over the entire junction temperature range for operation,

J

Symbol Parameter Conditions Typical

BATTERY CHARGER — Li ION MODE (MODE = LOW)

Restart Threshold Voltage

V

BAT-RST

(For 4.1V Cell)

Restart Threshold Voltage

(For 4.2V Cell)

Internal Current Sense

R

SENSE

Resistance

Internal Current Sense Resistor

Load Current

ICHG

t

EOC

MON

Diff-Amp Output

Time to EOC State

BATTERY CHARGER — NI-MH MODE (MODE = HIGH, LP3945 ONLY)

V

BATT-MAX

Battery Over Voltage Protection

LDO MODE (BIPB=HIGH)

V

OUT

Output Voltage Regulation

LOGIC LEVELS

V

IL

V

IH

I

IL

Low Level Input Voltage EN 0.4 V

High Level Input Voltage EN 2.0 V

Enable Pin Input Current

CHG-IN

= 5V, V

= 4V, C

BATT

V

BATT

EOC, to Pre-Qualification State

V

BATT

EOC, to Pre-Qualification State

= 1µF, C

CHG-IN

BATT

Falling, Transition from

Falling, Transition from

= 10µF. Typical values and limits appearing in nor-

3.9 3.77 4.02

4.00 3.86 4.12

(Note 7) 120 mΩ

(Note 7) 1.2 A

= 50 mA 0.583

I

CHG

= 500 mA 1.333

CHG

I

= 950 mA 2.090

CHG

0˚C to +85˚C (Note 7) 5.625 4.78 6.42

−40˚C to +85˚C (Note 7) 5.625 4.5 6.75

(Charging Current Decreases to

0 mA when V

Voltage), V

=50mA 4.10

I

LOAD

I

=950mA 4.06

LOAD

BATT

CHG-IN

is above this

= 5.6V

5.4 5.292 5.508 V

EN = LOW −10 +10

EN = HIGH −5 +5

Limit

Min Max

LP3945/LP3946

Units

V

VI

Hrs

V

µA

Electrical Characteristics, I2C Interface (LP3945 Only)

Unless otherwise noted, V

Limits appearing in boldface type apply over the entire junction temperature range for operation, T

6, 7, 8)

Symbol Parameter Conditions Typical

V

V

V

V

F

t

HOLD

IL

IH

OL

HYS

CLK

Low Level Input Voltage SDA & SCL 0.4 0.3 V

High Level Input Voltage SDA & SCL 0.7 V

Low Level Output Voltage SDA & SCL 0 0.2 V

Schmitt Trigger Input Hysteresis SDA & SCL 0.1 V

Clock Frequency 400 kHz

Hold Time Repeated START

Condition

t

CLK-LP

t

CLK-HP

t

SU

CLK Low Period (Note 7) 1.3 µs

CLK High Period (Note 7) 0.6 µs

Set-up Time Repeated START

Condition

t

DATA-HOLD

t

DATA-SU

t

SU

Data Hold Time (Note 7) 300 ns

Data Set-up Time (Note 7) 100 ns

Set-up Time for STOP Condition (Note 7) 0.6 µs

CHG-IN

= 5V, V

= 4V. Typical values and limits appearing in normal type apply for TJ= 25˚C.

BATT

(Note 7)

(Note 7)

= −40˚C to +85˚C. (Notes

J

Limit

Min Max

DDVDD

DD

+0.5 V

Units

DD

DD

0.6 µs

0.6 µs

www.national.com5

V

V

V

Page 6

Electrical Characteristics, I2C Interface (LP3945 Only) (Continued)

Unless otherwise noted, V

Limits appearing in boldface type apply over the entire junction temperature range for operation, T

6, 7, 8)

Symbol Parameter Conditions Typical

LP3945/LP3946

t

TRANS

Maximum Pulse Width of Spikes

that must be Suppressed by the

Input Filter of both DATA & CLK

signals.

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical

Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: The Absolute Maximum power dissipation depends on the ambient temperature and can be calculated using the formula

P=(T

where T

J

Absolute Maximum Ratings results from substituting the Absolute Maximum junction temperature, 150˚C, for T

be dissipated safely at ambient temperature below 85˚C. Less power can be dissipated safely at ambient temperatures above 85˚C. The Absolute Maximum power

dissipation can be increased by 27 mW for each degree below 85˚C, and it must be de-rated by 27 mW for each degree above 85˚C.

Note 4: The human-body model is 100 pF discharged through 1.5 kΩ. The machine model is 0Ω in series with 220pF

Note 5: Like the Absolute Maximum power dissipation, the maximum power dissipation for operation depends on the ambient temperature. The 1.08W rating

appearing under Operating Ratings results from substituting the maximum junction temperature for operation, 125˚C, for T

(1) above. More power can be dissipated at ambient temperatures below 85˚C. Less power can be dissipated at ambient temperatures above 85˚C. The maximum

power dissipation for operation can be increased by 27 mW for each degree below 85˚C, and it must be de-rated by 27 mW for each degree above 85˚C.

Note 6: All limits are guaranteed. All electrical characteristics having room-temperature limits are tested during production with T

guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 7: Guaranteed by design.

Note 8: LP3945 and LP3946 are not intended as a Li-Ion battery protection device, battery used in this application should have an adequate internal protection.

)/θJA, (1)

J—TA

is the junction temperature, TAis the ambient temperature, and θJAis the junction-to-ambient thermal resistance. The 1.76W rating appearing under

CHG-IN

= 5V, V

= 4V. Typical values and limits appearing in normal type apply for TJ= 25˚C.

BATT

= −40˚C to +85˚C. (Notes

J

Limit

Min Max

(Note 7)

50 ns

, 85˚C for TA, and 37˚C/W for θJA. More power can

J

, 85˚C for TA, and 37˚C/W for θJAinto

J

= 25˚C. All hot and cold limits are

J

Units

The end of charge current threshold default setting is at 0.1C, this threshold can be set to 0.15 or 0.2 by the controller (see bit chart for detail).

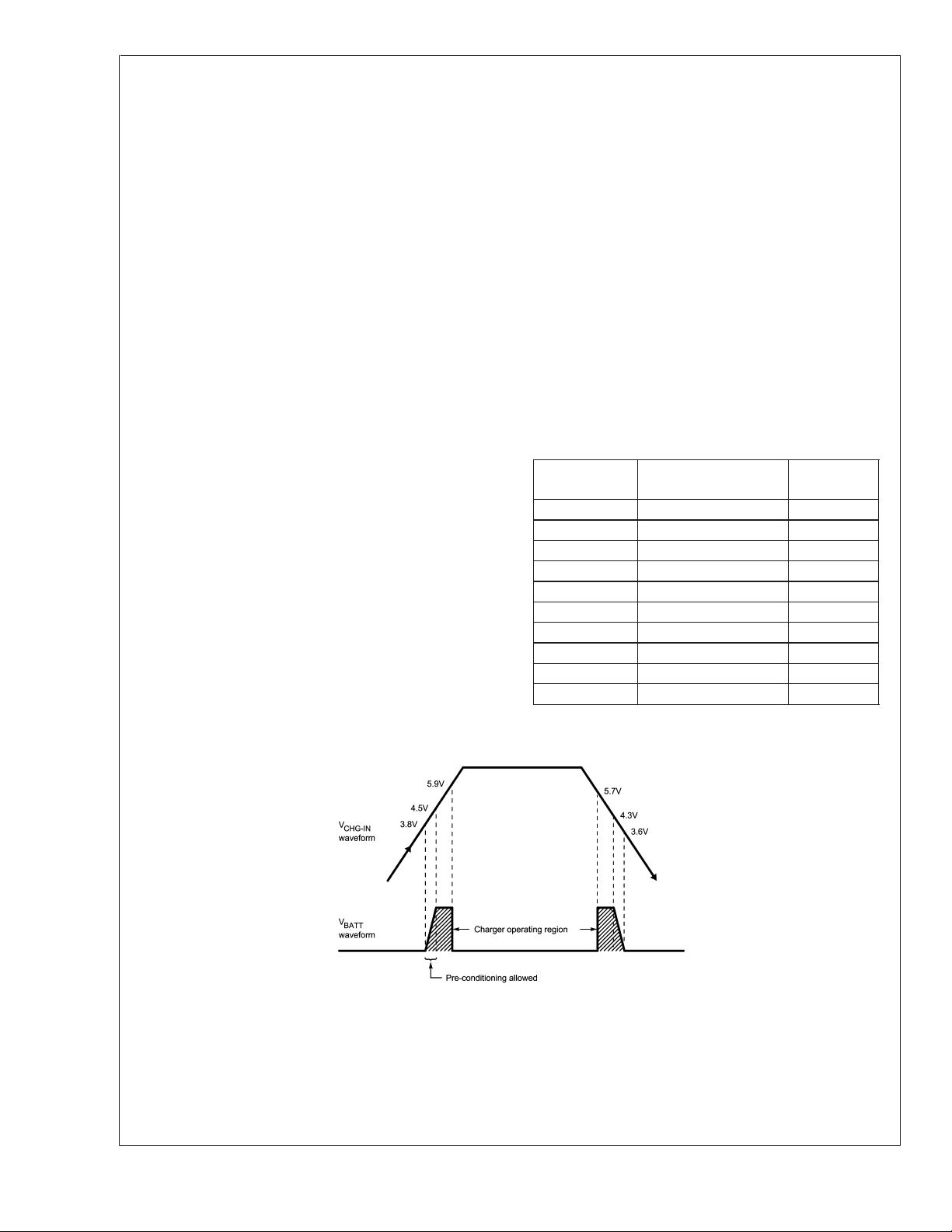

Li-Ion Charging Profile

www.national.com 6

20066504

Page 7

LP3945/LP3946

Typical Performance Characteristics Unless otherwise specified, T

4.1V Termination Voltage vs Temperature 500mA vs Temperature

20066531 20066532

950mA vs Temperature I

CHG

= 25˚C, V

A

vs Diff Amp

CHG-IN

= 5V.

20066533

20066534

www.national.com7

Page 8

Application Notes

LP3945 CHARGER OPERATION

The LP3945 is a complete battery charger with I

Charge cycle is initiated with wall adaptor insertion. If the

LP3945/LP3946

wall adaptor voltage appearing on the CHG-IN pin meets

under-voltage (V

UVLO-TSHD

the Adaptor OK signal is detected, then pre-conditioning

process begins (see Figure 1). In pre-qualification cycle, a

safe current level, less than 65 mA, is pumped into the

battery while the voltage across the battery terminals is

measured. Once this voltage exceeds 3.0V, the controller

will initiate constant current fast charge cycle. During this

cycle, the 5.6 hr safety timer is started and charge current is

increased to I

. The default value for I

CHG

manufacturing to 500 mA but it is user programmable from

500 mA to 950 mA in 50 mA step. The programmed current

is determined by battery type and manufacturers’ recommendation.

If safety timer times out during constant current cycle, charging will be terminated if StopModeEN pin is pulled high. If it

is pulled low, device will proceed to operate in maintenance

mode and have to be interrupted externally. This is not a

recommended mode of operation. Disabling the 5.6hr timer

can potentially expose the battery to prolong charge cycle

and damage the battery. If StopModeEN feature is used,

user must protect the battery from exposure to prolong

charge cycle.

As the battery is charged during constant current mode, the

voltage across pack terminal increases until it reaches 4.1V

(or 4.2V). As soon as pack terminal exceeds 4.1V (or 4.2V),

controller starts operating in constant voltage mode by applying regulated V

BATT

During this cycle, charge current, I

crease with time and when it drops below 0.1C (by default),

the EOC signal is activated indicating successful completion

of the charge cycle. The "C" term in 0.1C is the programmed

. For example, 0.1C of 700mA is 70mA, and 0.2C of

I

CHG

700mA is 140mA. EOC current can be programmed to 0.1C,

0.15C, or 0.2C. The default value is 0.1C. After completing

the full charge cycle, controller will start maintenance cycle

), over-voltage (V

OVLO-TSHD

CHG

voltage across the battery terminal.

, continues to de-

CHG

2

C interface.

), and

is set during

where battery pack voltage is monitored continuously. If

during the maintenance cycle, pack voltage drops below

3.9V, charge cycle will be initiated providing that the wall

adaptor is plugged in and is alive.

Ni-MH charge mode (LP3945 only), which is a constant

voltage mode charging, can be selected by setting the

“mode” bit to HIGH via the I

The LP3945 with I

2

C programming allows maximum flexibil-

2

C interface.

ity in selecting charge current, battery regulation voltage

(4.1V or 4.2V), EOC current and battery type (Li Ion or

Ni-MH). The LP3945 operates in default mode during power

up. See the “I

2

C Interface” section for more detail.

LP3946 CHARGER OPERATION

The LP3946 is a simpler version of the LP3945. It does not

have any I

2

C interface, thus the device operates on default

setting. The values in BOLD in Table 1 are the default

settings. Default settings can be set at the factory to customer’s specifications. For other options, please contact a National Semiconductor sales office.

The LP3946 charges only Li Ion type battery.

TABLE 1. LP3946 Performance Options

Battery Voltage

Regulation (V)

End of Charge Current

Threshold (mA)

Charge

Current (mA)

4.1 0.1C 500

4.2 0.15C 550

0.20C 600

650

700

750

800

850

900

950

FIGURE 1. Charger Power Up and Power Down Waveform

www.national.com 8

20066510

Page 9

Application Notes (Continued)

LP3945/LP3946

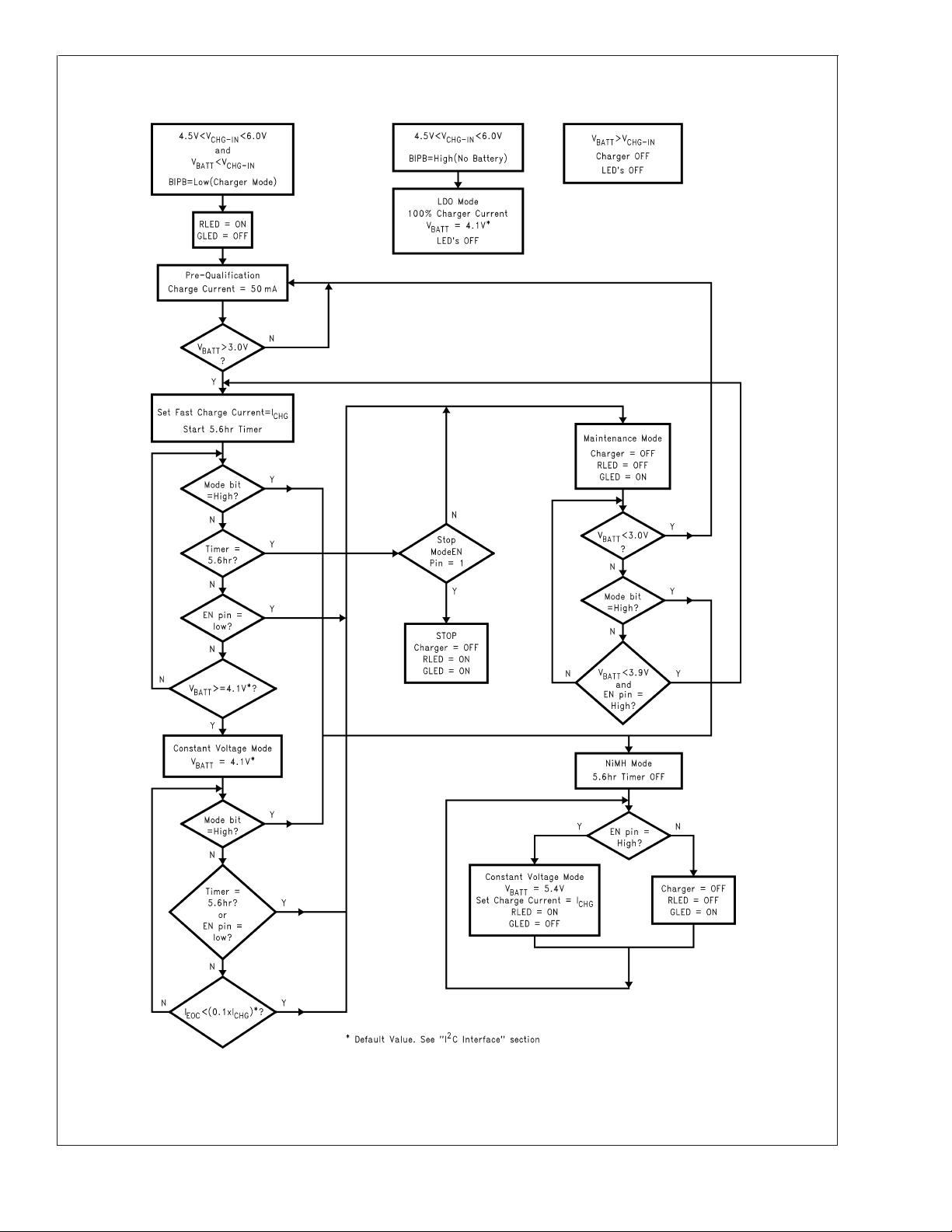

FIGURE 2. LP3945 Charger Flow Chart

20066511

www.national.com9

Page 10

Application Notes (Continued)

LP3945/LP3946

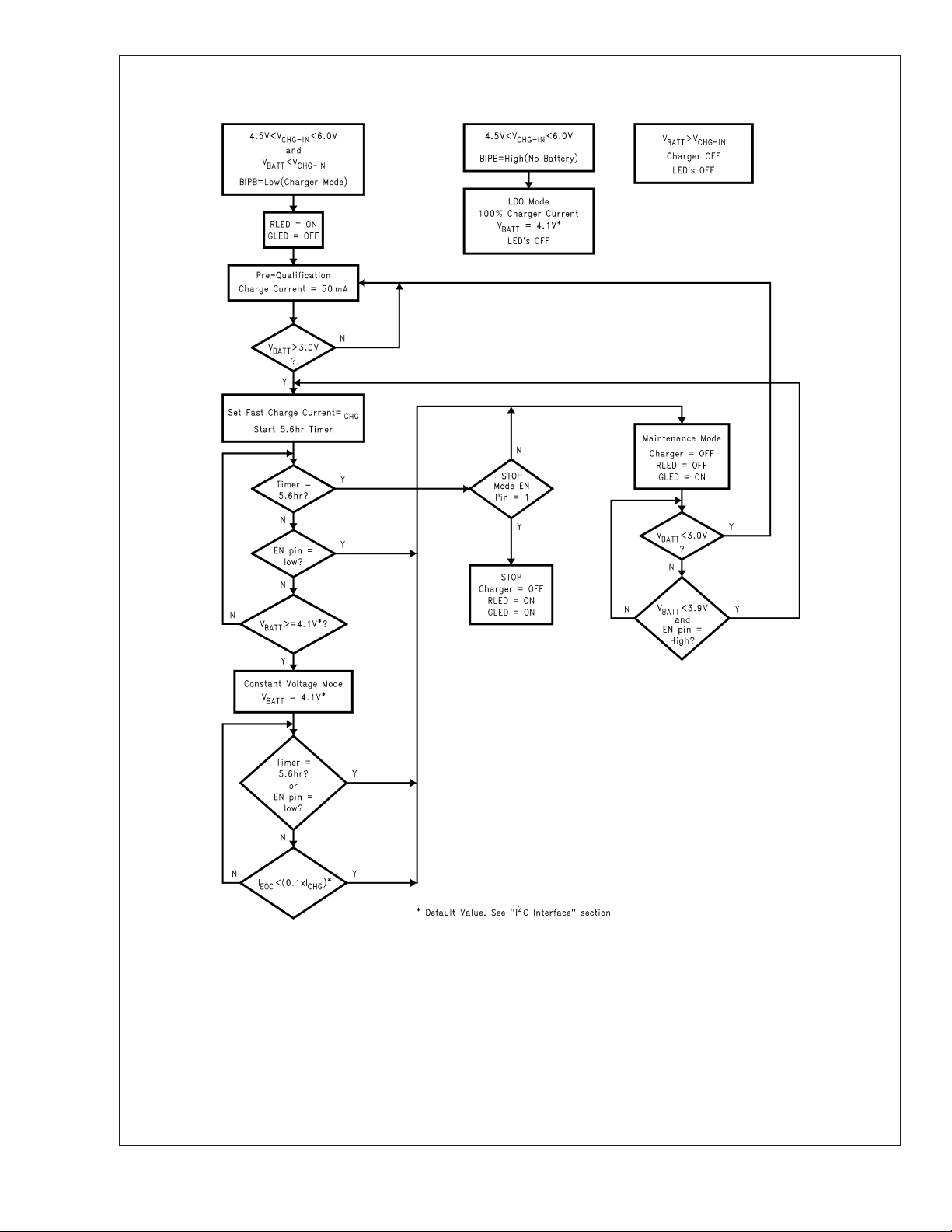

FIGURE 3. LP3946 Charger Flow Chart

www.national.com 10

20066512

Page 11

Application Notes (Continued)

CHARGE CURRENT SELECTION

The LP3945 and LP3946 are designed to provide a charge

current ranging from 500 mA to 950 mA, in 50 mA resolution,

to support batteries with different capacity ratings. No external resistor is required to set the charge current in the

LP3945 and LP3946. This entirely eliminates design time,

external component board space and stability issue.

The LP3945 uses the I

current while the LP3946 has a pre-programmed charge

current.

BATTERY VOLTAGE SELECTION

The battery voltage regulation is set to 4.1V during the

manufacturing. The 4.2V option can be selected on LP3945

via the I

2

C interface or set at the factory for LP3946.

The Ni-MH charge mode is only available in LP3945.

END OF CHARGE (EOC) CURRENT SELECTION

The EOC thresholds can be programmed to 0.1C, 0.15C and

0.2C in the LP3945. The default value is 0.1C, which provides the highest energy storage, but at the expense of

longer charging time. On the other hand, 0.2C takes the

least amount of charging time, but yields the least energy

2

C interface to program the charge

storage. The LP3946 has 0.1C as pre-programmed EOC

threshold. 0.15C and 0.2C options are available upon request.

No EOC function is available during Ni-MH charge cycle.

User must provide a reliable method for charge termination.

CHARGE CURRENT SENSE DIFFERENTIAL AMPLIFIER

The charge current is monitored across the internal 120 mΩ

current sense resistor. The differential amplifier provides the

analog representation of the charge current. Charge current

can be calculated using the following equation:

Where voltage at Diff Amp output (V

charge current (I

) is in amps.

CHG

) is in volt, and

DIFF

Monitoring the Diff Amp output during constant voltage cycle

can provide an accurate indication of the battery charge

status and the time remaining to EOC. This feature is particularly useful during Ni-MH charge cycle. The current

sense circuit is operational in the LDO mode as well. It can

be used to monitor the system current consumption during

testing.

LP3945/LP3946

FIGURE 4. Charge Current Monitoring Circuit (Diff-Amp)

LED CHARGE STATUS INDICATORS

The LP3945 and LP3946 are equipped with two open drain

outputs to drive a green LED and a red LED. These two

LEDs work together in combinations to indicate charge status or fault conditions. Table 2 shows all the conditions.

20066514

TABLE 2. LED Indicator Summary

Charger Status RED

LED

GREEN

LED

Charger Off OFF OFF

Charging Li Ion Battery* ON OFF

Maintenance Mode OFF ON

Charging Li Ion Battery after

OFF ON

Passing Maintenance Mode

Charging Ni-MH in Constant

ON OFF

Voltage Mode

EN Pin = LOW OFF ON

LDO Mode OFF OFF

5.6 Hr Safety Timer Flag ON ON

*Charging Li Ion battery for the first time after V

CHG-IN

insertion.

www.national.com11

Page 12

Application Notes (Continued)

BIPB PIN

BIPB pin is used to select between charger mode and LDO

mode. It is pulled HIGH internally to the CHG-IN pin, which is

the LDO mode. To select charger mode, this pin must be

LP3945/LP3946

connected to ground directly or pulled to ground via the

battery pack ID resistor. In the latter case, BIPB pin pulled

LOW confirms battery connection. Alternatively, this pin can

be pulled to LOW by the system micro-controller for added

flexibility.

LDO MODE

The charger is in the LDO mode when the BIPB pin is left

open or HIGH. This mode of operation is used primarily

during system level testing of the handset to eliminate the

need for battery insertion. CAUTION: battery may be damaged if device is operating in LDO mode with battery connected.

The internal power FET provides up to 1.2 amp of current at

BATT pin in this mode. The LDO output is set to 4.1V. When

operating at higher output currents, care must be taken not

to exceed the package power dissipation rating. See “Thermal Performance of LLP Package” section for more detail.

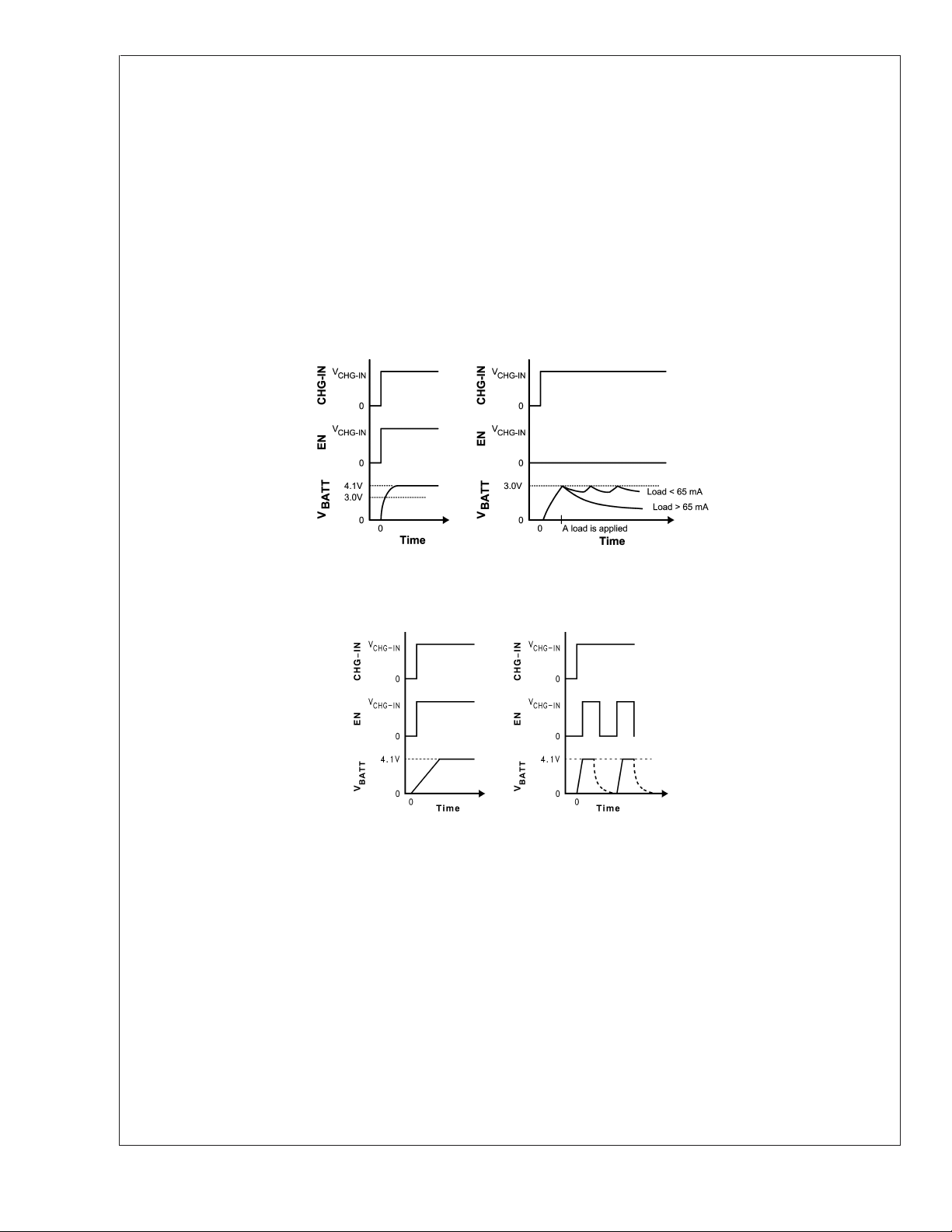

EN PIN

The Enable pin is used to enable/disable the charger, in both

charger mode and LDO mode, see Figure 5 and Figure 6.

The Enable pin is internally pulled HIGH to the CHG-IN pin.

When the charger is disabled, it draws less than 4 µA of

current.

FIGURE 5. Power Up Timing Diagram in Charger Mode (BIPB = LOW)

FIGURE 6. Power Up Timing Diagram in LDO Mode (BIPB = HIGH)

5.6 HR SAFETY TIMER IN CHARGER MODE

Both LP3945 and LP3946 have built-in 5.6 hr back up safety

timer to prevent over-charging a Li Ion battery. The 5.6 hr

timer starts counting when the charger enters constant current mode. It will turn the charger off when the 5.6 hr timer is

up while the charger is still in constant current mode. In this

case, both LEDs will turn on, indicating a fault condition.

In order for the 5.6 hr safety timer to function in the LP3945,

pin 13 should be left floating. CAUTION: disabling the back

up safety timer could create unsafe charging conditions. If

disabled, user must provide external protection to prevent

overcharging the battery.

20066515

20066516

StopModeEN PIN

To provide the flexibility of using an external back up timer,

StopModeEN allows “bypassing” of the 5.6 hr safety timer. It

is achieved by pulling pin 13 on the LP3945 to LOW. As

indicated in the LP3945 Flow Chart, this feature works only

in constant current mode with a Li Ion battery. Therefore, if a

Li Ion battery is in constant current mode and the 5.6 hr timer

times out, instead of the charger being turned off, it proceeds

to maintenance mode.

This is not a recommended mode of operation. Disabling the

5.6 hr timer can potentially expose the battery to prolong

charge cycle and damage the battery. If StopModeEn feature

is used, user must protect the battery from exposure to

prolong charge cycle. For normal operation, pin 13 should be

left floating.

www.national.com 12

Page 13

2

C INTERFACE (LP3945 ONLY)

Application Notes (Continued)

NI-MH MODE (LP3945 ONLY)

Programming the “mode” bit to HIGH sets the LP3945 to

Ni-MH mode and charges the battery in constant voltage

mode until the battery voltage reaches 5.4V. Since each cell

of the Ni-MH is 1.25V when fully charged, the LP3945 can

only charge exactly four cells. Charging is terminated by the

system micro-controller timer by monitoring the charge cur-

I

2

C interface is used in the LP3945 to program various

I

parameters as shown in Table 3. The LP3945 operates on

default settings during power up. Once programmed, the

LP3945 retains the register data as long as the battery

voltage is above 2.85V. Table 4 shows the charge current

and EOC current programming code.

2

Figures 7, 8 display I

C read/write format.

rent. The system micro-controller reads the charge current

value from the Diff Amp output. Charge current in Ni MH can

be programed as in Li Ion mode, from 950 mA to 500 mA in

50 mA step. The 5.6 hr timer is disabled in Ni-MH mode.

TABLE 3. LP3945 Serial Port Communication Address Code 7h'45

LP3945 Control and Data Codes

Addrs Register 7 6 5 4 3 2 1 0

8'h00 Charger

Register −1

8'h01 Charger

Register −2

Numbers in parentheses indicate default setting. “0” bit is set to low state, and “1” bit is set to high state. R/O — Read Only. All other bits are Read and Write.

Mode

(0) = Li-Ion

1 = Ni-MH

Batt Voltage

(0) = 4.1V

1 = 4.2V

EOC

(Green LED)

R/O

Charger

Current

Code 3

(0)

Charging

(Red LED)

R/O

Charger

Current

Code 2

(0)

EOC Sel −1

(0)

Charger

Current

Code 1

(0)

EOC Sel −0

(1)

Charger

Current

Code 0

(0)

LP3945/LP3946

TABLE 4. Charger Current and EOC Current Programming Code

Data Code

Charger Current Selection

SET

(mA)

Code I

Data Code

End of Charge Current

Selection Code

4h'00 500

4h'01 550 2h’1 0.1C

4h'02 600 2h’2 0.15C

4h'03 650 2h’3 0.2C

4h'04 700

4h'05 750

4h'06 800

4h'07 850

4h'08 900

4h'09 950

w = write (sda = “0”)

r = read (sda = “1”)

ack = acknowledge (sda pulled down by either master or slave)

rs = repeated start

FIGURE 7. LP3945 (Slave) Register Write

20066517

www.national.com13

Page 14

Application Notes (Continued)

LP3945/LP3946

w = write (sda = “0”)

r = read (sda = “1”)

ack = acknowledge (sda pulled down by either master or slave)

rs = repeated start

FIGURE 8. LP3945 (Slave) Register Read

THERMAL PERFORMANCE OF LLP PACKAGE

The LP3945 and LP3946 are monolithic devices with integrated pass transistors. To enhance the power dissipation

performance, the Leadless Lead frame Package, or LLP, is

used. The LLP package is designed for improved thermal

performance because of the exposed die attach pad at the

bottom center of the package. It brings advantage to thermal

performance by creating a very direct path for thermal dissipation. Compared to the traditional leaded packages where

the die attach pad is embedded inside the mold compound,

the LLP reduces a layer of thermal path.

The thermal advantage of the LLP package is fully realized

only when the exposed die attach pad is soldered down to a

thermal land on the PCB board and thermal vias are planted

underneath the thermal land. Based on a LLP thermal measurement, junction to ambient thermal resistance (θ

JA

) can

be improved by as much as two times if a LLP is soldered on

the board with thermal land and thermal vias than if not.

An example of how to calculate for LLP thermal performance

is shown below:

20066518

power dissipation for operation can be increased by 27 mW

for each degree below 70˚C, and it must be de-rated by 27

mW for each degree above 70˚C.

LAYOUT CONSIDERATION

The LP3945 and LP3946 have exposed die attach pad

located at the bottom center of the LLP package. It is imperative to create a thermal land on the PCB board when

designing a PCB layout for the LLP package. The thermal

land helps to conduct heat away from the die, and the land

should be the same dimension as the exposed pad on the

bottom of the LLP (1:1 ratio). In addition, thermal vias should

be added inside the thermal land to conduct more heat away

from the surface of the PCB to the ground plane. Typical

pitch and outer diameter for these thermal vias are 1.27 mm

and 0.33 mm respectively. Typical copper via barrel plating is

1 oz. although thicker copper may be used to improve thermal performance. The LP3945 and LP3946 bottom pad is

connected to ground. Therefore, the thermal land and vias

on the PCB board need to be connected to ground.

For more information on board layout techniques, refer to

Application Note 1187 “Leadless Leadframe Package

(LLP)”. The application note also discuss package handling,

solder stencil, and assembly.

By substituting 37˚C/W for θJA, 125˚C for TJand 70˚C for TA,

the maximum power dissipation allowed from the chip is

1.48W at T

= 70˚C. If V

A

is being charged, then 740 mA of I

is at 5.0V and a 3.0V battery

CHG-IN

can safely charge the

CHG

battery. More power can be safely dissipated at ambient

temperatures below 70˚C. Less power can be safely dissipated at ambient temperatures above 70˚C. The maximum

www.national.com 14

LP3945 AND LP3946 EVALUATION BOARDS

The LP3945 and LP3946 evaluation boards and instruction

manuals are available for order on National’s website

(www.national.com). The LP3945 evaluation board has on-

2

C interface capability for more flexibility. Please visit

board I

National’s website for more detail.

Page 15

Physical Dimensions inches (millimeters) unless otherwise noted

LP3945/LP3946 Battery Charge Management System

NS Package Number LDA14A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...