查询LMV2011供应商

LMV2011

High Precision, Rail-to-Rail Output Operational Amplifier

LMV2011 High Precision, Rail-to-Rail Output Operational Amplifier

April 2004

General Description

The LMV2011 is a new precision amplifier that offers unprecedented accuracy and stability at an affordable price and is

offered in miniature (SOT23-5) package and in 8 lead SOIC

package. This device utilizes patented techniques to measure and continually correct the input offset error voltage.

The result is an amplifier which is ultra stable over time and

temperature. It has excellent CMRR and PSRR ratings, and

does not exhibit the familiar 1/f voltage and current noise

increase that plagues traditional amplifiers. The combination

of the LMV2011 characteristics makes it a good choice for

transducer amplifiers, high gain configurations, ADC buffer

amplifiers, DAC I-V conversion, and any other 2.7V-5V application requiring precision and long term stability.

Other useful benefits of the LMV2011 are rail-to-rail output, a

low supply current of 930µA, and wide gain-bandwidth product of 3MHz. These extremely versatile features found in the

LMV2011 provide high performance and ease of use.

Connection Diagrams

5-Pin SOT23 8-Pin SOIC

Features

(For Vs = 5V, Typical unless otherwise noted)

n Low Guaranteed V

n Low Noise with no 1/f 35nV/

n High CMRR 130dB

n High PSRR 120dB

n High A

n Wide gain-bandwidth product 3MHz

n High slew rate 4V/µs

n Low supply current 930µA

n Rail-to-rail output 30mV

n No external capacitors required

VOL

over temperature 35µV

os

130dB

Applications

n Precision Instrumentation Amplifiers

n Thermocouple Amplifiers

n Strain Gauge Bridge Amplifier

Top View

20051502

Top View

20051538

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

5-Pin SOT23

8-Pin SOIC

© 2004 National Semiconductor Corporation DS200515 www.national.com

LMV2011MF

LMV2011MFX 3k Units Tape and Reel

LMV2011MA

LMV2011MAX 2.5k Units Tape and Reel

A84A

LMV2011MA

1k Units Tape and Reel

95 Units/Rail

MF05A

M08A

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LMV2011

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance

Human Body Model 2000V

Machine Model 200V

Supply Voltage 5.5V

Common-Mode Input Voltage −0.3≤ V

Differential Input Voltage

Current At Input Pin 30mA

≤ VCC+0.3V

CM

±

Supply Voltage

Current At Output Pin 30mA

Current At Power Supply Pin 50mA

Junction Temperature (T

) 150˚C

J

Lead Temperature (soldering

10 sec.) +300˚C

Operating Ratings (Note 1)

Supply Voltage 2.7V to 5.25V

Storage Temperature Range −65˚C to 150˚C

Operating Temperature Range 0˚C to 70˚C

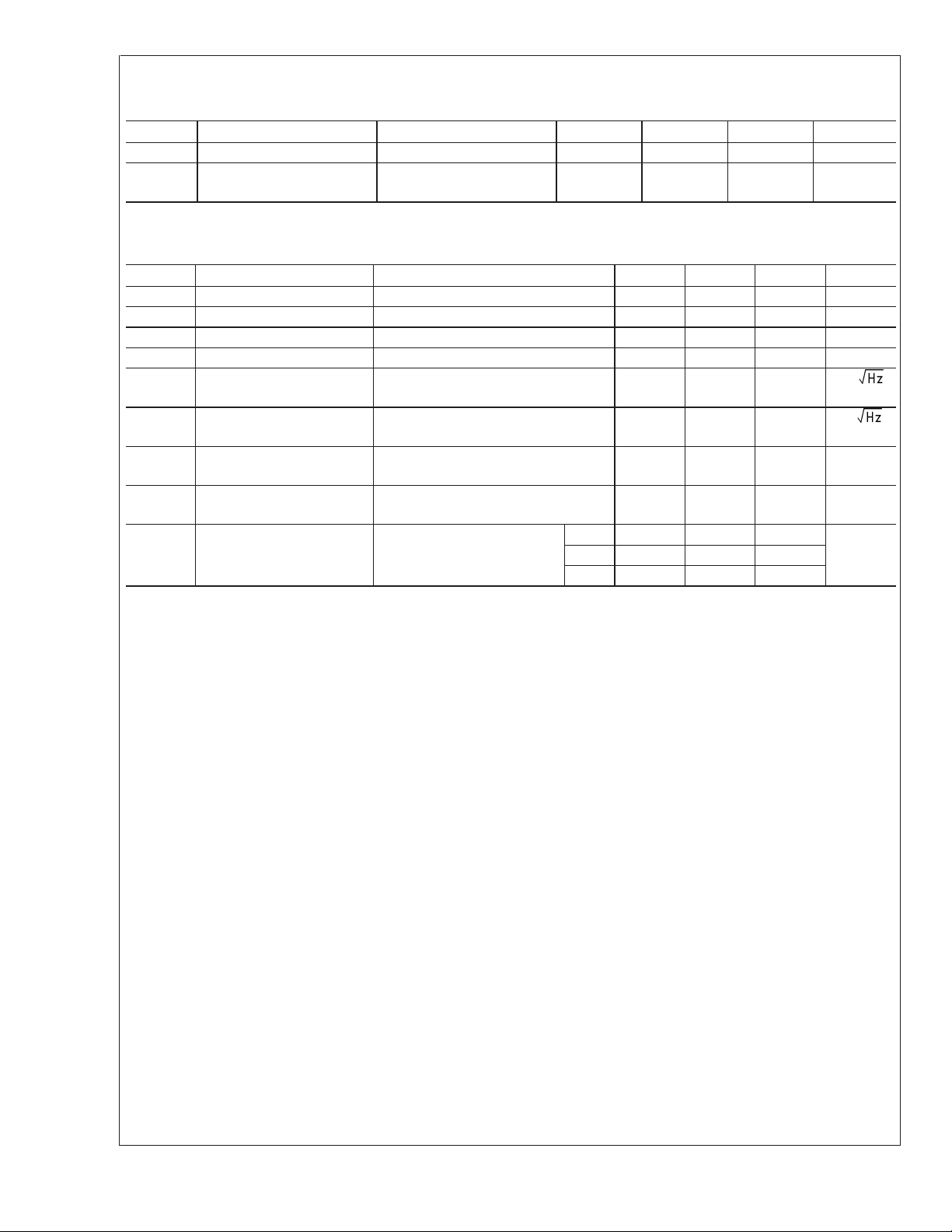

2.7V DC Electrical Characteristics Unless otherwise specified, all limits guaranteed for T

= 2.7V, V-= 0V, VCM= 1.35V, VO= 1.35V and R

>

1MΩ. Boldface limits apply at the temperature extremes.

L

= 25˚C, V

J

Symbol Parameter Conditions Min Typ Max Units

V

OS

Input Offset Voltage 0.8 25

35

Offset Calibration Time 0.5 10

12

TCV

Input Offset Voltage 0.015 µV/˚C

OS

Long-Term Offset Drift 0.006 µV/month

Lifetime V

I

IN

I

OS

R

IND

Input Current -3 pA

Input Offset Current 6 pA

Input Differential Resistance 9 MΩ

CMRR Common Mode Rejection

Ratio

PSRR Power Supply Rejection

Ratio

A

VOL

Open Loop Voltage Gain RL= 10kΩ 130 95

Drift 2.5 5 µV

OS

−0.3 ≤ V

0 ≤ V

CM

2.7V ≤ V

≤ 0.9V

CM

≤ 0.9V

+

≤ 5V 120 95

130 95

90

90

90

=2kΩ 124 90

R

L

85

V

O

Output Swing RL= 10kΩ to 1.35V

(diff) =±0.5V

V

IN

2.665

2.655

2.68

0.033 0.060

0.075

R

=2kΩ to 1.35V

L

(diff) =±0.5V

V

IN

2.630

2.615

2.65

0.061 0.085

0.105

I

O

R

OUT

I

S

Output Current Sourcing, VO=0V

(diff) =±0.5V

V

IN

Sinking, V

(diff) =±0.5V

V

IN

O

=5V

Output Impedance 0.05 Ω

Supply Current 0.919 1.20

12 5

18 5

3

mA

3

mA

1.50

+

µV

ms

dB

dB

dB

V

V

www.national.com 2

LMV2011

2.7V AC Electrical Characteristics T

>

1MΩ. Boldface limits apply at the temperature extremes.

= 25˚C, V+= 2.7V, V-= 0V, VCM= 1.35V, VO= 1.35V, and R

J

Symbol Parameter Conditions Min Typ Max Units

GBW Gain-Bandwidth Product 3 MHz

SR Slew Rate 4 V/µs

θ

m

G

m

e

n

Phase Margin 60 Deg

Gain Margin −14 dB

Input-Referred Voltage

35 nV/

Noise

i

n

Input-Referred Current

150 fA/

Noise

enp-p Input-Referred Voltage

RS= 100Ω, DC to 10Hz 850 nV

Noise

t

rec

Input Overload Recovery

50 ms

Time

t

s

Output Settling Time AV= −1, RL=2kΩ

1V Step

1% 0.9 µs

0.1% 49

0.01% 100

5V DC Electrical Characteristics Unless otherwise specified, all limits guaranteed for T

-

= 0V, VCM= 2.5V, VO= 2.5V and R

5V, V

>

1MΩ. Boldface limits apply at the temperature extremes.

L

= 25˚C, V+=

J

Symbol Parameter Conditions Min Typ Max Units

V

OS

Input Offset Voltage 0.12 25

µV

35

Offset Calibration Time 0.5 10

ms

12

TCV

Input Offset Voltage 0.015 µV/˚C

OS

Long-Term Offset Drift 0.006 µV/month

Lifetime V

I

IN

I

OS

R

IND

Input Current -3 pA

Input Offset Current 6 pA

Input Differential Resistance 9 MΩ

CMRR Common Mode Rejection

Ratio

PSRR Power Supply Rejection

Ratio

A

VOL

Open Loop Voltage Gain RL= 10kΩ 130 105

Drift 2.5 5 µV

OS

−0.3 ≤ V

0 ≤ V

CM

2.7V ≤ V

≤ 3.2

CM

≤ 3.2

+

≤ 5V 120 95

130 100

90

90

100

RL=2kΩ 132 95

dB

dB

dB

90

V

O

Output Swing RL= 10kΩ to 2.5V

(diff) =±0.5V

V

IN

4.96

4.95

4.978

0.040 0.070

V

0.085

R

=2kΩ to 2.5V

L

(diff) =±0.5V

V

IN

4.895

4.875

4.919

0.091 0.115

V

0.140

I

O

Output Current Sourcing, VO=0V

(diff) =±0.5V

V

IN

Sinking, V

(diff) =±0.5V

V

IN

O

=5V

15 8

17 8

6

mA

6

L

pp

www.national.com3

5V DC Electrical Characteristics Unless otherwise specified, all limits guaranteed for T

-

= 0V, VCM= 2.5V, VO= 2.5V and R

5V, V

>

1MΩ. Boldface limits apply at the temperature extremes. (Continued)

L

= 25˚C, V+=

J

LMV2011

Symbol Parameter Conditions Min Typ Max Units

R

OUT

I

S

Output Impedance 0.05 Ω

Supply Current per Channel 0.930 1.20

1.50

mA

5V AC Electrical Characteristics T

= 25˚C, V+= 5V, V-= 0V, VCM= 2.5V, VO= 2.5V, and R

J

>

L

1MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min Typ Max Units

GBW Gain-Bandwidth Product 3 MHz

SR Slew Rate 4 V/µs

θ

m

G

m

e

n

Phase Margin 60 deg

Gain Margin −15 dB

Input-Referred Voltage

35 nV/

Noise

i

n

Input-Referred Current

150 fA/

Noise

enp-p Input-Referred Voltage

RS= 100Ω, DC to 10Hz 850 nV

Noise

t

rec

Input Overload Recovery

50 ms

Time

t

s

Output Settling Time AV= −1, RL=2kΩ

1V Step

1% 0.8 us

0.1% 36

0.01% 100

Note 1: Absolute Maximum Ratings indicate limits beyond which damage may occur. Operating Ratings indicate conditions for which the device is intended to be

functional, but specific performance is not guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

pp

www.national.com 4

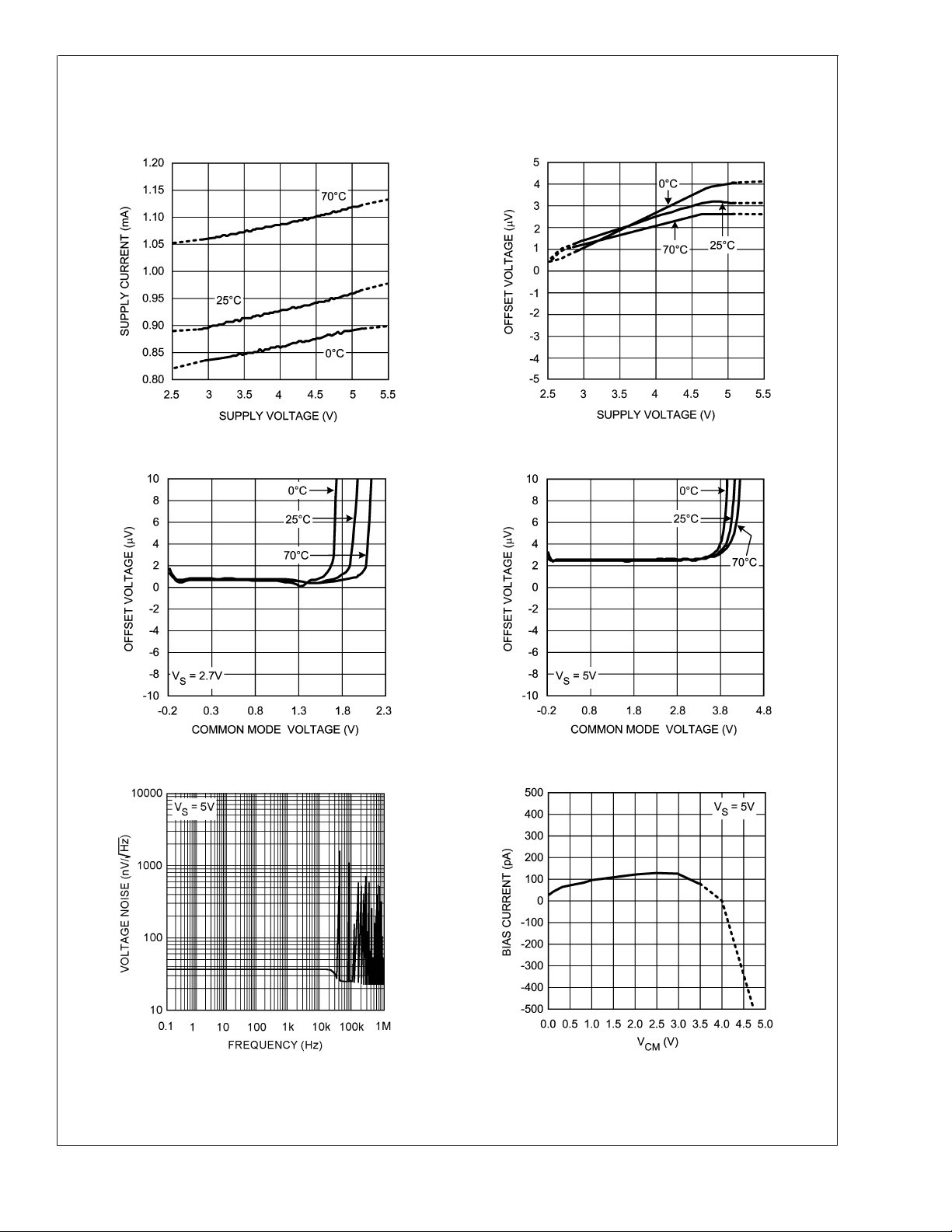

Typical Performance Characteristics

TA=25C, VS= 5V unless otherwise specified.

Supply Current vs. Supply Voltage Offset Voltage vs. Supply Voltage

LMV2011

20051524

Offset Voltage vs. Common Mode Offset Voltage vs. Common Mode

20051535 20051534

Voltage Noise vs. Frequency Input Bias Current vs. Common Mode

20051525

20051504

20051503

www.national.com5

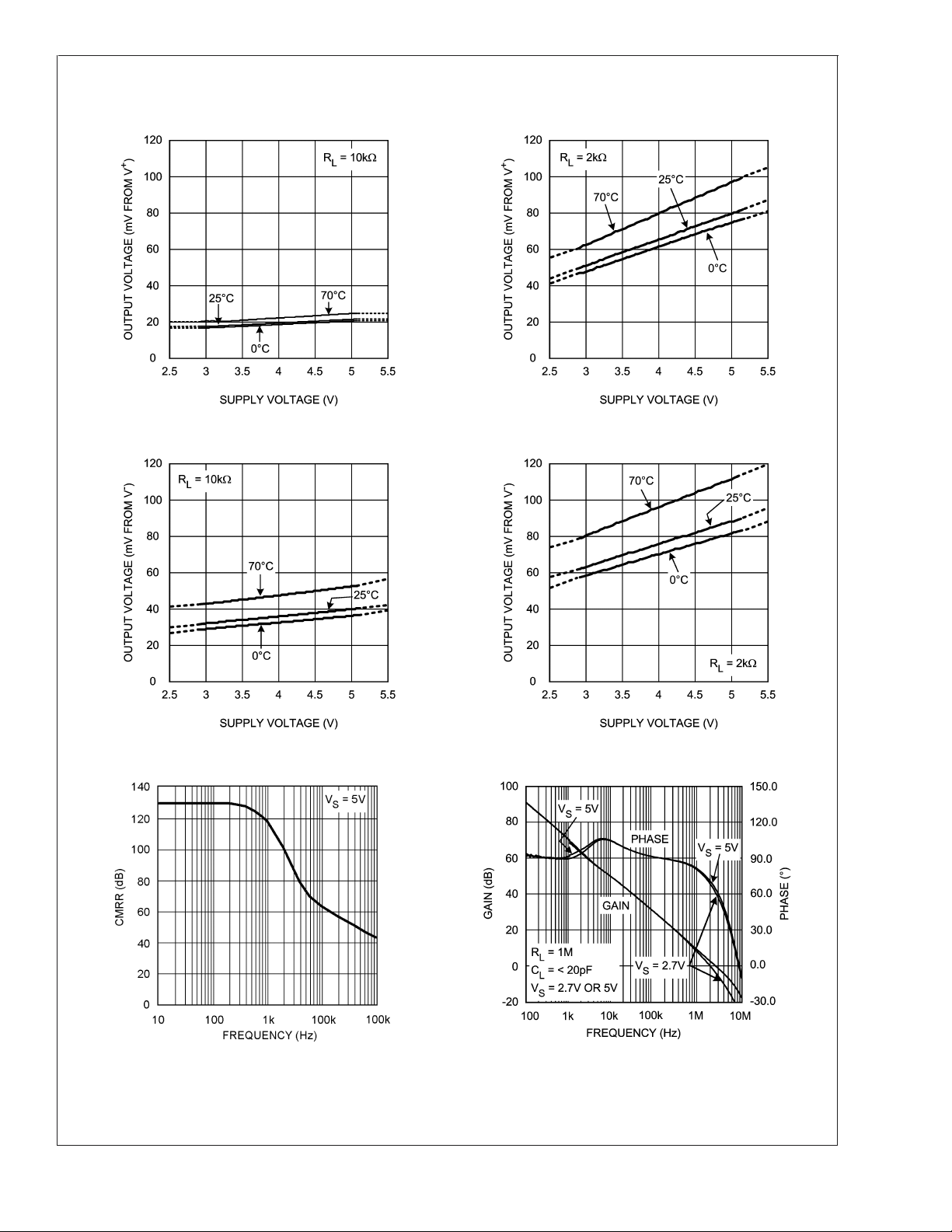

Typical Performance Characteristics (Continued)

LMV2011

PSRR vs. Frequency PSRR vs. Frequency

20051507 20051506

Output Sourcing@2.7V Output Sourcing@5V

20051526

Output Sinking@2.7V Output Sinking@5V

20051528 20051529

www.national.com 6

20051527

Typical Performance Characteristics (Continued)

Max Output Swing vs. Supply Voltage Max Output Swing vs. Supply Voltage

20051530 20051531

Min Output Swing vs. Supply Voltage Min Output Swing vs. Supply Voltage

LMV2011

20051532 20051533

CMRR vs. Frequency Open Loop Gain and Phase vs. Supply Voltage

20051505

20051508

www.national.com7

Typical Performance Characteristics (Continued)

LMV2011

Open Loop Gain and Phase vs. R

Open Loop Gain and Phase vs. C

@

2.7V Open Loop Gain and Phase vs. R

L

20051509 20051510

@

2.7V Open Loop Gain and Phase vs. C

L

@

5V

L

@

5V

L

20051511

20051512

Open Loop Gain and Phase vs. Temperature@2.7V Open Loop Gain and Phase vs. Temperature@5V

20051536 20051537

www.national.com 8

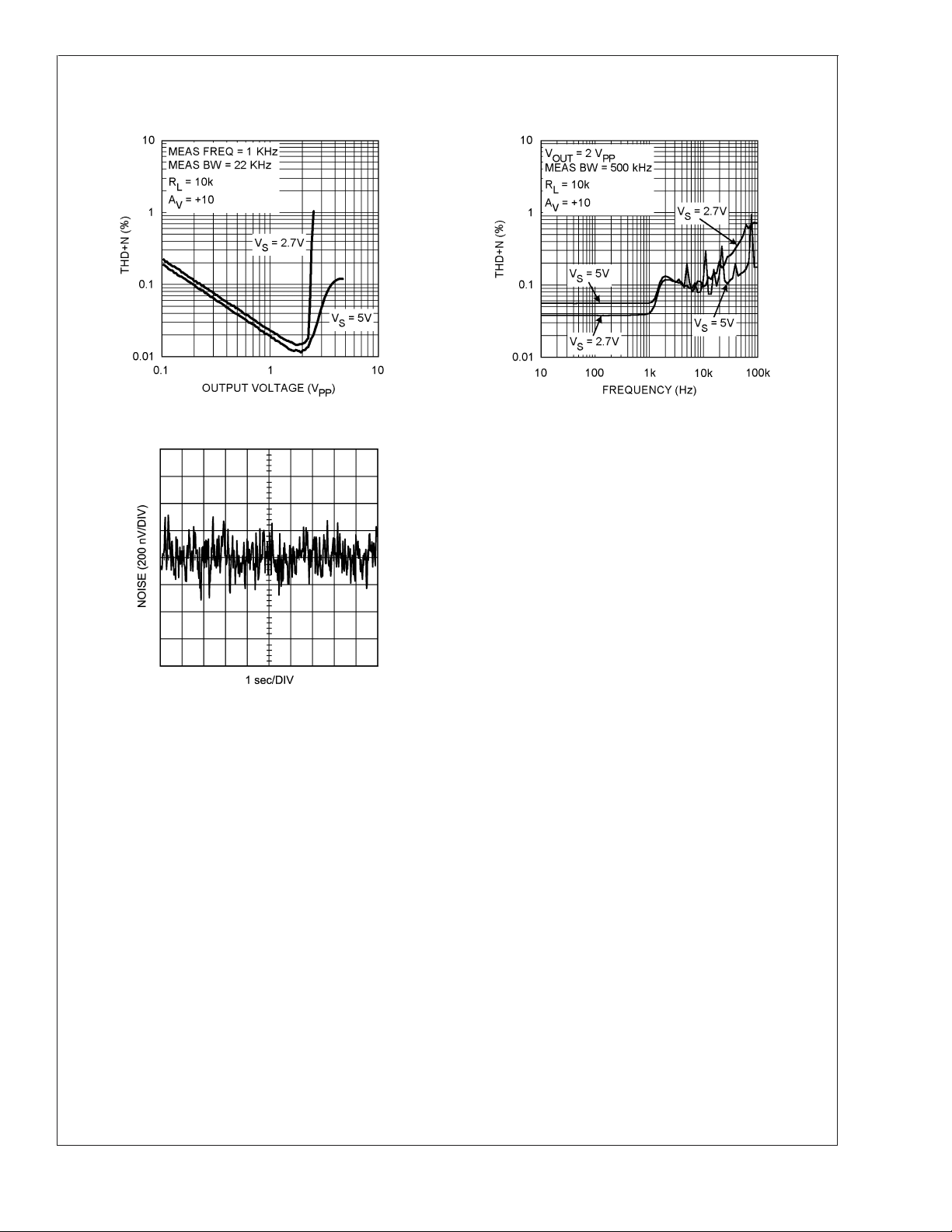

Typical Performance Characteristics (Continued)

THD+N vs. AMPL THD+N vs. Frequency

LMV2011

0.1Hz − 10Hz Noise vs. Time

20051514

20051515

20051513

www.national.com9

Application Information

THE BENEFITS OF LMV2011

LMV2011

NO 1/f NOISE

Using patented methods, the LMV2011 eliminates the 1/f

noise present in other amplifiers. That noise, which increases as frequency decreases, is a major source of measurement error in all DC-coupled measurements. Lowfrequency noise appears as a constantly-changing signal in

series with any measurement being made. As a result, even

when the measurement is made rapidly, this constantlychanging noise signal will corrupt the result. The value of this

noise signal can be surprisingly large. For example: If a

conventional amplifier has a flat-band noise level of 10nV/

and a noise corner of 10Hz, the RMS noise at 0.001Hz

is 1µV/

error, in the frequency range 0.001 Hz to 1.0 Hz. In a circuit

with a gain of 1000, this produces a 0.50mV peak-to-peak

output error. This number of 0.001 Hz might appear unreasonably low, but when a data acquisition system is operating

for 17 minutes, it has been on long enough to include this

error. In this same time, the LMV2011 will only have a

0.21mV output error. This is smaller by 2.4 x. Keep in mind

that this 1/f error gets even larger at lower frequencies. At the

extreme, many people try to reduce this error by integrating

or taking several samples of the same signal. This is also

doomed to failure because the 1/f nature of this noise means

that taking longer samples just moves the measurement into

lower frequencies where the noise level is even higher.

The LMV2011 eliminates this source of error. The noise level

is constant with frequency so that reducing the bandwidth

reduces the errors caused by noise.

Another source of error that is rarely mentioned is the error

voltage caused by the inadvertent thermocouples created

when the common "Kovar type" IC package lead materials

are soldered to a copper printed circuit board. These steelbased leadframe materials can produce over 35µV/˚C when

soldered onto a copper trace. This can result in thermocouple noise that is equal to the LMV2011 noise when there

is a temperature difference of only 0.0014˚C between the

lead and the board!

For this reason, the lead-frame of the LMV2011 is made of

copper. This results in equal and opposite junctions which

cancel this effect. The extremely small size of the SOT-23

package results in the leads being very close together. This

further reduces the probability of temperature differences

and hence decreases thermal noise.

OVERLOAD RECOVERY

The LMV2011 recovers from input overload much faster than

most chopper-stabilized opamps. Recovery from driving the

amplifier to 2X the full scale output, only requires about

40ms. Many chopper-stabilized amplifiers will take from

250ms to several seconds to recover from this same overload. This is because large capacitors are used to store the

unadjusted offset voltage.

. This is equivalent to a 0.50µV peak-to-peak

20051516

FIGURE 1.

The wide bandwidth of the LMV2011 enhances performance

when it is used as an amplifier to drive loads that inject

transients back into the output. ADCs (Analog-to-Digital Converters) and multiplexers are examples of this type of load.

To simulate this type of load, a pulse generator producing a

1V peak square wave was connected to the output through a

10pF capacitor. (Figure 1) The typical time for the output to

recover to 1% of the applied pulse is 80ns. To recover to

0.1% requires 860ns. This rapid recovery is due to the wide

bandwidth of the output stage and large total GBW.

NO EXTERNAL CAPACITORS REQUIRED

The LMV2011 does not need external capacitors. This eliminates the problems caused by capacitor leakage and dielectric absorption, which can cause delays of several seconds

from turn-on until the amplifier’s error has settled.

MORE BENEFITS

The LMV2011 offers the benefits mentioned above and

more. It has a rail-to-rail output and consumes only 950µA of

supply current while providing excellent DC and AC electrical

performance. In DC performance, the LMC2001 achieves

130dB of CMRR, 120dB of PSRR and 130dB of open loop

gain. In AC performance, the LMV2011 provides 3MHz of

gain-bandwidth product and 4V/µs of slew rate.

HOW THE LMV2011 WORKS

The LMV2011 uses new, patented techniques to achieve the

high DC accuracy traditionally associated with chopperstabilized amplifiers without the major drawbacks produced

by chopping. The LMV2011 continuously monitors the input

offset and corrects this error. The conventional chopping

process produces many mixing products, both sums and

differences, between the chopping frequency and the incoming signal frequency. This mixing causes large amounts of

distortion, particularly when the signal frequency approaches

the chopping frequency. Even without an incoming signal,

the chopper harmonics mix with each other to produce even

more trash. If this sounds unlikely or difficult to understand,

look at the plot (Figure 2), of the output of a typical (MAX432)

chopper-stabilized opamp. This is the output when there is

no incoming signal, just the amplifier in a gain of -10 with the

input grounded. The chopper is operating at about 150Hz;

the rest is mixing products. Add an input signal and the noise

gets much worse. Compare this plot with Figure 3 of the

LMV2011. This data was taken under the exact same conditions. The auto-zero action is visible at about 30kHz but

note the absence of mixing products at other frequencies. As

a result, the LMV2011 has very low distortion of 0.02% and

very low mixing products.

www.national.com 10

Application Information (Continued)

20051517

FIGURE 2.

LMV2011

PRECISION STRAIN-GAUGE AMPLIFIER

This Strain-Gauge amplifier (Figure 4) provides high gain

(1006 or~60 dB) with very low offset and drift. Using the

resistors’ tolerances as shown, the worst case CMRR will be

greater than 108 dB. The CMRR is directly related to the

resistor mismatch. The rejection of common-mode error, at

the output, is independent of the differential gain, which is

set by R3. The CMRR is further improved, if the resistor ratio

matching is improved, by specifying tighter-tolerance resistors, or by trimming.

20051518

20051504

FIGURE 3.

INPUT CURRENTS

The LMV2011’s input currents are different than standard

bipolar or CMOS input currents in that it appears as a current

flowing in one input and out the other. Under most operating

conditions, these currents are in the picoamp level and will

have little or no effect in most circuits. These currents tend to

increase slightly when the common-mode voltage is near the

minus supply. (See the typical curves.) At high temperatures

such as 85˚C, the input currents become larger, 0.5nA typical, and are both positive except when the V

is near V−.If

CM

operation is expected at low common-mode voltages and

high temperature, do not add resistance in series with the

inputs to balance the impedances. Doing this can cause an

increase in offset voltage. A small resistance such as 1kΩ

can provide some protection against very large transients or

overloads, and will not increase the offset significantly.

FIGURE 4.

Extending Supply Voltages and Output Swing by Using

a Composite Amplifier Configuration:

In cases where substantially higher output swing is required

with higher supply voltages, arrangements like the ones

shown in Figure 5 and Figure 6 could be used. These

configurations utilize the excellent DC performance of the

LMV2011 while at the same time allow the superior voltage

and frequency capabilities of the LM6171 to set the dynamic

performance of the overall amplifier. For example, it is pos-

±

sible to achieve

GBW (A

due to V

V

OS

12V output swing with 300MHz of overall

= 100) while keeping the worst case output shift

less than 4mV. The LMV2011 output voltage is

kept at about mid-point of its overall supply voltage, and its

input common mode voltage range allows the V- terminal to

be grounded in one case (Figure 5, inverting operation) and

tied to a small non-critical negative bias in another (Figure 6,

non-inverting operation). Higher closed-loop gains are also

possible with a corresponding reduction in realizable bandwidth. Table 1 shows some other closed loop gain possibilities along with the measured performance in each case.

www.national.com11

Application Information (Continued)

LMV2011

20051520

20051519

FIGURE 5.

TABLE 1. Composite Amplifier Measured Performance

AV R1

R2ΩC2pFBW

Ω

MHzSR(V/µs)

en p-p

(mV

PP

)

50 200 10k 8 3.3 178 37

100 100 10k 10 2.5 174 70

100 1k 100k 0.67 3.1 170 70

500 200 100k 1.75 1.4 96 250

1000 100 100k 2.2 0.98 64 400

In terms of the measured output peak-to-peak noise, the

following relationship holds between output noise voltage, e

p-p, for different closed-loop gain, AV, settings, where −3dB

Bandwidth is BW:

FIGURE 6.

It should be kept in mind that in order to minimize the output

noise voltage for a given closed-loop gain setting, one could

minimize the overall bandwidth. As can be seen from Equation 1 above, the output noise has a square-root relationship

to the Bandwidth.

In the case of the inverting configuration, it is also possible to

increase the input impedance of the overall amplifier, by

raising the value of R1, without having to increase the feedback resistor, R2, to impractical values, by utilizing a "Tee"

network as feedback. See the LMC6442 data sheet (Application Notes section) for more details on this.

n

FIGURE 7.

www.national.com 12

20051521

Application Information (Continued)

LMV2011 AS ADC INPUT AMPLIFIER

The LMV2011 is a great choice for an amplifier stage immediately before the input of an ADC (Analog-to-Digital Converter), whether AC or DC coupled. See Figure 7 and Figure

8. This is because of the following important characteristics:

A) Very low offset voltage and offset voltage drift over time

and temperature allow a high closed-loop gain setting

without introducing any short-term or long-term errors.

For example, when set to a closed-loop gain of 100 as

the analog input amplifier for a 12-bit A/D converter, the

overall conversion error over full operation temperature

and 30 years life of the part (operating at 50˚C) would be

less than 5 LSBs.

B) Fast large-signal settling time to 0.01% of final value

(1.4µs) allows 12 bit accuracy at 100KH

pling rate.

C) No flicker (1/f) noise means unsurpassed data accuracy

over any measurement period of time, no matter how

long. Consider the following opamp performance, based

on a typical low-noise, high-performance commerciallyavailable device, for comparison:

Opamp flatband noise = 8nV/

or more sam-

Z

1/f corner frequency = 100Hz

= 2000

A

V

Measurement time = 100 sec

Bandwidth = 2Hz

This example will result in about 2.2 mV

(1.9 LSB) of

PP

output noise contribution due to the opamp alone, compared to about 594µV

(less than 0.5 LSB) when that

PP

opamp is replaced with the LMV2011 which has no 1/f

contribution. If the measurement time is increased from

100 seconds to 1 hour, the improvement realized by

using the LMV2011 would be a factor of about 4.8 times

(2.86mV

compared to 596µV when LMV2011 is used)

PP

mainly because the LMV2011 accuracy is not compromised by increasing the observation time.

D) Copper leadframe construction minimizes any thermo-

couple effects which would degrade low level/high gain

data conversion application accuracy (see discussion

under "The Benefits of the LMV2011" section above).

E) Rail-to-Rail output swing maximizes the ADC dynamic

range in 5-Volt single-supply converter applications. Below are some typical block diagrams showing the

LMV2011 used as an ADC amplifier (Figure 7 and Figure

8).

LMV2011

FIGURE 8.

20051522

www.national.com13

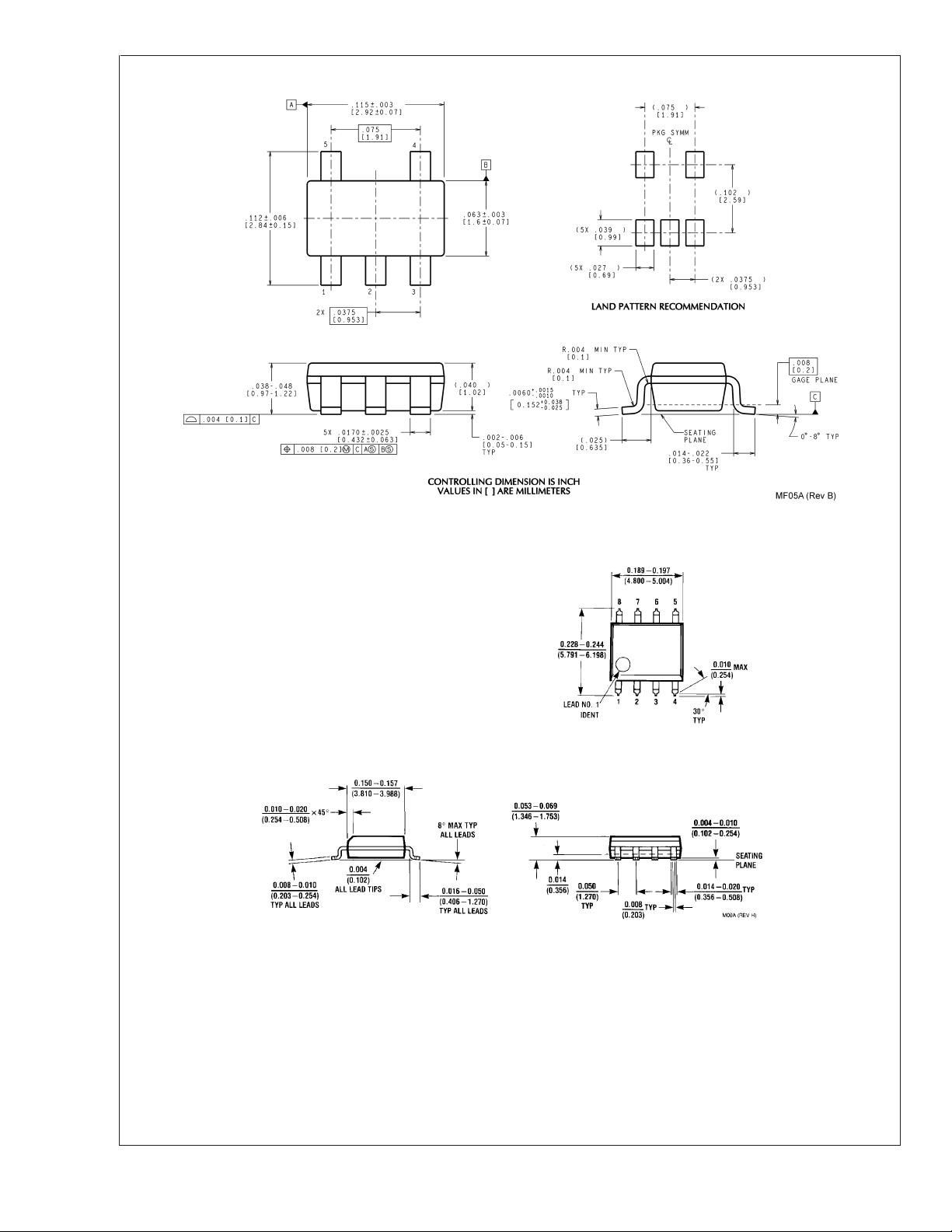

Physical Dimensions inches (millimeters) unless otherwise noted

LMV2011

5-Pin SOT23

NS Package Number MF0A5

8-Pin SOIC

NS Package Number M08A

www.national.com 14

Notes

LMV2011 High Precision, Rail-to-Rail Output Operational Amplifier

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...