Page 1

LMV841/LMV842/LMV844

CMOS Input, RRIO, Wide Supply Range Operational

Amplifiers

October 2007

LMV841 Single/ LMV842 Dual/ LMV844 Quad CMOS Input, RRIO, Wide Supply Range Operational

Amplifiers

General Description

The LMV841/LMV842/LMV844 are low-voltage and low-power operational amplifiers that operate with supply voltages

ranging from 2.7V to 12V and have rail-to-rail input and output

capability. Their low offset voltage, low supply current, and

MOS inputs make them ideal for sensor interface and batterypowered applications.

The single LMV841 is offered in the space-saving 5-Pin SC70

package, the dual LMV842 in the 8-Pin MSOP and 8-Pin

SOIC packages, and the quad LMV844 in the 14-Pin TSSOP

and 14-Pin SOIC packages. These small packages are ideal

solutions for area-constrained PC boards and portable electronics.

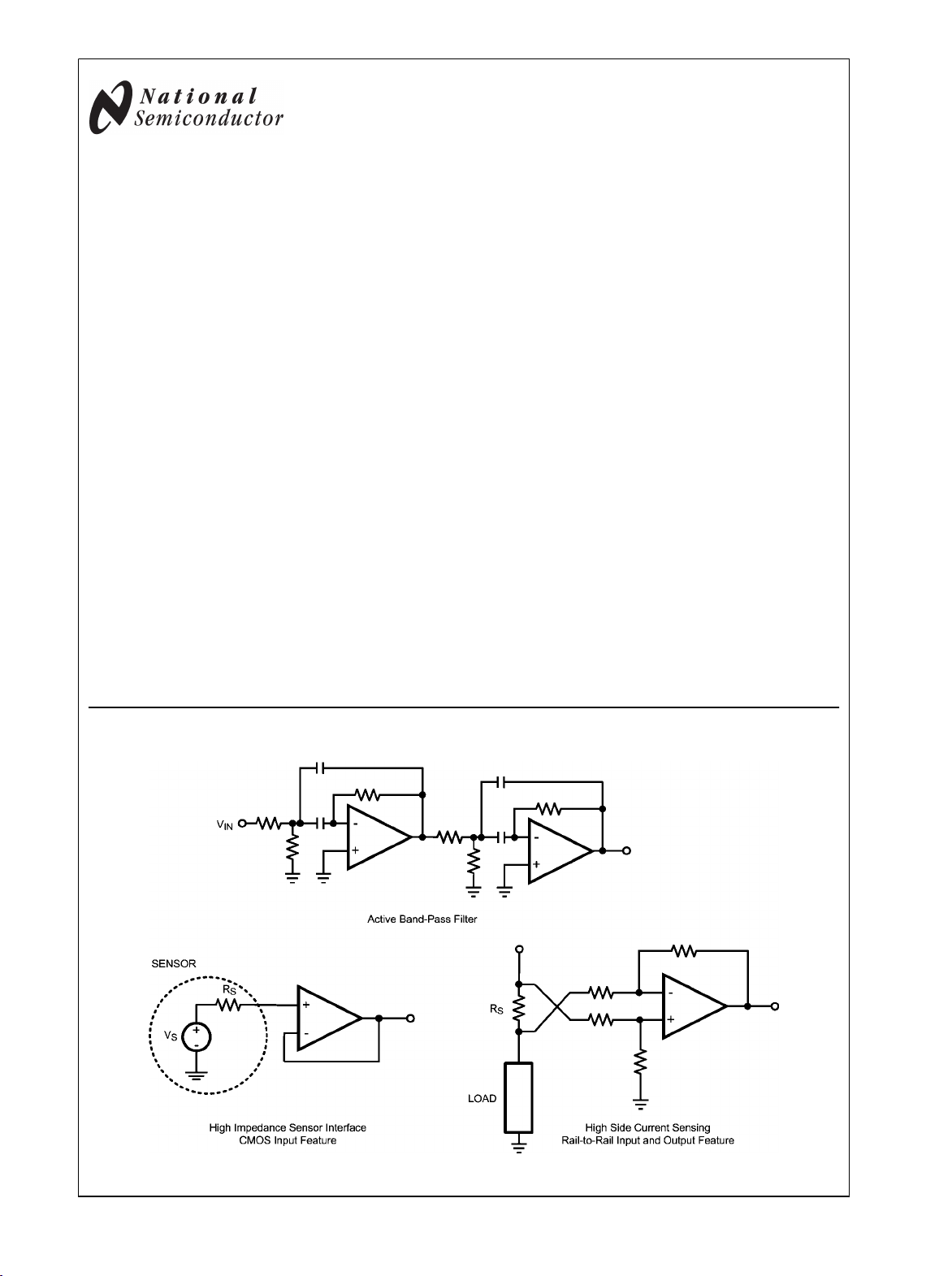

Typical Applications

Features

Unless otherwise noted, typical values at TA = 25°C, V+ = 5V.

Space saving 5-Pin SC70 package

■

Supply voltage range 2.7V to 12V

■

Guaranteed at 3.3V, 5V and ±5V

■

Low supply current 1 mA per channel

■

Unity gain bandwidth 4.5 MHz

■

Open loop gain 133 dB

■

Input offset voltage

■

Input bias current 0.3 pA

■

CMRR 112 dB

■

Input voltage noise 20 nV/√Hz

■

Temperature range −40°C to 125°C

■

Rail-to-Rail input

■

Rail-to-Rail output

■

500 μV max

Applications

High impedance sensor interface

■

Battery powered instrumentation

■

High gain amplifiers

■

DAC buffer

■

Instrumentation amplifiers

■

Active filters

■

20168301

© 2007 National Semiconductor Corporation 201683 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Soldering Information

Infrared or Convection (20 sec) 235°C

Wave Soldering Lead Temp. (10 sec) 260°C

Distributors for availability and specifications.

ESD Tolerance (Note 2)

Human Body Model 2 kV

Machine Model 200V

V

Differential

IN

Supply Voltage (V+ – V−)

±300 mV

13.2V

Voltage at Input/Output Pins V++0.3V, V− −0.3V

Input Current 10 mA

Storage Temperature Range −65°C to +150°C

Junction Temperature (Note 3) +150°C

Operating Ratings (Note 1)

Temperature Range (Note 3) −40°C to +125°C

Supply Voltage (V+ – V−)

Package Thermal Resistance (θJA (Note 3))

5-Pin SC70 334 °C/W

8-Pin MSOP 205 °C/W

8-Pin SOIC 126 °C/W

14-Pin TSSOP 110 °C/W

14-Pin SOIC 93 °C/W

2.7V to 12V

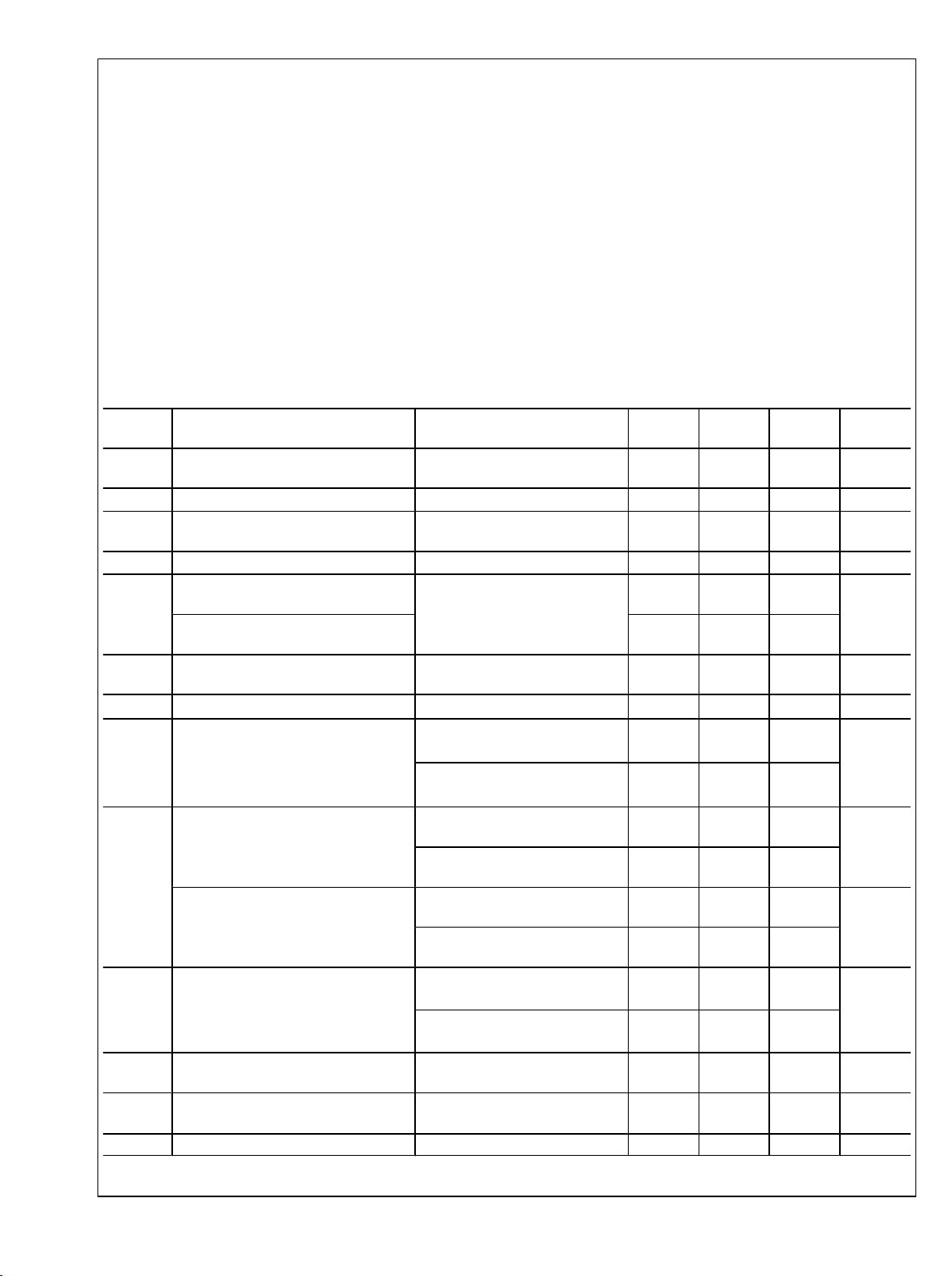

3.3V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 3.3V, V− = 0V, VCM = V+/2, and RL > 10 MΩ to V+/2.

Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

LMV841 Single/ LMV842 Dual/ LMV844 Quad

(Note 6)

V

OS

TCV

I

B

Input Offset Voltage ±50 ±500

Input Offset Voltage Drift (Note 7) 0.5 ±5

OS

Input Bias Current

0.3 10

(Notes 7, 8)

I

OS

CMRR Common Mode Rejection Ratio

PSRR Power Supply Rejection Ratio

Input Offset Current 40

84

80

77

75

86

LMV841

Common Mode Rejection Ratio

LMV842 and LMV844

0V ≤ V

CM

≤ 3.3V

2.7V ≤ V+ ≤ 12V, VO = V+/2

82

CMVR Input Common-Mode Voltage Range

A

VOL

V

O

Large Signal Voltage Gain

Output Swing High,

CMRR ≥ 50 dB

RL = 2 kΩ

VO = 0.3V to 3.0V

RL = 10 kΩ

VO = 0.2V to 3.1V

RL = 2 kΩ to V+/2

–0.1 3.4

100

96

100

96

52 80

(measured from V+)

28 50

65 100

Output Swing Low,

RL = 10 kΩ to V+/2

RL = 2 kΩ to V+/2

(measured from V−)

RL = 10 kΩ to V+/2

I

O

Output Short Circuit Current

(Notes 3, 9)

Sourcing VO = V+/2

VIN = 100 mV

Sinking VO = V+/2

VIN = −100 mV

I

S

Supply Current Per Channel 0.93 1.5

SR Slew Rate (Note 10) AV = +1, VO = 2.3 V

PP

33 65

20

15

20

15

2.5

10% to 90%

GBW Gain Bandwidth Product 4.5 MHz

Typ

(Note 5)

112

106

108

123

131

32

27

Max

(Note 6)

±800

300

120

70

120

75

2

Units

μV

μV/°C

pA

fA

dB

dB

V

dB

mV

mV

mA

mA

V/μs

www.national.com 2

Page 3

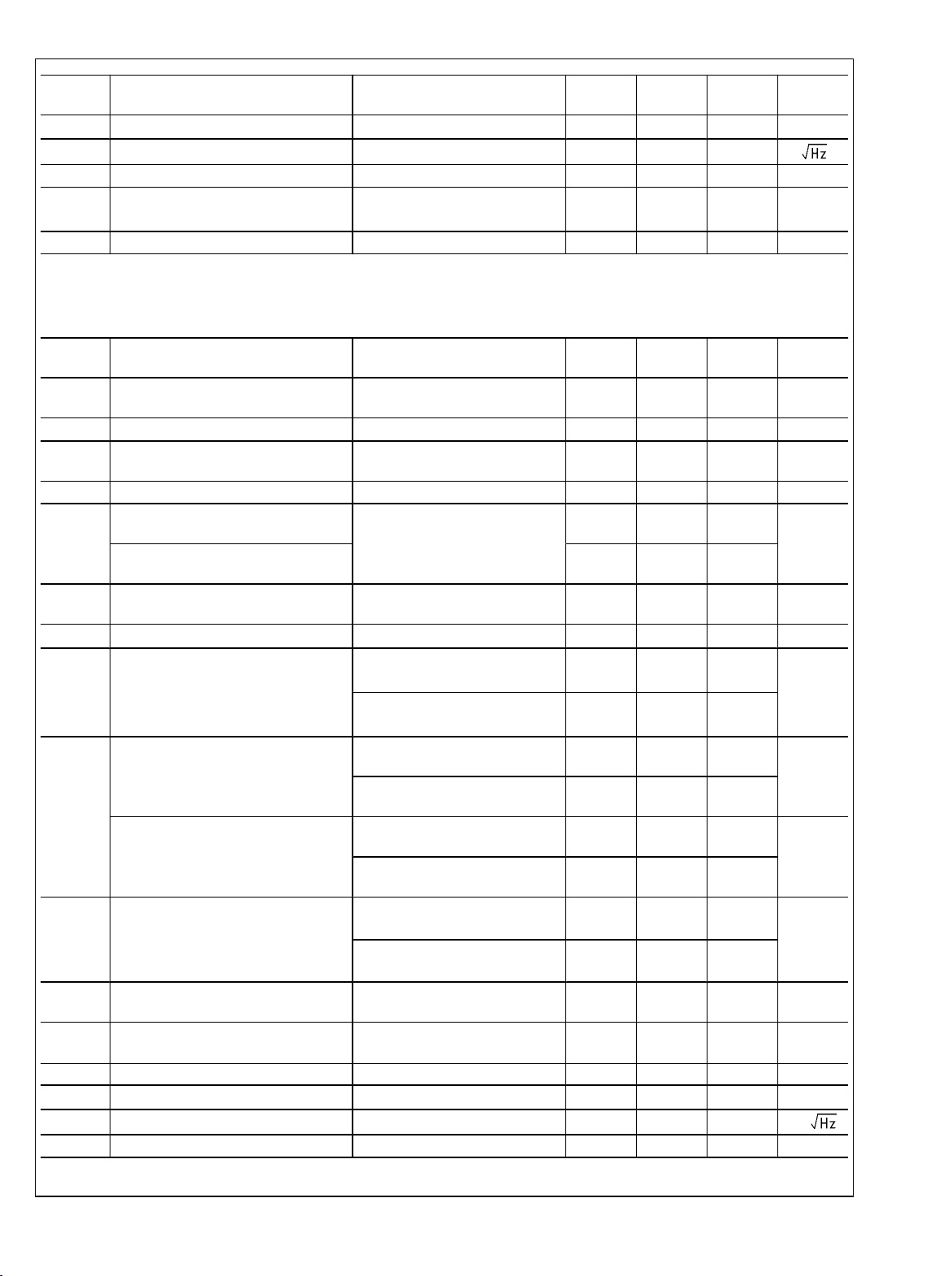

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Symbol Parameter Conditions Min

(Note 6)

Φ

m

e

n

R

OUT

Phase Margin 67

Input-Referred Voltage Noise f = 1 kHz 20

Open Loop Output Impedance f = 3 MHz 70

THD+N Total Harmonic Distortion + Noise f = 1 kHz , AV = 1

RL = 10 kΩ

C

IN

Input Capacitance 7

0.005

Typ

(Note 5)

Max

(Note 6)

Units

Deg

nV/

Ω

%

pF

5V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 5V, V− = 0V, VCM = V+/2, and RL > 10 MΩ to V+/2.

Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

V

OS

TCV

I

B

Input Offset Voltage ±50 ±500

Input Offset Voltage Drift (Note 7) 0.35 ±5

OS

Input Bias Current

0.3 10

(Notes 7, 8)

I

OS

CMRR Common Mode Rejection Ratio

PSRR Power Supply Rejection Ratio

Input Offset Current 40

86

80

81

79

86

LMV841

Common Mode Rejection Ratio

LMV842 and LMV844

0V ≤ V

CM

≤ 5V

2.7V ≤ V+ ≤ 12V, VO = V+/2

82

CMVR Input Common-Mode Voltage Range

A

VOL

V

O

Large Signal Voltage Gain

Output Swing High,

CMRR ≥ 50 dB

RL = 2 kΩ

VO = 0.3V to 4.7V

RL = 10 kΩ

VO = 0.2V to 4.8V

RL = 2 kΩ to V+/2

−0.2 5.2

100

96

100

96

68 100

(measured from V+)

32 50

78 120

Output Swing Low,

RL = 10 kΩ to V+/2

RL = 2 kΩ to V+/2

(measured from V-)

RL = 10 kΩ to V+/2

I

O

Output Short Circuit Current

(Notes 3, 9)

Sourcing VO = V+/2

VIN = 100 mV

Sinking VO = V+/2

VIN = −100 mV

I

S

Supply Current Per Channel 0.96 1.5

SR Slew Rate (Note 10) AV = +1, VO = 4 V

PP

38 70

20

15

20

15

2.5

10% to 90%

GBW Gain Bandwidth Product 4.5 MHz

Φ

m

e

n

R

OUT

Phase Margin 67

Input-Referred Voltage Noise f = 1 kHz 20

Open Loop Output Impedance f = 3 MHz 70

Typ

(Note 5)

112

106

108

125

133

33

28

Max

(Note 6)

±800

300

120

70

140

80

2

Units

μV

μV/°C

pA

fA

dB

dB

V

dB

mV

mV

mA

mA

V/μs

Deg

nV/

Ω

3 www.national.com

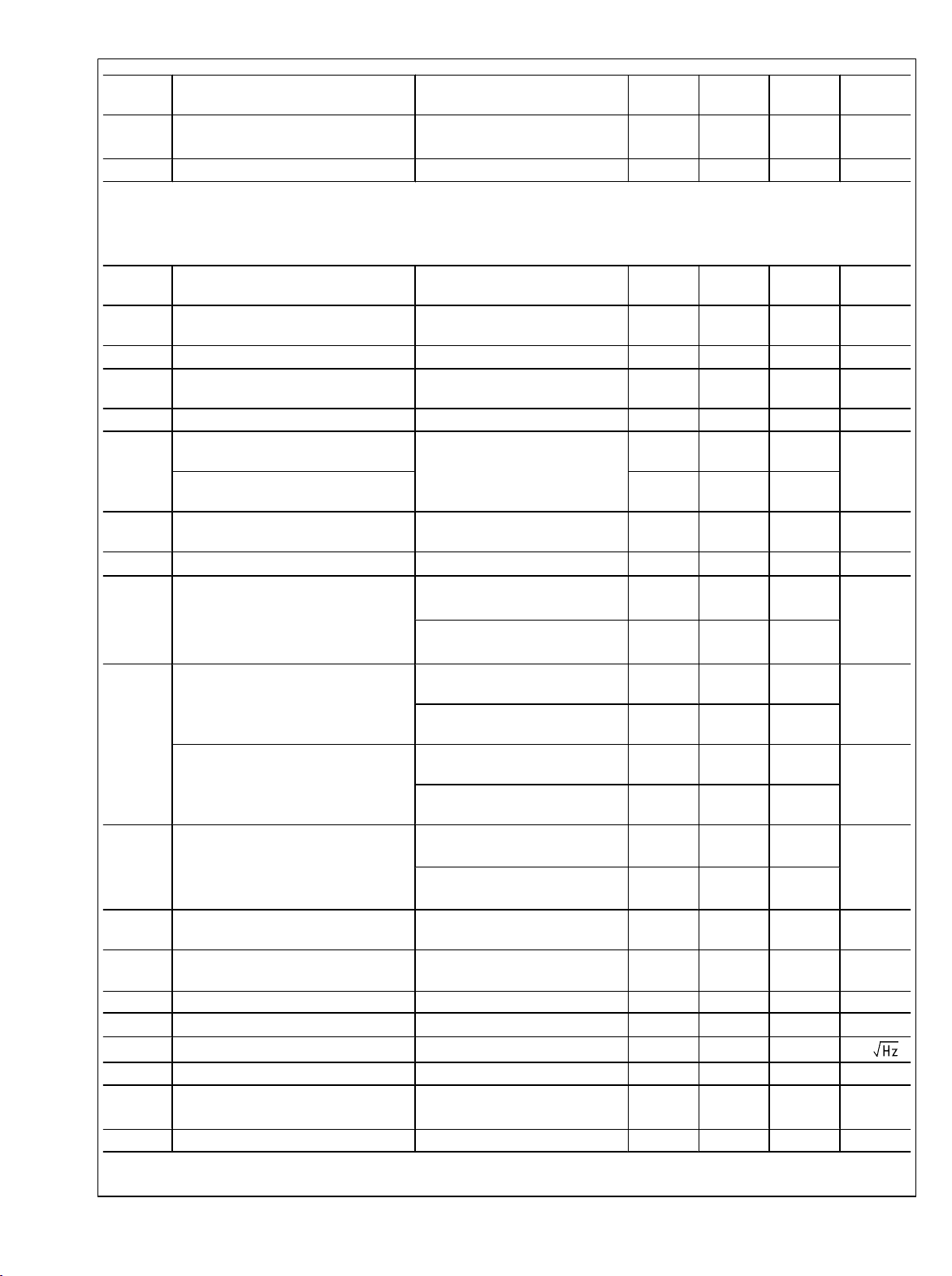

Page 4

Symbol Parameter Conditions Min

(Note 6)

THD+N Total Harmonic Distortion + Noise f = 1 kHz , AV = 1

0.003

Typ

(Note 5)

Max

(Note 6)

RL = 10 kΩ

C

IN

Input Capacitance 6

±5V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 5V, V− = –5V, VCM = 0V, and RL > 10 MΩ to VCM.

Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

V

OS

TCV

I

B

Input Offset Voltage ±50 ±500

Input Offset Voltage Drift (Note 7) 0.25 ±5

OS

Input Bias Current

0.3 10

(Notes 7, 8)

I

LMV841 Single/ LMV842 Dual/ LMV844 Quad

OS

CMRR Common Mode Rejection Ratio

PSRR Power Supply Rejection Ratio

Input Offset Current 40

86

80

86

80

86

LMV841

Common Mode Rejection Ratio

LMV842 and LMV844

–5V ≤ V

CM

≤ 5V

2.7V ≤ V+ ≤ 12V, VO = 0V

82

CMVR Input Common-Mode Voltage Range

A

VOL

V

O

Large Signal Voltage Gain

Output Swing High,

CMRR ≥ 50 dB

RL = 2 kΩ

VO = −4.7V to 4.7V

RL = 10 kΩ

VO = −4.8V to 4.8V

RL = 2 kΩ to 0V

−5.2 5.2

100

96

100

96

95 130

(measured from V+)

44 75

105 160

Output Swing Low,

RL = 10 kΩ to 0V

RL = 2 kΩ to 0V

(measured from V−)

RL = 10 kΩ to 0V

I

O

Output Short Circuit Current

(Notes 3, 9)

Sourcing VO = 0V

VIN = 100 mV

Sinking VO = 0V

VIN = −100 mV

I

S

Supply Current Per Channel 1.03 1.7

SR Slew Rate (Note 10) AV = +1, VO = 9 V

PP

52 80

20

15

20

15

2.5

10% to 90%

GBW Gain Bandwidth Product 4.5 MHz

Φ

m

e

n

R

OUT

THD+N Total Harmonic Distortion + Noise f = 1 kHz , AV = 1

Phase Margin 67

Input-Referred Voltage Noise f = 1 kHz 20

Open Loop Output Impedance f = 3 MHz 70

0.006

RL = 10 kΩ

C

IN

Input Capacitance 3

Typ

(Note 5)

112

106

108

126

136

37

29

Max

(Note 6)

±800

300

155

95

200

100

2

Units

%

pF

Units

μV

μV/°C

pA

fA

dB

dB

V

dB

mV

mV

mA

mA

V/μs

Deg

nV/

Ω

%

pF

www.national.com 4

Page 5

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics

Tables.

Note 2: Human Body Model, applicable std. MIL-STD-883, Method 3015.7. Machine Model, applicable std. JESD22-A115-A (ESD MM std. of JEDEC) FieldInduced Charge-Device Model, applicable std. JESD22-C101-C (ESD FICDM std. of JEDEC).

Note 3: The maximum power dissipation is a function of T

PD = (T

Note 4: Electrical table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device.

Note 5: Typical values represent the most likely parametric norm as determined at the time of characterization. Actual typical values may vary over time and will

also depend on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 6: Limits are 100% production tested at 25°C. Limits over the operating temperature range are guaranteed through correlations using statistical quality

control (SQC) method.

Note 7: This parameter is guaranteed by design and/or characterization and is not tested in production.

Note 8: Positive current corresponds to current flowing into the device.

Note 9: Short circuit test is a momentary test.

Note 10: Number specified is the slower of positive and negative slew rates.

- TA)/ θJA . All numbers apply for packages soldered directly onto a PC board.

J(MAX)

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

J(MAX)

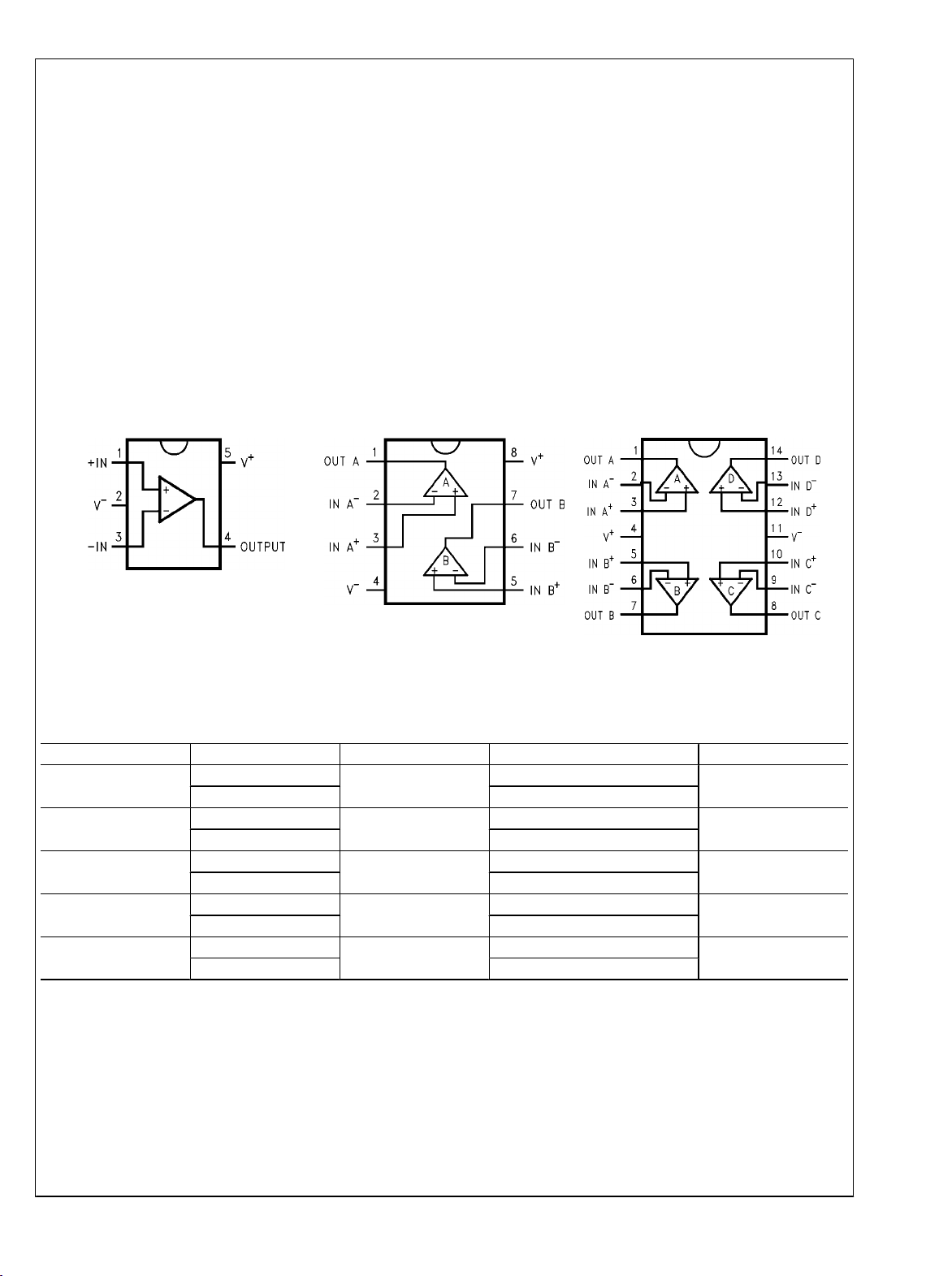

Connection Diagrams

LMV841 Single/ LMV842 Dual/ LMV844 Quad

5-Pin SC70

Top View

20168302

8-Pin SOIC and MSOP

Top View

14–Pin SOIC and TSSOP

20168303

Top View

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

5-Pin SC70

8-Pin MSOP

8-Pin SOIC

14-Pin SOIC

14-Pin TSSOP

LMV841MG

LMV841MGX 3k Units Tape and Reel

LMV842MM

LMV842MMX 3.5k Units Tape and reel

LMV842MA

LMV842MAX 2.5k Units Tape and Reel

LMV844MA

LMV844MAX 2.5k Units Tape and Reel

LMV844MT

LMV844MTX 2.5k Units Tape and Reel

A97

AC4A

LMV842MA

LMV844MA

LMV844MT

1k Units Tape and Reel

1k Units Tape and Reel

95 Units/Rail

55 Units/Rail

94 Units/Rail

20168304

MAA05A

MUA08A

M08A

M14A

MTC14

5 www.national.com

Page 6

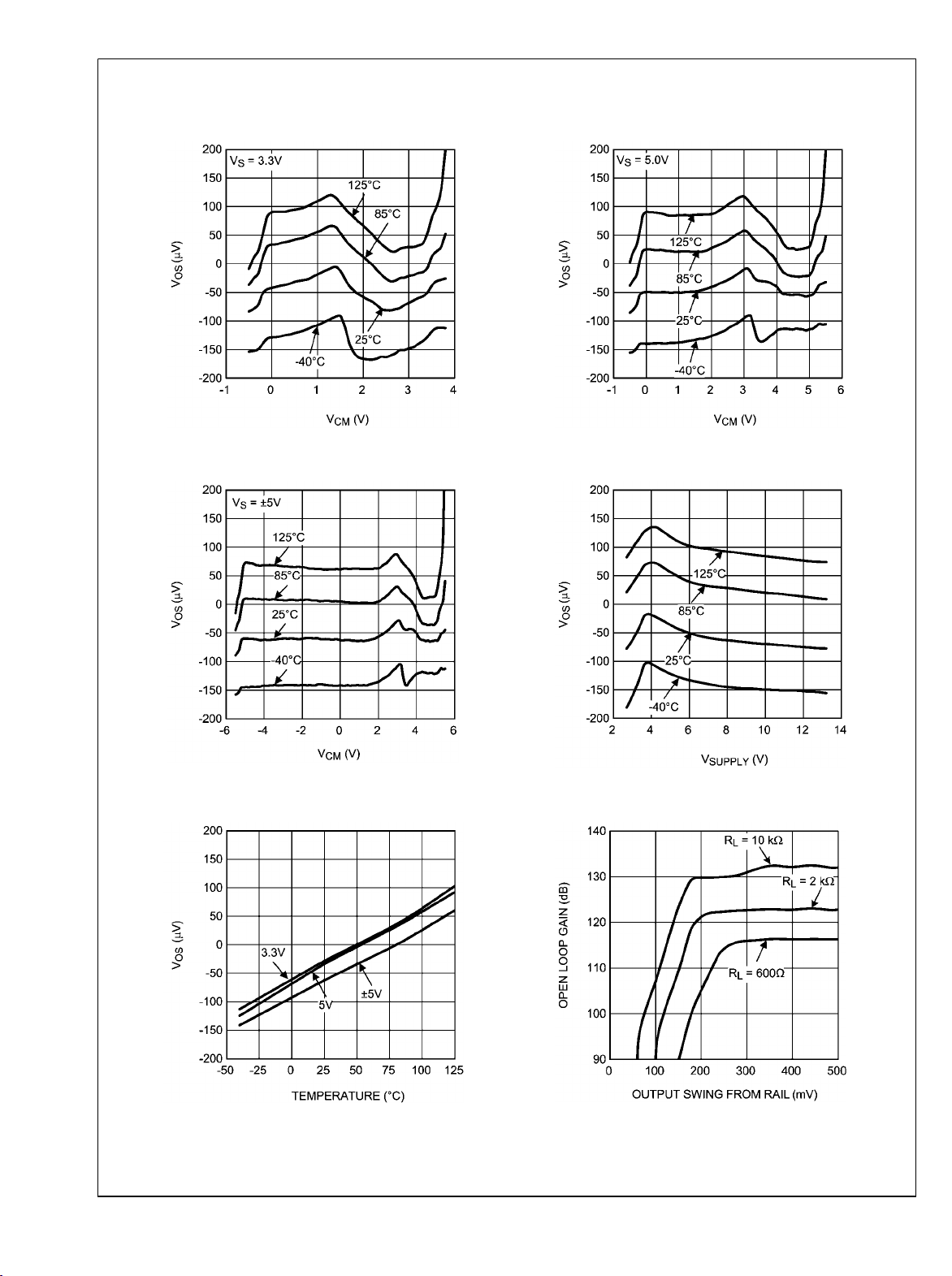

Typical Performance Characteristics At T

= 25°C, RL = 10 kΩ, VS = 5V. Unless otherwise specified.

A

VOS vs. VCM Over Temperature at 3.3V

LMV841 Single/ LMV842 Dual/ LMV844 Quad

20168310

V

vs. VCM Over Temperature at ±5.0V

OS

VOS vs. VCM Over Temperature at 5.0V

20168311

VOS vs. Supply Voltage

20168312

VOS vs. Temperature

20168314

www.national.com 6

DC Gain vs. V

20168313

OUT

20168315

Page 7

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Input Bias Current vs. V

Input Bias Current vs. V

CM

CM

20168316

Input Bias Current vs. V

CM

20168317

Supply Current per Channel vs. Supply Voltage

Sinking Current vs. Supply Voltage

20168318

20168320

20168319

Sourcing Current vs. Supply Voltage

20168321

7 www.national.com

Page 8

Output Swing High vs. Supply Voltage RL = 2 kΩ

Output Swing High vs. Supply Voltage RL = 10 kΩ

20168322

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Output Swing Low vs. Supply Voltage RL = 2 kΩ

20168324

Output Voltage Swing vs. Load Current

20168323

Output Swing Low vs. Supply Voltage RL = 10 kΩ

20168325

Open Loop Frequency Response Over Temperature

20168326

www.national.com 8

20168327

Page 9

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Open Loop Frequency Response Over Load Conditions

20168328

PSRR vs. Frequency

Phase Margin vs. C

CMRR vs. Frequency

L

20168329

Channel Separation vs. Frequency

20168330

20168332

20168331

Large Signal Step Response with Gain = 1

20168373

9 www.national.com

Page 10

Large Signal Step Response with Gain = 10

Small Signal Step Response with Gain = 1

20168374

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Small Signal Step Response with Gain = 10

20168376

Overshoot vs. C

L

20168375

Slew Rate vs Supply Voltage

20168337

Input Voltage Noise vs. Frequency

20168338

www.national.com 10

20168339

Page 11

LMV841 Single/ LMV842 Dual/ LMV844 Quad

THD+N vs. Frequency

20168340

Closed Loop Output Impedance vs. Frequency

THD+N vs. V

OUT

20168341

20168343

11 www.national.com

Page 12

Application Information

INTRODUCTION

The LMV841/LMV842/LMV844 are operational amplifiers

with near-precision specifications: low noise, low temperature

drift, low offset, and rail-to-rail input and output. Possible application areas include instrumentation, medical, test equipment, audio, and automotive applications.

Its low supply current of 1mA per amplifier, temperature range

of −40°C to 125°C, 12V supply with CMOS input, and the

small SC70 package for the LMV841 make the LMV841/

LMV842/LMV844 a unique op amp family and a perfect

choice for portable electronics.

INPUT PROTECTION

The LMV841/LMV842/LMV844 have a set of anti-parallel

diodes D1 and D2 between the input pins, as shown in Figure

1. These diodes are present to protect the input stage of the

amplifier. At the same time, they limit the amount of differential

input voltage that is allowed on the input pins.

LMV841 Single/ LMV842 Dual/ LMV844 Quad

A differential signal larger than one diode voltage drop can

damage the diodes. The differential signal between the inputs

needs to be limited to ±300 mV or the input current needs to

be limited to ±10 mA.

Note that when the op amp is slewing, a differential input voltage exists that forward biases the protection diodes. This may

result in current being drawn from the signal source. While

this current is already limited by the internal resistors R1 and

R2 (both 130Ω), a resistor of 1 kΩ can be placed in the feedback path, or a 500Ω resistor can be placed in series with the

input signal for further limitation.

region. Note that the CMRR and PSRR limits in the tables are

large-signal numbers that express the maximum variation of

the amplifier's input offset over the full common-mode voltage

and supply voltage range, respectively. When the amplifier's

common-mode input voltage is within the transition region,

the small signal CMRR and PSRR may be slightly lower than

the large signal limits.

CAPACITIVE LOAD

The LMV841/LMV842/LMV844 can be connected as non-inverting unity gain amplifiers. This configuration is the most

sensitive to capacitive loading. The combination of a capacitive load placed on the output of an amplifier along with the

amplifier’s output impedance creates a phase lag, which reduces the phase margin of the amplifier. If the phase margin

is significantly reduced, the response will be underdamped

which causes peaking in the transfer and, when there is too

much peaking, the op amp might start oscillating.

The LMV841/LMV842/LMV844 can directly drive capacitive

loads up to 100 pF without any stability issues. In order to

drive heavier capacitive loads, an isolation resistor, R

should be used, as shown in Figure 2. By using this isolation

ISO

resistor, the capacitive load is isolated from the amplifier’s

output, and hence, the pole caused by CL is no longer in the

feedback loop. The larger the value of R

the output voltage will be. If values of R

large, the feedback loop will be stable, independent of the

value of CL. However, larger values of R

output swing and reduced output current drive.

, the more stable

ISO

are sufficiently

ISO

result in reduced

ISO

,

20168351

FIGURE 1. Protection Diodes between the Input Pins

INPUT STAGE

The input stage of this amplifier consists of both a PMOS and

an NMOS input pair to achieve a rail-to-rail input range. For

input voltages close to the negative rail, only the PMOS pair

is active. Close to the positive rail, only the NMOS pair is active. In a transition region that extends from approximately 2V

below V+ to 1V below V+, both pairs are active, and one pair

gradually takes over from the other. In this transition region,

the input-referred offset voltage changes from the offset voltage associated with the PMOS pair to that of the NMOS pair.

The input pairs are trimmed independently to guarantee an

input offset voltage of less then 0.5 mV at room temperature

over the complete rail-to-rail input range. This also significantly improves the CMRR of the amplifier in the transition

20168350

FIGURE 2. Isolating Capacitive Load

DECOUPLING AND LAYOUT

For decoupling the supply lines it is suggested that 10 nF capacitors be placed as close as possible to the op amp.

For single supply, place a capacitor between V+ and V−. For

dual supplies, place one capacitor between V+ and the board

ground, and the second capacitor between ground and V−.

OP AMP CIRCUIT NOISE

The LMV841/LMV842/LMV844 have good noise specifications, and will frequently be used in low-noise applications.

Therefore it is important to determine the noise of the total

circuit. Besides the input referred noise of the op amp, the

feedback resistors may have an important contribution to the

total noise.

For applications with a voltage input configuration it is, in general, beneficial to keep the resistor values low. In these configurations high resistor values mean high noise levels.

However, using low resistor values will increase the power

consumption of the application. This is not always acceptable

for portable applications, so there is a trade-off between noise

level and power consumption.

Besides the noise contribution of the signal source, three

types of noise need to be taken into account for calculating

the noise performance of an op amp circuit:

www.national.com 12

Page 13

LMV841 Single/ LMV842 Dual/ LMV844 Quad

•

Input referred voltage noise of the op amp

•

Input referred current noise of the op amp

•

Noise sources of the resistors in the feedback network,

configuring the op amp

To calculate the noise voltage at the output of the op amp, the

first step is to determine a total equivalent noise source. This

requires the transformation of all noise sources to the same

reference node. A convenient choice for this node is the input

of the op amp circuit. The next step is to add all the noise

sources. The final step is to multiply the total equivalent input

voltage noise with the gain of the op amp configuration.

The input referred voltage noise of the op amp is already located at the input, we can use the input referred voltage noise

without further transferring. The input referred current noise

needs to be converted to an input referred voltage noise. The

current noise is negligibly small, as long as the equivalent resistance is not unrealistically large, so we can leave the

current noise out for these examples. That leaves us with the

noise sources of the resistors, being the thermal noise voltage. The influence of the resistors on the total noise can be

seen in the following examples, one with high resistor values

and one with low resistor values. Both examples describe an

op amp configuration with a gain of 101 which will give the

circuit a bandwidth of 44.5 kHz. The op amp noise is the same

for both cases, i.e. an input referred noise voltage of 20 nV/

and a negligibly small input referred noise current.

where:

enr = thermal noise voltage of the equivalent resistor

Req (V/ )

k = Boltzmann constant (1.38 x 10

–23

J/K)

T = absolute temperature (K)

Req = resistance (Ω)

The total equivalent input voltage noise is given by the equation:

where:

e

= total input equivalent voltage noise of the circuit

n in

env = input voltage noise of the op amp

The final step is multiplying the total input voltage noise by the

noise gain, which is in this case the gain of the op amp configuration:

The equivalent resistance for the first example with a resistor

RF of 10 MΩ and a resistor RG of 100 kΩ at 25°C (298 K)

equals:

20168377

FIGURE 3. Noise Circuit

To calculate the noise of the resistors in the feedback network, the equivalent input referred noise resistance is needed. For the example in Figure 3, this equivalent resistance

Req can be calculated using the following equation:

The voltage noise of the equivalent resistance can be calculated using the following equation:

Now the noise of the resistors can be calculated, yielding:

The total noise at the input of the op amp is:

For the first example, this input noise will, multiplied with the

noise gain, give a total output noise of:

In the second example, with a resistor RF of 10 kΩ and a resistor RG of 100Ω at 25°C (298 K), the equivalent resistance

equals:

13 www.national.com

Page 14

The resistor noise for the second example is:

The total noise at the input of the op amp is:

For the second example the input noise will, multiplied with

the noise gain, give an output noise of

LMV841 Single/ LMV842 Dual/ LMV844 Quad

a center frequency of approximately 10% from the frequency

of the total filter:

C = 33 nF

R1 = 2 kΩ

R2 = 6.2 kΩ

R3 = 45 Ω

This will give for filter A:

and for filter B with C = 27 nF:

Bandwidth can be calculated by:

In the first example the noise is dominated by the resistor

noise due to the very high resistor values, in the second example the very low resistor values add only a negligible

contribution to the noise and now the dominating factor is the

op amp itself. When selecting the resistor values, it is important to choose values that don't add extra noise to the application. Choosing values above 100 kΩ may increase the

noise too much. Low values will keep the noise within acceptable levels; choosing very low values however, will not make

the noise even lower, but will increase the current of the circuit.

ACTIVE FILTER

The rail-to-rail input and output of the LMV841/LMV842/

LMV844 and the wide supply voltage range make these amplifiers ideal to use in numerous applications. One of the

typical applications is an active filter as shown in Figure 4.

This example is a band-pass filter, for which the pass band is

widened. This is achieved by cascading two band-pass filters,

with slightly different center frequencies.

For filter A this will give:

and for filter B:

The response of the two filters and the combined filter is

shown in Figure 5.

20168358

FIGURE 4. Active Filter

The center frequency of the separate band-pass filters can be

calculated by:

In this example a filter was designed with its pass band at 10

kHz. The two separate band-pass filters are designed to have

www.national.com 14

20168359

FIGURE 5. Active Filter Curve

The responses of filter A and filter B are shown as the thin

lines in Figure 5; the response of the combined filter is shown

as the thick line. Shifting the center frequencies of the separate filters farther apart, will result in a wider band; however,

positioning the center frequencies too far apart will result in a

less flat gain within the band. For wider bands more bandpass filters can be cascaded.

Page 15

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Tip: Use the WEBENCH internet tools at www.national.com

for your filter application.

HIGH-SIDE CURRENT SENSING

The rail-to-rail input and the low VOS features make the

LMV841/LMV842/LMV844 ideal op amps for high-side current sensing applications.

To measure a current, a sense resistor is placed in series with

the load, as shown in Figure 6. The current flowing through

this sense resistor will result in a voltage drop, that is amplified

by the op amp.

Suppose it is necessary to measure a current between 0A and

2A using a sense resistor of 100 mΩ, and convert it to an

output voltage of 0 to 5V. A current of 2A flowing through the

load and the sense resistor will result in a voltage of 200 mV

across the sense resistor. The op amp will amplify this 200

mV to fit the current range to the output voltage range. Use

the formula:

V

= RF/RG * V

OUT

SENSE

to calculate the gain needed. For a load current of 2A and an

output voltage of 5V the gain would be V

OUT/VSENSE

= 25.

If the feedback resistor, RF, is 100 kΩ, then the value for R

will be 4 kΩ. The tolerance of the resistors has to be low to

obtain a good common-mode rejection.

20168371

FIGURE 6. High-Side Current Sensing

HIGH IMPEDANCE SENSOR INTERFACE

With CMOS inputs, the LMV841/LMV842/LMV844 are particularly suited to be used as high impedance sensor interfaces.

Many sensors have high source impedances that may range

up to 10 MΩ. The input bias current of an amplifier will load

the output of the sensor, and thus cause a voltage drop across

the source resistance, as shown in Figure 7. When an op amp

is selected with a relatively high input bias current, this error

may be unacceptable.

The low input current of the LMV841/LMV842/LMV844 significantly reduces such errors. The following examples show

the difference between a standard op amp input and the

CMOS input of the LMV841/LMV842/LMV844.

The voltage at the input of the op amp can be calculated with

V

= VS - IB * R

IN+

S

For a standard op amp the input bias Ib can be 10 nA. When

the sensor generates a signal of 1V (VS) and the sensors

impedance is 10 MΩ (RS), the signal at the op amp input will

be

VIN = 1V - 10 nA * 10 MΩ = 1V - 0.1V = 0.9V

For the CMOS input of the LMV841/LMV842/LMV844, which

has an input bias current of only 0.3 pA, this would give

VIN = 1V – 0.3 pA * 10 MΩ = 1V - 3 μV = 0.999997V

The conclusion is that a standard op amp, with its high input

bias current input, is not a good choice for use in impedance

sensor applications. The LMV841/LMV842/LMV844, in contrast, are much more suitable due to the low input bias current.

The error is negligibly small; therefore, the LMV841/LMV842/

LMV844 are a must for use with high impedance sensors.

G

20168352

FIGURE 7. High Impedance Sensor Interface

THERMOCOUPLE AMPLIFIER

The following is a typical example for a thermocouple amplifier application using an LMV841, LMV842, or LMV844. A

thermocouple senses a temperature and converts it into a

voltage. This signal is then amplified by the LMV841,

LMV842, or LMV844. An ADC can then convert the amplified

signal to a digital signal. For further processing the digital signal can be processed by a microprocessor, and can be used

to display or log the temperature, or the temperature data can

be used in a fabrication process.

Characteristics of a Thermocouple

A thermocouple is a junction of two different metals. These

metals produce a small voltage that increases with temperature.

The thermocouple used in this application is a K-type thermocouple. A K-type thermocouple is a junction between Nickel-Chromium and Nickel-Aluminum. This is one of the most

commonly used thermocouples. There are several reasons

for using the K-type thermocouple. These include temperature range, the linearity, the sensitivity, and the cost.

A K-type thermocouple has a wide temperature range. The

range of this thermocouple is from approximately −200°C to

approximately 1200°C, as can be seen in Figure 8. This cov-

ers the generally used temperature ranges.

Over the main part of the range the behavior is linear. This is

important for converting the analog signal to a digital signal.

The K-type thermocouple has good sensitivity when compared to many other types; the sensitivity is 41 uV/°C. Lower

sensitivity requires more gain and makes the application more

sensitive to noise.

In addition, a K-type thermocouple is not expensive, many

other thermocouples consist of more expensive materials or

are more difficult to produce.

15 www.national.com

Page 16

20168370

FIGURE 8. K-Type Thermocouple Response

LMV841 Single/ LMV842 Dual/ LMV844 Quad

Thermocouple Example

For this example suppose the range of interest is from 0°C to

500°C, and the resolution needed is 0.5°C. The power supply

for both the LMV841, LMV842, or LMV844 and the ADC is

3.3V.

The temperature range of 0°C to 500°C results in a voltage

range from 0 mV to 20.6 mV produced by the thermocouple.

This is shown in Figure 8

To obtain the best accuracy the full ADC range of 0 to 3.3V is

used and the gain needed for this full range can be calculated

as follows: AV = 3.3V/0.0206V = 160.

If RG is 2 kΩ, then the value for RF can be calculated with this

gain of 160. Since AV = RF/RG, RF can be calculated as follow:

RF = AV * RG = 160 x 2 kΩ = 320 kΩ.

To get a resolution of 0.5°C a step smaller then the minimum

resolution is needed. This means that at least 1000 steps are

necessary (500°C/0.5°C). A 10-bit ADC would be sufficient

as this will give 1024 steps. A 10-bit ADC such as the two

channel 10-bit ADC102S021 would be a good choice.

Unwanted Thermocouple Effect

At the point where the thermocouple wires are connected to

the circuit, usually copper wires or traces, an unwanted thermocouple effect will occur.

At this connection, this could be the connector on a PCB, the

thermocouple wiring forms a second thermocouple with the

connector. This second thermocouple disturbs the measurements from the intended thermocouple.

Using an isothermal block as a reference will compensate for

this additional thermocouple effect . An isothermal block is a

good heat conductor. This means that the two thermocouple

connections both have the same temperature. The temperature of the isothermal block can be measured, and thereby

the temperature of the thermocouple connections. This is

usually called the cold junction reference temperature.

In the example, an LM35 is used to measure this temperature.

This semiconductor temperature sensor can accurately measure temperatures from −55°C to 150°C.

The ADC in this example also coverts the signal from the

LM35 to a digital signal. Now the microprocessor can compensate the amplified thermocouple signal, for the unwanted

thermocouple effect.

FIGURE 9. Thermocouple Amplifier

www.national.com 16

20168353

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted

LMV841 Single/ LMV842 Dual/ LMV844 Quad

NS Package Number MAA05A

5-Pin SC70

NS Package Number MUA08A

8-Pin MSOP

17 www.national.com

Page 18

LMV841 Single/ LMV842 Dual/ LMV844 Quad

NS Package Number M08A

8-Pin SOIC

14-Pin SOIC

NS Package Number M14A

www.national.com 18

Page 19

14-Pin TSSOP

NS Package Number MTC14

LMV841 Single/ LMV842 Dual/ LMV844 Quad

19 www.national.com

Page 20

Amplifiers

Notes

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

LMV841 Single/ LMV842 Dual/ LMV844 Quad CMOS Input, RRIO, Wide Supply Range Operational

www.national.com

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...