LP3944

RGB/White/Blue 8-LED Fun Light Driver

LP3944 RGB/White/Blue 8-LED Fun Light Driver

November 2003

General Description

LP3944 is an integrated device capable of independently

driving 8 LEDs. This device also contains an internal precision oscillator that provides all the necessary timing required

for driving each LED. Two prescaler registers along with two

PWM registers provide a versatile duty cycle control. The

LP3944 contains the ability to dim LEDs in SMBUS/I

applications where it is required to cut down on bus traffic.

Traditionally, to dim LEDs using a serial shift register such as

74LS594/5 would require a large amount of traffic to be on

the serial bus. LP3944 instead requires only the setup of the

frequency and duty cycle for each output pin. From then on,

only a single command from the host is required to turn each

individual open drain output ON, OFF, or to cycle a programmed frequency and duty cycle. Maximum output sink

current is 25 mA per pin and 200 mA per package. Any ports

not used for controlling the LEDs can be used for general

purpose input/output expansion.

2

Typical Application Circuit

Features

n Internal power-on reset

n Active low reset

n Internal precision oscillator

n Variable dim rates (from 6.25 ms to 1.6s;

160 Hz– 0.625 Hz)

C

Key Specifications

n 8 LED driver (multiple programmable states — on, off,

input, and dimming at a specified rate)

n 8 Open drain outputs capable of driving up to 25 mA per

LED

Applications

n Customized flashing LED lights for cellular phones

n Portable Applications

n Digital Cameras

n Indicator Lamps

n General purpose I/O expander

n Toys

20085301

© 2003 National Semiconductor Corporation DS200853 www.national.com

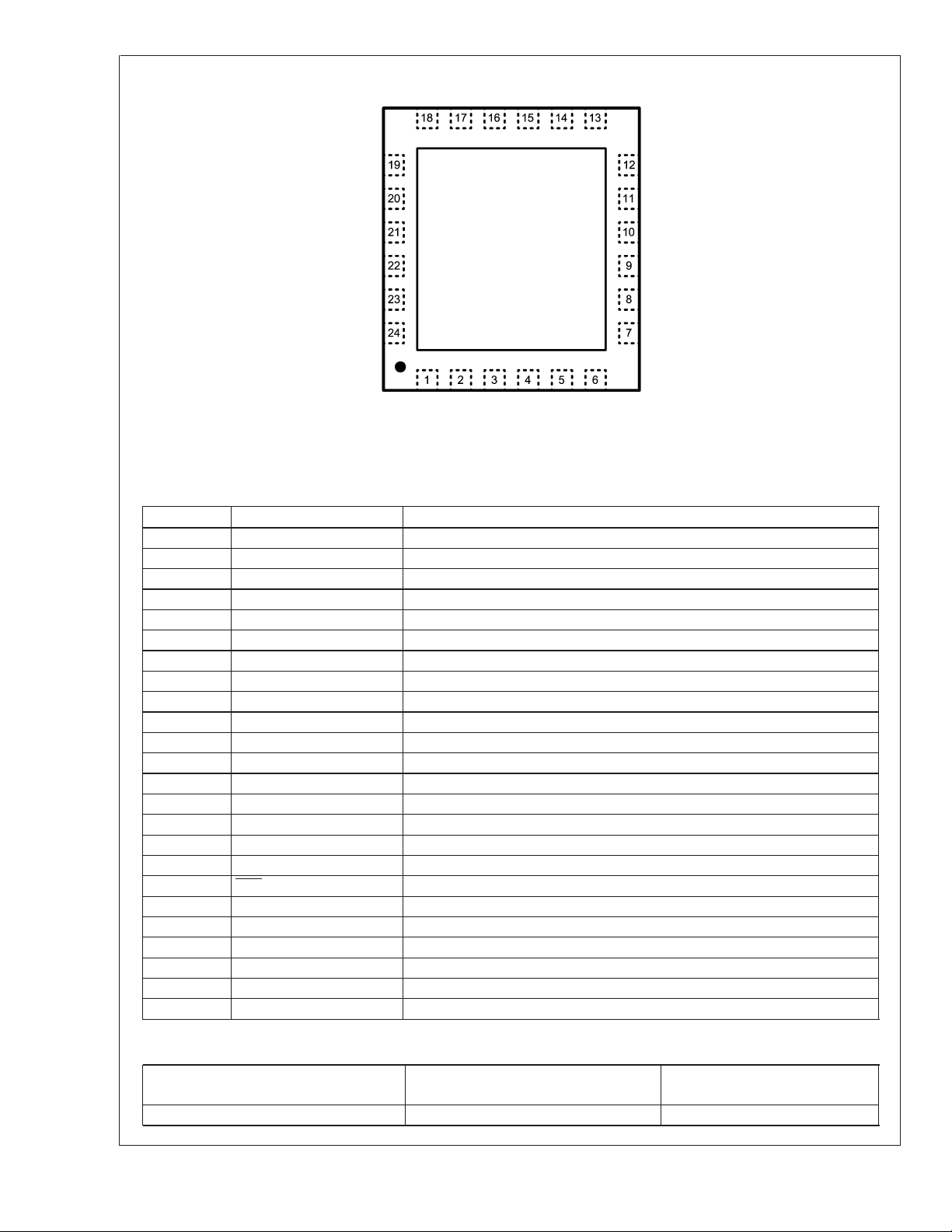

LP3944 Pin Out

LP3944

(Top View)

See NS Package Number SQA24A

LP3944 Pin Description

Pin # Name Description

1 LED0 Output of LED0 Driver

2 LED1 Output of LED1 Driver

3 LED2 Output of LED2 Driver

4 LED3 Output of LED3 Driver

5 LED4 Output of LED4 Driver

6 LED5 Output of LED5 Driver

7 LED6 Output of LED6 Driver

8 LED7 Output of LED7 Driver

9 GND Ground

10 NC No Connect

11 NC No Connect

12 NC No Connect

13 NC No Connect

14 NC No Connect

15 NC No Connect

16 NC No Connect

17 NC No Connect

18 RST

19 SCL Clock Line for I

20 SDA Serial Data Line for I

21 V

22 A0 Address Input 0

23 A1 Address Input 1

24 A2 Address Input 2

DD

Active Low Reset Input

Power Supply

2

C Interface

2

C Interface

20085302

Ordering Information

LP3944, Supplied as 1000 Units, Tape and

Reel

LP3944ISQ LP3944ISQX

www.national.com 2

LP3944, Supplied as 4500 Units, Tape

and Reel

Package Marking

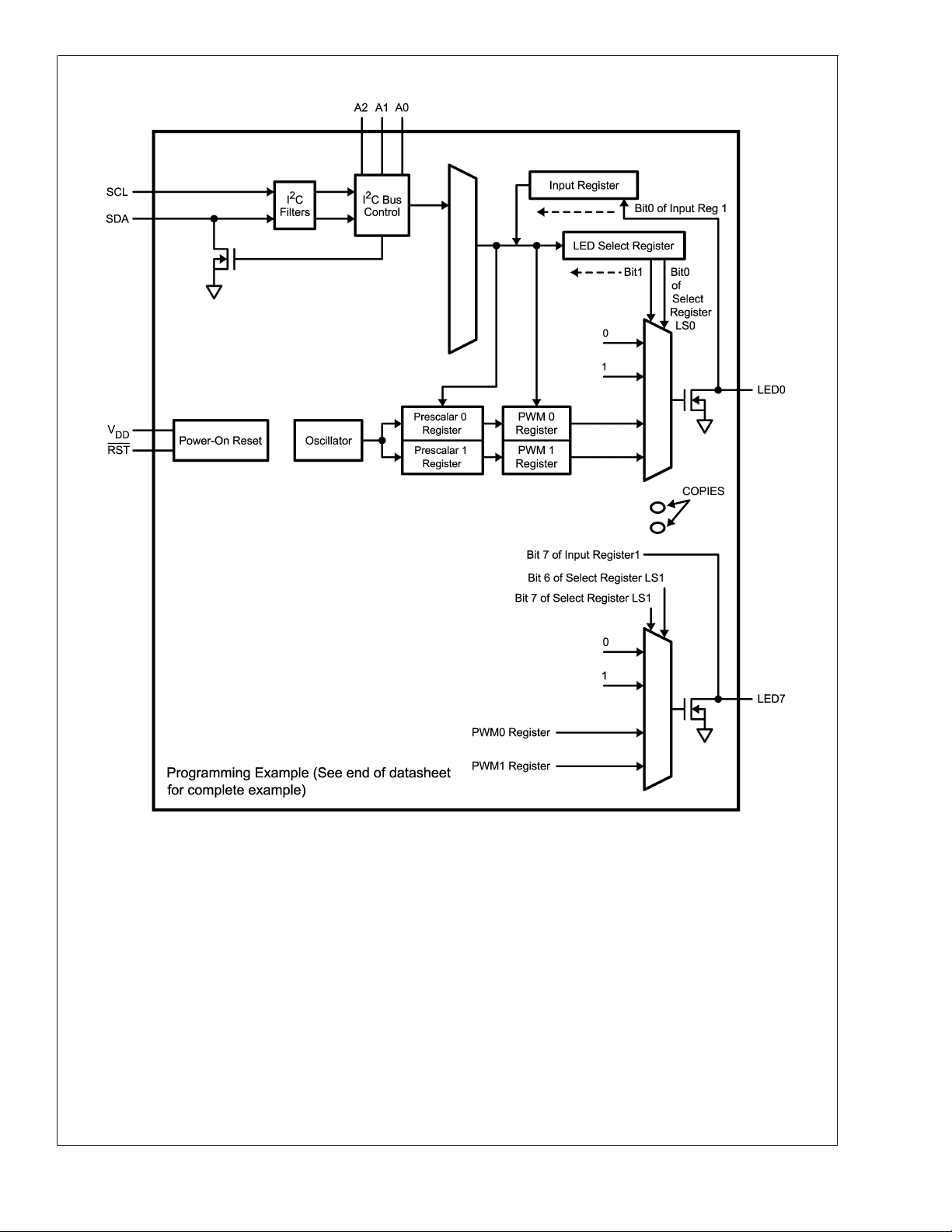

Architectural Block Diagram

LP3944

For Explanation of LP3944 Operation, Please Refer to “Theory of Operation” in Application Notes.

20085303

www.national.com3

Absolute Maximum Ratings (Notes 2,

1)

LP3944

If Military/Aerospace specified devices are required,

Human Body Model 2 kV

Machine Model 150V

Charge Device Model 1 kV

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

DD

−0.5V to 6V

A0, A1, A2, SCL, SDA, RST

(Collectively called digital pins)

Voltage on LED pins V

−0.5V to 6V

SS

Junction Temperature 150˚C

Storage Temperature −65˚C to 150˚C

Power Dissipation (Note 3) 1.76W

6V

Operating Ratings (Notes 1, 2)

V

DD

Junction Temperature −40˚C to +125˚C

Operating Ambient Temperature −40˚C to +85˚C

Thermal Resistance (θ

LLP24 (Note 3) 37˚C/W

Power Dissipation 1.08W

)

JA

ESD (Note 4)

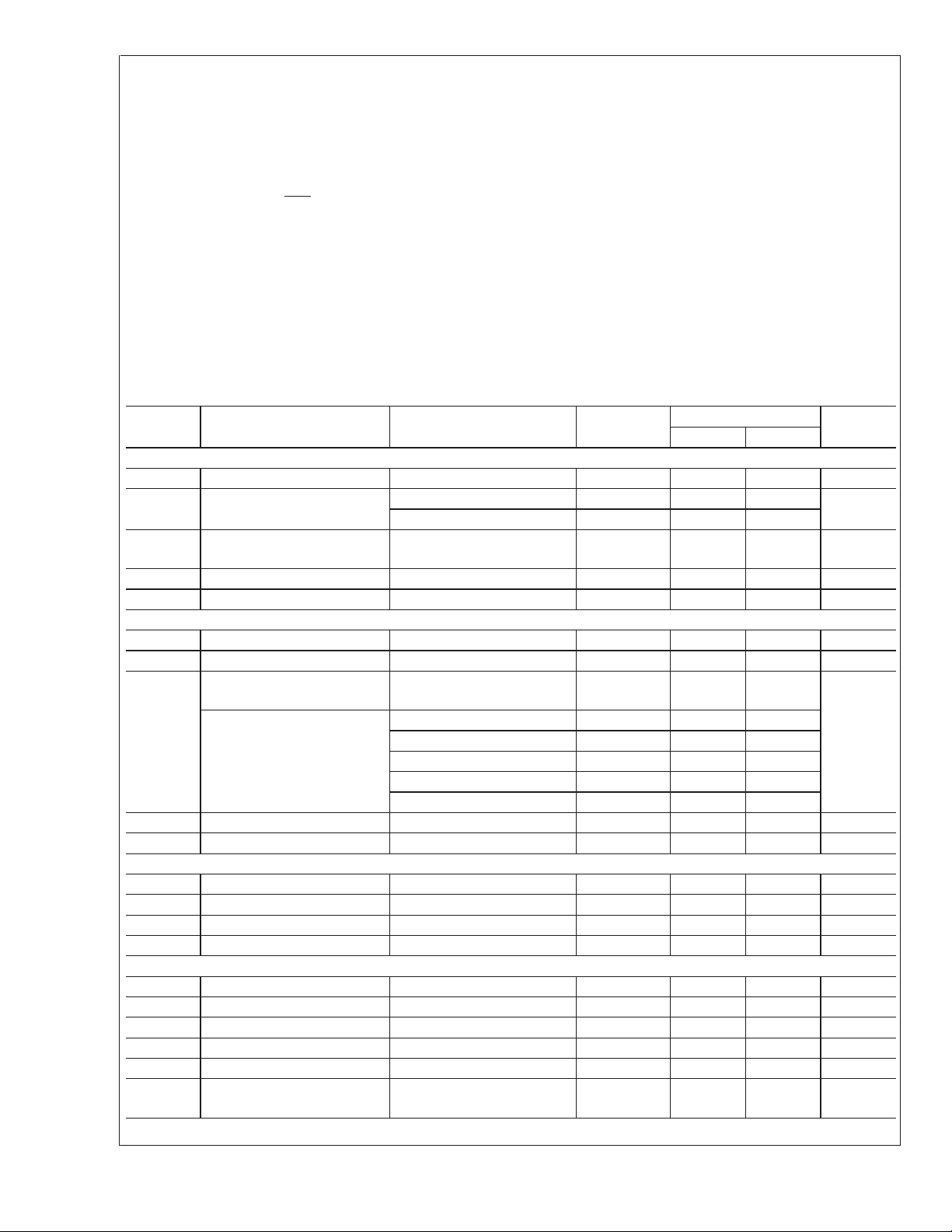

Electrical Characteristics

Unless otherwise noted, VDD= 5.5V. Typical values and limits appearing in normal type apply for TJ= 25˚C. Limits appearing

in boldface type apply over the entire junction temperature range for operation, T

Symbol Parameter Conditions Typical

POWER SUPPLY

V

DD

I

Q

Supply Voltage 5 2.3 5.5 V

Supply Current No Load 350 550

Standby 2.0 5

∆I

Q

Additional Standby Current VDD= 5.5V, every LED pin

at 4.3V

V

POR

t

w

Power-On Reset Voltage 1.8 1.96 V

Reset Pulse Width 10 ns

LED

V

IL

V

IH

I

OL

LOW Level Input Voltage −0.5 0.8 V

HIGH Level Input Voltage 2.0 5.5 V

Low Level Output Current

VOL= 0.4V, VDD= 2.3V

(Note 6)

VOL= 0.4V, VDD= 3.0V 12

V

= 0.4V, VDD= 5.0V 15

OL

V

= 0.7V, VDD= 2.3V 15

OL

V

= 0.7V, VDD= 3.0V 20

OL

V

= 0.7V, VDD= 5.0V 25

OL

I

LEAK

C

I/O

Input Leakage Current VDD= 3.6, VIN=0VorV

DD

Input/Output Capacitance (Note 7) 2.6 5 pF

ALL DIGITAL PINS (EXCEPT SCL AND SDA PINS)

V

IL

V

IH

I

LEAK

C

IN

2

I

C INTERFACE (SCL AND SDA PINS)

V

IL

V

IH

V

OL

I

OL

F

CLK

t

HOLD

LOW Level Input Voltage −0.5 0.8 V

HIGH Level Input Voltage 2.0 5.5 V

Input Leakage Current −1 1 µA

Input Capacitance VIN= 0V (Note 7) 2.3 5 pF

LOW Level Input Voltage -0.5 0.3V

HIGH Level Input Voltage 0.7V

LOW Level Output Voltage 0 0.2V

LOW Level Output Current VOL= 0.4V 6.5 3 mA

Clock Frequency (Note 7) 400 kHz

Hold Time Repeated START

(Note 7)

Condition

= −40˚C to +125˚C. (Note 5)

J

Limit

Min Max

9

−1 1 µA

DD

0.6 µs

2 mA

DD

5.5 V

DD

2.3V to 5.5V

Units

µA

mA

V

V

www.national.com 4

Electrical Characteristics (Continued)

Unless otherwise noted, VDD= 5.5V. Typical values and limits appearing in normal type apply for TJ= 25˚C. Limits appearing

in boldface type apply over the entire junction temperature range for operation, T

Symbol Parameter Conditions Typical

2

I

C INTERFACE (SCL AND SDA PINS)

t

CLK-LP

t

CLK-HP

t

SU

CLK Low Period (Note 7) 1.3 µs

CLK High Period (Note 7) 0.6 µs

Set-Up Time Repeated

(Note 7)

START Condition

t

DATA-HOLD

t

DATA-SU

t

SU

Data Hold Time (Note 7) 300 ns

Data Set-Up Time (Note 7) 100 ns

Set-Up Time for STOP

(Note 7)

Condition

t

TRANS

Maximum Pulse Width of

(Note 7)

Spikes that Must Be

Suppressed by the Input

Filter of Both DATA & CLK

Signals

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical

Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: The Absolute Maximum power dissipation depends on the ambient temperature and can be calculated using the formula

P=(T

where T

J

Absolute Maximum Ratings results from substituting the Absolute Maximum junction temperature, 150˚C, for T

be dissipated safely at ambient temperature below 85˚C. Less power can be dissipated safely at ambient temperatures above 85˚C. The Absolute Maximum power

dissipation can be increased by 27 mW for each degree below 85˚C, and it must be de-rated by 27 mW for each degree above 85˚C. For Operating Ratings

maximum power dissipation, T

Note 4: The human-body model is 100 pF discharged through 1.5 kΩ. The machine model is 0Ω in series with 220 pF.

Note 5: Limits are guaranteed. All electrical characteristics having room-temperature limits are tested during production with T

guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 6: Each LED pin should not exceed 25 mA and the package should not exceed a total of 200 mA.

Note 7: Guaranteed by design.

)/θJA, (1)

J—TA

is the junction temperature, TAis the ambient temperature, and θJAis the junction-to-ambient thermal resistance. The 1.76W rating appearing under

= 125˚C and TA= 85˚C

J

= −40˚C to +125˚C. (Note 5)

J

Limit

Min Max

Units

0.6 µs

0.6 µs

50 ns

, 85˚C for TA, and 37˚C/W for θJA. More power can

J

= 25˚C. All hot and cold limits are

J

LP3944

Typical Performance Characteristics

Frequency vs. Temp

= −40˚C to +85˚C),

(T

A

= 2.3V to 3.0V

V

DD

20085317

www.national.com5

Application Notes

LP3944

THEORY OF OPERATION

The LP3944 takes incoming data and feed them into several

registers that control the frequency and the duty cycle of the

LEDs. Two prescaler registers and two PWM registers provide two individual rates to dim or blink the LEDs (for more

information on these registers, refer to Table 1. LP3944

REGISTER TABLE). The baseband controller/

microprocessor can program each LED to be in one of four

states —on, off, DIM0 rate or DIM1 rate. One read-only

registers provide status on all 8 LEDs. The LP3944 can be

used to drive RGB LEDs and/or single-color LEDs to create

a colorful, entertaining, and informative setting. This is particularly suitable for accessory functions in cellular phones

and toys. Any LED pins not used to drive LED can be used

for General Purpose Parallel Input/Output (GPIO) expansion.

The LP3944 is equipped with Power-On Reset that holds the

chip in a reset state until V

Once V

is achieved, the LP3944 comes out of reset and

POR

reaches V

DD

during power up.

POR

initializes itself to the default state.

To bring the LP3944 into reset, hold the RST pin LOW for a

period of TW. This will put the chip to its default state. The

LP3944 can only be programmed after RST signal is HIGH

again.

2

I

C DATA VALIDITY

The data on SDA line must be stable during the HIGH period

of the clock signal (SCL). In other words, state of the data

line can only be changed when CLK is LOW.

20085306

FIGURE 1. I2C Data Validity

2

C START AND STOP CONDITIONS

I

START and STOP bits classify the beginning and the end of

2

C session. START condition is defined as SDA signal

the I

transitioning from HIGH to LOW while SCL line is HIGH.

STOP condition is defined as the SDA transitioning from

LOW to HIGH while SCL is HIGH. The I

2

C master always

FIGURE 2. I2C START and STOP Conditions

TRANSFERRING DATA

Every byte put on the SDA line must be eight bits long with

the most significant bit (MSB) being transferred first. The

number of bytes that can be transmitted per transfer is

unrestricted. Each byte of data has to be followed by an

acknowledge bit. The acknowledge related clock pulse is

generated by the master. The transmitter releases the SDA

line (HIGH) during the acknowledge clock pulse. The receiver must pull down the SDA line during the 9th clock

pulse, signifying an acknowledge.A receiver which has been

addressed must generate an acknowledge after each byte

has been received.

2

generates START and STOP bits. The I

to be busy after START condition and free after STOP condition. During data transmission, I

C bus is considered

2

C master can generate

repeated START conditions. First START and repeated

START conditions are equivalent, function-wise.

20085307

After the START condition, a chip address is sent by the I

2

master. This address is seven bits long followed by an eighth

bit which is a data direction bit (R/W). The LP3944 hardwires

bits 7 to 4 and leaves bits 3 to 1 selectable, as shown in

Figure 3. For the eighth bit, a “0” indicates a WRITE and a

“1” indicates a READ. The LP3944 supports only a WRITE

during chip addressing. The second byte selects the register

to which the data will be written. The third byte contains data

to write to the selected register.

C

www.national.com 6

Application Notes (Continued)

LP3944

20085308

FIGURE 3. Chip Address Byte

w = write (SDA = “0”)

r = read (SDA = “1”)

ack = acknowledge (SDA pulled down by either master or slave)

rs = repeated start

xx=60to67

FIGURE 4. LP3944 Register Write

However, if a READ function is to be accomplished, a

WRITE function must precede the READ function, as shown

in Figure 5.

w = write (SDA = “0”)

r = read (SDA = “1”)

ack = acknowledge (SDA pulled down by either master or slave)

rs = repeated start

xx=60to67

20085309

20085310

FIGURE 5. LP3944 Register Read

www.national.com7

Application Notes (Continued)

LP3944

AUTO INCREMENT

Auto increment is a special feature supported by the LP3944

to eliminate repeated chip and register addressing when

data are to be written to or read from registers in sequential

order. The auto increment bit is inside the register address

byte, as shown in Figure 6. Auto increment is enabled when

this bit is programmed to “1” and disabled when it is programmed to “0”.

20085311

FIGURE 6. Register Address Byte

In the READ mode, when auto increment is enabled, I

2

master could receive any number of bytes from LP3944

without selecting chip address and register address again.

Every time the I

increment the register address and the next data register will

be read. When I

2

C master reads a register, the LP3944 will

2

C master reaches the last register (09H

register), the register address will roll over to 00H.

In the WRITE mode, when auto increment is enabled, the

LP3944 will increment the register address every time I

2

master writes to register. When the last register (09H register) is reached, the register address will roll over to 02H,

FIGURE 7. Programming with Auto Increment Disabled (in WRITE Mode)

C

because the first two registers in LP3944 are read-only

registers. It is possible to write to these two registers, and the

LP3944 will acknowledge, but the data will be ignored.

In the LP3944, registers 0x01, 0x08 and 0x09 are not functional. However, it is still necessary to read from 0x01 and to

write to 0x08 and 0x09 in Auto Increment mode. They cannot

be skipped.

2

C

If auto increment is disabled, and the I

change register address, it will continue to write data into the

C master does not

same register.

20085312

FIGURE 8. Programming with Auto Increment Enabled (in WRITE Mode)

www.national.com 8

20085313

Application Notes (Continued)

TABLE 1. LP3944 REGISTER TABLE

Address (Hex) Register Name Read/Write Register Function

0x00 Input 1 Read Only LED0–7 Input Register

0x01 Register 1 Read Only None

0x02 PSC0 R/W Frequency Prescaler 0

0x03 PWM0 R/W PWM Register 0

0x04 PSC1 R/W Frequency Prescaler 1

0x05 PWM1 R/W PWM Register 1

0x06 LS0 R/W LED0–3 Selector

0x07 LS1 R/W LED4–7 Selector

0x08 Register 8 R/W None

0x09 Register 9 R/W None

Note: Registers 1, 8 and 9 are empty and non-functional registers. Register 1 is read-only, with all bits hard-wired to zero. Registers 8 and 9 can be written and read,

but the content does ot have any effect on the operation of the LP3944.

BINARY FOMAT FOR INPUT REGISTERS (READ ONLY)— ADDRESS 0x00 and 0x01

Address 0x00

Bit# 76543210

Default value XXXXXXXX

LED7 LED6 LED5 LED4 LED3 LED2 LED1 LED0

X = don’t care

LP3944

BINARY FORMAT FOR FREQUENCY PRESCALER AND PWM REGISTERS — ADDRESS 0x02 to 0x05

Address 0x02 (PSC0)

Bit# 76543210

Default value 00000000

PSC0 register is used to program the period of DIM0.

DIM0 = (PSC0+1)/160

The maximum period is 1.6s when PSC0 = 255.

Address 0x03 (PWM0)

Bit# 76543210

Default value 10000000

PWM0 register determines the duty cycle of DIM0. The LED outputs are LOW (LED on) when the count is less than the value in PWM0 and HIGH (LED off) when

it is greater. If PWM0 is programmed with 0x00, LED output is always HIGH (LED off).

The duty cycle of DIM0 is: PWM0/256

Default value is 50% duty cycle.

Address 0x04 (PSC1)

Bit# 76543210

Default value 00000000

PSC1 register is used to program the period of DIM1.

DIM1 = (PSC1 + 1)/160

The maximum period is 1.6s when PSC1 = 255.

www.national.com9

Application Notes (Continued)

LP3944

Bit# 76543210

Default value 10000000

PWM1 register determines the duty cycle of DIM1. The LED outputs are LOW (LED on) when the count is less than the value in PWM1 and HIGH (LED off) when

it is greater. If PWM1 is programmed with 0x00, LED output is always HIGH (LED off).

The duty cycle of DIM1 is: PWM1/256

Default value is 50% duty cycle.

BINARY FORMAT FOR SELECTOR REGISTERS — ADDRESS 0x06 to 0x07

Bit# 76543210

Default value 00000000

B1 B0 B1 B0 B1 B0 B1 B0

LED3 LED2 LED1 LED0

Bit# 76543210

Default value 00000000

B1 B0 B1 B0 B1 B0 B1 B0

LED7 LED6 LED5 LED4

Address 0x05 (PWM1)

Address 0x06 (LS0)

Address 0x07 (LS1)

LED States With Respect To Values in "B1" and "B0"

B1 B0 Function

0 0 Output Hi-Z

(LED off)

0 1 Output LOW

(LED on)

1 0 Output dims

(DIM0 rate)

1 1 Output dims

(DIM1 rate)

Programming Example:

Dim LEDs 0 to 7 at 1 Hz at 25% duty cycle

Step 1: Set PSC0 to achieve DIM0 of 1s

Step 2: Set PWM0 duty cycle to 25%

Step 3: Set PSC1 to achieve DIM1 of 0.2s

Step 4: Set LEDs 0 to 7 to point to DIM0

Step Description Register Name Set to (Hex)

1 Set DIM0 = 1s

PSC0 0x09F

1 = (PSC0 + 1)/160

PSC0 = 159

2 Set duty cycle to 25%

PWM0 0x40

Duty Cycle = PWM0/256

PWM0 = 64

3 Set DIM1 = 0.2s

PSC1 0x1F

0.2 = (PSC1 + 1)/160

PSC1 = 31

4 LEDs0to7

LS0, LS1 LS0 = 0xAA

Output = DIM0

LS1 = 0xAA

www.national.com 10

Application Notes (Continued)

REDUCING I

In many applications, the LEDs and the LP3944 share the

same V

When the LEDs are off, the LED pins are at a lower potential

WHEN LEDS ARE OFF

Q

, as shown in Section Typical Application Circuit.

DD

FIGURE 9. Methods to Reduce IQWhen LEDs Are Off

Application Circuit

than V

, causing extra supply current (∆IQ). To minimize

DD

this current, consider keeping the LED pins at a voltage

equal to or greater than V

.

DD

20085314

LP3944

20085315

www.national.com11

Physical Dimensions inches (millimeters) unless otherwise noted

NOTES: UNLESS OTHERWISE SPECIFIED

1. FOR LEAD FINISH THICKNESS AND COMPOSITION. SEE “SOLDER INFORMATION” IN THE PACKAGING SECTION

LP3944 RGB/White/Blue 8-LED Fun Light Driver

OF THE NATIONAL SEMICONDUCTOR WEB PAGE (www. national.com).

2. NO JEDEC REGISTRATION AS OF MARCH 2003.

Order Number LP3944ISQ or LP3944ISQX

NS Package Number SQA24C

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...