LP3881

0.8A Fast-Response Ultra Low Dropout Linear

Regulators

LP3881 0.8A Fast-Response Ultra Low Dropout Linear Regulators

August 2003

General Description

The LP3881 is a high current, fast response regulator which

can maintain output voltage regulation with minimum input to

output voltage drop. Fabricated on a CMOS process, the

device operates from two input voltages: Vbias provides

voltage to drive the gate of the N-MOS power transistor,

while Vin is the input voltage which supplies power to the

load. The use of an external bias rail allows the part to

operate from ultra low Vin voltages. Unlike bipolar regulators, the CMOS architecture consumes extremely low quiescent current at any output load current. The use of an

N-MOS power transistor results in wide bandwidth, yet minimum external capacitance is required to maintain loop stability.

The fast transient response of these devices makes them

suitable for use in powering DSP, Microcontroller Core voltages and Switch Mode Power Supply post regulators. The

parts are available in TO-220 and TO-263 packages.

@

Dropout Voltage: 75 mV (typ)

Ground Pin Current: 3 mA (typ) at full load.

Shutdown Current: 60 nA (typ) when S/D pin is low.

Precision Output Voltage: 1.5% room temperature accu-

racy.

0.8A load current.

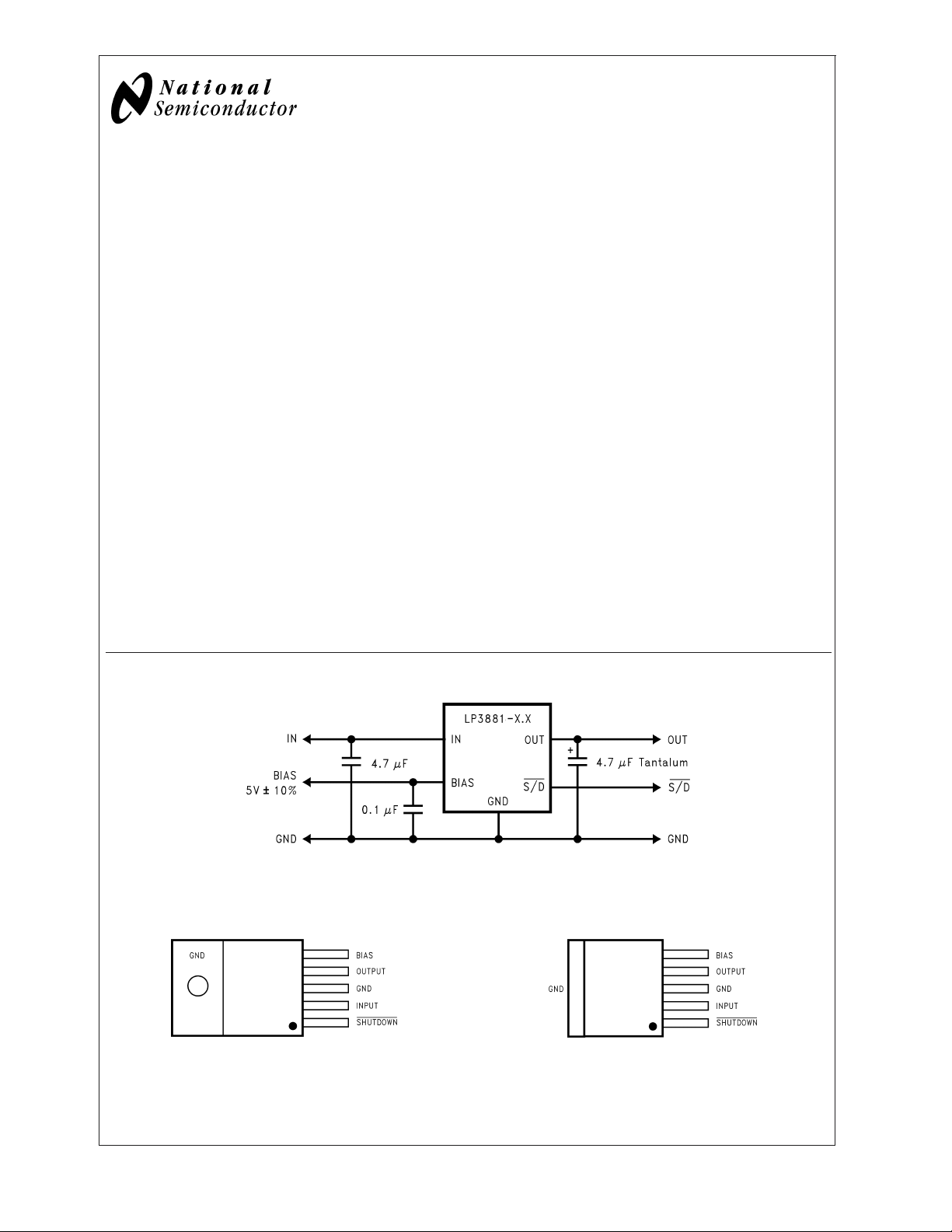

Typical Application Circuit

Features

n Ultra low dropout voltage (75 mV@0.8A typ)

n Low ground pin current

n Load regulation of 0.04%/A

n 60 nA typical quiescent current in shutdown

n 1.5% output accuracy (25˚C)

n TO-220, TO-263 packages

n Over temperature/over current protection

n −40˚C to +125˚C junction temperature range

Applications

n DSP Power Supplies

n Server Core and I/O Supplies

n PC Add-in-Cards

n Local Regulators in Set-Top Boxes

n Microcontroller Power Supplies

n High Efficiency Power Supplies

n SMPS Post-Regulators

At least 4.7 µF of input and output capacitance is required for stability.

20063001

Connection Diagrams

TO-220, Top View

© 2003 National Semiconductor Corporation DS200630 www.national.com

20063002

TO-263, Top View

20063003

Ordering Information

LP3881

Order Number Package Type Package Drawing Supplied As

LP3881ES-1.2 TO263-5 TS5B Rail

LP3881ESX-1.2 TO263-5 TS5B Tape and Reel

LP3881ET-1.2 TO220-5 T05D Rail

LP3881ES-1.5 TO263-5 TS5B Rail

LP3881ESX-1.5 TO263-5 TS5B Tape and Reel

LP3881ET-1.5 TO220-5 T05D Rail

LP3881ES-1.8 TO263-5 TS5B Rail

LP3881ESX-1.8 TO263-5 TS5B Tape and Reel

LP3881ET-1.8 TO220-5 T05D Rail

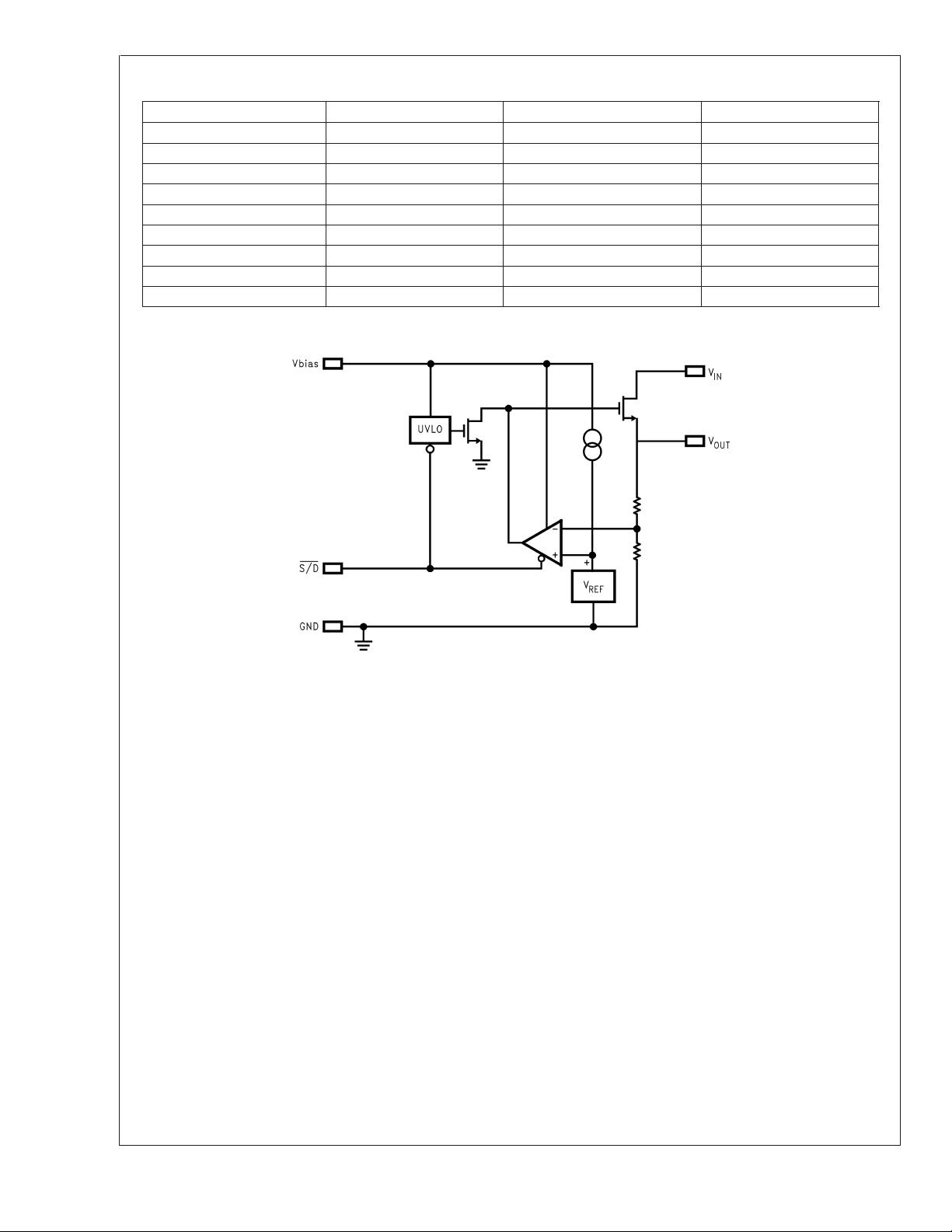

Block Diagram

20063024

www.national.com 2

LP3881

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Storage Temperature Range −65˚C to +150˚C

I

(Survival) Internally Limited

OUT

Output Voltage (Survival) −0.3V to +6V

Junction Temperature −40˚C to +150˚C

Operating Ratings

Lead Temp. (Soldering, 5 seconds) 260˚C

ESD Rating

Human Body Model (Note 3)

Machine Model (Note 10)

2kV

200V

Power Dissipation (Note 2) Internally Limited

Supply Voltage (Survival) −0.3V to +6V

V

IN

V

Supply Voltage (Survival) −0.3V to +7V

BIAS

VINSupply Voltage (V

Shutdown Input Voltage 0 to +6V

I

OUT

Operating Junction

Temperature Range

V

BIAS

Shutdown Input Voltage (Survival) −0.3V to +7V

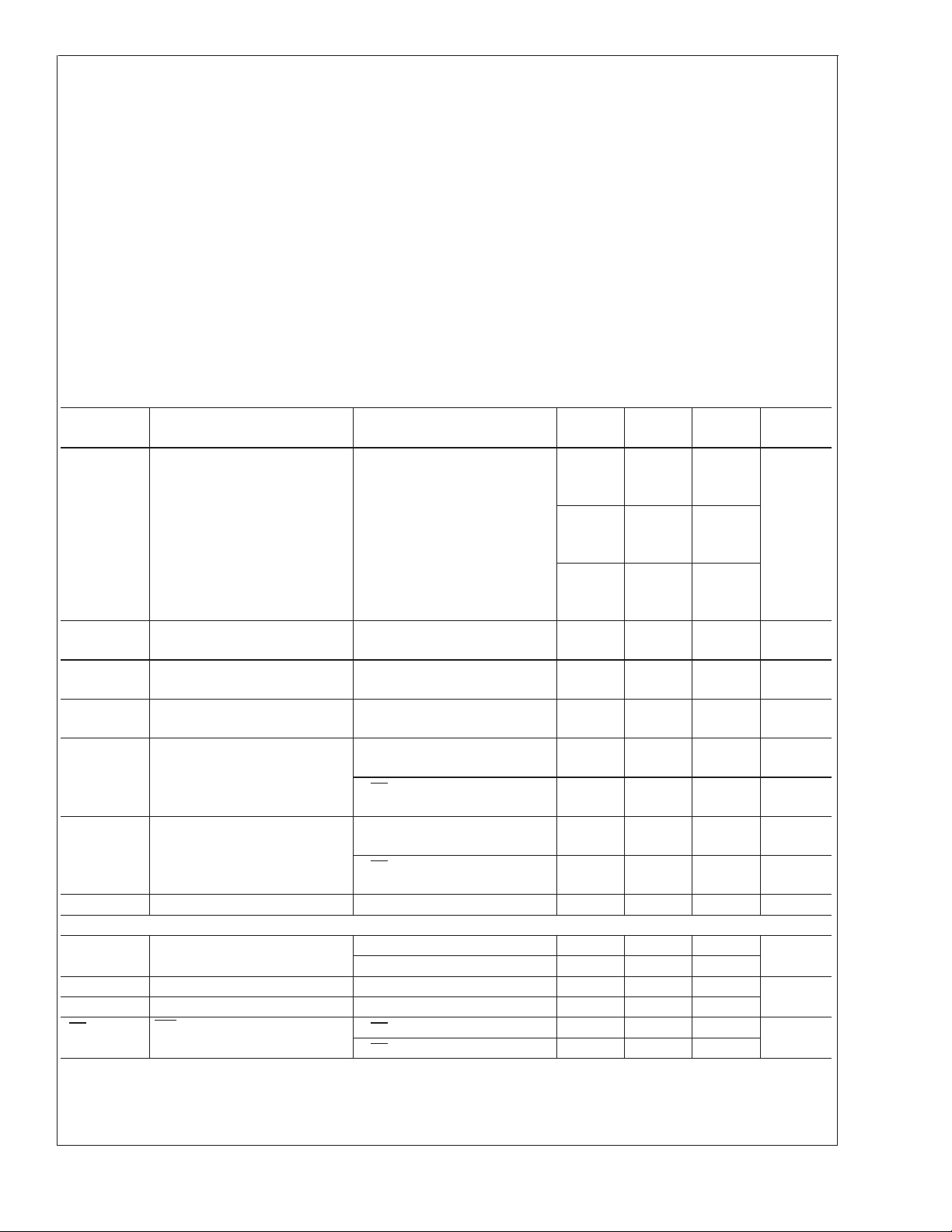

Electrical Characteristics Limits in standard typeface are for T

over the full operating temperature range. Unless otherwise specified: V

C

OUT

= 4.7 µF, V

S/D=VBIAS

.

Symbol Parameter Conditions

BIAS

<

0.8A

L

≤ 6V

V

∆V

O

Output Voltage Tolerance 10 mA<I

(NOM) + 1V ≤ VIN≤ 5.5V

V

O

4.5V ≤ V

/∆V

O

Output Voltage Line Regulation

IN

VO(NOM) + 1V ≤ VIN≤ 5.5V

(Note 7)

∆VO/∆I

L

Output Voltage Load Regulation

10 mA<I

<

0.8A 0.04

L

(Note 8)

V

DO

IQ(VIN) Quiescent Current Drawn from

I

Q(VBIAS

I

SC

Dropout Voltage (Note 9) IL= 0.8A

Supply

V

IN

) Quiescent Current Drawn from

Supply

V

BIAS

Short-Circuit Current V

<

10 mA

V

S/D

10 mA

V

S/D

OUT

<

I

0.8A

L

≤ 0.3V

<

<

I

0.8A

L

≤ 0.3V

= 0V 1.8 A

Shutdown Input

V

SDT

Output Turn-off Threshold Output = ON 0.7 1.3

Output = OFF 0.7 0.3

Td (OFF) Turn-OFF Delay R

Td (ON) Turn-ON Delay R

I

S/D

S/D Input Current V

XC

LOAD

XC

LOAD

=1.3V 1

S/D

V

≤ 0.3V −1

S/D

OUT

OUT

<<

<<

IN=VO

Td (OFF) 20

Td (ON) 15

OUT+VDO

) to 5.5V

0.8A

−40˚C to +125˚C

Supply Voltage 4.5V to 6V

= 25˚C, and limits in boldface type apply

J

(NOM) + 1V, V

Typical

(Note 4)

= 4.5V, IL= 10 mA, CIN=

BIAS

MIN

(Note 5)

1.198

MAX

(Note 5)

1.234

Units

1.216

1.186

1.478

1.246

1.522

V1.5

1.455

1.773

1.545

1.827

1.8

1.746

1.854

0.01 %/V

0.06

75

3

0.03

1

0.03

120

160

7

8

1

30

2

3

1

30

%/A

mV

mA

µA

mA

µA

V

µs

µA

www.national.com3

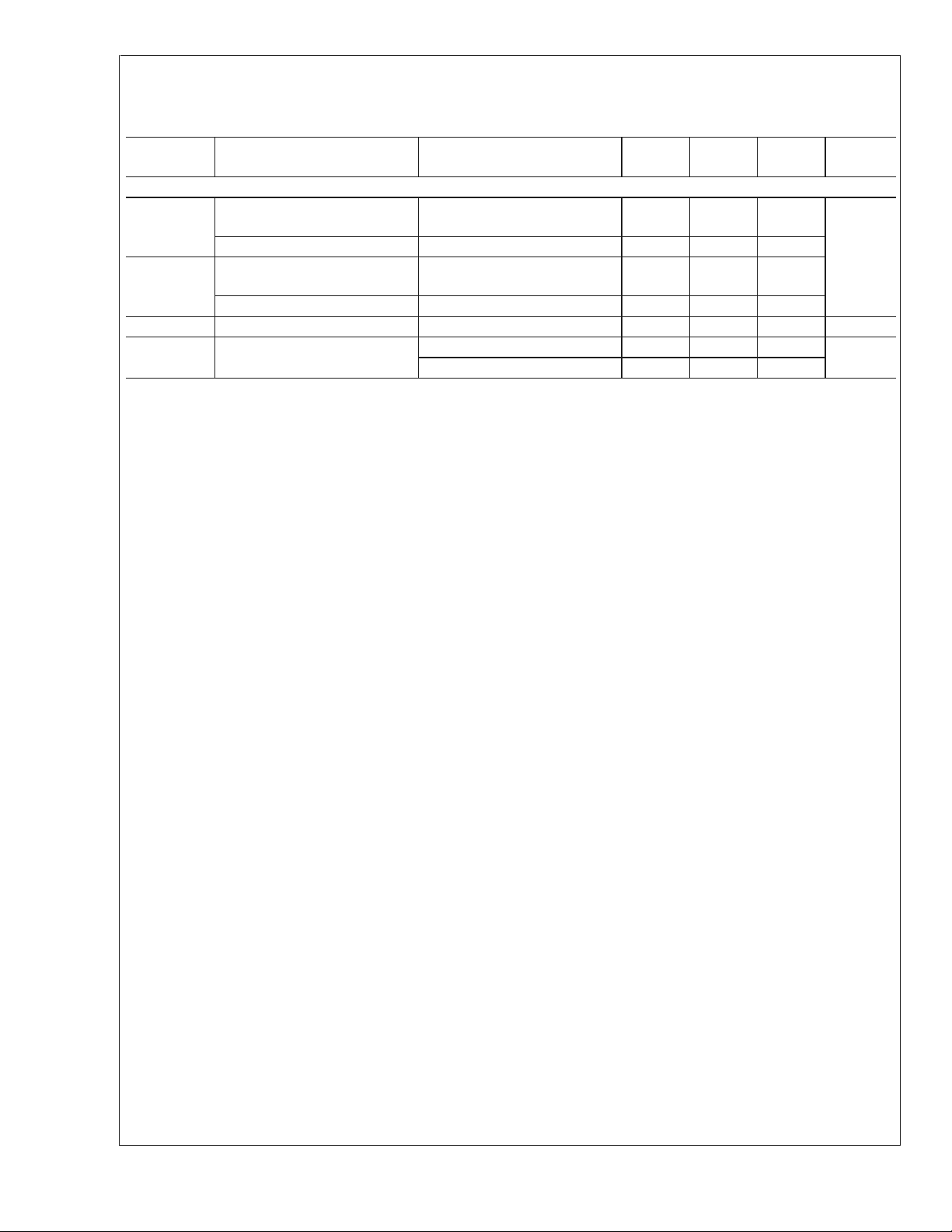

Electrical Characteristics Limits in standard typeface are for T

over the full operating temperature range. Unless otherwise specified: V

LP3881

C

OUT

= 4.7 µF, V

S/D=VBIAS

. (Continued)

IN=VO

= 25˚C, and limits in boldface type apply

J

(NOM) + 1V, V

= 4.5V, IL= 10 mA, CIN=

BIAS

Symbol Parameter Conditions

Typical

(Note 4)

MIN

(Note 5)

MAX

(Note 5)

AC Parameters

PSRR (V

PSRR

(V

BIAS

) Ripple Rejection for VINInput

IN

Voltage

Ripple Rejection for V

)

Voltage

BIAS

VIN=V

OUT

VIN=V

OUT

V

BIAS=VOUT

V

BIAS=VOUT

+1V, f = 120 Hz

80

+ 1V, f = 1 kHz 65

+ 3V, f = 120 Hz

70

+ 3V, f = 1 kHz 65

Output Noise Density f = 120 Hz 1 µV/root−Hz

e

n

Note 1: Absolute maximum ratings indicate limits beyond which damage to the component may occur. Operating ratings indicate conditions for which the device

is intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications, see Electrical Characteristics. Specifications do not

apply when operating the device outside of its rated operating conditions.

Note 2: At elevated temperatures, device power dissipation must be derated based on package thermal resistance and heatsink thermal values. θ

devices is 65˚C/W if no heatsink is used. If the TO-220 device is attached to a heatsink, a θ

approximately 40˚C/W if soldered down to a copper plane which is at least 1.5 square inches in area. If power dissipation causes the junction temperature to exceed

specified limits, the device will go into thermal shutdown.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5k resistor into each pin.

Note 4: Typical numbers represent the most likely parametric norm for 25˚C operation.

Note 5: Limits are guaranteed through testing, statistical correlation, or design.

Note 6: If used in a dual-supply system where the regulator load is returned to a negative supply, the output pin must be diode clamped to ground.

Note 7: Output voltage line regulation is defined as the change in output voltage from nominal value resulting from a change in input voltage.

Note 8: Output voltage load regulation is defined as the change in output voltage from nominal value as the load current increases from no load to full load.

Note 9: Dropout voltage is defined as the minimum input to output differential required to maintain the output with 2% of nominal value.

Note 10: The machine model is a 220 pF capacitor discharged directly into each pin. The machine model ESD rating of pin 5 is 100V.

Output Noise Voltage

= 1.8V

V

OUT

BW = 10 Hz − 100 kHz 150

BW = 300 Hz − 300 kHz 90

value of 4˚C/W can be assumed. θ

J-S

for TO-220

J-A

for TO-263 devices is

J-A

µV (rms)

Units

dB

www.national.com 4

Typical Performance Characteristics

Unless otherwise specified: TA= 25˚C, C

= 4.7µF, S/D pin is tied to V

BIAS,VIN

= 2.2V, V

= 4.7µF, Cin

OUT

OUT

= 1.8V

LP3881

Dropout vs I

V

vs Temperature DC Load Regulation

OUT

L

20063004

I

GND

vs VSD

20063005

Line Regulation vs V

20063006

IN

20063008 20063009

Line Regulation vs V

20063007

BIAS

www.national.com5

Typical Performance Characteristics Unless otherwise specified: T

4.7µF, S/D pin is tied to V

LP3881

vs I

= 2.2V, V

L

BIAS,VIN

I

BIAS

Noise Measurement V

= 1.8V (Continued)

OUT

20063010

= 25˚C, C

A

I

vs VSD

GND

Startup Waveform

OUT

= 4.7µF, Cin =

OUT

20063012

20063014

Line Regulation vs V

BIAS

20063018

www.national.com 6

Line Regulation vs V

20063015

BIAS

20063019

LP3881

Typical Performance Characteristics Unless otherwise specified: T

4.7µF, S/D pin is tied to V

BIAS,VIN

= 2.2V, V

VINPSRR VINPSRR

V

PSRR

BIAS

= 1.8V (Continued)

OUT

20063020 20063023

= 25˚C, C

A

= 4.7µF, Cin =

OUT

20063022

www.national.com7

Application Hints

LP3881

V

RESTRICTIONS FOR PROPER START-UP

BIAS

To prevent misoperation, ensure that V

before start-up is initiated. This scenario can occur in systems with a backup battery using reverse-biased "blocking"

diodes which may allow enough leakage current to flow into

the V

node to raise it’s voltage slightly above ground

BIAS

when the main power is removed. Using low leakage diodes

or a resistive pull down can prevent the voltage at V

rising above 50mV. Large bulk capacitors connected to

may also cause a start-up problem if they do not

V

BIAS

discharge fully before re-start is initiated (but only if V

allowed to fall below 1V). A resistor connected across the

capacitor will allow it to discharge more quickly. It should be

noted that the probability of a "false start" caused by incorrect logic states is extremely low.

EXTERNAL CAPACITORS

To assure regulator stability, input and output capacitors are

required as shown in the Typical Application Circuit.

OUTPUT CAPACITOR

At least 4.7µF of output capacitance is required for stability

(the amount of capacitance can be increased without limit).

The output capacitor must be located less than 1 cm from

the output pin of the IC and returned to a clean analog

ground. The ESR (equivalent series resistance) of the output

capacitor must be within the "stable" range as shown in the

graph below over the full operating temperature range for

stable operation.

is below 50mV

BIAS

BIAS

BIAS

from

Because the ESR of ceramic capacitors is only a few milli

Ohms, they are not suitable for use as output capacitors on

LP388X devices. The regulator output can tolerate ceramic

capacitance totaling up to 15% of the amount of Tantalum

capacitance connected from the output to ground.

OUTPUT "BYPASS" CAPACITORS

Many designers place small value "bypass" capacitors at

various circuit points to reduce noise. Ceramic capacitors in

the value range of about 1000pF to 0.1µF placed directly on

the output of a PNP or P-FET LDO regulator can cause a

loss of phase margin which can result in oscillations, even

is

when a Tantalum output capacitor is in parallel with it. This is

not unique to National Semiconductor LDO regulators, it is

true of any P-type LDO regulator.

The reason for this is that PNP or P-FET regulators have a

higher output impedance (compared to an NPN regulator),

which results in a pole-zero pair being formed by every

different capacitor connected to the output.

The zero frequency is approximately:

=1/(2Xπ XESRXC)

F

z

Where ESR is the equivalent series resistance of the capacitor, and C is the value of capacitance.

The pole frequency is:

=1/(2Xπ XRLXC)

F

p

Where R

is the load resistance connected to the regulator

L

output.

To understand why a small capacitor can reduce phase

margin: assume a typical LDO with a bandwidth of 1MHz,

which is delivering 0.5A of current from a 2.5V output (which

means R

is 5 Ohms). We then place a .047 µF capacitor on

L

the output. This creates a pole whose frequency is:

=1/(2Xπ X 5 X .047 X 10E-6) = 677 kHz

F

p

This pole would add close to 60 degrees of phase lag at the

crossover (unity gain) frequency of 1 MHz, which would

almost certainly make this regulator oscillate. Depending on

the load current, output voltage, and bandwidth, there are

usually values of small capacitors which can seriously reduce phase margin. If the capacitors are ceramic, they tend

to oscillate more easily because they have very little internal

inductance to damp it out. If bypass capacitors are used, it is

best to place them near the load and use trace inductance to

"decouple" them from the regulator output.

Minimum ESR vs Output Load Current

20063031

Tantalum capacitors are recommended for the output as

their ESR is ideally suited to the part’s requirements and the

ESR is very stable over temperature. Aluminum electrolytics

are not recommended because their ESR increases very

rapidly at temperatures below 10C. Aluminum caps can only

be used in applications where lower temperature operation

is not required.

A second problem with Al caps is that many have ESR’s

which are only specified at low frequencies. The typical loop

bandwidth of a linear regulator is a few hundred kHz to

several MHz. If an Al cap is used for the output cap, it must

be one whose ESR is specified at a frequency of 100 kHz or

more.

www.national.com 8

INPUT CAPACITOR

The input capacitor must be at least 4.7 µF, but can be

increased without limit. It’s purpose is to provide a low

source impedance for the regulator input. Ceramic capacitors work best for this, but Tantalums are also very good.

There is no ESR limitation on the input capacitor (the lower,

the better). Aluminum electrolytics can be used, but their

ESR increase very quickly at cold temperatures. They are

not recommended for any application where temperatures

go below about 10˚C.

BIAS CAPACITOR

The 0.1µF capacitor on the bias line can be any good quality

capacitor (ceramic is recommended).

BIAS VOLTAGE

The bias voltage is an external voltage rail required to get

gate drive for the N-FET pass transistor. Bias voltage must

be in the range of 4.5 - 6V to assure proper operation of the

part.

Application Hints (Continued)

UNDER VOLTAGE LOCKOUT

The bias voltage is monitored by a circuit which prevents the

regulator output from turning on if the bias voltage is below

approximately 4V.

SHUTDOWN OPERATION

Pulling down the shutdown (S/D) pin will turn-off the regulator. Pin S/D must be actively terminated through a pull-up

resistor (10 kΩ to 100 kΩ) for a proper operation. If this pin

is driven from a source that actively pulls high and low (such

as a CMOS rail to rail comparator), the pull-up resistor is not

required. This pin must be tied to Vin if not used.

POWER DISSIPATION/HEATSINKING

A heatsink may be required depending on the maximum

power dissipation and maximum ambient temperature of the

application. Under all possible conditions, the junction temperature must be within the range specified under operating

conditions. The total power dissipation of the device is given

by:

=(VIN−V

P

D

where I

OUT)IOUT

is the operating ground current of the device.

GND

The maximum allowable temperature rise (T

on the maximum ambient temperature (T

cation, and the maximum allowable junction temperature

):

(T

Jmax

=T

T

Rmax

Jmax−TAmax

The maximum allowable value for junction to ambient Thermal Resistance, θ

θ

JA=TRmax/PD

These parts are available in TO-220 and TO-263 packages.

The thermal resistance depends on amount of copper area

or heat sink, and on air flow. If the maximum allowable value

calculated above is ≥ 60 ˚C/W for TO-220 package

of θ

JA

and ≥ 60 ˚C/W for TO-263 package no heatsink is needed

since the package can dissipate enough heat to satisfy these

requirements. If the value for allowable θ

limits, a heat sink is required.

+(VIN)I

GND

) depends

Rmax

) of the appli-

Amax

, can be calculated using the formula:

JA

falls below these

JA

The heatsink to be used in the application should have a

heatsink to ambient thermal resistance,

θ

HA≤θJA

In this equation, θ

to the surface of the heat sink and θ

tance from the junction to the surface of the case. θ

about 3˚C/W for a TO220 package. The value for θ

pends on method of attachment, insulator, etc. θ

− θCH− θJC.

CH

is the thermal resistance from the case

is the thermal resis-

JC

JC

de-

CH

varies

CH

between 1.5˚C/W to 2.5˚C/W. If the exact value is unknown,

2˚C/W can be assumed.

HEATSINKING TO-263 PACKAGE

The TO-263 package uses the copper plane on the PCB as

a heatsink. The tab of these packages are soldered to the

copper plane for heat sinking. The graph below shows a

curve for the θ

of TO-263 package for different copper area

JA

sizes, using a typical PCB with 1 ounce copper and no solder

mask over the copper area for heat sinking.

20063025

FIGURE 1. θJAvs Copper (1 Ounce) Area for TO-263

package

LP3881

is

HEATSINKING TO-220 PACKAGE

The thermal resistance of a TO220 package can be reduced

by attaching it to a heat sink or a copper plane on a PC

board. If a copper plane is to be used, the values of θ

will

JA

be same as shown in next section for TO263 package.

www.national.com9

Application Hints (Continued)

LP3881

As shown in the graph below, increasing the copper area

beyond 1 square inch produces very little improvement. The

minimum value for θ

PCB is 32˚C/W.

Figure 2 shows the maximum allowable power dissipation

for TO-263 packages for different ambient temperatures,

assuming θ

is 35˚C/W and the maximum junction tempera-

JA

ture is 125˚C.

for the TO-263 package mounted to a

JA

20063026

FIGURE 2. Maximum power dissipation vs ambient

temperature for TO-263 package

www.national.com 10

Physical Dimensions inches (millimeters) unless otherwise noted

LP3881

TO220 5-lead, Molded, Stagger Bend Package (TO220-5)

NS Package Number T05D

www.national.com11

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

TO263 5-Lead, Molded, Surface Mount Package (TO263-5)

NS Package Number TS5B

LP3881 0.8A Fast-Response Ultra Low Dropout Linear Regulators

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...